Introduction

Prior to the identification of Anatolian tin, scholars argued that tin was necessarily traded into the region from Central Asia, Afghanistan or Europe for consumption in the Near East (see Muhly Reference Muhly1985, Reference Muhly1993; Stöllner et al. 2011). Rather than seeing early copper-tin alloys as products of long-distance exchange, we can now hypothesise that innovations in technology, which focused on the primary extraction of tin ores, allowed Early Bronze Age Anatolian alloys to be produced locally (Yener Reference Yener2009). They were also probably traded through regional networks that linked these regions to other areas of production and consumption in Anatolia.

Evidence that emerged in 1987 prompted the publication, in Antiquity, of the first stannite tin occurrence at Bolkardağ in the Taurus Mountains of southern Turkey (Yener & Özbal Reference Yener and Özbal1987); this radically altered implications for the source of tin used in the production of high-grade bronzes, especially for the third millennium BC. Subsequent excavations and surveys at the Early Bronze Age (calibrated radiocarbon date 3240–3100 BC to 2870–2200 BC) Kestel tin mine and its contemporary production centre, Göltepe, established the existence of a multi-tiered production, exchange and consumption system (Yener Reference Yener2000). Chronologically and functionally related, these two sites became the template for a highland production model of bronze manufacture for southern Anatolia in the Early Bronze Age.

The Early Bronze Age Anatolian highland production model (Yener Reference Yener2000) is one that involves the two-tiered production of metal artefacts and the use of a diverse resource base. The first tier encompassed mining and smelting operations in the regions where rich ore deposits and forests were located, usually in the mountains. The second tier comprised lowland urban centres where the processed ores, in the form of either metal ingots or semi-processed materials, were refined, re-melted, alloyed and cast into various idiosyncratic metal assemblages. In addition to the emergence of this hierarchical organisation of production, adapted technologies were selected to use the highly variable polymetallic ores of the Anatolian highlands. For example, evidence from Arslantepe, located along the Upper Euphrates near to modern Malatya, provides excellent evidence for the use of local polymetallic ores through time. At Arslantepe Late Chalcolithic communities used ores with significant traces of antimony, arsenic, bismuth, nickel and silver; by the Early Bronze Age copper-iron sulphides dominated (Palmieri et al. Reference Palmieri, Frangipane, Hess, Hauptmann, Pernicka, Rehren and Yalçın1999). Analysis of finished metal artefacts from this period, however, showed not only a predominance of arsenical copper but also the consumption of copper-silver and copper-arsenic-nickel (Hauptmann et al. Reference Hauptmann, Schmitt-Strecker, Begeman and Palmieri2002). A similar engagement with polymetallic ores and adapted technologies is evident in both highland Iran (Thornton Reference Thornton2009) and the Transcaucasus (Courcier Reference Courcier, Roberts and Thornton2014). Analysis of highland metallurgical debris and finished artefacts demonstrates that there was probably no one single optimal strategy in early metal production and, furthermore, that these production strategies represent the intentional use of a diverse resource base that was based on cultural knowledge.

This can be contrasted in part with our understanding of the organisation of metal production in the southern Levant. Thornton (Reference Thornton2009) correctly characterised production strategies in this region as distinct from those of highland Anatolia and Iran; in the southern Levant Thornton describes the well-known shift from site-centred smelting and melting in the Chalcolithic and Early Bronze Age I (c. 4200–3000 BC) into a more diversified, large-scale and centralised mode of production during the Early Bronze Age II–III (c. 3000–2300 BC). This shift also followed a pattern of production that took place outside of habitation areas where ingots of metal, rather than ores, were imported (see also Levy Reference Levy and Levy1995; Golden et al. Reference Golden, Levy and Hauptmann2001; Genz & Hauptmann Reference Genz, Hauptmann and Yalçın2002; Levy et al. Reference Levy, Adams, Hauptmann, Prange, Schmitt-Strecker and Najjar2002). This reorganisation of production is similar to our understanding of metal production in Syro-Mesopotamia (Stech Reference Stech and Pigott1999), where peripheral highland resource areas supplied lowland consumers with a range of valuable metal products (Algaze Reference Algaze2008).

