Nomenclature

- CFD

Computational Fluid Dynamics

- CRN

Chemical Reactor Network

- FC

Flameless Combustion

- ITB

Inter-Turbine Burner

- PaSR

Partially Stirred Reactor

- PSR

Perfectly Stirred Reactor

Symbol

- P

Pressure

- RR

Recirculation Ratio

- T

Temperature

- Φ

Global equivalence ratio

Subscripts

- in

Reactants

1.0 INTRODUCTION

The contribution of aviation to the emission of pollutants and greenhouse gases is estimated to increase despite the urgency for reducing emissions. Emissions of CO2 by international aviation were projected to increase by 144% between 2005 and 2025(Reference Macintosh and Wallace1) and the increase in CO2 emissions in China is projected to be 3.9% per year from 2013 till 2030(Reference Zhou, Wang, Yu, Chen and Zhu2). Subsequent to the required reduction in CO2 emissions, emission of minor pollutants such as CO and nitrogen oxides (NOx) also require attention. The photochemical smog and acid rains are caused by NOx, while NO2 is a greenhouse gas formed by the oxidation of NO in the atmosphere(Reference Glarborg, Miller, Ruscic and Klippenstein3). Moreover, non-CO2 pollutants behave differently when emitted at high altitude. For example, NOx contribute to the formation of O3 in the troposphere, a greenhouse gas(Reference Lee, Pitari, Grewe, Gierens, Penner, Petzold, Prather, Schumann, Bais, Berntsen and Iachetti4).

This scenario clearly suggests that innovation is required to keep up with the market growth while attaining the required reductions in emissions. Innovation is possible at many levels, from comprehensive solutions such as new aircraft configurations and alternative energy sources, to substantial improvements in combustion technology. Given the challenging nature of these goals, it is likely that the solution has to involve all levels.

The Flameless Combustion (FC) regime (also known as MILD combustion) has been pointed as a promising combustion technology, as it has the potential to maintain high combustion efficiency while achieving lower NOx emissions. The regime takes place at relatively high reactants’ temperatures and low O2 concentrations and is characterized by highly distributed reaction zones that yield lower peak temperatures and NOx emissions(Reference Perpignan, Rao and Roekaerts5). While FC is successfully applied to industrial furnaces, the challenges pertaining to the attainment of the FC regime in gas turbines were summarized by Perpignan et al.(Reference Perpignan, Rao and Roekaerts5) as: high power/heat density, low overall equivalence ratio, heat transfer characteristics, wide operating envelop and pressure loss requirements.

Conceptual design attempts for FC combustors relied on the recirculation of combustion products, either jet induced or by having large recirculation zones formed due to their geometries. However, the resulting operational ranges were usually narrow. Moreover, emissions posed problems, as CO tended to increase when NOx was at desirable levels and vice versa. Proposing a more comprehensive solution, the Advanced Hybrid Engines for Aircraft Development (AHEAD) project(Reference Yin and Rao6) involved the use of two sequential combustion chambers, having the high-pressure turbine between them (see Fig. 1).

Figure 1. Engine concept with an inter-turbine burner. Courtesy of Pratt and Whitney Rzeszów S.A., Copyright 2014.

The hybrid engine was designed to operate using fuels stored cryogenically in the first combustor and conventional or biofuels in the Inter-Turbine Burner (ITB). Additionally, the concept takes advantage of the presence of cryogenic fuels to cool the bleed air prior to its utilization to cool turbine vanes and blades, reducing the required air mass flows and, therefore, reducing losses. This process is also beneficial due to the preheating of the fuels prior to their entry in the main combustor. Another feature of the engine is the use of a contra-rotating fan, as shown in Fig. 2. As the aircraft was conceptualized as a blended wing body and the engines are positioned at the aft of the fuselage to allow for boundary layer ingestion, the contra-rotating configuration is advantageous because it enables more compact fans and higher propulsive efficiency at a given bypass ratio(Reference Rao, Yin and van Buijtenen7). From a combustion point of view, the configuration with two combustors facilitates the attainment of the FC regime in the second combustor, the ITB. This proposed inter-turbine flameless combustor is studied in the present paper.

Even though the concept looks promising(Reference Yin and Rao8), it has to be further developed as there are many unknowns. The design of an ITB, or any other combustor intending to employ FC, relies on accurate prediction and representation of both fluid dynamics and chemistry. Chemical kinetics is particularly important for the prediction of pollutant emissions since low emissions are the goal of employing FC in the first place.

Figure 2. The hybrid dual-combustor engine. Courtesy of Pratt and Whitney Rzeszów S.A., Copyright 2014.

1.1 Chemical kinetics under the FC regime

Even though there is not yet a consensus on the definition of FC, its beneficial characteristics are well documented. The well-distributed fashion in which reactions take place tends to cause low temperature gradients, low NOx emissions, stable reaction zones and low acoustic oscillations(Reference Li, Stankovic, Overman, Cornwell, Gutmark and Fuchs9). The lower NOx emissions are caused by the more homogeneous reaction zones that abate thermal NOx; by the reduction in the availability of the species involved in NOx formation, especially O2; and due to the effect on the production of NOx through the NNH, N2O-intermediate and prompt formation pathways(Reference Perpignan, Rao and Roekaerts5). However, the ways in which the pathways are influenced under FC and what parameters govern such influence are not yet fully understood.

