1. Introduction

With a closed tube of a hydrogel and some vigorous shaking one can create a wide range of stationary bubbles; see figure 1. These range in size over many decades. The smaller ones may be more spherical or elliptic, presumably as surface tension is significant. Larger bubbles can be quite angular and contain concavities. There is no obvious orientation with respect to gravity. The ability of the fluid to resist both buoyancy and surface tension forces and remain stationary necessitates a constitutive law with a finite (deviatoric) stress at zero strain rate, i.e. a yield stress or equivalent. This is a purely dimensional argument. The simplest such fluids are described by viscoplastic models such as the Bingham fluid.

Figure 1. A range of static bubbles in a Carbopol gel (similar effects with many commercial hair gels).

Viscoplastic fluids are ubiquitous in a wide variety of industrial and medical applications, as well as geophysical sciences. The common characteristic of all these materials is their yield stress, meaning that they flow only if the stress applied is greater than a yield value; otherwise they exhibit a solid-like behaviour (Balmforth, Frigaard & Ovarlez Reference Balmforth, Frigaard and Ovarlez2014). The dynamics of bubbles in viscoplastic fluids contains many interesting problems that are not fully explored. In this study, we focus on the boundary between flow and entrapment for single bubbles in a yield-stress fluid. As figure 1 suggests, shape, size and surface tension effects are all of importance and will be explored.

More than a toy problem, static bubbles in viscoplastic fluids occur in many industrial settings. In the oil sands industry, the by-products of the extraction of bitumen from oil sands have been stored in tailings ponds over many decades. Pond liquids, known as ‘fluid fine tailings’ and ‘mature fine tailings’ (FFT/MFT) are complex suspensions rheologically characterised as thixotropic yield-stress fluids (Derakhshandeh Reference Derakhshandeh2016). Anaerobic micro-organisms within the fluid form both carbon dioxide and methane. Management of emissions presents a difficult environmental challenge to the oil sands industry (Small et al. Reference Small, Cho, Hashisho and Ulrich2015), and there is consequent interest in estimating the degree to which FFT/MFT can retain gas bubbles. Similar phenomena occur in the nuclear waste slurry, where flammable (hydrogen) gas rises from the viscoplastic waste suspension (Johnson et al. Reference Johnson, Fairweather, Harbottle, Hunter, Peakall and Biggs2017). Detailed studies of gas bubbles in nuclear waste tanks, which also contain thixotropic yield-stress material, show a wide range of shapes in retained bubbles (Gauglitz et al. Reference Gauglitz, Rassat, Bredt, Konynenbelt, Tingey and Mendoza1996). Similar mechanisms occur in geological materials, such as shallow marine, terrestrial sediments and some flooded soils, giving a wider relevance to questions of bubble formation and release (Boudreau Reference Boudreau2012). In the food industry, entrapment of air bubbles inside products may give them a different texture and flavour, such as aerated chocolate. It may also affect the efficiency of fermentation processes. In the cosmetic industry, products such as hair gel are often sold by volume, bubbles included.

While the above are concerned with bubble entrapment in stationary fluids, the phenomenon is also of interest in flowing fluid. In the oil and gas industry, influx of formation gases into the drilling mud (generally a viscoplastic fluid) might occur during well construction, known as gas kick. If uncontrolled, the gas will rise to the surface, potentially causing a blowout with severe safety and environmental hazards. When controlling kicks the (gas cut) drilling mud is circulated slowly from the well, which is closed in and under pressure. Whereas large gas bubbles generally rise through the mud, smaller bubbles may remain trapped (Johnson & White Reference Johnson and White1991; Johnson et al. Reference Johnson, Rezmer-Cooper, Bailey and McCann1995). The trapped gas fraction is, however, hazardous to well control operations (Gonzalez, Shaughnessy & Grindle Reference Gonzalez, Shaughnessy and Grindle2000) and needs to be accounted for in operations. It is worth commenting that the trapping of gas by the yield stress of a fluid is analogous to the retention of dissolved gas under pressure e.g. carbon dioxide in deep lakes. Risks associated with these configurations (i.e. limnic eruptions), thus have yield-stress analogues for the industrial processes discussed.

Despite the interest in these problems, there are still relatively few studies. The motion of bubbles in a viscoplastic fluid has been studied theoretically and numerically in the literature by Dubash & Frigaard (Reference Dubash and Frigaard2004), Singh & Denn (Reference Singh and Denn2008), Tsamopoulos et al. (Reference Tsamopoulos, Dimakopoulos, Chatzidai, Karapetsas and Pavlidis2008), Dimakopoulos, Pavlidis & Tsamopoulos (Reference Dimakopoulos, Pavlidis and Tsamopoulos2013), Tripathi et al. (Reference Tripathi, Sahu, Karapetsas and Matar2015), Karapetsas et al. (Reference Karapetsas, Photeinos, Dimakopoulos and Tsamopoulos2019), Chaparian & Frigaard (Reference Chaparian and Frigaard2021) and Deoclecio et al. (Reference Deoclecio, Soares, Deka and Pierson2021). Tsamopoulos et al. (Reference Tsamopoulos, Dimakopoulos, Chatzidai, Karapetsas and Pavlidis2008) comprehensively studied the steady rise of a single axisymmetric bubble in a viscoplastic fluid. They investigated the effect of inertia, surface tension and yield stress on the bubble shape and velocity. Later, Dimakopoulos et al. (Reference Dimakopoulos, Pavlidis and Tsamopoulos2013) expanded the problem to Herschel–Bulkley fluids and compared the previous regularisation approach with the augmented Lagrangian method, finding relatively similar results. Interaction of multiple rising bubbles or falling droplets in a Bingham fluid is investigated in 2D by Singh & Denn (Reference Singh and Denn2008), again using a regularisation method. They observed that multiple bubbles with the same size, aligned vertically and close to each other, can overcome the yield stress, where a single bubble would remain trapped. In Chaparian & Frigaard (Reference Chaparian and Frigaard2021) we have studied the effects of multiple bubbles (clouds/suspensions) on the static stability limit using a Monte Carlo approach, finding that the interaction of clusters of bubbles is all important in determining the flow onset. Tripathi et al. (Reference Tripathi, Sahu, Karapetsas and Matar2015) studied the rise of axisymmetric bubbles in a Bingham fluid using a regularisation method. They have shown that, in the presence of inertia, high yield stress and low surface tension can lead to an unsteady oscillating rise of bubbles. Karapetsas et al. (Reference Karapetsas, Photeinos, Dimakopoulos and Tsamopoulos2019) have investigated the bubble rise dynamics when subjected to an acoustic pressure field and found that acoustic excitation accelerates the motion of the bubble by increasing the size of the yielded region surrounding the bubble. In a recent study, Deoclecio et al. (Reference Deoclecio, Soares, Deka and Pierson2021) have analysed the entrapment conditions of initially spherical and ellipsoidal bubbles in a regularised Bingham fluid. They found that surface tension does not play a role in entrapment of spherical bubbles, however, it will facilitate the rise of non-spherical bubbles by yielding of the surrounding fluid.

While in Newtonian fluids, the Stokes flow limit gives a slowly moving spherical bubble, the Stokes flow limit of a bubble in a yield-stress fluid is non-unique for static configurations. Tsamopoulos et al. (Reference Tsamopoulos, Dimakopoulos, Chatzidai, Karapetsas and Pavlidis2008) study these scenarios as a limit of steadily moving bubbles. For different Bond numbers the flow stops at different critical yield stresses. However, their procedure also iterates to find the shape of the steadily moving bubble: they take a spherical bubble as the initial shape only. Thus, shape effects are not studied independently in their formulation. As figure 1 shows, if the static problem is studied without limiting from a moving bubble, there is little restriction on the bubble shape that can be trapped. This explains our approach here, in which we control the shape and study the critical limit for flow onset. This non-uniqueness and the general theoretical framework for static bubbles was first expounded by Dubash & Frigaard (Reference Dubash and Frigaard2004), who formally defined the critical Bingham (yield) number above which a given bubble shape remains trapped in a viscoplastic fluid, using the variational methods. Here, we explore this approach computationally.

In addition to the numerical and analytical methods, there have been several experimental studies trying to better understand buoyancy-driven rise of bubbles in viscoplastic materials (Astarita & Apuzzo Reference Astarita and Apuzzo1965; Terasaka & Tsuge Reference Terasaka and Tsuge2001; Dubash & Frigaard Reference Dubash and Frigaard2007; Sikorski, Tabuteau & de Bruyn Reference Sikorski, Tabuteau and de Bruyn2009; Mougin, Magnin & Piau Reference Mougin, Magnin and Piau2012; Lopez, Naccache & de Souza Mendes Reference Lopez, Naccache and de Souza Mendes2018; Pourzahedi, Zare & Frigaard Reference Pourzahedi, Zare and Frigaard2021; Zare, Daneshi & Frigaard Reference Zare, Daneshi and Frigaard2021). The first notable work in this field was performed by Astarita & Apuzzo (Reference Astarita and Apuzzo1965), where they reported the shape as well as the correlation between velocity and volume of gas bubbles in various non-Newtonian fluids. Terasaka & Tsuge (Reference Terasaka and Tsuge2001) experimentally investigated the effect of operating parameters such as injection nozzle diameter, gas flow rate and rheological parameters on the bubble volume released into viscous yield-stress fluids. Dubash & Frigaard (Reference Dubash and Frigaard2007) as well as Sikorski et al. (Reference Sikorski, Tabuteau and de Bruyn2009) performed a similar experimental study, and used the results to predict the stopping condition for the rise of single bubbles using an energy budget model. In general, such models have not been successful in that they extrapolate from the behaviour of moving bubbles, which are typically far from the critical conditions, may have different shapes, etc. In another study, Mougin et al. (Reference Mougin, Magnin and Piau2012) performed particle image velocimetry analysis in order to find the local velocity and strain fields. They investigated the influence of internal stresses existing within the yield-stress fluids on the trajectory and shape of bubbles. Recently, Zare et al. (Reference Zare, Daneshi and Frigaard2021) have further explored the effect of ‘damaged’ pathways created by previous bubbles on the trajectory of the subsequent bubbles. Lopez et al. (Reference Lopez, Naccache and de Souza Mendes2018) studied the effect of yield stress, inertia, buoyancy and elasticity on the bubble shape and velocity using various concentrations of a Carbopol solution. An interesting feature of experimentally observed bubbles (Dubash & Frigaard Reference Dubash and Frigaard2007; Sikorski et al. Reference Sikorski, Tabuteau and de Bruyn2009; Lopez et al. Reference Lopez, Naccache and de Souza Mendes2018; Pourzahedi et al. Reference Pourzahedi, Zare and Frigaard2021) is that they tend to adopt an inverted teardrop shape as they rise. This is quite different to computational results and it has been suggested that the root cause is viscoelasticity, causing the tail to extend (Tsamopoulos et al. Reference Tsamopoulos, Dimakopoulos, Chatzidai, Karapetsas and Pavlidis2008).

