1 Introduction

Flow-induced motion, deformation and breakup of droplets on a solid surface have been the subject of intense research because of their scientific and technical importance (Dimitrakopoulos & Higdon Reference Dimitrakopoulos and Higdon1998; Spelt Reference Spelt2006; Dimitrakopoulos Reference Dimitrakopoulos2007; Ding & Spelt Reference Ding and Spelt2008; Gupta & Basu Reference Gupta and Basu2008; Sugiyama & Sbragaglia Reference Sugiyama and Sbragaglia2008; Ding, Gilani & Spelt Reference Ding, Gilani and Spelt2010). In many applications involving droplets on a solid surface, surfactants are often present as impurities or are added deliberately to the bulk fluid, which can critically affect the dynamics of multiphase flow systems. For example, in the petroleum industry, enhanced oil recovery depends strongly on the displacement of oil droplets through rock formation, and surfactants are commonly used to increase oil production by decreasing the interfacial tension between fluids and altering the wetting properties of rock surfaces (Shah & Schechter Reference Shah and Schechter2012; Hou et al. Reference Hou, Wang, Cao, Zhang, Song, Ding and Chen2016; Wei et al. Reference Wei, Hou, Sukop and Liu2019). In the coating industry, surfactants can mitigate the wetting failure (Schunk & Scriven Reference Schunk and Scriven1997; Liu et al. Reference Liu, Vandre, Carvalho and Kumar2016a,Reference Liu, Vandre, Carvalho and Kumarb), which occurs when the liquid no longer entirely displaces the ambient gas at the contact line, thus improving the uniformity required for precision film coating. Recently, rapid developments in microfluidic technologies have enabled reliable fabrication and manipulation of small droplets with controlled size using low-cost devices, where the addition of surfactants is essential to stabilise the droplets against coalescence (Binks et al. Reference Binks, Fletcher, Holt, Beaussoubre and Wong2010; Li, Wang & Luo Reference Li, Wang and Luo2017; Zinchenko & Davis Reference Zinchenko and Davis2017; Riaud et al. Reference Riaud, Zhang, Wang, Wang and Luo2018; Roumpea et al. Reference Roumpea, Kovalchuk, Chinaud, Nowak, Simmons and Angeli2019).

There have been a number of experimental studies investigating the motion of a liquid droplet on a solid surface in the presence of surfactants (Rafaïet al. Reference Rafaï, Sarker, Bergeron, Meunier and Bonn2002; Tan, Gee & Stevens Reference Tan, Gee and Stevens2003; Nikolov & Wasan Reference Nikolov and Wasan2015; Jiang, Sun & Santamarina Reference Jiang, Sun and Santamarina2016; Roumpea et al. Reference Roumpea, Kovalchuk, Chinaud, Nowak, Simmons and Angeli2019). Nevertheless, it is still very challenging to conduct precise experimental measurements of the local surfactant concentration and flow fields during the droplet movement, and experimental studies suffer from the difficulty to assess the effect of each influencing factor. Theoretical studies based on a lubrication approximation have been used for analysing the spreading and stability of a surfactant-covered droplet with a sufficiently small aspect ratio (defined by the maximum height of the droplet to its length) on a substrate (Clay & Miksis Reference Clay and Miksis2004; Jensen & Naire Reference Jensen and Naire2006; Karapetsas, Craster & Matar Reference Karapetsas, Craster and Matar2011a,Reference Karapetsas, Craster and Matarb; Weidner Reference Weidner2012; Wei Reference Wei2018). Unfortunately, they are unable to solve the instantaneous behaviour of a spherical cap droplet with a large contact angle due to the limitation of lubrication approximation. Numerical simulations can complement theoretical and experimental studies, providing additional insights into how the flow and physical parameters influence the dynamical behaviours of droplets on a solid surface in the presence of surfactants.

The efficient and accurate computational modelling of droplet motion on a solid surface with surfactants is a challenging task. The surfactant concentration at the interface alters the interfacial tension locally, and a non-uniform distribution of surfactants creates non-uniform capillary forces and tangential Marangoni stresses, which affect the flow field in a complicated manner. In turn, the flow field advects the surfactants and influences their distribution, causing the surfactant concentration and flow field to couple. From a numerical point of view, the surfactant evolution equation must be solved together with the hydrodynamic equations at moving and deforming interfaces, which may undergo topological changes such as breakup and coalescence. In addition, when the droplet moves over a solid surface, the contact angle should dynamically vary with the local surfactant concentration and the moving contact lines (MCL) need to be handled properly, which have for many years remained an issue of controversy and debate (Sui, Ding & Spelt Reference Sui, Ding and Spelt2014), posing an additional numerical challenge.

To tackle the aforementioned challenges, many efforts have been dedicated to the study of interfacial flows with both surfactants and contact-line dynamics. Yon & Pozrikidis (Reference Yon and Pozrikidis1999) studied the effect of insoluble surfactants on a droplet attached to a plane wall and subject to an overpassing shear flow in the limit of Stokes flow. To simplify the problem, they assumed that the contact line retains a circular shape and pins on the solid surface during the droplet deformation. Their results revealed that the overall behaviour of the droplet is determined not only by the capillary number and viscosity ratio, but also by the sensitivity of interfacial tension to variations in surfactant concentration. Schleizer & Bonnecaze (Reference Schleizer and Bonnecaze1999) presented a boundary-integral method to investigate the role of surfactants on the displacement of a two-dimensional (2-D) immiscible droplet over a solid wall in both shear and pressure-driven flows. They considered the contact lines either fixed or mobile, and assumed that, when the contact lines are allowed to move, the contact angle is independent of the slip velocity and is therefore equal to its static value. They found that for a neutral surface the critical capillary number, above which the droplet cannot reach a steady shape, is larger for droplets with MCL compared to those with pinned contact lines. Axisymmetric spreading of a liquid droplet containing soluble surfactants on an ideal substrate was numerically investigated by Chan & Borhan (Reference Chan and Borhan2006), where the slip velocity of a contact line was related to the dynamic contact angle through a constitutive equation. Lai, Tseng & Huang (Reference Lai, Tseng and Huang2010) developed an immersed boundary method to simulate a droplet on a solid substrate under the influence of insoluble surfactants. An unbalanced Young stress, resulting from the deviation of the dynamic contact angle from the static one, was incorporated into the momentum equations as a driving force for the contact-line motion. An arbitrary Lagrangian–Eulerian finite element scheme for a soluble surfactant droplet impingement on a horizontal surface was presented by Ganesan (Reference Ganesan2013). In his work, the dynamic contact angle was expressed as a function of the static contact angle and the local surfactant concentration. Xu & Ren (Reference Xu and Ren2014) presented a level-set method for the simulation of two-phase flows with insoluble surfactants and MCL. A contact angle condition, which relates the unbalanced Young stress to the slip velocity of the contact line, was used to include the effect of surfactants on surface wettability. By decomposing the fluid interface into segments with local Eulerian grids, af Klinteberg, Lindbo & Tornberg (Reference af Klinteberg, Lindbo and Tornberg2014) developed a numerical method for two-phase flows with insoluble surfactants and contact-line dynamics in two dimensions. To drive the movement of the contact line, they defined the tangential velocity in the vicinity of the contact line and used the Navier slip condition on the walls away from the contact line. Based on thermodynamic principles, Zhang, Xu & Ren (Reference Zhang, Xu and Ren2014) derived a continuous model for the dynamics of two immiscible fluids with MCL and insoluble surfactants, in which the condition for the dynamic contact angle was obtained by the consideration of energy dissipations. Recently, we presented a lattice-Boltzmann (LB) and finite-difference hybrid method for the simulation of a 2-D droplet moving on a solid wall subject to a linear shear flow (Zhang, Liu & Ba Reference Zhang, Liu and Ba2019). To model the fluid–surface interactions, a dynamic contact angle formulation that describes the dependence of the local contact angle on the surfactant concentration was derived, and the resulting contact angle was enforced by a geometrical wetting condition. By comparing a clean droplet with a surfactant-covered droplet at the same effective capillary number ( $Ca_{e}$), we explored, for the first time, how the presence of surfactants influences the droplet motion, deformation and breakup for varying

$Ca_{e}$), we explored, for the first time, how the presence of surfactants influences the droplet motion, deformation and breakup for varying  $Ca_{e}$. Wei et al. (Reference Wei, Hou, Sukop and Liu2019) conducted a pore-scale study of ternary amphiphilic fluid flow through a porous media using a bottom-up LB model, in which a dipole is introduced to capture the amphiphilic structure of surfactant molecules. It was found that surfactants could improve the oil recovery in all wetting conditions, but the surfactant loss due to adsorption onto walls diminishes the effect of interfacial tension reduction. In addition, Tang et al. (Reference Tang, Xiao, Lei, Yuan, Peng, He, Luo and Pei2019) carried out molecular dynamics simulations to study the surfactant flooding driven detachment of oil droplet in a nanosilica channel. They revealed that the surfactant molecules tend to migrate to the rear bottom of the oil molecular aggregate caused by the water flow effect and hydration of polar head groups of surfactants, which facilitate the penetration of water molecules into the oil–rock interface, and the oil molecule detachment occurs at the rear bottom of the oil molecular aggregate.

$Ca_{e}$. Wei et al. (Reference Wei, Hou, Sukop and Liu2019) conducted a pore-scale study of ternary amphiphilic fluid flow through a porous media using a bottom-up LB model, in which a dipole is introduced to capture the amphiphilic structure of surfactant molecules. It was found that surfactants could improve the oil recovery in all wetting conditions, but the surfactant loss due to adsorption onto walls diminishes the effect of interfacial tension reduction. In addition, Tang et al. (Reference Tang, Xiao, Lei, Yuan, Peng, He, Luo and Pei2019) carried out molecular dynamics simulations to study the surfactant flooding driven detachment of oil droplet in a nanosilica channel. They revealed that the surfactant molecules tend to migrate to the rear bottom of the oil molecular aggregate caused by the water flow effect and hydration of polar head groups of surfactants, which facilitate the penetration of water molecules into the oil–rock interface, and the oil molecule detachment occurs at the rear bottom of the oil molecular aggregate.

As reviewed above, most of the studies focus on developing numerical methods for computation of interfacial flows with both surfactants and contact-line dynamics, but these methods are not applicable when the local surfactant concentration approaches or exceeds the critical micelle concentration (CMC, at which surfactant molecules begin to self-associate to form stable aggregates known as micelles). In addition, although several works have studied the dynamical behaviour of a surfactant-covered droplet on a solid surface subject to a shear flow, e.g. Schleizer & Bonnecaze (Reference Schleizer and Bonnecaze1999), Yon & Pozrikidis (Reference Yon and Pozrikidis1999), Zhang et al. (Reference Zhang, Liu and Ba2019), they commonly suffer from the following drawbacks: (I) they either have not considered the MCL or are limited to two dimensions, which cannot reproduce the physical three-dimensional test conditions accurately; (II) the factors influencing the droplet motion and deformation have not yet been studied systematically; and (III) the critical conditions of droplet breakup, e.g. for varying viscosity ratio, have been rarely explored so far.

