Introduction

Archaeological and archaeometric data indicate that up to the early ninth century ce there was no local primary production of glass in the Iberian Peninsula. Only secondary glass working and the recycling of glass are well documented. During the fifth to eighth centuries ce, glazed ceramics are entirely absent from the archaeological record in Iberia, suggesting that there was no manufacture of glass or glazes before the Arab conquest. We recently identified clear evidence for the earliest local primary production of glass among the glass finds in Córdoba, dating to between the second half of the eighth century to the first quarter of the ninth century ce. This glass has a peculiarly high lead composition not encountered anywhere else. During the 870s, lead-glazed ceramics appear in al-Andalus too. Intriguingly, these early lead-glazed wares are compositionally related to the glass of Shaqunda (Salinas & Pradell, Reference Salinas and Pradell2018; Schibille et al., Reference Schibille, De Juan, Casal and Guerrot2020). These recent results have raised doubts about the theory which contends that glazing technology was introduced through a connection with other Islamic territories; rather, they suggest an autochthonous innovation and a transfer to glazes within al-Andalus.

Archaeological and historical evidence

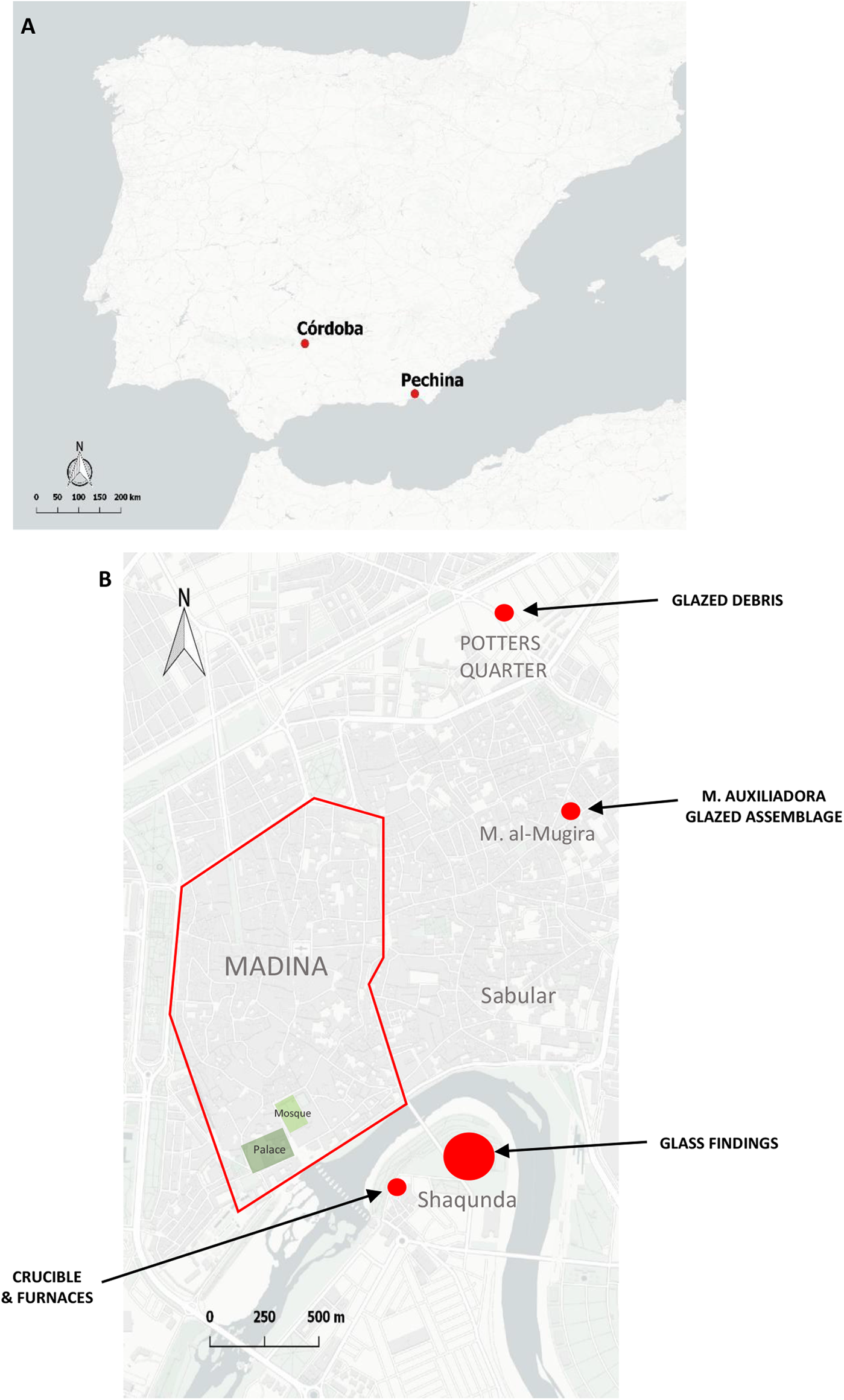

As elsewhere in the Mediterranean, the glass supply in the Iberian Peninsula during antiquity and the early Middle Ages relied exclusively on the import of glass from the primary production centres on the Levantine coast and Egypt (De Juan & Schibille, Reference De Juan Ares and Schibille2017). At the beginning of the eighth century, natron glass from the eastern Mediterranean no longer arrived in large quantities in Iberia, leading to increased recycling practices, reflected in an accidental contamination by colouring and opacifying agents (Freestone, Reference Freestone2015; De Juan et al., Reference De Juan, Vigil-Escalera, Cáceres and Schibille2019). Recycling of glass cullet was common practice since Roman times, but increased dramatically in the seventh and eighth centuries in the Iberian Peninsula, as well as in Italy (Mirti et al., Reference Mirti, Lepora and Saguì2000; Mirti et al., Reference Mirti, Davit, Gulmini and Saguì2001). The first evidence of an Iberian primary production of raw glass with a chemical composition different from Roman and Late Antique glass groups comes from the Rabad of Shaqunda (Schibille et al., Reference Schibille, De Juan, Casal and Guerrot2020), the largest Islamic suburb of Córdoba of the early Emirate (c. 750–818 ce) (Figure 1) (Casal, Reference Casal, Callegarin and Panzram2018). The most striking characteristic of approximately a quarter of the glass finds is that they contain lead and silica as their main constituents, which clearly distinguishes them from earlier soda-lime-silica glass as well as from Islamic plant-ash glass from the eastern Mediterranean (e.g. Henderson et al., Reference Henderson, Chenery, Faber and Kröger2016; Phelps et al., Reference Phelps, Freestone, Gorin-Rosen and Gratuze2016). Several structures, furnaces, lead fragments, and a vessel interpreted as a crucible, which supposedly belong to a glass workshop (Piñero et al., Reference Piñero, Navas and Salinas2009) (see Figure 1), have been found at the Rabad of Shaqunda at Córdoba, although they have not yet been analysed.