This important social shift during the Early Bronze Age II and III in the southern Levant also included changes in technology. Empirical evidence suggests that in earlier periods, smiths produced copper using crucible-based technologies and relatively homogenous iron-rich tile ores. Later, a shift towards the use of manganese-rich ores and furnace-based smelting allowed a larger scale production of relatively pure copper (Hauptmann et al. Reference Hauptmann, Begemann, Heitkemper, Pernicka and Schmitt-Strecker1992: 7; Craddock Reference Craddock2001). It was also during this time that the first tin-bronzes were produced in the southern Levant, which indicates a formal alloying technology using imported primary tin and copper ingots (Hauptmann Reference Hauptmann2003). This contrasts somewhat with Anatolia, which saw a similar degree of diversification and hierarchical production; in Anatolia, however, a more diverse resource base extended the range of technological possibilities. Traditionally, bronze making was thought to segue naturally from using arsenic as the alloying material in the formative fourth to third millennia BC to the use of tin in the third millennium BC. According to text-based evidence, during the early second millennium BC tin was brought from the exotic lands of the east, potentially including Afghanistan and Central Asia, by caravans of Assyrian traders in search of gold and silver in Turkey (ancient Anatolia). Old Assyrian texts found at Kültepe testify to the existence during this period of a highly organised and sophisticated metals trade that possibly linked tin resources from central Asia (see Boroffka et al. Reference Boroffka, Cierny, Lutz, Parzinger, Pernicka, Weisgerber, Boyle, Renfrew and Levine2002; Parzinger Reference Parzinger and Yalçin2002) to central Anatolia by way of Babylonia and Assyria (Larsen Reference Larsen1976; Dercksen Reference Dercksen1996, Reference Dercksen and Yalçın2005). With the decades of research that followed, this simple picture was shown to be far from complete, especially for Early Bronze Age Anatolia.

During the late 1980s excavations at an Early Bronze Age tin mine at Kestel and its associated miners’ village, Göltepe, in the central Taurus Mountains near Çamardı, Niğde, shed light on the origins of 5000-year-old tin bronze figurines, implements and crucible fragments previously found at Tell Judaidah in the Amuq valley, Hatay (Adriaens et al. Reference Adriaens, Earl, Özbal and Yener2002). Kestel mine was discovered by the Turkish Mining and Geological Directorate during mineralogical surveying in metal-rich zones of the Taurus; the results of subsequent archaeometallurgical investigations yielded the solution to a major enigma that had been puzzling scholars for decades—a source of the elusive tin of antiquity. The discovery of tin in Turkey attracted attention after its publication in Science (Yener et al. Reference Yener, Özbal, Kaptan, Pehlivan and Goodway1989) and much heated discussion followed (Muhly Reference Muhly1993). The realisation that multiple tin sources could have been exploited in the Near East was surprising, and the viability of extrapolating the sourcing of tin from second millennium BC contexts backwards into the earlier periods from c. 3000–2000 BC was called into question (Yener Reference Yener2000, Reference Yener2009).

Almost 30 years after the first publication, an archaeometallurgy survey has been conducted by the authors documenting the sources and occurrences of tin in Turkey; the highland tin-production model has now been extended to include the Hisarcık-Kıranardı, Kayseri Erciyes area north of the initial discovery of cassiterite reported in the Taurus range. This unexpected source of a polymetallic ore deposit of tin (cassiterite), combined with arsenic (yazganite), located in the foothills of the stratovolcano, Erciyes (Roman Argaeus) in the Kayseri Plain, 26km south of the site of Kültepe, has profound implications for defining a major production zone in the hinterland of the largest Early Bronze Age settlement in Central Anatolia, ancient Kanesh (see Ministry of Culture and Tourism of Turkey website 2013). The development and exploitation of local and exotic ore bodies for the production of copper alloys by these third-millennium BC polities could be viewed as one of the magnets attracting Assyrian merchants in the second millennium BC.

