1. Introduction

Flame initiation or forced ignition in a flammable mixture refers to the generation of a self-sustained propagating flame front from an ignition kernel. Flame initiation plays an important role in fundamental combustion research. Besides, understanding ignition is important for controlling ignition in advanced engines and preventing fire or explosion. In general, forced ignition is triggered by the deposition of a certain amount of thermal energy, such as an electric spark or a hot solid body, which raises the local temperature and induces intensive chemical reaction and thermal runaway (Joulin Reference Joulin1985; Ronney Reference Ronney1990; He Reference He2000; Chen & Ju Reference Chen and Ju2007).

Successful ignition is achieved only when the heat generation from chemical reaction overcomes heat loss to the surrounding environment. Adopting large activation energy asymptotics, Vázquez-Espí and Liñán (Reference Vázquez-Espí and Liñán2001, Reference Vázquez-Espı and Linán2002) analysed the ignition characteristics of a gaseous mixture subject to a point energy source. They identified two ignition regimes through comparing the relevant time scales including the homogeneous ignition time ![]() $({t_{ch}})$, the characteristic time for acoustic wave propagation

$({t_{ch}})$, the characteristic time for acoustic wave propagation ![]() $({t_a})$ and the characteristic time for heat conduction

$({t_a})$ and the characteristic time for heat conduction ![]() $({t_c})$. The ratio

$({t_c})$. The ratio ![]() ${t_a}/{t_c}$ is equivalent to the Knudsen number and it is typically quite small, i.e.

${t_a}/{t_c}$ is equivalent to the Knudsen number and it is typically quite small, i.e. ![]() ${t_a} \ll {t_c}$. The first regime is for fast ignition energy deposition with

${t_a} \ll {t_c}$. The first regime is for fast ignition energy deposition with ![]() ${t_{ch}} \cong {t_a} \ll {t_c}$. In this regime, the heat loss due to thermal expansion balances the heat release from chemical reaction. The second regime is for moderate ignition energy deposition with the corresponding reaction rate being comparable to the heat conduction rate, i.e.

${t_{ch}} \cong {t_a} \ll {t_c}$. In this regime, the heat loss due to thermal expansion balances the heat release from chemical reaction. The second regime is for moderate ignition energy deposition with the corresponding reaction rate being comparable to the heat conduction rate, i.e. ![]() ${t_a} \ll {t_{ch}} \cong {t_c}$. As the pressure wave passes across the hot spot, the local chemical reaction proceeds slightly. This regime corresponds to the diffusive ignition occurring under near isobaric conditions. In reality, the compressibility effects may become discernible at the initial moment when ignition energy is deposited (Maas & Warnatz Reference Maas and Warnatz1988; Kurdyumov et al. Reference Kurdyumov, Blasco, Sánchez Pérez and Liñán Martínez2004). However, during this induction period, the local equilibrium assumption becomes invalid, and the macroscopic balance equation can no longer be used (Champion, Deshaies & Joulin Reference Champion, Deshaies and Joulin1988). Assuming that the time scale for flame kernel evolution is longer than that induction period, it is legitimate to employ the constant pressure approximation and the usual macroscopic governing equations to study the spherical flame ignition. Therefore, we consider the ignition process in the second regime in this study.

${t_a} \ll {t_{ch}} \cong {t_c}$. As the pressure wave passes across the hot spot, the local chemical reaction proceeds slightly. This regime corresponds to the diffusive ignition occurring under near isobaric conditions. In reality, the compressibility effects may become discernible at the initial moment when ignition energy is deposited (Maas & Warnatz Reference Maas and Warnatz1988; Kurdyumov et al. Reference Kurdyumov, Blasco, Sánchez Pérez and Liñán Martínez2004). However, during this induction period, the local equilibrium assumption becomes invalid, and the macroscopic balance equation can no longer be used (Champion, Deshaies & Joulin Reference Champion, Deshaies and Joulin1988). Assuming that the time scale for flame kernel evolution is longer than that induction period, it is legitimate to employ the constant pressure approximation and the usual macroscopic governing equations to study the spherical flame ignition. Therefore, we consider the ignition process in the second regime in this study.

During the ignition process, the reactant consumption becomes relevant and thus the ignition kernel development is affected by the diffusive properties of the deficient reactant. Previous studies have widely investigated the diffusion-controlled premixed stationary spherical flame, which is also known as flame ball and closely related to ignition (Barenblatt Reference Barenblatt1985; Ronney Reference Ronney1989). Based on the thermal-diffusion model, Deshaies and Joulin (Reference Deshaies and Joulin1984) conducted linear stability analysis and found that the adiabatic flame ball is absolutely unstable. This indicates that a negative perturbation of the flame radius results in inward collapse and subsequent flame extinction, while a positive displacement perturbation leads to outward propagation. Therefore, the flame ball radius is popularly considered as the critical radius for successful ignition, beyond which the flame kernel can spontaneously evolve into a self-sustained flame (Chen & Ju Reference Chen and Ju2007; Kelley, Jomaas & Law Reference Kelley, Jomaas and Law2009). However, in premixtures with high Lewis numbers ![]() $(Le > 1)$, the critical radius for successful ignition is in fact much smaller than the flame ball radius (He Reference He2000; Chen, Burke & Ju Reference Chen, Burke and Ju2011). Consequently, the minimum ignition energy (MIE) could be greatly over-predicted based on the flame ball radius.

$(Le > 1)$, the critical radius for successful ignition is in fact much smaller than the flame ball radius (He Reference He2000; Chen, Burke & Ju Reference Chen, Burke and Ju2011). Consequently, the minimum ignition energy (MIE) could be greatly over-predicted based on the flame ball radius.

Practically ignition is usually triggered by the energy deposition, which can be approximately modelled as continuous central heating (Deshaies & Joulin Reference Deshaies and Joulin1984; Jackson, Kapila & Stewart Reference Jackson, Kapila and Stewart1989). When the heating power is sufficiently low, ignition fails and the self-sustained expanding flame cannot be achieved (Deshaies & Joulin Reference Deshaies and Joulin1984; Chen & Ju Reference Chen and Ju2007). Successful ignition is achieved only when the heating power is high enough to induce a continuous transition from flame kernel to self-sustained expanding flame. Once the flame kernel evolves in a self-sustained manner, the central heating becomes irrelevant and could be switched off after an appropriate duration of time. This yields a finite amount of energy deposition, and thereby we can determine the MIE (Chen et al. Reference Chen, Burke and Ju2011; Fernández-Tarrazo et al. Reference Fernández-Tarrazo, Sánchez-Sanz, Sánchez and Williams2016). Subject to external heating, the characteristics of the flame front, e.g. flame temperature, flame propagation speed and flame curvature/stretch, undergo substantial changes. This implies the necessity of taking account of the unsteady effects in the ignition process (Kurdyumov et al. Reference Kurdyumov, Blasco, Sánchez Pérez and Liñán Martínez2004; Chen et al. Reference Chen, Burke and Ju2011). According to He (Reference He2000), the duration for the flame to reach the critical radius ![]() ${t_h}$ can be evaluated by a nonlinear velocity-curvature relation derived based on a quasi-steady assumption. The product of

${t_h}$ can be evaluated by a nonlinear velocity-curvature relation derived based on a quasi-steady assumption. The product of ![]() ${t_h}$ with heating power

${t_h}$ with heating power ![]() ${Q_s}$ gives an estimation of MIE. Employing the thermal-diffusion model and comparing with numerical simulations, Chen et al. (Reference Chen, Burke and Ju2011) suggested that the MIE tends to be linearly proportional to the cube of the critical flame radius. However, the quasi-steady assumption implies that the system is fully developed, and correspondingly the temperature and mass fraction profiles across the reaction front are given by their final state after the long-term evolution. This quasi-steady assumption might not be suitable for describing the initial development of the ignition kernel.

${Q_s}$ gives an estimation of MIE. Employing the thermal-diffusion model and comparing with numerical simulations, Chen et al. (Reference Chen, Burke and Ju2011) suggested that the MIE tends to be linearly proportional to the cube of the critical flame radius. However, the quasi-steady assumption implies that the system is fully developed, and correspondingly the temperature and mass fraction profiles across the reaction front are given by their final state after the long-term evolution. This quasi-steady assumption might not be suitable for describing the initial development of the ignition kernel.

Due to the lack of characteristic time scale, the quasi-steady theory cannot rigorously interpret the dynamic behaviour of the flame kernel subsequent to switching off the heating source. For instance, the removal of the heating source would not cause immediate flame quench; instead the flame could propagate for a finite distance due to the memory effect (Joulin Reference Joulin1985; He Reference He2000; Vázquez-Espí & Liñán Reference Vázquez-Espí and Liñán2001). To interpret the unsteady effects, Joulin (Reference Joulin1985) investigated the flame kernel development in the neighbourhood of a stationary spherical flame and obtained an approximate nonlinear equation interpreting the time change of the flame front distance. Buckmaster and Joulin (Reference Buckmaster and Joulin1989) considered the radially propagating spherical flame in a mixture with ![]() $Le < 1$ and obtained the transient propagation of the self-extinguishing flame. Both theoretical studies were conducted by means of large activation energy asymptotics, whose mathematical procedure tends to be exceedingly complex. Besides, for mixtures with large Lewis number, the flame ball size is considerably larger than the critical radius and thus tends to be irrelevant to flame initiation (Chen et al. Reference Chen, Burke and Ju2011). Employing asymptotic analysis, Clavin (Reference Clavin2017) described the dynamic quenching of a spherical flame expanding at a large radius beyond flammability limits of planar flames, which has been observed in microgravity experiments (Ronney Reference Ronney1989, Reference Ronney1990). However, the unsteady effect was not considered by Clavin (Reference Clavin2017).

$Le < 1$ and obtained the transient propagation of the self-extinguishing flame. Both theoretical studies were conducted by means of large activation energy asymptotics, whose mathematical procedure tends to be exceedingly complex. Besides, for mixtures with large Lewis number, the flame ball size is considerably larger than the critical radius and thus tends to be irrelevant to flame initiation (Chen et al. Reference Chen, Burke and Ju2011). Employing asymptotic analysis, Clavin (Reference Clavin2017) described the dynamic quenching of a spherical flame expanding at a large radius beyond flammability limits of planar flames, which has been observed in microgravity experiments (Ronney Reference Ronney1989, Reference Ronney1990). However, the unsteady effect was not considered by Clavin (Reference Clavin2017).

Sensible evaluation of MIE requires analysing the propagation mechanism of the ignited flame kernel. The unsteady effect characterizing the time change of temperature and mass fraction across the flame front is expected to have a direct impact upon the flame propagation dynamics. However, the unsteady effect has not been clarified in previous theoretical studies. This work aims to develop a fully transient formulation describing the flame initiation process. It generalizes the quasi-steady theory by rigorously taking unsteady effects into account and is valid over the entire spatial domain for flame initiation. The transient formulation can be used to assess the unsteady effect on ignition kernel propagation and MIE.