Figure 1. (A) Location of the Andalusi sites studied. (B) Map of Madinat Qurtuba (Córdoba), during the Emirate period, with location of relevant archaeological sites.

Arabic written sources also allude to a local Córdoban invention of glass roughly around the time the site of Shaqunda was occupied. Ibn Ḥayyān, for instance, describes the invention of a method ‘to produce glass from mineral/stones’ (الحجارة) by Abbās Ibn Firnās (810?–887 ce; Ibn Ḥayyān, Reference Ibn Ḥayyān, Makkī and Corriente2001: 137). The same author attributes the introduction of the use of fine glass tableware instead of gold and silver at the court of the emir ‘Abd al-Raḥmān II (822-852 ce) to the famous singer Ziryāb from Bagdad (Ibn Ḥayyān, Reference Ibn Ḥayyān, Makkī and Corriente2001: 206).

Lead glazes were first produced in Anatolia during the first century bce. From there, the technology was adopted throughout the Roman and Byzantine worlds (De Benedetto et al., Reference De Benedetto, Acquafredda, Masieri, Quarta, Sabbatini and Zambonin2004; Waksman et al., Reference Waksman, Bouquillon, Cantin and Katona2008) and continued into the medieval Islamic culture of the eighth century in Syria and Egypt (Tite, Reference Tite2008; Watson, Reference Watson2014) and later in ninth-century Iraq (Wood et al., Reference Wood, Doherty and Rosser-Owen2009), where the previous Sassanid tradition involved alkali glaze technology (Mason & Tite, Reference Mason and Tite1997; Paynter, Reference Paynter2001).

The production of lead glazes involved the application of a suspension of either a lead oxide by itself, or a mixture of a lead oxide and silica in the Roman period (De Benedetto et al., Reference De Benedetto, Acquafredda, Masieri, Quarta, Sabbatini and Zambonin2004) and Byzantine era (Waksman et al., Reference Waksman, Bouquillon, Cantin and Katona2008). Contrary to alkali-lime glazes, lead glazes did not require previous fritting. In fact, the simplicity of the preparation and application was a main advantage of lead over alkali-lime glazes (Tite et al., Reference Tite, Freestone, Mason, Molera, Vendrell-Saz and Wood1998).

Although lead glazes continued to be produced in some European regions during the early medieval period, in particular in Italy (the so-called vetrina pesante), glazed ceramics disappeared completely in Iberia during the Visigothic period (476–711 ce) (e.g. Caballero et al., Reference Caballero, Retuerce and Mateos2003). The alleged existence of a pre-Islamic production of ‘thick glazed ceramics’ in the seventh and eighth centuries (Alba & Gutiérrez, Reference Alba Calzado, Gutiérrez Lloret, Bernal and Ribera2008) has since been refuted, and the ceramics have been recognized as crucibles for secondary glass production. At Pechina (Figure 1), the production of lead-glazed ware has long been regarded as the earliest evidence in al-Andalus after the disappearance of the Roman glazing tradition. This early pottery workshop has been dated to the second half of the ninth century (Castillo & Martínez, Reference Castillo, Martínez and Cuello1993). The analysis of the structures and debris found there has provided valuable information about the materials and procedures used in the production of lead glazes. According to the chaîne opératoire, the Pechina potters first produced a lead glass, which was then crushed and applied over the biscuit-fired ceramics and fired to produce a continuous glaze (Salinas et al., Reference Salinas, Pradell and Molera2018). This procedure has no parallels in earlier Roman and Byzantine or contemporary Islamic technology.