In this work we will extend our recently developed hybrid method to three dimensions for the simulation of a surfactant-covered droplet moving on a solid surface subject to a linear shear flow, where the droplet is of equal density to the ambient fluid and the Reynolds number is fixed at 1. Unlike its 2-D counterpart (Zhang et al. Reference Zhang, Liu and Ba2019), the present method is able to deal with the surfactant concentration beyond the CMC. In order to break the limitations of the existing works, we will study not only the droplet deformation and motion for varying effective capillary number, viscosity ratio and surfactant coverage, but also the critical conditions of droplet breakup for varying viscosity ratio, in which the roles of surfactants will be identified by comparing with the results of a clean droplet. The paper is organised as follows. In § 2 the mathematical model and numerical method are described briefly, and in § 3 the results of droplet motion, deformation and breakup are presented and discussed. The paper closes with a summary of the main results in § 4.

2 Problem statement and numerical method

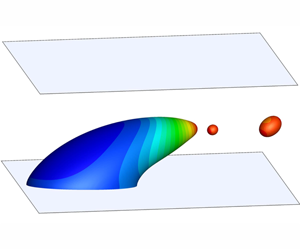

We consider the dynamical behaviour of a surfactant-covered droplet moving on a solid surface and subject to a three-dimensional (3-D) linear shear flow. As sketched in figure 1, two infinite walls, both parallel to the  $x$–

$x$– $y$ plane, are separated by a distance

$y$ plane, are separated by a distance  $H$. The bottom wall is stationary, and the top wall moves to the right with a constant velocity

$H$. The bottom wall is stationary, and the top wall moves to the right with a constant velocity  $u_{w}$, thus creating a shear flow with the shear rate

$u_{w}$, thus creating a shear flow with the shear rate  $\dot{\unicode[STIX]{x1D6FE}}=u_{w}/H$. Initially, a hemispherical droplet (red fluid) with the radius of

$\dot{\unicode[STIX]{x1D6FE}}=u_{w}/H$. Initially, a hemispherical droplet (red fluid) with the radius of  $R$ rests on the bottom wall. Both droplet and ambient fluid (blue fluid) are assumed to be incompressible, viscous and immiscible, and to have equal densities. The dynamic viscosities for the droplet and ambient fluid are

$R$ rests on the bottom wall. Both droplet and ambient fluid (blue fluid) are assumed to be incompressible, viscous and immiscible, and to have equal densities. The dynamic viscosities for the droplet and ambient fluid are  $\unicode[STIX]{x1D707}^{R}$ and

$\unicode[STIX]{x1D707}^{R}$ and  $\unicode[STIX]{x1D707}^{B}$, respectively. For the sake of simplicity, the surfactants are considered to be insoluble and present only at the interface between the droplet and the ambient fluid, and they are initially distributed uniformly at the droplet surface with a concentration of

$\unicode[STIX]{x1D707}^{B}$, respectively. For the sake of simplicity, the surfactants are considered to be insoluble and present only at the interface between the droplet and the ambient fluid, and they are initially distributed uniformly at the droplet surface with a concentration of  $\unicode[STIX]{x1D713}_{0}$.

$\unicode[STIX]{x1D713}_{0}$.

Figure 1. A hemispherical droplet sitting on a solid wall subject to a linear shear flow. The shear flow is created by moving the top wall with a constant velocity  $u_{w}$. The computational domain has a size of

$u_{w}$. The computational domain has a size of  $L\times W\times H=560\times 400\times 100$, and the droplet has an initial radius of

$L\times W\times H=560\times 400\times 100$, and the droplet has an initial radius of  $R=50$. The droplet and the ambient fluid are assumed to have equal densities, and their dynamic viscosities are

$R=50$. The droplet and the ambient fluid are assumed to have equal densities, and their dynamic viscosities are  $\unicode[STIX]{x1D707}^{R}$ and

$\unicode[STIX]{x1D707}^{R}$ and  $\unicode[STIX]{x1D707}^{B}$, which give a viscosity ratio of

$\unicode[STIX]{x1D707}^{B}$, which give a viscosity ratio of  $\unicode[STIX]{x1D706}=\unicode[STIX]{x1D707}^{R}/\unicode[STIX]{x1D707}^{B}$.

$\unicode[STIX]{x1D706}=\unicode[STIX]{x1D707}^{R}/\unicode[STIX]{x1D707}^{B}$.

Using the continuum surface force formulation, the fluid flow for such a multiphase system is governed by a single set of Navier–Stokes equations (NSE):

$$\begin{eqnarray}\displaystyle & \displaystyle \unicode[STIX]{x1D735}\boldsymbol{\cdot }\boldsymbol{u}=0, & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle \unicode[STIX]{x1D735}\boldsymbol{\cdot }\boldsymbol{u}=0, & \displaystyle\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & \displaystyle \unicode[STIX]{x2202}_{t}(\unicode[STIX]{x1D70C}\boldsymbol{u})+\unicode[STIX]{x1D735}\boldsymbol{\cdot }(\unicode[STIX]{x1D70C}\boldsymbol{u}\boldsymbol{u})=-\unicode[STIX]{x1D735}p+\unicode[STIX]{x1D735}\boldsymbol{\cdot }[\unicode[STIX]{x1D707}(\unicode[STIX]{x1D735}\boldsymbol{u}+\unicode[STIX]{x1D735}\boldsymbol{u}^{\text{T}})]+\boldsymbol{F}_{s}, & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle \unicode[STIX]{x2202}_{t}(\unicode[STIX]{x1D70C}\boldsymbol{u})+\unicode[STIX]{x1D735}\boldsymbol{\cdot }(\unicode[STIX]{x1D70C}\boldsymbol{u}\boldsymbol{u})=-\unicode[STIX]{x1D735}p+\unicode[STIX]{x1D735}\boldsymbol{\cdot }[\unicode[STIX]{x1D707}(\unicode[STIX]{x1D735}\boldsymbol{u}+\unicode[STIX]{x1D735}\boldsymbol{u}^{\text{T}})]+\boldsymbol{F}_{s}, & \displaystyle\end{eqnarray}$$ where  $t$ is the time,

$t$ is the time,  $\unicode[STIX]{x1D707}$ is the dynamic viscosity and

$\unicode[STIX]{x1D707}$ is the dynamic viscosity and  $\unicode[STIX]{x1D70C}$,

$\unicode[STIX]{x1D70C}$,  $\boldsymbol{u}$ and

$\boldsymbol{u}$ and  $p$ are the total density, fluid velocity and pressure, respectively. The last term in (2.2) represents the interfacial force which includes not only the interfacial tension force but also the Marangoni stress, and is defined as

$p$ are the total density, fluid velocity and pressure, respectively. The last term in (2.2) represents the interfacial force which includes not only the interfacial tension force but also the Marangoni stress, and is defined as

$$\begin{eqnarray}\boldsymbol{F}_{s}=\unicode[STIX]{x1D70E}\unicode[STIX]{x1D705}\boldsymbol{n}\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}+\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}\unicode[STIX]{x1D735}_{s}\unicode[STIX]{x1D70E},\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{F}_{s}=\unicode[STIX]{x1D70E}\unicode[STIX]{x1D705}\boldsymbol{n}\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}+\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}\unicode[STIX]{x1D735}_{s}\unicode[STIX]{x1D70E},\end{eqnarray}$$ where  $\unicode[STIX]{x1D70E}$ is the interfacial tension,

$\unicode[STIX]{x1D70E}$ is the interfacial tension,  $\unicode[STIX]{x1D705}$ is the interface curvature,

$\unicode[STIX]{x1D705}$ is the interface curvature,  $\boldsymbol{n}$ is the unit normal to the interface,

$\boldsymbol{n}$ is the unit normal to the interface,  $\unicode[STIX]{x1D735}_{s}=\unicode[STIX]{x1D735}-\boldsymbol{n}(\boldsymbol{n}\boldsymbol{\cdot }\unicode[STIX]{x1D735})$ is the surface gradient operator and

$\unicode[STIX]{x1D735}_{s}=\unicode[STIX]{x1D735}-\boldsymbol{n}(\boldsymbol{n}\boldsymbol{\cdot }\unicode[STIX]{x1D735})$ is the surface gradient operator and  $\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}$ is the Dirac delta function which should satisfy

$\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}$ is the Dirac delta function which should satisfy  $\int _{-\infty }^{\infty }\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}\text{d}\unicode[STIX]{x1D712}=1$ in order to recover properly the stress jump condition in the sharp-interface limit. Here

$\int _{-\infty }^{\infty }\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}\text{d}\unicode[STIX]{x1D712}=1$ in order to recover properly the stress jump condition in the sharp-interface limit. Here  $\unicode[STIX]{x1D712}$ is the spatial location normal to the interface.

$\unicode[STIX]{x1D712}$ is the spatial location normal to the interface.

In addition to (2.1) and (2.2), an advection equation has to be solved to capture the interface evolution in traditional multiphase solvers, e.g. the volume-of-fluid and level-set methods, where the sophisticated interface reconstruction algorithm or unphysical reinitialization process is often required. In order to avoid these issues, we use an improved LB colour-gradient model for immiscible two-phase flows with variable interfacial tension, where the surfactant concentration can be above the CMC. In the colour-gradient model, the red and blue distribution functions  $f_{i}^{R}$ and

$f_{i}^{R}$ and  $f_{i}^{B}$ are introduced to represent the droplet and the ambient fluid, respectively. The implementation of this model consists of three steps, i.e. collision, recolouring and streaming. The recolouring and streaming steps are exactly the same as those in Liu et al. (Reference Liu, Ba, Wu, Li, Xi and Zhang2018) and thus are not shown here. For the collision step, the total distribution function

$f_{i}^{B}$ are introduced to represent the droplet and the ambient fluid, respectively. The implementation of this model consists of three steps, i.e. collision, recolouring and streaming. The recolouring and streaming steps are exactly the same as those in Liu et al. (Reference Liu, Ba, Wu, Li, Xi and Zhang2018) and thus are not shown here. For the collision step, the total distribution function  $f_{i}=f_{i}^{R}+f_{i}^{B}$ evolves as

$f_{i}=f_{i}^{R}+f_{i}^{B}$ evolves as

$$\begin{eqnarray}f_{i}^{\dagger }(\boldsymbol{x},t)=f_{i}(\boldsymbol{x},t)+\unicode[STIX]{x1D6FA}_{i}(\boldsymbol{x},t)+\bar{F_{i}},\end{eqnarray}$$

$$\begin{eqnarray}f_{i}^{\dagger }(\boldsymbol{x},t)=f_{i}(\boldsymbol{x},t)+\unicode[STIX]{x1D6FA}_{i}(\boldsymbol{x},t)+\bar{F_{i}},\end{eqnarray}$$ where  $f_{i}(\boldsymbol{x},t)$ is the total distribution function in the

$f_{i}(\boldsymbol{x},t)$ is the total distribution function in the  $i$th velocity direction at the position

$i$th velocity direction at the position  $\boldsymbol{x}$ and time

$\boldsymbol{x}$ and time  $t$,

$t$,  $f_{i}^{\dagger }(\boldsymbol{x},t)$ is the post-collision total distribution function,

$f_{i}^{\dagger }(\boldsymbol{x},t)$ is the post-collision total distribution function,  $\unicode[STIX]{x1D6FA}_{i}(\boldsymbol{x},t)$ is the collision operator and

$\unicode[STIX]{x1D6FA}_{i}(\boldsymbol{x},t)$ is the collision operator and  $\bar{F_{i}}$ is the forcing term.

