1. Introduction

A fully developed Poiseuille flow regime with a pure diffusive miscible interface arises when a more-viscous fluid displaces another miscible fluid with less viscosity in a channel. Such a stable pattern is termed as a ‘pure-Poiseuille-diffusive’ finger (Mishra, De Wit & Sahu Reference Mishra, De Wit and Sahu2012). This stable displacement flow has been studied experimentally by Balasubramaniam et al. (Reference Balasubramaniam, Rashidnia, Maxworthy and Kuang2005), Rashindia, Balasubramanium & Schrder (Reference Rashindia, Balasubramanium and Schrder2004) and Etrati & Frigaard (Reference Etrati and Frigaard2018), in a vertical cylindrical tube. The asymmetric sinuous-shaped unstable interface separating the fluids is found when the flow is in the downward direction. At the same time, at a higher displacement speed, an axisymmetric finger with a needle-shaped spike propagates out from the main fingertip when the flow is against gravity. To the best of our knowledge, these are the only experiments that have discussed the displacement flow in a classically stable system. Numerically, Mishra et al. (Reference Mishra, De Wit and Sahu2012) showed that this classically stable situation could be destabilized when the fluids have different diffusivity and more discussions on such effects are presented in a review article by Govindarajan & Sahu (Reference Govindarajan and Sahu2014).

In the counterpart, i.e. when a less-viscous fluid pushes a more-viscous fluid, if the flow rate is high enough, then a needle-shaped spike at the tip of the finger can be observed, as was done by Lajeunesse et al. (Reference Lajeunesse, Martin, Rakotomalala, Salin and Yortsos1999), in a vertical Hele–Shaw cell. Similarly, when an elongated finger of less-viscous fluid penetrates into a more-viscous one in a channel or pipe, a velocity fluctuation generated by viscosity contrast can develop Kelvin–Helmholtz (K–H) instability type roll-ups (Sahu et al. Reference Sahu, Ding, Valluri and Matar2009a, Govindarajan & Sahu Reference Govindarajan and Sahu2014). Etrati & Frigaard (Reference Etrati and Frigaard2018) performed experiments in a vertical and inclined pipe, and compared the flow features, like averaged concentration profile and front velocities, with the numerical results.

Hence it is believed that in a non-reactive channel/pipe flow, hydrodynamic instability of fingering or K–H-type instability alongside the elongated finger occurs when a bulk of less-viscous fluid displaces a more-viscous fluid (Sahu et al. Reference Sahu, Ding, Valluri and Matar2009a; Etrati & Frigaard Reference Etrati and Frigaard2018). In particular, if the viscosity increases in the direction of propagation globally, then fingering and K–H instability are noticed. Alternatively, even when a bulk of more-viscous fluid displaces a less-viscous one, a local increase of viscosity in the direction of the flow by double-diffusive effects can lead to such instabilities (Mishra et al. Reference Mishra, De Wit and Sahu2012).

The effect of chemical reaction on interfacial instabilities has become a recent attraction for many researchers, as it can lead to alteration of density and viscosity of the fluids. Experimentally, the propagation of the miscible reactive front in the capillary tube (Nagatsu et al. Reference Nagatsu, Hosokawa, Kato, Tada and Ueda2008) and that of the autocatalytic reaction front in laminar flows (Leconte et al. Reference Leconte, Martin, Rakotomalala and Salin2002) have been studied. The difficulty of producing a locally varying viscosity to induce instability is eased by local changes in the molecular structure via a chemical reaction with complex structured fluids (Burghelea et al. Reference Burghelea, Wielage-Burchard, Frigaard, Martinez and Feng2007). Burghelea et al. (Reference Burghelea, Wielage-Burchard, Frigaard, Martinez and Feng2007) conducted three sets of experiments and arrived at the conclusion that the chemical reaction can be treated as a new tool for efficient mixing in microfluidic flows even at low Reynolds number. Also, an experimental investigation was carried out by Burghelea & Frigaard (Reference Burghelea and Frigaard2011), which revealed an instability triggered by a fast chemical reaction in a low-inertia parallel flow in a small channel. They focused on the transverse growth of mixed regions by controlling the initial interface position and the two fluids’ relative inflow. Nevertheless, the dispersion analysis of reactive flows (Reshadi & Saidi Reference Reshadi and Saidi2019; Taghizadeh, Valdés-Parada & Wood Reference Taghizadeh, Valdés-Parada and Wood2020) is an active area of research, which provides building blocks for understanding the complex instabilities in reactive pipe flows.

In the context of viscous fingering (VF) instability, experimentally, it has been shown (Nagatsu et al. Reference Nagatsu, Matsuda, Kato and Tada2007; Riolfo et al. Reference Riolfo, Nagatsu, Iwata, Maes, Trevelyan and De Wit2012) that viscosity depends on the concentration of the solutes, and hence a chemical reaction can alter the viscosity gradient generating fingers at the fluid–fluid interface. They used the pH dependency of the viscous solutions of polymers (aqueous polyacrylic acid (PAA)) that undergo a (![]() $A+B \rightarrow C$)-type reaction, which tunes the changes in the gradient of the mobility profile. In the experiments by Nagatsu et al. (Reference Nagatsu, Matsuda, Kato and Tada2007) and Riolfo et al. (Reference Riolfo, Nagatsu, Iwata, Maes, Trevelyan and De Wit2012), both the displacing and the displaced fluid had different viscosity, while Podgorski et al. (Reference Podgorski, Sostarecz, Zorman and Belmonte2007) used the same viscosity bulk fluids that underwent a chemical reaction of (

$A+B \rightarrow C$)-type reaction, which tunes the changes in the gradient of the mobility profile. In the experiments by Nagatsu et al. (Reference Nagatsu, Matsuda, Kato and Tada2007) and Riolfo et al. (Reference Riolfo, Nagatsu, Iwata, Maes, Trevelyan and De Wit2012), both the displacing and the displaced fluid had different viscosity, while Podgorski et al. (Reference Podgorski, Sostarecz, Zorman and Belmonte2007) used the same viscosity bulk fluids that underwent a chemical reaction of (![]() $A +B \rightarrow C$)-type producing a variety of fingering instabilities. In their experiments, they considered the aqueous solutions of the cationic surfactant cetyltrimethylammonium bromide (CTAB) and the organic salt sodium salicylate (NaSal). It was found that bringing CTAB and NaSal into contact produced a strongly viscoelastic micellar material, which caused a fingering instability at the underlying reactive interface. Subsequently, numerical studies on the reactive VF instability in both rectilinear (Gérard & De Wit Reference Gérard and De Wit2009) and radial (Sharma et al. Reference Sharma, Pramanik, Chen and Mishra2019) displacements in porous media have been performed. In these studies, the authors showed that reaction could induce VF-instability even if the underlying reactive fluids have the same viscosity. A considerable number of experimental studies of fingering instabilities by chemical reaction and numerical analysis in Darcy's regime is presented in a review article by De Wit (Reference De Wit2020). Also, De Wit (Reference De Wit2020) explicitly pointed out the lack of numerical analysis of chemohydrodynamic instabilities to date where Navier–Stokes equations govern the flow. Thus, a collective viewpoint from reactive experimental studies in the pipe flow and lack of numerical analysis of the chemohydrodynamic instabilities in the Navier–Stokes regime motivates the primary objective of this article.

$A +B \rightarrow C$)-type producing a variety of fingering instabilities. In their experiments, they considered the aqueous solutions of the cationic surfactant cetyltrimethylammonium bromide (CTAB) and the organic salt sodium salicylate (NaSal). It was found that bringing CTAB and NaSal into contact produced a strongly viscoelastic micellar material, which caused a fingering instability at the underlying reactive interface. Subsequently, numerical studies on the reactive VF instability in both rectilinear (Gérard & De Wit Reference Gérard and De Wit2009) and radial (Sharma et al. Reference Sharma, Pramanik, Chen and Mishra2019) displacements in porous media have been performed. In these studies, the authors showed that reaction could induce VF-instability even if the underlying reactive fluids have the same viscosity. A considerable number of experimental studies of fingering instabilities by chemical reaction and numerical analysis in Darcy's regime is presented in a review article by De Wit (Reference De Wit2020). Also, De Wit (Reference De Wit2020) explicitly pointed out the lack of numerical analysis of chemohydrodynamic instabilities to date where Navier–Stokes equations govern the flow. Thus, a collective viewpoint from reactive experimental studies in the pipe flow and lack of numerical analysis of the chemohydrodynamic instabilities in the Navier–Stokes regime motivates the primary objective of this article.

Here, we investigate how the reaction destabilizes the pressure-driven channel flow even if the displacement is between two isoviscous fluids. Further, we investigate how the chemical reaction alters the viscosity profile in the channel flow that may cause interfacial instability. We numerically analyse these investigations and successfully explain the mechanism and onset dynamics of the instability. In comparison to the Darcy flow in a Hele–Shaw cell or Stokes flow in a capillary tube, the fundamental difficulty is in solving the coupled convection–diffusion–reaction (CDR) equations for reactant and product species with the Navier–Stokes equation in channel geometry. We have successfully overcome these challenges in numerical modelling by using a finite volume method that uses a fifth-order weighted essentially non-oscillatory (WENO) approximation for convection of solute concentrations. We find K–H-type billows at the fluid–fluid interface, which are formed due to the isothermal chemical reaction between two isoviscous fluids, and discuss the changes in their dynamical properties with respect to various governing flow parameters. An interesting scaling behaviour on the onset of instability is obtained, which shows proportionate dynamics with respect to ![]() $Pe$, and the existence of a critical mobility ratio

$Pe$, and the existence of a critical mobility ratio ![]() $R_c$ for obtaining the interfacial billows is revealed.

