1 Introduction

The efficiency of solute transport inside microchannels is an important issue in microfluidics (Datta & Ghosal Reference Datta and Ghosal2009) because of its vast applications in different areas such as microfluidic mixing (Wu & Nguyen Reference Wu and Nguyen2005; Matsunaga, Lee & Nishino Reference Matsunaga, Lee and Nishino2013; Sadeghi Reference Sadeghi2016), capillary electrophoresis (Wu, Qin & Lin Reference Wu, Qin and Lin2008), capillary electrochromatography and capillary liquid chromatography (Feltkamp Reference Feltkamp1966), DNA amplification (Tripathi, Bozkurt & Chauhan Reference Tripathi, Bozkurt and Chauhan2005) and molecular separation (Garcia et al. Reference Garcia, Ista, Petsev, O’Brien, Bisong, Mammoli, Brueck and López2005). Solute transport occurs via advection, diffusion and hydrodynamic dispersion mechanisms. The first mechanism takes place when solutes move with the fluid flow and it is responsible for the transport of the centre of mass of an injected solute band. The diffusive dispersion is due to random thermal motion of solute molecules and a non-uniform velocity profile is the reason for hydrodynamic dispersion. Because of hydrodynamic dispersion, a solute band is stretched in the flow direction under a combined action of advection and diffusion (Masliyah & Bhattacharjee Reference Masliyah and Bhattacharjee2006). Depending on the flow profile, hydrodynamic dispersion may be more influential than molecular diffusion. For some applications, such as mixing, it is desirable to increase the degree of dispersion to shorten the mixing time. However, in applications like separation, it is preferable to decrease hydrodynamic dispersion to achieve a better resolution. Therefore, investigating the parameters controlling the hydrodynamic dispersion, such as the transport coefficients, is an important matter in the design of microfluidic devices involving solute transport.

The first study on hydrodynamic dispersion was conducted by Taylor (Reference Taylor1953) who introduced an effective dispersion coefficient for a steady laminar flow in a straight circular tube, which was then generalized by Aris (Reference Aris1956) by incorporating the effect of axial molecular diffusion utilizing the method of moments. After these pioneering studies, more research works were conducted to consider the effect of various parameters on the solute dispersion coefficient. Analysing band broadening from initial times after injection, Gill & Sankarasubramanian (Reference Gill and Sankarasubramanian1970) proposed a general model expressing the transport coefficients as a function of time in a steady-state flow. More progress was made by considering time variable flow (Gill & Sankarasubramanian Reference Gill and Sankarasubramanian1972; Sankarasubramanian & Gill Reference Sankarasubramanian and Gill1972; Vedel & Bruus Reference Vedel and Bruus2011), oscillating flow (Ng Reference Ng2006), non-uniformity of the injected solute band (Gill & Sankarasubramanian Reference Gill and Sankarasubramanian1971, Reference Gill and Sankarasubramanian1972) and interfacial as well boundary mass transfer (Sankarasubramanian & Gill Reference Sankarasubramanian and Gill1973; Phillips & Kaye Reference Phillips and Kaye1998; Ng Reference Ng2006).

One important issue in microfluidics is robust flow generation as the high working pressures required may lead to the failure of conventional pumping devices. To meet the pumping requirements at the microscale, various pumping mechanisms have been proposed among which electrokinetic phenomena such as electroosmosis have found widespread applications (Sadeghi, Sadeghi & Saidi Reference Sadeghi, Sadeghi and Saidi2016). Electroosmosis refers to flow mobilization of an electrolyte solution relative to a charged surface by utilizing an external electric filed. The movement of fluid in electroosmotic flow (EOF) is due to a redistribution of free ions in the solution because of surface charges, causing the formation of an electric double layer (EDL) adjacent to the surface (Masliyah & Bhattacharjee Reference Masliyah and Bhattacharjee2006; Keramati et al. Reference Keramati, Sadeghi, Saidi and Chakraborty2016; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Sadeghi2017). The non-uniformities of the velocity profile are restricted to this layer and, hence, EOF usually has a flatter velocity profile as compared to the Poiseuille flow. Accordingly, it can provide a better resolution in processes in which minimum dispersion is favoured (Ng & Zhou Reference Ng and Zhou2012). Besides low solute dispersion, EOF possesses other advantages, such as requiring no moving components, which is crucial for the manufacturing of EOF-based instruments at the microscale. Thanks to its advantages, EOF is now a widely used actuation method for flow generation in lab-on-a-chip devices (Vennela et al. Reference Vennela, Mondal, De and Bhattacharjee2012).

There are several research studies in the literature investigating the dispersion of electrokinetically actuated flow in microchannels, most of which are related to parallel-plate and circular geometries (Datta & Kotamarthi Reference Datta and Kotamarthi1990; Andreev & Lisin Reference Andreev and Lisin1993; Griffiths & Nilson Reference Griffiths and Nilson1999, Reference Griffiths and Nilson2000; Ng & Zhou Reference Ng and Zhou2012). Despite the importance of the rectangular geometry, much less attention has been given to hydrodynamic dispersion in rectangular microchannels (Dutta Reference Dutta2007; Paul & Ng Reference Paul and Ng2012). A very important aspect of solute dispersion in rectangular microchannels, that raises the need for separate analyses for this geometry, is that the dispersion coefficient for a rectangular microchannel of high aspect ratio does not reduce to the value for a parallel-plate microchannel (Paul & Ng Reference Paul and Ng2012).

The maximum achievable electroosmotic velocity for a given working fluid is dependent upon both the applied electric field and surface zeta potential. As utilizing large electric fields is accompanied by a high amount of Joule heating, which has several unfavourable effects such as increasing band broadening, the only healthy way for increasing the electroosmotic flow rate is to use surfaces having large zeta potentials. However, in many situations, the design objectives are not met by natural properties of the channel surface. In these cases, the surface may be altered to achieve the desired characteristics. One of the main approaches of surface treatment is to coat it with a polyelectrolyte layer (PEL), which may be formed by grafting polymer brushes having electrically charged groups, termed polyelectrolyte brushes, to the surface (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012). The presence of brushes alters the fluid flow by affecting it in a twofold manner. First, the brushes directly exert a resistive force on the fluid particles. Second, the fixed charged groups of the brushes indirectly amplify fluid flow via accumulating free electrolyte ions of opposite charge within the PEL. By appropriately adjusting the above-mentioned two effects, any desired flow conditions may be obtained. It has been shown that by grafting polyelectrolyte brushes to the inner surface of a microchannel, it is possible to increase the flow rate by more than one order of magnitude (Paumier et al. Reference Paumier, Sudor, Gue, Vinet, Li, Chabal, Estève and Djafari-Rouhani2008). On the other hand, in some applications, such as capillary electrophoresis, polymer coating is used to enhance the efficiency of separation by suppressing the generated electroosmotic flow (Chiari et al. Reference Chiari, Cretich, Damin, Ceriotti and Consonni2000; Hickey, Harden & Slater Reference Hickey, Harden and Slater2009). Because of the unique features of polyelectrolyte coating, it is used in different applications such as colloidal stabilization (Dautzenberg Reference Dautzenberg1985), enhancement of biomaterial capability (Ratner et al. Reference Ratner, Hoffman, Schoen and Lemons2004) and control of membrane permeability among others.

Despite the importance of PEL-grafted microchannels, little attention has been paid to the dispersion properties of electrokinetic flow in this type of microchannel. The only available research study, which is the work due to Hoshyargar et al. (Reference Hoshyargar, Khorami, Ashrafizadeh and Sadeghi2018), is based on the original study of Taylor and, hence, only the long-term dispersion coefficient is given. More importantly, in spite of the fact that most microfabrication techniques produce channels of rectangular cross-sectional area (Stone, Stroock & Ajdari Reference Stone, Stroock and Ajdari2004; Sadeghi, Saidi & Sadeghi Reference Sadeghi, Saidi and Sadeghi2017), this study deals with a parallel-plate geometry. Considering the importance of lateral walls on the dispersion properties, the findings of this study may not be appropriate to rectangular microchannels of even large aspect ratio. Last but not least, even though the presence of polyelectrolyte brushes provides appropriate circumstances for the adsorption of solutes at the channel walls, Hoshyargar et al. (Reference Hoshyargar, Khorami, Ashrafizadeh and Sadeghi2018) considered no-flux boundary conditions. All of these gaps are bridged in the present study by considering hydrodynamic dispersion by steady fully developed electroosmotic flow in a PEL-grafted slit/rectangular microchannel utilizing the generalized dispersion model proposed by Gill & Sankarasubramanian (Reference Gill and Sankarasubramanian1970). This model enables us to track an injected solute band from the time of injection by taking advantage of three time-dependent transport factors including the exchange, the convection and the dispersion coefficients. A first-order reaction is considered at the channel walls to account for probable surface adsorption of solute molecules. The solutions obtained are able to take any initial distribution of the solute band into account. Although the validity of the analytical solutions presented are restricted to low electric potentials, full numerical simulations are also performed to go beyond the Debye–Hückel limit. By comparing the analytical and numerical results, it is shown that the model developed is able to capture the dispersion properties of the problem under consideration.

2 Problem formulation

2.1 Problem definition

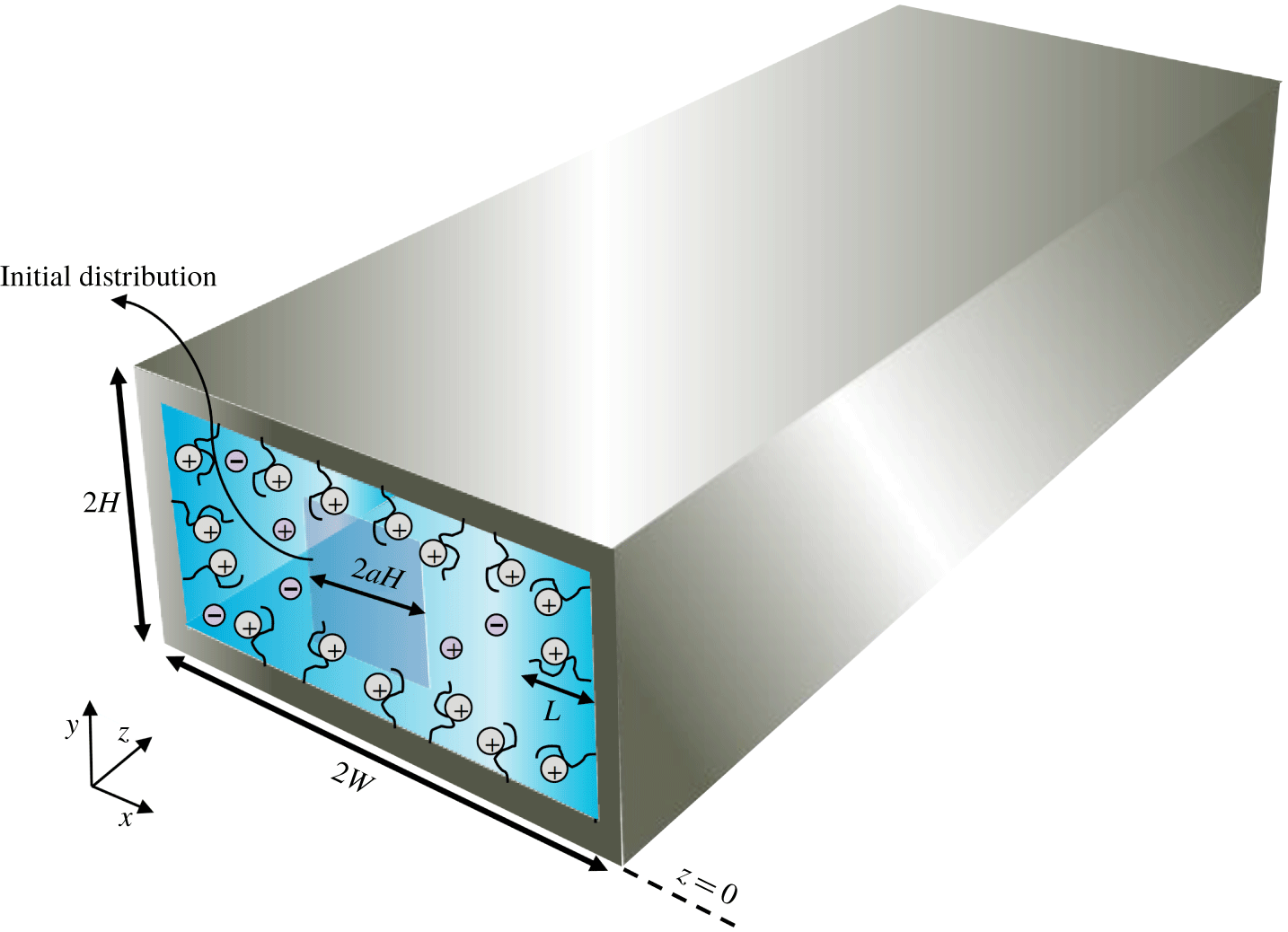

Consideration is given to the unsteady dispersion of a solute band by electroosmotic flow of a Newtonian liquid with constant physical properties in a straight rectangular microchannel with PEL-grafted walls. The channel dimensions, the coordinate system, located at the centre of the ![]() $X$–

$X$–![]() $Y$ plane at the channel entrance and other details are given in figure 1. It is assumed that the flow is both steady and fully developed. The probable adsorption/reaction of the solutes at the channel walls is accounted for via applying an irreversible first-order boundary reaction formula. The PEL is considered to have a constant and uniform charge density and a uniform thickness all around the channel with a sufficiently low grafting density to allow the use of the same values of permittivity and viscosity inside and outside the PEL. Since a low grafting density is considered, the volumetric density of the PEL fixed charges may be assumed to be low enough to permit application of the Debye–Hückel linearization when treating the problem analytically. It is further assumed that the Debye length is larger than the hydraulic diameter of the channel so that the concentration polarization effect arising due to the selective transport of ionic species can be ignored. Finally, the liquid is considered to contain an electrolyte of a completely dissociated symmetric salt. Owing to the symmetry, the analysis is limited to the first quarter of the channel.

