1. Introduction

Emulsions are encountered in a variety of environments, such as multiphase flow through fibrous materials, packed beds with complex pellet shapes and tortuous subsurface settings. Fields ranging from separations processes to oil recovery to microfluidics stand to profit from understanding of Stokes-flow droplet behaviour near complex surfaces. Efforts toward high-resolution microscale numerical models of non-wetting emulsions in complex environments have been stymied, chiefly due to the extremely close approach of fluid–fluid interfaces to solid surfaces. The intervening lubrication layer critically influences the interfacial dynamics, making it difficult to use a simplifying theory for these regions, while also presenting formidable challenges for numerical methods. To overcome some of these limitations, we introduce an extension to the boundary-integral method that leverages both adaptive meshing and high-order singularity subtraction to allow simulation of tight-squeezing drop motion between arbitrarily shaped smooth solid surfaces.

Although a common model for porous media is an ensemble of spherical particles packed in space, several interesting classes of material fall outside this description, such as packed beds of pellets or extrudates, fibrous material or experimental set-ups such as planar constrictions. Probing detailed flow behaviour in such cases is difficult, but there is a growing focus on pore-scale resolution (Blunt et al. Reference Blunt, Bijeljic, Dong, Gharbi, Iglauer, Mostaghimi, Paluszny and Pentland2013). Experimental velocimetry methods, such as magnetic resonance or X-ray tomography (Al-Abduwani et al. Reference Al-Abduwani, Farajzadeh, van den Broek, Currie and Zitha2005; Huang et al. Reference Huang, Mikolajczyk, Küstermann, Wilhelm, Odenbach and Dreher2017), for visualizing and quantifying confined flows are continually improving, strengthening the relationship with computational studies that can provide direct comparisons. For example, Zarikos et al. (Reference Zarikos, Terzis, Hassanizadeh and Weigand2018) used particle-tracking velocimetry to track the interface as well as internal circulation of non-wetting drops as they are trapped and remobilized within porous media. Krummel et al. (Reference Krummel, Datta, Münster and Weitz2013) and Oughanem et al. (Reference Oughanem, Youssef, Bauer, Peysson, Maire and Vizika2015) investigated the recovery of trapped oil, based on capillary number and oil ganglia size distribution, and they were able to resolve individual drops using confocal microscopy and high-resolution micro-computed tomography, respectively. Using similar techniques, Pak et al. (Reference Pak, Butler, Geiger, van Dijke and Sorbie2015) identified a new single-pore mechanism of drop fragmentation. Herring et al. (Reference Herring, Harper, Andersson, Sheppard, Bay and Wildenschild2013) demonstrate the dramatic effect that pore geometry has on the shape and connectivity of the non-wetting phase (e.g. see figure 9 therein). Typically these experiments involving porous media cover length scales beyond the reach of simulation, while resolving small-scale flow and interfacial behaviour remains the territory of high-resolution numerical models.

Simulation techniques for large-scale multiphase systems include the lattice-Boltzmann, volume of fluid and boundary-integral methods, each of which occupy a niche within the field of computational fluid dynamics. Lattice-Boltzmann techniques represent a powerful simulation tool for large-scale flows interacting with complex boundaries; the following four examples utilized various lattice-Boltzmann methods to model the behaviour of the non-wetting phase within porous media. Mantle, Sederman & Gladden (Reference Mantle, Sederman and Gladden2001) provide exact comparisons between magnetic resonance imaging results and lattice-Boltzmann simulations for Stokes flow in a packed bed of pellets, after scanning the experimental matrix and reconstructing it for their computer model. Pan, Hilpert & Miller (Reference Pan, Hilpert and Miller2004) demonstrated the application of three-dimensional (3-D) lattice-Boltzmann methods to large-scale, confined multiphase flow between spherical particles or within spherical cavities. Hao & Cheng (Reference Hao and Cheng2010) calculated the relative permeabilities of a packed-sphere bed, as well as that of carbon paper, modelled as a matrix of high-aspect-ratio fibres. They concluded that, for this anisotropic fibrous matrix, flow direction has negligible effect on the relative permeability. Finally, Yiotis, Talon & Salin (Reference Yiotis, Talon and Salin2013) showed the existence of several flow regimes depending on Bond number for liquid blobs within realistic 2-D pore structures. The volume of fluid method has also been used to model drop breakup when flowing between cylinders, such as the 2-D study of Dietsche & Neubauer (Reference Dietsche and Neubauer2009). Ardekani, Dabiri & Rangel (Reference Ardekani, Dabiri and Rangel2009) used this method to demonstrate that a drop may become perforated when pinched between two particles in shear flow. When implementing any of these techniques, a persistent problem is precisely capturing the evolution of the fluid–fluid interfaces, especially in the proximity of the solid phase. The boundary-integral method resolves these interfaces explicitly, by reformulating the multiphase Stokes problem such that collocation points need only exist on boundaries as pioneered by Rallison & Acrivos (Reference Rallison and Acrivos1978). The deformation and near breakup of drops confined between parallel plates was simulated by Janssen & Anderson (Reference Janssen and Anderson2008), demonstrating drop breakup modes consistent with experiment. Zinchenko & Davis (Reference Zinchenko and Davis2013) simulated many (50–100) clean drops in pressure-driven flow through a bed of randomly packed spheres, including treatment of cascading drop breakup.

The boundary-integral method (BIM) is a powerful tool for low-Reynolds-number flow, and utilizes an integral formulation of the Stokes equations to explicitly resolve interfaces. BIM allows for efficient calculation of interfacial motion at high orders of accuracy, but it comes at the cost of highly singular boundary integrals wherever two interfaces approach each other closely, as is certainly the case for tight-squeezing drops. This formidable numerical issue is typically addressed with adaptive meshing (see Kropinski (Reference Kropinski1999) for an example in two dimensions) or singularity subtraction techniques that rely on analytical expressions for various contributions to the potential (Rallison & Acrivos Reference Rallison and Acrivos1978). For example, Fan, Phan-Thien & Zheng (Reference Fan, Phan-Thien and Zheng1998) use a completed double-layer formulation to allow simulation of solid-sphere suspensions that can approach each to within 5 % of their radius. Zinchenko & Davis (Reference Zinchenko and Davis2006) were able to stably simulate drops trapped between solid particles with drop–solid spacing 1 % of the particle size, by constructing analytical expressions to desingularize the single- and double-layer contributions from spherical and spheroidal particles. Obtaining these closed-form expressions is non-trivial even for simple shapes; for spheroids, infinite series involving spheroidal harmonics are required. In the case of prolate and oblate spheroids, these expressions were shown to be fast convergent. Analytical desingularization of BIM is also successful for tight drop squeezing through a torus using the tool of toroidal harmonics (Ratcliffe, Zinchenko & Davis Reference Ratcliffe, Zinchenko and Davis2010). For more complex shapes, however, analytical BIM desingularizations are unlikely to be available. Therefore we introduce two methods, one of which is semi-analytical but limited to drop squeezing between axisymmetric shapes (in arbitrary 3-D orientations, though), and the second one is general for boundary-integral simulations of drops squeezing between arbitrary Lyapunov surfaces.

The general problem formulation, non-dimensional form and description of particle shapes are provided in § 2. The boundary-integral equations and additional implementation details are discussed in § 3. Two distinct methods for high-accuracy calculation of desingularization integrals over various classes of particles are introduced in § 4. The objective of devising these methods was to overcome a fundamental limitation of the boundary-integral method, namely its numerical breakdown when fluid interfaces closely approach solid surfaces, in cases where analytical or extrapolation techniques are not suitable. Using either of these methods in conjunction with the suite of high-order desingularization techniques outlined by Zinchenko & Davis (Reference Zinchenko and Davis2006), generalizes high-accuracy BIM simulations to previously untenable multiphase systems. One method is semi-analytical and applies to axisymmetric particles. The other, termed the multimesh method, is purely numerical but can accommodate arbitrary smooth shapes. Close agreement is observed between the two desingularization methods, for drop squeezing between cylindrical particles over a range of parameters. The semi-analytical method is considerably faster, and both methods are susceptible of parallelization. To achieve stable simulations over the full range of desired particle shapes, particularly those with high curvature, a coordinated adaptive remeshing scheme for the droplet was also devised, capable of economically maintaining the high resolution of an unstructured mesh within a specific spatial region. In §§ 5 and 6, we report the simulated behaviour of drops squeezing between several general classes of particle shapes.

2. Problem formulation

Consider a single freely suspended, neutrally buoyant drop within a uniform far-field flow, approaching one or more complex-shaped particles fixed in space; Newtonian quasi-steady Stokes flow is assumed inside and outside the drop. The boundary-integral formulation assumes all surfaces have smoothly varying normals. Still, the class of smooth, closed surfaces is an infinite parameter space; herein we focus on rounded cylinders (capsules) and thin, rounded cuboids (plates), as models for common experimental set-ups as well as fibrous and other porous media. Several well-defined asymmetric constrictions and particles are also considered (§§ 5.4 and 5.5), in order to elicit more complex drop behaviour. For spheres, capsules and derivative particles, the characteristic length ![]() $L$ is a radius of the solid particle (figure 1). In the case of rounded plates,

$L$ is a radius of the solid particle (figure 1). In the case of rounded plates, ![]() $L$ is defined as the gap between two plates forming a constriction. The drop centre is initially placed

$L$ is defined as the gap between two plates forming a constriction. The drop centre is initially placed ![]() $10L$ upstream from the particles’ basal plane, unless noted otherwise. The ratio of the drop viscosity (

$10L$ upstream from the particles’ basal plane, unless noted otherwise. The ratio of the drop viscosity (![]() $\mu _d$) and external medium viscosity (

$\mu _d$) and external medium viscosity (![]() $\mu _e$) is

$\mu _e$) is ![]() $\lambda = \mu _d/\mu _e$ and the uniform far-field velocity carrying the drop towards the constriction is

$\lambda = \mu _d/\mu _e$ and the uniform far-field velocity carrying the drop towards the constriction is ![]() $\boldsymbol {u}_{\infty }$. The capillary number is defined as

$\boldsymbol {u}_{\infty }$. The capillary number is defined as

where ![]() $\tilde {a}$ is the non-deformed drop radius and

$\tilde {a}$ is the non-deformed drop radius and ![]() $\sigma$ is the constant surface tension of the surfactant-free drop interface.

