1. Introduction

Taylor–Couette flow occurs between two concentric cylinders, one or both of which is rotating, and has been of interest to the fluids community, rheologists, process engineers and mathematicians over the past century (Taylor Reference Taylor1923; Donnelly Reference Donnelly1991). This is in part motivated by the fact that, in spite of its simple configuration, Taylor–Couette flow of Newtonian fluids can yield a vast array of complex dynamics, including a wide variety of steady and unsteady flow states (Coles Reference Coles1965; Andereck, Liu & Swinney Reference Andereck, Liu and Swinney1986), mode competition (Dutcher & Muller Reference Dutcher and Muller2009), chaos (Akonur & Lueptow Reference Akonur and Lueptow2003) and transition to turbulence (Grossmann, Lohse & Sun Reference Grossmann, Lohse and Sun2016; Gul, Elsinga & Westerweel Reference Gul, Elsinga and Westerweel2018). In the relatively simple case in which the outer cylinder is fixed, the system can be characterised using only the Reynolds number

where ![]() $\rho$ and

$\rho$ and ![]() $\mu$ are the fluid density and dynamic viscosity, respectively,

$\mu$ are the fluid density and dynamic viscosity, respectively, ![]() $\omega$ is the rotation speed,

$\omega$ is the rotation speed, ![]() $r_i$ are the radius of the inner cylinder, and

$r_i$ are the radius of the inner cylinder, and ![]() $d$ is the gap between the inner and outer cylinder radii (

$d$ is the gap between the inner and outer cylinder radii (![]() $d = r_o - r_i$). Likewise, the system geometry can be expressed using two non-dimensional groups; the radius ratio,

$d = r_o - r_i$). Likewise, the system geometry can be expressed using two non-dimensional groups; the radius ratio, ![]() $\eta = r_i / r_o$, and the aspect ratio,

$\eta = r_i / r_o$, and the aspect ratio, ![]() $\varGamma = L/d$, where

$\varGamma = L/d$, where ![]() $L$ is the cylinder length. When the Reynolds number is low, the flow is characterised by uniform shear (circular Couette flow, CCF), and at a critical point,

$L$ is the cylinder length. When the Reynolds number is low, the flow is characterised by uniform shear (circular Couette flow, CCF), and at a critical point, ![]() $Re_c$, the flow becomes unstable and a series of toroidal vortices form along the fluid annulus (Taylor vortex flow, TVF). Further increases in

$Re_c$, the flow becomes unstable and a series of toroidal vortices form along the fluid annulus (Taylor vortex flow, TVF). Further increases in ![]() $Re$ cause this state in turn to become unstable and undergo oscillations (wavy vortex flow, WVF). If the Reynolds number is increased further, additional frequencies appear, inducing a more complicated unsteady flow (Coughlin & Marcus Reference Coughlin and Marcus1992; Imomoh, Dusting & Balabani Reference Imomoh, Dusting and Balabani2010), until the flow ultimately becomes turbulent. Because of this rich set of dynamic states, Taylor–Couette flow has been widely used as a means to study flow transitions and instabilities (Fardin, Perge & Taberlet Reference Fardin, Perge and Taberlet2014).

$Re$ cause this state in turn to become unstable and undergo oscillations (wavy vortex flow, WVF). If the Reynolds number is increased further, additional frequencies appear, inducing a more complicated unsteady flow (Coughlin & Marcus Reference Coughlin and Marcus1992; Imomoh, Dusting & Balabani Reference Imomoh, Dusting and Balabani2010), until the flow ultimately becomes turbulent. Because of this rich set of dynamic states, Taylor–Couette flow has been widely used as a means to study flow transitions and instabilities (Fardin, Perge & Taberlet Reference Fardin, Perge and Taberlet2014).

This has also served as a motivation to study Taylor–Couette flow of non-Newtonian fluids, as it allows the effects of various rheological parameters on the flow stability to be examined (Muller Reference Muller2008). One of the most common features of non-Newtonian fluids is shear-thinning, which is observed in many polymer solutions (Larson & Desai Reference Larson and Desai2015), cell cultures (Cagney et al. Reference Cagney, Zhang, Bransgrove, Allen and Balabani2017) and particle suspensions (Mueller, Llewellin & Mader Reference Mueller, Llewellin and Mader2010), and is characterised by a viscosity that scales with strain rate, ![]() $\mu \sim \dot {\gamma }^{n-1}$, where

$\mu \sim \dot {\gamma }^{n-1}$, where ![]() $\dot {\gamma }$ is strain rate and

$\dot {\gamma }$ is strain rate and ![]() $n$ is the flow index (with

$n$ is the flow index (with ![]() $n=1$ for Newtonian fluids). This can lead to spatial and temporal variations in viscosity, requiring the use of a reference viscosity to calculate the Reynolds number; in Taylor–Couette flow it is common to define

$n=1$ for Newtonian fluids). This can lead to spatial and temporal variations in viscosity, requiring the use of a reference viscosity to calculate the Reynolds number; in Taylor–Couette flow it is common to define ![]() $Re$ with respect to the viscosity found at the ‘nominal’ strain rate,

$Re$ with respect to the viscosity found at the ‘nominal’ strain rate, ![]() $\omega r_i / d$.