$Y$ plane at the channel entrance and other details are given in figure 1. It is assumed that the flow is both steady and fully developed. The probable adsorption/reaction of the solutes at the channel walls is accounted for via applying an irreversible first-order boundary reaction formula. The PEL is considered to have a constant and uniform charge density and a uniform thickness all around the channel with a sufficiently low grafting density to allow the use of the same values of permittivity and viscosity inside and outside the PEL. Since a low grafting density is considered, the volumetric density of the PEL fixed charges may be assumed to be low enough to permit application of the Debye–Hückel linearization when treating the problem analytically. It is further assumed that the Debye length is larger than the hydraulic diameter of the channel so that the concentration polarization effect arising due to the selective transport of ionic species can be ignored. Finally, the liquid is considered to contain an electrolyte of a completely dissociated symmetric salt. Owing to the symmetry, the analysis is limited to the first quarter of the channel.

Figure 1. Schematic representation of the rectangular microchannel under consideration. The internal surface of the microchannel is coated with a polyelectrolyte layer of thickness ![]() $L$. The square of side length

$L$. The square of side length ![]() $2aH$ shows the shape of the initial solute distribution that is considered in the presentation of results.

$2aH$ shows the shape of the initial solute distribution that is considered in the presentation of results.

2.2 Electric potential field

The overall electric potential field ![]() $\unicode[STIX]{x1D6F7}(X,Y,Z)$ within the microchannel is the superposition of the externally applied electric potential

$\unicode[STIX]{x1D6F7}(X,Y,Z)$ within the microchannel is the superposition of the externally applied electric potential ![]() $\unicode[STIX]{x1D711}(Z)$ and the EDL electric potential

$\unicode[STIX]{x1D711}(Z)$ and the EDL electric potential ![]() $\unicode[STIX]{x1D6F9}(X,Y)$, that is

$\unicode[STIX]{x1D6F9}(X,Y)$, that is

The electric potential is governed by the Poisson equation, written as

where ![]() $\unicode[STIX]{x1D700}$ represents the permittivity and

$\unicode[STIX]{x1D700}$ represents the permittivity and ![]() $\unicode[STIX]{x1D70C}_{e}$ stands for the net electric charge density. As noted before, the same permittivities are assumed within and outside of the PEL. However, attention should be given to the fact that, since the permittivity of polyelectrolyte brushes is lower than that of water, the PEL permittivity is generally lower than solution permittivity. In fact, the range 52.8–78 is reported for the relative permittivity of the PEL (Sadeghi, Azari & Hardt Reference Sadeghi, Azari and Hardt2019). Whereas the lower limit differs significantly from water permittivity, the upper limit is quite close to it. This corresponds to the cases for which the grafting density is low, similar to the circumstances considered in the present study.

$\unicode[STIX]{x1D70C}_{e}$ stands for the net electric charge density. As noted before, the same permittivities are assumed within and outside of the PEL. However, attention should be given to the fact that, since the permittivity of polyelectrolyte brushes is lower than that of water, the PEL permittivity is generally lower than solution permittivity. In fact, the range 52.8–78 is reported for the relative permittivity of the PEL (Sadeghi, Azari & Hardt Reference Sadeghi, Azari and Hardt2019). Whereas the lower limit differs significantly from water permittivity, the upper limit is quite close to it. This corresponds to the cases for which the grafting density is low, similar to the circumstances considered in the present study.

There are two types of electric charge in the microchannel, namely solution ions, which move freely throughout the whole domain under consideration, and PEL charges that are fixed within this layer. The net electric charges of solution and PEL ions are respectively given as

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D70C}_{E} & = & \displaystyle ez_{E}(C_{+}-C_{-})=ez_{E}C^{\infty }\left[\exp \left(-\frac{ez_{E}\unicode[STIX]{x1D6F9}}{k_{B}T}\right)-\exp \left(\frac{ez_{E}\unicode[STIX]{x1D6F9}}{k_{B}T}\right)\right]\nonumber\\ \displaystyle & = & \displaystyle -2ez_{E}C^{\infty }\sinh \left(\frac{ez_{E}\unicode[STIX]{x1D6F9}}{k_{B}T}\right),\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D70C}_{E} & = & \displaystyle ez_{E}(C_{+}-C_{-})=ez_{E}C^{\infty }\left[\exp \left(-\frac{ez_{E}\unicode[STIX]{x1D6F9}}{k_{B}T}\right)-\exp \left(\frac{ez_{E}\unicode[STIX]{x1D6F9}}{k_{B}T}\right)\right]\nonumber\\ \displaystyle & = & \displaystyle -2ez_{E}C^{\infty }\sinh \left(\frac{ez_{E}\unicode[STIX]{x1D6F9}}{k_{B}T}\right),\end{eqnarray}$$ where ![]() $e$ is the proton charge,

$e$ is the proton charge, ![]() $K_{B}$ shows the Boltzmann constant,

$K_{B}$ shows the Boltzmann constant, ![]() $T$ indicates the absolute temperature,

$T$ indicates the absolute temperature, ![]() $z_{E}$ denote the valence of electrolyte ions and

$z_{E}$ denote the valence of electrolyte ions and ![]() $\mathbb{N}_{PEL}$ and

$\mathbb{N}_{PEL}$ and ![]() $z_{PEL}$ are the number density and valence of the PEL fixed charges, respectively. In addition,

$z_{PEL}$ are the number density and valence of the PEL fixed charges, respectively. In addition, ![]() $C_{+}$ and

$C_{+}$ and ![]() $C_{-}$ stand for the number concentrations of cations and anions, respectively, which both equal

$C_{-}$ stand for the number concentrations of cations and anions, respectively, which both equal ![]() $C^{\infty }$ at neutral conditions. Note that a Boltzmann distribution is assumed for the solution ions since the fluid velocity does not influence the ionic distribution in the normal direction to a rectilinear flow. Substituting (2.3) and (2.4) into (2.2) and recalling that

$C^{\infty }$ at neutral conditions. Note that a Boltzmann distribution is assumed for the solution ions since the fluid velocity does not influence the ionic distribution in the normal direction to a rectilinear flow. Substituting (2.3) and (2.4) into (2.2) and recalling that ![]() $\unicode[STIX]{x1D6FB}^{2}\unicode[STIX]{x1D711}=0$ for a constant applied electric field, one obtains

$\unicode[STIX]{x1D6FB}^{2}\unicode[STIX]{x1D711}=0$ for a constant applied electric field, one obtains

The parameter ![]() $\mathbb{N}$ appearing in (2.5), which is equal to

$\mathbb{N}$ appearing in (2.5), which is equal to ![]() $\mathbb{N}_{PEL}$ and 0 inside and outside of the grafted layer, respectively, reminds us of the fact that the existence of the fixed charges is limited to the PEL. It should be pointed out that the spatial distribution of the PEL fixed charges is generally non-uniform, with a decreasing dependence on the normal distance from the hard wall; however, depending on the properties of the electrolyte and brushes, situations may be found in which a uniform charge distribution, considered in this study, is reasonable (Sadeghi et al. Reference Sadeghi, Azari and Hardt2019). For low grafting densities, the electric potential is so low that the term

$\mathbb{N}_{PEL}$ and 0 inside and outside of the grafted layer, respectively, reminds us of the fact that the existence of the fixed charges is limited to the PEL. It should be pointed out that the spatial distribution of the PEL fixed charges is generally non-uniform, with a decreasing dependence on the normal distance from the hard wall; however, depending on the properties of the electrolyte and brushes, situations may be found in which a uniform charge distribution, considered in this study, is reasonable (Sadeghi et al. Reference Sadeghi, Azari and Hardt2019). For low grafting densities, the electric potential is so low that the term ![]() $\sinh (ez_{E}\unicode[STIX]{x1D6F9}/k_{B}T)$ can be approximated by

$\sinh (ez_{E}\unicode[STIX]{x1D6F9}/k_{B}T)$ can be approximated by ![]() $ez_{E}\unicode[STIX]{x1D6F9}/k_{B}T$. This approximation, known as Debye–Hückel linearization, modifies equation (2.5) as

$ez_{E}\unicode[STIX]{x1D6F9}/k_{B}T$. This approximation, known as Debye–Hückel linearization, modifies equation (2.5) as

By introducing the dimensionless parameters as below,

with ![]() $\unicode[STIX]{x1D706}_{E}=(k_{B}T\unicode[STIX]{x1D700}/2C^{\infty }e^{2}z_{E}^{2})^{1/2}$ and

$\unicode[STIX]{x1D706}_{E}=(k_{B}T\unicode[STIX]{x1D700}/2C^{\infty }e^{2}z_{E}^{2})^{1/2}$ and ![]() $\unicode[STIX]{x1D706}_{PEL}=(k_{B}T\unicode[STIX]{x1D700}/z_{E}z_{PEL}\mathbb{N}_{PEL}e^{2})^{1/2}$ being the characteristic and PEL Debye lengths, respectively, equation (2.6) is scaled as

$\unicode[STIX]{x1D706}_{PEL}=(k_{B}T\unicode[STIX]{x1D700}/z_{E}z_{PEL}\mathbb{N}_{PEL}e^{2})^{1/2}$ being the characteristic and PEL Debye lengths, respectively, equation (2.6) is scaled as

The boundary conditions associated with (2.8) include

where ![]() $w=W/H$. The boundary conditions (2.9) reflect symmetry at the centrelines and the neutrality of the rigid walls of the microchannel. Since the electrical potential and its gradient are continuous at the electrolyte–PEL interface, we consider for both domains a single solution of the form

$w=W/H$. The boundary conditions (2.9) reflect symmetry at the centrelines and the neutrality of the rigid walls of the microchannel. Since the electrical potential and its gradient are continuous at the electrolyte–PEL interface, we consider for both domains a single solution of the form

where ![]() $\unicode[STIX]{x1D709}_{l_{j}}=l_{j}\unicode[STIX]{x03C0}$ and

$\unicode[STIX]{x1D709}_{l_{j}}=l_{j}\unicode[STIX]{x03C0}$ and ![]() $\unicode[STIX]{x1D709}_{m_{j}}=m_{j}\unicode[STIX]{x03C0}$ with

$\unicode[STIX]{x1D709}_{m_{j}}=m_{j}\unicode[STIX]{x03C0}$ with ![]() $l_{j}=0,1,2,\ldots$ and

$l_{j}=0,1,2,\ldots$ and ![]() $m_{j}=0,1,2,\ldots$ . The form (2.10) satisfies the pertinent boundary conditions. Substituting this functional form into (2.8) results in

$m_{j}=0,1,2,\ldots$ . The form (2.10) satisfies the pertinent boundary conditions. Substituting this functional form into (2.8) results in

Multiplying both sides of (2.11) by ![]() $\cos (\unicode[STIX]{x1D709}_{l_{i}}y)\cos (\unicode[STIX]{x1D709}_{m_{i}}x/w)$, integrating over the dimensionless cross-sectional area and making use of the orthogonality conditions, we obtain

