1. Introduction

The viscoelastic properties of dilute polymer solutions are central to several applications (Larson Reference Larson1999). When the pure solvent is turbulent the most remarkable effect of the addition of polymers is a significant reduction of the turbulent drag below that of the solvent (Procaccia, L'Vov & Benzi Reference Procaccia, L'Vov and Benzi2008; White & Mungal Reference White and Mungal2008; Benzi Reference Benzi2010; Graham Reference Graham2014). This phenomenon, also known as the Toms effect (Toms Reference Toms1949, Reference Toms1977), is commonly utilized to reduce the energy losses in pipelines and hence the costs associated with the transport of crude oil. However, in a turbulent flow, polymers are subject to mechanical degradation due to the fluctuating strain rate, which stretches polymers and thus causes their scission. Since turbulent drag reduction decreases with the molecular weight of the dissolved polymers (Virk Reference Virk1975), the efficacy of polymers as drag reducing agents diminishes in time, with a strong impact on both industrial applications and laboratory experiments (Paterson & Abernathy (Reference Paterson and Abernathy1970), Moussa, Tiu & Sridhar (Reference Moussa, Tiu and Sridhar1993), den Toonder et al. (Reference den Toonder, Draad, Kuiken and Nieuwstadt1995), Choi et al. (Reference Choi, Lim, Lai and Chan2002), Vanapalli, Islam & Solomon (Reference Vanapalli, Islam and Solomon2005), Vanapalli, Ceccio & Solomon (Reference Vanapalli, Ceccio and Solomon2006), Elbing et al. (Reference Elbing, Winkel, Solomon and Ceccio2009), Pereira & Soares (Reference Pereira and Soares2012), Owolabi, Dennis & Poole (Reference Owolabi, Dennis and Poole2017), see also the editorial of Poole (Reference Poole2020) and the review of Soares (Reference Soares2020)).

Analogous mechanical degradation and, by association, practical limitations are observed in experiments of homogeneous and isotropic turbulence with polymer additives (Crawford et al. Reference Crawford, Mordant, Xu and Bodenschatz2008). Indeed, even though in isotropic turbulence the mean strain rate is zero, on average line elements are stretched exponentially at a rate proportional to the inverse of the Kolmogorov dissipation time scale (Bec et al. Reference Bec, Biferale, Boffetta, Cencini, Lanotte, Musacchio and Toschi2006). At large Reynolds numbers, polymers therefore experience strong straining events that can highly distort them. This has been confirmed in experiments and numerical simulations, both directly by examination of the probability distribution of polymer extensions (Vaithianathan & Collins Reference Vaithianathan and Collins2003; Vincenzi et al. Reference Vincenzi, Jin, Bodenschatz and Collins2007, Reference Vincenzi, Perlekar, Biferale and Toschi2015; Jin & Collins Reference Jin and Collins2008; Watanabe & Gotoh Reference Watanabe and Gotoh2010) and indirectly through the observation of a strong polymer feedback on the flow (De Angelis et al. Reference De Angelis, Casciola, Benzi and Piva2005; Perlekar, Mitra & Pandit Reference Perlekar, Mitra and Pandit2006, Reference Perlekar, Mitra and Pandit2010; Crawford et al. Reference Crawford, Mordant, Xu and Bodenschatz2008; Ouellette, Xu & Bodenschatz Reference Ouellette, Xu and Bodenschatz2009; Xi, Bodenschatz & Xu Reference Xi, Bodenschatz and Xu2013; Watanabe & Gotoh Reference Watanabe and Gotoh2013a,Reference Watanabe and Gotohb, Reference Watanabe and Gotoh2014; de Chaumont Quitry & Ouellette Reference de Chaumont Quitry and Ouellette2016). Furthermore, experimental measurements of polymer scission in different channel flows, by Vanapalli et al. (Reference Vanapalli, Ceccio and Solomon2006), show that the majority of polymers reside, and therefore break up, in the bulk of the fluid, where the flow approximates isotropic turbulence, rendering the scission results independent of channel geometry.

Mechanical degradation has also been reported in the regime of elastic turbulence (Groisman & Steinberg Reference Groisman and Steinberg2004). Although the Reynolds number of the solution is low in this case, elastic instabilities generate a chaotic flow with highly fluctuating velocity gradients that stretch polymers up to their maximum length (Liu & Steinberg Reference Liu and Steinberg2014).

A detailed knowledge of the statistics of polymer scission in turbulent flows is thus important for the design of experiments and the performance of realistic simulations of both turbulent drag reduction and elastic turbulence. In laminar flows, considerable progress has been made in the modelling and simulation of polymer scission (e.g. Cascales & de la Torre Reference Cascales and de la Torre1991, Reference Cascales and de la Torre1992; Hsieh, Park & Larson Reference Hsieh, Park and Larson2005; Sim, Khomami & Sureshkumar Reference Sim, Khomami and Sureshkumar2007; Wu et al. Reference Wu, Li, Zheng and Xu2018). However, the knowledge gained from the study of laminar flows cannot be directly applied to turbulent flows because of the different properties of the strain rate, and consequently of the flow-induced polymer stretching, in the two types of flows. In an extensional velocity field, for instance, the probability distribution of polymer extensions is dominated by a peak that shifts towards larger extensions as the strain rate increases (Perkins, Smith & Chu Reference Perkins, Smith and Chu1997), and therefore scission is observed only for a sufficiently large strain rate. In contrast, for turbulent flows, the distribution of the extensions has a wide power-law core due to the intensely fluctuating strain rate (Balkovsky, Fouxon & Lebedev Reference Balkovsky, Fouxon and Lebedev2000; Watanabe & Gotoh Reference Watanabe and Gotoh2010; Liu & Steinberg Reference Liu and Steinberg2014). Hence the scission rate may be non-negligible even at moderate Reynolds numbers (proportional to the average magnitude of the fluctuating strain rate).

Unlike the fragmentation of liquid jets, sheets, or drops (Villermaux Reference Villermaux2007, Reference Villermaux2020), the modelling of flow-driven scission in turbulent polymer solutions is still in its infancy (Soares Reference Soares2020). The reason for this has to be sought in the difficulty of including the microscopic details of the scission process in constitutive models of polymer solutions. To our knowledge, the only continuum model that takes scission into account has been proposed by Pereira, Mompean & Soares (Reference Pereira, Mompean and Soares2018) and assumes that the maximum contour length is a spatiotemporal scalar field that decays due to scission while being transported by the fluid. Further development of continuum models requires an in depth understanding of the statistics of scission and the consequent reduction of the relaxation time – in addition to the decrease in the maximum contour length – of the polymer fragments.

We therefore investigate the dynamics of polymers in a three-dimensional homogeneous and isotropic turbulent flow focusing on the scission statistics. A polymer is described as a bead-spring chain in a time-dependent, linear velocity field. This polymer model is known as the Rouse (Reference Rouse1953) model and represents one of the most common descriptions of a polymer molecule in a flow (in the case in which only two beads are considered, the Rouse model reduces to the elastic dumbbell model, see Bird et al. (Reference Bird, Curtiss, Armstrong and Hassager1977)). Even when the flow is turbulent, the assumption of a linear velocity field is justified, since the size of polymers is generally smaller than the Kolmogorov dissipation scale ![]() $\eta _K$, below which viscosity strongly damps the spatial fluctuations of the velocity. We introduce scission into the Rouse model by assuming that the bead-spring chain breaks into two shorter chains as soon as the tension in one of the springs exceeds a critical threshold.

$\eta _K$, below which viscosity strongly damps the spatial fluctuations of the velocity. We introduce scission into the Rouse model by assuming that the bead-spring chain breaks into two shorter chains as soon as the tension in one of the springs exceeds a critical threshold.

We begin by considering the statistics of the first scission. For passively transported polymers, for which the motion of the polymers does not modify the carrier velocity field, we derive qualitative analytical predictions by restricting ourselves to the Hookean dumbbell model and by using a decorrelated-in-time Gaussian stochastic velocity field (the approach is adapted from a study of droplet breakup conducted in Ray & Vincenzi (Reference Ray and Vincenzi2018)). The theoretical predictions are compared with Lagrangian direct numerical simulations (DNS) of the Rouse model in three-dimensional homogeneous isotropic turbulence. We then show that these results are qualitatively insensitive to the introduction of hydrodynamic interactions (HI) and excluded volume (EV) interactions among the beads of the polymer model. For active polymers, the statistics of the first scission is studied via hybrid Eulerian–Lagrangian simulations (Watanabe & Gotoh Reference Watanabe and Gotoh2013a,Reference Watanabe and Gotohb, Reference Watanabe and Gotoh2014), in which the feedback of (dumbbell-like) polymers onto the velocity field is taken into account. These simulations shed light on the transient nature of the dissipation-reduction effect, which owes its origin to polymer stretching and its demise to polymer scission. Finally, we analyse multiple scissions of passive polymers, via DNS in which a hierarchy of daughter polymers arise from successive breakups, each with their own statistics.

2. The Rouse chain

The Rouse model describes a polymer as a chain of ![]() $\mathscr {N}$ inertialess beads connected to their nearest neighbours by elastic springs. We consider finitely extensible nonlinear elastic (FENE) springs with spring constant

$\mathscr {N}$ inertialess beads connected to their nearest neighbours by elastic springs. We consider finitely extensible nonlinear elastic (FENE) springs with spring constant ![]() $H$ and maximum length

$H$ and maximum length ![]() $Q_m$. The fluid in which the chain is immersed is Newtonian and its motion is described by an incompressible velocity field

$Q_m$. The fluid in which the chain is immersed is Newtonian and its motion is described by an incompressible velocity field ![]() $\boldsymbol {u}(\boldsymbol {x},t)$. The drag force of the fluid on each bead is given by Stokes law with drag coefficient

$\boldsymbol {u}(\boldsymbol {x},t)$. The drag force of the fluid on each bead is given by Stokes law with drag coefficient ![]() $\zeta$; the collisions of the molecules of the fluid with a bead are described by Brownian motion. Finally, in the Rouse model, HI and EV interactions between different segments of the chain are disregarded. (These interactions do not affect the scission statistics qualitatively, as shown later in § 3.2.)

$\zeta$; the collisions of the molecules of the fluid with a bead are described by Brownian motion. Finally, in the Rouse model, HI and EV interactions between different segments of the chain are disregarded. (These interactions do not affect the scission statistics qualitatively, as shown later in § 3.2.)

