1. Introduction

Surfactants are surface active agents that exist between phases to reduce the interfacial energy and thereby stabilize interfaces that are otherwise unstable. They are present in numerous processes that affect our lives. Pulmonary surfactants coat the air–liquid interface of the alveoli and enable us to breath (Zasadzinski et al. Reference Zasadzinski, Ding, Warriner, Bringezu and Waring2001). Excessive amounts of insoluble surfactants on the ocean surface can lead to the formation of a visible layer of ‘slick’ that changes the viscoelasticity of the liquid–air interface and dampen waves (Cunliffe et al. Reference Cunliffe, Engel, Frka, Gašparović, Guitart, Murrell, Salter, Stolle, Upstill-Goddard and Wurl2013). Water-based paints require surfactants to improve wetting and disperse pigments (Hellgren, Weissenborn & Holmberg Reference Hellgren, Weissenborn and Holmberg1999). Surfactant-based dispersants are used as a chemical means of cleaning an oil spill and preventing the formation of oil slicks (Dave & Ghaly Reference Dave and Ghaly2011). The prevalence and importance of surfactants call for a fundamental understanding of their dynamical interactions at the interfaces of different materials, and this is a subject of much historical and present day active interest.

The nature of surfactants restricts these ambiphilic molecules to be most active at air–water or oil–water interfaces. Thin liquid films, therefore, are effective systems through which we can examine the dynamics of surfactants. There are several commonly used experimental techniques for generating thin films in surfactant solutions. One technique involves using a syringe to inject air just below a surfactant solution surface to generate a near-hemispherical bubble, whose film thickness at the apex can be measured via interferometric techniques (Champougny et al. Reference Champougny, Roché, Drenckhan and Rio2016).

With this method, one can easily study the film drainage rate and the relative importance of gravity to surface tension by changing the bubble volume (Lhuissier & Villermaux Reference Lhuissier and Villermaux2012). This technique allows researchers to examine the film evolution of large surface bubbles. Miguet et al. (Reference Miguet, Pasquet, Rouyer, Fang and Rio2021) studied the marginal regeneration phenomenon of surfactant films over bubbles with a radius of curvature of more than a centimetre. A characteristic visual example of this phenomenon can be found in figure 1 of Miguet et al. (Reference Miguet, Pasquet, Rouyer, Fang and Rio2021). Numerous numerical studies of free surface bubbles have been conducted (Pigeonneau & Sellier Reference Pigeonneau and Sellier2011; Atasi et al. Reference Atasi, Legendre, Haut, Zenit and Scheid2020). Atasi et al. (Reference Atasi, Legendre, Haut, Zenit and Scheid2020) studied the lifetime of surface bubbles in the presence of surfactants. The numerical study offers many insights into the relations between the evolution of film thickness, gravitational effects and surfactant coverage. However, the study is limited to axisymmetric film evolution and cannot capture the azimuthal flow inside the liquid film that coats the surface bubbles.

A second experimental approach introduces an air bubble at a distance from the interface between a surfactant solution bath and the ambient air. As the air bubble rises, its velocity (Borkowski, Kosior & Zawala Reference Borkowski, Kosior and Zawala2020) and path (Tagawa, Takagi & Matsumoto Reference Tagawa, Takagi and Matsumoto2014) can be studied. A third class of approaches involves mechanically forcing two interfaces close together. This can be achieved through a variety of geometric arrangements, summarized in figure 2 of Chatzigiannakis, Jaensson & Vermant (Reference Chatzigiannakis, Jaensson and Vermant2021). When this class of thin film generation technique is paired with digital imaging, one can obtain interferometric information on the temporal and spatial evolution of film thickness and symmetry. To set context, we introduce a few examples that are relevant to the present work.

Joye (Reference Joye1994) conducted film drainage experiments with a Scheludko-cell based design, where a thin film is formed by withdrawing liquid from an initially filled circular sample holder. Once the thin film has reached a desired thickness, the withdrawal is stopped and the film is allowed to evolve under various physical forces. An example of asymmetrical, aqueous surfactant film evolution can be found in figure IV-1 of Joye (Reference Joye1994). More recently, this type of apparatus has been improved to study the stratification of foam films (Ochoa et al. Reference Ochoa, Gao, Srivastava and Sharma2021).

The dynamic fluid-film interferometer (DFI) is another technique used to manually form a thin film (Frostad et al. Reference Frostad, Tammaro, Santollani, de Araujo and Fuller2016). In the DFI an air bubble or a liquid droplet is supported on a capillary and is fully submerged in a liquid chamber of interest. A motor brings the initially curved and flat faces together until the film is thin enough to form interference patterns. The interference video gives information on film thickness and film symmetry. This set-up has been used to visualize the flow of aqueous surfactant films. Frostad et al. (Reference Frostad, Tammaro, Santollani, de Araujo and Fuller2016) examine three commonly studied water-soluble surfactants (sodium dodecyl sulfate (SDS), cetrimonium bromide (CTAB) and Triton X-100), and their effects on aqueous surfactant films trapped in between an air bubble and the initially planar air–solution interface. The interference videos for all three species can be found in the supplementary files. In all three videos, the evolution of the film symmetry undergoes similar stages. In the first stage, the field of view of the interference patterns grows radially outward in an axisymmetric fashion. During this stage, the motor is forcing the two interfaces together, forming a dimple atop the air bubble. When the motor stops moving, the dimple ceases to expand in the radial direction, and the system succumbs to ambient disturbances. The disturbance first manifests itself around the rim of the dimple: at 2 s in the SDS video, at 4 s in the CTAB video and at 3 s in the Triton video. Thereafter, the asymmetry grows more pronounced and the previously axisymmetric dimple evolves to conform to the asymmetry at the rim. Eventually, the dimple discharges through a few contact points along the rim and the volume of the dimple drastically decreases. The dimple discharge event triggers secondary non-axisymmetric film evolution until the film thins down to nanoscopic thickness and the bubble coalesces. Understanding the physical forces that drive the onset of the disturbances in the surfactant film is of paramount importance because the symmetry breaking event triggers the subsequent rapid dimple discharge that contributes to drastic film thinning that affects the lifetime of the bubble. Highly asymmetrical patterns of insoluble surfactant films can be seen in figure 9 of Hermans et al. (Reference Hermans, Bhamla, Kao, Fuller and Vermant2015) and figures 6 and 7 of Bhamla et al. (Reference Bhamla, Chai, Alvarez-Valenzuela, Tajuelo and Fuller2017). Additional experimental examples of asymmetrical dynamic evolution of thin films are discussed in our previous work (Shi et al. Reference Shi, Rodríguez-Hakim, Shaqfeh and Fuller2021).

These examples of asymmetrical interference patterns suggest that there are common forces associated with surfactant film evolution that drive the system to develop in an asymmetrical fashion. To this end, we devote the present study to understanding the physical mechanism behind the asymmetrical evolution of water-soluble surfactant films, at a concentration below the critical micelle concentration. The article is organized as follows. We first introduce in detail the DFI set-up and the experimental procedures used for this study, followed by descriptions of the lubrication theory and the numerical methods. We then describe the experimental and computational evolution of an aqueous surfactant film over an air bubble, with a focus on capturing the onset of asymmetric disturbances. A linear stability analysis is presented to elucidate the mechanism behind the observed symmetry breaking events. The analysis also reveals mode selection for a given set of system parameters. We finish the article with a discussion of the factors that affect the mode selection and the mechanism of the instability.

2. Experiment

Surfactant film drainage experiments are conducted using a custom-made DFI. The equipment set-up is described in our previous work (Shi, Fuller & Shaqfeh Reference Shi, Fuller and Shaqfeh2020). For completeness, we shall only provide a succinct description of the apparatus and the experimental procedures.

The experimental apparatus is composed of a liquid sample chamber, which is mounted onto a motorized platform. Two of the four chamber walls are made of glass, enabling visualization into the chamber. A 16-gauge capillary with an inner diameter of 1.2 mm is held fixed and positioned at the centre of the chamber at the start of an experiment. The capillary is connected to a ![]() $100\ \mathrm {\mu } {\rm l}$ syringe filled with air.

$100\ \mathrm {\mu } {\rm l}$ syringe filled with air.

Prior to each sample loading, the cleanliness of the assembly is tested via the following procedure. The empty chamber is filled with deionized water and an air bubble of approximately ![]() $5\ \mathrm {\mu } {\rm l}$ is extruded from the capillary. The motorized platform then positions the apex of the bubble to be approximately 0.1 mm away from the air–water interface. The motor then translates the chamber downward for 0.4 mm at

$5\ \mathrm {\mu } {\rm l}$ is extruded from the capillary. The motorized platform then positions the apex of the bubble to be approximately 0.1 mm away from the air–water interface. The motor then translates the chamber downward for 0.4 mm at ![]() $0.1\ {\rm mm}\ {\rm s}^{-1}$. If the bubble coalesces within 5 s, then the chamber is deemed sufficiently clean and experiments with surfactant solutions may proceed. The cutoff time of 5 s is chosen because a surfactant-covered bubble that undergoes the same experimental procedure typically lasts longer than 12 s. If the bubble in the deionized water takes longer than 5 s to coalesce, then the chamber is taken from the platform and vigorously cleaned with deionized water. The test and cleaning are repeated until the assembly meets the criterion.

$0.1\ {\rm mm}\ {\rm s}^{-1}$. If the bubble coalesces within 5 s, then the chamber is deemed sufficiently clean and experiments with surfactant solutions may proceed. The cutoff time of 5 s is chosen because a surfactant-covered bubble that undergoes the same experimental procedure typically lasts longer than 12 s. If the bubble in the deionized water takes longer than 5 s to coalesce, then the chamber is taken from the platform and vigorously cleaned with deionized water. The test and cleaning are repeated until the assembly meets the criterion.

The model surfactant used in this study is Triton X-100, a widely studied non-ionic surfactant composed of a hydrophilic polyethylene oxide chain and a hydrophobic hydrocarbon chain. Furthermore, Triton X-100 readily adsorbs onto air–water interfaces, making it one of the more effective, water-soluble surfactants (Chang & Franses Reference Chang and Franses1995). For a typical experiment, approximately 4 ml of a Triton X-100 (laboratory grade, Sigma-Aldrich) aqueous solution is loaded into the chamber. The water used in making the solution is filtered by a Millipak Express 40 filter (![]() $0.22\ \mathrm {\mu } {\rm m}$ membrane) to remove particulates. For all the experiments presented in this paper, the concentration of the Triton X-100 solution is

$0.22\ \mathrm {\mu } {\rm m}$ membrane) to remove particulates. For all the experiments presented in this paper, the concentration of the Triton X-100 solution is ![]() $0.01\ {\rm mmol}\ {\rm l}^{-1}$, which is below the critical micelle concentration at

$0.01\ {\rm mmol}\ {\rm l}^{-1}$, which is below the critical micelle concentration at ![]() $25\,^\circ {\rm C}$ (Lin, McKeigue & Maldarelli Reference Lin, McKeigue and Maldarelli1990). An air bubble of approximately

$25\,^\circ {\rm C}$ (Lin, McKeigue & Maldarelli Reference Lin, McKeigue and Maldarelli1990). An air bubble of approximately ![]() $5\ \mathrm {\mu } {\rm l}$ is extruded from the capillary. The top of the chamber is then covered with a glass slide and the system is left to equilibrate for 30 min, such that the surfactant present in the bulk can adsorb onto the newly formed air bubble.