In this study we fill the knowledge gap of quantifying the limits for which bubbles rise or remain trapped. While we cannot cover all possible shapes, we study families of bubble shapes so that the characteristic effects of aspect ratio and curvature can be understood. For these families we explore the relative effects of surface tension and buoyancy on flow onset. Although we also compute non-zero flows, the emphasis is on the static limit. The definition of the problem and its governing equations is given in § 2. The computational methods are presented in § 3. We compare results for elliptical bubbles with the slipline theory (perfect plasticity), as a pseudo-benchmark. The effects of aspect ratio and surface tension on the critical yield number for two-dimensional (2-D) elliptical and quartic bubbles are explored in § 4. Axisymmetric results are presented in § 5. We study families of elliptic bubbles, where the results are qualitatively similar to the planar 2-D bubbles. We also explore inverted teardrop shaped bubbles similar to those found experimentally, far from the yield limit. We close the study with some concluding remarks regarding the findings and future directions.

2. Formulation

The general setting considered is that of a single bubble in an expanse of yield-stress fluid; see figure 2. We mostly consider the yield limit of bubbles, which is the same for all yield-stress fluids using a von Mises yield criterion, and hence we consider the simplest Bingham fluid model. Similarly, due to the focus on the yield limit, we may consider the flow to be incompressible and non-inertial. Throughout this paper, the ![]() $\hat {\cdot }$ accent signifies a dimensional parameter or variable

$\hat {\cdot }$ accent signifies a dimensional parameter or variable

Here ![]() $\hat{p}$ is the pressure inside the ambient yield-stress liquid and

$\hat{p}$ is the pressure inside the ambient yield-stress liquid and ![]() $\hat{\boldsymbol{\tau}}$ is the deviatoric stress tensor. The bubble is finite and the flow is driven by the buoyancy of the bubble. Thus, distant from the bubble, the stress falls below the yield stress of the fluid and the flow is stagnant. Without loss of generality we impose zero velocity on the flow in the far field.

$\hat{\boldsymbol{\tau}}$ is the deviatoric stress tensor. The bubble is finite and the flow is driven by the buoyancy of the bubble. Thus, distant from the bubble, the stress falls below the yield stress of the fluid and the flow is stagnant. Without loss of generality we impose zero velocity on the flow in the far field.

Figure 2. Schematic of the flow set-up.

2.1. Dimensionless model and relevant dimensionless groups

We scale the pressure (![]() $\hat {p}$) and the deviatoric stress tensor (

$\hat {p}$) and the deviatoric stress tensor (![]() $\hat {\boldsymbol {\tau }}$) with the buoyancy stress

$\hat {\boldsymbol {\tau }}$) with the buoyancy stress ![]() $( \hat {\rho }_f - \hat {\rho }_b ) \hat {g} \hat {\ell }$, and the velocity vector (

$( \hat {\rho }_f - \hat {\rho }_b ) \hat {g} \hat {\ell }$, and the velocity vector (![]() $\hat {\boldsymbol {u}}=(\hat {u},\hat {v})$) with the velocity

$\hat {\boldsymbol {u}}=(\hat {u},\hat {v})$) with the velocity ![]() $\hat {U}$

$\hat {U}$

which naturally arises from balancing the buoyancy stress with a viscous stress. In these equations, ![]() $\hat {\rho }_f$,

$\hat {\rho }_f$, ![]() $\hat {\rho }_b$,

$\hat {\rho }_b$, ![]() $\hat {g}$,

$\hat {g}$, ![]() $\boldsymbol {e}_g$ are respectively the densities of fluid, gas, the gravitational acceleration and its direction;

$\boldsymbol {e}_g$ are respectively the densities of fluid, gas, the gravitational acceleration and its direction; ![]() $\hat {\mu }$ is the plastic viscosity. The length

$\hat {\mu }$ is the plastic viscosity. The length ![]() $\hat {\ell }$ is fixed by the dimensional bubble size. For our 2-D planar flows,

$\hat {\ell }$ is fixed by the dimensional bubble size. For our 2-D planar flows, ![]() ${\rm \pi} \hat {\ell }^2 = \text {meas} (X)$, and for our 3-D axisymmetric flows,

${\rm \pi} \hat {\ell }^2 = \text {meas} (X)$, and for our 3-D axisymmetric flows, ![]() $(4/3) {\rm \pi}\hat {\ell }^3 = \text {meas}(X)$, i.e. considering the circle and sphere as reference geometries respectively. Thus, our scaled bubble domain

$(4/3) {\rm \pi}\hat {\ell }^3 = \text {meas}(X)$, i.e. considering the circle and sphere as reference geometries respectively. Thus, our scaled bubble domain ![]() $X$ will have area

$X$ will have area ![]() ${\rm \pi}$, or volume

${\rm \pi}$, or volume ![]() $(4/3) {\rm \pi}$.

$(4/3) {\rm \pi}$.

The dimensionless Stokes and the constitutive equations are,

and

\begin{equation} \left. \begin{array}{ll@{}} \boldsymbol{\tau} = \left( 1 + \displaystyle{\dfrac{Y}{\Vert\dot{\boldsymbol{\gamma}}\Vert}} \right) \dot{\boldsymbol{\gamma}} & \text{if}\ \Vert \boldsymbol{\tau} \Vert > Y,\\ \dot{\boldsymbol{\gamma}} = 0 & \text{if}\ \Vert \boldsymbol{\tau} \Vert \leqslant Y. \end{array} \right\} \end{equation}

\begin{equation} \left. \begin{array}{ll@{}} \boldsymbol{\tau} = \left( 1 + \displaystyle{\dfrac{Y}{\Vert\dot{\boldsymbol{\gamma}}\Vert}} \right) \dot{\boldsymbol{\gamma}} & \text{if}\ \Vert \boldsymbol{\tau} \Vert > Y,\\ \dot{\boldsymbol{\gamma}} = 0 & \text{if}\ \Vert \boldsymbol{\tau} \Vert \leqslant Y. \end{array} \right\} \end{equation}

The two dimensionless groups are the density ratio ![]() $\rho = \hat {\rho }_b / \hat {\rho }_f$, and

$\rho = \hat {\rho }_b / \hat {\rho }_f$, and ![]() $Y = \hat {\tau }_y/(\Delta \hat {\rho } \hat {g} \hat {\ell })$, which is the yield number. Generally, we expect

$Y = \hat {\tau }_y/(\Delta \hat {\rho } \hat {g} \hat {\ell })$, which is the yield number. Generally, we expect ![]() $\hat {\rho }_b \ll \hat {\rho }_f$, so that in practice

$\hat {\rho }_b \ll \hat {\rho }_f$, so that in practice ![]() $\Delta \hat {\rho } \approx \hat {\rho }_f$ and

$\Delta \hat {\rho } \approx \hat {\rho }_f$ and ![]() $\rho \approx 0$. In (2.5)

$\rho \approx 0$. In (2.5) ![]() $\dot {\boldsymbol {\gamma }}$ is the rate of strain tensor and

$\dot {\boldsymbol {\gamma }}$ is the rate of strain tensor and ![]() $\Vert \cdot \Vert$ is the norm associated with the tensor inner product

$\Vert \cdot \Vert$ is the norm associated with the tensor inner product

e.g. ![]() $\Vert \boldsymbol {\tau } \Vert = \sqrt {\boldsymbol {\tau } \boldsymbol {:} \boldsymbol {\tau }}$. The Cauchy stress tensor is

$\Vert \boldsymbol {\tau } \Vert = \sqrt {\boldsymbol {\tau } \boldsymbol {:} \boldsymbol {\tau }}$. The Cauchy stress tensor is ![]() $\boldsymbol {\sigma } = -p \boldsymbol {I}+\boldsymbol {\tau }$.

$\boldsymbol {\sigma } = -p \boldsymbol {I}+\boldsymbol {\tau }$.

The velocity vector and tangential components of the traction (i.e. ![]() $( \boldsymbol {\sigma } \boldsymbol {\cdot } \boldsymbol {n} ) \boldsymbol {\cdot } \boldsymbol {t}$) are continuous across the bubble surface

$( \boldsymbol {\sigma } \boldsymbol {\cdot } \boldsymbol {n} ) \boldsymbol {\cdot } \boldsymbol {t}$) are continuous across the bubble surface ![]() $\partial X$. Since the dynamic viscosity of the gas inside the bubble is generally negligible compared with the effective viscosity of yield-stress liquids, we assume

$\partial X$. Since the dynamic viscosity of the gas inside the bubble is generally negligible compared with the effective viscosity of yield-stress liquids, we assume

Thus, the tangential components of the traction vanish and the bubble can be regarded as inviscid; tangential velocities may slip and the normal velocity is continuous. The jump in the normal component of the traction is controlled by the dimensionless surface tension ![]() $\gamma \,(= \hat {\gamma } / \hat {\rho }_f \hat {g} \hat {\ell }^2$; the inverse of the Bond number),

$\gamma \,(= \hat {\gamma } / \hat {\rho }_f \hat {g} \hat {\ell }^2$; the inverse of the Bond number),

where

and ![]() $\kappa _1$ and

$\kappa _1$ and ![]() $\kappa _2$ are radii of curvature (in two dimensions

$\kappa _2$ are radii of curvature (in two dimensions ![]() $\kappa _2 = \infty$). In (2.8),

$\kappa _2 = \infty$). In (2.8), ![]() $p_b$ is the pressure inside the bubble which can be considered as a constant in the inviscid and incompressible limit.