$\bar{F_{i}}$ is the forcing term.

To obtain viscosity-independent wall location and contact-line dynamics, the multiple-relaxation-time collision operator is adopted instead of its Bhatnagar–Gross–Krook counterpart, and is given by (Zhang et al. Reference Zhang, Liu and Ba2019)

$$\begin{eqnarray}\unicode[STIX]{x1D6FA}_{i}(\boldsymbol{x},t)=-\mathop{\sum }_{j}(\unicode[STIX]{x1D648}^{-1}\unicode[STIX]{x1D64E}\unicode[STIX]{x1D648})_{ij}(f_{j}(\boldsymbol{x},t)-f_{j}^{eq}(\boldsymbol{x},t)),\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D6FA}_{i}(\boldsymbol{x},t)=-\mathop{\sum }_{j}(\unicode[STIX]{x1D648}^{-1}\unicode[STIX]{x1D64E}\unicode[STIX]{x1D648})_{ij}(f_{j}(\boldsymbol{x},t)-f_{j}^{eq}(\boldsymbol{x},t)),\end{eqnarray}$$ where  $\unicode[STIX]{x1D648}$ is the transformation matrix that linearly maps the distribution functions onto their moments and

$\unicode[STIX]{x1D648}$ is the transformation matrix that linearly maps the distribution functions onto their moments and  $\unicode[STIX]{x1D64E}$ is a diagonal relaxation matrix. Here

$\unicode[STIX]{x1D64E}$ is a diagonal relaxation matrix. Here  $f_{i}^{eq}$ is the equilibrium distribution function defined as

$f_{i}^{eq}$ is the equilibrium distribution function defined as

$$\begin{eqnarray}f_{i}^{eq}=\unicode[STIX]{x1D70C}w_{i}\left[1+\frac{\boldsymbol{e}_{i}\boldsymbol{\cdot }\boldsymbol{u}}{c_{s}^{2}}+\frac{(\boldsymbol{e}_{i}\boldsymbol{\cdot }\boldsymbol{u})^{2}}{2c_{s}^{4}}-\frac{\boldsymbol{u}^{2}}{2c_{s}^{2}}\right],\end{eqnarray}$$

$$\begin{eqnarray}f_{i}^{eq}=\unicode[STIX]{x1D70C}w_{i}\left[1+\frac{\boldsymbol{e}_{i}\boldsymbol{\cdot }\boldsymbol{u}}{c_{s}^{2}}+\frac{(\boldsymbol{e}_{i}\boldsymbol{\cdot }\boldsymbol{u})^{2}}{2c_{s}^{4}}-\frac{\boldsymbol{u}^{2}}{2c_{s}^{2}}\right],\end{eqnarray}$$ where  $\unicode[STIX]{x1D70C}$ is calculated by

$\unicode[STIX]{x1D70C}$ is calculated by  $\unicode[STIX]{x1D70C}=\unicode[STIX]{x1D70C}^{R}+\unicode[STIX]{x1D70C}^{B}$ with the superscripts ‘

$\unicode[STIX]{x1D70C}=\unicode[STIX]{x1D70C}^{R}+\unicode[STIX]{x1D70C}^{B}$ with the superscripts ‘ $R$’ and ‘

$R$’ and ‘ $B$’ referring to the droplet and ambient fluid respectively,

$B$’ referring to the droplet and ambient fluid respectively,  $\boldsymbol{e}_{i}$ is the lattice velocity in the

$\boldsymbol{e}_{i}$ is the lattice velocity in the  $i$th direction,

$i$th direction,  $w_{i}$ is the weighting factor and

$w_{i}$ is the weighting factor and  $c_{s}$ is the speed of sound. For the 3-D 19-velocity (D3Q19) lattice model used in the present study, the speed of sound

$c_{s}$ is the speed of sound. For the 3-D 19-velocity (D3Q19) lattice model used in the present study, the speed of sound  $c_{s}=\unicode[STIX]{x1D6FF}_{x}/(\sqrt{3}\unicode[STIX]{x1D6FF}_{t})=1/\sqrt{3}$, where the lattice spacing

$c_{s}=\unicode[STIX]{x1D6FF}_{x}/(\sqrt{3}\unicode[STIX]{x1D6FF}_{t})=1/\sqrt{3}$, where the lattice spacing  $\unicode[STIX]{x1D6FF}_{x}$ and the time step

$\unicode[STIX]{x1D6FF}_{x}$ and the time step  $\unicode[STIX]{x1D6FF}_{t}$ are both taken as 1, and the explicit expressions of

$\unicode[STIX]{x1D6FF}_{t}$ are both taken as 1, and the explicit expressions of  $\unicode[STIX]{x1D648}$,

$\unicode[STIX]{x1D648}$,  $\boldsymbol{e}_{i}$ and

$\boldsymbol{e}_{i}$ and  $w_{i}$ can be found in D’humières et al. (Reference D’humières, Ginzburg, Krafczyk, Lallemand and Luo2002).

$w_{i}$ can be found in D’humières et al. (Reference D’humières, Ginzburg, Krafczyk, Lallemand and Luo2002).

The diagonal relaxation matrix  $\unicode[STIX]{x1D64E}$ reads as (Ginzburg & d’Humières Reference Ginzburg and d’Humières2003; Wang, Liu & Zhang Reference Wang, Liu and Zhang2017)

$\unicode[STIX]{x1D64E}$ reads as (Ginzburg & d’Humières Reference Ginzburg and d’Humières2003; Wang, Liu & Zhang Reference Wang, Liu and Zhang2017)

$$\begin{eqnarray}\unicode[STIX]{x1D64E}=\text{diag}\left[0,s_{1},s_{2},0,s_{4},0,s_{4},0,s_{4},s_{9},s_{10},s_{9},s_{10},s_{13},s_{13},s_{13},s_{16},s_{16},s_{16}\right],\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D64E}=\text{diag}\left[0,s_{1},s_{2},0,s_{4},0,s_{4},0,s_{4},s_{9},s_{10},s_{9},s_{10},s_{13},s_{13},s_{13},s_{16},s_{16},s_{16}\right],\end{eqnarray}$$ with the relaxation rates  $s_{i}$ given as

$s_{i}$ given as

$$\begin{eqnarray}s_{1}=s_{2}=s_{9}=s_{10}=s_{13}=\unicode[STIX]{x1D714},\quad s_{4}=s_{16}=\frac{8(2-s_{1})}{8-s_{1}},\end{eqnarray}$$

$$\begin{eqnarray}s_{1}=s_{2}=s_{9}=s_{10}=s_{13}=\unicode[STIX]{x1D714},\quad s_{4}=s_{16}=\frac{8(2-s_{1})}{8-s_{1}},\end{eqnarray}$$ where  $\unicode[STIX]{x1D714}$ is the dimensionless relaxation parameter related to the dynamic viscosity

$\unicode[STIX]{x1D714}$ is the dimensionless relaxation parameter related to the dynamic viscosity  $\unicode[STIX]{x1D707}$ by

$\unicode[STIX]{x1D707}$ by  $\unicode[STIX]{x1D707}=(1/\unicode[STIX]{x1D714}-0.5)\unicode[STIX]{x1D70C}c_{s}^{2}\unicode[STIX]{x1D6FF}_{t}$. To account for unequal viscosities of the two fluids, the dynamic viscosity

$\unicode[STIX]{x1D707}=(1/\unicode[STIX]{x1D714}-0.5)\unicode[STIX]{x1D70C}c_{s}^{2}\unicode[STIX]{x1D6FF}_{t}$. To account for unequal viscosities of the two fluids, the dynamic viscosity  $\unicode[STIX]{x1D707}$ is determined by the harmonic mean as

$\unicode[STIX]{x1D707}$ is determined by the harmonic mean as

$$\begin{eqnarray}\frac{1}{\unicode[STIX]{x1D707}}=\frac{1+\unicode[STIX]{x1D70C}^{N}}{2\unicode[STIX]{x1D707}^{R}}+\frac{1-\unicode[STIX]{x1D70C}^{N}}{2\unicode[STIX]{x1D707}^{B}},\end{eqnarray}$$

$$\begin{eqnarray}\frac{1}{\unicode[STIX]{x1D707}}=\frac{1+\unicode[STIX]{x1D70C}^{N}}{2\unicode[STIX]{x1D707}^{R}}+\frac{1-\unicode[STIX]{x1D70C}^{N}}{2\unicode[STIX]{x1D707}^{B}},\end{eqnarray}$$ where  $\unicode[STIX]{x1D70C}^{N}$ is the phase field function responsible to identify the interface location, and is defined by

