1. Introduction

Suspensions of solid particles are ubiquitous in environmental (landslides), industrial (waste slurries) and biological flows (blood), and their study has continued to yield new discoveries (Jeffrey & Acrivos Reference Jeffrey and Acrivos1976; Stickel & Powell Reference Stickel and Powell2005). The vast majority of previous efforts were dedicated to Newtonian suspensions, while in many applications the suspending fluid is non-Newtonian (Chhabra Reference Chhabra2006). Viscoelasticity is a prominent non-Newtonian effect that alters the rheological and transport properties of the flow in complex and often unexpected ways, even in the absence of the particle phase. For instance, the addition of minute amounts of polymer additives to turbulent pipe flow renders the fluid viscoelastic, weakens the turbulence activity, and reduces the drag (Toms Reference Toms1948). In the absence of turbulence, however, the same practice can destabilize the flow in the transitional regime (Samanta et al. Reference Samanta, Dubief, Holzner, Schäfer, Morozov, Wagner and Hof2013; Lee & Zaki Reference Lee and Zaki2017) and can give rise to elastic turbulence in the absence of inertia (Groisman & Steinberg Reference Groisman and Steinberg2000). In this study, we computationally investigate the combined effects of viscoelasticity and concentrated particle suspension on the dynamics of turbulent channel flow. We begin with a brief account of the rheological properties of viscoelastic suspensions in the absence of turbulence, followed by a summary of the effects of fluid inertia and turbulence on particle-laden flows; the latter studies being mostly limited to Newtonian fluids.

1.1. Viscoelastic suspensions in inertialess flows

Early theoretical developments by Einstein for dilute Newtonian suspensions in the absence of inertia predict a relative increase in the so-called effective viscosity, or the bulk shear viscosity of the mixture, at a rate of ![]() $\sim (5/2)\varphi$ where

$\sim (5/2)\varphi$ where ![]() $\varphi$ is the bulk solid volume fraction (Happel & Brenner Reference Happel and Brenner2012). Einarsson, Yang & Shaqfeh (Reference Einarsson, Yang and Shaqfeh2018) reported a correction to the Einstein relation in the same limit of dilute suspension, but when the background fluid is viscoelastic. The shear dependent rheology of such suspensions, including for Boger fluids, exhibits shear-thickening (Zarraga, Hill & Leighton Reference Zarraga, Hill and Leighton2001; Scirocco, Vermant & Mewis Reference Scirocco, Vermant and Mewis2005). Two-dimensional numerical simulations confirmed this effect in disk suspensions in Oldroyd-B fluids (Hwang, Hulsen & Meijer Reference Hwang, Hulsen and Meijer2004). In a linear velocity field and in the limit of Weissenberg number

$\varphi$ is the bulk solid volume fraction (Happel & Brenner Reference Happel and Brenner2012). Einarsson, Yang & Shaqfeh (Reference Einarsson, Yang and Shaqfeh2018) reported a correction to the Einstein relation in the same limit of dilute suspension, but when the background fluid is viscoelastic. The shear dependent rheology of such suspensions, including for Boger fluids, exhibits shear-thickening (Zarraga, Hill & Leighton Reference Zarraga, Hill and Leighton2001; Scirocco, Vermant & Mewis Reference Scirocco, Vermant and Mewis2005). Two-dimensional numerical simulations confirmed this effect in disk suspensions in Oldroyd-B fluids (Hwang, Hulsen & Meijer Reference Hwang, Hulsen and Meijer2004). In a linear velocity field and in the limit of Weissenberg number ![]() $Wi \equiv \dot {\gamma } \lambda \ll 1$, where

$Wi \equiv \dot {\gamma } \lambda \ll 1$, where ![]() $\dot {\gamma }$ and

$\dot {\gamma }$ and ![]() $\lambda$ are the shear rate and the viscoelastic relaxation time, Koch & Subramanian (Reference Koch and Subramanian2006) theoretically explained that the contribution of particles to the bulk stress is two-fold: (i) polymer stresses modify the particle stresslet; (ii) velocity and pressure disturbances in the vicinity of the particles alter the polymer stress in the fluid. Recently, Yang & Shaqfeh (Reference Yang and Shaqfeh2018a) extended this analysis to moderate and high-Weissenberg numbers by boundary-fitted numerical simulations of a single sphere. Reportedly, the regions that contribute most to particle-induced fluid stresses are close to the sphere surface where streamlines form closed trajectories. In another effort, Yang & Shaqfeh (Reference Yang and Shaqfeh2018b) investigated suspensions at finite solid volume fractions (

$\lambda$ are the shear rate and the viscoelastic relaxation time, Koch & Subramanian (Reference Koch and Subramanian2006) theoretically explained that the contribution of particles to the bulk stress is two-fold: (i) polymer stresses modify the particle stresslet; (ii) velocity and pressure disturbances in the vicinity of the particles alter the polymer stress in the fluid. Recently, Yang & Shaqfeh (Reference Yang and Shaqfeh2018a) extended this analysis to moderate and high-Weissenberg numbers by boundary-fitted numerical simulations of a single sphere. Reportedly, the regions that contribute most to particle-induced fluid stresses are close to the sphere surface where streamlines form closed trajectories. In another effort, Yang & Shaqfeh (Reference Yang and Shaqfeh2018b) investigated suspensions at finite solid volume fractions (![]() $\varphi < 10\,\%$), and concluded that particle–particle interactions have a negligible influence on the bulk rheology of the flow.

$\varphi < 10\,\%$), and concluded that particle–particle interactions have a negligible influence on the bulk rheology of the flow.

At non-dilute concentrations (![]() $10\,\% <\varphi < 40\,\%$), previous studies reported a nonlinear relation between the effective viscosity and the solid volume fraction in both Newtonian and viscoelastic fluids (Denn & Morris Reference Denn and Morris2014; Dai & Tanner Reference Dai and Tanner2017). For the latter, studies of filled molten polymers highlight a complex rheology which primarily depends on the diffusion time scale of fillers (Brownian or non-Brownian particles), but also their shape, concentration, and nature of the carrier fluid (see Rueda et al. (Reference Rueda, Auscher, Fulchiron, Perie, Martin, Sonntag and Cassagnau2017), for a review). For other non-Newtonian effects, such as variable-viscosity and yield-stress fluids, we refer the reader to the review of Tanner (Reference Tanner2019).

$10\,\% <\varphi < 40\,\%$), previous studies reported a nonlinear relation between the effective viscosity and the solid volume fraction in both Newtonian and viscoelastic fluids (Denn & Morris Reference Denn and Morris2014; Dai & Tanner Reference Dai and Tanner2017). For the latter, studies of filled molten polymers highlight a complex rheology which primarily depends on the diffusion time scale of fillers (Brownian or non-Brownian particles), but also their shape, concentration, and nature of the carrier fluid (see Rueda et al. (Reference Rueda, Auscher, Fulchiron, Perie, Martin, Sonntag and Cassagnau2017), for a review). For other non-Newtonian effects, such as variable-viscosity and yield-stress fluids, we refer the reader to the review of Tanner (Reference Tanner2019).

1.2. Inertial effects and turbulence

In the presence of fluid inertia, the effective viscosity of suspensions increases. In the laminar regime, this observation is attributed to multiple effects, including the Reynolds stresses induced by particle fluctuations (Kulkarni & Morris Reference Kulkarni and Morris2008), particle and fluid phase acceleration (Rahmani, Hammouti & Wachs Reference Rahmani, Hammouti and Wachs2018) and anisotropy in microstructure leading to higher effective solid volume fractions (Picano et al. Reference Picano, Breugem, Mitra and Brandt2013). Since viscoelasticity influences both the hydrodynamic forces experienced by particles (Becker et al. Reference Becker, McKinley, Rasmussen and Hassager1994) and the local microstructure (D'Avino & Maffettone Reference D'Avino and Maffettone2015), it is interesting to consider whether and how the increase in effective viscosity is influenced by viscoelastic effects in the carrier fluid.

Beyond a critical Reynolds number, transition to turbulence takes place and the shear stress increases dramatically – a phenomenon that is modulated by both finite-size particles (Matas, Morris & Guazzelli Reference Matas, Morris and Guazzelli2003) and viscoelasticity (Draad, Kuiken & Nieuwstadt Reference Draad, Kuiken and Nieuwstadt1998; Lee & Zaki Reference Lee and Zaki2017). Dilute particle suspensions can promote instability and sustain a turbulent state at lower Reynolds numbers than a single-phase flow (Matas et al. Reference Matas, Morris and Guazzelli2003; Loisel et al. Reference Loisel, Abbas, Masbernat and Climent2013). Beyond the transitional regime, the literature on particle-turbulence interactions in a Newtonian fluid is extensive (cf. introduction by Agarwal, Brandt & Zaki (Reference Agarwal, Brandt and Zaki2014); Esteghamatian & Zaki (Reference Esteghamatian and Zaki2019), for a review). In brief, the effect of particles on Newtonian turbulence primarily depends on the solid volume fraction and the relative size of particles with respect to the Kolmogorov scale. In a concentrated suspension of finite-size spherical particles in wall-bounded turbulence, the Reynolds shear stress is attenuated. However, due to the addition of particle stresses the overall drag is increased (Shao, Wu & Yu Reference Shao, Wu and Yu2012; Picano, Breugem & Brandt Reference Picano, Breugem and Brandt2015). Hence, the propensity of particles to increase the drag grows with the solid volume fraction. In viscoelastic single-phase flows, linear theory has been developed to explain the new phenomenology that arises in the vorticity dynamics of wall-bounded flows, e.g. re-energization of streaks, reverse-Orr amplification, and non-local amplification of vorticity away from curved surfaces (Page & Zaki Reference Page and Zaki2014, Reference Page and Zaki2015, Reference Page and Zaki2016). A rigorous mathematical framework was also developed recently to derive perturbative expansion of the conformation tensor while maintaining the physical and geometrical consistency (Hameduddin, Gayme & Zaki Reference Hameduddin, Gayme and Zaki2019). A wealth of studies have been dedicated to the fully turbulent region (see review by White & Mungal (Reference White and Mungal2008)), and the mathematical theory has shed light on the appropriate mean polymer conformation tensor and measures of the disturbances relative to that mean (Hameduddin et al. Reference Hameduddin, Meneveau, Zaki and Gayme2018; Hameduddin & Zaki Reference Hameduddin and Zaki2019).