$\cos (\unicode[STIX]{x1D709}_{l_{i}}y)\cos (\unicode[STIX]{x1D709}_{m_{i}}x/w)$, integrating over the dimensionless cross-sectional area and making use of the orthogonality conditions, we obtain

$$\begin{eqnarray}\displaystyle & & \displaystyle b_{i}(\unicode[STIX]{x1D709}_{l_{i}}^{2}+\unicode[STIX]{x1D709}_{m_{i}}^{2}/w^{2}+K^{2})\int _{0}^{w}\int _{0}^{1}\cos ^{2}(\unicode[STIX]{x1D709}_{l_{i}}y)\cos ^{2}(\unicode[STIX]{x1D709}_{m_{i}}x/w)\,\text{d}y\,\text{d}x\nonumber\\ \displaystyle & & \displaystyle \quad =K^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{-2}\int _{0}^{w}\int _{0}^{1}\mathbb{N}^{\ast }\cos (\unicode[STIX]{x1D709}_{l_{i}}y)\cos (\unicode[STIX]{x1D709}_{m_{i}}x/w)\,\text{d}y\,\text{d}x.\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle b_{i}(\unicode[STIX]{x1D709}_{l_{i}}^{2}+\unicode[STIX]{x1D709}_{m_{i}}^{2}/w^{2}+K^{2})\int _{0}^{w}\int _{0}^{1}\cos ^{2}(\unicode[STIX]{x1D709}_{l_{i}}y)\cos ^{2}(\unicode[STIX]{x1D709}_{m_{i}}x/w)\,\text{d}y\,\text{d}x\nonumber\\ \displaystyle & & \displaystyle \quad =K^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{-2}\int _{0}^{w}\int _{0}^{1}\mathbb{N}^{\ast }\cos (\unicode[STIX]{x1D709}_{l_{i}}y)\cos (\unicode[STIX]{x1D709}_{m_{i}}x/w)\,\text{d}y\,\text{d}x.\end{eqnarray}$$ Performing the integrations, ![]() $b_{i}$ is obtained as

$b_{i}$ is obtained as ![]() $b_{i}=c_{i}/a_{i}$ where

$b_{i}=c_{i}/a_{i}$ where

$$\begin{eqnarray}\displaystyle c_{i} & = & \displaystyle K^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{-2}w\left.\unicode[STIX]{x27E6}\unicode[STIX]{x1D6FF}_{0,l_{i}+m_{i}}-\left\{\unicode[STIX]{x1D6FF}_{0,l_{i}}(1-l)+(1-\unicode[STIX]{x1D6FF}_{0,l_{i}})\frac{\sin [\unicode[STIX]{x1D709}_{l_{i}}(1-l)]}{\unicode[STIX]{x1D709}_{l_{i}}}\right\}\left\{\unicode[STIX]{x1D6FF}_{0,m_{i}}(1-l/w)\right.\right.\nonumber\\ \displaystyle & & \displaystyle +\left.\left.(1-\unicode[STIX]{x1D6FF}_{0,m_{i}})\frac{\sin [\unicode[STIX]{x1D709}_{m_{i}}(1-l/w)]}{\unicode[STIX]{x1D709}_{m_{i}}}\right\}\right.\unicode[STIX]{x27E7},\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle c_{i} & = & \displaystyle K^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{-2}w\left.\unicode[STIX]{x27E6}\unicode[STIX]{x1D6FF}_{0,l_{i}+m_{i}}-\left\{\unicode[STIX]{x1D6FF}_{0,l_{i}}(1-l)+(1-\unicode[STIX]{x1D6FF}_{0,l_{i}})\frac{\sin [\unicode[STIX]{x1D709}_{l_{i}}(1-l)]}{\unicode[STIX]{x1D709}_{l_{i}}}\right\}\left\{\unicode[STIX]{x1D6FF}_{0,m_{i}}(1-l/w)\right.\right.\nonumber\\ \displaystyle & & \displaystyle +\left.\left.(1-\unicode[STIX]{x1D6FF}_{0,m_{i}})\frac{\sin [\unicode[STIX]{x1D709}_{m_{i}}(1-l/w)]}{\unicode[STIX]{x1D709}_{m_{i}}}\right\}\right.\unicode[STIX]{x27E7},\end{eqnarray}$$2.2.1 Special solution for  $w\rightarrow \infty$

$w\rightarrow \infty$

When the channel aspect ratio is very large, that is for ![]() $1\ll w$, the dependence of the physical parameters on the

$1\ll w$, the dependence of the physical parameters on the ![]() $x$-coordinate vanishes. The solutions obtained under these circumstances are computationally less expensive and are more appropriate to experimentalists. The electric potential distribution for this case is found by solving the following ordinary differential equations for outside and inside the PEL, respectively,

$x$-coordinate vanishes. The solutions obtained under these circumstances are computationally less expensive and are more appropriate to experimentalists. The electric potential distribution for this case is found by solving the following ordinary differential equations for outside and inside the PEL, respectively,

which are subject to the following boundary and interfacial conditions:

It can be shown that the solutions of (2.14) and (2.15) subject to the pertinent boundary conditions are given as

where

$$\begin{eqnarray}\displaystyle b_{E1} & = & \displaystyle \unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{-2}\{\sinh [K(1-l)]\}^{-1}\{\!\tanh [K(1-l)]\nonumber\\ \displaystyle & & \displaystyle -\,\tanh K\!\}\unicode[STIX]{x27E6}\{\tanh [K(1-l)]\}^{-1}\{\tanh [K(1-l)]-\tanh K\}-1\nonumber\\ \displaystyle & & \displaystyle +\,\tanh K\tanh [K(1-l)]\unicode[STIX]{x27E7}^{-1},\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle b_{E1} & = & \displaystyle \unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{-2}\{\sinh [K(1-l)]\}^{-1}\{\!\tanh [K(1-l)]\nonumber\\ \displaystyle & & \displaystyle -\,\tanh K\!\}\unicode[STIX]{x27E6}\{\tanh [K(1-l)]\}^{-1}\{\tanh [K(1-l)]-\tanh K\}-1\nonumber\\ \displaystyle & & \displaystyle +\,\tanh K\tanh [K(1-l)]\unicode[STIX]{x27E7}^{-1},\end{eqnarray}$$2.3 Velocity distribution

For evaluation of the velocity field, the mathematical representation of the momentum conservation law must be solved. For an incompressible flow of Newtonian fluids with constant physical properties, the general form of the momentum equation reads

where parameters ![]() $\unicode[STIX]{x1D70C}$,

$\unicode[STIX]{x1D70C}$, ![]() $t$,

$t$, ![]() $\boldsymbol{U}$,

$\boldsymbol{U}$, ![]() $P$,

$P$, ![]() $\unicode[STIX]{x1D707}$ and

$\unicode[STIX]{x1D707}$ and ![]() $\boldsymbol{F}$ denote the density, time, velocity vector, pressure, dynamic viscosity and body force vector, respectively. Since the flow is assumed to be both steady and fully developed, the inertia term is dropped from the momentum equation and the axial velocity

$\boldsymbol{F}$ denote the density, time, velocity vector, pressure, dynamic viscosity and body force vector, respectively. Since the flow is assumed to be both steady and fully developed, the inertia term is dropped from the momentum equation and the axial velocity ![]() $U_{z}$ becomes a function of the transverse coordinates only. The body force vector

$U_{z}$ becomes a function of the transverse coordinates only. The body force vector ![]() $\boldsymbol{F}$ is the superposition of the force exerted on the ions by the electric field

$\boldsymbol{F}$ is the superposition of the force exerted on the ions by the electric field ![]() $\boldsymbol{E}$, given as

$\boldsymbol{E}$, given as ![]() $\unicode[STIX]{x1D70C}_{e}\boldsymbol{E}$, and the drag force created by the polyelectrolyte brushes. The widely accepted approach to accounting for the drag force is to consider a volumetric resistive force proportional to the velocity, which is equivalent to modelling the PEL as a porous medium utilizing the Brinkman equation. For a fully developed flow, such a resistive force is given as

$\unicode[STIX]{x1D70C}_{e}\boldsymbol{E}$, and the drag force created by the polyelectrolyte brushes. The widely accepted approach to accounting for the drag force is to consider a volumetric resistive force proportional to the velocity, which is equivalent to modelling the PEL as a porous medium utilizing the Brinkman equation. For a fully developed flow, such a resistive force is given as ![]() $f_{PEL}U_{z}$ where

$f_{PEL}U_{z}$ where ![]() $f_{PEL}$ is the friction coefficient of the PEL per unit volume. Adding the above-mentioned terms to the Navier–Stokes equation and substituting for

$f_{PEL}$ is the friction coefficient of the PEL per unit volume. Adding the above-mentioned terms to the Navier–Stokes equation and substituting for ![]() $\unicode[STIX]{x1D70C}_{e}$ from (2.3) and (2.4), the momentum equation in the axial direction becomes

$\unicode[STIX]{x1D70C}_{e}$ from (2.3) and (2.4), the momentum equation in the axial direction becomes

where ![]() $E_{z}$ is the applied electric field and the friction coefficient

$E_{z}$ is the applied electric field and the friction coefficient ![]() $f$ is equal to

$f$ is equal to ![]() $f_{PEL}$ inside the grafted layer and 0 within the electrolyte. By introducing the following new dimensionless parameters

$f_{PEL}$ inside the grafted layer and 0 within the electrolyte. By introducing the following new dimensionless parameters

with ![]() $U_{0}=-\unicode[STIX]{x1D700}k_{B}TE_{z}/e\unicode[STIX]{x1D707}z_{E}$ being the reference velocity, and performing the Debye–Hückel linearization, the momentum equation (2.21) can be scaled as

$U_{0}=-\unicode[STIX]{x1D700}k_{B}TE_{z}/e\unicode[STIX]{x1D707}z_{E}$ being the reference velocity, and performing the Debye–Hückel linearization, the momentum equation (2.21) can be scaled as

The momentum equation is subject to symmetry and no-slip boundary conditions, which are written in dimensionless form as

The solution of (2.23) satisfying the pertinent boundary conditions may be expressed as

where ![]() $\unicode[STIX]{x1D709}_{r_{j}}=(2r_{j}+1)\unicode[STIX]{x03C0}/2$ and

$\unicode[STIX]{x1D709}_{r_{j}}=(2r_{j}+1)\unicode[STIX]{x03C0}/2$ and ![]() $\unicode[STIX]{x1D709}_{q_{j}}=(2q_{j}+1)\unicode[STIX]{x03C0}/2$ with

$\unicode[STIX]{x1D709}_{q_{j}}=(2q_{j}+1)\unicode[STIX]{x03C0}/2$ with ![]() $r_{j}=0,1,2,\ldots$ and

$r_{j}=0,1,2,\ldots$ and ![]() $q_{j}=0,1,2,\ldots$ . Substituting the forms (2.10) and (2.25) into (2.23), multiplying both sides by

$q_{j}=0,1,2,\ldots$ . Substituting the forms (2.10) and (2.25) into (2.23), multiplying both sides by ![]() $\cos (\unicode[STIX]{x1D709}_{r_{i}}y)\cos (\unicode[STIX]{x1D709}_{q_{i}}x/w)$ and integrating over the dimensionless cross-sectional area, one gets

$\cos (\unicode[STIX]{x1D709}_{r_{i}}y)\cos (\unicode[STIX]{x1D709}_{q_{i}}x/w)$ and integrating over the dimensionless cross-sectional area, one gets

$$\begin{eqnarray}\displaystyle & & \displaystyle \mathop{\sum }_{j=1}^{\infty }d_{j}\int _{0}^{w}\int _{0}^{1}(\unicode[STIX]{x1D709}_{r_{j}}^{2}+\unicode[STIX]{x1D709}_{q_{j}}^{2}/w^{2}+\unicode[STIX]{x1D6FC}^{2}f^{\ast })\cos (\unicode[STIX]{x1D709}_{r_{i}}y)\cos (\unicode[STIX]{x1D709}_{q_{i}}x/w)\cos (\unicode[STIX]{x1D709}_{r_{j}}y)\cos (\unicode[STIX]{x1D709}_{q_{j}}x/w)\,\text{d}y\,\text{d}x\nonumber\\ \displaystyle & & \displaystyle \quad =K^{2}\mathop{\sum }_{j=1}^{\infty }b_{j}\int _{0}^{w}\int _{0}^{1}\cos (\unicode[STIX]{x1D709}_{r_{i}}y)\cos (\unicode[STIX]{x1D709}_{q_{i}}x/w)\cos (\unicode[STIX]{x1D709}_{l_{j}}y)\cos (\unicode[STIX]{x1D709}_{m_{j}}x/w)\,\text{d}y\,\text{d}x.\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle \mathop{\sum }_{j=1}^{\infty }d_{j}\int _{0}^{w}\int _{0}^{1}(\unicode[STIX]{x1D709}_{r_{j}}^{2}+\unicode[STIX]{x1D709}_{q_{j}}^{2}/w^{2}+\unicode[STIX]{x1D6FC}^{2}f^{\ast })\cos (\unicode[STIX]{x1D709}_{r_{i}}y)\cos (\unicode[STIX]{x1D709}_{q_{i}}x/w)\cos (\unicode[STIX]{x1D709}_{r_{j}}y)\cos (\unicode[STIX]{x1D709}_{q_{j}}x/w)\,\text{d}y\,\text{d}x\nonumber\\ \displaystyle & & \displaystyle \quad =K^{2}\mathop{\sum }_{j=1}^{\infty }b_{j}\int _{0}^{w}\int _{0}^{1}\cos (\unicode[STIX]{x1D709}_{r_{i}}y)\cos (\unicode[STIX]{x1D709}_{q_{i}}x/w)\cos (\unicode[STIX]{x1D709}_{l_{j}}y)\cos (\unicode[STIX]{x1D709}_{m_{j}}x/w)\,\text{d}y\,\text{d}x.\end{eqnarray}$$ It should be pointed out that, because of the position-dependent nature of ![]() $f^{\ast }$, the orthogonality condition does not hold for this case. Truncating the series on the left side from the

