Introduction

Weeds have to be managed to ensure crop profitability. First introduced in the late 1940s, herbicides revolutionized weed management, and the majority of farmers worldwide still rely on herbicides to control weeds. Herbicide-resistant weeds were reported soon after herbicides were adopted, but producers did not have to worry, because until the 1990s, new herbicides and new herbicide modes of action were constantly being discovered (Duke Reference Duke2011; Shaner Reference Shaner2014). Currently, herbicide discovery has slowed dramatically, and the discovery of new modes of action is almost nonexistent (Duke Reference Duke2011). Therefore, herbicide-resistant weed biotypes are now an increasing concern. Weeds that are resistant to one mode of action are consistently discovered (Heap Reference Heap2018) and are increasingly managed using herbicide mixtures with different modes of action and/or sequential applications of PRE followed by POST herbicides. Herbicide mixtures will delay the evolution of resistance (Evans et al. Reference Evans, Tranel, Hager, Schutte, Wu, Chatham and Davis2016) but are not a panacea, as biotypes with multiple resistance are also increasingly common (Heap Reference Heap2018). For example, in soybean and other broadleaf crops, broadleaf weeds such as Amaranthus spp. and Ambrosia spp. have been found to be resistant to up to five modes of action (e.g., waterhemp [Amaranthus tuberculatus (Moq.) J. D. Sauer]). These multiple-resistant biotypes continue to be selected for and spread across the continent. The adoption of a “herbicide-only” strategy can fail to the point where, in Georgia, Palmer amaranth [Amaranthus palmeri (S.) Watson] was hand weeded on 52% of cotton acreages (based on grower surveys) in the state at a cost of $57 per hand-weeded hectare (Sosnoskie and Culpepper Reference Sosnoskie and Culpepper2014).

When weeds are not controlled using herbicides, they can be managed using mechanical tools (Fennimore et al. Reference Fennimore, Slaughter, Siemens, Leon and Saber2016). Like herbicides, these methods generally aim at controlling weeds when they are small, during the critical period of weed–crop competition (Zimdahl Reference Zimdahl1988). Weeds that escape control during this period are generally harder to kill using any technique, and the extra effort needed will not translate into significant quantitative yield gains. Therefore, few mechanical options were used to target large or mature weeds until management of resistant weed seed production and dispersal became a concern. At the beginning of this century, an Australian farmer bought a cage mill used in the mining industry and tested its capacity to destroy resistant rigid ryegrass (Lolium rigidum Gaudin) seeds. This idea lead to the development of the Harrington Seed Destructor, a cage mill pulled behind the combine during wheat (Triticum aestivum L.) harvest. The device collects the chaff (usually spread on the ground) and destroys weeds seeds contained in it (Tidemann et al. Reference Tidemann, Hall, Harker and Beckie2017; Walsh et al. Reference Walsh, Harrington and Powles2012). However, in late-season (e.g., autumn) maturity crops such as soybean, greater than 70% of weed seeds can be shattered before harvest (Davis Reference Davis2008; Forcella et al. Reference Forcella, Peterson and Barbour1996) and must be managed before crop harvest if the return to the seedbank is to be decreased. Applying herbicides late in the season over maturing weeds using, for example, crop desiccants, is not always possible due to regulatory herbicide residue limits in crop seed and potential crop injury. Most importantly, this strategy will not necessarily limit weed seed production, as applications aim at defoliating and desiccating crop plants and weeds to increase harvest efficiency and crop quality, not at limiting weed seed formation or devitalizing maturing weed seeds (Griffin et al. Reference Griffin, Boudreaux and Miller2010). In organic production, weed management can limit the profitability of the crop more than other pest management costs, especially if hand hoeing is required (Clark et al. Reference Clark, Ferris, Klonsky, Lanini, van Bruggen and Zalom1998). Weeds can also escape mechanical control if spring conditions are inadequate. Wet conditions can allow weeds to recover and survive, even if they are uprooted (Curran Reference Curran2004). Under dry conditions, weeds can be more difficult to uproot by harrowing (Kurstjens et al. Reference Kurstjens, Perdok and Goense2000). Uncontrolled weeds can hinder harvest operations and replenish the seedbank. Hand pulling escaped weeds is recommended in organic crops (Curran Reference Curran2004). The Bourquin Organic Weed Puller® (Figure 1) was designed to pull tall weeds in organic crops and could be an option to limit weed seed inputs from herbicide-resistant biotypes in conventional crops without reverting to costly hand weeding. However, weeds must overtop the crop enough to be successfully pulled, and if pulled weeds are to be left on the ground, they have to be immature enough not to have viable seeds or produce viable seeds after extraction.