$R_c$ for obtaining the interfacial billows is revealed.

2. Mathematical formulation and numerical method

We consider the fluids containing the two reactants ![]() $\textbf {A}$,

$\textbf {A}$, ![]() $\textbf {B}$ and the product

$\textbf {B}$ and the product ![]() $\textbf {C}$ are miscible and Newtonian. We use a rectangular coordinate system

$\textbf {C}$ are miscible and Newtonian. We use a rectangular coordinate system ![]() $(x, y)$ to model the flow dynamics where

$(x, y)$ to model the flow dynamics where ![]() $x$ and

$x$ and ![]() $y$ denote the horizontal and vertical coordinates, respectively. The rigid and impermeable channel walls are located at

$y$ denote the horizontal and vertical coordinates, respectively. The rigid and impermeable channel walls are located at ![]() $y = 0$ and

$y = 0$ and ![]() $y = L_y$, while its inlet and outlet coincide with

$y = L_y$, while its inlet and outlet coincide with ![]() $x = 0$ and

$x = 0$ and ![]() $x = L_x$, respectively (figure 1). A solution of reactant

$x = L_x$, respectively (figure 1). A solution of reactant ![]() $\textbf {A}$ with viscosity

$\textbf {A}$ with viscosity ![]() $\mu =\mu _{1}$ is injected at the channel inlet, along the

$\mu =\mu _{1}$ is injected at the channel inlet, along the ![]() $x$ direction, into a solution of reactant

$x$ direction, into a solution of reactant ![]() $\textbf {B}$ having the same viscosity

$\textbf {B}$ having the same viscosity ![]() $\mu _{1}$ with average velocity

$\mu _{1}$ with average velocity ![]() $Q/L_y$, where

$Q/L_y$, where ![]() $Q$ denotes the total flow rate. Both reactants

$Q$ denotes the total flow rate. Both reactants ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$ are initially present in the same initial concentration

$\textbf {B}$ are initially present in the same initial concentration ![]() $\varPhi _0$. A second-order chemical reaction

$\varPhi _0$. A second-order chemical reaction ![]() $\textbf {A}+ \textbf {B} \xrightarrow {k} \textbf {C}$ takes place as soon as

$\textbf {A}+ \textbf {B} \xrightarrow {k} \textbf {C}$ takes place as soon as ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$ are put in contact to yield a high-viscosity product

$\textbf {B}$ are put in contact to yield a high-viscosity product ![]() $\textbf {C}$ with viscosity

$\textbf {C}$ with viscosity ![]() $\mu _{2}$ (

$\mu _{2}$ (![]() $\mu _{2}> \mu _{1}$). The flow dynamics is governed by incompressible Navier–Stokes equations:

$\mu _{2}> \mu _{1}$). The flow dynamics is governed by incompressible Navier–Stokes equations:

where ![]() $\boldsymbol {u} = (u, v)$ is the velocity vector with components

$\boldsymbol {u} = (u, v)$ is the velocity vector with components ![]() $u$ and

$u$ and ![]() $v$ in the

$v$ in the ![]() $x$ and

$x$ and ![]() $y$ directions, respectively, and

$y$ directions, respectively, and ![]() $p$ denotes pressure,

$p$ denotes pressure, ![]() $a,b,c$ denote the concentration of the two reactants

$a,b,c$ denote the concentration of the two reactants ![]() $(\textbf {A},\textbf {B})$ and the product

$(\textbf {A},\textbf {B})$ and the product ![]() $\textbf {C}$, respectively, and they satisfy the following system of CDR equations:

$\textbf {C}$, respectively, and they satisfy the following system of CDR equations:

Figure 1. Schematic of the initial configuration.

We assume the same diffusion coefficient ![]() $D$ of all the species

$D$ of all the species ![]() $\textbf {A},\textbf {B}$ and

$\textbf {A},\textbf {B}$ and ![]() $\textbf {C}$. Further it is assumed that the viscosity of the fluid varies exponentially with the product concentration as

$\textbf {C}$. Further it is assumed that the viscosity of the fluid varies exponentially with the product concentration as ![]() $\mu (c)=\mu _1 \,\textrm {e}^{ R_{c} c/\varPhi _0}$, where

$\mu (c)=\mu _1 \,\textrm {e}^{ R_{c} c/\varPhi _0}$, where ![]() $R_c = \ln (\mu _{2}/\mu _{1})$.

$R_c = \ln (\mu _{2}/\mu _{1})$.

2.1. Non-dimensionalization

We non-dimensionalize the equations using the characteristic length, time, velocity, pressure, viscosity and concentration as

where the tildes designate dimensionless quantities. After dropping tildes, the dimensionless governing equations become

The four dimensionless numbers arising in (2.5b–f) are

Here, Reynolds number ![]() $Re$ indicates the relative strength of convective to viscous force. As a direct consequence of the scaling, Péclet number

$Re$ indicates the relative strength of convective to viscous force. As a direct consequence of the scaling, Péclet number ![]() $Pe$ appears here in the system, which measures the relative importance of the advection to the solute diffusion. The Damköhler number

$Pe$ appears here in the system, which measures the relative importance of the advection to the solute diffusion. The Damköhler number ![]() $Da$ represents the ratio between advective time

$Da$ represents the ratio between advective time ![]() ${L_{y}^{2}}/{Q}$ and the reaction time

${L_{y}^{2}}/{Q}$ and the reaction time ![]() ${1}/{k \varPhi _{0}}$, which implies that the formation of the product is faster for a higher value of

${1}/{k \varPhi _{0}}$, which implies that the formation of the product is faster for a higher value of ![]() $Da$. The log-mobility ratio is demonstrated by

$Da$. The log-mobility ratio is demonstrated by ![]() $R_{c}$. The following initial and boundary conditions are employed for the non-dimensional model system (2.5a–f):

$R_{c}$. The following initial and boundary conditions are employed for the non-dimensional model system (2.5a–f):

Initial conditions,

\[ (a, b, c, u, v) |_{t=0}=\left\{\begin{array}{@{}ll} (1, 0, 0, 6y(1-y), 0) & \text{at } x=0, \ 0\le y \le 1 \\ (0, 1, 0, 0, 0) & 0< x\le L_{x}, \ 0\le y \le 1. \end{array}\right. \]

\[ (a, b, c, u, v) |_{t=0}=\left\{\begin{array}{@{}ll} (1, 0, 0, 6y(1-y), 0) & \text{at } x=0, \ 0\le y \le 1 \\ (0, 1, 0, 0, 0) & 0< x\le L_{x}, \ 0\le y \le 1. \end{array}\right. \]

Boundary conditions,

Solutes ![]() $a$,

$a$, ![]() $b$ and

$b$ and ![]() $c$ satisfy no-flux conditions at the top and bottom walls, i.e.

$c$ satisfy no-flux conditions at the top and bottom walls, i.e.

No-slip and no-penetration conditions are employed at the top and bottom walls, i.e.

A fully developed velocity profile with a unity flow rate is imposed at the inlet (Sahu et al. Reference Sahu, Ding, Valluri and Matar2009a) i.e.

The solute concentrations, ![]() $(a, b, c)=(1, 0, 0) \text { at } x=0$ (as

$(a, b, c)=(1, 0, 0) \text { at } x=0$ (as ![]() $a$ is continuously injected at the channel inlet). Neumann boundary conditions are used at the outlet, i.e.,

$a$ is continuously injected at the channel inlet). Neumann boundary conditions are used at the outlet, i.e.,

2.2. Numerical method and validations

The numerical method is employed with a collocated discretization strategy such that the pressure and solute concentrations are stored at cell centres, and the fluxes are evaluated on the cell faces where the velocity components are defined. A diffuse interface numerical scheme with such a strategy has initially been reported by Ding, Spelt & Shu (Reference Ding, Spelt and Shu2007) and used by Sahu et al. (Reference Sahu, Ding, Valluri and Matar2009a) to simulate pressure-driven neutrally buoyant miscible non-reactive channel flow with high viscosity contrast. In the reactive counterpart, we implement numerical approximations for the CDR equations (2.5c–e) in the following way:

\begin{align} \frac{\frac{3}{2}a^{n+1}-2a^{n}+\frac{1}{2}a^{n-1}}{\Delta t}&= \frac{1}{Pe}\nabla^{2}a^{n+1}-2\boldsymbol{\nabla}(\boldsymbol{u}^{n} \cdot a^{n})+ \boldsymbol{\nabla}(\boldsymbol{u}^{n-1} \cdot a^{n-1})\nonumber\\ &\quad -Da(2a^{n}b^{n}-a^{n-1}b^{n-1}), \end{align}

\begin{align} \frac{\frac{3}{2}a^{n+1}-2a^{n}+\frac{1}{2}a^{n-1}}{\Delta t}&= \frac{1}{Pe}\nabla^{2}a^{n+1}-2\boldsymbol{\nabla}(\boldsymbol{u}^{n} \cdot a^{n})+ \boldsymbol{\nabla}(\boldsymbol{u}^{n-1} \cdot a^{n-1})\nonumber\\ &\quad -Da(2a^{n}b^{n}-a^{n-1}b^{n-1}), \end{align} \begin{align} \frac{\frac{3}{2}b^{n+1}-2b^{n}+\frac{1}{2}b^{n-1}}{\Delta t}&= \frac{1}{Pe}\nabla^{2}b^{n+1}-2\boldsymbol{\nabla}(\boldsymbol{u}^{n} \cdot b^{n})+ \boldsymbol{\nabla}(\boldsymbol{u}^{n-1} \cdot b^{n-1})\nonumber\\ &\quad-Da(2a^{n}b^{n}-a^{n-1}b^{n-1}), \end{align}