The paper is organized as follows. In § 2, the transient formulation is proposed and solved analytically. The analytical solutions for the time-dependent temperature and reactant mass fraction distributions on each side of the flame front are obtained. The solutions describing the temporal evolution of flame temperature and flame propagation speed are obtained from matching conditions. In § 3, a thorough comparison between the transient formulation and the quasi-steady theory is presented with emphasis on the dynamic behaviour of flame front propagation, the evaluation of critical heating power and minimum ignition energy, and the assessment of the memory effect. The concluding remarks are given in § 4.

2. Formulation

2.1. Governing equations

Energy deposition into a combustible mixture increases the local temperature and subsequently generates an ignition kernel. For simplicity, we consider the development of the ignition kernel in a quiescent mixture under microgravity conditions. Providing that the stoichiometric ratio of the mixture is far away from the flammability limit, the impacts of radiation heat loss upon the propagation of the flame kernel appears to be quantitative instead of qualitative (Chen & Ju Reference Chen and Ju2008; Chen Reference Chen2017). The volumetric radiative heat loss is proportional to the cube of the flame kernel radius which is comparably small, i.e. less than the cube of critical radius ![]() ${R_{cr}}$. Accordingly, the radiative heat loss tends to be insubstantial in comparison with the thermal conduction at the flame front. For an ever-expanding spherical flame, the additional heat loss due to radiation may result in reduction of the flame propagation speed. For mixtures within their flammability limits, such quantitative deceleration of flame speed may not lead to flame extinguishment, and the physical scenario of the ignition system does not show a drastic change. This work focuses on understanding of the unsteady effect on ignition. Therefore, the effect of radiative loss is not considered here and it can be explored in future works.

${R_{cr}}$. Accordingly, the radiative heat loss tends to be insubstantial in comparison with the thermal conduction at the flame front. For an ever-expanding spherical flame, the additional heat loss due to radiation may result in reduction of the flame propagation speed. For mixtures within their flammability limits, such quantitative deceleration of flame speed may not lead to flame extinguishment, and the physical scenario of the ignition system does not show a drastic change. This work focuses on understanding of the unsteady effect on ignition. Therefore, the effect of radiative loss is not considered here and it can be explored in future works.

In this study, we aim to investigate the unsteady effect on the general behaviour of flame ignition by examining the transition of the flame kernel to a self-sustained spherical flame. In mathematics, the transient formulation differs from the quasi-steady theory by including the unsteady term in the governing equations for temperature and reactant mass fraction. To isolate the unsteady effect on flame kernel evolution during ignition process, we purposely select the condition in which all the remaining parameters are identical to those in the quasi-steady theory. Then, comparing with results given by quasi-steady theory, the very difference can be manifested to the unsteady effects during flame initiation, to which, a parametric study can be conducted. In accordance, we use the classical thermal-diffusive model, in which the density ![]() $\tilde{\rho }$, heat capacity

$\tilde{\rho }$, heat capacity ![]() ${\tilde{C}_p}$, thermal conductivity

${\tilde{C}_p}$, thermal conductivity ![]() $\tilde{\lambda }$, mass diffusion coefficient of the deficient reactant

$\tilde{\lambda }$, mass diffusion coefficient of the deficient reactant ![]() $\tilde{D}$ and heat of reaction

$\tilde{D}$ and heat of reaction ![]() $\tilde{q}$ are assumed to be constant. These assumptions have been widely adopted in theoretical studies (e.g. Joulin Reference Joulin1985; He Reference He2000; Chen & Ju Reference Chen and Ju2007), for understanding many aspects of flame behaviours. In most situations, the theoretical results are consistent with those obtained from experimental studies or detailed numerical simulation.

$\tilde{q}$ are assumed to be constant. These assumptions have been widely adopted in theoretical studies (e.g. Joulin Reference Joulin1985; He Reference He2000; Chen & Ju Reference Chen and Ju2007), for understanding many aspects of flame behaviours. In most situations, the theoretical results are consistent with those obtained from experimental studies or detailed numerical simulation.

By means of time scale analysis, Champion et al. (Reference Champion, Deshaies and Joulin1988) obtained an estimation of the flame Mach number ![]() $Ma_f^2 \propto {\textrm{e}^{ - {{\tilde{E}}_a}/{{\tilde{R}}^o}{{\tilde{T}}_{ad}}}}$, where

$Ma_f^2 \propto {\textrm{e}^{ - {{\tilde{E}}_a}/{{\tilde{R}}^o}{{\tilde{T}}_{ad}}}}$, where ![]() ${\tilde{E}_a}$ is the activation energy,

${\tilde{E}_a}$ is the activation energy, ![]() ${\tilde{R}^o}$ the universal gas constant and

${\tilde{R}^o}$ the universal gas constant and ![]() ${\tilde{T}_{ad}}$ the adiabatic flame temperature. At the instant when the ignition energy is deposited, the local temperature might be comparable with the activation energy, yielding a rapid propagation of flame front. However, such a period is exceedingly swift and meanwhile the non-equilibrium effect becomes so significant that the system should be described with equations of the Boltzmann type. Under normal situations, i.e. longer than the above-mentioned initial period, the adiabatic flame temperature is comparably lower than the activation temperature, and accordingly the flame Mach number can be considered small, which provides the requisite for the constant density assumption. Besides, for a spherically expanding flame, Bechtold and Matalon (Reference Bechtold and Matalon1987) demonstrated that for large activation energy and thin flame thickness, the variation of density in the burnt gas tends to be negligible.

${\tilde{T}_{ad}}$ the adiabatic flame temperature. At the instant when the ignition energy is deposited, the local temperature might be comparable with the activation energy, yielding a rapid propagation of flame front. However, such a period is exceedingly swift and meanwhile the non-equilibrium effect becomes so significant that the system should be described with equations of the Boltzmann type. Under normal situations, i.e. longer than the above-mentioned initial period, the adiabatic flame temperature is comparably lower than the activation temperature, and accordingly the flame Mach number can be considered small, which provides the requisite for the constant density assumption. Besides, for a spherically expanding flame, Bechtold and Matalon (Reference Bechtold and Matalon1987) demonstrated that for large activation energy and thin flame thickness, the variation of density in the burnt gas tends to be negligible.

In general, the transport properties are functions of temperature instead of constants. For a spherical flame, Matalon, Cui & Bechtold (Reference Matalon, Cui and Bechtold2003) showed that the flame must travel a longer distance before reaching the constant laminar speed when regarding the transport properties as functions of temperature, e.g. ![]() $\tilde{\lambda } \sim {\tilde{T}^{1/2}}$. Nevertheless, in most situations, there is little evidence, showing that the effects of variable transport properties can lead to a drastic change of the physical scenario of the system but quantitative improvements to the theoretical model.

$\tilde{\lambda } \sim {\tilde{T}^{1/2}}$. Nevertheless, in most situations, there is little evidence, showing that the effects of variable transport properties can lead to a drastic change of the physical scenario of the system but quantitative improvements to the theoretical model.

In the thermal-diffusive model, the thermal expansion or convective effect is not considered. According to Champion et al. (Reference Champion, Deshaies and Joulin1988), thermal expansion only quantitatively affects the MIE and the key features of ignition are covered by using the thermal-diffusive model.

The chemical reactions in combustion processes are exceedingly complicated, involving a large number of participant species and reactions. Thus, it is commonplace to adopt an overall one-step kinetic model in theoretical studies. The rate of the global reaction can be improved by considering two-step with thermally sensitive intermediate kinetics (Zhang & Chen Reference Zhang and Chen2011; Zhang, Guo & Chen Reference Zhang, Guo and Chen2013) or by adjusting the reaction power (Buckmaster et al. Reference Buckmaster, Clavin, Linan, Matalon, Peters, Sivashinsky and Williams2005). However, the quantitative improvement of the theoretical model comes at the price of additional mathematical complexity. For mathematical convenience, we assume an overall one-step exothermic reaction in the present study.

The preceding assumptions have been widely adopted in previous theoretical studies (He Reference He2000; Chen & Ju Reference Chen and Ju2007). The governing equations for temperature, ![]() $\tilde{T}$, and mass fraction of the deficient reactant,

$\tilde{T}$, and mass fraction of the deficient reactant, ![]() $\tilde{Y}$, are

$\tilde{Y}$, are

\begin{gather}\tilde{\rho }{\tilde{C}_p}\frac{{\partial \tilde{T}}}{{\partial \tilde{t}}} = \frac{1}{{{{\tilde{r}}^2}}}\frac{\partial }{{\partial \tilde{r}}}\left( {{{\tilde{r}}^2}\tilde{\lambda }\frac{{\partial \tilde{T}}}{{\partial \tilde{r}}}} \right) + \tilde{q}\tilde{\omega },\end{gather}

\begin{gather}\tilde{\rho }{\tilde{C}_p}\frac{{\partial \tilde{T}}}{{\partial \tilde{t}}} = \frac{1}{{{{\tilde{r}}^2}}}\frac{\partial }{{\partial \tilde{r}}}\left( {{{\tilde{r}}^2}\tilde{\lambda }\frac{{\partial \tilde{T}}}{{\partial \tilde{r}}}} \right) + \tilde{q}\tilde{\omega },\end{gather} \begin{gather}\tilde{\rho }\frac{{\partial \tilde{Y}}}{{\partial \tilde{t}}} = \frac{1}{{{{\tilde{r}}^2}}}\frac{\partial }{{\partial \tilde{r}}}\left( {{{\tilde{r}}^2}\tilde{\rho }\tilde{D}\frac{{\partial \tilde{Y}}}{{\partial \tilde{r}}}} \right) - \tilde{\omega },\end{gather}

\begin{gather}\tilde{\rho }\frac{{\partial \tilde{Y}}}{{\partial \tilde{t}}} = \frac{1}{{{{\tilde{r}}^2}}}\frac{\partial }{{\partial \tilde{r}}}\left( {{{\tilde{r}}^2}\tilde{\rho }\tilde{D}\frac{{\partial \tilde{Y}}}{{\partial \tilde{r}}}} \right) - \tilde{\omega },\end{gather}

where ![]() $\tilde{t}$ and

$\tilde{t}$ and ![]() $\tilde{r}$ are the time and radial coordinate, respectively. The reaction rate follows the Arrhenius law as

$\tilde{r}$ are the time and radial coordinate, respectively. The reaction rate follows the Arrhenius law as

\begin{equation}\tilde{\omega } = \tilde{\rho }\tilde{A}\tilde{Y}\,{\rm exp}\!\left( { - \frac{{{{\tilde{E}}_a}}}{{{{\tilde{R}}^0}\tilde{T}}}} \right),\end{equation}

\begin{equation}\tilde{\omega } = \tilde{\rho }\tilde{A}\tilde{Y}\,{\rm exp}\!\left( { - \frac{{{{\tilde{E}}_a}}}{{{{\tilde{R}}^0}\tilde{T}}}} \right),\end{equation}

where ![]() $\tilde{A}$ is the prefactor.