Figure 1 The Bourquin Organic Weed Puller® mounted on a tractor. The image is a screenshot of a video taken in soybean plots during the trial. A pulled, uprooted common lambsquarters is visible on the right.

Our objective was to evaluate the efficacy of the Bourquin Organic Weed Puller® at removing tall weeds before they shattered seeds in soybean and adzuki bean. Our hypothesis was that in soybean and adzuki bean, some broadleaf weed species would overtop the crop enough to be pulled successfully by the rotating wheels, at a stage immature enough to ensure extracted plants do not disperse viable seeds.

Materials and methods

Trials were set up at the Agriculture and Agri-Food Canada research farms located at Saint-Jean-sur-Richelieu (SJR), QC (45.29° N, 73.35° W) (2015 and 2016), and Harrow (HAR), ON (42.03° N, 82.90° W) (2016 only), on a loamy soil and a sandy soil, respectively. The sandy clay loam (46% sand, 27% silt, 27% clay) at SJR had a pH of 6.3 and an organic matter content of 3.8. The sandy loam (70% sand, 20% silt, 10% clay) at HAR had a pH of 6.1 and an organic matter content of 2.2. All fields were plowed in autumn and harrowed in the spring before seeding.

The Bourquin Organic Weed Puller® (1603 County Road AA, Colby, KS, USA, 67701, http://www.google.td/patents/US20120241177) (Figure 1) consists of a series of paired wheels on a rotating shaft that mechanically grasp and pull weeds from the soil. Each rotating wheel unit has one inflated rubber tire, one metal roller wrapped with a rubber lagging, and one notched metal disk (on new models) at the front (facing the crop). These wheel units are mounted on a beam held by a loader on the front of a tractor, and they are activated by a hydraulic system. The wheels were positioned at a 30° angle from the vertical, and the hydraulic system was set at 42%. For each wheel/roller pair, one wheel turns clockwise and the adjacent roller turns counterclockwise so that weed shoots/stems that touch the underside of the rotating wheels/rollers are caught by the notched disk plates facing the ground, dragged between the wheels/rollers, and pulled if the main stem does not break. The wheels/rollers had a rotation speed of 49 to 52 revolutions per minute (rpm). Tractor (model CASE-IH at SJR, model Case International 585 at HAR) (CNH Industrial, Racine, WI) speed was set at 0.64 km h−1. A higher speed of 1.28 km h−1 with a slower wheel rotation (29 rpm) was also tested in 2016 at SJR in extra plots. This latter setting did not modify weed-pulling efficacy (unpublished data). Faster speeds or higher rotation rates did not grip plants under the conditions of the trial (visual observations made during calibration).