\begin{align} \frac{\frac{3}{2}b^{n+1}-2b^{n}+\frac{1}{2}b^{n-1}}{\Delta t}&= \frac{1}{Pe}\nabla^{2}b^{n+1}-2\boldsymbol{\nabla}(\boldsymbol{u}^{n} \cdot b^{n})+ \boldsymbol{\nabla}(\boldsymbol{u}^{n-1} \cdot b^{n-1})\nonumber\\ &\quad-Da(2a^{n}b^{n}-a^{n-1}b^{n-1}), \end{align} \begin{align} \frac{\frac{3}{2}c^{n+1}-2c^{n}+\frac{1}{2}c^{n-1}}{\Delta t}&= \frac{1}{Pe}\nabla^{2}c^{n+1}-2\boldsymbol{\nabla}(\boldsymbol{u}^{n} \cdot c^{n})+ \boldsymbol{\nabla}(\boldsymbol{u}^{n-1} \cdot c^{n-1})\nonumber\\ &\quad+Da(2a^{n}b^{n}-a^{n-1}b^{n-1}), \end{align}

\begin{align} \frac{\frac{3}{2}c^{n+1}-2c^{n}+\frac{1}{2}c^{n-1}}{\Delta t}&= \frac{1}{Pe}\nabla^{2}c^{n+1}-2\boldsymbol{\nabla}(\boldsymbol{u}^{n} \cdot c^{n})+ \boldsymbol{\nabla}(\boldsymbol{u}^{n-1} \cdot c^{n-1})\nonumber\\ &\quad+Da(2a^{n}b^{n}-a^{n-1}b^{n-1}), \end{align}

where ![]() $\Delta t =t^{n+1}-t^{n}$, and superscript

$\Delta t =t^{n+1}-t^{n}$, and superscript ![]() $n$ stands for the discretization at the

$n$ stands for the discretization at the ![]() $n$th time step. A fifth-order WENO approximation is performed to handle the nonlinear convective terms in (2.7a–c), while the usual second-order central difference formula is used for the diffusive terms.

$n$th time step. A fifth-order WENO approximation is performed to handle the nonlinear convective terms in (2.7a–c), while the usual second-order central difference formula is used for the diffusive terms.

The equation (2.5b) is approximated using Adams–Bashforth and Crank–Nicolson methods for the convective and the dissipative term, which is given by

where ![]() $\boldsymbol {u}^{*}$ is the intermediate velocity. Here

$\boldsymbol {u}^{*}$ is the intermediate velocity. Here ![]() $\mathscr {C}$ and

$\mathscr {C}$ and ![]() $\mathscr {D}$ denote the discrete convection and diffusion operators, respectively. The intermediate velocity is corrected to the

$\mathscr {D}$ denote the discrete convection and diffusion operators, respectively. The intermediate velocity is corrected to the ![]() $(n+1)$th level by

$(n+1)$th level by

Since velocity field at the ![]() $(n+1)$th time step is divergence free, the pressure at the intermediate level is obtained using

$(n+1)$th time step is divergence free, the pressure at the intermediate level is obtained using

The following order from the ![]() $n$th to

$n$th to ![]() $(n+1)$th time step is maintained in the implementation of the numerical algorithm to solve (2.5a–f): the solute concentration at the

$(n+1)$th time step is maintained in the implementation of the numerical algorithm to solve (2.5a–f): the solute concentration at the ![]() $(n+1)$th time step is first obtained, by using the velocity fields at the

$(n+1)$th time step is first obtained, by using the velocity fields at the ![]() $n$th and

$n$th and ![]() $(n-1)$th time step in CDR equations (2.5c–e). Then the velocity fields are updated to the

$(n-1)$th time step in CDR equations (2.5c–e). Then the velocity fields are updated to the ![]() $(n+1)$th time step by solving the equation (2.5b) together with the continuity equation.

$(n+1)$th time step by solving the equation (2.5b) together with the continuity equation.

As schemes in (2.7a–c) are implicit–explicit type, a Gauss–Jacobi iterative solver is used to solve the fully discretized system ![]() $Ax=b$, and it is iterated until the convergence criteria of the numerical scheme is reached, i.e. when

$Ax=b$, and it is iterated until the convergence criteria of the numerical scheme is reached, i.e. when ![]() ${\|x_{n+1}-x_{n}\|}/{\|x_{n}\|}$ becomes less than

${\|x_{n+1}-x_{n}\|}/{\|x_{n}\|}$ becomes less than ![]() $10^{-10}$, where

$10^{-10}$, where ![]() $\|\cdot \|$ represents the max norm. The successive over-relaxation iterative method is implemented to solve the fully discretized version of (2.8) with relaxation parameter

$\|\cdot \|$ represents the max norm. The successive over-relaxation iterative method is implemented to solve the fully discretized version of (2.8) with relaxation parameter ![]() $\omega =0.2$, and the iterations are stopped when the max norm of residuals become less than

$\omega =0.2$, and the iterations are stopped when the max norm of residuals become less than ![]() $10^{-5}$.

$10^{-5}$.

To check the flow dynamics preserving property of the numerical scheme, in figure 2, we plot the mass of the dimensionless concentration of the product ![]() $\textbf {C}$ against time with respect to various grid sizes. Here,

$\textbf {C}$ against time with respect to various grid sizes. Here, ![]() $M_{c>0.01}$ represents the total mass of the product where the volume integration is applied using the concentrations of product

$M_{c>0.01}$ represents the total mass of the product where the volume integration is applied using the concentrations of product ![]() $c>0.01$. The parameter values chosen are

$c>0.01$. The parameter values chosen are ![]() $Da=10$,

$Da=10$, ![]() $Re=1000$,

$Re=1000$, ![]() $Pe=1 \times 10^{4}$,

$Pe=1 \times 10^{4}$, ![]() $R_{c}=3$, in order to carry out the reactive simulation. The results are obtained using a channel with a 1 : 40 aspect ratio. It is clear from figure 2 that the amount of product

$R_{c}=3$, in order to carry out the reactive simulation. The results are obtained using a channel with a 1 : 40 aspect ratio. It is clear from figure 2 that the amount of product ![]() $\textbf {C}$ formed does not differ much (maximum absolute error less than

$\textbf {C}$ formed does not differ much (maximum absolute error less than ![]() $0.02\,\%$) when the number of cells ranges from 41 to 101 and 1001 to 1751 in the

$0.02\,\%$) when the number of cells ranges from 41 to 101 and 1001 to 1751 in the ![]() $y$ and

$y$ and ![]() $x$ direction, respectively. Further, we check the temporal variation of the two interfaces

$x$ direction, respectively. Further, we check the temporal variation of the two interfaces ![]() $\textbf {A}$–

$\textbf {A}$–![]() $\textbf {C}$ and

$\textbf {C}$ and ![]() $\textbf {C}$–

$\textbf {C}$–![]() $\textbf {B}$ at the centre of the channel (with respect to the transverse direction) with the same parameters as in figure 3, by taking different mesh sizes. Here

$\textbf {B}$ at the centre of the channel (with respect to the transverse direction) with the same parameters as in figure 3, by taking different mesh sizes. Here ![]() $(x_{tip})_{\textbf {AC}}$,

$(x_{tip})_{\textbf {AC}}$, ![]() $(x_{tip})_{\textbf {CB}}$ represent the spatial location of the leading front of the two interfaces

$(x_{tip})_{\textbf {CB}}$ represent the spatial location of the leading front of the two interfaces ![]() $\textbf {A}$–

$\textbf {A}$–![]() $\textbf {C}$ and

$\textbf {C}$ and ![]() $\textbf {C}$–

$\textbf {C}$–![]() $\textbf {B}$ in figures 3(a) and 3(b), respectively. The plots are indistinguishable in figure 3(a,b), which reveals the convergence of the numerical scheme. The interfacial dynamics can be studied by measuring the speed of the fingertip at position

$\textbf {B}$ in figures 3(a) and 3(b), respectively. The plots are indistinguishable in figure 3(a,b), which reveals the convergence of the numerical scheme. The interfacial dynamics can be studied by measuring the speed of the fingertip at position ![]() $(x_{tip})_{\textbf {AC}}$,

$(x_{tip})_{\textbf {AC}}$, ![]() $(x_{tip})_{\textbf {CB}}$. As

$(x_{tip})_{\textbf {CB}}$. As ![]() $(x_{tip})_{\textbf {AC}}$,

$(x_{tip})_{\textbf {AC}}$, ![]() $(x_{tip})_{\textbf {CB}}$ both vary almost linearly with time, the two leading fronts can be seen to propagate with constant velocity. Similar linear evolution of the interface tip is found by Mishra et al. (Reference Mishra, De Wit and Sahu2012), where the underlying solutes have different diffusivity, and by Sahu et al. (Reference Sahu, Ding, Valluri and Matar2009a, Reference Sahu, Ding, Valluri and Matarb), where a less-viscous fluid pushes a more-viscous fluid. Afterwards, all the numerical results presented in this paper are obtained using an

$(x_{tip})_{\textbf {CB}}$ both vary almost linearly with time, the two leading fronts can be seen to propagate with constant velocity. Similar linear evolution of the interface tip is found by Mishra et al. (Reference Mishra, De Wit and Sahu2012), where the underlying solutes have different diffusivity, and by Sahu et al. (Reference Sahu, Ding, Valluri and Matar2009a, Reference Sahu, Ding, Valluri and Matarb), where a less-viscous fluid pushes a more-viscous fluid. Afterwards, all the numerical results presented in this paper are obtained using an ![]() $81 \times 1401$ mess for a channel of 1 : 40 aspect ratio.

$81 \times 1401$ mess for a channel of 1 : 40 aspect ratio.

