1. Introduction

It is well known that long-chain polymers and surfactants can significantly reduce the skin-friction drag of turbulent liquid flows by in excess of 60 %. This was first discovered for polymers by Toms (Reference Toms1948), and for surfactants by Mysels (Reference Mysels1949). Relative to polymers, early observations indicated that surfactants required greater concentrations to induce a comparably similar drag-reduction percentage (DR). For example, Mysels (Reference Mysels1949) used 2.5%–4.5 % by weight of surfactant, while Toms (Reference Toms1948) used approximately 0.05 % by weight of polymer to produce a similar amount of DR. Despite the economic benefit of requiring lower concentrations, polymer chains tend to break apart when exposed to high amounts of shear within the flow. This causes a permanent decay in the amount of DR – a process known as mechanical degradation (den Toonder et al. Reference den Toonder, Draad, Kuiken and Nieuwstadt1995). In contrast, the micelles formed from aggregating surfactant molecules possess a feature of self-reparability that prevents permanent mechanical degradation (Qi & Zakin Reference Qi and Zakin2002). As a result, polymer additives are generally confined to once-through systems, such as the Trans Alaska pipeline, where the fluid is not perpetually recirculated through high-shear devices (Burger, Munk & Wahl Reference Burger, Munk and Wahl1982). Surfactants, on the other hand, are often used to conserve pumping costs in closed-loop systems; significant in applications such as district heating and cooling (Krope & Lipus Reference Krope and Lipus2009). Similar to their respective practical applications, the research into polymer and surfactant drag reduction has taken different trajectories. Investigations have generally been confined to either polymers or surfactants, but rarely a direct comparison of the two. The focus of the current investigation is to conduct a detailed comparison of the rheology and turbulent flow field of polymer and surfactant drag-reduced flows. In the following discussion, we will review previous investigations of the rheology and turbulence pertinent to polymer and surfactant drag reducers.

Polymer drag reducers are classified as having either a flexible or a rigid molecular structure (Virk & Wagger Reference Virk, Wagger and A.1990). When dissolved in water, both flexible and rigid polymers form a solution that is generally shear thinning (Escudier, Presti & Smith Reference Escudier, Presti and Smith1999; Pereira, Andrade & Soares Reference Pereira, Andrade and Soares2013). Despite this common rheological feature, the traits that are typically attributed to drag reduction are the extensional viscosity and the elastic moduli (Lumley Reference Lumley1969; Tabor & de Gennes Reference Tabor and de Gennes1986). Both features are attributed to stretching of the polymer molecules; however, they imply different interactions between the polymer molecules and the turbulent flow (White & Mungal Reference White and Mungal2008). Using an opposed nozzle rheometer, Escudier et al. (Reference Escudier, Presti and Smith1999) showed that the DR of rigid and flexible polymer solutions was related to their extensional viscosity at low strain rates. For solutions of flexible polyacrylamide polymers, Owolabi, Dennis & Poole (Reference Owolabi, Dennis and Poole2017) demonstrated a correlation between DR and a characteristic relaxation time. The latter was obtained based on extensional stress growth using a capillary breakup extensional rheometer (CaBER), which is a more accurate means of measuring the extensional viscosity compared to the opposed nozzle apparatus (Dontula et al. Reference Dontula, Pasquali, Scriven and Macosko1997). However, such a relaxation time has not been reported for samples of rigid polymer solutions. The filament tends to break up rapidly upon filament extension using standard CaBER systems, owing to the significantly lower extensional viscosity of rigid polymer solutions (Pereira et al. Reference Pereira, Andrade and Soares2013; Mohammadtabar, Sanders & Ghaemi Reference Mohammadtabar, Sanders and Ghaemi2020). With regards to elasticity, a correlation between the elastic moduli of flexible and rigid polymer solutions and DR has yet to be confirmed experimentally (Pereira et al. Reference Pereira, Andrade and Soares2013; Mohammadtabar et al. Reference Mohammadtabar, Sanders and Ghaemi2020). Therefore, a common rheological property amongst flexible and rigid polymer solutions that correlates with DR has not been determined. Despite the apparent difference in the rheology of flexible and rigid polymer solutions, both polymer types significantly modify turbulent wall-bounded flows.

One of the most pronounced effects of polymer drag reducers is the redistribution of the mean velocity profile relative to the Newtonian law of the wall. The elastic sublayer model of Virk (Reference Virk1971) described drag-reduced flows of intermediate DR as having three layers: a viscous sublayer, a buffer layer – that was re-termed the elastic sublayer – and a logarithmic layer that was referred to as the Newtonian plug layer. Relative to Newtonian flows, the viscous and elastic sublayers of a polymer drag-reduced flow are thicker. The Newtonian plug layer possesses a similar slope as the logarithmic layer of a Newtonian flow, but a larger intercept due to the thickened buffer or elastic sublayer. At maximum drag reduction (MDR), the Newtonian plug layer is eradicated and the elastic sublayer demonstrates an ultimate profile, known as the MDR asymptote, determined empirically as ![]() ${\langle U\rangle ^ + } = 11.7\,\textrm{ln}({y^ + }) - 17$ . Where, U is the streamwise velocity, y is the wall-normal distance from the wall and the

${\langle U\rangle ^ + } = 11.7\,\textrm{ln}({y^ + }) - 17$ . Where, U is the streamwise velocity, y is the wall-normal distance from the wall and the ![]() $\langle \cdots \rangle$ symbol denotes time averaging. The superscript + indicates inner normalization in which velocity is normalized by the friction velocity, uτ, and y is normalized by ν/uτ, where ν is the kinematic viscosity of the fluid. The elastic sublayer model and the MDR asymptote have been observed in a number of experimental and numerical investigations (Min, Choi & Yoo Reference Min, Choi and Yoo2003; Ptasinski et al. Reference Ptasinski, Boersma, Nieuwstadt, Hulsen, van den Brule and Hunt2003; Kim et al. Reference Kim, Islam, Shen, Siriviente and Solomon2004; White, Somandepalli & Mungal Reference White, Somandepalli and Mungal2004). However, the model has since been adapted, stemming from the contributions of Warholic, Massah & Hanratty (Reference Warholic, Massah and Hanratty1999a) and White, Dubief & Klewicki (Reference White, Dubief and Klewicki2012). The most significant modification found by White et al. (Reference White, Dubief and Klewicki2012) was the discovery that the exact shape of the mean velocity profile at MDR is not logarithmic. They also conjectured that the slope of the profile may depend on the Reynolds number, Re, the canonical flow type or properties of the drag-reducing additive (see also, Elbing et al. Reference Elbing, Perlin, Dowling and Ceccio2013; White, Dubief & Klewicki Reference White, Dubief and Klewicki2018).

$\langle \cdots \rangle$ symbol denotes time averaging. The superscript + indicates inner normalization in which velocity is normalized by the friction velocity, uτ, and y is normalized by ν/uτ, where ν is the kinematic viscosity of the fluid. The elastic sublayer model and the MDR asymptote have been observed in a number of experimental and numerical investigations (Min, Choi & Yoo Reference Min, Choi and Yoo2003; Ptasinski et al. Reference Ptasinski, Boersma, Nieuwstadt, Hulsen, van den Brule and Hunt2003; Kim et al. Reference Kim, Islam, Shen, Siriviente and Solomon2004; White, Somandepalli & Mungal Reference White, Somandepalli and Mungal2004). However, the model has since been adapted, stemming from the contributions of Warholic, Massah & Hanratty (Reference Warholic, Massah and Hanratty1999a) and White, Dubief & Klewicki (Reference White, Dubief and Klewicki2012). The most significant modification found by White et al. (Reference White, Dubief and Klewicki2012) was the discovery that the exact shape of the mean velocity profile at MDR is not logarithmic. They also conjectured that the slope of the profile may depend on the Reynolds number, Re, the canonical flow type or properties of the drag-reducing additive (see also, Elbing et al. Reference Elbing, Perlin, Dowling and Ceccio2013; White, Dubief & Klewicki Reference White, Dubief and Klewicki2018).

In addition to the redistribution of the mean velocity profile, the Reynolds stress distributions are also modified in polymer drag-reduced flows relative to those of a Newtonian flow, as confirmed by several experimental investigations (Ptasinski, Nieuwstadt & Hulsen Reference Ptasinski, Nieuwstadt and Hulsen2001; Escudier, Presti & Smith Reference Escudier, Nickson and Poole2009; Mohammadtabar, Sanders & Ghaemi Reference Mohammadtabar, Sanders and Ghaemi2017). Warholic et al. (Reference Warholic, Massah and Hanratty1999a) showed that polymer drag-reduced flows have different inner-normalized Reynolds stress profiles depending on whether the DR was in a state of ‘low’ or ‘high’ DR. The transition between these two states occurred at approximately 40 % DR, and was also noticed by an eradication of the Newtonian plug layer (White et al. Reference White, Dubief and Klewicki2012). The main distinction in the Reynolds stresses in the low and high DR regimes was the change in the peak value of the Reynolds stresses (Warholic et al. Reference Warholic, Massah and Hanratty1999a; Escudier et al. Reference Escudier, Nickson and Poole2009). For polymer drag-reduced flows of low DR, an increase in DR was accompanied by an increase in the peak streamwise Reynolds stress, ![]() ${\langle {u^2}\rangle ^ + }$, and an attenuation in the wall-normal,

${\langle {u^2}\rangle ^ + }$, and an attenuation in the wall-normal, ![]() ${\langle {v^2}\rangle ^ + }$, and spanwise Reynolds stresses,

