1. Introduction

Roughness plays an important role in the fluid dynamics of numerous transport processes. Most surfaces in engineering applications are rough and, as a consequence, rough-wall turbulent flows have also been studied by many investigators. A major difference between smooth- and rough-wall flows is that for smooth walls, there is only viscous drag, while for rough-wall flows, both pressure (form) drag and viscous drag exist. In a smooth-wall pipe or channel flow, there is only a favourable mean pressure gradient. However, for pipe or channel flows having sufficiently organized roughness, there can be spatially localized regions in which an adverse mean pressure gradient persists, as seen, for example, in the region upstream of spanwise rib roughness, e.g. Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003).

Hydraulic pipes or channels are often designed with different wall geometries in order to accommodate specific design objectives, such as industrial and compact heat exchangers, blood oxygenators in extra-corporeal systems, membrane separators, vortex wave membrane bioreactors, etc. One of the popular forms is a wavy shape. Two common configurations in wavy passages have been reported in several investigations. One is a pipe or channel with periodically converging–diverging cross-section where the flow axis is straight. The other is a pipe or channel with uniform cross-section but with a wavy flow axis. These two configurations are usually referred to as symmetric and asymmetric flow passages respectively. Symmetric wavy flow passages can take the form of different geometries such as triangular (Sparrow & Prata Reference Sparrow and Prata1983; Faghri & Asako Reference Faghri and Asako1987; Hossain & Islam Reference Hossain and Islam2004; Eiamsa-ard & Promvonge Reference Eiamsa-ard and Promvonge2007), arc shaped (Tatsuo et al. Reference Tatsuo, Shinichiro, Shingho and Yuji1990; Bahaidarah, Anand & Chen Reference Bahaidarah, Anand and Chen2005) or an ‘egg-carton’ shape (Sawyers, Sen & Chang Reference Sawyers, Sen and Chang1998). Asymmetric wavy passages with uniform cross-section commonly have either zigzag (O’Brien Reference O’Brien1982; Asako & Faghri Reference Asako and Faghri1987; Faghri & Asako Reference Faghri and Asako1987; Hwang, Jang & Cho Reference Hwang, Jang and Cho2006) or sinusoidal flow axes (Popiel & Van der Merwe Reference Popiel and Van der Merwe1996; Wang & Du Reference Wang and Du2008; Guzmán et al. Reference Guzmán, Cárdenas, Urzúa and Araya2009; Sui, Teo & Lee Reference Sui, Teo and Lee2012). In addition, different types of spiral shapes (another kind of waviness) are commonly used for promoting mixing, e.g. helical pipes (Cookson, Doorly & Sherwin Reference Cookson, Doorly and Sherwin2009). However, an asymmetric pipe with a sinusoidal flow axis provides more vigorous mixing through the alternating bends than, for example, in coiled pipes (Shimizu et al. Reference Shimizu, Sugino, Kuzuhara and Murakami1982).

Various linear stability analyses have been presented of incompressible flows in corrugated channels and pipes. It is accepted that laminar flow in straight pipes is linearly stable at all Reynolds numbers investigated to date. The two studies most relevant to the present work are those by Cotrell, MacFadden & Alder (Reference Cotrell, MacFadden and Alder2008) and Loh & Blackburn (Reference Loh and Blackburn2011), which both analysed flows in axisymmetrically corrugated pipes. Cotrell et al. (Reference Cotrell, MacFadden and Alder2008) mainly analysed axisymmetric instability for axis wavelengths incommensurate with the corrugation wavelength

![]() $L_{m}=0.5D$

and showed that the addition of corrugation makes the laminar flow unstable to axisymmetric disturbances, although, for the corrugation amplitudes employed in the present work, at rather large Reynolds numbers. Loh & Blackburn (Reference Loh and Blackburn2011) concentrated instead on three-dimensional disturbances in wavy-wall pipes at the same corrugation wavelength of

$L_{m}=0.5D$

and showed that the addition of corrugation makes the laminar flow unstable to axisymmetric disturbances, although, for the corrugation amplitudes employed in the present work, at rather large Reynolds numbers. Loh & Blackburn (Reference Loh and Blackburn2011) concentrated instead on three-dimensional disturbances in wavy-wall pipes at the same corrugation wavelength of

![]() $L_{m}=0.5D$

employed by Cotrell et al. (Reference Cotrell, MacFadden and Alder2008) and demonstrated that the laminar flow became unstable to disturbances of low azimuthal wavenumber

$L_{m}=0.5D$

employed by Cotrell et al. (Reference Cotrell, MacFadden and Alder2008) and demonstrated that the laminar flow became unstable to disturbances of low azimuthal wavenumber

![]() $k_{o}=3$

, 4 at Reynolds numbers of order 2000–3000 for comparatively small corrugation amplitudes. We will return to consideration of these findings in relation to our results in §§ 4 and 6.

$k_{o}=3$

, 4 at Reynolds numbers of order 2000–3000 for comparatively small corrugation amplitudes. We will return to consideration of these findings in relation to our results in §§ 4 and 6.

Direct numerical simulations (DNS) of turbulent flow for wavy walls and walls with transverse ribs have been carried out by many researchers; in part to gain a deeper understanding of rough-wall turbulent flows. These geometries are commonly accepted as idealizations of ‘rough-wall’ turbulent flows. To date, however, DNS of turbulent fluid flow in symmetric wavy-wall pipes is relatively limited, although some related studies have been conducted which consider asymmetric wavy pipe or channel flows. The present effort on symmetric wavy-wall pipes builds upon the initial study of Blackburn, Ooi & Chong (Reference Blackburn, Ooi and Chong2007). The most recent DNS of fluid flow and heat transfer in asymmetric sinusoidal wavy channels were performed by Guzmán et al. (Reference Guzmán, Cárdenas, Urzúa and Araya2009) and Sui et al. (Reference Sui, Teo and Lee2012). These investigations were, however, limited to the laminar and transitional regimes. Wang & Du (Reference Wang and Du2008) carried out DNS studies of viscous flow in a pipe having asymmetric sinusoidal wall corrugations for a friction Reynolds number

![]() $\mathit{Re}_{{\it\tau}}$

of up to 670.

$\mathit{Re}_{{\it\tau}}$

of up to 670.

A knowledge of the scaling properties of turbulent flow for the cases of smooth, transitionally rough and fully rough pipe or channel flows is important to the design of many commercial applications. The roughness height of a surface,

![]() $k$

, was considered by Nikuradse (Reference Nikuradse1933) to usefully characterize the roughness-induced properties of the mean profile. The concept of ‘equivalent sand-grain roughness’,

$k$

, was considered by Nikuradse (Reference Nikuradse1933) to usefully characterize the roughness-induced properties of the mean profile. The concept of ‘equivalent sand-grain roughness’,

![]() $k_{s}$

, was discussed in Nikuradse (Reference Nikuradse1933) and Schlichting (Reference Schlichting1936), and is commonly used by engineers to classify the so-called fully smooth, fully rough or transitionally rough conditions. This classification has been employed in numerous studies (e.g. Jimenez Reference Jimenez2004; Gioia, Chakraborty & Bombardelli Reference Gioia, Chakraborty and Bombardelli2006; Shockling, Allen & Smits Reference Shockling, Allen and Smits2006; Allen, Shockling, Kunkel & Smits Reference Allen, Shockling, Kunkel and Smits2007; Flack & Schultz Reference Flack and Schultz2010). More recently, Mehdi, Klewicki & White (Reference Mehdi, Klewicki and White2013) provided evidence that, because of the combined dependences on roughness and Reynolds number, there exists a richer set of dynamically distinct roughness regimes than indicated by the traditional classification. In general, these regimes become more apparent as the overall scale separation (friction Reynolds number) becomes large.

$k_{s}$

, was discussed in Nikuradse (Reference Nikuradse1933) and Schlichting (Reference Schlichting1936), and is commonly used by engineers to classify the so-called fully smooth, fully rough or transitionally rough conditions. This classification has been employed in numerous studies (e.g. Jimenez Reference Jimenez2004; Gioia, Chakraborty & Bombardelli Reference Gioia, Chakraborty and Bombardelli2006; Shockling, Allen & Smits Reference Shockling, Allen and Smits2006; Allen, Shockling, Kunkel & Smits Reference Allen, Shockling, Kunkel and Smits2007; Flack & Schultz Reference Flack and Schultz2010). More recently, Mehdi, Klewicki & White (Reference Mehdi, Klewicki and White2013) provided evidence that, because of the combined dependences on roughness and Reynolds number, there exists a richer set of dynamically distinct roughness regimes than indicated by the traditional classification. In general, these regimes become more apparent as the overall scale separation (friction Reynolds number) becomes large.

The highly regular form of roughness considered in the present investigation is not typical of many practical applications. It does, however, afford opportunities to theoretically relate various important parameters, like the pressure drop and friction factor, to the roughness topography. This is contrasted with the classical view of Nikuradse (Reference Nikuradse1933) and Schlichting (Reference Schlichting1936) which, at least partially, supports a broad framework for roughness scalings based upon the notion of equivalent sand-grain roughness. Consider, for example, a fully developed pipe flow having a small but dimensionally fixed roughness. At a low Reynolds number, when normalized equivalent sand-grain roughness

![]() $k_{s}^{+}=k_{s}u_{{\it\tau}}/{\it\nu}$

is small, the flow is hydraulically smooth and there is no detectable effect of roughness. With an increase in the Reynolds number, the flow becomes transitionally rough. Here, the friction factor is higher than in smooth-wall flow, and is a function of both the roughness height and the Reynolds number. Further increase in the Reynolds number forces the flow to become fully rough. Here,

$k_{s}^{+}=k_{s}u_{{\it\tau}}/{\it\nu}$

is small, the flow is hydraulically smooth and there is no detectable effect of roughness. With an increase in the Reynolds number, the flow becomes transitionally rough. Here, the friction factor is higher than in smooth-wall flow, and is a function of both the roughness height and the Reynolds number. Further increase in the Reynolds number forces the flow to become fully rough. Here,

![]() $k_{s}^{+}$

is large, and the friction factor essentially loses its dependence on the Reynolds number.

