1 Introduction

The understanding and quantification of the different events following the impact of drops on solid substrates is of interest in many different areas of science and technology, such as printing, heat transfer, the spreading and propagation of contaminants or diseases and forensic science (Adam Reference Adam2012; Brodbeck Reference Brodbeck2012; Laan et al. Reference Laan, de Bruin, Slenter, Wilhelm, Jermy and Bonn2015; Josserand & Thoroddsen Reference Josserand and Thoroddsen2016; Gilet & Bourouiba Reference Gilet and Bourouiba2018; Lejeune, Gilet & Bourouiba Reference Lejeune, Gilet and Bourouiba2018). This process is also present in our daily life experience and usually captures our attention when, for instance, we realise that the effect of rain drops falling on the sidewalk does not only depend on the drop velocity and direction but also on whether the substrate is dry or wet. In this latter case, it can be observed with the naked eye that the sequence of events following the impact of the drop is very much dependent on the liquid film thickness (see, e.g. Josserand & Thoroddsen (Reference Josserand and Thoroddsen2016), Gielen et al. (Reference Gielen, Sleutel, Benschop, Riepen, Voronina, Visser, Lohse, Snoeijer, Versluis and Gelderblom2017) and the references therein).

Since the impact of drops on surfaces depend on a large number of different parameters, we will restrict our study to those cases in which the substrate is smooth and dry, the liquid partially wets the solid and the impact velocity is below the splashing threshold, a fact meaning that we will consider here that the drop does not disintegrate into smaller pieces, but simply spreads along the impacting wall. Indeed, for the case of partially wetting surfaces, if the relative velocity between the solid and the drop is sufficiently large, forces of aerodynamic origin lift the edge of the advancing liquid sheet from the substrate. When this happens, the toroidal rim limiting the expansion of the liquid film subsequently breaks into tiny droplets as a result of the growth of capillary instabilities, giving rise to what is termed drop splashing (Riboux & Gordillo Reference Riboux and Gordillo2014, Reference Riboux and Gordillo2015; Gordillo & Riboux Reference Gordillo and Riboux2019). Very recently, Quetzeri-Santiago et al. (Reference Quetzeri-Santiago, Yokoi, Castrejón-Pita and Castrejón-Pita2019) adapted the physical ideas and the criterion deduced in Riboux & Gordillo (Reference Riboux and Gordillo2014) with the purpose of explaining their own experimental observations, which correctly indicate that the splash threshold velocity for the case of superhydrophobic substrates was reduced with respect to the case of partially wetting solids. In fact, it is described in Gordillo & Riboux (Reference Gordillo and Riboux2019) that the effect of wettability can be accounted for by slightly modifying the value of the angle  $\unicode[STIX]{x1D6FC}$ of the advancing wedge in the theory by Riboux & Gordillo (Reference Riboux and Gordillo2014) by

$\unicode[STIX]{x1D6FC}$ of the advancing wedge in the theory by Riboux & Gordillo (Reference Riboux and Gordillo2014) by  $\pm 6\,\%$ around the nominal value of

$\pm 6\,\%$ around the nominal value of  $60^{\circ }$, but this approximation is, unfortunately, only valid for a limited range of values of the static contact angle and is clearly not valid for the case of non-wetting solids. In fact, the splashing of drops impacting superhydrophobic substrates is not determined by aerodynamic lift forces because the edge of the liquid sheet is never in contact with the solid wall, this fact notably reducing the splash threshold velocity with respect to the case of partially wetting substrates. Indeed, by including the effect of the viscous friction at the wall, Quintero, Riboux & Gordillo (Reference Quintero, Riboux and Gordillo2019) extended the splashing criterion deduced for the case of Leidenfrost drops in Riboux & Gordillo (Reference Riboux and Gordillo2016) to the case of superhydrophobic solids, deducing a splash condition that explains the observations. Since the splashing criterion for the case of non-wetting substrates is conceptually different from the one deduced in Riboux & Gordillo (Reference Riboux and Gordillo2014) for the case of partially wetting substrates, the attempts to adapt the ideas in Riboux & Gordillo (Reference Riboux and Gordillo2014) to explain the observations for the case of superhydrophobic solids as it was done, for instance, in Quetzeri-Santiago et al. (Reference Quetzeri-Santiago, Yokoi, Castrejón-Pita and Castrejón-Pita2019), is not fully justified.

$60^{\circ }$, but this approximation is, unfortunately, only valid for a limited range of values of the static contact angle and is clearly not valid for the case of non-wetting solids. In fact, the splashing of drops impacting superhydrophobic substrates is not determined by aerodynamic lift forces because the edge of the liquid sheet is never in contact with the solid wall, this fact notably reducing the splash threshold velocity with respect to the case of partially wetting substrates. Indeed, by including the effect of the viscous friction at the wall, Quintero, Riboux & Gordillo (Reference Quintero, Riboux and Gordillo2019) extended the splashing criterion deduced for the case of Leidenfrost drops in Riboux & Gordillo (Reference Riboux and Gordillo2016) to the case of superhydrophobic solids, deducing a splash condition that explains the observations. Since the splashing criterion for the case of non-wetting substrates is conceptually different from the one deduced in Riboux & Gordillo (Reference Riboux and Gordillo2014) for the case of partially wetting substrates, the attempts to adapt the ideas in Riboux & Gordillo (Reference Riboux and Gordillo2014) to explain the observations for the case of superhydrophobic solids as it was done, for instance, in Quetzeri-Santiago et al. (Reference Quetzeri-Santiago, Yokoi, Castrejón-Pita and Castrejón-Pita2019), is not fully justified.

Because of the fact that the experimental range of impact velocities for which the drop spreads over the solid without breaking into smaller droplets is noticeably smaller for the case of superhydrophobic surfaces, we have chosen here to focus on the quantification of the effect of the impact direction on the spreading of drops falling over partially wetting substrates, which are much more common than superhydrophobic ones. The case of drop deformation and fragmentation upon impact on inclined superhydrophobic substrates will be the subject of a separate study.

The rich and complex dynamics exhibited by a small subset of all possible different experimental conditions, which will be the subject of the present study, could explain the fact that, even though for most practical situations impacting drops follow a trajectory which is not perpendicular to the surface, the number of contributions dealing with the effect of the angle formed between the drop impact direction and the normal to the solid are far more scarce than those describing the perpendicular spreading or splashing of drops impacting dry substrates; see, for instance, Roisman, Rioboo & Tropea (Reference Roisman, Rioboo and Tropea2002), Roisman, Berberović & Tropea (Reference Roisman, Berberović and Tropea2009), Roisman (Reference Roisman2009), Rozhkov, Prunet-Foch & Vignes-Adler (Reference Rozhkov, Prunet-Foch and Vignes-Adler2002), Villermaux & Bossa (Reference Villermaux and Bossa2011), Eggers et al. (Reference Eggers, Fontelos, Josserand and Zaleski2010), Laan et al. (Reference Laan, de Bruin, Bartolo, Josserand and Bonn2014), Visser et al. (Reference Visser, Frommhold, Wildeman, Mettin, Lohse and Sun2015), Wildeman et al. (Reference Wildeman, Visser, Sun and Lohse2016), Lee et al. (Reference Lee, Laan, de Bruin, Skantzaris, Shahidzadeh, Derome, Carmeliet and Bonn2016) and Riboux & Gordillo (Reference Riboux and Gordillo2014).

Figure 1. This figure sketches the types of inclined impact of drops that we intend to describe in this contribution: (a) the impact of a drop that falls over a horizontal substrate following a trajectory that forms an angle  $\unicode[STIX]{x1D712}$ with the vertical direction or (b) the impact of a drop falling vertically on an inclined substrate that forms an angle

$\unicode[STIX]{x1D712}$ with the vertical direction or (b) the impact of a drop falling vertically on an inclined substrate that forms an angle  $\unicode[STIX]{x1D712}$ with the horizontal. (c) Sketch showing, in the moving frame of reference, the definitions of the angle

$\unicode[STIX]{x1D712}$ with the horizontal. (c) Sketch showing, in the moving frame of reference, the definitions of the angle  $\unicode[STIX]{x1D703}$ and the different regions in which the drop is divided in order to characterize the spreading process, namely the drop region, which extends from

$\unicode[STIX]{x1D703}$ and the different regions in which the drop is divided in order to characterize the spreading process, namely the drop region, which extends from  $r=0$ to

$r=0$ to  $r=\sqrt{3t}$ and where pressure gradients cannot be neglected, the lamella region, which extends from

$r=\sqrt{3t}$ and where pressure gradients cannot be neglected, the lamella region, which extends from  $r=\sqrt{3t}$ to

$r=\sqrt{3t}$ to  $r=s(\unicode[STIX]{x1D703},t)$ and where pressure gradients can be neglected and the rim region, which is the thick portion of fluid located at

$r=s(\unicode[STIX]{x1D703},t)$ and where pressure gradients can be neglected and the rim region, which is the thick portion of fluid located at  $r=s(\unicode[STIX]{x1D703},t)$ bordering the perimeter of the spreading drop. The figure also illustrates the definitions of the rim velocity

$r=s(\unicode[STIX]{x1D703},t)$ bordering the perimeter of the spreading drop. The figure also illustrates the definitions of the rim velocity  $v(\unicode[STIX]{x1D703},t)$ and the rim thickness

$v(\unicode[STIX]{x1D703},t)$ and the rim thickness  $b(\unicode[STIX]{x1D703},t)$. In (c),

$b(\unicode[STIX]{x1D703},t)$. In (c),  $\ell (\unicode[STIX]{x03C0}/2,t)$ and

$\ell (\unicode[STIX]{x03C0}/2,t)$ and  $\ell (3\unicode[STIX]{x03C0}/2,t)$ are defined as the distances of the rim portions located respectively at

$\ell (3\unicode[STIX]{x03C0}/2,t)$ are defined as the distances of the rim portions located respectively at  $\unicode[STIX]{x1D703}=\unicode[STIX]{x03C0}/2$ and

$\unicode[STIX]{x1D703}=\unicode[STIX]{x03C0}/2$ and  $\unicode[STIX]{x1D703}=3\unicode[STIX]{x03C0}/2$ from the impact point, which is a fixed point in the laboratory frame of reference and it is the point in the substrate where the drop first touches the solid.

$\unicode[STIX]{x1D703}=3\unicode[STIX]{x03C0}/2$ from the impact point, which is a fixed point in the laboratory frame of reference and it is the point in the substrate where the drop first touches the solid.

