1 Introduction

The addition of a small amount of polymers of high molecular weight can lead to a pressure drop decrease in turbulent flows. Since the first observations reported by Forrest & Grierson (Reference Forrest and Grierson1931), Toms (Reference Toms1948) and Mysels (Reference Mysels1949), numerous experimental studies have been conducted in attempts to make practical use of polymer-induced drag reduction (DR), including long-distance transport of liquids (Sellin et al. Reference Sellin, Hoyt, Poliert and Scrivener1982), oil well operations (Burger & Chorn Reference Burger and Chorn1980), fire fighting (Fabula Reference Fabula1971), transport of suspensions and slurries (Golda Reference Golda1986) and biomedical applications (Greene, Mostardi & Nokes Reference Greene, Mostardi and Nokes1980). In a remarkable and pioneering paper, Virk, Mickley & Smith (Reference Virk, Mickley and Smith1967) performed a careful analysis with an experimental turbulent pipe flow apparatus and showed that if the friction drag for pipe flows is plotted in Prandtl–Kármán coordinates, it departs from the Prandtl–Kármán law (the onset of DR) to its bound, the so-called maximum drag reduction (MDR) or Virk’s asymptote, as a result of an increase in either the Reynolds number, the polymer concentration or the polymer’s molecular weight. Over the years, researchers have successfully analysed relevant aspects of this phenomenon and a significant literature is available, e.g. Hershey & Zakin (Reference Hershey and Zakin1967), Paterson & Abernathy (Reference Paterson and Abernathy1970), Virk, Mickley & Smith (Reference Virk, Mickley and Smith1970), Virk (Reference Virk1975), Bewersdorff (Reference Bewersdorff1982), Bewersdorff & Singh (Reference Bewersdorff and Singh1988), Moussa & Tiu (Reference Moussa and Tiu1994), Gyr & Tsinober (Reference Gyr and Tsinober1995), Kalashnikov (Reference Kalashnikov1998). However, up to now, there has been no definitive consensus concerning the interactions between the turbulent energy and the deformations of the polymer.

Phenomenological explanations for polymer drag reduction gravitate around two major theories. According to the viscous theory, independently proposed by Lumley (Reference Lumley1969) and Seyer & Metzner (Reference Seyer and Metzner1969) and supported by Ryskin (Reference Ryskin1987), polymer stretching in a turbulent flow produces an increase in the effective viscosity in a region outside of the viscous sublayer and in the buffer layer, which suppresses turbulent fluctuations, increasing the thickness of the buffer layer and reducing the wall friction. The elastic theory postulated by Tabor & de Gennes (Reference Tabor and de Gennes1986) assumes that the elastic energy stored by the polymer becomes comparable to the kinetic energy in the buffer layer. Since the corresponding viscoelastic length scale is larger than the Kolmogorov scale, the usual energy cascade is inhibited, which thickens the buffer layer and reduces the drag (see also Joseph Reference Joseph1990).

Numerically, polymer-induced drag reduction theories have been intensively investigated for over a decade since the first simulations conducted by den Toonder, Nieuwstadt & Kuiken (Reference den Toonder, Nieuwstadt and Kuiken1995) and Orlandi (Reference Orlandi1996). Using an inelastic generalized Newtonian fluid to analyse pipe (den Toonder et al. Reference den Toonder, Nieuwstadt and Kuiken1995) and channel (Orlandi Reference Orlandi1996) flows, both researchers argued that DR seems to be closely related to the anisotropy of the elongational viscosity, a parameter that measures the resistance of the fluid against stretching deformations. Such an argument was also presented by Sureshkumar, Beris & Handler (Reference Sureshkumar, Beris and Handler1997), who performed the first self-consistent direct numerical simulation (DNS) of turbulent channel flow of a viscoelastic finitely extensible nonlinear elastic in the Peterlin approximation (FENE-P) fluid (Peterlin Reference Peterlin1961), at a zero shear friction Reynolds number of 125. Their results suggest a partial suppression of turbulence within the buffer layer after the onset of drag reduction, which is linked with an enhanced effective viscosity attributed to the extension of polymers dispersed in the flow.

The explanations proposed in the three papers referred to above (den Toonder et al. Reference den Toonder, Nieuwstadt and Kuiken1995; Orlandi Reference Orlandi1996; Sureshkumar et al. Reference Sureshkumar, Beris and Handler1997) seem to corroborate Lumley’s theory. In an attempt to quantify this viscous scenario, L’vov et al. (Reference L’vov, Pomyalov, Procaccia and Tiberkevich2004) used conservation principles to show that an additional effective viscosity growing linearly with the distance from the wall in the buffer layer has similar effects to those observed by the addition of flexible polymers in turbulent flows. This theoretical prediction was later confirmed by De Angelis et al. (Reference De Angelis, Casciola, L’vov, Pomyalov, Procaccia and Tiberkevich2004), who performed a DNS of Newtonian turbulent flows with an added viscosity profile obtaining results previously observed in viscoelastic FENE-P simulations. Additionally, using this simple linear viscosity model, De Angelis et al. (Reference De Angelis, Casciola, L’vov, Pomyalov, Procaccia and Tiberkevich2004) were able to predict the maximum drag reduction asymptote, a point discussed in detail by Benzi et al. (Reference Benzi, Angelis, L’vov and Procaccia2005).

It is important to note that the elastic theory has also been actively explored. Min et al. (Reference Min, Yoo, Choi and Joseph2003) conducted a DNS of turbulent drag reducing channel flows in which the dilute polymer solution is simulated using the Oldroyd-B model. Their results showed good agreement with previous theoretical and experimental predictions of the onset of DR at specific friction Weissenberg numbers which is interpreted based on the elastic theory. Min et al. (Reference Min, Yoo, Choi and Joseph2003) and Dallas, Vassilicos & Hewitt (Reference Dallas, Vassilicos and Hewitt2010) describe an elastic scenario in which the elastic energy stored in the near-wall region due to the uncoiling of polymer molecules is transported to and, to some extent, released in the buffer and log-law layers. This storage of energy around the near-wall vortices was confirmed by Dubief et al. (Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004), who performed a DNS of turbulent polymer solutions in a channel using the FENE-P model, although, in contrast to Min et al. (Reference Min, Yoo, Choi and Joseph2003) and Dallas et al. (Reference Dallas, Vassilicos and Hewitt2010), they proposed an autonomous regeneration cycle of polymer wall turbulence in which the coherent release of energy occurs in the very near-wall region, just above the viscous sublayer. In order to clarify the dynamics of the polymer–turbulence interaction, Thais, Gatski & Mompean (Reference Thais, Gatski and Mompean2012) used the DNS of a fully developed turbulent channel flow of Newtonian and viscoelastic FENE-P fluids at zero shear friction Reynolds numbers up to 1000 and carefully examined the budgets of turbulent kinetic energy and the elastic energy budget in drag reducing flows. The authors showed that the elastic energy production is small in the very near-wall region, growing with the distance from the wall and reaching a maximum value in the log-law region. This elastic energy production acts simultaneously as the dominant source of elastic energy and as the dominant sink of turbulent energy. This is rather in line with Tabor and De Gennes’s description. However, recently, Thais, Gatski & Mompean (Reference Thais, Gatski and Mompean2013) emphasized that at

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=1000$

, the elastic coupling between the turbulence and the polymer does not depend on the drag reduction regime (the level of viscoelasticity), which is in disagreement with the elastic theory.

$Re_{\unicode[STIX]{x1D70F}_{0}}=1000$

, the elastic coupling between the turbulence and the polymer does not depend on the drag reduction regime (the level of viscoelasticity), which is in disagreement with the elastic theory.

Despite the discrepancies between the two most prominent theories, what seems to be in accordance with both scenarios is the relevance of the polymer coil–stretch process, which further imposes a transient behaviour on the drag reduction as well as a subsequent polymer degradation, a consequence of polymer elongation (Merrill & Horn Reference Merrill and Horn1984; Pereira, Andrade & Soares Reference Pereira, Andrade and Soares2013; Soares et al. Reference Soares, Sandoval, Silveira, Pereira, Trevelin and Thomaz2015). In order to understand the polymer coil–stretch process, Bagheri et al. (Reference Bagheri, Mitra, Perlekar and Brandt2012) presented direct numerical simulations of turbulent channel flow with passive Lagrangian linear (Oldroyd-B) and nonlinear (FENE) polymers. For the FENE model, the polymers are more elongated within the near-wall region although such extension becomes less heterogeneous as the Weissenberg number increases. Furthermore, a much stronger orientational trend is seen close to the wall, where the polymers are well aligned along the streamwise direction. The authors also verified the alignment of the end-to-end vector with respect to the principal directions of the rate-of-strain tensor and the vorticity vector. Nevertheless, they did not identify possible tensors capable of stretching the polymers, which would reveal more details about the uncoiling mechanism.

It is clear that the DR phenomenon is not completely understood and many aspects of the problem remain unclear. Any attempt to completely elucidate polymer-induced drag reduction must consider, at least, four important issues: the mechanism of polymer coil–stretch; the development of turbulent structures in viscoelastic flows; the exchange of energy between the turbulence and the polymers; and the breaking of the polymer molecules.