The discovery of the Hisarcık deposits

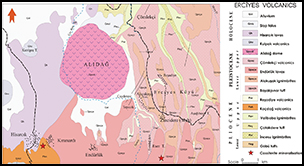

The Hisarcık cassiterite deposits were discovered by the General Directorate of Mineral Research and Exploration, specifically by geologist Evren Yazgan (Pehlivan et al. Reference Pehlivan, Yıldırım, Tufan, Tuvar, Yiğit and Yazgan2005; Yazgan Reference Yazgan2005). Cassiterite was observed together with other oxides of iron and arsenic on the north-east slopes of Erciyes Dağ near modern Hisarcık and Zincidere in the province of Kayseri. The tin is unevenly mineralised inside pyroclastic rocks with acid composition formed by volcanic emissions ejected into the atmosphere, which then settled as bedded deposits, forming the foundations for long ridges such as Senir Sırtı (Figure 1) where scores of mining galleries were located. These ridges formed through seasonal erosion by intermittent streams, leaving in some places exposed rocky outcroppings (Figure 2). The evidence clearly indicates a complex relationship between the tin and the volcano, Erciyes (Figure 3). Archaeologists generally associated volcanoes in Turkey with obsidian sources; they were not known to be a source of metal ores, much less tin.

Figure 1. Topographical map of Senir Sırtı; contour intervals at 10m; map by Y.S. Hayakawa.

Figure 2. Gallery wall at Senir Sırtı Kerim household showing extracted zone and remnant arsenic, iron and tin oxide mineralisations; photograph by J.W. Lehner.

Figure 3. Simplified geological map of Senir Sırtı and vicinity, after Türkecan et al. Reference Türkecan, Acarlar, Dönmez and Bilgin1998.

The iron-tin-arsenic ores were deposited in fumeroles within soft, easily carved material, allowing the mineral to be readily extracted, even with antler and horn. The new mineral (NaFe3+ 2(Mg, Mn)(AsO4)3 H2O) was named yazganite after Evren Yazgan who discovered it. This mineral is unique to the andesitic volcanic complex, occurring in association with tridymite, hematite, cassiterite, magnetite, orpiment and realgar (Sarp & Cerny Reference Sarp and Cerny2005). Independent analyses of the ore deposits near Hisarcık (Yalçın & Özbal Reference Yalçın and Özbal2009) confirmed the presence of tin in the still extant occurrences. The Erciyes volcanic rocks present a petrographic composition that changes from a basalt to basaltic andesite, andesite, dacite or rhyolite. The illustrated samples bearing cassiterite and yazganite minerals (Figures 4 & 5) come from the edges of fissures in the porphyric pyroxene andesitic rocks at Senir Sırtı. At Senir Sırtı these fissures were developed as near-surface extension fractures on the north-western and south-eastern sides during the Upper Pliocene. Cassiterite, yazganite, hematite and trydimite mineral paragenesis have developed on the cavity walls as coating materials in the near-surface open fractures. According to fluid inclusions studies, the common formation temperature for cassiterite and yazganite is between 460–580° C. Four hundred degrees Celsius is a critical temperature for the hydrothermal solutions; above 400° C all of the aqueous solutions transform in a gaseous phase (Yazgan in press). The metallic elements Sn (tin), As (arsenic), Fe (iron) and Mg (magnesium) are transported with halogene group elements F (fluorine), Cl (chlorine), Br (bromine) and I (iodine) in the fumerolian gaseous phase, which is why the cassiterite and yazganite minerals form on the cavity walls as coating materials. Oxides form during the gaseous phase and deposit, presumably upon cooling at near surface temperatures. Similar shallow levels of tin-mineralisation emplacement with close associations with stratovolcanic processes were also observed in Bolivia (Sillitoe et al. Reference Sillitoe, Halls and Grant1975). It is important to emphasise that unlike the Kestel mine, many of the Hisarcık deposits are not vein-type deposits, but are more superficially deposited on the interior surfaces of the fumeroles and fissures; those observed at Zincidere are the exception. The natural exposure of these fissures would have enabled extraction of the ore deposits without the time- and energy-intensive mining technologies associated with extracting ores from veins in hard host rocks.

Figure 4. Cassiterite and yazganite minerals under a binocular microscope; photograph by E. Yazgan.

Figure 5. Cassiterite (Cass), hematite (Hem), and yazganite (Yaz) minerals on plagioclase (Plg) minerals of the host rock in thin section under a polarised light microscope; photograph by E. Yazgan.

