Introduction

Archaeological destruction events are recognised globally and are characterised by the richness of in situ remains; they provide excellent opportunities to study social and historical processes with high resolution (Torrence & Grattan Reference Torrence, Grattan, Torrence and Grattan2002). The combinations of circumstances that lead to destruction, be they natural or anthropogenic, result in a variety of material manifestations (Driessen Reference Driessen2013). In the Near East, the phenomenon of destruction by fire is recognised in many Bronze and Iron Age sites with varying magnitudes across time and space (Finkelstein Reference Finkelstein and Schloen2009). Near Eastern destruction layers are characterised by floors covered with large amounts of restorable pottery, abundant ash, charcoal, and faunal, botanical and metal remains. In many cases, these floors and remains are sealed by thick piles of burnt mud-bricks.

Chaff-tempered, sun-dried mud-bricks are prevalent in archaeological sites in the Near East, from Neolithic to modern times. Recent studies have highlighted their utility as ‘recorders’ of human decision-making through the choice of raw material, the organisation of labour, symbolic communication and settlement abandonment (Nodarou et al. Reference Nodarou, Frederick and Hein2008; Friesem et al. Reference Friesem, Boaretto, Eliyahu-Behar and Shahack-Gross2011, Reference Friesem, Karkanas, Tsartsidou and Shahack-Gross2014a; Homsher Reference Homsher2012; Love Reference Love2012, Reference Love2013). Their utility as recorders of thermal processes during destruction by fire has, however, only rarely been addressed, with the majority of studies focusing on colour changes (e.g. Stevanović Reference Stevanović1997; Twiss et al. Reference Twiss, Bogaard, Bogdan, Carter, Charles, Farid, Russell, Stevanović, Yalman and Yeomans2008).

Forget et al. (Reference Forget, Regev, Friesem and Shahack-Gross2015) recently reported an experimental study that explored the thermal behaviour of chaff-tempered mud-bricks. Their experiments revealed interesting phenomena that proved useful for the reconstruction of conflagration temperatures in one of the largest destruction events known in the ancient Near East: Stratum VIA, dating to the late Iron Age I, in Tel Megiddo, Israel. They showed that the organic matter within the bricks (which includes both the chaff and soil organic matter) ignites during heating, causing temperatures within the heated bricks to be more than 100°C higher than the external environmental temperature. Furthermore, they demonstrated that the organic matter does not sustain combustion after ignition (i.e. the process is not autocatalytic). Rather, an ongoing source of energy is needed in order to burn a brick thoroughly. The team also used infrared spectroscopy to study the effects of heat intensity, heat duration and heating atmosphere (oxidising vs reducing) on structural changes in clay minerals. Forget et al. (Reference Forget, Regev, Friesem and Shahack-Gross2015) noted that the position of the main clay absorbance band depends not only on temperature but also on heating atmosphere, resulting in an overlap of its position at different heating temperatures. This hampers the use of infrared spectroscopy as a means of reconstructing past heating temperatures. They therefore considered the width of the main clay absorbance band and showed that combining the position and width parameters allowed for a more accurate reconstruction of the temperatures reached by burnt mud-bricks (see Forget et al. Reference Forget, Regev, Friesem and Shahack-Gross2015: fig. 13). With this new methodological advancement, Forget and colleagues studied a sectioned mud-brick wall, recently excavated in one of the largest destruction layers known in Israel, at the late Iron Age I Canaanite city at Tel Megiddo. They were able to show that mud-bricks were heated unevenly across the wall section, with areas of the innermost part being heated to the lowest temperatures (below 500°C). Forget et al. (Reference Forget, Regev, Friesem and Shahack-Gross2015) thus concluded that the wall was built from sun-dried (previously unheated) mud-bricks, which later burnt while forming part of the architecture of the ancient city.

This interpretation may not seem surprising, yet it is important, and not just because it supplies empirical evidence for such an event. A previous study in Israel, using a similar methodology to study three mud-bricks in the context of the destruction of the Iron IIA city of Gath (Tell es-Safi/Gath), suggested that those bricks had been pre-heated in furnaces prior to construction, thereby suggesting that the destructive fire was not as fierce as had been thought (Namdar et al. Reference Namdar, Zukerman, Maeir, Katz, Cabanes, Trueman, Shahack-Gross and Weiner2011). This conclusion was based on the well-established fact that clay is a good insulator (Carter & Norton Reference Carter and Norton2013). It was therefore hard to conceive that mud-bricks as large as those commonly found in Bronze and Iron Age archaeological sites (sometimes as large as 500 × 400 × 300mm) could be evenly heated to temperatures as high as 500–800°C (Namdar et al. Reference Namdar, Zukerman, Maeir, Katz, Cabanes, Trueman, Shahack-Gross and Weiner2011; Forget et al. Reference Forget, Regev, Friesem and Shahack-Gross2015) in a conflagration event.