$p_b$ is the pressure inside the bubble which can be considered as a constant in the inviscid and incompressible limit.

The drag force on the bubble surface should balance the buoyancy of the bubble, ![]() $F$. In our 2-D flows

$F$. In our 2-D flows

or in dimensionless form

We will use these expressions later in § 3.3.

2.2. Limit of zero flow

In the present study, we are mainly interested in the yield limit of bubble motion, i.e. conditions under which the bubble is held static. From the variational principles derived by Dubash & Frigaard (Reference Dubash and Frigaard2004), we can conclude that

From left to right, the integrals above represent the plastic dissipation, denoted ![]() $j(\boldsymbol {u})$, the work done by buoyancy and by surface tension, denoted

$j(\boldsymbol {u})$, the work done by buoyancy and by surface tension, denoted ![]() $L(\boldsymbol {u})$ and

$L(\boldsymbol {u})$ and ![]() $T(\boldsymbol {u})$, respectively. In terms of these functionals, for

$T(\boldsymbol {u})$, respectively. In terms of these functionals, for ![]() $\boldsymbol {u} \neq 0$, we have

$\boldsymbol {u} \neq 0$, we have

\begin{equation} Y \leqslant - \frac{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{e}_g \,\text{d} \varOmega}{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \Vert \dot{\boldsymbol{\gamma}} \Vert \,\text{d} \varOmega} - \frac{\displaystyle \int_{\partial X} \frac{\gamma}{\kappa} \left( \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{n} \right) \,\text{d}S}{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \Vert \dot{\boldsymbol{\gamma}} \Vert \,\text{d} \varOmega} \equiv \frac{L(\boldsymbol{u})}{j(\boldsymbol{u})} + \frac{T(\boldsymbol{u})}{j(\boldsymbol{u})}. \end{equation}

\begin{equation} Y \leqslant - \frac{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{e}_g \,\text{d} \varOmega}{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \Vert \dot{\boldsymbol{\gamma}} \Vert \,\text{d} \varOmega} - \frac{\displaystyle \int_{\partial X} \frac{\gamma}{\kappa} \left( \boldsymbol{u} \boldsymbol{\cdot} \boldsymbol{n} \right) \,\text{d}S}{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \Vert \dot{\boldsymbol{\gamma}} \Vert \,\text{d} \varOmega} \equiv \frac{L(\boldsymbol{u})}{j(\boldsymbol{u})} + \frac{T(\boldsymbol{u})}{j(\boldsymbol{u})}. \end{equation}

Hence, for a given shape of bubble, the critical yield number ![]() $Y_c$ above which the bubble will not rise is

$Y_c$ above which the bubble will not rise is

\begin{equation} Y_c \equiv \sup_{\boldsymbol{v} \in \boldsymbol{V},\,\boldsymbol{v} \neq 0} \left\{ - \frac{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{e}_g \,\text{d} \varOmega}{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \Vert \dot{\boldsymbol{\gamma}} \left( \boldsymbol{v} \right) \Vert \,\text{d} \varOmega} - \frac{\displaystyle \int_{\partial X} \frac{\gamma}{\kappa} \left( \boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{n} \right) \,\text{d}S}{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \Vert \dot{\boldsymbol{\gamma}} \left( \boldsymbol{v} \right) \Vert \,\text{d} \varOmega} \right\}, \end{equation}

\begin{equation} Y_c \equiv \sup_{\boldsymbol{v} \in \boldsymbol{V},\,\boldsymbol{v} \neq 0} \left\{ - \frac{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{e}_g \,\text{d} \varOmega}{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \Vert \dot{\boldsymbol{\gamma}} \left( \boldsymbol{v} \right) \Vert \,\text{d} \varOmega} - \frac{\displaystyle \int_{\partial X} \frac{\gamma}{\kappa} \left( \boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{n} \right) \,\text{d}S}{\displaystyle \int_{{\varOmega} \setminus \bar{X}} \Vert \dot{\boldsymbol{\gamma}} \left( \boldsymbol{v} \right) \Vert \,\text{d} \varOmega} \right\}, \end{equation}

where ![]() $\boldsymbol {v}$ is any admissible velocity field from the set

$\boldsymbol {v}$ is any admissible velocity field from the set ![]() $\boldsymbol {V}$ of all admissible fields. The first term on the right-hand side represents the effect of the buoyancy stress on yielding; the numerator is the flux due to the bubble. This first term also appears in similar problems involving solid particles (Putz & Frigaard Reference Putz and Frigaard2010; Chaparian & Frigaard Reference Chaparian and Frigaard2017b), although there the interfacial conditions are different and

$\boldsymbol {V}$ of all admissible fields. The first term on the right-hand side represents the effect of the buoyancy stress on yielding; the numerator is the flux due to the bubble. This first term also appears in similar problems involving solid particles (Putz & Frigaard Reference Putz and Frigaard2010; Chaparian & Frigaard Reference Chaparian and Frigaard2017b), although there the interfacial conditions are different and ![]() $\rho \neq 0$. The second term represents the effect of the surface tension.

$\rho \neq 0$. The second term represents the effect of the surface tension.

Since ![]() $\boldsymbol {v}$ is an admissible velocity field, it is also divergence free and the net flux through the bubble surface is consequently zero

$\boldsymbol {v}$ is an admissible velocity field, it is also divergence free and the net flux through the bubble surface is consequently zero

We can split ![]() $\boldsymbol {v}$ into two components: the mean bubble speed

$\boldsymbol {v}$ into two components: the mean bubble speed ![]() $V_b$ and a perturbation

$V_b$ and a perturbation ![]() $\boldsymbol {v}^{\prime }$

$\boldsymbol {v}^{\prime }$

\begin{equation} \boldsymbol{v} = \frac{- \displaystyle \int_{\varOmega \setminus \bar{X}} (\boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{e}_g) \,\text{d}\varOmega}{\rm \pi} \,\boldsymbol{e}_g + \boldsymbol{v}^{\prime}= V_b ~\boldsymbol{e}_g + \boldsymbol{v}^{\prime}\quad \text{on}\ \partial X. \end{equation}

\begin{equation} \boldsymbol{v} = \frac{- \displaystyle \int_{\varOmega \setminus \bar{X}} (\boldsymbol{v} \boldsymbol{\cdot} \boldsymbol{e}_g) \,\text{d}\varOmega}{\rm \pi} \,\boldsymbol{e}_g + \boldsymbol{v}^{\prime}= V_b ~\boldsymbol{e}_g + \boldsymbol{v}^{\prime}\quad \text{on}\ \partial X. \end{equation}The surface flux can now be rewritten as

It is clear that ![]() $\displaystyle \int _{\partial X} (\boldsymbol {n} \boldsymbol {\cdot } \boldsymbol {e}_g)\,\text {d}S$ is zero, and therefore

$\displaystyle \int _{\partial X} (\boldsymbol {n} \boldsymbol {\cdot } \boldsymbol {e}_g)\,\text {d}S$ is zero, and therefore

Turning to the second term in (2.14), since ![]() $\kappa$ is not a constant for a general bubble shape along

$\kappa$ is not a constant for a general bubble shape along ![]() $\partial X$

$\partial X$

in general. The only case in which this term is definitely zero is a sphere (or a circular bubble in two dimensions). Physically, this means that, in the case of a spherical (or circular) bubble, only buoyancy controls the yielding of the bubble; surface tension plays no role. This is intuitive for these equilibrium shapes, i.e. we expect the surface tension to deform the bubble towards its equilibrium shape. For a general bubble shape, ![]() $Y_c$ is clearly also a function of the surface tension. Later, to analyse this effect the yield-capillary number is defined as

$Y_c$ is clearly also a function of the surface tension. Later, to analyse this effect the yield-capillary number is defined as

3. Methodology and benchmarking

In overview, we use an augmented Lagrangian method coupled with an adaptive finite element method (Roquet & Saramito Reference Roquet and Saramito2003) implemented in FreeFem++ (Hecht Reference Hecht2012) to solve for the flow at fixed shape, ![]() $\gamma$ and

$\gamma$ and ![]() $Y$. To determine

$Y$. To determine ![]() $Y_c$ we then iteratively increase

$Y_c$ we then iteratively increase ![]() $Y$ until the flow stops. This basic procedure has been validated extensively in previous studies (Roustaei et al. Reference Roustaei, Chevalier, Talon and Frigaard2016; Chaparian & Frigaard Reference Chaparian and Frigaard2017b; Chaparian et al. Reference Chaparian, Izbassarov, De Vita, Brandt and Tammisola2020; Chaparian & Tammisola Reference Chaparian and Tammisola2021), including those with particles. The mesh refinement nicely captures the yield surfaces after a few refinements.

$Y$ until the flow stops. This basic procedure has been validated extensively in previous studies (Roustaei et al. Reference Roustaei, Chevalier, Talon and Frigaard2016; Chaparian & Frigaard Reference Chaparian and Frigaard2017b; Chaparian et al. Reference Chaparian, Izbassarov, De Vita, Brandt and Tammisola2020; Chaparian & Tammisola Reference Chaparian and Tammisola2021), including those with particles. The mesh refinement nicely captures the yield surfaces after a few refinements.