The motion of the chain is described in terms of the position of its centre of mass, ![]() $\boldsymbol {X}_c$, and the separation vectors between the beads,

$\boldsymbol {X}_c$, and the separation vectors between the beads, ![]() $\boldsymbol {Q}_i$ (

$\boldsymbol {Q}_i$ (![]() $i=1,\dots ,\mathscr {N}-1$). This set of coordinates evolves according to the equations (Bird et al. Reference Bird, Curtiss, Armstrong and Hassager1977; Öttinger Reference Öttinger1996)

$i=1,\dots ,\mathscr {N}-1$). This set of coordinates evolves according to the equations (Bird et al. Reference Bird, Curtiss, Armstrong and Hassager1977; Öttinger Reference Öttinger1996)

\begin{gather} \dot{\boldsymbol{X}}_c = \boldsymbol{u}(\boldsymbol{X}_c(t),t)+\dfrac{1}{\mathscr{N}}\sqrt{\frac{Q_{eq}^2}{6\tau}} \sum_{i=1}^{\mathscr{N}}\boldsymbol{\xi}_i(t),\end{gather}

\begin{gather} \dot{\boldsymbol{X}}_c = \boldsymbol{u}(\boldsymbol{X}_c(t),t)+\dfrac{1}{\mathscr{N}}\sqrt{\frac{Q_{eq}^2}{6\tau}} \sum_{i=1}^{\mathscr{N}}\boldsymbol{\xi}_i(t),\end{gather} \begin{gather} \dot{\boldsymbol{Q}_i} = \boldsymbol{\kappa}(t)\boldsymbol{\cdot}\boldsymbol{Q}_i(t)-\dfrac{1}{4\tau} [2\,f_i\boldsymbol{Q}_i(t)-\,f_{i+1}\boldsymbol{Q}_{i+1}(t)-\,f_{i-1}\boldsymbol{Q}_{i-1}(t)] \nonumber\\ \quad+\sqrt{\dfrac{Q_{eq}^2}{6\tau}} [\boldsymbol{\xi}_{i+1}(t)-\boldsymbol{\xi}_i(t)],\quad i=1,\dots,\mathscr{N}-1, \end{gather}

\begin{gather} \dot{\boldsymbol{Q}_i} = \boldsymbol{\kappa}(t)\boldsymbol{\cdot}\boldsymbol{Q}_i(t)-\dfrac{1}{4\tau} [2\,f_i\boldsymbol{Q}_i(t)-\,f_{i+1}\boldsymbol{Q}_{i+1}(t)-\,f_{i-1}\boldsymbol{Q}_{i-1}(t)] \nonumber\\ \quad+\sqrt{\dfrac{Q_{eq}^2}{6\tau}} [\boldsymbol{\xi}_{i+1}(t)-\boldsymbol{\xi}_i(t)],\quad i=1,\dots,\mathscr{N}-1, \end{gather}

where ![]() $\kappa ^{\alpha \beta }(t)=\nabla ^\beta u^\alpha (\boldsymbol {X}_c(t),t)$ is the velocity gradient evaluated at the position of the centre of mass,

$\kappa ^{\alpha \beta }(t)=\nabla ^\beta u^\alpha (\boldsymbol {X}_c(t),t)$ is the velocity gradient evaluated at the position of the centre of mass, ![]() $\tau =\zeta /4H$ is the characteristic time scale of the springs,

$\tau =\zeta /4H$ is the characteristic time scale of the springs, ![]() $Q_{eq}=\sqrt {3k_BT/H}$ is their equilibrium root mean square (r.m.s.) extension (

$Q_{eq}=\sqrt {3k_BT/H}$ is their equilibrium root mean square (r.m.s.) extension (![]() $k_B$ denotes the Boltzmann constant and

$k_B$ denotes the Boltzmann constant and ![]() $T$ is temperature), and

$T$ is temperature), and ![]() $\boldsymbol {\xi }_i(t)$ (

$\boldsymbol {\xi }_i(t)$ (![]() $i=1,\dots ,\mathscr {N}$) are independent, vectorial, white noises. The coefficients

$i=1,\dots ,\mathscr {N}$) are independent, vectorial, white noises. The coefficients

characterize the FENE interactions and ensure that the extension of each spring does not exceed its maximum length ![]() $Q_m$. Obviously, in the equations for

$Q_m$. Obviously, in the equations for ![]() $\boldsymbol {Q}_1$ and

$\boldsymbol {Q}_1$ and ![]() $\boldsymbol {Q}_{\mathscr {N}-1}$ it is assumed that

$\boldsymbol {Q}_{\mathscr {N}-1}$ it is assumed that ![]() $\boldsymbol {Q}_0=\boldsymbol {Q}_{\mathscr {N}}=0$.

$\boldsymbol {Q}_0=\boldsymbol {Q}_{\mathscr {N}}=0$.

The end-to-end separation or extension vector of the polymer is defined as ![]() $\boldsymbol {R}=\sum _{i=1}^{\mathscr {N}-1}\boldsymbol {Q}_i$. In a still fluid, the equilibrium r.m.s. value of

$\boldsymbol {R}=\sum _{i=1}^{\mathscr {N}-1}\boldsymbol {Q}_i$. In a still fluid, the equilibrium r.m.s. value of ![]() $\vert \boldsymbol {R}\vert$ is

$\vert \boldsymbol {R}\vert$ is ![]() $r_{eq}=Q_{eq}\sqrt {\mathscr {N}-1}$ (Bird et al. Reference Bird, Curtiss, Armstrong and Hassager1977).

$r_{eq}=Q_{eq}\sqrt {\mathscr {N}-1}$ (Bird et al. Reference Bird, Curtiss, Armstrong and Hassager1977).

We modify the Rouse model in order to account for the scission of the polymer when the tension in any of the springs exceeds a critical value. Since the relation between the tension and the extension of a spring can be easily inverted (Thiffeault Reference Thiffeault2003), we can, equivalently, assume that for each spring of the chain there exists a critical scission length ![]() $\ell _{{sc}}$ such that the spring breaks if the length of the corresponding separation vector exceeds

$\ell _{{sc}}$ such that the spring breaks if the length of the corresponding separation vector exceeds ![]() $\ell _{{sc}}$ (i.e. the chain breaks if

$\ell _{{sc}}$ (i.e. the chain breaks if ![]() $\vert \boldsymbol {Q}_i\vert \geqslant \ell _{{sc}}$ for any

$\vert \boldsymbol {Q}_i\vert \geqslant \ell _{{sc}}$ for any ![]() $1\leqslant i\leqslant \mathscr {N}-1$).

$1\leqslant i\leqslant \mathscr {N}-1$).

The scission process is non-stationary; the dynamics of the chain therefore depends on its initial configuration and, in particular, on its initial end-to-end separation ![]() $r_0=\vert \boldsymbol {R}(0)\vert$. In the following we shall assume that

$r_0=\vert \boldsymbol {R}(0)\vert$. In the following we shall assume that ![]() $\ell _{{sc}}$ is much greater than

$\ell _{{sc}}$ is much greater than ![]() $r_0/(\mathscr {N}-1)$ and that

$r_0/(\mathscr {N}-1)$ and that ![]() $r_0$ is equal to

$r_0$ is equal to ![]() $r_{eq}$ or greater than it. (In principle, r 0 could also be taken smaller than

$r_{eq}$ or greater than it. (In principle, r 0 could also be taken smaller than ![]() $r_{eq}$, but we have checked that this case does not differ appreciably from the

$r_{eq}$, but we have checked that this case does not differ appreciably from the ![]() $r_0\simeq r_{eq}$ one.)

$r_0\simeq r_{eq}$ one.)

Finally, the size of the chain always remains smaller than ![]() $\eta _{K}$, so that the velocity field at the scale of the chain can be considered as linear and the dynamics of the polymer is entirely determined by the velocity gradient at the location of the centre of mass, consistent with the Rouse model.

$\eta _{K}$, so that the velocity field at the scale of the chain can be considered as linear and the dynamics of the polymer is entirely determined by the velocity gradient at the location of the centre of mass, consistent with the Rouse model.

To summarize, the spatial scales that characterize the system are arranged as follows: ![]() $r_{eq}\leqslant r_0\ll \ell _{{sc}}(\mathscr {N}-1) < Q_m(\mathscr {N}-1) < \eta _{K}$.

$r_{eq}\leqslant r_0\ll \ell _{{sc}}(\mathscr {N}-1) < Q_m(\mathscr {N}-1) < \eta _{K}$.

3. First-scission statistics

3.1. Passive polymers

3.1.1. Analytical predictions

Here we make some simplifying assumptions on both the polymer model and the carrier flow in order to derive analytical predictions for the statistics of polymer scission.

First of all, we only consider the statistics of the first scission. We then restrict ourselves to the ![]() $\mathscr {N}=2$ case, also known as the dumbbell model (Bird et al. Reference Bird, Curtiss, Armstrong and Hassager1977; Öttinger Reference Öttinger1996), i.e. we focus on the slowest deformation mode of the polymer. Many results on single-polymer dynamics in random or turbulent flows have been obtained by using the dumbbell model (see Vincenzi et al. (Reference Vincenzi, Perlekar, Biferale and Toschi2015) and references therein) and the most common constitutive models of polymer solutions, namely the Oldroyd-B (Oldroyd Reference Oldroyd1950) and the FENE-P (Bird, Dotson & Johnson Reference Bird, Dotson and Johnson1980) models, are based on it. The legitimacy of this approach is supported by the numerical simulations in Jin & Collins (Reference Jin and Collins2008) and Watanabe & Gotoh (Reference Watanabe and Gotoh2010), where it is shown that, in isotropic turbulence and in the absence of scission, the statistics of the end-to-end separation of a dumbbell and that of an

$\mathscr {N}=2$ case, also known as the dumbbell model (Bird et al. Reference Bird, Curtiss, Armstrong and Hassager1977; Öttinger Reference Öttinger1996), i.e. we focus on the slowest deformation mode of the polymer. Many results on single-polymer dynamics in random or turbulent flows have been obtained by using the dumbbell model (see Vincenzi et al. (Reference Vincenzi, Perlekar, Biferale and Toschi2015) and references therein) and the most common constitutive models of polymer solutions, namely the Oldroyd-B (Oldroyd Reference Oldroyd1950) and the FENE-P (Bird, Dotson & Johnson Reference Bird, Dotson and Johnson1980) models, are based on it. The legitimacy of this approach is supported by the numerical simulations in Jin & Collins (Reference Jin and Collins2008) and Watanabe & Gotoh (Reference Watanabe and Gotoh2010), where it is shown that, in isotropic turbulence and in the absence of scission, the statistics of the end-to-end separation of a dumbbell and that of an ![]() $\mathscr {N}=20$ chain coincide (provided, of course, that a proper mapping between the parameters of the two systems is applied). Finally, we replace the nonlinear spring with a Hookean one (