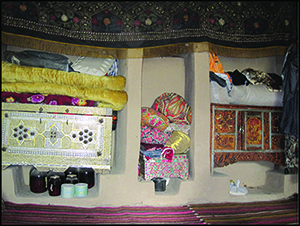

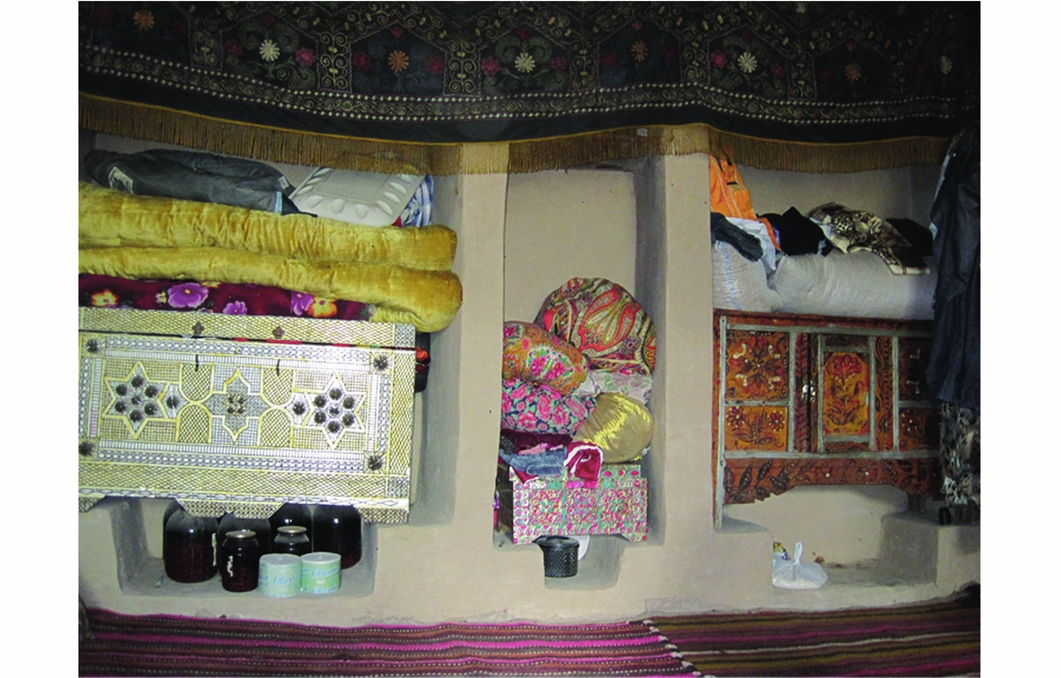

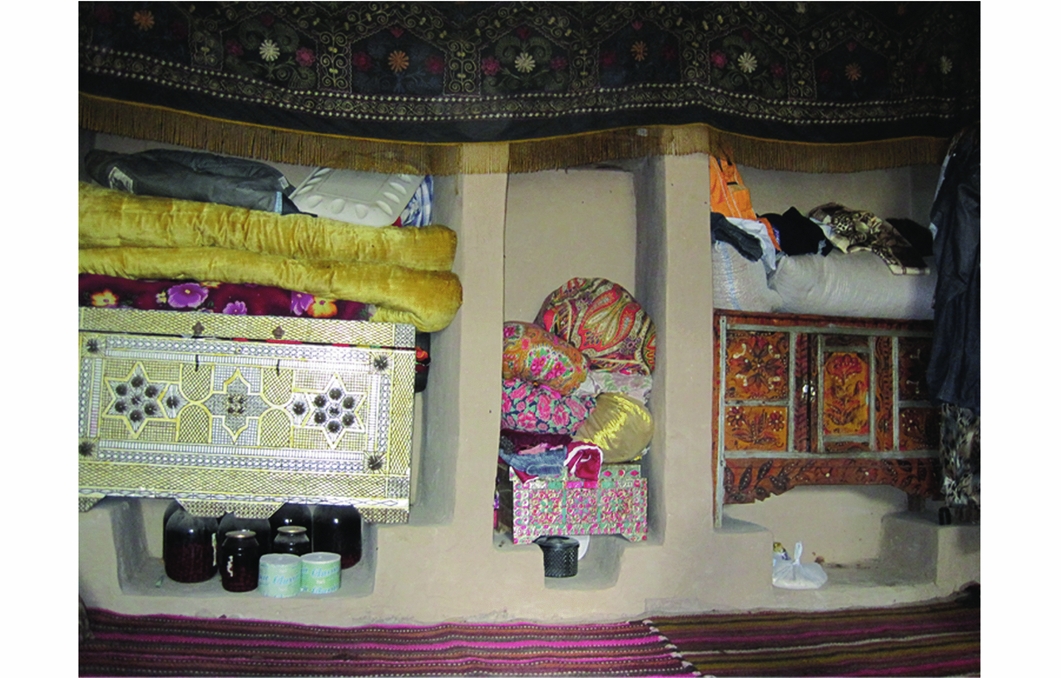

The actual duration of conflagration events in ancient cities is unknown. Intensive fires triggered by the collapse of combustibles onto active fire installations have been recorded in pre-industrial cities affected by earthquakes (Nur & Burgess Reference Nur and Burgess2008). Intensive fires that lasted several days have been recorded after earthquakes; for example, Basel in AD 1356 and Lisbon in AD 1755 (Cline Reference Cline, Finkelstein and Na'aman2011). This indicates that in pre-industrial settlements there were enough combustibles to sustain fires for long periods. Based on ethnographic examples from pre-modern traditional rural settlements in the southern Levant (for example Canaan Reference Canaan1932–Reference Canaan1933; Dalman Reference Dalman1928–Reference Dalman1942), combustibles expected at pre-industrial settlements include vegetal roof construction materials, supporting poles, wooden furniture, matting, basketry, stored dried food, stored oil, sheep wool and goat hair, leather, bedding materials, stored fuel and animal fodder (Figure 1). Notably, many field archaeologists refer to an association between evidence for fire and the presence of storage jars, presumably for olive oil, suggesting that fires in antiquity would have been more intensive when in proximity to oil, which served as an inadvertent fuel during site destruction (e.g. at Hazor; Ben-Tor Reference Ben-Tor2013: 31). In summary, it appears that long-lasting, destructive fires could have occurred in antiquity, and these may have baked single mud-bricks as well as whole walls or segments.