Very limited studies have been dedicated to the combined effects of finite-size particles, viscoelasticity and turbulence. For particles smaller than the Kolmogorov scale (in one-way coupling regime), De Lillo, Boffetta & Musacchio (Reference De Lillo, Boffetta and Musacchio2012) and Nowbahar et al. (Reference Nowbahar, Sardina, Picano and Brandt2013) investigated the influence of viscoelasticity on the particle clustering. In a weakly viscoelastic duct flow, experimental findings by Zade, Lundell & Brandt (Reference Zade, Lundell and Brandt2019) reported a less effective drag reduction in the particle-laden condition compared with the single-phase counterpart. For suspensions at dilute limits (![]() $\varphi =5\,\%$), while the particles significantly contribute to the turbulence suppression, Esteghamatian & Zaki (Reference Esteghamatian and Zaki2019) showed that they can also modify the cycles of low and high turbulence intensity which Xi & Graham (Reference Xi and Graham2010) termed ‘hibernating’ and ‘active’ turbulence. Extended periods of hibernating turbulence gives rise to the particles’ migration towards the channel centre, while the infrequent bursts of active turbulence redistributes the particles across the channel. Given the dual effect of particles in attenuating the Reynolds stresses while increasing the polymer stresses, the newly established momentum balance is expected to depend on the solid volume fraction. However, similar detailed studies of particle-laden viscoelastic flows at higher particle concentrations are absent from the literature – a matter that is addressed herein.

$\varphi =5\,\%$), while the particles significantly contribute to the turbulence suppression, Esteghamatian & Zaki (Reference Esteghamatian and Zaki2019) showed that they can also modify the cycles of low and high turbulence intensity which Xi & Graham (Reference Xi and Graham2010) termed ‘hibernating’ and ‘active’ turbulence. Extended periods of hibernating turbulence gives rise to the particles’ migration towards the channel centre, while the infrequent bursts of active turbulence redistributes the particles across the channel. Given the dual effect of particles in attenuating the Reynolds stresses while increasing the polymer stresses, the newly established momentum balance is expected to depend on the solid volume fraction. However, similar detailed studies of particle-laden viscoelastic flows at higher particle concentrations are absent from the literature – a matter that is addressed herein.

The present study reports on direct numerical simulations of particle-laden viscoelastic turbulent flows at 20 % solid volume fraction and over a wide range of viscoelasticity. The computations resolve the flow at the scale of particles, and polymer forces are obtained by solving an evolution equation for the polymer conformation tensors. The flow configuration, governing equations and computational set-up are described in § 2. Drag modulations, polymer and turbulence modification, and particle dynamics are analysed in § 3. Concluding remarks are provided in § 4.

2. Flow configuration and numerical approach

The computational domain is a plane channel, where ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ correspond to the streamwise, wall-normal and spanwise directions (figure 1). The flow is maintained at a constant mass flux in the

$z$ correspond to the streamwise, wall-normal and spanwise directions (figure 1). The flow is maintained at a constant mass flux in the ![]() $x$ direction. The bulk velocity,

$x$ direction. The bulk velocity, ![]() $U_b$, and the channel half-height,

$U_b$, and the channel half-height, ![]() $h$, are chosen as characteristic scales. The associated Reynolds and Weissenberg numbers are

$h$, are chosen as characteristic scales. The associated Reynolds and Weissenberg numbers are ![]() $Re \equiv hU_b/\nu$ and

$Re \equiv hU_b/\nu$ and ![]() $Wi \equiv \lambda U_b/h$, where

$Wi \equiv \lambda U_b/h$, where ![]() $\nu$ and

$\nu$ and ![]() $\lambda$ are the fluid total kinematic viscosity and viscoelastic relaxation time. When present, particles are spherical, their density matches that of the fluid

$\lambda$ are the fluid total kinematic viscosity and viscoelastic relaxation time. When present, particles are spherical, their density matches that of the fluid ![]() $\rho$, and their diameter is denoted

$\rho$, and their diameter is denoted ![]() $d_p$. The bulk volume fraction is

$d_p$. The bulk volume fraction is ![]() $\varphi \equiv N_p \mathcal {V}_p/\mathcal {V}_t$, where

$\varphi \equiv N_p \mathcal {V}_p/\mathcal {V}_t$, where ![]() $N_p$,

$N_p$, ![]() $\mathcal {V}_p$ and

$\mathcal {V}_p$ and ![]() $\mathcal {V}_t$ are the total number of particles, the volume of a particle and the volume of the computational domain. The flow is periodic in the

$\mathcal {V}_t$ are the total number of particles, the volume of a particle and the volume of the computational domain. The flow is periodic in the ![]() $x$ and

$x$ and ![]() $z$ directions, while a no-slip boundary condition is set at the bottom and top walls

$z$ directions, while a no-slip boundary condition is set at the bottom and top walls ![]() $y=\{0,2\}$, as well as at the surfaces of particles.

$y=\{0,2\}$, as well as at the surfaces of particles.

Figure 1. Schematic of the particle-laden flow configuration. Periodic boundary conditions are imposed in the ![]() $x$ and

$x$ and ![]() $z$ directions, and no-slip conditions

$z$ directions, and no-slip conditions ![]() $\boldsymbol {u}_f = 0$ are enforced at

$\boldsymbol {u}_f = 0$ are enforced at ![]() $y=\{0,2\}$.

$y=\{0,2\}$.

The non-dimensional governing equations for the fluid velocity ![]() $\boldsymbol {u}_f$, the hydrodynamic pressure

$\boldsymbol {u}_f$, the hydrodynamic pressure ![]() $p$, and the conformation tensor

$p$, and the conformation tensor ![]() $\boldsymbol{\mathsf{c}}$ are

$\boldsymbol{\mathsf{c}}$ are

The solvent to total viscosity ratio is denoted ![]() $\beta \equiv {\mu _s}/{\mu _s+\mu _p}$, where

$\beta \equiv {\mu _s}/{\mu _s+\mu _p}$, where ![]() $\mu _s$ and

$\mu _s$ and ![]() $\mu _p$ denote the solvent and polymer contributions, and

$\mu _p$ denote the solvent and polymer contributions, and ![]() $\boldsymbol {F}$ represent a generic force field. Additionally, the viscoelastic stress tensor

$\boldsymbol {F}$ represent a generic force field. Additionally, the viscoelastic stress tensor ![]() ${\boldsymbol{\mathsf{T}}}$ is expressed in terms of the conformation tensor with a FENE-P model,

${\boldsymbol{\mathsf{T}}}$ is expressed in terms of the conformation tensor with a FENE-P model,

where ![]() $\boldsymbol{\mathsf{I}}$ and

$\boldsymbol{\mathsf{I}}$ and ![]() $L_{max}$ are the unit tensor and maximum extensibility of the polymer chains. The rigid-body motion of particles is governed by the Newton–Euler equations,

$L_{max}$ are the unit tensor and maximum extensibility of the polymer chains. The rigid-body motion of particles is governed by the Newton–Euler equations,

where ![]() $\boldsymbol {u}_p$ and

$\boldsymbol {u}_p$ and ![]() $\boldsymbol {\omega }_p$ are the particle translational and angular velocities. The hydrodynamic stress tensor comprising both Newtonian and viscoelastic contributions is denoted

$\boldsymbol {\omega }_p$ are the particle translational and angular velocities. The hydrodynamic stress tensor comprising both Newtonian and viscoelastic contributions is denoted ![]() $\boldsymbol {\sigma }_f$, while

$\boldsymbol {\sigma }_f$, while ![]() ${\mathcal {V}_p} = {{\rm \pi} d_p^3}/{6}$ and

${\mathcal {V}_p} = {{\rm \pi} d_p^3}/{6}$ and ![]() ${\mathcal {I}_p}= {{\rm \pi} d_p^5}/{60}$ are the dimensionless volume and moment of inertia of a spherical particle. The particle–particle and particle–wall repulsive collision forces,

${\mathcal {I}_p}= {{\rm \pi} d_p^5}/{60}$ are the dimensionless volume and moment of inertia of a spherical particle. The particle–particle and particle–wall repulsive collision forces, ![]() $\boldsymbol {F}_c$, are adopted from Glowinski et al. (Reference Glowinski, Pan, Hesla, Joseph and Périaux2001), and are applied in the opposite direction to the outward unit vector

$\boldsymbol {F}_c$, are adopted from Glowinski et al. (Reference Glowinski, Pan, Hesla, Joseph and Périaux2001), and are applied in the opposite direction to the outward unit vector ![]() $\boldsymbol {n}$ at the surface.

$\boldsymbol {n}$ at the surface.