Pechina is not the only lead glaze workshop identified in al-Andalus in the Umayyad Emirate. Evidence of local lead glaze production has also been found in Córdoba and Málaga, with characteristic ceramic and glaze compositions (Salinas & Pradell, Reference Salinas and Pradell2020). Furthermore, an early consumption of lead-glazed wares has been identified in some urban settlements; in particular, the lead glaze assemblage excavated in the eastern area of Córdoba at María Auxiliadora Street (Cánovas, Reference Cánovas2006; see Figure 1 for location), together with numerous parallels in other ninth-century archaeological sites in Córdoba (Fuertes & Hidalgo, Reference Fuertes, Hidalgo, Caballero, Retuerce and Mateos2003; Salinas, Reference Salinas2013), have been analysed (Salinas & Pradell, Reference Salinas and Pradell2018). The chemical composition of the glazes shows a striking similarity to the lead glass from Shaqunda (Schibille et al., Reference Schibille, De Juan, Casal and Guerrot2020).

The Córdoba glaze workshop was only recently located when a collection of lead-glazed ceramic wasters was found in the north-eastern part of the potters’ quarter of the city (Zumbacón) (see Figure 1 for location). These discoveries have not yet been analysed; their study will prove particularly important as they may represent the missing link between lead glass and lead glaze production in the Iberian Peninsula.

Glass and glaze

The first local glass production in Córdoba (at Shaqunda) dates to c. 750–818 ce, while the earliest glaze workshop found in Córdoba (at Zumbacón) dates to the second half of the ninth century, indicating that the Shaqunda lead glass predates the first production of lead-glazed ware in Córdoba. Furthermore, their compositional similarities suggest a technological transfer from glassmaking to the manufacture of glazes in al-Andalus.

The origins of high-lead glass are at present unclear. The first objects may be dated back to the Chinese Han dynasty (202 bce–220 ce), when glass and glazed eye-beads of strikingly similar composition were produced, suggesting a link between the productions (Brill, Reference Brill1999; Wood, Reference Wood2001; Henderson et al., Reference Henderson, An and Ma2018). High-lead glasses are quite rare further west (Brill, Reference Brill1999; Krueger, Reference Krueger2014; Pollak, Reference Pollak, Wolf and de Pury-Gysel2017). Examples in the eastern Islamic world typically date from the ninth to the twelfth centuries, thus somewhat later than the lead glass recovered from Córdoba (Oliver, Reference Oliver1961; Carboni & Whitehouse, Reference Carboni and Whitehouse2001). These eastern Islamic high-lead glasses are overwhelmingly of a deep emerald green colour, and associated with deep-cut examples or with the emerald green upper layers of elaborately cut cameo vessels, the high lead content of the emerald green glass facilitating the cutting (Carboni & Whitehouse, Reference Carboni and Whitehouse2001). Lead glass has also been used for undecorated and mould-blown vessels (Shindo, Reference Shindo and Kawatoki2007; Krueger, Reference Krueger2014; Wypyski, Reference Wypyski2015; Pollak, Reference Pollak, Wolf and de Pury-Gysel2017). It is likely that the high-lead family of glasses evolved from some closely related technology, such as ceramic glazing, glass or metal enamelling, or the manufacture of imitation gems (Carboni & Whitehouse, Reference Carboni and Whitehouse2001).

The objective of this study is therefore two-fold: on the one hand, to ascertain the singularity and originality of the earliest Córdoba glass production and its connection with the production of glazed ware in Córdoba; and, on the other hand, to establish whether the technological transfer from glass to glaze can be verified. For this, glass fragments from domestic, manufacturing, and commercial contexts in Shaqunda and a crucible found in the glass workshop of Shaqunda are studied. Finally, a collection of glazed wasters from the Córdoba glaze workshop at Zumbacón together with the glazed wares from a Córdoba suburb (María Auxiliadora Street) are analysed and compared to the Córdoba glass.

Archaeological Context

The Córdoba suburb and workshop of Shaqunda

The suburb of Shaqunda is located on the south bank of the Guadalquivir river, opposite the Madina, the centre of political and religious power. Its construction began during the period of the independent Emirate of al-Andalus, established by the Umayyad emir ‘Abd al-Raḥmān I in 756 ce. The conservation of a large sector containing archaeological structures and artefacts in this quarter has made it possible to propose an early urban model of the Emirate period. The houses are arranged next to the various areas destined for commercial, productive/artisanal, and storage purposes (Casal, Reference Casal, Callegarin and Panzram2018; Piñero et al., Reference Piñero, Navas and Salinas2009). The study of the pottery, coins, and dietary habits of the population demonstrates an Islamized and Arabized society. Since it was razed to the ground by the emir al-Ḥakam I, Shaqunda was occupied over a short and precise time span (c. 750–818 ce).