The comparatively few studies existing in the literature addressing the inclined impact of drops on solids can be classified according to whether the substrate is placed perpendicularly to the direction of gravity (see figure 1a) or not (see figure 1b). Because we will show next that the asymmetries depicted in the spreading of drops impacting inclined substrates sketched in figure 1 are caused by the asymmetries in the boundary layer developing at the wall and by the asymmetries in the pinning condition of the advancing rim on the substrate, we will also include within the first type of experimental set-ups in figure 1(a) the works by Mundo, Sommerfeld & Tropea (Reference Mundo, Sommerfeld and Tropea1995), Hao & Green (Reference Hao and Green2017), Almohammadi & Amirfazli (Reference Almohammadi and Amirfazli2017a,Reference Almohammadi and Amirfazlib), Buksh et al. (Reference Buksh, Almohammadi, Marengo and Amirfazli2019), in which a drop falls perpendicularly over a substrate that moves with a prescribed velocity. Moreover, since the time scale associated with the spreading of the drop is so short that gravity does not have time to sufficiently modify the initial liquid velocity during the impact time and, in addition, capillary forces overcome, by far, the weight of the rim bordering the expanding liquid sheet of millimetric or submillimetric impacting drops of interest here, gravitational effects will be neglected in the description of the spreading process. Hence, the experimental results obtained with either the set-ups represented in figure 1 or with those detailed in Mundo et al. (Reference Mundo, Sommerfeld and Tropea1995), Hao & Green (Reference Hao and Green2017), Almohammadi & Amirfazli (Reference Almohammadi and Amirfazli2017a,Reference Almohammadi and Amirfazlib), Buksh et al. (Reference Buksh, Almohammadi, Marengo and Amirfazli2019) will be described here using the common framework sketched in figure 1(c).

Within the types of set-ups in which a drop falls over a horizontal substrate, Mundo et al. (Reference Mundo, Sommerfeld and Tropea1995) reported experiments of drops impacting over smooth and rough substrates and also provided us with a correlation determining the conditions under which a drop falling over a moving substrate spreads or splashes, emphasizing the role played by the normal component of the drop velocity relative to the wall. By impacting drops that fall vertically over a moving substrate Bird, Tsai & Stone (Reference Bird, Tsai and Stone2009), Almohammadi & Amirfazli (Reference Almohammadi and Amirfazli2017b) also reported experiments on the spreading–splashing transition. However, Mundo et al. (Reference Mundo, Sommerfeld and Tropea1995), Bird et al. (Reference Bird, Tsai and Stone2009) and Almohammadi & Amirfazli (Reference Almohammadi and Amirfazli2017b) did not explore or report about the effect of the surrounding gaseous atmosphere on the conditions under which an impacting drop disintegrates into smaller droplets or not, which is known to be the reason for drop splashing over smooth partially wetting substrates (Xu, Zhang & Nagel Reference Xu, Zhang and Nagel2005). Later on, the essential role played by the gas in the transition to splashing of drops impacting moving substrates was addressed by Hao & Green (Reference Hao and Green2017) making use of the theory in Riboux & Gordillo (Reference Riboux and Gordillo2014). Using a similar set-up as that employed in Almohammadi & Amirfazli (Reference Almohammadi and Amirfazli2017a,Reference Almohammadi and Amirfazlib), Buksh et al. (Reference Buksh, Almohammadi, Marengo and Amirfazli2019) have reported detailed experiments revealing the strong asymmetric deformations experienced by drops falling vertically onto a moving plate, also providing us with correlations that, in spite of not being deduced from first principles, reproduce the observations well. Very recently, Cimpeanu & Papageorgiou (Reference Cimpeanu and Papageorgiou2018) and Raman (Reference Raman2019) described, using different numerical methods, the spreading and splashing of drops impacting obliquely over horizontal substrates.

But, because it is far easier to build, most of the contributions in the literature studying the inclined impact of drops, make use the type of set-up sketched in figure 1(b), which illustrates a drop falling vertically onto a plane that can be inclined at will. Using this type of set-up, Sikalo & Ganic (Reference Sikalo and Ganic2005) reported experiments of drops with different viscosities falling over smooth and rough substrates with different wettabilities for a limited range of impact velocities, showing that the drop can rebound or spread, deforming asymmetrically with respect to the impact point. A similar experimental set-up was used more recently by Laan et al. (Reference Laan, de Bruin, Bartolo, Josserand and Bonn2014) who provided an algebraic fit, valid for arbitrary values of the inclination angle, that approximates well the maximum width of the impacting drop and also by Hao et al. (Reference Hao, Lu, Lee, Wu, Hu and Floryan2019), who analysed the effect of the properties of the surrounding gaseous atmosphere and of the inclination angle on the splash transition of drops impacting partially wetting substrates. With the purpose of modelling the spreading of diseases by rain, Lejeune & Gilet (Reference Lejeune and Gilet2019) reported careful experimental observations of drops falling near the edge of an inclined plate, also providing us with useful correlations to quantify the observations. Although not considered here, for its implications in many different technological applications and in natural flows, let us mention that there exists a growing interest in the recent literature to describe the spreading, bouncing and splashing of vertically falling drops impacting inclined superhydrophobic substrates; see, e.g. Antonini, Villa & Marengo (Reference Antonini, Villa and Marengo2014), Yeong et al. (Reference Yeong, Burton, Loth and Bayer2014), LeClear et al. (Reference LeClear, LeClear, Park and Choi2016), Regulagadda, Bakshi & Das (Reference Regulagadda, Bakshi and Das2018), Aboud & Kietzig (Reference Aboud and Kietzig2018).

Almohammadi & Amirfazli (Reference Almohammadi and Amirfazli2017a,Reference Almohammadi and Amirfazlib), Buksh et al. (Reference Buksh, Almohammadi, Marengo and Amirfazli2019) and Lejeune & Gilet (Reference Lejeune and Gilet2019) have provided us with useful correlations to predict the time-evolving shapes of drops impacting an inclined or moving substrate, and have also provided us with useful fits to the data of the type reported in Clanet et al. (Reference Clanet, Béguin, Richard and Quéré2004), Laan et al. (Reference Laan, de Bruin, Bartolo, Josserand and Bonn2014) to predict the maximum width of the deformed drop. However, in spite of these research efforts, we have not identified any study in the literature that, starting from basic principles, explains and quantifies the experimental observations.

Then, it will be our main purpose in this contribution to provide a self-consistent theoretical framework to predict the time-evolving spreading process of drops impacting with an angle a partially wetting substrate. Also, these theoretical results will serve to deduce simplified equations to predict, in an approximate way, the shape of the liquid stain that remains when the drop stops. Here, we will not make use of energetic arguments, like those employed in Wildeman et al. (Reference Wildeman, Visser, Sun and Lohse2016), but will write equations for the balances of mass and momentum at the rim as it was done, for instance, in Taylor (Reference Taylor1959), Roisman et al. (Reference Roisman, Rioboo and Tropea2002), Rozhkov et al. (Reference Rozhkov, Prunet-Foch and Vignes-Adler2002), Eggers et al. (Reference Eggers, Fontelos, Josserand and Zaleski2010), Villermaux & Bossa (Reference Villermaux and Bossa2011) and Gordillo, Riboux & Quintero (Reference Gordillo, Riboux and Quintero2019). We have chosen to extend here the framework in Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) because, to the best of our knowledge, this is the only self-consistent theoretical study which is capable of reproducing the time-evolving shapes of drops impacting perpendicularly onto substrates of different wettabilities and also the results for the frictionless case reported in Riboux & Gordillo (Reference Riboux and Gordillo2016). In addition, the theory in Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) permits us to deduce an algebraic equation that reproduces the experimental observations for the maximum radius of drops impacting perpendicularly a substrate, thus providing also a physical explanation for the fits to the experimental data reported in Clanet et al. (Reference Clanet, Béguin, Richard and Quéré2004), Laan et al. (Reference Laan, de Bruin, Bartolo, Josserand and Bonn2014).

Here we will describe the impact of a drop of radius  $R$ and velocity

$R$ and velocity  $V$ of a liquid of density

$V$ of a liquid of density  $\unicode[STIX]{x1D70C}$ and viscosity

$\unicode[STIX]{x1D70C}$ and viscosity  $\unicode[STIX]{x1D707}$ against a flat solid wall, when the angle

$\unicode[STIX]{x1D707}$ against a flat solid wall, when the angle  $\unicode[STIX]{x1D712}$ formed between the impact direction and the normal vector to the partially wetting substrate is different from zero – see figure 1 – paying special attention to the description of the spreading process taking place during the initial instants after impact. We will make use of the ideas in Gordillo & Riboux (Reference Gordillo and Riboux2019) and describe the impact process sketched in figure 1 in a frame of reference moving tangentially to the solid with a constant velocity

$\unicode[STIX]{x1D712}$ formed between the impact direction and the normal vector to the partially wetting substrate is different from zero – see figure 1 – paying special attention to the description of the spreading process taking place during the initial instants after impact. We will make use of the ideas in Gordillo & Riboux (Reference Gordillo and Riboux2019) and describe the impact process sketched in figure 1 in a frame of reference moving tangentially to the solid with a constant velocity  $V_{t}=V\sin \unicode[STIX]{x1D712}$ (see figure 1c). The reason for this choice is that, an observer moving with this particular frame of reference, would see the drop impacting the solid perpendicularly, with a velocity

$V_{t}=V\sin \unicode[STIX]{x1D712}$ (see figure 1c). The reason for this choice is that, an observer moving with this particular frame of reference, would see the drop impacting the solid perpendicularly, with a velocity  $V_{n}=V\cos \unicode[STIX]{x1D712}$. Therefore, the results obtained for the case of the normal impact of drops on dry substrates in Riboux & Gordillo (Reference Riboux and Gordillo2016), Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) can be easily extended to describe the inclined impact of drops shown in figure 1. To illustrate the advantages of describing the flow in the moving frame of reference, it is convenient to consider first the inviscid limit. Indeed, the impact of a drop moving with a velocity

$V_{n}=V\cos \unicode[STIX]{x1D712}$. Therefore, the results obtained for the case of the normal impact of drops on dry substrates in Riboux & Gordillo (Reference Riboux and Gordillo2016), Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) can be easily extended to describe the inclined impact of drops shown in figure 1. To illustrate the advantages of describing the flow in the moving frame of reference, it is convenient to consider first the inviscid limit. Indeed, the impact of a drop moving with a velocity  $V$ and forming an angle

$V$ and forming an angle  $\unicode[STIX]{x1D712}$ with the normal to the substrate is, in the irrotational case and when the contact line does not pin to the substrate, the solution given in Riboux & Gordillo (Reference Riboux and Gordillo2016) when the normal impact velocity is