$5\ \mathrm {\mu } {\rm l}$ is extruded from the capillary. The top of the chamber is then covered with a glass slide and the system is left to equilibrate for 30 min, such that the surfactant present in the bulk can adsorb onto the newly formed air bubble.

After the equilibration period, the glass cover is removed and the motorized platform moves the chamber downward such that the apex of the bubble is positioned as close as possible to the flat liquid–air interface without penetrating the interface (approximately 0.1 mm of apex clearance). This procedure ensures the applicability of lubrication theory, developed to describe the dynamics of the film. After a one minute pause, the motor moves the chamber assembly downward by 0.4 mm at a speed of ![]() $0.1\ {\rm mm}\ {\rm s}^{-1}$. The motor then stops the translation. The top camera records the interference patterns of the thin liquid film atop the air bubble throughout this process. Film thickness and symmetry information are obtained by analysing the interference video.

$0.1\ {\rm mm}\ {\rm s}^{-1}$. The motor then stops the translation. The top camera records the interference patterns of the thin liquid film atop the air bubble throughout this process. Film thickness and symmetry information are obtained by analysing the interference video.

3. Theoretical model

3.1. Lubrication equations

We consider a spherical, non-deformable air bubble of radius ![]() $a$, approaching an initially flat interface between air and an aqueous surfactant solution (figure 1). At the start of the experiment, the apex of the bubble is positioned a distance

$a$, approaching an initially flat interface between air and an aqueous surfactant solution (figure 1). At the start of the experiment, the apex of the bubble is positioned a distance ![]() $b$ below the top air–liquid interface. It is assumed that

$b$ below the top air–liquid interface. It is assumed that ![]() $\epsilon \equiv b/a \ll 1$, such that the lubrication approximation applies. The bulk liquid phase is composed of an aqueous surfactant solution with a bulk surfactant concentration of

$\epsilon \equiv b/a \ll 1$, such that the lubrication approximation applies. The bulk liquid phase is composed of an aqueous surfactant solution with a bulk surfactant concentration of ![]() $c_0$. We assume that at the start of the experiment, the surfactant in the solution and the surfactant adsorbed onto the two air–liquid interfaces are in equilibrium and the equilibrium surface concentration is

$c_0$. We assume that at the start of the experiment, the surfactant in the solution and the surfactant adsorbed onto the two air–liquid interfaces are in equilibrium and the equilibrium surface concentration is ![]() $\varGamma _0$. The surfactant is characterized by a bulk diffusivity of

$\varGamma _0$. The surfactant is characterized by a bulk diffusivity of ![]() $D$ and a surface diffusivity of

$D$ and a surface diffusivity of ![]() $D_s$. The bulk concentration of the surfactant is below the critical micelle concentration and is small enough such that the solution density and viscosity are the same as those of the Newtonian solvent,

$D_s$. The bulk concentration of the surfactant is below the critical micelle concentration and is small enough such that the solution density and viscosity are the same as those of the Newtonian solvent, ![]() $\rho$ and

$\rho$ and ![]() $\mu$, respectively. At

$\mu$, respectively. At ![]() $t^* = 0$, the bubble is moved upwards, against gravity, for a distance

$t^* = 0$, the bubble is moved upwards, against gravity, for a distance ![]() $d$ at a speed of

$d$ at a speed of ![]() $U$. The bubble is then held fixed after

$U$. The bubble is then held fixed after ![]() $t^*_{stop} = d/U$. For simplicity, the capillary-pinned bubble in the experiment is treated in the theoretical model as a non-deformable sphere with a non-zero surface velocity. As shown in later sections, this simplifying assumption still allows us to capture the onset of symmetry breaking. Furthermore, because the Reynolds number

$t^*_{stop} = d/U$. For simplicity, the capillary-pinned bubble in the experiment is treated in the theoretical model as a non-deformable sphere with a non-zero surface velocity. As shown in later sections, this simplifying assumption still allows us to capture the onset of symmetry breaking. Furthermore, because the Reynolds number ![]() $Re \equiv (\rho U b)/\mu \ll 1$, we neglect all inertial effects. We also neglect the effects of evaporation-driven film thinning and evaporation-generated Marangoni flows (Poulain, Villermaux & Bourouiba Reference Poulain, Villermaux and Bourouiba2018) to focus on the effects of surfactant transport-induced phenomena. As will be shown in the results section, the model is only used to capture the dynamics during the onset of the disturbance. During this time, the minimum film thickness is around 200 nm, thus, we neglect the effects of the disjoining pressure (Stubenrauch & Von Klitzing Reference Stubenrauch and Von Klitzing2003).

$Re \equiv (\rho U b)/\mu \ll 1$, we neglect all inertial effects. We also neglect the effects of evaporation-driven film thinning and evaporation-generated Marangoni flows (Poulain, Villermaux & Bourouiba Reference Poulain, Villermaux and Bourouiba2018) to focus on the effects of surfactant transport-induced phenomena. As will be shown in the results section, the model is only used to capture the dynamics during the onset of the disturbance. During this time, the minimum film thickness is around 200 nm, thus, we neglect the effects of the disjoining pressure (Stubenrauch & Von Klitzing Reference Stubenrauch and Von Klitzing2003).

Figure 1. Schematic of a spherical air bubble approaching the interface between air and aqueous surfactant solution.

A cylindrical coordinate system (![]() $z^*, r^*, \theta$) is used to accommodate the geometry of the system and the motion of the bubble. The origin is placed at the intersection of the initially flat liquid–air interface and the vertical axis of the bubble. The vertical axis is represented by

$z^*, r^*, \theta$) is used to accommodate the geometry of the system and the motion of the bubble. The origin is placed at the intersection of the initially flat liquid–air interface and the vertical axis of the bubble. The vertical axis is represented by ![]() $z^*$, the radial coordinate is represented by

$z^*$, the radial coordinate is represented by ![]() $r^*$ and

$r^*$ and ![]() $\theta$ represents the azimuthal angle. The asterisk represents dimensional quantities.

$\theta$ represents the azimuthal angle. The asterisk represents dimensional quantities.

The following scales are chosen to render the governing equations dimensionless. The lubrication length scales in the axial and radial directions are ![]() $b$ and

$b$ and ![]() $\sqrt {ab}$, respectively. The vertical velocity (

$\sqrt {ab}$, respectively. The vertical velocity (![]() $v_z^*$) is scaled by the motor speed (

$v_z^*$) is scaled by the motor speed (![]() $U$). Mass conservation demands the velocities in the radial (

$U$). Mass conservation demands the velocities in the radial (![]() $v_r^*$) and azimuthal (

$v_r^*$) and azimuthal (![]() $v_\theta ^*$) directions be scaled by

$v_\theta ^*$) directions be scaled by ![]() $U/\sqrt {\epsilon }$. Time is non-dimensionalized by

$U/\sqrt {\epsilon }$. Time is non-dimensionalized by ![]() $b/U$ and the pressure scale is

$b/U$ and the pressure scale is ![]() $(1/\epsilon ^2)(\mu U/a)$. The scale for the bulk surfactant molar concentration is

$(1/\epsilon ^2)(\mu U/a)$. The scale for the bulk surfactant molar concentration is ![]() $c_0$. The surface adsorbed surfactant concentration (

$c_0$. The surface adsorbed surfactant concentration (![]() $\varGamma ^*$) is non-dimensionalized by the maximum packing concentration (

$\varGamma ^*$) is non-dimensionalized by the maximum packing concentration (![]() $\varGamma _\infty$). The scale for surfactant adsorption fluxes (

$\varGamma _\infty$). The scale for surfactant adsorption fluxes (![]() $(U\varGamma _\infty )/b$) is obtained when non-dimensionalizing the mass transfer equation of the surface adsorbed species.

$(U\varGamma _\infty )/b$) is obtained when non-dimensionalizing the mass transfer equation of the surface adsorbed species.

With the above scales, we proceed to non-dimensionalize the governing equations, expand all variables in ![]() $\epsilon$:

$\epsilon$: ![]() $\psi = \psi ^{(0)} + \epsilon \psi ^{(1)} + \epsilon ^2 \psi ^{(2)} + \dots$ and extract the governing equations for variables at each order. Similar to our previous study (Shi et al. Reference Shi, Fuller and Shaqfeh2020), we need to examine the combined effects of the

$\psi = \psi ^{(0)} + \epsilon \psi ^{(1)} + \epsilon ^2 \psi ^{(2)} + \dots$ and extract the governing equations for variables at each order. Similar to our previous study (Shi et al. Reference Shi, Fuller and Shaqfeh2020), we need to examine the combined effects of the ![]() $O(1)$ and the

$O(1)$ and the ![]() $O(\epsilon )$ terms, such that when the concentration of the surfactant goes to zero, the governing equations of a clean air–liquid interface are recovered. The order-combined variables are denoted with a hat:

$O(\epsilon )$ terms, such that when the concentration of the surfactant goes to zero, the governing equations of a clean air–liquid interface are recovered. The order-combined variables are denoted with a hat: ![]() $\hat {\psi } \equiv \psi ^{(0)} + \epsilon \psi ^{(1)}$. We introduce only the final form of the governing equations. Detailed treatment of the order-combined variables can be found in the Appendix of Shi et al. (Reference Shi, Fuller and Shaqfeh2020) and § A.7.3 of Barakat (Reference Barakat2018).

$\hat {\psi } \equiv \psi ^{(0)} + \epsilon \psi ^{(1)}$. We introduce only the final form of the governing equations. Detailed treatment of the order-combined variables can be found in the Appendix of Shi et al. (Reference Shi, Fuller and Shaqfeh2020) and § A.7.3 of Barakat (Reference Barakat2018).