${\langle {v^2}\rangle ^ + }$, and spanwise Reynolds stresses, ![]() ${\langle {w^2}\rangle ^ + }$. Here, u, v and w indicate streamwise, wall-normal and spanwise velocity fluctuations. In contrast, polymer drag-reduced flows of high DR showed a decrease in all Reynolds stresses with increasing DR. The Reynolds shear stress,

${\langle {w^2}\rangle ^ + }$. Here, u, v and w indicate streamwise, wall-normal and spanwise velocity fluctuations. In contrast, polymer drag-reduced flows of high DR showed a decrease in all Reynolds stresses with increasing DR. The Reynolds shear stress, ![]() ${\langle uv\rangle ^ + }$, of a polymer drag-reduced flow decreased monotonically with increasing DR in both low and high DR regimes. Warholic et al. (Reference Warholic, Massah and Hanratty1999a) found that the profile of

${\langle uv\rangle ^ + }$, of a polymer drag-reduced flow decreased monotonically with increasing DR in both low and high DR regimes. Warholic et al. (Reference Warholic, Massah and Hanratty1999a) found that the profile of ![]() ${\langle uv\rangle ^ + }$ for drag-reduced flows close to MDR was approximately zero for all y+. Contrary to the findings of Warholic et al. (Reference Warholic, Massah and Hanratty1999a), other experiments and simulations have suggested a

${\langle uv\rangle ^ + }$ for drag-reduced flows close to MDR was approximately zero for all y+. Contrary to the findings of Warholic et al. (Reference Warholic, Massah and Hanratty1999a), other experiments and simulations have suggested a ![]() ${\langle uv\rangle ^ + }$ profile equal to zero is not a necessary condition for MDR (Ptasinski et al. Reference Ptasinski, Boersma, Nieuwstadt, Hulsen, van den Brule and Hunt2003). The discrepancy still remains unexplained, but it is generally accepted that flows near MDR have a significantly attenuated Reynolds shear stress profile (White & Mungal Reference White and Mungal2008).

${\langle uv\rangle ^ + }$ profile equal to zero is not a necessary condition for MDR (Ptasinski et al. Reference Ptasinski, Boersma, Nieuwstadt, Hulsen, van den Brule and Hunt2003). The discrepancy still remains unexplained, but it is generally accepted that flows near MDR have a significantly attenuated Reynolds shear stress profile (White & Mungal Reference White and Mungal2008).

Cryogenic transmission electron microscope images of drag-reducing surfactant solutions at rest are comprised of long threadlike micelles (Zhang et al. Reference Zhang, Schmidt, Talmon and Zakin2005). Although their presence has not been verified in a turbulent flow, these threadlike micelles are believed to be associated with a surfactant solutions ability to reduce drag (Bewersdorff & Ohlendorf Reference Bewersdorff and Ohlendorf1988). A common surfactant drag reducer is a cationic surfactant, which is readily used due to its affinity to produce DR over large temperature ranges and lack of precipitation when introduced to common minerals in domestic tap water (Qi & Zakin Reference Qi and Zakin2002). Cationic surfactants are characterized by their positively charged, hydrophilic head group and long alkyl chain. Some common examples of cationic surfactants include cetyltrimethylammonium bromide or trimethyltetradecylammonium chloride. When combined with a hydrophobic counterion, such as sodium salicylate or 3,5-dichlorobenzoate, repulsion forces between the positively charged surfactant molecules decrease, causing the molecules to aggregate and form micelles (Lu et al. Reference Lu, Li, Scriven, Davis, Talmon and Zakin1998). The resulting solution is often viscoelastic and drag reducing (Qi & Zakin Reference Qi and Zakin2002). Older experiments, such as Bewersdorff & Ohlendorf (Reference Bewersdorff and Ohlendorf1988) or Warholic, Schmidt & Hanratty (Reference Warholic, Schmidt and Hanratty1999b), used large surfactant concentrations of approximately 0.1%–0.2 % by weight to induce DR greater than 60 %. However, more recent experiments have used concentrations as low as 0.0065 % (65 ppm) to produce comparably large amounts of DR (Tamano et al. Reference Tamano, Itoh, Inoue, Kato and Yokota2009).

Depending on the type of surfactant, the concentration, and the temperature, the solution can exhibit a variety of rheological characteristics. Qi & Zakin (Reference Qi and Zakin2002) investigated rheological properties commonly found in solutions of drag-reducing surfactants, the likes of which include: shear-induced structures (SISs), a large extensional viscosity, and other viscoelastic properties. Extensional viscosity and viscoelasticity are rheological properties that are also common in polymer drag-reducing solutions and were briefly discussed earlier. SISs, on the other hand, are a unique property of surfactant solutions (Bewersdorff & Ohlendorf Reference Bewersdorff and Ohlendorf1988; Escudier et al. Reference Escudier, Nickson and Poole2009). SISs refer to an abrupt shear-thickening trend observed in the steady shear viscosity measurements at a critical shear rate (Ohlendorf, Interthal& Hoffman Reference Ohlendorf, Interthal and Hoffman1986; Hofmann, Rauscher & Hoffmann Reference Hofmann, Rauscher and Hoffmann1991). If the shear rate is increased further, well above this critical shear rate, the viscosity then decreases gradually, becoming shear thinning like most semi-dilute or concentrated polymer solutions (Qi & Zakin Reference Qi and Zakin2002; Escudier et al. Reference Escudier, Nickson and Poole2009). Authors such as Zakin, Myska & Chara (Reference Zakin, Myska and Chara1996) and Lu et al. (Reference Lu, Li, Scriven, Davis, Talmon and Zakin1998) have insinuated that SISs are a necessary condition for DR. However, in compiling several experimental results from existing literature, Qi & Zakin (Reference Qi and Zakin2002) concluded the contrary: that SISs are not necessary for DR. Qi & Zakin (Reference Qi and Zakin2002) referenced Lin (Reference Lin2000), who showed that high concentration surfactant solutions were capable of producing large amounts of DR (approximately 70 %) despite having no SISs, a zero first normal stress difference and an extensional viscosity comparable to water. Similar to polymer solutions, the rheological property of surfactant solutions that correlates with their DR is still unknown.

Several investigations have reported mean velocity profiles of surfactant drag-reduced flows that surpass the MDR asymptote of polymeric flows (Bewersdorff & Ohlendorf Reference Bewersdorff and Ohlendorf1988; Chara et al. Reference Chara, Zakin, Severa and Myska1993; Zakin et al. Reference Zakin, Myska and Chara1996). Zakin et al. (Reference Zakin, Myska and Chara1996) postulated a new limiting asymptote, ![]() ${\langle U\rangle ^ + } = 23.4\,\textrm{ln}({y^ + }) - 65$, for surfactant drag-reducing additives based on the measurements of twelve different investigations. However, recent experiments have yet to replicate the findings of Zakin et al. (Reference Zakin, Myska and Chara1996). Warholic et al. (Reference Warholic, Schmidt and Hanratty1999b) used two-component laser Doppler velocimetry (LDV) to measure the mean velocity profile of a channel flow comprised of one of the surfactant solutions discussed in Zakin et al. (Reference Zakin, Myska and Chara1996). The results of Warholic et al. (Reference Warholic, Schmidt and Hanratty1999b) showed agreement with the MDR asymptote from Virk, Mickley & Smith (Reference Virk, Mickley and Smith1970) for polymer drag-reduced flows and not the unique limit proposed by Zakin et al. (Reference Zakin, Myska and Chara1996). Tamano et al. (Reference Tamano, Uchikawa, Ito and Morinishi2018) used particle image velocimetry and two-component LDV to measure the mean velocity profile of surfactant drag-reduced boundary layer flows using heterogeneous wall injection of a concentrated master solution. Tamano et al. (Reference Tamano, Uchikawa, Ito and Morinishi2018) observed a modification in the mean velocity profile that was in conformance with the elastic sublayer model proposed by Virk (Reference Virk1971). Findings from Warholic et al. (Reference Warholic, Schmidt and Hanratty1999b) and Tamano et al. (Reference Tamano, Uchikawa, Ito and Morinishi2018) suggest surfactants modify the mean velocity profile in a similar manner as polymers.

${\langle U\rangle ^ + } = 23.4\,\textrm{ln}({y^ + }) - 65$, for surfactant drag-reducing additives based on the measurements of twelve different investigations. However, recent experiments have yet to replicate the findings of Zakin et al. (Reference Zakin, Myska and Chara1996). Warholic et al. (Reference Warholic, Schmidt and Hanratty1999b) used two-component laser Doppler velocimetry (LDV) to measure the mean velocity profile of a channel flow comprised of one of the surfactant solutions discussed in Zakin et al. (Reference Zakin, Myska and Chara1996). The results of Warholic et al. (Reference Warholic, Schmidt and Hanratty1999b) showed agreement with the MDR asymptote from Virk, Mickley & Smith (Reference Virk, Mickley and Smith1970) for polymer drag-reduced flows and not the unique limit proposed by Zakin et al. (Reference Zakin, Myska and Chara1996). Tamano et al. (Reference Tamano, Uchikawa, Ito and Morinishi2018) used particle image velocimetry and two-component LDV to measure the mean velocity profile of surfactant drag-reduced boundary layer flows using heterogeneous wall injection of a concentrated master solution. Tamano et al. (Reference Tamano, Uchikawa, Ito and Morinishi2018) observed a modification in the mean velocity profile that was in conformance with the elastic sublayer model proposed by Virk (Reference Virk1971). Findings from Warholic et al. (Reference Warholic, Schmidt and Hanratty1999b) and Tamano et al. (Reference Tamano, Uchikawa, Ito and Morinishi2018) suggest surfactants modify the mean velocity profile in a similar manner as polymers.