$\unicode[STIX]{x1D70C}^{N}$ is the phase field function responsible to identify the interface location, and is defined by

$$\begin{eqnarray}\unicode[STIX]{x1D70C}^{N}(\boldsymbol{x},t)=\frac{\unicode[STIX]{x1D70C}^{R}(\boldsymbol{x},t)-\unicode[STIX]{x1D70C}^{B}(\boldsymbol{x},t)}{\unicode[STIX]{x1D70C}^{R}(\boldsymbol{x},t)+\unicode[STIX]{x1D70C}^{B}(\boldsymbol{x},t)}.\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D70C}^{N}(\boldsymbol{x},t)=\frac{\unicode[STIX]{x1D70C}^{R}(\boldsymbol{x},t)-\unicode[STIX]{x1D70C}^{B}(\boldsymbol{x},t)}{\unicode[STIX]{x1D70C}^{R}(\boldsymbol{x},t)+\unicode[STIX]{x1D70C}^{B}(\boldsymbol{x},t)}.\end{eqnarray}$$The CMC is the surfactant concentration above which surfactant molecules aggregate to form micelles, and it is an important parameter that characterises the surfactant behaviour. Before reaching the CMC, the interfacial tension decreases rapidly with the surfactant concentration, and the Langmuir equation of state can be adopted to describe the relation between the surfactant concentration and the interfacial tension. However, after reaching the CMC, the interfacial tension changes slowly with the surfactant concentration or even remains a constant (Zhao et al. Reference Zhao, Zhang, Xu, Li and Liu2017; Kovalchuk et al. Reference Kovalchuk, Roumpea, Nowak, Chinaud, Angeli and Simmons2018). To allow for surfactant concentration beyond the CMC, a modified Langmuir equation of state is often used and it reads as (Pawar & Stebe Reference Pawar and Stebe1996; Young et al. Reference Young, Booty, Siegel and Li2009; Ngangia et al. Reference Ngangia, Young, Vlahovska and Blawzdziewicz2013)

$$\begin{eqnarray}\unicode[STIX]{x1D70E}(\unicode[STIX]{x1D713})=\max \{\unicode[STIX]{x1D70E}_{0}[1+E_{0}\ln (1-\unicode[STIX]{x1D713}/\unicode[STIX]{x1D713}_{\infty })],\unicode[STIX]{x1D70E}_{min}\},\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D70E}(\unicode[STIX]{x1D713})=\max \{\unicode[STIX]{x1D70E}_{0}[1+E_{0}\ln (1-\unicode[STIX]{x1D713}/\unicode[STIX]{x1D713}_{\infty })],\unicode[STIX]{x1D70E}_{min}\},\end{eqnarray}$$ where  $\unicode[STIX]{x1D713}_{\infty }$ is the surfactant concentration at the maximum packing,

$\unicode[STIX]{x1D713}_{\infty }$ is the surfactant concentration at the maximum packing,  $\unicode[STIX]{x1D70E}_{0}$ is the interfacial tension of a clean interface (i.e.

$\unicode[STIX]{x1D70E}_{0}$ is the interfacial tension of a clean interface (i.e.  $\unicode[STIX]{x1D713}=0$),

$\unicode[STIX]{x1D713}=0$),  $E_{0}$ is the elasticity number that measures the sensitivity of

$E_{0}$ is the elasticity number that measures the sensitivity of  $\unicode[STIX]{x1D70E}$ to the variation of

$\unicode[STIX]{x1D70E}$ to the variation of  $\unicode[STIX]{x1D713}$ and

$\unicode[STIX]{x1D713}$ and  $\unicode[STIX]{x1D70E}_{min}$ is the interfacial tension after reaching the CMC. Note that the value of

$\unicode[STIX]{x1D70E}_{min}$ is the interfacial tension after reaching the CMC. Note that the value of  $\unicode[STIX]{x1D70E}_{min}$ varies for different combinations of fluids and surfactants. In the present study, we follow the previous works (De Bruijn Reference De Bruijn1993; Ngangia et al. Reference Ngangia, Young, Vlahovska and Blawzdziewicz2013) to simply take

$\unicode[STIX]{x1D70E}_{min}$ varies for different combinations of fluids and surfactants. In the present study, we follow the previous works (De Bruijn Reference De Bruijn1993; Ngangia et al. Reference Ngangia, Young, Vlahovska and Blawzdziewicz2013) to simply take  $\unicode[STIX]{x1D70E}_{min}=\unicode[STIX]{x1D70E}_{0}/10$. The value of CMC, according to its definition, can be computed by equating the two terms in max function. As previously done by Xu et al. (Reference Xu, Li, Lowengrub and Zhao2006) and Liu et al. (Reference Liu, Ba, Wu, Li, Xi and Zhang2018), we also quantify the initial average surfactant concentration

$\unicode[STIX]{x1D70E}_{min}=\unicode[STIX]{x1D70E}_{0}/10$. The value of CMC, according to its definition, can be computed by equating the two terms in max function. As previously done by Xu et al. (Reference Xu, Li, Lowengrub and Zhao2006) and Liu et al. (Reference Liu, Ba, Wu, Li, Xi and Zhang2018), we also quantify the initial average surfactant concentration  $\unicode[STIX]{x1D713}_{0}$ through the surfactant coverage, which is defined as

$\unicode[STIX]{x1D713}_{0}$ through the surfactant coverage, which is defined as  $x_{in}=\unicode[STIX]{x1D713}_{0}/\unicode[STIX]{x1D713}_{\infty }$.

$x_{in}=\unicode[STIX]{x1D713}_{0}/\unicode[STIX]{x1D713}_{\infty }$.

By defining  $\boldsymbol{n}=-\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}/|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|$ and

$\boldsymbol{n}=-\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}/|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|$ and  $\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}=|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|/2$ and substituting the above equation of state, (2.3) can be further written as

$\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}=|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|/2$ and substituting the above equation of state, (2.3) can be further written as

$$\begin{eqnarray}\boldsymbol{F}_{s}=\left\{\begin{array}{@{}ll@{}}\displaystyle -\frac{1}{2}\unicode[STIX]{x1D70E}\unicode[STIX]{x1D705}\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}-\frac{1}{2}|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|\frac{\unicode[STIX]{x1D70E}_{0}E_{0}}{\unicode[STIX]{x1D713}_{\infty }-\unicode[STIX]{x1D713}}\left[\unicode[STIX]{x1D735}\unicode[STIX]{x1D713}-(\boldsymbol{n}\boldsymbol{\cdot }\unicode[STIX]{x1D735}\unicode[STIX]{x1D713})\boldsymbol{n}\right], & \unicode[STIX]{x1D713}<\text{CMC},\\ \displaystyle -\frac{1}{2}\unicode[STIX]{x1D70E}\unicode[STIX]{x1D705}\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}, & \unicode[STIX]{x1D713}\geqslant \text{CMC},\end{array}\right.\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{F}_{s}=\left\{\begin{array}{@{}ll@{}}\displaystyle -\frac{1}{2}\unicode[STIX]{x1D70E}\unicode[STIX]{x1D705}\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}-\frac{1}{2}|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|\frac{\unicode[STIX]{x1D70E}_{0}E_{0}}{\unicode[STIX]{x1D713}_{\infty }-\unicode[STIX]{x1D713}}\left[\unicode[STIX]{x1D735}\unicode[STIX]{x1D713}-(\boldsymbol{n}\boldsymbol{\cdot }\unicode[STIX]{x1D735}\unicode[STIX]{x1D713})\boldsymbol{n}\right], & \unicode[STIX]{x1D713}<\text{CMC},\\ \displaystyle -\frac{1}{2}\unicode[STIX]{x1D70E}\unicode[STIX]{x1D705}\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}, & \unicode[STIX]{x1D713}\geqslant \text{CMC},\end{array}\right.\end{eqnarray}$$ where the interface curvature  $\unicode[STIX]{x1D705}$ is related to

$\unicode[STIX]{x1D705}$ is related to  $\boldsymbol{n}$ by

$\boldsymbol{n}$ by  $\unicode[STIX]{x1D705}=-\unicode[STIX]{x1D735}_{s}\boldsymbol{\cdot }\boldsymbol{n}$. With the interfacial force given by (2.12), the forcing term

$\unicode[STIX]{x1D705}=-\unicode[STIX]{x1D735}_{s}\boldsymbol{\cdot }\boldsymbol{n}$. With the interfacial force given by (2.12), the forcing term  $\bar{F_{i}}$ that is applied to realize the interfacial tension effect reads as (Yu & Fan Reference Yu and Fan2010)

$\bar{F_{i}}$ that is applied to realize the interfacial tension effect reads as (Yu & Fan Reference Yu and Fan2010)

$$\begin{eqnarray}\bar{\boldsymbol{F}}=\unicode[STIX]{x1D648}^{-1}\left(\unicode[STIX]{x1D644}-{\textstyle \frac{1}{2}}\unicode[STIX]{x1D64E}\right)\unicode[STIX]{x1D648}\widetilde{\boldsymbol{F}},\end{eqnarray}$$

$$\begin{eqnarray}\bar{\boldsymbol{F}}=\unicode[STIX]{x1D648}^{-1}\left(\unicode[STIX]{x1D644}-{\textstyle \frac{1}{2}}\unicode[STIX]{x1D64E}\right)\unicode[STIX]{x1D648}\widetilde{\boldsymbol{F}},\end{eqnarray}$$ where  $\unicode[STIX]{x1D644}$ is a

$\unicode[STIX]{x1D644}$ is a  $19\times 19$ unit matrix,

$19\times 19$ unit matrix,  $\bar{\boldsymbol{F}}=[\bar{F}_{0},\bar{F}_{1},\bar{F}_{2},\ldots ,\bar{F}_{18}]^{\text{T}}$ and

$\bar{\boldsymbol{F}}=[\bar{F}_{0},\bar{F}_{1},\bar{F}_{2},\ldots ,\bar{F}_{18}]^{\text{T}}$ and  $\widetilde{\boldsymbol{F}}=[\widetilde{F}_{0},\widetilde{F}_{1},\widetilde{F}_{2},\ldots ,\widetilde{F}_{18}]^{\text{T}}$ is given by Guo, Zheng & Shi (Reference Guo, Zheng and Shi2002):

$\widetilde{\boldsymbol{F}}=[\widetilde{F}_{0},\widetilde{F}_{1},\widetilde{F}_{2},\ldots ,\widetilde{F}_{18}]^{\text{T}}$ is given by Guo, Zheng & Shi (Reference Guo, Zheng and Shi2002):

$$\begin{eqnarray}\widetilde{F}_{i}=w_{i}\left[\frac{\boldsymbol{e}_{i}-\boldsymbol{u}}{c_{s}^{2}}+\frac{(\boldsymbol{e}_{i}\boldsymbol{\cdot }\boldsymbol{u})\boldsymbol{e}_{i}}{c_{s}^{4}}\right]\boldsymbol{\cdot }\boldsymbol{F}_{s}\unicode[STIX]{x1D6FF}_{t}.\end{eqnarray}$$

$$\begin{eqnarray}\widetilde{F}_{i}=w_{i}\left[\frac{\boldsymbol{e}_{i}-\boldsymbol{u}}{c_{s}^{2}}+\frac{(\boldsymbol{e}_{i}\boldsymbol{\cdot }\boldsymbol{u})\boldsymbol{e}_{i}}{c_{s}^{4}}\right]\boldsymbol{\cdot }\boldsymbol{F}_{s}\unicode[STIX]{x1D6FF}_{t}.\end{eqnarray}$$Using the Chapman–Enskog multiscale expansion, equation (2.4) can reduce to the NSE in the low frequency, long wavelength limit with the pressure and the fluid velocity given by

$$\begin{eqnarray}p=\unicode[STIX]{x1D70C}c_{s}^{2},\quad \unicode[STIX]{x1D70C}\boldsymbol{u}(\boldsymbol{x},t)=\mathop{\sum }_{i}f_{i}(\boldsymbol{x},t)\boldsymbol{e}_{i}+\boldsymbol{F}_{s}(\boldsymbol{x},t)\unicode[STIX]{x1D6FF}_{t}/2.\end{eqnarray}$$