$\unicode[STIX]{x1D712}$ with the normal to the substrate is, in the irrotational case and when the contact line does not pin to the substrate, the solution given in Riboux & Gordillo (Reference Riboux and Gordillo2016) when the normal impact velocity is  $V\cos \unicode[STIX]{x1D712}$. This is due to the fact that, in the potential flow limit, the no slip boundary condition does not need to be satisfied and the falling drop is informed of the presence of the wall only through the impenetrability condition. In a real case, however, the wall moves tangentially with a speed

$V\cos \unicode[STIX]{x1D712}$. This is due to the fact that, in the potential flow limit, the no slip boundary condition does not need to be satisfied and the falling drop is informed of the presence of the wall only through the impenetrability condition. In a real case, however, the wall moves tangentially with a speed  $V\sin \unicode[STIX]{x1D712}$ in the translating frame of reference, see figure 1(c), and the flow induced by this motion is confined within a boundary layer. Since the exact solution for the inviscid limit was already provided in Riboux & Gordillo (Reference Riboux and Gordillo2016), Gordillo et al. (Reference Gordillo, Riboux and Quintero2019), our main contribution here will be, precisely, to extend the results in our previous works and provide a theory on the spreading process of drops impacting a dry substrate with an inclination angle

$V\sin \unicode[STIX]{x1D712}$ in the translating frame of reference, see figure 1(c), and the flow induced by this motion is confined within a boundary layer. Since the exact solution for the inviscid limit was already provided in Riboux & Gordillo (Reference Riboux and Gordillo2016), Gordillo et al. (Reference Gordillo, Riboux and Quintero2019), our main contribution here will be, precisely, to extend the results in our previous works and provide a theory on the spreading process of drops impacting a dry substrate with an inclination angle  $\unicode[STIX]{x1D712}\neq 0$ that accounts, in a self-consistent way, for the effect of the asymmetric boundary layer flow and for the fact that the advancing rim pins asymmetrically on the substrate.

$\unicode[STIX]{x1D712}\neq 0$ that accounts, in a self-consistent way, for the effect of the asymmetric boundary layer flow and for the fact that the advancing rim pins asymmetrically on the substrate.

Let us also emphasize that our main goal will be to describe the first instants after impact, during which the drop spreads along the substrate, this unsteady process taking place in a characteristic time scale of a few milliseconds, which is so short that gravity will not play any kind of role in the description of the drop deformation process taking place from the instant the drop touches the solid until the rim pins the substrate.

The paper is structured as follows. In § 2 we deduce the equations of motion describing the drop spreading process. In § 3 we compare the theoretical predictions with experimental observations. In § 4, simplified algebraic equations for the final shapes of the impacting drops are deduced and compared with experiments. The main conclusions are summarized in § 5.

2 Theory describing the drop spreading process

For reasons explained above, the unsteady flow taking place during the drop deformation process will be described in a frame of reference translating with a velocity  $V_{t}=V\sin \unicode[STIX]{x1D712}$ (see figures 1 and 2). Lengths, velocities, times and pressures will be made dimensionless using

$V_{t}=V\sin \unicode[STIX]{x1D712}$ (see figures 1 and 2). Lengths, velocities, times and pressures will be made dimensionless using  $R$,

$R$,  $V_{n}=V\cos \unicode[STIX]{x1D712}$,

$V_{n}=V\cos \unicode[STIX]{x1D712}$,  $R/V_{n}$,

$R/V_{n}$,  $\unicode[STIX]{x1D70C}V_{n}^{2}$ as the characteristic values of length, velocity, time and pressure and, therefore, the drop spreading process will then be characterized in terms of the following dimensionless parameters:

$\unicode[STIX]{x1D70C}V_{n}^{2}$ as the characteristic values of length, velocity, time and pressure and, therefore, the drop spreading process will then be characterized in terms of the following dimensionless parameters:

$$\begin{eqnarray}Re={\displaystyle \frac{\unicode[STIX]{x1D70C}V_{n}R}{\unicode[STIX]{x1D707}}},\quad Oh={\displaystyle \frac{\unicode[STIX]{x1D707}}{\sqrt{\unicode[STIX]{x1D70C}R\unicode[STIX]{x1D70E}}}},\quad Ca={\displaystyle \frac{\unicode[STIX]{x1D707}V_{n}}{\unicode[STIX]{x1D70E}}},\quad We={\displaystyle \frac{\unicode[STIX]{x1D70C}V_{n}^{2}R}{\unicode[STIX]{x1D70E}}},\quad Fr={\displaystyle \frac{V_{n}^{2}}{gR}}\quad \text{and}\quad Bo={\displaystyle \frac{\unicode[STIX]{x1D70C}gR^{2}}{\unicode[STIX]{x1D70E}}}.\end{eqnarray}$$

$$\begin{eqnarray}Re={\displaystyle \frac{\unicode[STIX]{x1D70C}V_{n}R}{\unicode[STIX]{x1D707}}},\quad Oh={\displaystyle \frac{\unicode[STIX]{x1D707}}{\sqrt{\unicode[STIX]{x1D70C}R\unicode[STIX]{x1D70E}}}},\quad Ca={\displaystyle \frac{\unicode[STIX]{x1D707}V_{n}}{\unicode[STIX]{x1D70E}}},\quad We={\displaystyle \frac{\unicode[STIX]{x1D70C}V_{n}^{2}R}{\unicode[STIX]{x1D70E}}},\quad Fr={\displaystyle \frac{V_{n}^{2}}{gR}}\quad \text{and}\quad Bo={\displaystyle \frac{\unicode[STIX]{x1D70C}gR^{2}}{\unicode[STIX]{x1D70E}}}.\end{eqnarray}$$ Here  $g$ indicates the gravitational acceleration.

$g$ indicates the gravitational acceleration.

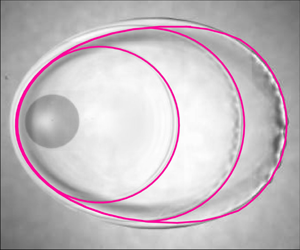

Figure 2. In the following, the experimental images corresponding to the deformed drops will be presented with a vertical orientation and then the sketch included in figure 1(c) represents a  $\unicode[STIX]{x03C0}/2$ radians clockwise rotation of the experimental visualizations. The experimental measurements of

$\unicode[STIX]{x03C0}/2$ radians clockwise rotation of the experimental visualizations. The experimental measurements of  $s(\unicode[STIX]{x1D703},t)$ to be presented next, represent the distance of the outer perimeter of the drop measured from the origin of the moving frame of reference. The continuous lines in this figure represent the results of the detection algorithm included in the Matlab toolbox. The distances to the impact point,

$s(\unicode[STIX]{x1D703},t)$ to be presented next, represent the distance of the outer perimeter of the drop measured from the origin of the moving frame of reference. The continuous lines in this figure represent the results of the detection algorithm included in the Matlab toolbox. The distances to the impact point,  $\ell (\unicode[STIX]{x03C0}/2,t)$ and

$\ell (\unicode[STIX]{x03C0}/2,t)$ and  $\ell (3\unicode[STIX]{x03C0}/2,t)$, corresponding to the rim portions respectively located at

$\ell (3\unicode[STIX]{x03C0}/2,t)$, corresponding to the rim portions respectively located at  $\unicode[STIX]{x03C0}/2$ and

$\unicode[STIX]{x03C0}/2$ and  $3\unicode[STIX]{x03C0}/2$ (see also figure 1c), as well as the definition of the drop width,

$3\unicode[STIX]{x03C0}/2$ (see also figure 1c), as well as the definition of the drop width,  $w(t)$, are indicated in the figure to highlight the fact that the asymmetric shape of the drop can be characterized by two different length scales, namely

$w(t)$, are indicated in the figure to highlight the fact that the asymmetric shape of the drop can be characterized by two different length scales, namely  $w(t)$ and

$w(t)$ and  $(\ell (\unicode[STIX]{x03C0}/2,t)+\ell (3\unicode[STIX]{x03C0}/2,t))/2$. Note that capital letters are used to denote dimensional quantities in order to differentiate them from their dimensionless versions, written using lower case letters. Then,

$(\ell (\unicode[STIX]{x03C0}/2,t)+\ell (3\unicode[STIX]{x03C0}/2,t))/2$. Note that capital letters are used to denote dimensional quantities in order to differentiate them from their dimensionless versions, written using lower case letters. Then,  $W=Rw$,

$W=Rw$,  $L=R\ell$,

$L=R\ell$,  $T=R/(V\cos \unicode[STIX]{x1D712})t$. Here,

$T=R/(V\cos \unicode[STIX]{x1D712})t$. Here,  $\unicode[STIX]{x1D712}=45^{\circ }$,

$\unicode[STIX]{x1D712}=45^{\circ }$,  $R=1.48\times 10^{-3}~\text{m}$ and

$R=1.48\times 10^{-3}~\text{m}$ and  $Oh=3.1\times 10^{-3}$,

$Oh=3.1\times 10^{-3}$,  $V_{n}=V\cos \unicode[STIX]{x1D712}=1.73~\text{m}~\text{s}^{-1}$,

$V_{n}=V\cos \unicode[STIX]{x1D712}=1.73~\text{m}~\text{s}^{-1}$,  $V_{t}=V_{n}\tan \unicode[STIX]{x1D712}=1.73~\text{m}~\text{s}^{-1}$ and

$V_{t}=V_{n}\tan \unicode[STIX]{x1D712}=1.73~\text{m}~\text{s}^{-1}$ and  $We=61$. The instants of time in the sequence are

$We=61$. The instants of time in the sequence are  $T_{1}=0.85\times 10^{-3}~\text{s}$,

$T_{1}=0.85\times 10^{-3}~\text{s}$,  $T_{2}=2.58\times 10^{-3}~\text{s}$,

$T_{2}=2.58\times 10^{-3}~\text{s}$,  $T_{3}=4.30\times 10^{-3}~\text{s}$, which correspond to the following values of the dimensionless times:

$T_{3}=4.30\times 10^{-3}~\text{s}$, which correspond to the following values of the dimensionless times:  $t_{1}=T_{1}V_{n}/R=1$,

$t_{1}=T_{1}V_{n}/R=1$,  $t_{2}=T_{2}V_{n}/R=3$,

$t_{2}=T_{2}V_{n}/R=3$,  $t_{3}=T_{3}V_{n}/R=5$. Values of

$t_{3}=T_{3}V_{n}/R=5$. Values of  $t\pm 0.04$.

$t\pm 0.04$.