$k_{s}^{+}$

is large, and the friction factor essentially loses its dependence on the Reynolds number.

The two-layer theory of Millikan (Reference Millikan, den Hartog and Peters1938) has been applied to the transitionally rough and fully rough regimes. In accord with observations, this theory provides for a formulation of the mean velocity profile that accounts for an additive constant that depends on the roughness length scale. All traditional rough-wall scaling theories are based on either the smooth-wall variable,

![]() $y^{+}$

, or the rough-wall variable,

$y^{+}$

, or the rough-wall variable,

![]() $y/k$

, as considered by Benedict (Reference Benedict1980), Raupach, Antonia & Rajagopalan (Reference Raupach, Antonia and Rajagopalan1991), Jimenez (Reference Jimenez2004) and many others. In this case, the additive constant in the logarithmic mean profile formula is supplemented with the roughness function,

$y/k$

, as considered by Benedict (Reference Benedict1980), Raupach, Antonia & Rajagopalan (Reference Raupach, Antonia and Rajagopalan1991), Jimenez (Reference Jimenez2004) and many others. In this case, the additive constant in the logarithmic mean profile formula is supplemented with the roughness function,

![]() ${\rm\Delta}U^{+}$

, as proposed by Clauser (Reference Clauser1954) and Hama (Reference Hama1954). Physically,

${\rm\Delta}U^{+}$

, as proposed by Clauser (Reference Clauser1954) and Hama (Reference Hama1954). Physically,

![]() ${\rm\Delta}U^{+}$

represents a loss of mean momentum relative to the smooth-wall flow, as it generally describes an increasing downward shift in the mean velocity profile with increasing roughness (due to an increasing drag force). Hence, a number of methods have been explored to determine the roughness function

${\rm\Delta}U^{+}$

represents a loss of mean momentum relative to the smooth-wall flow, as it generally describes an increasing downward shift in the mean velocity profile with increasing roughness (due to an increasing drag force). Hence, a number of methods have been explored to determine the roughness function

![]() ${\rm\Delta}U^{+}$

(Granville Reference Granville1987; Schultz & Myers Reference Schultz and Myers2003).

${\rm\Delta}U^{+}$

(Granville Reference Granville1987; Schultz & Myers Reference Schultz and Myers2003).

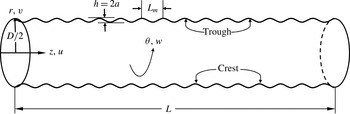

Figure 1. Schematic view of the simulation domain for the wavy-wall pipe along with the cylindrical-coordinate system.

Townsend (Reference Townsend1956) observed that for

![]() $k/D\ll 1$

the profiles of

$k/D\ll 1$

the profiles of

![]() $U^{+}$

and

$U^{+}$

and

![]() $\langle u^{\prime }\rangle ^{+}$

, when plotted versus the outer-normalized distance from the wall, do not exhibit a dependence on the surface roughness. He hypothesized that the influence of roughness at high Reynolds number was only localized in a region where the roughness scales directly influenced the scales of the turbulence. This wall-similarity hypothesis has been shown to at least approximately hold for a variety of roughness topographies, including cylindrical roughness, sand-grain, mesh, spheres and two-dimensional grooves (Flack, Schultz & Shapiro Reference Flack, Schultz and Shapiro2005). There are also notable cases, such as two-dimensional bars, where this hypothesis apparently fails to hold, e.g. see Mehdi et al. (Reference Mehdi, Klewicki and White2013). Recently, Chung, Monty & Ooi (Reference Chung, Monty and Ooi2014) presented an idealized assessment of Townsend’s outer-layer similarity hypothesis by using uniform shear-stress boundary conditions. Their results suggested that wall-turbulence motions of energetic significance obtained their character from the wall shear stress and wall impermeability. All these considerations motivate the exploration of how the present corrugation height influences outer-layer similarity.

$\langle u^{\prime }\rangle ^{+}$

, when plotted versus the outer-normalized distance from the wall, do not exhibit a dependence on the surface roughness. He hypothesized that the influence of roughness at high Reynolds number was only localized in a region where the roughness scales directly influenced the scales of the turbulence. This wall-similarity hypothesis has been shown to at least approximately hold for a variety of roughness topographies, including cylindrical roughness, sand-grain, mesh, spheres and two-dimensional grooves (Flack, Schultz & Shapiro Reference Flack, Schultz and Shapiro2005). There are also notable cases, such as two-dimensional bars, where this hypothesis apparently fails to hold, e.g. see Mehdi et al. (Reference Mehdi, Klewicki and White2013). Recently, Chung, Monty & Ooi (Reference Chung, Monty and Ooi2014) presented an idealized assessment of Townsend’s outer-layer similarity hypothesis by using uniform shear-stress boundary conditions. Their results suggested that wall-turbulence motions of energetic significance obtained their character from the wall shear stress and wall impermeability. All these considerations motivate the exploration of how the present corrugation height influences outer-layer similarity.

Afzal & Seena (Reference Afzal and Seena2007), Afzal (Reference Afzal2013) and Afzal, Seena & Bushra (Reference Afzal, Seena and Bushra2013) recently proposed roughness scaling laws for transitionally rough pipes which employ alternate variables. They defined an inner transitional roughness variable as the ratio of the wall-normal coordinate measured above the mean roughness level to the actual wall roughness level. They provided evidence that this allows one to express the mean velocity profile and friction factor in a universal form for the transitionally rough flows that they considered. Similarly, using the same alternate variables Afzal, Seena & Bushra (Reference Afzal, Seena and Bushra2006) also proposed an alternate power-law velocity profile for transitionally rough pipe flows. These same authors also developed expressions for the scaling properties of an intermediate layer in a transitionally rough channel flow (Seena & Afzal Reference Seena and Afzal2008). By proposing a matched asymptotic expansion solution, they showed evidence of an intermediate layer having its own characteristic scaling and existing between the traditional inner and outer layers. Herein, we explore the validity of intermediate variables that arise by directly considering invariant forms admitted by mean momentum equation.

In the present work we study DNS of incompressible flows within straight pipes whose walls have smooth sinusoidal corrugations, e.g. as shown in figure 1. The corrugation wavelength is maintained constant and the amplitude of the wave is varied, thus allowing a straightforward parametric variation of the corrugation height. At any Reynolds number, this means that the wavelength is constant with respect to streamwise length scales of flow in a smooth pipe. We note, however, that the corrugations so generated are not geometrically self-similar. We investigate variations of both the wave height and the Reynolds number. The present Reynolds number range spans from the laminar regime, through the transitional regime and into the low-Reynolds-number turbulent regime. Our analysis focuses on examining the effect of variations in

![]() $h/D$

, where

$h/D$

, where

![]() $h$

is the peak-to-peak wave height at a fixed

$h$

is the peak-to-peak wave height at a fixed

![]() $\mathit{Re}_{{\it\tau}}$

while allowing the bulk-flow Reynolds number,

$\mathit{Re}_{{\it\tau}}$

while allowing the bulk-flow Reynolds number,

![]() $\mathit{Re}_{D}$

, to vary. The outcomes are not readily extended to cover the effect of variations of

$\mathit{Re}_{D}$

, to vary. The outcomes are not readily extended to cover the effect of variations of

![]() $h/D$

at fixed

$h/D$

at fixed

![]() $\mathit{Re}_{D}$

.

$\mathit{Re}_{D}$

.

2. Mathematical formulation

2.1. Problem definition

The dynamics of the flow is established by the incompressible Navier–Stokes equations,

The fundamental length scale is the diameter

![]() $D$

of the corresponding smooth pipe. The highest Kármán number or friction Reynolds number is

$D$

of the corresponding smooth pipe. The highest Kármán number or friction Reynolds number is

![]() $\mathit{Re}_{{\it\tau}}=u_{{\it\tau}}D/2{\it\nu}=314$

. Here, the friction velocity is defined by

$\mathit{Re}_{{\it\tau}}=u_{{\it\tau}}D/2{\it\nu}=314$

. Here, the friction velocity is defined by

![]() $u_{{\it\tau}}=({\it\tau}_{o}/{\it\rho})^{1/2}$

, where

$u_{{\it\tau}}=({\it\tau}_{o}/{\it\rho})^{1/2}$

, where

![]() ${\it\tau}_{o}$

is the mean wall shear stress. The axial mean pressure gradient per unit mass

${\it\tau}_{o}$

is the mean wall shear stress. The axial mean pressure gradient per unit mass

![]() $g_{o}=4{\it\tau}_{o}/{\it\rho}D={\it\lambda}{\it\rho}U_{b}^{2}/2D$

(where

$g_{o}=4{\it\tau}_{o}/{\it\rho}D={\it\lambda}{\it\rho}U_{b}^{2}/2D$

(where

![]() $U_{b}$

is the bulk-flow velocity) is required to drive the flow in a smooth pipe, and the friction factor

$U_{b}$

is the bulk-flow velocity) is required to drive the flow in a smooth pipe, and the friction factor