$$\begin{eqnarray}p=\unicode[STIX]{x1D70C}c_{s}^{2},\quad \unicode[STIX]{x1D70C}\boldsymbol{u}(\boldsymbol{x},t)=\mathop{\sum }_{i}f_{i}(\boldsymbol{x},t)\boldsymbol{e}_{i}+\boldsymbol{F}_{s}(\boldsymbol{x},t)\unicode[STIX]{x1D6FF}_{t}/2.\end{eqnarray}$$With a diffuse-interface description, the surfactant transport is governed by a convection–diffusion equation with the Dirac function (Teigen et al. Reference Teigen, Song, Lowengrub and Voigt2011)

$$\begin{eqnarray}\unicode[STIX]{x2202}_{t}(\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}\unicode[STIX]{x1D713})+\unicode[STIX]{x1D735}\boldsymbol{\cdot }(\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}\unicode[STIX]{x1D713}\boldsymbol{u})=D_{s}\unicode[STIX]{x1D735}\boldsymbol{\cdot }(\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}\unicode[STIX]{x1D735}\unicode[STIX]{x1D713}),\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x2202}_{t}(\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}\unicode[STIX]{x1D713})+\unicode[STIX]{x1D735}\boldsymbol{\cdot }(\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}\unicode[STIX]{x1D713}\boldsymbol{u})=D_{s}\unicode[STIX]{x1D735}\boldsymbol{\cdot }(\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}\unicode[STIX]{x1D735}\unicode[STIX]{x1D713}),\end{eqnarray}$$ where  $D_{s}$ is the surfactant diffusivity. The asymptotic analysis showed that (2.16) could converge to the commonly used surfactant evolution equation of sharp-interface form as the interface thickness approaches zero (Teigen et al. Reference Teigen, Li, Lowengrub, Wang and Voigt2009). Unlike the evolution equation of sharp-interface form, equation (2.16) not only allows for the solution of surfactant concentration in the entire fluid domain without additional extension or initialization procedures, but also offers great simplicity in dealing with topological changes such as the droplet breakup and coalescence. Some remarks are made here on the surfactant transport. When the surfactant concentration exceeds the CMC, from the physical point of view, an additional equation should be introduced to describe the evolution of micelle concentration (Edmonstone, Matar & Craster Reference Edmonstone, Matar and Craster2006; Craster & Matar Reference Craster and Matar2009), which would greatly increase the complexity of numerical modelling and simulation. For the sake of simplicity, we assume that the surfactant transport still follows (2.16) even though the surfactant concentration exceeds the CMC, as previously done by De Bruijn (Reference De Bruijn1993), Pawar & Stebe (Reference Pawar and Stebe1996), Young et al. (Reference Young, Booty, Siegel and Li2009) and Ngangia et al. (Reference Ngangia, Young, Vlahovska and Blawzdziewicz2013). Finally, it should be noted that, to the best of our knowledge, none of the existing simulations have considered the surfactant transport with micelle dynamics.

$D_{s}$ is the surfactant diffusivity. The asymptotic analysis showed that (2.16) could converge to the commonly used surfactant evolution equation of sharp-interface form as the interface thickness approaches zero (Teigen et al. Reference Teigen, Li, Lowengrub, Wang and Voigt2009). Unlike the evolution equation of sharp-interface form, equation (2.16) not only allows for the solution of surfactant concentration in the entire fluid domain without additional extension or initialization procedures, but also offers great simplicity in dealing with topological changes such as the droplet breakup and coalescence. Some remarks are made here on the surfactant transport. When the surfactant concentration exceeds the CMC, from the physical point of view, an additional equation should be introduced to describe the evolution of micelle concentration (Edmonstone, Matar & Craster Reference Edmonstone, Matar and Craster2006; Craster & Matar Reference Craster and Matar2009), which would greatly increase the complexity of numerical modelling and simulation. For the sake of simplicity, we assume that the surfactant transport still follows (2.16) even though the surfactant concentration exceeds the CMC, as previously done by De Bruijn (Reference De Bruijn1993), Pawar & Stebe (Reference Pawar and Stebe1996), Young et al. (Reference Young, Booty, Siegel and Li2009) and Ngangia et al. (Reference Ngangia, Young, Vlahovska and Blawzdziewicz2013). Finally, it should be noted that, to the best of our knowledge, none of the existing simulations have considered the surfactant transport with micelle dynamics.

After replacing  $\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}$ with

$\unicode[STIX]{x1D6FF}_{\unicode[STIX]{x1D6E4}}$ with  $|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|/2$, equation (2.16) can be solved by the finite-difference method (Liu et al. Reference Liu, Ba, Wu, Li, Xi and Zhang2018). Specifically, a modified Crank–Nicholson scheme is used for the time discretization, and the resulting spatial derivatives are all discretized using the standard central difference schemes except for the convection term

$|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|/2$, equation (2.16) can be solved by the finite-difference method (Liu et al. Reference Liu, Ba, Wu, Li, Xi and Zhang2018). Specifically, a modified Crank–Nicholson scheme is used for the time discretization, and the resulting spatial derivatives are all discretized using the standard central difference schemes except for the convection term  $\unicode[STIX]{x1D735}\boldsymbol{\cdot }(|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|\unicode[STIX]{x1D713}\boldsymbol{u})$, which is discretized by the third-order weighted essentially non-oscillatory (WENO) scheme (Jiang & Shu Reference Jiang and Shu1996; Xu & Zhao Reference Xu and Zhao2003; Liu et al. Reference Liu, Ba, Wu, Li, Xi and Zhang2018). In order to apply the third-order WENO scheme, two layers of solid nodes (also termed as ghost nodes) neighbouring to a solid wall need to be considered. Take the bottom wall, which is located halfway between the first layer of solid nodes

$\unicode[STIX]{x1D735}\boldsymbol{\cdot }(|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|\unicode[STIX]{x1D713}\boldsymbol{u})$, which is discretized by the third-order weighted essentially non-oscillatory (WENO) scheme (Jiang & Shu Reference Jiang and Shu1996; Xu & Zhao Reference Xu and Zhao2003; Liu et al. Reference Liu, Ba, Wu, Li, Xi and Zhang2018). In order to apply the third-order WENO scheme, two layers of solid nodes (also termed as ghost nodes) neighbouring to a solid wall need to be considered. Take the bottom wall, which is located halfway between the first layer of solid nodes  $z=0$ and the first layer of fluid nodes

$z=0$ and the first layer of fluid nodes  $z=1$, as an example, the values of

$z=1$, as an example, the values of  $\boldsymbol{u}$,

$\boldsymbol{u}$,  $\unicode[STIX]{x1D713}$ and

$\unicode[STIX]{x1D713}$ and  $|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|$ at the ghost nodes, i.e.

$|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|$ at the ghost nodes, i.e.  $z=-1$ and

$z=-1$ and  $z=0$, can be specified as

$z=0$, can be specified as  $\boldsymbol{u}_{x,y,-1}=-\boldsymbol{u}_{x,y,2}$,

$\boldsymbol{u}_{x,y,-1}=-\boldsymbol{u}_{x,y,2}$,  $\boldsymbol{u}_{x,y,0}=-\boldsymbol{u}_{x,y,1}$,

$\boldsymbol{u}_{x,y,0}=-\boldsymbol{u}_{x,y,1}$,  $\unicode[STIX]{x1D713}_{x,y,-1}=\unicode[STIX]{x1D713}_{x,y,2}$,

$\unicode[STIX]{x1D713}_{x,y,-1}=\unicode[STIX]{x1D713}_{x,y,2}$,  $\unicode[STIX]{x1D713}_{x,y,0}=\unicode[STIX]{x1D713}_{x,y,1}$,

$\unicode[STIX]{x1D713}_{x,y,0}=\unicode[STIX]{x1D713}_{x,y,1}$,  $|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|_{x,y,-1}=|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|_{x,y,2}$ and

$|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|_{x,y,-1}=|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|_{x,y,2}$ and  $|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|_{x,y,0}=|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|_{x,y,1}$, which can ensure the continuity of velocity and zero flux of surfactants across the solid wall. The algebraic equation system arising from the discretization is then solved by the successive over relaxation method with the relaxation factor of 1.2. In addition, we impose the conservation of surfactant mass at each time step, which is achieved by multiplying the surfactant concentration by a constant factor (Xu et al. Reference Xu, Li, Lowengrub and Zhao2006).

$|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|_{x,y,0}=|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}|_{x,y,1}$, which can ensure the continuity of velocity and zero flux of surfactants across the solid wall. The algebraic equation system arising from the discretization is then solved by the successive over relaxation method with the relaxation factor of 1.2. In addition, we impose the conservation of surfactant mass at each time step, which is achieved by multiplying the surfactant concentration by a constant factor (Xu et al. Reference Xu, Li, Lowengrub and Zhao2006).

It is known that the presence of surfactants not only reduces the interfacial tension between fluids but also alters the wetting properties of solid surfaces. The wetting properties are usually evaluated through the contact angle, which is defined as the angle between the tangent to the droplet surface and the solid surface at the contact line. Assuming that the surfactants are only present at the interface between the droplet and the ambient fluid, a dynamic contact angle formulation, which describes the dependence of the contact angle on the local surfactant concentration, can be established (Zhang et al. Reference Zhang, Liu and Ba2019)

$$\begin{eqnarray}\unicode[STIX]{x1D703}(\unicode[STIX]{x1D713})=\arccos \left(\frac{\unicode[STIX]{x1D70E}_{0}\cos \unicode[STIX]{x1D703}_{0}}{\unicode[STIX]{x1D70E}(\unicode[STIX]{x1D713})}\right),\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D703}(\unicode[STIX]{x1D713})=\arccos \left(\frac{\unicode[STIX]{x1D70E}_{0}\cos \unicode[STIX]{x1D703}_{0}}{\unicode[STIX]{x1D70E}(\unicode[STIX]{x1D713})}\right),\end{eqnarray}$$ where  $\unicode[STIX]{x1D703}_{0}$ is the static contact angle in the absence of surfactants (

$\unicode[STIX]{x1D703}_{0}$ is the static contact angle in the absence of surfactants ( $\unicode[STIX]{x1D713}=0$) and

$\unicode[STIX]{x1D713}=0$) and  $\unicode[STIX]{x1D703}$ is the dynamic contact angle in the presence of surfactants. Note that (2.17) is only valid within the range of

$\unicode[STIX]{x1D703}$ is the dynamic contact angle in the presence of surfactants. Note that (2.17) is only valid within the range of  $-1\leqslant (\unicode[STIX]{x1D70E}_{0}\cos \unicode[STIX]{x1D703}_{0})/(\unicode[STIX]{x1D70E})\leqslant 1$. However, for a hydrophilic or hydrophobic surface (i.e.