The use of ideal chemical reactors to model the chemical processes in FC is a powerful tool because it allows the use of detailed chemical reaction mechanisms at relatively low computational costs. Additionally, the assumptions and simplifications of such reactors usually fit well with the distributed reactions conditions linked to FC. Nicolle and Dagaut(Reference Nicolle and Dagaut10) showed interesting results by using partially stirred reactor calculations. The authors pointed to the contribution of the N2O pathway to be as important as that of thermal NOx, as well as the relevant contribution of both NNH and prompt pathways. The occurrence of NO reburning was also relevant. The high recirculation usually present in FC systems increases NO reburning. Since the first studies on FC(Reference Wünning and Wünning11), different chemical mechanisms to take reburning into account have been proposed(Reference Mancini, Schwöppe, Weber and Orsino12,Reference Li, Wang, Mi, Dally, Mei, Zhang and Parente13) .

For conventional gas turbine combustors, the thermal (or Zel’dovich) pathway is constantly pointed as the dominant source, with minor contributions of prompt and N2O-intermediate pathways, the latter for leaner conditions(Reference Correa14,Reference Lefebvre and Ballal15) . The conditions for increased N2O impact were already associated with more distributed conditions (before any mention to FC), as described by Correa(Reference Correa14). However, the formation (and destruction) of NOx can occur through more pathways, as recently reviewed by Glarborg et al.(Reference Glarborg, Miller, Ruscic and Klippenstein3), as the authors added the NNH pathway, NO reburning, as well as the oxidation mechanisms of HCN, HNCO and NH3 (as fuel-NOx subsets), to the thermal, prompt and N2O pathways.

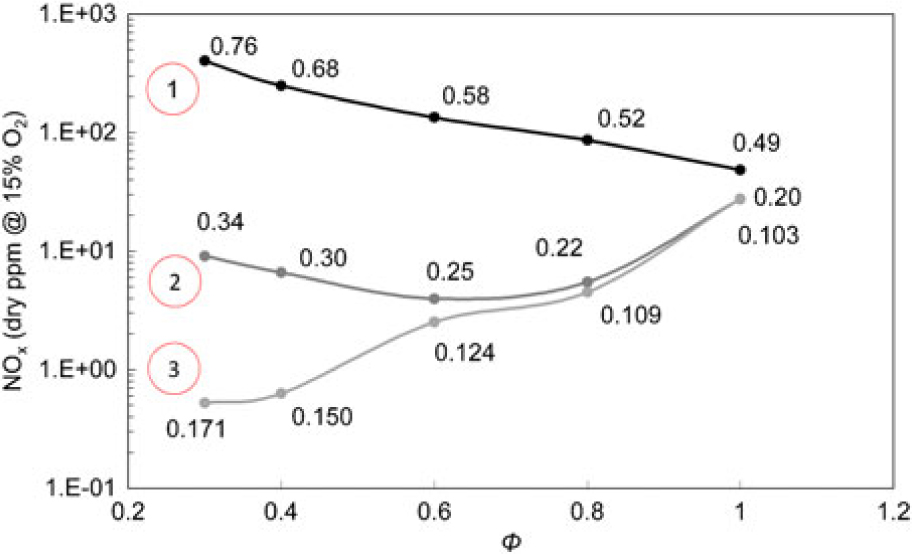

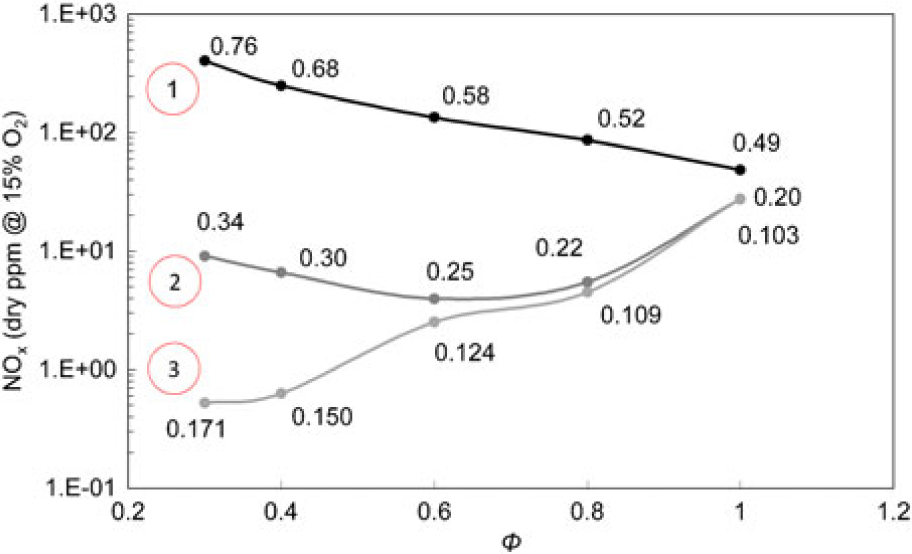

It has been shown that NOx emissions may display a non-monotonic behaviour with increasing equivalence ratio, with the peak being at lean equivalence ratios in systems in which the FC regime is attained via high recirculation of combustion products. It is known that NOx emissions usually peak on the lean side with changing equivalence ratio, but just adjacent to stoichiometry(Reference Rink and Lefebvre16), as the competition between fuel and nitrogen for O2 to oxidize reduces NOx at stoichiometry. The behaviour shown for some FC applications is, however, at values further away from stoichiometry, as shown in Fig. 3.