![]() ${\it\lambda}$

in smooth pipes is given by

${\it\lambda}$

in smooth pipes is given by

Here,

![]() $U_{b}$

is used to define the bulk-flow Reynolds number as

$U_{b}$

is used to define the bulk-flow Reynolds number as

![]() $\mathit{Re}_{D}=U_{b}D/{\it\nu}=4\langle Q\rangle /{\rm\pi}D{\it\nu}$

, where

$\mathit{Re}_{D}=U_{b}D/{\it\nu}=4\langle Q\rangle /{\rm\pi}D{\it\nu}$

, where

![]() $\langle Q\rangle$

is the average volumetric flow rate. From the definitions above one can also determine that

$\langle Q\rangle$

is the average volumetric flow rate. From the definitions above one can also determine that

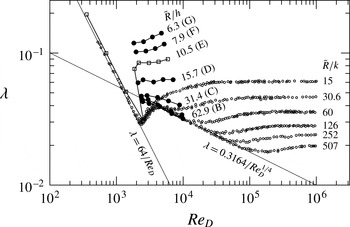

The methodology pursued in the present work produces sets of simulations, each with constant

![]() $\mathit{Re}_{{\it\tau}}$

, from the maximum value

$\mathit{Re}_{{\it\tau}}$

, from the maximum value

![]() $\mathit{Re}_{{\it\tau}}=314$

down to the laminar regime, typically with the driving force per unit mass

$\mathit{Re}_{{\it\tau}}=314$

down to the laminar regime, typically with the driving force per unit mass

![]() $g_{o}$

halved between successive sets. Since

$g_{o}$

halved between successive sets. Since

the friction Reynolds number typically varies by a factor of

![]() $(2)^{-1/2}$

between successive sets of simulations. It should be noted that the Blasius friction factor correlation for smooth pipes is given by

$(2)^{-1/2}$

between successive sets of simulations. It should be noted that the Blasius friction factor correlation for smooth pipes is given by

![]() ${\it\lambda}=0.3164\mathit{Re}_{D}^{-1/4}$

(Nikuradse Reference Nikuradse1933); for moderate turbulent Reynolds numbers this yields the relationship

${\it\lambda}=0.3164\mathit{Re}_{D}^{-1/4}$

(Nikuradse Reference Nikuradse1933); for moderate turbulent Reynolds numbers this yields the relationship

![]() $\mathit{Re}_{{\it\tau}}=0.09944\mathit{Re}_{D}^{7/8}$

. Consequently, the maximum value of the bulk-flow Reynolds number in the smooth pipe for the present work, with

$\mathit{Re}_{{\it\tau}}=0.09944\mathit{Re}_{D}^{7/8}$

. Consequently, the maximum value of the bulk-flow Reynolds number in the smooth pipe for the present work, with

![]() $\mathit{Re}_{{\it\tau}}=314$

, is

$\mathit{Re}_{{\it\tau}}=314$

, is

![]() $\mathit{Re}_{D}\approx 10\,000$

.

$\mathit{Re}_{D}\approx 10\,000$

.

All the domains have the same mean radius

![]() $\bar{R}=D/2$

, and for turbulent flow calculations the same axial length

$\bar{R}=D/2$

, and for turbulent flow calculations the same axial length

![]() $L=2{\rm\pi}D$

. The length to diameter ratio was chosen based on the previous pipe length convergence studies by Chin et al. (Reference Chin, Ooi, Marusic and Blackburn2010). They showed that a pipe length of at least

$L=2{\rm\pi}D$

. The length to diameter ratio was chosen based on the previous pipe length convergence studies by Chin et al. (Reference Chin, Ooi, Marusic and Blackburn2010). They showed that a pipe length of at least

![]() $2{\rm\pi}D$

is required to achieve converged turbulent-flow statistics for

$2{\rm\pi}D$

is required to achieve converged turbulent-flow statistics for

![]() $\mathit{Re}_{{\it\tau}}\approx 500$

.

$\mathit{Re}_{{\it\tau}}\approx 500$

.

For the wavy-wall flows, 15 corrugation wavelengths were chosen within the domain length of

![]() $2{\rm\pi}D$

. This number is large enough to ensure that, even at transitional Reynolds numbers, the number of wavelengths is sufficient to reduce the streamwise correlation of near-wall structures to acceptably low values at half the domain length (Chin et al.

Reference Chin, Ooi, Marusic and Blackburn2010). With a corrugation amplitude of

$2{\rm\pi}D$

. This number is large enough to ensure that, even at transitional Reynolds numbers, the number of wavelengths is sufficient to reduce the streamwise correlation of near-wall structures to acceptably low values at half the domain length (Chin et al.

Reference Chin, Ooi, Marusic and Blackburn2010). With a corrugation amplitude of

![]() $a=h/2$

, the radius of the wavy pipe,

$a=h/2$

, the radius of the wavy pipe,

![]() $R(z)$

, is given by

$R(z)$

, is given by

as illustrated in figure 1. For laminar-flow calculations, only a single module of the axial wave is represented, i.e. the domain length is reduced to

![]() $L_{m}=2{\rm\pi}D/15\approx 0.41888D$

.

$L_{m}=2{\rm\pi}D/15\approx 0.41888D$

.

When attempting to define both the bulk-flow and friction Reynolds numbers for a wavy-wall (or any non-uniform) pipe, one needs an equivalent diameter. For simplicity, we have adopted the mean diameter

![]() $D=2\bar{R}$

for this measure. However, for a constant mean radius the volume of the domain increases as the corrugation height increases, and thus we reduce the driving force

$D=2\bar{R}$

for this measure. However, for a constant mean radius the volume of the domain increases as the corrugation height increases, and thus we reduce the driving force

![]() $g$

as

$g$

as

![]() $h$

increases in order to maintain the total body force constant at each

$h$

increases in order to maintain the total body force constant at each

![]() $\mathit{Re}_{{\it\tau}}$

.

$\mathit{Re}_{{\it\tau}}$

.

From Pappus’ second theorem (Kern & Bland Reference Kern and Bland1948), the domain volume can be found in closed form as

![]() ${\rm\pi}(\bar{R}^{2}+h^{2}/8)L$

, provided that the length comprises an integral number of wavelengths. Using the equivalent diameter, an equivalent mean wall shear stress is found by equating the mean wall tractive force to the mean body force on the domain, i.e.

${\rm\pi}(\bar{R}^{2}+h^{2}/8)L$

, provided that the length comprises an integral number of wavelengths. Using the equivalent diameter, an equivalent mean wall shear stress is found by equating the mean wall tractive force to the mean body force on the domain, i.e.

from which

Thus, if one wishes to keep the friction velocity and hence

![]() $\mathit{Re}_{{\it\tau}}$

constant as

$\mathit{Re}_{{\it\tau}}$

constant as

![]() $h$

increases, the driving force per unit mass

$h$

increases, the driving force per unit mass

![]() $g$

must be reduced as

$g$

must be reduced as

![]() $h$

increases according to

$h$

increases according to

Here,

![]() $V_{o}$

is the volume of the smooth-wall pipe and

$V_{o}$

is the volume of the smooth-wall pipe and

![]() $g_{o}$

is the corresponding axial driving force.

$g_{o}$

is the corresponding axial driving force.

By employing

![]() $u_{{\it\tau}}$

and

$u_{{\it\tau}}$

and

![]() $D$

for normalization, equation (2.1) takes on the dimensionless form

$D$

for normalization, equation (2.1) takes on the dimensionless form

where

![]() $\boldsymbol{F}^{+}=(4V_{o}/V,0,0)$

and the ‘

$\boldsymbol{F}^{+}=(4V_{o}/V,0,0)$

and the ‘

![]() $+$

’ superscript indicates normalization by

$+$

’ superscript indicates normalization by

![]() ${\it\nu}$

and

${\it\nu}$

and

![]() $u_{{\it\tau}}$

. The use of (2.9) is well-suited for numerical simulation, as one only needs to assign the value of

$u_{{\it\tau}}$

. The use of (2.9) is well-suited for numerical simulation, as one only needs to assign the value of

![]() $\mathit{Re}_{{\it\tau}}$

. The resultant value of

$\mathit{Re}_{{\it\tau}}$

. The resultant value of

![]() $\mathit{Re}_{D}$

can be easily evaluated after the flow field becomes statistically stationary.

$\mathit{Re}_{D}$

can be easily evaluated after the flow field becomes statistically stationary.

Napoli, Armenio & De Marchis (Reference Napoli, Armenio and De Marchis2008) introduced an important roughness parameter called the ‘effective slope’ (ES). The effective slope ES accounts for the roughness corrugation shape, and is defined by

where, in the present case,

![]() $L$

is an integral number of corrugations. This function will allow us to investigate the influence of a rough wall on the roughness function as well as friction and pressure drag.

$L$

is an integral number of corrugations. This function will allow us to investigate the influence of a rough wall on the roughness function as well as friction and pressure drag.

Table 1 summarizes the main parameters of the wavy-wall geometries. The maximum peak-to-peak corrugation amplitude of

![]() $h/D=0.07952$

was chosen to be 50 wall units at

$h/D=0.07952$

was chosen to be 50 wall units at

![]() $\mathit{Re}_{{\it\tau}}=314$

, i.e.

$\mathit{Re}_{{\it\tau}}=314$

, i.e.