The position of the top liquid–air interface (![]() $\hat {h}_1$) is described by

$\hat {h}_1$) is described by

\begin{equation} \frac{\partial {\hat{h}_1}}{\partial {t}} + \frac{1}{r}\frac{\partial}{\partial r}\left(r\hat{h}\widehat{\left\langle {v_r} \right\rangle}\right) + \frac{1}{r}\frac{\partial }{\partial \theta}\left( {\hat{h}\widehat{\left\langle {v_\theta} \right\rangle}} \right) =\begin{cases} 1, & (t \leqslant t_{stop}),\\ 0, & (t > t_{stop}), \end{cases} \end{equation}

\begin{equation} \frac{\partial {\hat{h}_1}}{\partial {t}} + \frac{1}{r}\frac{\partial}{\partial r}\left(r\hat{h}\widehat{\left\langle {v_r} \right\rangle}\right) + \frac{1}{r}\frac{\partial }{\partial \theta}\left( {\hat{h}\widehat{\left\langle {v_\theta} \right\rangle}} \right) =\begin{cases} 1, & (t \leqslant t_{stop}),\\ 0, & (t > t_{stop}), \end{cases} \end{equation}

where ![]() $\hat {h} \equiv \hat {h}_1 - h_2$ and

$\hat {h} \equiv \hat {h}_1 - h_2$ and ![]() $t_{stop} \equiv d/b$. The position of the bubble–liquid interface (

$t_{stop} \equiv d/b$. The position of the bubble–liquid interface (![]() $h_2$) is known at all times, as we assume no bubble deformation, i.e.

$h_2$) is known at all times, as we assume no bubble deformation, i.e.

\begin{equation} h_2 \equiv \begin{cases} -1 - r^2/2 + t, & (t \leqslant t_{stop}), \\ -1 - r^2/2 + t_{stop}, & (t > t_{stop}). \end{cases} \end{equation}

\begin{equation} h_2 \equiv \begin{cases} -1 - r^2/2 + t, & (t \leqslant t_{stop}), \\ -1 - r^2/2 + t_{stop}, & (t > t_{stop}). \end{cases} \end{equation}

The bracket around the radial and azimuthal velocities indicates depth averaging: ![]() $\hat {\left \langle {\psi } \right \rangle } \equiv ({1}/{\hat {h}})\int _{h_2}^{\hat {h}_1} \hat {\psi } \,{\rm d}z$, where

$\hat {\left \langle {\psi } \right \rangle } \equiv ({1}/{\hat {h}})\int _{h_2}^{\hat {h}_1} \hat {\psi } \,{\rm d}z$, where ![]() $\psi = v_r$ and

$\psi = v_r$ and ![]() $v_\theta$. The normal stress balance across the top liquid–air interface is

$v_\theta$. The normal stress balance across the top liquid–air interface is

\begin{equation} \frac{1}{r}\frac{\partial}{\partial r}\left(r\frac{\partial {\hat{h}_1} }{\partial r}\right) + \frac{1}{r^2}\frac{\partial^2 \hat{h}_1}{\partial \theta^2} - Bo \hat{h}_1 + Ca \hat{P} + 2\epsilon Ca \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r\widehat{\left\langle {v_r} \right\rangle}\right) + \frac{1}{r}\frac{\partial \widehat{\left\langle {v_\theta} \right\rangle}}{\partial \theta}} \right) = 0, \end{equation}

\begin{equation} \frac{1}{r}\frac{\partial}{\partial r}\left(r\frac{\partial {\hat{h}_1} }{\partial r}\right) + \frac{1}{r^2}\frac{\partial^2 \hat{h}_1}{\partial \theta^2} - Bo \hat{h}_1 + Ca \hat{P} + 2\epsilon Ca \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r\widehat{\left\langle {v_r} \right\rangle}\right) + \frac{1}{r}\frac{\partial \widehat{\left\langle {v_\theta} \right\rangle}}{\partial \theta}} \right) = 0, \end{equation}

where ![]() $Bo \equiv \rho g a b/\gamma _{water}$ and

$Bo \equiv \rho g a b/\gamma _{water}$ and ![]() $Ca \equiv (1/\epsilon ^2) (\mu U/\gamma _{water})$. The gravitational acceleration is denoted by

$Ca \equiv (1/\epsilon ^2) (\mu U/\gamma _{water})$. The gravitational acceleration is denoted by ![]() $g = 9.8\ {\rm m}\ {\rm s}^{-2}$. The first non-dimensional parameter is the Bond number, which compares the relative importance of gravity to the surface tension of a clean interface. The second non-dimensional number is the capillary number, which compares viscous stresses to capillary stresses. The tangential stress balances in the radial and azimuthal directions are

$g = 9.8\ {\rm m}\ {\rm s}^{-2}$. The first non-dimensional parameter is the Bond number, which compares the relative importance of gravity to the surface tension of a clean interface. The second non-dimensional number is the capillary number, which compares viscous stresses to capillary stresses. The tangential stress balances in the radial and azimuthal directions are

\begin{align} \frac{\partial {\hat{P}}}{\partial {r}} &= \frac{1}{\hat{h}} \frac{1}{\epsilon Ca} \left( { \frac{\partial { \left( {-\varPi^{(0)}_1} \right) }}{\partial {r}} + \frac{\partial { \left( {-\varPi^{(0)}_2} \right) }}{\partial {r}} } \right) \nonumber\\ &\quad + \epsilon \left\{\vphantom{\frac{1}{\hat{h}} \frac{1}{r}\frac{\partial \hat{h}}{\partial \theta} \left( { \frac{1}{r}\frac{\partial \widehat{\left\langle {v_r} \right\rangle} }{\partial \theta} + r \frac{\partial {}}{\partial {r}} \left( {\frac{ \widehat{\left\langle {v_\theta} \right\rangle} }{r} } \right) } \right)} 2 \frac{\partial {}}{\partial {r}}\left( {\frac{1}{r}\frac{\partial}{\partial r}\left(r \widehat{\left\langle {v_r} \right\rangle} \right)} \right) + \frac{\partial {}}{\partial {r}} \left( {\frac{1}{r}\frac{\partial \widehat{\left\langle {v_\theta} \right\rangle} }{\partial \theta}} \right) + \frac{1}{r^2}\frac{\partial^2 \widehat{\left\langle {v_r} \right\rangle} }{\partial \theta^2} - \frac{2}{r^2}\frac{\partial { \widehat{\left\langle {v_\theta} \right\rangle} }}{\partial {\theta}} \right. \nonumber\\ &\quad\left. +\,\frac{2}{\hat{h}} \frac{\partial { \hat{h} }}{\partial {r}} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r \widehat{\left\langle {v_r} \right\rangle} \right) + \frac{\partial { \widehat{\left\langle {v_r} \right\rangle} }}{\partial {r}} + \frac{1}{r}\frac{\partial \widehat{\left\langle {v_\theta} \right\rangle} }{\partial \theta} } \right) +\frac{1}{\hat{h}} \frac{1}{r}\frac{\partial \hat{h}}{\partial \theta} \left( { \frac{1}{r}\frac{\partial \widehat{\left\langle {v_r} \right\rangle} }{\partial \theta} + r \frac{\partial {}}{\partial {r}} \left( {\frac{ \widehat{\left\langle {v_\theta} \right\rangle} }{r} } \right) } \right) \right\} \end{align}

\begin{align} \frac{\partial {\hat{P}}}{\partial {r}} &= \frac{1}{\hat{h}} \frac{1}{\epsilon Ca} \left( { \frac{\partial { \left( {-\varPi^{(0)}_1} \right) }}{\partial {r}} + \frac{\partial { \left( {-\varPi^{(0)}_2} \right) }}{\partial {r}} } \right) \nonumber\\ &\quad + \epsilon \left\{\vphantom{\frac{1}{\hat{h}} \frac{1}{r}\frac{\partial \hat{h}}{\partial \theta} \left( { \frac{1}{r}\frac{\partial \widehat{\left\langle {v_r} \right\rangle} }{\partial \theta} + r \frac{\partial {}}{\partial {r}} \left( {\frac{ \widehat{\left\langle {v_\theta} \right\rangle} }{r} } \right) } \right)} 2 \frac{\partial {}}{\partial {r}}\left( {\frac{1}{r}\frac{\partial}{\partial r}\left(r \widehat{\left\langle {v_r} \right\rangle} \right)} \right) + \frac{\partial {}}{\partial {r}} \left( {\frac{1}{r}\frac{\partial \widehat{\left\langle {v_\theta} \right\rangle} }{\partial \theta}} \right) + \frac{1}{r^2}\frac{\partial^2 \widehat{\left\langle {v_r} \right\rangle} }{\partial \theta^2} - \frac{2}{r^2}\frac{\partial { \widehat{\left\langle {v_\theta} \right\rangle} }}{\partial {\theta}} \right. \nonumber\\ &\quad\left. +\,\frac{2}{\hat{h}} \frac{\partial { \hat{h} }}{\partial {r}} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r \widehat{\left\langle {v_r} \right\rangle} \right) + \frac{\partial { \widehat{\left\langle {v_r} \right\rangle} }}{\partial {r}} + \frac{1}{r}\frac{\partial \widehat{\left\langle {v_\theta} \right\rangle} }{\partial \theta} } \right) +\frac{1}{\hat{h}} \frac{1}{r}\frac{\partial \hat{h}}{\partial \theta} \left( { \frac{1}{r}\frac{\partial \widehat{\left\langle {v_r} \right\rangle} }{\partial \theta} + r \frac{\partial {}}{\partial {r}} \left( {\frac{ \widehat{\left\langle {v_\theta} \right\rangle} }{r} } \right) } \right) \right\} \end{align}and

\begin{align} \frac{1}{r}\frac{\partial \hat{P}}{\partial \theta} &= \frac{1}{\hat{h}}\frac{1}{\epsilon Ca} \left( { \frac{1}{r}\frac{\partial \left( {-\varPi^{(0)}_1} \right) }{\partial \theta} + \frac{1}{r}\frac{\partial \left( {-\varPi^{(0)}_2} \right) }{\partial \theta} } \right) \nonumber\\ &\quad + \epsilon \left\{\vphantom{\frac{1}{\hat{h}} \frac{1}{r}\frac{\partial \hat{h}}{\partial \theta} \left( { \frac{1}{r}\frac{\partial \widehat{\left\langle {v_r} \right\rangle} }{\partial \theta} + r \frac{\partial {}}{\partial {r}} \left( {\frac{ \widehat{\left\langle {v_\theta} \right\rangle} }{r} } \right) } \right)} \frac{2}{r^2} \frac{\partial {^2 \widehat{\left\langle {v_\theta} \right\rangle} }}{\partial {\theta^2}} +\frac{\partial {}}{\partial {r}} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r \widehat{\left\langle {v_\theta} \right\rangle} \right) } \right) + \frac{1}{r}\frac{\partial }{\partial \theta}\left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r \widehat{\left\langle {v_r} \right\rangle} \right) } \right) + \frac{2}{r^2}\frac{\partial { \widehat{\left\langle {v_r} \right\rangle} }}{\partial {\theta}}\right. \nonumber\\ &\quad \left.+\,\frac{2}{\hat{h}} \frac{1}{r}\frac{\partial \hat{h}}{\partial \theta} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r \widehat{\left\langle {v_r} \right\rangle} \right) + \frac{ \widehat{\left\langle {v_r} \right\rangle} }{r} + \frac{2}{r}\frac{\partial { \widehat{\left\langle {v_\theta} \right\rangle} }}{\partial {\theta}} } \right) +\frac{1}{\hat{h}} \frac{\partial { \hat{h} }}{\partial {r}} \left( { \frac{1}{r}\frac{\partial \widehat{\left\langle {v_r} \right\rangle} }{\partial \theta} + r \frac{\partial {}}{\partial {r}} \left( {\frac{ \widehat{\left\langle {v_\theta} \right\rangle} }{r}} \right) } \right) \right\}, \end{align}