Figure 3. Measured NOx emissions as a function of equivalence ratio for three different systems with high recirculation: a combustion chamber with jet-induced stabilization(Reference Veríssimo, Rocha and Costa17), an inter-turbine burner(Reference Perpignan, Talboom, Levy and Rao20), and a cyclonic prismatic chamber for two different estimated residence times(Reference Sorrentino, Sabia, de Joannon, Bozza and Ragucci18). The values from Perpignan et al.(Reference Perpignan, Talboom, Levy and Rao20) are shown with respect to the local equivalence ratio, and not the global equivalence ratio, as defined by the authors.

The three systems depicted in Fig. 3 have significant differences between each other. The work of Veríssimo et al.(Reference Veríssimo, Rocha and Costa17) utilized a cylindrical combustion chamber with a jet-based burner, in which the central air jet was surrounded by 16 CH4 jets. The prismatic combustion chamber utilized by Sorrentino et al.(Reference Sorrentino, Sabia, de Joannon, Bozza and Ragucci18) is characterized by a large central recirculation zone and relatively high residence times. Air and C3H8 were added to the chamber via pipes positioned in two opposing corners of the chamber. Lastly, the model combustor based on the design presented by Levy et al.(Reference Levy, Erenburg, Sherbaum and Gaissinski19) (an 18-degree sector aimed at representing the ITB) had some of its experimental data presented by Perpignan et al.(Reference Perpignan, Talboom, Levy and Rao20). It was fuelled by CH4 and the inlet oxidiser could be pure or diluted air. Despite being different, all combustors were aimed at attaining FC and showed a similar NOx emissions behaviour with respect to equivalence ratio.

The authors, however, provided different explanations for this behaviour in each case. Veríssimo et al.(Reference Veríssimo, Rocha and Costa17) pointed to a switch between FC and conventional lean combustion caused by mixing characteristics between the burner jets and the recirculating combustion products. Sorrentino et al.(Reference Sorrentino, Sabia, de Joannon, Bozza and Ragucci18) explained that higher temperatures were attained at the prismatic combustion chamber at higher equivalence ratios, which activated NO reburning. Lastly, supported by results from a chemical reactor network (CRN), Perpignan et al.(Reference Perpignan, Talboom, Levy and Rao20) showed the prominent role of prompt NOx formation in the non-monotonic behaviour.

The use and development of CRNs have been done both in manual(Reference Lebedev, Secundov, Starik, Titova and Schepin21–Reference Park, Nguyen, Joung, Huh and Lee23) and automated forms(Reference Cuoci, Frassoldati, Stagni, Faravelli, Ranzi and Buzzi-Ferraris24–Reference Fichet, Kanniche, Plion and Gicquel26). Both approaches have shown good results with respect to predicting emissions. The development of CRNs requires a degree of knowledge about the flow field in order to divide the domain into areas of similar expected conditions (temperature, concentrations, velocity, and/or fluctuations). This preceding knowledge may come from CFD simulations or experiments.

The present work intends to further investigate the effects of recirculating combustion products, to compare the performance of chemical reaction mechanisms for CH4 combustion, and to understand the effect of T and p on the NOx emissions of the ITB. This is performed by utilizing CRNs and the modelling approach described in Section 2.