$f^{\ast }$, the orthogonality condition does not hold for this case. Truncating the series on the left side from the ![]() $N$th term and that on the right side from the

$N$th term and that on the right side from the ![]() $M$th term and performing the integrations, a system of

$M$th term and performing the integrations, a system of ![]() $N$ equations of

$N$ equations of ![]() $N$ unknowns including

$N$ unknowns including ![]() $d_{1},d_{2},\ldots ,d_{N}$ are obtained that may be written in matrix form as

$d_{1},d_{2},\ldots ,d_{N}$ are obtained that may be written in matrix form as

where the matrix ![]() $\unicode[STIX]{x1D640}$ and vector

$\unicode[STIX]{x1D640}$ and vector ![]() $\boldsymbol{H}$ have the following elements:

$\boldsymbol{H}$ have the following elements:

$$\begin{eqnarray}\displaystyle e_{ij} & = & \displaystyle \frac{\unicode[STIX]{x1D6FF}_{r_{i},r_{j}}\unicode[STIX]{x1D6FF}_{q_{i},q_{j}}}{4w}(w^{2}\unicode[STIX]{x1D709}_{r_{i}}\unicode[STIX]{x1D709}_{r_{j}}+\unicode[STIX]{x1D709}_{q_{i}}\unicode[STIX]{x1D709}_{q_{j}})+\frac{\unicode[STIX]{x1D6FC}^{2}}{4}w\unicode[STIX]{x1D6FF}_{r_{i},r_{j}}\unicode[STIX]{x1D6FF}_{q_{i},q_{j}}\nonumber\\ \displaystyle & & \displaystyle -\,\frac{\unicode[STIX]{x1D6FC}^{2}w}{4}\left.\unicode[STIX]{x27E6}\unicode[STIX]{x1D6FF}_{r_{i},r_{j}}\left\{1-l+\frac{\sin [2\unicode[STIX]{x1D709}_{r_{i}}(1-l)]}{2\unicode[STIX]{x1D709}_{r_{i}}}\right\}\right.\nonumber\\ \displaystyle & & \displaystyle +\left.(1-\unicode[STIX]{x1D6FF}_{r_{i},r_{j}})\left\{\frac{\sin [(\unicode[STIX]{x1D709}_{r_{i}}-\unicode[STIX]{x1D709}_{r_{j}})(1-l)]}{\unicode[STIX]{x1D709}_{r_{i}}-\unicode[STIX]{x1D709}_{r_{j}}}-\frac{\sin [(\unicode[STIX]{x1D709}_{r_{i}}+\unicode[STIX]{x1D709}_{r_{j}})(1-l)]}{\unicode[STIX]{x1D709}_{r_{i}}+\unicode[STIX]{x1D709}_{r_{j}}}\right\}\right.\unicode[STIX]{x27E7}\left.\unicode[STIX]{x27E6}\unicode[STIX]{x1D6FF}_{q_{i},q_{j}}\left\{1-l/w\right.\right.\nonumber\\ \displaystyle & & \displaystyle +\left.\frac{\sin [2\unicode[STIX]{x1D709}_{q_{i}}(1-l/w)]}{2\unicode[STIX]{x1D709}_{q_{i}}}\right\}\nonumber\\ \displaystyle & & \displaystyle +\left.(1-\unicode[STIX]{x1D6FF}_{q_{i},q_{j}})\left\{\frac{\sin [(\unicode[STIX]{x1D709}_{q_{i}}-\unicode[STIX]{x1D709}_{q_{j}})(1-l/w)]}{\unicode[STIX]{x1D709}_{q_{i}}-\unicode[STIX]{x1D709}_{q_{j}}}+\frac{\sin [(\unicode[STIX]{x1D709}_{q_{i}}+\unicode[STIX]{x1D709}_{q_{j}})(1-l/w)]}{\unicode[STIX]{x1D709}_{q_{i}}+\unicode[STIX]{x1D709}_{q_{j}}}\right\}\right.\unicode[STIX]{x27E7},\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle e_{ij} & = & \displaystyle \frac{\unicode[STIX]{x1D6FF}_{r_{i},r_{j}}\unicode[STIX]{x1D6FF}_{q_{i},q_{j}}}{4w}(w^{2}\unicode[STIX]{x1D709}_{r_{i}}\unicode[STIX]{x1D709}_{r_{j}}+\unicode[STIX]{x1D709}_{q_{i}}\unicode[STIX]{x1D709}_{q_{j}})+\frac{\unicode[STIX]{x1D6FC}^{2}}{4}w\unicode[STIX]{x1D6FF}_{r_{i},r_{j}}\unicode[STIX]{x1D6FF}_{q_{i},q_{j}}\nonumber\\ \displaystyle & & \displaystyle -\,\frac{\unicode[STIX]{x1D6FC}^{2}w}{4}\left.\unicode[STIX]{x27E6}\unicode[STIX]{x1D6FF}_{r_{i},r_{j}}\left\{1-l+\frac{\sin [2\unicode[STIX]{x1D709}_{r_{i}}(1-l)]}{2\unicode[STIX]{x1D709}_{r_{i}}}\right\}\right.\nonumber\\ \displaystyle & & \displaystyle +\left.(1-\unicode[STIX]{x1D6FF}_{r_{i},r_{j}})\left\{\frac{\sin [(\unicode[STIX]{x1D709}_{r_{i}}-\unicode[STIX]{x1D709}_{r_{j}})(1-l)]}{\unicode[STIX]{x1D709}_{r_{i}}-\unicode[STIX]{x1D709}_{r_{j}}}-\frac{\sin [(\unicode[STIX]{x1D709}_{r_{i}}+\unicode[STIX]{x1D709}_{r_{j}})(1-l)]}{\unicode[STIX]{x1D709}_{r_{i}}+\unicode[STIX]{x1D709}_{r_{j}}}\right\}\right.\unicode[STIX]{x27E7}\left.\unicode[STIX]{x27E6}\unicode[STIX]{x1D6FF}_{q_{i},q_{j}}\left\{1-l/w\right.\right.\nonumber\\ \displaystyle & & \displaystyle +\left.\frac{\sin [2\unicode[STIX]{x1D709}_{q_{i}}(1-l/w)]}{2\unicode[STIX]{x1D709}_{q_{i}}}\right\}\nonumber\\ \displaystyle & & \displaystyle +\left.(1-\unicode[STIX]{x1D6FF}_{q_{i},q_{j}})\left\{\frac{\sin [(\unicode[STIX]{x1D709}_{q_{i}}-\unicode[STIX]{x1D709}_{q_{j}})(1-l/w)]}{\unicode[STIX]{x1D709}_{q_{i}}-\unicode[STIX]{x1D709}_{q_{j}}}+\frac{\sin [(\unicode[STIX]{x1D709}_{q_{i}}+\unicode[STIX]{x1D709}_{q_{j}})(1-l/w)]}{\unicode[STIX]{x1D709}_{q_{i}}+\unicode[STIX]{x1D709}_{q_{j}}}\right\}\right.\unicode[STIX]{x27E7},\end{eqnarray}$$ So the vector ![]() $\boldsymbol{d}$, which stands for the coefficients

$\boldsymbol{d}$, which stands for the coefficients ![]() $d_{j}$, can be readily obtained as

$d_{j}$, can be readily obtained as ![]() $\boldsymbol{d}=\unicode[STIX]{x1D640}^{-1}\boldsymbol{H}$.

$\boldsymbol{d}=\unicode[STIX]{x1D640}^{-1}\boldsymbol{H}$.

As soon as the dimensionless velocity ![]() $u$ is obtained, the dimensionless mean velocity can be evaluated as

$u$ is obtained, the dimensionless mean velocity can be evaluated as

$$\begin{eqnarray}u_{m}=\frac{\displaystyle \int _{0}^{w}\int _{0}^{1}u\,\text{d}y\,\text{d}x}{\displaystyle \int _{0}^{w}\int _{0}^{1}\,\text{d}y\,\text{d}x}=\mathop{\sum }_{j=1}^{N}\frac{d_{j}(-1)^{r_{j}+q_{j}}}{\unicode[STIX]{x1D709}_{r_{j}}\unicode[STIX]{x1D709}_{q_{j}}}.\end{eqnarray}$$

$$\begin{eqnarray}u_{m}=\frac{\displaystyle \int _{0}^{w}\int _{0}^{1}u\,\text{d}y\,\text{d}x}{\displaystyle \int _{0}^{w}\int _{0}^{1}\,\text{d}y\,\text{d}x}=\mathop{\sum }_{j=1}^{N}\frac{d_{j}(-1)^{r_{j}+q_{j}}}{\unicode[STIX]{x1D709}_{r_{j}}\unicode[STIX]{x1D709}_{q_{j}}}.\end{eqnarray}$$2.3.1 Special solution for  $w\rightarrow \infty$

$w\rightarrow \infty$

The momentum equation for this case reduces to the following equations for the electrolyte and the PEL:

In addition, the boundary and interfacial conditions read

It can be demonstrated that the solutions of (2.30) and (2.31) subject to the conditions (2.32) are given as

$$\begin{eqnarray}\displaystyle u_{PEL} & = & \displaystyle b_{PEL2}[\cosh (\unicode[STIX]{x1D6FC}y)-\coth \unicode[STIX]{x1D6FC}\sinh (\unicode[STIX]{x1D6FC}y)]\nonumber\\ \displaystyle & & \displaystyle +\,\left[(\cosh K)^{-1}\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)-\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}\right]\frac{\sinh (\unicode[STIX]{x1D6FC}y)}{\sinh \unicode[STIX]{x1D6FC}}\nonumber\\ \displaystyle & & \displaystyle -\,\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\cosh (Ky)+\tanh K\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\sinh (Ky)+\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}},\qquad\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle u_{PEL} & = & \displaystyle b_{PEL2}[\cosh (\unicode[STIX]{x1D6FC}y)-\coth \unicode[STIX]{x1D6FC}\sinh (\unicode[STIX]{x1D6FC}y)]\nonumber\\ \displaystyle & & \displaystyle +\,\left[(\cosh K)^{-1}\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)-\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}\right]\frac{\sinh (\unicode[STIX]{x1D6FC}y)}{\sinh \unicode[STIX]{x1D6FC}}\nonumber\\ \displaystyle & & \displaystyle -\,\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\cosh (Ky)+\tanh K\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\sinh (Ky)+\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}},\qquad\end{eqnarray}$$where