Few experiments have been performed where the turbulent Reynolds stresses have been measured in homogenous solutions of surfactant drag-reduced flows. The trend in the peak of the ![]() ${\langle {u^2}\rangle ^ + }$ profile of surfactant drag-reduced flows, appears to depend on Re. For surfactant flows at MDR, Warholic et al. (Reference Warholic, Schmidt and Hanratty1999b) observed a smaller peak in

${\langle {u^2}\rangle ^ + }$ profile of surfactant drag-reduced flows, appears to depend on Re. For surfactant flows at MDR, Warholic et al. (Reference Warholic, Schmidt and Hanratty1999b) observed a smaller peak in ![]() ${\langle {u^2}\rangle ^ + }$ at the lowest tested Re relative to the Newtonian flow of water, but a greater

${\langle {u^2}\rangle ^ + }$ at the lowest tested Re relative to the Newtonian flow of water, but a greater ![]() ${\langle {u^2}\rangle ^ + }$ for two larger cases of Re. The investigation of Li et al. (Reference Li, Kawaguchi, Segawa and Hishida2005) also demonstrated that the Reynolds stress distribution of surfactant solutions depends on Re. The dependence of

${\langle {u^2}\rangle ^ + }$ for two larger cases of Re. The investigation of Li et al. (Reference Li, Kawaguchi, Segawa and Hishida2005) also demonstrated that the Reynolds stress distribution of surfactant solutions depends on Re. The dependence of ![]() ${\langle {u^2}\rangle ^ + }$ on both Re and DR, and the smaller

${\langle {u^2}\rangle ^ + }$ on both Re and DR, and the smaller ![]() ${\langle {u^2}\rangle ^ + }$ with respect to

${\langle {u^2}\rangle ^ + }$ with respect to ![]() ${\langle {u^2}\rangle ^ + }$ of a Newtonian flow, are not consistent with polymer drag-reduced flows. Warholic et al. (Reference Warholic, Schmidt and Hanratty1999b) demonstrated that the surfactant solutions at MDR had a significantly attenuated

${\langle {u^2}\rangle ^ + }$ of a Newtonian flow, are not consistent with polymer drag-reduced flows. Warholic et al. (Reference Warholic, Schmidt and Hanratty1999b) demonstrated that the surfactant solutions at MDR had a significantly attenuated ![]() ${\langle {v^2}\rangle ^ + }$ profile and a

${\langle {v^2}\rangle ^ + }$ profile and a ![]() ${\langle uv\rangle ^ + }$ distribution approximately equal to zero. Li et al. (Reference Li, Kawaguchi, Segawa and Hishida2005) also showed suppression in the

${\langle uv\rangle ^ + }$ distribution approximately equal to zero. Li et al. (Reference Li, Kawaguchi, Segawa and Hishida2005) also showed suppression in the ![]() ${\langle {v^2}\rangle ^ + }$ profile, but a non-zero

${\langle {v^2}\rangle ^ + }$ profile, but a non-zero ![]() ${\langle uv\rangle ^ + }$ distribution for solutions close to MDR. In addition, the trend in

${\langle uv\rangle ^ + }$ distribution for solutions close to MDR. In addition, the trend in ![]() ${\langle {w^2}\rangle ^ + }$ has yet to be measured for a surfactant drag-reduced channel flow. Therefore, additional measurements of the Reynolds stresses of surfactant drag-reduced flows are required to confirm the trends and identify the anomalies.

${\langle {w^2}\rangle ^ + }$ has yet to be measured for a surfactant drag-reduced channel flow. Therefore, additional measurements of the Reynolds stresses of surfactant drag-reduced flows are required to confirm the trends and identify the anomalies.

The above summary could not point at any common rheological property that can be attributed to DR for drag-reducing surfactant and polymer solutions. This brings up the question of whether polymer and surfactant solutions share a similar mechanism for turbulent drag reduction. To address this question, the first step is to compare the turbulence statistics of polymer and surfactant drag-reducing solutions. Although using previously published experimental results might be possible, such a comparison of turbulent statistics is likely subject to errors brought about by inconsistencies in the flow conditions and the amount of DR. Better yet, would be to perform an experiment directly comparing the different additives. For this purpose, we have carried out a detailed measurement of turbulent statistics in drag-reducing polymer and surfactant solutions while maintaining the same mass flow rate and wall shear stress. The latter parameter is equivalent to maintaining the same DR, and was fulfilled by tuning the concentration and mechanical degradation of the drag-reducing additives. This would not only yield an effective comparison between the turbulence statistics of the polymer and surfactant solutions, but also allows evaluation of the rheology of solutions that produce the same DR.

The current investigation compares three drag-reducing additives that have significantly different molecular structures; a flexible polymer, a rigid polymer and a surfactant. The additive solutions are prepared such that the solutions impose the same level of wall shear stress at the same mass flow rate, i.e. same DR at the same mass flow rate. Two scenarios of DR are considered: a DR of approximately 58 % referred to as high drag reduction (HDR), and a MDR case with DR of approximately 70 %. To measure all three components of the velocity field with a high spatial resolution, we apply a novel three-dimensional particle tracking velocimetry (3D-PTV) based on the ‘shake-the-box’ (STB) algorithm (Schanz et al. Reference Schanz, Gesemann, Schröder, Wieneke and Novara2013). In addition, we also characterize the rheology of the drag-reduced solutions using a torsional rheometer and a capillary break-up extensional rheometer. The details of our experimental methodology are discussed in § 2, and are followed by a presentation of the results in § 3.

2. Experimental methodology

2.1. Flow facility

The present experiments were carried out in a recirculating flow loop comprised of a channel section, as shown in figure 1. The channel section had a rectangular cross-section with a height, H, of 15 mm and width, W, of 120 mm. It also consisted of four sub-sections connected with flanges as seen in figure 1. The third section from the channel inlet was made with glass walls for optical measurements. The measurements were carried out at the middle of this third section which was situated 107H downstream from the inlet of the channel section. This ensured a fully developed turbulent channel flow. The walls of the channel sections immediately upstream and downstream of the measurement section were cast acrylic. Transition fittings, 30 cm in length, were used to convert the cross-section from circular to rectangular, and vice versa. The complete length of the channel section was 168H. Figure 2 demonstrates the cross-section of the measurement section and the coordinate system used here. Position along the streamwise direction is denoted as x, while y is the wall-normal direction and z is the spanwise direction. The coordinate system is centred at the mid-span of the lower channel wall.

Figure 1. Annotated top view of experimental flow facility showing the pipe loop connected to the channel section.

Figure 2. Isometric view of the cross-section of the test section used for flow measurements.

Fluid was driven using a centrifugal pump (LCC-M 50-230, GIW Industries Inc.) controlled by a variable frequency drive. A thermocouple (Type K) and a double pipe heat exchanger were used to measure and maintain a temperature of 25 ± 0.5 °C. The mass flow rate, ![]() $\dot{m}$, was measured using a Coriolis flow meter (Micro Motion F-series, Emerson Process Management) with an accuracy of ±0.2 %. A proportional integral derivative controller was used to maintain a constant

$\dot{m}$, was measured using a Coriolis flow meter (Micro Motion F-series, Emerson Process Management) with an accuracy of ±0.2 %. A proportional integral derivative controller was used to maintain a constant ![]() $\dot{m}$ by controlling the input frequency to the pump. Static pressure loss along the channel was measured using a differential pressure transducer (DP-15, Validyne) with a 0.5 psi diaphragm. Ports for the pressure transducer were separated 109H, with the upstream port being 34H from the channel inlet.

$\dot{m}$ by controlling the input frequency to the pump. Static pressure loss along the channel was measured using a differential pressure transducer (DP-15, Validyne) with a 0.5 psi diaphragm. Ports for the pressure transducer were separated 109H, with the upstream port being 34H from the channel inlet.

Two methods are used to determine the wall shear stress, τw. The first method used measurements of the pressure drop, ΔP, where τw ,1 = hΔP/Δx, and h is half-channel height (H/2). Subscript, 1, is used to distinguish this first method and, going forward, will denote variables calculated based on ΔP. In the second method, τw ,2 characterized by the subscript 2, was determined using a wall-normal gradient of the mean velocity obtained from 3D-PTV measurements, and will be discussed in § 2.3. The drag-reduction percentage, DR, was established based on a comparison of τw of a drag-reduced flow and that of the flow of water at the same mass flow rate, ![]() $\dot{m}$, according to,

$\dot{m}$, according to,

where τw ,A is the wall shear stress of the additive solution and τw ,N is the wall shear stress of the Newtonian flow of water at the same ![]() $\dot{m}$. We defined the DR derived from ΔP (and τw ,1) as DR 1, which is equivalent to DR 1 = 100(1 − ΔPA/ΔPN). In this equation, ΔPA is the streamwise pressure drop for an additive solution and ΔPN is the streamwise pressure drop for the flow of water at the same

$\dot{m}$. We defined the DR derived from ΔP (and τw ,1) as DR 1, which is equivalent to DR 1 = 100(1 − ΔPA/ΔPN). In this equation, ΔPA is the streamwise pressure drop for an additive solution and ΔPN is the streamwise pressure drop for the flow of water at the same ![]() $\dot{m}$. All experiments with drag-reducing additives were performed at a