$\sigma$ is the constant surface tension of the surfactant-free drop interface.

Figure 1. Particle shapes used to construct constrictions (as well as individual-particle obstacles, in the case of the capsule). The capsule is a cylinder capped with hemispheres on either end. The half-capsule is a capsule cut in half lengthwise, and then capped with a bevel of radius ![]() $0.2L$. The flat plate is a simple

$0.2L$. The flat plate is a simple ![]() $4\times 8\times 0.2L$ rectangular prism with bevelled edges. Particles not shown to scale.

$4\times 8\times 0.2L$ rectangular prism with bevelled edges. Particles not shown to scale.

Other important metrics used to quantify drop dynamics include the drop–particle gap and the drop velocity. The gap between the drop and each solid particle is defined as the minimum distance between the two mesh polyhedra, assuming flat triangulation. The high-resolution solid-particle meshes were used for increased accuracy of the gap calculation. The instantaneous drop velocity ![]() $\boldsymbol {U}$, defined as the volume-averaged fluid velocity

$\boldsymbol {U}$, defined as the volume-averaged fluid velocity ![]() $\boldsymbol {u}$ inside the drop, can be calculated through the divergence theorem as

$\boldsymbol {u}$ inside the drop, can be calculated through the divergence theorem as

where ![]() $\tilde {V}$ is the drop volume,

$\tilde {V}$ is the drop volume, ![]() $\boldsymbol {n}$ are outward surface unit normals at points

$\boldsymbol {n}$ are outward surface unit normals at points ![]() $\boldsymbol {x}$ on the surface and

$\boldsymbol {x}$ on the surface and ![]() $\tilde {\boldsymbol {x}}^{c}$ is the drop centroid. In what follows,

$\tilde {\boldsymbol {x}}^{c}$ is the drop centroid. In what follows, ![]() $U$ is the component of

$U$ is the component of ![]() $\boldsymbol {U}$ along

$\boldsymbol {U}$ along ![]() $\boldsymbol {u}_{\infty }$.

$\boldsymbol {u}_{\infty }$.

The solid particles used to build constrictions are shown in figure 1. A capsule, or spherocylinder, is a round cylinder capped with hemispheres, with a maximum dimension ![]() $\mathcal {L}$. A range of lengths

$\mathcal {L}$. A range of lengths ![]() $\mathcal {L}$ are tested; however, a default of

$\mathcal {L}$ are tested; however, a default of ![]() $\mathcal {L}=6$ is used for parametric studies. A half-capsule is constructed by dividing a capsule (

$\mathcal {L}=6$ is used for parametric studies. A half-capsule is constructed by dividing a capsule (![]() $\mathcal {L}=6$) in half lengthwise, and capping the resulting sharp edge with a circular bevel of radius

$\mathcal {L}=6$) in half lengthwise, and capping the resulting sharp edge with a circular bevel of radius ![]() $0.2L$. As shown below, constrictions are formed by two parallel capsules or half-capsules, separated by a minimum gap of

$0.2L$. As shown below, constrictions are formed by two parallel capsules or half-capsules, separated by a minimum gap of ![]() $0.5L$. A plate is a rectangular prism bevelled to preserve its original maximal dimensions. The plate dimensions are

$0.5L$. A plate is a rectangular prism bevelled to preserve its original maximal dimensions. The plate dimensions are ![]() $4\times 8\times 0.2L$, where

$4\times 8\times 0.2L$, where ![]() $L$ is the minimum distance between two plates forming a constriction. In addition to satisfying the assumption of smooth surfaces in the boundary-integral formulation below, rounding sharp edges on solids also serves to preserve a finite lubrication layer between the drop and solid and prevent excessive local deformation of the drop interface.

$L$ is the minimum distance between two plates forming a constriction. In addition to satisfying the assumption of smooth surfaces in the boundary-integral formulation below, rounding sharp edges on solids also serves to preserve a finite lubrication layer between the drop and solid and prevent excessive local deformation of the drop interface.

3. Desingularized boundary-integral formulation

The present boundary-integral formulation for drops interacting with arbitrary smooth particles utilizes the suite of desingularization methods detailed by Zinchenko & Davis (Reference Zinchenko and Davis2006), but replaces all involved analytical desingularization integrals with semi-analytical or numerical integrals. The semi-analytical desingularization for axisymmetric particles and the numerical method for arbitrary surfaces are outlined in § 4. The Hebeker representation is used for each solid-particle contribution as a linear combination of single-layer and double-layer potentials, and the interfacial stress contribution is desingularized for both drop self-interactions and drop–solid contributions. The resulting Fredholm integral equations of the second kind are well behaved for tight-squeezing drops, for which drop–solid separation distances can be several orders of magnitude smaller than the system's characteristic length.

Let ![]() $\tilde {N}$ be, for generality, the number of drops in the system (with the same viscosity ratio

$\tilde {N}$ be, for generality, the number of drops in the system (with the same viscosity ratio ![]() $\lambda$),

$\lambda$), ![]() $\tilde {S}$ be the surfaces of these drops,

$\tilde {S}$ be the surfaces of these drops, ![]() $\hat {N}$ be the number of solid particles and

$\hat {N}$ be the number of solid particles and ![]() $\hat {S}$ be the surfaces of these particles. The no-slip boundary condition

$\hat {S}$ be the surfaces of these particles. The no-slip boundary condition ![]() $\boldsymbol {u} = \boldsymbol {0}$ is enforced for the fluid velocity on the solid boundaries. The far-field velocity

$\boldsymbol {u} = \boldsymbol {0}$ is enforced for the fluid velocity on the solid boundaries. The far-field velocity ![]() $\boldsymbol {u}_{\infty }(\boldsymbol {y})$ away from the particles and drops can be an arbitrary Stokes flow (although a uniform

$\boldsymbol {u}_{\infty }(\boldsymbol {y})$ away from the particles and drops can be an arbitrary Stokes flow (although a uniform ![]() $\boldsymbol {u}_{\infty }$ was assumed in the present simulations). Standard Wielandt's deflation is beneficial to avoid ill conditioning at extreme viscosity ratios. To this end, the system is cast in terms of

$\boldsymbol {u}_{\infty }$ was assumed in the present simulations). Standard Wielandt's deflation is beneficial to avoid ill conditioning at extreme viscosity ratios. To this end, the system is cast in terms of ![]() $\boldsymbol {w}=\boldsymbol {u}-\kappa \boldsymbol {u}'$, where

$\boldsymbol {w}=\boldsymbol {u}-\kappa \boldsymbol {u}'$, where ![]() $\kappa = (\lambda -1)/(\lambda +1)$ and

$\kappa = (\lambda -1)/(\lambda +1)$ and ![]() $\boldsymbol {u}'$ is the rigid-body projection (see below) of

$\boldsymbol {u}'$ is the rigid-body projection (see below) of ![]() $\boldsymbol {u}$ on a drop surface. At every time step, the following system of equations is solved for modified interface velocity

$\boldsymbol {u}$ on a drop surface. At every time step, the following system of equations is solved for modified interface velocity ![]() $\boldsymbol {w}$ on drops and Hebeker density

$\boldsymbol {w}$ on drops and Hebeker density ![]() $\boldsymbol {q}$ on solid surfaces (Zinchenko & Davis Reference Zinchenko and Davis2006):

$\boldsymbol {q}$ on solid surfaces (Zinchenko & Davis Reference Zinchenko and Davis2006):

\begin{align} \boldsymbol{w}(\boldsymbol{y}) &= \frac{2\boldsymbol{F}(\boldsymbol{y})}{\lambda+1} + \kappa \left[ 2 \sum_{\beta =1}^{\tilde{N}} \int_{\tilde{S}_\beta} \boldsymbol{w}(\boldsymbol{x}) \boldsymbol{\cdot} \boldsymbol{\tau} (\boldsymbol{r}) \boldsymbol{\cdot} \boldsymbol{n}(\boldsymbol{x}) \,\mbox{d} S_x - \boldsymbol{w}'(\boldsymbol{y}) + \frac{\boldsymbol{n}(\boldsymbol{y})}{\tilde{S}_\alpha} \int_{\tilde{S}_\alpha} \boldsymbol{w} \boldsymbol{\cdot} \boldsymbol{n} \,\mbox{d} S \right] \nonumber\\ &\quad +\frac{2}{\lambda + 1} \sum_{\beta =1}^{\hat{N}} \int_{\hat{S}_\beta} \boldsymbol{q}(\boldsymbol{x}) \boldsymbol{\cdot} [2\boldsymbol{\tau}(\boldsymbol{r})\boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x}) + \eta \textbf{G}(\boldsymbol{r})]\,\mbox{d} S_x \end{align}

\begin{align} \boldsymbol{w}(\boldsymbol{y}) &= \frac{2\boldsymbol{F}(\boldsymbol{y})}{\lambda+1} + \kappa \left[ 2 \sum_{\beta =1}^{\tilde{N}} \int_{\tilde{S}_\beta} \boldsymbol{w}(\boldsymbol{x}) \boldsymbol{\cdot} \boldsymbol{\tau} (\boldsymbol{r}) \boldsymbol{\cdot} \boldsymbol{n}(\boldsymbol{x}) \,\mbox{d} S_x - \boldsymbol{w}'(\boldsymbol{y}) + \frac{\boldsymbol{n}(\boldsymbol{y})}{\tilde{S}_\alpha} \int_{\tilde{S}_\alpha} \boldsymbol{w} \boldsymbol{\cdot} \boldsymbol{n} \,\mbox{d} S \right] \nonumber\\ &\quad +\frac{2}{\lambda + 1} \sum_{\beta =1}^{\hat{N}} \int_{\hat{S}_\beta} \boldsymbol{q}(\boldsymbol{x}) \boldsymbol{\cdot} [2\boldsymbol{\tau}(\boldsymbol{r})\boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x}) + \eta \textbf{G}(\boldsymbol{r})]\,\mbox{d} S_x \end{align}

for ![]() $\boldsymbol {y} \in \tilde {S}_\alpha \ (\alpha =1\cdots \tilde {N})$ and