![]() $h^{+}=50$

. Direct numerical simulations were performed for a range of Reynolds numbers at this corrugation height (case G). The post-transitional turbulent regime simulations were at

$h^{+}=50$

. Direct numerical simulations were performed for a range of Reynolds numbers at this corrugation height (case G). The post-transitional turbulent regime simulations were at

![]() $\mathit{Re}_{{\it\tau}}=180$

and 250, as also listed in table 1. Simulations were also carried out for corrugation heights of

$\mathit{Re}_{{\it\tau}}=180$

and 250, as also listed in table 1. Simulations were also carried out for corrugation heights of

![]() $h^{+}=40$

, 30, 20, 10, 5 and 0 (all at

$h^{+}=40$

, 30, 20, 10, 5 and 0 (all at

![]() $\mathit{Re}_{{\it\tau}}=314$

). It can be seen that the fractional increase in volume,

$\mathit{Re}_{{\it\tau}}=314$

). It can be seen that the fractional increase in volume,

![]() $V/V_{o}$

, and hence the fractional reduction in driving force, is less than half a per cent even at the largest corrugation height, case G. The corrugation wavelength,

$V/V_{o}$

, and hence the fractional reduction in driving force, is less than half a per cent even at the largest corrugation height, case G. The corrugation wavelength,

![]() $L_{m}=2{\rm\pi}D/15$

, corresponds to 263 wall units at

$L_{m}=2{\rm\pi}D/15$

, corresponds to 263 wall units at

![]() $\mathit{Re}_{{\it\tau}}=314$

.

$\mathit{Re}_{{\it\tau}}=314$

.

Table 1. Summary of the wavy-wall geometric parameters and simulations. Here,

![]() $h^{+}$

is the peak-to-peak wave height expressed in wall units at the corresponding

$h^{+}$

is the peak-to-peak wave height expressed in wall units at the corresponding

![]() $\mathit{Re}_{{\it\tau}}$

;

$\mathit{Re}_{{\it\tau}}$

;

![]() $V/V_{o}$

is the domain volume normalized by that for the smooth pipe (case A).

$V/V_{o}$

is the domain volume normalized by that for the smooth pipe (case A).

2.2. Mean momentum equation

The mean momentum equation for flow inside a wavy-walled pipe is developed and discussed in this section according to the analysis of Wei et al. (Reference Wei, Fife, Klewicki and McMurtry2005a ,Reference Wei, McMurtry, Klewicki and Fife b ). By applying the Reynolds decomposition, time averaging and simplifying for statistically stationary axisymmetric flow, the streamwise component of (2.1) becomes

where

![]() $U$

is the mean velocity component in the

$U$

is the mean velocity component in the

![]() $z$

direction,

$z$

direction,

![]() $P$

is the mean pressure and

$P$

is the mean pressure and

![]() $\langle u^{\prime }v^{\prime }\rangle$

is the Reynolds shear stress. The expression for the mean pressure gradient (2.8) allows (2.11) to be written as

$\langle u^{\prime }v^{\prime }\rangle$

is the Reynolds shear stress. The expression for the mean pressure gradient (2.8) allows (2.11) to be written as

Equation (2.12) contains two unknown functions,

![]() $U$

and

$U$

and

![]() $\langle u^{\prime }v^{\prime }\rangle$

, and thus is unclosed. The boundary conditions at the pipe centreline,

$\langle u^{\prime }v^{\prime }\rangle$

, and thus is unclosed. The boundary conditions at the pipe centreline,

![]() $r=0$

, are

$r=0$

, are

Integrating (2.12) with respect to

![]() $r$

and making use of (2.13) yields

$r$

and making use of (2.13) yields

Using (2.14), (2.12) then becomes

It is convenient to rewrite (2.15) using

![]() $y=\bar{R}-r$

, where it is understood that

$y=\bar{R}-r$

, where it is understood that

![]() $y$

is the average wall position. With this, one obtains

$y$

is the average wall position. With this, one obtains

The friction velocity,

![]() $u_{{\it\tau}}$

, inner length scale,

$u_{{\it\tau}}$

, inner length scale,

![]() ${\it\nu}/u_{{\it\tau}}$

, and outer length scale,

${\it\nu}/u_{{\it\tau}}$

, and outer length scale,

![]() $\bar{R}$

, constitute the basic normalization parameters. Hence, the inner-normalized mean momentum equation can be obtained from (2.16) as

$\bar{R}$

, constitute the basic normalization parameters. Hence, the inner-normalized mean momentum equation can be obtained from (2.16) as

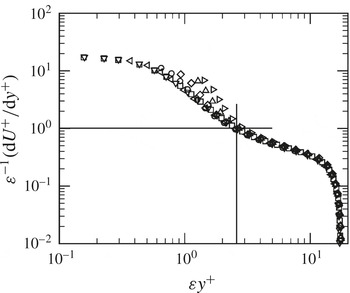

where

![]() ${\it\varepsilon}\rightarrow 0$

as

${\it\varepsilon}\rightarrow 0$

as

![]() $\mathit{Re}_{{\it\tau}}\rightarrow \infty$

,

$\mathit{Re}_{{\it\tau}}\rightarrow \infty$

,

![]() $y^{+}=yu_{{\it\tau}}/{\it\nu}$

is the inner-wall-normalized distance,

$y^{+}=yu_{{\it\tau}}/{\it\nu}$

is the inner-wall-normalized distance,

![]() $U^{+}=U/u_{{\it\tau}}$

is the inner-normalized streamwise-mean velocity and

$U^{+}=U/u_{{\it\tau}}$

is the inner-normalized streamwise-mean velocity and

![]() $T_{u}^{+}=-\langle u^{\prime }v^{\prime }\rangle /u_{{\it\tau}}^{2}$

is the inner-normalized Reynolds shear stress. It is important to note that

$T_{u}^{+}=-\langle u^{\prime }v^{\prime }\rangle /u_{{\it\tau}}^{2}$

is the inner-normalized Reynolds shear stress. It is important to note that

![]() ${\it\varepsilon}$

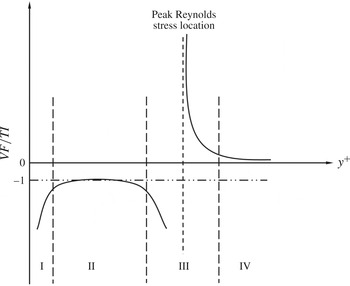

explicitly contains the roughness effect, thus indicating the combined roughness and Reynolds number nature of the problem. Equation (2.17) indicates a balance of three terms, namely

${\it\varepsilon}$

explicitly contains the roughness effect, thus indicating the combined roughness and Reynolds number nature of the problem. Equation (2.17) indicates a balance of three terms, namely

![]() $\mathit{VF}=\text{the mean viscous force}$

(viscous stress gradient),

$\mathit{VF}=\text{the mean viscous force}$

(viscous stress gradient),

![]() $\mathit{TI}=\text{the mean effect of turbulent inertia}$

(Reynolds shear-stress gradient) and

$\mathit{TI}=\text{the mean effect of turbulent inertia}$

(Reynolds shear-stress gradient) and

![]() $\mathit{PG}=\text{the mean pressure gradient}$

. The relative magnitudes of these three terms determine a distinct layer structure characterized by the leading-order balances in (2.17).

$\mathit{PG}=\text{the mean pressure gradient}$

. The relative magnitudes of these three terms determine a distinct layer structure characterized by the leading-order balances in (2.17).

The outer form of the equation uses the mean pipe radius

![]() $\bar{R}$

to normalize the wall-normal distance

$\bar{R}$

to normalize the wall-normal distance

![]() ${\it\eta}=y/\bar{R}$

. This gives

${\it\eta}=y/\bar{R}$

. This gives

and the boundary conditions at

![]() ${\it\eta}=1$

are

${\it\eta}=1$

are

Equations (2.17)–(2.21) are considered in § 5 to help to clarify the scaling behaviours associated with the mean dynamics.

3. Numerical methods

3.1. Discretization

A cylindrical-coordinate spectral element/Fourier spatial discretization is employed (Blackburn & Sherwin Reference Blackburn and Sherwin2004). Nodal spectral elements are deployed to discretize the meridional semi-plane, and Fourier expansions are used in the azimuthal direction. This is possible because the domain is axisymmetric. The velocity,

![]() $\boldsymbol{u}^{+}$

, and pressure,

$\boldsymbol{u}^{+}$

, and pressure,

![]() $p^{+}$

, can be projected onto a set of two-dimensional complex Fourier modes,

$p^{+}$

, can be projected onto a set of two-dimensional complex Fourier modes,

where

![]() $k_{o}$

is the azimuthal wavenumber. Only a finite number of these modes are represented in the calculation.

$k_{o}$

is the azimuthal wavenumber. Only a finite number of these modes are represented in the calculation.

The nonlinear advection terms

![]() $\boldsymbol{N}(\boldsymbol{u}^{+})$

are computed in skew-symmetric form

$\boldsymbol{N}(\boldsymbol{u}^{+})$

are computed in skew-symmetric form

![]() $\boldsymbol{N}(\boldsymbol{u}^{+})=(\boldsymbol{u}^{+}\boldsymbol{\cdot }\boldsymbol{{\rm\nabla}}\boldsymbol{u}^{+}+\boldsymbol{{\rm\nabla}}\boldsymbol{\cdot }\boldsymbol{u}^{+}\boldsymbol{u}^{+})/2$

for robustness, but are not explicitly dealiased. Time integration is carried out via a second-order mixed implicit–explicit pseudo-spectral velocity correction scheme (Karniadakis, Israeli & Orszag Reference Karniadakis, Israeli and Orszag1991; Guermond & Shen Reference Guermond and Shen2003). More detail about the numerical method is presented by Blackburn & Sherwin (Reference Blackburn and Sherwin2004), who demonstrate that the method attains spectral convergence for non-axisymmetric flows and provide a full explanation of how geometric singularities at the axis are overcome.

$\boldsymbol{N}(\boldsymbol{u}^{+})=(\boldsymbol{u}^{+}\boldsymbol{\cdot }\boldsymbol{{\rm\nabla}}\boldsymbol{u}^{+}+\boldsymbol{{\rm\nabla}}\boldsymbol{\cdot }\boldsymbol{u}^{+}\boldsymbol{u}^{+})/2$

for robustness, but are not explicitly dealiased. Time integration is carried out via a second-order mixed implicit–explicit pseudo-spectral velocity correction scheme (Karniadakis, Israeli & Orszag Reference Karniadakis, Israeli and Orszag1991; Guermond & Shen Reference Guermond and Shen2003). More detail about the numerical method is presented by Blackburn & Sherwin (Reference Blackburn and Sherwin2004), who demonstrate that the method attains spectral convergence for non-axisymmetric flows and provide a full explanation of how geometric singularities at the axis are overcome.