$\omega r_i / d$.

Several researchers have addressed the effect of shear-thinning on the critical Reynolds number for the formation of Taylor vortices, predicting a decrease in ![]() $Re_c$ with increased shear-thinning for large values of

$Re_c$ with increased shear-thinning for large values of ![]() $\eta$ (i.e. when curvature effects are small) (Coronado-Matutti, Souza Mendes & Carvalho Reference Coronado-Matutti, Souza Mendes and Carvalho2004; Caton Reference Caton2006; Ashrafi Reference Ashrafi2011), which has been supported by various numerical and experimental studies (Lockett, Richardson & Worraker Reference Lockett, Richardson and Worraker1992; Khali, Nebbali & Bouhadef Reference Khali, Nebbali and Bouhadef2013; Cagney & Balabani Reference Cagney and Balabani2019b). Bahrani et al. (Reference Bahrani, Nouar, Neveu and Becker2015) found that for a very large gap,

$\eta$ (i.e. when curvature effects are small) (Coronado-Matutti, Souza Mendes & Carvalho Reference Coronado-Matutti, Souza Mendes and Carvalho2004; Caton Reference Caton2006; Ashrafi Reference Ashrafi2011), which has been supported by various numerical and experimental studies (Lockett, Richardson & Worraker Reference Lockett, Richardson and Worraker1992; Khali, Nebbali & Bouhadef Reference Khali, Nebbali and Bouhadef2013; Cagney & Balabani Reference Cagney and Balabani2019b). Bahrani et al. (Reference Bahrani, Nouar, Neveu and Becker2015) found that for a very large gap, ![]() $\eta = 0.4$, shear-thinning led to an increase in the wavelength of Taylor vortex flow (i.e. a decrease in the number of vortices), in agreement with their predictions from linear stability theory. Escudier, Gouldson & Jones (Reference Escudier, Gouldson and Jones1995) also observed an increase in wavelength associated with shear-thinning, and using laser-Doppler velocimetry showed that the non-Newtonian rheology affected the structure of individual vortices, noting an increase in the asymmetry between the strength of the inward and outward jets between vortices. They also found that for the two shear-thinning fluids they examined (aqueous suspensions of xanthan gum and a Laponite/CMC blend, the latter of which was also thixotropic), the vortices exhibited a slow axial drift, which they assumed to be a steady-state process.

$\eta = 0.4$, shear-thinning led to an increase in the wavelength of Taylor vortex flow (i.e. a decrease in the number of vortices), in agreement with their predictions from linear stability theory. Escudier, Gouldson & Jones (Reference Escudier, Gouldson and Jones1995) also observed an increase in wavelength associated with shear-thinning, and using laser-Doppler velocimetry showed that the non-Newtonian rheology affected the structure of individual vortices, noting an increase in the asymmetry between the strength of the inward and outward jets between vortices. They also found that for the two shear-thinning fluids they examined (aqueous suspensions of xanthan gum and a Laponite/CMC blend, the latter of which was also thixotropic), the vortices exhibited a slow axial drift, which they assumed to be a steady-state process.

Recent work by the current authors (Cagney & Balabani Reference Cagney and Balabani2019a,Reference Cagney and Balabanib), using particle image velocimetry and flow visualisation to study Taylor–Couette flow of xanthan gum solutions, showed that shear-thinning also altered the wavy state, inducing significant variability in the amplitude of the waves along the axis, despite the relatively small aspect ratio, ![]() $\varGamma = 12.97$. With increased shear-thinning, the spacing of vortices became increasingly irregular as

$\varGamma = 12.97$. With increased shear-thinning, the spacing of vortices became increasingly irregular as ![]() $Re$ increased, similar to the drift noted by Escudier et al. (Reference Escudier, Gouldson and Jones1995), suggesting that as well as increasing the global wavelength of the flow, shear-thinning caused the wavelength to become more variable along the cylinder axis. The wavelength was also found to change as