3.1. Computational method

As we are concerned with finding the critical flow/no-flow condition (i.e. ![]() $Y_c$), which represents a limiting balance between buoyancy, surface tension and plastic dissipation functionals, i.e. (2.14), we compute the flows by solving the variational formulation of the exact non-smooth Bingham model. The alternative viscosity regularisation methods are simple and effective in many cases, but have two drawbacks. First, characteristic features such as the yield surface shape are very sensitive to the regularisation used (Burgos, Alexandrou & Entov Reference Burgos, Alexandrou and Entov1999). Second, large errors can result when computing flows that are close to the critical no-flow limit, e.g. as shown recently by Ahmadi & Karimfazli (Reference Ahmadi and Karimfazli2021). The issue is that as the regularisation parameter is taken to its limiting value, the velocity field of the regularised model does converge to the exact Bingham velocity, but there is no guarantee that the stress field will converge (Frigaard & Nouar Reference Frigaard and Nouar2005).

$Y_c$), which represents a limiting balance between buoyancy, surface tension and plastic dissipation functionals, i.e. (2.14), we compute the flows by solving the variational formulation of the exact non-smooth Bingham model. The alternative viscosity regularisation methods are simple and effective in many cases, but have two drawbacks. First, characteristic features such as the yield surface shape are very sensitive to the regularisation used (Burgos, Alexandrou & Entov Reference Burgos, Alexandrou and Entov1999). Second, large errors can result when computing flows that are close to the critical no-flow limit, e.g. as shown recently by Ahmadi & Karimfazli (Reference Ahmadi and Karimfazli2021). The issue is that as the regularisation parameter is taken to its limiting value, the velocity field of the regularised model does converge to the exact Bingham velocity, but there is no guarantee that the stress field will converge (Frigaard & Nouar Reference Frigaard and Nouar2005).

The variational formulation of the Bingham fluid dates back to Prager (Reference Prager1954) and was formalised by Duvaut & Lions (Reference Duvaut and Lions1976). They established two inequalities for the Stokes flow of Bingham fluid: a minimisation based on velocity field (primal variable in optimisation literature) and a maximisation based on the stress field (dual variable). The two functionals are

The first term in (3.1) is half of the viscous dissipation, denoted ![]() $a(\boldsymbol {v},\boldsymbol {v})$. An admissible velocity field

$a(\boldsymbol {v},\boldsymbol {v})$. An admissible velocity field ![]() $\boldsymbol {v} \in \mathcal {V}$ is any divergence free velocity satisfying the boundary conditions. An admissible stress field

$\boldsymbol {v} \in \mathcal {V}$ is any divergence free velocity satisfying the boundary conditions. An admissible stress field ![]() $\boldsymbol {\tau }$ is any stress field satisfying the momentum equations (2.1) including the stress boundary conditions. A pair

$\boldsymbol {\tau }$ is any stress field satisfying the momentum equations (2.1) including the stress boundary conditions. A pair ![]() $(\boldsymbol {u}^\ast,\boldsymbol {\tau }^\ast )$ that solve the Stokes problem will result in

$(\boldsymbol {u}^\ast,\boldsymbol {\tau }^\ast )$ that solve the Stokes problem will result in ![]() $H(\boldsymbol {u}^\ast )=-K(\boldsymbol {\tau }^\ast )$. Note that the velocity is unique, but not the stress. For any other pair of admissible velocity/stress fields there is a difference between these values that is referred to as the duality gap. As discussed in Treskatis et al. (Reference Treskatis, Roustaei, Frigaard and Wachs2018), the duality gap is the most reliable measure to make sure we have computed accurate stress fields as well as velocity fields, particularly close to the yield point.

$H(\boldsymbol {u}^\ast )=-K(\boldsymbol {\tau }^\ast )$. Note that the velocity is unique, but not the stress. For any other pair of admissible velocity/stress fields there is a difference between these values that is referred to as the duality gap. As discussed in Treskatis et al. (Reference Treskatis, Roustaei, Frigaard and Wachs2018), the duality gap is the most reliable measure to make sure we have computed accurate stress fields as well as velocity fields, particularly close to the yield point.

Glowinski, Lions & Trémolières (Reference Glowinski, Lions and Trémolières1981) developed the augmented Lagrangian (AL) method for solving the velocity maximisation (primal formulation). The AL has been successfully used to solve various flows e.g. in ducts (Saramito & Roquet Reference Saramito and Roquet2001), around objects (Roquet & Saramito Reference Roquet and Saramito2003) and for inertial flows (Roustaei & Frigaard Reference Roustaei and Frigaard2015). Advances in computational optimisation have led to a re-exploration of these flows recently, using algorithms that exploit the duality. A variation of the FISTA (fast iterative shrinkage-thresholding algorithm) was applied to the stress maximisation formulation by Treskatis, Moyers-González & Price (Reference Treskatis, Moyers-González and Price2016), which achieves a higher order of convergence in terms of the duality gap. Here, we have used both AL and FISTA algorithms for our flows. This provides a basis to compare and cross-validate. We have used the duality gap as the criterion for measuring the convergence of the solutions and find very little difference in converged solutions with either algorithm; see the Appendix.

3.2. Benchmark flow

As a benchmark, we have computed 2-D flows around circular and elliptical bubbles parameterised by an aspect ratio ![]() $\chi$, i.e. the bubble surface is

$\chi$, i.e. the bubble surface is

The limiting solutions are explored fully later in the paper. Figure 3 shows the viscous dissipation ![]() $a(\boldsymbol {u},\boldsymbol {u})$, plastic dissipation

$a(\boldsymbol {u},\boldsymbol {u})$, plastic dissipation ![]() $j(\boldsymbol {u})$ and buoyancy work

$j(\boldsymbol {u})$ and buoyancy work ![]() $L(\boldsymbol {u})$ functionals for

$L(\boldsymbol {u})$ functionals for ![]() $\chi =1$. All functionals decay with a power-law behaviour as the yield number approaches the critical value. The viscous dissipation decays faster compared with the other functionals, in accordance with the computations of Dimakopoulos et al. (Reference Dimakopoulos, Pavlidis and Tsamopoulos2013), and as must be true theoretically (Putz & Frigaard Reference Putz and Frigaard2010). Evidently,

$\chi =1$. All functionals decay with a power-law behaviour as the yield number approaches the critical value. The viscous dissipation decays faster compared with the other functionals, in accordance with the computations of Dimakopoulos et al. (Reference Dimakopoulos, Pavlidis and Tsamopoulos2013), and as must be true theoretically (Putz & Frigaard Reference Putz and Frigaard2010). Evidently, ![]() $j(\boldsymbol {u}) \sim L(\boldsymbol {u})$ as they decay, as is implicit from (2.14) in the absence of surface tension. The velocity field for two cases of

$j(\boldsymbol {u}) \sim L(\boldsymbol {u})$ as they decay, as is implicit from (2.14) in the absence of surface tension. The velocity field for two cases of ![]() ${1-Y/Y_c = 0.011,\ 0.419}$ are shown as insets. At yield numbers far away from the critical yield number (i.e. higher values of

${1-Y/Y_c = 0.011,\ 0.419}$ are shown as insets. At yield numbers far away from the critical yield number (i.e. higher values of ![]() $1-Y/Y_c$), the yield surface surrounding the bubble is distant, and the yield surface at the bubble equator is small. As

$1-Y/Y_c$), the yield surface surrounding the bubble is distant, and the yield surface at the bubble equator is small. As ![]() $Y$ gets closer to

$Y$ gets closer to ![]() $Y_c$ the outer yield surface shrinks and the inner yield surface expands until they merge at

$Y_c$ the outer yield surface shrinks and the inner yield surface expands until they merge at ![]() $Y=Y_c$, where the bubble becomes entrapped.

$Y=Y_c$, where the bubble becomes entrapped.

Figure 3. Viscous dissipation (![]() $\bigcirc$), plastic dissipation (

$\bigcirc$), plastic dissipation (![]() $\triangle$) and buoyancy work (

$\triangle$) and buoyancy work (![]() $\square$) functionals for

$\square$) functionals for ![]() $\chi =1$ and

$\chi =1$ and ![]() $\gamma =0$. Insets illustrate the velocity field (

$\gamma =0$. Insets illustrate the velocity field (![]() $\vert \boldsymbol {u} \vert$) for the cases of

$\vert \boldsymbol {u} \vert$) for the cases of ![]() $1-Y/Y_c = 0.011$ (top left) and 0.419 (bottom right).

$1-Y/Y_c = 0.011$ (top left) and 0.419 (bottom right).

To explore the effects of surface tension we set ![]() $\chi =2$, so that the bubble is not in its equilibrium shape. Figure 4 shows the surface tension functional

$\chi =2$, so that the bubble is not in its equilibrium shape. Figure 4 shows the surface tension functional ![]() $T(\boldsymbol {u})$ in addition to the previous functionals, for

$T(\boldsymbol {u})$ in addition to the previous functionals, for ![]() $\gamma =0, 1$ and 10. Again, all functionals decay with a power-law behaviour as the yield number approaches the critical value and the viscous dissipation decay is the fastest. In the absence of surface tension, buoyancy work mainly dissipates into plastic deformation. At

$\gamma =0, 1$ and 10. Again, all functionals decay with a power-law behaviour as the yield number approaches the critical value and the viscous dissipation decay is the fastest. In the absence of surface tension, buoyancy work mainly dissipates into plastic deformation. At ![]() $\gamma = 1$ we see an approximately equal

$\gamma = 1$ we see an approximately equal ![]() $T(\boldsymbol {u}) \sim L(\boldsymbol {u})$, both balanced by

$T(\boldsymbol {u}) \sim L(\boldsymbol {u})$, both balanced by ![]() $j(\boldsymbol {u})$. As the surface tension forces increase to dominate the flow (e.g.

