Published online by Cambridge University Press: 07 October 2005

Conceptual design produces a number of functions the designed product is to fulfill, several solution principles (means) for each function, and multiple overall principle solutions (concepts). Besides concept synthesis, it is important to determine the (few) early solution properties that are of interest at the concept stage. Further activities are assessing the consequences of the chosen means and their instantiation, the effects of changes, and how decisions affect other elements. Using a quantitative functional representation can facilitate these tasks, but a balance is needed between product-dependent tools predicting many detailed properties, and product-independent, generally applicable tools with limited prediction capabilities. A balance between a closed, general set of predefined building blocks and extensibility by modeling application-specific, individual elements is also necessary. In this paper, a generally applicable conceptual design model is presented, which has been established by theoretical reasoning applied to a number of products. These products were the subjects of previous company-ordered student projects. The resulting information model spans continuously from requirements to concepts and permits modeling desired functionality (functions), achieved functionality (means and their value choices), and explicit constraints (internal and external relations between parameters of requirements, functions and means). To indicate the suitability in principle, the model has been implemented in an interactive, incremental prototype for computer support that permits modeling, storage, and reuse in a database. It can be concluded that the model permits explicit modeling of complex relations, automatic change propagation, and handling of many concept alternatives. Integrated, bidirectional, and continuous connections from requirements to concepts facilitate conceptual design, reuse, documentation of the results, and allow changes to be made and their effects assessed easily. Incremental constraint networks are approved, for example, in configuration design or geometry modelers, and the significance of this article is to enable their use also for quantitative analysis of incomplete, evolving concepts in original design tasks allowing different principle solutions, and for various products of mechanical design.

Computer-aided functional modeling has been a concern for researchers since the 1970s (see Kuttig, 1993, sect. 2, for four references from 1971 to 1974). Graphical function modeling, made possible by progress in computer technology, is used in Kuttig (1993), where an example of computer-based functional modeling for conceptual design with a rich model of flow-based function structures is described. The transition from a functional description (which is suitable during conceptual design) to parametric models (which are suitable for embodiment design) has been identified as an important research question. This problem is stated and addressed, for example, in Yekula et al. (2003), where a method for the construction of parametric models from functional models is presented. Even the research behind this article aims at integrating functional models and synthesis based on these functions with parametric analysis models. The use of constraints to couple different partial models of several engineering domains in embodiment design is described in Kleiner et al. (2003), and the feasibility of such a constraint interlinking approach is shown. Previous research on the topic has also suggested the use of function/means trees (F/M trees) in a combination with constraint networks in order to support interactive conceptual design (O'Sullivan, 2002a, 2002b). The use of the expert system shell CLIPS and F/M trees to produce concepts (schemes) and simulation models from library elements by linking them in bond graphs is described in Bracewell and Sharpe (1996), but relies on the existence of a closed set of building blocks from which concepts can be combined and uses calculation mainly in later phases in the form of detailed Dymola simulation models. Support using an incremental constraint network, with a focus on structural modeling, is described together with the SyDeR tool in Feldkamp et al. (1998). Constraint networks, spanning continuously from requirements to the product structure, are used in the function oriented product model that can be found in Leemhuis et al. (2002). The two latter systems do not focus on a detailed model for multiple concepts and solution principles.

The objective of the work described in this paper is to use incremental constraint networks to quantitatively model evolving, incomplete concepts during conceptual design. This is combined with a hierarchical F/M tree (see Hansen, 1995) for the qualitative aspects. Functions are entities used to describe a general and intended relation between their input and output parameters with the aim of fulfilling a task (Pahl et al., 2003), and thus express necessary functionality. Means state how (by which solution principles) this functionality actually is achieved. The main focus is on early calculations involving relations on the few parameters that are of conceptual significance, rather than on the deduction of more complete models suitable for detailed calculations in later phases. The quantities that can be used in calculations are not limited to energy quantities, but can be any parameter (e.g., weight, cost, transmission ratio, etc.). The artificial intelligence (AI) technology of constraint networks is not an object of research in this work; it is merely applied to achieve the actual contribution: a model, working procedure, and tool constituting more suitable support for the early phases of engineering design. The tool can be used to support solving complex engineering problems. By allowing both qualitative (e.g., textual descriptions, relations such as “function is solved by means” or “means needs specific subfunctions”) and quantitative contents (e.g., parameters such as the size of the solution element “electric motor”), traditional design methodology, AI techniques, and numerical analysis can be combined.