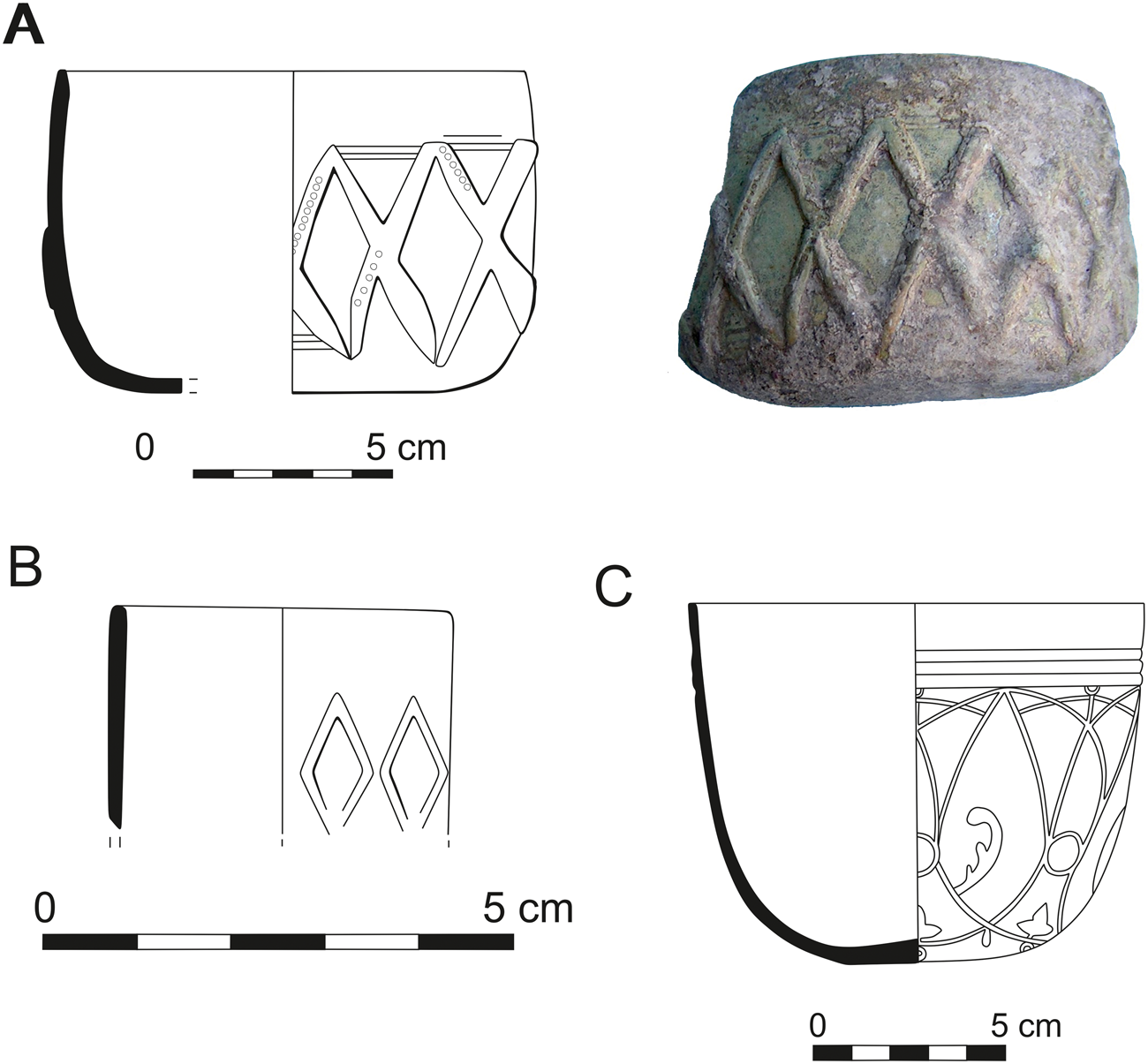

A number of glass objects and domestic pottery were recovered from the core of the suburb (Casal et al., Reference Casal, Castro, López and Salinas2005). The glass finds consist partly of recycled material, some plant-ash glass imported from the Islamic East, and about one third of the assemblage is a high-lead glass (Schibille et al., Reference Schibille, De Juan, Casal and Guerrot2020). The lead glass group is composed of fifteen glass vessels, including small bottles or ointment containers, some beakers and bowls (Figure 2), and one glass bracelet. The only decorations are glass threads applied to the surface of some fragments. Some edges are roughly worked, possibly related to the low viscosity and high density (weight) of lead glass that made it difficult to blow and work. All the pottery recovered from Shaqunda is unglazed and mostly related to domestic uses, such as cooking ware, tableware, lamps, as well as large storage jars. The pottery repertoire combines both pre-Islamic and Islamic traditions, while the decoration is very simple and limited to painted daubs, incisions, and impressions (Casal et al., Reference Casal, Castro, López and Salinas2005). No imported ceramics have been recovered.

Figure 2. Shaqunda lead glass assemblage. Drawing reproduced from Schibille et al., Reference Schibille, De Juan, Casal and Guerrot2020.