$\boldsymbol {y} \in \tilde {S}_\alpha \ (\alpha =1\cdots \tilde {N})$ and

\begin{align} \boldsymbol{q}(\boldsymbol{y}) &= \boldsymbol{F}(\boldsymbol{y}) + (\lambda-1) \sum_{\beta =1}^{\tilde{N}} \int_{\tilde{S}_\beta} \boldsymbol{w}(\boldsymbol{x}) \boldsymbol{\cdot} \boldsymbol{\tau} (\boldsymbol{r}) \boldsymbol{\cdot} \boldsymbol{n}(\boldsymbol{x}) \,\mbox{d} S_x \nonumber\\ &\quad +\sum_{\beta =1}^{\hat{N}} \int_{\hat{S}_\beta} \boldsymbol{q}(\boldsymbol{x}) \boldsymbol{\cdot} [2\boldsymbol{\tau}(\boldsymbol{r}) \boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x}) + \eta \textbf{G}(\boldsymbol{r})]\,\mbox{d} S_x \end{align}

\begin{align} \boldsymbol{q}(\boldsymbol{y}) &= \boldsymbol{F}(\boldsymbol{y}) + (\lambda-1) \sum_{\beta =1}^{\tilde{N}} \int_{\tilde{S}_\beta} \boldsymbol{w}(\boldsymbol{x}) \boldsymbol{\cdot} \boldsymbol{\tau} (\boldsymbol{r}) \boldsymbol{\cdot} \boldsymbol{n}(\boldsymbol{x}) \,\mbox{d} S_x \nonumber\\ &\quad +\sum_{\beta =1}^{\hat{N}} \int_{\hat{S}_\beta} \boldsymbol{q}(\boldsymbol{x}) \boldsymbol{\cdot} [2\boldsymbol{\tau}(\boldsymbol{r}) \boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x}) + \eta \textbf{G}(\boldsymbol{r})]\,\mbox{d} S_x \end{align}

on solid-particle surfaces (![]() $\boldsymbol {y}\in \hat {S}_{\alpha },\ \alpha =1\cdots \hat {N}$). Here,

$\boldsymbol {y}\in \hat {S}_{\alpha },\ \alpha =1\cdots \hat {N}$). Here, ![]() $\mbox {d} S_x$ is the surface element for the integration point

$\mbox {d} S_x$ is the surface element for the integration point ![]() $\boldsymbol {x}$,

$\boldsymbol {x}$, ![]() $\boldsymbol {r} = \boldsymbol {x}-\boldsymbol {y}$,

$\boldsymbol {r} = \boldsymbol {x}-\boldsymbol {y}$, ![]() $\boldsymbol {n}$ is the unit normal to a surface,

$\boldsymbol {n}$ is the unit normal to a surface, ![]() $\eta >0$ is the Hebeker parameter (the choice of

$\eta >0$ is the Hebeker parameter (the choice of ![]() $\eta$ affects the algorithm robustness, but not the solution upon numerical convergence) and prime indicates rigid-body projection. The latter is calculated as

$\eta$ affects the algorithm robustness, but not the solution upon numerical convergence) and prime indicates rigid-body projection. The latter is calculated as ![]() $\boldsymbol {w}'(\boldsymbol {y})=\boldsymbol {A}+\boldsymbol {B}\times (\boldsymbol {y}-\tilde {\boldsymbol {x}}^{c}_\alpha )$, where

$\boldsymbol {w}'(\boldsymbol {y})=\boldsymbol {A}+\boldsymbol {B}\times (\boldsymbol {y}-\tilde {\boldsymbol {x}}^{c}_\alpha )$, where ![]() $\boldsymbol {A}$ is the average of

$\boldsymbol {A}$ is the average of ![]() $\boldsymbol {w}$ over the drop surface

$\boldsymbol {w}$ over the drop surface ![]() $\tilde {S}_{\alpha }$,

$\tilde {S}_{\alpha }$, ![]() $\tilde {\boldsymbol {x}}^{c}_{\alpha }$ is the drop surface centroid and the vector

$\tilde {\boldsymbol {x}}^{c}_{\alpha }$ is the drop surface centroid and the vector ![]() $\boldsymbol {B}$ is calculated from the solution of a

$\boldsymbol {B}$ is calculated from the solution of a ![]() $3\times 3$ system with a positive–definite matrix (Zinchenko, Rother & Davis Reference Zinchenko, Rother and Davis1997):

$3\times 3$ system with a positive–definite matrix (Zinchenko, Rother & Davis Reference Zinchenko, Rother and Davis1997):

The single-layer terms containing the Hebeker parameter ![]() $\eta$ serve to complete the range of boundary-integral operators; without these terms, the double-layer boundary-integral contribution could not accommodate non-zero hydrodynamic forces or torques acting on the solid particles. The inhomogeneous term is

$\eta$ serve to complete the range of boundary-integral operators; without these terms, the double-layer boundary-integral contribution could not accommodate non-zero hydrodynamic forces or torques acting on the solid particles. The inhomogeneous term is

\begin{equation} \boldsymbol{F}(\boldsymbol{y}) = \boldsymbol{u}_\infty(\boldsymbol{y}) + \frac{2\sigma}{\mu_e}\sum_{\beta =1}^{\tilde{N}} \int_{\tilde{S}_\beta} k(\boldsymbol{x}) \boldsymbol{n}(\boldsymbol{x}) \boldsymbol{\cdot} \textbf{G}(\boldsymbol{r}) \,\mbox{d} S_x, \end{equation}

\begin{equation} \boldsymbol{F}(\boldsymbol{y}) = \boldsymbol{u}_\infty(\boldsymbol{y}) + \frac{2\sigma}{\mu_e}\sum_{\beta =1}^{\tilde{N}} \int_{\tilde{S}_\beta} k(\boldsymbol{x}) \boldsymbol{n}(\boldsymbol{x}) \boldsymbol{\cdot} \textbf{G}(\boldsymbol{r}) \,\mbox{d} S_x, \end{equation}

where ![]() $k$ is the mean surface curvature

$k$ is the mean surface curvature ![]() $k(\boldsymbol {x})=(k_1+k_2)/2$, with

$k(\boldsymbol {x})=(k_1+k_2)/2$, with ![]() $k_1$,

$k_1$, ![]() $k_2$ being the principal curvatures at

$k_2$ being the principal curvatures at ![]() $\boldsymbol {x}$. Normal vectors and curvatures are calculated using the high-order method introduced in Zinchenko & Davis (Reference Zinchenko and Davis2006), which provides accurate values even for very elongated drops; a validation of this method is provided in appendix C. Finally,

$\boldsymbol {x}$. Normal vectors and curvatures are calculated using the high-order method introduced in Zinchenko & Davis (Reference Zinchenko and Davis2006), which provides accurate values even for very elongated drops; a validation of this method is provided in appendix C. Finally, ![]() $\textbf {G}(\boldsymbol {r})$ and

$\textbf {G}(\boldsymbol {r})$ and ![]() $\boldsymbol {\tau }(\boldsymbol {r})$ are the free-space Green tensor and the corresponding fundamental stresslet, respectively

$\boldsymbol {\tau }(\boldsymbol {r})$ are the free-space Green tensor and the corresponding fundamental stresslet, respectively

Despite the singularities in the kernels (3.5a,b) at ![]() $r\to 0$, all self-integrals (3.1), (3.2) and (3.4) (i.e. when the observation point

$r\to 0$, all self-integrals (3.1), (3.2) and (3.4) (i.e. when the observation point ![]() $\boldsymbol {y}$ lies on an integration surface) are convergent due to

$\boldsymbol {y}$ lies on an integration surface) are convergent due to ![]() $\boldsymbol {\tau } \boldsymbol {\cdot } \boldsymbol {n} =O(1/r)$ (cf.

$\boldsymbol {\tau } \boldsymbol {\cdot } \boldsymbol {n} =O(1/r)$ (cf. ![]() $|\boldsymbol {\tau }|{\sim }1/r^{2}$). However, the singular and near-singular behaviour of the integrands (for droplet–droplet, droplet–particle and particle–particle interactions) must be alleviated, as described in the next section, for a successful numerical solution. After such desingularizations, (3.1) and (3.2) are solved by Generalized Minimal Residual (GMRES) iterations, and the drop node positions are time integrated using a second-order Runge–Kutta scheme. The time step is determined by the empirical formula introduced by Zinchenko & Davis (Reference Zinchenko and Davis2005)

$|\boldsymbol {\tau }|{\sim }1/r^{2}$). However, the singular and near-singular behaviour of the integrands (for droplet–droplet, droplet–particle and particle–particle interactions) must be alleviated, as described in the next section, for a successful numerical solution. After such desingularizations, (3.1) and (3.2) are solved by Generalized Minimal Residual (GMRES) iterations, and the drop node positions are time integrated using a second-order Runge–Kutta scheme. The time step is determined by the empirical formula introduced by Zinchenko & Davis (Reference Zinchenko and Davis2005)

where

is the minimum distance between mesh nodes on the drop and a solid surface, but excluding pairs (![]() $i$,

$i$,![]() $j$) for which

$j$) for which ![]() $\boldsymbol {x}_j$ is the solid-particle node closest to

$\boldsymbol {x}_j$ is the solid-particle node closest to ![]() $\boldsymbol {x}_i$, or

$\boldsymbol {x}_i$, or ![]() $\boldsymbol {x}_i$ is the drop node closest to

$\boldsymbol {x}_i$ is the drop node closest to ![]() $\boldsymbol {x}_j$. This exclusion is possible due to near-singularity subtractions, and the coefficient 0.7 is an empirical correction. A value of

$\boldsymbol {x}_j$. This exclusion is possible due to near-singularity subtractions, and the coefficient 0.7 is an empirical correction. A value of ![]() $K_{{\rm \Delta} t}=8.75$ was found to be economical and stable over a wide range of parameters. Mesh quality (roughly, the absence of nearly degenerate mesh triangles) is maintained using passive mesh stabilization, as in Zinchenko & Davis (Reference Zinchenko and Davis2006), and in some cases the customizable remeshing technique described in § 4.