$j(\boldsymbol {u})$. As the surface tension forces increase to dominate the flow (e.g. ![]() $\gamma =10$), it can be seen that most of the plastic dissipation originates from balancing the surface tension work

$\gamma =10$), it can be seen that most of the plastic dissipation originates from balancing the surface tension work ![]() $T(\boldsymbol {u})$.

$T(\boldsymbol {u})$.

Figure 4. Viscous dissipation (![]() $\bigcirc$), plastic dissipation (

$\bigcirc$), plastic dissipation (![]() $\triangle$), buoyancy (

$\triangle$), buoyancy (![]() $\square$) and surface tension work (

$\square$) and surface tension work (![]() $*$) functional for

$*$) functional for ![]() $\chi =2$. Cases of

$\chi =2$. Cases of ![]() $\gamma =0$,

$\gamma =0$, ![]() $\gamma =1$ and

$\gamma =1$ and ![]() $\gamma =10$ are shown in red, blue and black symbols, respectively.

$\gamma =10$ are shown in red, blue and black symbols, respectively.

3.3. Slipline analysis for 2-D bubbles

As the viscous dissipation is irrelevant to the yield limit, a natural direction to look for comparison is the theory of perfect plasticity, for which ![]() $\Vert \hat {\boldsymbol {\tau }}^* \Vert = \hat {\tau }_y$, since

$\Vert \hat {\boldsymbol {\tau }}^* \Vert = \hat {\tau }_y$, since

Here, we will use an asterisk to avoid mixing up with the viscoplastic variables. The unrestricted 2-D perfectly plastic flow can be transformed to an orthogonal curvilinear coordinate system (![]() $\alpha$ and

$\alpha$ and ![]() $\beta$) in which the directions coincide with the maximum shear stress (

$\beta$) in which the directions coincide with the maximum shear stress (![]() $\hat {\tau }_{\alpha \beta } = \pm \hat {\tau }_y$) directions (Hill Reference Hill1950; Chakrabarty Reference Chakrabarty2012). These orthogonal directions (i.e.

$\hat {\tau }_{\alpha \beta } = \pm \hat {\tau }_y$) directions (Hill Reference Hill1950; Chakrabarty Reference Chakrabarty2012). These orthogonal directions (i.e. ![]() $\alpha\text{-}$ and

$\alpha\text{-}$ and ![]() $\beta\text{-}$directions) are the characteristic lines of the hyperbolic momentum equations in a 2-D flow, known as the sliplines. Finding the sliplines does not require extensive computational effort and therefore this theory has been developed to compare with the viscoplastic ‘yield limit’ for many different problems such as particle sedimentation (Hewitt & Balmforth Reference Hewitt and Balmforth2018; Chaparian & Frigaard Reference Chaparian and Frigaard2017a,Reference Chaparian and Frigaardb; Chaparian & Tammisola Reference Chaparian and Tammisola2021); swimming (Hewitt & Balmforth Reference Hewitt and Balmforth2017; Supekar, Hewitt & Balmforth Reference Supekar, Hewitt and Balmforth2020); and different studies in slump/dam-break type problems (Dubash et al. Reference Dubash, Balmforth, Slim and Cochard2009; Liu et al. Reference Liu, Balmforth, Hormozi and Hewitt2016; Chaparian & Nasouri Reference Chaparian and Nasouri2018). The solution procedure consists of postulating an admissible stress field by means of the sliplines and calculating the lower bound for the limiting force. An upper bound of the force also can be calculated using an admissible velocity field. The solution is more exact if the gap between the lower and upper bounds is small. This is the perfectly plastic version of the duality gap.

$\beta\text{-}$directions) are the characteristic lines of the hyperbolic momentum equations in a 2-D flow, known as the sliplines. Finding the sliplines does not require extensive computational effort and therefore this theory has been developed to compare with the viscoplastic ‘yield limit’ for many different problems such as particle sedimentation (Hewitt & Balmforth Reference Hewitt and Balmforth2018; Chaparian & Frigaard Reference Chaparian and Frigaard2017a,Reference Chaparian and Frigaardb; Chaparian & Tammisola Reference Chaparian and Tammisola2021); swimming (Hewitt & Balmforth Reference Hewitt and Balmforth2017; Supekar, Hewitt & Balmforth Reference Supekar, Hewitt and Balmforth2020); and different studies in slump/dam-break type problems (Dubash et al. Reference Dubash, Balmforth, Slim and Cochard2009; Liu et al. Reference Liu, Balmforth, Hormozi and Hewitt2016; Chaparian & Nasouri Reference Chaparian and Nasouri2018). The solution procedure consists of postulating an admissible stress field by means of the sliplines and calculating the lower bound for the limiting force. An upper bound of the force also can be calculated using an admissible velocity field. The solution is more exact if the gap between the lower and upper bounds is small. This is the perfectly plastic version of the duality gap.

Randolph & Houlsby (Reference Randolph and Houlsby1984) proposed a slipline solution for flow around a laterally moving circular pile in soil to calculate the resistance. This solution has been used as a test problem in the context of 2-D particle sedimentation in yield-stress fluids (e.g. see Chaparian & Frigaard Reference Chaparian and Frigaard2017b). One of the less explored parts of Randolph & Houlsby's solution is the case of non-adhesive soil. In this case, the tangential shear stress at the pile surface is less than ![]() $\hat {\tau }_y$; namely

$\hat {\tau }_y$; namely ![]() $( \hat {\boldsymbol {\tau }}^* \boldsymbol {\cdot } \boldsymbol {n} ) \boldsymbol {t} = \alpha _s \hat {\tau }_y$, where

$( \hat {\boldsymbol {\tau }}^* \boldsymbol {\cdot } \boldsymbol {n} ) \boldsymbol {t} = \alpha _s \hat {\tau }_y$, where ![]() $0 \leqslant \alpha _s \leqslant 1$ is the adhesion factor. This implies that one family of sliplines (say

$0 \leqslant \alpha _s \leqslant 1$ is the adhesion factor. This implies that one family of sliplines (say ![]() $\alpha\text{-}$family) makes an angle

$\alpha\text{-}$family) makes an angle ![]() $[ {{\rm \pi} }/{2} - \sin ^{-1} (\alpha _s) ]/2$ with the pile interface. In other words, when

$[ {{\rm \pi} }/{2} - \sin ^{-1} (\alpha _s) ]/2$ with the pile interface. In other words, when ![]() $\alpha _s =1$, the

$\alpha _s =1$, the ![]() $\alpha\text{-}$lines are tangential to the pile surface and when

$\alpha\text{-}$lines are tangential to the pile surface and when ![]() $\alpha _s=0$,

$\alpha _s=0$, ![]() $\alpha\text{-}$lines make

$\alpha\text{-}$lines make ![]() ${{\rm \pi} }/{4}$ angle with the tangent to the pile surface. In the viscoplastic fluid context, Chaparian & Tammisola (Reference Chaparian and Tammisola2021) have shown that

${{\rm \pi} }/{4}$ angle with the tangent to the pile surface. In the viscoplastic fluid context, Chaparian & Tammisola (Reference Chaparian and Tammisola2021) have shown that ![]() $\alpha _s$ represents the ratio of the ‘sliding yield stress’ to the fluid yield stress. Hence,

$\alpha _s$ represents the ratio of the ‘sliding yield stress’ to the fluid yield stress. Hence, ![]() $\alpha _s = 1$ is indeed equivalent to imposing no-slip boundary condition on the object (e.g. particle in a yield-stress fluid) and

$\alpha _s = 1$ is indeed equivalent to imposing no-slip boundary condition on the object (e.g. particle in a yield-stress fluid) and ![]() $\alpha _s=0$ is the same as having Navier slip (i.e. zero sliding yield stress) on the object. It is natural therefore to apply the same solution to the bubble yield limit in the limit of

$\alpha _s=0$ is the same as having Navier slip (i.e. zero sliding yield stress) on the object. It is natural therefore to apply the same solution to the bubble yield limit in the limit of ![]() $\gamma \to 0$ (as surface tension is not accounted for). A closer look at the boundary condition (2.7) reveals that for a 2-D circular bubble, the solution is the same as Randolph & Houlsby (Reference Randolph and Houlsby1984) for

$\gamma \to 0$ (as surface tension is not accounted for). A closer look at the boundary condition (2.7) reveals that for a 2-D circular bubble, the solution is the same as Randolph & Houlsby (Reference Randolph and Houlsby1984) for ![]() $\alpha _s = 0$. We therefore briefly revisit the Randolph & Houlsby (Reference Randolph and Houlsby1984) solution for the case of 2-D circular bubble and then extend it for an elliptical bubble with aspect ratio

$\alpha _s = 0$. We therefore briefly revisit the Randolph & Houlsby (Reference Randolph and Houlsby1984) solution for the case of 2-D circular bubble and then extend it for an elliptical bubble with aspect ratio ![]() $\chi$.

$\chi$.

3.3.1. Circular bubble

This is covered in more detail in Chaparian & Tammisola (Reference Chaparian and Tammisola2021). The maximum normal stress direction is perpendicular to the bubble surface. This is directly dictated by the boundary condition on the bubble surface where the bubble pressure ![]() $p_b$, is constant along

$p_b$, is constant along ![]() $\partial X$. Hence, the

$\partial X$. Hence, the ![]() $\beta\text{-}$lines make an angle

$\beta\text{-}$lines make an angle ![]() ${\rm \pi} / 4$ with the normal vector. As discussed above, the shear stress in the tangential direction is zero and therefore the

${\rm \pi} / 4$ with the normal vector. As discussed above, the shear stress in the tangential direction is zero and therefore the ![]() $\alpha\text{-}$lines make an angle

$\alpha\text{-}$lines make an angle ![]() ${\rm \pi} / 4$ with the tangent to the bubble surface; see figure 5. From the symmetry constraints, along the vertical line of symmetry (

${\rm \pi} / 4$ with the tangent to the bubble surface; see figure 5. From the symmetry constraints, along the vertical line of symmetry (![]() $x=0$), the shear stress is zero (

$x=0$), the shear stress is zero (![]() $\tau ^*_{xy}=0$), while along the horizontal axis (

$\tau ^*_{xy}=0$), while along the horizontal axis (![]() $y=0$), it is maximum. Translating this into the slipline network, it means that the horizontal axis is itself an

$y=0$), it is maximum. Translating this into the slipline network, it means that the horizontal axis is itself an ![]() $\alpha\text{-}$line and all the sliplines that intercept the vertical axis should make an angle

$\alpha\text{-}$line and all the sliplines that intercept the vertical axis should make an angle ![]() ${\rm \pi} / 4$ with it.