For a detailed description of the herein-adopted numerical algorithm for simulating particle-laden viscoelastic turbulence, the reader is referred to Esteghamatian & Zaki (Reference Esteghamatian and Zaki2019). For completeness, only the principal features of the algorithm are summarized here: the flow equations (2.1) and (2.2) are discretized using a control volume formulation and marched in time by a fractional step method (Rosenfeld, Kwak & Vinokur Reference Rosenfeld, Kwak and Vinokur1991). The diffusion terms are treated implicitly by a Crank–Nicolson scheme, while an explicit Adams–Bashforth scheme is adopted for advection. The conformation-tensor (2.3) are solved using a third-order accurate Runge–Kutta method, an explicit Adams–Bashforth discretization for advection and stretching terms and a semi-implicit approach for the polymer stress term in order to ensure finite extensibility of the polymers (Dubief et al. Reference Dubief, Terrapon, White, Shaqfeh, Moin and Lele2005; Lee & Zaki Reference Lee and Zaki2017). The advection term in (2.3) is evaluated with a second-order accurate spatial discretization as long as the conformation tensor remains positive definite; when its smallest eigenvalue approaches zero, the discretization is replaced by the one-sided difference which maximizes the minimum eigenvalue (see appendix B in Hameduddin et al. (Reference Hameduddin, Meneveau, Zaki and Gayme2018)). A sharp-interface immersed boundary force field (Nicolaou, Jung & Zaki Reference Nicolaou, Jung and Zaki2015) is employed to enforce a no-slip boundary condition at the surface of the particles (![]() $\boldsymbol {F} = \boldsymbol {F}_{\text {IB}}$ in (2.2)), and the conformation tensor is set to unity inside the solid domain. In addition, a short-range repulsive force equivalent to the one proposed by Glowinski et al. (Reference Glowinski, Pan, Hesla, Joseph and Périaux2001) is used to avoid particle–particle and particle–wall overlap.

$\boldsymbol {F} = \boldsymbol {F}_{\text {IB}}$ in (2.2)), and the conformation tensor is set to unity inside the solid domain. In addition, a short-range repulsive force equivalent to the one proposed by Glowinski et al. (Reference Glowinski, Pan, Hesla, Joseph and Périaux2001) is used to avoid particle–particle and particle–wall overlap.

Our numerical method has been previously validated in single-phase Newtonian (Lee et al. Reference Lee, Jung, Sung and Zaki2013) and viscoelastic turbulence (Lee & Zaki Reference Lee and Zaki2017), as well as in several fluid/particle configurations in both Newtonian and viscoelastic conditions (Esteghamatian & Zaki Reference Esteghamatian and Zaki2019). In the Appendix, we present an additional validation case to demonstrate the accuracy of our particle-laden viscoelastic solver in the simulation of lateral migration of a sphere in Newtonian and viscoelastic fluids.

Direct numerical simulations were performed for a Newtonian and five viscoelastic fluids, each without and with the particle phase. The physical and computational parameters of the simulations are provided in table 1. In the Newtonian single-phase configuration, the friction Reynolds number ![]() $Re_\tau \equiv hu_\tau /\nu \approx 180$, where

$Re_\tau \equiv hu_\tau /\nu \approx 180$, where ![]() $u_\tau \equiv \sqrt {\langle \tau _{w} \rangle /\rho }$ denotes the friction velocity and

$u_\tau \equiv \sqrt {\langle \tau _{w} \rangle /\rho }$ denotes the friction velocity and ![]() $\langle \tau _{w} \rangle$ is the average wall shear stress. In particle-laden cases, the particle size in wall units

$\langle \tau _{w} \rangle$ is the average wall shear stress. In particle-laden cases, the particle size in wall units ![]() $d_p\nu /u_\tau$ ranges from 18 to 21. A designation is introduced to identify each flow configuration: the letter

$d_p\nu /u_\tau$ ranges from 18 to 21. A designation is introduced to identify each flow configuration: the letter ![]() $W$ is followed by the Weissenberg number

$W$ is followed by the Weissenberg number ![]() $Wi$ and

$Wi$ and ![]() $P$ by the bulk solid volume fraction of the system

$P$ by the bulk solid volume fraction of the system ![]() $\varphi (\%)$.

$\varphi (\%)$.

Table 1. Physical and computational parameters of the simulations. Reynolds number ![]() $Re \equiv hU_b/\nu$ and Weissenberg number

$Re \equiv hU_b/\nu$ and Weissenberg number ![]() $Wi \equiv \lambda U_b/h$ are based on the channel half-height

$Wi \equiv \lambda U_b/h$ are based on the channel half-height ![]() $h$, the bulk velocity

$h$, the bulk velocity ![]() $U_b$, total kinematic viscosity

$U_b$, total kinematic viscosity ![]() $\nu$ and viscoelastic fluid relaxation time

$\nu$ and viscoelastic fluid relaxation time ![]() $\lambda$. The domain sizes are

$\lambda$. The domain sizes are ![]() $L_{\{x,y,z\}}$ in the

$L_{\{x,y,z\}}$ in the ![]() $\{x,y,z\}$ directions, and the numbers of grid cells are

$\{x,y,z\}$ directions, and the numbers of grid cells are ![]() $N_{\{x,y,z\}}$. The noted line types and symbols are adopted in all figures unless otherwise stated.

$N_{\{x,y,z\}}$. The noted line types and symbols are adopted in all figures unless otherwise stated.

The computational grid was uniform in the streamwise and spanwise directions. In the wall-normal direction, the grid spacing was also uniform in the particle-laden simulations and a hyperbolic tangent grid stretching was adopted in the single-phase simulations. In order to properly capture the flow field in the vicinity of the particles, the grid-cell size in those simulation was set to ![]() $d_p/ {\rm \Delta} x=16$, commensurate with earlier studies (Goyal & Derksen Reference Goyal and Derksen2012; Costa et al. Reference Costa, Picano, Brandt and Breugem2018).

$d_p/ {\rm \Delta} x=16$, commensurate with earlier studies (Goyal & Derksen Reference Goyal and Derksen2012; Costa et al. Reference Costa, Picano, Brandt and Breugem2018).

Randomly seeded particles naturally trigger the breakdown to turbulence in the Newtonian cases, while the single-phase Newtonian case was initialized with a superposition of laminar Poiseuille flow and random fluctuations. The viscoelastic cases were initialized with the velocity and pressure fields adopted from their Newtonian counterparts after the breakdown to turbulence.

Beyond an initial transient, once a statistically stationary state is achieved, conditional ensemble-averaging is performed in the particle and fluid phases and is denoted ![]() $\langle o_{\{\,f, p\}}\rangle _{\{f, p\}}$. By defining a phase indicator

$\langle o_{\{\,f, p\}}\rangle _{\{f, p\}}$. By defining a phase indicator ![]() $\chi$ that is zero and one in the fluid and solid phases, the unconditional mixture average can be related to the phase-averaged quantities,

$\chi$ that is zero and one in the fluid and solid phases, the unconditional mixture average can be related to the phase-averaged quantities,

where ![]() $\phi$ denotes the solid volume fraction. For brevity, the subscripts

$\phi$ denotes the solid volume fraction. For brevity, the subscripts ![]() $\{f,p\}$ are hereafter omitted from the averaging symbol. Fluctuations in fluid and particle phases are defined relative to their respective means,

$\{f,p\}$ are hereafter omitted from the averaging symbol. Fluctuations in fluid and particle phases are defined relative to their respective means, ![]() $o'_{\{f, p\}}= o_{\{f, p\}}- \langle o_{\{f, p\}} \rangle$. Averaging the polymer conformation tensor requires special care: owing to the Riemannian structure of the manifold of positive-definite tensors, the arithmetic mean is not physically representative of the ensemble of polymer conformation tensors. Hameduddin & Zaki (Reference Hameduddin and Zaki2019) proposed alternative means, namely a geometric and a log-Euclidean mean, which enable a proper representation of stretches and volume of the conformation tensor. The log-Euclidean mean, denoted

$o'_{\{f, p\}}= o_{\{f, p\}}- \langle o_{\{f, p\}} \rangle$. Averaging the polymer conformation tensor requires special care: owing to the Riemannian structure of the manifold of positive-definite tensors, the arithmetic mean is not physically representative of the ensemble of polymer conformation tensors. Hameduddin & Zaki (Reference Hameduddin and Zaki2019) proposed alternative means, namely a geometric and a log-Euclidean mean, which enable a proper representation of stretches and volume of the conformation tensor. The log-Euclidean mean, denoted ![]() $\langle \bullet \rangle _{\log }$, is adopted in this work for conditional averaging of the conformation tensors.

$\langle \bullet \rangle _{\log }$, is adopted in this work for conditional averaging of the conformation tensors.

3. Results

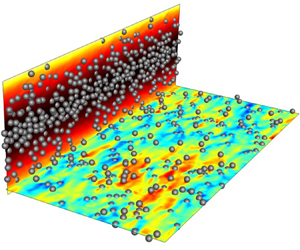

Visualizations of instantaneous fields from the Newtonian (W0P20) and viscoelastic (W25P20) particle-laden simulations are provided in figure 2, and serve to highlight the striking differences between the two conditions: in the viscoelastic case, the streamwise fluid velocity is appreciably higher in the channel centre, as shown by contours of instantaneous ![]() $u_f$ (vertical planes) and by the mean velocity profiles. Furthermore, contours of

$u_f$ (vertical planes) and by the mean velocity profiles. Furthermore, contours of ![]() $u_f \text {--} \langle u_f \rangle$ (horizontal planes) show that the turbulence motion is highly subdued by viscoelasticity. Also, the accumulation of particles in the centre of the channel in the viscoelastic condition is a signature of their migration. In the following, we extensively analyse the state of the flow, polymers and particles in order to explain the origins of these contrasting features.

$u_f \text {--} \langle u_f \rangle$ (horizontal planes) show that the turbulence motion is highly subdued by viscoelasticity. Also, the accumulation of particles in the centre of the channel in the viscoelastic condition is a signature of their migration. In the following, we extensively analyse the state of the flow, polymers and particles in order to explain the origins of these contrasting features.