Figure 2. Temporal evolution of the mass of formed ![]() $\textbf {C}$ for different grid sizes, when

$\textbf {C}$ for different grid sizes, when ![]() $Da=10$,

$Da=10$, ![]() $Re=1000$,

$Re=1000$, ![]() $Pe=10\,000$,

$Pe=10\,000$, ![]() $R_{c}=3$.

$R_{c}=3$.

Figure 3. Temporal evolution of separating leading front (a) at the ![]() $\textbf {A}$–

$\textbf {A}$–![]() $\textbf {C}$ interface i.e.

$\textbf {C}$ interface i.e. ![]() $(x_{tip})_{\textbf {AC}}$ and (b) at the

$(x_{tip})_{\textbf {AC}}$ and (b) at the ![]() $\textbf {C}$–

$\textbf {C}$–![]() $\textbf {B}$ interface i.e.

$\textbf {B}$ interface i.e. ![]() $(x_{tip})_{\textbf {CB}}$, with

$(x_{tip})_{\textbf {CB}}$, with ![]() $Da=10$,

$Da=10$, ![]() $Re=1000$,

$Re=1000$, ![]() $Pe=10\,000$,

$Pe=10\,000$, ![]() $R_{c}=3$.

$R_{c}=3$.

3. Results and discussion

In the absence of a reaction, when a fluid ![]() $\textbf {A}$ pushes an isoviscous fluid

$\textbf {A}$ pushes an isoviscous fluid ![]() $\textbf {B}$, the flow results in a pure dispersive interface and that grows as a Poiseuille flow like pattern, as mentioned in § 1. In a reactive system, when the reactant

$\textbf {B}$, the flow results in a pure dispersive interface and that grows as a Poiseuille flow like pattern, as mentioned in § 1. In a reactive system, when the reactant ![]() $\textbf {A}$ meets the reactant

$\textbf {A}$ meets the reactant ![]() $\textbf {B}$, the product

$\textbf {B}$, the product ![]() $\textbf {C}$ is formed and its viscosity can be the same or different from that of the reactants. For

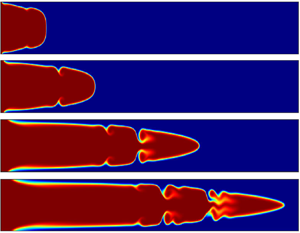

$\textbf {C}$ is formed and its viscosity can be the same or different from that of the reactants. For ![]() $R_{c}=0$ (figure 4a), i.e. when the viscosity of the product

$R_{c}=0$ (figure 4a), i.e. when the viscosity of the product ![]() $\textbf {C}$ is equal to that of the reactants

$\textbf {C}$ is equal to that of the reactants ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$, the interface temporally evolves in a stable form. It shows that the product is first formed at the miscible interface between the reactants, and then diffuses with time without distorting the pure dispersive parabolic profile (see supplementary movie 1 available at https://doi.org/10.1017/jfm.2021.630). It is seen that when the flow starts inside the channel, the velocity field suddenly changes the product concentration distribution in the interior of the cell, while the product concentration at the wall changes due to diffusion only, similar to the observed phenomena between the two miscible fluid cases studied by Goyal & Meiburg (Reference Goyal and Meiburg2006). In figure 4(b), we show the corresponding time evolution of the concentration field of reactant

$\textbf {B}$, the interface temporally evolves in a stable form. It shows that the product is first formed at the miscible interface between the reactants, and then diffuses with time without distorting the pure dispersive parabolic profile (see supplementary movie 1 available at https://doi.org/10.1017/jfm.2021.630). It is seen that when the flow starts inside the channel, the velocity field suddenly changes the product concentration distribution in the interior of the cell, while the product concentration at the wall changes due to diffusion only, similar to the observed phenomena between the two miscible fluid cases studied by Goyal & Meiburg (Reference Goyal and Meiburg2006). In figure 4(b), we show the corresponding time evolution of the concentration field of reactant ![]() $\textbf {A}$. However, if the reaction generates a more-viscous product than the reactants (i.e for

$\textbf {A}$. However, if the reaction generates a more-viscous product than the reactants (i.e for ![]() $R_{c}=5$), we observe the formation of K–H rolling type instability in figure 4(c) (corresponding evolution of reactant

$R_{c}=5$), we observe the formation of K–H rolling type instability in figure 4(c) (corresponding evolution of reactant ![]() $\textbf {A}$ is shown in figure 4d). So the question arises, how does a chemical reaction induce such instability in the flow? To understand the mechanism of the instability, we investigate the spatio-temporal evolution of a transversely averaged viscosity profile

$\textbf {A}$ is shown in figure 4d). So the question arises, how does a chemical reaction induce such instability in the flow? To understand the mechanism of the instability, we investigate the spatio-temporal evolution of a transversely averaged viscosity profile ![]() $\bar {\mu }_y(x,t)=\int _0^{L_{y}} \mu (x,y,t)\, \textrm {d} y$ in figure 5. The observed non-monotonic viscosity profiles at different times in figure 5 are mainly responsible for the instability. Such non-monotonic profiles are seen due to the formation of the higher viscosity product than the reactants (see the density plots of product concentration

$\bar {\mu }_y(x,t)=\int _0^{L_{y}} \mu (x,y,t)\, \textrm {d} y$ in figure 5. The observed non-monotonic viscosity profiles at different times in figure 5 are mainly responsible for the instability. Such non-monotonic profiles are seen due to the formation of the higher viscosity product than the reactants (see the density plots of product concentration ![]() $c$ in figure 4c). At the

$c$ in figure 4c). At the ![]() $\textbf {A}$–

$\textbf {A}$–![]() $\textbf {C}$ interface, in the flow direction, a local increase in viscosity occurs (i.e. the viscosity gradient is from less to high), and for a favourable velocity gradient (at some positions away from both the wall and the channel centreline), such billows of K–H-type develop due to the coupling effect of shear and oscillations in the viscosity profile. Whereas at the

$\textbf {C}$ interface, in the flow direction, a local increase in viscosity occurs (i.e. the viscosity gradient is from less to high), and for a favourable velocity gradient (at some positions away from both the wall and the channel centreline), such billows of K–H-type develop due to the coupling effect of shear and oscillations in the viscosity profile. Whereas at the ![]() $\textbf {C}$–

$\textbf {C}$–![]() $\textbf {B}$ interface, the viscosity gradient is from high to less, which opposes the growth of such roll-ups.

$\textbf {B}$ interface, the viscosity gradient is from high to less, which opposes the growth of such roll-ups.

Figure 4. Spatio-temporal evolution of concentration of the product ![]() $\textbf {C}$ at successive times for (a)

$\textbf {C}$ at successive times for (a) ![]() $R_{c}=0$, (b) corresponding concentration evolution of reactant

$R_{c}=0$, (b) corresponding concentration evolution of reactant ![]() $\textbf {A}$, (c)

$\textbf {A}$, (c) ![]() $R_{c}=5$, (d) corresponding concentration evolution of reactant

$R_{c}=5$, (d) corresponding concentration evolution of reactant ![]() $\textbf {A}$. The other parameter values are

$\textbf {A}$. The other parameter values are ![]() $Da=50$,

$Da=50$, ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$.

$Pe=10\,000$.

Figure 5. Evolution of transversely averaged viscosity profile ![]() $\bar {\mu }_{y}(x)$ in a space–time domain with

$\bar {\mu }_{y}(x)$ in a space–time domain with ![]() $R_{c}=5$,

$R_{c}=5$, ![]() $Da=50$,

$Da=50$, ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$. (Inset: the positions of the K–H billows are shown in the density plots of product concentration at

$Pe=10\,000$. (Inset: the positions of the K–H billows are shown in the density plots of product concentration at ![]() $t=28$ by comparing the corresponding local maximums of

$t=28$ by comparing the corresponding local maximums of ![]() $\bar {\mu }_{y}(x)$.)

$\bar {\mu }_{y}(x)$.)

The initial increment near to the inlet (at the wall) and the spike near to the tip (at the channel centreline) in the averaged viscosity profiles of figure 5 do not contribute to the K–H-instability. This is because they fall either in the zone near the wall where the axial velocity is very low or in a very high-velocity zone near the centreline. The unfavourable ![]() $y$-gradient of the axial velocity component

$y$-gradient of the axial velocity component ![]() $u$ hinders the occurrence of K–H billows at these positions even though there is a viscosity stratification at the fluid–fluid interface. Furthermore, before and at time

$u$ hinders the occurrence of K–H billows at these positions even though there is a viscosity stratification at the fluid–fluid interface. Furthermore, before and at time ![]() $t=5$, there is one local maximum between the positions of the inlet and tip (see figure 5), and this maximum attains a higher value at time

$t=5$, there is one local maximum between the positions of the inlet and tip (see figure 5), and this maximum attains a higher value at time ![]() $t=10$. Again at

$t=10$. Again at ![]() $t=10$, two more local maxima with relatively small amplitude are generated. Oscillations in the neighbourhood of these local maxima further amplify at subsequent times. These local maxima give the exact locations for where the corresponding K–H-type billows occur in figure 4(c) at the respective times. Such spatial positions of K–H-type billows in the corresponding density plot at

$t=10$, two more local maxima with relatively small amplitude are generated. Oscillations in the neighbourhood of these local maxima further amplify at subsequent times. These local maxima give the exact locations for where the corresponding K–H-type billows occur in figure 4(c) at the respective times. Such spatial positions of K–H-type billows in the corresponding density plot at ![]() $t=28$ are compared with the spatial positions of local maxima of

$t=28$ are compared with the spatial positions of local maxima of ![]() $\bar {\mu }_y$ in figure 5. Hence it is evident that viscosity jumps with intermediate shear gradient produce velocity fluctuation, which leads to the formation of such roll-ups.