In the western area of the suburb, close to the cemetery, there was a structure identified as a glass workshop, which presumably belonged to a large artisanal area. The workshop comprises several rooms and three furnaces (Figure 3), two of which (2 and 3) were attributed to a first phase, while furnace no. 1 is associated with a second phase. The furnaces are structurally different: furnace no. 2 is circular, furnace no. 3, although badly preserved, was rectangular, and furnace no. 1 is semi-quadrangular with an annexed circular structure where the crucible was supposedly placed. The furnaces are made of bricks and pebbles and show evidence of having been exposed to fire. It was the presence of a crucible with a greenish vitreous layer and some irregular lead fragments that led the archaeologists to interpret this building as a glass workshop (Piñero et al., Reference Piñero, Navas and Salinas2009), although no glass waste was found. This lack of glass waste can be explained by the fact that the workshop was not abandoned but moved to another place.

Figure 3. Shaqunda glass workshop. Furnaces 1 and 2 show the characteristic round shape. The small size and shape of the furnaces are consistent with their use in the production of secondary glass. Scale on images: 1 metre.

The Córdoba Pottery Quarter

The main quarter for pottery production in Córdoba during the Islamic period was located in the north-east of the city, outside the walls (Figure 1). Its long history spanned the ninth to the early thirteenth century. In the area known today as Zumbacón, more than 100 pottery kilns dated to the Emirate period (ninth to early tenth century) have been identified. Hence, the pottery workshop was active after Shaqunda was abandoned in 818 ce. The unglazed pottery recovered from the Zumbacón dumps are similar to those from Shaqunda but have a more diverse repertoire of shapes and decorations. This is due to the fact that Zumbacón glazed ceramics are slightly later (ninth century instead of eighth century), as confirmed by the stratigraphic sequences of other archaeological sites in Córdoba. The pottery wasters include the first evidence of glazed pottery production: glazed wasters, bars, and kiln stilts. The main glazed ceramic shapes recovered are closed forms such as beakers and pitchers, but also some open forms such as dishes (Figure 4). Monochrome glazes are combined with simple incisions and clay applications recalling glass vessels. With regard to the combination of glaze colours, two groups can be distinguished: vessels with a single colour glaze (green, honey-coloured, or brown) and those with two colours (one colour on each surface). Nineteen glazed ceramic vessels from this workshop have been analysed.

Figure 4. Representative glazed ceramic debris from the Córdoba pottery workshop showing incised decoration in (A) honey-coloured and (C) green glazes, applied threads in (B) brown and (D) green glazes. Overfired and cemented pieces (E) and (F).

The glazed ware from María Auxiliadora Street (Córdoba)

A glazed ware assemblage was excavated in the eastern area of the city of Córdoba, at María Auxiliadora Street (Cánovas & Salinas, Reference Cánovas and Salinas2010), identified by some historians as the Munyat al-Mugira suburb (Ocaña, Reference Ocaña1963) (Figure 1). A collection of glazed and unglazed wares was recovered from the early medieval archaeological sequence dated to the late ninth to early tenth century. The assemblage shows numerous parallels with other archaeological sites in ninth-century Córdoba. Regarding the glazed pottery, five sherds are monochrome glazed pitchers, three of which have incised decorations; a further three beaker sherds are bichrome (honey and green) (see Figure 7A).

Results

This section presents the results of the scientific and archaeological analyses. The analytical methods are included in the Supplementary Material.

Glass from the Shaqunda suburb (Córdoba)

The compositional structure of the glass assemblage from Shaqunda offers insights into the transition from the natron glass technology, which prevailed throughout antiquity, towards the new plant-ash glassmaking recipes that emerged in the Middle Ages (Schibille et al., Reference Schibille, De Juan, Casal and Guerrot2020). The majority of the glass finds are natron-type with low magnesia and potash derived from the recycling of old material. Only a few fragments correspond to the contemporary natron glass groups from Islamic Egypt. A small fraction are plant-ash glasses of Mesopotamian origin with higher magnesium and potassium oxides, the earliest so far identified in al-Andalus.

The most relevant group for the present study is a group of high-lead glass that differs compositionally from Islamic lead silica glass from the eastern Mediterranean and Mesopotamia. It has on average 52 per cent lead and 34 per cent silica, with significant levels of alumina (4.7%), lime (4%), as well as some iron (1.7%) and potash (1.4%) (Supplementary Material: Table S1). It has elevated barium contents, but low silver and bismuth concentrations that suggest the use of lead slags generated during the smelting of lead ore. The analysis of the isotopic signature of five samples revealed that the plumbiferous material came from the mining districts north of Córdoba. Hence, it is the first known primary glass locally produced in the Iberian Peninsula (Schibille et al., Reference Schibille, De Juan, Casal and Guerrot2020).

The crucible from the Shaqunda workshop (Córdoba)

The vitreous layer inside the ceramic crucible (Figure 5A–C) proved to be transparent high-lead glass (51% PbO) with a very low content of sodium (<1% NaO2) (Supplementary Material: Table S1). The glass has a greenish colour due to the presence of Fe2+ resulting from the reducing conditions during firing. Wollastonite and diopside crystallites formed by the interaction of the ceramic with the glass have been identified and are shown in Figure 5H, together with some carbon particles probably from ashes. The exterior (Figure 5D and 5E) has a darkened partially glazed surface probably resulting from having been directly placed in the fire.