Figure 2. Instantaneous particles positions and contours of (side view) ![]() $u_f$ and (top view at

$u_f$ and (top view at ![]() $y=d_p$)

$y=d_p$) ![]() $u_f\text {--}\langle u_f \rangle$ for (a) Newtonian case W0P20; (b) viscoelastic case W25P20. For clarity, only particles that are cut by the planes are displayed. Isosurfaces mark (a)

$u_f\text {--}\langle u_f \rangle$ for (a) Newtonian case W0P20; (b) viscoelastic case W25P20. For clarity, only particles that are cut by the planes are displayed. Isosurfaces mark (a) ![]() $u\text {--}\langle u_f\rangle = \pm 0.2$ and (b)

$u\text {--}\langle u_f\rangle = \pm 0.2$ and (b) ![]() $u\text {--}\langle u_f\rangle = \pm 0.08$ in a subregion above the horizontal plane. Wall-normal profiles of the mean streamwise fluid velocity are also schematically displayed.

$u\text {--}\langle u_f\rangle = \pm 0.08$ in a subregion above the horizontal plane. Wall-normal profiles of the mean streamwise fluid velocity are also schematically displayed.

3.1. Drag modulation and stress balance

The fluid viscosity, turbulence, polymers and particle phase all contribute to the total stress within the channel. In order to assess their relative contributions, the mean total stress ![]() $\tau _{tot}$ can be expressed in terms of its constituents,

$\tau _{tot}$ can be expressed in terms of its constituents,

\begin{align} &\overbrace{\dfrac{\beta}{Re} (1-\phi) \dfrac{\boldsymbol{\text{d}}{\langle u_f \rangle}}{\text{d}{y}}}^{\displaystyle\tau_{\mu}} \

\overbrace{-[(1-\phi) \langle u'_f v'_f \rangle + \phi \langle u'_p v'_p \rangle]}^{\displaystyle\tau_{Re}} \nonumber\\

&\quad + \underbrace{\dfrac{(1-\beta)}{Re}(1-\phi) \langle \boldsymbol{\mathsf{T}}_{xy} \rangle}_{\displaystyle\tau_{\beta}} +

\underbrace{\phi \langle \sigma_{p,xy} \rangle}_{\displaystyle\tau_{\phi}} =

\underbrace{\langle \tau_{w}\rangle(1-y)}_{\displaystyle\tau_{tot}}. \end{align}

\begin{align} &\overbrace{\dfrac{\beta}{Re} (1-\phi) \dfrac{\boldsymbol{\text{d}}{\langle u_f \rangle}}{\text{d}{y}}}^{\displaystyle\tau_{\mu}} \

\overbrace{-[(1-\phi) \langle u'_f v'_f \rangle + \phi \langle u'_p v'_p \rangle]}^{\displaystyle\tau_{Re}} \nonumber\\

&\quad + \underbrace{\dfrac{(1-\beta)}{Re}(1-\phi) \langle \boldsymbol{\mathsf{T}}_{xy} \rangle}_{\displaystyle\tau_{\beta}} +

\underbrace{\phi \langle \sigma_{p,xy} \rangle}_{\displaystyle\tau_{\phi}} =

\underbrace{\langle \tau_{w}\rangle(1-y)}_{\displaystyle\tau_{tot}}. \end{align}

From left to right, the components are the viscous stress ![]() $\tau _\mu$, the turbulent Reynolds stress

$\tau _\mu$, the turbulent Reynolds stress ![]() $\tau _{Re}$, the polymer stress

$\tau _{Re}$, the polymer stress ![]() $\tau _\beta$ and the particle stress

$\tau _\beta$ and the particle stress ![]() $\tau _\phi$. When integrated over

$\tau _\phi$. When integrated over ![]() $0<y<1$ and normalized by

$0<y<1$ and normalized by ![]() $0.5\langle \tau _{w} \rangle ^{{\text {W0}}}$ from the single-phase Newtonian case, the right-hand side of (3.1) reduces to

$0.5\langle \tau _{w} \rangle ^{{\text {W0}}}$ from the single-phase Newtonian case, the right-hand side of (3.1) reduces to ![]() $\langle \tau _{w} \rangle /\langle \tau _{w} \rangle ^{{\text {W0}}}$, i.e. the normalized mean wall shear stress (drag), and the left-hand side expresses the contribution of different stress constituents. Figure 3 reports the normalized total drag (height of the bars) and its constituents (layering of the bars) from the various flow conditions. While the primary focus of the present work is on dense concentration (

$\langle \tau _{w} \rangle /\langle \tau _{w} \rangle ^{{\text {W0}}}$, i.e. the normalized mean wall shear stress (drag), and the left-hand side expresses the contribution of different stress constituents. Figure 3 reports the normalized total drag (height of the bars) and its constituents (layering of the bars) from the various flow conditions. While the primary focus of the present work is on dense concentration (![]() $\varphi = 20\,\%$), for the purpose of comparison two dilute cases (

$\varphi = 20\,\%$), for the purpose of comparison two dilute cases (![]() $\varphi = 5\,\%$) from Esteghamatian & Zaki (Reference Esteghamatian and Zaki2019) are also included.

$\varphi = 5\,\%$) from Esteghamatian & Zaki (Reference Esteghamatian and Zaki2019) are also included.

Figure 3. Contributions of different stress components to the total drag, integrated between ![]() $0<y<1$ and normalized by

$0<y<1$ and normalized by ![]() $0.5\langle \tau _{w} \rangle ^{{\text {W0}}}$. Results are arranged to display the effect of (a) Weissenberg number, (b) solid volume fraction. The intensity of fluctuations of the total stress in time, measured by the standard deviation of

$0.5\langle \tau _{w} \rangle ^{{\text {W0}}}$. Results are arranged to display the effect of (a) Weissenberg number, (b) solid volume fraction. The intensity of fluctuations of the total stress in time, measured by the standard deviation of ![]() $\langle \tau _{w} \rangle _{xz}/\langle \tau _{w} \rangle ^{{\text {W0}}}$, is shown by uncertainty bars. Case designations are listed in table 1.

$\langle \tau _{w} \rangle _{xz}/\langle \tau _{w} \rangle ^{{\text {W0}}}$, is shown by uncertainty bars. Case designations are listed in table 1.

We first focus on the effect of the Weissenberg number (figure 3a). In single-phase flows, with increasing viscoelasticity, the Reynolds shear stress markedly diminishes while the polymer stress is marginally enhanced. The net effect is the well-established reduction in the total drag. At ![]() $20\,\%$ particle concentration, increasing viscoelasticity results in the reduction of the Reynolds shear stress, a mild increase in the particle stress and significant enhancement of the polymer stress.

$20\,\%$ particle concentration, increasing viscoelasticity results in the reduction of the Reynolds shear stress, a mild increase in the particle stress and significant enhancement of the polymer stress.

These combined effects give rise to a non-monotonic behaviour in the total stress: the drag is decreased with an increase in viscoelasticity up to the point where the Reynolds shear stress is nearly eradicated in case W5P20. Beyond ![]() $Wi=5$, further increasing

$Wi=5$, further increasing ![]() $Wi$ only enhances the polymer and particle stresses and, in turn, the total drag.

$Wi$ only enhances the polymer and particle stresses and, in turn, the total drag.

The non-monotonic trend is not universal for all particle concentrations. Results from the earlier study at ![]() $5\,\%$ particle concentration (Esteghamatian & Zaki Reference Esteghamatian and Zaki2019) predicted smaller particle and polymer stresses and lower drag relative to the

$5\,\%$ particle concentration (Esteghamatian & Zaki Reference Esteghamatian and Zaki2019) predicted smaller particle and polymer stresses and lower drag relative to the ![]() $20\,\%$ cases, and a consistent reduction in the total stress with increasing elasticity. The Reynolds stress,

$20\,\%$ cases, and a consistent reduction in the total stress with increasing elasticity. The Reynolds stress, ![]() $\tau _{Re}$, was also eradicated in the dilute case, but only at the highest Weissenberg number (case W25P5) – an indication that turbulence inhibition in particle-laden viscoelastic flows is weaker at dilute conditions. A comparison of the drag makeup at both concentrations suggests that increasing the Weissenberg number beyond

$\tau _{Re}$, was also eradicated in the dilute case, but only at the highest Weissenberg number (case W25P5) – an indication that turbulence inhibition in particle-laden viscoelastic flows is weaker at dilute conditions. A comparison of the drag makeup at both concentrations suggests that increasing the Weissenberg number beyond ![]() $Wi=25$ in the dilute case (

$Wi=25$ in the dilute case (![]() $\varphi =5\,\%$) would enhance the polymer stress and potentially increase the total drag, although additional simulations at the lower concentration would be required to verify this outcome. Nonetheless, the general conclusion is that increasing

$\varphi =5\,\%$) would enhance the polymer stress and potentially increase the total drag, although additional simulations at the lower concentration would be required to verify this outcome. Nonetheless, the general conclusion is that increasing ![]() $Wi$ in particle-laden flows reduces drag when the reduction in

$Wi$ in particle-laden flows reduces drag when the reduction in ![]() $\tau _{Re}$ is appreciable, and hence

$\tau _{Re}$ is appreciable, and hence ![]() $\tau _{Re}$ must be finite.

$\tau _{Re}$ must be finite.

The intensity of fluctuations of the total stress in time, measured by the standard deviation of ![]() $\langle \tau _{w} \rangle _{xz}/\langle \tau _{w} \rangle ^{{\text {W0}}}$, is shown by uncertainty bars in figure 3. Strong fluctuations in time are a signature of intermittency, or the alternation of the turbulence between a hibernating and an active state – an effect that intensifies at higher

$\langle \tau _{w} \rangle _{xz}/\langle \tau _{w} \rangle ^{{\text {W0}}}$, is shown by uncertainty bars in figure 3. Strong fluctuations in time are a signature of intermittency, or the alternation of the turbulence between a hibernating and an active state – an effect that intensifies at higher ![]() $Wi$. In cases where the turbulence is eradicated, the intermittency thus vanishes. At

$Wi$. In cases where the turbulence is eradicated, the intermittency thus vanishes. At ![]() $\varphi = 20\,\%$, the intermittency is most pronounced at

$\varphi = 20\,\%$, the intermittency is most pronounced at ![]() $Wi=3$. The results highlight that intermittency sets in and is most pronounced at lower

$Wi=3$. The results highlight that intermittency sets in and is most pronounced at lower ![]() $Wi$ for larger particle concentrations.