$\tilde{A}$ is the prefactor.

The flame thickness ![]() $\tilde{\delta }_L^0 = \tilde{\lambda }/(\tilde{\rho }{\tilde{c}_p}\tilde{S}_L^0)$ and characteristic flame time

$\tilde{\delta }_L^0 = \tilde{\lambda }/(\tilde{\rho }{\tilde{c}_p}\tilde{S}_L^0)$ and characteristic flame time ![]() $\tilde{t}_L^0 = \tilde{\delta }_L^0/\tilde{S}_L^0$ for the adiabatic planar flame are used as the reference length and time, respectively. Here

$\tilde{t}_L^0 = \tilde{\delta }_L^0/\tilde{S}_L^0$ for the adiabatic planar flame are used as the reference length and time, respectively. Here ![]() $\tilde{S}_L^0$ is the laminar flame speed. The non-dimensional quantities are defined as

$\tilde{S}_L^0$ is the laminar flame speed. The non-dimensional quantities are defined as

In addition, the normalized temperature and mass fraction are defined by

where ![]() ${\tilde{T}_\infty }$ and

${\tilde{T}_\infty }$ and ![]() ${\tilde{Y}_\infty }$ are, respectively, the temperature and mass fraction of the deficient reactant of the unburned mixture. The adiabatic flame temperature can be determined in the form

${\tilde{Y}_\infty }$ are, respectively, the temperature and mass fraction of the deficient reactant of the unburned mixture. The adiabatic flame temperature can be determined in the form ![]() ${\tilde{T}_{ad}} = {\tilde{T}_\infty } + {\tilde{Y}_\infty }\tilde{q}/{\tilde{c}_p}$.

${\tilde{T}_{ad}} = {\tilde{T}_\infty } + {\tilde{Y}_\infty }\tilde{q}/{\tilde{c}_p}$.

The non-dimensional form for the governing equations (2.1) and (2.) is

where ![]() $Le = \tilde{\lambda }/(\tilde{\rho }{\tilde{c}_p}\tilde{D})$ is the Lewis number. The non-dimensional chemical reaction rate is

$Le = \tilde{\lambda }/(\tilde{\rho }{\tilde{c}_p}\tilde{D})$ is the Lewis number. The non-dimensional chemical reaction rate is ![]() $\omega = \tilde{\delta }_L^0\tilde{\omega }/(\tilde{\rho }\tilde{S}_L^0{\tilde{Y}_\infty })$. The parameters with and without tilde symbol denote the dimensional and non-dimensional variables, respectively.

$\omega = \tilde{\delta }_L^0\tilde{\omega }/(\tilde{\rho }\tilde{S}_L^0{\tilde{Y}_\infty })$. The parameters with and without tilde symbol denote the dimensional and non-dimensional variables, respectively.

In the limit of large activation energy, the reaction zone appears to be infinitely thin, and the reaction rate can be modelled by a delta function located at the reaction zone (Law Reference Law2006; Veeraragavan & Cadou Reference Veeraragavan and Cadou2011; Wu & Chen Reference Wu and Chen2012), i.e.

where ![]() ${T_f}$ is the normalized flame temperature, R the flame front position (or flame radius),

${T_f}$ is the normalized flame temperature, R the flame front position (or flame radius), ![]() $Z = {\tilde{E}_a}(1 - {\epsilon _T})/{\tilde{R}^0}{\tilde{T}_{ad}}$ the Zel'dovich number and

$Z = {\tilde{E}_a}(1 - {\epsilon _T})/{\tilde{R}^0}{\tilde{T}_{ad}}$ the Zel'dovich number and ![]() ${\epsilon _T} = {\tilde{T}_\infty }/{\tilde{T}_{ad}}$ the expansion ratio.

${\epsilon _T} = {\tilde{T}_\infty }/{\tilde{T}_{ad}}$ the expansion ratio.

The flame front separates the unburnt and burnt regions. In these two regions, the reaction term does not appear in the governing equations. Therefore, the governing equations can be written in the burnt and unburnt regions as

(burnt region)

(unburnt region)

where the subscripts u and b represent states in the unburnt and burnt regimes, respectively.

The initial and boundary conditions can be written as

\begin{equation}\left.

{\begin{array}{*{20}{ll@{}}} t = 0{:}&\quad {T_b} = T_b^0 \ \& \ {Y_b} =

0\ \textrm{for}\ r \le R(t),&\quad \ {T_u} = 0 \ \& \ {Y_u} =

1\ \textrm{for}\ r > R(t),\\

r = 0{:}&\quad {r^2}(\partial {T_b}/\partial r) ={-} Q(t)\ \&\ {Y_b} =

0, &\quad \ {\textrm{NA}},\\

r = R(t){:}&\quad {T_b} = {T_f}(t)\ \&\ {Y_b} = 0, &\quad \ {T_u} = {T_f}(t)\ \& \ {Y_u} =

0,\\ r \to \infty {:}&\quad \textrm{NA},&\quad\ {T_u} = 0\ \&\ {Y_u} = 1, \end{array}}

\right\}\end{equation}

\begin{equation}\left.

{\begin{array}{*{20}{ll@{}}} t = 0{:}&\quad {T_b} = T_b^0 \ \& \ {Y_b} =

0\ \textrm{for}\ r \le R(t),&\quad \ {T_u} = 0 \ \& \ {Y_u} =

1\ \textrm{for}\ r > R(t),\\

r = 0{:}&\quad {r^2}(\partial {T_b}/\partial r) ={-} Q(t)\ \&\ {Y_b} =

0, &\quad \ {\textrm{NA}},\\

r = R(t){:}&\quad {T_b} = {T_f}(t)\ \&\ {Y_b} = 0, &\quad \ {T_u} = {T_f}(t)\ \& \ {Y_u} =

0,\\ r \to \infty {:}&\quad \textrm{NA},&\quad\ {T_u} = 0\ \&\ {Y_u} = 1, \end{array}}

\right\}\end{equation} where Q is the heating power of the external source at the centre. The flame temperature can be equivalently regarded as a function of flame location. Accordingly, the time derivative of ![]() ${T_f}$ can be determined via the chain rule,

${T_f}$ can be determined via the chain rule, ![]() $\textrm{d}{T_f}/\textrm{d}t = U(\textrm{d}{T_f}/\textrm{d}R)$, where

$\textrm{d}{T_f}/\textrm{d}t = U(\textrm{d}{T_f}/\textrm{d}R)$, where ![]() $U = \textrm{d}R/\textrm{d}t$ is the propagation speed of the flame front, which is non-dimensionalized by the laminar flame speed

$U = \textrm{d}R/\textrm{d}t$ is the propagation speed of the flame front, which is non-dimensionalized by the laminar flame speed ![]() $\tilde{S}_L^0$. It can be seen that (2.10) subject to the above initial and boundary conditions has the unique solution of

$\tilde{S}_L^0$. It can be seen that (2.10) subject to the above initial and boundary conditions has the unique solution of ![]() ${Y_b} = 0$ in the whole burnt region.

${Y_b} = 0$ in the whole burnt region.

Nevertheless, the preceding formulation is not in closed form since the flame temperature ![]() ${T_f}$ and flame location R remain to be determined. The contribution of chemical reaction to the change of Y and T is characterized by the jump relations at the flame interface. The jump relations across the flame front are derived as the leading-order solution of the large activation energy asymptotic analysis (Chen & Ju Reference Chen and Ju2007; Wu & Chen Reference Wu and Chen2012), i.e.

${T_f}$ and flame location R remain to be determined. The contribution of chemical reaction to the change of Y and T is characterized by the jump relations at the flame interface. The jump relations across the flame front are derived as the leading-order solution of the large activation energy asymptotic analysis (Chen & Ju Reference Chen and Ju2007; Wu & Chen Reference Wu and Chen2012), i.e.

where the subscripts ![]() ${R^ + }$ and

${R^ + }$ and ![]() ${R^ - }$ denote the corresponding derivatives evaluated at, respectively, the unburnt and burnt side of the flame front. Substituting the solutions for T and Y into the jump conditions, the desired flame temperature

${R^ - }$ denote the corresponding derivatives evaluated at, respectively, the unburnt and burnt side of the flame front. Substituting the solutions for T and Y into the jump conditions, the desired flame temperature ![]() ${T_f}$ and flame location R could be determined, and hence the formulation is in closed form.

${T_f}$ and flame location R could be determined, and hence the formulation is in closed form.

2.2. Analytical solutions

The time change of the flame front, ![]() $R = R(t)$, causes considerable difficulty in solving the governing equations analytically. Mathematically, the flame front can be considered as a moving boundary, which can be removed by introducing a scaled coordinate (Law & Sirignano Reference Law and Sirignano1977; Yu & Chen Reference Yu and Chen2020),

$R = R(t)$, causes considerable difficulty in solving the governing equations analytically. Mathematically, the flame front can be considered as a moving boundary, which can be removed by introducing a scaled coordinate (Law & Sirignano Reference Law and Sirignano1977; Yu & Chen Reference Yu and Chen2020),

In terms of ![]() ${\sigma _s}$ and

${\sigma _s}$ and ![]() ${t_s}$, the governing equations become

${t_s}$, the governing equations become

(burnt region)

(unburnt region)

Because of the differences in boundary conditions, the temperature and mass fraction distributions in burnt and unburnt regions are solved in different ways.

First, we consider the unburnt region. To further simplify the governing equations, we introduce the following pair of F-functions for temperature and mass fraction, respectively:

With the help of F-functions, we can define a pair of new coordinates, i.e.

\begin{gather}{\xi _{uT}} = \frac{{\displaystyle\int_1^{{\sigma _s}} {F_{uT}}({{\sigma ^{\prime}}_s})\,\textrm{d}{{\sigma ^{\prime}}_s}}}{{\displaystyle\int_1^\infty {F_{uT}}({\sigma _s})\,\textrm{d}{\sigma _s}}},\end{gather}

\begin{gather}{\xi _{uT}} = \frac{{\displaystyle\int_1^{{\sigma _s}} {F_{uT}}({{\sigma ^{\prime}}_s})\,\textrm{d}{{\sigma ^{\prime}}_s}}}{{\displaystyle\int_1^\infty {F_{uT}}({\sigma _s})\,\textrm{d}{\sigma _s}}},\end{gather} \begin{gather}{\xi _{uY}} = \frac{{\displaystyle\int_1^{{\sigma _s}} {F_{uY}}({{\sigma ^{\prime}}_s})\,\textrm{d}{{\sigma ^{\prime}}_s}}}{{\displaystyle\int_1^\infty {F_{uY}}({\sigma _s})\,\textrm{d}{\sigma _s}}}.\end{gather}

\begin{gather}{\xi _{uY}} = \frac{{\displaystyle\int_1^{{\sigma _s}} {F_{uY}}({{\sigma ^{\prime}}_s})\,\textrm{d}{{\sigma ^{\prime}}_s}}}{{\displaystyle\int_1^\infty {F_{uY}}({\sigma _s})\,\textrm{d}{\sigma _s}}}.\end{gather} In terms of ![]() ${\xi _{uT}}$ and