\begin{align} \frac{1}{r}\frac{\partial \hat{P}}{\partial \theta} &= \frac{1}{\hat{h}}\frac{1}{\epsilon Ca} \left( { \frac{1}{r}\frac{\partial \left( {-\varPi^{(0)}_1} \right) }{\partial \theta} + \frac{1}{r}\frac{\partial \left( {-\varPi^{(0)}_2} \right) }{\partial \theta} } \right) \nonumber\\ &\quad + \epsilon \left\{\vphantom{\frac{1}{\hat{h}} \frac{1}{r}\frac{\partial \hat{h}}{\partial \theta} \left( { \frac{1}{r}\frac{\partial \widehat{\left\langle {v_r} \right\rangle} }{\partial \theta} + r \frac{\partial {}}{\partial {r}} \left( {\frac{ \widehat{\left\langle {v_\theta} \right\rangle} }{r} } \right) } \right)} \frac{2}{r^2} \frac{\partial {^2 \widehat{\left\langle {v_\theta} \right\rangle} }}{\partial {\theta^2}} +\frac{\partial {}}{\partial {r}} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r \widehat{\left\langle {v_\theta} \right\rangle} \right) } \right) + \frac{1}{r}\frac{\partial }{\partial \theta}\left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r \widehat{\left\langle {v_r} \right\rangle} \right) } \right) + \frac{2}{r^2}\frac{\partial { \widehat{\left\langle {v_r} \right\rangle} }}{\partial {\theta}}\right. \nonumber\\ &\quad \left.+\,\frac{2}{\hat{h}} \frac{1}{r}\frac{\partial \hat{h}}{\partial \theta} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r \widehat{\left\langle {v_r} \right\rangle} \right) + \frac{ \widehat{\left\langle {v_r} \right\rangle} }{r} + \frac{2}{r}\frac{\partial { \widehat{\left\langle {v_\theta} \right\rangle} }}{\partial {\theta}} } \right) +\frac{1}{\hat{h}} \frac{\partial { \hat{h} }}{\partial {r}} \left( { \frac{1}{r}\frac{\partial \widehat{\left\langle {v_r} \right\rangle} }{\partial \theta} + r \frac{\partial {}}{\partial {r}} \left( {\frac{ \widehat{\left\langle {v_\theta} \right\rangle} }{r}} \right) } \right) \right\}, \end{align}

where ![]() $\varPi _1^{(0)}$ and

$\varPi _1^{(0)}$ and ![]() $\varPi _2^{(0)}$ are the surface pressures exerted by the adsorbed surfactant on the top and bottom interfaces, respectively. The surface pressures represent the reduction in surface tension caused by the presence of the surfactant on the interfaces. Non-dimensionalizing surface tension with

$\varPi _2^{(0)}$ are the surface pressures exerted by the adsorbed surfactant on the top and bottom interfaces, respectively. The surface pressures represent the reduction in surface tension caused by the presence of the surfactant on the interfaces. Non-dimensionalizing surface tension with ![]() $\gamma _{water} = 72\ {\rm mN}\ {\rm m}^{-1}$ we obtain

$\gamma _{water} = 72\ {\rm mN}\ {\rm m}^{-1}$ we obtain ![]() $\gamma _1 = 1 - \varPi _1^{(0)}$ and

$\gamma _1 = 1 - \varPi _1^{(0)}$ and ![]() $\gamma _2 = 1 - \varPi _2^{(0)}$.

$\gamma _2 = 1 - \varPi _2^{(0)}$.

At ![]() $t = 0$, the bulk surfactant and the adsorbed surfactant are assumed to be in equilibrium and the adsorbed surfactant concentration is assumed to be

$t = 0$, the bulk surfactant and the adsorbed surfactant are assumed to be in equilibrium and the adsorbed surfactant concentration is assumed to be ![]() $\varGamma _0$ on both interfaces, despite the difference in the curvature of the two interfaces. Based on this assumption and by letting

$\varGamma _0$ on both interfaces, despite the difference in the curvature of the two interfaces. Based on this assumption and by letting ![]() $\varGamma _1^{(0)}$ and

$\varGamma _1^{(0)}$ and ![]() $\varGamma _2^{(0)}$ have the same boundary conditions, we further simplify the equations

$\varGamma _2^{(0)}$ have the same boundary conditions, we further simplify the equations ![]() $\varGamma _1^{(0)} = \varGamma _2^{(0)} \equiv \varGamma ^{(0)}$. Consequently, the flux of surfactant adsorbing from the bulk onto the two interfaces are the same, i.e.

$\varGamma _1^{(0)} = \varGamma _2^{(0)} \equiv \varGamma ^{(0)}$. Consequently, the flux of surfactant adsorbing from the bulk onto the two interfaces are the same, i.e. ![]() $j_{n1} = j_{n2} \equiv j_n$, and the surface pressures are the same, i.e.

$j_{n1} = j_{n2} \equiv j_n$, and the surface pressures are the same, i.e. ![]() $\varPi _1^{(0)} = \varPi _2^{(0)} \equiv \varPi ^{(0)}$. Without committing to any specific surfactant species, we now express the transport equations for the surfactant species present in the bulk and on the liquid–air interfaces.

$\varPi _1^{(0)} = \varPi _2^{(0)} \equiv \varPi ^{(0)}$. Without committing to any specific surfactant species, we now express the transport equations for the surfactant species present in the bulk and on the liquid–air interfaces.

\begin{align} & \frac{\partial {c^{(0)}}}{\partial {t}} + \widehat{\left\langle {v_r} \right\rangle} \frac{\partial {c^{(0)}}}{\partial {r}} + \widehat{\left\langle {v_\theta} \right\rangle} \frac{1}{r}\frac{\partial c^{(0)}}{\partial \theta} - \frac{1}{Pe} \left( {\frac{1}{r}\frac{\partial}{\partial r}\left(r\frac{\partial {c^{(0)}} }{\partial r}\right) + \frac{1}{r^2}\frac{\partial^2 c^{(0)}}{\partial \theta^2}} \right) \nonumber\\ & \quad-\frac{1}{Pe} \frac{1}{\hat{h}} \left( { \frac{\partial {\hat{h}}}{\partial {r}}\frac{\partial {c^{(0)}}}{\partial {r}} +\frac{1}{r}\frac{\partial \hat{h}}{\partial \theta}\frac{1}{r}\frac{\partial c^{(0)}}{\partial \theta} } \right) ={-} \frac{2\beta}{\hat{h}} j_n \end{align}

\begin{align} & \frac{\partial {c^{(0)}}}{\partial {t}} + \widehat{\left\langle {v_r} \right\rangle} \frac{\partial {c^{(0)}}}{\partial {r}} + \widehat{\left\langle {v_\theta} \right\rangle} \frac{1}{r}\frac{\partial c^{(0)}}{\partial \theta} - \frac{1}{Pe} \left( {\frac{1}{r}\frac{\partial}{\partial r}\left(r\frac{\partial {c^{(0)}} }{\partial r}\right) + \frac{1}{r^2}\frac{\partial^2 c^{(0)}}{\partial \theta^2}} \right) \nonumber\\ & \quad-\frac{1}{Pe} \frac{1}{\hat{h}} \left( { \frac{\partial {\hat{h}}}{\partial {r}}\frac{\partial {c^{(0)}}}{\partial {r}} +\frac{1}{r}\frac{\partial \hat{h}}{\partial \theta}\frac{1}{r}\frac{\partial c^{(0)}}{\partial \theta} } \right) ={-} \frac{2\beta}{\hat{h}} j_n \end{align}and

\begin{align} & \frac{\partial {\varGamma^{(0)}}}{\partial {t}} + \frac{1}{r}\frac{\partial}{\partial r}\left(r\varGamma^{(0)} v_{r,s}\right) + \frac{1}{r}\frac{\partial }{\partial \theta} \left( {\varGamma^{(0)} v_{\theta, s}} \right) - \frac{1}{Pe_s} \left( {\frac{1}{r}\frac{\partial}{\partial r}\left(r\frac{\partial {\varGamma^{(0)}} }{\partial r}\right) + \frac{1}{r^2}\frac{\partial^2 \varGamma^{(0)}}{\partial \theta^2}} \right) \nonumber\\ &\quad = j_{n}, \end{align}

\begin{align} & \frac{\partial {\varGamma^{(0)}}}{\partial {t}} + \frac{1}{r}\frac{\partial}{\partial r}\left(r\varGamma^{(0)} v_{r,s}\right) + \frac{1}{r}\frac{\partial }{\partial \theta} \left( {\varGamma^{(0)} v_{\theta, s}} \right) - \frac{1}{Pe_s} \left( {\frac{1}{r}\frac{\partial}{\partial r}\left(r\frac{\partial {\varGamma^{(0)}} }{\partial r}\right) + \frac{1}{r^2}\frac{\partial^2 \varGamma^{(0)}}{\partial \theta^2}} \right) \nonumber\\ &\quad = j_{n}, \end{align}

where ![]() $\beta \equiv \varGamma _\infty / (c_0 b)$. The bulk Péclet number (

$\beta \equiv \varGamma _\infty / (c_0 b)$. The bulk Péclet number (![]() $Pe \equiv aU/D$) compares convection to bulk diffusion. The surface Péclet number (

$Pe \equiv aU/D$) compares convection to bulk diffusion. The surface Péclet number (![]() $Pe_s \equiv aU/D_s$) compares the effects of convection to surface diffusion for the adsorbed surfactants. The surface velocities (

$Pe_s \equiv aU/D_s$) compares the effects of convection to surface diffusion for the adsorbed surfactants. The surface velocities (![]() $v_{r,s}$ and

$v_{r,s}$ and ![]() $v_{\theta,s}$) can be obtained by integrating the Stokes equations and incorporating the

$v_{\theta,s}$) can be obtained by integrating the Stokes equations and incorporating the ![]() $O(1)$ tangential stress balances, i.e.