$K_{{\rm \Delta} t}=8.75$ was found to be economical and stable over a wide range of parameters. Mesh quality (roughly, the absence of nearly degenerate mesh triangles) is maintained using passive mesh stabilization, as in Zinchenko & Davis (Reference Zinchenko and Davis2006), and in some cases the customizable remeshing technique described in § 4.

4. Numerical method

4.1. General desingularization formulae

A repository of desingularization techniques that permit stable hydrodynamic interactions between drops and solid particles is provided by Zinchenko & Davis (Reference Zinchenko and Davis2006), including drop and solid self-interactions, solid–solid interaction, solid–drop and drop–solid contributions. In certain cases (solid self-interaction, solid–solid interaction and solid–drop contributions), additional integrals appear during the subtraction procedure that must be calculated with near-analytical accuracy to facilitate tight-squeezing simulations. The complete desingularization expressions and relevant ‘high-accuracy integrals’ in each case are listed below.

For solid self-interaction (![]() $\boldsymbol {y}\in \hat {S}_\alpha$), singularity subtraction is provided by

$\boldsymbol {y}\in \hat {S}_\alpha$), singularity subtraction is provided by

\begin{align} & \int_{\hat{S}_\alpha} \boldsymbol{q}(\boldsymbol{x})\boldsymbol{\cdot}[2\boldsymbol{\tau} (\boldsymbol{r})\boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x})+ \eta \boldsymbol{G}(\boldsymbol{r})] \,\mbox{d} S_x \nonumber\\ &\quad =\boldsymbol{q}(\boldsymbol{y}) + \int_{\hat{S}_\alpha} [\boldsymbol{q}(\boldsymbol{x})-\boldsymbol{q}(\boldsymbol{y})] \boldsymbol{\cdot}[2\boldsymbol{\tau}(\boldsymbol{r}) \boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x})+\eta \boldsymbol{G}(\boldsymbol{r})] \, \mbox{d} S_x + \eta\boldsymbol{q}(\boldsymbol{y})\int_{\hat{S}_\alpha} \boldsymbol{G}(\boldsymbol{r}) \,\mbox{d} S_x, \end{align}

\begin{align} & \int_{\hat{S}_\alpha} \boldsymbol{q}(\boldsymbol{x})\boldsymbol{\cdot}[2\boldsymbol{\tau} (\boldsymbol{r})\boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x})+ \eta \boldsymbol{G}(\boldsymbol{r})] \,\mbox{d} S_x \nonumber\\ &\quad =\boldsymbol{q}(\boldsymbol{y}) + \int_{\hat{S}_\alpha} [\boldsymbol{q}(\boldsymbol{x})-\boldsymbol{q}(\boldsymbol{y})] \boldsymbol{\cdot}[2\boldsymbol{\tau}(\boldsymbol{r}) \boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x})+\eta \boldsymbol{G}(\boldsymbol{r})] \, \mbox{d} S_x + \eta\boldsymbol{q}(\boldsymbol{y})\int_{\hat{S}_\alpha} \boldsymbol{G}(\boldsymbol{r}) \,\mbox{d} S_x, \end{align}where the final integral on the right-hand side of (4.1) must be computed with high accuracy.

Solid–solid interactions are transformed slightly differently, but contain the same integral requiring near-analytical treatment

\begin{align} & \int_{\hat{S}_\beta} \boldsymbol{q}(\boldsymbol{x})\boldsymbol{\cdot}[2\boldsymbol{\tau} (\boldsymbol{r})\boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x})+ \eta \boldsymbol{G}(\boldsymbol{r})] \,\mbox{d} S_x \nonumber\\ &\quad =\int_{\hat{S}_\beta} [\boldsymbol{q}(\boldsymbol{x})-\boldsymbol{q}(\boldsymbol{x}^{*})] \boldsymbol{\cdot}[2\boldsymbol{\tau}(\boldsymbol{r})\boldsymbol{\cdot}\boldsymbol{n} (\boldsymbol{x})+\eta \boldsymbol{G}(\boldsymbol{r})] \,\mbox{d} S_x + \eta\boldsymbol{q}(\boldsymbol{x}^{*})\int_{\hat{S}_\beta}\boldsymbol{G}(\boldsymbol{r}) \,\mbox{d} S_x, \end{align}

\begin{align} & \int_{\hat{S}_\beta} \boldsymbol{q}(\boldsymbol{x})\boldsymbol{\cdot}[2\boldsymbol{\tau} (\boldsymbol{r})\boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x})+ \eta \boldsymbol{G}(\boldsymbol{r})] \,\mbox{d} S_x \nonumber\\ &\quad =\int_{\hat{S}_\beta} [\boldsymbol{q}(\boldsymbol{x})-\boldsymbol{q}(\boldsymbol{x}^{*})] \boldsymbol{\cdot}[2\boldsymbol{\tau}(\boldsymbol{r})\boldsymbol{\cdot}\boldsymbol{n} (\boldsymbol{x})+\eta \boldsymbol{G}(\boldsymbol{r})] \,\mbox{d} S_x + \eta\boldsymbol{q}(\boldsymbol{x}^{*})\int_{\hat{S}_\beta}\boldsymbol{G}(\boldsymbol{r}) \,\mbox{d} S_x, \end{align}

where ![]() $\boldsymbol {x}^{*} = \boldsymbol {x}^{*}(\boldsymbol {y},\beta )$ is the mesh node on

$\boldsymbol {x}^{*} = \boldsymbol {x}^{*}(\boldsymbol {y},\beta )$ is the mesh node on ![]() $\hat {S}_\beta$ closest to

$\hat {S}_\beta$ closest to ![]() $\boldsymbol {y}\in \hat {S}_\alpha \neq \hat {S}_\beta$.

$\boldsymbol {y}\in \hat {S}_\alpha \neq \hat {S}_\beta$.

Likewise, the single-layer part of the solid–drop contribution utilizes a simple regularization also involving ![]() $\boldsymbol {G}(\boldsymbol {r})$

$\boldsymbol {G}(\boldsymbol {r})$

Finally, the high-order near-singularity subtraction used for the solid–drop double-layer contribution was found to be especially critical for stable tight-squeezing simulations. To this end, for ![]() $\boldsymbol {y}$ on a drop surface

$\boldsymbol {y}$ on a drop surface ![]() $\tilde {S}_{\alpha }$ and its nearest mesh node

$\tilde {S}_{\alpha }$ and its nearest mesh node ![]() $\boldsymbol {x}^{*}$ on a solid surface

$\boldsymbol {x}^{*}$ on a solid surface ![]() $\hat {S}_{\beta }$, the density function

$\hat {S}_{\beta }$, the density function ![]() $\boldsymbol {q}(\boldsymbol {x})$ near

$\boldsymbol {q}(\boldsymbol {x})$ near ![]() $\boldsymbol {x}^{*}$ is approximated by

$\boldsymbol {x}^{*}$ is approximated by ![]() $\boldsymbol {q}(\boldsymbol {x^{*}})$ plus a linear function

$\boldsymbol {q}(\boldsymbol {x^{*}})$ plus a linear function ![]() $\mathscr {L}(\boldsymbol {x}-\boldsymbol {x}^{*})$; the coefficients of the linear form

$\mathscr {L}(\boldsymbol {x}-\boldsymbol {x}^{*})$; the coefficients of the linear form ![]() $\mathscr {L}$ are found by least-squares fitting to the values of

$\mathscr {L}$ are found by least-squares fitting to the values of ![]() ${\rm \Delta} \boldsymbol {q}(\boldsymbol {x}^{j})=\boldsymbol {q}(\boldsymbol {x}^{j})-\boldsymbol {q}(\boldsymbol {x}^{*})$ in the solid mesh nodes

${\rm \Delta} \boldsymbol {q}(\boldsymbol {x}^{j})=\boldsymbol {q}(\boldsymbol {x}^{j})-\boldsymbol {q}(\boldsymbol {x}^{*})$ in the solid mesh nodes ![]() $\boldsymbol {x}^{j}$ directly connected to

$\boldsymbol {x}^{j}$ directly connected to ![]() $\boldsymbol {x}^{*}$. Subtracting

$\boldsymbol {x}^{*}$. Subtracting ![]() $\boldsymbol {q}(\boldsymbol {x}^{*})+\mathscr {L}(\boldsymbol {x}-\boldsymbol {x}^{*})$ from

$\boldsymbol {q}(\boldsymbol {x}^{*})+\mathscr {L}(\boldsymbol {x}-\boldsymbol {x}^{*})$ from ![]() $\boldsymbol {q}(\boldsymbol {x})$ completely desingularizes the double-layer part of the solid–drop contribution in (3.1), but gives rise to added-back integrals, which need to be handled either analytically (possible only for a few shapes), or, in general, numerically with high accuracy. This desingularization can be written as