In this article, functional representations are thus used to do the following:

This section describes insights from design methodology related to conceptual design and their implications regarding the intended support.

According to design methodology (e.g., VDI, 1997; Pahl et al., 2003), the steps carried out during conceptual design are identification of an overall function, decomposition into a number of subfunctions and a search for solution principles. Solution principles are identified for all functions, according to VDI (1997) with regard to both effects and shapes (see Fig. 1). The figure shows the steps in conceptual design (shown as rectangles), the databases that can provide appropriate input information during the steps (cylinders), and the results of the respective steps (parallelograms). The arrows on the right indicate that iterations back to earlier steps are possible; the arrows on the left show that requirements both affect and can be affected by all steps.

The conceptual design and access to knowledge bases. Adapted from VDI (1997, fig. 3).

Conceptual design thus progresses from requirements to functions, from functions to their subfunctions, and from subfunctions to solution principles (means), which then, after sufficient decomposition, are combined to form overall principle solutions (concepts). This concept synthesis is achieved by combining several effects or mechanisms into an overall principle solution (cf. the arrow from “effects”/“kinematic mechanisms” and “3.1”/“3.2” to “principle solutions” in Fig. 1). The focus in this article is on steps 2.1–3.1.

The aim of this work is to provide a model for conceptual design, constituting a partial model for concept development in a larger product model. At present, sophisticated models and support are available for both earlier and later stages, that is, requirement handling and embodiment design [e.g., geometry modeling using commercial computer-aided design (CAD) modelers]. At the transition between conceptual design and early embodiment design, work has also been done on engineering design synthesis, for example, the tool for compositional synthesis of mechanisms FuncSION described in Chakrabarti (2002, chap. 11). On the other hand, apart from some academic or special-purpose systems, no software support is available for innovative conceptual design. In addition, many systems that might be used for conceptual design (e.g., computerized design catalogs as outlined in Birkhofer and Keutgen, 1999, and Franke et al., 2004, Tech Optimizer as assessed in Lindemann et al., 1998, etc.) are powerful when providing solutions, but neither allow the instantiation of suggested solutions, that is, adaptation to the actual task at hand, nor support the continuous synthesis of the suggested solutions into an overall solution inside the system.

Another purpose of this work is to enable a tool that allows explorative, creative conceptual design even when carried out with computer support. Using software to assist with operations such as maintaining information for added means, selecting/deselecting means in concepts, choosing values, and evaluating how the chosen values affect requirements, the time and effort needed to perform routine tasks can be reduced, while the designer can simultaneously carry out creative steps.

One aim of such computer-supported conceptual design is to be able to handle and compare multiple concept variants, which is suggested by design methodology (Pahl et al., 2003, sect. 2.2.4). Using computer support, more alternatives can be evaluated in a given time, and quantitative support permits the degree of requirement fulfilment of several concepts to be assessed. Reaching better-verified concepts is facilitated by performing early calculations on a number of parameters that are of conceptual significance.

Furthermore, a well-defined model and functional representation are prerequisites for meaningful reuse, which can yield additional time benefits.

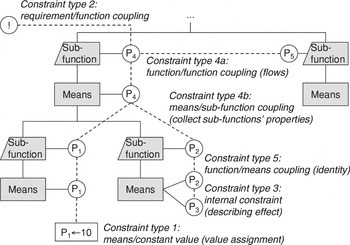

The basic approach to accomplishing support for conceptual design is to apply the well-known F/M tree for qualitative modeling and combine it with constraint networks for quantitative modeling. An overview of the used elements is given in Figure 2 (for a more detailed description of the elements, see Section 3). The functional decomposition is modeled using a hierarchy of functions (cf. 3.2) and means (cf. 3.3). Parameters (e.g., L and Pi), accounting for the quantitative description, can be assigned to both functions and means. Requirements (cf. 3.1), grouped in dimensioning cases (cf. 3.7), are assigned to the relevant parameters. Relations between parameters are modeled using constraints, shown as dashed lines (cf. 3.5). Operating states (cf. 3.7) can be used to group several functions that are active only for certain time periods or under certain conditions. Concepts are obtained by selecting one means for each function (cf. 3.6). For clarity, only two of the “is contained in” relations between concepts and means are shown (as dotted lines) in Figure 2.

The elements and relations of the support for conceptual design.

The support is also suitable for innovative original design problems, which require a broad variety of alternative means. Both analysis and synthesis steps can be supported. The support is suitable for problems that are possible to characterize by parameters and algebraic constraints between them, that is, static calculations. Tightly coupled systems or dynamic calculations, which, for example, occur in many mechatronic systems, are not efficiently supported unless they can be simplified into static calculations.