$O(1)$ tangential stress balances, i.e.

and

The corresponding initial and boundary conditions for these equations are

\begin{align} & \text{at } t = 0: \hat{h}_1 = 0,\quad \hat{P} = 0,\quad \widehat{\left\langle {v_r} \right\rangle} = 0, \quad\widehat{\left\langle {v_\theta} \right\rangle} = 0, \quad c^{(0)} = 1, \quad \varGamma^{(0)} = \varGamma_0/\varGamma_\infty, \nonumber\\ & \text{as } r\rightarrow \infty: \hat{h}_1 \rightarrow 0, \quad\hat{P} \rightarrow 0,\quad \widehat{\left\langle {v_r} \right\rangle} \rightarrow 0, \quad\widehat{\left\langle {v_\theta} \right\rangle} \rightarrow 0,\quad c^{(0)} \rightarrow 1, \quad\varGamma^{(0)} \rightarrow \varGamma_0/\varGamma_\infty, \nonumber\\ & \text{and } \psi(\theta) = \psi(\theta + 2{\rm \pi}),\quad\text{where } \psi = \hat{h}_1, \hat{P},\ \widehat{\left\langle {v_r} \right\rangle},\ \widehat{\left\langle {v_\theta} \right\rangle},\ c^{(0)},\ \varGamma^{(0)}. \end{align}

\begin{align} & \text{at } t = 0: \hat{h}_1 = 0,\quad \hat{P} = 0,\quad \widehat{\left\langle {v_r} \right\rangle} = 0, \quad\widehat{\left\langle {v_\theta} \right\rangle} = 0, \quad c^{(0)} = 1, \quad \varGamma^{(0)} = \varGamma_0/\varGamma_\infty, \nonumber\\ & \text{as } r\rightarrow \infty: \hat{h}_1 \rightarrow 0, \quad\hat{P} \rightarrow 0,\quad \widehat{\left\langle {v_r} \right\rangle} \rightarrow 0, \quad\widehat{\left\langle {v_\theta} \right\rangle} \rightarrow 0,\quad c^{(0)} \rightarrow 1, \quad\varGamma^{(0)} \rightarrow \varGamma_0/\varGamma_\infty, \nonumber\\ & \text{and } \psi(\theta) = \psi(\theta + 2{\rm \pi}),\quad\text{where } \psi = \hat{h}_1, \hat{P},\ \widehat{\left\langle {v_r} \right\rangle},\ \widehat{\left\langle {v_\theta} \right\rangle},\ c^{(0)},\ \varGamma^{(0)}. \end{align}3.2. Surfactant specific parameters

The isotherms that relate the surface pressure to the adsorbed surfactant concentration are dependent on the surfactant species. In this section we describe the isotherm and the associated adsorption and desorption fluxes for Triton X-100. Lin et al. (Reference Lin, McKeigue and Maldarelli1990) published a detailed study of Triton X-100 using a pendant drop tensiometry apparatus. All Triton X-100 associated parameters are extracted from their study. The diffusivity of Triton X-100 in water is ![]() $D = 2.6 \times 10^{-10}\ {\rm m}^2\ {\rm s}^{-1}$. The surface diffusivity is assumed to be ten times larger than bulk diffusivity. Figure 7 of Lin et al. (Reference Lin, McKeigue and Maldarelli1990) describes the equilibrium isotherms for Triton X-100 aqueous solutions. There are no significant differences between the Frumkin and Langmuir isotherms for bulk concentrations between

$D = 2.6 \times 10^{-10}\ {\rm m}^2\ {\rm s}^{-1}$. The surface diffusivity is assumed to be ten times larger than bulk diffusivity. Figure 7 of Lin et al. (Reference Lin, McKeigue and Maldarelli1990) describes the equilibrium isotherms for Triton X-100 aqueous solutions. There are no significant differences between the Frumkin and Langmuir isotherms for bulk concentrations between ![]() $1\ \mathrm {\mu } {\rm M}$ and

$1\ \mathrm {\mu } {\rm M}$ and ![]() $100\ \mathrm {\mu } {\rm M}$. In this paper, for the sake of simplicity, we use the Langmuir isotherm

$100\ \mathrm {\mu } {\rm M}$. In this paper, for the sake of simplicity, we use the Langmuir isotherm

where the Marangoni number is ![]() $Ma \equiv \epsilon RT\varGamma _\infty /(\mu U)$. After applying the above definition of surface pressure, the Marangoni number appears in the non-dimensionalized radial and azimuthal stress balances. It is a multiplier to the dimensionless concentration whose gradient drives Marangoni flow. Here

$Ma \equiv \epsilon RT\varGamma _\infty /(\mu U)$. After applying the above definition of surface pressure, the Marangoni number appears in the non-dimensionalized radial and azimuthal stress balances. It is a multiplier to the dimensionless concentration whose gradient drives Marangoni flow. Here ![]() $\varGamma _\infty$ is obtained by fitting data to the Langmuir–von Szyszkowski's equation,

$\varGamma _\infty$ is obtained by fitting data to the Langmuir–von Szyszkowski's equation, ![]() $\gamma = 1 - RT\varGamma _\infty /\gamma _{water} \log [1 + c^*/c_{fit}]$, yielding

$\gamma = 1 - RT\varGamma _\infty /\gamma _{water} \log [1 + c^*/c_{fit}]$, yielding ![]() $\varGamma _\infty = 2.91\times 10^{-6}\ {\rm mol}\ {\rm m}^{-2}$ and

$\varGamma _\infty = 2.91\times 10^{-6}\ {\rm mol}\ {\rm m}^{-2}$ and ![]() $c_{fit} = 6.62 \times 10^{-4}\ {\rm mol}\ {\rm m}^{-3}$.

$c_{fit} = 6.62 \times 10^{-4}\ {\rm mol}\ {\rm m}^{-3}$.

Langmuir kinetics is used to describe the dynamics of surfactant adsorbing onto the air–water interface and the bubble surface. The adsorption flux is defined as ![]() $j_{ads}^* = k_a c^*(\varGamma ^* - \varGamma _\infty )$ and the desorption flux is

$j_{ads}^* = k_a c^*(\varGamma ^* - \varGamma _\infty )$ and the desorption flux is ![]() $j_{des}^* = k_d\varGamma ^*$. The adsorption coefficient,

$j_{des}^* = k_d\varGamma ^*$. The adsorption coefficient, ![]() $k_a = 50\ {\rm m}^3\ {\rm s}^{-1}\ {\rm mol}^{-1}$, is extracted from figure 10 of Lin et al. (Reference Lin, McKeigue and Maldarelli1990). It follows that the desorption coefficient

$k_a = 50\ {\rm m}^3\ {\rm s}^{-1}\ {\rm mol}^{-1}$, is extracted from figure 10 of Lin et al. (Reference Lin, McKeigue and Maldarelli1990). It follows that the desorption coefficient ![]() $k_d = c_{fit} k_a = 0.033\ {\rm s}^{-1}$. Non-dimensionalizing the total flux of surfactant adsorbing onto an air–water interface we obtain

$k_d = c_{fit} k_a = 0.033\ {\rm s}^{-1}$. Non-dimensionalizing the total flux of surfactant adsorbing onto an air–water interface we obtain ![]() $j_n \equiv \alpha \left ( { c(1 - \varGamma ) - \varGamma /La } \right )$, where

$j_n \equiv \alpha \left ( { c(1 - \varGamma ) - \varGamma /La } \right )$, where ![]() $La \equiv (k_a c_0)/k_d$ and

$La \equiv (k_a c_0)/k_d$ and ![]() $\alpha \equiv (b k_a c_0)/U$. All of the extracted values are also consistent with the values published in table 4 of Shen et al. (Reference Shen, Gleason, McKinley and Stone2002). Table 1 contains a summary of all the non-dimensional parameters and their values used in this study.

$\alpha \equiv (b k_a c_0)/U$. All of the extracted values are also consistent with the values published in table 4 of Shen et al. (Reference Shen, Gleason, McKinley and Stone2002). Table 1 contains a summary of all the non-dimensional parameters and their values used in this study.

Table 1. Dimensionless parameters used in this study.

3.3. Numerical considerations

The set of six nonlinear governing equations describes the relationship among six unknowns. The initial and boundary conditions of four of these are homogeneous. Here ![]() $c^{(0)}$ and

$c^{(0)}$ and ![]() $\varGamma ^{(0)}$ are the variables with non-homogeneous initial and boundary conditions. In the numerical implementation, we solve for the respective variables:

$\varGamma ^{(0)}$ are the variables with non-homogeneous initial and boundary conditions. In the numerical implementation, we solve for the respective variables: ![]() $\log (c^{(0)})$ and

$\log (c^{(0)})$ and ![]() $\varGamma ^{(0)} - \varGamma _0/\varGamma _\infty$. The governing equations are spatially discretized using the finite difference method. In the radial mesh a stretched mesh is used such that in each radial direction,

$\varGamma ^{(0)} - \varGamma _0/\varGamma _\infty$. The governing equations are spatially discretized using the finite difference method. In the radial mesh a stretched mesh is used such that in each radial direction, ![]() $50\,\%$ of the grid points are positioned on

$50\,\%$ of the grid points are positioned on ![]() $r \in [0, 1]$ and the rest of the points are positioned on

$r \in [0, 1]$ and the rest of the points are positioned on ![]() $r \in (1, R_{max}]$. In the azimuthal direction the mesh is evenly divided into 60 slices such that the disturbance onset can be reasonably resolved. A Crank–Nicolson, adaptive time stepping is used for time advancement. At each iteration, the governing equations are solved using a lower–upper (LU) factorization based direct solver provided in the PETSc package (Balay et al. Reference Balay2019). Validation of the numerical solution is discussed in detail in the following sections.

$r \in (1, R_{max}]$. In the azimuthal direction the mesh is evenly divided into 60 slices such that the disturbance onset can be reasonably resolved. A Crank–Nicolson, adaptive time stepping is used for time advancement. At each iteration, the governing equations are solved using a lower–upper (LU) factorization based direct solver provided in the PETSc package (Balay et al. Reference Balay2019). Validation of the numerical solution is discussed in detail in the following sections.

4. Results and discussion

4.1. Thin film evolution and disturbance onset

Figure 2 shows the validation experimental and simulation data associated with the dynamical evolution of a Triton X-100 aqueous film over an air bubble. The experimental conditions and experimental parameters are presented in table 1 with ![]() $t_{stop} = 3.11$. Figure 2(a) shows the temporal evolution of the maximum film thickness. For the experimental data,

$t_{stop} = 3.11$. Figure 2(a) shows the temporal evolution of the maximum film thickness. For the experimental data, ![]() $\hat {h}_{max}$ is defined to be the maximum measurable film thickness within the field of view, while in the simulation,

$\hat {h}_{max}$ is defined to be the maximum measurable film thickness within the field of view, while in the simulation, ![]() $\hat {h}_{max} = \max (\hat {h}(t, r \leqslant R(\theta ), \theta ))$, where

$\hat {h}_{max} = \max (\hat {h}(t, r \leqslant R(\theta ), \theta ))$, where ![]() $R(\theta )$ corresponds to the radial position of minimum film thickness for a given azimuthal direction. Here

$R(\theta )$ corresponds to the radial position of minimum film thickness for a given azimuthal direction. Here ![]() $R(\theta )$, the rim, bounds the so-called dimple.