$$\begin{eqnarray}\displaystyle & & \displaystyle b_{E2}=b_{PEL2}\{\cosh [\unicode[STIX]{x1D6FC}(1-l)]-\coth \unicode[STIX]{x1D6FC}\sinh [\unicode[STIX]{x1D6FC}(1-l)]\}\nonumber\\ \displaystyle & & \displaystyle \quad +\,\left[(\cosh K)^{-1}\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)-\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}\right]\frac{\sinh [\unicode[STIX]{x1D6FC}(1-l)]}{\sinh \unicode[STIX]{x1D6FC}}-\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\cosh [K(1-l)]\nonumber\\ \displaystyle & & \displaystyle \quad +\,\tanh K\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\sinh [K(1-l)]+\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}+b_{E1}\cosh [K(1-l)],\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle b_{E2}=b_{PEL2}\{\cosh [\unicode[STIX]{x1D6FC}(1-l)]-\coth \unicode[STIX]{x1D6FC}\sinh [\unicode[STIX]{x1D6FC}(1-l)]\}\nonumber\\ \displaystyle & & \displaystyle \quad +\,\left[(\cosh K)^{-1}\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)-\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}\right]\frac{\sinh [\unicode[STIX]{x1D6FC}(1-l)]}{\sinh \unicode[STIX]{x1D6FC}}-\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\cosh [K(1-l)]\nonumber\\ \displaystyle & & \displaystyle \quad +\,\tanh K\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\sinh [K(1-l)]+\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}+b_{E1}\cosh [K(1-l)],\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle b_{PEL2} & = & \displaystyle \unicode[STIX]{x1D6FC}^{-1}\{\sinh [\unicode[STIX]{x1D6FC}(1-l)]-\coth \unicode[STIX]{x1D6FC}\cosh [\unicode[STIX]{x1D6FC}(1-l)]\}^{-1}\left\{-b_{E1}K\sinh [K(1-l)]\right.\nonumber\\ \displaystyle & & \displaystyle -\,\unicode[STIX]{x1D6FC}\left[(\cosh K)^{-1}\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)-\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}\right]\nonumber\\ \displaystyle & & \displaystyle \times \,\frac{\cosh [\unicode[STIX]{x1D6FC}(1-l)]}{\sinh \unicode[STIX]{x1D6FC}}+\left(\frac{K^{3}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\sinh [K(1-l)]\nonumber\\ \displaystyle & & \displaystyle -\left.\left(\frac{K^{3}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\tanh K\cosh [K(1-l)]\right\}.\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle b_{PEL2} & = & \displaystyle \unicode[STIX]{x1D6FC}^{-1}\{\sinh [\unicode[STIX]{x1D6FC}(1-l)]-\coth \unicode[STIX]{x1D6FC}\cosh [\unicode[STIX]{x1D6FC}(1-l)]\}^{-1}\left\{-b_{E1}K\sinh [K(1-l)]\right.\nonumber\\ \displaystyle & & \displaystyle -\,\unicode[STIX]{x1D6FC}\left[(\cosh K)^{-1}\left(\frac{K^{2}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)-\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}\right]\nonumber\\ \displaystyle & & \displaystyle \times \,\frac{\cosh [\unicode[STIX]{x1D6FC}(1-l)]}{\sinh \unicode[STIX]{x1D6FC}}+\left(\frac{K^{3}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\sinh [K(1-l)]\nonumber\\ \displaystyle & & \displaystyle -\left.\left(\frac{K^{3}b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\tanh K\cosh [K(1-l)]\right\}.\end{eqnarray}$$And the mean velocity becomes

$$\begin{eqnarray}\displaystyle u_{m} & = & \displaystyle \int _{0}^{1-l}u_{E}\,\text{d}y+\int _{1-l}^{1}u_{PEL}\,\text{d}y\nonumber\\ \displaystyle & = & \displaystyle -\frac{b_{E1}}{K}\sinh [K(1-l)]+b_{E2}(1-l)\nonumber\\ \displaystyle & & \displaystyle -\,\unicode[STIX]{x1D6FC}^{-1}b_{PEL2}\{\sinh [\unicode[STIX]{x1D6FC}(1-l)]-\coth \unicode[STIX]{x1D6FC}\cosh [\unicode[STIX]{x1D6FC}(1-l)]+(\sinh \unicode[STIX]{x1D6FC})^{-1}\}\nonumber\\ \displaystyle & & \displaystyle +\,K^{2}\unicode[STIX]{x1D6FC}^{-1}\left[(\cosh K)^{-1}\left(\frac{b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)-\unicode[STIX]{x1D6FC}^{-2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{-2}\right]\left\{\coth \unicode[STIX]{x1D6FC}-\frac{\cosh [\unicode[STIX]{x1D6FC}(1-l)]}{\sinh \unicode[STIX]{x1D6FC}}\right\}\nonumber\\ \displaystyle & & \displaystyle -\,\left(\frac{Kb_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\{\sinh K-\sinh [K(1-l)]\}+\tanh K\left(\frac{Kb_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\nonumber\\ \displaystyle & & \displaystyle \times \,\{\cosh K-\cosh [K(1-l)]\}+\frac{K^{2}l}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}.\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle u_{m} & = & \displaystyle \int _{0}^{1-l}u_{E}\,\text{d}y+\int _{1-l}^{1}u_{PEL}\,\text{d}y\nonumber\\ \displaystyle & = & \displaystyle -\frac{b_{E1}}{K}\sinh [K(1-l)]+b_{E2}(1-l)\nonumber\\ \displaystyle & & \displaystyle -\,\unicode[STIX]{x1D6FC}^{-1}b_{PEL2}\{\sinh [\unicode[STIX]{x1D6FC}(1-l)]-\coth \unicode[STIX]{x1D6FC}\cosh [\unicode[STIX]{x1D6FC}(1-l)]+(\sinh \unicode[STIX]{x1D6FC})^{-1}\}\nonumber\\ \displaystyle & & \displaystyle +\,K^{2}\unicode[STIX]{x1D6FC}^{-1}\left[(\cosh K)^{-1}\left(\frac{b_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)-\unicode[STIX]{x1D6FC}^{-2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{-2}\right]\left\{\coth \unicode[STIX]{x1D6FC}-\frac{\cosh [\unicode[STIX]{x1D6FC}(1-l)]}{\sinh \unicode[STIX]{x1D6FC}}\right\}\nonumber\\ \displaystyle & & \displaystyle -\,\left(\frac{Kb_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\{\sinh K-\sinh [K(1-l)]\}+\tanh K\left(\frac{Kb_{PEL1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\nonumber\\ \displaystyle & & \displaystyle \times \,\{\cosh K-\cosh [K(1-l)]\}+\frac{K^{2}l}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}.\end{eqnarray}$$2.4 Concentration field

The solute concentration distribution due to an injection source at ![]() $z=0$ can be described by the following transient advective–diffusive equation:

$z=0$ can be described by the following transient advective–diffusive equation:

where ![]() $\unicode[STIX]{x1D70F}$ denotes the time,

$\unicode[STIX]{x1D70F}$ denotes the time, ![]() $D$ stands for the molecular diffusivity and

$D$ stands for the molecular diffusivity and ![]() $C$ is the number concentration of solutes. Note that, due to the presence of polyelectrolyte brushes, the molecular diffusivity in the PEL is smaller than that in the bulk. Nevertheless, considering the fact that the effective diffusion coefficient in a porous medium of high porosity is approximately the same as that in void spaces (Vafai Reference Vafai2005), the diffusion coefficient in the soft layer may be considered the same as that in the bulk due to the small grafting densities assumed in the analysis. As we would like to perform separate analyses for slit and rectangular microchannels, the subscripts 1 and 2 are hereafter used for these geometries, respectively, to distinguish between the associated concentrations. Since we consider a fully developed flow of a liquid with constant thermophysical properties, equation (2.37) can be simplified to yield the following equations for slit and rectangular geometries, respectively,

$C$ is the number concentration of solutes. Note that, due to the presence of polyelectrolyte brushes, the molecular diffusivity in the PEL is smaller than that in the bulk. Nevertheless, considering the fact that the effective diffusion coefficient in a porous medium of high porosity is approximately the same as that in void spaces (Vafai Reference Vafai2005), the diffusion coefficient in the soft layer may be considered the same as that in the bulk due to the small grafting densities assumed in the analysis. As we would like to perform separate analyses for slit and rectangular microchannels, the subscripts 1 and 2 are hereafter used for these geometries, respectively, to distinguish between the associated concentrations. Since we consider a fully developed flow of a liquid with constant thermophysical properties, equation (2.37) can be simplified to yield the following equations for slit and rectangular geometries, respectively,

which are subject to the following initial and boundary conditions:

Equations (2.38) and (2.39) are made dimensionless by using the following dimensionless parameters:

The dimensionless solute transport equations and the pertinent initial and boundary conditions then become

The unsteady transport equation with the associated initial and boundary conditions can be solved using the method proposed by Gill & Sankarasubramanian (Reference Gill and Sankarasubramanian1970). In this method, the solute concentration ![]() $c$ is expanded in an infinite series as follows:

$c$ is expanded in an infinite series as follows:

where the dimensionless mean concentration ![]() $c_{m}(t,z)$ is defined as

$c_{m}(t,z)$ is defined as

$$\begin{eqnarray}\displaystyle & \displaystyle c_{m,2}(t,z)=\frac{\displaystyle \int _{0}^{w}\int _{0}^{1}c_{2}\,\text{d}y\,\text{d}x}{w}. & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle c_{m,2}(t,z)=\frac{\displaystyle \int _{0}^{w}\int _{0}^{1}c_{2}\,\text{d}y\,\text{d}x}{w}. & \displaystyle\end{eqnarray}$$By integrating the dimensionless concentration equations (2.43) and (2.45) over the microchannel cross-sectional area and using the mean concentration definition in (2.49) and (2.50) we will have

$$\begin{eqnarray}\displaystyle \frac{\unicode[STIX]{x2202}c_{m,2}}{\unicode[STIX]{x2202}t} & = & \displaystyle \frac{1}{Pe^{2}}\frac{\unicode[STIX]{x2202}^{2}c_{m,2}}{\unicode[STIX]{x2202}z^{2}}+\frac{1}{w}\left(\int _{0}^{1}\left.\frac{\unicode[STIX]{x2202}c_{2}}{\unicode[STIX]{x2202}x}\right|_{x=w}\,\text{d}y+\int _{0}^{w}\left.\frac{\unicode[STIX]{x2202}c_{2}}{\unicode[STIX]{x2202}y}\right|_{y=1}\,\text{d}x\right)\nonumber\\ \displaystyle & & \displaystyle -\,\frac{1}{w}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}z}\int _{0}^{1}\int _{0}^{w}u_{2}c_{2}\,\text{d}x\,\text{d}y.\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \frac{\unicode[STIX]{x2202}c_{m,2}}{\unicode[STIX]{x2202}t} & = & \displaystyle \frac{1}{Pe^{2}}\frac{\unicode[STIX]{x2202}^{2}c_{m,2}}{\unicode[STIX]{x2202}z^{2}}+\frac{1}{w}\left(\int _{0}^{1}\left.\frac{\unicode[STIX]{x2202}c_{2}}{\unicode[STIX]{x2202}x}\right|_{x=w}\,\text{d}y+\int _{0}^{w}\left.\frac{\unicode[STIX]{x2202}c_{2}}{\unicode[STIX]{x2202}y}\right|_{y=1}\,\text{d}x\right)\nonumber\\ \displaystyle & & \displaystyle -\,\frac{1}{w}\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}z}\int _{0}^{1}\int _{0}^{w}u_{2}c_{2}\,\text{d}x\,\text{d}y.\end{eqnarray}$$ Then, substituting the local concentration formulas from (2.47) and (2.48) into (2.51) and (2.52) and rearranging gives the following dispersion model for ![]() $c_{m}$:

$c_{m}$:

where the coefficients ![]() $K_{n,i}(t)$ are

$K_{n,i}(t)$ are

$$\begin{eqnarray}\displaystyle K_{n,2}(t) & = & \displaystyle \frac{\unicode[STIX]{x1D6FF}_{n,2}}{Pe^{2}}+\frac{1}{w}\left(\int _{0}^{1}\left.\frac{\unicode[STIX]{x2202}f_{n,2}}{\unicode[STIX]{x2202}x}\right|_{x=w}\,\text{d}y+\int _{0}^{w}\left.\frac{\unicode[STIX]{x2202}f_{n,2}}{\unicode[STIX]{x2202}y}\right|_{y=1}\,\text{d}x\right)\nonumber\\ \displaystyle & & \displaystyle -\,\frac{1}{w}\int _{0}^{1}\int _{0}^{w}u_{2}(x,y)f_{n-1,2}\,\text{d}x\,\text{d}y,\quad n=0,1,2\ldots .\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle K_{n,2}(t) & = & \displaystyle \frac{\unicode[STIX]{x1D6FF}_{n,2}}{Pe^{2}}+\frac{1}{w}\left(\int _{0}^{1}\left.\frac{\unicode[STIX]{x2202}f_{n,2}}{\unicode[STIX]{x2202}x}\right|_{x=w}\,\text{d}y+\int _{0}^{w}\left.\frac{\unicode[STIX]{x2202}f_{n,2}}{\unicode[STIX]{x2202}y}\right|_{y=1}\,\text{d}x\right)\nonumber\\ \displaystyle & & \displaystyle -\,\frac{1}{w}\int _{0}^{1}\int _{0}^{w}u_{2}(x,y)f_{n-1,2}\,\text{d}x\,\text{d}y,\quad n=0,1,2\ldots .\end{eqnarray}$$ Neglecting the terms with ![]() $3\leqslant n$ due to their negligible contribution to the dispersion of the mean concentration, equation (2.53) is reduced to

$3\leqslant n$ due to their negligible contribution to the dispersion of the mean concentration, equation (2.53) is reduced to

where ![]() $K_{0,i}(t)$ is the exchange coefficient due to non-zero solute flux at the tube wall,

$K_{0,i}(t)$ is the exchange coefficient due to non-zero solute flux at the tube wall, ![]() $K_{1,i}(t)$ is the convection coefficient due to convective transport of the solutes and

$K_{1,i}(t)$ is the convection coefficient due to convective transport of the solutes and ![]() $K_{2,i}(t)$ is the dispersion coefficient due to molecular diffusion and non-uniformity of the velocity profile. So the behaviour of solute dispersion can be described well by evaluating these three transport coefficients.