$\boldsymbol {q}(\boldsymbol {x})$ completely desingularizes the double-layer part of the solid–drop contribution in (3.1), but gives rise to added-back integrals, which need to be handled either analytically (possible only for a few shapes), or, in general, numerically with high accuracy. This desingularization can be written as

\begin{align} & \int_{\hat{S}_\beta} \boldsymbol{q}(\boldsymbol{x})\boldsymbol{\cdot}\boldsymbol{\tau}(\boldsymbol{r}) \boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x}) \,\mbox{d} S_x \nonumber\\ &\quad =\int_{\hat{S}_\beta}\left[ \boldsymbol{q}(\boldsymbol{x})-\boldsymbol{q}(\boldsymbol{x}^{*})- \sum_{j\in\mathcal{A}(\boldsymbol{x}^{*})} (\boldsymbol{c}_j \boldsymbol{\cdot}(\boldsymbol{x}-\boldsymbol{x}^{*})){\rm \Delta}\boldsymbol{q}(\boldsymbol{x}^{j})\right] \boldsymbol{\cdot} \boldsymbol{\tau}(\boldsymbol{r}) \boldsymbol{\cdot} \boldsymbol{n}(\boldsymbol{x}) \,\mbox{d} S_x \nonumber\\ &\qquad +\sum_{j\in\mathcal{A}(\boldsymbol{x}^{*})} [\boldsymbol{c}_j{\rm \Delta}\boldsymbol{q}(\boldsymbol{x}^{j})]\boldsymbol{\cdot}\frac{3}{4{\rm \pi}} \int_{\hat{S}_\beta} \frac{[\boldsymbol{r}\boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x})] \boldsymbol{r}\boldsymbol{r}\boldsymbol{r}}{r^{5}}\,\mbox{d} S_x, \end{align}

\begin{align} & \int_{\hat{S}_\beta} \boldsymbol{q}(\boldsymbol{x})\boldsymbol{\cdot}\boldsymbol{\tau}(\boldsymbol{r}) \boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x}) \,\mbox{d} S_x \nonumber\\ &\quad =\int_{\hat{S}_\beta}\left[ \boldsymbol{q}(\boldsymbol{x})-\boldsymbol{q}(\boldsymbol{x}^{*})- \sum_{j\in\mathcal{A}(\boldsymbol{x}^{*})} (\boldsymbol{c}_j \boldsymbol{\cdot}(\boldsymbol{x}-\boldsymbol{x}^{*})){\rm \Delta}\boldsymbol{q}(\boldsymbol{x}^{j})\right] \boldsymbol{\cdot} \boldsymbol{\tau}(\boldsymbol{r}) \boldsymbol{\cdot} \boldsymbol{n}(\boldsymbol{x}) \,\mbox{d} S_x \nonumber\\ &\qquad +\sum_{j\in\mathcal{A}(\boldsymbol{x}^{*})} [\boldsymbol{c}_j{\rm \Delta}\boldsymbol{q}(\boldsymbol{x}^{j})]\boldsymbol{\cdot}\frac{3}{4{\rm \pi}} \int_{\hat{S}_\beta} \frac{[\boldsymbol{r}\boldsymbol{\cdot}\boldsymbol{n}(\boldsymbol{x})] \boldsymbol{r}\boldsymbol{r}\boldsymbol{r}}{r^{5}}\,\mbox{d} S_x, \end{align}

where ![]() $\mathcal {A}(\boldsymbol {x}^{*})$ is the set of nodes directly connected to

$\mathcal {A}(\boldsymbol {x}^{*})$ is the set of nodes directly connected to ![]() $\boldsymbol {x}^{*}$; the vector coefficients

$\boldsymbol {x}^{*}$; the vector coefficients ![]() $\boldsymbol {c}_j$ depend only on the local mesh geometry near

$\boldsymbol {c}_j$ depend only on the local mesh geometry near ![]() $\boldsymbol {x}^{*}$ and are pre-calculated as detailed in § 3 of Zinchenko & Davis (Reference Zinchenko and Davis2006).

$\boldsymbol {x}^{*}$ and are pre-calculated as detailed in § 3 of Zinchenko & Davis (Reference Zinchenko and Davis2006).

So, high-accuracy computation of three integral terms is required. Up to a factor, we denote these terms as

It is advantageous that the second-rank tensor ![]() $\boldsymbol {G}_2$ and the third-rank tensor

$\boldsymbol {G}_2$ and the third-rank tensor ![]() $\boldsymbol {\varPsi }$ are fully permutable in their indices, thus reducing the amount of work to calculate these tensors.

$\boldsymbol {\varPsi }$ are fully permutable in their indices, thus reducing the amount of work to calculate these tensors.

4.2. Semi-analytical desingularization for axisymmetric particles

Axisymmetric particles permit semi-analytical calculation of the integrals (4.5a,b) and (4.6), by closed-form azimuthal integration around the particle axis of rotation, with external numerical integration along the particle half-contour. This kind of approach has been widely used in axisymmetric boundary-integral solutions (e.g. Rallison & Acrivos Reference Rallison and Acrivos1978; Lee & Leal Reference Lee and Leal1982; Davis Reference Davis1999; Ratcliffe et al. Reference Ratcliffe, Zinchenko and Davis2010) by reducing the azimuthal integration to elliptic integrals (as discussed in detail by Pozrikidis Reference Pozrikidis1992). In the present 3-D work, analytical azimuthal integration for the high-order subtraction tensor (4.6) is a more cumbersome, but still very efficient approach. As shown in figure 2, a representative integration circumference ![]() $C$ is the perimeter of a representative disk of radius

$C$ is the perimeter of a representative disk of radius ![]() $\rho$, a sufficient number

$\rho$, a sufficient number ![]() of which form an approximation to the axisymmetric volume. The surface integral of a function

of which form an approximation to the axisymmetric volume. The surface integral of a function ![]() $f(\boldsymbol {x})$ is simply

$f(\boldsymbol {x})$ is simply

where ![]() $\varPsi \in [-{\rm \pi} ,{\rm \pi} ]$ is the azimuthal angle of rotation around the particle axis, and

$\varPsi \in [-{\rm \pi} ,{\rm \pi} ]$ is the azimuthal angle of rotation around the particle axis, and ![]() $\mbox {d}s$ is the contour length element along the particle's half-contour.

$\mbox {d}s$ is the contour length element along the particle's half-contour.

Figure 2. An axisymmetric particle oriented as a surface of revolution ![]() $\hat {S}_\beta$ around the

$\hat {S}_\beta$ around the ![]() $z$-axis. The single- and double-layer contributions of circular segments can be calculated analytically using elliptic integrals. For a given representative circle

$z$-axis. The single- and double-layer contributions of circular segments can be calculated analytically using elliptic integrals. For a given representative circle ![]() $C$, the origin

$C$, the origin ![]() $\boldsymbol {O}$ may be placed at its centre, with the

$\boldsymbol {O}$ may be placed at its centre, with the ![]() $x$-axis in plane but oriented away from the observation point

$x$-axis in plane but oriented away from the observation point ![]() $\boldsymbol {x}_0$. Cylindrical coordinates (

$\boldsymbol {x}_0$. Cylindrical coordinates (![]() $\rho ,\psi ,z$) are used for deriving elliptic integral calculations.

$\rho ,\psi ,z$) are used for deriving elliptic integral calculations.

Now, we outline derivations for closed-form expressions for the integrals (4.5a,b) and (4.6) over a representative circumference ![]() $C$, in terms of complete elliptic integrals of the first and second kind. Let the origin

$C$, in terms of complete elliptic integrals of the first and second kind. Let the origin ![]() $\boldsymbol {O}$ of the temporary coordinate system

$\boldsymbol {O}$ of the temporary coordinate system ![]() $(\rho \cos {\psi },\rho \sin {\psi },z)$ be at the centre of

$(\rho \cos {\psi },\rho \sin {\psi },z)$ be at the centre of ![]() $C$, with its axis of revolution along the

$C$, with its axis of revolution along the ![]() $z$-axis (figure 2). Without loss of generality, the

$z$-axis (figure 2). Without loss of generality, the ![]() $x$-axis can be defined as antiparallel to the shortest vector from the

$x$-axis can be defined as antiparallel to the shortest vector from the ![]() $z$-axis to the observation point

$z$-axis to the observation point ![]() $\boldsymbol {x}_0$. The observation point is then

$\boldsymbol {x}_0$. The observation point is then ![]() $\boldsymbol {x}_0 = (-\rho _0,0,z_0)$ and the vector

$\boldsymbol {x}_0 = (-\rho _0,0,z_0)$ and the vector ![]() $\boldsymbol {r}=\boldsymbol {x}-\boldsymbol {x}_0$ between

$\boldsymbol {r}=\boldsymbol {x}-\boldsymbol {x}_0$ between ![]() $\boldsymbol {x}_0$ and a integration point

$\boldsymbol {x}_0$ and a integration point ![]() $\boldsymbol {x}$ on

$\boldsymbol {x}$ on ![]() $C$ is given by

$C$ is given by

and

The simplest contour integral over ![]() $C$ relevant to computing

$C$ relevant to computing ![]() $G_1$ may be expressed as

$G_1$ may be expressed as

\begin{equation} \int_{-{\rm \pi}}^{\rm \pi} \frac{1}{r} \mbox{d} \psi = c_0\int_{-{\rm \pi}}^{\rm \pi} \left[1-k^{2}\sin^{2}{\frac{\psi}{2}}\right]^{{-}1/2}\mbox{d} \psi = 4c_0F, \end{equation}

\begin{equation} \int_{-{\rm \pi}}^{\rm \pi} \frac{1}{r} \mbox{d} \psi = c_0\int_{-{\rm \pi}}^{\rm \pi} \left[1-k^{2}\sin^{2}{\frac{\psi}{2}}\right]^{{-}1/2}\mbox{d} \psi = 4c_0F, \end{equation}

where ![]() $c_0 = ((\rho +\rho _0)^{2}+(z-z_0)^{2})^{-1/2}$ and

$c_0 = ((\rho +\rho _0)^{2}+(z-z_0)^{2})^{-1/2}$ and ![]() $F$ is the complete elliptic integral of the first kind with modulus

$F$ is the complete elliptic integral of the first kind with modulus ![]() $k$. The relevant integrals over

$k$. The relevant integrals over ![]() $C$ for

$C$ for ![]() $\boldsymbol {G}_2$ and

$\boldsymbol {G}_2$ and ![]() $\boldsymbol {\varPsi }$ can be derived in a similar manner and final expressions are provided in appendix A. Once

$\boldsymbol {\varPsi }$ can be derived in a similar manner and final expressions are provided in appendix A. Once ![]() $\boldsymbol {G}_2$ and

$\boldsymbol {G}_2$ and ![]() $\boldsymbol {\varPsi }$ are computed in the special coordinate basis defined above, they are then transformed by usual tensor transformation rules to the global basis used in the squeezing simulation.