$Re$ increased, similar to the drift noted by Escudier et al. (Reference Escudier, Gouldson and Jones1995), suggesting that as well as increasing the global wavelength of the flow, shear-thinning caused the wavelength to become more variable along the cylinder axis. The wavelength was also found to change as ![]() $Re$ was slowly increased, via the sudden creation and destruction of vortices (Cagney & Balabani Reference Cagney and Balabani2019a). Such transitions have been noted in previous studies of Taylor–Couette flow of Newtonian fluids and are associated with the wavy instability, which leads to an expansion of vortices near the centre of the flow cell and a squeezing of vortices near the ends, until the squeezed vortices are ultimately destroyed via merger with their neighbours (Park & Crawford Reference Park and Crawford1982; Crawford, Park & Donnelly Reference Crawford, Park and Donnelly1985). Beavers & Joseph (Reference Beavers and Joseph1974) also reported the merger of vortices in a solution of polyacrlyamide (PAA) in glycerol–water as the Reynolds number was increased, which they found to be strongly hysteretic, but they did not present information on the rheology of their fluid.

$Re$ was slowly increased, via the sudden creation and destruction of vortices (Cagney & Balabani Reference Cagney and Balabani2019a). Such transitions have been noted in previous studies of Taylor–Couette flow of Newtonian fluids and are associated with the wavy instability, which leads to an expansion of vortices near the centre of the flow cell and a squeezing of vortices near the ends, until the squeezed vortices are ultimately destroyed via merger with their neighbours (Park & Crawford Reference Park and Crawford1982; Crawford, Park & Donnelly Reference Crawford, Park and Donnelly1985). Beavers & Joseph (Reference Beavers and Joseph1974) also reported the merger of vortices in a solution of polyacrlyamide (PAA) in glycerol–water as the Reynolds number was increased, which they found to be strongly hysteretic, but they did not present information on the rheology of their fluid.

While several researchers have commented on the lack of experimental data on Taylor–Couette flow of shear-thinning fluids (Escudier et al. Reference Escudier, Gouldson and Jones1995; Coronado-Matutti et al. Reference Coronado-Matutti, Souza Mendes and Carvalho2004; Ashrafi Reference Ashrafi2011; Alibenyahia et al. Reference Alibenyahia, Lemaitre, Nouar and Ait-Messaoudene2012), by comparison there has been extensive work in recent decades examining Taylor–Couette flow of viscoelastic fluids. In this case, as well as inertial and viscous forces, the fluids are affected by elastic forces, typically due to dispersed polymers. This requires an additional non-dimensional group, the Deborah number, ![]() $De = \lambda _r \dot {\gamma }$ (which in this context is equivalent to the Weissenberg number (Schäfer, Morozov & Wagner Reference Schäfer, Morozov and Wagner2018)), where

$De = \lambda _r \dot {\gamma }$ (which in this context is equivalent to the Weissenberg number (Schäfer, Morozov & Wagner Reference Schäfer, Morozov and Wagner2018)), where ![]() $\lambda _r$ is the relaxation time of the fluid. The relative importance of viscoelasticity in Taylor–Couette flow is often expressed using the ratio of the Deborah and Reynolds number,

$\lambda _r$ is the relaxation time of the fluid. The relative importance of viscoelasticity in Taylor–Couette flow is often expressed using the ratio of the Deborah and Reynolds number, ![]() $De/Re$ (Groisman & Steinberg Reference Groisman and Steinberg1998; Latrache et al. Reference Latrache, Abcha, Crumeyrolle and Mutabazi2016), referred to as the elasticity number.

$De/Re$ (Groisman & Steinberg Reference Groisman and Steinberg1998; Latrache et al. Reference Latrache, Abcha, Crumeyrolle and Mutabazi2016), referred to as the elasticity number.

Early studies showed that the addition of a small amount of polymers led to an increase in the critical Reynolds number (Rubin & Elata Reference Rubin and Elata1966; Denn & Roisman Reference Denn and Roisman1969), but as Muller (Reference Muller2008) notes, the relevance of many early studies is limited due to incomplete rheological characterisation of the fluids. Several more recent studies have examined the dynamics of viscoelastic fluids with negligible shear-thinning (Boger fluids). For dilute suspensions with very weak elasticity, ![]() $De/Re \leq 0.023$, the elasticity has a non-monotonic effect on the critical Reynolds numbers for various flow regimes, but these do not differ significantly from those seen in the Newtonian case (Dutcher & Muller Reference Dutcher and Muller2011). At slightly higher elasticity,