Figure 1. Potential combustibles within traditional houses. Niches within a traditional mud-brick house in present-day Uzbekistan filled with wooden boxes, bedding and textiles, while wool carpets cover the floors.

On the other hand, Friesem et al. (Reference Friesem, Karkanas, Tsartsidou and Shahack-Gross2014b) describe an ethnoarchaeological study of the effect of an accidental fire on the mud-brick walls of a barn. They note that the clay mineral components of the mud-bricks were affected by heat only on the surface (up to 5mm into the brick); the bulk of the brick was not altered. This observation accords with expectations based on clay's function as a good insulating material. Friesem et al. (Reference Friesem, Karkanas, Tsartsidou and Shahack-Gross2014b) did not, however, have information on the duration of the conflagration; it is therefore possible that the mud-bricks from the barn were not exposed to the fire for long enough to cause intensive brick alteration (baking).

The above examples indicate that a better understanding of the duration of destructive conflagration events in antiquity will reveal information on the intensity of these events, as well as on construction methods (i.e. sun-dried vs pre-heated mud-bricks). In this article, we document the results of experiments with chaff-tempered mud-bricks, which make it possible to estimate the duration of conflagration events in archaeological sites. The following hypotheses guided this research:

-

1. The more vegetal temper in a brick, the faster it will heat.

-

2. The larger the brick (i.e. having a higher volume), the longer it takes to heat thoroughly.

-

3. Bricks with different shapes but similar volumes will heat in a similar manner.

-

4. The higher the rate of heating, the faster the brick will be thoroughly heated.

The first hypothesis relates to the thermal effect reported by Forget et al. (Reference Forget, Regev, Friesem and Shahack-Gross2015), and to the assumption that when organic temper burns within a brick, it forms voids through which heat may be rapidly conducted. The other three relate to clay's insulation properties. The goal of our experiments was to provide empirical data that could be used to construct equations for the calculation of the time needed to heat large mud-bricks to their core, as seen in Near Eastern Bronze and Iron Age destructions.

Materials and methods

Chaff-tempered mud-bricks were prepared in the laboratory based on Forget et al. (Reference Forget, Regev, Friesem and Shahack-Gross2015)’s protocol. Briefly, sediment collected in the Jezreel Valley (northern Israel) was manually broken into aggregates smaller than 5mm, and stones larger than 3mm were removed. Weighed aliquots of sediment, wheat chaff and water were mixed manually until a homogeneous paste was obtained. Bricks of different shapes and sizes were formed (‘thin box’, ‘thick box’ and ‘cube’; Table 1) and put in an oven at 50°C. After about half a day, when the bricks were firm but soft, a metal wire was pressed into them to create an elongated void, into which a thermocouple was later inserted (see Forget et al. Reference Forget, Regev, Friesem and Shahack-Gross2015: figs 4 & 5). Oven-drying then continued for two to three days. The proportions for brick length, width and thickness were kept constant for each shape (Table 1).

Table 1. Relative proportions of length (L), width (W) and thickness (T) in centimetres within the three shape types of experimental mud-bricks.

Dried, experimental bricks were placed, one at a time, into a laboratory furnace. One thermocouple was inserted into the pre-designed elongated void, and a second thermocouple was placed next to the brick to record the temperature in the furnace's chamber during heating. The temperature was simultaneously recorded in both thermocouples every five seconds using a MultiCon CMC-141 data recorder (by Simex), and processed using the software DAQ Manager. Bricks were heated to 600°C and kept at this temperature for two hours. Heat was conducted from all directions. We chose to heat the experimental mud-bricks to 600°C because previous studies have shown that this is the temperature to which most bricks in destruction layers have been exposed (Namdar et al. Reference Namdar, Zukerman, Maeir, Katz, Cabanes, Trueman, Shahack-Gross and Weiner2011; Forget et al. Reference Forget, Regev, Friesem and Shahack-Gross2015). At the end of heating, the oven was kept closed and allowed to cool down slowly for five to six hours. The time required to reach 600°C in the brick's core was taken to indicate the time required for homogeneous heating of the total volume of the brick.

In order to test the research hypotheses, a first set of experiments included mud-bricks in the form of a ‘thin box’ prepared in two sizes: large (around 89 × 62 × 22mm) and small (around 53 × 36 × 15mm). To test hypothesis 1, bricks with the following different chaff to sediment ratios (by weight) were prepared and heated: 4:100, 2:100 and 0:100 (control sample with no chaff). The experiment was carried out at two heating rates (thus also addressing hypothesis 4), with duplicates (Table 2). To test hypotheses 2 and 3, data were collected from bricks of various shapes and sizes (Table 2). In order to compare the time required by all of the experimental bricks to reach 600°C at their cores, data were normalised so that the time recorded reflected the time taken for the temperature to increase from 50 to 600°C.