In the present paper, we investigate the polymer coil–stretch process with the aid of direct numerical simulations of the turbulent channel flow of a viscoelastic FENE-P fluid taking into account a wide range of zero shear friction Reynolds numbers (from 180 up to 1000). Tensorial and statistical analyses are developed in an attempt to highlight the role played by three relevant kinematic tensor entities in the polymer extension mechanism: the velocity fluctuation product tensor (which can be physically interpreted as an instantaneous Reynolds stress), the rate-of-strain tensor and the rate-of-rotation tensor. As the primary focus, the relative polymer stretch and the alignment between the conformation tensor and these three important tensor entities will be confronted. Additionally, joint probability density functions will be used in order to correlate the polymer–turbulence exchanges of energy and polymer orientations. Lastly, the flow will be divided into two distinct regions, following the

![]() $Q$

-criterion of vortex identification (see Hunt, Wray & Moin Reference Hunt, Wray and Moin1988): an elliptical (or vortical) part where the second invariant of the velocity gradient tensor is positive and a hyperbolic (or extensional) part which is determined by the negative values of the second invariant of the velocity gradient tensor. The polymer work fluctuation will then be investigated within these regions, separately. The analyses that came out from these tools enable the proposition of a polymer coil–stretch mechanism based on the autonomous regeneration cycle reported by Dubief et al. (Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004), which in turn was based on that conceived for Newtonian turbulent flows, previously presented by Jiménez & Pinelli (Reference Jiménez and Pinelli1999).

$Q$

-criterion of vortex identification (see Hunt, Wray & Moin Reference Hunt, Wray and Moin1988): an elliptical (or vortical) part where the second invariant of the velocity gradient tensor is positive and a hyperbolic (or extensional) part which is determined by the negative values of the second invariant of the velocity gradient tensor. The polymer work fluctuation will then be investigated within these regions, separately. The analyses that came out from these tools enable the proposition of a polymer coil–stretch mechanism based on the autonomous regeneration cycle reported by Dubief et al. (Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004), which in turn was based on that conceived for Newtonian turbulent flows, previously presented by Jiménez & Pinelli (Reference Jiménez and Pinelli1999).

Following the description of the physical formulation and numerical methodology presented in § 2, our main results are separated into three parts: §§ 3–5. In the first part (§ 3), some classical time-averaged quantities are initially presented. In § 4, we analyse the distribution of polymer stretch across the wall distance, of which the effects on near-wall vortices and the dependence on

![]() $L$

and

$L$

and

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}$

are investigated as well, as exposed in § 4.1. Tensor analyses are conducted in § 4.2 in an attempt to verify the alignment between the conformation tensor and the other three relevant entities. In § 5, joint probability density functions are used in order to correlate the polymer–turbulence exchanges of energy and polymer alignments (§ 5.1). Additionally, the coil–stretch polymer process is linked with the coherent structures within the flow (§ 5.2). In § 6, these interactions are finally employed to describe a detailed cyclic mechanism of the polymer–turbulence interaction.

$Wi_{\unicode[STIX]{x1D70F}_{0}}$

are investigated as well, as exposed in § 4.1. Tensor analyses are conducted in § 4.2 in an attempt to verify the alignment between the conformation tensor and the other three relevant entities. In § 5, joint probability density functions are used in order to correlate the polymer–turbulence exchanges of energy and polymer alignments (§ 5.1). Additionally, the coil–stretch polymer process is linked with the coherent structures within the flow (§ 5.2). In § 6, these interactions are finally employed to describe a detailed cyclic mechanism of the polymer–turbulence interaction.

2 Physical formulation and numerical methodology

A turbulent channel flow of an incompressible dilute polymer solution is considered. Such a geometry is commonly adopted in direct numerical simulations due to its simplicity as well as its attractiveness for both experimental and theoretical studies of near-wall turbulent interactions. Here, the channel streamwise direction is

![]() $x_{1}=x$

, the spanwise direction is

$x_{1}=x$

, the spanwise direction is

![]() $x_{2}=y$

and the direction normal to the wall is

$x_{2}=y$

and the direction normal to the wall is

![]() $x_{3}=z$

.

$x_{3}=z$

.

The instantaneous velocity field in the respective directions is

![]() $(u_{x},u_{y},u_{z})=(u,v,w)$

and is solenoidal (

$(u_{x},u_{y},u_{z})=(u,v,w)$

and is solenoidal (

![]() $\unicode[STIX]{x1D735}\boldsymbol{\cdot }\boldsymbol{u}=0$

, where

$\unicode[STIX]{x1D735}\boldsymbol{\cdot }\boldsymbol{u}=0$

, where

![]() $\boldsymbol{u}$

denotes the velocity vector). The governing equations are scaled with the channel half-width,

$\boldsymbol{u}$

denotes the velocity vector). The governing equations are scaled with the channel half-width,

![]() $h$

, the bulk velocity,

$h$

, the bulk velocity,

![]() $U_{h}$

, and the fluid density,

$U_{h}$

, and the fluid density,

![]() $\unicode[STIX]{x1D70C}$

.

$\unicode[STIX]{x1D70C}$

.

The scaled momentum equations are

In (2.1),

![]() $p$

is the pressure,

$p$

is the pressure,

![]() $\unicode[STIX]{x1D6FD}_{0}$

is the ratio of the Newtonian solvent kinematic viscosity (

$\unicode[STIX]{x1D6FD}_{0}$

is the ratio of the Newtonian solvent kinematic viscosity (

![]() $\unicode[STIX]{x1D708}_{N}$

) to the total zero shear kinematic viscosity (

$\unicode[STIX]{x1D708}_{N}$

) to the total zero shear kinematic viscosity (

![]() $\unicode[STIX]{x1D708}_{0}=\unicode[STIX]{x1D708}_{N}+\unicode[STIX]{x1D708}_{p0}$

) and the bulk Reynolds number is

$\unicode[STIX]{x1D708}_{0}=\unicode[STIX]{x1D708}_{N}+\unicode[STIX]{x1D708}_{p0}$

) and the bulk Reynolds number is

![]() $Re_{h}=U_{h}h/\unicode[STIX]{x1D708}_{0}$

. The extra stress tensor components are denoted by

$Re_{h}=U_{h}h/\unicode[STIX]{x1D708}_{0}$

. The extra stress tensor components are denoted by

![]() $\unicode[STIX]{x1D6EF}_{ij}$

. The formalism of (2.1) includes the assumption of a homogeneous polymer concentration which is governed by the viscosity ratio

$\unicode[STIX]{x1D6EF}_{ij}$

. The formalism of (2.1) includes the assumption of a homogeneous polymer concentration which is governed by the viscosity ratio

![]() $\unicode[STIX]{x1D6FD}_{0}$

, where

$\unicode[STIX]{x1D6FD}_{0}$

, where

![]() $\unicode[STIX]{x1D6FD}_{0}=1$

yields the limiting behaviour of the Newtonian case.

$\unicode[STIX]{x1D6FD}_{0}=1$

yields the limiting behaviour of the Newtonian case.

The extra stress tensor components (

![]() $\unicode[STIX]{x1D6EF}_{ij}$

) in (2.1) represent the polymer’s contribution to the stress of the solution. This contribution is accounted for by a single spring–dumbbell model. We employ here the FENE-P kinetic theory (Bird, Armstrong & Hassager Reference Bird, Armstrong and Hassager1987), which is the most preferred one due to its physically realistic finite extensibility of the polymer molecules and to its relatively simple second-order closure. This model employs the phase-averaged conformation tensor,

$\unicode[STIX]{x1D6EF}_{ij}$

) in (2.1) represent the polymer’s contribution to the stress of the solution. This contribution is accounted for by a single spring–dumbbell model. We employ here the FENE-P kinetic theory (Bird, Armstrong & Hassager Reference Bird, Armstrong and Hassager1987), which is the most preferred one due to its physically realistic finite extensibility of the polymer molecules and to its relatively simple second-order closure. This model employs the phase-averaged conformation tensor,

![]() $\unicode[STIX]{x1D63E}$

. The components of the extra stress tensor are then

$\unicode[STIX]{x1D63E}$

. The components of the extra stress tensor are then

in which

![]() $Wi_{h}=\unicode[STIX]{x1D706}U_{h}/h$

is the bulk Weissenberg number (

$Wi_{h}=\unicode[STIX]{x1D706}U_{h}/h$

is the bulk Weissenberg number (

![]() $\unicode[STIX]{x1D706}$

being the relaxation time scale),

$\unicode[STIX]{x1D706}$

being the relaxation time scale),

![]() $\unicode[STIX]{x1D6FF}_{ij}$

is the Kronecker delta operator and

$\unicode[STIX]{x1D6FF}_{ij}$

is the Kronecker delta operator and

![]() $f\{\text{tr}(\unicode[STIX]{x1D63E})\}$

is given by the Peterlin approximation

$f\{\text{tr}(\unicode[STIX]{x1D63E})\}$

is given by the Peterlin approximation

where

![]() $L$

is the maximum polymer molecule extensibility and

$L$

is the maximum polymer molecule extensibility and

![]() $\text{tr}(\cdot )$

represents the trace operator. The governing equation for the conformation tensor are

$\text{tr}(\cdot )$

represents the trace operator. The governing equation for the conformation tensor are

in which

![]() $Sc_{c}=\unicode[STIX]{x1D708}_{0}/\unicode[STIX]{x1D705}_{c}$

is the Schmidt number defined as the ratio of the total kinematic zero shear rate viscosity (

$Sc_{c}=\unicode[STIX]{x1D708}_{0}/\unicode[STIX]{x1D705}_{c}$

is the Schmidt number defined as the ratio of the total kinematic zero shear rate viscosity (

![]() $\unicode[STIX]{x1D708}_{0}$

) to an artificial stress diffusivity

$\unicode[STIX]{x1D708}_{0}$

) to an artificial stress diffusivity

![]() $\unicode[STIX]{x1D705}_{c}$

. This explicit elliptic diffusion term included in (2.4) is an artefact used to improve numerical stability in pseudo-spectral simulations of viscoelastic fluids. This dissipative term was first introduced in this context by Sureshkumar & Beris (Reference Sureshkumar and Beris1995), and the methodology was subsequently validated under a variety of flows and material parameters (see Housiadas & Beris Reference Housiadas and Beris2003).