The computational meshes retain a quadrilateral spectral element strategy that has been successfully implemented in our previous DNS and wall-resolving large-eddy simulations for smooth-wall geometries (Schmidt et al.

Reference Schmidt, McIver, Blackburn, Rudman and Nathan2001; Blackburn & Schmidt Reference Blackburn and Schmidt2003; Chin et al.

Reference Chin, Ooi, Marusic and Blackburn2010; Saha et al.

Reference Saha, Chin, Blackburn and Ooi2011). The viscous length scale,

![]() $\ell _{v}={\it\nu}/u_{{\it\tau}}$

, is first determined for the maximum Reynolds number to be attempted. In the radial direction, the distance of the first element boundary from the wall is set at

$\ell _{v}={\it\nu}/u_{{\it\tau}}$

, is first determined for the maximum Reynolds number to be attempted. In the radial direction, the distance of the first element boundary from the wall is set at

![]() $10\ell _{v}$

. This resolves the viscous sublayer. The distance from the wall to the second element boundary is then set near the height of maximum turbulent energy production (here, we have used

$10\ell _{v}$

. This resolves the viscous sublayer. The distance from the wall to the second element boundary is then set near the height of maximum turbulent energy production (here, we have used

![]() $25\ell _{v}$

). The remaining element heights to the pipe centreline form a geometric progression, where the number of elements is chosen on the basis of experience. The result is then checked to ensure that features near the centreline of the pipe are adequately resolved.

$25\ell _{v}$

). The remaining element heights to the pipe centreline form a geometric progression, where the number of elements is chosen on the basis of experience. The result is then checked to ensure that features near the centreline of the pipe are adequately resolved.

To estimate the remaining mesh parameters, rules of thumb for resolving wall-flow DNS are adopted from Piomelli (Reference Piomelli, Liu and Liu1997). Near the wall,

![]() ${\it\Delta}_{y}^{+}<1$

,

${\it\Delta}_{y}^{+}<1$

,

![]() ${\it\Delta}_{z}^{+}\approx 15$

and

${\it\Delta}_{z}^{+}\approx 15$

and

![]() ${\it\Delta}_{{\it\theta}}^{+}\approx 6$

in the wall-normal, streamwise and cross-flow directions respectively. Given the wall-normal height of the first element, we employ 10th-order nodal shape functions (i.e. with 11 points along the edge of an element) in order to satisfy

${\it\Delta}_{{\it\theta}}^{+}\approx 6$

in the wall-normal, streamwise and cross-flow directions respectively. Given the wall-normal height of the first element, we employ 10th-order nodal shape functions (i.e. with 11 points along the edge of an element) in order to satisfy

![]() ${\it\Delta}_{y}^{+}<1$

. Because the elements employ equal-order tensor-product shape functions, there is the same number of points within each element in the streamwise direction as in the wall-normal direction, and we use

${\it\Delta}_{y}^{+}<1$

. Because the elements employ equal-order tensor-product shape functions, there is the same number of points within each element in the streamwise direction as in the wall-normal direction, and we use

![]() ${\it\Delta}_{z}^{+}\approx 15$

for the streamwise length of a near-wall element. In the present case, this requires 26 elements to reach the streamwise domain length of

${\it\Delta}_{z}^{+}\approx 15$

for the streamwise length of a near-wall element. In the present case, this requires 26 elements to reach the streamwise domain length of

![]() $2{\rm\pi}D$

.

$2{\rm\pi}D$

.

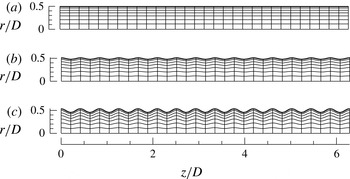

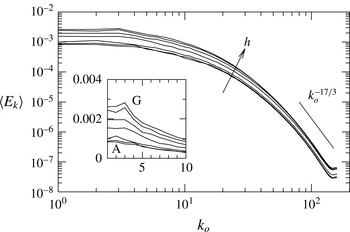

We therefore adopt 30 elements in the streamwise direction for convenience, allowing two elements per geometric wavelength. For the present problem, the added complexity of a hierarchical mesh design to resolve fine-scale near-wall geometric features is not required or justified, and thus we have a simple (logically rectangular)

![]() $30\times 8$

array of elements to cover the meridional semi-plane. These elements are distorted isoparametrically to accommodate the wavy-wall shapes, as shown in figure 2. In order to establish the number of planes of data required in the azimuthal direction, we find from

$30\times 8$

array of elements to cover the meridional semi-plane. These elements are distorted isoparametrically to accommodate the wavy-wall shapes, as shown in figure 2. In order to establish the number of planes of data required in the azimuthal direction, we find from

![]() ${\it\Delta}_{{\it\theta}}^{+}\approx 6$

that 320 planes (160 Fourier modes) are adequate at

${\it\Delta}_{{\it\theta}}^{+}\approx 6$

that 320 planes (160 Fourier modes) are adequate at

![]() $\mathit{Re}_{{\it\tau}}=314$

. Overall, the number of independent mesh nodes in the meridional semi-plane is 7020, and the total number of nodes is then approximately 2.25 million for the simulations conducted at

$\mathit{Re}_{{\it\tau}}=314$

. Overall, the number of independent mesh nodes in the meridional semi-plane is 7020, and the total number of nodes is then approximately 2.25 million for the simulations conducted at

![]() $\mathit{Re}_{{\it\tau}}=314$

. Fewer mesh nodes are required at lower values of

$\mathit{Re}_{{\it\tau}}=314$

. Fewer mesh nodes are required at lower values of

![]() $\mathit{Re}_{{\it\tau}}$

. The same spectral element outlines are retained, but the orders of the element shape functions and Fourier azimuthal interpolants are reduced as appropriate.

$\mathit{Re}_{{\it\tau}}$

. The same spectral element outlines are retained, but the orders of the element shape functions and Fourier azimuthal interpolants are reduced as appropriate.

Figure 2. Spectral element meshes, each with 240 elements in the meridional semi-plane. Here,

![]() $h$

is the peak-to-peak wave height and

$h$

is the peak-to-peak wave height and

![]() $a=h/2$

is the corrugation amplitude. The labels match those used in table 1: (a) smooth-wall pipe; (b)

$a=h/2$

is the corrugation amplitude. The labels match those used in table 1: (a) smooth-wall pipe; (b)

![]() $h_{314}^{+}=20$

; (c)

$h_{314}^{+}=20$

; (c)

![]() $h_{314}^{+}=50$

.

$h_{314}^{+}=50$

.

We note that since the corrugated domains are two-dimensional, it follows that the associated time-mean flows and local turbulent statistics are too. When we present one-dimensional profile data for turbulence statistics below, the values have also been averaged in the streamwise direction. This implies that profiles representing averages of product terms, such as Reynolds stresses, contain contributions from streamwise averages of products of the deviations of the time-mean flow velocity components from the streamwise-mean profile as well as from the streamwise averages of the local fluctuation products. Contributions from the time-mean or ‘coherent’ streamwise fluctuations from the mean velocity profile are typically only significant within one corrugation height of the mean radius.

3.2. Validation for smooth-pipe flow

Due to the lack of availability of wavy-wall pipe flow data, the veracity of the smooth-wall turbulent-flow calculations was tested by comparing statistical profiles with laser Doppler velocimetry (LDV) measurements obtained at

![]() $\mathit{Re}_{{\it\tau}}=314.5$

by den Toonder & Nieuwstadt (Reference den Toonder and Nieuwstadt1997). Comparisons were presented in figure 7 of Blackburn et al. (Reference Blackburn, Ooi and Chong2007). It should be noted that statistical data were only calculated after all the initial transients had convected out of the computational domain and the flow field had reached a statistically stationary state. The mean velocity showed excellent agreement with the measurements. The comparison of the second-order statistics between the DNS and measurements was also very good, except in the near-wall region where measurement inaccuracies became apparent. The r.m.s. profile of the radial fluctuations was also slightly but consistently lower than the experimental measurements. Such deviations are, however, common, e.g. as observed by Westerweel (Reference Westerweel1993) and den Toonder & Nieuwstadt (Reference den Toonder and Nieuwstadt1997). The reasons behind this underestimation of the radial velocity r.m.s. apparently remains an open question.

$\mathit{Re}_{{\it\tau}}=314.5$

by den Toonder & Nieuwstadt (Reference den Toonder and Nieuwstadt1997). Comparisons were presented in figure 7 of Blackburn et al. (Reference Blackburn, Ooi and Chong2007). It should be noted that statistical data were only calculated after all the initial transients had convected out of the computational domain and the flow field had reached a statistically stationary state. The mean velocity showed excellent agreement with the measurements. The comparison of the second-order statistics between the DNS and measurements was also very good, except in the near-wall region where measurement inaccuracies became apparent. The r.m.s. profile of the radial fluctuations was also slightly but consistently lower than the experimental measurements. Such deviations are, however, common, e.g. as observed by Westerweel (Reference Westerweel1993) and den Toonder & Nieuwstadt (Reference den Toonder and Nieuwstadt1997). The reasons behind this underestimation of the radial velocity r.m.s. apparently remains an open question.