By introducing means, modeling using solution elements and reuse of earlier realized, well-proven solutions is made possible.

Several requirements with regard to support software, which have been identified in prior research, are also relevant to the present work. Kuttig (1993) mentions the high information turnover in conceptual design, and that a tool therefore must provide abstract visualizations. Shifting between different types of information (e.g. text, geometry, formulae or structure) and several methods for modeling are required. According to Feldkamp et al. (1998), there should be no restriction to a fixed set of components, as technical progress requires extensibility. A graphical editor and a simple user interface that can be used by all engineers are needed. Reuse of larger elements (over and above simple components) should be possible. The working procedure should be interactive and allow structural decomposition into smaller, more manageable subproblems. It must be possible to iterate steps and revoke earlier decisions. In Leemhuis et al. (2002), mentioned requirements are that the tool should reduce costs, accelerate design, allow modularization and reuse, and that it covers all phases from requirements to part modeling. Domain-independent applicability to many products and an incremental, iterative procedure are required. A clear description of interrelations between requirements, function and structure, handling of and free choice between alternative variants, handling of incomplete and inconsistent specifications, and the availability of abstract views of early designs are named as issues. Even here, possibilities to revoke decisions and an arbitrary order of steps are called for, as well as change propagation, decomposition and reuse. In Bracewell and Sharpe (1996), the automatic deduction of exact simulation models using bond graphs is a requirement that was fulfilled, at the cost of functions needing to be standardized and limited to a predefined library.

In this work, the main requirement is to provide a tool for innovative concept synthesis that will enable to both work with principle solution elements and early calculations. The model must be continuous (i.e., relations are possible in several steps from requirements to concepts) and bidirectional (i.e., qualitative and quantitative descriptions are coupled and updated in both directions). Qualitative and quantitative descriptions are integrated: changes in means modeling are, for example, reflected by adding or removing constraints and changed values are reflected by updating properties of means or requirements. The model is separated into partial models, that is, one piece of information is only stored at one location to facilitate modularity and exchangeability. Additional requirements that are of concern are to offer methods for flexible work with solution principles in alternative concepts, reuse of solution principles (not only components), explicit storage of principle variants as concepts, and work with incomplete and inconsistent data at any stage. Another requirement is that the model must be generally applicable to a broad range of products. Functions, means, and parameter types are not limited to a predefined closed set, but can be extended individually.

To achieve an efficient tool, the design of the tool and the working procedures when using it must harmonize with the users' mental models. To be suitable for conceptual design, the working procedure was therefore chosen to be largely interactive and incremental. The individual steps can be performed in arbitrary order (the only deliberately chosen restriction is that means cannot be added prior to the function they are to fulfill). The major steps in the procedure involve the following:

These major steps outline an iterative procedure from requirements to quantitatively verified concepts. Inside the major steps, there is a succession of specifying, solving, changing (including change propagation), and assessing operations. It is possible to create, modify, and assess several variants during each step. The major advantage compared to traditional configuration design operating on parts is that even different principle solutions can be modeled by introducing functions and means.

Regarding the envisaged use of the tool by an engineer, it can be stated that the system is intended to constitute an assisting system. The aim is not to provide an automatic system that would allow the synthesis of complete solutions solely from a specified list of requirements. In Table 1, the supported steps and the actions performed manually by the designer as well as the actions automatically performed by the tool are given.

Interplay of the tool and the designer using it

The tool is thus based on the assumption that the computer is used to assist by automating routine tasks, such as constraint propagation or activation/deactivation of subfunctions, depending on the chosen means. The complex decision steps (e.g., identification of suitable interelement constraints) are not automated but carried out by the designer, although there are opportunities for further automated steps (e.g., automatic combination and evaluation as outlined in Wilhelms & Derelöv, 2004).

This section describes the information model used to formalize conceptual design. Figure 3 shows how the chosen model objects in the lower part correspond with the phases and phenomena described in VDI (1997) in the upper part, which was chosen as background theory. The models for requirements, functions, means, and concepts have been built as partial models without intersections, that is, a concept description contains no functional description; it merely references the functions it includes.

The structure of the information model elements, interconnecting constraint network, and correspondence to VDI 2221.

The constraint network can connect all occurring objects from requirements to concepts. The dotted objects on the right-hand side are not yet implemented in the prototype implementation, but are shown to illustrate that even parametric geometry models can be connected in a similar way.