In 2013 as part of the Kültepe survey and excavations, investigations began at the second tin source on the foothills of the volcano Erciyes at Hisarcık and Zincidere. A portable X-ray fluorescence analyser was used alongside the survey efforts to identify the presence or absence of major ore types rapidly. Semi-quantitative analysis of ores was conducted using an internally calibrated procedure developed for the compositional analysis of ores; this analysis was conducted using the instrument in mining mode, which is a suitable method for measuring major and minor concentrations of metal elements (for the basic limitations of current portable X-ray fluorescence technology, see Liritzis & Zacharias Reference Liritzis, Zacharias and Shackley2011). These new tools have also allowed the rapid identification and characterisation of complex ore bodies, and the discovery of new and hitherto unknown alloys and sophisticated crafting of ancient metal artefacts in museums. Multiple, semi-quantitative portable X-ray fluorescence analyses (in weight per cent, wt.%) of the Hisarcık ores at the Kerim household location yielded significant but variable values up to 90.7% Fe2O3, 20.4% SnO2 and 11.8% As, in addition to significant impurities of antimony, manganese and zinc (Table 1 & Figure 6).

Table 1. pXRF analyses of ore samples from Senir Sırtı Kerim household location (J.W. Lehner).

Figure 6. Spectra of pXRF analyses of ore samples from the Senir Sırtı Kerim household (J.W. Lehner).

The concurrence of tin and iron would have presented significant challenges to ancient smelters hoping to reduce tin metal from these ores. Given the similarity in the reducibility of iron and tin oxides, tin smelters would have faced a trade-off. Under low reducing conditions, slags rich in tin would be produced, effectively reducing the efficiency of the smelt, even if metallic prills of tin could be retrieved. Conversely, to reduce the amount of tin-rich slag under high reducing conditions, significant quantities of iron would also be reduced into a product called hardhead (an iron-tin alloy) (Wright Reference Wright1982; Grant Reference Grant1994: 456; Smith Reference Smith1996: 91). The Hisarcık ores could also have been used in co-smelting or mixed smelting operations to produce tin alloys directly through a primary smelting process. Rovira et al. Reference Rovira, Montreo-Ruiz, Renzi, Kienlin and Roberts2009 demonstrated a simple co-smelting technique, experimenting by adding copper ores with cassiterite into a crucible to produce prills that were highly variable in tin (up to 81%). The pXRF analyses were confirmed by more precise measurements using a Field Emission Scanning Electron Microscope and Inductively Coupled Plasma Mass Spectrometer at KUYTAM (Surface Technologies Center) at Koҫ University in Istanbul.

Early Bronze Age II–III and even earlier Late Chalcolithic ceramics (Figure 7 & Figure 8: 1–6) found in association with the mining galleries shed light on the preliminary dating of the mines. Similar Red Slip wares, such as are seen in Figure 7 (7 & 9) and Figure 8 (3 & 4), stem from west Anatolian Early Bronze Age settlements. Red- and fine-burnished wares such as are shown in Figure 7 (4 & 6) and Figure 8 (5 & 6) were also excavated at Göltepe and dated to the Early Bronze Age II and III. Wares with mottling and dark or light burnishing, as seen in Figure 7 (1–3) and Figure 8 (1 & 2), are also known from the Late Chalcolithic to Early Bronze Age in this region. Soundings planned for the future will hopefully provide samples for radiocarbon dates. The diagnostic sherds were found on Senir Sırtı, one of the ridges that had multiple mining galleries. Comparable with archaeometallurgical finds at the Kestel mine and Göltepe (Kaptan Reference Kaptan1995; Yener Reference Yener2000, Reference Yener, Yalçın, Özbal and Paşamehmetoğlu2008), the ceramics as well as grinding stones were strewn on the surface near the gallery entrances, presumably as part of seasonal workshops for the initial processing of the ore at the mines.

Figure 7. Late Chalcolithic and Early Bronze II–III ceramics from Senir Sırtı; drawing by H. Sudo, Y. Yamaguchi and A. Hacar.

Figure 8. Ceramics from Senir Sırtı and Teknekayası; photograph by A. Hacar.