1.2 The ITB experimental model

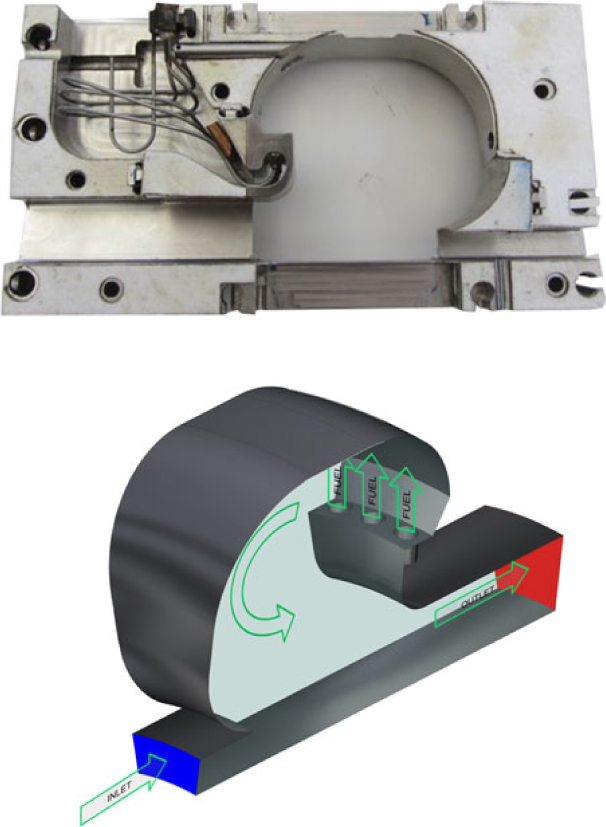

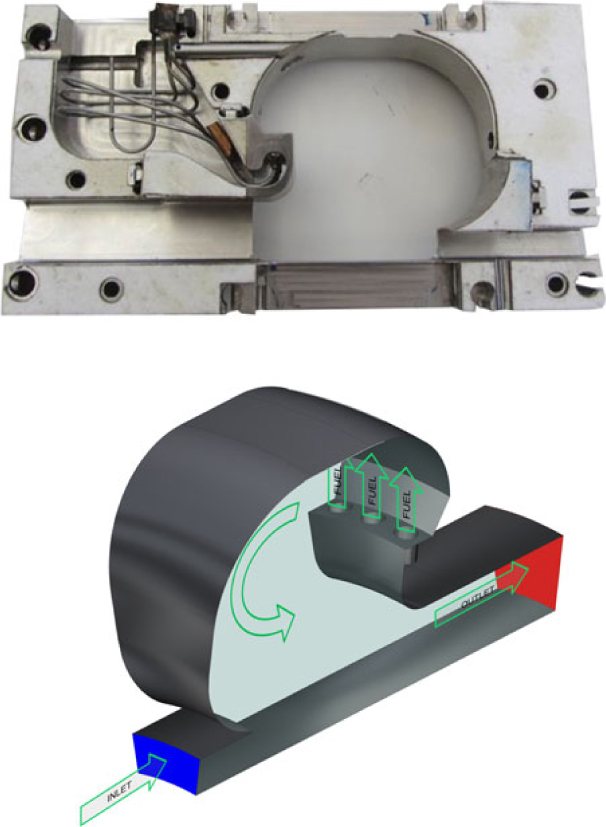

The ITB and the CRN developed to represent its experimental model are the focus of the present paper. The 18-degree sector model was developed to mimic the phenomena expected on the full-scale ITB designed by Levy et al.(Reference Levy, Erenburg, Sherbaum and Gaissinski19) and had three CH4 injectors that entered the chamber along with a coflow of oxidizer (combustion air). Another portion of the oxidizer (dilution air) entered the chamber via a different port (see Fig. 4). Reactions took place in the large recirculation zone. The oxidizer was preheated to 560 K and the experiments were performed at atmospheric pressure.

Figure 4. Schematic of the model combustor employ for experiments(Reference Sorrentino, Sabia, de Joannon, Bozza and Ragucci18). The 18-degree sector contained three fuel ports, which were fed along with oxidizer. The remainder of the oxidizer was fed through the port indicated in blue. The side walls were quartz windows to allow visualisation.

The analysis performed by Perpignan et al.(Reference Perpignan, Talboom, Levy and Rao20) showed that the developed CRN was able to reproduce the experimental results to a good extent and there were significant differences between the two chemical reaction mechanisms employed (GRI 2.11 and GRI 3.0). The reasons for such differences were not entirely clear, although there was evidence that the prompt NO chemistry was responsible.

The development of the ITB concept, and of FC in general, is highly dependent on the computational tools’ ability to accurately predict pollutant emissions since the design is aimed at taking advantage of the vitiated oxidiser to reduce emissions. Therefore, assessing and understanding the performance of chemical reaction mechanisms is of great importance. Moreover, the understanding regarding the NOx emissions in systems with high recirculation intended to operate under the FC regime is still limited.

2.0 NUMERICAL SIMULATIONS

In order to understand the effects of recirculating combustion products on NOx emissions, as well as the effects of different chemical reaction mechanism and operating conditions, numerical simulations were carried out. The CRN simulations were comprised of two different approaches. Firstly, a simple CRN was developed to systematically evaluate the effect of recirculation, equivalence ratio and residence times on NOx emissions behaviour. Secondly, the CRN of the ITB (developed by Perpignan et al.(Reference Perpignan, Talboom, Levy and Rao20)) was used to evaluate the chemical reaction mechanisms and operating conditions relevant for the ITB application and development. All simulations were performed using Cantera(Reference Goodwin, Moffat and Speth27), an open-source computational tool focused on chemical kinetics.

The CRN approach allows the use of detailed chemical reaction mechanisms. The current work explored five different mechanisms for CH4 combustion: GRI 2.11(Reference Bowman, Hanson, Davidson, Gardiner, Lissianski, Smith, Golden, Frenklach and Goldenberg28), GRI 3.0(Reference Smith, Golden, Frenklach, Moriarty, Eiteneer, Goldenberg, Bowman, Hanson, Song, Gardiner, Lissianski and Qin29), Konnov(Reference Konnov30), GDF-Kin® 3.0 NCN(Reference Pillier, Desgroux, Lefort, Gasnot, Pauwels and Da Costa31) and POLIMI C1C3HT(Reference Ranzi, Frassoldati, Grana, Cuoci, Faravelli, Kelley and Law32).

The Gas Research Institute (GRI) mechanisms(Reference Bowman, Hanson, Davidson, Gardiner, Lissianski, Smith, Golden, Frenklach and Goldenberg28,Reference Smith, Golden, Frenklach, Moriarty, Eiteneer, Goldenberg, Bowman, Hanson, Song, Gardiner, Lissianski and Qin29) were developed with an aim of representing methane and natural gas flames and their ignition. The GRI 2.11 is comprised of 49 species and 277 reactions. The GRI 3.0 comprises 53 species and 325 reactions and has been optimized for conditions between 1,000 and 2,500 K, 1.333ṁ103 to 1.013ṡ106 Pa, and equivalence ratios from 0.1 to 5 in premixed systems.