$Wi$ for larger particle concentrations.

Figure 3(b) draws the focus to the effect of the solid volume fraction on different components of the total stress. In both Newtonian and viscoelastic conditions, the addition of particles increases the total drag. In the Newtonian cases, underlying the increase in total drag is a non-monotonic behaviour of the Reynolds stress: as the particle concentration is increased, ![]() $\tau _{Re}$ first increases (W0P5) and then reduces (W0P20) relative to the single-phase configuration. This trend is consistent with a previous study in Newtonian flows and similar conditions by Picano et al. (Reference Picano, Breugem and Brandt2015). The increase in the total drag at higher particle concentration is more pronounced for the viscoelastic conditions due to the significant increase of the particle and polymer stresses with the solid volume fraction. Also, the non-monotonic trend in the Reynolds stress reported for Newtonian carrier fluids disappears in the viscoelastic cases: the addition of particles monotonically reduces and ultimately eliminates

$\tau _{Re}$ first increases (W0P5) and then reduces (W0P20) relative to the single-phase configuration. This trend is consistent with a previous study in Newtonian flows and similar conditions by Picano et al. (Reference Picano, Breugem and Brandt2015). The increase in the total drag at higher particle concentration is more pronounced for the viscoelastic conditions due to the significant increase of the particle and polymer stresses with the solid volume fraction. Also, the non-monotonic trend in the Reynolds stress reported for Newtonian carrier fluids disappears in the viscoelastic cases: the addition of particles monotonically reduces and ultimately eliminates ![]() $\tau _{Re}$.

$\tau _{Re}$.

The particle stress ![]() $\tau _\phi$ makes an important contribution to the total drag at

$\tau _\phi$ makes an important contribution to the total drag at ![]() $\varphi = 20\,\%$, and warrants consideration. Two relevant quantities are the solid volume fraction

$\varphi = 20\,\%$, and warrants consideration. Two relevant quantities are the solid volume fraction ![]() $\phi$ and the mean shear rate

$\phi$ and the mean shear rate ![]() $\dot {\gamma } \equiv {\boldsymbol {\text {d}}{\langle u_f \rangle }}/{\text {d}{y}}$ (figure 4a,b). For

$\dot {\gamma } \equiv {\boldsymbol {\text {d}}{\langle u_f \rangle }}/{\text {d}{y}}$ (figure 4a,b). For ![]() $Wi\ge 5$, particles migrate away from the wall in all the particle-laden cases and the solid volume fraction reaches near

$Wi\ge 5$, particles migrate away from the wall in all the particle-laden cases and the solid volume fraction reaches near ![]() $45\,\%$ at the channel centre (figure 4a) – an explanation of this migration trend is provided in § 3.4. In all cases, the

$45\,\%$ at the channel centre (figure 4a) – an explanation of this migration trend is provided in § 3.4. In all cases, the ![]() $\phi$ profile has a local maximum near

$\phi$ profile has a local maximum near ![]() $y\approx d_p$, due to the asymmetric interaction of near-wall particles that are stabilized by the wall lubrication. For

$y\approx d_p$, due to the asymmetric interaction of near-wall particles that are stabilized by the wall lubrication. For ![]() $Wi \geq 5$, a second local maximum near

$Wi \geq 5$, a second local maximum near ![]() $y\approx 2d_p$ is indicative of a propensity for the particles to form a layered structure in the absence of a vertical mixing mechanism. The mean shear rate (figure 4b) exhibits a non-monotonic behaviour with increasing viscoelasticity. At the wall, it decreases to a minimum at

$y\approx 2d_p$ is indicative of a propensity for the particles to form a layered structure in the absence of a vertical mixing mechanism. The mean shear rate (figure 4b) exhibits a non-monotonic behaviour with increasing viscoelasticity. At the wall, it decreases to a minimum at ![]() $Wi=5$ and increases beyond that value. Away from the wall,

$Wi=5$ and increases beyond that value. Away from the wall, ![]() $y \ge 0.2$, that trend is reversed and the mean shear rate is the highest for

$y \ge 0.2$, that trend is reversed and the mean shear rate is the highest for ![]() $Wi=5$ and decreases at higher

$Wi=5$ and decreases at higher ![]() $Wi$.

$Wi$.

Figure 4. Wall-normal profiles of (a) solid volume fraction; (b) mean shear rate ![]() $\dot {\gamma } \equiv {\boldsymbol {\text {d}}{\langle u_f \rangle }}/{\text {d}{y}}$ in particle-laden cases; (c) particle stress

$\dot {\gamma } \equiv {\boldsymbol {\text {d}}{\langle u_f \rangle }}/{\text {d}{y}}$ in particle-laden cases; (c) particle stress ![]() $\tau _\phi$; and polymer stress

$\tau _\phi$; and polymer stress ![]() $\tau _\beta$ in (d) single-phase and (e) particle-laden conditions. Line types are listed in table 1.

$\tau _\beta$ in (d) single-phase and (e) particle-laden conditions. Line types are listed in table 1.

The profile of ![]() $\tau _\phi$ (figure 4c) is influenced by viscoelasticity in three ways. (i) The polymers directly increase the stresslet contribution to the particle stress by altering the surface traction (Einarsson et al. Reference Einarsson, Yang and Shaqfeh2018). (ii) The mean shear rates are higher in the region

$\tau _\phi$ (figure 4c) is influenced by viscoelasticity in three ways. (i) The polymers directly increase the stresslet contribution to the particle stress by altering the surface traction (Einarsson et al. Reference Einarsson, Yang and Shaqfeh2018). (ii) The mean shear rates are higher in the region ![]() $y\ge 0.2$. Since particles resist deformation under shear, the stresslet contribution to the particle stress is enhanced in that region. (iii) Due to the migration of particles towards the channel centre, the particle concentration and in turn the particle stress are larger at

$y\ge 0.2$. Since particles resist deformation under shear, the stresslet contribution to the particle stress is enhanced in that region. (iii) Due to the migration of particles towards the channel centre, the particle concentration and in turn the particle stress are larger at ![]() $y\geq 0.65$. A combination of all these effects leads to the larger particle stresses in the viscoelastic cases away from the wall. Near the wall, local peaks in

$y\geq 0.65$. A combination of all these effects leads to the larger particle stresses in the viscoelastic cases away from the wall. Near the wall, local peaks in ![]() $\tau _\phi$ coincide with the local maxima in the solid volume fraction. In addition, conditions with the stronger near-wall shear rates (

$\tau _\phi$ coincide with the local maxima in the solid volume fraction. In addition, conditions with the stronger near-wall shear rates (![]() $Wi<5$ cases) have larger peaks in the particle stress profiles.

$Wi<5$ cases) have larger peaks in the particle stress profiles.

The other important contribution to drag in the particle-laden viscoelastic cases is the polymer stress, especially when compared with the single-phase cases (figures 4d and 4e). The latter sustain small levels of ![]() $\tau _\beta$, with very weak variation in the wall-normal direction. In contrast, in presence of the particle phase, the polymer stress increases appreciably, is highest in the near-wall region where particle layering is observed, and decays to zero towards the channel centre. Evidently, the particles contribute to the deformation of polymers and, in turn, increasing the polymer stress. It is unexpected, however, that the polymer stress vanishes in the region where the particles are most accumulated (

$\tau _\beta$, with very weak variation in the wall-normal direction. In contrast, in presence of the particle phase, the polymer stress increases appreciably, is highest in the near-wall region where particle layering is observed, and decays to zero towards the channel centre. Evidently, the particles contribute to the deformation of polymers and, in turn, increasing the polymer stress. It is unexpected, however, that the polymer stress vanishes in the region where the particles are most accumulated (![]() $0.8 < y < 1.0$). In this region, the mean flow is akin to a plug profile with negligible shear rate due to the high concentration of particles (see figure 4b for the shear rate). This observation underscores that the presence of particles and of a finite shear rate are two essential components for effective polymer deformation. The differences between the polymer conformation in the near-wall region and the channel centre are further examined in § 3.3.

$0.8 < y < 1.0$). In this region, the mean flow is akin to a plug profile with negligible shear rate due to the high concentration of particles (see figure 4b for the shear rate). This observation underscores that the presence of particles and of a finite shear rate are two essential components for effective polymer deformation. The differences between the polymer conformation in the near-wall region and the channel centre are further examined in § 3.3.

3.2. Flow structures and statistics

In this section, we examine the effect of particles on turbulent structures, mean flow statistics and Reynolds stresses. Figure 5 compares the instantaneous contours of ![]() $u_f - \langle u_f \rangle$, and the correlation of

$u_f - \langle u_f \rangle$, and the correlation of ![]() $u'_f$ in the spanwise direction,

$u'_f$ in the spanwise direction,

\begin{equation} R_{u'_fu'_f}(y, {\rm \Delta} z) = \dfrac{\langle u'_f(x,y,z,t)u'_f(x,y,z+{\rm \Delta} z,t)\rangle}{ \langle u'_f(x,y,z,t)u'_f(x,y,z,t)\rangle}. \end{equation}

\begin{equation} R_{u'_fu'_f}(y, {\rm \Delta} z) = \dfrac{\langle u'_f(x,y,z,t)u'_f(x,y,z+{\rm \Delta} z,t)\rangle}{ \langle u'_f(x,y,z,t)u'_f(x,y,z,t)\rangle}. \end{equation}

In single phase, relative to the Newtonian streaks, viscoelasticity inflates these structures (see figures 5a and 5b). Addition of particles to a Newtonian flow also increases the width of the streamwise structures (figure 5c). The particle-laden viscoelastic case is markedly different: the classical turbulent streaks are nearly absent at ![]() $Wi =25$ (figure 5d), and the spanwise correlation length reduces to the order of a particle diameter.