$\dot{m}$. All experiments with drag-reducing additives were performed at a ![]() $\dot{m}$ of 3.294 kg s−1, which corresponds to a bulk velocity, Ub, of 1.839 m s−1. For the flow of water, this flow rate equates to a bulk Reynolds number (ReH = UbH/ν) of 31 900 and friction Reynolds number (Reτ = uτh/ν) of 793. Certain drag-reducing solutions have a viscosity that is larger than that of water (Escudier et al. Reference Escudier, Nickson and Poole2009). Such an increase in kinematic viscosity of the flow will result in a decrease in Re although

$\dot{m}$ of 3.294 kg s−1, which corresponds to a bulk velocity, Ub, of 1.839 m s−1. For the flow of water, this flow rate equates to a bulk Reynolds number (ReH = UbH/ν) of 31 900 and friction Reynolds number (Reτ = uτh/ν) of 793. Certain drag-reducing solutions have a viscosity that is larger than that of water (Escudier et al. Reference Escudier, Nickson and Poole2009). Such an increase in kinematic viscosity of the flow will result in a decrease in Re although ![]() $\dot{m}$ and ΔP are kept constant. It is challenging to maintain a constant Re for the drag-reduced flows, since Re is calculated using the viscosity of the fluid at the wall-shear-rate, which is unknown a priori. In addition, changing

$\dot{m}$ and ΔP are kept constant. It is challenging to maintain a constant Re for the drag-reduced flows, since Re is calculated using the viscosity of the fluid at the wall-shear-rate, which is unknown a priori. In addition, changing ![]() $\dot{m}$ to set a desired Re, will vary ΔP and therefore the DR.

$\dot{m}$ to set a desired Re, will vary ΔP and therefore the DR.

Additional measurements were also performed for water at lower ![]() $\dot{m}$ to match the Reτ of the drag-reduced flows. Table 1 lists Ub, ReH, ΔP and τw ,1 for each flow case of water. Table 1 also provides τw ,2, the friction velocity uτ = (τw ,2/ρ)1/2, wall units λ = ν/u τ, and Reτ of each water flow experiment. Here ρ is the density of the fluid. The variables in the last four columns of table 1 are derived based on the estimated τw ,2 from 3D-PTV measurements. The method will be discussed and evaluated in § 2.3.

$\dot{m}$ to match the Reτ of the drag-reduced flows. Table 1 lists Ub, ReH, ΔP and τw ,1 for each flow case of water. Table 1 also provides τw ,2, the friction velocity uτ = (τw ,2/ρ)1/2, wall units λ = ν/u τ, and Reτ of each water flow experiment. Here ρ is the density of the fluid. The variables in the last four columns of table 1 are derived based on the estimated τw ,2 from 3D-PTV measurements. The method will be discussed and evaluated in § 2.3.

Table 1. Flow properties for channel flow experiments using water as the working fluid.

2.2. Drag-reducing additives

Three different types of drag-reducing additives were chosen: a flexible polymer, a rigid polymer and a surfactant. To prepare the additive solutions, drag-reducing powders were weighed using a digital scale (AB104-S, Mettler Toldeo) with a 0.1 mg resolution, and added to 15 l of tap water. The combination was then agitated for approximately 2 h using a stand mixer equipped with a three-blade impeller set to 100 revolutions per minute (Model 1750, Arrow Engineering Mixing Products) and left to rest for approximately 16 h (Abu Rowin, Sanders & Ghaemi Reference Abu Rowin, Sanders and Ghaemi2018). The master solution was then added to the reservoir labelled in figure 1. The pump effectively mixed and diluted the 15 l concentrated master solution with 120 l of tap water, to bring the fluid to the desired concentration, c.

Two different cases of DR were considered for the present experiments. The first was a comparison of additive solutions at a high level of drag reduction (HDR). This case evaluated three drag-reduced solutions at a similar DR 1, approximately equal to 57.7 % ± 1.2 %. Seeing as the DR 1 is greater than 40 %, this comparison is in the ‘HDR’ regime according to Warholic et al. (Reference Warholic, Massah and Hanratty1999a). The HDR amount of 57.7 % was selected based on the largest DR that could be obtained using the rigid polymer. The second scenario was a comparison of the flexible polymer and surfactant solutions at MDR, which occurs at DR 1 of approximately 70.3 % ± 1.8 % for the Re considered here.

A common species of flexible polymers known as polyacrylamide (PAM) obtained from SNF Floerger was used here. PAM has been readily used in other experiments and has been shown to induce large amount of DR for relatively low values of c (Escudier et al. Reference Escudier, Presti and Smith1999, Reference Escudier, Nickson and Poole2009; Ptasinski et al. Reference Ptasinski, Nieuwstadt and Hulsen2001; Owolabi et al. Reference Owolabi, Dennis and Poole2017). Solutions of PAM are also transparent, which was ideal for the 3D-PTV measurements. When the concentration of PAM increased beyond 50 ppm, it was observed that DR 1 plateaued at approximately 68.5 %, as demonstrated by figure 3(a). This suggested that 50 ppm of PAM could generate the required MDR state. To achieve the HDR case, with smaller DR 1, the rotational speed of the centrifugal pump was increased to reduce DR 1 to the desired value by using mechanical degradation. Figure 3(b) demonstrates how this procedure was executed on a 50 ppm PAM solution. Upon initially adding the master solution to the reservoir and letting the loop mix the solution for about 2 minutes at a low pump speed, DR 1 was 68.5 % for a pump speed of 600 revolutions per minute (desired ![]() $\dot{m}$ of 3.294 kg s−1). At this pump speed mechanical degradation is negligible and DR 1 remains constant. At t = 360 s, the pump speed was increased significantly to promote mechanical degradation. After approximately 720 s at a high pump speed, the pump speed was then returned to 600 revolutions per minute and the DR 1 became approximately equal to 58.0 %. While lower levels of c for PAM could produce the same effect, mechanical degradation at lower values of c would have been greater, making flow measurements challenging (Virk & Wagger Reference Virk, Wagger and A.1990; Pereira et al. Reference Pereira, Andrade and Soares2013). Therefore, we decided to use a degraded, 50 ppm PAM solution as opposed to a lower concentration solution of PAM for the case of HDR.

$\dot{m}$ of 3.294 kg s−1). At this pump speed mechanical degradation is negligible and DR 1 remains constant. At t = 360 s, the pump speed was increased significantly to promote mechanical degradation. After approximately 720 s at a high pump speed, the pump speed was then returned to 600 revolutions per minute and the DR 1 became approximately equal to 58.0 %. While lower levels of c for PAM could produce the same effect, mechanical degradation at lower values of c would have been greater, making flow measurements challenging (Virk & Wagger Reference Virk, Wagger and A.1990; Pereira et al. Reference Pereira, Andrade and Soares2013). Therefore, we decided to use a degraded, 50 ppm PAM solution as opposed to a lower concentration solution of PAM for the case of HDR.

Figure 3. (a) Value of DR 1, as a function of c for PAM, (b) DR 1 of c = 50 ppm solution of PAM as a function of time, t, (c) DR 1 of XG as a function of c, (d) DR 1 of C14/NaSal (1 : 2 mM) as a function of c.

Most rigid polymers are polysaccharides that naturally occur and are biodegradable (Pereira et al. Reference Pereira, Andrade and Soares2013). The rigid polymer used here was xanthan gum (XG) from Sigma Aldrich (CAS No. 1138-66-2). Figure 3(c) demonstrates that the largest DR 1 achieved was 58.5 %, exhibited by 300 ppm of XG. The XG solution showed negligible amounts of degradation, similar to the findings of Pereira et al. (Reference Pereira, Andrade and Soares2013). The largest DR 1 achieved using XG was chosen as the common HDR value. Due to the limited drag-reduction capability of XG, no MDR case was achieved.

Cationic surfactants have a chemical structure: CnH2n+1N+(CH3)3Cl, where n is an integer generally from 12 to 18. Compounds are often referred to as Cn depending on the number of carbon atoms in a surfactant's alkyl chain, n. Based on our preliminary investigations, Trimethyltetradecylammonium chloride (n = 14) in combination with a sodium salicylate counterion (NaSal) at a molar ratio of 1 : 2 was deemed an appropriate surfactant-counterion pairing. Going forward this compound will be referred to as C14. Figure 3(d) shows that a 200 ppm (0.685 mM) solution of C14 produced DR 1 of 72.0 %. No increase in DR 1 was observed if the c of C14 was increased further. Therefore, 200 ppm of C14 was perceived to produce MDR. Choosing a c equal to 150 ppm of C14 (0.521 mM), with the same 1 : 2 molar ratio of C14 to NaSal, produced DR 1 of 56.5 % for HDR tests. The measurements of ΔP and DR 1 are listed in table 2 for each drag-reduced flow.

Table 2. Bulk flow measurements from Coriolis flow meter and pressure transducer. To reiterate, DR 1 is calculated based on ΔP. *Solution was subject to mechanical degradation.