The experimental design was a randomized complete block design split-split plot with four replicate blocks. Adjacent main plots (40-m long by 36-m wide) were either treated with herbicides to control both grass and broadleaf weeds (weed free) or with only a grass herbicide (broadleaf weeds present). Subplots (40 m by 18 m) were seeded with crops of different heights (short or tall), and sub-subplots (40 m by 6 m) had 8 crop rows (2 tractor passes) and included two pulling dates (early and late) and a control (weedy, no weed-puller pass). At SJR, the entire trial was sprayed with fluazifop-P-butyl at a dose of 125 g ai ha−1 as a graminicide on June 12, 2015, or June 10, 2016, and the weed-free plots were also treated with imazethapyr at a rate of 100.8 g ai ha−1, on June 19, 2015, or bentazon at 560 g ai ha−1 on June 15, 2016. At HAR, the entire trial was sprayed with quizalofop-P-ethyl at 0.072 kg ai ha−1+0.5% v/v petroleum oil surfactant blend on June 14 and again on June 30, 2016, to control grasses. Weed-free treatments were also sprayed with fomesafen at 0.24 kg ai ha−1+0.25% v/v nonionic surfactant (in adzuki plots) or glyphosate at 0.9 kg ae ha−1 (in soybean plots, glyphosate resistant) on June 21. The pulled weed species were the dominant dicotyledonous weeds in the plots. In the weed-free plots, the weed puller passed at the same height and speed as in the plots where weeds were pulled to evaluate potential yield reduction, as some crop leaves get pruned by the rollers during the weeding operation. Different crop heights were generated by different soybean cultivars (short: ‘PO4T10', 40-cm height; tall: ‘Medea R2', 77-cm height) at SJR or adzuki bean (short: ‘Erimo') and soybean (tall: ‘DK 32-61RY') at HAR. Adzuki beans were chosen at HAR to ensure that there was a large enough height differential between short and tall plants. Early weed-pulling dates were late July or early August, and late weed-pulling dates were set 2 wk later (Table 1). The corresponding growing degree days (5 C base) after crop planting are indicated in Table 1. At SJR, soybean was seeded in 76-cm rows at a density of 375,500 seeds ha−1 on May 15, 2015, and May 19, 2016. At HAR, soybean and adzuki bean were seeded in 76-cm rows and at a density of 380,952 seeds ha−1 and 242,424 seeds ha−1 respectively, on June 1. Soil moisture was evaluated before each weed pulling. At SJR, one soil core (20-cm deep by 5-cm diameter) per plot was randomly sampled (at least 1 m away from each end, on either side of the center row), carefully extracted using a metallic cylinder, and dried at 110 C for 70 h to calculate volumetric water content (Carter and Gregorich Reference Carter and Gregorich2008). At HAR, soil moisture was evaluated using a Field Scout Digital Moisture Sensor (TDR 300). Three readings were taken in the middle and near the top and bottom of each plot (at least 1 m away from each end, on either side of the center row). The pulled weeds included two species per location: common lambsquarters (both locations) and common ragweed at SJR or redroot pigweed at HAR. Due to the size of the plots required to test the efficacy of the weed puller, we could not seed a weed species that was not present at a location without risking the introduction of the species on the farm.

Table 1 Weed pulling dates, corresponding growing degree days (GDD, base 5 C) and soil moisture before treatment at each location.

Weeds overtopping the soybean canopy by at least 10 cm were tagged and characterized by measuring height, BBCH (Biologische Bundesanstalt, Bundessortenamt and CHemical industry) stage (Lancashire et al. Reference Lancashire, Bleiholder, Langelϋddecke, Stauss, Van den Boom, Weber and Witzenberger1991) and location across rows. Crop height (per plot) and general stage of development were also noted. A total of 20 weeds were tagged per sub-subplot. Damage from the weed puller was rated as 1, pulled (desired effect); 2, cut; 3, folded; 4, stripped; and 5, intact (Figure 2). Only pulled plants were uprooted (a section of the root system was visible). When plants were not uprooted, the pulling force either sectioned the plants (rated as cut), twisted and folded the plant until the wheel units had passed (rated as folded), or stripped the plant of top leaves and inflorescences (rated as stripped) (Figure 2). The seed production of damaged and intact weeds was also assessed by bagging a subsample of 6 to 10 tagged plants per damage rate. Plants were bagged after flowering using pollen bags. When weeds were mature, all seeds within bags were separated and weighed. Seed numbers were estimated from weights, and the viability of seeds produced was evaluated on a subsample of these seeds using a standard tetrazolium chloride test (AOSA/SCST 2010). Crop yield was evaluated at soybean maturity in the center of each plot by harvesting by hand 2 soybean rows over 2 m in the center of each plot at crop maturity (September 28, 2015 and October 24, 2016 at SJR, October 6, 2016 [for adzuki], and November 1, 2016 [soybean] at HAR). Yield was adjusted to a 12% moisture content.

Figure 2 Weeds showing the observed damages after the weed puller went over the plot. (A) Pulled (uprooted) pigweed, (B) cut common lambsquarters (arrow indicates location of cut), (C) folded redroot pigweed (arrow indicates location of fold), (D) stripped common ragweed, and (E) intact common lambsquarters.

Statistical Analyses

Statistical analyses were performed using the MIXED model of SAS. Block was a random effect, and all other variables were fixed. Year and location were never treated as random effects, because the experiment was repeated only 2 yr for only one of the two locations. Results are generally presented by location, year, species, and pulling date due to the presence of significant multiple interactions and different weed species and crops and to homogenize presentation. Response variables included weed height, crop height, weed stage (crop stage was not analyzed, only visually evaluated once per pulling date and cultivar), percentage of pulled plants, and crop yield. We also compared the height of intact, damaged, and pulled weeds and the seed production of intact and pulled weeds at SJR (too few weeds were pulled at HAR). The assumption of homogeneity of variance was respected. Multiple comparisons were performed using Tukey’s HSD test.