$R(\theta )$, the rim, bounds the so-called dimple.

Figure 2. Evolution of a Triton X-100 aqueous film over an air bubble. (a) Dynamics of the maximum film thickness measured in the experiment (circles) and obtained via 2-D numerical simulation (solid line). The experimental parameters and simulation parameters are reported in table 1, with a ![]() $t_{stop} = 3.11$. The twelve filled circles correspond to the twelve interference patterns displayed in (b). The diameter for each of the interferograms corresponds to 1.2 mm. The location of

$t_{stop} = 3.11$. The twelve filled circles correspond to the twelve interference patterns displayed in (b). The diameter for each of the interferograms corresponds to 1.2 mm. The location of ![]() $\hat {h}_{max}$ is marked with an ‘x’.

$\hat {h}_{max}$ is marked with an ‘x’.

In both the experiment and the simulation, ![]() $\hat {h}_{max}$ decreases with time as a result of the squeezing motion of the motor driving the two interfaces together. Similar to the experiments done by Frostad et al. (Reference Frostad, Tammaro, Santollani, de Araujo and Fuller2016), this experiment also shows three stages of film evolution. The first stage corresponds to the time when the motor is moving:

$\hat {h}_{max}$ decreases with time as a result of the squeezing motion of the motor driving the two interfaces together. Similar to the experiments done by Frostad et al. (Reference Frostad, Tammaro, Santollani, de Araujo and Fuller2016), this experiment also shows three stages of film evolution. The first stage corresponds to the time when the motor is moving: ![]() $0 < t < t_{stop}$. During this period, the bubble is forced upward and the dimple grows from

$0 < t < t_{stop}$. During this period, the bubble is forced upward and the dimple grows from ![]() $r = 0$ radially outward in an axisymmetric fashion (figure 2b1–3). The second stage corresponds to the rapid change in film thickness after

$r = 0$ radially outward in an axisymmetric fashion (figure 2b1–3). The second stage corresponds to the rapid change in film thickness after ![]() $t_{stop} = 3.11$ (

$t_{stop} = 3.11$ (![]() $t_{stop} < t < 5$, figure 2b4–10). Figure 3(a) provides the film thickness contour that corresponds to the interference pattern in figure 2(b4). Shortly after the motor has stopped moving, the system succumbs to ambient disturbances that break the axial symmetry of the outermost blue ring that corresponds to the rim location (figure 2b5). Figure 3(b) shows the effect of the disturbances on the film thickness at

$t_{stop} < t < 5$, figure 2b4–10). Figure 3(a) provides the film thickness contour that corresponds to the interference pattern in figure 2(b4). Shortly after the motor has stopped moving, the system succumbs to ambient disturbances that break the axial symmetry of the outermost blue ring that corresponds to the rim location (figure 2b5). Figure 3(b) shows the effect of the disturbances on the film thickness at ![]() $t = 3.65$. As the amplitude of the disturbance grows, the thin film becomes more asymmetrical, and the previously centred

$t = 3.65$. As the amplitude of the disturbance grows, the thin film becomes more asymmetrical, and the previously centred ![]() $\hat {h}_{max}$ is convected away from

$\hat {h}_{max}$ is convected away from ![]() $r = 0$ (figures 2b6–8 and 3c). Eventually, the dimple discharges from the side (figure 2b9 and 2b10), leaving behind a plume of a very non-axisymmetric film (figure 2b11 and 2b12). The film enters the last stage of its evolution, where the non-axisymmetric film continues to thin at a rate that is slowed relative to that during the dimple discharge (figure 2a). The bubble eventually coalesces as a result of further ambient disturbances.

$r = 0$ (figures 2b6–8 and 3c). Eventually, the dimple discharges from the side (figure 2b9 and 2b10), leaving behind a plume of a very non-axisymmetric film (figure 2b11 and 2b12). The film enters the last stage of its evolution, where the non-axisymmetric film continues to thin at a rate that is slowed relative to that during the dimple discharge (figure 2a). The bubble eventually coalesces as a result of further ambient disturbances.

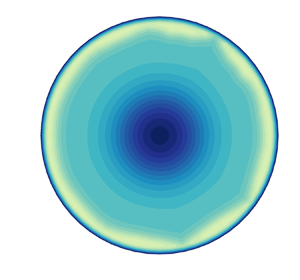

Figure 3. Experimental film thickness profiles during the symmetry breaking event for an aqueous solution of Triton X-100 at a concentration of 0.01 mM; (a) ![]() $t = 3.47$, (b)

$t = 3.47$, (b) ![]() $t = 3.65$, (c)

$t = 3.65$, (c) ![]() $t = 3.83$. These contour maps correspond to the interference patterns presented in figures 2(b4), (b5) and (b6).

$t = 3.83$. These contour maps correspond to the interference patterns presented in figures 2(b4), (b5) and (b6).

In contrast to the experimental evolution of ![]() $\hat {h}_{max}$, the simulated maximum film thickness thins at a faster rate during

$\hat {h}_{max}$, the simulated maximum film thickness thins at a faster rate during ![]() $0 < t < 1$, leading to a thinner film during

$0 < t < 1$, leading to a thinner film during ![]() $1 < t < 4.22$. We believe the differences are mainly the result of our assumption that the lower surface is non-deformable. This assumption can be evaluated by examining the deformation of a freely rising bubble in a surfactant free liquid (Pigeonneau & Sellier Reference Pigeonneau and Sellier2011). The Bond number in this study is close to the parameter used in figure 9(a) of Pigeonneau & Sellier (Reference Pigeonneau and Sellier2011), where an air bubble freely rises toward an initially flat liquid–air interface with a one-radius initial clearance over the apex of the bubble. In their study, a small amount of deformation is observed when the bubble freely rises until the minimum film thickness approaches the numerical resolution. In fact, Pigeonneau & Sellier (Reference Pigeonneau and Sellier2011) have deemed the deformation to be small enough such that ‘the bubble remains nearly spherical when rising’. However, in our study, a motor forces the bubble upward, thus moving beyond the position described in figure 9(a) of Pigeonneau & Sellier (Reference Pigeonneau and Sellier2011). It is possible that the actual bubble deformation exceeds that reported by Pigeonneau & Sellier (Reference Pigeonneau and Sellier2011). Furthermore, due to the limitations in the azimuthal mesh size, the simulation can capture the evolution of the film up to

$1 < t < 4.22$. We believe the differences are mainly the result of our assumption that the lower surface is non-deformable. This assumption can be evaluated by examining the deformation of a freely rising bubble in a surfactant free liquid (Pigeonneau & Sellier Reference Pigeonneau and Sellier2011). The Bond number in this study is close to the parameter used in figure 9(a) of Pigeonneau & Sellier (Reference Pigeonneau and Sellier2011), where an air bubble freely rises toward an initially flat liquid–air interface with a one-radius initial clearance over the apex of the bubble. In their study, a small amount of deformation is observed when the bubble freely rises until the minimum film thickness approaches the numerical resolution. In fact, Pigeonneau & Sellier (Reference Pigeonneau and Sellier2011) have deemed the deformation to be small enough such that ‘the bubble remains nearly spherical when rising’. However, in our study, a motor forces the bubble upward, thus moving beyond the position described in figure 9(a) of Pigeonneau & Sellier (Reference Pigeonneau and Sellier2011). It is possible that the actual bubble deformation exceeds that reported by Pigeonneau & Sellier (Reference Pigeonneau and Sellier2011). Furthermore, due to the limitations in the azimuthal mesh size, the simulation can capture the evolution of the film up to ![]() $t = 4.22$, at which time the accumulated numerical round-off errors act to disturb the rim. Despite the limitations of the numerical tool, we can still capture the onset of the symmetry breaking event. Understanding the underlying physics that drives the symmetry breaking is the first step to understanding the subsequent rapid dimple discharge that affects the overall bubble lifetime. For the remainder of this paper, we focus on understanding the onset of symmetry breaking as shown in figures 2(b5) and 3(b).

$t = 4.22$, at which time the accumulated numerical round-off errors act to disturb the rim. Despite the limitations of the numerical tool, we can still capture the onset of the symmetry breaking event. Understanding the underlying physics that drives the symmetry breaking is the first step to understanding the subsequent rapid dimple discharge that affects the overall bubble lifetime. For the remainder of this paper, we focus on understanding the onset of symmetry breaking as shown in figures 2(b5) and 3(b).

Figure 4 provides the onset of symmetry breaking observed in the two-dimensional (2-D) simulation. At ![]() $t = 4.10$, the film thickness profile and the adsorbed surfactant distribution are both axisymmetric (figure 4a,d). The film thickness profile shows the presence of a dimple, which is the volume of liquid bounded by a ring of thin film at the rim,

$t = 4.10$, the film thickness profile and the adsorbed surfactant distribution are both axisymmetric (figure 4a,d). The film thickness profile shows the presence of a dimple, which is the volume of liquid bounded by a ring of thin film at the rim, ![]() $R = 0.88$. The adsorbed surfactant concentration is depleted inside the dimple and approaches the initial adsorbed concentration of

$R = 0.88$. The adsorbed surfactant concentration is depleted inside the dimple and approaches the initial adsorbed concentration of ![]() $\varGamma _0/\varGamma _\infty$ for

$\varGamma _0/\varGamma _\infty$ for ![]() $r > R$ (figure 4d). At

$r > R$ (figure 4d). At ![]() $t = 4.20$, the effects of the instability are evident. Wrinkles in the rim location are observed in the film thickness contour plot (figure 4b). Fluctuations in the adsorbed surfactant concentration gradient in the radial direction can also be seen near

$t = 4.20$, the effects of the instability are evident. Wrinkles in the rim location are observed in the film thickness contour plot (figure 4b). Fluctuations in the adsorbed surfactant concentration gradient in the radial direction can also be seen near ![]() $r = 0.88$ in all azimuthal directions (figure 4e). Soon afterward, at

$r = 0.88$ in all azimuthal directions (figure 4e). Soon afterward, at ![]() $t = 4.22$, the rim wrinkling becomes even more pronounced, such that fluctuations in

$t = 4.22$, the rim wrinkling becomes even more pronounced, such that fluctuations in ![]() $\hat {h}(t = 4.22, r = R,\theta )$ can easily be seen in figure 4(c). Correspondingly,

$\hat {h}(t = 4.22, r = R,\theta )$ can easily be seen in figure 4(c). Correspondingly, ![]() ${\partial \varGamma ^{(0)}}/\partial r$ becomes more non-axisymmetric, with regions achieving a more dense surfactant packing than the initially adsorbed concentration (see the black regions in figure 4f). The topology presented in figure 4(c) is reminiscent of the interference pattern shown in figure 3(b). Due to the limitation in the numerical tool, the rest of the study is focused on examining the transition from an axisymmetric film to a non-axisymmetric film, as captured in figure 4 and figure 3(a,b).