${\rm \pi} / 4$ with it.

Figure 5. Schematic of the slipline network about a 2-D circular bubble. A quarter of the domain is shown due to symmetry.

We can construct an admissible stress field around the bubble with the aid of the sliplines and then integrate the force on the bubble surface in the direction ![]() $\boldsymbol {e}_g$ to find

$\boldsymbol {e}_g$ to find ![]() $[ \hat {F}^*_c ]_L$, the lower bound of the limiting force. The effect of buoyancy is absent in this admissible stress field, but by balancing the drag force with

$[ \hat {F}^*_c ]_L$, the lower bound of the limiting force. The effect of buoyancy is absent in this admissible stress field, but by balancing the drag force with ![]() $\Delta \hat {\rho } \hat {g} \hat {A} = \Delta \hat {\rho } \hat {g} {\rm \pi}\ell ^2$, we can find the equivalent

$\Delta \hat {\rho } \hat {g} \hat {A} = \Delta \hat {\rho } \hat {g} {\rm \pi}\ell ^2$, we can find the equivalent ![]() $Y_c$. The limiting plastic drag coefficient is defined as follows, where

$Y_c$. The limiting plastic drag coefficient is defined as follows, where ![]() $\hat {\ell }_\bot$ is the linear length of bubble perpendicular to the flow direction, e.g. twice the radius

$\hat {\ell }_\bot$ is the linear length of bubble perpendicular to the flow direction, e.g. twice the radius ![]() $\hat {R}$ for a circular bubble

$\hat {R}$ for a circular bubble

\begin{equation} C_{d,c}^p = \frac{\hat{F}}{\hat{\tau}_y \hat{\ell}_\bot} = \frac{\hat{F}}{2 \hat{R}\hat{\tau}_y }, \end{equation}

\begin{equation} C_{d,c}^p = \frac{\hat{F}}{\hat{\tau}_y \hat{\ell}_\bot} = \frac{\hat{F}}{2 \hat{R}\hat{\tau}_y }, \end{equation}and from the slipline analysis we find

Hence, we balance buoyancy and the lower bound of the drag force

and find the upper bound of the critical yield number as

3.3.2. Ellipse

For the planar elliptical bubble (3.3), with aspect ratio ![]() $\chi$, we calculate the lower bound force from

$\chi$, we calculate the lower bound force from

where ![]() $\theta _1 = \tan ^{-1} [ \chi ^{-1} \tan {\theta } ]$ and

$\theta _1 = \tan ^{-1} [ \chi ^{-1} \tan {\theta } ]$ and ![]() $\zeta = \tan ^{-1} ( \chi \cot \theta _1 )$. Details of this type of calculation can be found in Chaparian & Frigaard (Reference Chaparian and Frigaard2017b) and Chaparian & Tammisola (Reference Chaparian and Tammisola2021).

$\zeta = \tan ^{-1} ( \chi \cot \theta _1 )$. Details of this type of calculation can be found in Chaparian & Frigaard (Reference Chaparian and Frigaard2017b) and Chaparian & Tammisola (Reference Chaparian and Tammisola2021).

This force lower bound converts to

\begin{equation} \left[ Y_c \right]_U = \frac{\rm \pi}{4 \left[ \hat{F}^* \right]_L}. \end{equation}

\begin{equation} \left[ Y_c \right]_U = \frac{\rm \pi}{4 \left[ \hat{F}^* \right]_L}. \end{equation}3.3.3. Comparing slipline and viscoplastic solutions

Figure 6 compares the slipline network with the viscoplastic solution for ![]() $\chi = 1,\ 2$, for

$\chi = 1,\ 2$, for ![]() $Y$ just below

$Y$ just below ![]() $Y_c$. Although not precisely the same, the envelope of the sliplines approximates the yielded region of the viscoplastic fluid. The white line denotes the yield surface in the viscoplastic fluid and we see that the fluid is unyielded over a large part of the bubble surface, extending from the horizontal axis.

$Y_c$. Although not precisely the same, the envelope of the sliplines approximates the yielded region of the viscoplastic fluid. The white line denotes the yield surface in the viscoplastic fluid and we see that the fluid is unyielded over a large part of the bubble surface, extending from the horizontal axis.

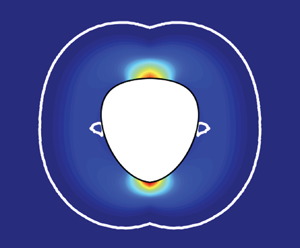

Figure 6. (a,b) Slipline network about a 2-D circular bubble and a 2-D ellipse with ![]() $\chi =2$. (c,d) Velocity

$\chi =2$. (c,d) Velocity ![]() $\vert \boldsymbol {u} \vert$ contour;

$\vert \boldsymbol {u} \vert$ contour; ![]() $Y=0.17$ and

$Y=0.17$ and ![]() $Y=0.255$ for the circular and elliptical bubble, respectively. Unyielded regions are marked with white solid lines.

$Y=0.255$ for the circular and elliptical bubble, respectively. Unyielded regions are marked with white solid lines.

As we increase ![]() $Y$ we find

$Y$ we find ![]() $Y_c$ computationally for the viscoplastic flow, which can be compared with that from (3.9) and (3.10). We find

$Y_c$ computationally for the viscoplastic flow, which can be compared with that from (3.9) and (3.10). We find ![]() $\chi =1:Y_c \approx 0.172$,

$\chi =1:Y_c \approx 0.172$, ![]() $\chi =2:Y_c \approx 0.27$ and

$\chi =2:Y_c \approx 0.27$ and ![]() $\chi =5: Y_c \approx 0.5$ from the slipline method, compared with

$\chi =5: Y_c \approx 0.5$ from the slipline method, compared with ![]() $\chi =1:Y_c \approx 0.172$,

$\chi =1:Y_c \approx 0.172$, ![]() $\chi =2:Y_c \approx 0.267$ and

$\chi =2:Y_c \approx 0.267$ and ![]() $\chi =5:Y_c \approx 0.460$, from the limiting viscoplastic flow computations. Figure 7 shows this comparison graphically over a wider range of

$\chi =5:Y_c \approx 0.460$, from the limiting viscoplastic flow computations. Figure 7 shows this comparison graphically over a wider range of ![]() $\chi$, from which we can see a growing discrepancy between the two limits as

$\chi$, from which we can see a growing discrepancy between the two limits as ![]() $\chi$ increases.

$\chi$ increases.

There are two reasons for this discrepancy. First, we should note that the slipline solutions and limiting viscoplastic solutions are not quite simply the same. Although both flows limit to zero motion at ![]() $Y_c$, the stress fields are not the same. In the viscoplastic solution the yield surfaces bound regions within which the stress is at or below the yield stress. In the perfectly plastic solution the stress is constrained to be at the yield value everywhere within the slipline envelope. The slipline stress field can be used to construct an admissible stress field for the viscoplastic problem (if it can be extended outside the slipline envelope), and using the stress maximisation principle one can infer that this will lead to an upper bound for the viscoplastic

$Y_c$, the stress fields are not the same. In the viscoplastic solution the yield surfaces bound regions within which the stress is at or below the yield stress. In the perfectly plastic solution the stress is constrained to be at the yield value everywhere within the slipline envelope. The slipline stress field can be used to construct an admissible stress field for the viscoplastic problem (if it can be extended outside the slipline envelope), and using the stress maximisation principle one can infer that this will lead to an upper bound for the viscoplastic ![]() $Y_c$, as is observed.

$Y_c$, as is observed.

The second reason for the discrepancy is that, although it is widely believed that the Randolph & Houlsby (Reference Randolph and Houlsby1984) solution is exact (i.e. the lower and upper bounds of the drag are the same for the whole range of ![]() $\alpha _s$), this is not the case. An issue was first detected by Murff, Wagner & Randolph (Reference Murff, Wagner and Randolph1989): for

$\alpha _s$), this is not the case. An issue was first detected by Murff, Wagner & Randolph (Reference Murff, Wagner and Randolph1989): for ![]() $\alpha _s<1$, there is a region in the vicinity of the pile surface in which the rate of strain is negative and its absolute value should consequently be taken into account in calculating the upper bound, to avoid negative plastic dissipation. If one does so, then there is a discrepancy between the lower and upper bounds, i.e. for

$\alpha _s<1$, there is a region in the vicinity of the pile surface in which the rate of strain is negative and its absolute value should consequently be taken into account in calculating the upper bound, to avoid negative plastic dissipation. If one does so, then there is a discrepancy between the lower and upper bounds, i.e. for ![]() $\alpha _s<1$ the Randolph & Houlsby (Reference Randolph and Houlsby1984) solution is not exact for the perfectly plastic problem. Martin & Randolph (Reference Martin and Randolph2006) postulated two new velocity fields which improved the upper bound predictions to some extent. See Chaparian & Tammisola (Reference Chaparian and Tammisola2021) for a detailed comparison with the viscoplastic flow about a solid particle. Also Supekar et al. (Reference Supekar, Hewitt and Balmforth2020) have shown that the Martin & Randolph (Reference Martin and Randolph2006) solution is indeed superior compared with the lower bound solution.