$Wi =25$ (figure 5d), and the spanwise correlation length reduces to the order of a particle diameter.

Figure 5. Instantaneous contours and isosurfaces of ![]() $u_f\text {--}\langle u_f\rangle$ and particle positions in

$u_f\text {--}\langle u_f\rangle$ and particle positions in ![]() $xz$ plane (top); and two-point correlation of

$xz$ plane (top); and two-point correlation of ![]() $u'_f$ as a function of spanwise spacing (bottom). (a) Single-phase Newtonian (W0); (b) single-phase viscoelastic (W25); (c) particle-laden Newtonian (W0P20); (d) particle-laden viscoelastic (W25P20). The wall-normal location of the contours and correlations is

$u'_f$ as a function of spanwise spacing (bottom). (a) Single-phase Newtonian (W0); (b) single-phase viscoelastic (W25); (c) particle-laden Newtonian (W0P20); (d) particle-laden viscoelastic (W25P20). The wall-normal location of the contours and correlations is ![]() $y u_\tau /\nu \approx 20$.

$y u_\tau /\nu \approx 20$.

The mean fluid-velocity profiles and their deviation from Poiseuille flow are reported in figure 6. In single-phase flows, the mean profiles monotonically approach the Poiseuille condition with increasing elasticity. In particle-laden flows, a non-monotonic behaviour that is consistent with the change in drag is observed: the flow approaches the laminar condition with increasing elasticity up to ![]() $Wi=5$ at which the turbulence is completely eradicated. Beyond that level, the polymer stress dominates the momentum transfer in the wall-normal direction. As a result, the mean velocity profiles are flattened with further increase in elasticity.

$Wi=5$ at which the turbulence is completely eradicated. Beyond that level, the polymer stress dominates the momentum transfer in the wall-normal direction. As a result, the mean velocity profiles are flattened with further increase in elasticity.

Figure 6. Mean streamwise fluid velocity (top); and its deviation from the laminar profile ![]() $u_{{L}}$ (bottom) in (a) single-phase and (b) 20 % particle concentration. Line types are listed in table 1.

$u_{{L}}$ (bottom) in (a) single-phase and (b) 20 % particle concentration. Line types are listed in table 1.

The normal components of the Reynolds stress tensor are plotted in figure 7. In single-phase flows, the peak of ![]() $\langle u'_f u'_f \rangle$ shifts away from the wall with increasing elasticity due to the swelling of the streamwise streaks, and the stresses in the cross-flow plane are progressively attenuated at higher

$\langle u'_f u'_f \rangle$ shifts away from the wall with increasing elasticity due to the swelling of the streamwise streaks, and the stresses in the cross-flow plane are progressively attenuated at higher ![]() $Wi$. In particle-laden conditions, the co-presence of the solid phase and elasticity effectively suppresses the turbulent fluctuations. At

$Wi$. In particle-laden conditions, the co-presence of the solid phase and elasticity effectively suppresses the turbulent fluctuations. At ![]() $Wi\ge 5$, fluctuations are significantly suppressed in all three directions and become independent of elasticity. This observation reinforces our previous interpretation of flow perturbations (figure 5): they are not due to conventional turbulent eddies, but rather fluctuations due to the particles in shear.

$Wi\ge 5$, fluctuations are significantly suppressed in all three directions and become independent of elasticity. This observation reinforces our previous interpretation of flow perturbations (figure 5): they are not due to conventional turbulent eddies, but rather fluctuations due to the particles in shear.

Figure 7. Wall-normal profiles of (a,d) streamwise, (b,e) wall-normal and (c,f) spanwise fluid velocity fluctuations. Line types are listed in table 1.

Quadrant analysis of the Reynolds shear stress is reported in figure 8. The second and fourth quadrants (![]() $\langle u'_f v'_f \rangle _\text {Q2}$ and

$\langle u'_f v'_f \rangle _\text {Q2}$ and ![]() $\langle u'_f v'_f \rangle _\text {Q4}$) are associated with ejections and sweeps that are responsible for the turbulence production, while

$\langle u'_f v'_f \rangle _\text {Q4}$) are associated with ejections and sweeps that are responsible for the turbulence production, while ![]() $\langle u'_f v'_f \rangle _\text {Q1}$ and

$\langle u'_f v'_f \rangle _\text {Q1}$ and ![]() $\langle u'_f v'_f \rangle _\text {Q3}$ correspond to interaction events that counter the wall-normal momentum flux (Wallace, Eckelmann & Brodkey Reference Wallace, Eckelmann and Brodkey1972). In single-phase flows, elasticity reduces the magnitude of

$\langle u'_f v'_f \rangle _\text {Q3}$ correspond to interaction events that counter the wall-normal momentum flux (Wallace, Eckelmann & Brodkey Reference Wallace, Eckelmann and Brodkey1972). In single-phase flows, elasticity reduces the magnitude of ![]() $u_f'v_f'$ in all quadrants, while the largest drops are associated with

$u_f'v_f'$ in all quadrants, while the largest drops are associated with ![]() $\langle u'_f v'_f \rangle _\text {Q2}$ and

$\langle u'_f v'_f \rangle _\text {Q2}$ and ![]() $\langle u'_f v'_f \rangle _\text {Q4}$. As a result, the net effect is a reduction in the turbulent shear stress and in turn the wall-normal momentum transfer.

$\langle u'_f v'_f \rangle _\text {Q4}$. As a result, the net effect is a reduction in the turbulent shear stress and in turn the wall-normal momentum transfer.

Figure 8. Quadrant analysis of the Reynolds shear stress, ![]() $\langle u'_f v'_f \rangle$, in (a) single-phase and (b) particle-laden conditions. Line types are listed in table 1.

$\langle u'_f v'_f \rangle$, in (a) single-phase and (b) particle-laden conditions. Line types are listed in table 1.

The addition of particles to the Newtonian flow increases the contributions in ![]() $\langle u'_f v'_f \rangle _\text {Q1}$,

$\langle u'_f v'_f \rangle _\text {Q1}$, ![]() $\langle u'_f v'_f \rangle _\text {Q3}$ and

$\langle u'_f v'_f \rangle _\text {Q3}$ and ![]() $\langle u'_f v'_f \rangle _\text {Q4}$, while weakening

$\langle u'_f v'_f \rangle _\text {Q4}$, while weakening ![]() $\langle u'_f v'_f \rangle _\text {Q2}$ ejection events. These modifications are marginal, and their net effect is an

$\langle u'_f v'_f \rangle _\text {Q2}$ ejection events. These modifications are marginal, and their net effect is an ![]() $11\,\%$ reduction in the turbulent shear stress relative to the single-phase condition. At

$11\,\%$ reduction in the turbulent shear stress relative to the single-phase condition. At ![]() $Wi=\{1,3\}$ the turbulence is still active, and the addition of particles results in

$Wi=\{1,3\}$ the turbulence is still active, and the addition of particles results in ![]() $\{15,31\}\%$ decrease in the turbulent shear stress mostly due to weakened

$\{15,31\}\%$ decrease in the turbulent shear stress mostly due to weakened ![]() $\langle u'_f v'_f \rangle _\text {Q2}$ ejection events. Beyond

$\langle u'_f v'_f \rangle _\text {Q2}$ ejection events. Beyond ![]() $Wi = 5$, a steep reduction in the contributions to

$Wi = 5$, a steep reduction in the contributions to ![]() $\langle u'_fv'_f\rangle$ is observed in all four quadrants. The nearly symmetric contributions of

$\langle u'_fv'_f\rangle$ is observed in all four quadrants. The nearly symmetric contributions of ![]() $\langle u'_f v'_f \rangle _\text {Q1}$ to

$\langle u'_f v'_f \rangle _\text {Q1}$ to ![]() $\langle u'_f v'_f \rangle _\text {Q4}$ highlights that the turbulence production is completely disrupted. Also, the remarkable drop in the peak values underlines the reduction in correlated motions in the

$\langle u'_f v'_f \rangle _\text {Q4}$ highlights that the turbulence production is completely disrupted. Also, the remarkable drop in the peak values underlines the reduction in correlated motions in the ![]() $x$ and

$x$ and ![]() $y$ directions.

$y$ directions.