${\partial \varGamma ^{(0)}}/\partial r$ becomes more non-axisymmetric, with regions achieving a more dense surfactant packing than the initially adsorbed concentration (see the black regions in figure 4f). The topology presented in figure 4(c) is reminiscent of the interference pattern shown in figure 3(b). Due to the limitation in the numerical tool, the rest of the study is focused on examining the transition from an axisymmetric film to a non-axisymmetric film, as captured in figure 4 and figure 3(a,b).

Figure 4. Film thickness ((a–c), ![]() $\hat {h}$) and adsorbed surfactant concentration deviation from the initial concentration ((d,e),

$\hat {h}$) and adsorbed surfactant concentration deviation from the initial concentration ((d,e), ![]() $\varGamma ^{(0)} - \varGamma _0/\varGamma _\infty$) during the symmetry breaking event observed in a 2-D numerical simulation (

$\varGamma ^{(0)} - \varGamma _0/\varGamma _\infty$) during the symmetry breaking event observed in a 2-D numerical simulation (![]() $t = 4.10, 4.20, 4.22$). The simulation is conducted at

$t = 4.10, 4.20, 4.22$). The simulation is conducted at ![]() $\epsilon = 0.108$,

$\epsilon = 0.108$, ![]() $t_{stop} = 3.11$,

$t_{stop} = 3.11$, ![]() $Ca = 1.2 \times 10^{-4}$,

$Ca = 1.2 \times 10^{-4}$, ![]() $Bo = 0.021$,

$Bo = 0.021$, ![]() $Ma = 7665$,

$Ma = 7665$, ![]() $Pe = 458$,

$Pe = 458$, ![]() $Pe_S = 4580$,

$Pe_S = 4580$, ![]() $\varGamma _0/\varGamma _\infty = 0.938$,

$\varGamma _0/\varGamma _\infty = 0.938$, ![]() $\alpha = 0.644$,

$\alpha = 0.644$, ![]() $\beta = 2.26$,

$\beta = 2.26$, ![]() $La = 15.1$. This parameter set corresponds to the experimental conditions described in figure 2. In this simulation the source of disturbance is the accumulated numerical error.

$La = 15.1$. This parameter set corresponds to the experimental conditions described in figure 2. In this simulation the source of disturbance is the accumulated numerical error.

To further compare the evolution of the disturbance in the experiment and the simulation, we compare the Fourier transform of ![]() $R$,

$R$,

where ![]() $m$ is the wavenumber and

$m$ is the wavenumber and ![]() $R_{avg}$ is the location of the rim averaged over all azimuthal directions. Figure 5(a) shows the magnitude of

$R_{avg}$ is the location of the rim averaged over all azimuthal directions. Figure 5(a) shows the magnitude of ![]() $C_m$ deviation from

$C_m$ deviation from ![]() $C_m(t = 3.49)$ at selected time points during the symmetry breaking event in the experiment. The subtraction of

$C_m(t = 3.49)$ at selected time points during the symmetry breaking event in the experiment. The subtraction of ![]() $|C_m(t = 3.49)|$ allows us to discard the signals associated with the pixelated nature of the interfograms and focus on the signals that grow over time as a result of disturbance growth. The experimental data shows that wavenumbers 9, 11, 13, 14 and 17 have significant disturbance growth. Among these wavenumbers,

$|C_m(t = 3.49)|$ allows us to discard the signals associated with the pixelated nature of the interfograms and focus on the signals that grow over time as a result of disturbance growth. The experimental data shows that wavenumbers 9, 11, 13, 14 and 17 have significant disturbance growth. Among these wavenumbers, ![]() $m = 11$ corresponds to the most prominent growth. In the corresponding 2-D simulation (figure 5b), wavenumbers 8 and 10 are the top two amplified modes. Despite the difference in the sources of disturbance for the experiment and the simulation, the rapid growth of modes associated with intermediate wavenumbers are observed. The good agreement between the experiment and the simulation gives us confidence in the ability of the theoretical model to capture the disturbance onset. To understand the symmetry breaking mechanism and the driving forces behind the mode selection, we therefore conduct a linear stability analysis.

$m = 11$ corresponds to the most prominent growth. In the corresponding 2-D simulation (figure 5b), wavenumbers 8 and 10 are the top two amplified modes. Despite the difference in the sources of disturbance for the experiment and the simulation, the rapid growth of modes associated with intermediate wavenumbers are observed. The good agreement between the experiment and the simulation gives us confidence in the ability of the theoretical model to capture the disturbance onset. To understand the symmetry breaking mechanism and the driving forces behind the mode selection, we therefore conduct a linear stability analysis.

4.2. Linear stability analysis

In this section we examine the linear responses of the system subjected to a small perturbation. Experimental and simulation observations suggest that after the external forcing stops, the system soon succumbs to ambient disturbance and non-axisymmetric patterns with an intermediate wavenumber first developing around the rim of the film. To understand the system behaviour, we employ a linearized stability analysis.

The base state is the axisymmetric, one-dimensional (1-D) solution to the governing equations. Similar to our previous study (Shi et al. Reference Shi, Rodríguez-Hakim, Shaqfeh and Fuller2021), the base state evolves in time and in the radial direction. The linearized stability equations are derived by subtracting the axisymmetric, 1-D governing equations from the 2-D governing equations described in the theory section, followed by discarding all nonlinear terms in the disturbance quantities, ![]() $\tilde {\psi }(t, r, \theta ) \equiv \psi (t, r, \theta ) - \psi _{1D}(t, r)$, where

$\tilde {\psi }(t, r, \theta ) \equiv \psi (t, r, \theta ) - \psi _{1D}(t, r)$, where ![]() $\psi$ represents

$\psi$ represents ![]() $\hat {h}_1$,

$\hat {h}_1$, ![]() $\hat {P}$,

$\hat {P}$, ![]() $\widehat {\left \langle {v_r} \right \rangle }$,

$\widehat {\left \langle {v_r} \right \rangle }$, ![]() $\widehat {\left \langle {v_\theta } \right \rangle }$,

$\widehat {\left \langle {v_\theta } \right \rangle }$, ![]() $c^{(0)}$ and

$c^{(0)}$ and ![]() $\varGamma ^{(0)}$. Based on the amplified perturbation in the experiment and in the simulation, we seek solutions in the form of

$\varGamma ^{(0)}$. Based on the amplified perturbation in the experiment and in the simulation, we seek solutions in the form of ![]() $\tilde {\psi } = \exp ({\rm i}m\theta ) \bar {\psi }(t, r)$, without making the usual assumption of exponential disturbance growth in time. After some algebra, we obtain the linearized governing equations for

$\tilde {\psi } = \exp ({\rm i}m\theta ) \bar {\psi }(t, r)$, without making the usual assumption of exponential disturbance growth in time. After some algebra, we obtain the linearized governing equations for ![]() $\bar {\psi }(t, r)$.

$\bar {\psi }(t, r)$.

The linearized disturbance equations associated with the mass and species balances are

\begin{align} & \frac{\partial {\bar{c}}}{\partial {t}} + \left\langle {v_r} \right\rangle_{1D}\frac{\partial {\bar{c}}}{\partial {r}} +\overline{\left\langle {v_r} \right\rangle} \frac{\partial {c_{1D}}}{\partial {r}} -\frac{1}{Pe} \left( {\frac{1}{r}\frac{\partial}{\partial r}\left(r\frac{\partial {\bar{c}} }{\partial r}\right) - \frac{m^2}{r^2}\bar{c} } \right) \nonumber\\ & \qquad -\frac{1}{Pe} \frac{1}{h_{1D}} \left( { \frac{\partial {h_{1D}}}{\partial {r}}\frac{\partial {\bar{c}}}{\partial {r}} +\frac{\partial {\bar{h}_1}}{\partial {r}}\frac{\partial {c_{1D}}}{\partial {r}} -\frac{\bar{h}_1}{h_{1D}} \frac{\partial {h_{1D}}}{\partial {r}} \frac{\partial {c_{1D}}}{\partial {r}} } \right) \nonumber\\ & \quad ={-}\frac{2\alpha\beta}{h_{1D}} \left( { \bar{c} - \bar{c}\varGamma_{1D} - c_{1D}\bar{\varGamma} - \bar{\varGamma}/La } \right) + \frac{2\alpha\beta}{h_{1D}^2} \bar{h}_1 \left( { c_{1D}(1 - \varGamma_{1D}) - \varGamma_{1D}/La } \right) \end{align}

\begin{align} & \frac{\partial {\bar{c}}}{\partial {t}} + \left\langle {v_r} \right\rangle_{1D}\frac{\partial {\bar{c}}}{\partial {r}} +\overline{\left\langle {v_r} \right\rangle} \frac{\partial {c_{1D}}}{\partial {r}} -\frac{1}{Pe} \left( {\frac{1}{r}\frac{\partial}{\partial r}\left(r\frac{\partial {\bar{c}} }{\partial r}\right) - \frac{m^2}{r^2}\bar{c} } \right) \nonumber\\ & \qquad -\frac{1}{Pe} \frac{1}{h_{1D}} \left( { \frac{\partial {h_{1D}}}{\partial {r}}\frac{\partial {\bar{c}}}{\partial {r}} +\frac{\partial {\bar{h}_1}}{\partial {r}}\frac{\partial {c_{1D}}}{\partial {r}} -\frac{\bar{h}_1}{h_{1D}} \frac{\partial {h_{1D}}}{\partial {r}} \frac{\partial {c_{1D}}}{\partial {r}} } \right) \nonumber\\ & \quad ={-}\frac{2\alpha\beta}{h_{1D}} \left( { \bar{c} - \bar{c}\varGamma_{1D} - c_{1D}\bar{\varGamma} - \bar{\varGamma}/La } \right) + \frac{2\alpha\beta}{h_{1D}^2} \bar{h}_1 \left( { c_{1D}(1 - \varGamma_{1D}) - \varGamma_{1D}/La } \right) \end{align}and

\begin{align} &\frac{\partial {\bar{\varGamma}}}{\partial {t}} + \frac{1}{r}\frac{\partial}{\partial r}\left(r\varGamma_{1D}^{(0)} \bar{v}_{r,s}\right) + \frac{1}{r}\frac{\partial}{\partial r}\left(r\bar{\varGamma} v_{r,s,1D}\right) + \frac{{\rm i}m}{r} \varGamma_{1D}^{(0)} \bar{v}_{\theta, s} \nonumber\\ & \quad -\frac{1}{Pe_s} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r\frac{\partial {\bar{\varGamma}} }{\partial r}\right) - \frac{m^2}{r^2}\bar{\varGamma} } \right) =\alpha ({\bar{c} - \bar{c}\varGamma_{1D}^{(0)} - c_{1D}^{(0)} \bar{\varGamma} - \bar{\varGamma}/La }), \end{align}