$\bar {\mu }_y$ in figure 5. Hence it is evident that viscosity jumps with intermediate shear gradient produce velocity fluctuation, which leads to the formation of such roll-ups.

3.1. Reaction rate dynamics on the instability

To provide more insight into the moving reactive zone, we compute the reaction rate defined by Gérard & De Wit (Reference Gérard and De Wit2009) as

Figure 6 depicts the comparison of the spatio-temporal evolution of reaction rate ![]() $\mathcal {R}(x,y,t)$ with the product concentration

$\mathcal {R}(x,y,t)$ with the product concentration ![]() $c$ by superimposing a representative concentration contour of

$c$ by superimposing a representative concentration contour of ![]() $c=0.05$ on the density plot of

$c=0.05$ on the density plot of ![]() $\mathcal {R}(x,y,t)$ for

$\mathcal {R}(x,y,t)$ for ![]() $R_c=5$ with

$R_c=5$ with ![]() $Da=50$,

$Da=50$, ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$. Interestingly, the reaction rate distribution remains very localized near the interface, despite the billows of product

$Pe=10\,000$. Interestingly, the reaction rate distribution remains very localized near the interface, despite the billows of product ![]() $\textbf {C}$ (see contours in figure 6) spiralling more towards the centreline of the channel due to the interplay of convection, diffusion and reaction. It is apparent from the spatial distribution of the reaction rate that, in the region where more product is formed,

$\textbf {C}$ (see contours in figure 6) spiralling more towards the centreline of the channel due to the interplay of convection, diffusion and reaction. It is apparent from the spatial distribution of the reaction rate that, in the region where more product is formed, ![]() $\mathcal {R}(x,y,t)$ is decreased, which reveals the fact that a higher product concentration

$\mathcal {R}(x,y,t)$ is decreased, which reveals the fact that a higher product concentration ![]() $c$ can act as a barrier for the reaction to happen. Moreover, it is noticed from the contour plots in figure 6, the roll-ups start colliding at the

$c$ can act as a barrier for the reaction to happen. Moreover, it is noticed from the contour plots in figure 6, the roll-ups start colliding at the ![]() $\textbf {A}$–

$\textbf {A}$–![]() $\textbf {C}$ interface just right of the unstable billow of K–H-type and the product

$\textbf {C}$ interface just right of the unstable billow of K–H-type and the product ![]() $\textbf {C}$ traps the reactant

$\textbf {C}$ traps the reactant ![]() $\textbf {A}$ (clearly visible in the supplementary movie 3). Further, diffusion dominates, which results in the reduction of the trapped area with time, and the reaction rate

$\textbf {A}$ (clearly visible in the supplementary movie 3). Further, diffusion dominates, which results in the reduction of the trapped area with time, and the reaction rate ![]() $\mathcal {R}$ becomes negligible in that zone.

$\mathcal {R}$ becomes negligible in that zone.

Figure 6. Temporal evolution of reaction rate ![]() $\mathcal {R}$ (density plots) superimposed with a concentration contour of

$\mathcal {R}$ (density plots) superimposed with a concentration contour of ![]() $c=0.05$ for

$c=0.05$ for ![]() $R_{c}=5$,

$R_{c}=5$, ![]() $Da=50$,

$Da=50$, ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$.

$Pe=10\,000$.

3.2. Effects of the log-mobility ratio  $R_c$

$R_c$

To understand more about the influence of the log-mobility ratio on the instability, we plot the viscosity fields at a fixed time ![]() $t=22$ for different

$t=22$ for different ![]() $R_{c}$ values in figure 7(a) with the rest of the parameters the same as in figure 2. It is observed that even for

$R_{c}$ values in figure 7(a) with the rest of the parameters the same as in figure 2. It is observed that even for ![]() $R_{c}=1$, the viscosity of the product is more than 1, no roll-ups occur (see the supplementary movie 2); however in the latter two cases, i.e. for

$R_{c}=1$, the viscosity of the product is more than 1, no roll-ups occur (see the supplementary movie 2); however in the latter two cases, i.e. for ![]() $R_{c}=3$ and

$R_{c}=3$ and ![]() $5$, two roll-ups are formed, and the axial gap between them is increased with increasing log-mobility ratio. Such instability patterns are clearly visible in the density plot of the respective concentration field

$5$, two roll-ups are formed, and the axial gap between them is increased with increasing log-mobility ratio. Such instability patterns are clearly visible in the density plot of the respective concentration field ![]() $a(x,y,t)$ of the reactant

$a(x,y,t)$ of the reactant ![]() $\textbf {A}$ (see figure 7c). In order to see the effects of such

$\textbf {A}$ (see figure 7c). In order to see the effects of such ![]() $R_c$ on the formation of the roll-up, the corresponding transversely averaged viscosity profiles

$R_c$ on the formation of the roll-up, the corresponding transversely averaged viscosity profiles ![]() $\bar {\mu }_{y}(x)$ at time

$\bar {\mu }_{y}(x)$ at time ![]() $t=22$ for different values of

$t=22$ for different values of ![]() $R_c$ are shown in figure 7(b). It shows that for

$R_c$ are shown in figure 7(b). It shows that for ![]() $R_c=1$, the spatially varying viscosity distributions reached a plateau; however for

$R_c=1$, the spatially varying viscosity distributions reached a plateau; however for ![]() $R_c=3, 5$, the viscosity distributions oscillate with several local optimum values away from the inlet and the tip, which is the primary reason for the K–H instability in the flow. The increase in the amplitude of these oscillations with a rising log-mobility ratio (in figure 7b) explains the growing deformation of the interface. Note that the local optima of

$R_c=3, 5$, the viscosity distributions oscillate with several local optimum values away from the inlet and the tip, which is the primary reason for the K–H instability in the flow. The increase in the amplitude of these oscillations with a rising log-mobility ratio (in figure 7b) explains the growing deformation of the interface. Note that the local optima of ![]() $\bar {\mu }_{y}(x)$ just right of the inlet and at the tip (near to channel centreline) attain higher values with increasing

$\bar {\mu }_{y}(x)$ just right of the inlet and at the tip (near to channel centreline) attain higher values with increasing ![]() $R_{c}$. This is only a consequence of the fact that the presence of

$R_{c}$. This is only a consequence of the fact that the presence of ![]() $\textbf {C}$ is slightly more across the

$\textbf {C}$ is slightly more across the ![]() $y$-axis than the neighbouring axial positions, and the average is taken over the

$y$-axis than the neighbouring axial positions, and the average is taken over the ![]() $y$-domain. Hence, near the inlet and the tip, because of the Arrhenius relation between the viscosity and concentration

$y$-domain. Hence, near the inlet and the tip, because of the Arrhenius relation between the viscosity and concentration ![]() $c$, the local optimum values increase with the increase in

$c$, the local optimum values increase with the increase in ![]() $R_{c}$. However, as previously discussed, the unfavourable

$R_{c}$. However, as previously discussed, the unfavourable ![]() $y$-gradient of the axial velocity component

$y$-gradient of the axial velocity component ![]() $u$ is responsible for the non-occurrence of K–H billows at these positions.

$u$ is responsible for the non-occurrence of K–H billows at these positions.

Figure 7. (a) Density plot of viscosity ![]() $\mu (x,y,t)$, (b) corresponding transversely averaged viscosity profile

$\mu (x,y,t)$, (b) corresponding transversely averaged viscosity profile ![]() $\bar {\mu }_{y}(x)$, (c) density plot of concentration

$\bar {\mu }_{y}(x)$, (c) density plot of concentration ![]() $a(x,y,t)$ of the reactant

$a(x,y,t)$ of the reactant ![]() $\textbf {A}$ for different values of

$\textbf {A}$ for different values of ![]() $R_{c}$ at time

$R_{c}$ at time ![]() $t=22$ with

$t=22$ with ![]() $Da=50$,

$Da=50$, ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$.

$Pe=10\,000$.

Unlike the averaged viscosity profiles seen in the case study of double-diffusive effects (Mishra et al. Reference Mishra, De Wit and Sahu2012), here as the viscosity is related to the product ![]() $\textbf {C}$ only by an Arrhenius relation, it takes the constant value of one wherever the fluid

$\textbf {C}$ only by an Arrhenius relation, it takes the constant value of one wherever the fluid ![]() $\textbf {C}$ is absent. In figure 6(b,c) of the paper by Mishra et al. (Reference Mishra, De Wit and Sahu2012), the averaged viscosity profile varies between two positive constants (because the flow is between two non-isoviscous bulk fluids), and instability is generated due to local increase of viscosity in the flow direction. While here, the local oscillations in the viscosity occur due to the high-viscosity product of the reaction. A spike/cap-like tip due to double diffusive effects (Mishra et al. Reference Mishra, De Wit and Sahu2012) or distortion of a mushroom-like tip (Sahu et al. Reference Sahu, Ding, Valluri and Matar2009a) occurs as the result of displacement between two non-isoviscous bulk fluids. However, here, since the displacement is between two reactant bulk fluids

$\textbf {C}$ is absent. In figure 6(b,c) of the paper by Mishra et al. (Reference Mishra, De Wit and Sahu2012), the averaged viscosity profile varies between two positive constants (because the flow is between two non-isoviscous bulk fluids), and instability is generated due to local increase of viscosity in the flow direction. While here, the local oscillations in the viscosity occur due to the high-viscosity product of the reaction. A spike/cap-like tip due to double diffusive effects (Mishra et al. Reference Mishra, De Wit and Sahu2012) or distortion of a mushroom-like tip (Sahu et al. Reference Sahu, Ding, Valluri and Matar2009a) occurs as the result of displacement between two non-isoviscous bulk fluids. However, here, since the displacement is between two reactant bulk fluids ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$ of the same viscosity, and only a thin layer of a more-viscous product is formed at the interface, a Poiseuille-like tip propagates with time. K–H billows are seen only at the locations with a favourable velocity gradient where the less-viscous reactant

$\textbf {B}$ of the same viscosity, and only a thin layer of a more-viscous product is formed at the interface, a Poiseuille-like tip propagates with time. K–H billows are seen only at the locations with a favourable velocity gradient where the less-viscous reactant ![]() $\textbf {A}$ is suspended on the more-viscous product

$\textbf {A}$ is suspended on the more-viscous product ![]() $\textbf {C}$ or vice versa.