$\boldsymbol {\varPsi }$ are computed in the special coordinate basis defined above, they are then transformed by usual tensor transformation rules to the global basis used in the squeezing simulation.

The present semi-analytical approach results in very fast and accurate calculation of single- and double-layer desingularization integrals (4.5a,b) and (4.6) for axisymmetric particles. Surface integrals calculated by (4.7) converge quickly with respect to ![]() (with second-order Euler external integration). For example, using a capsule (

(with second-order Euler external integration). For example, using a capsule (![]() $\mathcal {L}=6$) as a test particle and an observation point

$\mathcal {L}=6$) as a test particle and an observation point ![]() $0.01L$ away from the cylindrical section of particle surface, all

$0.01L$ away from the cylindrical section of particle surface, all ![]() $\boldsymbol {\varPsi }$ terms agree to within at least the fifth decimal point for

$\boldsymbol {\varPsi }$ terms agree to within at least the fifth decimal point for ![]() values of 1000 and 10 000. The former corresponds to a representative disk width of 0.006. Further convergence tests and comparisons with the multimesh method are provided in § 5.1.

values of 1000 and 10 000. The former corresponds to a representative disk width of 0.006. Further convergence tests and comparisons with the multimesh method are provided in § 5.1.

4.3. Multimesh desingularization

Desingularization for arbitrarily shaped particles can be achieved with direct numerical calculation of ![]() $G_1$,

$G_1$, ![]() $\boldsymbol {G}_2$ and

$\boldsymbol {G}_2$ and ![]() $\boldsymbol {\varPsi }$ (4.5a,b) and (4.6), if sufficiently high resolution meshes are used to discretize these surface integrals. Note that this ‘multimesh desingularization method’ still requires particles to have smoothly varying normals (i.e. to be Lyapunov surfaces). Extremely high resolutions are required for single- and double-layer contributions to approach exact values, in order to accurately and stably reproduce analytical or semi-analytical tight-squeezing results. Due to the singular nature of the integrals, accuracy is more sensitive to mesh resolution as the observation point approaches the particle surface; therefore, a hierarchy of embedded meshes is used for multimesh desingularization.

$\boldsymbol {\varPsi }$ (4.5a,b) and (4.6), if sufficiently high resolution meshes are used to discretize these surface integrals. Note that this ‘multimesh desingularization method’ still requires particles to have smoothly varying normals (i.e. to be Lyapunov surfaces). Extremely high resolutions are required for single- and double-layer contributions to approach exact values, in order to accurately and stably reproduce analytical or semi-analytical tight-squeezing results. Due to the singular nature of the integrals, accuracy is more sensitive to mesh resolution as the observation point approaches the particle surface; therefore, a hierarchy of embedded meshes is used for multimesh desingularization.

Two high-resolution auxiliary meshes are used to compute the desingularization integrals. The first high-resolution mesh typically has four times more triangles than the basic mesh used for BIM calculations. The second is an ultra-high-resolution mesh, typically 64 times denser than the basic mesh, as shown in figure 3(a,b). For particles with higher surface area, the ultra-high-resolution mesh may have in excess of 2.5 million triangles. Therefore, the two meshes are chained to each other: the indices of the 16 ultra-high-resolution triangles within each high-resolution triangle are pre-calculated and stored. In contrast to boundary-integral calculations for desingularized terms on the basic mesh, with mesh triangle contribution reassigned to vertices (a procedure due to Rallison (Reference Rallison1981) used in many prior simulations), such reassignment is disadvantageous for multimesh calculations of the desingularization tensors. A primitive form is used instead:

where the summation is over all triangles for a given triangulation of the surface ![]() $\hat {S}_\beta$,

$\hat {S}_\beta$, ![]() $\boldsymbol {x}_i$ is the triangle centroid and

$\boldsymbol {x}_i$ is the triangle centroid and ![]() ${\rm \Delta} S_i$ is the flat triangle area. This form makes it straightforward to use one mesh within a given cutoff distance

${\rm \Delta} S_i$ is the flat triangle area. This form makes it straightforward to use one mesh within a given cutoff distance ![]() $r_c$ from the observation point, and another one beyond that radius, as illustrated in figure 3(c). Specifically, the distance between a given observation point

$r_c$ from the observation point, and another one beyond that radius, as illustrated in figure 3(c). Specifically, the distance between a given observation point ![]() $\boldsymbol {x}_0$ and high-resolution triangle is determined using the triangle centroid. If this distance is greater than the prescribed distance cutoff

$\boldsymbol {x}_0$ and high-resolution triangle is determined using the triangle centroid. If this distance is greater than the prescribed distance cutoff ![]() $r_c$, then this triangle is used as an area element

$r_c$, then this triangle is used as an area element ![]() ${\rm \Delta} S_i$ of the surface integral in (4.11). Otherwise, the 16 corresponding ultra-high-resolution triangles are substituted to represent this triangle contribution to (4.11). The desingularization integrals for solid self-interaction and solid–solid interactions are calculated only once at the start of each simulation, so a high distance cutoff (

${\rm \Delta} S_i$ of the surface integral in (4.11). Otherwise, the 16 corresponding ultra-high-resolution triangles are substituted to represent this triangle contribution to (4.11). The desingularization integrals for solid self-interaction and solid–solid interactions are calculated only once at the start of each simulation, so a high distance cutoff (![]() $r_c=1.0L$) was used with a negligible penalty on total CPU time. The solid–drop contribution to the desingularization integrals is computed outside of GMRES iterations, but still represents the slowest operation of the multimesh method. A distance cutoff of

$r_c=1.0L$) was used with a negligible penalty on total CPU time. The solid–drop contribution to the desingularization integrals is computed outside of GMRES iterations, but still represents the slowest operation of the multimesh method. A distance cutoff of ![]() $r_c=0.4L$ for the solid–drop contribution was found sufficient to stably model tight-squeezing or trapped drops with an accuracy approaching that of analytical methods, as discussed in § 5.1.

$r_c=0.4L$ for the solid–drop contribution was found sufficient to stably model tight-squeezing or trapped drops with an accuracy approaching that of analytical methods, as discussed in § 5.1.

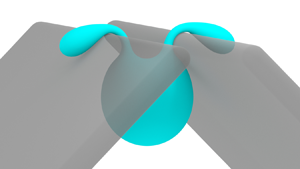

Figure 3. Solid-particle meshes used for the ![]() $\mathcal {L}=4$ capsule by the multimesh desingularization method. (a) The high-resolution (

$\mathcal {L}=4$ capsule by the multimesh desingularization method. (a) The high-resolution (![]() $\hat {N}_{\triangle }=52\ \text {K}$) and ultra-high-resolution (

$\hat {N}_{\triangle }=52\ \text {K}$) and ultra-high-resolution (![]() $\hat {N}_{\triangle }=840\ \text {K}$) meshes used for numerical desingularization. The additional edges of the ultra-high-resolution mesh are coloured cyan. (b) The basic mesh (

$\hat {N}_{\triangle }=840\ \text {K}$) meshes used for numerical desingularization. The additional edges of the ultra-high-resolution mesh are coloured cyan. (b) The basic mesh (![]() $\hat {N}_{\triangle }=13\ \text {K}$) used by the BIM simulation for desingularized terms. (c) A given observation point

$\hat {N}_{\triangle }=13\ \text {K}$) used by the BIM simulation for desingularized terms. (c) A given observation point ![]() $\boldsymbol {x}_0$ calculates per-triangle values from the ultra-high-resolution mesh within a cutoff

$\boldsymbol {x}_0$ calculates per-triangle values from the ultra-high-resolution mesh within a cutoff ![]() $r_c$.

$r_c$.

Several technical issues arise due to the requirements of (i) quality meshing of arbitrary shapes, (ii) obtaining machine precision for node positions, (iii) memory requirements of ultra-high-resolution meshes and (iv) mesh chaining. An approximate mesh for each particle resolution was created using the powerful open-source software Blender, which has no limitation on mesh size and can easily handle meshes with ![]() $N_{\triangle }>2.5\ \mbox {M}$, but uses single-precision floating-point format for coordinates (which may create unwanted numerical errors in tight-squeezing simulations). After node positions and connectivity are exported from Blender, coordinates are read into the BIM program and adjusted to double precision according to piecewise analytical functions that define a given particle shape. Similarly, the surface normals at each node are calculated using analytical formulae for a particular surface. A more general approach would be to use just node positions on the solid surfaces and calculate the normals by the same tools as we employ for the triangulated drop surface (appendix C), but such generality was not pursued in the present calculations. Due to memory considerations, only one instance of each desingularization mesh is saved in memory, and is translated and/or mirrored (see § 4.4) during calculations over a given particle. Finally, an efficient algorithm was written to chain two meshes to each other, i.e. to determine which ultra-high-resolution triangles lie within each high-resolution triangle. The algorithm requires knowledge only of the node positions and connectivity of the two meshes, assuming every high-resolution node coincides with an ultra-high-resolution node. Briefly, coinciding nodes between the meshes are determined by position, and a nearby ultra-high-resolution triangle is associated with a given high-resolution triangle if its centroid (projected along the surface normal) lies within the perimeter of the high-resolution triangle.