The Unified Modeling Language class diagram in Figure 4 gives a more detailed overview of the information model. The figure contains the classes for modeling the F/M tree (Function and Means), parameters and constraints (Parameter/Variable; ConstraintNetwork; Constraint; FormulaParser, which calculates numerical values during constraint propagation; and MapleConnect, a link to the commercial symbolic math software Maple, which is used to solve equations for the necessary variable), concepts (Concept representing one overall principle solution, Realization representing one means choice, and Assignment representing one value choice), grouping of functions and requirements (OperatingState, DimensioningCase), and the possibility to store justifications [Truth Maintenance System (TMS), Justification, Node]. All the objects belonging to the actual design task are stored in a Document object.

The information model as Unified Modeling Language class diagram.

Even though the implementation of the justification-based TMS (Doyle, 1979) permits a more extensive use, the TMS is currently only utilized for storing and managing justification objects. A justification object is automatically created or updated for each constraint that is added or modified, with the justifications carrying information about the reason why the constraint exists. For an equality constraint, reasons could involve, for example, a reference to the physical law behind the equation or the way a structure is arranged (e.g., serial or parallel architecture resulting in an identity or a sum constraint for a fluid flow rate). For a value assignment, the justification contains the reason why the specific value was chosen, for example, a reference to empirical data for a coefficient of friction. Reasons are stored in the form of textual information with semantic value only to the designer. So far, there is no active use of the TMS exceeding this recording of justifications. The tool could, however, be extended to apply justification objects to resolve inconsistencies with conflicting constraints by dependency directed backtracking in a similar fashion as described in Feldkamp et al. (1998, sect. 7).

Requirement objects describe functional requirements or restricting requirements. Functional requirements are assigned to a function's parameter, in this way declaring the function responsible to deliver the required flow, for example, to create a certain output torque. Restricting requirements limit a parameter value, for example, the largest possible motor size given by the available space, into which the mounted motor must fit.

The requirement contains a value for the desired value, and the design model (function) provides a value for the actual value the design in its current state delivers. In this way, requirement fulfilment can be checked.

Requirements of different types (exact value, interval) and strengths (desire, requirement) can be modeled (Pahl et al., 2003, chap. 5).

As widely recognized (Kuttig, 1993; VDI, 1993; Leemhuis et al., 2002; Pahl et al., 2003), functional modeling is an essential part of conceptual design and is a prerequisite for modularization, varying the solution principle using more abstract function information and reuse. The functional representations used here are both a hierarchic decomposition and a flow-based function structure. Functions express purposes of the artefact by stating desired or required behavior.

According to VDI (1993), a function is the relationship between the input and output flows and the state variables of a system, described independently of a particular solution. The quantitative representation here uses a function object with connected flows. Each flow, either input flow, output flow, or internal parameter, is represented by a parameter object connected to the function. A textual description of the function by verb and noun is also possible. The qualitative representation is achieved by assigning a set of means capable of fulfilling each function to it.

A means is here used to model one way of achieving functionality. Means also have assigned parameters, and internal constraints are used to quantitatively describe the effect on which a means is based (e.g., the relation of input and output torque for a pair of gears).

As different means may require different subfunctions, means can contain links to specific subfunctions, that is, subfunctions that are only active when the means is selected into the current concept.

The basic idea is that using a division into functions and means, only those parameters can be modeled that are of conceptual importance for the actual task. As not all of the properties of means that might be modeled are equally important, the parameters that were chosen when modeling the functions determine which of the means' parameters are exposed to the environment, a selective approach similar to Langlotz (2000, pp. 90–91).

Parts are objects that serve as placeholders for externally modeled geometry, for example, in CAD systems. Even here, parameters such as geometric dimensions can be connected to the constraint network.

Constraints are applied to model quantitative relations to enable early calculations. As in Leemhuis et al. (2002), constraints span across different partial models from requirements to concepts and geometry. Five different types of constraints are used to interconnect the elements (see Fig. 5).

The constraint types available in the tool for modeling relations.

Value assignments (constraint type 1) are used to assign a definitive value to a parameter. These value assignments are concept specific; the same means can thus have different parameter values when they occur in different concepts. Constraint type 2 connects requirements and function parameters. Internal constraints (type 3) are used to describe the physical effects a means is based upon. External constraints model flow between different functions (type 4a) or collect properties from a means' subfunctions (type 4b). All these constraints are added manually and subsequently activated or deactivated automatically, depending on the chosen means. In contrast, constraints of type 5 are set automatically and model the identity of a corresponding function and means parameter.