Figure 5. (A) Glass crucible showing a (B) greenish transparent glassy layer on the walls and (C) a darkened glassy layer covering the interior. The exterior of the crucible (D) shows evident signs of having been in contact with a fire. Optical (F) and SEM-BSE images (G) and (H) of the glassy layer.

The inner surface of the ceramic does not show any protective layer, and the glass adheres directly to the ceramic. The presence of some carbon particles suggests the possible presence of ash in the crucible, either from the fire applied below, or used to protect the inner surface. The results are therefore consistent with its use as a crucible for glass working. The composition of the vitreous layer matches that of the glass objects found in the area. These results confirm that transparent high-lead glass objects were blown and shaped in the workshop.

Glazed ware from the pottery quarter (Córdoba)

The chemical analyses of the transparent lead glazes are shown in Supplementary Material Table S1. The ceramics have one or two colours (one on each surface), green due to the addition of copper (1.5–4.7% CuO) and honey-coloured from the addition of iron (1.7–6.9% FeO). They are lead glazes with highly variable lead contents (33.6–58.2% PbO), possibly because they were all wasters that had been exposed to high temperatures or prolonged firings. As a consequence, part of the lead may have been lost through volatilization, while elements belonging to the ceramic fabrics may have diffused more extensively into the glaze.

Calcium contents range typically from 2.6 to 6.5 per cent CaO, aluminium varies from 2.5 to 6.3 per cent Al2O3, and potassium contents are between 0.7 and 2.4 per cent K2O, of which the higher amounts are associated with ceramic fragments that appear to a large degree overfired. With the exception of two extremely overfired samples (Z72 and Z45), sodium and magnesium contents are very low (< 1%). The two types of colour glazes are honey-coloured, which contains between 1.5 and 6.9 per cent FeO and very little copper mainly below the detection limits (~0.2% CuO), and green that contains between 1.5 and 4.7 per cent CuO and between 1.1 and 3.5 per cent FeO.

The glazes are usually well preserved, showing occasional bubbles and undissolved quartz grains. Some glazes exhibit cracks perpendicular to the surface that formed by differential shrinkage of the glaze and ceramic body during cooling. The interfaces between the glaze and the fabric are developed and full of lead feldspars and iron pyroxene crystallites.

Glazed ware from María Auxiliadora Street (Córdoba)

The data in Table S1 show that all glazes contain between 43.5 and 53.5 per cent PbO, between 1.1 and 5.6 per cent CaO, 3.4 and 5.2 per cent Al2O3, and 1.2 and 2.1 per cent K2O, while sodium and magnesium contents are very low (<1%). The chemical composition of the glazes from the monochrome group is fairly homogeneous: the colours are green, obtained by the addition of copper with typical contents varying between 1.2 and 1.9 per cent CuO, or honey-coloured, with higher iron contents between 2 and 3.6 per cent FeO. Only one example is a bichrome transparent glaze (see Figure 7A) and has a honey-coloured inner surface, containing higher amounts of iron (3% FeO), while the outer surface is green and contains copper (1.7% CuO) (Salinas & Pradell, Reference Salinas and Pradell2018).

Discussion

Comparing the compositional and stylistic features, we can confidently rule out any technological link between the earliest glazed wares from al-Andalus and those from other Islamic regions (Salinas & Pradell, Reference Salinas and Pradell2018). A North African connection with Ifriqiya (present-day Tunisia) was excluded due to a different technological tradition (i.e. alkali glazes) despite the geographical proximity of the two regions. No similarities in shape or decoration have been found between Andalusi and Abbasid high-lead glaze wares from, for example, Raqqa and Basra, or with Byzantine glazed ceramics. While the early Andalusi glazed repertoire is foot free and uses only one or two colours (green and honey/brown), contemporary glazed vessels from other Islamic lands are characterized by footed shapes, a wider range of colours (i.e. white, blue, yellow) and polychrome painted decorations. By contrast, close parallels between glazed ceramics and glass objects can be noted not only in al-Andalus (Salinas, Reference Salinas2013), such as the glass objects from Madῑnat Ilbira (Malpica, Reference Malpica Cuello2013) and Madῑnat al-Zahrā’ dated to the ninth to tenth centuries (Rontomé, Reference Rontomé, Rontomé and Pastor2006), but also in the eastern Islamic world (i.e. Syria, Mesopotamia, Nishapur) (Carboni & Whitehouse, Reference Carboni and Whitehouse2001).

The chemical composition of the ceramic glazes, the Shaqunda glasses, and the glassy layer in the crucibles are very similar across the majority of base glass elements (Figure 6, Table S1). Minor differences in the alkali, alkaline earths, iron, and titanium levels can be ascribed to differing production procedures. High iron concentrations especially in the honey-coloured glazes, for instance, is caused by the deliberate addition of iron as a colouring agent, which probably also resulted in an increase in the titanium contents (Figure 6). The interaction between the ceramic body and the glaze during firing may account for the higher content of CaO, MgO, and K2O, and lower PbO, and generally broader compositional variability. Glass produced in large containers is less prone to contamination, and the subsequent firing in the crucibles to the softening temperature is made at a lower temperature and for a shorter amount of time than the glaze ware firing. Nevertheless, the lower Na2O contents of the glazes and the concomitantly enhanced MgO and K2O levels could also be the result of the use of ash to protect the crucible during the glass softening process, or these phenomena may simply be caused by fuel ash contamination.