Results and Discussion

Weed and Crop Characteristics

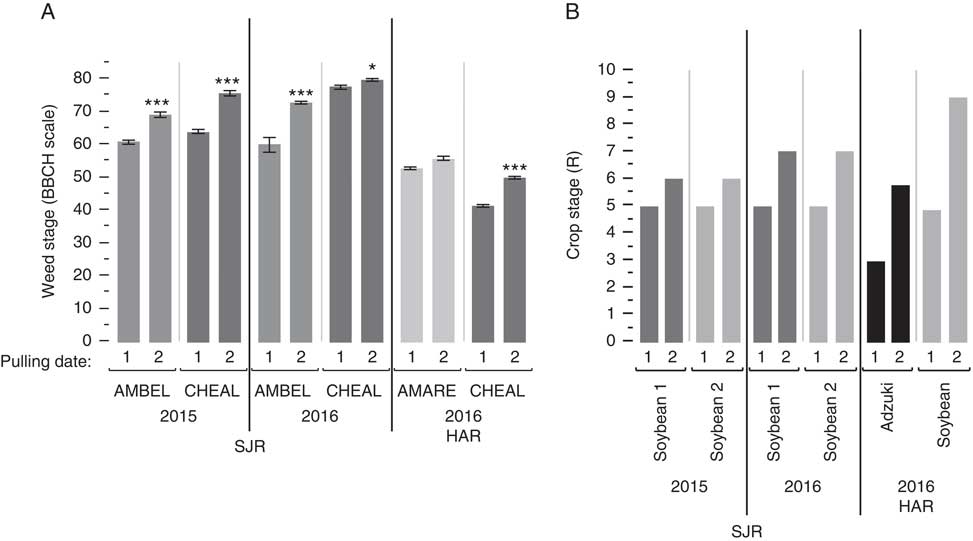

Tall weeds (>10 cm above crop canopy) were not evenly distributed across rows (P<0.05). For all weed species and locations, tall weeds were most prevalent in interrows (>50%), rather than close to the row (19% to 37%) or within the row (<12%). This was expected, as crop competition is higher within the rows. Also unsurprisingly, weed height varied among species (P<0.001). At any pulling date, common lambsquarters was always taller than common ragweed at SJR and taller than redroot pigweed at HAR. This was also expected, because common lambsquarters typically grows taller (up to 250 cm) than common ragweed and redroot pigweed (Basset and Crompton Reference Basset and Crompton1975, Reference Basset and Crompton1978; Costea et al. Reference Costea, Weaver and Tardif2004). Average weed height and crop height were higher during the second pulling date at HAR (P<0.001). At SJR, higher values during the second pulling date were only observed for common lambsquarters in 2015 (+10.4 cm) (P=0.005) (Figure 3). The first pulling date in HAR was done in July, and plants (weeds and soybean) had not yet attained their full height potential. At SJR, soybeans were actually shorter during the second pulling date (Figure 3), probably due to a slight lodging. There were height differences between soybean cultivars at SJR, but the magnitude (±6.3 cm on average) of this difference was lower than the expected 37 cm difference, as the short (40-cm) cultivar (soy1, PO4T10) reached more than 84 cm and was actually taller than the other cultivar during the second pulling date in 2015 (Figure 3). Factors such as higher seeding density and high soil fertility (Bharati Reference Bharati1984) as well as cool and wet climatic conditions can increase soybean height. Tall plants will also lodge more readily (Wilcox and Sedimaya Reference Wilcox and Sedimaya1981). Our seeding densities were average and identical for both cultivars. Therefore, climatic conditions and soil fertility were probably responsible for observed heights, and the short cultivar responded more to these conditions than the other cultivar. At HAR, there was a 22.6-cm height difference between the adzuki and the soybean during pulling events. The adzuki crop did not grow as tall as the soybean, as expected (Figure 3). Except for common lambsquarters at SJR in 2016, weeds were in the flowering stage or at earlier stages during the first pulling date (Figure 4). During the second pulling date, weed species had reached fruit development (BBCH 70) at SJR but not at HAR (Figure 4). Common ragweed plants were at an earlier stage than common lambsquarters at SJR during all pulling events, while common lambsquarters were at an earlier stage than redroot pigweed at HAR (Figure 4). The soybean was always at the R5 stage on the first pulling date and reached R6 to R7 (2016) at SJR and R9 at HAR during the second pulling date. The adzuki bean was at R3 on the first date and reached R6 on the second (Figure 4).