$-1\leqslant (\unicode[STIX]{x1D70E}_{0}\cos \unicode[STIX]{x1D703}_{0})/(\unicode[STIX]{x1D70E})\leqslant 1$. However, for a hydrophilic or hydrophobic surface (i.e.  $\unicode[STIX]{x1D703}_{0}\neq 90^{\circ }$), the value of

$\unicode[STIX]{x1D703}_{0}\neq 90^{\circ }$), the value of  $(\unicode[STIX]{x1D70E}_{0}\cos \unicode[STIX]{x1D703}_{0})/(\unicode[STIX]{x1D70E})$ may be beyond this range as the interfacial tension decreases. To avoid the unsolvability of (2.17), two threshold values of contact angle, e.g.

$(\unicode[STIX]{x1D70E}_{0}\cos \unicode[STIX]{x1D703}_{0})/(\unicode[STIX]{x1D70E})$ may be beyond this range as the interfacial tension decreases. To avoid the unsolvability of (2.17), two threshold values of contact angle, e.g.  $\unicode[STIX]{x1D703}_{min}=10^{\circ }$ and

$\unicode[STIX]{x1D703}_{min}=10^{\circ }$ and  $\unicode[STIX]{x1D703}_{max}=170^{\circ }$, are introduced, and we directly take

$\unicode[STIX]{x1D703}_{max}=170^{\circ }$, are introduced, and we directly take  $\unicode[STIX]{x1D703}=\unicode[STIX]{x1D703}_{min}$ when

$\unicode[STIX]{x1D703}=\unicode[STIX]{x1D703}_{min}$ when  $(\unicode[STIX]{x1D70E}_{0}\cos \unicode[STIX]{x1D703}_{0})/(\unicode[STIX]{x1D70E})>\cos (\unicode[STIX]{x1D703}_{min})$ and

$(\unicode[STIX]{x1D70E}_{0}\cos \unicode[STIX]{x1D703}_{0})/(\unicode[STIX]{x1D70E})>\cos (\unicode[STIX]{x1D703}_{min})$ and  $\unicode[STIX]{x1D703}=\unicode[STIX]{x1D703}_{max}$ when

$\unicode[STIX]{x1D703}=\unicode[STIX]{x1D703}_{max}$ when  $(\unicode[STIX]{x1D70E}_{0}\cos \unicode[STIX]{x1D703}_{0})/(\unicode[STIX]{x1D70E})<\cos (\unicode[STIX]{x1D703}_{max})$.

$(\unicode[STIX]{x1D70E}_{0}\cos \unicode[STIX]{x1D703}_{0})/(\unicode[STIX]{x1D70E})<\cos (\unicode[STIX]{x1D703}_{max})$.

Once the dynamic contact angle  $\unicode[STIX]{x1D703}$ is determined on the solid surface, it can be enforced through the geometrical formulation proposed by Ding & Spelt (Reference Ding and Spelt2007):

$\unicode[STIX]{x1D703}$ is determined on the solid surface, it can be enforced through the geometrical formulation proposed by Ding & Spelt (Reference Ding and Spelt2007):

$$\begin{eqnarray}\boldsymbol{n}_{w}\boldsymbol{\cdot }\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}=-\tan \left(\frac{\unicode[STIX]{x03C0}}{2}-\unicode[STIX]{x1D703}\right)\left|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}-(\boldsymbol{n}_{\text{w}}\boldsymbol{\cdot }\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N})\boldsymbol{n}_{\text{w}}\right|.\end{eqnarray}$$

$$\begin{eqnarray}\boldsymbol{n}_{w}\boldsymbol{\cdot }\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}=-\tan \left(\frac{\unicode[STIX]{x03C0}}{2}-\unicode[STIX]{x1D703}\right)\left|\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N}-(\boldsymbol{n}_{\text{w}}\boldsymbol{\cdot }\unicode[STIX]{x1D735}\unicode[STIX]{x1D70C}^{N})\boldsymbol{n}_{\text{w}}\right|.\end{eqnarray}$$ Here  $\boldsymbol{n}_{w}$ is the unit normal vector to wall pointing towards the fluids. The enforcement of (2.18) is realized also through a layer of ghost nodes, which are a half-lattice spacing away from the wall. Again, we consider the case of the bottom wall, where the no-slip boundary condition is imposed by the halfway bounce-back scheme (Ladd Reference Ladd1994). Spatial discretization of (2.18) leads to (Huang, Huang & Wang Reference Huang, Huang and Wang2014)

$\boldsymbol{n}_{w}$ is the unit normal vector to wall pointing towards the fluids. The enforcement of (2.18) is realized also through a layer of ghost nodes, which are a half-lattice spacing away from the wall. Again, we consider the case of the bottom wall, where the no-slip boundary condition is imposed by the halfway bounce-back scheme (Ladd Reference Ladd1994). Spatial discretization of (2.18) leads to (Huang, Huang & Wang Reference Huang, Huang and Wang2014)

$$\begin{eqnarray}\unicode[STIX]{x1D70C}_{x,y,0}^{N}=\unicode[STIX]{x1D70C}_{x,y,1}^{N}+\tan \left(\frac{\unicode[STIX]{x03C0}}{2}-\unicode[STIX]{x1D703}\right)\unicode[STIX]{x1D709},\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D70C}_{x,y,0}^{N}=\unicode[STIX]{x1D70C}_{x,y,1}^{N}+\tan \left(\frac{\unicode[STIX]{x03C0}}{2}-\unicode[STIX]{x1D703}\right)\unicode[STIX]{x1D709},\end{eqnarray}$$with

$$\begin{eqnarray}\unicode[STIX]{x1D709}=\sqrt{(1.5\unicode[STIX]{x2202}_{x}\unicode[STIX]{x1D70C}^{N}|_{x,y,1}-0.5\unicode[STIX]{x2202}_{x}\unicode[STIX]{x1D70C}^{N}|_{x,y,2})^{2}+(1.5\unicode[STIX]{x2202}_{y}\unicode[STIX]{x1D70C}^{N}|_{x,y,1}-0.5\unicode[STIX]{x2202}_{y}\unicode[STIX]{x1D70C}^{N}|_{x,y,2})^{2}},\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D709}=\sqrt{(1.5\unicode[STIX]{x2202}_{x}\unicode[STIX]{x1D70C}^{N}|_{x,y,1}-0.5\unicode[STIX]{x2202}_{x}\unicode[STIX]{x1D70C}^{N}|_{x,y,2})^{2}+(1.5\unicode[STIX]{x2202}_{y}\unicode[STIX]{x1D70C}^{N}|_{x,y,1}-0.5\unicode[STIX]{x2202}_{y}\unicode[STIX]{x1D70C}^{N}|_{x,y,2})^{2}},\end{eqnarray}$$ where all the derivatives can be easily evaluated by the second-order central difference approximation. Using the values of  $\unicode[STIX]{x1D70C}_{x,y,0}^{N}$, we are then able to compute the partial derivatives of

$\unicode[STIX]{x1D70C}_{x,y,0}^{N}$, we are then able to compute the partial derivatives of  $\unicode[STIX]{x1D70C}^{N}$ at all fluids nodes through the fourth-order isotropic finite-difference scheme (Liu, Valocchi & Kang Reference Liu, Valocchi and Kang2012). As such, the dynamic contact angle is implicitly imposed on the solid surface.

$\unicode[STIX]{x1D70C}^{N}$ at all fluids nodes through the fourth-order isotropic finite-difference scheme (Liu, Valocchi & Kang Reference Liu, Valocchi and Kang2012). As such, the dynamic contact angle is implicitly imposed on the solid surface.

As a diffuse-interface model, the present method simulates the contact-line dynamics with an artificially enlarged interface thickness, which results in an effective slip length far greater than the one that an experiment represents. Thus, the obtained droplet velocity is faster than the experimental result (Ding et al. Reference Ding, Zhu, Gao and Lu2018). Even so, the diffuse-interface simulations are still able to produce impressive results and important insights in the interplay between the macroscopic motion and the contact-line dynamics (Sui et al. Reference Sui, Ding and Spelt2014). For example, Ding et al. (Reference Ding, Zhu, Gao and Lu2018) obtained experiment-matched droplet shapes for a climbing droplet on a vibrated oblique plate; using the LB colour-gradient model, we quantitatively reproduced the two-phase displacement process observed in micromodel experiments (Xu, Liu & Valocchi Reference Xu, Liu and Valocchi2017).

We run the simulations in a lattice domain of  $L\times W\times H=11.2R\times 8R\times 2R$. The droplet is initially centred at a distance of

$L\times W\times H=11.2R\times 8R\times 2R$. The droplet is initially centred at a distance of  $2R$ away from the left boundary. The boundary conditions are imposed as follows. In the

$2R$ away from the left boundary. The boundary conditions are imposed as follows. In the  $x$ and

$x$ and  $y$ directions, the periodic boundary conditions are used; while on the top and bottom walls in the

$y$ directions, the periodic boundary conditions are used; while on the top and bottom walls in the  $z$ direction, the wetting boundary condition described above is imposed with the static contact angle

$z$ direction, the wetting boundary condition described above is imposed with the static contact angle  $\unicode[STIX]{x1D703}_{0}=90^{\circ }$.

$\unicode[STIX]{x1D703}_{0}=90^{\circ }$.