$\unicode[STIX]{x1D705}_{c}$

. This explicit elliptic diffusion term included in (2.4) is an artefact used to improve numerical stability in pseudo-spectral simulations of viscoelastic fluids. This dissipative term was first introduced in this context by Sureshkumar & Beris (Reference Sureshkumar and Beris1995), and the methodology was subsequently validated under a variety of flows and material parameters (see Housiadas & Beris Reference Housiadas and Beris2003).

Since the numerical scheme for DNS was already given in detail by Thais et al. (Reference Thais, Tejada-Martinez, Gatski and Mompean2011), we present here a brief description of the mathematical and numerical approaches. The hybrid MPI/OPENMP algorithm used was tailored to run properly in massively parallel architectures. The hybrid spatial scheme includes Fourier spectral accuracy in the two homogeneous directions (

![]() $x$

and

$x$

and

![]() $y$

) and sixth-order compact finite differences for the first- and second-order wall-normal derivatives (

$y$

) and sixth-order compact finite differences for the first- and second-order wall-normal derivatives (

![]() $z$

direction). Time marching can be up to fourth-order accurate by the use of the Adams–Moulton scheme for the viscous terms and Adams–Bashforth for the explicit terms. Pressure–velocity coupling is facilitated by a higher-order generalization of the semi-implicit fractional step method on a non-staggered grid arrangement analysed by Armfield & Street (Reference Armfield and Street2000). In order to attenuate high wavenumber energy accumulation, de-aliasing and fourth-order filtering are performed in the two homogeneous and wall-normal directions, respectively.

$z$

direction). Time marching can be up to fourth-order accurate by the use of the Adams–Moulton scheme for the viscous terms and Adams–Bashforth for the explicit terms. Pressure–velocity coupling is facilitated by a higher-order generalization of the semi-implicit fractional step method on a non-staggered grid arrangement analysed by Armfield & Street (Reference Armfield and Street2000). In order to attenuate high wavenumber energy accumulation, de-aliasing and fourth-order filtering are performed in the two homogeneous and wall-normal directions, respectively.

Table 1. Parameters for the DNS of Newtonian and FENE-P turbulent channel flows.

The parameters for the turbulent Newtonian and FENE-P channel flows studied here are summarized in table 1. Our simulated cases were chosen keeping in mind that viscoelastic fluids can have significantly different statistical behaviour from a Newtonian fluid. For a given turbulence level, as parametrized by the zero shear friction Reynolds number

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}$

(defined as

$Re_{\unicode[STIX]{x1D70F}_{0}}$

(defined as

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=u_{\unicode[STIX]{x1D70F}}h/\unicode[STIX]{x1D708}_{0}$

, where

$Re_{\unicode[STIX]{x1D70F}_{0}}=u_{\unicode[STIX]{x1D70F}}h/\unicode[STIX]{x1D708}_{0}$

, where

![]() $u_{\unicode[STIX]{x1D70F}}$

denotes the friction velocity), this effect can vary with the friction Weissenberg number,

$u_{\unicode[STIX]{x1D70F}}$

denotes the friction velocity), this effect can vary with the friction Weissenberg number,

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}$

(where

$Wi_{\unicode[STIX]{x1D70F}_{0}}$

(where

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}=\unicode[STIX]{x1D706}{u_{\unicode[STIX]{x1D70F}}}^{2}/\unicode[STIX]{x1D708}_{0}$

) and the maximum polymer extension length,

$Wi_{\unicode[STIX]{x1D70F}_{0}}=\unicode[STIX]{x1D706}{u_{\unicode[STIX]{x1D70F}}}^{2}/\unicode[STIX]{x1D708}_{0}$

) and the maximum polymer extension length,

![]() $L$

. In this paper, four Newtonian flows and seven viscoelastic flows were examined, keeping the viscosity ratio

$L$

. In this paper, four Newtonian flows and seven viscoelastic flows were examined, keeping the viscosity ratio

![]() $\unicode[STIX]{x1D6FD}_{0}$

fixed at 0.9 and taking into account four different values of the zero shear friction Reynolds number (

$\unicode[STIX]{x1D6FD}_{0}$

fixed at 0.9 and taking into account four different values of the zero shear friction Reynolds number (

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=180$

,

$Re_{\unicode[STIX]{x1D70F}_{0}}=180$

,

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=395$

,

$Re_{\unicode[STIX]{x1D70F}_{0}}=395$

,

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=590$

and

$Re_{\unicode[STIX]{x1D70F}_{0}}=590$

and

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=1000$

) and two different values of the friction Weissenberg number and the maximum polymer molecule extensibility (

$Re_{\unicode[STIX]{x1D70F}_{0}}=1000$

) and two different values of the friction Weissenberg number and the maximum polymer molecule extensibility (

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}=50$

;

$Wi_{\unicode[STIX]{x1D70F}_{0}}=50$

;

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}=115$

;

$Wi_{\unicode[STIX]{x1D70F}_{0}}=115$

;

![]() $L=30$

;

$L=30$

;

![]() $L=100$

), which provided drag reduction regimes from 28.5 % up to 62.3 %.

$L=100$

), which provided drag reduction regimes from 28.5 % up to 62.3 %.

The simulations were conducted at constant pressure gradient, leaving the mass flow rate of non-Newtonian flows to increase and then oscillate about a steady state characterized by a new time-averaged Reynolds number,

![]() $Re_{h}$

. The drag reduction is evaluated as

$Re_{h}$

. The drag reduction is evaluated as

where

accounts for the shear-thinning property of the FENE-P model (Housiadas & Beris Reference Housiadas and Beris2004). In this expression,

![]() $Re_{h,NEWT}$

is the bulk Reynolds number related to the corresponding Newtonian case (the Newtonian case at the same

$Re_{h,NEWT}$

is the bulk Reynolds number related to the corresponding Newtonian case (the Newtonian case at the same

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}$

),

$Re_{\unicode[STIX]{x1D70F}_{0}}$

),

![]() ${<}\unicode[STIX]{x1D70F}_{w}>$

denotes the area-averaged wall shear stress and

${<}\unicode[STIX]{x1D70F}_{w}>$

denotes the area-averaged wall shear stress and

![]() $n=1.14286$

is the exponent of the Dean correlation, which relates the bulk and friction Reynolds numbers for Newtonian turbulent channel flow (Dean Reference Dean1978). Time averaging of DNS data is taken in time over some 500 flow snapshots spanning several eddy turnover times, while spatial averaging (indicated by ‘

$n=1.14286$

is the exponent of the Dean correlation, which relates the bulk and friction Reynolds numbers for Newtonian turbulent channel flow (Dean Reference Dean1978). Time averaging of DNS data is taken in time over some 500 flow snapshots spanning several eddy turnover times, while spatial averaging (indicated by ‘

![]() $\langle \,\rangle$

’) is taken in the two homogeneous channel directions (

$\langle \,\rangle$

’) is taken in the two homogeneous channel directions (

![]() $x$

,

$x$

,

![]() $y$

).

$y$

).

Two drag reducing regimes are shown in table 1: the high drag reduction (HDR;

![]() $DR>40\,\%$

) regime and the low drag reduction (LDR;

$DR>40\,\%$

) regime and the low drag reduction (LDR;

![]() $DR\leqslant 40\,\%$

) regime. Physically, the main difference between these two regimes consists in the fact that for LDR flows, the Reynolds stresses play a major role, whereas in the HDR regime, the near-wall dynamics of the flow is dominated by the polymer stresses (White & Mungal Reference White and Mungal2008).

$DR\leqslant 40\,\%$

) regime. Physically, the main difference between these two regimes consists in the fact that for LDR flows, the Reynolds stresses play a major role, whereas in the HDR regime, the near-wall dynamics of the flow is dominated by the polymer stresses (White & Mungal Reference White and Mungal2008).