4. Axisymmetric laminar flows

Steady laminar axisymmetric flows were computed on a domain of one axial wavelength,

![]() $L_{m}=2{\rm\pi}D/15$

, and steady flows were computed using an adaptation of a time-stepping code that uses a matrix-free Newton–Raphson method based on Stokes preconditioning (Tuckerman & Barkley Reference Tuckerman, Barkley, Doedel and Tuckerman2000; Blackburn Reference Blackburn2002). Results were computed for

$L_{m}=2{\rm\pi}D/15$

, and steady flows were computed using an adaptation of a time-stepping code that uses a matrix-free Newton–Raphson method based on Stokes preconditioning (Tuckerman & Barkley Reference Tuckerman, Barkley, Doedel and Tuckerman2000; Blackburn Reference Blackburn2002). Results were computed for

![]() $\mathit{Re}_{{\it\tau}}=27.8$

, 39.3, 55.6 and 78.6 (

$\mathit{Re}_{{\it\tau}}=27.8$

, 39.3, 55.6 and 78.6 (

![]() $\mathit{Re}_{D}\approx 300{-}3000$

). These laminar flows for all wave heights investigated are stable to axisymmetric disturbances at these Reynolds numbers. A further check that the axisymmetric flows are stable to axisymmetric perturbations in the wavy pipe can be made by computing the flow in the whole domain using the two-dimensional unsteady Navier–Stokes equations, and perturbing the solution impulsively with white noise. This was done at

$\mathit{Re}_{D}\approx 300{-}3000$

). These laminar flows for all wave heights investigated are stable to axisymmetric disturbances at these Reynolds numbers. A further check that the axisymmetric flows are stable to axisymmetric perturbations in the wavy pipe can be made by computing the flow in the whole domain using the two-dimensional unsteady Navier–Stokes equations, and perturbing the solution impulsively with white noise. This was done at

![]() $\mathit{Re}_{{\it\tau}}=78.6$

for the largest wave height (case G), and it was found that the perturbed solution returned to the steady-state solution. We note that these flows may be unstable to non-axisymmetric disturbances. Stability analysis carried out by Loh & Blackburn (Reference Loh and Blackburn2011) for corrugated pipes with a similar corrugation wavelength to that employed here showed that the flow first became unstable to disturbances with azimuthal wavenumbers

$\mathit{Re}_{{\it\tau}}=78.6$

for the largest wave height (case G), and it was found that the perturbed solution returned to the steady-state solution. We note that these flows may be unstable to non-axisymmetric disturbances. Stability analysis carried out by Loh & Blackburn (Reference Loh and Blackburn2011) for corrugated pipes with a similar corrugation wavelength to that employed here showed that the flow first became unstable to disturbances with azimuthal wavenumbers

![]() $k_{o}=3$

, 4 and at bulk Reynolds numbers similar to the upper end of the range we have used.

$k_{o}=3$

, 4 and at bulk Reynolds numbers similar to the upper end of the range we have used.

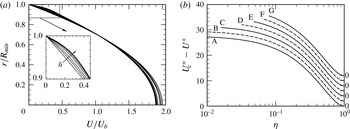

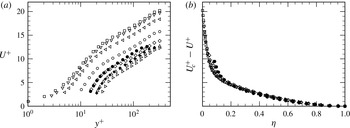

Example streamwise velocity profiles extracted at the axial location corresponding to

![]() $R_{min}$

for laminar flows computed at

$R_{min}$

for laminar flows computed at

![]() $\mathit{Re}_{{\it\tau}}=55.6$

are shown in figure 3(a). (It should be noted that the pipe cross-section of minimum radius is located at

$\mathit{Re}_{{\it\tau}}=55.6$

are shown in figure 3(a). (It should be noted that the pipe cross-section of minimum radius is located at

![]() $z=L_{m}/2$

.) The profile for the smooth pipe matches the parabolic Hagen–Poiseuille solution, and has a peak velocity of twice the bulk velocity. The rough-wall profiles are distorted near the wall but approach a parabolic profile near the pipe centreline. The velocity defect plot, shown in figure 3(b), confirms that well away from the wall, the profiles all approach a common shape. Thus, the axial-average flow near the centre of the pipe is not greatly influenced by the detail of the wall corrugation, other than through the influence this has on the surface shear stress.

$z=L_{m}/2$

.) The profile for the smooth pipe matches the parabolic Hagen–Poiseuille solution, and has a peak velocity of twice the bulk velocity. The rough-wall profiles are distorted near the wall but approach a parabolic profile near the pipe centreline. The velocity defect plot, shown in figure 3(b), confirms that well away from the wall, the profiles all approach a common shape. Thus, the axial-average flow near the centre of the pipe is not greatly influenced by the detail of the wall corrugation, other than through the influence this has on the surface shear stress.

Figure 3. Velocity profiles for laminar flow at

![]() $\mathit{Re}_{{\it\tau}}=55.6$

. (a) Profiles obtained at the axial location of the minimum pipe radius,

$\mathit{Re}_{{\it\tau}}=55.6$

. (a) Profiles obtained at the axial location of the minimum pipe radius,

![]() $R_{min}=\bar{R}-a$

, normalized by the bulk velocity in that section. The arrow indicates increasing wave height,

$R_{min}=\bar{R}-a$

, normalized by the bulk velocity in that section. The arrow indicates increasing wave height,

![]() $h$

. (b) Axial-average velocity defect. Note the vertical separation applied to the curves.

$h$

. (b) Axial-average velocity defect. Note the vertical separation applied to the curves.

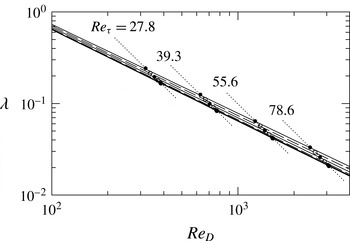

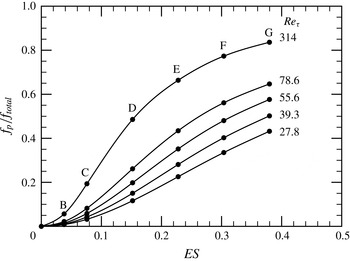

We now turn to an examination of the friction factor,

![]() ${\it\lambda}$

, for the laminar flows. From velocity profiles extracted at

${\it\lambda}$

, for the laminar flows. From velocity profiles extracted at

![]() $z=L_{m}/2$

, the volumetric flow rates were computed, followed by the bulk-flow Reynolds numbers based on the mean diameter, i.e.

$z=L_{m}/2$

, the volumetric flow rates were computed, followed by the bulk-flow Reynolds numbers based on the mean diameter, i.e.

![]() $\mathit{Re}_{D}$

, and then from (2.3) the pipe friction factor,

$\mathit{Re}_{D}$

, and then from (2.3) the pipe friction factor,

![]() ${\it\lambda}$

. The data for the four laminar-flow Reynolds numbers are shown in figure 4. Several points are worth noting. First, on this log–log plot, lines of constant

${\it\lambda}$

. The data for the four laminar-flow Reynolds numbers are shown in figure 4. Several points are worth noting. First, on this log–log plot, lines of constant

![]() $\mathit{Re}_{{\it\tau}}$

have a slope of

$\mathit{Re}_{{\it\tau}}$

have a slope of

![]() $-2$

(see (2.3)), hence each set of data falls along such a line. Second, the data for the smooth pipe fall exactly on the analytical result

$-2$

(see (2.3)), hence each set of data falls along such a line. Second, the data for the smooth pipe fall exactly on the analytical result

![]() ${\it\lambda}=64/\mathit{Re}_{D}$

, as expected (the slope and intercept values for a power-law curve fit through the four smooth-pipe data points match the analytical values to five-digit accuracy). Third, the friction factors for the wavy-wall cases are greater than those for a smooth pipe. While it is conventional to accept that in laminar flow roughness has no effect on the friction factor, some reflection suggests that this is an approximate result for small roughness height that can only be true in the smooth-pipe limit. Fourth, power laws fitted through the wavy wall results (the dashed and solid lines in figure 4) have slopes that progressively become somewhat less negative with increasing wave height.

${\it\lambda}=64/\mathit{Re}_{D}$

, as expected (the slope and intercept values for a power-law curve fit through the four smooth-pipe data points match the analytical values to five-digit accuracy). Third, the friction factors for the wavy-wall cases are greater than those for a smooth pipe. While it is conventional to accept that in laminar flow roughness has no effect on the friction factor, some reflection suggests that this is an approximate result for small roughness height that can only be true in the smooth-pipe limit. Fourth, power laws fitted through the wavy wall results (the dashed and solid lines in figure 4) have slopes that progressively become somewhat less negative with increasing wave height.

Figure 4. Pipe friction factor

![]() ${\it\lambda}$

as a function of

${\it\lambda}$

as a function of

![]() $\mathit{Re}_{D}$

for laminar flows at four different values of

$\mathit{Re}_{D}$

for laminar flows at four different values of

![]() $\mathit{Re}_{{\it\tau}}$

. In each set, the lowest point corresponds to the smooth pipe and the upper point corresponds to the highest-amplitude wave, case G. The solid and dashed lines through the data points show best-fit power laws,

$\mathit{Re}_{{\it\tau}}$

. In each set, the lowest point corresponds to the smooth pipe and the upper point corresponds to the highest-amplitude wave, case G. The solid and dashed lines through the data points show best-fit power laws,

![]() ${\it\lambda}=64/[1-0.8(h/D)^{1.2}]\mathit{Re}_{D}$

.

${\it\lambda}=64/[1-0.8(h/D)^{1.2}]\mathit{Re}_{D}$

.