Leemhuis et al. (2002) state the need to explicitly document concepts, and they note that available commercial software offers no satisfactory support for concept modeling. For this reason, concepts are a central part of the information model presented here.

A concept is an object that encapsulates a number of means choices and a number of value choices. In this way, concepts can be used for a parametric description of an overall principle solution to the design task.

The constraint network is used to describe relations between parameters. To facilitate modeling of products that are more complex, compound objects can be constructed by grouping several objects, which then can be treated as a single entity. An example of this is to group several functions into operating states or several requirements into dimensioning cases (cf. Fig. 2). When doing so, a whole group of requirements can be activated or deactivated by simply changing the dimensioning case under consideration.

To implement the information model described in Section 3 and to verify its suitability in principle, a software prototype has been implemented as an engineering application of constraint networks for computer-supported conceptual design.

According to Kuttig (1993), computer-aided functional modeling involves a product model; methods for modeling, analyzing, selecting and evaluating; design databases; and communication with the designer. In this section, the product model, a computer-internal representation of the information model presented earlier, is described in terms of these aspects.

The general architecture of the prototype is shown in Figure 6. The product model of the conceptual design modeler is realized as an object-oriented C++ document-object model in primary memory. It is visualized using the Microsoft Foundation Class library. Persistent storage of models is made possible through serialization, and independently of this, a design library in the form of a relational database enables storage of means for reuse. The product model can be exported into and imported from an XML document, and views of the product model can be saved as bitmap or vector graphics.

The architecture of the prototype.

The applied constraint solver is DeltaBlue (Freeman–Benson et al., 1990), an incremental constraint solver well suited for working with incomplete, possibly contradictory concepts. Constraints are entered in symbolic, implicit form (e.g., a = b + c), and external commercial symbolic algebra software is used to solve the necessary explicit forms of the equation for each variable (e.g., solve for b = a − c).

The constraint network is used to model the quantitative relations between parameters. Different strengths are used to model constraints. The strength “required” is applied to link a requirement variable to a function variable, for definitive user-made value assignments, user-defined formula constraints, and automatically set identity constraints between corresponding parameters of function and the selected means. The strength “preferred” is applied for facultative user-made value assignments. “Weak default” is used to set initial values. The structural, qualitative relations in the model, for example, that a number of means belong to a specific function, are realized using pointers between objects.

The C++ objects described offer a number of manipulation methods for the product model. All objects offer the usual adding/removing/accessing member routines for their child objects, for example, accessing the means belonging to a function.

In addition, concept objects (cf. Fig. 4) offer a more complex event handler that is called when a concept is to be activated or deactivated upon user request (functions OnActivate() and OnDeactivate() in class CConcept). This routine will activate or deactivate the necessary means (by forwarding the call to Select/Deselect() in the CMeans class) and set or remove the necessary identity constraints between corresponding function and means parameters (using Create/DestroyConnectionConstraints() in the CRealization class). When a subfunction during this operation is deactivated, the external constraints of the function are moved to a list of inactive constraints and removed from the constraint network. Upon reactivation, these constraints are restored from the list and written back to the constraint network. When a means is deactivated, its current parameter values are stored in a list for future reference when it is reactivated (using Save/RestoreParameterValues() in class CRealization). In this way, even parameter values that have no definitive value assignment are preserved. Furthermore, all means and subfunctions below the actual function are recursively activated or deactivated.

Hirtz et al. (2002, appendix A) provide a taxonomy for functions and flows. Flows are divided into categories such as liquid flow, effort flow, or pneumatic air flow caused by pressure. The design library in the present work is based on similar thoughts, but for constraint networks to be applicable, the flows are expressed by a set of standardized parameters. For this purpose, the 24 IQ quantities from Roth (1994, fig. 5.2) were chosen as parameter types (see Table 2).

IQ quantities

Roth (1994) defined IQ quantities as the physical quantities that determine power (denoted as intensity, “I”) or amount (quantity, “Q”). IQ quantities are used as functional parameters that define the physical facts of the task, that is, constitute parameters describing input and output of the desired functions. The desired relation of IQ-quantities on a function's input and output is thereafter actually achieved by choosing suitable design parameters, defined as a realized design solution's physical quantities that describe the direct relation between its IQ quantities. For a desired function “Convert force to linear movement”, with input IQ-quantity force (F) and output IQ-quantity displacement (s), the principle solution “linear material elasticity” could be chosen, with the material stiffness (c) as the design parameter that connects force and displacement, giving rise to the internal constraint F = c · s.