3 Results

In the presence of surfactants, the dimensionless parameters that characterize the droplet behaviour could be defined as follows: the Reynolds number  $Re=\unicode[STIX]{x1D70C}^{B}\dot{\unicode[STIX]{x1D6FE}}R^{2}/\unicode[STIX]{x1D707}^{B}$ (the ratio of inertial to viscous forces), the capillary number

$Re=\unicode[STIX]{x1D70C}^{B}\dot{\unicode[STIX]{x1D6FE}}R^{2}/\unicode[STIX]{x1D707}^{B}$ (the ratio of inertial to viscous forces), the capillary number  $Ca=\unicode[STIX]{x1D707}^{B}\dot{\unicode[STIX]{x1D6FE}}R/\unicode[STIX]{x1D70E}_{0}$ (the ratio of viscous to capillary forces), the surface Péclet number

$Ca=\unicode[STIX]{x1D707}^{B}\dot{\unicode[STIX]{x1D6FE}}R/\unicode[STIX]{x1D70E}_{0}$ (the ratio of viscous to capillary forces), the surface Péclet number  $Pe=\dot{\unicode[STIX]{x1D6FE}}R^{2}/D_{s}$ (the ratio of the convective to diffusive transport of surfactants) and the viscosity ratio

$Pe=\dot{\unicode[STIX]{x1D6FE}}R^{2}/D_{s}$ (the ratio of the convective to diffusive transport of surfactants) and the viscosity ratio  $\unicode[STIX]{x1D706}=\unicode[STIX]{x1D707}^{R}/\unicode[STIX]{x1D707}^{B}$. Since the presence of surfactants leads to a reduction of interfacial tension, the effective capillary number

$\unicode[STIX]{x1D706}=\unicode[STIX]{x1D707}^{R}/\unicode[STIX]{x1D707}^{B}$. Since the presence of surfactants leads to a reduction of interfacial tension, the effective capillary number

$$\begin{eqnarray}Ca_{e}=\frac{\unicode[STIX]{x1D707}^{B}\dot{\unicode[STIX]{x1D6FE}}R}{\unicode[STIX]{x1D70E}_{0}[1+\text{E}_{0}\ln (1-x_{in})]}=\frac{Ca}{1+\text{E}_{0}\ln (1-x_{in})}\end{eqnarray}$$

$$\begin{eqnarray}Ca_{e}=\frac{\unicode[STIX]{x1D707}^{B}\dot{\unicode[STIX]{x1D6FE}}R}{\unicode[STIX]{x1D70E}_{0}[1+\text{E}_{0}\ln (1-x_{in})]}=\frac{Ca}{1+\text{E}_{0}\ln (1-x_{in})}\end{eqnarray}$$ is used instead of  $Ca$ in order to rule out the effect of average surfactant concentration in reducing interfacial tension. Throughout this study, the Reynolds number and the surface Péclet number are fixed at 1 and 10, respectively. Unless otherwise stated, we choose

$Ca$ in order to rule out the effect of average surfactant concentration in reducing interfacial tension. Throughout this study, the Reynolds number and the surface Péclet number are fixed at 1 and 10, respectively. Unless otherwise stated, we choose  $\unicode[STIX]{x1D706}=1$ and

$\unicode[STIX]{x1D706}=1$ and  $x_{in}=0.3$. In many cases, the numerical results are compared with those of a clean droplet at the same value of

$x_{in}=0.3$. In many cases, the numerical results are compared with those of a clean droplet at the same value of  $Ca_{e}$, and the difference in their results is attributed to two factors: (1) non-uniform effects from non-uniform capillary pressure at the droplet interface and Marangoni stresses along the interface; and (2) surfactant dilution due to the interfacial stretching. In addition, the elasticity number is set as

$Ca_{e}$, and the difference in their results is attributed to two factors: (1) non-uniform effects from non-uniform capillary pressure at the droplet interface and Marangoni stresses along the interface; and (2) surfactant dilution due to the interfacial stretching. In addition, the elasticity number is set as  $E_{0}=0.5$ and the effective interfacial tension, defined as

$E_{0}=0.5$ and the effective interfacial tension, defined as  $\unicode[STIX]{x1D70E}_{e}=\unicode[STIX]{x1D70E}_{0}[1+E_{0}\ln (1-x_{in})]$, is fixed at

$\unicode[STIX]{x1D70E}_{e}=\unicode[STIX]{x1D70E}_{0}[1+E_{0}\ln (1-x_{in})]$, is fixed at  $1\times 10^{-3}$ for both clean (

$1\times 10^{-3}$ for both clean ( $x_{in}=0$) and surfactant-covered droplets.

$x_{in}=0$) and surfactant-covered droplets.

Since the grid resolution may influence the simulation results, it is necessary to carry out a grid independence test to minimise the simulation error. The grid independence test is conducted for  $Ca_{e}=0.15$,

$Ca_{e}=0.15$,  $x_{in}=0.3$ and

$x_{in}=0.3$ and  $\unicode[STIX]{x1D706}=1$. Three different grid resolutions, i.e.

$\unicode[STIX]{x1D706}=1$. Three different grid resolutions, i.e.  $R=25$,

$R=25$,  $50$ and

$50$ and  $65$, are considered, and the corresponding domain sizes are

$65$, are considered, and the corresponding domain sizes are  $280\times 200\times 50$,

$280\times 200\times 50$,  $560\times 400\times 100$ and

$560\times 400\times 100$ and  $728\times 520\times 130$, respectively. Table 1 shows the steady state results at three different grid resolutions. In this table,

$728\times 520\times 130$, respectively. Table 1 shows the steady state results at three different grid resolutions. In this table,  $S_{0}$ and

$S_{0}$ and  $S$ are the surface areas of the initial droplet and the equilibrium droplet,

$S$ are the surface areas of the initial droplet and the equilibrium droplet,  $u_{d}$ is the moving velocity of the equilibrium droplet, and

$u_{d}$ is the moving velocity of the equilibrium droplet, and  $\unicode[STIX]{x1D713}_{min}^{\ast }$ and

$\unicode[STIX]{x1D713}_{min}^{\ast }$ and  $\unicode[STIX]{x1D713}_{max}^{\ast }$ are the minimum and maximum values of

$\unicode[STIX]{x1D713}_{max}^{\ast }$ are the minimum and maximum values of  $\unicode[STIX]{x1D713}^{\ast }$ on the droplet surface (represented by

$\unicode[STIX]{x1D713}^{\ast }$ on the droplet surface (represented by  $\unicode[STIX]{x1D70C}^{N}=0$), where

$\unicode[STIX]{x1D70C}^{N}=0$), where  $\unicode[STIX]{x1D713}^{\ast }=\unicode[STIX]{x1D713}/\unicode[STIX]{x1D713}_{0}$ is the dimensionless surfactant concentration. It is seen that the grid resolutions of

$\unicode[STIX]{x1D713}^{\ast }=\unicode[STIX]{x1D713}/\unicode[STIX]{x1D713}_{0}$ is the dimensionless surfactant concentration. It is seen that the grid resolutions of  $R=50$ and

$R=50$ and  $R=65$ produce nearly identical results (with a relative difference below 1.5

$R=65$ produce nearly identical results (with a relative difference below 1.5 $\%$). Therefore, the grid resolution of

$\%$). Therefore, the grid resolution of  $R=50$ lattice cells will be used in the subsequent simulations.

$R=50$ lattice cells will be used in the subsequent simulations.

Table 1. Steady state results of different grid sizes for  $Ca_{e}=0.15$ and

$Ca_{e}=0.15$ and  $x_{in}=0.3$.

$x_{in}=0.3$.

3.1 Droplet deformation

In this section we restrict our simulations to low values of  $Ca_{e}$ where the droplet eventually reaches a steady shape, and investigate the influence of effective capillary number, viscosity ratio and surfactant coverage on the droplet motion and deformation in a 3-D linear shear flow. Note that only the steady state results will be presented in the following discussion.

$Ca_{e}$ where the droplet eventually reaches a steady shape, and investigate the influence of effective capillary number, viscosity ratio and surfactant coverage on the droplet motion and deformation in a 3-D linear shear flow. Note that only the steady state results will be presented in the following discussion.

3.1.1 Effect of effective capillary number

The effect of  $Ca_{e}$ on the droplet deformation is investigated by increasing

$Ca_{e}$ on the droplet deformation is investigated by increasing  $Ca_{e}$ from zero with an increment of

$Ca_{e}$ from zero with an increment of  $0.05$. In the deformation mode, the droplet eventually reaches a steady shape and moves over the solid surface at a constant velocity. It is found that droplet deformation occurs at

$0.05$. In the deformation mode, the droplet eventually reaches a steady shape and moves over the solid surface at a constant velocity. It is found that droplet deformation occurs at  $Ca_{e}\leqslant 0.3$ for the surfactant-covered droplet, but at

$Ca_{e}\leqslant 0.3$ for the surfactant-covered droplet, but at  $Ca_{e}\leqslant 0.34$ for the clean droplet. Figure 2 illustrates the snapshots of the moving droplet at the effective capillary numbers of

$Ca_{e}\leqslant 0.34$ for the clean droplet. Figure 2 illustrates the snapshots of the moving droplet at the effective capillary numbers of  $0.15$ and

$0.15$ and  $0.3$ for the clean and surfactant-covered droplets. In this figure, the droplet surface is coloured by the dimensionless surfactant concentration

$0.3$ for the clean and surfactant-covered droplets. In this figure, the droplet surface is coloured by the dimensionless surfactant concentration  $\unicode[STIX]{x1D713}^{\ast }$ for the surfactant-covered droplet. As

$\unicode[STIX]{x1D713}^{\ast }$ for the surfactant-covered droplet. As  $Ca_{e}$ increases, droplet deformation increases in both the clean and surfactant-covered cases. At the same

$Ca_{e}$ increases, droplet deformation increases in both the clean and surfactant-covered cases. At the same  $Ca_{e}$, the surfactant-covered droplet exhibits a larger deformation and moves faster than the clean one. The increased droplet deformation in the surfactant-covered case is attributed to the non-uniform distribution of surfactants, which is shown in figure 2(b,d). In the presence of surfactants, the shear flow sweeps the surfactants along the droplet interface from the rear to the front, which results in a high surfactant concentration and thus a low interfacial tension at the droplet front. Since the interfacial tension acts to resist against the droplet deformation, the low interfacial tension at the droplet front contributes to the increased droplet deformation in the surfactant-covered case.

$Ca_{e}$, the surfactant-covered droplet exhibits a larger deformation and moves faster than the clean one. The increased droplet deformation in the surfactant-covered case is attributed to the non-uniform distribution of surfactants, which is shown in figure 2(b,d). In the presence of surfactants, the shear flow sweeps the surfactants along the droplet interface from the rear to the front, which results in a high surfactant concentration and thus a low interfacial tension at the droplet front. Since the interfacial tension acts to resist against the droplet deformation, the low interfacial tension at the droplet front contributes to the increased droplet deformation in the surfactant-covered case.

Figure 2. The snapshots of a droplet sliding along the solid wall for (a,b)  $Ca_{e}=0.15$ at

$Ca_{e}=0.15$ at  $\dot{\unicode[STIX]{x1D6FE}}t=15$ and (c,d)

$\dot{\unicode[STIX]{x1D6FE}}t=15$ and (c,d)  $Ca_{e}=0.3$ at

$Ca_{e}=0.3$ at  $\dot{\unicode[STIX]{x1D6FE}}t=25$; (a) and (c) correspond to the clean droplet, while (b) and (d) correspond to the surfactant-covered droplet, for which the surface is shaded by the dimensionless surfactant concentration

$\dot{\unicode[STIX]{x1D6FE}}t=25$; (a) and (c) correspond to the clean droplet, while (b) and (d) correspond to the surfactant-covered droplet, for which the surface is shaded by the dimensionless surfactant concentration  $\unicode[STIX]{x1D713}^{\ast }$.

$\unicode[STIX]{x1D713}^{\ast }$.