$\mathscr {N}=20$ chain coincide (provided, of course, that a proper mapping between the parameters of the two systems is applied). Finally, we replace the nonlinear spring with a Hookean one (![]() $f_i=1$); this is because the nonlinearity of the elastic force enters into play only at extensions close to the scission length, and we shall see from our simulations in § 3.1.2 that it does not affect the qualitative properties of the scission process. For

$f_i=1$); this is because the nonlinearity of the elastic force enters into play only at extensions close to the scission length, and we shall see from our simulations in § 3.1.2 that it does not affect the qualitative properties of the scission process. For ![]() $\mathscr {N}=2$, (2.1) reduce to

$\mathscr {N}=2$, (2.1) reduce to

\begin{gather}\dot{\boldsymbol{R}} = \boldsymbol{\kappa}(t)\boldsymbol{\cdot}\boldsymbol{R}(t)-\dfrac{\boldsymbol{R}(t)}{2\tau} +\sqrt{\dfrac{r_{eq}^2}{3\tau}}\, \boldsymbol{\zeta}_2(t), \end{gather}

\begin{gather}\dot{\boldsymbol{R}} = \boldsymbol{\kappa}(t)\boldsymbol{\cdot}\boldsymbol{R}(t)-\dfrac{\boldsymbol{R}(t)}{2\tau} +\sqrt{\dfrac{r_{eq}^2}{3\tau}}\, \boldsymbol{\zeta}_2(t), \end{gather}

where ![]() $\boldsymbol {\zeta }_1(t)$ and

$\boldsymbol {\zeta }_1(t)$ and ![]() $\boldsymbol {\zeta }_2(t)$ are (non-independent) vectorial white noises.

$\boldsymbol {\zeta }_2(t)$ are (non-independent) vectorial white noises.

We model the flow via the smooth (also known as Batchelor) regime of the Kraichnan (Reference Kraichnan1968) model. This model has been widely employed in the study of turbulent transport (Falkovich, Gawȩdzki & Vergassola Reference Falkovich, Gawȩdzki and Vergassola2001) and has yielded several theoretical results on the coil-stretch transition in random or turbulent flows (see Plan, Ali & Vincenzi (Reference Plan, Ali and Vincenzi2016) and references therein). The velocity is a divergenceless and spatially smooth Gaussian vector field. It is statistically stationary in time and homogeneous, isotropic, and parity invariant in space; it has zero mean and zero correlation time. Under these assumptions, ![]() $\boldsymbol {\kappa }(t)$ is a tensorial white noise with two-time correlation (Falkovich et al. Reference Falkovich, Gawȩdzki and Vergassola2001)

$\boldsymbol {\kappa }(t)$ is a tensorial white noise with two-time correlation (Falkovich et al. Reference Falkovich, Gawȩdzki and Vergassola2001)

where

and ![]() $\lambda$ is the maximum Lyapunov exponent of the flow. Obviously, the assumption of temporal decorrelation is a strong approximation, since an isotropic turbulent flow has Kubo number

$\lambda$ is the maximum Lyapunov exponent of the flow. Obviously, the assumption of temporal decorrelation is a strong approximation, since an isotropic turbulent flow has Kubo number ![]() $\mathit {Ku}=\lambda t_{{corr}}\approx 0.6$, where

$\mathit {Ku}=\lambda t_{{corr}}\approx 0.6$, where ![]() $t_{{corr}}$ is the correlation time of the flow (Girimaji & Pope Reference Girimaji and Pope1990; Bec et al. Reference Bec, Biferale, Boffetta, Cencini, Lanotte, Musacchio and Toschi2006; Watanabe & Gotoh Reference Watanabe and Gotoh2010). However, it was shown in Musacchio & Vincenzi (Reference Musacchio and Vincenzi2011) that, for a stochastic flow with comparable

$t_{{corr}}$ is the correlation time of the flow (Girimaji & Pope Reference Girimaji and Pope1990; Bec et al. Reference Bec, Biferale, Boffetta, Cencini, Lanotte, Musacchio and Toschi2006; Watanabe & Gotoh Reference Watanabe and Gotoh2010). However, it was shown in Musacchio & Vincenzi (Reference Musacchio and Vincenzi2011) that, for a stochastic flow with comparable ![]() $\mathit {Ku}$, the statistics of polymer extension is captured qualitatively by a time decorrelated velocity field.

$\mathit {Ku}$, the statistics of polymer extension is captured qualitatively by a time decorrelated velocity field.

The Weissenberg number ![]() $\mathit {Wi}=\lambda \tau$ determines to what extent polymers are stretched by the flow. In particular, the coil-stretch transition occurs when

$\mathit {Wi}=\lambda \tau$ determines to what extent polymers are stretched by the flow. In particular, the coil-stretch transition occurs when ![]() $\mathit {Wi}$ exceeds the critical value

$\mathit {Wi}$ exceeds the critical value ![]() $\mathit {Wi}_{cr}=1/2$ ( (Lumley Reference Lumley1972; Balkovsky et al. Reference Balkovsky, Fouxon and Lebedev2000) – note that our definition of

$\mathit {Wi}_{cr}=1/2$ ( (Lumley Reference Lumley1972; Balkovsky et al. Reference Balkovsky, Fouxon and Lebedev2000) – note that our definition of ![]() $\tau$ and hence that of

$\tau$ and hence that of ![]() $\mathit {Wi}$ differ from that of Balkovsky et al. (Reference Balkovsky, Fouxon and Lebedev2000) by a factor of 2).

$\mathit {Wi}$ differ from that of Balkovsky et al. (Reference Balkovsky, Fouxon and Lebedev2000) by a factor of 2).

As the velocity field is homogeneous and isotropic in space, the statistics of ![]() $R=\vert \boldsymbol {R}\vert$ is independent of the position of the centre of mass and of the direction of

$R=\vert \boldsymbol {R}\vert$ is independent of the position of the centre of mass and of the direction of ![]() $\boldsymbol {R}$. To study polymer scission, it is therefore sufficient to focus on the probability density function (p.d.f.) of

$\boldsymbol {R}$. To study polymer scission, it is therefore sufficient to focus on the probability density function (p.d.f.) of ![]() $R$, which will be denoted as

$R$, which will be denoted as ![]() $P(R,t)$. When

$P(R,t)$. When ![]() $\boldsymbol {\kappa }(t)$ has the properties described above,

$\boldsymbol {\kappa }(t)$ has the properties described above, ![]() $P(R,t)$ satisfies the Fokker–Planck equation (Chertkov Reference Chertkov2000; Celani, Musacchio & Vincenzi Reference Celani, Musacchio and Vincenzi2005)

$P(R,t)$ satisfies the Fokker–Planck equation (Chertkov Reference Chertkov2000; Celani, Musacchio & Vincenzi Reference Celani, Musacchio and Vincenzi2005)

with rescaled time ![]() $t'=t/2\tau$ and coefficients

$t'=t/2\tau$ and coefficients

(once again our definition of ![]() $\mathit {Wi}$ differs from that used in Chertkov (Reference Chertkov2000) and Celani et al. (Reference Celani, Musacchio and Vincenzi2005) by a factor of 2). The appropriate boundary conditions are reflecting at

$\mathit {Wi}$ differs from that used in Chertkov (Reference Chertkov2000) and Celani et al. (Reference Celani, Musacchio and Vincenzi2005) by a factor of 2). The appropriate boundary conditions are reflecting at ![]() $R=0$ and absorbing at

$R=0$ and absorbing at ![]() $R=\ell _{{sc}}$, i.e.

$R=\ell _{{sc}}$, i.e.

for all ![]() $t$. The former condition ensures that the extension of the polymer stays positive, while the latter describes scission at

$t$. The former condition ensures that the extension of the polymer stays positive, while the latter describes scission at ![]() $R=\ell _{{sc}}$. The analysis of (3.4a,b) to (3.6) closely follows that in Ray & Vincenzi (Reference Ray and Vincenzi2018) for the breakup of sub-Kolmogorov droplets in isotropic turbulence. (The results presented here are deduced directly from those in § 3 of Ray & Vincenzi (Reference Ray and Vincenzi2018) by setting

$R=\ell _{{sc}}$. The analysis of (3.4a,b) to (3.6) closely follows that in Ray & Vincenzi (Reference Ray and Vincenzi2018) for the breakup of sub-Kolmogorov droplets in isotropic turbulence. (The results presented here are deduced directly from those in § 3 of Ray & Vincenzi (Reference Ray and Vincenzi2018) by setting ![]() $\mathit {Ca}=\mathit {Wi}$,

$\mathit {Ca}=\mathit {Wi}$, ![]() $\mu =1$,

$\mu =1$, ![]() $r_{{eq}}^2= Q_{eq}^2/3$, and

$r_{{eq}}^2= Q_{eq}^2/3$, and ![]() $f_1(\mu )=\,f_2(\mu )=\gamma (\mu )=1$.) We therefore skip the details of the derivations and directly present the predictions of scission statistics.

$f_1(\mu )=\,f_2(\mu )=\gamma (\mu )=1$.) We therefore skip the details of the derivations and directly present the predictions of scission statistics.

The number of unbroken polymers that survive at time ![]() $t$,

$t$, ![]() $N_p(t)$, is related to

$N_p(t)$, is related to ![]() $P(R,t)$ as follows:

$P(R,t)$ as follows:

At times ![]() $t\gg \tau$,

$t\gg \tau$, ![]() $N_p(t)$ therefore decays exponentially as

$N_p(t)$ therefore decays exponentially as

where the decay time ![]() $T_d$ is the reciprocal of the lowest eigenvalue of the operator

$T_d$ is the reciprocal of the lowest eigenvalue of the operator ![]() $\mathbb {L}$ with boundary conditions (3.6). The eigenfunctions of

$\mathbb {L}$ with boundary conditions (3.6). The eigenfunctions of ![]() $\mathbb {L}$ are hypergeometric functions with parameters depending on

$\mathbb {L}$ are hypergeometric functions with parameters depending on ![]() $r_{eq}$,

$r_{eq}$, ![]() $r_0$,

$r_0$, ![]() $\mathit {Wi}$ and form a discrete set selected by the boundary condition at

$\mathit {Wi}$ and form a discrete set selected by the boundary condition at ![]() $R=\ell _{{sc}}$. A calculation of the lowest eigenvalue shows that

$R=\ell _{{sc}}$. A calculation of the lowest eigenvalue shows that ![]() $T_d$ depends weakly on

$T_d$ depends weakly on ![]() $\mathit {Wi}$ for small

$\mathit {Wi}$ for small ![]() $\mathit {Wi}$, decreases rapidly as

$\mathit {Wi}$, decreases rapidly as ![]() $\mathit {Wi}$ exceeds

$\mathit {Wi}$ exceeds ![]() $\mathit {Wi}_{cr}$, and saturates at large

$\mathit {Wi}_{cr}$, and saturates at large ![]() $\mathit {Wi}$.