However, for clarity reasons, the theoretical shapes of the drops will not be represented in the moving frame of reference, but in the laboratory frame of reference in order to compare with the experimental visualizations like the ones depicted in figure 2, which will always be oriented vertically, in contrast with the sketch in figure 1(c), rotated  $\unicode[STIX]{x03C0}/2$ radians clockwise. In order to fix ideas, figures 1(c) and 2 also represent the impact point, which is the point at which the drop first touches the substrate and it is a fixed point in the laboratory frame of reference. Figure 2 also shows the origin of the moving frame of reference, which translates with a tangential velocity

$\unicode[STIX]{x03C0}/2$ radians clockwise. In order to fix ideas, figures 1(c) and 2 also represent the impact point, which is the point at which the drop first touches the substrate and it is a fixed point in the laboratory frame of reference. Figure 2 also shows the origin of the moving frame of reference, which translates with a tangential velocity  $V\sin \unicode[STIX]{x1D712}$ – or

$V\sin \unicode[STIX]{x1D712}$ – or  $\tan \unicode[STIX]{x1D712}$ in dimensionless form – with respect to the impact point. The origin of the moving frame of reference is the origin of radial distances and

$\tan \unicode[STIX]{x1D712}$ in dimensionless form – with respect to the impact point. The origin of the moving frame of reference is the origin of radial distances and  $\unicode[STIX]{x1D703}$ is measured counterclockwise with respect to the horizontal direction, which is the line contained in the plane of the substrate perpendicular to the plane of symmetry of the drop.

$\unicode[STIX]{x1D703}$ is measured counterclockwise with respect to the horizontal direction, which is the line contained in the plane of the substrate perpendicular to the plane of symmetry of the drop.

The theoretical results to be presented here could be used to describe most of the practical situations related to the spreading of drops of low viscosity liquids such as water or ethanol. Indeed, we will assume that the ranges of values of the dimensionless parameters defined in (2.1) are such that  $Oh\ll 1$,

$Oh\ll 1$,  $We\gtrsim 10$,

$We\gtrsim 10$,  $Re\gtrsim 100$,

$Re\gtrsim 100$,  $Fr\gtrsim 30$ a fact implying that the drop is noticeably deformed after impact – see figure 2 – and that viscous effects are confined within a narrow boundary layer. Moreover, it is also assumed that the diameters of the drops are in the range of a few millimetres or below, a fact implying that

$Fr\gtrsim 30$ a fact implying that the drop is noticeably deformed after impact – see figure 2 – and that viscous effects are confined within a narrow boundary layer. Moreover, it is also assumed that the diameters of the drops are in the range of a few millimetres or below, a fact implying that  $Bo=\unicode[STIX]{x1D70C}gR^{2}/\unicode[STIX]{x1D70E}\lesssim O(1)$. However, capillary forces are much larger than the weight of the rim bordering the expanding liquid sheet, i.e.

$Bo=\unicode[STIX]{x1D70C}gR^{2}/\unicode[STIX]{x1D70E}\lesssim O(1)$. However, capillary forces are much larger than the weight of the rim bordering the expanding liquid sheet, i.e.  $b^{2}Bo=\unicode[STIX]{x1D70C}gR^{2}b^{2}/\unicode[STIX]{x1D70E}\ll 1$, with

$b^{2}Bo=\unicode[STIX]{x1D70C}gR^{2}b^{2}/\unicode[STIX]{x1D70E}\ll 1$, with  $b\ll 1$ the dimensionless rim thickness (see figures 1 and 2) and since, in addition,

$b\ll 1$ the dimensionless rim thickness (see figures 1 and 2) and since, in addition,  $Fr^{-1}=gR/V_{n}^{2}\ll 1$, namely that gravity does not have the time to sufficiently modify the initial drop velocity during the characteristic time the drop impacts the substrate, gravitational effects will be neglected in the analysis that follows.

$Fr^{-1}=gR/V_{n}^{2}\ll 1$, namely that gravity does not have the time to sufficiently modify the initial drop velocity during the characteristic time the drop impacts the substrate, gravitational effects will be neglected in the analysis that follows.

Since the analysis will be carried out following the notation in Gordillo et al. (Reference Gordillo, Riboux and Quintero2019), from now on, lower case variables will be used to denote the dimensionless version of dimensional quantities, which will be written using capital letters. The origin of times is set at the instant the drop first touches the substrate at the so-called impact point (see figures 1c and 2).

In order to describe the time evolution of the rim position and thickness, it will prove essential to use the ideas in Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) and divide the flow into the following well defined regions (see figure 1): (i) the drop region, where the liquid is accelerated thanks to pressure gradients and extends from  $r=0$ to

$r=0$ to  $r=\sqrt{3t}$; (ii) the lamella, which is a slender region where the pressure gradient can be neglected and connects the end of the drop region, located at

$r=\sqrt{3t}$; (ii) the lamella, which is a slender region where the pressure gradient can be neglected and connects the end of the drop region, located at  $r=\sqrt{3t}$, with the third region, the rim; (iii) the rim, which is located at a distance from the origin of the moving frame of reference

$r=\sqrt{3t}$, with the third region, the rim; (iii) the rim, which is located at a distance from the origin of the moving frame of reference  $r=s(\unicode[STIX]{x1D703},t)$ and denotes the portion of fluid of thickness

$r=s(\unicode[STIX]{x1D703},t)$ and denotes the portion of fluid of thickness  $b(\unicode[STIX]{x1D703},t)$ and velocity

$b(\unicode[STIX]{x1D703},t)$ and velocity  $v(\unicode[STIX]{x1D703},t)$ that limits the perimeter of the spreading drop.

$v(\unicode[STIX]{x1D703},t)$ that limits the perimeter of the spreading drop.

Both the radial position and thickness of the rim can be calculated in the moving frame of reference by making use of the balances of mass and momentum (Taylor Reference Taylor1959; Eggers et al. Reference Eggers, Fontelos, Josserand and Zaleski2010; Villermaux & Bossa Reference Villermaux and Bossa2011; Gordillo et al. Reference Gordillo, Riboux and Quintero2019), i.e.

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\unicode[STIX]{x1D6FC}{\displaystyle \frac{\unicode[STIX]{x03C0}}{4}}{\displaystyle \frac{\text{d}b^{2}}{\text{d}t}}=[u(s,\unicode[STIX]{x1D703},t)-v]h(s,\unicode[STIX]{x1D703},t),\quad {\displaystyle \frac{\text{d}s}{\text{d}t}}=v,\\ \unicode[STIX]{x1D6FC}{\displaystyle \frac{\unicode[STIX]{x03C0}b^{2}}{4}}{\displaystyle \frac{\text{d}v}{\text{d}t}}=[u(s,\unicode[STIX]{x1D703},t)-v]^{2}h(s,\unicode[STIX]{x1D703},t)-(1+\unicode[STIX]{x1D6FD})\mathit{We}^{-1}-\unicode[STIX]{x1D6FE}We^{-1}Ca(v-\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}),\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}\unicode[STIX]{x1D6FC}{\displaystyle \frac{\unicode[STIX]{x03C0}}{4}}{\displaystyle \frac{\text{d}b^{2}}{\text{d}t}}=[u(s,\unicode[STIX]{x1D703},t)-v]h(s,\unicode[STIX]{x1D703},t),\quad {\displaystyle \frac{\text{d}s}{\text{d}t}}=v,\\ \unicode[STIX]{x1D6FC}{\displaystyle \frac{\unicode[STIX]{x03C0}b^{2}}{4}}{\displaystyle \frac{\text{d}v}{\text{d}t}}=[u(s,\unicode[STIX]{x1D703},t)-v]^{2}h(s,\unicode[STIX]{x1D703},t)-(1+\unicode[STIX]{x1D6FD})\mathit{We}^{-1}-\unicode[STIX]{x1D6FE}We^{-1}Ca(v-\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}),\end{array}\right\}\end{eqnarray}$$ with  $u(s,\unicode[STIX]{x1D703},t)$ and

$u(s,\unicode[STIX]{x1D703},t)$ and  $h(s,\unicode[STIX]{x1D703},t)$ in (2.2) the averaged radial velocity and the thickness of the thin film – the lamella – which, as it was mentioned above, extends along the spatio-temporal region

$h(s,\unicode[STIX]{x1D703},t)$ in (2.2) the averaged radial velocity and the thickness of the thin film – the lamella – which, as it was mentioned above, extends along the spatio-temporal region  $\sqrt{3t}\leqslant r\leqslant s(\unicode[STIX]{x1D703},t)$ (see figure 1). In (2.2),

$\sqrt{3t}\leqslant r\leqslant s(\unicode[STIX]{x1D703},t)$ (see figure 1). In (2.2),  $\unicode[STIX]{x1D6FC}$ and

$\unicode[STIX]{x1D6FC}$ and  $\unicode[STIX]{x1D6FD}$ depend on the wetting properties of the solid and, for the case at hand, which corresponds to hydrophilic substrates,

$\unicode[STIX]{x1D6FD}$ depend on the wetting properties of the solid and, for the case at hand, which corresponds to hydrophilic substrates,  $\unicode[STIX]{x1D6FC}=1/2$ and

$\unicode[STIX]{x1D6FC}=1/2$ and  $\unicode[STIX]{x1D6FD}=0$ because the rim cross-sectional area will be approximated by that of a semicircle and the value of the advancing contact angle is assumed to be constant and equal to

$\unicode[STIX]{x1D6FD}=0$ because the rim cross-sectional area will be approximated by that of a semicircle and the value of the advancing contact angle is assumed to be constant and equal to  $\unicode[STIX]{x03C0}/2$. The last term in the momentum equation in (2.2), which represents the integral of the viscous shear forces at the wall

$\unicode[STIX]{x03C0}/2$. The last term in the momentum equation in (2.2), which represents the integral of the viscous shear forces at the wall  ${\sim}Re^{-1}(v-\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703})/b$ along the rim region of width

${\sim}Re^{-1}(v-\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703})/b$ along the rim region of width  ${\sim}b$, with

${\sim}b$, with  $\unicode[STIX]{x1D6FE}\sim O(1)$, will be neglected in what follows because the range of parameters investigated here is such that

$\unicode[STIX]{x1D6FE}\sim O(1)$, will be neglected in what follows because the range of parameters investigated here is such that  $Ca\ll 1$.

$Ca\ll 1$.