3.3. Polymer conformation

Velocity gradients in the fluid phase, whether induced by the mean shear, turbulent fluctuations or particles, modify the polymer conformation away from equilibrium. As explained in detail by Hameduddin et al. (Reference Hameduddin, Meneveau, Zaki and Gayme2018), these modifications cannot be accurately interpreted with reference to isolated components of ![]() $\boldsymbol{\mathsf{c}}$. Instead, those authors introduced three rigorous measures to characterize the conformation tensor and its perturbations: (i) the logarithmic volume ratio,

$\boldsymbol{\mathsf{c}}$. Instead, those authors introduced three rigorous measures to characterize the conformation tensor and its perturbations: (i) the logarithmic volume ratio, ![]() $\log (\det (\boldsymbol{\mathsf{c}})/\det (\bar {\boldsymbol{\mathsf{c}}}))$, which compares the volume of the instantaneous polymer conformation

$\log (\det (\boldsymbol{\mathsf{c}})/\det (\bar {\boldsymbol{\mathsf{c}}}))$, which compares the volume of the instantaneous polymer conformation ![]() $\boldsymbol{\mathsf{c}}$ relative to a reference conformation tensor

$\boldsymbol{\mathsf{c}}$ relative to a reference conformation tensor ![]() $\bar {\boldsymbol{\mathsf{c}}}$; (ii) the squared geodesic distance between

$\bar {\boldsymbol{\mathsf{c}}}$; (ii) the squared geodesic distance between ![]() $\boldsymbol{\mathsf{c}}$ and

$\boldsymbol{\mathsf{c}}$ and ![]() $\bar {\boldsymbol{\mathsf{c}}}$ on the manifold of positive-definite matrices; (iii) the anisotropy which is a function of (i) and (ii), and therefore is not considered in the present study. The squared geodesic distance between a pair of positive-definite matrices

$\bar {\boldsymbol{\mathsf{c}}}$ on the manifold of positive-definite matrices; (iii) the anisotropy which is a function of (i) and (ii), and therefore is not considered in the present study. The squared geodesic distance between a pair of positive-definite matrices ![]() ${\boldsymbol{\mathsf{A}}}$ and

${\boldsymbol{\mathsf{A}}}$ and ![]() ${\boldsymbol{\mathsf{B}}}$ is defined by

${\boldsymbol{\mathsf{B}}}$ is defined by

Wall-normal profiles of the first two scalar measures are reported in figure 9, where the reference tensor was selected to be ![]() $\bar {\boldsymbol{\mathsf{c}}} = \boldsymbol{\mathsf{I}}$ in order to highlight the departure of the polymer from the isotropic equilibrium state. This choice of the reference state also affords a fair comparison across the different flow configurations. In both the single-phase and particle-laden cases,

$\bar {\boldsymbol{\mathsf{c}}} = \boldsymbol{\mathsf{I}}$ in order to highlight the departure of the polymer from the isotropic equilibrium state. This choice of the reference state also affords a fair comparison across the different flow configurations. In both the single-phase and particle-laden cases, ![]() $\langle \log (\det (\boldsymbol{\mathsf{c}}))\rangle$ and

$\langle \log (\det (\boldsymbol{\mathsf{c}}))\rangle$ and ![]() $\langle \textrm {d}^2(\boldsymbol{\mathsf{I}},\boldsymbol{\mathsf{c}}) \rangle$ increase with

$\langle \textrm {d}^2(\boldsymbol{\mathsf{I}},\boldsymbol{\mathsf{c}}) \rangle$ increase with ![]() $Wi$, with marginal difference between

$Wi$, with marginal difference between ![]() $Wi = 15$ and

$Wi = 15$ and ![]() $Wi=25$. In single-phase flows, and at the lowest

$Wi=25$. In single-phase flows, and at the lowest ![]() $Wi$, the profiles of both measures decay in the outer flow due to the fast polymer relaxation away from the peak turbulence production. At the higher

$Wi$, the profiles of both measures decay in the outer flow due to the fast polymer relaxation away from the peak turbulence production. At the higher ![]() $Wi$ cases, the profiles only have weak variations in the wall-normal direction. Due to the long polymers’ relaxation times in these cases, the perturbations in polymer conformations are effectively transported by turbulent motion across the channel, explaining the almost uniform profile of both measures in the bulk of the channel at

$Wi$ cases, the profiles only have weak variations in the wall-normal direction. Due to the long polymers’ relaxation times in these cases, the perturbations in polymer conformations are effectively transported by turbulent motion across the channel, explaining the almost uniform profile of both measures in the bulk of the channel at ![]() $Wi=\{15,25\}$. In the particle-laden cases with

$Wi=\{15,25\}$. In the particle-laden cases with ![]() $Wi \ge 5$, the wall-normal mixing is inhibited due to the suppression of turbulence (cf. figure 8b), yet both measures still exhibit small variations in most of the channel, except near the centre. The controlling factors in polymer perturbations in particle-laden cases with

$Wi \ge 5$, the wall-normal mixing is inhibited due to the suppression of turbulence (cf. figure 8b), yet both measures still exhibit small variations in most of the channel, except near the centre. The controlling factors in polymer perturbations in particle-laden cases with ![]() $Wi \ge 5$ are the mean shear rate and the particle concentration. From the wall to the centre, the polymer perturbation is enhanced with an increase in the number of particles, yet hindered by a decrease in the mean shear rate. These competing effects explain the weak variations in most of the channel. Nevertheless, near the channel centre where the mean shear decays to zero and the particles population is the highest, the significant drop in both measures of polymer deformation is a signature of a different particle–polymer interaction mechanism, which is further detailed in the following.

$Wi \ge 5$ are the mean shear rate and the particle concentration. From the wall to the centre, the polymer perturbation is enhanced with an increase in the number of particles, yet hindered by a decrease in the mean shear rate. These competing effects explain the weak variations in most of the channel. Nevertheless, near the channel centre where the mean shear decays to zero and the particles population is the highest, the significant drop in both measures of polymer deformation is a signature of a different particle–polymer interaction mechanism, which is further detailed in the following.

Profiles of ![]() $\langle \textrm {d}^2(\langle \boldsymbol{\mathsf{c}} \rangle _{\log },\boldsymbol{\mathsf{c}}) \rangle$ are reported for the single-phase and particle-laden conditions in figure 10. This quantity is the average of the squared geodesic distance between the instantaneous and the log-Euclidean mean conformation, and is therefore a measure of the intensity of the perturbation from that mean at different

$\langle \textrm {d}^2(\langle \boldsymbol{\mathsf{c}} \rangle _{\log },\boldsymbol{\mathsf{c}}) \rangle$ are reported for the single-phase and particle-laden conditions in figure 10. This quantity is the average of the squared geodesic distance between the instantaneous and the log-Euclidean mean conformation, and is therefore a measure of the intensity of the perturbation from that mean at different ![]() $y$ locations. Note that since volumetric compressions and expansions of polymers with respect to

$y$ locations. Note that since volumetric compressions and expansions of polymers with respect to ![]() $\langle \boldsymbol{\mathsf{c}} \rangle _{\log }$ are symmetric, the average value of

$\langle \boldsymbol{\mathsf{c}} \rangle _{\log }$ are symmetric, the average value of ![]() $\log (\det (\boldsymbol{\mathsf{c}})/\det (\langle \boldsymbol{\mathsf{c}} \rangle _{\log }))$ is zero and is therefore not reported. In the single-phase flows, higher elasticity is associated with larger departures of the conformation from its mean value, and the profiles of

$\log (\det (\boldsymbol{\mathsf{c}})/\det (\langle \boldsymbol{\mathsf{c}} \rangle _{\log }))$ is zero and is therefore not reported. In the single-phase flows, higher elasticity is associated with larger departures of the conformation from its mean value, and the profiles of ![]() $\langle \textrm {d}^2(\langle \boldsymbol{\mathsf{c}} \rangle _{\log },\boldsymbol{\mathsf{c}}) \rangle$ become nearly flat for

$\langle \textrm {d}^2(\langle \boldsymbol{\mathsf{c}} \rangle _{\log },\boldsymbol{\mathsf{c}}) \rangle$ become nearly flat for ![]() $Wi \geq 5$. The recorded values are, as can be anticipated, smaller than

$Wi \geq 5$. The recorded values are, as can be anticipated, smaller than ![]() $\langle \textrm {d}^2(\boldsymbol{\mathsf{I}}, \boldsymbol{\mathsf{c}}) \rangle$. Another notable difference is the appreciable near-wall drop in figure 10(a) relative to figure 9(c): although the polymers are highly deformed in the near-wall region, the fluctuations away from their log-Euclidean mean are relatively small. In the particle-laden cases, local maxima near the wall coincide with the peaks of the solid volume fraction profiles (cf. figure 4a). In the outer bulk flow, where the particle population is larger, the perturbations relative to the mean are enhanced at larger

$\langle \textrm {d}^2(\boldsymbol{\mathsf{I}}, \boldsymbol{\mathsf{c}}) \rangle$. Another notable difference is the appreciable near-wall drop in figure 10(a) relative to figure 9(c): although the polymers are highly deformed in the near-wall region, the fluctuations away from their log-Euclidean mean are relatively small. In the particle-laden cases, local maxima near the wall coincide with the peaks of the solid volume fraction profiles (cf. figure 4a). In the outer bulk flow, where the particle population is larger, the perturbations relative to the mean are enhanced at larger ![]() $Wi$. Nevertheless, in all cases the fluctuations decay significantly beyond

$Wi$. Nevertheless, in all cases the fluctuations decay significantly beyond ![]() $y \approx 0.8$, confirming the trends in the profiles of

$y \approx 0.8$, confirming the trends in the profiles of ![]() $\langle \log (\det (\boldsymbol{\mathsf{c}}))\rangle$ and

$\langle \log (\det (\boldsymbol{\mathsf{c}}))\rangle$ and ![]() $\langle \textrm {d}^2(\boldsymbol{\mathsf{c}}, \boldsymbol{\mathsf{I}}) \rangle$ in figures 9(b) and 9(d).

$\langle \textrm {d}^2(\boldsymbol{\mathsf{c}}, \boldsymbol{\mathsf{I}}) \rangle$ in figures 9(b) and 9(d).

Figure 10. Wall-normal profiles of the mean squared geodesic distance between instantaneous and the log-Euclidean mean conformation tensors in (a) single-phase and (b) particle-laden conditions. Line types are listed table 1.