The Konnov mechanism(Reference Konnov30) was developed to model the combustion of H2, CO, CH2O, CH3OH, CH4 and C2-C3 hydrocarbons(Reference Konnov33). The mechanism comprises 129 species and 1,231 reactions. The original mechanism underwent modifications related to the prompt NO pathway: instead of the HCN route, the NCN route was implemented. The same route is present in the GDF-Kin® 3.0 NCN mechanism(Reference Pillier, Desgroux, Lefort, Gasnot, Pauwels and Da Costa31), as the authors compared the performance of the mechanism with both routes. Intended to simulate natural gas combustion, the mechanism is composed of 119 species and 883 reactions.

Lastly, the POLIMI C1C3HT(Reference Ranzi, Frassoldati, Grana, Cuoci, Faravelli, Kelley and Law32) was developed to simulate the combustion and pyrolysis of hydrocarbons with up to 3 carbon atoms. Its development was mostly based on flame speed data for several species (H2 and H2/CO mixtures, small and large hydrocarbons, alcohols and hydrocarbon mixtures). The prompt NOx HCN route is adopted in the mechanism. The mechanism contains 115 species and 2,141 reactions.

In order to quantify the contributions of each formation pathway, the CRN was also run with deactivated reactions. The deactivated reactions for each pathway in each chemical reaction mechanism are shown in the Appendix.

2.1 Four-reactor CRN

As discussed in Section 1.1, the recirculation of combustion products employed to attain the FC regime is one of the main factors involved in the reduction of NOx. However, its effects are not fully understood, and to elaborate on the involved phenomena, a simple CRN composed of four PSRs was developed to showcase the effect of recirculation and equivalence ratio on NOx emissions (Fig. 5). Moreover, the simple model enables the discussion of some of the results attained with the ITB model. The names of the PSRs in Fig. 5 are merely representative of the expected function each PSR is expected to have in the simulations. The combustor PSR was assigned with 75% of the total volume, while the mixer, outlet and recirculation PSRs had 15, 6 and 4%, respectively. Different total volumes were assigned in order to assess the effect of residence time. Heat losses were included since they are present in virtually every experimental investigation related to FC (including the works from Fig. 3). Losses play an important role in NOx formation under FC, especially due to their effect on the thermal pathway. All simulations of this CRN were performed using the GRI 3.0 mechanism.

Figure 5. Scheme of the CRN designed to investigate the effect of recirculation of products in the behaviour of NOx emissions

Different values of Φ were tested. The total amount of mass flow was kept constant, causing both air and fuel mass flows to be different for each value of Φ. The amount of recirculation was quantified by the recirculation ratio (RR), shown in Equation (1)

$$ RR = {\dot{m}_{recirc} \over \dot{m}_{air}+\dot{m}_{fuel}}$$

$$ RR = {\dot{m}_{recirc} \over \dot{m}_{air}+\dot{m}_{fuel}}$$

2.2 Four-reactor CRN results and limitations

The four-reactor CRN results are shown first in order to discuss some general aspects of systems with high recirculation and the difficulties in modelling emissions in such systems. Examining the effect of recirculation, an increase in RR for the same value of Tin and Φ may increase or decrease NOx. Additionally, the influence of RR on the absolute values of NOx is quite low for the settings used in Fig. 6. The differences caused by RR are less than 1 ppm.

Figure 6. NOx emissions as a function of RR for the four-reactor CRN. Four different Φ. Mean residence time = 0.12 s. Tin = 600 K.

Nevertheless, analysing the results in Fig. 6, it is possible to notice that recirculation of products has two competing effects: on one hand, the composition of the products tends to reduce reaction rates of the incoming reactants; on the other hand, the products have high temperatures, which tends to increase reaction rates. This explains why for leaner cases, higher RR tends to increase NOx, as combustion products contain larger amounts of O2 and N2 available for the oxidation.

The sub-ppm changes in NOx emissions with changing RR in this CRN model can be explained by the large relative size of the combustor reactor and the very assumption underlying a PSR, namely perfect and instantaneous mixing. The large volume of the reactor causes most of the reactions to take place in that reactor. Therefore, the temperature rise occurs in it and adding combustion products has little influence in heating up the incoming reactants.

In a simple model as the present CRN, residence times play an even more central role. The simulations were performed maintaining the total mass flow constant. However, as the temperature increase is lower for leaner cases, these had higher residence times due to lower density. The plot in Fig. 7 shows how the NOx emissions behave with Φ for three different volume settings. For residence times varying from 0.49 to 0.76 s across the values of Φ(case 1 in Fig. 7), lower Φ causes higher NOx. On the other hand, when the values vary from 0.103 to 0.171 s (case 3 in Fig. 7), NOx increases with Φ. This is explained by two effects: (i) the increasing NOx due to longer time available for reactions to proceed and (ii) the increasing NOx due to reactants being exposed to higher temperatures. The case varying from 0.20 to 0.34 s (case 2) has a non-monotonic trend, indicating the shift between these two effects.

Figure 7. NOx emissions as a function of Φ for the four-reactor CRN. Three different reactor volume settings. Values of residence time shown in seconds for each data-point. Tin = 600 K. RR = 0.2.

The overall NOx behaviour is complex and is dependent on the temperatures attained in the reactors, residence time, and recirculation ratio. Understanding the complexity and how the parameters involved act aids the analysis of the ITB CRN.