The skin-friction coefficient, ![]() ${C_f} = 2{\tau _w}_{,1}/\rho U_b^2$, as a function of ReH, is demonstrated in figure 4 for flows of drag-reducing solutions and water. For drag-reduced flows, the kinematic viscosity, ν, that is used to calculate ReH, corresponds to the measured shear viscosity at the wall shear rate. The procedure will be discussed in §§ 3.1 and 3.3. The error bars shown in figure 4 propagate from random and systematic uncertainties in measurements of the flow rate, viscosity and streamwise pressure gradient. Figure 4 also presents two empirical correlations. The upper line in figure 4, corresponds to the

${C_f} = 2{\tau _w}_{,1}/\rho U_b^2$, as a function of ReH, is demonstrated in figure 4 for flows of drag-reducing solutions and water. For drag-reduced flows, the kinematic viscosity, ν, that is used to calculate ReH, corresponds to the measured shear viscosity at the wall shear rate. The procedure will be discussed in §§ 3.1 and 3.3. The error bars shown in figure 4 propagate from random and systematic uncertainties in measurements of the flow rate, viscosity and streamwise pressure gradient. Figure 4 also presents two empirical correlations. The upper line in figure 4, corresponds to the ![]() ${C_f} = 0.073Re_H^{ - 0.25}$ correlation from Dean (Reference Dean1978) for a Newtonian turbulent channel flow that has a cross-section with W/H greater than 7. The measured Cf for the experimental data of water, shown by the blue markers in figure 4, are marginally lower than the Dean (Reference Dean1978) correlation equation. However, the results are in agreement with other turbulent channel flow experiments, several of which were used by Dean (Reference Dean1978) to obtain the correlation. The lower line in figure 4 corresponds to the MDR asymptote proposed by Virk et al. (Reference Virk, Mickley and Smith1970). The original correlation was intended to be used for pipe flows. To adapt the equation to a channel flow, similar to Owolabi et al. (Reference Owolabi, Dennis and Poole2017), the MDR asymptote is plotted using a Re that is calculated based on the hydraulic diameter,

${C_f} = 0.073Re_H^{ - 0.25}$ correlation from Dean (Reference Dean1978) for a Newtonian turbulent channel flow that has a cross-section with W/H greater than 7. The measured Cf for the experimental data of water, shown by the blue markers in figure 4, are marginally lower than the Dean (Reference Dean1978) correlation equation. However, the results are in agreement with other turbulent channel flow experiments, several of which were used by Dean (Reference Dean1978) to obtain the correlation. The lower line in figure 4 corresponds to the MDR asymptote proposed by Virk et al. (Reference Virk, Mickley and Smith1970). The original correlation was intended to be used for pipe flows. To adapt the equation to a channel flow, similar to Owolabi et al. (Reference Owolabi, Dennis and Poole2017), the MDR asymptote is plotted using a Re that is calculated based on the hydraulic diameter, ![]() $R{e_{{D_h}}} = {U_b}{D_h}/\nu$, where Dh = 2HW/(H + W). The Cf of drag-reduced flows at MDR are about 15 % greater than the Cf of the correlation. It should be noted that there is considerable ambiguity in the equation describing the MDR asymptote in channel flows. Escudier et al. (Reference Escudier, Nickson and Poole2009) applied a correction factor to Re to account for potential secondary flows, while Ptasinski et al. (Reference Ptasinski, Boersma, Nieuwstadt, Hulsen, van den Brule and Hunt2003) simply used ReH. The choice of the length scale in defining Re will raise or lower the MDR asymptote along the vertical axis of the plot of Cf. Also, Virk et al. (Reference Virk, Mickley and Smith1970) remarked that the Cf relationship was derived from an integration of the asymptotic mean velocity profile. White et al. (Reference White, Dubief and Klewicki2012), among others, had cast doubt on the exactness of the mean velocity profile of drag-reduced flows at MDR. Therefore, the Cf distribution at MDR may also be erroneous and conditionally on the canonical flow type, Reynolds number and additive type (White et al. Reference White, Dubief and Klewicki2012).

$R{e_{{D_h}}} = {U_b}{D_h}/\nu$, where Dh = 2HW/(H + W). The Cf of drag-reduced flows at MDR are about 15 % greater than the Cf of the correlation. It should be noted that there is considerable ambiguity in the equation describing the MDR asymptote in channel flows. Escudier et al. (Reference Escudier, Nickson and Poole2009) applied a correction factor to Re to account for potential secondary flows, while Ptasinski et al. (Reference Ptasinski, Boersma, Nieuwstadt, Hulsen, van den Brule and Hunt2003) simply used ReH. The choice of the length scale in defining Re will raise or lower the MDR asymptote along the vertical axis of the plot of Cf. Also, Virk et al. (Reference Virk, Mickley and Smith1970) remarked that the Cf relationship was derived from an integration of the asymptotic mean velocity profile. White et al. (Reference White, Dubief and Klewicki2012), among others, had cast doubt on the exactness of the mean velocity profile of drag-reduced flows at MDR. Therefore, the Cf distribution at MDR may also be erroneous and conditionally on the canonical flow type, Reynolds number and additive type (White et al. Reference White, Dubief and Klewicki2012).

Figure 4. Skin-friction coefficient as a function of bulk Reynolds number for drag-reduced flows and water. The upper equation shows the Dean (Reference Dean1978) correlation for Newtonian channel flows and the lower equation shows the MDR asymptote adapted for channel flows.

Shear and extensional viscosity measurements were performed on samples of each drag-reducing solution. The samples were collected from the flow loop using an outlet valve at the corresponding DR and the rheology measurements were performed immediately afterwards. The apparent shear viscosity, μ, as a function of shear rate, ![]() $\dot{\gamma }$, for each additive solution and water, was determined using a torsional rheometer equipped with a double gap cylinder geometry (HR-2, TA Instruments). The four radii of the geometry, in increasing order, were defined as the inside cup radius (15.1 mm), the inside bob radius (16.0 mm), the outside bob radius (17.5 mm) and the outside cup radius (18.5 mm). The height of the sample immersed in the bob and cup was 53.0 mm. Shear viscosity measurements were performed three times for each sample listed in table 2 (including water) to establish the uncertainty of the measurements.

$\dot{\gamma }$, for each additive solution and water, was determined using a torsional rheometer equipped with a double gap cylinder geometry (HR-2, TA Instruments). The four radii of the geometry, in increasing order, were defined as the inside cup radius (15.1 mm), the inside bob radius (16.0 mm), the outside bob radius (17.5 mm) and the outside cup radius (18.5 mm). The height of the sample immersed in the bob and cup was 53.0 mm. Shear viscosity measurements were performed three times for each sample listed in table 2 (including water) to establish the uncertainty of the measurements.

Relaxation time based on extensional viscosity, λE, was established using a CaBER (Haake CaBER, Thermo Scientific). Samples were placed between two circular plates, both of which were 6 mm in diameter and had a 3 mm separation from one another. After loading the sample, the top plate was displaced causing the solution to stretch in uniaxial extension (Barnes, Hutton & Walters Reference Barnes, Hutton and Walters1989; Rodd et al. Reference Rodd, Scott, Cooper-White and Mckinley2005). The final gap between the plates was 9 mm and the strike time to attain that final displacement was 50 ms. A laser micrometer was used to measure the midpoint diameter, D, of the sample as a function of time, t. Extensional characteristics, such as λE, were derived from fitting an equation of the form D(t) = Ae−Bt − Ct + E to the measurements of filament diameter, D, with respect to time, t (Anna & Mckinley Reference Anna and Mckinley2001; Miller, Clasen & Rothstein Reference Miller, Clasen and Rothstein2009), where A, B, C and E are fitting parameters. The value of B = λE/3 characterizes the relaxation time of the fluid, while C is indicative of the steady-state extensional viscosity (Anna & Mckinley Reference Anna and Mckinley2000). For the present experiment, the focus was prioritized on deriving λE for each sample and qualitatively comparing the uniaxial extensibility of each solution. CaBER measurements were also repeated three times for each solution.

2.3. Lagrangian 3D-PTV measurements

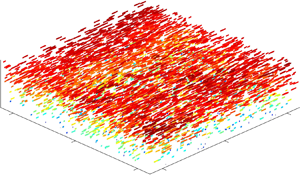

We carried out 3D-PTV using the state-of-the-art STB algorithm devised by Schanz, Gesemann & Schröder (Reference Schanz, Gesemann and Schröder2016). The STB algorithm predicts the three-dimensional particle position based on the established trajectories of previous time steps. The prediction is then corrected using an iterative particle reconstruction (Wieneke Reference Wieneke2013), where the particles are shifted (‘shaked’) in the volume (‘box’) until residual errors are minimized and a trajectory is established. The algorithm can analyse images with high seeding densities, allowing measurement of spatially resolved turbulent statistics and instantaneous flow structures. The efficacy of STB was exemplified by Schröder et al. (Reference Schröder, Schanz, Geisler, Gesemann and Willert2015), where the turbulent Reynolds stresses were accurately measured for y+ as low as 1.5.

The 3D-PTV system consisted of four high-speed cameras (v611, Phantom) and a high-repetition Nd:YLF laser (DM20-527 Photonoics Industries). Figure 5 provides a visual representation of the cameras and laser configuration. The laser emitted light with a wavelength of 532 nm and a maximum pulse energy of 20 mJ pulse−1. As seen in figure 5, the circular laser beam was directed in the spanwise direction of the channel (negative z). A lens combination shaped and collimated the beam into an oval profile. The resulting oval profile was then cropped to form a rectangular cross-section with 5 mm thickness in the wall-normal direction, covering from y = 0 to 5 mm. The laser sheet was 16 mm in the streamwise direction, x. To increase the light intensity for the backward scattered camera, the laser sheet was also reflected back onto itself using a large mirror situated on the opposite side of the test section (Ghaemi & Scarano Reference Ghaemi and Scarano2010).

Figure 5. Three-dimensional rendering of high-speed laser and camera array for 3D-PTV.