The channel extent for the flow cases at

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}$

up to of 590 was

$Re_{\unicode[STIX]{x1D70F}_{0}}$

up to of 590 was

![]() $Lx\times Ly\times Lz$

=

$Lx\times Ly\times Lz$

=

![]() $8\unicode[STIX]{x03C0}\times 1.5\unicode[STIX]{x03C0}\times 2.0$

. For the highest zero shear friction Reynolds number flow,

$8\unicode[STIX]{x03C0}\times 1.5\unicode[STIX]{x03C0}\times 2.0$

. For the highest zero shear friction Reynolds number flow,

![]() $Lx\times Ly\times Lz$

=

$Lx\times Ly\times Lz$

=

![]() $6\unicode[STIX]{x03C0}\times 1.5\unicode[STIX]{x03C0}\times 2.0$

. The number of mesh points (

$6\unicode[STIX]{x03C0}\times 1.5\unicode[STIX]{x03C0}\times 2.0$

. The number of mesh points (

![]() $Nx\times Ny\times Nz$

) shown in table 1 for each case corresponds to a grid resolution of

$Nx\times Ny\times Nz$

) shown in table 1 for each case corresponds to a grid resolution of

![]() $8.8\leqslant \unicode[STIX]{x0394}x^{+}\leqslant 12.3$

,

$8.8\leqslant \unicode[STIX]{x0394}x^{+}\leqslant 12.3$

,

![]() $5.4\leqslant \unicode[STIX]{x0394}y^{+}\leqslant 7.3$

, and

$5.4\leqslant \unicode[STIX]{x0394}y^{+}\leqslant 7.3$

, and

![]() $0.2\leqslant \unicode[STIX]{x0394}z^{+}\leqslant 12.1$

. The superscript ‘

$0.2\leqslant \unicode[STIX]{x0394}z^{+}\leqslant 12.1$

. The superscript ‘

![]() $+$

’ indicates normalization by the friction velocity, defined by

$+$

’ indicates normalization by the friction velocity, defined by

![]() $u_{\unicode[STIX]{x1D70F}}=\sqrt{\unicode[STIX]{x1D70F}_{w}/\unicode[STIX]{x1D70C}}$

, and the total kinematic zero shear rate viscosity. The Schmidt number

$u_{\unicode[STIX]{x1D70F}}=\sqrt{\unicode[STIX]{x1D70F}_{w}/\unicode[STIX]{x1D70C}}$

, and the total kinematic zero shear rate viscosity. The Schmidt number

![]() $Sc_{c}=0.1$

was necessary to keep the algorithm stable and the conformation tensor symmetric positive definite.

$Sc_{c}=0.1$

was necessary to keep the algorithm stable and the conformation tensor symmetric positive definite.

3 Statistics of the flow

3.1 Time-averaged statistics

The distributions of the mean velocity in wall coordinates,

![]() $\langle \overline{U_{x}}^{+}\rangle$

, for turbulent channel flows of Newtonian and viscoelastic solutions are displayed in figure 1(a). The bar indicates the time average and ‘

$\langle \overline{U_{x}}^{+}\rangle$

, for turbulent channel flows of Newtonian and viscoelastic solutions are displayed in figure 1(a). The bar indicates the time average and ‘

![]() $\langle \,\rangle$

’ denotes the

$\langle \,\rangle$

’ denotes the

![]() $x$

–

$x$

–

![]() $y$

plane average. The grey circles represent the Newtonian mean velocity profile at

$y$

plane average. The grey circles represent the Newtonian mean velocity profile at

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=180$

while the other symbols represent the viscoelastic flows. In the viscous sublayer (

$Re_{\unicode[STIX]{x1D70F}_{0}}=180$

while the other symbols represent the viscoelastic flows. In the viscous sublayer (

![]() $0<z^{+}<5$

), where the total stress is predominantly associated with viscous effects, the mean velocities converge to the same linear shape

$0<z^{+}<5$

), where the total stress is predominantly associated with viscous effects, the mean velocities converge to the same linear shape

![]() $\langle \overline{U_{x}}^{+}\rangle =z^{+}$

represented by the solid grey line. As the wall distance increases, the Reynolds stress becomes important and comparable to the viscous stress within the Newtonian buffer layer (

$\langle \overline{U_{x}}^{+}\rangle =z^{+}$

represented by the solid grey line. As the wall distance increases, the Reynolds stress becomes important and comparable to the viscous stress within the Newtonian buffer layer (

![]() $5<z^{+}<30$

). Then, the Newtonian mean velocity departs quickly from the linear profile, taking on a logarithmic dependence on

$5<z^{+}<30$

). Then, the Newtonian mean velocity departs quickly from the linear profile, taking on a logarithmic dependence on

![]() $z^{+}$

(grey dashed line) in the Newtonian log-law region,

$z^{+}$

(grey dashed line) in the Newtonian log-law region,

![]() $z^{+}>30$

,

$z^{+}>30$

,

![]() $\langle \overline{U_{x}}^{+}\rangle =(1/\unicode[STIX]{x1D705})\ln (z^{+})+A_{1}$

where

$\langle \overline{U_{x}}^{+}\rangle =(1/\unicode[STIX]{x1D705})\ln (z^{+})+A_{1}$

where

![]() $\unicode[STIX]{x1D705}$

is commonly called the von Kármán coefficient (

$\unicode[STIX]{x1D705}$

is commonly called the von Kármán coefficient (

![]() $1/\unicode[STIX]{x1D705}$

is the slope) and

$1/\unicode[STIX]{x1D705}$

is the slope) and

![]() $A_{1}$

is the intercept at

$A_{1}$

is the intercept at

![]() $z^{+}=1$

. For Newtonian channel flows over a hydraulically smooth wall,

$z^{+}=1$

. For Newtonian channel flows over a hydraulically smooth wall,

![]() $\unicode[STIX]{x1D705}=0.4$

and

$\unicode[STIX]{x1D705}=0.4$

and

![]() $A_{1}=5.5$

(Kim, Moin & Moser Reference Kim, Moin and Moser1987). In order to better describe our results, we use the boundaries of the viscous sublayer, the buffer layer and the log-law Newtonian regions to define regions I, II and III, respectively. It is important to emphasize, however, that regions II and III do not necessarily represent the buffer layer and the log-law region for the viscoelastic cases, since the polymers can increase the former layer, reducing the latter.

$A_{1}=5.5$

(Kim, Moin & Moser Reference Kim, Moin and Moser1987). In order to better describe our results, we use the boundaries of the viscous sublayer, the buffer layer and the log-law Newtonian regions to define regions I, II and III, respectively. It is important to emphasize, however, that regions II and III do not necessarily represent the buffer layer and the log-law region for the viscoelastic cases, since the polymers can increase the former layer, reducing the latter.

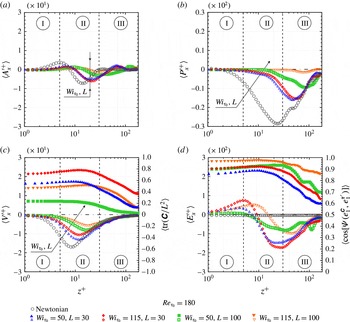

Figure 1. Mean velocity profiles in the streamwise direction (a),

![]() $\langle \overline{U_{x}}^{+}\rangle$

, and normal components of the Reynolds stress (b–d) for Newtonian and viscoelastic channel flows, against the normalized wall distance.

$\langle \overline{U_{x}}^{+}\rangle$

, and normal components of the Reynolds stress (b–d) for Newtonian and viscoelastic channel flows, against the normalized wall distance.

The interactions between the viscoelastic fluid dynamics and the turbulent flow dynamics result in changes in the mean velocity profile relative to the Newtonian fluid. The polymer drag reduction phenomenon leads to an increased bulk mean velocity, as observed by comparing the viscoelastic profiles plotted in figure 1. When a high enough polymer concentration is used, the maximum level of drag reduction (MDR) is attained. In that state, the velocity profile is commonly represented by the Virk’s asymptote (Virk et al.

Reference Virk, Mickley and Smith1970),

![]() $\langle \overline{U_{x}}^{+}\rangle =11.7\ln (z^{+})+17.8$

which is a matter of recent controversy (White, Dubief, & Klewicki Reference White, Dubief and Klewicki2012). Experimental and recent numerical results based on DNS (Escudier, Presti & Smith Reference Escudier, Presti and Smith1999; Ptasinski et al.

Reference Ptasinski, Nieuwstadt, Van den Brule and Hulsen2001; Escudier, Nickson, & Poole Reference Escudier, Nickson and Poole2009; Thais et al.

Reference Thais, Gatski and Mompean2012) indicate a parallel upward shift of the logarithmic region of the mean velocity profile with increasing DR, which is clearly perceived at high Reynolds numbers (see Thais et al.

Reference Thais, Gatski and Mompean2013). Such a behaviour suggests a significant extension of the buffer layer region into the channel caused by the polymers. For viscoelastic fluids, the cross-over to a presumed Newtonian plug flow occurs at a distance from the wall where the Reynolds stress momentum flux is no longer negligible compared to that of the polymer/viscous stress. Figure 1(b–d) show the normal components of the Reynolds stress tensor, whose components are defined as the time average of the velocity fluctuation product (

$\langle \overline{U_{x}}^{+}\rangle =11.7\ln (z^{+})+17.8$

which is a matter of recent controversy (White, Dubief, & Klewicki Reference White, Dubief and Klewicki2012). Experimental and recent numerical results based on DNS (Escudier, Presti & Smith Reference Escudier, Presti and Smith1999; Ptasinski et al.

Reference Ptasinski, Nieuwstadt, Van den Brule and Hulsen2001; Escudier, Nickson, & Poole Reference Escudier, Nickson and Poole2009; Thais et al.

Reference Thais, Gatski and Mompean2012) indicate a parallel upward shift of the logarithmic region of the mean velocity profile with increasing DR, which is clearly perceived at high Reynolds numbers (see Thais et al.