${\xi _{uT}}$ and ![]() ${\xi _{uY}}$, the governing equations for temperature and mass fraction are simplified to

${\xi _{uY}}$, the governing equations for temperature and mass fraction are simplified to

\begin{gather}\frac{{\partial {T_u}}}{{\partial {t_s}}} = {{\mathcal F}}_{uT}^2\frac{{{\textrm{d}^2}{T_u}}}{{\textrm{d}\xi _{u,T}^2}},\end{gather}

\begin{gather}\frac{{\partial {T_u}}}{{\partial {t_s}}} = {{\mathcal F}}_{uT}^2\frac{{{\textrm{d}^2}{T_u}}}{{\textrm{d}\xi _{u,T}^2}},\end{gather} \begin{gather}\frac{{\partial {Y_u}}}{{\partial {t_s}}} = \frac{{{{\mathcal F}}_{uY}^2}}{{Le}}\frac{{{\textrm{d}^2}{Y_u}}}{{\textrm{d}\xi _{u,Y}^2}},\end{gather}

\begin{gather}\frac{{\partial {Y_u}}}{{\partial {t_s}}} = \frac{{{{\mathcal F}}_{uY}^2}}{{Le}}\frac{{{\textrm{d}^2}{Y_u}}}{{\textrm{d}\xi _{u,Y}^2}},\end{gather}

where the factors ![]() ${{{\mathcal F}}_{uY}}$ and

${{{\mathcal F}}_{uY}}$ and ![]() ${{{\mathcal F}}_{uT}}$ are functions of

${{{\mathcal F}}_{uT}}$ are functions of ![]() ${\sigma _s}$, as follows:

${\sigma _s}$, as follows:

\begin{gather}{{{\mathcal F}}_{uT}} = \frac{{\textrm{d}{\xi _{uT}}}}{{\textrm{d}{\sigma _s}}} = \frac{{{F_{uT}}({\sigma _s})}}{{\displaystyle\int_1^\infty {F_{uT}}({\sigma _s})\,\textrm{d}{\sigma _s}}},\end{gather}

\begin{gather}{{{\mathcal F}}_{uT}} = \frac{{\textrm{d}{\xi _{uT}}}}{{\textrm{d}{\sigma _s}}} = \frac{{{F_{uT}}({\sigma _s})}}{{\displaystyle\int_1^\infty {F_{uT}}({\sigma _s})\,\textrm{d}{\sigma _s}}},\end{gather} \begin{gather}{{{\mathcal F}}_{uY}} = \frac{{\textrm{d}{\xi _{uY}}}}{{\textrm{d}{\sigma _s}}} = \frac{{{F_{uY}}({\sigma _s})}}{{\displaystyle\int_1^\infty {F_{uY}}({\sigma _s})\,\textrm{d}{\sigma _s}}}.\end{gather}

\begin{gather}{{{\mathcal F}}_{uY}} = \frac{{\textrm{d}{\xi _{uY}}}}{{\textrm{d}{\sigma _s}}} = \frac{{{F_{uY}}({\sigma _s})}}{{\displaystyle\int_1^\infty {F_{uY}}({\sigma _s})\,\textrm{d}{\sigma _s}}}.\end{gather} In the ![]() ${t_s} - {\xi _{uT}}$ and

${t_s} - {\xi _{uT}}$ and ![]() ${t_s} - {\xi _{uY}}$ coordinate systems, the initial and boundary conditions become

${t_s} - {\xi _{uY}}$ coordinate systems, the initial and boundary conditions become

\begin{equation}\left.

{\begin{array}{*{20}{l@{}}} {{t_s} = 0}{:}&\quad {{T_u} =

0;}&\quad {{t_s} = 0}{:}&\quad {{Y_u} = 1}\\

{{\xi_{uT}} = 0}{:}&\quad {{T_u} = {T_f}(t);}&\quad {{\xi_{uY}} =

0}{:}&\quad {{Y_u} = 0}\\ {{\xi_{uT}} =

1}{:}&\quad {{T_u} = 0;}&\quad {{\xi_{uY}} = 1}{:}&\quad {{Y_u} = 1} \end{array}}

\right\}\end{equation}

\begin{equation}\left.

{\begin{array}{*{20}{l@{}}} {{t_s} = 0}{:}&\quad {{T_u} =

0;}&\quad {{t_s} = 0}{:}&\quad {{Y_u} = 1}\\

{{\xi_{uT}} = 0}{:}&\quad {{T_u} = {T_f}(t);}&\quad {{\xi_{uY}} =

0}{:}&\quad {{Y_u} = 0}\\ {{\xi_{uT}} =

1}{:}&\quad {{T_u} = 0;}&\quad {{\xi_{uY}} = 1}{:}&\quad {{Y_u} = 1} \end{array}}

\right\}\end{equation}The analytical solutions can be obtained as

\begin{align}

{T_u}({\xi _{uT}},{t_s}) & = {T_f}(1 - {\xi _{uT}})\notag\\ &

\quad - 2{T_f}\mathop \sum \limits_{n = 1}^\infty

\dfrac{{\sin (n{\rm \pi} {\xi _{uT}})}}{{n{\rm \pi} }}\left(

{\dfrac{{T_b^0}}{{{T_f}}} + {R^2}U\dfrac{{\textrm{d}\ln

{T_f}}}{{\textrm{d}R}}\dfrac{{{\textrm{e}^{{{\mathcal

F}}_{uT}^2{n^2}{{\rm \pi}^2}{t_s}}} - 1}}{{{{\mathcal

F}}_{uT}^2{n^2}{{\rm \pi}^2}}}} \right)\,{\textrm{e}^{ -

{{\mathcal F}}_{uT}^2{n^2}{{\rm \pi} ^2}{t_s}}}\notag\\ & \approx

{T_f}(1 - {\xi _{uT}}) - 2T_b^0\mathop \sum \limits_{n =

1}^\infty \dfrac{{\sin (n{\rm \pi} {\xi _{uT}})}}{{n{\rm \pi}

}}\,{\textrm{e}^{ - {{\mathcal F}}_{uT}^2{n^2}{{\rm \pi}

^2}{t_s}}},

\end{align}

\begin{align}

{T_u}({\xi _{uT}},{t_s}) & = {T_f}(1 - {\xi _{uT}})\notag\\ &

\quad - 2{T_f}\mathop \sum \limits_{n = 1}^\infty

\dfrac{{\sin (n{\rm \pi} {\xi _{uT}})}}{{n{\rm \pi} }}\left(

{\dfrac{{T_b^0}}{{{T_f}}} + {R^2}U\dfrac{{\textrm{d}\ln

{T_f}}}{{\textrm{d}R}}\dfrac{{{\textrm{e}^{{{\mathcal

F}}_{uT}^2{n^2}{{\rm \pi}^2}{t_s}}} - 1}}{{{{\mathcal

F}}_{uT}^2{n^2}{{\rm \pi}^2}}}} \right)\,{\textrm{e}^{ -

{{\mathcal F}}_{uT}^2{n^2}{{\rm \pi} ^2}{t_s}}}\notag\\ & \approx

{T_f}(1 - {\xi _{uT}}) - 2T_b^0\mathop \sum \limits_{n =

1}^\infty \dfrac{{\sin (n{\rm \pi} {\xi _{uT}})}}{{n{\rm \pi}

}}\,{\textrm{e}^{ - {{\mathcal F}}_{uT}^2{n^2}{{\rm \pi}

^2}{t_s}}},

\end{align} \begin{align}{Y_u}({\xi

_{uY}},{t_s}) &= {\xi _{uY}} + 2\mathop \sum \limits_{n =

1}^\infty \frac{{\sin (n{\rm \pi} {\xi _{uY}})\,{\textrm{e}^{ -

{{\mathcal F}}_{uY}^2{n^2}{{\rm \pi} ^2}{t_s}/Le}}}}{{n{\rm \pi}

}},\end{align}

\begin{align}{Y_u}({\xi

_{uY}},{t_s}) &= {\xi _{uY}} + 2\mathop \sum \limits_{n =

1}^\infty \frac{{\sin (n{\rm \pi} {\xi _{uY}})\,{\textrm{e}^{ -

{{\mathcal F}}_{uY}^2{n^2}{{\rm \pi} ^2}{t_s}/Le}}}}{{n{\rm \pi}

}},\end{align}

where ![]() $T_b^0$ refers to the onset flame temperature and will be specified in the subsequent section. During flame propagation, the heat release from reaction and the heat conduction towards the preheat zone tends to balance dynamically. We postulate that the flame temperature

$T_b^0$ refers to the onset flame temperature and will be specified in the subsequent section. During flame propagation, the heat release from reaction and the heat conduction towards the preheat zone tends to balance dynamically. We postulate that the flame temperature ![]() ${T_f}$ does not change rapidly as the flame moves outwardly, i.e.

${T_f}$ does not change rapidly as the flame moves outwardly, i.e.

Consequently, the approximation in (2.30) can be made.

Transforming equations (2.29) and (2.30) back to the ![]() $r - t$ coordinate system, we obtain the transient evolution of temperature and mass fraction profiles in the unburnt region. The unsteady solutions for

$r - t$ coordinate system, we obtain the transient evolution of temperature and mass fraction profiles in the unburnt region. The unsteady solutions for ![]() ${T_u}$ and

${T_u}$ and ![]() ${Y_u}$, given by (2.29) and (2.30), consist of two components: one is time-independent and characterizes the asymptotic distributions of temperature and mass fraction at the final stage, and the other is time-dependent and represents the change of

${Y_u}$, given by (2.29) and (2.30), consist of two components: one is time-independent and characterizes the asymptotic distributions of temperature and mass fraction at the final stage, and the other is time-dependent and represents the change of ![]() ${T_u}$ and

${T_u}$ and ![]() ${Y_u}$ due to heat conduction and mass diffusion. It can be verified that for low to moderate time lapse, the time-dependent component, i.e. the summation of exponential terms, would have comparable magnitude, indicating that the unsteady effect is pronounced during flame kernel development. Therefore, the quasi-steady solution cannot accurately describe the initial development of the flame kernel.

${Y_u}$ due to heat conduction and mass diffusion. It can be verified that for low to moderate time lapse, the time-dependent component, i.e. the summation of exponential terms, would have comparable magnitude, indicating that the unsteady effect is pronounced during flame kernel development. Therefore, the quasi-steady solution cannot accurately describe the initial development of the flame kernel.