$N_{\triangle }>2.5\ \mbox {M}$, but uses single-precision floating-point format for coordinates (which may create unwanted numerical errors in tight-squeezing simulations). After node positions and connectivity are exported from Blender, coordinates are read into the BIM program and adjusted to double precision according to piecewise analytical functions that define a given particle shape. Similarly, the surface normals at each node are calculated using analytical formulae for a particular surface. A more general approach would be to use just node positions on the solid surfaces and calculate the normals by the same tools as we employ for the triangulated drop surface (appendix C), but such generality was not pursued in the present calculations. Due to memory considerations, only one instance of each desingularization mesh is saved in memory, and is translated and/or mirrored (see § 4.4) during calculations over a given particle. Finally, an efficient algorithm was written to chain two meshes to each other, i.e. to determine which ultra-high-resolution triangles lie within each high-resolution triangle. The algorithm requires knowledge only of the node positions and connectivity of the two meshes, assuming every high-resolution node coincides with an ultra-high-resolution node. Briefly, coinciding nodes between the meshes are determined by position, and a nearby ultra-high-resolution triangle is associated with a given high-resolution triangle if its centroid (projected along the surface normal) lies within the perimeter of the high-resolution triangle.

4.4. Additional numerical considerations

Two configurations, drop flow around a single capsule and between two flat plates, presented particular challenges regarding numerical stability and drop mesh quality. A useful extension of the commonly used triangle subdivision scheme introduced by Cristini, Bławzdziewicz & Loewenberg (Reference Cristini, Bławzdziewicz and Loewenberg2001) was developed, which is particularly effective when remeshing contiguous regions on a drop. The simple idea is, given a list of all triangles to be subdivided within a given region, a uniform mesh four times denser than the original can immediately result, by adding nodes at all edge midpoints and appropriately connecting them (see appendix B). Connectivity around the perimeter of this region can also be determined simply, e.g. in the manner of Cristini et al. (Reference Cristini, Bławzdziewicz and Loewenberg2001) (§ A.1.2. therein). Occasional node addition on regions of contiguous triangles had two benefits. First, a much cleaner mesh immediately resulted, such that further relaxation tangential to the drop surface was unneeded. Second, updating the mesh topology was required much less often, resulting in a more efficient algorithm. For example, in the case of a single drop approaching a single fibre, passive mesh stabilization alone (in the form of Zinchenko & Davis Reference Zinchenko and Davis2006) was found to be inadequate due to the large drop deformation. This simulation was greatly extended by defining an upper limit on triangle area, and whenever this limit was reached, executing node addition on all triangles within a cutoff distance of the triangle with maximal area. In this case, similar simulation times were reached by actively redistributing nodes using an advanced potential energy function (Zinchenko & Davis Reference Zinchenko and Davis2013). A fourth-order variation of the best-paraboloid method (Zinchenko & Davis Reference Zinchenko and Davis2006) was used to used to choose coordinates for the inserted nodes. Including the second- and third-level neighbours in the fit improved the local curvatures at inserted nodes, in areas of both low and high curvature, and allowed the simulation to continue stably without the intermediate step of relaxing inserted nodes. Note that a four-times-denser triangle mesh corresponds to mesh edges one half their original length; the tighter Courant stability limitation on the time step was not prohibitive for any systems presented herein. To maintain mesh quality on the whole drop, passive mesh stabilization (Zinchenko & Davis Reference Zinchenko and Davis2006) is also enforced for all nodes at every time step.

The above ‘coordinated adaptive remeshing’ scheme was extended to allow added nodes to be subsequently removed. In the case of a drop squeezing between thin plates, especially at low capillary numbers, it was necessary to include a spatially dependent remeshing scheme for the drop surface, with criteria defined to increase mesh resolution within near-contact regions of the drop (figure 4a,b). In this case, the drop does not experience particularly high deformation or curvatures, yet mesh stability greatly benefits from increased resolution in specific regions. This criteria-based local remeshing is achieved by remembering the original mesh connectivity, restoring it and re-evaluating the given criteria for refinement (every so many time steps). Therefore, the region of higher mesh resolution shown in figure 4 remains constant as the drop moves through the constriction. This technique was also necessary for certain half-capsule configurations at low capillary number.

Figure 4. Adaptive mesh schemes for droplet squeezing between plates. (a) Coordinated adaptive meshing of drop surface based on spatial criteria. By storing the original mesh connectivity and re-evaluating the criteria before every remeshing, the region of denser triangulation remains constant as the drop moves through the constriction. (b) Orthogonal view of the same drop, with solid particles hidden.

To prevent symmetry breaking during drop flow, it was necessary that individual solid-particle meshes were made symmetric with respect to all three orthogonal planes that pass through the constriction centre. Also, for the flat-plate system, a fixed adaptive mesh was used for solid particles to increase node density in near-contact regions. Mesh density within two unit lengths of the constriction centre was increased between four and sixteen times, depending on proximity to the constriction centre. This base mesh was refined to create the higher-resolution desingularization meshes. In order to maintain the aforementioned symmetry, while also storing only one copy of the higher-resolution meshes in memory, a value is associated with each particle to indicate whether or not to use the mirror image of a given mesh. Inverting a coordinate is not computationally intensive, allowing for symmetric systems with non-uniform meshes to be efficiently treated within the framework of the multimesh desingularization method.

5. Numerical results

All values from the numerical simulations of drop tight squeezing are reported in non-dimensional form. The characteristic length scale ![]() $L$ is taken as the solid-particle radius

$L$ is taken as the solid-particle radius ![]() $\hat {a}$ for capsules and derivative particles; for plates,

$\hat {a}$ for capsules and derivative particles; for plates, ![]() $L$ is the gap between two particles. The velocity and times scales are

$L$ is the gap between two particles. The velocity and times scales are ![]() $|\boldsymbol {u}_{\infty }|$ and

$|\boldsymbol {u}_{\infty }|$ and ![]() $L/|\boldsymbol {u}_{\infty }|$, respectively. The Hebeker parameter

$L/|\boldsymbol {u}_{\infty }|$, respectively. The Hebeker parameter ![]() $\eta$ in the boundary-integral formulation (3.2) and (3.1) is set to unity. The initial drop shape is spherical and far upstream from the constriction. The definitions of

$\eta$ in the boundary-integral formulation (3.2) and (3.1) is set to unity. The initial drop shape is spherical and far upstream from the constriction. The definitions of ![]() $Ca$ and

$Ca$ and ![]() $\lambda$ are provided in § 2. Hereafter,

$\lambda$ are provided in § 2. Hereafter, ![]() $\hat {N}_{\triangle }$ and

$\hat {N}_{\triangle }$ and ![]() $\tilde {N}_{\triangle }$ will refer to the number of triangles in each solid-particle and drop mesh, respectively. For brevity, the abbreviations 5, 8.6 and 11.5 K will be used for

$\tilde {N}_{\triangle }$ will refer to the number of triangles in each solid-particle and drop mesh, respectively. For brevity, the abbreviations 5, 8.6 and 11.5 K will be used for ![]() $\hat {N}_{\triangle } = 5120, 8640, 11\,520$. Higher solid-particle resolutions, whose nodes are typically not uniformly distributed, with be similarly rounded. Unless noted otherwise, the droplet resolution is 11 520 (

$\hat {N}_{\triangle } = 5120, 8640, 11\,520$. Higher solid-particle resolutions, whose nodes are typically not uniformly distributed, with be similarly rounded. Unless noted otherwise, the droplet resolution is 11 520 (![]() $\tilde {N}_{\triangle }=11.5\ \text {K}$).Three meshes are used for each solid particle in the multimesh desingularization method. Their triangle counts are reported as a multiple of the basic mesh resolution. For example, if the high-resolution mesh is four times denser than the basic mesh, and the ultra-high-resolution is 16 times denser than the high-resolution mesh, all three triangles counts are reported as

$\tilde {N}_{\triangle }=11.5\ \text {K}$).Three meshes are used for each solid particle in the multimesh desingularization method. Their triangle counts are reported as a multiple of the basic mesh resolution. For example, if the high-resolution mesh is four times denser than the basic mesh, and the ultra-high-resolution is 16 times denser than the high-resolution mesh, all three triangles counts are reported as ![]() $\hat {N}_{\triangle }=8.6\ \text {K}\times 4\times 16$. Note that, due to the quasi-steady character of the Stokes equations, a drop initially placed at a large, but finite distance upstream, immediately feels the constriction presence, resulting in some deviation of the initial drop velocity from the far-field velocity. It is also worth noting that the disturbance of the far-field velocity field due to the constriction decays slowly, like the inverse distance from the constriction. Still, our initial vertical drop separation from the constriction was large enough, so that increasing the initial vertical drop offset, even twofold from

$\hat {N}_{\triangle }=8.6\ \text {K}\times 4\times 16$. Note that, due to the quasi-steady character of the Stokes equations, a drop initially placed at a large, but finite distance upstream, immediately feels the constriction presence, resulting in some deviation of the initial drop velocity from the far-field velocity. It is also worth noting that the disturbance of the far-field velocity field due to the constriction decays slowly, like the inverse distance from the constriction. Still, our initial vertical drop separation from the constriction was large enough, so that increasing the initial vertical drop offset, even twofold from ![]() $10L$ to

$10L$ to ![]() $20L$ for figure 5(b) below, had no perceptible effect on the whole drop trajectory

$20L$ for figure 5(b) below, had no perceptible effect on the whole drop trajectory ![]() $U(t)$. Of course, such a comparison necessarily required a time shift to match the drop position at the

$U(t)$. Of course, such a comparison necessarily required a time shift to match the drop position at the ![]() $10L$ initial offset between the two simulations.

$10L$ initial offset between the two simulations.