$\mathit {Wi}$.

As we shall see below, the p.d.f. of ![]() $R$ integrated over time,

$R$ integrated over time,

allows us to estimate the mean lifetime of a polymer before its first scission. If the initial distribution of polymer sizes is ‘monodisperse’, i.e. ![]() $P(R,0)=\delta (R-r_0)$, then

$P(R,0)=\delta (R-r_0)$, then ![]() $\hat {P}(R)$ takes the form

$\hat {P}(R)$ takes the form

\begin{equation} \hat{P}(R)\propto \begin{cases} \textrm{e}^{-\varPhi(R)}[\phi(\ell_{{sc}})-\phi(r_0)] & \text{if $0\leqslant R\leqslant r_0$}, \\ \textrm{e}^{-\varPhi(R)}[\phi(\ell_{{sc}})-\phi(R)] & \text{if $r_0< R\leqslant\ell_{{sc}}$} \end{cases} \end{equation}

\begin{equation} \hat{P}(R)\propto \begin{cases} \textrm{e}^{-\varPhi(R)}[\phi(\ell_{{sc}})-\phi(r_0)] & \text{if $0\leqslant R\leqslant r_0$}, \\ \textrm{e}^{-\varPhi(R)}[\phi(\ell_{{sc}})-\phi(R)] & \text{if $r_0< R\leqslant\ell_{{sc}}$} \end{cases} \end{equation}with

and hence

\begin{equation} \hat{P}(R)\sim \begin{cases} r_{eq}^{-2}r_0^ {-1}R^2 & \text{if $0\leqslant R\ll r_{eq}$,}\\ \vert r_0^\alpha-\ell_{{sc}}^\alpha\vert R^{-1-\alpha} & \text{if $r_{eq}\ll R\ll r_0$,}\\ \ell_{{sc}}^\beta R^{-1-\beta} & \text{if $r_0\ll R\ll\ell_{{sc}}$}, \end{cases} \end{equation}

\begin{equation} \hat{P}(R)\sim \begin{cases} r_{eq}^{-2}r_0^ {-1}R^2 & \text{if $0\leqslant R\ll r_{eq}$,}\\ \vert r_0^\alpha-\ell_{{sc}}^\alpha\vert R^{-1-\alpha} & \text{if $r_{eq}\ll R\ll r_0$,}\\ \ell_{{sc}}^\beta R^{-1-\beta} & \text{if $r_0\ll R\ll\ell_{{sc}}$}, \end{cases} \end{equation}

where ![]() $\alpha =3(\mathit {Wi}^{-1}-2)/2$ and

$\alpha =3(\mathit {Wi}^{-1}-2)/2$ and

\begin{equation} \beta = \begin{cases} \alpha & \text{if $\mathit{Wi}<\mathit{Wi}_{cr}$,}\\ 0 & \text{if $\mathit{Wi}>\mathit{Wi}_{cr}$}. \end{cases} \end{equation}

\begin{equation} \beta = \begin{cases} \alpha & \text{if $\mathit{Wi}<\mathit{Wi}_{cr}$,}\\ 0 & \text{if $\mathit{Wi}>\mathit{Wi}_{cr}$}. \end{cases} \end{equation}

Therefore, above the coil-stretch transition, the right-hand tail of ![]() $\hat {P}(R)$ saturates to the power-law

$\hat {P}(R)$ saturates to the power-law ![]() $R^{-1}$. An analogous behaviour was found previously for the size distribution of sub-Kolmogorov droplets in isotropic turbulence (Biferale, Meneveau & Verzicco Reference Biferale, Meneveau and Verzicco2014; Ray & Vincenzi Reference Ray and Vincenzi2018). Also note that the exponent

$R^{-1}$. An analogous behaviour was found previously for the size distribution of sub-Kolmogorov droplets in isotropic turbulence (Biferale, Meneveau & Verzicco Reference Biferale, Meneveau and Verzicco2014; Ray & Vincenzi Reference Ray and Vincenzi2018). Also note that the exponent ![]() $\alpha$ coincides with the one obtained by Balkovsky et al. (Reference Balkovsky, Fouxon and Lebedev2000) for the p.d.f. of intermediate extensions in the absence of scission.

$\alpha$ coincides with the one obtained by Balkovsky et al. (Reference Balkovsky, Fouxon and Lebedev2000) for the p.d.f. of intermediate extensions in the absence of scission.

If the initial distribution of polymer sizes is broad but nonetheless admits a maximum size ![]() $r_0$, then the left (

$r_0$, then the left (![]() $R\ll r_{eq}$) and right (

$R\ll r_{eq}$) and right (![]() $r_0\ll R\ll \ell _{{sc}}$) power-law tails continue to exist, but

$r_0\ll R\ll \ell _{{sc}}$) power-law tails continue to exist, but ![]() $\hat {P}(R)$ no longer behaves as a power-law for extensions

$\hat {P}(R)$ no longer behaves as a power-law for extensions ![]() $r_{eq}\ll R\ll r_0$.

$r_{eq}\ll R\ll r_0$.

The mean time ![]() $\langle T _{{sc}}\rangle$ it takes for a polymer to undergo its first scission can be deduced from the behaviour of

$\langle T _{{sc}}\rangle$ it takes for a polymer to undergo its first scission can be deduced from the behaviour of ![]() $\hat {P}(R)$ via the relation

$\hat {P}(R)$ via the relation

Equation (3.12) then yields two different behaviours below and above the coil-stretch transition

\begin{equation} \lambda\langle T_{{sc}}\rangle\sim \begin{cases} (\ell_{{sc}}/r_0)^\beta & \text{if $\mathit{Wi}<\mathit{Wi}_{cr}$},\\ \ln (\ell_{{sc}}/r_0) & \text{if $\mathit{Wi}>\mathit{Wi}_{cr}$}. \end{cases} \end{equation}

\begin{equation} \lambda\langle T_{{sc}}\rangle\sim \begin{cases} (\ell_{{sc}}/r_0)^\beta & \text{if $\mathit{Wi}<\mathit{Wi}_{cr}$},\\ \ln (\ell_{{sc}}/r_0) & \text{if $\mathit{Wi}>\mathit{Wi}_{cr}$}. \end{cases} \end{equation}3.1.2. DNS

In this section, we present numerical simulations of the Rouse model (2.1) in homogeneous and isotropic turbulence and compare them with the analytical predictions of § 3.1.1. The velocity field ![]() $\boldsymbol {u}(\boldsymbol {x},t)$ is the solution of the incompressible Navier–Stokes equations,

$\boldsymbol {u}(\boldsymbol {x},t)$ is the solution of the incompressible Navier–Stokes equations,

over the periodic cube ![]() $[0,2{\rm \pi} ]^3$. Here

$[0,2{\rm \pi} ]^3$. Here ![]() $p$ is pressure,

$p$ is pressure, ![]() $\nu _f$ is the kinematic viscosity and

$\nu _f$ is the kinematic viscosity and ![]() $\boldsymbol {F}(\boldsymbol {x},t)$ is a body force that maintains a constant kinetic energy input

$\boldsymbol {F}(\boldsymbol {x},t)$ is a body force that maintains a constant kinetic energy input ![]() $\epsilon _{in}$. The numerical integration uses a standard, fully dealiased pseudo-spectral method with

$\epsilon _{in}$. The numerical integration uses a standard, fully dealiased pseudo-spectral method with ![]() $512^3$ collocation points and, for the time evolution, a second-order slaved Adams–Bashforth scheme with time step

$512^3$ collocation points and, for the time evolution, a second-order slaved Adams–Bashforth scheme with time step ![]() $\textrm {d}t=4\times 10^{-4}$. The values of

$\textrm {d}t=4\times 10^{-4}$. The values of ![]() $\nu _f$ and

$\nu _f$ and ![]() $\epsilon _{in}$ are such that the Taylor-microscale Reynolds number is

$\epsilon _{in}$ are such that the Taylor-microscale Reynolds number is ![]() $\mathit {Re}_\lambda =111$. The Lyapunov exponent of the flow is

$\mathit {Re}_\lambda =111$. The Lyapunov exponent of the flow is ![]() $\lambda =0.15\tau _\eta ^{-1}$, where

$\lambda =0.15\tau _\eta ^{-1}$, where ![]() $\tau _\eta$ denotes the Kolmogorov time scale, consistent with the value found earlier in Bec et al. (Reference Bec, Biferale, Boffetta, Cencini, Lanotte, Musacchio and Toschi2006) and Watanabe & Gotoh (Reference Watanabe and Gotoh2010).

$\tau _\eta$ denotes the Kolmogorov time scale, consistent with the value found earlier in Bec et al. (Reference Bec, Biferale, Boffetta, Cencini, Lanotte, Musacchio and Toschi2006) and Watanabe & Gotoh (Reference Watanabe and Gotoh2010).