2.3 The inter-turbine burner CRN

The CRN employed for the ITB simulations was developed and employed by Perpignan et al.(Reference Perpignan, Talboom, Levy and Rao20). The regions assigned to each reactor were based on the results of CFD calculations, like velocity, temperature and species concentrations fields, were taken into account to divide the domain. The resulting CRN had 11 PSRs, as shown in Fig. 8.

Figure 8. The CRN developed by Perpignan et al.(Reference Perpignan, Talboom, Levy and Rao20). Each region of the combustor was represented by a PSR. Arrows indicate the presence of mass exchange between reactors or reservoirs.

The recirculation inside the ITB was one of the most important factors to reproduce experimental data. The mass flows between the reactors were estimated based on the CFD simulations. Heat losses were assigned to each reactor based on the available temperature measurements and on the temperature attained inside the reactor.

3. RESULTS AND DISCUSSION

The results regarding the ITB are discussed in this section. A comparison between the different chemical reaction mechanisms is drawn in Section 3.1. The subsequent sections discuss the results of different reactants temperature (Section 3.2) and operating pressure (Section 3.3).

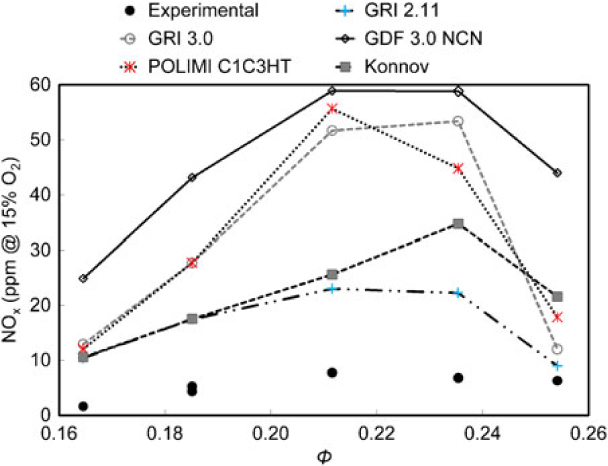

3.1 Chemical reaction mechanisms

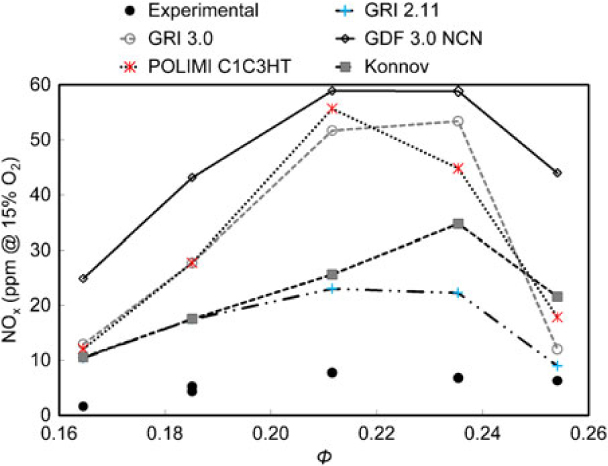

Comparing the various available chemical reaction mechanisms is important in order to understand as to how they differ in their performance and to check the dependency of the resulting emission trend on the mechanism. The results of Fig. 9 show that all mechanisms are able to predict the non-monotonic trend while overpredicting the emissions of the ITB. The reason for the overprediction appears to be the prompt NOx formation, which plays an important role according to all chemical reaction mechanisms. Apparently, the results are independent of the NCN pathway for prompt formation (instead of HCN), as it is nowadays known to be the way reactions proceed(Reference Glarborg, Miller, Ruscic and Klippenstein3). The POLIMI and both GRI mechanisms (2.11 and 3.0) consider prompt NOx via the HCN route, while the other two mechanisms employ the NCN route.

Previous studies have shown that the relative importance of the NNH and N2O-intermediate pathways increases under FC(Reference Galletti, Ferrarotti, Parente and Tognotti34). However, the contribution of prompt NOx is responsible for the difference between the mechanisms in this case. Table 1 shows that the overprediction shown in Fig. 9 is correlated with the mean contribution of prompt NOx.

Figure 9. NOx emissions as a function of global equivalence ratio for various chemical reaction mechanisms.

Table 1 Results for the different chemical reaction mechanisms across the investigated equivalence ratios with respect to prompt NOx contribution and deviation from experiments

The results suggest that there is a systematic overprediction of prompt NOx. It is unclear whether this is universal for every system with recirculation of combustion products. However, further studies should be focused on prompt NOx chemistry in order to clarify if reaction rates should be lower when vitiated conditions are attained, or if reactions progress through different routes.

3.2 Effect of reactants temperature on the ITB

The investigation for higher temperatures and pressures was conducted using the GRI 2.11 mechanism, due to its better performance when compared to experiments. These conditions were investigated to achieve settings closer to those expected in the dual-combustor engine(Reference Yin and Rao6).