The four Phantom v611 cameras had a 1280 × 800 pixel complementary metal oxide semiconductor sensor with pixel size of 20 × 20 μm2 and 12 bit resolution. Scheimpflug adapters and Nikon lenses with a focal length of f = 105 mm were connected to the cameras. A reduced sensor resolution of 900 × 800 pixel was used to enable higher recording rates. The forward/backward scattering cameras (cameras 2 and 3 in figure 5) were placed along the z-direction and set to a lens aperture of f/16. The side scattering cameras (cameras 1 and 4) were placed along the streamwise x-direction with a lens aperture setting of f/11. The line of sight of cameras 2 and 3 had an angle of 60° with respect to each other, while the side scattering cameras were placed at 30° with respect to each other. The distance of the cameras to the measurement location was approximately 290 mm. This imaging configuration resulted in a magnification of approximately 0.56 and a resolution of 27.9 μm pixel−1. The cameras and laser were synchronized using a programmable timing unit (PTU X, LaVision GmbH). Fluids were seeded with 10 μm silver coated hollow glass spheres (S-HGS-10, Dantec Dynamics). The density of the tracers in the images was approximately 0.05 particles per pixel. The fidelity for which the tracer particles can follow the fluid flow can be defined by two parameters, the Stokes number, St, and Froude number, Fr (Bewley, Sreenivasan & Lathrop Reference Bewley, Sreenivasan and Lathrop2008). The local values of St and Fr of the particles can be approximated as St = tp/tf and Fr = up/uτ, and describe the significance of particle inertia and particle settling. The particle response time is ![]() ${t_p} = {\rho _p}d_p^2/18{\mu _w}$, and the settling velocity is

${t_p} = {\rho _p}d_p^2/18{\mu _w}$, and the settling velocity is ![]() ${u_p} = ({\rho _p}-\rho)d_p^2g/18\mu$. Here ρp is the density of the particles and dp the diameter. The characteristic fluid response time, tf, was approximated as λ/uτ. The value of St was between 0.012 and 0.087 depending on the flow conditions. While the Fr for all flows was of the order of magnitude, 10−3–10−4. Therefore, particle inertia and particle settling was considered inconsequential.

${u_p} = ({\rho _p}-\rho)d_p^2g/18\mu$. Here ρp is the density of the particles and dp the diameter. The characteristic fluid response time, tf, was approximated as λ/uτ. The value of St was between 0.012 and 0.087 depending on the flow conditions. While the Fr for all flows was of the order of magnitude, 10−3–10−4. Therefore, particle inertia and particle settling was considered inconsequential.

One time-resolved data set, for each drag-reduced and Newtonian flow, consisted of 6800 single-frame images captured at a frequency between 2.5 and 4.5 kHz. Therefore, one data set was between 1.5 and 2.7 s in duration. Depending on Ub of the flow being measured, the image capture rate was determined such that a maximum particle displacement of approximately 10 pixels across successive frames was maintained. After recording the images, the minimum intensity of each data set was computed and subtracted to remove any glare points caused by surface scratches and tracer particles stuck to the bottom wall. Images were further enhanced by applying a sliding minimum subtraction with kernel of 7 pixels and local intensity normalization over a kernel of 50 pixels.

Calibration of the imaging system was carried out by fitting a third-order polynomial mapping function onto images recorded from a dual-plane calibration target (058-5, LaVision GmbH). To improve the accuracy of the mapping function, volume self-calibration was employed (Wieneke Reference Wieneke2008), which brought the average disparity down to 0.02 pixels. An optical transfer function was generated for iterative particle reconstruction in STB (Schanz et al. Reference Schanz, Gesemann, Schröder, Wieneke and Novara2013). The measurement volume was in the mid-span of the test section and had dimensions of (Δx, Δy, Δz) = 670 × 180 × 670 voxel = 24 × 5 × 24 mm3. Additional image and volume cropping mitigated noise common along the borders of the volume. Lastly, the STB algorithm was performed in DaVis 8.4 (LaVision GmbH). The maximum triangulation error was constrained to 1 voxel. Particle displacement was limited to a maximum value of 15 voxels. In addition, particles with a change in velocity exceeding 2 pixels or 20 % in successive image frames were discarded.

A moving second-order polynomial was fit on the particle trajectories in MATLAB. The length of the polynomial (kernel) was five time steps (1.11–2 ms) for obtaining first-order turbulence statistics. To mitigate noise in Reynolds stresses, a kernel with a length of 11 time steps (2.4–4.4 ms) was used. Trajectories less than the respective kernel length were removed from consideration. To obtain the velocity statistics, particle tracks were binned into slabs parallel with the wall, covering the entire measurement domain in the x and z directions. Each slab was 10 μm thick in the y direction for evaluating the mean velocity profiles (Δy+ ˜ 0.4–0.7) and 100 μm in the y direction for the Reynolds stresses (Δy+ ˜ 4.0–6.7). Both procedures incorporated a 75 % overlap between neighbouring slabs in the y direction. The statistics were obtained by averaging in time and the homogenous directions (x and z), and are indicated by angle brackets, ![]() $\langle \cdots \rangle$. To obtain instantaneous velocity fields in a Eulerian frame of reference, the particle tracks were binned into 24 × 24 × 24 voxel cubes with 75 % overlap in all three directions. The instantaneous velocities in x, y and z directions were denoted by U, V and W, respectively. The corresponding velocity fluctuations were represented by u, v, w.

$\langle \cdots \rangle$. To obtain instantaneous velocity fields in a Eulerian frame of reference, the particle tracks were binned into 24 × 24 × 24 voxel cubes with 75 % overlap in all three directions. The instantaneous velocities in x, y and z directions were denoted by U, V and W, respectively. The corresponding velocity fluctuations were represented by u, v, w.

As previously established, a superscript of + is indicative of inner normalization by friction velocity, uτ, defined as (τw ,2/ρ)1/2, and wall unit, λ = ν/uτ. Here, ν is equivalent to μ w/ρ. For the inner normalizations, the wall shear stress is calculated as ![]() ${\tau _w}_{,2} = {\mu _w}\,\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$, where

${\tau _w}_{,2} = {\mu _w}\,\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$, where ![]() $\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$ is the mean velocity gradient at the wall. Drag-reducing solutions can exhibit shear-thinning characteristics, where μ decreases with respect to

$\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$ is the mean velocity gradient at the wall. Drag-reducing solutions can exhibit shear-thinning characteristics, where μ decreases with respect to ![]() $\dot{\gamma }$ (Warholic et al. Reference Warholic, Schmidt and Hanratty1999b; Ptasinski et al. Reference Ptasinski, Nieuwstadt and Hulsen2001; Escudier et al. Reference Escudier, Nickson and Poole2009). Therefore, the shear viscosity measurements, discussed in § 2.2, were used to estimate μ w at the wall shear rate, i.e. at

$\dot{\gamma }$ (Warholic et al. Reference Warholic, Schmidt and Hanratty1999b; Ptasinski et al. Reference Ptasinski, Nieuwstadt and Hulsen2001; Escudier et al. Reference Escudier, Nickson and Poole2009). Therefore, the shear viscosity measurements, discussed in § 2.2, were used to estimate μ w at the wall shear rate, i.e. at ![]() $\dot{\gamma } = \textrm{d}\langle U\rangle /\textrm{d}y{|_w}$. To determine

$\dot{\gamma } = \textrm{d}\langle U\rangle /\textrm{d}y{|_w}$. To determine ![]() $\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$, a linear fit was applied on the mean velocity profile within 2–4 < y+ < 5 in the linear viscous sublayer. The lower bound varied depending on the flow Reτ but it corresponded to y ≈ 60 μm. The efficacy of this procedure is discussed in § 3.2 by comparing the normalized mean velocity profile and Reynolds stresses for turbulent channel flow of water with results from direct numerical simulation (DNS) at a similar Reτ. Such an estimate of τw using the near-wall gradient of the mean velocity profile is an approximation for the drag-reduced flows. Solutions that are shear thinning can exhibit instantaneous variations in

$\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$, a linear fit was applied on the mean velocity profile within 2–4 < y+ < 5 in the linear viscous sublayer. The lower bound varied depending on the flow Reτ but it corresponded to y ≈ 60 μm. The efficacy of this procedure is discussed in § 3.2 by comparing the normalized mean velocity profile and Reynolds stresses for turbulent channel flow of water with results from direct numerical simulation (DNS) at a similar Reτ. Such an estimate of τw using the near-wall gradient of the mean velocity profile is an approximation for the drag-reduced flows. Solutions that are shear thinning can exhibit instantaneous variations in ![]() $\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$ and therefore variations in μ w with time. To ensure τw ,2 of the drag-reduced flows was reasonable, we validated these results by comparing the estimated DR 2 with the DR 1 that was obtained using measurements of ΔP.

$\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$ and therefore variations in μ w with time. To ensure τw ,2 of the drag-reduced flows was reasonable, we validated these results by comparing the estimated DR 2 with the DR 1 that was obtained using measurements of ΔP.

Uncertainty in the normalized velocity and Reynolds stresses are quantified based on two sources of error. The first source propagates from the uncertainty in measurements of μ. This was estimated by repeating the measurements of μ, which will be shown in § 3.1. The uncertainty in μ affects variables used for inner scaling, that is uτ and λ, following a root-sum-of-squares propagation of uncertainty (Wheeler & Ganji Reference Wheeler and Ganji2010). The second source of uncertainty is a random noise in the measured flow velocity associated with particle positioning in 3D-PTV. Using a spectral analysis of the particle tracks, Abu Rowin & Ghaemi (Reference Abu Rowin and & Ghaemi2019) and Ebrahimian, Sanders & Ghaemi (Reference Ebrahimian, Sanders and Ghaemi2019) showed that an error of 0.1, 0.2 and 0.1 pixel was present in particle displacements along the x, y and z directions, respectively. Combined, these two sources of uncertainty contribute to the total uncertainty in normalized mean velocity, Reynolds stresses and wall-normal location. The estimated uncertainty is shown as error bars in the figures demonstrated in § 3.