Reference Thais, Gatski and Mompean2013). Such a behaviour suggests a significant extension of the buffer layer region into the channel caused by the polymers. For viscoelastic fluids, the cross-over to a presumed Newtonian plug flow occurs at a distance from the wall where the Reynolds stress momentum flux is no longer negligible compared to that of the polymer/viscous stress. Figure 1(b–d) show the normal components of the Reynolds stress tensor, whose components are defined as the time average of the velocity fluctuation product (

![]() $\overline{{u^{\prime }}_{i}{u^{\prime }}_{j}}^{+}$

). The mean effect of the polymer on the turbulence is anisotropic and induces an increase in the streamwise normal Reynolds stress component (figure 1

b), while weakening both the spanwise (figure 1

c) and the wall-normal (figure 1

d) terms, as experimentally found by many researchers such as Pinho & Whitelaw (Reference Pinho and Whitelaw1990), Warholic, Massah & Hanratty (Reference Warholic, Massah and Hanratty1999) and White, Somandepalli & Mungal (Reference White, Somandepalli and Mungal2004). This effect is more pronounced as the elasticity increases, as indicated by the solid black arrows. In the most elastic flow at

$\overline{{u^{\prime }}_{i}{u^{\prime }}_{j}}^{+}$

). The mean effect of the polymer on the turbulence is anisotropic and induces an increase in the streamwise normal Reynolds stress component (figure 1

b), while weakening both the spanwise (figure 1

c) and the wall-normal (figure 1

d) terms, as experimentally found by many researchers such as Pinho & Whitelaw (Reference Pinho and Whitelaw1990), Warholic, Massah & Hanratty (Reference Warholic, Massah and Hanratty1999) and White, Somandepalli & Mungal (Reference White, Somandepalli and Mungal2004). This effect is more pronounced as the elasticity increases, as indicated by the solid black arrows. In the most elastic flow at

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=180$

(orange inverted triangles), for instance, the peak of

$Re_{\unicode[STIX]{x1D70F}_{0}}=180$

(orange inverted triangles), for instance, the peak of

![]() $\langle \overline{{u^{\prime }}_{x}{u^{\prime }}_{x}}^{+}\rangle$

moves from

$\langle \overline{{u^{\prime }}_{x}{u^{\prime }}_{x}}^{+}\rangle$

moves from

![]() $z^{+}\approx 12$

(region II) to

$z^{+}\approx 12$

(region II) to

![]() $z^{+}\approx 32$

and its value is one order of magnitude greater than the Newtonian one (grey open circles). In addition, the other components also shift away from the wall, but their peaks decrease by one order of magnitude compared to the Newtonian flow. Since vortices produce significant transverse fluctuations, the reduction of both

$z^{+}\approx 32$

and its value is one order of magnitude greater than the Newtonian one (grey open circles). In addition, the other components also shift away from the wall, but their peaks decrease by one order of magnitude compared to the Newtonian flow. Since vortices produce significant transverse fluctuations, the reduction of both

![]() ${u^{\prime }}_{y}$

and

${u^{\prime }}_{y}$

and

![]() ${u^{\prime }}_{z}$

suggests a strong interaction between these intermittent structures and polymers (Dubief et al.

Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004). Lastly, the dashed arrows indicate that the normal Reynolds stress components are an increasing function of

${u^{\prime }}_{z}$

suggests a strong interaction between these intermittent structures and polymers (Dubief et al.

Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004). Lastly, the dashed arrows indicate that the normal Reynolds stress components are an increasing function of

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}$

. Their peaks move towards the channel centre with increasing Reynolds number.

$Re_{\unicode[STIX]{x1D70F}_{0}}$

. Their peaks move towards the channel centre with increasing Reynolds number.

Figure 2. (a) Evolution of the mean relative polymer extension,

![]() $\langle \text{tr}(\overline{\unicode[STIX]{x1D63E}})/L^{2}\rangle$

, against the normalized wall distance. (b) Effects of mean shear stress profile on polymer extension.

$\langle \text{tr}(\overline{\unicode[STIX]{x1D63E}})/L^{2}\rangle$

, against the normalized wall distance. (b) Effects of mean shear stress profile on polymer extension.

The variations in polymer mean stresses across the channel can be highlighted by analysing the polymer mean stretch, which is linked with the former by the Peterlin function (2.3). The distribution of the relative polymer mean stretch

![]() $\langle \text{tr}(\overline{\unicode[STIX]{x1D63E}})/L^{2}\rangle$

as a function of

$\langle \text{tr}(\overline{\unicode[STIX]{x1D63E}})/L^{2}\rangle$

as a function of

![]() $z^{+}$

is displayed in figure 2(a), for all viscoelastic cases studied in the present paper. As a common point, the polymer molecules exhibit a significant extension at the wall, which increases in the buffer layer, where its peak is attained. This peak magnitude, as well as its location, is a decreasing function of

$z^{+}$

is displayed in figure 2(a), for all viscoelastic cases studied in the present paper. As a common point, the polymer molecules exhibit a significant extension at the wall, which increases in the buffer layer, where its peak is attained. This peak magnitude, as well as its location, is a decreasing function of

![]() $L$

, but increases with increasing

$L$

, but increases with increasing

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}$

(these trends are discussed in § 4.1). As the wall distance increases further,

$Wi_{\unicode[STIX]{x1D70F}_{0}}$

(these trends are discussed in § 4.1). As the wall distance increases further,

![]() $\langle \text{tr}(\overline{\unicode[STIX]{x1D63E}})/L^{2}\rangle$

becomes less pronounced until achieving its minimum level at

$\langle \text{tr}(\overline{\unicode[STIX]{x1D63E}})/L^{2}\rangle$

becomes less pronounced until achieving its minimum level at

![]() $z^{+}=180$

. A very simple method to clarify the polymer stretching mechanism consists in solving (2.4) using different mean velocity profiles. The result is illustrated in figure 2(b), where the less elastic flow is considered (grey open circles), as well as the polymer extension produced in this fluid by a turbulent-channel-like velocity profile

$z^{+}=180$

. A very simple method to clarify the polymer stretching mechanism consists in solving (2.4) using different mean velocity profiles. The result is illustrated in figure 2(b), where the less elastic flow is considered (grey open circles), as well as the polymer extension produced in this fluid by a turbulent-channel-like velocity profile

![]() $\overline{U_{x}}=(9/8)[1-(z/h)^{8}]$

(Dallas et al.

Reference Dallas, Vassilicos and Hewitt2010). As the derivative of the mean velocity with respect to the wall-normal direction increases, the polymers stretch considerably, due to the increase of the shear stress. More specifically, the profile of

$\overline{U_{x}}=(9/8)[1-(z/h)^{8}]$

(Dallas et al.

Reference Dallas, Vassilicos and Hewitt2010). As the derivative of the mean velocity with respect to the wall-normal direction increases, the polymers stretch considerably, due to the increase of the shear stress. More specifically, the profile of

![]() $\langle \text{tr}(\overline{\unicode[STIX]{x1D63E}})/L^{2}\rangle$

follows the mean viscous shear stress feature. Comparing the relative polymer extensions obtained from a turbulent-like mean velocity profile (orange inverted triangles) and DNS results (grey open circles), it is interesting to observe that both curves depart from the same level (

$\langle \text{tr}(\overline{\unicode[STIX]{x1D63E}})/L^{2}\rangle$

follows the mean viscous shear stress feature. Comparing the relative polymer extensions obtained from a turbulent-like mean velocity profile (orange inverted triangles) and DNS results (grey open circles), it is interesting to observe that both curves depart from the same level (

![]() ${\approx}0.54$

), at

${\approx}0.54$

), at

![]() $z^{+}=0$

. However, as the wall distance increases, the discrepancy between them becomes pronounced. In fact, near the wall, the increasing

$z^{+}=0$

. However, as the wall distance increases, the discrepancy between them becomes pronounced. In fact, near the wall, the increasing

![]() $\langle \text{tr}(\overline{\unicode[STIX]{x1D63E}})/L^{2}\rangle$

noticed for the grey circles curve suggests that in this region there is a particular flow topology capable of producing an increase in the polymer extension beyond the viscous mean shear level represented by the orange inverted triangles. In other words, the viscous mean stress is responsible for a relevant polymer stretching, which is incremented since the turbulent structures interact with the polymer molecules, providing a supplementary polymer extension. We believe these intermittent polymer–turbulence interactions are also responsible for the polymer coil–stretch process, which will be analysed in later subsections from statistical and tensorial perspectives.

$\langle \text{tr}(\overline{\unicode[STIX]{x1D63E}})/L^{2}\rangle$

noticed for the grey circles curve suggests that in this region there is a particular flow topology capable of producing an increase in the polymer extension beyond the viscous mean shear level represented by the orange inverted triangles. In other words, the viscous mean stress is responsible for a relevant polymer stretching, which is incremented since the turbulent structures interact with the polymer molecules, providing a supplementary polymer extension. We believe these intermittent polymer–turbulence interactions are also responsible for the polymer coil–stretch process, which will be analysed in later subsections from statistical and tensorial perspectives.

All the trends discussed above considering

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=180$

are also observed at higher zero shear friction Reynolds numbers, as previously reported by Thais et al. (Reference Thais, Gatski and Mompean2012) and Thais et al. (Reference Thais, Gatski and Mompean2013).

$Re_{\unicode[STIX]{x1D70F}_{0}}=180$

are also observed at higher zero shear friction Reynolds numbers, as previously reported by Thais et al. (Reference Thais, Gatski and Mompean2012) and Thais et al. (Reference Thais, Gatski and Mompean2013).