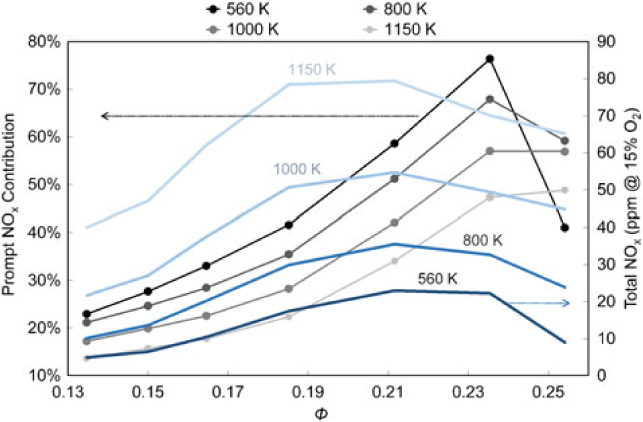

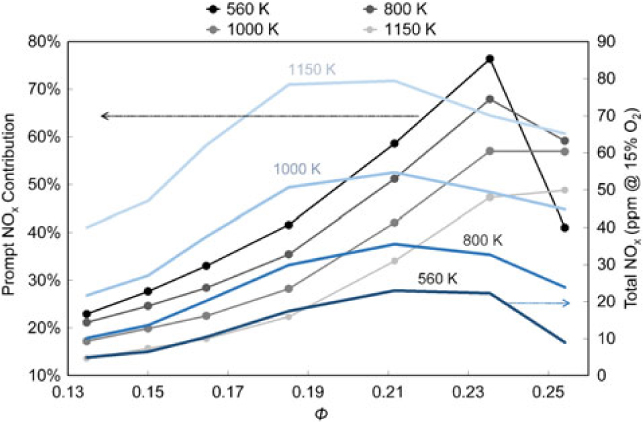

Increasing temperatures cause the overall contribution of prompt NOx to decrease, as thermal NOx tends to increase its contribution (Fig. 10). Moreover, the role of prompt NOx in causing the non-monotonic behaviour is no longer important for higher inlet temperatures. Instead, the NNH pathway becomes the most important driver.

Figure 10. Total NOx emissions and relative prompt NOx contribution as functions of global equivalence ratio for various Tin.

The overall trend of NOx emissions is maintained with increasing temperatures. However, the higher the Tin, the leaner is the NOx peak located. This is partially explained by the effect of residence time, in a similar fashion of that shown in Section 2.2. As the power input is maintained for every case, higher Tin causes lower residence times due to the decrease in density. This shows that the volume of the ITB (for a given design) can be optimized for a given inlet temperature. In turn, Tin is determined by the power setting, the energy fraction between the main combustor and the ITB and the high-pressure turbine pressure ratio.

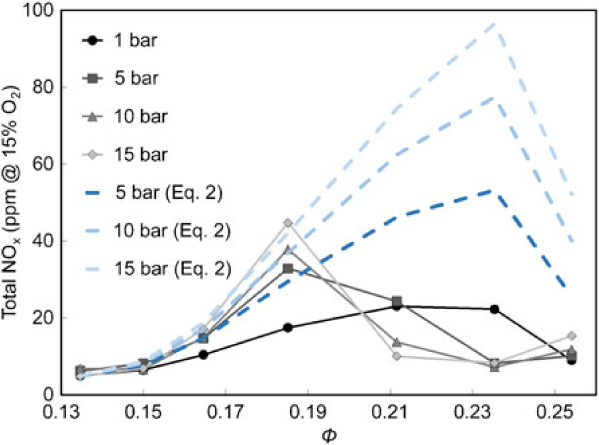

3.3 Effect of operating pressure on the ITB

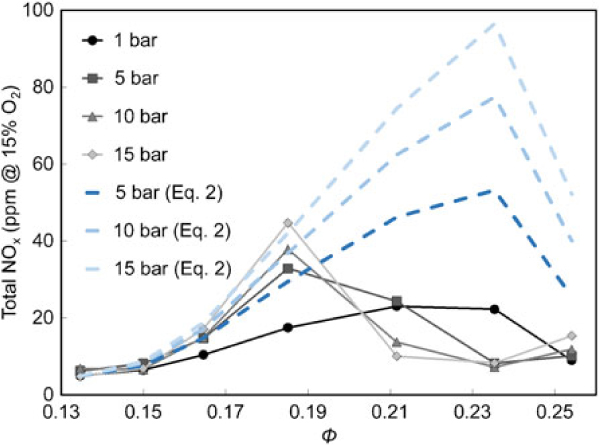

For conventional combustors, the scaling of NOx has been reported to follow the expression of Equation (2). The exponent n usually has a value between 0.5 and 0.8 for values closer to stoichiometry(Reference Lefebvre and Ballal15), while leaner equivalence ratios are not usually affected by p, having n equal to 0(Reference Correa14). For the comparison carried out in Fig. 11, the value of n was assumed to be 0 at the leanest condition and it was increased linearly up to 0.65 for the richest case.

Figure 11. NOx emissions as a function of global equivalence ratio for various operational pressure values of the ITB CRN. Dashed lines represent the values obtained when considering the correlation of Equation (2).

The effect of pressure on NOx emissions is more complex than that of temperature, as shown in Fig. 11. The leaner portion of the investigated Φ behaves similarly to conventional combustors: higher pressures increase NOx emissions as in Equation (2). The increase is caused by the increase in residence times at higher p, similarly to the effect described in Section 2.2. At Φ ≈ 0.21, NOx emissions drop below the value attained at 1 bar.