Figure 6. Comparison of the chemical composition from the Shaqunda lead glass (red), the Shaqunda lead glass from the crucible (black), the Zumbacón glazes (blue) and the M. Auxiliadora glazes (green). The greater variability in the composition of the glazes is related to the interaction of the glazes with the ceramics during firing, but also because the glazes analysed are overfired debris.

Figure 7. Parallels between glass and glazed beakers: (A) glazed ceramic from Córdoba; (B) glass from Madῑnat Ilbira (redrawn from Malpica, Reference Malpica Cuello2013: 143, SOM01.IA.09.2033.1); (C) glass from Madῑnat al-Zahra (redrawn from Rontomé, Reference Rontomé, Rontomé and Pastor2006: fig. 2).

The exact date for the start of glaze production in Córdoba is unknown, although comparison of the unglazed and glazed repertoire from the Zumbacón area with other glazed assemblages from Córdoba and al-Andalus confirms that it is later in date than the Shaqunda glasses. Not a single fragment of glazed pottery, either local or imported, was found in Shaqunda, the most important urban suburb of the capital of al-Andalus at that early time. On the other hand, the striking similarities in terms of colours, shapes, and some decorations with those from the Pechina workshop strongly suggest that the production of the Zumbacón workshop was contemporary with that at Pechina, in the second half of the ninth and early tenth centuries. Analyses of the workshop debris found in the industrial zone of the Córdoba glazed ware workshop agrees with the data provided by other contemporary Andalusi workshops such as Pechina (c. 875-900 ce), Málaga (c. 900-950 ce) and Murcia (c. 925-950 ce) (Molera et al., Reference Molera, Pradell, Salvadó, Vendrell, Shortland, Freestone and Rehren2009; Salinas et al., Reference Salinas, Pradell and Molera2018). These early Andalusi glaze workshops seem to have shared the same glazing method, in which a high-lead glass was first synthesized and then applied over a biscuit-fired ceramic vessel (Salinas et al., Reference Salinas, Pradell and Molera2018), but they show different glaze compositions, a fact that allows us to recognize the production of each al-Andalus workshop. This glazing technology differed substantially from the Roman, contemporaneous European, and Byzantine, or indeed other early Islamic techniques, where lead oxide or a mixture of lead oxide and sand was directly applied to the surface of the ceramic object before firing (Walton & Tite, Reference Walton and Tite2010).

Taken together, the data demonstrate that the production of lead glass was already well established by the time production of lead-glazed ceramics first emerged in al-Andalus. Hence, contrary to what is commonly assumed for other Islamic regions (Brill, Reference Brill, Carboni and Whitehouse2001, Reference Brill, Allan and Bass2009), in Córdoba and more generally in al-Andalus, lead glass was produced first and later employed to produce glazed wares. Thus, al-Andalus presents a rare instance of a technological transfer from glass production to glazes and not vice versa, as appears to be the case in the eastern Islamic world.

The glass objects from the various archaeological sites in Córdoba dating to the late eighth to the early ninth centuries encompass bottles, beakers, and bowls. Due to the fragmentary nature of the finds, it is difficult to reconstruct their entire shape. The earliest glazed ceramics from Córdoba have been dated from the 870s–880s ce and are mainly pitchers, beakers, and bowls or dishes characterized by the absence of feet and showing a distinctive decoration (Salinas, Reference Salinas2013). The chronological gap between the assemblages precludes any direct typological comparison of glass objects and ceramic ware. However, glass objects from Córdoba and Madīnat al-Zahrā’ belonging to the Caliphate (929–1031 ce) and Madīnat Ilbīra (ninth–tenth centuries) have similar shapes and decorations as Late Emirate glazed ceramics (c. 875–929 ce) (Figure 7A–C). Moreover, lead glass and glazes continued to be produced in the Caliphate period but with some differences in composition (Duckworth et al., Reference Duckworth, Córdoba, Faber, Govantes and Henderson2014; De Juan Ares & Schibille, Reference De Juan Ares and Schibille2017; Molera et al., Reference Molera, Carvajal López, Molina and Pradell2018). The data therefore seem to indicate, on the one hand, a change in the shapes and decorative motifs both in glass and glazed ceramics over time and, on the other hand, a link between glass and glazed ware beyond the technology of production.

The decorative style of the earliest glazed ceramics from Córdoba is very characteristic, namely semi-circular incisions made with a half-ring or vertical and rhomboidal threads applied over a plain background, similar to the glass beaker found in Madīnat Ilbira and dated to the ninth–tenth century (Malpica, Reference Malpica Cuello2013: 143) (Figure 7B) as well as other eastern Islamic glass objects (Carboni & Whitehouse, Reference Carboni and Whitehouse2001). An explanation for these decorative features may be that the potters were copying glass and metallic models rather than contemporary Islamic glazed ceramics, reinforcing the idea of a technological connection between glass and glazes.