For this notation and the case that one of the 24 IQ quantities is converted to another, a matrix of physical effects known to perform these conversions is available in Roth (1994, sect. 5.5.2), and VDI (1997, sect. 4.2.2; see Fig. 7). Effect is hereby defined as physical, chemical, or biological law, relation or phenomenon with which a desired function can be performed. The effects in the matrix constitute an initial basis for the design library. The IQ quantities are intended for use when connecting functions' input and output flows, but do not constitute a complete set that is able to express all necessary parameters. For internal parameters describing the design quantities, additional types may be used by adding user-specific types, for example, the transmission ratio for a gearbox.

The functional parameter matrix (above) and excerpt of the solution database for field 1.2 converting force to displacement (below).

The design library is structured as a relational database with seven tables (see Fig. 8).

The database schema as Unified Modeling Language class diagram.

Storage to the database is performed by issuing a “store in database for reuse” command on a means after it has been modeled in the graphical environment. When processing the command, the modeled functions and means will be entered into the database together with their parameters. Internal constraints and external constraints within the scope of reuse (i.e., from means to subfunctions and between subfunctions) will be added to the database. Identifiers and pointers will be translated to the database keys. The chosen method of data collection thus corresponds to online knowledge capturing as described by Jensen (1999, p. 192), but with the advantage that the stored models conserve their functionality (constraints continue to operate even in reused models) and also allow reasoning to some extent (even if directly creative steps are not supported).

Upon later reuse, which is initiated by issuing a “search means” command on a function, a search for suitable means will be specified using the input and output flows of that desired function. For a function “multiply torque,” a search could, for example, be specified by stating that the desired function has a torque both as its input and its output; a free text search for the word “torque” could also be specified. This query is entered interactively in a dialog box and then automatically translated to the Structured Query Language (SQL) statement shown in Figure 9. The resulting means are then presented to the designer as a list of suggestions. The corresponding F/M tree segment that includes the assigned constraints can be opened and viewed for each suggestion.

The generated SQL statement querying the design library.

As already stated, functional modeling and computer supported conceptual design have been a research concern for a long time. As pointed out in Kuttig (1993), because of the progress in technical development, the provided computer support evolved from alphanumeric, difficult to handle systems to more suitable interactive modeling with graphical user interfaces. This prototype also uses abstract graphical views to let the designer interact with the underlying product model.

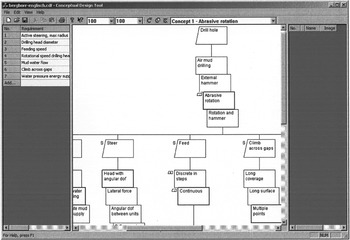

The user interface was implemented using a splitter window, divided horizontally into three areas. In the section on the left (see Fig. 10, left, which shows the example described in more detail in Section 5), requirements are listed with desired and actual values. The section to the right gives access to a list of suggestions for reuse from the design library. In the middle section, one of several views can be chosen to visualize and modify the product model. At present, two views are available: a flow-based function structure view (see Fig. 10) and a hierarchical F/M tree view (see Fig. 11). The function structure view contains functions and the flows interconnecting them. The functions and constraints are drawn automatically, whereas the designer is free to place the functions at the desired positions. The F/M tree view is rendered fully automatically. In this view, drag and drop operations are used to move functions and means. When moved in this way, the model relations are updated accordingly, for example, that a means receives another function as its parent function. Both views provide access to the methods of the individual functions or means using a context menu with different menu entries depending on the actual object (e.g., reuse only for functions).

A screen layout of the prototype with requirements (left) and function structure view activated (middle).

A screen layout with function/means tree view activated (middle).

Concepts can be generated flexibly by double clicking on means in the tree view; the selected means will then be displayed with a red border. If means have specific subfunctions (i.e., subfunctions that are only active for a particular means), then the tree will be redrawn to show these subfunctions. With the combo-box element in the toolbox at the top, the designer can easily change between a set of alternative concepts. Here, too, the tree will be redrawn to reflect the selections of another concept.

If the constraint network is affected by any of the operations, it will be updated. As means are selected or deselected, internal constraints will thus be activated or deactivated and identity constraints be set or removed. Value assignments will be set or removed depending on the chosen concept. Requirement fulfilment is checked by comparing required value (stored in the requirement) and achieved value (provided by the function in the design) and will be displayed using a color code (green for fulfilled requirements/wishes, yellow for violated wishes, or red for violated requirements). During all steps, constraint propagation will be performed to forward any changes.