$\alpha _s<1$ the Randolph & Houlsby (Reference Randolph and Houlsby1984) solution is not exact for the perfectly plastic problem. Martin & Randolph (Reference Martin and Randolph2006) postulated two new velocity fields which improved the upper bound predictions to some extent. See Chaparian & Tammisola (Reference Chaparian and Tammisola2021) for a detailed comparison with the viscoplastic flow about a solid particle. Also Supekar et al. (Reference Supekar, Hewitt and Balmforth2020) have shown that the Martin & Randolph (Reference Martin and Randolph2006) solution is indeed superior compared with the lower bound solution.

Note that this does not affect the results here in figure 7, which are taken from (3.9) and (3.10) and use the slipline stress field (the lower bound). Indeed, our conclusion is that the slipline method is a valuable check on computed limiting solutions. It exhibits very similar geometric features and often gives a close estimate to ![]() $Y_c$. A similar conclusion was reached in our study of solid particles (Chaparian & Frigaard Reference Chaparian and Frigaard2017b), for which the Randolph & Houlsby (Reference Randolph and Houlsby1984) slipline solution is both correct and exact (

$Y_c$. A similar conclusion was reached in our study of solid particles (Chaparian & Frigaard Reference Chaparian and Frigaard2017b), for which the Randolph & Houlsby (Reference Randolph and Houlsby1984) slipline solution is both correct and exact (![]() $\alpha _s=1$).

$\alpha _s=1$).

4. Results for 2-D bubbles

4.1. Elliptic bubbles

Here, we investigate the behaviour of critical yield number (![]() $Y_c$) with respect to both aspect ratio (

$Y_c$) with respect to both aspect ratio (![]() $\chi$) and the dimensionless surface tension (

$\chi$) and the dimensionless surface tension (![]() $\gamma$) for 2-D elliptical bubbles described by (3.3). The range of aspect ratios considered are between 0.1 and 10 and the range of surface tensions considered are between 0 and 10. Regarding realistic values of (

$\gamma$) for 2-D elliptical bubbles described by (3.3). The range of aspect ratios considered are between 0.1 and 10 and the range of surface tensions considered are between 0 and 10. Regarding realistic values of (![]() $\chi$) and (

$\chi$) and (![]() $\gamma$), there are two main sources of information. First, we refer to the discussion of different static bubble shapes in § 1. Second, we can look at experimental studies of rising bubbles in yield-stress fluids (Dubash & Frigaard Reference Dubash and Frigaard2007; Sikorski et al. Reference Sikorski, Tabuteau and de Bruyn2009; Lopez et al. Reference Lopez, Naccache and de Souza Mendes2018; Pourzahedi et al. Reference Pourzahedi, Zare and Frigaard2021), where they find aspect ratios 0.2–5, and

$\gamma$), there are two main sources of information. First, we refer to the discussion of different static bubble shapes in § 1. Second, we can look at experimental studies of rising bubbles in yield-stress fluids (Dubash & Frigaard Reference Dubash and Frigaard2007; Sikorski et al. Reference Sikorski, Tabuteau and de Bruyn2009; Lopez et al. Reference Lopez, Naccache and de Souza Mendes2018; Pourzahedi et al. Reference Pourzahedi, Zare and Frigaard2021), where they find aspect ratios 0.2–5, and ![]() $\gamma$ in the range 0.01–0.5. Evidently, experimental bubble shapes are not elliptical (nor planar) and we also note that moving bubbles in experiments tend to be larger than stationary (increased buoyancy). Thus, our range of parameters is practically motivated. In order to find

$\gamma$ in the range 0.01–0.5. Evidently, experimental bubble shapes are not elliptical (nor planar) and we also note that moving bubbles in experiments tend to be larger than stationary (increased buoyancy). Thus, our range of parameters is practically motivated. In order to find ![]() $Y_c$, we vary the yield number until the flow field reaches zero everywhere in the domain using the computational methods discussed in previous section.

$Y_c$, we vary the yield number until the flow field reaches zero everywhere in the domain using the computational methods discussed in previous section.

Figure 8 shows how the critical yield number varies with aspect ratio for different surface tension parameters ![]() $\gamma$. For

$\gamma$. For ![]() $\gamma = 0$,

$\gamma = 0$, ![]() $Y_c$ increases with

$Y_c$ increases with ![]() $\chi$: prolate bubbles (

$\chi$: prolate bubbles (![]() $\chi > 1$) can flow easier compared with oblate bubbles (

$\chi > 1$) can flow easier compared with oblate bubbles (![]() $\chi < 1$). One physically intuitive interpretation of the increases is that, for increasing

$\chi < 1$). One physically intuitive interpretation of the increases is that, for increasing ![]() $\chi$, the bubbles create a static pressure differential proportional to their height: a higher yield stress is consequently required to overcome the stresses created. The height of the bubble scales with

$\chi$, the bubbles create a static pressure differential proportional to their height: a higher yield stress is consequently required to overcome the stresses created. The height of the bubble scales with ![]() $\sqrt {\chi }$, which is approximately the slope of the

$\sqrt {\chi }$, which is approximately the slope of the ![]() $\gamma = 0$ curve. Although attractive in its simplicity, the same explanation does not account for our axisymmetric results later, which suggests that there is more going on here and a different explanation needed. We consider

$\gamma = 0$ curve. Although attractive in its simplicity, the same explanation does not account for our axisymmetric results later, which suggests that there is more going on here and a different explanation needed. We consider ![]() $\chi < 1$ and

$\chi < 1$ and ![]() $\chi > 1$ separately.

$\chi > 1$ separately.

Figure 8. Critical yield number against aspect ratio for various surface tensions for elliptic bubbles.

For ![]() $\chi < 1$, it is apparent that, in order for the bubble to propagate, the fluid must move around an increasingly wide obstacle as

$\chi < 1$, it is apparent that, in order for the bubble to propagate, the fluid must move around an increasingly wide obstacle as ![]() $\chi \to 0$. Primarily the bubble pushes the fluid out of the way, suggesting that normal stresses at the interface are important and tangential stresses less relevant. In this sense oblate bubbles and particles may be similar in their yield limit behaviour. In Chaparian & Frigaard (Reference Chaparian and Frigaard2017b), the yield limit of planar elliptical particles for

$\chi \to 0$. Primarily the bubble pushes the fluid out of the way, suggesting that normal stresses at the interface are important and tangential stresses less relevant. In this sense oblate bubbles and particles may be similar in their yield limit behaviour. In Chaparian & Frigaard (Reference Chaparian and Frigaard2017b), the yield limit of planar elliptical particles for ![]() $\chi \ll 1$ varies as

$\chi \ll 1$ varies as ![]() $Y_c \sim \chi ^{0.5}$, just as here. However, the rigid particle displaces a triangular region of unyielded fluid ahead of it, which then pushes a ring of fluid around the particle at constant speed; see figure 10(c) in Chaparian & Frigaard (Reference Chaparian and Frigaard2017b). This simple flow structure allows us to estimate

$Y_c \sim \chi ^{0.5}$, just as here. However, the rigid particle displaces a triangular region of unyielded fluid ahead of it, which then pushes a ring of fluid around the particle at constant speed; see figure 10(c) in Chaparian & Frigaard (Reference Chaparian and Frigaard2017b). This simple flow structure allows us to estimate ![]() $Y_c$ directly for the particle.

$Y_c$ directly for the particle.

When we explore the flow around the bubble as ![]() $Y \sim Y_c$, for

$Y \sim Y_c$, for ![]() $\chi < 1$, we observe that the yielded fluid is confined within two disks of approximate radius

$\chi < 1$, we observe that the yielded fluid is confined within two disks of approximate radius ![]() $\sqrt {2/\chi }$, centred at the ends of the bubble. This feature is just like the flow around elliptical particles. Unlike the rigid particle, the flow is significantly less structured, without sharp gradients. This prevents us from easily deriving an approximation to

$\sqrt {2/\chi }$, centred at the ends of the bubble. This feature is just like the flow around elliptical particles. Unlike the rigid particle, the flow is significantly less structured, without sharp gradients. This prevents us from easily deriving an approximation to ![]() $Y_c$, but the order of

$Y_c$, but the order of ![]() $Y_c$ as

$Y_c$ as ![]() $\chi \to 0$ can be estimated. From (2.14), we see that

$\chi \to 0$ can be estimated. From (2.14), we see that ![]() $Y_c \approx L(\boldsymbol {u})/j(\boldsymbol {u})$ for the limiting solutions

$Y_c \approx L(\boldsymbol {u})/j(\boldsymbol {u})$ for the limiting solutions ![]() $\boldsymbol {u}$. If

$\boldsymbol {u}$. If ![]() $U_b$ represents the mean bubble rise velocity, then we also have

$U_b$ represents the mean bubble rise velocity, then we also have ![]() $L(\boldsymbol {u}) \sim U_b$, due to incompressibility. The bubble width is

$L(\boldsymbol {u}) \sim U_b$, due to incompressibility. The bubble width is ![]() $2a$, also giving the length scale of the yielded region. The strain rate is likely to scale with

$2a$, also giving the length scale of the yielded region. The strain rate is likely to scale with ![]() $U_b /a$ within the yielded region, leading to

$U_b /a$ within the yielded region, leading to ![]() $j(\boldsymbol {u}) \sim U_b/a \times a^2 = a U_b$. Dividing through we have

$j(\boldsymbol {u}) \sim U_b/a \times a^2 = a U_b$. Dividing through we have ![]() $Y_c \approx L(\boldsymbol {u})/j(\boldsymbol {u}) \sim 1/a \sim \chi ^{0.5}$, as we have observed.

$Y_c \approx L(\boldsymbol {u})/j(\boldsymbol {u}) \sim 1/a \sim \chi ^{0.5}$, as we have observed.