Why did this technological transfer occur in Córdoba in the ninth century? Several explanations can be advanced. First, in the absence of previous glazing traditions in the Iberian Peninsula, unlike in other regions where the glazing technology continued (Roman, Byzantine, and Coptic lead-glazed wares), the potters were forced to look for other solutions. Second, the remote geographical position of al-Andalus in relation to the core of the Abbasid caliphate meant that Abbasid potters were not encouraged to settle in Umayyad Córdoba or other Andalusi urban sites. Judging by the domestic ceramics from different early Andalusi settlements such as Shaqunda (Casal et al., Reference Casal, Castro, López and Salinas2005) and el Tolmo de Minateda (Amorós, Reference Amorós2018), new unglazed ceramic forms were incorporated into the local repertoire, related to novel culinary and domestic customs (portable baking ovens, drinking pitchers, oil lamps, globular bottles), in addition to agricultural practices (pots for waterwheels). These novelties were seen as proof of Islamization and Arabization (Gutiérrez, Reference Gutiérrez, Molinari, Santangeli Valenzani and Spera2016). Nevertheless, neither eastern nor North African unglazed ceramic vessels have so far been identified in early Andalusi phases. Conversely, chemical analyses of some of the Shaqunda glass objects confirmed them to be Islamic imports (Schibille et al., Reference Schibille, De Juan, Casal and Guerrot2020). This corroborates the arrival of exogenous luxury glass, but not ceramics during the eighth–early ninth century. Currently, the earliest evidence of glazed imports, identified as Samarra type, has been reported at Ilbῑra and dated to the second half of the ninth century (Carvajal, Reference Carvajal2013).

Finally, the abundance of lead deposits in al-Andalus (Ibn Ḥayyān, Reference Ibn Ḥayyān, Makkī and Corriente2001: 203–04) and waste products associated with the smelting of lead ores that form a glassy slag means that a ready-to-use relatively cheap material was available and could easily be transformed into glass and glazes. The temperature required for high-lead glass is lower than that needed to produce alkali silica glazes. It may not be a coincidence that the two earliest glazed ware production centres, Córdoba and Pechina, are located close to lead ore deposits that were exploited at the time. Access to the main raw material was an advantage that undoubtedly facilitated the development of this emerging technology.

In addition to these technical considerations, we should highlight a significant increase in the demand for material refinements and luxury goods related to the presence of the court and urban elites from ‘Abd al-Raḥmān II (822–852 ce) and the new Abbasid fashions imposed by Ziryab. Even though the technical know-how for the production of glass and glaze did not reach al-Andalus in the eighth and ninth centuries, some new (so far not archaeologically documented) types and luxury objects should have arrived from the eastern Islamic world, at least from the second half of the ninth century if not before. This may have generated a local demand, leading to the invention of lead glass, which was used a few decades later to manufacture lead-glazed wares. The increase in demand for glass during the ninth century may have prompted the development of the production of transparent high-lead glazes in al-Andalus, since it was less fragile and probably cheaper than glass. There is no clear evidence of Emirate-period glass production outside Córdoba (even in Pechina), while, by contrast, the manufacture of glazed tableware spread quickly to other urban centres, like Málaga and Murcia, in the tenth century.

Conclusions

The historical, archaeological, and technological data presented here reflect the autochthonous innovation of a new glass technology and the subsequent technological transfer to glazing techniques in early Islamic al-Andalus in Spain. This development is diametrically opposed to what has been observed in other archaeological contexts where glazing technologies paved the way for glassmaking. The growth of both technologies in ninth-century al-Andalus was probably motivated by various factors, such as the lack of supplies of fresh raw glass from the eastern Mediterranean and the somewhat isolated geographical position of Umayyad al-Andalus in relation to both Latin Europe and the Islamic East, which appears to have prevented technological transmission but not the arrival of some novel artistic fashion trends emanating from the Abbasid court. The progress of local glassmaking and later lead glazing enabled the Umayyads of al-Andalus to take advantage of the abundant natural resources of their territory and at the same time promote their own industry of luxury products to develop and compete with eastern imports. It has previously been assumed that glaze technology came from the East. However, Andalusi potters employed a completely different technology. There is no evidence for the technological transfer of pottery glazing from the eastern Islamic lands or other Mediterranean regions to al-Andalus. Instead, the transfer came from local innovations in the glass industry.

Supplementary Material

To view supplementary material for this article, please visit https://doi.org/10.1017/eaa.2021.23.

Acknowledgments

We would like to thank Isabel Larrea and the Gerencia de Urbanismo del Ayuntamiento de Córdoba for providing the samples analysed from the Córdoba potters’ quarter. This project received funding from the European Union's Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie scheme (grant agreement IGATO no. 702019 to ES), an ERC Consolidator Grant (grant agreement no. 647315 to Nadine Schibille), and from MINECO (Spain) (grant no. MAT2016-77753-R to Trinitat Pradell). The funding organization had no influence on the study design, data collection and analysis, decision to publish, or preparation of the manuscript.