Table 2. Number of bricks heated according to size (V: volume), shape, composition (ratio of grams of chaff to grams of sediment) and the heating rate.

Results

1. The effects of the chaff to sediment ratio and heating rate

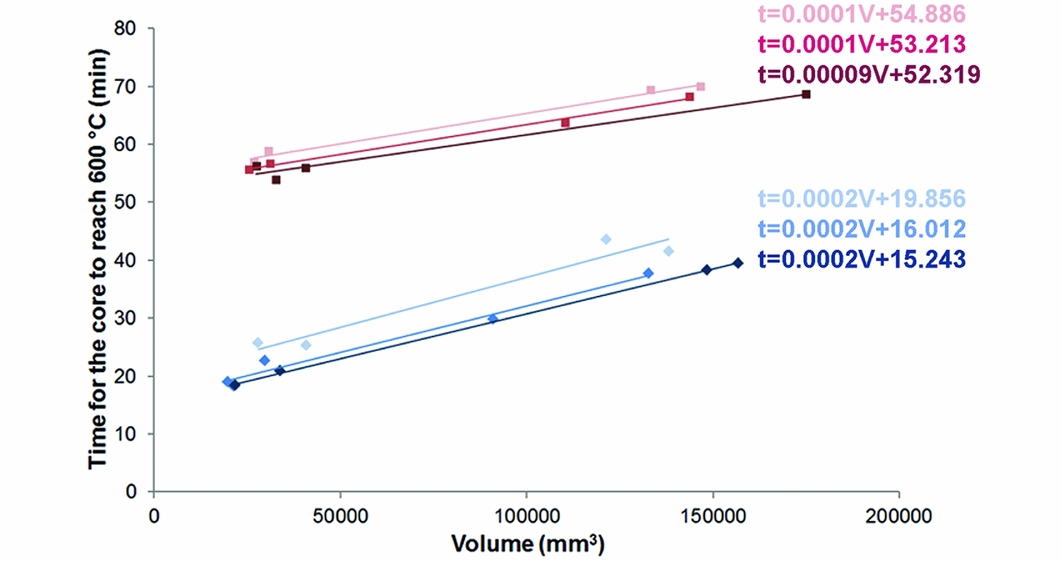

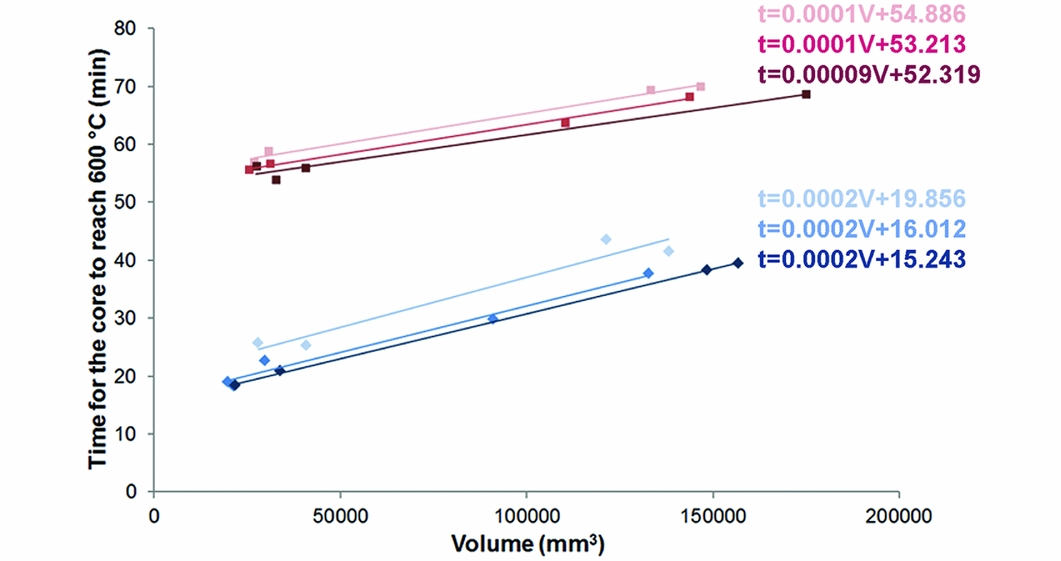

The experiment conducted on bricks composed of three different ratios of chaff/sediment, two distinct size categories and two different rates of heating shows that the parameter that most affects the rate of heat diffusion is the heating rate (Figure 2). Bricks with higher chaff to sediment ratios heated faster, but the difference in heat diffusion for the different compositional ratios was insignificant. The time required to reach 600°C in the core of the brick almost doubled using the slow heating regime (10°C/min), compared to the time required when heating rapidly (40°C/min). In addition, the larger the volume of the brick, the more time is needed to heat it (as would be expected). Moreover, the linear equations of the trend lines obtained, for each ratio and each heating speed, show similar slopes for the same heating speed: about 0.0001 for slow heating and 0.0002 for fast heating. From this observation, it becomes apparent that the impact of the chaff on the required time to reach 600°C inside the bricks is negligible. Volume and the rate of heating seem to be important variables. The following experiments therefore tested mud-bricks with varying shapes and sizes (and thus volumes), heated at two different rates.