5. Inner and outer normalizations in the turbulent regime

5.1. Mean velocity profiles

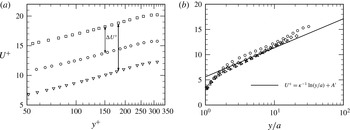

The effects of the corrugation height and Reynolds number are evident in the behaviour of the mean velocity profile. Figure 5 presents mean velocity profiles in both inner and velocity defect forms. The results for the smooth-wall pipe (case A) are also included for comparison. The mean statistics in the corrugated pipe were computed by averaging over

![]() $z{-}{\it\theta}$

planes uniformly up to the minimum sensible radius

$z{-}{\it\theta}$

planes uniformly up to the minimum sensible radius

![]() $R_{min}$

. The velocity field around the wavy surface is strongly influenced by the surface profile. This is clearly seen by comparing the near-wall flow with the smooth-wall case. With an increase in corrugation height, the maximum centreline velocity decreases in comparison to the smooth pipe. The offset in the maximum mean velocity profiles depends on the magnitude of the corrugation amplitude, as suggested by Blackburn et al. (Reference Blackburn, Ooi and Chong2007). By plotting the mean velocity profiles for case G for

$R_{min}$

. The velocity field around the wavy surface is strongly influenced by the surface profile. This is clearly seen by comparing the near-wall flow with the smooth-wall case. With an increase in corrugation height, the maximum centreline velocity decreases in comparison to the smooth pipe. The offset in the maximum mean velocity profiles depends on the magnitude of the corrugation amplitude, as suggested by Blackburn et al. (Reference Blackburn, Ooi and Chong2007). By plotting the mean velocity profiles for case G for

![]() $\mathit{Re}_{{\it\tau}}=180\,250$

and 314, figure 5(a) shows an increasing downward shift of the inner-normalized profiles with increasing Reynolds number. The near-wall velocity profiles also remain substantially different from the smooth-wall pipe flow. The existence of the no-slip boundary condition causes the mean velocity profiles to vary sharply within the near-wall corrugated region. Hence, the overall velocity field (averaged over

$\mathit{Re}_{{\it\tau}}=180\,250$

and 314, figure 5(a) shows an increasing downward shift of the inner-normalized profiles with increasing Reynolds number. The near-wall velocity profiles also remain substantially different from the smooth-wall pipe flow. The existence of the no-slip boundary condition causes the mean velocity profiles to vary sharply within the near-wall corrugated region. Hence, the overall velocity field (averaged over

![]() $z{-}{\it\theta}$

planes) exhibits a larger momentum deficit when compared with the smooth-wall flow. In contrast, the mean velocity profiles in defect form (figure 5

b) exhibit agreement for all cases in the region

$z{-}{\it\theta}$

planes) exhibits a larger momentum deficit when compared with the smooth-wall flow. In contrast, the mean velocity profiles in defect form (figure 5

b) exhibit agreement for all cases in the region

![]() ${\it\eta}\geqslant 0.2$

for the present conditions. This is in accord with Townsend’s wall-similarity hypothesis (Townsend Reference Townsend1956). Observations similar to these were made by Shockling et al. (Reference Shockling, Allen and Smits2006) for distributed roughness pipe flows in the transitionally and fully rough regimes. The mean profiles systematically vary as a function of corrugation amplitude within the corrugated sublayer. This is consistent with the study of Wu & Christensen (Reference Wu and Christensen2007).

${\it\eta}\geqslant 0.2$

for the present conditions. This is in accord with Townsend’s wall-similarity hypothesis (Townsend Reference Townsend1956). Observations similar to these were made by Shockling et al. (Reference Shockling, Allen and Smits2006) for distributed roughness pipe flows in the transitionally and fully rough regimes. The mean profiles systematically vary as a function of corrugation amplitude within the corrugated sublayer. This is consistent with the study of Wu & Christensen (Reference Wu and Christensen2007).

Figure 5. Mean velocity profile for different corrugation heights at

![]() $\mathit{Re}_{{\it\tau}}=314$

and for different values of

$\mathit{Re}_{{\it\tau}}=314$

and for different values of

![]() $\mathit{Re}_{{\it\tau}}$

at the highest corrugation height (

$\mathit{Re}_{{\it\tau}}$

at the highest corrugation height (

![]() $h/D=0.46024$

): (a) inner scaling and (b) outer scaling (velocity defect law). The symbol shapes for the DNS data are given in table 1.

$h/D=0.46024$

): (a) inner scaling and (b) outer scaling (velocity defect law). The symbol shapes for the DNS data are given in table 1.

The effect of the corrugation height is characterized here using a corrugation amplitude,

![]() $a=h/2$

. This has similarity to an equivalent sand-grain roughness height,

$a=h/2$

. This has similarity to an equivalent sand-grain roughness height,

![]() $k_{s}$

(Nikuradse Reference Nikuradse1933; Schlichting Reference Schlichting1936). When

$k_{s}$

(Nikuradse Reference Nikuradse1933; Schlichting Reference Schlichting1936). When

![]() $a$

increases to become comparable to

$a$

increases to become comparable to

![]() ${\it\nu}/u_{{\it\tau}}$

, the inner-scaled profiles exhibit a downward shift relative to the smooth-wall profile. The wall-normal extent of this deficit, which can be interpreted as an internal layer within which the length scales imposed by the corrugated surface directly impact the dynamics, is surface-dependent, with the highest corrugation height showing the largest wall-normal extent of velocity deficit (

${\it\nu}/u_{{\it\tau}}$

, the inner-scaled profiles exhibit a downward shift relative to the smooth-wall profile. The wall-normal extent of this deficit, which can be interpreted as an internal layer within which the length scales imposed by the corrugated surface directly impact the dynamics, is surface-dependent, with the highest corrugation height showing the largest wall-normal extent of velocity deficit (

![]() $y^{+}\geqslant 50$

). Consistent with enhanced drag, this deficit increases with increasing corrugation height, and is largest for case G. For the set of conditions explored, the mean velocity profile can be expressed as

$y^{+}\geqslant 50$

). Consistent with enhanced drag, this deficit increases with increasing corrugation height, and is largest for case G. For the set of conditions explored, the mean velocity profile can be expressed as

where

![]() ${\rm\Delta}U^{+}$

is denoted as the corrugation function. Analogous to the roughness function of Hama (Reference Hama1954), the corrugation function depends on

${\rm\Delta}U^{+}$

is denoted as the corrugation function. Analogous to the roughness function of Hama (Reference Hama1954), the corrugation function depends on

![]() $a^{+}$

or

$a^{+}$

or

![]() $h^{+}$

. The relationship between

$h^{+}$

. The relationship between

![]() ${\rm\Delta}U^{+}$

and

${\rm\Delta}U^{+}$

and

![]() $a^{+}$

follows from the concept of equivalent sand-grain roughness. For the profiles of figure 6(a),

$a^{+}$

follows from the concept of equivalent sand-grain roughness. For the profiles of figure 6(a),

![]() ${\rm\Delta}U^{+}=4.45$

and 8.0 for

${\rm\Delta}U^{+}=4.45$

and 8.0 for

![]() $h_{314}^{+}=20$

and 50 respectively. According to the analogy with equivalent sand-grain roughness, for sufficiently large

$h_{314}^{+}=20$

and 50 respectively. According to the analogy with equivalent sand-grain roughness, for sufficiently large

![]() $a^{+}$

there should be a loss of dependence on viscosity, allowing the log-law velocity profile to be written as

$a^{+}$

there should be a loss of dependence on viscosity, allowing the log-law velocity profile to be written as

where

![]() $A^{\prime }$

is the effective corrugation function, analogous to the Nikuradse roughness function.

$A^{\prime }$

is the effective corrugation function, analogous to the Nikuradse roughness function.

Figure 6. Mean velocity profile plotted (a) against

![]() $y^{+}$

showing the logarithmic region and (b) against

$y^{+}$

showing the logarithmic region and (b) against

![]() $y/a$

. The data sets are as for figure 5.

$y/a$

. The data sets are as for figure 5.

Figure 6(b) plots

![]() $U^{+}$

versus

$U^{+}$

versus

![]() $y/a$

. In the fully rough regime, the viscous sublayer no longer exists. Consistently, the effective corrugation function appears to approach an approximately constant value of

$y/a$

. In the fully rough regime, the viscous sublayer no longer exists. Consistently, the effective corrugation function appears to approach an approximately constant value of

![]() $A^{\prime }\simeq 5.6$

, which is smaller than the Nikuradse roughness function value of approximately 8.5 in the fully rough regime. We also observe that for the conditions explored herein the increasing

$A^{\prime }\simeq 5.6$

, which is smaller than the Nikuradse roughness function value of approximately 8.5 in the fully rough regime. We also observe that for the conditions explored herein the increasing

![]() $a^{+}$

profiles at fixed

$a^{+}$

profiles at fixed

![]() $\mathit{Re}_{{\it\tau}}$

continue to exhibit a small but apparently persistent variation. This probably indicates that the largest

$\mathit{Re}_{{\it\tau}}$

continue to exhibit a small but apparently persistent variation. This probably indicates that the largest

![]() $a^{+}$

condition may still not be in the fully rough (fully corrugated) regime. For completeness we note that from (5.1) and (5.2), the corrugation function in the fully rough regime is given by

$a^{+}$

condition may still not be in the fully rough (fully corrugated) regime. For completeness we note that from (5.1) and (5.2), the corrugation function in the fully rough regime is given by

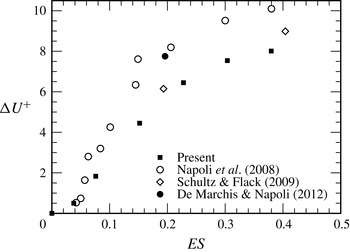

In the present work, the corrugation function

![]() ${\rm\Delta}U^{+}$

is plotted against the ES as shown in figure 7. For comparison, data from Napoli et al. (Reference Napoli, Armenio and De Marchis2008), Schultz & Flack (Reference Schultz and Flack2009) and De Marchis & Napoli (Reference De Marchis and Napoli2012) are included in the plot. The results are presented for

${\rm\Delta}U^{+}$

is plotted against the ES as shown in figure 7. For comparison, data from Napoli et al. (Reference Napoli, Armenio and De Marchis2008), Schultz & Flack (Reference Schultz and Flack2009) and De Marchis & Napoli (Reference De Marchis and Napoli2012) are included in the plot. The results are presented for

![]() $0\leqslant \mathit{ES}\leqslant 0.38$

at the highest Reynolds number and are found to show a trend similar to other observations. Napoli et al. (Reference Napoli, Armenio and De Marchis2008) observed linear variation of

$0\leqslant \mathit{ES}\leqslant 0.38$

at the highest Reynolds number and are found to show a trend similar to other observations. Napoli et al. (Reference Napoli, Armenio and De Marchis2008) observed linear variation of

![]() ${\rm\Delta}U^{+}$

for

${\rm\Delta}U^{+}$

for

![]() $\mathit{ES}\leqslant 0.15$

, whereas the corrugation function for sinusoidally corrugated pipes increases linearly up to approximately

$\mathit{ES}\leqslant 0.15$

, whereas the corrugation function for sinusoidally corrugated pipes increases linearly up to approximately

![]() $\mathit{ES}\sim 0.24$

.