Subsequently, we deal with the burnt region, where we only need obtain the analytical solution for temperature. Without external heating or radiative loss, the temperature in the burnt regime should be uniform and equal to the flame temperature, ![]() ${T_f}$. The heat addition at the centre leads to an increment of temperature from

${T_f}$. The heat addition at the centre leads to an increment of temperature from ![]() ${T_f}$. We denote

${T_f}$. We denote ![]() ${T^{\prime}_b} = {T_b} - T_b^0$, which satisfies the same governing equation for

${T^{\prime}_b} = {T_b} - T_b^0$, which satisfies the same governing equation for ![]() ${T_b}$ while the initial condition is replaced by

${T_b}$ while the initial condition is replaced by ![]() ${T^{\prime}_b} = 0$ at

${T^{\prime}_b} = 0$ at ![]() ${t_s} = 0$. To simplify the governing equation, we introduce the radial coordinate weighted temperature discrepancy,

${t_s} = 0$. To simplify the governing equation, we introduce the radial coordinate weighted temperature discrepancy, ![]() ${\bar{T}_b} = r{T^{\prime}_b}$, which satisfies

${\bar{T}_b} = r{T^{\prime}_b}$, which satisfies

Accordingly, the initial and boundary conditions become

\begin{equation}\left.

{\begin{array}{*{20}{l@{}}} {t = 0}{:}&\quad {{{\bar{T}}_b} =

0\;\textrm{for}\;r \le R(t)}\\ {r =

0}{:}&\quad {{{\bar{T}}_b} = Q(t)}\\ {r =

R(t)}{:}&\quad {{{\bar{T}}_b} = R({T_f} - T_b^0)} \end{array}}

\right\}\end{equation}

\begin{equation}\left.

{\begin{array}{*{20}{l@{}}} {t = 0}{:}&\quad {{{\bar{T}}_b} =

0\;\textrm{for}\;r \le R(t)}\\ {r =

0}{:}&\quad {{{\bar{T}}_b} = Q(t)}\\ {r =

R(t)}{:}&\quad {{{\bar{T}}_b} = R({T_f} - T_b^0)} \end{array}}

\right\}\end{equation}

To remove the moving boundary effect due to the flame front propagation, the governing equations for ![]() ${\bar{T}_b}$ can be written in the scaled coordinate

${\bar{T}_b}$ can be written in the scaled coordinate ![]() ${\sigma _s}$ and

${\sigma _s}$ and ![]() ${t_s}$ as

${t_s}$ as

To simplify the governing equations, we introduce the following F-function:

With the help of ![]() ${F_{bT}}$, we can define the coordinates

${F_{bT}}$, we can define the coordinates ![]() ${\xi _{bT}}$ in the following form:

${\xi _{bT}}$ in the following form:

\begin{equation}{\xi _{bT}} = \frac{{\displaystyle\int_0^{{\sigma _s}} {F_{b,T}}({{\sigma ^{\prime}}_s})\,\textrm{d}{{\sigma ^{\prime}}_s}}}{{\displaystyle\int_0^1 {F_{bT}}({\sigma _s})\,\textrm{d}{\sigma _s}}} = \frac{{{\rm erf}({\sigma _s}\sqrt {RU/2} )}}{{{\rm erf}(\sqrt {RU/2} )}}.\end{equation}

\begin{equation}{\xi _{bT}} = \frac{{\displaystyle\int_0^{{\sigma _s}} {F_{b,T}}({{\sigma ^{\prime}}_s})\,\textrm{d}{{\sigma ^{\prime}}_s}}}{{\displaystyle\int_0^1 {F_{bT}}({\sigma _s})\,\textrm{d}{\sigma _s}}} = \frac{{{\rm erf}({\sigma _s}\sqrt {RU/2} )}}{{{\rm erf}(\sqrt {RU/2} )}}.\end{equation} In the transformed coordinate ![]() ${\xi _{bT}}$, the governing equation for

${\xi _{bT}}$, the governing equation for ![]() ${\bar{T}_b}$ can be written as

${\bar{T}_b}$ can be written as

where

\begin{equation}{{{\mathcal F}}_{bT}} = \frac{{\textrm{d}{\xi _{bT}}}}{{\textrm{d}{\sigma _s}}} = \frac{{2\sqrt {RU/2} \,{\textrm{e}^{ - \sigma _s^2RU/2}}}}{{\sqrt {\rm \pi}\,{\rm erf}(\sqrt {RU/2} )}},\end{equation}

\begin{equation}{{{\mathcal F}}_{bT}} = \frac{{\textrm{d}{\xi _{bT}}}}{{\textrm{d}{\sigma _s}}} = \frac{{2\sqrt {RU/2} \,{\textrm{e}^{ - \sigma _s^2RU/2}}}}{{\sqrt {\rm \pi}\,{\rm erf}(\sqrt {RU/2} )}},\end{equation}subject to the following initial and boundary conditions:

\begin{equation}\left. {\begin{array}{*{20}{l@{}}} {{t_s} = 0}{:}&\quad {{{\bar{T}}_b} = 0}\\ {{\xi_{bT}} = 0}{:}&\quad {{{\bar{T}}_b} = Q(t)}\\ {{\xi_{bT}} = 1}{:}&\quad {{{\bar{T}}_b} = R({T_f} - T_b^0)} \end{array}} \right\}\end{equation}

\begin{equation}\left. {\begin{array}{*{20}{l@{}}} {{t_s} = 0}{:}&\quad {{{\bar{T}}_b} = 0}\\ {{\xi_{bT}} = 0}{:}&\quad {{{\bar{T}}_b} = Q(t)}\\ {{\xi_{bT}} = 1}{:}&\quad {{{\bar{T}}_b} = R({T_f} - T_b^0)} \end{array}} \right\}\end{equation} The analytical solution for ![]() ${\bar{T}_b}$ can be obtained as

${\bar{T}_b}$ can be obtained as

\begin{equation}{\bar{T}_b}({\xi _{b,T}},{t_s}) = Q({t_s}) + {\xi _{bT}}[R({T_f} - T_b^0) - Q({t_s})] + 2\mathop \sum \limits_{n = 1}^\infty \sin (n{\rm \pi} {\xi _{bT}})\,{\textrm{e}^{ - {{\mathcal F}}_{bT}^2{n^2}{{\rm \pi} ^2}{t_s}}}{R_n}({t_s}),\end{equation}

\begin{equation}{\bar{T}_b}({\xi _{b,T}},{t_s}) = Q({t_s}) + {\xi _{bT}}[R({T_f} - T_b^0) - Q({t_s})] + 2\mathop \sum \limits_{n = 1}^\infty \sin (n{\rm \pi} {\xi _{bT}})\,{\textrm{e}^{ - {{\mathcal F}}_{bT}^2{n^2}{{\rm \pi} ^2}{t_s}}}{R_n}({t_s}),\end{equation}where

The flame temperature ![]() ${T_f}$ and flame radius R can be solved via the matching conditions in (2.14) and (2.15), which requires the gradients of temperature and mass fraction at the flame front in the physical coordinate. From the chain rule, the gradients in the unburnt region can be evaluated as

${T_f}$ and flame radius R can be solved via the matching conditions in (2.14) and (2.15), which requires the gradients of temperature and mass fraction at the flame front in the physical coordinate. From the chain rule, the gradients in the unburnt region can be evaluated as

where ![]() ${{\hat{{\mathcal F}}}_{uT}} = {{{\mathcal F}}_{uT}}({\sigma _s} = 1)$ and

${{\hat{{\mathcal F}}}_{uT}} = {{{\mathcal F}}_{uT}}({\sigma _s} = 1)$ and ![]() ${{\hat{{\mathcal F}}}_{uY}} = {{{\mathcal F}}_{uY}}({\sigma _s} = 1)$. The Jacobi theta function

${{\hat{{\mathcal F}}}_{uY}} = {{{\mathcal F}}_{uY}}({\sigma _s} = 1)$. The Jacobi theta function ![]() ${\vartheta _3}$ denotes the subsequent sum

${\vartheta _3}$ denotes the subsequent sum

\begin{equation}{\vartheta _3}(x) = 1 + 2\mathop \sum \limits_{n = 1}^\infty {x^{{n^2}}}.\end{equation}

\begin{equation}{\vartheta _3}(x) = 1 + 2\mathop \sum \limits_{n = 1}^\infty {x^{{n^2}}}.\end{equation}Similarly, the gradients in the burnt region can be written in the following form:

\begin{equation}\begin{array}{ll}

{\left( {\dfrac{{\partial {T_b}}}{{\partial r}}}

\right)_{{R^ - }}}\!\!\!\!\! & ={-} \dfrac{{{{{\hat{{\mathcal

F}}}}_{bT}}}}{{{R^2}}}\{{Q({t_s}) +

Q(0)[{\vartheta_4}({\textrm{e}^{ - {\hat{{\mathcal

F}}}_{bT}^2{{\rm \pi}^2}t/{R^2}}}) - 1]\; } \\ & \quad \left. { +\,

2\mathop \sum \limits_{n = 1}^\infty {{( -

1)}^n}\,{\textrm{e}^{ - {\hat{{\mathcal

F}}}_{bT}^2{n^2}{{\rm \pi}^2}t/{R^2}}}\int_0^t

{{\textrm{e}^{{\hat{{\mathcal

F}}}_{bT}^2{n^2}{{\rm \pi}^2}\tau

/{R^2}}}\dfrac{{\textrm{d}Q}}{{\textrm{d}\tau

}}\,\textrm{d}\tau } } \right\}\\ & \quad + \,

\dfrac{1}{R}({{{\hat{{\mathcal F}}}}_{bT}} -

1)({T_f} - T_b^0),

\end{array}\end{equation}

\begin{equation}\begin{array}{ll}

{\left( {\dfrac{{\partial {T_b}}}{{\partial r}}}

\right)_{{R^ - }}}\!\!\!\!\! & ={-} \dfrac{{{{{\hat{{\mathcal

F}}}}_{bT}}}}{{{R^2}}}\{{Q({t_s}) +

Q(0)[{\vartheta_4}({\textrm{e}^{ - {\hat{{\mathcal

F}}}_{bT}^2{{\rm \pi}^2}t/{R^2}}}) - 1]\; } \\ & \quad \left. { +\,

2\mathop \sum \limits_{n = 1}^\infty {{( -

1)}^n}\,{\textrm{e}^{ - {\hat{{\mathcal

F}}}_{bT}^2{n^2}{{\rm \pi}^2}t/{R^2}}}\int_0^t

{{\textrm{e}^{{\hat{{\mathcal

F}}}_{bT}^2{n^2}{{\rm \pi}^2}\tau

/{R^2}}}\dfrac{{\textrm{d}Q}}{{\textrm{d}\tau

}}\,\textrm{d}\tau } } \right\}\\ & \quad + \,

\dfrac{1}{R}({{{\hat{{\mathcal F}}}}_{bT}} -

1)({T_f} - T_b^0),

\end{array}\end{equation}

where ![]() ${{\hat{{\mathcal F}}}_{bT}} = {{{\mathcal F}}_{bT}}({\sigma _s} = 1)$, and

${{\hat{{\mathcal F}}}_{bT}} = {{{\mathcal F}}_{bT}}({\sigma _s} = 1)$, and ![]() ${\vartheta _4}$ is another Jacobi theta function that represents

${\vartheta _4}$ is another Jacobi theta function that represents

\begin{equation}{\vartheta _4}(x) = 1 + 2\mathop \sum \limits_{n = 1}^\infty {( - 1)^n}{x^{{n^2}}}.\end{equation}

\begin{equation}{\vartheta _4}(x) = 1 + 2\mathop \sum \limits_{n = 1}^\infty {( - 1)^n}{x^{{n^2}}}.\end{equation} To model the external heating source with a finite duration time of ![]() ${t_h}$, we use the Heaviside function

${t_h}$, we use the Heaviside function ![]() $H(t)$ so that external heating is switched on at

$H(t)$ so that external heating is switched on at ![]() $t = 0$ and switched off at

$t = 0$ and switched off at ![]() $t = {t_h}$, i.e.