$K_{2,i}(t)$ is the dispersion coefficient due to molecular diffusion and non-uniformity of the velocity profile. So the behaviour of solute dispersion can be described well by evaluating these three transport coefficients.

Besides appropriate initial and boundary conditions, the determination of ![]() $K_{0,i}(t)$,

$K_{0,i}(t)$, ![]() $K_{1,i}(t)$ and

$K_{1,i}(t)$ and ![]() $K_{2,i}(t)$ is needed to solve (2.56). Considering (2.54) and (2.55), we must first evaluate functions

$K_{2,i}(t)$ is needed to solve (2.56). Considering (2.54) and (2.55), we must first evaluate functions ![]() $f_{n}$. The equations governing

$f_{n}$. The equations governing ![]() $f_{n}$ can be achieved by substituting the local concentration distributions from (2.47) and (2.48) and also the time derivative of

$f_{n}$ can be achieved by substituting the local concentration distributions from (2.47) and (2.48) and also the time derivative of ![]() $c_{m}$ from (2.53) into (2.43) and (2.45) and then equating the coefficients of

$c_{m}$ from (2.53) into (2.43) and (2.45) and then equating the coefficients of ![]() $\unicode[STIX]{x2202}^{n}c_{m}/\unicode[STIX]{x2202}z^{n}$. The desired equations then read

$\unicode[STIX]{x2202}^{n}c_{m}/\unicode[STIX]{x2202}z^{n}$. The desired equations then read

where ![]() $f_{-1}=f_{-2}=\cdots =0$. Substituting (2.47) and (2.48) into (2.44) and (2.46) and recalling that

$f_{-1}=f_{-2}=\cdots =0$. Substituting (2.47) and (2.48) into (2.44) and (2.46) and recalling that ![]() $c_{m,i}(0,z)=Pe^{-1}\unicode[STIX]{x1D6FF}(z)\unicode[STIX]{x1D703}_{m,i}$ where

$c_{m,i}(0,z)=Pe^{-1}\unicode[STIX]{x1D6FF}(z)\unicode[STIX]{x1D703}_{m,i}$ where ![]() $\unicode[STIX]{x1D703}_{m,1}=\int _{0}^{1}\unicode[STIX]{x1D703}_{1}\,\text{d}y$ and

$\unicode[STIX]{x1D703}_{m,1}=\int _{0}^{1}\unicode[STIX]{x1D703}_{1}\,\text{d}y$ and ![]() $\unicode[STIX]{x1D703}_{m,2}=\int _{0}^{1}\int _{0}^{w}\unicode[STIX]{x1D703}_{2}\,\text{d}x\,\text{d}y/w$, the associated initial and boundary conditions are obtained as

$\unicode[STIX]{x1D703}_{m,2}=\int _{0}^{1}\int _{0}^{w}\unicode[STIX]{x1D703}_{2}\,\text{d}x\,\text{d}y/w$, the associated initial and boundary conditions are obtained as

Now, integrating (2.59a) and (2.60a) over the dimensionless cross-sectional area provides

In order to obtain the unsteady solution transport in the microchannel, the unknown parameters ![]() $K_{0,i}(t)$,

$K_{0,i}(t)$, ![]() $K_{1,i}(t)$,

$K_{1,i}(t)$, ![]() $K_{2,i}(t)$ and

$K_{2,i}(t)$ and ![]() $f_{0,i}(t,x,y)$,

$f_{0,i}(t,x,y)$, ![]() $f_{1,i}(t,x,y)$ and

$f_{1,i}(t,x,y)$ and ![]() $f_{2,i}(t,x,y)$ must be evaluated via solving the coupled systems of (2.57) and (2.58) subject to the associated boundary conditions given in (2.59) and (2.60). An appropriate method is to utilize the eigenfunction expansion, a method that is adopted here.

$f_{2,i}(t,x,y)$ must be evaluated via solving the coupled systems of (2.57) and (2.58) subject to the associated boundary conditions given in (2.59) and (2.60). An appropriate method is to utilize the eigenfunction expansion, a method that is adopted here.

2.4.1 Exchange coefficient

The equation governing the parameter ![]() $f_{0}$ can be written by substituting

$f_{0}$ can be written by substituting ![]() $n=0$ into (2.57) and (2.58) as follows:

$n=0$ into (2.57) and (2.58) as follows:

with the associated initial and boundary conditions, given in (2.59) and (2.60), for ![]() $n=0$. The solution of

$n=0$. The solution of ![]() $f_{0}$ can be determined as

$f_{0}$ can be determined as

where

The eigenvalues ![]() $\unicode[STIX]{x1D706}_{rn}$ and

$\unicode[STIX]{x1D706}_{rn}$ and ![]() $\unicode[STIX]{x1D6FE}_{sn}$ or

$\unicode[STIX]{x1D6FE}_{sn}$ or ![]() $\unicode[STIX]{x1D706}_{n}$ must satisfy the following equations:

$\unicode[STIX]{x1D706}_{n}$ must satisfy the following equations:

Moreover, the constants ![]() $A_{n,i}$ are determined, by the substitution of the form (2.65) into (2.59a) and (2.60a) for

$A_{n,i}$ are determined, by the substitution of the form (2.65) into (2.59a) and (2.60a) for ![]() $n=0$, as

$n=0$, as

$$\begin{eqnarray}A_{n,i}=\frac{\displaystyle \int _{0}^{1}\left[\unicode[STIX]{x1D703}\unicode[STIX]{x1D6FF}_{1,i}\text{COS}(n,x,y,1)+\unicode[STIX]{x1D6FF}_{2,i}\int _{0}^{w}\unicode[STIX]{x1D703}\text{COS}(n,x,y,2)\,\text{d}x\right]\,\text{d}y}{\unicode[STIX]{x1D703}_{m,i}\text{INTCOS}(n,i)},\end{eqnarray}$$

$$\begin{eqnarray}A_{n,i}=\frac{\displaystyle \int _{0}^{1}\left[\unicode[STIX]{x1D703}\unicode[STIX]{x1D6FF}_{1,i}\text{COS}(n,x,y,1)+\unicode[STIX]{x1D6FF}_{2,i}\int _{0}^{w}\unicode[STIX]{x1D703}\text{COS}(n,x,y,2)\,\text{d}x\right]\,\text{d}y}{\unicode[STIX]{x1D703}_{m,i}\text{INTCOS}(n,i)},\end{eqnarray}$$where

$$\begin{eqnarray}\displaystyle \text{Intcos}\_2(n) & = & \displaystyle \int _{0}^{w}\int _{0}^{1}\cos ^{2}(\unicode[STIX]{x1D6FE}_{sn}x)\cos ^{2}(\unicode[STIX]{x1D706}_{rn}y)\,\text{d}y\,\text{d}x\nonumber\\ \displaystyle & = & \displaystyle \left[\frac{1}{2}+\frac{1}{4\unicode[STIX]{x1D706}_{rn}}\sin (2\unicode[STIX]{x1D706}_{rn})\right]\left[\frac{w}{2}+\frac{1}{4\unicode[STIX]{x1D6FE}_{sn}}\sin (2w\unicode[STIX]{x1D6FE}_{sn})\right].\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \text{Intcos}\_2(n) & = & \displaystyle \int _{0}^{w}\int _{0}^{1}\cos ^{2}(\unicode[STIX]{x1D6FE}_{sn}x)\cos ^{2}(\unicode[STIX]{x1D706}_{rn}y)\,\text{d}y\,\text{d}x\nonumber\\ \displaystyle & = & \displaystyle \left[\frac{1}{2}+\frac{1}{4\unicode[STIX]{x1D706}_{rn}}\sin (2\unicode[STIX]{x1D706}_{rn})\right]\left[\frac{w}{2}+\frac{1}{4\unicode[STIX]{x1D6FE}_{sn}}\sin (2w\unicode[STIX]{x1D6FE}_{sn})\right].\end{eqnarray}$$Using the integral condition in (2.61) and (2.62), one obtains

$$\begin{eqnarray}\exp \left[-\int _{0}^{t}K_{0,i}(s)\,\text{d}s\right]=\frac{\unicode[STIX]{x1D6FF}_{1,i}+\unicode[STIX]{x1D6FF}_{2,i}w}{\displaystyle \mathop{\sum }_{n=1}^{\infty }A_{n,i}\text{EXP}(n,t,i)\text{INTEIGEN}(n,i)},\end{eqnarray}$$

$$\begin{eqnarray}\exp \left[-\int _{0}^{t}K_{0,i}(s)\,\text{d}s\right]=\frac{\unicode[STIX]{x1D6FF}_{1,i}+\unicode[STIX]{x1D6FF}_{2,i}w}{\displaystyle \mathop{\sum }_{n=1}^{\infty }A_{n,i}\text{EXP}(n,t,i)\text{INTEIGEN}(n,i)},\end{eqnarray}$$where

So the function ![]() $f_{0,i}$ is obtained as

$f_{0,i}$ is obtained as

$$\begin{eqnarray}f_{0,i}(x,y,t)=\frac{\displaystyle (\unicode[STIX]{x1D6FF}_{1,i}+\unicode[STIX]{x1D6FF}_{2,i}w)\mathop{\sum }_{n=0}^{\infty }A_{n,i}\text{EXP}(n,t,i)\text{COS}(n,x,y,i)}{\displaystyle \mathop{\sum }_{n=1}^{\infty }A_{n,i}\text{EXP}(n,t,i)\text{INTEIGEN}(n,i)}.\end{eqnarray}$$

$$\begin{eqnarray}f_{0,i}(x,y,t)=\frac{\displaystyle (\unicode[STIX]{x1D6FF}_{1,i}+\unicode[STIX]{x1D6FF}_{2,i}w)\mathop{\sum }_{n=0}^{\infty }A_{n,i}\text{EXP}(n,t,i)\text{COS}(n,x,y,i)}{\displaystyle \mathop{\sum }_{n=1}^{\infty }A_{n,i}\text{EXP}(n,t,i)\text{INTEIGEN}(n,i)}.\end{eqnarray}$$ The exchange coefficient can now be determined from (2.54) and (2.55) for ![]() $n=0$ as

$n=0$ as

$$\begin{eqnarray}K_{0,i}(t)=-\frac{\displaystyle Da\mathop{\sum }_{n=0}^{\infty }A_{n,i}\text{EXP}(n,t,i)\mathbb{F}(n,i)}{\displaystyle \mathop{\sum }_{n=0}^{\infty }A_{n,i}\text{EXP}(n,t,i)\text{INTEIGEN}(n,i)},\end{eqnarray}$$

$$\begin{eqnarray}K_{0,i}(t)=-\frac{\displaystyle Da\mathop{\sum }_{n=0}^{\infty }A_{n,i}\text{EXP}(n,t,i)\mathbb{F}(n,i)}{\displaystyle \mathop{\sum }_{n=0}^{\infty }A_{n,i}\text{EXP}(n,t,i)\text{INTEIGEN}(n,i)},\end{eqnarray}$$where

2.4.2 Convection coefficient

The equation governing the function ![]() $f_{1}$ can be derived from (2.57) and (2.58) by setting

$f_{1}$ can be derived from (2.57) and (2.58) by setting ![]() $n=1$ as

$n=1$ as

The associated initial and boundary conditions are obtained by setting ![]() $n=1$ in (2.59) and (2.60). The solution for

$n=1$ in (2.59) and (2.60). The solution for ![]() $f_{1}$ satisfying the initial and boundary conditions can be determined as below