Requirements and parameters are displayed as lines in grid controls (cf. Fig. 10, left). For parameters, values can simply be changed by entering a new value, which will then be kept as a weak default (and may change until the designer chooses to constrain it with a definitive value assignment). Even here, color coding is used: values that are determined by other constraints and are not editable are displayed in grey. Fulfilled constraints are shown in green, violated ones in red.

As an example, a water hydraulic rock drill was modeled in the prototype. This design example was taken from a live, company-ordered design project (Adolfsson et al., 2002), which was previously carried out by fourth-year mechanical engineering students and supervised by the author. The conceptual design task was to redesign an existing drill, so that it supported the reactive force and torque from drilling inside the drilled hole instead of outside. Several principle solution alternatives were suggested by the students in their project work, in which they used a traditional F/M tree and separate paper-based calculations. This design project has been used both for developing the presented information model and tool, suitable for the needs discovered during the project, and for providing an application example.

Using the prototype described in this article, an F/M tree with integrated early calculations was modeled for the drill example. The F/M tree, as it is automatically rendered by the prototype, is shown in Figure 12. The letter S to the left of a function indicates that the function in question is a specific subfunction, that is, it is active only as long as the means that it belongs to (indicated by a minus sign inside a small function symbol) remains selected (indicated by a thick border; red on screen display) and is part of the current concept. Functions without an S are active independent of the chosen means (i.e., are common to all means).

A function/means tree of a rock drill rendered by the prototype.

The functions of the F/M tree are interconnected by flows, each of which is represented by an external constraint (type 4a). Parameters in the model are uniquely identified by their function name, followed by a dot and the parameter name, for example, “Supply water.Q” for parameter Q representing the output flow in function “Supply water” or “Drill.M” denoting the output torque M of function “Drill”. The constraints are then entered using the text strings given below. Figure 13 shows the type 4a constraints for the first decomposition level related to water flow and rotation. These constraints express the balance of input volume flows (Supply water.Q = Remove mud.Q + Drill by rotation.Qin + Feed.Q) and output volume flows (Carry off water.Q = Remove mud.Qout + Feed.Qout + Drill by rotation.Qout) and that connected functions have the same parameter values regarding torque and penetration speed (Drill by rotation.M = Support reactive torque.M, Drill by rotation.v = Feed.v).

A function structure with interlinking flows (each represented by one external constraint).

An important issue that can be covered is the concurrent development of hierarchical function structures and the F/M tree. The functions “Drill by rotation” and “Feed” are for example decomposed into four subfunctions each in the F/M tree (cf. Fig. 12). The same subfunctions can be found in the function structure, located inside the boxes of the two parent functions. In Figure 14, these subfunctions are shown, and detailed by giving their constraints:

A snapshot of the function structure in the prototype.

In Figure 14, the corresponding screenshot of the prototype is given. It shows how an underdefined function structure (the functions “Steer,” “Feed continuously,” or “Climb across gaps” have not yet been quantified) already can be used for quantitative modeling in some parts (in function “Drill by rotation”). Functions are shown as rectangles with input flows on their left edge, output flows on their right edge, and internal parameters at the bottom. The number left to the function name indicates the function's level of decomposition in the F/M tree. Connecting lines represent the constraints.

The function structure is automatically rendered from the F/M tree and constraint network information. The designer is free to move the functions from their initial positions at wish, and, if applicable, subfunctions will be moved together with their parent functions. Upon changes in the F/M tree, the function structure will be updated, for example, by automatically replacing the subfunctions if a means with different specific subfunctions is chosen. The connecting lines representing the constraints are drawn by the prototype automatically.

Internal constraints (type 3) describe how the chosen means achieve the interconnection of input and output parameters. Internal constraints are, for example, F = μ · FN for the means “friction” or p = F/A for “cylinder.” For the means “Rotating abrasive diamond bit” associated with function “Drill,” internal constraints indicate the following:

Value assignment constraints (type 1) are used to set values of variables, for example, the necessary feeding force or weight on bit (F = 30 kN, steered by the drilling head data), the estimated friction coefficient (μ = 0.2) or the recommended rotations per cm of the drilling head (n/v = 80 cm−1).