Figure 2. Time needed to reach 600°C in the cores of experimental mud-bricks, plotted according to the volume of the bricks for different chaff to sediment ratios: 0:100 (without chaff), light colour; 2:100, middle shade; 4:100, dark colour. Red squares correspond to the slow heating rate (10°C/min), and the blue diamonds correspond to the fast heating rate (40°C/min). The trend lines with their corresponding equations are also presented.

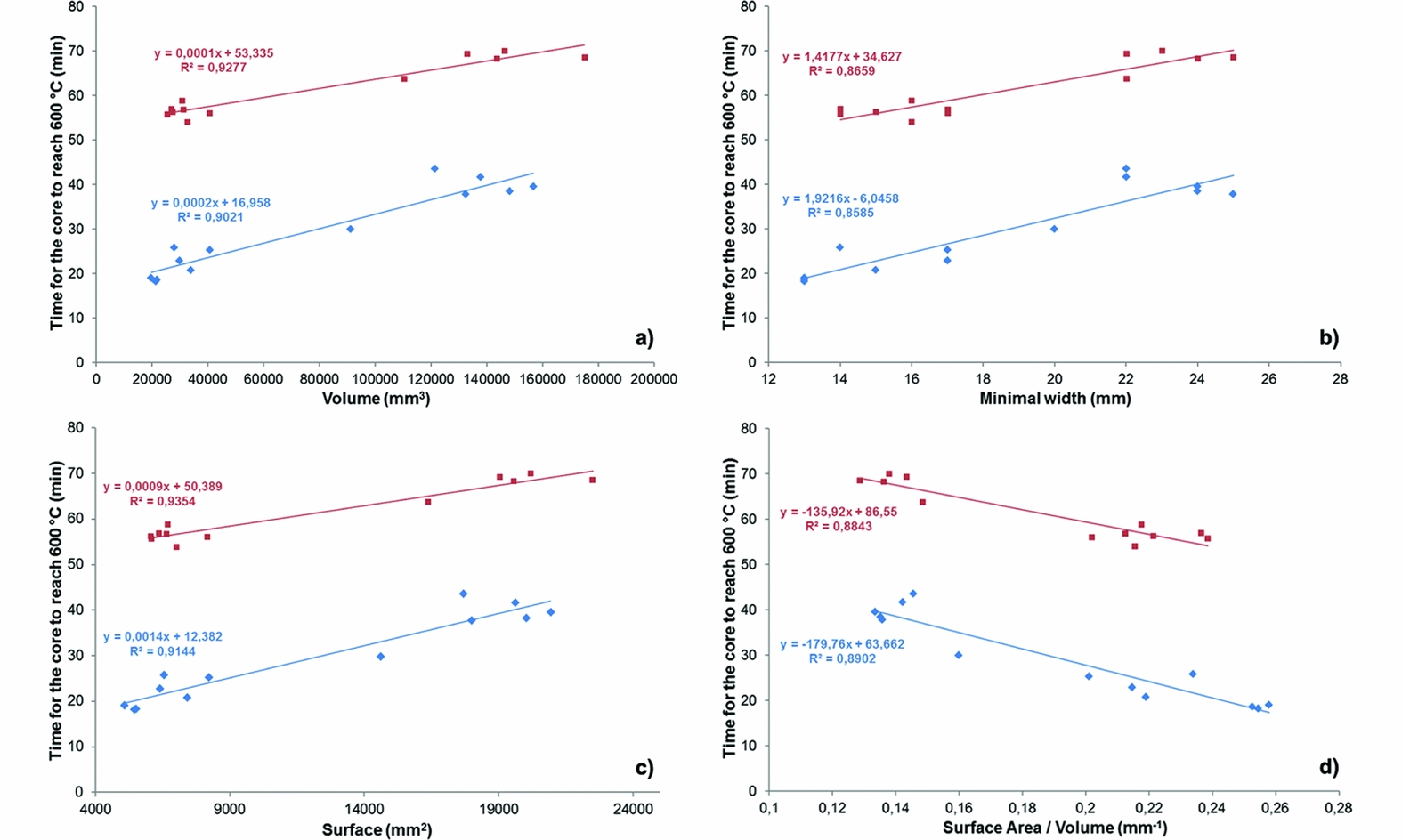

2. The effect of volume, thickness and surface area using the same shape

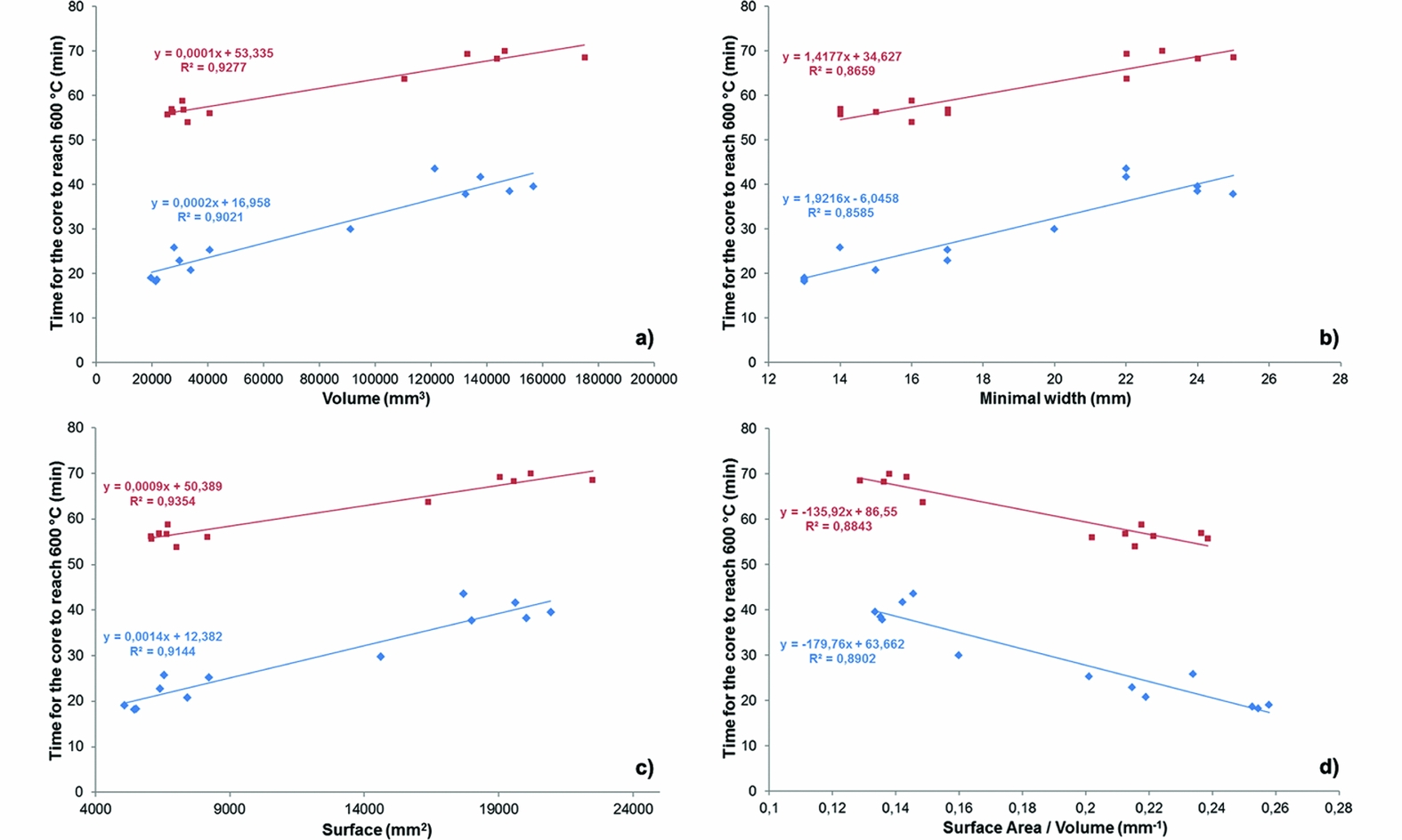

Bricks of the same shape (thin box) but of different sizes (and thus volumes) were heated. Figure 3a shows the relationship between volume and the time needed to reach 600°C in the cores of the bricks. The trend (with a good linear fit of R2>0.9) indicates that the higher the brick's volume, the more time is needed to heat its core. Two other dimension variables were tested in the same set of bricks: thickness (Figure 3b) and surface area (Figure 3c). Good linear fits also exist for the other two variables (R2 around 0.9), but the equations obtained using one variable only are different, meaning that the calculation of heat duration from bricks will yield different time estimates depending on the equation used.

Figure 3. Time needed to reach 600°C in the core of the experimental bricks, plotted according to different variables: the volume of the bricks (a); the minimum width (or thickness) of the brick (b); the surface area of the brick (c); and the ratio of the surface area to volume of the brick (d). The red squares are the experimental data for slow heating (10°C/min), and the blue diamonds are for fast heating (40°C/min). The trend lines for each heating speed with their corresponding equations are presented.

As it is clear that these size variables affect the time needed to heat a mud-brick thoroughly, the parameters of volume and surface area were chosen as the best representation that encompasses all size variables. Figure 3d presents the relationship between the time needed to reach 600°C in the bricks’ cores and the ratio between surface area and volume.