$\textbf {C}$ or vice versa.

Since the more-viscous product ![]() $\textbf {C}$ is responsible for the interfacial instability, it is crucial to do a quantitative analysis of the total product formation and its control on the instability. To do so, we compute

$\textbf {C}$ is responsible for the interfacial instability, it is crucial to do a quantitative analysis of the total product formation and its control on the instability. To do so, we compute

and plot its temporal evolution for different ![]() $R_{c}$ values in figure 8(a) while the other parameters are fixed. It is found that for the cases of

$R_{c}$ values in figure 8(a) while the other parameters are fixed. It is found that for the cases of ![]() $R_{c}=0$ and

$R_{c}=0$ and ![]() $R_{c}=1$, the

$R_{c}=1$, the ![]() $c_{tot}$ grows temporally in a similar fashion, while for the

$c_{tot}$ grows temporally in a similar fashion, while for the ![]() $R_{c}=3$ and

$R_{c}=3$ and ![]() $R_{c}=5$ cases, the curve deviates from that of the

$R_{c}=5$ cases, the curve deviates from that of the ![]() $R_{c}=0$ case after some time. Hence the instability helps in the formation of more product than the stable case. It is shown in the context of VF (Brau & De Wit Reference Brau and De Wit2020) that

$R_{c}=0$ case after some time. Hence the instability helps in the formation of more product than the stable case. It is shown in the context of VF (Brau & De Wit Reference Brau and De Wit2020) that ![]() $c_{tot}$ grows as

$c_{tot}$ grows as ![]() $t^{1/2}$ in advection–diffusion–reaction (ADR) system for a rectilinear geometry and linearly for the radial advection, where speed depends on the injection flow rate and the circle radius. Here since the channel aspect ratio is 1 : 40, the growing contact area for the reaction increases with time, as the reactive interface is axially spread over the whole domain as time evolves. Hence the total product

$t^{1/2}$ in advection–diffusion–reaction (ADR) system for a rectilinear geometry and linearly for the radial advection, where speed depends on the injection flow rate and the circle radius. Here since the channel aspect ratio is 1 : 40, the growing contact area for the reaction increases with time, as the reactive interface is axially spread over the whole domain as time evolves. Hence the total product ![]() $c$ grows proportional to

$c$ grows proportional to ![]() $t^{1.5}$ (see the log–log plot in the inset of figure 8a for the stable case (

$t^{1.5}$ (see the log–log plot in the inset of figure 8a for the stable case (![]() $R_{c}=0$) which is an even faster rate as compared with the reactive VF results Brau & De Wit Reference Brau and De Wit2020). Moreover in the unstable situation (

$R_{c}=0$) which is an even faster rate as compared with the reactive VF results Brau & De Wit Reference Brau and De Wit2020). Moreover in the unstable situation (![]() $R_{c}=5$), the product formation follows a

$R_{c}=5$), the product formation follows a ![]() $t^{1.55}$-type growth after time

$t^{1.55}$-type growth after time ![]() $t=10$.

$t=10$.

Figure 8. (a) Time evolution of ![]() $c_{tot}$ and (b) total reaction rate

$c_{tot}$ and (b) total reaction rate ![]() $\mathcal {R}_{tot}$ for different values of

$\mathcal {R}_{tot}$ for different values of ![]() $R_{c}$, when

$R_{c}$, when ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$,

$Pe=10\,000$, ![]() $Da=50$.

$Da=50$.

To further explore the influence of instability on reaction rate with different ![]() $R_c$, we compute

$R_c$, we compute ![]() $\mathcal {R}_{tot}(t)$ which is defined as (Gérard & De Wit Reference Gérard and De Wit2009)

$\mathcal {R}_{tot}(t)$ which is defined as (Gérard & De Wit Reference Gérard and De Wit2009)

The temporal evolution of ![]() $\mathcal {R}_{tot}(t)$ is shown in figure 8(b). It is observed that initially the

$\mathcal {R}_{tot}(t)$ is shown in figure 8(b). It is observed that initially the ![]() $\mathcal {R}_{tot}$ value increases from zero to a maximum value and then starts decreasing. This is because the initial reaction area is largest when reactants

$\mathcal {R}_{tot}$ value increases from zero to a maximum value and then starts decreasing. This is because the initial reaction area is largest when reactants ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$ come into contact for the first time, and it subsequently decreases as the product

$\textbf {B}$ come into contact for the first time, and it subsequently decreases as the product ![]() $\textbf {C}$ is formed, which acts as an obstacle between the reactants to react. For the

$\textbf {C}$ is formed, which acts as an obstacle between the reactants to react. For the ![]() $R_c=0$ case (see figure 7b of Gérard & De Wit Reference Gérard and De Wit2009) in Hele–Shaw flow, i.e. for a pure reaction–diffusion (RD) systems, the total reaction rate initially attains a higher value and decreases further when the system enters diffusion-limited dynamics. However, when

$R_c=0$ case (see figure 7b of Gérard & De Wit Reference Gérard and De Wit2009) in Hele–Shaw flow, i.e. for a pure reaction–diffusion (RD) systems, the total reaction rate initially attains a higher value and decreases further when the system enters diffusion-limited dynamics. However, when ![]() $R_c=0$ in the present channel flow case,

$R_c=0$ in the present channel flow case, ![]() $R_{tot}$ starts increasing after attaining a local minimum, unlike the Hele–Shaw flow case. The parabolic interface created from a non-uniform velocity distribution is responsible for the increasing

$R_{tot}$ starts increasing after attaining a local minimum, unlike the Hele–Shaw flow case. The parabolic interface created from a non-uniform velocity distribution is responsible for the increasing ![]() $\mathcal {R}_{tot}$ for all values of

$\mathcal {R}_{tot}$ for all values of ![]() $R_{c}$ helping the fresh reactants to come more and more into contact at successive times. Also, in contrast to the results in Hele–Shaw flow (Gérard & De Wit Reference Gérard and De Wit2009) when

$R_{c}$ helping the fresh reactants to come more and more into contact at successive times. Also, in contrast to the results in Hele–Shaw flow (Gérard & De Wit Reference Gérard and De Wit2009) when ![]() $R_c>0$, here we see that instability does not produce oscillations in the later evolution of

$R_c>0$, here we see that instability does not produce oscillations in the later evolution of ![]() $\mathcal {R}_{tot}$ after achieving the local minima. It implies that even if the interface changes its shape due to the occurrence of K–H-type billows, enough area of accessibility between the reactants

$\mathcal {R}_{tot}$ after achieving the local minima. It implies that even if the interface changes its shape due to the occurrence of K–H-type billows, enough area of accessibility between the reactants ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$ is neither frequently created nor annihilated to generate oscillations in

$\textbf {B}$ is neither frequently created nor annihilated to generate oscillations in ![]() $\mathcal {R}_{tot}(t)$.

$\mathcal {R}_{tot}(t)$.

3.2.1. Vorticity and enstrophy dynamics

An explanation for the mechanism of the development of roll-ups can be provided through the vorticity ![]() $\boldsymbol {\nabla } \times V$, where

$\boldsymbol {\nabla } \times V$, where ![]() $V=(u,v)$. To do so, we plot the vorticity field's density for different values of

$V=(u,v)$. To do so, we plot the vorticity field's density for different values of ![]() $R_{c}$ in figure 9. In the inset of figure 9, we show the vorticity's directional field at the inlet by zooming-in on the portion where the interaction of the reactant and product occurs near the wall. It is evident that when the product's viscosity increases, it acts as an obstruction to the reacting fluid that changes the direction of the flow, which can be seen from the increased bending of the directional field's arrows for a larger

$R_{c}$ in figure 9. In the inset of figure 9, we show the vorticity's directional field at the inlet by zooming-in on the portion where the interaction of the reactant and product occurs near the wall. It is evident that when the product's viscosity increases, it acts as an obstruction to the reacting fluid that changes the direction of the flow, which can be seen from the increased bending of the directional field's arrows for a larger ![]() $R_{c}$ value (see figure 9). It can be seen that a horseshoe-type vortex is developing near the wall, but it cannot complete the full rotation as in the case study by Launay et al. (Reference Launay, Mignot, Riviere and Perkins2017) where the vortex is created by the interaction of a free-surface flow and an emerging obstacle. The reason is only a thin layer of high-viscosity product is acting as an obstruction to the low-viscosity reactant that affects the velocity field. The strength of the vorticity is known as the enstrophy (Miura Reference Miura1997), and can be used to understand the impact of the roll-ups on the flow globally in the whole of the channel. The enstrophy is defined as

$R_{c}$ value (see figure 9). It can be seen that a horseshoe-type vortex is developing near the wall, but it cannot complete the full rotation as in the case study by Launay et al. (Reference Launay, Mignot, Riviere and Perkins2017) where the vortex is created by the interaction of a free-surface flow and an emerging obstacle. The reason is only a thin layer of high-viscosity product is acting as an obstruction to the low-viscosity reactant that affects the velocity field. The strength of the vorticity is known as the enstrophy (Miura Reference Miura1997), and can be used to understand the impact of the roll-ups on the flow globally in the whole of the channel. The enstrophy is defined as

Indeed, Matsumoto & Hoshino (Reference Matsumoto and Hoshino2004) used its temporal evolution to find the onset of the secondary roll-ups occurring in the magnetohydrodynamic K–H instability. Hence we plot the normalized enstrophy ![]() $E/E^{*}$ for the

$E/E^{*}$ for the ![]() $R_{c}=3$ and

$R_{c}=3$ and ![]() $R_{c}=5$ cases in figure 10, where

$R_{c}=5$ cases in figure 10, where ![]() $E^{*}$ represents the enstrophy for the stable

$E^{*}$ represents the enstrophy for the stable ![]() $R_{c}=0$ case. It is found that enstrophy increases monotonically with time, which reveals that roll-ups become stronger as time progresses. Also, it attains a higher value for a larger

$R_{c}=0$ case. It is found that enstrophy increases monotonically with time, which reveals that roll-ups become stronger as time progresses. Also, it attains a higher value for a larger ![]() $R_{c}$ at each instance of time, which results in a stronger change in the directional field with increasing mobility ratio due to the presence of roll-ups with relatively higher amplitude.