$f_{1}$ satisfying the initial and boundary conditions can be determined as below

$$\begin{eqnarray}\displaystyle f_{1,i} & = & \displaystyle -\exp \left[-\int _{0}^{t}K_{0,i}(s)\,\text{d}s\right]\mathop{\sum }_{p=0}^{\infty }\left\{\mathop{\sum }_{n=0}^{\infty }\left[\frac{A_{n,i}\text{INTU}2(n,p)}{\text{INTCOS}(p,i)}\text{INTEXP}(n,p,t)\right]\right.\nonumber\\ \displaystyle & & \displaystyle +\left.A_{p,i}\text{EXP}(p,t,i)\int _{0}^{t}K_{1,i}(s)\,\text{d}s\right\}\text{COS}(p,x,y,i),\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle f_{1,i} & = & \displaystyle -\exp \left[-\int _{0}^{t}K_{0,i}(s)\,\text{d}s\right]\mathop{\sum }_{p=0}^{\infty }\left\{\mathop{\sum }_{n=0}^{\infty }\left[\frac{A_{n,i}\text{INTU}2(n,p)}{\text{INTCOS}(p,i)}\text{INTEXP}(n,p,t)\right]\right.\nonumber\\ \displaystyle & & \displaystyle +\left.A_{p,i}\text{EXP}(p,t,i)\int _{0}^{t}K_{1,i}(s)\,\text{d}s\right\}\text{COS}(p,x,y,i),\end{eqnarray}$$where

$$\begin{eqnarray}\displaystyle \text{IntU}2\_2(n,p) & = & \displaystyle \int _{0}^{w}\int _{0}^{1}u_{2}\cos (\unicode[STIX]{x1D6FE}_{sn}x)\cos (\unicode[STIX]{x1D6FE}_{sp}x)\cos (\unicode[STIX]{x1D706}_{rn}y)\cos (\unicode[STIX]{x1D706}_{rp}y)\,\text{d}y\,\text{d}x\nonumber\\ \displaystyle & = & \displaystyle \mathop{\sum }_{j=1}^{N}d_{j}\frac{(-1)^{r_{j}+q_{j}}}{16}\left[\frac{\cos (\unicode[STIX]{x1D706}_{rn}+\unicode[STIX]{x1D706}_{rp})}{\unicode[STIX]{x1D709}_{r_{j}}-\unicode[STIX]{x1D706}_{rn}-\unicode[STIX]{x1D706}_{rp}}+\frac{\cos (\unicode[STIX]{x1D706}_{rn}-\unicode[STIX]{x1D706}_{rp})}{\unicode[STIX]{x1D709}_{r_{j}}-\unicode[STIX]{x1D706}_{rn}+\unicode[STIX]{x1D706}_{rp}}+\frac{\cos (\unicode[STIX]{x1D706}_{rn}-\unicode[STIX]{x1D706}_{rp})}{\unicode[STIX]{x1D709}_{r_{j}}+\unicode[STIX]{x1D706}_{rn}-\unicode[STIX]{x1D706}_{rp}}\right.\nonumber\\ \displaystyle & & \displaystyle +\left.\frac{\cos (\unicode[STIX]{x1D706}_{rn}+\unicode[STIX]{x1D706}_{rp})}{\unicode[STIX]{x1D709}_{r_{j}}+\unicode[STIX]{x1D706}_{rn}+\unicode[STIX]{x1D706}_{rp}}\right]\left\{\frac{\cos [w(\unicode[STIX]{x1D6FE}_{sn}+\unicode[STIX]{x1D6FE}_{sp})]}{\unicode[STIX]{x1D709}_{q_{j}}-\unicode[STIX]{x1D6FE}_{sn}-\unicode[STIX]{x1D6FE}_{sp}}+\frac{\cos [w(\unicode[STIX]{x1D6FE}_{sn}-\unicode[STIX]{x1D6FE}_{sp})]}{\unicode[STIX]{x1D709}_{q_{j}}-\unicode[STIX]{x1D6FE}_{sn}+\unicode[STIX]{x1D6FE}_{sp}}\right.\nonumber\\ \displaystyle & & \displaystyle +\left.\frac{\cos [w(\unicode[STIX]{x1D6FE}_{sn}-\unicode[STIX]{x1D6FE}_{sp})]}{\unicode[STIX]{x1D709}_{q_{j}}+\unicode[STIX]{x1D6FE}_{sn}-\unicode[STIX]{x1D6FE}_{sp}}+\frac{\cos [w(\unicode[STIX]{x1D6FE}_{sn}+\unicode[STIX]{x1D6FE}_{sp})]}{\unicode[STIX]{x1D709}_{q_{j}}+\unicode[STIX]{x1D6FE}_{sn}+\unicode[STIX]{x1D6FE}_{sp}}\right\},\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \text{IntU}2\_2(n,p) & = & \displaystyle \int _{0}^{w}\int _{0}^{1}u_{2}\cos (\unicode[STIX]{x1D6FE}_{sn}x)\cos (\unicode[STIX]{x1D6FE}_{sp}x)\cos (\unicode[STIX]{x1D706}_{rn}y)\cos (\unicode[STIX]{x1D706}_{rp}y)\,\text{d}y\,\text{d}x\nonumber\\ \displaystyle & = & \displaystyle \mathop{\sum }_{j=1}^{N}d_{j}\frac{(-1)^{r_{j}+q_{j}}}{16}\left[\frac{\cos (\unicode[STIX]{x1D706}_{rn}+\unicode[STIX]{x1D706}_{rp})}{\unicode[STIX]{x1D709}_{r_{j}}-\unicode[STIX]{x1D706}_{rn}-\unicode[STIX]{x1D706}_{rp}}+\frac{\cos (\unicode[STIX]{x1D706}_{rn}-\unicode[STIX]{x1D706}_{rp})}{\unicode[STIX]{x1D709}_{r_{j}}-\unicode[STIX]{x1D706}_{rn}+\unicode[STIX]{x1D706}_{rp}}+\frac{\cos (\unicode[STIX]{x1D706}_{rn}-\unicode[STIX]{x1D706}_{rp})}{\unicode[STIX]{x1D709}_{r_{j}}+\unicode[STIX]{x1D706}_{rn}-\unicode[STIX]{x1D706}_{rp}}\right.\nonumber\\ \displaystyle & & \displaystyle +\left.\frac{\cos (\unicode[STIX]{x1D706}_{rn}+\unicode[STIX]{x1D706}_{rp})}{\unicode[STIX]{x1D709}_{r_{j}}+\unicode[STIX]{x1D706}_{rn}+\unicode[STIX]{x1D706}_{rp}}\right]\left\{\frac{\cos [w(\unicode[STIX]{x1D6FE}_{sn}+\unicode[STIX]{x1D6FE}_{sp})]}{\unicode[STIX]{x1D709}_{q_{j}}-\unicode[STIX]{x1D6FE}_{sn}-\unicode[STIX]{x1D6FE}_{sp}}+\frac{\cos [w(\unicode[STIX]{x1D6FE}_{sn}-\unicode[STIX]{x1D6FE}_{sp})]}{\unicode[STIX]{x1D709}_{q_{j}}-\unicode[STIX]{x1D6FE}_{sn}+\unicode[STIX]{x1D6FE}_{sp}}\right.\nonumber\\ \displaystyle & & \displaystyle +\left.\frac{\cos [w(\unicode[STIX]{x1D6FE}_{sn}-\unicode[STIX]{x1D6FE}_{sp})]}{\unicode[STIX]{x1D709}_{q_{j}}+\unicode[STIX]{x1D6FE}_{sn}-\unicode[STIX]{x1D6FE}_{sp}}+\frac{\cos [w(\unicode[STIX]{x1D6FE}_{sn}+\unicode[STIX]{x1D6FE}_{sp})]}{\unicode[STIX]{x1D709}_{q_{j}}+\unicode[STIX]{x1D6FE}_{sn}+\unicode[STIX]{x1D6FE}_{sp}}\right\},\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle \text{Intexp}\_2(n,p,t) & = & \displaystyle (1-\unicode[STIX]{x1D6FF}_{n,p})\frac{\exp [-(\unicode[STIX]{x1D706}_{rn}^{2}+\unicode[STIX]{x1D6FE}_{sn}^{2})t]-\exp [-(\unicode[STIX]{x1D706}_{rp}^{2}+\unicode[STIX]{x1D6FE}_{sp}^{2})t]}{\unicode[STIX]{x1D706}_{rp}^{2}-\unicode[STIX]{x1D706}_{rn}^{2}+\unicode[STIX]{x1D6FE}_{sp}^{2}-\unicode[STIX]{x1D6FE}_{sn}^{2}}\nonumber\\ \displaystyle & & \displaystyle +\,\unicode[STIX]{x1D6FF}_{n,p}t\exp [-(\unicode[STIX]{x1D706}_{rn}^{2}+\unicode[STIX]{x1D6FE}_{sn}^{2})t].\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \text{Intexp}\_2(n,p,t) & = & \displaystyle (1-\unicode[STIX]{x1D6FF}_{n,p})\frac{\exp [-(\unicode[STIX]{x1D706}_{rn}^{2}+\unicode[STIX]{x1D6FE}_{sn}^{2})t]-\exp [-(\unicode[STIX]{x1D706}_{rp}^{2}+\unicode[STIX]{x1D6FE}_{sp}^{2})t]}{\unicode[STIX]{x1D706}_{rp}^{2}-\unicode[STIX]{x1D706}_{rn}^{2}+\unicode[STIX]{x1D6FE}_{sp}^{2}-\unicode[STIX]{x1D6FE}_{sn}^{2}}\nonumber\\ \displaystyle & & \displaystyle +\,\unicode[STIX]{x1D6FF}_{n,p}t\exp [-(\unicode[STIX]{x1D706}_{rn}^{2}+\unicode[STIX]{x1D6FE}_{sn}^{2})t].\end{eqnarray}$$ The term ![]() $\int _{0}^{t}K_{1}(s)\,\text{d}s$ can be found, by applying the integral conditions in (2.61) and (2.62), as

$\int _{0}^{t}K_{1}(s)\,\text{d}s$ can be found, by applying the integral conditions in (2.61) and (2.62), as

$$\begin{eqnarray}\int _{0}^{t}K_{1,i}(s)\,\text{d}s=-\frac{\displaystyle \mathop{\sum }_{p=0}^{\infty }\left[\mathop{\sum }_{n=0}^{\infty }\frac{A_{n,i}\text{INTU}2(n,p)}{\text{INTCOS}(p)}\text{INTEXP}(n,p,t)\right]\text{INTEIGEN}(p,i)}{\displaystyle \mathop{\sum }_{p=0}^{\infty }A_{p,i}\text{EXP}(p,t,i)\text{INTEIGEN}(p,i)}.\end{eqnarray}$$

$$\begin{eqnarray}\int _{0}^{t}K_{1,i}(s)\,\text{d}s=-\frac{\displaystyle \mathop{\sum }_{p=0}^{\infty }\left[\mathop{\sum }_{n=0}^{\infty }\frac{A_{n,i}\text{INTU}2(n,p)}{\text{INTCOS}(p)}\text{INTEXP}(n,p,t)\right]\text{INTEIGEN}(p,i)}{\displaystyle \mathop{\sum }_{p=0}^{\infty }A_{p,i}\text{EXP}(p,t,i)\text{INTEIGEN}(p,i)}.\end{eqnarray}$$It is now time to derive the expression of the convection coefficient that is obtained from (2.54) and (2.55) as

$$\begin{eqnarray}\displaystyle & & \displaystyle K_{1,i}(t)\nonumber\\ \displaystyle & & \displaystyle \quad =\frac{Da}{\unicode[STIX]{x1D6FF}_{2,i}w+\unicode[STIX]{x1D6FF}_{1,i}}\exp \left[-\int _{0}^{t}K_{0i}(s)\,\text{d}s\right]\mathop{\sum }_{p=0}^{\infty }\left\{\mathop{\sum }_{n=0}^{\infty }\left[\frac{A_{ni}\text{INTU}2(n,p)}{\text{INTCOS}(p)}\text{INTEXP}(n,p,t)\right]\right.\nonumber\\ \displaystyle & & \displaystyle \quad +\left.A_{p,i}\text{EXP}(p,t,i)\int _{0}^{t}K_{1,i}(s)\,\text{d}s\right\}\mathbb{F}(p,i)\nonumber\\ \displaystyle & & \displaystyle \quad -\,\frac{\displaystyle \exp \left[-\int _{0}^{t}K_{0,i}(s)\,\text{d}s\right]}{\unicode[STIX]{x1D6FF}_{2,i}w+\unicode[STIX]{x1D6FF}_{1,i}}\mathop{\sum }_{n=0}^{\infty }A_{n,i}\text{EXP}(n,t,i)\text{INTU}1(n,i),\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle K_{1,i}(t)\nonumber\\ \displaystyle & & \displaystyle \quad =\frac{Da}{\unicode[STIX]{x1D6FF}_{2,i}w+\unicode[STIX]{x1D6FF}_{1,i}}\exp \left[-\int _{0}^{t}K_{0i}(s)\,\text{d}s\right]\mathop{\sum }_{p=0}^{\infty }\left\{\mathop{\sum }_{n=0}^{\infty }\left[\frac{A_{ni}\text{INTU}2(n,p)}{\text{INTCOS}(p)}\text{INTEXP}(n,p,t)\right]\right.\nonumber\\ \displaystyle & & \displaystyle \quad +\left.A_{p,i}\text{EXP}(p,t,i)\int _{0}^{t}K_{1,i}(s)\,\text{d}s\right\}\mathbb{F}(p,i)\nonumber\\ \displaystyle & & \displaystyle \quad -\,\frac{\displaystyle \exp \left[-\int _{0}^{t}K_{0,i}(s)\,\text{d}s\right]}{\unicode[STIX]{x1D6FF}_{2,i}w+\unicode[STIX]{x1D6FF}_{1,i}}\mathop{\sum }_{n=0}^{\infty }A_{n,i}\text{EXP}(n,t,i)\text{INTU}1(n,i),\end{eqnarray}$$where