$t = {t_h}$, i.e.

where ![]() ${Q_m}$ represents the magnitude of the heating power. The derivative of

${Q_m}$ represents the magnitude of the heating power. The derivative of ![]() $Q(t)$ is given in terms of delta function

$Q(t)$ is given in terms of delta function

Therefore, the integral involving ![]() $(\textrm{d}Q/\textrm{d}\tau )$ shall be evaluated separately for

$(\textrm{d}Q/\textrm{d}\tau )$ shall be evaluated separately for ![]() $t < {t_h}$ and

$t < {t_h}$ and ![]() $t > {t_h}$ as

$t > {t_h}$ as

Substituting equation (2.49) into (2.45) yields

where the function S is defined as

\begin{equation}S(t,U,R) = \left\{ {\begin{array}{*{20}{@{}l}} {{\vartheta_4}({\textrm{e}^{ - {\hat{{\mathcal F}}}_{bT}^2{{\rm \pi}^2}t/{R^2}}}),}&{t < {t_h}}\\ {{\vartheta_4}({\textrm{e}^{ - {\hat{{\mathcal F}}}_{bT}^2{{\rm \pi}^2}t/{R^2}}}) - {\vartheta_4}({\textrm{e}^{ - {\hat{{\mathcal F}}}_{bT}^2{{\rm \pi}^2}({t - {t_h}} )/{R^2}}}),\; }&{t > {t_h}} \end{array}} \right..\end{equation}

\begin{equation}S(t,U,R) = \left\{ {\begin{array}{*{20}{@{}l}} {{\vartheta_4}({\textrm{e}^{ - {\hat{{\mathcal F}}}_{bT}^2{{\rm \pi}^2}t/{R^2}}}),}&{t < {t_h}}\\ {{\vartheta_4}({\textrm{e}^{ - {\hat{{\mathcal F}}}_{bT}^2{{\rm \pi}^2}t/{R^2}}}) - {\vartheta_4}({\textrm{e}^{ - {\hat{{\mathcal F}}}_{bT}^2{{\rm \pi}^2}({t - {t_h}} )/{R^2}}}),\; }&{t > {t_h}} \end{array}} \right..\end{equation}

Substituting equations (2.42), (2.43), (2.45) and ![]() ${(\partial {Y_b}/\partial r)_{{R^ - }}} = 0$ into (2.14) and (2.15), one obtains the following expression for flame temperature and the condition characterizing the consumption of reactant by chemical reaction, respectively:

${(\partial {Y_b}/\partial r)_{{R^ - }}} = 0$ into (2.14) and (2.15), one obtains the following expression for flame temperature and the condition characterizing the consumption of reactant by chemical reaction, respectively:

\begin{gather}{T_f} = T_b^0 + \frac{{{{{\hat{{\mathcal F}}}}_{uY}}{\vartheta _3}({\textrm{e}^{ - {{\rm \pi} ^2}{\hat{{\mathcal F}}}_{uY}^2t/{R^2}Le}})/Le + {Q_m}{{{\hat{{\mathcal F}}}}_{bT}}S(t,U,R)/R - {{{\hat{{\mathcal F}}}}_{uT}}T_b^0{\vartheta _3}({\textrm{e}^{ - {\hat{{\mathcal F}}}_{uT}^2{{\rm \pi} ^2}t/{R^2}}})}}{{{{{\hat{{\mathcal F}}}}_{bT}} + {{{\hat{{\mathcal F}}}}_{uT}} - 1}},\end{gather}

\begin{gather}{T_f} = T_b^0 + \frac{{{{{\hat{{\mathcal F}}}}_{uY}}{\vartheta _3}({\textrm{e}^{ - {{\rm \pi} ^2}{\hat{{\mathcal F}}}_{uY}^2t/{R^2}Le}})/Le + {Q_m}{{{\hat{{\mathcal F}}}}_{bT}}S(t,U,R)/R - {{{\hat{{\mathcal F}}}}_{uT}}T_b^0{\vartheta _3}({\textrm{e}^{ - {\hat{{\mathcal F}}}_{uT}^2{{\rm \pi} ^2}t/{R^2}}})}}{{{{{\hat{{\mathcal F}}}}_{bT}} + {{{\hat{{\mathcal F}}}}_{uT}} - 1}},\end{gather} At the initial instant the Jacobi theta functions in (2.53) is equal to ![]() ${\vartheta _3}(1)$, which is infinitely large. It can be understood that the non-dimensional temperature profile is piecewise constant, i.e.

${\vartheta _3}(1)$, which is infinitely large. It can be understood that the non-dimensional temperature profile is piecewise constant, i.e. ![]() $T = T_b^0$ for

$T = T_b^0$ for ![]() $r < {R_0}$ and

$r < {R_0}$ and ![]() $T = 0$ for

$T = 0$ for ![]() $r > {R_0}$, which gives that the temperature gradient at

$r > {R_0}$, which gives that the temperature gradient at ![]() $r = {R_0}$ is infinitely large. However, the chemical reaction rate always has a finite value. Such inconsistency in (2.53) implies that the flame kernel cannot be established at

$r = {R_0}$ is infinitely large. However, the chemical reaction rate always has a finite value. Such inconsistency in (2.53) implies that the flame kernel cannot be established at ![]() $t = 0$. In the course of time, the temperature jump is smoothed by conduction, which reduces the temperature gradient at

$t = 0$. In the course of time, the temperature jump is smoothed by conduction, which reduces the temperature gradient at ![]() $r = {R_0}$. Therefore, it needs an induction period, denoted by

$r = {R_0}$. Therefore, it needs an induction period, denoted by ![]() ${t_{ig}}$, after which the local heat loss, quantified in terms of

${t_{ig}}$, after which the local heat loss, quantified in terms of ![]() ${(\textrm{d}T/\textrm{d}r)_{r = {R_0}}}$, can be in balance with the heat release from chemical reaction. It gives birth to the flame structure, which progressively accelerates from

${(\textrm{d}T/\textrm{d}r)_{r = {R_0}}}$, can be in balance with the heat release from chemical reaction. It gives birth to the flame structure, which progressively accelerates from ![]() $U = 0$. According to the definition of

$U = 0$. According to the definition of ![]() $T_b^0$, i.e.

$T_b^0$, i.e. ![]() $T_b^0 = {T_f}(t = {t_{ig}})$, the onset flame temperature is

$T_b^0 = {T_f}(t = {t_{ig}})$, the onset flame temperature is

\begin{equation}T_b^0 = \frac{1}{{Le}}\frac{{{\vartheta _3}({\textrm{e}^{ - {{\rm \pi} ^2}{t_{ig}}/R_0^2Le}})}}{{{\vartheta _3}({\textrm{e}^{ - {{\rm \pi} ^2}{t_{ig}}/R_0^2}})}} + \frac{{{Q_m}}}{{{R_0}}}\frac{{S({t_{ig}},0,{R_0})}}{{{\vartheta _3}({\textrm{e}^{ - {{\rm \pi} ^2}{t_{ig}}/R_0^2}})}}.\end{equation}

\begin{equation}T_b^0 = \frac{1}{{Le}}\frac{{{\vartheta _3}({\textrm{e}^{ - {{\rm \pi} ^2}{t_{ig}}/R_0^2Le}})}}{{{\vartheta _3}({\textrm{e}^{ - {{\rm \pi} ^2}{t_{ig}}/R_0^2}})}} + \frac{{{Q_m}}}{{{R_0}}}\frac{{S({t_{ig}},0,{R_0})}}{{{\vartheta _3}({\textrm{e}^{ - {{\rm \pi} ^2}{t_{ig}}/R_0^2}})}}.\end{equation}and (2.53) becomes

Given initial flame kernel radius ![]() ${R_0}$, the onset flame temperature

${R_0}$, the onset flame temperature ![]() $T_b^0$ and the ignition time

$T_b^0$ and the ignition time ![]() ${t_{ig}}$ can be determined by simultaneously solving (2.54) and (2.55). The rate of change of the temperature profile

${t_{ig}}$ can be determined by simultaneously solving (2.54) and (2.55). The rate of change of the temperature profile ![]() ${(\textrm{d}T/\textrm{d}r)_{r = {R_0}}}$ is proportional to

${(\textrm{d}T/\textrm{d}r)_{r = {R_0}}}$ is proportional to ![]() $1/{R_0}$, and thus the magnitude of

$1/{R_0}$, and thus the magnitude of ![]() ${t_{ig}}$ increases with

${t_{ig}}$ increases with ![]() ${R_0}$. Typically, the induction period is considerably short compared with the total time lapse of the ignition stage. The factors

${R_0}$. Typically, the induction period is considerably short compared with the total time lapse of the ignition stage. The factors ![]() ${{\hat{{\mathcal F}}}_{uT}}$,

${{\hat{{\mathcal F}}}_{uT}}$, ![]() ${{\hat{{\mathcal F}}}_{uY}}$ and

${{\hat{{\mathcal F}}}_{uY}}$ and ![]() ${{\hat{{\mathcal F}}}_{bT}}$ are functions of flame location R and propagating speed

${{\hat{{\mathcal F}}}_{bT}}$ are functions of flame location R and propagating speed ![]() $U = \textrm{d}R/\textrm{d}t$. For

$U = \textrm{d}R/\textrm{d}t$. For ![]() $U = 0$, we have

$U = 0$, we have ![]() ${{\hat{{\mathcal F}}}_{uT}} = {{\hat{{\mathcal F}}}_{uY}} = {{\hat{{\mathcal F}}}_{bT}} = 1$.

${{\hat{{\mathcal F}}}_{uT}} = {{\hat{{\mathcal F}}}_{uY}} = {{\hat{{\mathcal F}}}_{bT}} = 1$.

Successful ignition refers to the generation of a self-sustained expanding flame. In the absence of external heating, there is a critical radius, below which the heat loss by conduction dominates over the heat release from chemical reaction, and thereby successful ignition cannot occur (Joulin Reference Joulin1985; Chen & Ju Reference Chen and Ju2007). When the mixture's Lewis number is not considerably greater than unity, the critical radius is identical to the flame ball radius (He Reference He2000; Chen et al. Reference Chen, Burke and Ju2011). Setting ![]() $U = 0$ in the matching conditions (2.52) and (2.53), the flame ball radius can be obtained as

$U = 0$ in the matching conditions (2.52) and (2.53), the flame ball radius can be obtained as

which is a function of the mixture's thermophysical properties. The above expression for flame ball radius agrees with the Zel'dovich theory (Barenblatt Reference Barenblatt1985). The flame ball radius becomes larger at higher Lewis number.