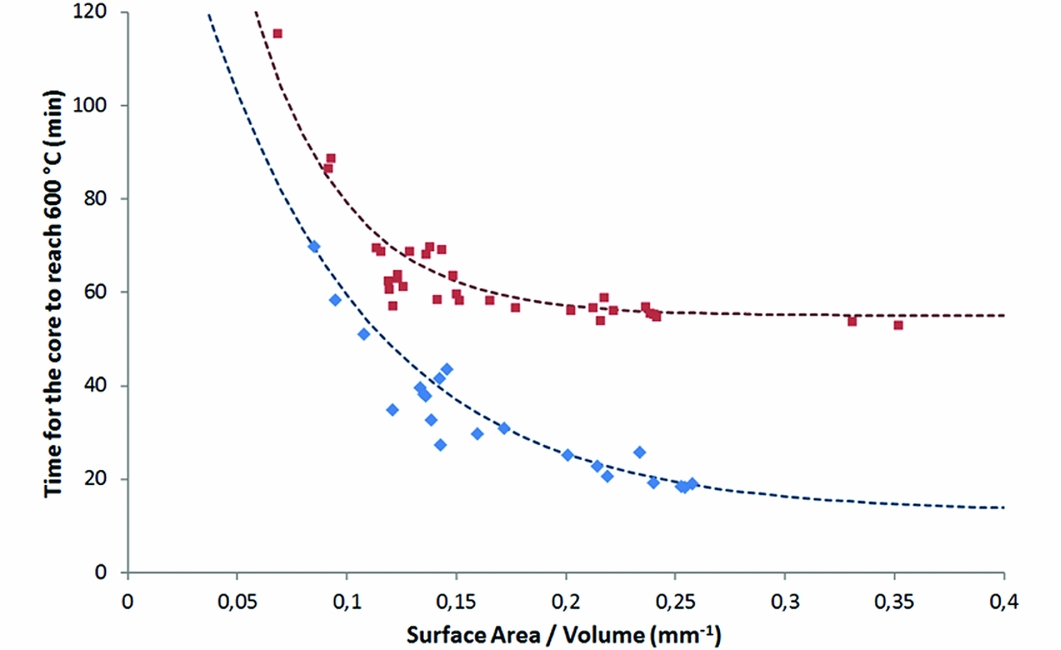

Realising that the ratio of surface area to volume is an important parameter, we tested its validity using bricks of various shapes (Figure 3d). While linear equations are expected when plotting time vs one parameter (Figure 3a–c), linearity should not be expected when plotting time vs the ratio of surface area (cm2) to volume (cm3), yet linearity was obtained under the latter calculation (Figure 3d). We suspected that this is due to the small size of the experimental bricks, and therefore carried out experiments with larger bricks where we expected the non-linear relationship between surface area and volume to be obtained empirically.

3. Different shapes and large volumes

Figure 4 presents the relationship between the time needed to reach 600°C in the cores of mud-bricks of different shapes and sizes, including large-sized bricks, and their surface area/volume ratio. The expected non-linearity is evident. The following exponential equations were obtained:

Figure 4. Time needed to reach 600°C in the core of an experimental brick, plotted according to the ratio of surface area to volume, for different sizes, shapes and compositions of bricks. The red squares are for slow heating (10°C/min), and the blue diamonds are for fast heating (40°C/min). The dashed lines are the corresponding trend lines.

Equation 1. Slow heating

Equation 2. Fast heating

In conclusion, we propose that these two equations can be applied to reconstruct the time needed to reach 600°C in the core of archaeological mud-bricks that contain any amount of chaff, and that are comprised of variable shapes and sizes.

Archaeological application

The equations obtained experimentally were applied to the case study of the destruction of Tel Megiddo at the end of the Iron Age I (Figure 5). Forget et al. (Reference Forget, Regev, Friesem and Shahack-Gross2015) found that dozens of mud-bricks in the collapse debris of Stratum VIA had been uniformly heated to about 600°C. The shape of these mud-bricks is close to the ‘thin box’ used here, with average dimensions of length 458±93mm, width 297±39mm and thickness 119±13mm. Two complete mud-bricks have surface areas of 480400mm² and 673400mm², with volumes of 17160000mm3 and 27885000mm3. Using our equations, the time required to reach 600°C in the cores of these mud-bricks was between 133 and 188 minutes for one brick, and 139 and 201 minutes for the other (with the shorter time estimate corresponding to the fast heating rate, and the longer time estimate to the slow heating rate). The time estimates are generally in the range of two to three hours of conflagration, which is much shorter than expected. Below, we discuss the implications of the experiments and the results of this archaeological example.

Figure 5. Photograph showing an excavated 5 × 5m square at Tel Megiddo, illustrating the remains of the late Iron Age I conflagration event, as observed in excavation Area Q at the end of the 2014 excavation season. Note the blackened floor and a pile of burnt mud-bricks, over 1m thick, in the section on the left. Blue tags indicate sediment sample locations, and the white upright block is a sample of the floor makeup collected for micromorphological analysis (photograph courtesy of the Megiddo Expedition).

Discussion

Our study provides, for the first time, a quantitative tool by which archaeologists could estimate the duration of destructive conflagration events using the aforementioned equations. We have shown that the amount of vegetal temper has only a negligible effect on the time needed to heat a mud-brick homogeneously, and that size and shape variables can be best represented by the surface area to volume ratio. One limitation of our model is the unknown variable—the rate of heating—yet, as illustrated in Figure 4, the difference in the results produced by fast and slow heating rates diminishes with a decreased surface area to volume ratio, i.e. as bricks become larger. Our largest experimental bricks are significantly smaller than most Bronze and Iron Age mud-bricks recorded in the Near East, thus the rate of heating should not pose a methodological problem when reconstructing past heat duration. Another limitation inherent in our model is that it is designed for the single temperature of 600°C. It cannot be used with high accuracy in cases where brick cores have been heated to lower or higher temperatures. Yet, in studies conducted by several scholars, in the southern Levant, this temperature seems to represent the heat intensity often identified in destructive conflagration events (e.g. Namdar et al. Reference Namdar, Zukerman, Maeir, Katz, Cabanes, Trueman, Shahack-Gross and Weiner2011; Forget et al. Reference Forget, Regev, Friesem and Shahack-Gross2015; and in certain areas identified by Berna et al. Reference Berna, Behar, Shahack-Gross, Berg, Boaretto, Gilboa, Sharon, Shalev, Shilstein, Yahalom-Mack, Zorn and Weiner2007). A third limitation pertains to the availability of methods by which heat intensity in the cores of mud-bricks can be estimated. Forget et al. (Reference Forget, Regev, Friesem and Shahack-Gross2015) present guidelines in this respect, based on infrared spectroscopy.