The system of (2.2) is integrated specifying the initial conditions at the instant  $t_{e}$ the lamella is initially ejected. In Riboux & Gordillo (Reference Riboux and Gordillo2014, Reference Riboux and Gordillo2017) it is predicted and verified experimentally that the ejection time can be expressed as

$t_{e}$ the lamella is initially ejected. In Riboux & Gordillo (Reference Riboux and Gordillo2014, Reference Riboux and Gordillo2017) it is predicted and verified experimentally that the ejection time can be expressed as  $t_{e}=1.05\,\mathit{We}^{-2/3}$ and also that

$t_{e}=1.05\,\mathit{We}^{-2/3}$ and also that

$$\begin{eqnarray}s(t_{e})=\sqrt{3t_{e}},\quad v(t_{e})=1/2\sqrt{3/t_{e}}\quad \text{and}\quad b(t_{e})={\displaystyle \frac{\sqrt{12}}{\unicode[STIX]{x03C0}}}t_{e}^{3/2}\end{eqnarray}$$

$$\begin{eqnarray}s(t_{e})=\sqrt{3t_{e}},\quad v(t_{e})=1/2\sqrt{3/t_{e}}\quad \text{and}\quad b(t_{e})={\displaystyle \frac{\sqrt{12}}{\unicode[STIX]{x03C0}}}t_{e}^{3/2}\end{eqnarray}$$ if  $\mathit{Re}^{1/6}\mathit{Oh}^{2/3}<0.25$, which is the case for the experiments reported here and also for many other usual experimental conditions.

$\mathit{Re}^{1/6}\mathit{Oh}^{2/3}<0.25$, which is the case for the experiments reported here and also for many other usual experimental conditions.

Clearly, the system (2.2) can only be integrated once the functions  $u(r,\unicode[STIX]{x1D703},t)$ and

$u(r,\unicode[STIX]{x1D703},t)$ and  $h(r,\unicode[STIX]{x1D703},t)$ describing the averaged velocity and height of the lamella are particularized at the radial position where the rim is located, namely

$h(r,\unicode[STIX]{x1D703},t)$ describing the averaged velocity and height of the lamella are particularized at the radial position where the rim is located, namely  $r=s(\unicode[STIX]{x1D703},t)$. Applying local balances of mass and momentum in a differential portion of the lamella, it is shown in appendix A, that

$r=s(\unicode[STIX]{x1D703},t)$. Applying local balances of mass and momentum in a differential portion of the lamella, it is shown in appendix A, that  $u$ and

$u$ and  $h$ satisfy the system of equations

$h$ satisfy the system of equations

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}{\displaystyle \frac{\unicode[STIX]{x2202}(rh)}{\unicode[STIX]{x2202}t}}+u{\displaystyle \frac{\unicode[STIX]{x2202}(rh)}{\unicode[STIX]{x2202}r}}+rh{\displaystyle \frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}r}}=\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}{\displaystyle \frac{\unicode[STIX]{x1D6FF}}{2}},\\ {\displaystyle \frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}t}}+u{\displaystyle \frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}r}}=-\unicode[STIX]{x1D706}{\displaystyle \frac{u}{h\sqrt{\mathit{Re }t}}},\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}{\displaystyle \frac{\unicode[STIX]{x2202}(rh)}{\unicode[STIX]{x2202}t}}+u{\displaystyle \frac{\unicode[STIX]{x2202}(rh)}{\unicode[STIX]{x2202}r}}+rh{\displaystyle \frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}r}}=\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}{\displaystyle \frac{\unicode[STIX]{x1D6FF}}{2}},\\ {\displaystyle \frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}t}}+u{\displaystyle \frac{\unicode[STIX]{x2202}u}{\unicode[STIX]{x2202}r}}=-\unicode[STIX]{x1D706}{\displaystyle \frac{u}{h\sqrt{\mathit{Re }t}}},\end{array}\right\}\end{eqnarray}$$with the friction factor given by

$$\begin{eqnarray}\unicode[STIX]{x1D706}(r,\unicode[STIX]{x1D703},t)\simeq 1-\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}\sqrt{{\displaystyle \frac{x}{3}}}+{\displaystyle \frac{\tan ^{2}\unicode[STIX]{x1D712}\cos ^{2}\unicode[STIX]{x1D703}}{18}}x\quad \text{where }x=3\left({\displaystyle \frac{t}{r}}\right)^{2}\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D706}(r,\unicode[STIX]{x1D703},t)\simeq 1-\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}\sqrt{{\displaystyle \frac{x}{3}}}+{\displaystyle \frac{\tan ^{2}\unicode[STIX]{x1D712}\cos ^{2}\unicode[STIX]{x1D703}}{18}}x\quad \text{where }x=3\left({\displaystyle \frac{t}{r}}\right)^{2}\end{eqnarray}$$and

$$\begin{eqnarray}\unicode[STIX]{x1D6FF}=\sqrt{{\displaystyle \frac{t}{Re}}}\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D6FF}=\sqrt{{\displaystyle \frac{t}{Re}}}\end{eqnarray}$$ indicating the boundary layer thickness which, in a first approximation, does not depend on either  $r$ or

$r$ or  $\unicode[STIX]{x1D703}$, as it is demonstrated in appendix B.

$\unicode[STIX]{x1D703}$, as it is demonstrated in appendix B.

The partial differential equations (2.4) can be approximately solved, in the limit  $Re\gg 1$, expressing

$Re\gg 1$, expressing  $u$ and

$u$ and  $h$ as (Gordillo et al. Reference Gordillo, Riboux and Quintero2019)

$h$ as (Gordillo et al. Reference Gordillo, Riboux and Quintero2019)

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}u(r,\unicode[STIX]{x1D703},t)=u_{0}(r,t)+\mathit{Re}^{-1/2}u_{1}(r,\unicode[STIX]{x1D703},t)+O(\mathit{Re}^{-1}),\\ h(r,\unicode[STIX]{x1D703},t)=h_{0}(r,t)+\mathit{Re}^{-1/2}h_{1}(r,\unicode[STIX]{x1D703},t)+O(\mathit{Re}^{-1}).\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}u(r,\unicode[STIX]{x1D703},t)=u_{0}(r,t)+\mathit{Re}^{-1/2}u_{1}(r,\unicode[STIX]{x1D703},t)+O(\mathit{Re}^{-1}),\\ h(r,\unicode[STIX]{x1D703},t)=h_{0}(r,t)+\mathit{Re}^{-1/2}h_{1}(r,\unicode[STIX]{x1D703},t)+O(\mathit{Re}^{-1}).\end{array}\right\}\end{eqnarray}$$ The substitution of the ansatz (2.7) into the system (2.4), yields the following four partial differential equations for  $u_{0}(r,t)$,

$u_{0}(r,t)$,  $h_{0}(r,t)$,

$h_{0}(r,t)$,  $u_{1}(r,\unicode[STIX]{x1D703},t)$ and

$u_{1}(r,\unicode[STIX]{x1D703},t)$ and  $h_{1}(r,\unicode[STIX]{x1D703},t)$:

$h_{1}(r,\unicode[STIX]{x1D703},t)$:

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}t}}+u_{0}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}=0\quad \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}u_{0}}{\text{D}t}}=0,\\ {\displaystyle \frac{\unicode[STIX]{x2202}(rh_{0})}{\unicode[STIX]{x2202}t}}+u_{0}{\displaystyle \frac{\unicode[STIX]{x2202}(rh_{0})}{\unicode[STIX]{x2202}r}}+rh_{0}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}=0\quad \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}(rh_{0})}{\text{D}t}}=-rh_{0}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}},\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}t}}+u_{0}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}=0\quad \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}u_{0}}{\text{D}t}}=0,\\ {\displaystyle \frac{\unicode[STIX]{x2202}(rh_{0})}{\unicode[STIX]{x2202}t}}+u_{0}{\displaystyle \frac{\unicode[STIX]{x2202}(rh_{0})}{\unicode[STIX]{x2202}r}}+rh_{0}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}=0\quad \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}(rh_{0})}{\text{D}t}}=-rh_{0}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}},\end{array}\right\}\end{eqnarray}$$ $$\begin{eqnarray}\left.\begin{array}{@{}c@{}}{\displaystyle \frac{\unicode[STIX]{x2202}u_{1}}{\unicode[STIX]{x2202}t}}+u_{0}{\displaystyle \frac{\unicode[STIX]{x2202}u_{1}}{\unicode[STIX]{x2202}r}}+u_{1}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}=-{\displaystyle \frac{\unicode[STIX]{x1D706}u_{0}}{h_{0}\sqrt{t}}}\quad \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}u_{1}}{\text{D}t}}+u_{1}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}=-{\displaystyle \frac{\unicode[STIX]{x1D706}u_{0}}{h_{0}\sqrt{t}}},\\ {\displaystyle \frac{\unicode[STIX]{x2202}(rh_{1})}{\unicode[STIX]{x2202}t}}+u_{0}{\displaystyle \frac{\unicode[STIX]{x2202}(rh_{1})}{\unicode[STIX]{x2202}r}}+u_{1}{\displaystyle \frac{\unicode[STIX]{x2202}(rh_{0})}{\unicode[STIX]{x2202}r}}+rh_{0}{\displaystyle \frac{\unicode[STIX]{x2202}u_{1}}{\unicode[STIX]{x2202}r}}+rh_{1}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}-\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}{\displaystyle \frac{\sqrt{t}}{2}}=0\\ \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}(rh_{1})}{\text{D}t}}+rh_{1}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}=\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}{\displaystyle \frac{\sqrt{t}}{2}}-{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}}(u_{1}rh_{0}).\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}{\displaystyle \frac{\unicode[STIX]{x2202}u_{1}}{\unicode[STIX]{x2202}t}}+u_{0}{\displaystyle \frac{\unicode[STIX]{x2202}u_{1}}{\unicode[STIX]{x2202}r}}+u_{1}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}=-{\displaystyle \frac{\unicode[STIX]{x1D706}u_{0}}{h_{0}\sqrt{t}}}\quad \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}u_{1}}{\text{D}t}}+u_{1}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}=-{\displaystyle \frac{\unicode[STIX]{x1D706}u_{0}}{h_{0}\sqrt{t}}},\\ {\displaystyle \frac{\unicode[STIX]{x2202}(rh_{1})}{\unicode[STIX]{x2202}t}}+u_{0}{\displaystyle \frac{\unicode[STIX]{x2202}(rh_{1})}{\unicode[STIX]{x2202}r}}+u_{1}{\displaystyle \frac{\unicode[STIX]{x2202}(rh_{0})}{\unicode[STIX]{x2202}r}}+rh_{0}{\displaystyle \frac{\unicode[STIX]{x2202}u_{1}}{\unicode[STIX]{x2202}r}}+rh_{1}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}-\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}{\displaystyle \frac{\sqrt{t}}{2}}=0\\ \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}(rh_{1})}{\text{D}t}}+rh_{1}{\displaystyle \frac{\unicode[STIX]{x2202}u_{0}}{\unicode[STIX]{x2202}r}}=\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}{\displaystyle \frac{\sqrt{t}}{2}}-{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}}(u_{1}rh_{0}).\end{array}\right\}\end{eqnarray}$$ Here  $\text{D}/\text{D}t\equiv \unicode[STIX]{x2202}/\unicode[STIX]{x2202}t+u_{0}\unicode[STIX]{x2202}/\unicode[STIX]{x2202}r$.