Substituting (2.52) into (2.53), one obtains an implicit ordinary differential equation for flame radius R subject to the initial conditions ![]() $R = {R_0}$ at

$R = {R_0}$ at ![]() $t = {t_{ig}}$. When

$t = {t_{ig}}$. When ![]() $R = R(t)$ is obtained, the flame propagation speed is obtained via

$R = R(t)$ is obtained, the flame propagation speed is obtained via ![]() $U(t) = \textrm{d}R/\textrm{d}t$. Substituting

$U(t) = \textrm{d}R/\textrm{d}t$. Substituting ![]() $R(t)$ and

$R(t)$ and ![]() $U(t)$ into (2.52), the flame temperature is obtained and thereby the flame kernel development is completely solved. Then, the unsteady evolution of temperature and mass fraction distributions during the flame ignition process can be obtained from (2.30), (2.31) and (2.47).

$U(t)$ into (2.52), the flame temperature is obtained and thereby the flame kernel development is completely solved. Then, the unsteady evolution of temperature and mass fraction distributions during the flame ignition process can be obtained from (2.30), (2.31) and (2.47).

In previous studies considering flame kernel evolution, the quasi-steady approximation has been widely adopted. In quasi-steady theory, the time derivatives in the conservation equations are neglected and the following expressions can be obtained from the matching conditions (He Reference He2000; Chen & Ju Reference Chen and Ju2007):

\begin{gather}{T_f} = \left( {\frac{{{\textrm{e}^{ - UR(Le - 1)}}}}{{Le\displaystyle\int_R^\infty {\tau^{ - 2}}\,{\textrm{e}^{ - U\tau Le}}\,\textrm{d}\tau }} + {Q_m}} \right)\int_R^\infty {{\tau ^{ - 2}}\,{\textrm{e}^{ - U\tau }}\,\textrm{d}\tau } ,\end{gather}

\begin{gather}{T_f} = \left( {\frac{{{\textrm{e}^{ - UR(Le - 1)}}}}{{Le\displaystyle\int_R^\infty {\tau^{ - 2}}\,{\textrm{e}^{ - U\tau Le}}\,\textrm{d}\tau }} + {Q_m}} \right)\int_R^\infty {{\tau ^{ - 2}}\,{\textrm{e}^{ - U\tau }}\,\textrm{d}\tau } ,\end{gather} \begin{gather}\frac{{{\textrm{e}^{ - UR}}}}{{{R^2}}}\left( {\frac{{{T_f}}}{{\displaystyle\int_R^\infty {\tau^{ - 2}}\,{\textrm{e}^{ - U\tau }}\,\textrm{d}\tau }} - {Q_m}} \right) = {[{\epsilon _T} + (1 - {\epsilon _T}){T_f}]^2}\,{\rm exp}\!\left\{ {\frac{{Z({T_f} - 1)}}{{2[{\epsilon_T} + (1 - {\epsilon_T}){T_f}]}}} \right\}.\end{gather}

\begin{gather}\frac{{{\textrm{e}^{ - UR}}}}{{{R^2}}}\left( {\frac{{{T_f}}}{{\displaystyle\int_R^\infty {\tau^{ - 2}}\,{\textrm{e}^{ - U\tau }}\,\textrm{d}\tau }} - {Q_m}} \right) = {[{\epsilon _T} + (1 - {\epsilon _T}){T_f}]^2}\,{\rm exp}\!\left\{ {\frac{{Z({T_f} - 1)}}{{2[{\epsilon_T} + (1 - {\epsilon_T}){T_f}]}}} \right\}.\end{gather} Substituting equation (2.57) into (2.58) yields a nonlinear equation which describes the change of flame propagation speed with flame radius during the flame kernel development, i.e. ![]() $U = U(R)$. In particular, the flame ball radius

$U = U(R)$. In particular, the flame ball radius ![]() ${R^{\prime}_Z}$ can be determined in quasi-steady theory by setting

${R^{\prime}_Z}$ can be determined in quasi-steady theory by setting ![]() $U = 0$ in (2.57) and (2.58), and it is identical with that derived based on a transient formulation given by (2.56). When the flame radius becomes infinitely large, the planar flame solution is reached, and both the non-dimensional flame propagation speed and flame temperature are unity. At such conditions, the matching conditions for both quasi-steady theory and transient formulation become identical again. Therefore, in the limits of both stationary flame ball

$U = 0$ in (2.57) and (2.58), and it is identical with that derived based on a transient formulation given by (2.56). When the flame radius becomes infinitely large, the planar flame solution is reached, and both the non-dimensional flame propagation speed and flame temperature are unity. At such conditions, the matching conditions for both quasi-steady theory and transient formulation become identical again. Therefore, in the limits of both stationary flame ball ![]() $(U = 0)$ and planar flame

$(U = 0)$ and planar flame ![]() $(R \to \infty )$, the present transient formulation degenerates to the quasi-steady theory.

$(R \to \infty )$, the present transient formulation degenerates to the quasi-steady theory.

The transient formulation in this study rigorously takes into account the unsteady evolution of temperature and mass fraction distributions during the flame ignition process. The analytical solutions explicitly indicate that the temperature and mass fraction profiles on each side of the flame front change with time. However, in quasi-steady theory, the temperature and mass fraction are regarded as functions of spatial coordinate, characterizing their distributions in the final state, i.e. subsequent to sufficiently long-term evolution. According to the matching conditions at the flame interface, (2.14) and (2.15), the transience in temperature and mass fraction gradients implies the time-dependence of flame temperature, which directly affects the dynamical behaviour of the expanding flame. Moreover, finite energy deposition can be appropriately considered in the present transient formulation. The heating duration introduces a definite characteristic time, which is not considered in the quasi-steady theory.

3. Results and discussion

The transient propagation of the ignition kernel, the critical heating power and MIE for successful ignition can be described by (2.52) and (2.53). Using these equations, we shall demonstrate how the unsteady effect influences the flame initiation process and critical ignition conditions. For typical premixed flames, we choose ![]() $Z = 10$ and

$Z = 10$ and ![]() ${\epsilon _T} = 0.15$ according to previous studies (Chen et al. Reference Chen, Burke and Ju2011; Wu & Chen Reference Wu and Chen2012). In the present formulation, we have four variables, namely, the initial flame kernel radius

${\epsilon _T} = 0.15$ according to previous studies (Chen et al. Reference Chen, Burke and Ju2011; Wu & Chen Reference Wu and Chen2012). In the present formulation, we have four variables, namely, the initial flame kernel radius ![]() ${R_0}$ (under forced ignition condition), the mixture's Lewis number

${R_0}$ (under forced ignition condition), the mixture's Lewis number ![]() $Le$, the heating power

$Le$, the heating power ![]() ${Q_m}$ and the heating duration

${Q_m}$ and the heating duration ![]() ${t_h}$. Given

${t_h}$. Given ![]() ${R_0}$, the induction time

${R_0}$, the induction time ![]() ${t_{ig}}$ and initial flame kernel temperature

${t_{ig}}$ and initial flame kernel temperature ![]() $T_b^0$ can be determined simultaneously.

$T_b^0$ can be determined simultaneously.

3.1. Flame initiation without central heating

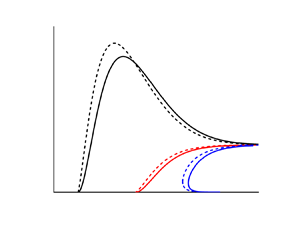

We first consider the case without ignition energy deposition at the centre, i.e. ![]() ${Q_m} = 0$. The flame kernel development can be described in the U–R diagram as shown in figure 1. The dynamic behaviour of the flame front propagation based on the quasi-steady theory agrees qualitatively with that predicted by the transient formulation. Specifically, figure 1 shows that the transient formulation and quasi-steady theory yield identical flame ball radii at

${Q_m} = 0$. The flame kernel development can be described in the U–R diagram as shown in figure 1. The dynamic behaviour of the flame front propagation based on the quasi-steady theory agrees qualitatively with that predicted by the transient formulation. Specifically, figure 1 shows that the transient formulation and quasi-steady theory yield identical flame ball radii at ![]() $U = 0$ and consistently interpret the flame kernel propagation toward a quasi-planar flame at large distance

$U = 0$ and consistently interpret the flame kernel propagation toward a quasi-planar flame at large distance ![]() $R \to \infty $. Moreover, the transient formulation reconciles with the quasi-steady theory in terms of the Lewis number effect. Specifically, for a mixture with Lewis number close to or smaller than unity, the flame ball radius is the critical radius beyond which the flame can propagate outwardly in a self-sustained manner. When the Lewis number is sufficiently small, e.g.

$R \to \infty $. Moreover, the transient formulation reconciles with the quasi-steady theory in terms of the Lewis number effect. Specifically, for a mixture with Lewis number close to or smaller than unity, the flame ball radius is the critical radius beyond which the flame can propagate outwardly in a self-sustained manner. When the Lewis number is sufficiently small, e.g. ![]() $Le = 0.5$, the curvature effect creates a superadiabatic condition, driven by which the flame kernel accelerates rapidly with propagation speed considerably higher than that of planar flame. This implies that a flame can be ignited beyond the flammability limit and undergoes self-extinguishing under certain conditions (Ronney Reference Ronney1989; Ronney & Sivashinsky Reference Ronney and Sivashinsky1989). The curvature effect tends to be alleviated when the flame propagates outwardly.

$Le = 0.5$, the curvature effect creates a superadiabatic condition, driven by which the flame kernel accelerates rapidly with propagation speed considerably higher than that of planar flame. This implies that a flame can be ignited beyond the flammability limit and undergoes self-extinguishing under certain conditions (Ronney Reference Ronney1989; Ronney & Sivashinsky Reference Ronney and Sivashinsky1989). The curvature effect tends to be alleviated when the flame propagates outwardly.

Figure 1. Change of flame propagation speed with flame radius for different Lewis numbers. The solid and dashed lines represent results from transition formulation and quasi-steady theory, respectively. The mixture's Lewis number ![]() $(Le = 0.5,\; 1.0,\; 2.0)$ is indicated by the colour (black/red/blue) of lines. Here

$(Le = 0.5,\; 1.0,\; 2.0)$ is indicated by the colour (black/red/blue) of lines. Here ![]() ${R_Z}$ and

${R_Z}$ and ![]() ${R_c}$, respectively, denote the flame ball radius and critical radius for flame initiation.

${R_c}$, respectively, denote the flame ball radius and critical radius for flame initiation.