$R_{c}$ at each instance of time, which results in a stronger change in the directional field with increasing mobility ratio due to the presence of roll-ups with relatively higher amplitude.

Figure 9. Density plot of vorticity for different values of ![]() $R_{c}$ at time

$R_{c}$ at time ![]() $t=22$ with

$t=22$ with ![]() $Da=50$,

$Da=50$, ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$. Inset: the directional field of velocity at the inlet near the wall, where the reactant

$Pe=10\,000$. Inset: the directional field of velocity at the inlet near the wall, where the reactant ![]() $\textbf {A}$ pushes the product

$\textbf {A}$ pushes the product ![]() $\textbf {C}$.

$\textbf {C}$.

Figure 10. Time evolution of normalized enstrophy ![]() $E/E^{*}$ for different values of

$E/E^{*}$ for different values of ![]() $R_{c}$, when

$R_{c}$, when ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$,

$Pe=10\,000$, ![]() $Da=50$.

$Da=50$.

3.2.2. Mixing dynamics due to the reaction

Since the product from the reaction induces instability, we use the product concentration ![]() $c$ to define the degree of product mixing with respect to the stable case without any loss of generality. We define the degree of product mixing as

$c$ to define the degree of product mixing with respect to the stable case without any loss of generality. We define the degree of product mixing as

where ![]() $\sigma ^{2}_{*}(t)=\sigma ^{2}(t)|_{R_{c}=0}$. The global variance is known as

$\sigma ^{2}_{*}(t)=\sigma ^{2}(t)|_{R_{c}=0}$. The global variance is known as ![]() $\sigma ^{2} =\langle c^{2}\rangle -\langle c\rangle ^{2}$, with

$\sigma ^{2} =\langle c^{2}\rangle -\langle c\rangle ^{2}$, with ![]() $\langle \cdot \rangle$ denoting spatial averaging over the domain of the channel (Jha, Cueto-Felgueroso & Juanes Reference Jha, Cueto-Felgueroso and Juanes2011). Here the degree of product mixing

$\langle \cdot \rangle$ denoting spatial averaging over the domain of the channel (Jha, Cueto-Felgueroso & Juanes Reference Jha, Cueto-Felgueroso and Juanes2011). Here the degree of product mixing ![]() $\chi _{c}(t)$ for the stable

$\chi _{c}(t)$ for the stable ![]() $R_{c}=0$ case is zero. It should be noted that here we do not have a direct relationship between

$R_{c}=0$ case is zero. It should be noted that here we do not have a direct relationship between ![]() $\sigma ^{2}$ and the dissipation rate

$\sigma ^{2}$ and the dissipation rate ![]() $\epsilon =\langle |\boldsymbol {\nabla } c|^{2}\rangle /Pe$ (see equation (2) of Jha et al. Reference Jha, Cueto-Felgueroso and Juanes2011), as we have an entry flow situation with the reaction acting as a source term. Still, we can talk about relative mixing through

$\epsilon =\langle |\boldsymbol {\nabla } c|^{2}\rangle /Pe$ (see equation (2) of Jha et al. Reference Jha, Cueto-Felgueroso and Juanes2011), as we have an entry flow situation with the reaction acting as a source term. Still, we can talk about relative mixing through ![]() $\chi _{c}(t)$ as a function of governing flow parameters. Figure 11(a) shows the temporal evolution of global variance

$\chi _{c}(t)$ as a function of governing flow parameters. Figure 11(a) shows the temporal evolution of global variance ![]() $\sigma ^{2}$ for different values of

$\sigma ^{2}$ for different values of ![]() $R_{c}$ with

$R_{c}$ with ![]() $Da=50$,

$Da=50$, ![]() $Pe=10\,000$,

$Pe=10\,000$, ![]() $Re=500$. The

$Re=500$. The ![]() $\sigma ^{2}$ increases with respect to time, as the fresh product keeps forming due to reaction between

$\sigma ^{2}$ increases with respect to time, as the fresh product keeps forming due to reaction between ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$. As

$\textbf {B}$. As ![]() $R_{c}$ increases, the value of

$R_{c}$ increases, the value of ![]() $\sigma ^{2}$ also increases due to the increment of the total mass volume of the product. We plot

$\sigma ^{2}$ also increases due to the increment of the total mass volume of the product. We plot ![]() $\chi _{c}(t)$ with respect to time in figure 11(b) for

$\chi _{c}(t)$ with respect to time in figure 11(b) for ![]() $R_{c}=3,5$ with the rest of the parameters fixed as in figure 11(a). The mixing due to the roll-ups can be analysed from the temporal evolution of

$R_{c}=3,5$ with the rest of the parameters fixed as in figure 11(a). The mixing due to the roll-ups can be analysed from the temporal evolution of ![]() $\chi _{c}(t)$ (figure 11b). For

$\chi _{c}(t)$ (figure 11b). For ![]() $R_{c}=3$, it shows that till

$R_{c}=3$, it shows that till ![]() $t\approx 10$,

$t\approx 10$, ![]() $\chi _{c}(t)$ monotonically increases to attain a maximum value then starts decreasing. However for

$\chi _{c}(t)$ monotonically increases to attain a maximum value then starts decreasing. However for ![]() $R_{c}=5$,

$R_{c}=5$, ![]() $\chi _{c}(t)$ monotonically increases up to

$\chi _{c}(t)$ monotonically increases up to ![]() $t\approx 22$ with a greater value than that of the

$t\approx 22$ with a greater value than that of the ![]() $R_{c}=3$ case at each instant of time. The maximum of

$R_{c}=3$ case at each instant of time. The maximum of ![]() $\chi _{c}(t)$ for the

$\chi _{c}(t)$ for the ![]() $R_{c}=5$ case is close to 0.04, which signifies the fact that an unstable case can result in

$R_{c}=5$ case is close to 0.04, which signifies the fact that an unstable case can result in ![]() $4\,\%$ more mixing than that of the stable case when

$4\,\%$ more mixing than that of the stable case when ![]() $Da=50$,

$Da=50$, ![]() $Pe=10\,000$,

$Pe=10\,000$, ![]() $Re=500$. Both the curves in figure 11(b) depict that the relative mixing with respect to the

$Re=500$. Both the curves in figure 11(b) depict that the relative mixing with respect to the ![]() $R_{c}=0$ case, i.e. the amount of spreading and mixing occurring in the stable case is less than that in the

$R_{c}=0$ case, i.e. the amount of spreading and mixing occurring in the stable case is less than that in the ![]() $R_{c}=3,5$ cases. In other words, the mixing occurs more efficiently due to the presence of roll-ups in the flow.

$R_{c}=3,5$ cases. In other words, the mixing occurs more efficiently due to the presence of roll-ups in the flow.

Figure 11. (a) Time evolution of ![]() $\sigma ^{2}(t)$, (b) time evolution of

$\sigma ^{2}(t)$, (b) time evolution of ![]() $\chi _{c}(t)$ for different values of

$\chi _{c}(t)$ for different values of ![]() $R_{c}$, when

$R_{c}$, when ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$,

$Pe=10\,000$, ![]() $Da=50$.

$Da=50$.

3.3. Effects of  $Da$

$Da$

In this reactive flow system, the governing parameters, other than the mobility ratio ![]() $R_c$, are Damköhler number

$R_c$, are Damköhler number ![]() $Da$, Péclet number

$Da$, Péclet number ![]() $Pe$ and Reynolds number

$Pe$ and Reynolds number ![]() $Re$. To understand how these parameters influence the reactive interface's instability, we sequentially depict the effects of each of these parameters subsection-wise. In this sub-section, we discuss the effects of the Damköhler number on the flow, keeping the rest of the parameter values fixed as

$Re$. To understand how these parameters influence the reactive interface's instability, we sequentially depict the effects of each of these parameters subsection-wise. In this sub-section, we discuss the effects of the Damköhler number on the flow, keeping the rest of the parameter values fixed as ![]() $R_{c}=5$,

$R_{c}=5$, ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$. In figure 12(a) the density fields of the reactant

$Pe=10\,000$. In figure 12(a) the density fields of the reactant ![]() $\textbf {A}$ at a fixed time

$\textbf {A}$ at a fixed time ![]() $t=25$ are shown for different

$t=25$ are shown for different ![]() $Da$ values. An increase in

$Da$ values. An increase in ![]() $Da$ produces more product

$Da$ produces more product ![]() $\textbf {C}$ due to more consumption of reactants

$\textbf {C}$ due to more consumption of reactants ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$ in the process of the reaction. Since the product is more viscous, more formation of

$\textbf {B}$ in the process of the reaction. Since the product is more viscous, more formation of ![]() $\textbf {C}$ produces more gradient in the viscosity, which leads to high-velocity fluctuations and hence the greater deformation in the interface (see figure 12a). The reason for the formation of one billow of K–H-type, in the case of

$\textbf {C}$ produces more gradient in the viscosity, which leads to high-velocity fluctuations and hence the greater deformation in the interface (see figure 12a). The reason for the formation of one billow of K–H-type, in the case of ![]() $Da=1$, is clear from the corresponding averaged

$Da=1$, is clear from the corresponding averaged ![]() $\bar {\mu }_{y}(x)$ shown in figure 12(b), as only one cycle of oscillation is present between the tip and the inlet. Similarly, for the later cases (

$\bar {\mu }_{y}(x)$ shown in figure 12(b), as only one cycle of oscillation is present between the tip and the inlet. Similarly, for the later cases (![]() $Da=10$,

$Da=10$, ![]() $Da=50$), more than one local optimum is seen (see figure 12b), which is depicted by the higher number of roll-ups in the density plots of figure 12(a).