The position of the centre of mass of the polymer is obtained by integrating (2.1a) via a second-order Adam–Bashforth method with the same ![]() $\textrm {d}t$ as for the Navier–Stokes equations. The noise term in (2.1a) is disregarded, because it has a negligible effect when

$\textrm {d}t$ as for the Navier–Stokes equations. The noise term in (2.1a) is disregarded, because it has a negligible effect when ![]() $\boldsymbol {u}(\boldsymbol {x},t)$ is turbulent. Moreover, its amplitude is smaller than that of the noise terms in the equations for the separation vectors by a factor of

$\boldsymbol {u}(\boldsymbol {x},t)$ is turbulent. Moreover, its amplitude is smaller than that of the noise terms in the equations for the separation vectors by a factor of ![]() $\mathscr {N}$. As

$\mathscr {N}$. As ![]() $\boldsymbol {u}(\boldsymbol {x},t)$ is only known over a discrete grid, the integration of (2.1a) requires interpolation to reconstruct the velocity field at

$\boldsymbol {u}(\boldsymbol {x},t)$ is only known over a discrete grid, the integration of (2.1a) requires interpolation to reconstruct the velocity field at ![]() $\boldsymbol {X}_c(t)$ – a trilinear scheme is used for this purpose. The same approach allows the calculation of the velocity gradient along the trajectory of the centre of mass,

$\boldsymbol {X}_c(t)$ – a trilinear scheme is used for this purpose. The same approach allows the calculation of the velocity gradient along the trajectory of the centre of mass, ![]() $\boldsymbol {\kappa }(t)$, and hence the integration of (2.1b) by means of the Euler–Maruyama method with time step

$\boldsymbol {\kappa }(t)$, and hence the integration of (2.1b) by means of the Euler–Maruyama method with time step ![]() $\textrm {d}t$. Since in this section we focus on the statistics of the first scission, a chain is removed from the simulation as soon as it breaks according to the criterion discussed above. The time origin for (2.1b) (

$\textrm {d}t$. Since in this section we focus on the statistics of the first scission, a chain is removed from the simulation as soon as it breaks according to the criterion discussed above. The time origin for (2.1b) (![]() $t=0$) is taken in the statistically steady state of the carrier turbulent flow, so that the temporal dynamics of polymers is not influenced by the initial transient evolution of

$t=0$) is taken in the statistically steady state of the carrier turbulent flow, so that the temporal dynamics of polymers is not influenced by the initial transient evolution of ![]() $\boldsymbol {u}(\boldsymbol {x},t)$. Note that, in the present context, it is not necessary to use integration schemes specifically designed to prevent the extension of the links from exceeding

$\boldsymbol {u}(\boldsymbol {x},t)$. Note that, in the present context, it is not necessary to use integration schemes specifically designed to prevent the extension of the links from exceeding ![]() $Q_m$, since the links, by construction, break well before their extension approaches

$Q_m$, since the links, by construction, break well before their extension approaches ![]() $Q_m$.

$Q_m$.

In our simulations, we consider ![]() $N_p(0)=9\times 10^5$ polymers, whose positions at time

$N_p(0)=9\times 10^5$ polymers, whose positions at time ![]() $t=0$ are uniformly distributed in space. Since the statistics of polymer extension depends on the initial size of polymers but not on their orientation, for simplicity the initial condition for the separation vectors is taken to be

$t=0$ are uniformly distributed in space. Since the statistics of polymer extension depends on the initial size of polymers but not on their orientation, for simplicity the initial condition for the separation vectors is taken to be ![]() $\boldsymbol {Q}_i(0)=Q_0 (1,1,1)/\sqrt {3}$ with

$\boldsymbol {Q}_i(0)=Q_0 (1,1,1)/\sqrt {3}$ with ![]() $Q_0>0$ for all polymers, i.e. the polymers are in a straight configuration and

$Q_0>0$ for all polymers, i.e. the polymers are in a straight configuration and ![]() $P(R,0)=\delta (R-r_0)$ with

$P(R,0)=\delta (R-r_0)$ with ![]() $r_0=(\mathscr {N}-1)Q_0$.

$r_0=(\mathscr {N}-1)Q_0$.

In order to compare chains with different numbers of beads, an appropriate mapping of the chain parameters is needed. We use the mapping proposed by Jin & Collins (Reference Jin and Collins2008) and also used by Watanabe & Gotoh (Reference Watanabe and Gotoh2010). If the parameters of the individual links of an ![]() $\mathscr {N}$-bead chain are

$\mathscr {N}$-bead chain are ![]() $\tau$,

$\tau$, ![]() $Q_{eq}$,

$Q_{eq}$, ![]() $Q_m$,

$Q_m$, ![]() $\ell _{{sc}}$, then the statistics of the end-to-end separation of the chain is equivalent to that of a dumbbell with the following parameters:

$\ell _{{sc}}$, then the statistics of the end-to-end separation of the chain is equivalent to that of a dumbbell with the following parameters:

where the last relation is introduced for compatibility with the expression of ![]() $Q_m^D$. This mapping allows us to compare chains with different numbers of beads by using the dumbbell model as a reference.

$Q_m^D$. This mapping allows us to compare chains with different numbers of beads by using the dumbbell model as a reference.

Following Watanabe & Gotoh (Reference Watanabe and Gotoh2010), we define the Weissenberg number for a Rouse chain as ![]() $\mathit {Wi}=\lambda \tau ^{D}$. In our simulations,

$\mathit {Wi}=\lambda \tau ^{D}$. In our simulations, ![]() $0.4\leqslant \mathit {Wi} \leqslant 8$. (Note that small-

$0.4\leqslant \mathit {Wi} \leqslant 8$. (Note that small-![]() $\mathit {Wi}$ simulations are computationally more demanding, because the calculation of quantities like

$\mathit {Wi}$ simulations are computationally more demanding, because the calculation of quantities like ![]() $\hat {P}(R)$ and

$\hat {P}(R)$ and ![]() $\langle T _{{sc}}\rangle$ requires that the time evolution is long enough for all polymers to break, and the time at which the scission process is complete becomes longer and longer as

$\langle T _{{sc}}\rangle$ requires that the time evolution is long enough for all polymers to break, and the time at which the scission process is complete becomes longer and longer as ![]() $\mathit {Wi}$ decreases.)

$\mathit {Wi}$ decreases.)

As for the choice of the other parameters, we take ![]() $r_{eq}=1$,

$r_{eq}=1$, ![]() $Q_m^{D}=\sqrt {3000}$ (also following Jin & Collins (Reference Jin and Collins2008) and Watanabe & Gotoh (Reference Watanabe and Gotoh2010)), and, unless otherwise specified,

$Q_m^{D}=\sqrt {3000}$ (also following Jin & Collins (Reference Jin and Collins2008) and Watanabe & Gotoh (Reference Watanabe and Gotoh2010)), and, unless otherwise specified, ![]() $r_0=r_{eq}$. In addition, it is assumed that a spring breaks as soon as its extension exceeds

$r_0=r_{eq}$. In addition, it is assumed that a spring breaks as soon as its extension exceeds ![]() $\ell _{{sc}}=0.8Q_m$. The number of beads is set to

$\ell _{{sc}}=0.8Q_m$. The number of beads is set to ![]() $\mathscr {N}=10$. We have also performed simulations with different sets of parameters, which support the generality of the results presented below.

$\mathscr {N}=10$. We have also performed simulations with different sets of parameters, which support the generality of the results presented below.

It is worth mentioning that the above parameters are compatible with those of the experiment of Crawford et al. (Reference Crawford, Mordant, Xu and Bodenschatz2008), which investigates bulk turbulence in a water solution of polyacrylamide (known as PAM) with molecular weight ![]() $M_w=18\times 10^6$, maximum extension

$M_w=18\times 10^6$, maximum extension ![]() $L=77\ \mathrm {\mu } \textrm {m}$ and relaxation time

$L=77\ \mathrm {\mu } \textrm {m}$ and relaxation time ![]() $\tau _p=43\ \textrm {ms}$. Mechanical degradation is observed at

$\tau _p=43\ \textrm {ms}$. Mechanical degradation is observed at ![]() $R_\lambda =485$. For this value of

$R_\lambda =485$. For this value of ![]() $R_\lambda$, the Kolmogorov time scale is reported to be

$R_\lambda$, the Kolmogorov time scale is reported to be ![]() $\tau _\eta =2.63\ \textrm {ms}$, and hence the Weissenberg number based on the Lyapunov exponent can be estimated as

$\tau _\eta =2.63\ \textrm {ms}$, and hence the Weissenberg number based on the Lyapunov exponent can be estimated as ![]() $\mathit {Wi}\approx 2.5$.

$\mathit {Wi}\approx 2.5$.

Figure 1(a) shows the temporal evolution of the fraction of unbroken polymers. The decay is exponential with a time scale ![]() $T_d$ that decreases rapidly as

$T_d$ that decreases rapidly as ![]() $\mathit {Wi}$ exceeds its critical value (figure 1b), in agreement with the predictions of § 3.1.1. We shall see in § 3.3 that, for a dumbbell, it is possible to write an explicit expression for

$\mathit {Wi}$ exceeds its critical value (figure 1b), in agreement with the predictions of § 3.1.1. We shall see in § 3.3 that, for a dumbbell, it is possible to write an explicit expression for ![]() $T_d$ as a function of

$T_d$ as a function of ![]() $\mathit {Wi}$.

$\mathit {Wi}$.

Figure 1. Passive polymers: (a) exponential decay of the fraction of unbroken polymers for different values of ![]() $\mathit {Wi}$; (b) decay time of the fraction of unbroken polymers rescaled by the Kolmogorov time

$\mathit {Wi}$; (b) decay time of the fraction of unbroken polymers rescaled by the Kolmogorov time ![]() $\tau _\eta$ as a function of

$\tau _\eta$ as a function of ![]() $\mathit {Wi}/\mathit {Wi}_{cr}$.

$\mathit {Wi}/\mathit {Wi}_{cr}$.

The time-integrated p.d.f. of the end-to-end extension of unbroken polymers is shown in figure 2(a) for an initial polymer size ![]() $r_0=r_{eq}$ and different values of

$r_0=r_{eq}$ and different values of ![]() $\mathit {Wi}$. The p.d.f. displays a power-law behaviour for both

$\mathit {Wi}$. The p.d.f. displays a power-law behaviour for both ![]() $R\ll r_{eq}$ and

$R\ll r_{eq}$ and ![]() $r_0=r_{eq}\ll R\ll \ell _{{sc}}(\mathscr {N}-1)$. The left-hand tail is proportional to

$r_0=r_{eq}\ll R\ll \ell _{{sc}}(\mathscr {N}-1)$. The left-hand tail is proportional to ![]() $R^2$, because the small separations are dominated by thermal fluctuations. The right-hand tail rises as a function of

$R^2$, because the small separations are dominated by thermal fluctuations. The right-hand tail rises as a function of ![]() $\mathit {Wi}$, until the power-law saturates to

$\mathit {Wi}$, until the power-law saturates to ![]() $R^{-1}$ for

$R^{-1}$ for ![]() $\mathit {Wi}>\mathit {Wi}_{cr}$. A third power-law emerges for intermediate extensions if

$\mathit {Wi}>\mathit {Wi}_{cr}$. A third power-law emerges for intermediate extensions if ![]() $r_0>r_{eq}$ (figure 2b). In this case, the exponent

$r_0>r_{eq}$ (figure 2b). In this case, the exponent ![]() $-1-\alpha$ changes from negative to positive as

$-1-\alpha$ changes from negative to positive as ![]() $\mathit {Wi}$ increases and saturates to

$\mathit {Wi}$ increases and saturates to ![]() $2$ at large

$2$ at large ![]() $\mathit {Wi}$. To appreciate the coexistence of these three power-laws more clearly, in figure 3a we also consider

$\mathit {Wi}$. To appreciate the coexistence of these three power-laws more clearly, in figure 3a we also consider ![]() $\hat {P}(R)$ for a much larger value of

$\hat {P}(R)$ for a much larger value of ![]() $Q_m^D$ and a larger separation between

$Q_m^D$ and a larger separation between ![]() $r_{eq}$,

$r_{eq}$, ![]() $r_0$ and

$r_0$ and ![]() $(\mathscr {N}-1)\ell _{{sc}}$. All these results confirm the predictions reported in § 3.1.1.