When the Lewis number is higher than some critical value moderately above unity, e.g. ![]() $Le = 2.0$, the U–R diagram exhibits a C-shaped curve. The turning point of the C-shaped U–R diagram corresponds to the critical radius of

$Le = 2.0$, the U–R diagram exhibits a C-shaped curve. The turning point of the C-shaped U–R diagram corresponds to the critical radius of ![]() ${R_c}$. The flame kernel structure cannot be established for

${R_c}$. The flame kernel structure cannot be established for ![]() $R < {R_c}$ due to severe conductive heat loss in large curvature condition. Figure 1 shows that for

$R < {R_c}$ due to severe conductive heat loss in large curvature condition. Figure 1 shows that for ![]() $Le = 2$, the flame ball radius is larger than the critical radius, i.e.

$Le = 2$, the flame ball radius is larger than the critical radius, i.e. ![]() ${R_Z} > {R_c}$. Therefore, the stationary flame ball radius is no longer the minimum radius that controls flame initiation in mixtures with large Lewis number (Chen et al. Reference Chen, Burke and Ju2011).

${R_Z} > {R_c}$. Therefore, the stationary flame ball radius is no longer the minimum radius that controls flame initiation in mixtures with large Lewis number (Chen et al. Reference Chen, Burke and Ju2011).

From a quantitative aspect, results in figure 1 indicate that the U–R relation based on the quasi-steady theory deviates from that predicted by the transient formulation at intermediate values of U and R. Such a discrepancy could be elucidated by examining the time scales characterizing the flame propagation and change of temperature gradient. The reference time scale for flame propagation can be characterized by ![]() ${t_{fp}} = 1/U$. According to the unsteady solution of

${t_{fp}} = 1/U$. According to the unsteady solution of ![]() $\partial {T_u}/\partial t$ given by (2.42), the characteristic time for the change of temperature gradient is

$\partial {T_u}/\partial t$ given by (2.42), the characteristic time for the change of temperature gradient is ![]() ${t_{un}} = {R^2}{{\mathcal F}}_{uT}^2/{{\rm \pi} ^2}$.

${t_{un}} = {R^2}{{\mathcal F}}_{uT}^2/{{\rm \pi} ^2}$.

For low to moderate values of ![]() $RU$, the factors

$RU$, the factors ![]() ${{{\mathcal F}}_{uT}}$ and

${{{\mathcal F}}_{uT}}$ and ![]() ${{{\mathcal F}}_{bT}}$ can be expanded in series of the product

${{{\mathcal F}}_{bT}}$ can be expanded in series of the product ![]() $RU$, where the first-order correction must be retained, yielding

$RU$, where the first-order correction must be retained, yielding

Substituting the simplified ![]() ${{{\mathcal F}}_{uT}}$ and

${{{\mathcal F}}_{uT}}$ and ![]() ${{{\mathcal F}}_{uY}}$ into the matching conditions, the flame propagation speed can be estimated by

${{{\mathcal F}}_{uY}}$ into the matching conditions, the flame propagation speed can be estimated by

\begin{equation}U \approx \frac{{2{{({R_Z}/R - 1)}^2}}}{{{\rm \pi} RLe{{({R_Z}/R + {F_R})}^2}}},\end{equation}

\begin{equation}U \approx \frac{{2{{({R_Z}/R - 1)}^2}}}{{{\rm \pi} RLe{{({R_Z}/R + {F_R})}^2}}},\end{equation}

where the factor ![]() ${F_R}$ is

${F_R}$ is

\begin{equation}{F_R} = \frac{{(1 - 1/\sqrt {Le} )\{ 4({\epsilon _T} - 1)[1 + {\epsilon _T}(Le - 1)] - LeZ\} }}{{2{{[1 + (Le - 1){\epsilon _T}]}^2}}}.\end{equation}

\begin{equation}{F_R} = \frac{{(1 - 1/\sqrt {Le} )\{ 4({\epsilon _T} - 1)[1 + {\epsilon _T}(Le - 1)] - LeZ\} }}{{2{{[1 + (Le - 1){\epsilon _T}]}^2}}}.\end{equation} According to the definition of reference time for flame propagation and (3.2), ![]() ${t_{fp}}$ can be quantified in the form

${t_{fp}}$ can be quantified in the form

\begin{equation}{t_{fp}} \sim \frac{{{\rm \pi} RLe{{({R_Z}/R + {F_R})}^2}}}{{2{{({R_Z}/R - 1)}^2}}}.\end{equation}

\begin{equation}{t_{fp}} \sim \frac{{{\rm \pi} RLe{{({R_Z}/R + {F_R})}^2}}}{{2{{({R_Z}/R - 1)}^2}}}.\end{equation} At the onset of flame kernel, the radius is close to that of a flame ball, i.e. ![]() ${R_Z}/R - 1 \ll 1$, and thereby

${R_Z}/R - 1 \ll 1$, and thereby ![]() ${t_{fp}} \gg 1$. However, the characteristic time for temperature gradient evolution, according to its definition, appears at most of order unity, i.e.

${t_{fp}} \gg 1$. However, the characteristic time for temperature gradient evolution, according to its definition, appears at most of order unity, i.e. ![]() ${t_{un}}\sim O(1)$. The exceedingly slow propagating speed provides sufficient time for the local temperature gradient to develop into the steady-state distribution. Therefore, for flame radius close to flame ball size, the unsteady effect is negligible, resulting in the consistency between the quasi-steady theory and transient formulation in the limit of

${t_{un}}\sim O(1)$. The exceedingly slow propagating speed provides sufficient time for the local temperature gradient to develop into the steady-state distribution. Therefore, for flame radius close to flame ball size, the unsteady effect is negligible, resulting in the consistency between the quasi-steady theory and transient formulation in the limit of ![]() $U \to 0$.

$U \to 0$.

At moderate values of ![]() $RU$, one has

$RU$, one has

\begin{equation}\frac{{{t_{fp}}}}{{{t_{un}}}} \sim \frac{{{\rm \pi} RLe{{({R_Z}/R + {F_R})}^2}}}{{2{{({R_Z}/R - 1)}^2}}} \sim O(1).\end{equation}

\begin{equation}\frac{{{t_{fp}}}}{{{t_{un}}}} \sim \frac{{{\rm \pi} RLe{{({R_Z}/R + {F_R})}^2}}}{{2{{({R_Z}/R - 1)}^2}}} \sim O(1).\end{equation}It indicates that the flame propagation speed and the time change rate of local temperature gradient would be of the same order of magnitude, implying that the unsteady effects may have consequential impacts on flame propagation.

As the flame continues to propagate outwardly, we have ![]() $R \gg 1$ and

$R \gg 1$ and ![]() $U \approx 1$. The factor

$U \approx 1$. The factor ![]() ${{{\mathcal F}}_{uT}}$ can be expanded by treating

${{{\mathcal F}}_{uT}}$ can be expanded by treating ![]() $1/(RU)$ as a small parameter, yielding

$1/(RU)$ as a small parameter, yielding ![]() ${{{\mathcal F}}_{uT}} \approx 1/R$. The characteristic time for temperature gradient evolution can be estimated by

${{{\mathcal F}}_{uT}} \approx 1/R$. The characteristic time for temperature gradient evolution can be estimated by ![]() ${t_{un}} = 1/{{\rm \pi} ^2}$. Meanwhile, the flame propagation time is given by

${t_{un}} = 1/{{\rm \pi} ^2}$. Meanwhile, the flame propagation time is given by ![]() ${t_{fp}} = 1/U \approx 1$; therefore, we have

${t_{fp}} = 1/U \approx 1$; therefore, we have ![]() ${t_{fp}} \approx 10{t_{un}}$. This indicates that when the expanding flame is approaching the quasi-planar flame, the local temperature gradient has sufficient time to develop into the steady state distribution. This again leads to the consistency between quasi-steady theory and transient formulation in the limit of

${t_{fp}} \approx 10{t_{un}}$. This indicates that when the expanding flame is approaching the quasi-planar flame, the local temperature gradient has sufficient time to develop into the steady state distribution. This again leads to the consistency between quasi-steady theory and transient formulation in the limit of ![]() $R \to \infty $.

$R \to \infty $.

The above time scale analysis indicates that for low to moderate Lewis numbers, the unsteady effects become important at some intermediate flame radius, where the propagating speed is comparable with the time change rate of local temperature gradient. This is consistent with the work of Joulin (Reference Joulin1985).

In comparison with quasi-steady theory, it shows that the unsteady effect tends to lower the propagation speed (in the range with moderate value of ![]() $RU$). Figure 2 plots the profiles of the temperature and mass fraction of the deficient reactant for a propagating flame with

$RU$). Figure 2 plots the profiles of the temperature and mass fraction of the deficient reactant for a propagating flame with ![]() $Le = 1$ at the moment when the flame radius is

$Le = 1$ at the moment when the flame radius is ![]() $R = 2$. In quasi-steady theory, the temperature and mass fraction profiles has been fully developed, yielding lower gradients across the flame front in the unburnt region

$R = 2$. In quasi-steady theory, the temperature and mass fraction profiles has been fully developed, yielding lower gradients across the flame front in the unburnt region ![]() $(r > 2)$ than those based only transient formulation, as shown in figure 2. It indicates that the rate of diffusion for reactant mixture predicted by transient formulation tends to be higher than that based on quasi-steady theory. As the flame kernel expands, the flame front propagates outwardly. In the reference of coordinate fixed at the flame front, it is equivalent to an inward flow, which leads to convective transport of reactant mixture to feed the flame in addition to diffusion. Nevertheless, the flame temperature predicted by the transient formulation is almost identical to that obtained by quasi-steady theory according to profiles presented in figure 2. Since the consumption rate of reactant is determined by the flame temperature, the higher diffusion rate in the transient formulation shall be associated with a lower convective transport of reactant to the flame front, i.e. a slower propagating speed as shown in figure 1.

$(r > 2)$ than those based only transient formulation, as shown in figure 2. It indicates that the rate of diffusion for reactant mixture predicted by transient formulation tends to be higher than that based on quasi-steady theory. As the flame kernel expands, the flame front propagates outwardly. In the reference of coordinate fixed at the flame front, it is equivalent to an inward flow, which leads to convective transport of reactant mixture to feed the flame in addition to diffusion. Nevertheless, the flame temperature predicted by the transient formulation is almost identical to that obtained by quasi-steady theory according to profiles presented in figure 2. Since the consumption rate of reactant is determined by the flame temperature, the higher diffusion rate in the transient formulation shall be associated with a lower convective transport of reactant to the flame front, i.e. a slower propagating speed as shown in figure 1.

Figure 2. Profiles of temperature and mass fraction of the deficient reactant determined by transient formulation (solid lines) and quasi-steady theory (dashed lines) for ![]() $R = 2$,

$R = 2$, ![]() $Le = 1$ and

$Le = 1$ and ![]() ${Q_m} = 0$.

${Q_m} = 0$.

For mixtures with relatively large Lewis number, the stationary flame ball radius differs from the critical radius characterizing flame ignition. Figure 1 shows that the critical radius predicted by quasi-steady theory, ![]() ${R_c} \approx 14$, is shorter than that based on transient formulation,