4 Polymer stretching and alignment

In order to analyse the effects of instantaneous polymer stretching on the flow, the following data and results were evaluated at the same instant of simulation, after a statistical steady state was achieved. Such an instantaneous analysis is justified by the fact that in turbulent flows, the polymer action is likely to be as intermittent as the near-wall vortices (see Dubief et al. Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004). Hence, these intermittent events may be hidden by a time-averaging procedure. In other words, such an analysis of the instantaneous quantities could reveal less expressive but important events for the DR phenomenon.

Figure 3. The three-dimensional structures represent isosurfaces of vortical regions defined as a positive value of the second invariant of velocity gradient tensor,

![]() $\unicode[STIX]{x1D735}\boldsymbol{u}$

. The colours indicate the polymer stretching,

$\unicode[STIX]{x1D735}\boldsymbol{u}$

. The colours indicate the polymer stretching,

![]() $\text{tr}(\unicode[STIX]{x1D63E})/L^{2}$

.

$\text{tr}(\unicode[STIX]{x1D63E})/L^{2}$

.

Although in this subsection we analyse the effects of the elasticity on the stretching and alignment of the polymers at a low zero shear friction Reynolds number,

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=180$

, it is important to emphasize that the trends shown below are observed for all viscoelastic cases studied. In other words, the physical aspects of DR discussed here are not affected by low Reynolds number effects.

$Re_{\unicode[STIX]{x1D70F}_{0}}=180$

, it is important to emphasize that the trends shown below are observed for all viscoelastic cases studied. In other words, the physical aspects of DR discussed here are not affected by low Reynolds number effects.

4.1 Polymer stretching

The three-dimensional structures shown in figure 3 represent the isosurfaces of the vortical regions, defined as the positive second invariant of the velocity gradient tensor,

![]() $\unicode[STIX]{x1D735}\boldsymbol{u}$

, in Newtonian (a) and viscoelastic (b–e) flows. For incompressible flows, the second invariant of

$\unicode[STIX]{x1D735}\boldsymbol{u}$

, in Newtonian (a) and viscoelastic (b–e) flows. For incompressible flows, the second invariant of

![]() $\unicode[STIX]{x1D735}\boldsymbol{u}$

,

$\unicode[STIX]{x1D735}\boldsymbol{u}$

,

![]() $Q$

, can be used to identify vortical structures, the so-called

$Q$

, can be used to identify vortical structures, the so-called

![]() $Q$

-criterion (see Hunt et al.

Reference Hunt, Wray and Moin1988), and simplified as

$Q$

-criterion (see Hunt et al.

Reference Hunt, Wray and Moin1988), and simplified as

which indicates the spatial regions where the Euclidean norm of the rate-of-rotation tensor,

![]() $\Vert \unicode[STIX]{x1D652}\Vert$

, dominates that of the rate of strain,

$\Vert \unicode[STIX]{x1D652}\Vert$

, dominates that of the rate of strain,

![]() $\Vert \unicode[STIX]{x1D63F}\Vert$

(the Euclidean norm of a generic second-order tensor

$\Vert \unicode[STIX]{x1D63F}\Vert$

(the Euclidean norm of a generic second-order tensor

![]() $\unicode[STIX]{x1D63C}$

is

$\unicode[STIX]{x1D63C}$

is

![]() $\Vert \unicode[STIX]{x1D63C}\Vert =\sqrt{\text{tr}(\unicode[STIX]{x1D63C}\boldsymbol{\cdot }\unicode[STIX]{x1D63C}^{\unicode[STIX]{x1D64F}})}$

). These structures follow an organized hierarchy across the channel. In the vicinity of the wall (

$\Vert \unicode[STIX]{x1D63C}\Vert =\sqrt{\text{tr}(\unicode[STIX]{x1D63C}\boldsymbol{\cdot }\unicode[STIX]{x1D63C}^{\unicode[STIX]{x1D64F}})}$

). These structures follow an organized hierarchy across the channel. In the vicinity of the wall (

![]() $z^{+}<20$

), eddies are found to be pairs of counter-rotating quasi-streamwise vortices, while for

$z^{+}<20$

), eddies are found to be pairs of counter-rotating quasi-streamwise vortices, while for

![]() $z^{+}>30$

, these eddies resemble hairpins (the so-called horseshoe vortices). The formation of such morphologies is induced by combined second-quadrant ejection (

$z^{+}>30$

, these eddies resemble hairpins (the so-called horseshoe vortices). The formation of such morphologies is induced by combined second-quadrant ejection (

![]() $u_{x}^{\prime }<0,u_{z}^{\prime }>0$

; Q2 event) and fourth-quadrant sweep (

$u_{x}^{\prime }<0,u_{z}^{\prime }>0$

; Q2 event) and fourth-quadrant sweep (

![]() $u_{x}^{\prime }>0,u_{z}^{\prime }<0$

; Q4 event) events within the flow (see Adrian Reference Adrian2007). Specifically, the hairpin vortices are composed of three well defined parts. The legs are regions of rotation quasi-aligned with the streamwise direction. The head is a rotation part aligned with the spanwise direction. The necks are the connections between the legs and the head of the hairpin. These three parts, as well as the velocity fluctuations associated with them, can be seen in detail in figure 4, where a typical hairpin extracted from our less elastic flow (

$u_{x}^{\prime }>0,u_{z}^{\prime }<0$

; Q4 event) events within the flow (see Adrian Reference Adrian2007). Specifically, the hairpin vortices are composed of three well defined parts. The legs are regions of rotation quasi-aligned with the streamwise direction. The head is a rotation part aligned with the spanwise direction. The necks are the connections between the legs and the head of the hairpin. These three parts, as well as the velocity fluctuations associated with them, can be seen in detail in figure 4, where a typical hairpin extracted from our less elastic flow (

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=180$

,

$Re_{\unicode[STIX]{x1D70F}_{0}}=180$

,

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}=50$

and

$Wi_{\unicode[STIX]{x1D70F}_{0}}=50$

and

![]() $L=30$

) is coloured by the

$L=30$

) is coloured by the

![]() $Q$

events.

$Q$

events.

Figure 4. Typical hairpin extracted from a viscoelastic flow (

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}=180$

;

$Re_{\unicode[STIX]{x1D70F}_{0}}=180$

;

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}=50$

;

$Wi_{\unicode[STIX]{x1D70F}_{0}}=50$

;

![]() $L=30$

) with

$L=30$

) with

![]() $Q=0.7$

and coloured by the Q1 (

$Q=0.7$

and coloured by the Q1 (

![]() $u_{x}^{\prime }>0,u_{z}^{\prime }>0$

), Q2 (

$u_{x}^{\prime }>0,u_{z}^{\prime }>0$

), Q2 (

![]() $u_{x}^{\prime }<0,u_{z}^{\prime }>0$

), Q3 (

$u_{x}^{\prime }<0,u_{z}^{\prime }>0$

), Q3 (

![]() $u_{x}^{\prime }<0,u_{z}^{\prime }<0$

) and Q4 (

$u_{x}^{\prime }<0,u_{z}^{\prime }<0$

) and Q4 (

![]() $u_{x}^{\prime }>0,u_{z}^{\prime }<0$

) events.

$u_{x}^{\prime }>0,u_{z}^{\prime }<0$

) events.

Comparing figure 3(a–e), it can be seen that the number of vortices with a value of the

![]() $Q$

-criterion equal to 0.7 decreases with increasing elasticity (

$Q$

-criterion equal to 0.7 decreases with increasing elasticity (

![]() $We$

and

$We$

and

![]() $L$

). For

$L$

). For

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}=115$

and

$Wi_{\unicode[STIX]{x1D70F}_{0}}=115$

and

![]() $L=100$

, which provides

$L=100$

, which provides

![]() $DR=62.3\,\%$

, the vortices with

$DR=62.3\,\%$

, the vortices with

![]() $Q=0.7$

are completely gone and the vortices with

$Q=0.7$

are completely gone and the vortices with

![]() $Q=0.1$

(figure 3

e) are only found close to the walls. In viscoelastic flows, the vortical structures are significantly weaker than in the Newtonian flow, which is considered fundamental evidence of the polymer–turbulence interactions and the consequent drag reduction (Terrapon et al.

Reference Terrapon, Dubief, Moin, Shaqfeh and Lele2004; Kim et al.

Reference Kim, Li, Sureshkumar, Balachandar and Adrian2007, Reference Kim, Adrian, Balachandar and Sureshkumar2008; White & Mungal Reference White and Mungal2008). As the elasticity increases, some characteristics of the vortices change: their thicknesses and streamwise lengths increase, while their strengths weaken, which is clearly observed by comparing figure 3(a,e). Furthermore, the vortices become more parallel to the wall. In the log-law region, the hairpin head is strongly weakened. It has been experimentally and numerically shown that in drag reducing flows, the streamwise component of the Reynolds normal stresses increases relative to the Newtonian case, while the other components of the Reynolds stress tensors decrease (Wei & Willmarth Reference Wei and Willmarth1992; Warholic et al.

Reference Warholic, Massah and Hanratty1999; Ptasinski et al.

Reference Ptasinski, Nieuwstadt, Van den Brule and Hulsen2001; Kim et al.

Reference Kim, Li, Sureshkumar, Balachandar and Adrian2007; Thais et al.

Reference Thais, Gatski and Mompean2012). These variations seem to be closely connected with the coil–stretch polymer transition and the consequent vortex structural changes (Dimitropoulos et al.