Figure 3 plots the dimensionless surfactant concentration  $\unicode[STIX]{x1D713}^{\ast }$ as a function of the arclength

$\unicode[STIX]{x1D713}^{\ast }$ as a function of the arclength  $s$ in the

$s$ in the  $x$–

$x$– $z$ mid-plane for various values of

$z$ mid-plane for various values of  $Ca_{e}$. The arclength

$Ca_{e}$. The arclength  $s$, measured clockwise along the droplet interface from the receding to advancing contact points (i.e. the intersection points between the contact line and

$s$, measured clockwise along the droplet interface from the receding to advancing contact points (i.e. the intersection points between the contact line and  $x$–

$x$– $z$ mid-plane), is normalized by the initial droplet radius

$z$ mid-plane), is normalized by the initial droplet radius  $R$. When the shear flow is imposed, i.e.

$R$. When the shear flow is imposed, i.e.  $Ca_{e}>0$, the surfactant distribution becomes non-uniform, and there exist a maximum surfactant concentration (

$Ca_{e}>0$, the surfactant distribution becomes non-uniform, and there exist a maximum surfactant concentration ( $\unicode[STIX]{x1D713}_{max}^{\ast }$) and two minimum surfactant concentrations (

$\unicode[STIX]{x1D713}_{max}^{\ast }$) and two minimum surfactant concentrations ( $\unicode[STIX]{x1D713}_{min}^{\ast }$) which occur at the front and rear interfaces bounded by the droplet tip. As

$\unicode[STIX]{x1D713}_{min}^{\ast }$) which occur at the front and rear interfaces bounded by the droplet tip. As  $Ca_{e}$ increases, the enhanced shear flow can sweep more surfactants from the rear to the front, so

$Ca_{e}$ increases, the enhanced shear flow can sweep more surfactants from the rear to the front, so  $\unicode[STIX]{x1D713}_{min}^{\ast }$ at the rear decreases and

$\unicode[STIX]{x1D713}_{min}^{\ast }$ at the rear decreases and  $\unicode[STIX]{x1D713}_{max}^{\ast }$ increases (see the inset of figure 3). Meanwhile,

$\unicode[STIX]{x1D713}_{max}^{\ast }$ increases (see the inset of figure 3). Meanwhile,  $\unicode[STIX]{x1D713}_{min}^{\ast }$ at the front is expected to monotonously increase. However, it does not increase but rapidly decreases with increasing

$\unicode[STIX]{x1D713}_{min}^{\ast }$ at the front is expected to monotonously increase. However, it does not increase but rapidly decreases with increasing  $Ca_{e}$ from 0.25 to 0.3. This is because at relatively high

$Ca_{e}$ from 0.25 to 0.3. This is because at relatively high  $Ca_{e}$ the droplet is highly stretched, leading to an excessive dilution of surfactants. As can be seen from figure 3, for each

$Ca_{e}$ the droplet is highly stretched, leading to an excessive dilution of surfactants. As can be seen from figure 3, for each  $Ca_{e}$, the non-uniformity of surfactants consists of two parts, namely the rear part and the front part, which can be quantified by the difference between

$Ca_{e}$, the non-uniformity of surfactants consists of two parts, namely the rear part and the front part, which can be quantified by the difference between  $\unicode[STIX]{x1D713}_{max}^{\ast }$ and

$\unicode[STIX]{x1D713}_{max}^{\ast }$ and  $\unicode[STIX]{x1D713}_{min}^{\ast }$ at the rear and by the difference between

$\unicode[STIX]{x1D713}_{min}^{\ast }$ at the rear and by the difference between  $\unicode[STIX]{x1D713}_{max}^{\ast }$ and

$\unicode[STIX]{x1D713}_{max}^{\ast }$ and  $\unicode[STIX]{x1D713}_{min}^{\ast }$ at the front, respectively. It is clear that both differences increase and, thus, the non-uniformity of surfactants increases with

$\unicode[STIX]{x1D713}_{min}^{\ast }$ at the front, respectively. It is clear that both differences increase and, thus, the non-uniformity of surfactants increases with  $Ca_{e}$. In addition, we note that

$Ca_{e}$. In addition, we note that  $\unicode[STIX]{x1D713}_{min}^{\ast }$ at the rear and

$\unicode[STIX]{x1D713}_{min}^{\ast }$ at the rear and  $\unicode[STIX]{x1D713}_{min}^{\ast }$ at the front are positioned close to the receding contact point and the advancing contact point, respectively. On the other hand, the position of

$\unicode[STIX]{x1D713}_{min}^{\ast }$ at the front are positioned close to the receding contact point and the advancing contact point, respectively. On the other hand, the position of  $\unicode[STIX]{x1D713}_{max}$ gradually moves away from the advancing point with the increase of

$\unicode[STIX]{x1D713}_{max}$ gradually moves away from the advancing point with the increase of  $Ca_{e}$, which can be explained as the increased interface curvature at the droplet tip where the surfactants prefer accumulation.

$Ca_{e}$, which can be explained as the increased interface curvature at the droplet tip where the surfactants prefer accumulation.

Figure 3. The dimensionless surfactant concentration  $\unicode[STIX]{x1D713}^{\ast }$ as a function of the arclength

$\unicode[STIX]{x1D713}^{\ast }$ as a function of the arclength  $s$ in the

$s$ in the  $x$-

$x$- $z$ mid-plane for various values of

$z$ mid-plane for various values of  $Ca_{e}$. The inset shows the variation of the maximum and minimum surfactant concentrations (denoted as

$Ca_{e}$. The inset shows the variation of the maximum and minimum surfactant concentrations (denoted as  $\unicode[STIX]{x1D713}_{max}^{\ast }$ and

$\unicode[STIX]{x1D713}_{max}^{\ast }$ and  $\unicode[STIX]{x1D713}_{min}^{\ast }$, respectively) with

$\unicode[STIX]{x1D713}_{min}^{\ast }$, respectively) with  $Ca_{e}$. It should be noted that there are two minimum surfactant concentrations, which occur at the front (downstream) and rear (upstream) interfaces bounded by the droplet tip.

$Ca_{e}$. It should be noted that there are two minimum surfactant concentrations, which occur at the front (downstream) and rear (upstream) interfaces bounded by the droplet tip.

The droplet deformation can be quantified by the relative surface area, defined as  $S_{r}=(S-S_{0})/S_{0}$. It is noted that the greater

$S_{r}=(S-S_{0})/S_{0}$. It is noted that the greater  $S_{r}$ is, the more the droplet will deform. Figure 4 shows the variation of

$S_{r}$ is, the more the droplet will deform. Figure 4 shows the variation of  $S_{r}$ with

$S_{r}$ with  $Ca_{e}$ for both clean and surfactant-covered droplets. Consistent with the observation in figure 2, the droplet deformation increases with

$Ca_{e}$ for both clean and surfactant-covered droplets. Consistent with the observation in figure 2, the droplet deformation increases with  $Ca_{e}$ in both the clean and surfactant-covered cases, and the surfactant-covered droplet always undergoes a larger deformation at each value of

$Ca_{e}$ in both the clean and surfactant-covered cases, and the surfactant-covered droplet always undergoes a larger deformation at each value of  $Ca_{e}$. Similar results were also obtained by Schleizer & Bonnecaze (Reference Schleizer and Bonnecaze1999) for a droplet adhering to a substrate subject to a shear flow. As stated above, the increased droplet deformation in the surfactant-covered case is caused by the non-uniform distribution of surfactants, and thus increasing non-uniformity of surfactants leads to a bigger difference in

$Ca_{e}$. Similar results were also obtained by Schleizer & Bonnecaze (Reference Schleizer and Bonnecaze1999) for a droplet adhering to a substrate subject to a shear flow. As stated above, the increased droplet deformation in the surfactant-covered case is caused by the non-uniform distribution of surfactants, and thus increasing non-uniformity of surfactants leads to a bigger difference in  $S_{r}$ between the clean and surfactant-covered droplets. The results of figure 3 suggest that the non-uniformity of surfactants increases with

$S_{r}$ between the clean and surfactant-covered droplets. The results of figure 3 suggest that the non-uniformity of surfactants increases with  $Ca_{e}$, so the difference in

$Ca_{e}$, so the difference in  $S_{r}$ between the clean and surfactant-covered droplets increases with

$S_{r}$ between the clean and surfactant-covered droplets increases with  $Ca_{e}$, which can be clearly seen in figure 4.

$Ca_{e}$, which can be clearly seen in figure 4.

Figure 4. The relative interfacial area  $S_{r}$ as a function of the effective capillary number

$S_{r}$ as a function of the effective capillary number  $Ca_{e}$ for both clean and surfactant-covered droplets.

$Ca_{e}$ for both clean and surfactant-covered droplets.

When the droplet eventually moves over the surface at a constant velocity  $u_{d}$, the forces acting on the droplet would reach a balance, which consist of the viscous force exerted by the ambient fluid, the wall stress on the wetted surface and the capillary force at the contact line (CL). The force balance can be written as (Ding et al. Reference Ding, Gilani and Spelt2010)

$u_{d}$, the forces acting on the droplet would reach a balance, which consist of the viscous force exerted by the ambient fluid, the wall stress on the wetted surface and the capillary force at the contact line (CL). The force balance can be written as (Ding et al. Reference Ding, Gilani and Spelt2010)

$$\begin{eqnarray}\int _{S_{I}}\boldsymbol{n}\boldsymbol{\cdot }\boldsymbol{T}\,\text{d}S-\int _{S_{w}}\boldsymbol{n}_{w}\boldsymbol{\cdot }\boldsymbol{T}\,\text{d}S+\oint _{CL}\unicode[STIX]{x1D70E}\boldsymbol{t}\,\text{d}l=0,\end{eqnarray}$$

$$\begin{eqnarray}\int _{S_{I}}\boldsymbol{n}\boldsymbol{\cdot }\boldsymbol{T}\,\text{d}S-\int _{S_{w}}\boldsymbol{n}_{w}\boldsymbol{\cdot }\boldsymbol{T}\,\text{d}S+\oint _{CL}\unicode[STIX]{x1D70E}\boldsymbol{t}\,\text{d}l=0,\end{eqnarray}$$ where  $S_{I}$ is the fluid–fluid interface,

$S_{I}$ is the fluid–fluid interface,  $S_{w}$ is the wetted area by the droplet,

$S_{w}$ is the wetted area by the droplet,  $\boldsymbol{T}$ is the stress tensor and

$\boldsymbol{T}$ is the stress tensor and  $\boldsymbol{t}$ is the unit vector tangent to the fluid–fluid interface in the plane spanned by the vectors normal to the substrate and to the CL. As previously done by Ding et al. (Reference Ding, Gilani and Spelt2010), the capillary force

$\boldsymbol{t}$ is the unit vector tangent to the fluid–fluid interface in the plane spanned by the vectors normal to the substrate and to the CL. As previously done by Ding et al. (Reference Ding, Gilani and Spelt2010), the capillary force  $\oint _{CL}\unicode[STIX]{x1D70E}\boldsymbol{t}\,\text{d}l$ can be written as