The ratio between surface area and volume is a classical parameter used to describe shape and is therefore commonly used in materials science (Carter & Norton Reference Carter and Norton2013; Nagarani et al. Reference Nagarani, Mayilsamy, Murugesan and Sathesh Kumar2014). In relation to the thermal insulation in mud-brick houses in India, Mishra and Usmani (Reference Mishra and Usmani2014) showed that a low ratio between surface area and volume reduces heat gain (i.e. it keeps houses cooler). This observation corresponds with our own results, where it is shown that more time is required to heat a brick of a lower surface area to volume ratio (Figure 4). To our knowledge, the study reported here is the first that supplies quantitative empirical data that allow reconstruction of the time needed to heat large chaff-tempered mud-bricks thoroughly.

An important question that arises concerns the amount of fuel material needed to sustain constant burning for two to three hours. As previously shown by the authors (Forget et al. Reference Forget, Regev, Friesem and Shahack-Gross2015), even large amounts of organic matter in sun-dried mud-bricks will not sustain combustion unless energy is supplied. In our experiments, this energy was supplied by a furnace oven, where heat was conducted from all directions. Gur-Arieh et al. (Reference Gur-Arieh, Boaretto, Maeir and Shahack-Gross2012) showed that 5kg of wood on a 1 × 1m open fire can maintain a temperature of about 600°C for around two hours. By extrapolation, maintaining 600°C for two hours in a structure of about 100m2 would require approximately 500kg of vegetal fuel. If we assume that such an area could be roofed using five to six wooden poles 10m in length, spaced 2m apart, and that each pole weighs several tens of kilograms, this amounts to a few hundred kilograms of wood in the roof alone. Together with thatch, furnishing and other organic materials, enough fuel may have been present to fuel the minimum of two to three hours of continuous fire required to heat mud-bricks to around 600°C. Can a situation where the long-term supply of heat energy conducted from various directions occur when mud-brick houses are destroyed by fire? We currently have no answer to this question, yet in order to heat large mud-bricks and thick walls thoroughly, ancient houses would need to burn in a manner that reproduced the conditions present within a furnace oven. Understanding this phenomenon requires more research.

With regard to the baking of entire walls two to three bricks wide (i.e. a surface area to volume ratio even lower than that of a single brick), we note that they too would need to be evenly heated for a minimum of two to three hours.

Conclusion

The study presented here supplies, for the first time, a quantitative estimate of the minimum duration of an ancient event of destruction by fire. We show that mud-bricks may serve as good proxies for such estimations, provided that the temperature to which they have been exposed in their cores is reconstructed. Our results indicate that destruction events in Bronze and Iron Age cities in the southern Levant involved fire that lasted a minimum of two to three hours. Given these results, we predict that there should not be a significant difference in the archaeological appearance of bricks damaged by accidental conflagration or intentional arson. This assertion is based on thermal data only and assumes that if buildings are heated by the combustion of their own organic contents, the same temperatures are expected to be achieved whether the combustion is accidental or intentional. This suggestion poses a methodological problem that may be approached using forensic fire investigation guidelines, yet the archaeological literature strives to produce historical and social implications from archaeological destruction layers without sufficient thermal data. Providing such data from mud-bricks and other materials associated with destruction levels allows for not only the reconstruction of the minimal duration of the conflagration, as attempted in the current study, but also the identification of areas of differential heat exposure, suggesting ignition points and the possibility of tracing fire paths. Regev et al. (Reference Regev, Cabanes, Homsher, Kleiman, Weiner, Finkelstein and Shahack-Gross2015) recently achieved such a reconstruction during a study of a small-scale destruction event in an Iron IIA context in Tel Megiddo. Stevanović (Reference Stevanović1997) and Twiss et al. (Reference Twiss, Bogaard, Bogdan, Carter, Charles, Farid, Russell, Stevanović, Yalman and Yeomans2008) used the identification of areas of ignition to suggest a distinction between intentional and accidental fire. Overall, the current study provides a new approach by which it is possible to address and shed new light on archaeological conflagration events in the ancient Near East and beyond.

Acknowledgements

This study was supported by a European Research Council Advanced Grant (229418), titled ‘Reconstructing Ancient Israel: The Exact and Life Sciences Perspective’, and directed by Israel Finkelstein of Tel Aviv University and Steve Weiner of the Weizmann Institute of Science (where Ruth Shahack-Gross acted as the geoarchaeology track leader). We thank Steve Weiner for fruitful discussions, and the ongoing support of the Kimmel Center for Archaeological Science, Weizmann Institute of Science. We also thank the Megiddo Expedition (directed by Israel Finkelstein) for the collaborative research opportunities, and two anonymous reviewers for helpful comments.