We now direct the focus to select ![]() $y$ locations where we provide a further detailed account of the polymer deformation when

$y$ locations where we provide a further detailed account of the polymer deformation when ![]() $Wi=25$; the results for

$Wi=25$; the results for ![]() $Wi=15$ are qualitatively similar. Figure 11 shows the joint probability density function (JPDF) of

$Wi=15$ are qualitatively similar. Figure 11 shows the joint probability density function (JPDF) of ![]() $\langle \textrm {d}^2(\boldsymbol{\mathsf{I}}, \boldsymbol{\mathsf{c}}) \rangle$ and

$\langle \textrm {d}^2(\boldsymbol{\mathsf{I}}, \boldsymbol{\mathsf{c}}) \rangle$ and ![]() $\log (\det (\boldsymbol{\mathsf{c}}))$. At

$\log (\det (\boldsymbol{\mathsf{c}}))$. At ![]() $y=0.15$, polymers depart appreciably from the isotropic state and, in the particle-laden condition, are more deformed and expanded compared with the single-phase counterpart (figure 11a). The figure also shows instantaneous realizations of the polymer conformation, visualized using ellipsoids whose axes are the eigenvectors of the tensor each scaled by the corresponding eigenvalues; the ellipsoid are also coloured by the logarithm of the volume of the tensor. These visualizations suggest dissimilar mechanisms for polymers’ deformation in the single-phase and particle-laden cases. In the former, polymers are most perturbed in the vicinity of the coherent turbulent structures, visualized by contours of

$y=0.15$, polymers depart appreciably from the isotropic state and, in the particle-laden condition, are more deformed and expanded compared with the single-phase counterpart (figure 11a). The figure also shows instantaneous realizations of the polymer conformation, visualized using ellipsoids whose axes are the eigenvectors of the tensor each scaled by the corresponding eigenvalues; the ellipsoid are also coloured by the logarithm of the volume of the tensor. These visualizations suggest dissimilar mechanisms for polymers’ deformation in the single-phase and particle-laden cases. In the former, polymers are most perturbed in the vicinity of the coherent turbulent structures, visualized by contours of ![]() $u_f\text {--}\langle u_f \rangle$. On the other hand, in the particle-laden condition, large polymer deformation are observed in the vicinity of particles. The JPDF of

$u_f\text {--}\langle u_f \rangle$. On the other hand, in the particle-laden condition, large polymer deformation are observed in the vicinity of particles. The JPDF of ![]() $\langle \textrm {d}^2(\boldsymbol{\mathsf{I}}, \boldsymbol{\mathsf{c}}) \rangle$ and

$\langle \textrm {d}^2(\boldsymbol{\mathsf{I}}, \boldsymbol{\mathsf{c}}) \rangle$ and ![]() $\log (\det (\boldsymbol{\mathsf{c}}))$ at the channel centre (figure 11b) shows appreciable departure of the polymer from equilibrium in the single-phase condition. In contrast, in the particle-laden case the polymer conformation is most akin to the isotropic equilibrium state.

$\log (\det (\boldsymbol{\mathsf{c}}))$ at the channel centre (figure 11b) shows appreciable departure of the polymer from equilibrium in the single-phase condition. In contrast, in the particle-laden case the polymer conformation is most akin to the isotropic equilibrium state.

Figure 11. The JPDF of squared geodesic distance ![]() $\textrm {d}^2(\boldsymbol{\mathsf{I}},\boldsymbol{\mathsf{c}})$ and the logarithmic volume

$\textrm {d}^2(\boldsymbol{\mathsf{I}},\boldsymbol{\mathsf{c}})$ and the logarithmic volume ![]() $\log (\det (\boldsymbol{\mathsf{c}}))$ at (a)

$\log (\det (\boldsymbol{\mathsf{c}}))$ at (a) ![]() $y=0.15$ and (b)

$y=0.15$ and (b) ![]() $y = 1$. Flood (particle-laden) and line (single-phase) contours are plotted in the same range, and refer to the cases with the

$y = 1$. Flood (particle-laden) and line (single-phase) contours are plotted in the same range, and refer to the cases with the ![]() $Wi=25$ condition. Flow visualizations show snapshots of

$Wi=25$ condition. Flow visualizations show snapshots of ![]() $u_f\text {--}\langle u_f \rangle$ contours in the single-phase condition and position of particles that are cut by the

$u_f\text {--}\langle u_f \rangle$ contours in the single-phase condition and position of particles that are cut by the ![]() $x$–

$x$–![]() $z$ plane in the particle-laden case. The ellipsoids represent instantaneous realizations of the polymer conformation, are coloured by the logarithmic volume of

$z$ plane in the particle-laden case. The ellipsoids represent instantaneous realizations of the polymer conformation, are coloured by the logarithmic volume of ![]() $\boldsymbol{\mathsf{c}}$, and their axes are the eigenvectors of

$\boldsymbol{\mathsf{c}}$, and their axes are the eigenvectors of ![]() $\boldsymbol{\mathsf{c}}$ scaled by the corresponding eigenvalues.

$\boldsymbol{\mathsf{c}}$ scaled by the corresponding eigenvalues.

The instantaneous visualizations at ![]() $y=1$ show that the polymer conformation is relatively small in volume in the two-phase case, in the confined regions between the crowd of particles. Scattered instances of deformed polymer conformation are still observable, although their presence is rare and their magnitude is small (note that the colourbars for

$y=1$ show that the polymer conformation is relatively small in volume in the two-phase case, in the confined regions between the crowd of particles. Scattered instances of deformed polymer conformation are still observable, although their presence is rare and their magnitude is small (note that the colourbars for ![]() $\log (\det (\boldsymbol{\mathsf{c}}))$ in the particle-laden condition have different ranges in figures 11a and 11b).

$\log (\det (\boldsymbol{\mathsf{c}}))$ in the particle-laden condition have different ranges in figures 11a and 11b).

So far, we have shown that the particles appreciably alter the polymer deformation and, in turn, the associated stresses. We will now examine how these deformations take place at the particle scale. To this end, we first describe the particles’ microstructure by evaluating the particle-pair distribution function, ![]() $q(r,\psi ,\theta )$, which depends on the pair separation

$q(r,\psi ,\theta )$, which depends on the pair separation ![]() $r$, the polar angle

$r$, the polar angle ![]() $\psi$ relative to the positive

$\psi$ relative to the positive ![]() $z$ axis, and the azimuthal angle

$z$ axis, and the azimuthal angle ![]() $\theta$ measured anticlockwise from the positive

$\theta$ measured anticlockwise from the positive ![]() $x$ axis,

$x$ axis,

\begin{gather}\text{d}N(r,\psi,\theta) = \sum_{m=1}^{N_p} \delta(r-|{\boldsymbol{r}}_{m}|)\delta(\psi - \psi_{m})\delta(\theta - \theta_{m}), \end{gather}

\begin{gather}\text{d}N(r,\psi,\theta) = \sum_{m=1}^{N_p} \delta(r-|{\boldsymbol{r}}_{m}|)\delta(\psi - \psi_{m})\delta(\theta - \theta_{m}), \end{gather}

The number of neighbouring particles within each bin is denoted ![]() $\text {d}N$, and

$\text {d}N$, and ![]() ${\boldsymbol {P}}$ refers to the particles’ position vector. Similar to our previous study (Esteghamatian & Zaki Reference Esteghamatian and Zaki2019), the particle-pair distribution function

${\boldsymbol {P}}$ refers to the particles’ position vector. Similar to our previous study (Esteghamatian & Zaki Reference Esteghamatian and Zaki2019), the particle-pair distribution function ![]() $q$ is normalized by

$q$ is normalized by ![]() $\textrm {d}N^R$ which corresponds to a random distribution of particles with a no-overlap condition and the case-specific wall-normal profile of the mean solid fraction, in order to eliminate bias in the interpretation of the results.

$\textrm {d}N^R$ which corresponds to a random distribution of particles with a no-overlap condition and the case-specific wall-normal profile of the mean solid fraction, in order to eliminate bias in the interpretation of the results.

Results for reference particles located at ![]() $y=0.2$ are shown in figure 12(a). Contours of

$y=0.2$ are shown in figure 12(a). Contours of ![]() $q(r = 1.05d_p)$ are projected onto the particle surface. In terms of the particle-attached coordinates,

$q(r = 1.05d_p)$ are projected onto the particle surface. In terms of the particle-attached coordinates, ![]() $\tilde {{\boldsymbol {x}}}=\boldsymbol {x} - {\boldsymbol {P}}_{ref}$, the pairwise distribution function shows accumulations of neighbouring particles in the regions

$\tilde {{\boldsymbol {x}}}=\boldsymbol {x} - {\boldsymbol {P}}_{ref}$, the pairwise distribution function shows accumulations of neighbouring particles in the regions ![]() $\tilde {x}\tilde {y}<0$ and depletion

$\tilde {x}\tilde {y}<0$ and depletion ![]() $\tilde {x}\tilde {y}>0$. This microstructure is generally observed when finite-size particles are suspended in shear flows: particles at

$\tilde {x}\tilde {y}>0$. This microstructure is generally observed when finite-size particles are suspended in shear flows: particles at ![]() $\tilde {y}>0$ advect faster than the reference one and, as a result, are more likely to accumulate behind it. A similar explanation describes the asymmetry of

$\tilde {y}>0$ advect faster than the reference one and, as a result, are more likely to accumulate behind it. A similar explanation describes the asymmetry of ![]() $q$ with respect to the

$q$ with respect to the ![]() $\tilde {y}$ axis at

$\tilde {y}$ axis at ![]() $\tilde {y}<0$ locations, where the neighbouring particles advect more slowly than the reference one.

$\tilde {y}<0$ locations, where the neighbouring particles advect more slowly than the reference one.

Figure 12. Particle-pair distribution and polymer conformation for case W25P20. (a) Reference particle located at ![]() $y=0.2$ coloured by

$y=0.2$ coloured by ![]() $q(r = 1.05d_p)$. Ellipsoids represent the particle-conditioned log-Euclidean mean conformation

$q(r = 1.05d_p)$. Ellipsoids represent the particle-conditioned log-Euclidean mean conformation ![]() $\langle \boldsymbol{\mathsf{c}} \rangle _{\log }$ coloured by their logarithmic volume and plotted in the particle coordinates (