$(\mathscr {N}-1)\ell _{{sc}}$. All these results confirm the predictions reported in § 3.1.1.

Figure 2. Passive polymers: (a) time-integrated p.d.f. of the end-to-end extension of unbroken polymers for ![]() $r_0=r_{eq}$ and for different values of

$r_0=r_{eq}$ and for different values of ![]() $\mathit {Wi}$. The inset shows the value of

$\mathit {Wi}$. The inset shows the value of ![]() $\beta$, which determines the exponent of the right-hand tail of the p.d.f. (i.e.

$\beta$, which determines the exponent of the right-hand tail of the p.d.f. (i.e. ![]() $\hat {P}(R)\propto R^{-1-\beta }$ for

$\hat {P}(R)\propto R^{-1-\beta }$ for ![]() $r_0\ll R\ll \ell _{{sc}}$), as a function of

$r_0\ll R\ll \ell _{{sc}}$), as a function of ![]() $\mathit {Wi}/\mathit {Wi}_{cr}$; (b) time-integrated p.d.f. of the end-to-end extension of unbroken polymers for

$\mathit {Wi}/\mathit {Wi}_{cr}$; (b) time-integrated p.d.f. of the end-to-end extension of unbroken polymers for ![]() $r_0=40r_{eq}$ and for different values of

$r_0=40r_{eq}$ and for different values of ![]() $\mathit {Wi}$. The inset shows the value of

$\mathit {Wi}$. The inset shows the value of ![]() $\alpha$, which determines the power-law behaviour of the p.d.f. for intermediate extensions (i.e.

$\alpha$, which determines the power-law behaviour of the p.d.f. for intermediate extensions (i.e. ![]() $\hat {P}(R)\propto R^{-1-\alpha }$ for

$\hat {P}(R)\propto R^{-1-\alpha }$ for ![]() $r_{eq}\ll R\ll r_0$), as a function of

$r_{eq}\ll R\ll r_0$), as a function of ![]() $\mathit {Wi}/\mathit {Wi}_{cr}$. In both panels (a) and (b), the p.d.f.s are normalized to unity for the sake of comparison.

$\mathit {Wi}/\mathit {Wi}_{cr}$. In both panels (a) and (b), the p.d.f.s are normalized to unity for the sake of comparison.

Figure 3. Passive polymers: (a) time-integrated p.d.f. of the end-to-end extension of unbroken polymers for ![]() $Q^D_m=10^4$,

$Q^D_m=10^4$, ![]() $r_{eq}=1$,

$r_{eq}=1$, ![]() $r_0=10^2$ and different values of

$r_0=10^2$ and different values of ![]() $\mathit {Wi}$; (b) time-integrated p.d.f. of the end-to-end extension of unbroken polymers for

$\mathit {Wi}$; (b) time-integrated p.d.f. of the end-to-end extension of unbroken polymers for ![]() $Q^{D}_m=10^4$,

$Q^{D}_m=10^4$, ![]() $r_{eq}=1$,

$r_{eq}=1$, ![]() $r_0=5\times 10^2$,

$r_0=5\times 10^2$, ![]() $\mathit {Wi}=1$, and an initial size distribution that is either monodisperse (dotted magenta line) or uniform (between

$\mathit {Wi}=1$, and an initial size distribution that is either monodisperse (dotted magenta line) or uniform (between ![]() $r_{eq}$ and

$r_{eq}$ and ![]() $r_0$; solid grey line). In both panels, the p.d.f.s are normalized to unity for the sake of comparison.

$r_0$; solid grey line). In both panels, the p.d.f.s are normalized to unity for the sake of comparison.

The p.d.f.s presented so far correspond to a ‘monodisperse’ initial state ![]() $P(R)=\delta (R-r_0)$ in which all polymers have the same end-to-end distance. However, as mentioned in § 3.1.1, the behaviour of

$P(R)=\delta (R-r_0)$ in which all polymers have the same end-to-end distance. However, as mentioned in § 3.1.1, the behaviour of ![]() $\hat {P}(R)$ for intermediate extensions is expected to change if the initial distribution of polymer extensions is broad. To confirm this prediction, we have considered an initial state in which the end-to-end distance of polymers is distributed uniformly between

$\hat {P}(R)$ for intermediate extensions is expected to change if the initial distribution of polymer extensions is broad. To confirm this prediction, we have considered an initial state in which the end-to-end distance of polymers is distributed uniformly between ![]() $r_{eq}$ and a maximum initial extension

$r_{eq}$ and a maximum initial extension ![]() $r_0>r_{eq}$. The time-integrated p.d.f.s given in figure 3(b) show that only the left- and right-hand power-law tails persist in this case, while

$r_0>r_{eq}$. The time-integrated p.d.f.s given in figure 3(b) show that only the left- and right-hand power-law tails persist in this case, while ![]() $\hat {P}(R)$ does not behave as a power-law for intermediate extensions.

$\hat {P}(R)$ does not behave as a power-law for intermediate extensions.

We now turn to the statistics of the lifetime ![]() $T_{{sc}}$ of a polymer. The DNS suggest that the p.d.f. of

$T_{{sc}}$ of a polymer. The DNS suggest that the p.d.f. of ![]() $T_{{sc}}$ has an exponential tail with a time scale

$T_{{sc}}$ has an exponential tail with a time scale ![]() $\gamma ^{-1}$ that, beyond

$\gamma ^{-1}$ that, beyond ![]() $\mathit {Wi}_{cr}$, decreases rapidly as a function of

$\mathit {Wi}_{cr}$, decreases rapidly as a function of ![]() $\mathit {Wi}$ (figure 4a). For all values of the Weissenberg number,

$\mathit {Wi}$ (figure 4a). For all values of the Weissenberg number, ![]() $\gamma ^{-1}$ is approximately the same as the decay time

$\gamma ^{-1}$ is approximately the same as the decay time ![]() $T_d$ of the fraction of unbroken polymers owing to the exponential decay of the latter at long times (see § 3.1.1). However,

$T_d$ of the fraction of unbroken polymers owing to the exponential decay of the latter at long times (see § 3.1.1). However, ![]() $\gamma ^{-1}$ differs from

$\gamma ^{-1}$ differs from ![]() $\langle T_{ sc}\rangle$, because the exponential behaviour of the p.d.f. of

$\langle T_{ sc}\rangle$, because the exponential behaviour of the p.d.f. of ![]() $T_{{sc}}$ sets in only at relatively large values of

$T_{{sc}}$ sets in only at relatively large values of ![]() $T_{{sc}}$. For a fixed

$T_{{sc}}$. For a fixed ![]() $\mathit {Wi}$, the mean lifetime

$\mathit {Wi}$, the mean lifetime ![]() $\langle T_{sc}\rangle$ behaves as a power of

$\langle T_{sc}\rangle$ behaves as a power of ![]() $\ell _{{sc}}/Q_0$ below the coil-stretch transition and as the logarithm of

$\ell _{{sc}}/Q_0$ below the coil-stretch transition and as the logarithm of ![]() $\ell _{{sc}}/Q_0$ beyond that (see figures 4b and 4c) – we remind the reader that

$\ell _{{sc}}/Q_0$ beyond that (see figures 4b and 4c) – we remind the reader that ![]() $Q_0$ is the initial length of any link of the chain. Small deviations are only observed for

$Q_0$ is the initial length of any link of the chain. Small deviations are only observed for ![]() $\ell _{{sc}}\gg Q_0$. Moreover, we have checked that, for

$\ell _{{sc}}\gg Q_0$. Moreover, we have checked that, for ![]() $\mathit {Wi}<\mathit {Wi}_{cr}$, the exponent

$\mathit {Wi}<\mathit {Wi}_{cr}$, the exponent ![]() $\beta$ that gives the dependence of

$\beta$ that gives the dependence of ![]() $\langle T _{{sc}}\rangle$ on

$\langle T _{{sc}}\rangle$ on ![]() $\ell _{{sc}}/Q_0$ is the same as the exponent that describes the right-hand tail of

$\ell _{{sc}}/Q_0$ is the same as the exponent that describes the right-hand tail of ![]() $\hat {P}(R)$, i.e.

$\hat {P}(R)$, i.e. ![]() $\hat {P}(R)\propto R^{-1-\beta }$ for

$\hat {P}(R)\propto R^{-1-\beta }$ for ![]() $r_0\ll R\ll (\mathscr {N}-1) \ell _{{sc}}$, in agreement with (3.15). Thus, the statistics of

$r_0\ll R\ll (\mathscr {N}-1) \ell _{{sc}}$, in agreement with (3.15). Thus, the statistics of ![]() $T_{{sc}}$ in a turbulent flow is correctly described by the predictions of § 3.1.1.

$T_{{sc}}$ in a turbulent flow is correctly described by the predictions of § 3.1.1.