Reference Dimitropoulos, Dubief, Shaqfeh, Moin and Lele2005). The colours in figure 3(b–e) indicate the relative polymer stretch,

$Q=0.1$

(figure 3

e) are only found close to the walls. In viscoelastic flows, the vortical structures are significantly weaker than in the Newtonian flow, which is considered fundamental evidence of the polymer–turbulence interactions and the consequent drag reduction (Terrapon et al.

Reference Terrapon, Dubief, Moin, Shaqfeh and Lele2004; Kim et al.

Reference Kim, Li, Sureshkumar, Balachandar and Adrian2007, Reference Kim, Adrian, Balachandar and Sureshkumar2008; White & Mungal Reference White and Mungal2008). As the elasticity increases, some characteristics of the vortices change: their thicknesses and streamwise lengths increase, while their strengths weaken, which is clearly observed by comparing figure 3(a,e). Furthermore, the vortices become more parallel to the wall. In the log-law region, the hairpin head is strongly weakened. It has been experimentally and numerically shown that in drag reducing flows, the streamwise component of the Reynolds normal stresses increases relative to the Newtonian case, while the other components of the Reynolds stress tensors decrease (Wei & Willmarth Reference Wei and Willmarth1992; Warholic et al.

Reference Warholic, Massah and Hanratty1999; Ptasinski et al.

Reference Ptasinski, Nieuwstadt, Van den Brule and Hulsen2001; Kim et al.

Reference Kim, Li, Sureshkumar, Balachandar and Adrian2007; Thais et al.

Reference Thais, Gatski and Mompean2012). These variations seem to be closely connected with the coil–stretch polymer transition and the consequent vortex structural changes (Dimitropoulos et al.

Reference Dimitropoulos, Dubief, Shaqfeh, Moin and Lele2005). The colours in figure 3(b–e) indicate the relative polymer stretch,

![]() $\text{tr}(\unicode[STIX]{x1D63E})/L^{2}$

. The

$\text{tr}(\unicode[STIX]{x1D63E})/L^{2}$

. The

![]() $y$

–

$y$

–

![]() $z$

planes show that for all four viscoelastic flows, the polymers are more stretched close to the wall (yellow and red regions). In contrast, the polymer extensions are less pronounced in the middle of the channel (blue regions). The isosurface colours and those of the intersections between vortical structures and

$z$

planes show that for all four viscoelastic flows, the polymers are more stretched close to the wall (yellow and red regions). In contrast, the polymer extensions are less pronounced in the middle of the channel (blue regions). The isosurface colours and those of the intersections between vortical structures and

![]() $y$

–

$y$

–

![]() $z$

planes show that the polymers are more extended around the near-wall vortices.

$z$

planes show that the polymers are more extended around the near-wall vortices.

Figure 5. Normalized conformation tensor as a function of the normalized wall distance. Streamwise normal components of

![]() $\unicode[STIX]{x1D63E}$

and

$\unicode[STIX]{x1D63E}$

and

![]() $\text{tr}(\unicode[STIX]{x1D63E})/L^{2}$

(open and solid in a, respectively). Spanwise normal component of

$\text{tr}(\unicode[STIX]{x1D63E})/L^{2}$

(open and solid in a, respectively). Spanwise normal component of

![]() $\unicode[STIX]{x1D63E}$

(b). Wall-normal component of

$\unicode[STIX]{x1D63E}$

(b). Wall-normal component of

![]() $\unicode[STIX]{x1D63E}$

(c). Cross-components (d).

$\unicode[STIX]{x1D63E}$

(c). Cross-components (d).

The stretching of the polymers can be seen more clearly in figure 5(a), where the evolution of the

![]() $x$

–

$x$

–

![]() $y$

-plane-averaged normalized trace of the instantaneous conformation tensor,

$y$

-plane-averaged normalized trace of the instantaneous conformation tensor,

![]() $\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle$

, is plotted against the wall distance

$\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle$

, is plotted against the wall distance

![]() $z^{+}$

(solid symbols) together with the normalized streamwise normal component of the conformation tensor,

$z^{+}$

(solid symbols) together with the normalized streamwise normal component of the conformation tensor,

![]() $\langle C_{xx}/L^{2}\rangle$

(open symbols). The percentage of polymer extension,

$\langle C_{xx}/L^{2}\rangle$

(open symbols). The percentage of polymer extension,

![]() $\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle$

, is relatively high at the wall, achieving a peak in the very near-wall region (

$\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle$

, is relatively high at the wall, achieving a peak in the very near-wall region (

![]() $z^{+}<20$

), the exact location of which varies with

$z^{+}<20$

), the exact location of which varies with

![]() $L$

and

$L$

and

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}$

. This peak is commonly associated with the streamwise vortices (see Dubief et al.

Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004; Dimitropoulos et al.

Reference Dimitropoulos, Dubief, Shaqfeh, Moin and Lele2005; Dallas et al.

Reference Dallas, Vassilicos and Hewitt2010). After this point,

$Wi_{\unicode[STIX]{x1D70F}_{0}}$

. This peak is commonly associated with the streamwise vortices (see Dubief et al.

Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004; Dimitropoulos et al.

Reference Dimitropoulos, Dubief, Shaqfeh, Moin and Lele2005; Dallas et al.

Reference Dallas, Vassilicos and Hewitt2010). After this point,

![]() $\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle$

starts to decrease, until reaching its minimum at the channel centre. In comparing the grey solid circles with the red solid diamonds, or the blue solid triangles with the green solid squares, it can be clearly seen that

$\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle$

starts to decrease, until reaching its minimum at the channel centre. In comparing the grey solid circles with the red solid diamonds, or the blue solid triangles with the green solid squares, it can be clearly seen that

![]() $\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle$

decreases with increasing

$\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle$

decreases with increasing

![]() $L$

, for fixed

$L$

, for fixed

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}$

and

$Re_{\unicode[STIX]{x1D70F}_{0}}$

and

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}$

, which suggests that the large polymer molecules could be less susceptible to chain scission degradation (Pereira & Soares Reference Pereira and Soares2012). A further comparison of the grey solid circles with the blue solid triangles, or of the red solid diamonds with the green solid squares, reveals that the relative polymer extension becomes greater as the friction Weissenberg number increases, since higher values of the polymer time scale induce the polymer molecules to be influenced by a wider spectrum of time scales of the flow (Dallas et al.

Reference Dallas, Vassilicos and Hewitt2010). Figure 5(a) also shows that the dominant contribution to the trace of the conformation tensor comes from

$Wi_{\unicode[STIX]{x1D70F}_{0}}$

, which suggests that the large polymer molecules could be less susceptible to chain scission degradation (Pereira & Soares Reference Pereira and Soares2012). A further comparison of the grey solid circles with the blue solid triangles, or of the red solid diamonds with the green solid squares, reveals that the relative polymer extension becomes greater as the friction Weissenberg number increases, since higher values of the polymer time scale induce the polymer molecules to be influenced by a wider spectrum of time scales of the flow (Dallas et al.

Reference Dallas, Vassilicos and Hewitt2010). Figure 5(a) also shows that the dominant contribution to the trace of the conformation tensor comes from

![]() $C_{xx}$

, i.e.

$C_{xx}$

, i.e.

![]() $\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle \approx \langle C_{xx}/L^{2}\rangle$

(especially near the wall and for the highest value of

$\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle \approx \langle C_{xx}/L^{2}\rangle$

(especially near the wall and for the highest value of

![]() $L$

,

$L$

,

![]() $L=100$

). This distribution suggests a significant stretching of the polymers in the streamwise direction. The other component with a non-zero wall value is the off-diagonal component

$L=100$

). This distribution suggests a significant stretching of the polymers in the streamwise direction. The other component with a non-zero wall value is the off-diagonal component

![]() $C_{xz}$

, normalized and displayed in figure 5(d). However, its value at the wall is almost two orders of magnitude smaller than that of the

$C_{xz}$

, normalized and displayed in figure 5(d). However, its value at the wall is almost two orders of magnitude smaller than that of the

![]() $C_{xx}$

component. Moreover, as

$C_{xx}$

component. Moreover, as

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}$

and

$Wi_{\unicode[STIX]{x1D70F}_{0}}$

and

![]() $L$

increase, the profile of

$L$

increase, the profile of

![]() $\langle C_{xz}/L^{2}\rangle$

follows the same tendencies noted in figure 5(a), reaching its peaks at

$\langle C_{xz}/L^{2}\rangle$

follows the same tendencies noted in figure 5(a), reaching its peaks at

![]() $z^{+}$

not much different from those observed for

$z^{+}$

not much different from those observed for

![]() $C_{xx}$

. The peak magnitude of the off-diagonal component

$C_{xx}$

. The peak magnitude of the off-diagonal component

![]() $C_{xz}$

is comparable to that of the

$C_{xz}$

is comparable to that of the

![]() $C_{zz}$

component (plotted in figure 5

b), although both are only slightly smaller than the peak magnitude of the

$C_{zz}$

component (plotted in figure 5

b), although both are only slightly smaller than the peak magnitude of the

![]() $C_{yy}$

component (shown in figure 5

c). It is worth noting that

$C_{yy}$

component (shown in figure 5

c). It is worth noting that

![]() $\langle C_{xz}/L^{2}\rangle$

is an increasing function of the molecular relaxation time (the variations of which are here computed by changing