$Da=50$), more than one local optimum is seen (see figure 12b), which is depicted by the higher number of roll-ups in the density plots of figure 12(a).

Figure 12. (a) Spatial distribution of reactant ![]() $\textbf {A}$ concentration, (b) corresponding averaged viscosity

$\textbf {A}$ concentration, (b) corresponding averaged viscosity ![]() $\bar {\mu }_{y}(x)$ for

$\bar {\mu }_{y}(x)$ for ![]() $R_{c}=5$ at time

$R_{c}=5$ at time ![]() $t=25$ for different values of

$t=25$ for different values of ![]() $Da$, when

$Da$, when ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$.

$Pe=10\,000$.

In figure 13(a), we plot ![]() $c_{tot}$ against time for different values of

$c_{tot}$ against time for different values of ![]() $Da$. At each time with increasing

$Da$. At each time with increasing ![]() $Da$,

$Da$, ![]() $c_{tot}$ attains a higher value since more consumption of reactants

$c_{tot}$ attains a higher value since more consumption of reactants ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$ is enhancing the product

$\textbf {B}$ is enhancing the product ![]() $\textbf {C}$ formation. Moreover, for a smaller value of

$\textbf {C}$ formation. Moreover, for a smaller value of ![]() $Da$, although the value of

$Da$, although the value of ![]() $c_{tot}$ remains smaller as compared with the cases where

$c_{tot}$ remains smaller as compared with the cases where ![]() $Da$ are large, it grows with a faster rate at a later time (

$Da$ are large, it grows with a faster rate at a later time (![]() $t>8$) than that in the case of a larger

$t>8$) than that in the case of a larger ![]() $Da$. This can be seen from the inset of the figure 13(a), where the log–log plot shows that, as Da increases,

$Da$. This can be seen from the inset of the figure 13(a), where the log–log plot shows that, as Da increases, ![]() $c_{tot}$ follows

$c_{tot}$ follows ![]() $t^{\beta }$-type growth, where the exponent

$t^{\beta }$-type growth, where the exponent ![]() $\beta$ decreases from 1.93 (

$\beta$ decreases from 1.93 (![]() $Da=1$) to 1.55 (

$Da=1$) to 1.55 (![]() $Da=50$). However, with increasing

$Da=50$). However, with increasing ![]() $Da$, the proportionally constant (not shown) in the obtained power-law increases, so

$Da$, the proportionally constant (not shown) in the obtained power-law increases, so ![]() $c_{tot}$ attains a higher value for a higher

$c_{tot}$ attains a higher value for a higher ![]() $Da$ (figure 13a). As

$Da$ (figure 13a). As ![]() $Da$ is directly proportional to the reaction rate

$Da$ is directly proportional to the reaction rate ![]() $\mathcal {R}(x,y,t)$,

$\mathcal {R}(x,y,t)$, ![]() $\mathcal {R}_{tot}(t)$ attains a higher value for higher

$\mathcal {R}_{tot}(t)$ attains a higher value for higher ![]() $Da$ at each instant of time (figure 13b). As mentioned earlier in § 3.2, initially

$Da$ at each instant of time (figure 13b). As mentioned earlier in § 3.2, initially ![]() $\mathcal {R}_{tot}(t)$ attains a higher value due to the reactive area being highest when

$\mathcal {R}_{tot}(t)$ attains a higher value due to the reactive area being highest when ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$ meet for the first time. The value of this local maximum decreases as the reaction rate slows with lower

$\textbf {B}$ meet for the first time. The value of this local maximum decreases as the reaction rate slows with lower ![]() $Da$. When

$Da$. When ![]() $Da=1$,

$Da=1$, ![]() $\mathcal {R}_{tot}(t)$ follows a monotonic profile since the rate of reaction is not fast enough, although the reactants

$\mathcal {R}_{tot}(t)$ follows a monotonic profile since the rate of reaction is not fast enough, although the reactants ![]() $\textbf {A}$ and

$\textbf {A}$ and ![]() $\textbf {B}$ have the highest accessibility to each other at the initial stage. When the

$\textbf {B}$ have the highest accessibility to each other at the initial stage. When the ![]() $Da$ value is high enough, it is evident that (see figure 13b) even though both the parabolic interface and instability accelerate the process of the reaction later, the initial reaction rate can be more than that at intermediate times.

$Da$ value is high enough, it is evident that (see figure 13b) even though both the parabolic interface and instability accelerate the process of the reaction later, the initial reaction rate can be more than that at intermediate times.

Figure 13. (a) Time evolution of ![]() $c_{tot}$ and (b) total reaction rate

$c_{tot}$ and (b) total reaction rate ![]() $\mathcal {R}_{tot}$ for different values of

$\mathcal {R}_{tot}$ for different values of ![]() $Da$, when

$Da$, when ![]() $R_{c}=5$,

$R_{c}=5$, ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$.

$Pe=10\,000$.

The strengthening of the roll-ups for higher values of ![]() $Da$ is depicted from the plots of

$Da$ is depicted from the plots of ![]() $E/E^{*}$ versus

$E/E^{*}$ versus ![]() $t$ in figure 14(a). In the case of

$t$ in figure 14(a). In the case of ![]() $Da=1$, since there is one visible roll-up (see figure 12a) with a small amplitude, the

$Da=1$, since there is one visible roll-up (see figure 12a) with a small amplitude, the ![]() $E/E^{*}$ value monotonically increases from 1 as time advances. This increment of

$E/E^{*}$ value monotonically increases from 1 as time advances. This increment of ![]() $E/E^{*}$ from 1 indicates the change in the directional field from the stable situation. Other than the

$E/E^{*}$ from 1 indicates the change in the directional field from the stable situation. Other than the ![]() $Da=1$ case, for other three values of

$Da=1$ case, for other three values of ![]() $Da$,

$Da$, ![]() $E/E^{*}$ evolves by closely following a monotonic profile with the attainment of a higher value for a greater

$E/E^{*}$ evolves by closely following a monotonic profile with the attainment of a higher value for a greater ![]() $Da$ at each time

$Da$ at each time ![]() $t>0$. From figures 12 and 14(a), it is intuitive that in the regime of

$t>0$. From figures 12 and 14(a), it is intuitive that in the regime of ![]() $Da=5$ to

$Da=5$ to ![]() $Da=50$, the formation of only two more prominent roll-ups occurs. Moreover, adjacent smaller roll-ups to these prominent ones contribute only to a slight increment in the magnitude of the directional field compared with their corresponding stable cases. In figure 14(b) the time evolution of

$Da=50$, the formation of only two more prominent roll-ups occurs. Moreover, adjacent smaller roll-ups to these prominent ones contribute only to a slight increment in the magnitude of the directional field compared with their corresponding stable cases. In figure 14(b) the time evolution of ![]() $\chi _{c}(t)$ shows when

$\chi _{c}(t)$ shows when ![]() $Da$ is increased, more mixing occurs as compared with the stable (

$Da$ is increased, more mixing occurs as compared with the stable (![]() $R_{c}=0$) case. The

$R_{c}=0$) case. The ![]() $Da=1$ case is mixed less than the rest of the

$Da=1$ case is mixed less than the rest of the ![]() $Da$ values (

$Da$ values (![]() $Da=5, 10, 50$). In the

$Da=5, 10, 50$). In the ![]() $Da=5$ case, the

$Da=5$ case, the ![]() $\chi _{c}(t)$ profile shows monotonic increment as time advances, with a point of inflection followed by a local maximum which signifies the more nonlinear effects of K–H billows on mixing dynamics in the flow as compared with the

$\chi _{c}(t)$ profile shows monotonic increment as time advances, with a point of inflection followed by a local maximum which signifies the more nonlinear effects of K–H billows on mixing dynamics in the flow as compared with the ![]() $Da=1$ case. When the

$Da=1$ case. When the ![]() $Da$ value is further increased, the degree of mixing attains higher values than the

$Da$ value is further increased, the degree of mixing attains higher values than the ![]() $Da=5$ case at each instant of time, which indicates that more efficient mixing occurs due to stronger K–H roll-ups.

$Da=5$ case at each instant of time, which indicates that more efficient mixing occurs due to stronger K–H roll-ups.

Figure 14. (a) Time evolution of scaled enstrophy ![]() $E/E^{*}$ and (b)

$E/E^{*}$ and (b) ![]() $\chi _{c}(t)$ for different values of

$\chi _{c}(t)$ for different values of ![]() $Da$, when

$Da$, when ![]() $R_{c}=5$,

$R_{c}=5$, ![]() $Re=500$,

$Re=500$, ![]() $Pe=10\,000$.

$Pe=10\,000$.

3.4. Effects of  $Pe$

$Pe$

It should be noted here that the Péclet number ![]() $Pe$ can be represented as the product of the Schmidt number