\begin{align} &\frac{\partial {\bar{\varGamma}}}{\partial {t}} + \frac{1}{r}\frac{\partial}{\partial r}\left(r\varGamma_{1D}^{(0)} \bar{v}_{r,s}\right) + \frac{1}{r}\frac{\partial}{\partial r}\left(r\bar{\varGamma} v_{r,s,1D}\right) + \frac{{\rm i}m}{r} \varGamma_{1D}^{(0)} \bar{v}_{\theta, s} \nonumber\\ & \quad -\frac{1}{Pe_s} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r\frac{\partial {\bar{\varGamma}} }{\partial r}\right) - \frac{m^2}{r^2}\bar{\varGamma} } \right) =\alpha ({\bar{c} - \bar{c}\varGamma_{1D}^{(0)} - c_{1D}^{(0)} \bar{\varGamma} - \bar{\varGamma}/La }), \end{align}where

\begin{equation} \bar{v}_{r, s} = \overline{\left\langle {v_r} \right\rangle} -\frac{Ma}{6} \frac{\bar{h}_1}{1 - \varGamma_{1D}^{(0)}} \frac{\partial {\varGamma_{1D}^{(0)}}}{\partial {r}} -\frac{Ma}{6} \hat{h}_{1D} \left( { \frac{1}{1 - \varGamma_{1D}^{(0)}} \frac{\partial {\bar{\varGamma}}}{\partial {r}} +\frac{\bar{\varGamma}}{\left( {1 - \varGamma_{1D}^{(0)}} \right)^2} \frac{\partial {\varGamma_{1D}^{(0)}}}{\partial {r}} } \right) \end{equation}

\begin{equation} \bar{v}_{r, s} = \overline{\left\langle {v_r} \right\rangle} -\frac{Ma}{6} \frac{\bar{h}_1}{1 - \varGamma_{1D}^{(0)}} \frac{\partial {\varGamma_{1D}^{(0)}}}{\partial {r}} -\frac{Ma}{6} \hat{h}_{1D} \left( { \frac{1}{1 - \varGamma_{1D}^{(0)}} \frac{\partial {\bar{\varGamma}}}{\partial {r}} +\frac{\bar{\varGamma}}{\left( {1 - \varGamma_{1D}^{(0)}} \right)^2} \frac{\partial {\varGamma_{1D}^{(0)}}}{\partial {r}} } \right) \end{equation}and

\begin{equation} \bar{v}_{\theta, s} = \overline{\left\langle {v_\theta} \right\rangle} - \frac{Ma}{6} \frac{{\rm i}m}{r} \frac{\hat{h}_{1D}}{1 - \varGamma_{1D}^{(0)}} \bar{\varGamma}. \end{equation}

\begin{equation} \bar{v}_{\theta, s} = \overline{\left\langle {v_\theta} \right\rangle} - \frac{Ma}{6} \frac{{\rm i}m}{r} \frac{\hat{h}_{1D}}{1 - \varGamma_{1D}^{(0)}} \bar{\varGamma}. \end{equation}The linearized disturbance equations associated with the stress balances at the interfaces are

\begin{align} &\frac{\partial {\bar{P}}}{\partial {r}} = \frac{2 Ma}{\hat{h}_{1D}} \left( { \frac{-1}{1 - \varGamma_{1D}^{(0)}} \frac{\partial {\bar{\varGamma}}}{\partial {r}} - \frac{\bar{\varGamma}}{(1 - \varGamma_{1D}^{(0)})^2} \frac{\partial {\varGamma_{1D}^{(0)}}}{\partial {r}} + \frac{\bar{h}_1}{\hat{h}_{1D}} \frac{1}{1 - \varGamma_{1D}^{(0)}} \frac{\partial {\varGamma_{1D}^{(0)}}}{\partial {r}} } \right) \nonumber\\ & \quad\quad +\epsilon \left( { 2 \frac{\partial}{\partial r}\left(\frac{1}{r}\frac{\partial}{\partial r}(r {\overline{\left\langle {v_r} \right\rangle} } )\right) - \frac{m^2}{r^2} \overline{\left\langle {v_r} \right\rangle} + \frac{\partial { }}{\partial {r}} \left( { \frac{im}{r} \overline{\left\langle {v_\theta} \right\rangle} } \right) -\frac{2{\rm i}m}{r^2} \overline{\left\langle {v_\theta} \right\rangle} } \right) \nonumber\\ & \quad\quad + \epsilon \frac{2}{\hat{h}_{1D}} \frac{\partial {\hat{h}_{1D}}}{\partial {r}} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r \overline{\left\langle {v_r} \right\rangle} \right) + \frac{\partial { \overline{\left\langle {v_r} \right\rangle} }}{\partial {r}} + \frac{{\rm i}m}{r} \overline{\left\langle {v_\theta} \right\rangle} } \right) \nonumber\\ & \quad\quad + \epsilon \frac{2}{\hat{h}_{1D}} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r\left\langle {v_r} \right\rangle_{1D}\right) + \frac{\partial {\left\langle {v_r} \right\rangle_{1D}}}{\partial {r}} } \right) \left( {\frac{\partial {\bar{h}_1}}{\partial {r}} - \frac{\bar{h}_1}{\hat{h}_{1D}} \frac{\partial {\hat{h}_{1D}}}{\partial {r}} } \right) \end{align}

\begin{align} &\frac{\partial {\bar{P}}}{\partial {r}} = \frac{2 Ma}{\hat{h}_{1D}} \left( { \frac{-1}{1 - \varGamma_{1D}^{(0)}} \frac{\partial {\bar{\varGamma}}}{\partial {r}} - \frac{\bar{\varGamma}}{(1 - \varGamma_{1D}^{(0)})^2} \frac{\partial {\varGamma_{1D}^{(0)}}}{\partial {r}} + \frac{\bar{h}_1}{\hat{h}_{1D}} \frac{1}{1 - \varGamma_{1D}^{(0)}} \frac{\partial {\varGamma_{1D}^{(0)}}}{\partial {r}} } \right) \nonumber\\ & \quad\quad +\epsilon \left( { 2 \frac{\partial}{\partial r}\left(\frac{1}{r}\frac{\partial}{\partial r}(r {\overline{\left\langle {v_r} \right\rangle} } )\right) - \frac{m^2}{r^2} \overline{\left\langle {v_r} \right\rangle} + \frac{\partial { }}{\partial {r}} \left( { \frac{im}{r} \overline{\left\langle {v_\theta} \right\rangle} } \right) -\frac{2{\rm i}m}{r^2} \overline{\left\langle {v_\theta} \right\rangle} } \right) \nonumber\\ & \quad\quad + \epsilon \frac{2}{\hat{h}_{1D}} \frac{\partial {\hat{h}_{1D}}}{\partial {r}} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r \overline{\left\langle {v_r} \right\rangle} \right) + \frac{\partial { \overline{\left\langle {v_r} \right\rangle} }}{\partial {r}} + \frac{{\rm i}m}{r} \overline{\left\langle {v_\theta} \right\rangle} } \right) \nonumber\\ & \quad\quad + \epsilon \frac{2}{\hat{h}_{1D}} \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r\left\langle {v_r} \right\rangle_{1D}\right) + \frac{\partial {\left\langle {v_r} \right\rangle_{1D}}}{\partial {r}} } \right) \left( {\frac{\partial {\bar{h}_1}}{\partial {r}} - \frac{\bar{h}_1}{\hat{h}_{1D}} \frac{\partial {\hat{h}_{1D}}}{\partial {r}} } \right) \end{align}and

\begin{align} \frac{{\rm i}m}{r} \bar{P} &= \frac{{\rm i}m}{r}\frac{2Ma}{\hat{h}_{1D}} \frac{-\bar{\varGamma}}{1 - \varGamma_{1D}^{(0)}} \nonumber\\ &\quad + \epsilon \left( { -\frac{2m^2}{r^2} \overline{\left\langle {v_\theta} \right\rangle} +\frac{\partial}{\partial r}\left(\frac{1}{r}\frac{\partial}{\partial r}(r { \overline{\left\langle {v_\theta} \right\rangle} } )\right) +\frac{{\rm i}m}{r}\frac{1}{r}\frac{\partial}{\partial r}\left(r \overline{\left\langle {v_r} \right\rangle} \right) +\frac{2 {\rm i}m}{r^2} \overline{\left\langle {v_r} \right\rangle} } \right) \nonumber\\ & \quad + \epsilon \frac{{\rm i}m}{r} \frac{2}{\hat{h}_{1D}} \bar{h}_1 \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r\left\langle {v_r} \right\rangle_{1D}\right) + \frac{\left\langle {v_r} \right\rangle_{1D}}{r} } \right)\nonumber\\ &\quad + \epsilon \frac{1}{\hat{h}_{1D}} \frac{\partial {\hat{h}_{1D}}}{\partial {r}} \left( { \frac{{\rm i}m}{r} \overline{\left\langle {v_r} \right\rangle} + r \frac{\partial {}}{\partial {r}} \left( { \frac{\overline{\left\langle {v_\theta} \right\rangle}}{r} } \right) } \right). \end{align}

\begin{align} \frac{{\rm i}m}{r} \bar{P} &= \frac{{\rm i}m}{r}\frac{2Ma}{\hat{h}_{1D}} \frac{-\bar{\varGamma}}{1 - \varGamma_{1D}^{(0)}} \nonumber\\ &\quad + \epsilon \left( { -\frac{2m^2}{r^2} \overline{\left\langle {v_\theta} \right\rangle} +\frac{\partial}{\partial r}\left(\frac{1}{r}\frac{\partial}{\partial r}(r { \overline{\left\langle {v_\theta} \right\rangle} } )\right) +\frac{{\rm i}m}{r}\frac{1}{r}\frac{\partial}{\partial r}\left(r \overline{\left\langle {v_r} \right\rangle} \right) +\frac{2 {\rm i}m}{r^2} \overline{\left\langle {v_r} \right\rangle} } \right) \nonumber\\ & \quad + \epsilon \frac{{\rm i}m}{r} \frac{2}{\hat{h}_{1D}} \bar{h}_1 \left( { \frac{1}{r}\frac{\partial}{\partial r}\left(r\left\langle {v_r} \right\rangle_{1D}\right) + \frac{\left\langle {v_r} \right\rangle_{1D}}{r} } \right)\nonumber\\ &\quad + \epsilon \frac{1}{\hat{h}_{1D}} \frac{\partial {\hat{h}_{1D}}}{\partial {r}} \left( { \frac{{\rm i}m}{r} \overline{\left\langle {v_r} \right\rangle} + r \frac{\partial {}}{\partial {r}} \left( { \frac{\overline{\left\langle {v_\theta} \right\rangle}}{r} } \right) } \right). \end{align}

In the far field (![]() $r \rightarrow \infty$) these variables and their radial derivatives decay to zero.