Figure 4. Passive polymers: (a) p.d.f. of the lifetime of a polymer for different values of ![]() $\mathit {Wi}$. The inset compares the decay time of the fraction of unbroken polymers, the mean lifetime of a polymer and the time scale

$\mathit {Wi}$. The inset compares the decay time of the fraction of unbroken polymers, the mean lifetime of a polymer and the time scale ![]() $\gamma ^{-1}$ in the exponential tail of the p.d.f. (

$\gamma ^{-1}$ in the exponential tail of the p.d.f. (![]() $P(T_{sc})\sim \textrm {e}^{-\gamma T_{sc}}$ for

$P(T_{sc})\sim \textrm {e}^{-\gamma T_{sc}}$ for ![]() $T_{sc}/\tau _\eta \gg 1$) as a function of

$T_{sc}/\tau _\eta \gg 1$) as a function of ![]() $\mathit {Wi}/\mathit {Wi}_{cr}$; (b) mean lifetime as a function of

$\mathit {Wi}/\mathit {Wi}_{cr}$; (b) mean lifetime as a function of ![]() $\ell _{{sc}}/Q_0$ below the coil-stretch transition. Here

$\ell _{{sc}}/Q_0$ below the coil-stretch transition. Here ![]() $T_{sc}'$ is a fitting parameter for the dashed lines. The data for

$T_{sc}'$ is a fitting parameter for the dashed lines. The data for ![]() $\mathit {Wi}=0.4$ (respectively,

$\mathit {Wi}=0.4$ (respectively, ![]() $\mathit {Wi}=0.45$) are multiplied by a factor of

$\mathit {Wi}=0.45$) are multiplied by a factor of ![]() $10^2$ (respectively, 10) in order to make the three lines more easily distinguishable; (c) the same as in panel (b) above the coil-stretch transition.

$10^2$ (respectively, 10) in order to make the three lines more easily distinguishable; (c) the same as in panel (b) above the coil-stretch transition.

We also note that the exponential tail of the distribution of ![]() $T_{sc}$ originates from the fact that scission is caused by the cumulative action of the fluctuating strain rate. This is in contrast to the fragmentation of sub-Kolmogorov inextensible fibres, for which the internal tension depends on the instantaneous velocity gradient projected along the fibre. The p.d.f. of the scission time for fibres, therefore, reflects the intermittent statistics of the velocity gradient and is strongly non-exponential (Allende, Henry & Bec Reference Allende, Henry and Bec2020).

$T_{sc}$ originates from the fact that scission is caused by the cumulative action of the fluctuating strain rate. This is in contrast to the fragmentation of sub-Kolmogorov inextensible fibres, for which the internal tension depends on the instantaneous velocity gradient projected along the fibre. The p.d.f. of the scission time for fibres, therefore, reflects the intermittent statistics of the velocity gradient and is strongly non-exponential (Allende, Henry & Bec Reference Allende, Henry and Bec2020).

Figure 5 presents further results on the statistics of the scission process. As previously observed in experiments (Horn & Merrill Reference Horn and Merrill1984), scission preferentially happens at the midpoint of the polymer. However, the probability of scission happening at the middle link decreases with ![]() $\mathit {Wi}$. The reason for this is that, for small

$\mathit {Wi}$. The reason for this is that, for small ![]() $\mathit {Wi}$, the chain is most of the time in a coiled state and scission occurs because of a sequence of very strong fluctuations of

$\mathit {Wi}$, the chain is most of the time in a coiled state and scission occurs because of a sequence of very strong fluctuations of ![]() $\boldsymbol {\nabla }\boldsymbol {u}$, whereas for large

$\boldsymbol {\nabla }\boldsymbol {u}$, whereas for large ![]() $\mathit {Wi}$ all links are consistently stretched near to the scission length. The insets of figure 5 show that the probability of more than one link breaking simultaneously is generally very small.

$\mathit {Wi}$ all links are consistently stretched near to the scission length. The insets of figure 5 show that the probability of more than one link breaking simultaneously is generally very small.

Figure 5. Passive polymers: probability of polymer scission occurring at the ![]() $j_{sc}$-th link for different values of

$j_{sc}$-th link for different values of ![]() $\mathit {Wi}$. The insets shows the probability of

$\mathit {Wi}$. The insets shows the probability of ![]() $n_L$ links breaking simultaneously.

$n_L$ links breaking simultaneously.

Finally, it was mentioned in § 3.1.1 that, in the absence of scission, the dumbbell model (![]() $\mathscr {N}=2$) captures the statistics of the end-to-end extension of a full chain remarkably well, provided the mapping in (3.17a–d) is applied (see Watanabe & Gotoh Reference Watanabe and Gotoh2010). We have performed an analogous comparison in the presence of scission. The time-integrated p.d.f.s in figure 6(a) show that, after the parameters of the chain are suitably rescaled, the time-independent statistics of the end-to-end distance is independent of

$\mathscr {N}=2$) captures the statistics of the end-to-end extension of a full chain remarkably well, provided the mapping in (3.17a–d) is applied (see Watanabe & Gotoh Reference Watanabe and Gotoh2010). We have performed an analogous comparison in the presence of scission. The time-integrated p.d.f.s in figure 6(a) show that, after the parameters of the chain are suitably rescaled, the time-independent statistics of the end-to-end distance is independent of ![]() $\mathscr {N}$, except for small deviations close to the maximum extension. Indeed, for a dumbbell, scission is defined in terms of the end-to-end separation, whereas chains with larger

$\mathscr {N}$, except for small deviations close to the maximum extension. Indeed, for a dumbbell, scission is defined in terms of the end-to-end separation, whereas chains with larger ![]() $\mathscr {N}$ break before all the links can stretch up to

$\mathscr {N}$ break before all the links can stretch up to ![]() $\ell _{{sc}}$. These small differences, however, have a significant impact on time-dependent quantities, such as the fraction of unbroken polymers: small-

$\ell _{{sc}}$. These small differences, however, have a significant impact on time-dependent quantities, such as the fraction of unbroken polymers: small-![]() $\mathscr {N}$ chains capture the temporal decay qualitatively, but underestimate the scission rate (see figure 6b). The results also suggest that the discrepancies between chains with

$\mathscr {N}$ chains capture the temporal decay qualitatively, but underestimate the scission rate (see figure 6b). The results also suggest that the discrepancies between chains with ![]() $\mathscr {N}-1$ and

$\mathscr {N}-1$ and ![]() $\mathscr {N}$ beads diminish as

$\mathscr {N}$ beads diminish as ![]() $\mathscr {N}$ increases (figure 6b) as well as when

$\mathscr {N}$ increases (figure 6b) as well as when ![]() $\mathit {Wi}$ increases (not shown). We conclude that it is important to consider the dynamics of a full bead-spring chain in order to accurately describe the scission process and achieve quantitative agreement between experiments and models of polymer solutions.

$\mathit {Wi}$ increases (not shown). We conclude that it is important to consider the dynamics of a full bead-spring chain in order to accurately describe the scission process and achieve quantitative agreement between experiments and models of polymer solutions.

Figure 6. Passive polymers: (a) time-integrated p.d.f. of the end-to-end extension of unbroken polymers for ![]() $\mathit {Wi}=0.6$ and different numbers of beads

$\mathit {Wi}=0.6$ and different numbers of beads ![]() $\mathscr {N}$; (b) fraction of unbroken polymers as a function of time for

$\mathscr {N}$; (b) fraction of unbroken polymers as a function of time for ![]() $\mathit {Wi}=0.6$ and different numbers of beads

$\mathit {Wi}=0.6$ and different numbers of beads ![]() $\mathscr {N}$.

$\mathscr {N}$.

3.2. Effect of hydrodynamic and excluded volume interactions

When modelling the rheological properties of dilute polymer solutions, it is important to include HI between the beads of the Rouse model in order to capture effects such as the dependence of solution viscosity on the molecular weight and strain rate, and a non-zero second normal stress difference (Öttinger Reference Öttinger1996). However, HI have no qualitative impact on the stretching dynamics of individual polymers in laminar flows (Jendrejack, de Pablo & Graham Reference Jendrejack, de Pablo and Graham2002; Schroeder, Shaqfeh & Chu Reference Schroeder, Shaqfeh and Chu2004). Moreover, these forces weaken as a polymer is stretched so that elongated polymers are nearly unaffected by HI (Stone & Graham Reference Stone and Graham2003). This is also true for EV interactions (Cifre & de la Torre Reference Cifre and de la Torre1999; Stone & Graham Reference Stone and Graham2003). Thus, we expect the qualitative nature of scission statistics to be unaffected by both HI and EV forces. Indeed, this has been demonstrated for polymers with HI in laminar flows (Cascales & de la Torre Reference Cascales and de la Torre1991; Knudsen, Hernández Cifre & García de la Torre Reference Knudsen, Hernández Cifre and García de la Torre1996; Sim et al. Reference Sim, Khomami and Sureshkumar2007), where the only effect of HI is a quantitative decrease in the scission rate.

All the studies mentioned above, however, have been conducted in non-turbulent flows. Therefore, it is important to check whether the effects of HI and EV forces on polymer scission remain purely quantitative even in turbulent flows. Towards this end, we modify the model in § 2 to incorporate both HI and EV forces, as described in appendix A. This introduces two non-dimensional parameters, ![]() $h$ (related to the bead radius) and

$h$ (related to the bead radius) and ![]() $\nu$, which determine the magnitude of the HI and EV forces, respectively. Setting these parameters to zero recovers the Rouse model of § 2.

$\nu$, which determine the magnitude of the HI and EV forces, respectively. Setting these parameters to zero recovers the Rouse model of § 2.

Our DNS calculations for these ![]() $\textrm {HI}+\textrm {EV}$ chains (with

$\textrm {HI}+\textrm {EV}$ chains (with ![]() $\mathscr {N} = 10$ beads) show that, while the scission statistics remain qualitatively the same, the scission rate is decreased by HI while it is increased by EV forces. These effects are clearly demonstrated by figures 7(a) and 7(b), which depict the evolution of the fraction of surviving polymers and the distribution of polymer lifetimes, respectively. These figures present results for

$\mathscr {N} = 10$ beads) show that, while the scission statistics remain qualitatively the same, the scission rate is decreased by HI while it is increased by EV forces. These effects are clearly demonstrated by figures 7(a) and 7(b), which depict the evolution of the fraction of surviving polymers and the distribution of polymer lifetimes, respectively. These figures present results for ![]() $\mathit {Wi} = 0.9$ for three cases: without HI and EV (red), with only HI (green) and with HI and EV (blue). The decay of the number of unbroken polymers, as well as the distribution of lifetimes, remains exponential in nature even after including HI and EV interactions. However, the scission rate clearly reduces when HI are included and then increases again once EV are also considered. Thus, HI and EV effects oppose each other, reducing their overall impact.

$\mathit {Wi} = 0.9$ for three cases: without HI and EV (red), with only HI (green) and with HI and EV (blue). The decay of the number of unbroken polymers, as well as the distribution of lifetimes, remains exponential in nature even after including HI and EV interactions. However, the scission rate clearly reduces when HI are included and then increases again once EV are also considered. Thus, HI and EV effects oppose each other, reducing their overall impact.