Figure 5. Convergence testing for the two-capsule constriction (![]() $\tilde {a}=0.5$,

$\tilde {a}=0.5$, ![]() $\epsilon =0.5$,

$\epsilon =0.5$, ![]() $\mathcal {L}=6$). (a) Drop velocity when squeezing between two capsules, with respect to solid-particle mesh resolution

$\mathcal {L}=6$). (a) Drop velocity when squeezing between two capsules, with respect to solid-particle mesh resolution ![]() $\hat {N}_{\triangle }$ and number of characteristic disks

$\hat {N}_{\triangle }$ and number of characteristic disks ![]() used for semi-analytical desingularization (

used for semi-analytical desingularization (![]() $Ca=0.9$,

$Ca=0.9$, ![]() $\lambda =4$). (b) Convergence testing at lower viscosity ratio (

$\lambda =4$). (b) Convergence testing at lower viscosity ratio (![]() $Ca=1.5$,

$Ca=1.5$, ![]() $\lambda =0.25$). At

$\lambda =0.25$). At ![]() $\hat {N}_{\triangle }=20.2K$ the curve for

$\hat {N}_{\triangle }=20.2K$ the curve for ![]() (not shown) is indistinguishable from that for

(not shown) is indistinguishable from that for ![]() .

.

5.1. Convergence with mesh resolution and desingularization methods

Convergence of results for the default capsule length (![]() $\mathcal {L} = 6$) with respect to solid-particle mesh resolution is shown in figure 5. The

$\mathcal {L} = 6$) with respect to solid-particle mesh resolution is shown in figure 5. The ![]() $\hat {N}_{\triangle } = 35.6\ \text {K}$ mesh utilized adaptive resolution such that the mesh was four times denser within a distance of

$\hat {N}_{\triangle } = 35.6\ \text {K}$ mesh utilized adaptive resolution such that the mesh was four times denser within a distance of ![]() ${\approx }1.4$ from the constriction centre, compared to the

${\approx }1.4$ from the constriction centre, compared to the ![]() $\hat {N}_{\triangle } = 20.2\ \text {K}$ mesh. Although

$\hat {N}_{\triangle } = 20.2\ \text {K}$ mesh. Although ![]() was set throughout this work for the number of characteristic disks used in the semi-analytical method (increased for longer capsules to provide an equivalent linear density), figure 5 also shows that half that number produces reasonable results (resulting in an eight-times speedup for desingularization as compared to the multimesh method). Indeed, halving the number of characteristic disks (

was set throughout this work for the number of characteristic disks used in the semi-analytical method (increased for longer capsules to provide an equivalent linear density), figure 5 also shows that half that number produces reasonable results (resulting in an eight-times speedup for desingularization as compared to the multimesh method). Indeed, halving the number of characteristic disks (![]() ) results in agreement near the solution tolerance (

) results in agreement near the solution tolerance (![]() $1\times 10^{-5}$) for the majority of the squeezing process.

$1\times 10^{-5}$) for the majority of the squeezing process.

The multimesh implementation was validated against previous results that used analytical desingularization (Zinchenko & Davis Reference Zinchenko and Davis2006), and the multimesh and semi-analytical methods were compared against each other. As shown in figure 6, good agreement is seen for drops squeezing between spheres and spheroidal particles. These two-particle constrictions are prone to symmetry breaking and sensitive to mesh resolutions, so reproducing these tight-squeezing results efficiently and without analytical expressions was unexpected. In particular, the spheroidal system in figure 6(b) is metastable and undergoes symmetry breaking shortly after the minimum drop velocity, with one side of the drop advancing slightly farther downstream than the other, even for the analytical system. For these tests, each higher-resolution mesh was 16 times denser than the previous mesh in the hierarchy. Further increasing these desingularization-mesh densities negatively impacted performance while negligibly affecting droplet dynamics. As shown in figure 9, close agreement was also observed between the multimesh and semi-analytical desingularization techniques for drop squeezing between axisymmetric particles, even for tight squeezing.

Figure 6. Comparison between two types of desingularization methods (![]() $\tilde {N}_{\triangle }=8.6\ \text {K}$,

$\tilde {N}_{\triangle }=8.6\ \text {K}$, ![]() $\hat {N}_{\triangle }=5\ \text {K}\times 16\times 16$). Insets shows snapshot of simulation at

$\hat {N}_{\triangle }=5\ \text {K}\times 16\times 16$). Insets shows snapshot of simulation at ![]() $U_{min}$. (a) Multimesh and analytical desingularization methods agree well for drop squeezing between two spheres (

$U_{min}$. (a) Multimesh and analytical desingularization methods agree well for drop squeezing between two spheres (![]() $\epsilon =0.5,\tilde {a}=0.9,Ca=0.63,\lambda =4.0$). (b) Drop squeezing between two parallel oblate spheroids with major and minor axes of 1 and 0.4, respectively (

$\epsilon =0.5,\tilde {a}=0.9,Ca=0.63,\lambda =4.0$). (b) Drop squeezing between two parallel oblate spheroids with major and minor axes of 1 and 0.4, respectively (![]() $\epsilon =0.5,\tilde {a}=0.75,Ca=0.4,\lambda =1.0$). (c) Absolute error for various methods of calculating the desingularization tensor

$\epsilon =0.5,\tilde {a}=0.75,Ca=0.4,\lambda =1.0$). (c) Absolute error for various methods of calculating the desingularization tensor ![]() $\boldsymbol {\varPsi }$, as compared to the analytical values for the oblate spheroid shown in (b). The semi-analytical method uses 3000 characteristic disks with adaptive resolution for the disk spacing.

$\boldsymbol {\varPsi }$, as compared to the analytical values for the oblate spheroid shown in (b). The semi-analytical method uses 3000 characteristic disks with adaptive resolution for the disk spacing.

The absolute error of the semi-analytical and multimesh methods for ![]() $\boldsymbol {\varPsi }(\boldsymbol {y})$-calculation is shown in figure 6(c) for an oblate spheroid (one of those in the insert of figure 6b), with the error of the basic mesh (without desingularization) shown for comparison. This error is quantified through root-mean-square deviation of the components

$\boldsymbol {\varPsi }(\boldsymbol {y})$-calculation is shown in figure 6(c) for an oblate spheroid (one of those in the insert of figure 6b), with the error of the basic mesh (without desingularization) shown for comparison. This error is quantified through root-mean-square deviation of the components ![]() $\varPsi _{ijk}$ from the analytical values available for this shape (Zinchenko & Davis Reference Zinchenko and Davis2006). Unlike with the cylindrical particles discussed below,

$\varPsi _{ijk}$ from the analytical values available for this shape (Zinchenko & Davis Reference Zinchenko and Davis2006). Unlike with the cylindrical particles discussed below, ![]() $\boldsymbol {\varPsi }$ is calculated for observation points

$\boldsymbol {\varPsi }$ is calculated for observation points ![]() $\boldsymbol {y}$ near characteristic disks with radii approaching zero, where the characteristic disk radius is indicated by the vertical height of the spheroid in figure 6(c). It was found that a higher density of characteristic disks is required when the radius is near zero. For example, when using 10 000 equally spaced disks for the oblate spheroid (disk width of

$\boldsymbol {y}$ near characteristic disks with radii approaching zero, where the characteristic disk radius is indicated by the vertical height of the spheroid in figure 6(c). It was found that a higher density of characteristic disks is required when the radius is near zero. For example, when using 10 000 equally spaced disks for the oblate spheroid (disk width of ![]() $8\times 10^{-5}$), the semi-analytical method was conspicuously less accurate than the multimesh method, especially near the horizontal axis of figure 6(c). It was necessary to use an adaptive density of disks in this case, whose positions were defined by starting with 1500 points equally spaced on the vertical axis, and determining their (horizontal) location on the spheroid surface using the equation for the spheroid itself. This discretization resulted in 3000 total disks with a minimum width of

$8\times 10^{-5}$), the semi-analytical method was conspicuously less accurate than the multimesh method, especially near the horizontal axis of figure 6(c). It was necessary to use an adaptive density of disks in this case, whose positions were defined by starting with 1500 points equally spaced on the vertical axis, and determining their (horizontal) location on the spheroid surface using the equation for the spheroid itself. This discretization resulted in 3000 total disks with a minimum width of ![]() $1.8\times 10^{-7}$ and a maximum width of

$1.8\times 10^{-7}$ and a maximum width of ![]() $7.3\times 10^{-3}$ (near the top of the spheroid). The values for the arc lengths

$7.3\times 10^{-3}$ (near the top of the spheroid). The values for the arc lengths ![]() $\mbox {d}s$ in (4.7) were tabulated beforehand using incomplete elliptic integrals of the second kind. In short, the semi-analytical implementation herein is most efficient, and straightforward, when desingularization accuracy is not critical near the high-curvature solid-particle tips.

$\mbox {d}s$ in (4.7) were tabulated beforehand using incomplete elliptic integrals of the second kind. In short, the semi-analytical implementation herein is most efficient, and straightforward, when desingularization accuracy is not critical near the high-curvature solid-particle tips.

5.2. Single capsule

Capsules are presented as a prototype for fibrous material. First, consider a drop approaching a single capsule (![]() $\mathcal {L}=6$). Patel et al. (Reference Patel, Shaqfeh, Butler, Cristini, Bławzdziewicz and Loewenberg2003) introduced this configuration experimentally, defining the capillary number the same way as herein, and provided boundary-integral results for a drop approaching an infinitely long cylinder. Patel et al. avoided the Stokes paradox (due to an infinite cylinder extent in the third dimension) by using the flow field around the cylinder, which would exist in the absence of the drop, based on the Brinkman equation for an isotropic porous medium, to approximately model the far-field effect of the surrounding fibres in the dilute limit. The boundary-integral problem for the drop was then solved assuming that the drop is immersed into this field, without actual interaction with the cylinder. In the present case, we consider a capsule of finite length only, but solve the problem with full hydrodynamical interaction between the drop and the capsule. The effect of particle length is discussed in more detail in the context of the two-capsule constriction.