Predictably, akin to the linked and functionally related sites of Göltepe and Kestel Mine, 2km away from the mines on Senir Sırtı was a fortified processing site, Teknekayası Höyük (Figure 9), a major second-tier site. Located 24km from Kültepe, the mound measures 250 × 180m, and it was discovered during the Kayseri survey (Kontani et al. Reference Kontani, Sudo, Yamaguchi, Hayakawa, Kulakoğlu, Emre, Ezer and Öztürk2012, Reference Kontani, Sudo, Yamaguchi, Hayakawa, Odaka, Barjamovic and Fairbairn2014a & Reference Kontani, Odaka, Sudo, Hayakawa, Kulakoğlu, Emre and Öztürkb). A preliminary surface survey on this site in 2013 yielded Early Bronze Age II pottery together with Middle Bronze Age, Late Bronze Age and Iron Age pottery (Figure 10). Furthermore, ore-processing mortars, hammer stones, multi-hollow anvils and grinding equipment found on the surface are components of the highland production model, and are therefore suggestive of a second-tier specialised processing and habitation site.

Figure 9. Teknekayası processing site photograph viewed from the Senir Sırtı mines by G. Dardeniz.

Figure 10. Surface ceramics from Teknekayası; drawing by H. Sudo, Y. Yamaguchi and A. Hacar.

Discussion

The highland production model is one that involves metals, precious not only in terms of economic value but also critical beyond calculation for their role in the negotiation of status and power, and their embodiment of a value-added commodity for trade. These new ways of making things and organising production reveal much about the nature of society. Recent research in ancient metallurgy and its sources have led to a better understanding of cultural relations, especially during the formative periods of metal technology and state formation in Anatolia. Once metal became locked into a cultural system as an indicator of wealth, disparities in access to labour and resources influenced how individuals operated within and between communities of producers and consumers. These relations often linked distant groups together into cooperative agreements, hence the Assyrian commercial network. Therefore, metal technologies are strategically placed in complex networks and institutions of production, exchange and consumption that effectively unite disparate highland resource areas and agricultural lowlands (Lehner & Yener Reference Lehner, Yener, Roberts and Thornton2014).

Clearly, the hinterland of the Early Bronze Age kingdom of Kanesh has provided extensive evidence of a rich and varied industrial resource for production and trade supplementing its abundant agricultural yields from the Kayseri region. We use the term ‘kingdom’ advisedly; texts such as the later šar tamhari, ‘King of Battle’ legends of Akkadian kings Naram-Sin and Sargon (Özgüҫ Reference Özgüç, Canby, Porada, Ridgway and Stech1986; Westenholz Reference Westenholz1997), refer to a ‘king’ of Kanesh in the third millennium BC. Recent surface surveys (Kontani et al. Reference Kontani, Odaka, Sudo, Hayakawa, Kulakoğlu, Emre and Öztürk2014b) indicate that by the Early Bronze Age a three-tiered settlement hierarchy, indicative of a markedly complex settlement system, existed in proximity to the massive site of Kültepe. The three-tiered characteristic of the production sites near Kültepe-Kanesh is the relationship between mine, processing site and urban centre; this system of interconnected tiers suggests that some networks established in the Early Bronze Age were at least maintained and possibly strengthened in later periods. Furthermore, they were the backdrop of the subsequent Assyrian merchant trade. While the lower town (karum) of Kanesh was the location of multiple metal workshops in the second millennium BC (Özgüҫ Reference Özgüç1955; Lehner Reference Lehner, Atıcı, Kulakoğlu, Barjamovic and Fairbairn2014a), it is not yet known whether levels III and IV in the lower town were established prior to the Assyrian merchants’ presence, nor whether the Early Bronze Age levels on the mound contained metal workshops; these all remain future avenues for investigation (Kulakoğlu Reference Kulakoğlu, Kulakoğlu and Kangal2010, Reference Kulakoğlu, Steadman and McMahon2011; Kulakoğlu & Kangal Reference Kulakoğlu and Kangal2010; Ezer Reference Ezer, Barjamovic and Fairbairn2014). Furthermore, the specific consequences for local bronze of the ready availability of Assyrian commercial tin in the second millennium BC remains a question for future investigation. Qualitative X-ray fluorescence analysis of a crucible with slaggy encrustations from the new mound excavations at Early Bronze Age Kanesh demonstrates that the crucible was used to process copper with tin and arsenic. These results are consistent with copper melting and the secondary production of copper alloys at the site. Primary metal products or scrap were therefore probably transported to the site for secondary production into finished objects. This pattern of production and trade is observed in later contexts at Kanesh and also at Late Bronze Age regional centres such as Hattusha and Alalakh.