Requirement constraints (type 2) are used to relate requirements (e.g., the necessary rate of penetration of v = 3 m/min) to the corresponding function parameter (Drill.v), which allows actual values to propagate to the requirement and enables to check the requirement fulfilment by comparing actual and required value. By these constraints, the connection between requirements and design parameters is achieved. In a similar way, the other requirements on rotational speed (n), diameter (D), flow (Q), steering radius (R), gap length (L), and water pressure (p) are connected to Drill.n, Drill.D, Remove mud.Q, Steer.R, Climb across gaps.L, and Provide normal force.p.

Identity constraints (type 5) are set automatically as soon as concepts are created by choosing means. These constraints bind the corresponding parameters of function and means, for example, “Create drilling normal force.F = Cylinder.F,” and in this way connect the two separate networks of external and internal constraints.

The rock drill proved to be an example of a design task that is well suited for support using the described methods and tool. Using this model, easy conceptual decisions can be modeled and assessed, for example, which consequences a different drilling head requiring other water flows or speeds has for the other functions. However, it can also be seen that conceptual modeling quickly become extremely complex when different solution principles are involved, and a restriction is therefore necessary on few parameters to avoid that concept modeling requires more effort than it saves.

This article presents a way of supporting conceptual design with regard to both concept synthesis and quantitative verification of concepts using a hierarchical F/M tree decomposition and integrated constraint networks. This work extends previous research on computer-supported conceptual design and the use of constraint networks from other researchers (Feldkamp et al., 1998; Leemhuis et al., 2002; O'Sullivan, 2002b).

The original contribution of the underlying research in this project is to provide an information model for conceptual design that permits parametric, constraint-based modeling of concept synthesis from solution elements that are based on solution principles, not only on components, subassemblies or parts. Specifically, in this article, the original contribution is a method for using a database to store previous principle solution elements for future reuse, where the separation from the old context and the insertion into a new context is achieved by a division into external constraints (type 4a, not reused, except for subfunctions) and internal constraints (type 3, reused) and the use of special identity constraints between corresponding function and means parameters (type 5) that are easy to remove and reinsert. A whole tree segment including subfunctions and parametric model can in this way be detached, stored and reused, and in this way, reuse of larger principle solution elements is made possible in a more flexible manner, and the library becomes extensible. The basic ideas behind the prototype and a relational database with SQL statements implementing the mentioned reuse are also described.

The presented information model and the tool incorporating it constitute an aid for supporting a discursive procedure for obtaining verified quantitative concepts. In this way, support of early conceptual design, taking into account different principle variants and alternative concepts, is made accessible to computer support, and more concepts can be evaluated and verified in the same time. Concept synthesis and early calculations are integrated, and bidirectional propagation in change operations is provided.

The tool supports incremental work, where all elements such as means or concepts can be added and modified at any time. The elements do not have to be fully defined from the beginning and can be individual, that is, also not predefined. Parameters, constraints, and value assignments can likewise be flexibly added, changed, or removed at any time to enable an incremental, interactive and explorative way of working, which is believed to be suitable for conceptual design.

During development of the tool, several realistic design problems from prior company-ordered student projects in a fourth-year mechanical engineering master's course (Engineering Design–Product Development) have been used, and the model was designed to be able to express them. The suitability of the model has thus been shown by theoretic reasoning and self-observation while modeling the examples. The practical applicability has not yet been further verified in setup empirical tests on any realistically sized projects in companies. To reach results beyond trivial observations and not to be too hampered by prototype instabilities, this requires a fairly stable and implemented prototype, which has not been available until recently.

It should also be noted that the supported part of conceptual design, yet doubtlessly important, is only a small part of product design. There are numerous other important activities beyond the scope of this tool, for example, shape design and layout, aesthetic properties, or customer perception that cannot easily be expressed by simple parameters, more complex relations that cannot be expressed by simple algorithmic relations, and so forth.

The conceptual design and access to knowledge bases. Adapted from VDI (1997, fig. 3).

The elements and relations of the support for conceptual design.

Interplay of the tool and the designer using it

The structure of the information model elements, interconnecting constraint network, and correspondence to VDI 2221.

The information model as Unified Modeling Language class diagram.

The constraint types available in the tool for modeling relations.

The architecture of the prototype.

IQ quantities

The functional parameter matrix (above) and excerpt of the solution database for field 1.2 converting force to displacement (below).

The database schema as Unified Modeling Language class diagram.

The generated SQL statement querying the design library.

A screen layout of the prototype with requirements (left) and function structure view activated (middle).

A screen layout with function/means tree view activated (middle).

A function/means tree of a rock drill rendered by the prototype.

A function structure with interlinking flows (each represented by one external constraint).

A snapshot of the function structure in the prototype.