$\mathit{ES}\sim 0.24$

.

Figure 7. Dependence of the roughness function

![]() ${\rm\Delta}U^{+}$

on the ES of the wall corrugations at

${\rm\Delta}U^{+}$

on the ES of the wall corrugations at

![]() $\mathit{Re}_{{\it\tau}}=314$

. Data for different types of wall corrugation and

$\mathit{Re}_{{\it\tau}}=314$

. Data for different types of wall corrugation and

![]() $\mathit{Re}_{{\it\tau}}$

from Napoli et al. (Reference Napoli, Armenio and De Marchis2008), Schultz & Flack (Reference Schultz and Flack2009) and De Marchis & Napoli (Reference De Marchis and Napoli2012) are included here for comparison.

$\mathit{Re}_{{\it\tau}}$

from Napoli et al. (Reference Napoli, Armenio and De Marchis2008), Schultz & Flack (Reference Schultz and Flack2009) and De Marchis & Napoli (Reference De Marchis and Napoli2012) are included here for comparison.

5.2. Velocity fluctuation r.m.s. profiles

The effects of roughness in the inner and outer regions of the flow are examined in the context of Townsend’s outer similarity hypothesis by comparing the turbulence intensity profiles from the wavy- and smooth-wall pipes. Figure 8(a–f) shows the turbulence intensities in the streamwise, wall-normal and azimuthal directions as normalized by the friction velocity, and for both inner- and outer-normalized corrugation heights. The root-mean-square (r.m.s.) profiles of the streamwise velocity fluctuations in figure 8(a) do not vary with the presence of corrugation for

![]() $y^{+}\geqslant 60$

, and agree very well with the results for the smooth-pipe flow in the outer region of the flow. As the wall is approached, however, the wavy-wall data fall below the smooth-wall data. This is generically consistent with the findings for other rough-wall pipe flows, e.g. Allen et al. (Reference Allen, Shockling, Kunkel and Smits2007).

$y^{+}\geqslant 60$

, and agree very well with the results for the smooth-pipe flow in the outer region of the flow. As the wall is approached, however, the wavy-wall data fall below the smooth-wall data. This is generically consistent with the findings for other rough-wall pipe flows, e.g. Allen et al. (Reference Allen, Shockling, Kunkel and Smits2007).

Figure 8. Root mean square profiles of turbulent intensities for different corrugation heights at

![]() $\mathit{Re}_{{\it\tau}}=314$

and for different values of

$\mathit{Re}_{{\it\tau}}=314$

and for different values of

![]() $\mathit{Re}_{{\it\tau}}$

at the largest corrugation height (

$\mathit{Re}_{{\it\tau}}$

at the largest corrugation height (

![]() $h/D=0.46024$

): (a,b) streamwise velocity fluctuation; (c,d) radial velocity fluctuation; (e,f) azimuthal velocity fluctuation; (a,c,e) profiles representing inner normalization; (b,d,f) profiles in outer-scaled variables. The data sets are as for figure 5.

$h/D=0.46024$

): (a,b) streamwise velocity fluctuation; (c,d) radial velocity fluctuation; (e,f) azimuthal velocity fluctuation; (a,c,e) profiles representing inner normalization; (b,d,f) profiles in outer-scaled variables. The data sets are as for figure 5.

The profiles of radial and tangential velocity fluctuation (see figure 8

c–f) also merge outside the corrugated sublayer. These findings are consistent with the notion of outer-layer similarity. Relative to

![]() ${u^{\prime }}_{rms}^{+}$

, the effect of the roughness is more subtly realized for the

${u^{\prime }}_{rms}^{+}$

, the effect of the roughness is more subtly realized for the

![]() ${v^{\prime }}_{rms}^{+}$

and

${v^{\prime }}_{rms}^{+}$

and

![]() ${w^{\prime }}_{rms}^{+}$

profiles, whose near-wall peak values and locations show little change from the smooth-wall profile. Overall, the main influence on the

${w^{\prime }}_{rms}^{+}$

profiles, whose near-wall peak values and locations show little change from the smooth-wall profile. Overall, the main influence on the

![]() ${u^{\prime }}_{rms}^{+}$

profile is that its peak value attenuates near the wavy wall and shifts away from the wall with increasing

${u^{\prime }}_{rms}^{+}$

profile is that its peak value attenuates near the wavy wall and shifts away from the wall with increasing

![]() $h^{+}$

. On the other hand, the primary apparent effect on the

$h^{+}$

. On the other hand, the primary apparent effect on the

![]() ${v^{\prime }}_{rms}^{+}$

and

${v^{\prime }}_{rms}^{+}$

and

![]() ${w^{\prime }}_{rms}^{+}$

profiles is that the locations of their peaks shift slightly towards the pipe centre with increasing

${w^{\prime }}_{rms}^{+}$

profiles is that the locations of their peaks shift slightly towards the pipe centre with increasing

![]() $h^{+}$

.

$h^{+}$

.

By considering increasing

![]() $\mathit{Re}_{{\it\tau}}$

for a fixed corrugation height, the traditional description leads to the expectation of encountering a dynamically smooth wall, followed by a transitionally rough wall and culminating with a fully rough-wall flow. The Reynolds number range of the present study (

$\mathit{Re}_{{\it\tau}}$

for a fixed corrugation height, the traditional description leads to the expectation of encountering a dynamically smooth wall, followed by a transitionally rough wall and culminating with a fully rough-wall flow. The Reynolds number range of the present study (

![]() $\mathit{Re}_{{\it\tau}}=180,250,314$

), however, apparently only resides in the transitional rough-wall regime. This is even so for the case of the largest corrugation height (

$\mathit{Re}_{{\it\tau}}=180,250,314$

), however, apparently only resides in the transitional rough-wall regime. This is even so for the case of the largest corrugation height (

![]() $h/D=0.07952$

), which corresponds to

$h/D=0.07952$

), which corresponds to

![]() $h^{+}\approx 30,40$

and 50 respectively. Figure 8 also displays the inner- and outer-normalized turbulence intensities for the cases G180 and G250. These data indicate an increasing trend in the peak values of

$h^{+}\approx 30,40$

and 50 respectively. Figure 8 also displays the inner- and outer-normalized turbulence intensities for the cases G180 and G250. These data indicate an increasing trend in the peak values of

![]() ${v^{\prime }}_{rms}^{+}$

and

${v^{\prime }}_{rms}^{+}$

and

![]() ${w^{\prime }}_{rms}^{+}$

with

${w^{\prime }}_{rms}^{+}$

with

![]() $\mathit{Re}_{{\it\tau}}$

, while the peak in the

$\mathit{Re}_{{\it\tau}}$

, while the peak in the

![]() ${u^{\prime }}_{rms}^{+}$

profile decreases. Continued profile variations of the type displayed for increasing

${u^{\prime }}_{rms}^{+}$

profile decreases. Continued profile variations of the type displayed for increasing

![]() $h^{+}$

provide evidence of transitional rough-wall flow. The data in the outer region are in imperfect agreement with Townsend’s similarity hypothesis, indicating results similar to those presented by Flack et al. (Reference Flack, Schultz and Shapiro2005). Likely reasons for this include low Reynolds number and insufficiently small

$h^{+}$

provide evidence of transitional rough-wall flow. The data in the outer region are in imperfect agreement with Townsend’s similarity hypothesis, indicating results similar to those presented by Flack et al. (Reference Flack, Schultz and Shapiro2005). Likely reasons for this include low Reynolds number and insufficiently small

![]() ${\it\delta}/h$

.

${\it\delta}/h$

.

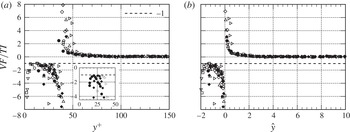

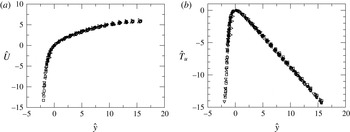

5.3. Reynolds shear-stress profile

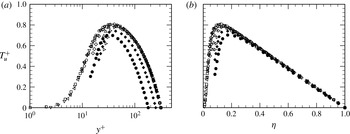

Profiles of the Reynolds shear stress are presented in figure 9. Over a considerable outer-region extent, and for inner- and outer-normalized distance from the wall, the wavy-wall profiles

![]() $T_{u}^{+}=-\langle uv\rangle ^{+}$