Given the complex Middle Bronze Age copper alloys of Kanesh, which demonstrate a major grouping of copper-tin alloys with greater than 1% arsenic (Esin Reference Esin1969; Lehner Reference Lehner, Atıcı, Kulakoğlu, Barjamovic and Fairbairn2014a), it is increasingly likely that the knowledge of making bronzes using local sources of tin and arsenic was already established long before Assyrian merchants described the importation and trade of tin in economic texts. Understanding the existence and importance of such ternary alloys of bronze containing tin and arsenic, as well as other exotic alloys such as high-nickel- and high-antimony-bronzes, has taken on a new urgency. Analyses just completed by Lehner of third and second millennium BC copper alloys from Boğazköy-Hattuša (Lehner Reference Lehner, Atıcı, Kulakoğlu, Barjamovic and Fairbairn2014b; Lehner & Schachner in press) and Kültepe-Kanesh, as well as new analyses of Late Bronze Age Alalakh (Özbal Reference Özbal2006), and Tarsus bronzes (Kuruҫayirlı & Özbal Reference Kuruçayırlı, Özbal and Özyar2005; Kuruҫayirlı Reference Kuruçayırlı2007) have all revealed these unusual alloying combinations. Such ternary alloys have often been attributed to the re-melting of scrap metals, the collapse of trade networks, scarcity and other socio-economic reasons. Closer examination of the ore deposits has, however, revealed an alternative explanation: local production using the variations within myriad regional ore bodies. A similar observation has also been published by Radivojević et al. (Reference Radivojević, Rehren, Kuzmanović-Cvetković, Jovanović and Northover2013) for the Balkans. They suggest that mixed smelting of stannite, fahlore and chalcopyrite produced compositionally variable copper-tin alloys c. 6500 BP. Here we see the importance of mixed smelting in the earliest dated copper-tin alloys. This study gives the survey and characterisation of smaller occurrences of tin more urgency. Archaeological and geological survey of tin placer deposits in river valleys at Mount Cer in western Serbia, for example, shows a rise in possible Bronze Age settlements in locations particularly rich with tin placer ores (Huska et al. Reference Huska, Powell, Mitrovic, Bankoff, Bulatovic, Filipovic and Boger2014), which further suggests that the localised production of tin-bronzes in south-east Europe is increasingly plausible.

Conclusions

The suggestion that highland regions promote diversity is not a novel concept. Regional environments and resource distributions in the Anatolian highlands influenced diverse institutions of production and specialisation; the Hisarcık complex is only one example. The highland mining communities are one subset of such specialised institutions. These communities seemed to emerge with the greater demand for resources used in the creation of utilitarian and wealth objects during the mid-fourth millennium BC and especially the third millennium BC. The questions to research in the future are how these production zones were organised, managed and specifically how they developed into multiple tiers of production. Was it the result of emergent complexity or were they somehow coercively set in place? Furthermore, what were the exchange destinations of these raw materials and their impact on the consumers? For the more southern highland tin-production sites of Göltepe and Kestel, the second-tier destination was most likely the as yet unexcavated ancient city of Naḫita underneath modern Niğde and beyond the Taurus Mountains, southwards into the Cilician and the Amuq plains, where the Early Bronze I tin bronze figurines, crucibles and utensils of Judaidah appeared. We suggest that the destination of the Hisarcık ores and the products of the first-tier processing centres in the hinterland of the Erciyes volcano was the Early Bronze Age regional centre of Kanesh.

Acknowledgements

The authors would like to acknowledge the support of Abdullah Kocapınar, Monuments and Museums Director; Melik Ayaz, Head of the Department of Excavations and Surveys; Orhan Düzgün, Kayseri governor; Mehmet Özhaseki, Kayseri Mayor; Abdülkadir Gürer, Faculty of Language and History-Geography Dean, Ankara Üniversity and Sami Gülgöz, College of Social Sciences and Humanities Dean, Koҫ University. We would like to acknowledge: Șükrü Zekier, who brought the cassiterite-rich samples to the attention of E. Yazgan; Gregor Borg, who made possible the use of a Thermo Niton XL3t pXRF analyser; and the generous financial and logistical support of the Alexander von Humboldt Foundation and Curt-Engelhorn-Zentrum Archäometrie.