Figure 7. Passive polymers with HI and EV: comparison of the scission statistics for polymers without HI and EV (![]() $h =0, \nu = 0$), with only HI (

$h =0, \nu = 0$), with only HI (![]() $\nu = 0$), and with HI and EV (legend in panel (c)). In all three cases

$\nu = 0$), and with HI and EV (legend in panel (c)). In all three cases ![]() $\mathit {Wi} = 0.9$. Panel (a) presents the decay of the fraction of unbroken polymers, with its inset showing the corresponding results for a larger value of

$\mathit {Wi} = 0.9$. Panel (a) presents the decay of the fraction of unbroken polymers, with its inset showing the corresponding results for a larger value of ![]() $\mathit {Wi} = 2.0$. Panel (b) presents the distribution of lifetimes

$\mathit {Wi} = 2.0$. Panel (b) presents the distribution of lifetimes ![]() $T_{sc}$, while its inset compares typical time traces of the end-to-end extension of polymers with and without HI. Panel (c) shows the time-integrated p.d.f. of the end-to-end extension.

$T_{sc}$, while its inset compares typical time traces of the end-to-end extension of polymers with and without HI. Panel (c) shows the time-integrated p.d.f. of the end-to-end extension.

The effects of HI and EV forces diminish as ![]() $\mathit {Wi}$ is increased, as shown by the inset of figure 7(a), which presents the evolution of the number of unbroken polymers for a larger value of the Weissenberg number (

$\mathit {Wi}$ is increased, as shown by the inset of figure 7(a), which presents the evolution of the number of unbroken polymers for a larger value of the Weissenberg number (![]() $\mathit {Wi} = 2$) than the main panel. This occurs because polymers stretch out with increasing ease as

$\mathit {Wi} = 2$) than the main panel. This occurs because polymers stretch out with increasing ease as ![]() $\mathit {Wi}$ increases, while both HI and EV forces are significant only when polymers are coiled and have small extensions. The impotence of these forces, especially EV, at large extensions is reinforced by figure 7(c) which presents the time-integrated p.d.f. of polymer extension for all three cases. The three curves are seen to nearly overlap at large extensions, with significant differences arising only for

$\mathit {Wi}$ increases, while both HI and EV forces are significant only when polymers are coiled and have small extensions. The impotence of these forces, especially EV, at large extensions is reinforced by figure 7(c) which presents the time-integrated p.d.f. of polymer extension for all three cases. The three curves are seen to nearly overlap at large extensions, with significant differences arising only for ![]() $R \lesssim R_{eq}$. Indeed, HI and EV affect the scission rate by modifying the initial stretching dynamics of small coiled polymers. The HI are known to inhibit and delay the uncoiling of a coiled polymer in laminar flows (Sim et al. Reference Sim, Khomami and Sureshkumar2007). We find that this is true even in a turbulent flow, as illustrated by the inset of figure 7(b) which compares two typical time traces of the end-to-end extension for polymers with and without HI. Thus, HI typically increase the time it takes for a polymer to reach large extensions and thereby reduce the scission rate in an ensemble of polymers. The EV interactions, in contrast, promote the elongation of a coiled polymer and thus hasten its scission. The dynamics near the scission event, however, are unaffected by HI and EV forces, and we therefore find that the distribution of broken link locations (not shown) remains the same as that for Rouse chains (cf. figure 5).

$R \lesssim R_{eq}$. Indeed, HI and EV affect the scission rate by modifying the initial stretching dynamics of small coiled polymers. The HI are known to inhibit and delay the uncoiling of a coiled polymer in laminar flows (Sim et al. Reference Sim, Khomami and Sureshkumar2007). We find that this is true even in a turbulent flow, as illustrated by the inset of figure 7(b) which compares two typical time traces of the end-to-end extension for polymers with and without HI. Thus, HI typically increase the time it takes for a polymer to reach large extensions and thereby reduce the scission rate in an ensemble of polymers. The EV interactions, in contrast, promote the elongation of a coiled polymer and thus hasten its scission. The dynamics near the scission event, however, are unaffected by HI and EV forces, and we therefore find that the distribution of broken link locations (not shown) remains the same as that for Rouse chains (cf. figure 5).

Having seen that HI and EV interactions have no qualitative impact on the scission statistics, we disregard them in the subsequent sections, wherein the computational burden increases significantly due to either the inclusion of polymer feedback onto the flow or the tracking of broken polymer fragments as they undergo repeated scissions.

3.3. Active polymers

We now investigate the implications of the results obtained so far for the two-way-coupling regime in which polymers perturb the surrounding flow.

When polymers break, their effective relaxation time ![]() $\tau ^D$ decreases according to (3.17a–d) and the solution, at any point in time, consists of polymers with different

$\tau ^D$ decreases according to (3.17a–d) and the solution, at any point in time, consists of polymers with different ![]() $\tau ^D$. We can then introduce a mean Weissenberg number

$\tau ^D$. We can then introduce a mean Weissenberg number ![]() $\langle \mathit {Wi}\rangle (t)$, which is defined as the average of

$\langle \mathit {Wi}\rangle (t)$, which is defined as the average of ![]() $\lambda \tau ^D$ over all polymers that compose the solution at time

$\lambda \tau ^D$ over all polymers that compose the solution at time ![]() $t$. Studying the evolution of

$t$. Studying the evolution of ![]() $\langle \mathit {Wi}\rangle (t)$, in a one-way-coupling simulation, helps us foresee how the effect of polymer feedback on the flow would decay due to scission.

$\langle \mathit {Wi}\rangle (t)$, in a one-way-coupling simulation, helps us foresee how the effect of polymer feedback on the flow would decay due to scission.

Let us, for the sake of simplicity, consider the case of dumbbells (![]() $\mathscr {N}=2$) and take an initial ensemble of

$\mathscr {N}=2$) and take an initial ensemble of ![]() $N_p(0)$ dumbbells with Weissenberg number

$N_p(0)$ dumbbells with Weissenberg number ![]() $\mathit {Wi}_0$. When a dumbbell breaks it forms two beads which formally have zero Weissenberg number. Thus, at time

$\mathit {Wi}_0$. When a dumbbell breaks it forms two beads which formally have zero Weissenberg number. Thus, at time ![]() $t$, the system consists of

$t$, the system consists of ![]() $N_p(t)$ dumbbells with

$N_p(t)$ dumbbells with ![]() $\mathit {Wi}=\mathit {Wi}_0$ and

$\mathit {Wi}=\mathit {Wi}_0$ and ![]() $2[N_p(0)-N_p(t)]$ single beads with

$2[N_p(0)-N_p(t)]$ single beads with ![]() $\mathit {Wi}=0$. Hence, for an ensemble of dumbbells,

$\mathit {Wi}=0$. Hence, for an ensemble of dumbbells,

The temporal evolution of ![]() $\langle \mathit {Wi}\rangle$ is obtained by calculating

$\langle \mathit {Wi}\rangle$ is obtained by calculating ![]() $N_p(t)$ from the Lagrangian database used in § 3.1.2 and is shown in figure 8(a) for different values of

$N_p(t)$ from the Lagrangian database used in § 3.1.2 and is shown in figure 8(a) for different values of ![]() $\mathit {Wi}_0>\mathit {Wi}_{cr}$. Dumbbells with larger

$\mathit {Wi}_0>\mathit {Wi}_{cr}$. Dumbbells with larger ![]() $\mathit {Wi}_0$ have a larger scission rate, and therefore

$\mathit {Wi}_0$ have a larger scission rate, and therefore ![]() $\langle \mathit {Wi}\rangle$ vanishes rapidly. In contrast, dumbbells with smaller

$\langle \mathit {Wi}\rangle$ vanishes rapidly. In contrast, dumbbells with smaller ![]() $\mathit {Wi}_0$ break relatively slowly and the mean

$\mathit {Wi}_0$ break relatively slowly and the mean ![]() $\mathit {Wi}$ of the solution remains non-zero for a longer time. We note, en passant, that

$\mathit {Wi}$ of the solution remains non-zero for a longer time. We note, en passant, that ![]() $\langle \mathit {Wi}\rangle$ becomes approximately equal to

$\langle \mathit {Wi}\rangle$ becomes approximately equal to ![]() $\mathit {Wi}_{cr}$ at

$\mathit {Wi}_{cr}$ at ![]() $t\approx 50\tau _\eta$ for all

$t\approx 50\tau _\eta$ for all ![]() $\mathit {Wi}_0$. By substituting (3.8) into (3.18), we thus deduce the following empirical expression for the scission rate of dumbbells (see figure 8b):

$\mathit {Wi}_0$. By substituting (3.8) into (3.18), we thus deduce the following empirical expression for the scission rate of dumbbells (see figure 8b):

The behaviour of ![]() $\langle \mathit {Wi}\rangle$ shown in figure 8(a) suggests that a large value of

$\langle \mathit {Wi}\rangle$ shown in figure 8(a) suggests that a large value of ![]() $\mathit {Wi}_0$ will produce a polymer feedback that is initially strong but short-lived, decaying rapidly due to scission. In contrast, a moderate value of

$\mathit {Wi}_0$ will produce a polymer feedback that is initially strong but short-lived, decaying rapidly due to scission. In contrast, a moderate value of ![]() $\mathit {Wi}_0$ yields a feedback that, albeit weaker, should last for a longer time and may therefore be more effective.

$\mathit {Wi}_0$ yields a feedback that, albeit weaker, should last for a longer time and may therefore be more effective.

Figure 8. Passive polymers: (a) mean Weissenberg number as a function of time for ![]() $\mathscr {N}=2$ and different values of

$\mathscr {N}=2$ and different values of ![]() $\mathit {Wi}_0$; (b) reciprocal of

$\mathit {Wi}_0$; (b) reciprocal of ![]() $T_d$ (multiplied by the Kolmogorov time scale) as a function of

$T_d$ (multiplied by the Kolmogorov time scale) as a function of ![]() $1+\mathit {Wi}/\mathit {Wi}_{cr}$. The dashed line is proportional to

$1+\mathit {Wi}/\mathit {Wi}_{cr}$. The dashed line is proportional to ![]() $\ln [( 1+ \mathit {Wi}/\mathit {Wi}_{cr})/2]$.

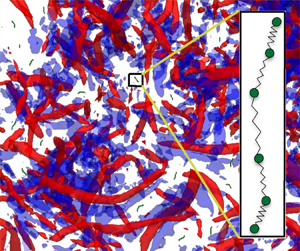

$\ln [( 1+ \mathit {Wi}/\mathit {Wi}_{cr})/2]$.