$\langle C_{xz}/L^{2}\rangle$

is an increasing function of the molecular relaxation time (the variations of which are here computed by changing

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}$

at fixed

$Wi_{\unicode[STIX]{x1D70F}_{0}}$

at fixed

![]() $Re_{\unicode[STIX]{x1D70F}_{0}}$

) although a saturation effect is observed when increasing the elasticity (the red diamonds and green square curves are close). This saturation effect is also seen for

$Re_{\unicode[STIX]{x1D70F}_{0}}$

) although a saturation effect is observed when increasing the elasticity (the red diamonds and green square curves are close). This saturation effect is also seen for

![]() $C_{zz}$

(figure 5

b) and

$C_{zz}$

(figure 5

b) and

![]() $C_{yy}$

(figure 5

c). The peak magnitude of the normal components

$C_{yy}$

(figure 5

c). The peak magnitude of the normal components

![]() $C_{zz}$

and

$C_{zz}$

and

![]() $C_{yy}$

are both one order of magnitude smaller than that of the

$C_{yy}$

are both one order of magnitude smaller than that of the

![]() $C_{xx}$

component, starting with a zero wall value. Lastly, as

$C_{xx}$

component, starting with a zero wall value. Lastly, as

![]() $Wi_{\unicode[STIX]{x1D70F}_{0}}$

increases,

$Wi_{\unicode[STIX]{x1D70F}_{0}}$

increases,

![]() $C_{zz}$

and

$C_{zz}$

and

![]() $C_{yy}$

increase. The opposite behaviour is observed with increasing

$C_{yy}$

increase. The opposite behaviour is observed with increasing

![]() $L$

. These two normal components exhibit maximum values within region III (

$L$

. These two normal components exhibit maximum values within region III (

![]() $60<z^{+}<90$

), as previously reported by Thais et al. (Reference Thais, Gatski and Mompean2012), which is currently linked to the straining flows around the vortices (Dubief et al.

Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004; Dimitropoulos et al.

Reference Dimitropoulos, Dubief, Shaqfeh, Moin and Lele2005).

$60<z^{+}<90$

), as previously reported by Thais et al. (Reference Thais, Gatski and Mompean2012), which is currently linked to the straining flows around the vortices (Dubief et al.

Reference Dubief, White, Terrapon, Shaqfeh, Moin and Lele2004; Dimitropoulos et al.

Reference Dimitropoulos, Dubief, Shaqfeh, Moin and Lele2005).

In figure 5, it is worth noting that

![]() $C_{xx}\gg C_{yy}>C_{zz}\approx C_{xz}$

indicates a strong anisotropic behaviour of the conformation tensor. This anisotropy seems to dramatically influence the statistics of the fluctuating velocity fields, especially at small scales. The analysis of the trace of the conformation tensor reveals two locations of interest that will be systematically explored in this paper:

$C_{xx}\gg C_{yy}>C_{zz}\approx C_{xz}$

indicates a strong anisotropic behaviour of the conformation tensor. This anisotropy seems to dramatically influence the statistics of the fluctuating velocity fields, especially at small scales. The analysis of the trace of the conformation tensor reveals two locations of interest that will be systematically explored in this paper:

![]() $z^{+}=8.2$

, the approximate position where

$z^{+}=8.2$

, the approximate position where

![]() $\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle$

is a maximum;

$\langle \text{tr}(\unicode[STIX]{x1D63E})/L^{2}\rangle$

is a maximum;

![]() $z^{+}=180$

, where the trace of the conformation tensor reaches its minimum value with respect to

$z^{+}=180$

, where the trace of the conformation tensor reaches its minimum value with respect to

![]() $L^{2}$

.

$L^{2}$

.

4.2 Polymer alignment

Figure 6 shows the average values in the

![]() $x$

–

$x$

–

![]() $y$

plane of the cosines of the angles

$y$

plane of the cosines of the angles

![]() $\unicode[STIX]{x1D6F9}$

between the first principal direction,

$\unicode[STIX]{x1D6F9}$

between the first principal direction,

![]() $e_{1}$

, of our three relevant tensor entities (the eigenvector related to the largest eigenvalue) and the three unit vectors

$e_{1}$

, of our three relevant tensor entities (the eigenvector related to the largest eigenvalue) and the three unit vectors

![]() $e_{x}$

(streamwise; figure 6

a),

$e_{x}$

(streamwise; figure 6

a),

![]() $e_{y}$

(spanwise; figure 6

b) and

$e_{y}$

(spanwise; figure 6

b) and

![]() $e_{z}$

(wall normal; figure 6

c) against the normalized wall distance, for the Newtonian case.

$e_{z}$

(wall normal; figure 6

c) against the normalized wall distance, for the Newtonian case.

The alignment between the first principal direction of the velocity fluctuation product tensor,

![]() $\unicode[STIX]{x1D749}^{\prime }$

(whose components are defined by

$\unicode[STIX]{x1D749}^{\prime }$

(whose components are defined by

![]() $u_{i}^{\prime }u_{j}^{\prime }$

), and

$u_{i}^{\prime }u_{j}^{\prime }$

), and

![]() $e_{x}$

, indicated in figure 6(a) by the blue open triangles, is accentuated near the wall, growing within the buffer layer, where

$e_{x}$

, indicated in figure 6(a) by the blue open triangles, is accentuated near the wall, growing within the buffer layer, where

![]() $\langle \cos \unicode[STIX]{x1D6F9}(e_{1}^{\unicode[STIX]{x1D749}^{\prime }},e_{x})\rangle$

achieves its peak magnitude (

$\langle \cos \unicode[STIX]{x1D6F9}(e_{1}^{\unicode[STIX]{x1D749}^{\prime }},e_{x})\rangle$

achieves its peak magnitude (

![]() ${\approx}0.85$

) at

${\approx}0.85$

) at

![]() $z^{+}\approx 8.2$

. This is consistent with the fact that

$z^{+}\approx 8.2$

. This is consistent with the fact that

![]() $u_{x}^{\prime }u_{x}^{\prime }$

is the most important component of

$u_{x}^{\prime }u_{x}^{\prime }$

is the most important component of

![]() $\unicode[STIX]{x1D749}^{\prime }$

in the near-wall region. However, as the wall distance increases,

$\unicode[STIX]{x1D749}^{\prime }$

in the near-wall region. However, as the wall distance increases,

![]() $u_{y}^{\prime }u_{y}^{\prime }$

,

$u_{y}^{\prime }u_{y}^{\prime }$

,

![]() $u_{z}^{\prime }u_{z}^{\prime }$

and

$u_{z}^{\prime }u_{z}^{\prime }$

and

![]() $u_{x}^{\prime }u_{z}^{\prime }$

become important while

$u_{x}^{\prime }u_{z}^{\prime }$

become important while

![]() $u_{x}^{\prime }u_{x}^{\prime }$

decreases, considerably reducing

$u_{x}^{\prime }u_{x}^{\prime }$

decreases, considerably reducing

![]() $\langle \cos \unicode[STIX]{x1D6F9}(e_{1}^{\unicode[STIX]{x1D749}^{\prime }},e_{x})\rangle$

in the middle of the channel (

$\langle \cos \unicode[STIX]{x1D6F9}(e_{1}^{\unicode[STIX]{x1D749}^{\prime }},e_{x})\rangle$

in the middle of the channel (

![]() ${\approx}$

0.57). A different behaviour is observed by analysing the angles between

${\approx}$

0.57). A different behaviour is observed by analysing the angles between

![]() $e_{1}^{\unicode[STIX]{x1D749}^{\prime }}$

and both the spanwise and wall-normal directions as functions of

$e_{1}^{\unicode[STIX]{x1D749}^{\prime }}$

and both the spanwise and wall-normal directions as functions of

![]() $z^{+}$

, as shown in figures 6(b) and 6(c), respectively. Firstly, at the wall,

$z^{+}$

, as shown in figures 6(b) and 6(c), respectively. Firstly, at the wall,

![]() $\langle \cos \unicode[STIX]{x1D6F9}(e_{1}^{\unicode[STIX]{x1D749}^{\prime }},e_{y})\rangle \approx 0.48$

while

$\langle \cos \unicode[STIX]{x1D6F9}(e_{1}^{\unicode[STIX]{x1D749}^{\prime }},e_{y})\rangle \approx 0.48$

while

![]() $\langle \cos \unicode[STIX]{x1D6F9}(e_{1}^{\unicode[STIX]{x1D749}^{\prime }},e_{z})\rangle =0$

. Although an increase in

$\langle \cos \unicode[STIX]{x1D6F9}(e_{1}^{\unicode[STIX]{x1D749}^{\prime }},e_{z})\rangle =0$

. Although an increase in

![]() $\langle \cos \unicode[STIX]{x1D6F9}(e_{1}^{\unicode[STIX]{x1D749}^{\prime }},e_{z})\rangle$

with

$\langle \cos \unicode[STIX]{x1D6F9}(e_{1}^{\unicode[STIX]{x1D749}^{\prime }},e_{z})\rangle$

with

![]() $z^{+}$

is noted, the buffer layer favours the alignment between

$z^{+}$

is noted, the buffer layer favours the alignment between

![]() $\unicode[STIX]{x1D749}^{\prime }$

and the streamwise direction. Consequently,

$\unicode[STIX]{x1D749}^{\prime }$

and the streamwise direction. Consequently,