$\text{D}/\text{D}t\equiv \unicode[STIX]{x2202}/\unicode[STIX]{x2202}t+u_{0}\unicode[STIX]{x2202}/\unicode[STIX]{x2202}r$.

Equations (2.8)–(2.9) will be solved using the method of characteristics, as we already did in Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) for the case of normal impact ( $\unicode[STIX]{x1D712}=0$), once appropriate boundary conditions are imposed at the spatio-temporal boundary

$\unicode[STIX]{x1D712}=0$), once appropriate boundary conditions are imposed at the spatio-temporal boundary  $(r,t)=(\sqrt{3x},x)$ separating the drop and the lamella regions. For that purpose, note that at the spatio-temporal boundary

$(r,t)=(\sqrt{3x},x)$ separating the drop and the lamella regions. For that purpose, note that at the spatio-temporal boundary  $r=\sqrt{3x}$ both the height of the lamella and the liquid velocity were deduced in the potential flow limit (frictionless limit) in Riboux & Gordillo (Reference Riboux and Gordillo2014, Reference Riboux and Gordillo2016):

$r=\sqrt{3x}$ both the height of the lamella and the liquid velocity were deduced in the potential flow limit (frictionless limit) in Riboux & Gordillo (Reference Riboux and Gordillo2014, Reference Riboux and Gordillo2016):  $u(\sqrt{3x})=u_{a}(x)=\sqrt{3/x}$ and

$u(\sqrt{3x})=u_{a}(x)=\sqrt{3/x}$ and  $h(\sqrt{3x},x)=h_{a}(x)$, with

$h(\sqrt{3x},x)=h_{a}(x)$, with  $h_{a}(x)$ a function determined numerically in Riboux & Gordillo (Reference Riboux and Gordillo2016), which can be approximated as (Gordillo et al. Reference Gordillo, Riboux and Quintero2019)

$h_{a}(x)$ a function determined numerically in Riboux & Gordillo (Reference Riboux and Gordillo2016), which can be approximated as (Gordillo et al. Reference Gordillo, Riboux and Quintero2019)

$$\begin{eqnarray}\displaystyle h_{a}(x)=P(x) & = & \displaystyle \mathop{\sum }_{i=0}^{9}p_{i}x^{i}\nonumber\\ \displaystyle & & \displaystyle \text{with}\quad p_{0}=3.95812707\times 10^{-4},\quad p_{1}=1.22669850\times 10^{-1},\nonumber\\ \displaystyle & & \displaystyle p_{2}=-1.04054024\times 10^{-1},\quad p_{3}=4.37229580\times 10^{-2},\nonumber\\ \displaystyle & & \displaystyle p_{4}=-1.09184802\times 10^{-2},\quad p_{5}=1.70579418\times 10^{-3},\nonumber\\ \displaystyle & & \displaystyle p_{6}=-1.67926979\times 10^{-4},\quad p_{7}=1.01063551\times 10^{-5},\nonumber\\ \displaystyle & & \displaystyle p_{8}=-3.39290090\times 10^{-7}\quad p_{9}=4.86535897\times 10^{-9}.\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle h_{a}(x)=P(x) & = & \displaystyle \mathop{\sum }_{i=0}^{9}p_{i}x^{i}\nonumber\\ \displaystyle & & \displaystyle \text{with}\quad p_{0}=3.95812707\times 10^{-4},\quad p_{1}=1.22669850\times 10^{-1},\nonumber\\ \displaystyle & & \displaystyle p_{2}=-1.04054024\times 10^{-1},\quad p_{3}=4.37229580\times 10^{-2},\nonumber\\ \displaystyle & & \displaystyle p_{4}=-1.09184802\times 10^{-2},\quad p_{5}=1.70579418\times 10^{-3},\nonumber\\ \displaystyle & & \displaystyle p_{6}=-1.67926979\times 10^{-4},\quad p_{7}=1.01063551\times 10^{-5},\nonumber\\ \displaystyle & & \displaystyle p_{8}=-3.39290090\times 10^{-7}\quad p_{9}=4.86535897\times 10^{-9}.\end{eqnarray}$$ The presence of the boundary layer does not change, to leading order, the normal velocity field at the surface of the drop with respect to the potential flow solution. Therefore, the mass balance demands that the mass flux per unit length at  $r=\sqrt{3x}$ in a real case, namely when a boundary layer is present, is identical to this quantity in the frictionless limit. Hence, (Gordillo et al. Reference Gordillo, Riboux and Quintero2019)

$r=\sqrt{3x}$ in a real case, namely when a boundary layer is present, is identical to this quantity in the frictionless limit. Hence, (Gordillo et al. Reference Gordillo, Riboux and Quintero2019)

$$\begin{eqnarray}h_{a}(x)u_{a}(x)=u_{a}(h-\unicode[STIX]{x1D6FF})+{\displaystyle \frac{\unicode[STIX]{x1D6FF}}{2}}(u_{a}+\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703})=u(r=\sqrt{3x},\unicode[STIX]{x1D703},x)h(\sqrt{3x},\unicode[STIX]{x1D703},x),\end{eqnarray}$$

$$\begin{eqnarray}h_{a}(x)u_{a}(x)=u_{a}(h-\unicode[STIX]{x1D6FF})+{\displaystyle \frac{\unicode[STIX]{x1D6FF}}{2}}(u_{a}+\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703})=u(r=\sqrt{3x},\unicode[STIX]{x1D703},x)h(\sqrt{3x},\unicode[STIX]{x1D703},x),\end{eqnarray}$$where we have assumed that the velocity profiles are linear within the boundary layer (see (A 5) in appendix A). Therefore, from the two equations in (2.11) it can be deduced that

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}h(\sqrt{3x},\unicode[STIX]{x1D703},x)=h_{a}\left(1+{\displaystyle \frac{\unicode[STIX]{x1D6FF}}{2h_{a}}}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{u_{a}}}\right)\right),\\ u(\sqrt{3x},\unicode[STIX]{x1D703},x)=u_{a}\left(1+{\displaystyle \frac{\unicode[STIX]{x1D6FF}}{2h_{a}}}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{u_{a}}}\right)\right)^{-1},\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}h(\sqrt{3x},\unicode[STIX]{x1D703},x)=h_{a}\left(1+{\displaystyle \frac{\unicode[STIX]{x1D6FF}}{2h_{a}}}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{u_{a}}}\right)\right),\\ u(\sqrt{3x},\unicode[STIX]{x1D703},x)=u_{a}\left(1+{\displaystyle \frac{\unicode[STIX]{x1D6FF}}{2h_{a}}}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{u_{a}}}\right)\right)^{-1},\end{array}\right\}\end{eqnarray}$$ with  $u_{a}=\sqrt{3/x}$ and

$u_{a}=\sqrt{3/x}$ and  $\unicode[STIX]{x1D6FF}(x)=\sqrt{x/Re}$.

$\unicode[STIX]{x1D6FF}(x)=\sqrt{x/Re}$.

In the limit  $Re\gg 1$, (2.12) can be linearized to give

$Re\gg 1$, (2.12) can be linearized to give

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}h(\sqrt{3x},\unicode[STIX]{x1D703},x)=h_{a}(x)+{\displaystyle \frac{\sqrt{x}}{2}}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)Re^{-1/2},\\ u(\sqrt{3x},\unicode[STIX]{x1D703},x)\simeq \sqrt{{\displaystyle \frac{3}{x}}}-{\displaystyle \frac{\sqrt{3}}{2h_{a}(x)}}\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)Re^{-1/2},\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}h(\sqrt{3x},\unicode[STIX]{x1D703},x)=h_{a}(x)+{\displaystyle \frac{\sqrt{x}}{2}}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)Re^{-1/2},\\ u(\sqrt{3x},\unicode[STIX]{x1D703},x)\simeq \sqrt{{\displaystyle \frac{3}{x}}}-{\displaystyle \frac{\sqrt{3}}{2h_{a}(x)}}\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)Re^{-1/2},\end{array}\right\}\end{eqnarray}$$ with  $\unicode[STIX]{x1D709}$ a variable such that the expression in (2.13) is a good approximation to the exact value of

$\unicode[STIX]{x1D709}$ a variable such that the expression in (2.13) is a good approximation to the exact value of  $u$ in (2.12) for all values of

$u$ in (2.12) for all values of  $x$. For instance, when

$x$. For instance, when  $\unicode[STIX]{x1D6FF}\ll h_{a}$,

$\unicode[STIX]{x1D6FF}\ll h_{a}$,  $\unicode[STIX]{x1D709}=1$, while if

$\unicode[STIX]{x1D709}=1$, while if  $\unicode[STIX]{x1D6FF}\sim h_{a}$, the approximation in (2.13) to the exact value will be good if

$\unicode[STIX]{x1D6FF}\sim h_{a}$, the approximation in (2.13) to the exact value will be good if  $\unicode[STIX]{x1D709}\simeq 2/3$. The range of Ohnesorge numbers considered here,

$\unicode[STIX]{x1D709}\simeq 2/3$. The range of Ohnesorge numbers considered here,  $10^{-3}\leqslant Oh\leqslant 10^{-2}$, is such that the ratio

$10^{-3}\leqslant Oh\leqslant 10^{-2}$, is such that the ratio  $\unicode[STIX]{x1D6FF}/h_{a}$ is of order unity and, then, all the results presented here are calculated taking the value

$\unicode[STIX]{x1D6FF}/h_{a}$ is of order unity and, then, all the results presented here are calculated taking the value  $\unicode[STIX]{x1D709}=2/3$ (Gordillo et al. Reference Gordillo, Riboux and Quintero2019).

$\unicode[STIX]{x1D709}=2/3$ (Gordillo et al. Reference Gordillo, Riboux and Quintero2019).