3. Results

3.1. Fluid rheology

The results of the shear viscosity measurements using the torsional rheometer are shown in figure 6(a). The demonstrated shear viscosities are the average of the thrice repeated measurements for each sample. Error bars are the range in the measurements at each ![]() $\dot{\gamma }$. Within the presented values of

$\dot{\gamma }$. Within the presented values of ![]() $\dot{\gamma }$, the measurements of μ show good repeatability and low random error; the range in the measurements are less than 5.7 %. Based on figure 6(a), the measured μ of domestic tap water at 25 °C is 0.861 ± 0.049 mPa s. The results for water can be contrasted with shear viscosity measurements of Nagashima (Reference Nagashima1977) and Collings & Bajenov (Reference Collings and Bajenov1983). They measured the viscosity of distilled water at 25 °C; finding it to be 0.891 mPa s. The discrepancy between the results of figure 6(a) for water and the measurements of Nagashima (Reference Nagashima1977) and Collings & Bajenov (Reference Collings and Bajenov1983) is within the estimated uncertainty based on the three repeated measurements, and is attributed to systematic uncertainties inherent with the torsional rheometer.

$\dot{\gamma }$, the measurements of μ show good repeatability and low random error; the range in the measurements are less than 5.7 %. Based on figure 6(a), the measured μ of domestic tap water at 25 °C is 0.861 ± 0.049 mPa s. The results for water can be contrasted with shear viscosity measurements of Nagashima (Reference Nagashima1977) and Collings & Bajenov (Reference Collings and Bajenov1983). They measured the viscosity of distilled water at 25 °C; finding it to be 0.891 mPa s. The discrepancy between the results of figure 6(a) for water and the measurements of Nagashima (Reference Nagashima1977) and Collings & Bajenov (Reference Collings and Bajenov1983) is within the estimated uncertainty based on the three repeated measurements, and is attributed to systematic uncertainties inherent with the torsional rheometer.

Figure 6. Rheology of aqueous solutions of drag-reduced additives including (a) shear viscosity as a function of shear rate, and (b) mid-point filament diameter with respect to time from uniaxial filament extension.

From visual inspection of figure 6(a), it is apparent that the XG solution is shear thinning. The viscosity of the XG solution reduces by 80.4 % between ![]() $\dot{\gamma }$ of 5 and 400 s−1. For

$\dot{\gamma }$ of 5 and 400 s−1. For ![]() $\dot{\gamma }\; \gt 400\;{\textrm{s}^{ - 1}}$, Taylor instabilities produce a sudden increase in μ and the results were discarded. The values of

$\dot{\gamma }\; \gt 400\;{\textrm{s}^{ - 1}}$, Taylor instabilities produce a sudden increase in μ and the results were discarded. The values of ![]() $\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$ for the drag-reduced, turbulent flows being investigated are beyond 2000 s−1, much greater than the maximum achievable

$\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$ for the drag-reduced, turbulent flows being investigated are beyond 2000 s−1, much greater than the maximum achievable ![]() $\dot{\gamma }$ of 400 s−1 using this rheometer. Therefore, a predictive model is used to extrapolate the data and estimate μ w of the drag-reduced turbulent flows. For the XG solution, the Carreau–Yasuda (CY) model (Carreau Reference Carreau1972; Yasuda, Armstrong & Cohen Reference Yasuda, Armstrong and Cohen1981) fit the measurements appropriately and is shown by the solid line in figure 6(a). The CY model is represented by the following equation,

$\dot{\gamma }$ of 400 s−1 using this rheometer. Therefore, a predictive model is used to extrapolate the data and estimate μ w of the drag-reduced turbulent flows. For the XG solution, the Carreau–Yasuda (CY) model (Carreau Reference Carreau1972; Yasuda, Armstrong & Cohen Reference Yasuda, Armstrong and Cohen1981) fit the measurements appropriately and is shown by the solid line in figure 6(a). The CY model is represented by the following equation,

where μ 0 is the zero-shear-rate viscosity, μ ∞ is the infinite-shear-rate viscosity, λt is a fitting constant with a dimension of time, n is a dimensionless exponent and a is an additional fitting parameter introduced by Yasuda et al. (Reference Yasuda, Armstrong and Cohen1981). For XG, μ 0 is 0.019 Pa s, μ ∞ is 0.937 mPa s, λt is 0.517 s, n is 0.466 and a is 1.935. The uncertainty in the extrapolated shear viscosity for XG is taken to be the maximum range in the thrice-repeated measurements of μ. Using the above (3.1), the μ w of XG at HDR, which corresponds to the value of ![]() $\dot{\gamma }$ that was equal to

$\dot{\gamma }$ that was equal to ![]() $\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$, is 1.576 mPa s. Extrapolating the CY model may be subject to errors that can influence the variables derived for inner scaling, including τw ,2, uτ and λ (Singh et al. Reference Singh, Rudman, Blackburn, Chryss, Pullum and Graham2016). We will go on to demonstrate that the DR 2 derived using these rheology measurements is within 5 % of the DR 1 determined from measurements of the streamwise pressure gradient. Propagation of uncertainty accounts for additional errors in the inner-scaling variables that can be seen by error bars in plots of the mean velocity profile and Reynolds stresses.

$\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$, is 1.576 mPa s. Extrapolating the CY model may be subject to errors that can influence the variables derived for inner scaling, including τw ,2, uτ and λ (Singh et al. Reference Singh, Rudman, Blackburn, Chryss, Pullum and Graham2016). We will go on to demonstrate that the DR 2 derived using these rheology measurements is within 5 % of the DR 1 determined from measurements of the streamwise pressure gradient. Propagation of uncertainty accounts for additional errors in the inner-scaling variables that can be seen by error bars in plots of the mean velocity profile and Reynolds stresses.

Solutions of PAM also demonstrate shear-thinning qualities, but to a much lesser extent than XG. The viscosity of PAM at MDR reduced by 7.4 % between ![]() $\dot{\gamma }$ of 10 and 180 s−1. The viscosity of PAM at HDR reduces by 6.1 % across the same range in

$\dot{\gamma }$ of 10 and 180 s−1. The viscosity of PAM at HDR reduces by 6.1 % across the same range in ![]() $\dot{\gamma }$. Below

$\dot{\gamma }$. Below ![]() $\dot{\gamma }$ of 10 s−1, measurements of μ were noisy and ambiguous. In either scenario, measurements of μ are approximately constant for

$\dot{\gamma }$ of 10 s−1, measurements of μ were noisy and ambiguous. In either scenario, measurements of μ are approximately constant for ![]() $\dot{\gamma }\; \gt 180\;{\textrm{s}^{ - 1}}$, which is the maximum measurable

$\dot{\gamma }\; \gt 180\;{\textrm{s}^{ - 1}}$, which is the maximum measurable ![]() $\dot{\gamma }$ of both PAM solutions (HDR and MDR) before Taylor instabilities impair the measurements. The Sisko (SI) model (Sisko Reference Sisko1958) was used to represent μ of the PAM solutions at moderate and large values of

$\dot{\gamma }$ of both PAM solutions (HDR and MDR) before Taylor instabilities impair the measurements. The Sisko (SI) model (Sisko Reference Sisko1958) was used to represent μ of the PAM solutions at moderate and large values of ![]() $\dot{\gamma }$. This model is typically used when measurements close to the zero-shear-rate viscosity are lacking (Barnes et al. Reference Barnes, Hutton and Walters1989). The fitted SI model is shown in figure 6(a) using a dashed line and is represented by the following equation,

$\dot{\gamma }$. This model is typically used when measurements close to the zero-shear-rate viscosity are lacking (Barnes et al. Reference Barnes, Hutton and Walters1989). The fitted SI model is shown in figure 6(a) using a dashed line and is represented by the following equation,

where K and n are constants used to describe the power law decay in μ. The infinite-shear-rate viscosity, μ ∞, for PAM at HDR and MDR are estimated to be 1.072 and 1.087 mPa s, respectively. The fitting parameter n and K are 0.349 and 0.455 mPa sn for PAM at HDR and 0.101 and 0.985 mPa sn for PAM at MDR. Using the above (3.2), the μ w of PAM at HDR and MDR is 1.074 and 1.088 mPa s respectively, not much greater than the corresponding values of μ ∞.

There is a negligible difference in measured values of μ for the 150 ppm C14 solution at HDR and the 200 ppm C14 solution at MDR. Unlike PAM and XG, solutions of C14 exhibit a Newtonian trend with constant μ for ![]() $10\;{\textrm{s}^{ - 1}} \lt \dot{\gamma }\; \lt 100\;{\textrm{s}^{ - 1}}$. Therefore, their viscosities were assumed constant for

$10\;{\textrm{s}^{ - 1}} \lt \dot{\gamma }\; \lt 100\;{\textrm{s}^{ - 1}}$. Therefore, their viscosities were assumed constant for ![]() $\dot{\gamma }\; \gt 100\;{\textrm{s}^{ - 1}}$. The estimated μ w of C14 at HDR is 0.911 ± 0.036 mPa s and C14 at MDR is 0.912 ± 0.024 mPa s. No SISs are observed for C14; however, that does not rule out the possibility of their presence at higher values of

$\dot{\gamma }\; \gt 100\;{\textrm{s}^{ - 1}}$. The estimated μ w of C14 at HDR is 0.911 ± 0.036 mPa s and C14 at MDR is 0.912 ± 0.024 mPa s. No SISs are observed for C14; however, that does not rule out the possibility of their presence at higher values of ![]() $\dot{\gamma }$.