Figure 3 Average height of (A) weeds: common ragweed (AMBEL), common lambsquarters (CHEAL), and redroot pigweed (AMARE), and (B) crop plants: soybean and adzuki bean, during each pulling date (1,2) at Saint-Jean-sur-Richelieu (SJR) in 2015 and 2016 and at Harrow (HAR) in 2016. Asterisks indicate plant height was significantly different between pulling dates at α= 0.01(**), or 0.001 (***). Bars represent SE.

Figure 4 Average stage of (A) weeds: common ragweed (AMBEL), common lambsquarters (CHEAL), and redroot pigweed (AMARE), and general stage of (B) crop plants: soybean and adzuki bean, during each pulling date (1,2) at Saint-Jean-sur-Richelieu (SJR) in 2015 and 2016 and at Harrow (HAR) in 2016. Asterisks indicate weed stage was significantly different between pulling dates at α=0.05 (*), or 0.001 (***). Bars represent SE.

Pulling Efficacy

Fewer than 50% of individuals of each species were pulled during a given pulling event, leaving most weeds damaged and some intact (Figure 5). Pulling rates varied with species (P<0.001), and there was a location effect (tested for common lambsquarters only) (P<0.001). For common lambsquarters, pulling rates did not vary between years (at SJR) and dates (both locations) (Figure 5). There was a year and pulling date effect for common ragweed, as fewer weeds were pulled during the first pulling date in 2016 than during other trials at SJR (P=0.04). Fewer than one-third of common ragweed or redroot pigweed plants were pulled during any treatment combination. The highest pulling success was observed for common lambsquarters at SJR in 2015 during the first pulling date (47.5%), but this value is not significantly different from that of other pulling trials at the same location. The average pulling rate for common lambsquarters at SJR was 39.7%. At HAR, few weeds were pulled (<4% of all weeds), and most were cut (Figure 5). At SJR, damaged common lambsquarters were generally stripped (Figure 5). Pulled or damaged weeds were taller than those left intact (P<0.01). However, damaged plants and pulled plants had equivalent height, and in all treatment combinations, folded plants were taller than plants that suffered other types of damage (unpublished data). To successfully pull a weed, the weed must overtop the crop canopy. However, as the plant increases in size, its root system also increases in length (Ennos and Fitter Reference Ennos and Fitter1992) and biomass (Poorter et al. Reference Poorter, Niklas, Reich, Oleksyn, Poot and Mommer2012). As a result, taller weeds are harder to pull, especially under dry soil conditions (Ennos Reference Ennos1989). At HAR, the soil is sandy and soil moisture was low on the second pulling date (Table 1). At SJR, the soil texture is finer and soil moisture was generally higher (Table 1). Additional soil moisture measurements (throughout the life cycle of the weeds) and data on root biomass and architecture could also have been useful for determining whether partitioning to roots could also explain the lower pulling efficacy at HAR. Plants generally respond to lower water availability by allocating more biomass to root systems rather than shoots and extending roots deeper into the soil profile (Agren and Franklin Reference Agren and Franklin2003; Gallardo et al. Reference Gallardo, Jackson and Thompson1996). As weeds get taller, they reach the developmental stages when seed formation starts, and seed production can be completed even if plants are uprooted.

Figure 5 Proportion of common ragweed (AMBEL), common lambsquarters (CHEAL), and redroot pigweed (AMARE) left intact, damaged, or pulled during each pulling date (1,2) at Saint-Jean-sur-Richelieu (SJR) in 2015 and 2016 and at Harrow (HAR) in 2016. Asterisk indicates proportion of pulled AMBEL plants was significantly different between pulling dates at α=0.05 (*). Bars represent SE of intact, damaged (not separated by type of damage), or pulled plants.

Weed Seed Production

At HAR, the seed production of pulled plants could not be evaluated, as too few plants were pulled. The seed production of damaged plants was nevertheless evaluated and was equivalent to that of intact plants (unpublished data). At SJR, the few common ragweed plants pulled during the first pulling date (2015 only) did not produce seeds, as seed formation had not commenced. On the second pulling date, an average of 7.5 or 123.6 viable seeds per plant formed on pulled plants in 2015 and 2016, respectively, while intact plants produced more than 1,100 viable seeds (Table 2). This indicates that common ragweed plants growing in soybean could be pulled and left on the ground in August without significantly increasing seedbank inputs in the area. However, this is not the case for common lambsquarters. Pulled common lambsquarters left on the ground produced more than 2,000 viable seeds on the first pulling date and more than 9,500 viable seeds on the second pulling date (Table 2).