In contrast, for ![]() $\chi > 1$ we cannot expect that the bubble yield limit behaves as the particle yield limit. The particle is strongly influenced by a thin yielded boundary layer (Chaparian & Frigaard Reference Chaparian and Frigaard2017b; Hewitt & Balmforth Reference Hewitt and Balmforth2018). For

$\chi > 1$ we cannot expect that the bubble yield limit behaves as the particle yield limit. The particle is strongly influenced by a thin yielded boundary layer (Chaparian & Frigaard Reference Chaparian and Frigaard2017b; Hewitt & Balmforth Reference Hewitt and Balmforth2018). For ![]() $Y \sim Y_c$, we find that for tall bubbles much of the bubble surface is covered by an unyielded plug that moves slowly downwards as the bubble slips against it. This plug region is surrounded by a yielded shear layer and then bounded by the outer yield envelope. In the shear layer the shear stress

$Y \sim Y_c$, we find that for tall bubbles much of the bubble surface is covered by an unyielded plug that moves slowly downwards as the bubble slips against it. This plug region is surrounded by a yielded shear layer and then bounded by the outer yield envelope. In the shear layer the shear stress ![]() $\Vert \boldsymbol {\tau } \Vert$ exceeds the yield stress

$\Vert \boldsymbol {\tau } \Vert$ exceeds the yield stress ![]() $Y$. We may suppose that

$Y$. We may suppose that ![]() $\Vert \dot {\boldsymbol {\gamma }}\Vert \sim (\Vert \boldsymbol {\tau } \Vert - Y) \propto d K$, where

$\Vert \dot {\boldsymbol {\gamma }}\Vert \sim (\Vert \boldsymbol {\tau } \Vert - Y) \propto d K$, where ![]() $d$ represents the distance from the outer yielded envelope to the inner plug, and

$d$ represents the distance from the outer yielded envelope to the inner plug, and ![]() $K$ is the size of the pressure gradient oriented along the flow in the shear layer. Thus, now

$K$ is the size of the pressure gradient oriented along the flow in the shear layer. Thus, now ![]() $j(\boldsymbol {u}) \sim d^2 K \chi ^{0.5}$, if we estimate the shear layer as having size

$j(\boldsymbol {u}) \sim d^2 K \chi ^{0.5}$, if we estimate the shear layer as having size ![]() $d \times \chi ^{0.5}$. For the velocity within the yielded envelope, we integrate once more to find

$d \times \chi ^{0.5}$. For the velocity within the yielded envelope, we integrate once more to find ![]() $|\boldsymbol {u}| \propto d^2 K$ and now integrate over the entire region within the yielded envelope to give

$|\boldsymbol {u}| \propto d^2 K$ and now integrate over the entire region within the yielded envelope to give ![]() $L(\boldsymbol {u}) \sim d^2 K \chi$, i.e. not only across the width of the shear layer. Note that both the height and width of the yielded envelope appear to scale with

$L(\boldsymbol {u}) \sim d^2 K \chi$, i.e. not only across the width of the shear layer. Note that both the height and width of the yielded envelope appear to scale with ![]() $\chi ^{0.5}$. Thus again we find

$\chi ^{0.5}$. Thus again we find ![]() $Y_c \approx L(\boldsymbol {u})/j(\boldsymbol {u}) \sim \chi ^{0.5}$.

$Y_c \approx L(\boldsymbol {u})/j(\boldsymbol {u}) \sim \chi ^{0.5}$.

For ![]() $\gamma > 0$ we see a departure from the

$\gamma > 0$ we see a departure from the ![]() $\gamma = 0$ curve. Surface tension has no effect at

$\gamma = 0$ curve. Surface tension has no effect at ![]() $\chi = 1$, and deviation from the

$\chi = 1$, and deviation from the ![]() $\gamma = 0$ curve is more abrupt for larger

$\gamma = 0$ curve is more abrupt for larger ![]() $\gamma$. As

$\gamma$. As ![]() $\gamma$ increases, the curves become increasingly symmetrical about

$\gamma$ increases, the curves become increasingly symmetrical about ![]() $\chi =1$, meaning that deformation occurs mainly due to surface tension. This behaviour is better illustrated in figure 9, where

$\chi =1$, meaning that deformation occurs mainly due to surface tension. This behaviour is better illustrated in figure 9, where ![]() $Y_c$ is plotted with respect to

$Y_c$ is plotted with respect to ![]() $\gamma$ for various aspect ratios. It can be observed that the

$\gamma$ for various aspect ratios. It can be observed that the ![]() $Y_c$ values for specific

$Y_c$ values for specific ![]() $\chi$ and

$\chi$ and ![]() $1/\chi$ collapse on each other for high values of

$1/\chi$ collapse on each other for high values of ![]() $\gamma$ (e.g.

$\gamma$ (e.g. ![]() $\chi =2, 0.5$). The overlap of the curves for

$\chi =2, 0.5$). The overlap of the curves for ![]() $\chi$ and

$\chi$ and ![]() $1/\chi$ in figure 9 suggests that the high curvature of the more pointed ends of the bubble leads to a dominant effect on the stress field that must be resisted by the yield stress. Therefore, eventually we expect to find a direct balance between yield stress and surface tension. The ratio of yield number to surface tension is the yield-capillary number discussed earlier. The critical value with respect to aspect ratio is plotted for various values of

$1/\chi$ in figure 9 suggests that the high curvature of the more pointed ends of the bubble leads to a dominant effect on the stress field that must be resisted by the yield stress. Therefore, eventually we expect to find a direct balance between yield stress and surface tension. The ratio of yield number to surface tension is the yield-capillary number discussed earlier. The critical value with respect to aspect ratio is plotted for various values of ![]() $\gamma$ in figure 10. As

$\gamma$ in figure 10. As ![]() $\gamma \to \infty$ the curves appear to collapse to a limiting curve, confirming this interpretation. We may also evaluate the maximal curvature of the bubble, as a function of

$\gamma \to \infty$ the curves appear to collapse to a limiting curve, confirming this interpretation. We may also evaluate the maximal curvature of the bubble, as a function of ![]() $\chi$, which occurs at the top and bottom for

$\chi$, which occurs at the top and bottom for ![]() $\chi >1$ and at the sides for

$\chi >1$ and at the sides for ![]() $\chi < 1$. We find that the maximal contribution of the surface tension to the jump in pressures is given by

$\chi < 1$. We find that the maximal contribution of the surface tension to the jump in pressures is given by ![]() $\gamma \chi ^{1.5}$ for

$\gamma \chi ^{1.5}$ for ![]() $\chi >1$, and by

$\chi >1$, and by ![]() $\gamma \chi ^{-1.5}$ for

$\gamma \chi ^{-1.5}$ for ![]() $\chi <1$. The symmetry for large/small

$\chi <1$. The symmetry for large/small ![]() $\chi$ is evident in the planar bubble shape. On returning to figure 8, we note that for large

$\chi$ is evident in the planar bubble shape. On returning to figure 8, we note that for large ![]() $\gamma$ the slopes of the

$\gamma$ the slopes of the ![]() $Y_c$-curves align well with

$Y_c$-curves align well with ![]() $\sim \chi ^{1.5}$ for

$\sim \chi ^{1.5}$ for ![]() $\chi \gg 1$, and

$\chi \gg 1$, and ![]() $\sim \chi ^{-1.5}$ for

$\sim \chi ^{-1.5}$ for ![]() $\chi \ll 1$.

$\chi \ll 1$.

Figure 9. Critical yield number against surface tension for various aspect ratios of elliptic bubbles; ![]() $\chi <1$ is plotted in dotted lines.

$\chi <1$ is plotted in dotted lines.

Figure 10. Yield-capillary number against aspect ratio for various surface tensions for elliptic bubbles.

The effect of the surface tension on the velocity field around moving bubbles, with ![]() $\chi =2$ and

$\chi =2$ and ![]() $\chi =0.5$, is depicted in figure 11(a–h). In all cases, the yield number is selected to satisfy

$\chi =0.5$, is depicted in figure 11(a–h). In all cases, the yield number is selected to satisfy ![]() $1-Y/Y_c =0.1$. It can be seen that velocity magnitudes increase with surface tension for both aspect ratios, suggesting that larger yield number is required to immobilise the bubble at higher surface tension values. We emphasise that these velocity fields do not represent steadily moving bubbles, but are simply Stokes flow solutions for these specific shapes. In the case of

$1-Y/Y_c =0.1$. It can be seen that velocity magnitudes increase with surface tension for both aspect ratios, suggesting that larger yield number is required to immobilise the bubble at higher surface tension values. We emphasise that these velocity fields do not represent steadily moving bubbles, but are simply Stokes flow solutions for these specific shapes. In the case of ![]() $\gamma =0$ for both aspect ratios the flow field as well as the unyielded regions are symmetrical in the upper and lower halves of the bubble (figure 11a,e). For the case of

$\gamma =0$ for both aspect ratios the flow field as well as the unyielded regions are symmetrical in the upper and lower halves of the bubble (figure 11a,e). For the case of ![]() $\chi =2$, in addition to the outer field unyielded region, an unyielded region forms around the bubble equator at low surface tensions, and the yielded fluid circulates from the top to bottom in the pathway between the two regions (figure 11b). Interestingly, the unyielded region attached to the equator shrinks as surface tension increases, and the outer unyielded region surrounds the lower tip (figure 11c). This can be explained by considering the role of surface tension in defining the bubble shape. Surface tension tends to push the bubble boundary into its equilibrium shape (i.e. circle). In the lower half, buoyancy and surface tension forces add up as they both push upwards. However, in the upper half of the bubble, the surface tension force changes direction and pulls downwards. Therefore, they cancel each other out partly. Thus, higher yield stress is required to immobilise the lower half of the bubble compared with the upper half. Further increasing the surface tension creates stronger forces at the tips, which again starts to yield the fluid around the upper tip of the bubble (figure 11d). The unyielded region in the lower half is larger than the upper half due to the same reason explained above.