$\dot{\gamma }$.

Using the CaBER system, it was not feasible to measure λE of XG and C14 solutions, since the filament immediately ruptured upon moving the endplates. Similar findings for rigid polymer and surfactant solutions have been reported by previous investigations (Lin Reference Lin2000; Escudier et al. Reference Escudier, Nickson and Poole2009; Mohammadtabar et al. Reference Mohammadtabar, Sanders and Ghaemi2020). The two PAM solutions were the only fluids that showed a measurable λE using the CaBER apparatus. Figure 6(b) demonstrates the filament diameter, D, as a function of time, t. Here t = 0 indicates the end of the top plate displacement. Similar to the shear viscosity measurements, the thrice-repeated measurements of D(t) were averaged for each sample and the error bars show the range of the measurements. The solid black line represents the exponential fit of D(t) = Ae−Bt − Ct + E. The resulting λE for PAM at HDR and PAM at MDR were 4.3 and 11.0 ms, respectively. For the purposes of our analysis, a comprehension that solutions of PAM have significantly larger extensional characteristics than those of XG and C14, will suffice.

Despite producing similar DR at HDR or MDR (see table 2), each drag-reducing solution exhibits a different shear viscosity and extensional characteristics. Of the additive solutions, XG has the largest overall μ and a strong shear-thinning behaviour. PAM has the next largest distribution in μ; however, only approximately 20 % larger than the average μ of water. C14, on the other hand, has a water-like distribution in μ. Although we were unable to measure λE for C14 and XG using the CaBER system, the fact that λE for PAM solutions could be measured implies that PAM has a larger λE than C14 and XG. Rodd et al. (Reference Rodd, Scott, Cooper-White and Mckinley2005) specified that the operable range of the CaBER is constrained to fluids with λE larger than approximately 1 ms when μ is smaller than 70 mPa s. Given the measured shear viscosities of XG and C14 are less than 70 mPa s, it is possible that their λE are less than 1 ms. However, further measurements of the extensional rheology are needed to confirm this hypothesis, one possible method being the dripping-onto-substrate technique detailed in Dinic, Jimenez & Sharma (Reference Dinic, Jimenez and Sharma2017). Such a method was capable of measuring the pinch-off dynamics of fluids with μ less than 20 mPa s and λ E less than 1 ms, according to Dinic et al. (Reference Dinic, Jimenez and Sharma2017). Nonetheless, a correlation relating DR to λE, similar to that proposed by Owolabi et al. (Reference Owolabi, Dennis and Poole2017) for flexible polymers, may not apply to solutions of XG or C14. The above analysis using conventional torsional and extensional rheometers highlights that the drag-reduced solutions demonstrate different rheological characteristics.

Other authors have demonstrated that flows obtained from DNS and using the FENE-P (finitely extensible non-linear elastic spring, with a Peterlin approximation) model with large Weissenberg number, ![]() $Wi = {\lambda _E}\,\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$, have an effective viscosity that increases with distance from the wall (Procaccia et al. Reference Procaccia, L'vov and Benzi2008). A viscosity that increases monotonically with distance from the wall is achieved inherently by shear-thinning fluids. We find it intriguing that DR exists for both XG with relatively small λE and large shear-thinning behaviour, and PAM with large λE and minimal shear-thinning characteristics. This could suggest that polymers achieve DR using a viscosity that increases monotonically with y. Flexible polymers achieve this viscosity gradient using polymer elasticity (i.e. Wi), while rigid polymers are naturally shear thinning. Such a hypothesis is only speculative. Measurements connecting the role of shear-thinning characteristics to DR are warranted.

$Wi = {\lambda _E}\,\textrm{d}\langle U\rangle /\textrm{d}y{|_w}$, have an effective viscosity that increases with distance from the wall (Procaccia et al. Reference Procaccia, L'vov and Benzi2008). A viscosity that increases monotonically with distance from the wall is achieved inherently by shear-thinning fluids. We find it intriguing that DR exists for both XG with relatively small λE and large shear-thinning behaviour, and PAM with large λE and minimal shear-thinning characteristics. This could suggest that polymers achieve DR using a viscosity that increases monotonically with y. Flexible polymers achieve this viscosity gradient using polymer elasticity (i.e. Wi), while rigid polymers are naturally shear thinning. Such a hypothesis is only speculative. Measurements connecting the role of shear-thinning characteristics to DR are warranted.

3.2. Newtonian turbulent channel flow

The following section seeks to evaluate the 3D-PTV measurements for water by comparing them with DNS of Iwamoto, Suzuki & Kasagi (Reference Iwamoto, Suzuki and Kasagi2002) at Reτ = 300, Moser, Kim & Mansour (Reference Moser, Kim and Mansour1999) at Reτ = 395, and Lee & Moser (Reference Lee and Moser2015) at Reτ = 550. The previously listed DNS data, in that order, are compared with the experimental water data at Reτ = 307, 425 and 511, respectively, in figures 7 and 8. The comparison involves an evaluation of ![]() ${\langle U\rangle ^ + }$ in figure 7 and the Reynolds stress distributions in figure 8. The error bars in figures 7 and 8 originate from a propagation of uncertainty stemming from errors in velocity and shear viscosity measurements. For clarity of the figures, the error bars are down sampled in figures 7 and 8.

${\langle U\rangle ^ + }$ in figure 7 and the Reynolds stress distributions in figure 8. The error bars in figures 7 and 8 originate from a propagation of uncertainty stemming from errors in velocity and shear viscosity measurements. For clarity of the figures, the error bars are down sampled in figures 7 and 8.

Figure 7. Inner-normalized mean streamwise velocity from 3D-PTV measurement for water in comparison with DNS and the law of the wall. The three profiles are shifted upward along the vertical axis by 10. 3D-PTV measurements at Reτ = [307, 425, 511] are compared with DNS from Iwamoto et al. (Reference Iwamoto, Suzuki and Kasagi2002) with Reτ = 300; Moser et al. (Reference Moser, Kim and Mansour1999) with Reτ = 395; and Lee & Moser (Reference Lee and Moser2015) with Reτ = 550.

Figure 8. Reynolds stresses from 3D-PTV of water compared with DNS. (a) ![]() ${\langle {u^2}\rangle ^ + }$, where each data set is shifted upward along the vertical axis by 5, (b)

${\langle {u^2}\rangle ^ + }$, where each data set is shifted upward along the vertical axis by 5, (b) ![]() ${\langle {v^2}\rangle ^ + }$ where each data set is shifted by 1, (c)

${\langle {v^2}\rangle ^ + }$ where each data set is shifted by 1, (c) ![]() ${\langle {w^2}\rangle ^ + }$ where each data set is shifted by 1 and lastly (d)

${\langle {w^2}\rangle ^ + }$ where each data set is shifted by 1 and lastly (d) ![]() ${\langle uv\rangle ^ + }$where each data set is shifted by −1. The legends are similar to figure 7. The 3D-PTV results with Reτ = [307, 425, 511] are compared with DNS from Iwamoto et al. (Reference Iwamoto, Suzuki and Kasagi2002) with Reτ = 300; Moser et al. (Reference Moser, Kim and Mansour1999) with Reτ = 395; and Lee & Moser (Reference Lee and Moser2015) with Reτ = 550.

${\langle uv\rangle ^ + }$where each data set is shifted by −1. The legends are similar to figure 7. The 3D-PTV results with Reτ = [307, 425, 511] are compared with DNS from Iwamoto et al. (Reference Iwamoto, Suzuki and Kasagi2002) with Reτ = 300; Moser et al. (Reference Moser, Kim and Mansour1999) with Reτ = 395; and Lee & Moser (Reference Lee and Moser2015) with Reτ = 550.

As demonstrated in figure 7, the 3D-PTV measurements of mean velocity at the three Reτ agree with the distributions established using DNS and the law of the wall. Rather remarkable is the spatial resolution at which these measurements can be attained. For the lowest velocity case of Reτ = 307, the spacing of data points along y+ is 0.4λ and the velocity measurements are obtained for y+ as low as 2 (~60 μm from the wall). The spatial resolution of the velocity measurements with respect to inner scaling decreases with increasing Reτ. For Reτ = 511, the spatial resolution is 0.7λ and a minimum y+ of 4 (~60 μm from the wall). The closest data point to the wall is limited by the size of the tracer particles and glare spots that formed due to a reflection of the laser sheet from imperfections on the surface (small scratches and particles stuck to the wall). As shown in figure 7, there is no observable noise in the velocity distributions obtained from 3D-PTV based on STB.

The 3D-PTV measurements of the Reynolds stress profiles are compared with those of DNS in figure 8. The results from 3D-PTV and DNS agree well with one another, although there are some minor deviations. The maximum discrepancy in the peak streamwise Reynolds stress, ![]() ${\langle {u^2}\rangle ^ + }$, shown in figure 8(a), is approximately

${\langle {u^2}\rangle ^ + }$, shown in figure 8(a), is approximately ![]() $0.4u_\tau ^2$. The maximum deviation in the y+ location of the peak in