$$\begin{eqnarray}\displaystyle \text{IntU}1\_2(n) & = & \displaystyle \int _{0}^{w}\int _{0}^{1}u_{2}\cos (\unicode[STIX]{x1D6FE}_{sn}x)\cos (\unicode[STIX]{x1D706}_{rn}y)\,\text{d}y\,\text{d}x\nonumber\\ \displaystyle & = & \displaystyle \mathop{\sum }_{j=1}^{N}d_{j}\frac{(-1)^{r_{j}+q_{j}}\unicode[STIX]{x1D709}_{r_{j}}\unicode[STIX]{x1D709}_{q_{j}}\cos \unicode[STIX]{x1D706}_{rn}\cos (\unicode[STIX]{x1D6FE}_{sn}w)}{(\unicode[STIX]{x1D709}_{r_{j}}^{2}-\unicode[STIX]{x1D706}_{rn}^{2})(\unicode[STIX]{x1D709}_{q_{j}}^{2}-\unicode[STIX]{x1D6FE}_{sn}^{2}w^{2})},\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \text{IntU}1\_2(n) & = & \displaystyle \int _{0}^{w}\int _{0}^{1}u_{2}\cos (\unicode[STIX]{x1D6FE}_{sn}x)\cos (\unicode[STIX]{x1D706}_{rn}y)\,\text{d}y\,\text{d}x\nonumber\\ \displaystyle & = & \displaystyle \mathop{\sum }_{j=1}^{N}d_{j}\frac{(-1)^{r_{j}+q_{j}}\unicode[STIX]{x1D709}_{r_{j}}\unicode[STIX]{x1D709}_{q_{j}}\cos \unicode[STIX]{x1D706}_{rn}\cos (\unicode[STIX]{x1D6FE}_{sn}w)}{(\unicode[STIX]{x1D709}_{r_{j}}^{2}-\unicode[STIX]{x1D706}_{rn}^{2})(\unicode[STIX]{x1D709}_{q_{j}}^{2}-\unicode[STIX]{x1D6FE}_{sn}^{2}w^{2})},\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & & \displaystyle \text{IntU}1\_1(n)=\int _{0}^{1}u_{1}\cos (\unicode[STIX]{x1D706}_{n}y)\,\text{d}y=\int _{1-l}^{1}u_{PEL}\cos (\unicode[STIX]{x1D706}_{n}y)\,\text{d}y+\int _{0}^{1-l}u_{E}\cos (\unicode[STIX]{x1D706}_{n}y)\,\text{d}y\nonumber\\ \displaystyle & & \displaystyle \quad =\frac{B_{2}}{\unicode[STIX]{x1D6FC}^{2}+\unicode[STIX]{x1D706}_{n}^{2}}\{\!\unicode[STIX]{x1D706}_{n}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\cosh [\unicode[STIX]{x1D6FC}(l-1)]+\unicode[STIX]{x1D6FC}\cos [\unicode[STIX]{x1D706}_{n}(l-1)]\sinh [\unicode[STIX]{x1D6FC}(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\unicode[STIX]{x1D706}_{n}\sin \unicode[STIX]{x1D706}_{n}\cosh \unicode[STIX]{x1D6FC}+\unicode[STIX]{x1D6FC}\cos \unicode[STIX]{x1D706}_{n}\sinh \unicode[STIX]{x1D6FC}\!\}\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\frac{\displaystyle \left(B_{2}\coth \unicode[STIX]{x1D6FC}-\frac{1}{\sinh \unicode[STIX]{x1D6FC}}\left[(\cosh K)^{-1}\left(\frac{K^{2}B_{1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)-\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}\right]\right)}{\unicode[STIX]{x1D6FC}^{2}+\unicode[STIX]{x1D706}_{n}^{2}}\nonumber\\ \displaystyle & & \displaystyle \qquad \times \,\{\!\unicode[STIX]{x1D6FC}\cos [\unicode[STIX]{x1D706}_{n}(l-1)]\cosh [\unicode[STIX]{x1D6FC}(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\unicode[STIX]{x1D706}_{n}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\sinh [\unicode[STIX]{x1D6FC}(l-1)]-\unicode[STIX]{x1D6FC}\cos \unicode[STIX]{x1D706}_{n}\cosh \unicode[STIX]{x1D6FC}-\unicode[STIX]{x1D706}_{n}\sin \unicode[STIX]{x1D706}_{n}\sinh \unicode[STIX]{x1D6FC}\!\}\nonumber\\ \displaystyle & & \displaystyle \qquad -\,\frac{K^{2}B_{1}}{(K^{2}-\unicode[STIX]{x1D6FC}^{2})(K^{2}+\unicode[STIX]{x1D706}_{n}^{2})}\{\!\unicode[STIX]{x1D706}_{n}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\cosh [K(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad +\,K\cos [\unicode[STIX]{x1D706}_{n}(l-1)]\sinh [K(l-1)]+\unicode[STIX]{x1D706}_{n}\sin \unicode[STIX]{x1D706}_{n}\cosh K+K\cos \unicode[STIX]{x1D706}_{n}\sinh K\!\}\nonumber\\ \displaystyle & & \displaystyle \qquad -\,\left(\frac{\tanh K}{\unicode[STIX]{x1D6FC}^{2}+\unicode[STIX]{x1D706}_{n}^{2}}\right)\left(\frac{K^{2}B_{1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\{\!K\cos [\unicode[STIX]{x1D706}_{n}(l-1)]\cosh [K(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\unicode[STIX]{x1D706}_{n}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\sinh [K(l-1)]-K\cos \unicode[STIX]{x1D706}_{n}\cosh K-\unicode[STIX]{x1D706}_{n}\sin \unicode[STIX]{x1D706}_{n}\sinh K\!\}\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\frac{K^{2}}{\unicode[STIX]{x1D706}_{n}\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}\{\sin [\unicode[STIX]{x1D706}_{n}(l-1)]+\sin \unicode[STIX]{x1D706}_{n}\}\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\frac{1}{\unicode[STIX]{x1D706}_{n}(K^{2}+\unicode[STIX]{x1D706}_{n}^{2})}\{\!\unicode[STIX]{x1D706}_{n}^{2}A_{1}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\cosh [K(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad +\,A_{1}K\unicode[STIX]{x1D706}_{n}\cos [\unicode[STIX]{x1D706}_{n}(l-1)]\sinh [K(l-1)]-A_{2}K^{2}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad -\,\unicode[STIX]{x1D706}_{n}^{2}A_{2}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\!\}.\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle \text{IntU}1\_1(n)=\int _{0}^{1}u_{1}\cos (\unicode[STIX]{x1D706}_{n}y)\,\text{d}y=\int _{1-l}^{1}u_{PEL}\cos (\unicode[STIX]{x1D706}_{n}y)\,\text{d}y+\int _{0}^{1-l}u_{E}\cos (\unicode[STIX]{x1D706}_{n}y)\,\text{d}y\nonumber\\ \displaystyle & & \displaystyle \quad =\frac{B_{2}}{\unicode[STIX]{x1D6FC}^{2}+\unicode[STIX]{x1D706}_{n}^{2}}\{\!\unicode[STIX]{x1D706}_{n}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\cosh [\unicode[STIX]{x1D6FC}(l-1)]+\unicode[STIX]{x1D6FC}\cos [\unicode[STIX]{x1D706}_{n}(l-1)]\sinh [\unicode[STIX]{x1D6FC}(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\unicode[STIX]{x1D706}_{n}\sin \unicode[STIX]{x1D706}_{n}\cosh \unicode[STIX]{x1D6FC}+\unicode[STIX]{x1D6FC}\cos \unicode[STIX]{x1D706}_{n}\sinh \unicode[STIX]{x1D6FC}\!\}\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\frac{\displaystyle \left(B_{2}\coth \unicode[STIX]{x1D6FC}-\frac{1}{\sinh \unicode[STIX]{x1D6FC}}\left[(\cosh K)^{-1}\left(\frac{K^{2}B_{1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)-\frac{K^{2}}{\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}\right]\right)}{\unicode[STIX]{x1D6FC}^{2}+\unicode[STIX]{x1D706}_{n}^{2}}\nonumber\\ \displaystyle & & \displaystyle \qquad \times \,\{\!\unicode[STIX]{x1D6FC}\cos [\unicode[STIX]{x1D706}_{n}(l-1)]\cosh [\unicode[STIX]{x1D6FC}(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\unicode[STIX]{x1D706}_{n}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\sinh [\unicode[STIX]{x1D6FC}(l-1)]-\unicode[STIX]{x1D6FC}\cos \unicode[STIX]{x1D706}_{n}\cosh \unicode[STIX]{x1D6FC}-\unicode[STIX]{x1D706}_{n}\sin \unicode[STIX]{x1D706}_{n}\sinh \unicode[STIX]{x1D6FC}\!\}\nonumber\\ \displaystyle & & \displaystyle \qquad -\,\frac{K^{2}B_{1}}{(K^{2}-\unicode[STIX]{x1D6FC}^{2})(K^{2}+\unicode[STIX]{x1D706}_{n}^{2})}\{\!\unicode[STIX]{x1D706}_{n}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\cosh [K(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad +\,K\cos [\unicode[STIX]{x1D706}_{n}(l-1)]\sinh [K(l-1)]+\unicode[STIX]{x1D706}_{n}\sin \unicode[STIX]{x1D706}_{n}\cosh K+K\cos \unicode[STIX]{x1D706}_{n}\sinh K\!\}\nonumber\\ \displaystyle & & \displaystyle \qquad -\,\left(\frac{\tanh K}{\unicode[STIX]{x1D6FC}^{2}+\unicode[STIX]{x1D706}_{n}^{2}}\right)\left(\frac{K^{2}B_{1}}{K^{2}-\unicode[STIX]{x1D6FC}^{2}}\right)\{\!K\cos [\unicode[STIX]{x1D706}_{n}(l-1)]\cosh [K(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\unicode[STIX]{x1D706}_{n}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\sinh [K(l-1)]-K\cos \unicode[STIX]{x1D706}_{n}\cosh K-\unicode[STIX]{x1D706}_{n}\sin \unicode[STIX]{x1D706}_{n}\sinh K\!\}\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\frac{K^{2}}{\unicode[STIX]{x1D706}_{n}\unicode[STIX]{x1D6FC}^{2}\unicode[STIX]{x1D702}_{\unicode[STIX]{x1D706}}^{2}}\{\sin [\unicode[STIX]{x1D706}_{n}(l-1)]+\sin \unicode[STIX]{x1D706}_{n}\}\nonumber\\ \displaystyle & & \displaystyle \qquad +\,\frac{1}{\unicode[STIX]{x1D706}_{n}(K^{2}+\unicode[STIX]{x1D706}_{n}^{2})}\{\!\unicode[STIX]{x1D706}_{n}^{2}A_{1}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\cosh [K(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad +\,A_{1}K\unicode[STIX]{x1D706}_{n}\cos [\unicode[STIX]{x1D706}_{n}(l-1)]\sinh [K(l-1)]-A_{2}K^{2}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\nonumber\\ \displaystyle & & \displaystyle \qquad -\,\unicode[STIX]{x1D706}_{n}^{2}A_{2}\sin [\unicode[STIX]{x1D706}_{n}(l-1)]\!\}.\end{eqnarray}$$2.4.3 Dispersion coefficient

Setting ![]() $n=2$ in (2.57) and (2.58), the equations governing

$n=2$ in (2.57) and (2.58), the equations governing ![]() $f_{2}$ are derived as below

$f_{2}$ are derived as below

which are to be solved subject to initial and boundary conditions given by (2.59) and (2.60) for ![]() $n=2$. Using the method of eigenfunction expansion, the solution for

$n=2$. Using the method of eigenfunction expansion, the solution for ![]() $f_{2}$ satisfying the initial and boundary conditions can be obtained as

$f_{2}$ satisfying the initial and boundary conditions can be obtained as