Perpignan et al.(Reference Perpignan, Talboom, Levy and Rao20) showed that at this point, thermal NOx starts decreasing (for p = 1 bar) while reburning and prompt increase, with the former becoming dominant along with the NNH pathway. The reduction of the thermal pathway (caused by the favourable conditions for reburning) and the increase in reburning still occurs for higher p. However, the prompt NOx contribution is lower, a known effect of increasing p (Reference Correa14,Reference Biagioli and Güthe35) . Additionally, the NNH pathway has lower production than at p = 1 bar. Subsequently, NOx emissions increase at the richer condition due to an increase in the thermal and N2O-intermediate pathways, indicating that the higher temperatures attained at higher Φ play a more important role for the overall NOx formation.

The results suggest that experimental data on emissions at high pressures for systems intended to operate under the FC are necessary. Given the reported importance of prompt NOx as a contributor at atmospheric pressures, the design of an ITB may take advantage of its suppression at higher pressures.

3.4 Overall comments

The non-monotonic NOx emission curves with lean Φ shown in Fig. 3 were explained differently by their authors. Given the complexity of the phenomena involved, as shown in the current analysis, it may be the case that the results are truly caused by different reasons.

In view of the influence of residence time shown in Fig. 7, the results of Sorrentino et al.(Reference Sorrentino, Sabia, de Joannon, Bozza and Ragucci18) may be a consequence of a similar phenomenon. As temperatures were higher for higher Φ, residence times tended to be lower due to the reduction in density, justifying the lower NOx emissions. This effect is not likely to be the most prominent for the cases of Veríssimo et al.(Reference Veríssimo, Rocha and Costa17) and Perpignan et al.(Reference Perpignan, Talboom, Levy and Rao20), since leaner conditions had higher mass flows as fuel input was maintained. A more likely explanation is related to the alteration of prompt NOx and the effect of RR, similarly to what is shown in Fig. 6. Due to the different mass flows and heat release characteristics, the amount and composition of recirculated gases is different for each Φ. Nonetheless, it is also important to take local phenomena into account, as changes in mixing patterns and heat losses have the potential to greatly influence the progress of chemistry.

4.0 CONCLUSIONS

The development of new combustion technologies aimed at reducing pollutant emissions is highly dependent on the capability of computational tools to predict emissions. The current paper examines the trends in NOx emissions of an ITB intended to be operated under the FC regime. The analysis was performed by means of CRNs, and the effects of different chemical reaction mechanisms, reactants temperature, operating pressure, and recirculation ratio were shown.

The conclusions of the analysis are summarized as follows:

1. The overall behaviour of NOx emissions in systems with high recirculation ratios is complex and is dependent on several factors as reactants temperature, heat losses, amount of recirculation, and residence time.

2. The presence of combustion products and recirculation increase the relative importance of the prompt and NNH pathways, as well as NO reburning. The contribution of thermal NOx tends to decrease with RR.

3. All investigated chemical reaction mechanisms resulted in overprediction of NOx and in dominance of the prompt pathway. Prompt NOx contribution was proportional to the overprediction, indicating that the reaction subset and its reaction rates for vitiated conditions may require revisions.

4. The role of prompt NOx was shown to be prominent in the ITB experiments at atmospheric pressure and relatively low reactants temperature.

5. Increasing reactants’ temperature did not alter the behaviour of NOx with Φ. The overall emissions increased with increasing Tin and the NOx peak moved to lower Φ due to lower residence times for higher temperatures.

6. The increase in operational pressure had complex effects on the behaviour of emissions with Φ. Leaner conditions had behaviour similar to that of conventional combustors (increase in NOx). However, NOx dropped with further increase in Φ due to the suppression of prompt NOx production and due to the presence of reburning.

7. Given that all simulations herein presented were performed with CRNs, it is advisable to conduct experiments and simulations taking into account the fluid dynamics and turbulence effects in order to confirm the findings shown herein.

The consequences of the results discussed in this paper for the design of an ITB or any design intended to apply FC to aeronautical gas turbines are:

1. A successful ITB design should take advantage of the particularities of NOx formation in lean conditions, optimizing emissions by altering residence times, operating pressure, and volume.

2. Classical correlations for the effect of pressure on the NOx emissions of gas turbine combustors should not be employed for combustors with high recirculation rates.

3. The split of oxidiser between primary and dilution zones has more complex consequences in combustors with high recirculation than in conventional combustors. Besides influencing the amount of recirculation, the split also influences the chemistry of pollutant species.

4. The presence of extra degrees of freedom (energy split between primary and secondary combustors, and the design parameters of the ITB), as well as the existence of local minima in the pollutant emissions, makes the design of a dual-combustor system challenging but promising.

ACKNOWLEDGEMENTS

The authors would like to thank National Counsel of Technological and Scientific Development – Brazil (CNPq) for the financial support. The authors would also like to thank Prof. Yeshayhaou Levy from Technion (Israel Institute of Technology) for sharing the details of the experiments carried out within the AHEAD project.

APPENDIX

The table below shows the deactivated reaction for each chemical reaction mechanism employed for each reaction pathway. The overall guideline was to deactivate the least amount of reactions, prioritizing initiation reactions in order to impose less disturbance to the remainder of the mechanism. The error was estimated by summing the NOx emissions obtained with each set of deactivated reactions and comparing the obtained value to that of the full mechanism.