Table 2 Average number and percent viability of seeds produced by intact and pulled (and left on the ground) common ragweed (AMBEL) and common lambsquarters (CHEAL) at Saint-Jean-sur-Richelieu, QC, in 2015 and 2016.

a Plants were pulled early (date 1) or late (date 2) August.

Crop Yield

Pulling date had no effect on crop yield during any trial (P>0.10) and did not modify the effect of other variables (i.e., no significant interactions). This was expected, as the two pulling dates only differed by a few weeks and crop plants were all in the reproductive phase. Crop yield was not significantly lower in the weedy plots where no weeds had been pulled versus pulled plots or herbicide-treated (weed-free) plots at SJR in 2015 (Table 3). However, at SJR in 2016, crop yield was lower in the weedy plots, and weedy plots that had been pulled had the lowest yield (Table 3). At HAR, crop yield was not significantly lower in the weedy plots where no weeds had been pulled compared with the pulled plots, but yield was higher in the herbicide-treated (weed-free) plots (Table 3). This indicates the weed population was high enough to significantly reduce yield at HAR and in SJR in 2016 and that weed removal by pulling did not prevent yield loss. The weed pulling was performed after the critical weed-free period in soybean (VE to V3) and probably in adzuki bean (crop stage unclassified). Any weed management carried out after the critical weed-free period is unlikely to prevent yield losses at physiological maturity (Knezevic et al. Reference Knezevic, Evans, Blankenship, Van Acker and Lindquist2002). In the herbicide-treated plots, crop yield was not significantly lower where the weed puller had passed than where the weed puller had not passed in any trial (Table 3). Therefore, trimming of crop leaves by the weed puller and/or trampling by tractor wheels did not significantly reduce crop yield.

Table 3 Mean soybean and adzuki bean yield after pulling treatments at Saint-Jean-sur-Richelieu (SJR), QC, in 2015 and 2016 and Harrow (HAR), ON, in 2016.

a Soybean 1, ‘PO4T10’; Soybean 2, ‘Medea R2’; Adzuki, ‘Erimo’; Soybean 3, ‘DK 32-61RY’.

b Lowercase letters denote significant differences based on a Tukey adjusted comparison of means (α=0.05).

Conclusions

For a tool such as the Bourquin Organic Weed Puller® to successfully manage weed populations, weeds must be immature enough not to form viable seeds when they are pulled but tall enough to overtop the crop canopy. All five weed species (common lambsquarters, common ragweed, giant foxtail [Setaria faberi Herrm.], jimsonweed [Datura stramonium L.], and velvetleaf [Abutilon theophrasti Medik.]) cut or treated with glyphosate by Hill et al. (Reference Hill, Renner, VanGessel, Bellinder and Scott2016) when immature seeds were present, formed viable seeds if left on the ground. Therefore, weeds that started seed formation when pulled would have to be collected or treated to avoid seed production. Another issue to consider is the number of weeds that will not overtop the canopy but still produce seed. Even weeds that germinate after a POST herbicide application and do not overtop the canopy can produce seeds that will replenish the seedbank (Simard and Benoit Reference Simard and Benoit2012; Simard et al. Reference Simard, Rouane and Leroux2011). For the taller common lambsquarters, only 30.1% of the total weed population was 10 cm above the soybean canopy in August. For common ragweed in soybean, this proportion drops to 18.7%. In a separate study repeated across 3 yr, less than 30% of a common ragweed population overtopped the soybean canopy (M-JS, unpublished data). Therefore, the weed pulling only controlled a maximum of 15% of all common lambsquarters (50% of 30%) in soybean, and efficacy on common ragweed dropped to less than 10% (33% of 18.7% to 30%). Therefore, this type of weed pulling could be improved but would not be recommended as a single strategy to control weeds in soybean. It would be interesting to test a unit with at least two parallel rows of smaller (diameter) wheel units to grasp a higher number of smaller weeds (before they start producing seeds). Because weeds have to overtop the crop and tractor speed is limited, shorter high-value crops are more appropriate for this type of weed management.

Acknowledgments

We thank Manon Bélanger, Kerry Bosveld, Sylvain Fortin, and Luc Marchand for their technical expertise and all of the student assistants who collected data. We also thank Aline Philibert for her help with data analysis. No conflicts of interest have been declared. This research was funded by Agriculture and Agri-Food Canada (project ID: J-000919).