Therefore, making use of (2.7) and (2.13) it can be deduced that

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}u_{0}(\sqrt{3x},\unicode[STIX]{x1D703},x)=\sqrt{{\displaystyle \frac{3}{x}}},\quad u_{1}(\sqrt{3x},\unicode[STIX]{x1D703},x)=-{\displaystyle \frac{\sqrt{3}}{2h_{a}(x)}}\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right),\\ h_{0}(\sqrt{3x},\unicode[STIX]{x1D703},x)=h_{a}(x)\quad \text{and}\quad h_{1}(\sqrt{3x},\unicode[STIX]{x1D703},x)={\displaystyle \frac{\sqrt{x}}{2}}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right).\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}u_{0}(\sqrt{3x},\unicode[STIX]{x1D703},x)=\sqrt{{\displaystyle \frac{3}{x}}},\quad u_{1}(\sqrt{3x},\unicode[STIX]{x1D703},x)=-{\displaystyle \frac{\sqrt{3}}{2h_{a}(x)}}\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right),\\ h_{0}(\sqrt{3x},\unicode[STIX]{x1D703},x)=h_{a}(x)\quad \text{and}\quad h_{1}(\sqrt{3x},\unicode[STIX]{x1D703},x)={\displaystyle \frac{\sqrt{x}}{2}}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right).\end{array}\right\}\end{eqnarray}$$ We now follow the steps in Gordillo et al. (Reference Gordillo, Riboux and Quintero2019) and integrate the momentum equation in (2.8) along rays  $\text{d}r/\text{d}t=\sqrt{3/x}$ subjected to the corresponding boundary condition in (2.14), yielding

$\text{d}r/\text{d}t=\sqrt{3/x}$ subjected to the corresponding boundary condition in (2.14), yielding

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}u_{0}(r,t)=\sqrt{{\displaystyle \frac{3}{x}}}\quad \text{along}\quad {\displaystyle \frac{\text{d}r}{\text{d}t}}=\sqrt{{\displaystyle \frac{3}{x}}}\quad \;\Longrightarrow \;\quad r=\sqrt{3x}+\sqrt{{\displaystyle \frac{3}{x}}}(t-x)\\ \;\Longrightarrow \;\quad r=\sqrt{{\displaystyle \frac{3}{x}}}t\quad \;\Longrightarrow \;x=3\left({\displaystyle \frac{t}{r}}\right)^{2}\quad \;\Longrightarrow \;\quad u_{0}(r,t)=\sqrt{{\displaystyle \frac{3}{3(t/r)^{2}}}}={\displaystyle \frac{r}{t}}.\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}u_{0}(r,t)=\sqrt{{\displaystyle \frac{3}{x}}}\quad \text{along}\quad {\displaystyle \frac{\text{d}r}{\text{d}t}}=\sqrt{{\displaystyle \frac{3}{x}}}\quad \;\Longrightarrow \;\quad r=\sqrt{3x}+\sqrt{{\displaystyle \frac{3}{x}}}(t-x)\\ \;\Longrightarrow \;\quad r=\sqrt{{\displaystyle \frac{3}{x}}}t\quad \;\Longrightarrow \;x=3\left({\displaystyle \frac{t}{r}}\right)^{2}\quad \;\Longrightarrow \;\quad u_{0}(r,t)=\sqrt{{\displaystyle \frac{3}{3(t/r)^{2}}}}={\displaystyle \frac{r}{t}}.\end{array}\right\}\end{eqnarray}$$ Moreover, the integration of the equation for  $h_{0}(r,t)$ in (2.8) along the ray

$h_{0}(r,t)$ in (2.8) along the ray  $\text{d}r/\text{d}t=\sqrt{3/x}$ yields

$\text{d}r/\text{d}t=\sqrt{3/x}$ yields

$$\begin{eqnarray}{\displaystyle \frac{\unicode[STIX]{x2202}(rh_{0})}{\unicode[STIX]{x2202}t}}+u_{0}{\displaystyle \frac{\unicode[STIX]{x2202}(rh_{0})}{\unicode[STIX]{x2202}r}}+{\displaystyle \frac{rh_{0}}{t}}=0\quad \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}(rh_{0}t)}{\text{D}t}}=0\quad \;\Longrightarrow \;\quad h_{0}(r,t)=9{\displaystyle \frac{t^{2}}{r^{4}}}h_{a}[3(t/r)^{2}],\end{eqnarray}$$

$$\begin{eqnarray}{\displaystyle \frac{\unicode[STIX]{x2202}(rh_{0})}{\unicode[STIX]{x2202}t}}+u_{0}{\displaystyle \frac{\unicode[STIX]{x2202}(rh_{0})}{\unicode[STIX]{x2202}r}}+{\displaystyle \frac{rh_{0}}{t}}=0\quad \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}(rh_{0}t)}{\text{D}t}}=0\quad \;\Longrightarrow \;\quad h_{0}(r,t)=9{\displaystyle \frac{t^{2}}{r^{4}}}h_{a}[3(t/r)^{2}],\end{eqnarray}$$ where we have made use of the fact that  $\unicode[STIX]{x2202}u_{0}/\unicode[STIX]{x2202}r=1/t$, the relationship between

$\unicode[STIX]{x2202}u_{0}/\unicode[STIX]{x2202}r=1/t$, the relationship between  $x$ with

$x$ with  $r$ and

$r$ and  $t$ in (2.15) and of the corresponding boundary condition in (2.14). Equations (2.15)–(2.16) recovers the result in Gordillo et al. (Reference Gordillo, Riboux and Quintero2019).

$t$ in (2.15) and of the corresponding boundary condition in (2.14). Equations (2.15)–(2.16) recovers the result in Gordillo et al. (Reference Gordillo, Riboux and Quintero2019).

Now, using the expression for  $u_{0}$ in (2.15) and multiplying both sides of the equations in (2.9) by

$u_{0}$ in (2.15) and multiplying both sides of the equations in (2.9) by  $t$, we find that

$t$, we find that

$$\begin{eqnarray}{\displaystyle \frac{\text{D}(u_{1}t)}{\text{D}t}}=-{\displaystyle \frac{\unicode[STIX]{x1D706}u_{0}}{h_{0}\sqrt{t}}}t,\quad {\displaystyle \frac{\text{D}(rh_{1}t)}{\text{D}t}}=-{\displaystyle \frac{1}{t}}{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}}(rh_{0}tu_{1}t)+\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}{\displaystyle \frac{t^{3/2}}{2}}.\end{eqnarray}$$

$$\begin{eqnarray}{\displaystyle \frac{\text{D}(u_{1}t)}{\text{D}t}}=-{\displaystyle \frac{\unicode[STIX]{x1D706}u_{0}}{h_{0}\sqrt{t}}}t,\quad {\displaystyle \frac{\text{D}(rh_{1}t)}{\text{D}t}}=-{\displaystyle \frac{1}{t}}{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}}(rh_{0}tu_{1}t)+\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}{\displaystyle \frac{t^{3/2}}{2}}.\end{eqnarray}$$ The equation for  $u_{1}$ in (2.17) can be integrated along rays

$u_{1}$ in (2.17) can be integrated along rays  $r=\sqrt{3/x}\,t$ taking into account that, by virtue of (2.16),

$r=\sqrt{3/x}\,t$ taking into account that, by virtue of (2.16),  $\text{D}(rh_{0}t)/\text{D}t=0$,

$\text{D}(rh_{0}t)/\text{D}t=0$,

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}{\displaystyle \frac{\text{D}(u_{1}t)}{\text{D}t}}=-{\displaystyle \frac{\unicode[STIX]{x1D706}u_{0}}{h_{0}\sqrt{t}}}t\quad \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}(u_{1}trh_{0}t)}{\text{D}t}}={\displaystyle \frac{-3\unicode[STIX]{x1D706}}{x}}t^{5/2}\quad \;\Longrightarrow \;\\ u_{1}(r,\unicode[STIX]{x1D703},t)=-{\displaystyle \frac{1}{th_{a}(x)}}\left[{\displaystyle \frac{\sqrt{3}x}{2}}\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)+{\displaystyle \frac{2\sqrt{3}\unicode[STIX]{x1D706}}{7x^{5/2}}}(t^{7/2}-x^{7/2})\right],\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}{\displaystyle \frac{\text{D}(u_{1}t)}{\text{D}t}}=-{\displaystyle \frac{\unicode[STIX]{x1D706}u_{0}}{h_{0}\sqrt{t}}}t\quad \;\Longrightarrow \;\quad {\displaystyle \frac{\text{D}(u_{1}trh_{0}t)}{\text{D}t}}={\displaystyle \frac{-3\unicode[STIX]{x1D706}}{x}}t^{5/2}\quad \;\Longrightarrow \;\\ u_{1}(r,\unicode[STIX]{x1D703},t)=-{\displaystyle \frac{1}{th_{a}(x)}}\left[{\displaystyle \frac{\sqrt{3}x}{2}}\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)+{\displaystyle \frac{2\sqrt{3}\unicode[STIX]{x1D706}}{7x^{5/2}}}(t^{7/2}-x^{7/2})\right],\end{array}\right\}\end{eqnarray}$$ where we made use of the boundary condition for  $u_{1}$ in (2.14) and also of the fact that, along rays

$u_{1}$ in (2.14) and also of the fact that, along rays  $\text{d}r/\text{d}t=u_{0}=\sqrt{3/x}$ departing from the spatio-temporal boundary

$\text{d}r/\text{d}t=u_{0}=\sqrt{3/x}$ departing from the spatio-temporal boundary  $(r,t)=(\sqrt{3x},x)$,

$(r,t)=(\sqrt{3x},x)$,  $r=\sqrt{3/x}t$,

$r=\sqrt{3/x}t$,  $u_{0}=\sqrt{3/x}$ and

$u_{0}=\sqrt{3/x}$ and  $rh_{0}t=\sqrt{3x}h_{a}(x)x$.

$rh_{0}t=\sqrt{3x}h_{a}(x)x$.

To integrate the equation for  $h_{1}$ in (2.17) we make use of our previous ideas in Gordillo et al. (Reference Gordillo, Riboux and Quintero2019), which we reproduce here for clarity purposes, and note that

$h_{1}$ in (2.17) we make use of our previous ideas in Gordillo et al. (Reference Gordillo, Riboux and Quintero2019), which we reproduce here for clarity purposes, and note that  $\unicode[STIX]{x2202}(u_{1}trh_{0}t)/\unicode[STIX]{x2202}r$ can be calculated as the increment

$\unicode[STIX]{x2202}(u_{1}trh_{0}t)/\unicode[STIX]{x2202}r$ can be calculated as the increment  $\text{d}(u_{1}trh_{0}t)$ between two neighbouring rays departing from the spatio-temporal boundary

$\text{d}(u_{1}trh_{0}t)$ between two neighbouring rays departing from the spatio-temporal boundary  $(r,t)=(\sqrt{3x},x)$ at the consecutive instants

$(r,t)=(\sqrt{3x},x)$ at the consecutive instants  $x-\text{d}x$ and

$x-\text{d}x$ and  $x$ which, at a given instant

$x$ which, at a given instant  $t$ are thus separated by a distance

$t$ are thus separated by a distance  $\text{d}r=\sqrt{3}/2x^{-3/2}t\,\text{d}x$. Consequently, making use of the solution for

$\text{d}r=\sqrt{3}/2x^{-3/2}t\,\text{d}x$. Consequently, making use of the solution for  $u_{1}trh_{0}t$ in (2.18) and of the boundary condition for

$u_{1}trh_{0}t$ in (2.18) and of the boundary condition for  $u_{1}$ in (2.14),

$u_{1}$ in (2.14),

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}rh_{0}tu_{1}t-(rh_{0}tu_{1}t)(x)=-{\displaystyle \frac{6\unicode[STIX]{x1D706}}{7x}}(t^{7/2}-x^{7/2})\quad \text{with}\\ (rh_{0}tu_{1}t)(x)=-{\displaystyle \frac{\sqrt{3}}{2}}\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)x^{2}\sqrt{3x}\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}rh_{0}tu_{1}t-(rh_{0}tu_{1}t)(x)=-{\displaystyle \frac{6\unicode[STIX]{x1D706}}{7x}}(t^{7/2}-x^{7/2})\quad \text{with}\\ (rh_{0}tu_{1}t)(x)=-{\displaystyle \frac{\sqrt{3}}{2}}\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)x^{2}\sqrt{3x}\end{array}\right\}\end{eqnarray}$$ and taking into account that  $\text{d}r=\sqrt{3}/2x^{-3/2}t\,\text{d}x$,

$\text{d}r=\sqrt{3}/2x^{-3/2}t\,\text{d}x$,

$$\begin{eqnarray}-{\displaystyle \frac{1}{t}}{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}}(u_{1}trh_{0}t)={\displaystyle \frac{2x^{3/2}}{\sqrt{3}}}{\displaystyle \frac{1}{t^{2}}}{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}x}}(rh_{0}tu_{1}t(x))-{\displaystyle \frac{12x^{3/2}}{7\sqrt{3}}}{\displaystyle \frac{1}{t^{2}}}{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}x}}\left[{\displaystyle \frac{\unicode[STIX]{x1D706}}{x}}(t^{7/2}-x^{7/2})\right].\end{eqnarray}$$

$$\begin{eqnarray}-{\displaystyle \frac{1}{t}}{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}}(u_{1}trh_{0}t)={\displaystyle \frac{2x^{3/2}}{\sqrt{3}}}{\displaystyle \frac{1}{t^{2}}}{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}x}}(rh_{0}tu_{1}t(x))-{\displaystyle \frac{12x^{3/2}}{7\sqrt{3}}}{\displaystyle \frac{1}{t^{2}}}{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}x}}\left[{\displaystyle \frac{\unicode[STIX]{x1D706}}{x}}(t^{7/2}-x^{7/2})\right].\end{eqnarray}$$Hence,

$$\begin{eqnarray}\displaystyle -{\displaystyle \frac{1}{t}}{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}}(u_{1}trh_{0}t) & = & \displaystyle -{\displaystyle \frac{2}{14\sqrt{3}t^{2}}}\left[\left(52.5\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)-30\unicode[STIX]{x1D706}\right)x^{3}-12\unicode[STIX]{x1D706}x^{-1/2}t^{7/2}\right]\nonumber\\ \displaystyle & & \displaystyle +\,{\displaystyle \frac{x^{4}}{2\sqrt{x}}}{\displaystyle \frac{\unicode[STIX]{x1D709}}{t^{2}}}\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}-{\displaystyle \frac{12x^{3/2}}{7\sqrt{3}}}{\displaystyle \frac{1}{xt^{2}}}(t^{7/2}-x^{7/2}){\displaystyle \frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D706}}{\unicode[STIX]{x2202}x}},\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle -{\displaystyle \frac{1}{t}}{\displaystyle \frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}r}}(u_{1}trh_{0}t) & = & \displaystyle -{\displaystyle \frac{2}{14\sqrt{3}t^{2}}}\left[\left(52.5\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)-30\unicode[STIX]{x1D706}\right)x^{3}-12\unicode[STIX]{x1D706}x^{-1/2}t^{7/2}\right]\nonumber\\ \displaystyle & & \displaystyle +\,{\displaystyle \frac{x^{4}}{2\sqrt{x}}}{\displaystyle \frac{\unicode[STIX]{x1D709}}{t^{2}}}\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}-{\displaystyle \frac{12x^{3/2}}{7\sqrt{3}}}{\displaystyle \frac{1}{xt^{2}}}(t^{7/2}-x^{7/2}){\displaystyle \frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D706}}{\unicode[STIX]{x2202}x}},\end{eqnarray}$$with

$$\begin{eqnarray}{\displaystyle \frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D706}}{\unicode[STIX]{x2202}x}}={\displaystyle \frac{1}{2}}\left(-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3x}}}+{\displaystyle \frac{\tan ^{2}\unicode[STIX]{x1D712}\cos ^{2}\unicode[STIX]{x1D703}}{9}}\right)\end{eqnarray}$$

$$\begin{eqnarray}{\displaystyle \frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D706}}{\unicode[STIX]{x2202}x}}={\displaystyle \frac{1}{2}}\left(-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3x}}}+{\displaystyle \frac{\tan ^{2}\unicode[STIX]{x1D712}\cos ^{2}\unicode[STIX]{x1D703}}{9}}\right)\end{eqnarray}$$ and where use of the boundary condition for  $u_{1}$ in (2.14) has been made.

$u_{1}$ in (2.14) has been made.

The substitution of (2.21)–(2.22) into (2.17) and the integration of the resulting equation for  $h_{1}$ along the ray

$h_{1}$ along the ray  $\text{d}r/\text{d}t=\sqrt{3/x}$ yields an expression that, once it is inserted into the ansatz (2.7), yields the following expressions for

$\text{d}r/\text{d}t=\sqrt{3/x}$ yields an expression that, once it is inserted into the ansatz (2.7), yields the following expressions for  $u(r,\unicode[STIX]{x1D703},t)$ and

$u(r,\unicode[STIX]{x1D703},t)$ and  $h(r,\unicode[STIX]{x1D703},t)$:

$h(r,\unicode[STIX]{x1D703},t)$:

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}u(r,\unicode[STIX]{x1D703},t)={\displaystyle \frac{r}{t}}-{\displaystyle \frac{\mathit{Re}^{-1/2}}{t}}\left[{\displaystyle \frac{\sqrt{3}x}{2h_{a}(x)}}\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)\right.\\ +\left.{\displaystyle \frac{2\sqrt{3}\unicode[STIX]{x1D706}}{7h_{a}(x)x^{5/2}}}(t^{7/2}-x^{7/2})\right],\\ h(r,\unicode[STIX]{x1D703},t)=9{\displaystyle \frac{t^{2}}{r^{4}}}h_{a}[3(t/r)^{2}]+{\displaystyle \frac{Re^{-1/2}}{rt}}\left[{\displaystyle \frac{\sqrt{3}}{2}}x^{2}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)\right.\\ +\left.{\displaystyle \frac{1}{5}}\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}(t^{5/2}-x^{5/2})\right.\\ +{\displaystyle \frac{\sqrt{3}}{42}}\left(105\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)-60\unicode[STIX]{x1D706}\right)x^{3}(t^{-1}-x^{-1})+{\displaystyle \frac{24\sqrt{3}\unicode[STIX]{x1D706}}{105}}x^{-1/2}(t^{5/2}-x^{5/2})\\ \left.-x^{4}(t^{-1}-x^{-1})\left({\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{2\sqrt{x}}}\unicode[STIX]{x1D709}+{\displaystyle \frac{6}{7\sqrt{3}}}\left(-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3x}}}+{\displaystyle \frac{\tan ^{2}\unicode[STIX]{x1D712}\cos ^{2}\unicode[STIX]{x1D703}}{9}}\right)\right)\right.\\ \left.-{\displaystyle \frac{12x^{1/2}}{35\sqrt{3}}}\left(-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3x}}}+{\displaystyle \frac{\tan ^{2}\unicode[STIX]{x1D712}\cos ^{2}\unicode[STIX]{x1D703}}{9}}\right)(t^{5/2}-x^{5/2})\vphantom{{\displaystyle \frac{\sqrt{3}}{2}}}\right].\end{array}\right\}\end{eqnarray}$$

$$\begin{eqnarray}\left.\begin{array}{@{}c@{}}u(r,\unicode[STIX]{x1D703},t)={\displaystyle \frac{r}{t}}-{\displaystyle \frac{\mathit{Re}^{-1/2}}{t}}\left[{\displaystyle \frac{\sqrt{3}x}{2h_{a}(x)}}\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)\right.\\ +\left.{\displaystyle \frac{2\sqrt{3}\unicode[STIX]{x1D706}}{7h_{a}(x)x^{5/2}}}(t^{7/2}-x^{7/2})\right],\\ h(r,\unicode[STIX]{x1D703},t)=9{\displaystyle \frac{t^{2}}{r^{4}}}h_{a}[3(t/r)^{2}]+{\displaystyle \frac{Re^{-1/2}}{rt}}\left[{\displaystyle \frac{\sqrt{3}}{2}}x^{2}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)\right.\\ +\left.{\displaystyle \frac{1}{5}}\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}(t^{5/2}-x^{5/2})\right.\\ +{\displaystyle \frac{\sqrt{3}}{42}}\left(105\unicode[STIX]{x1D709}\left(1-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3}}}\sqrt{x}\right)-60\unicode[STIX]{x1D706}\right)x^{3}(t^{-1}-x^{-1})+{\displaystyle \frac{24\sqrt{3}\unicode[STIX]{x1D706}}{105}}x^{-1/2}(t^{5/2}-x^{5/2})\\ \left.-x^{4}(t^{-1}-x^{-1})\left({\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{2\sqrt{x}}}\unicode[STIX]{x1D709}+{\displaystyle \frac{6}{7\sqrt{3}}}\left(-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3x}}}+{\displaystyle \frac{\tan ^{2}\unicode[STIX]{x1D712}\cos ^{2}\unicode[STIX]{x1D703}}{9}}\right)\right)\right.\\ \left.-{\displaystyle \frac{12x^{1/2}}{35\sqrt{3}}}\left(-{\displaystyle \frac{\tan \unicode[STIX]{x1D712}\sin \unicode[STIX]{x1D703}}{\sqrt{3x}}}+{\displaystyle \frac{\tan ^{2}\unicode[STIX]{x1D712}\cos ^{2}\unicode[STIX]{x1D703}}{9}}\right)(t^{5/2}-x^{5/2})\vphantom{{\displaystyle \frac{\sqrt{3}}{2}}}\right].\end{array}\right\}\end{eqnarray}$$Here we have also made use of (2.15), (2.16) and (2.18).

As expected, (2.23) recovers, in the limit  $\unicode[STIX]{x1D712}=0$, the equations for