$De/Re \leq 0.023$, the elasticity has a non-monotonic effect on the critical Reynolds numbers for various flow regimes, but these do not differ significantly from those seen in the Newtonian case (Dutcher & Muller Reference Dutcher and Muller2011). At slightly higher elasticity, ![]() $De/Re \gtrsim 0.1$, the flow transitions from circular Couette flow to an unsteady state, characterised by standing waves (Groisman & Steinberg Reference Groisman and Steinberg1996; Baumert & Muller Reference Baumert and Muller1999; Dutcher & Muller Reference Dutcher and Muller2013), ‘disordered oscillations’ (Groisman & Steinberg Reference Groisman and Steinberg1996, Reference Groisman and Steinberg1997), elastic turbulence (Liu & Khomami Reference Liu and Khomami2013) or ‘spiral’ or ‘ribbon’ states (Thomas et al. Reference Thomas, Al-Mubaiyadh, Sureshkumar and Khomami2006; Latrache et al. Reference Latrache, Abcha, Crumeyrolle and Mutabazi2016). At higher values of

$De/Re \gtrsim 0.1$, the flow transitions from circular Couette flow to an unsteady state, characterised by standing waves (Groisman & Steinberg Reference Groisman and Steinberg1996; Baumert & Muller Reference Baumert and Muller1999; Dutcher & Muller Reference Dutcher and Muller2013), ‘disordered oscillations’ (Groisman & Steinberg Reference Groisman and Steinberg1996, Reference Groisman and Steinberg1997), elastic turbulence (Liu & Khomami Reference Liu and Khomami2013) or ‘spiral’ or ‘ribbon’ states (Thomas et al. Reference Thomas, Al-Mubaiyadh, Sureshkumar and Khomami2006; Latrache et al. Reference Latrache, Abcha, Crumeyrolle and Mutabazi2016). At higher values of ![]() $De/Re$, a purely elastic instability occurs, which is independent of Reynolds number (Groisman & Steinberg Reference Groisman and Steinberg1998) and is characterised by isolated vortex pairs called ‘diwhirls’ (Groisman & Steinberg Reference Groisman and Steinberg1997; Kumar & Graham Reference Kumar and Graham2000; Lange & Eckhardt Reference Lange and Eckhardt2001).

$De/Re$, a purely elastic instability occurs, which is independent of Reynolds number (Groisman & Steinberg Reference Groisman and Steinberg1998) and is characterised by isolated vortex pairs called ‘diwhirls’ (Groisman & Steinberg Reference Groisman and Steinberg1997; Kumar & Graham Reference Kumar and Graham2000; Lange & Eckhardt Reference Lange and Eckhardt2001).

Most polymer solutions that are not very dilute or have a highly viscous suspending medium will exhibit both shear-thinning and viscoelasticity (Larson Reference Larson1992). Larson (Reference Larson1989) modelled Taylor–Couette flow of a Doi–Edwards fluid (viscoelastic and strongly shear-thinning) and found that while the viscoelasticity has a non-monotonic effect on the critical Reynolds number, shear-thinning was always destabilising. This observation was supported by the experimental studies of Yi & Kim (Reference Yi and Kim1997), who examined the stability of ultra-dilute solutions of PAA, polyacrylic acid and xanthan gum, and Crumeyrolle & Mutabazi (Reference Crumeyrolle and Mutabazi2002), who measured the stability of aqueous solutions of polyethyleneoxide (PEO). Crumeyrolle and Mutabazi found that for dilute concentrations, ![]() $c < 500\ \textrm {ppm}$, the flow exhibited the same progression of states as a Newtonian fluid (

$c < 500\ \textrm {ppm}$, the flow exhibited the same progression of states as a Newtonian fluid (![]() $\textrm {CCF}\rightarrow \textrm {TVF} \rightarrow \textrm {WVF}$), but for

$\textrm {CCF}\rightarrow \textrm {TVF} \rightarrow \textrm {WVF}$), but for ![]() $c > 500\ \textrm {ppm}$, they found that the flow transitioned to a standing wave, which was attributed to an increase in elasticity. However, it should be noted that the relaxation time was inferred from the flow curves, rather than being estimated directly from dynamic rheological tests, and, therefore, the elasticity values may not be reliable.

$c > 500\ \textrm {ppm}$, they found that the flow transitioned to a standing wave, which was attributed to an increase in elasticity. However, it should be noted that the relaxation time was inferred from the flow curves, rather than being estimated directly from dynamic rheological tests, and, therefore, the elasticity values may not be reliable.

It is clear that there is a lack of experimental data on Taylor–Couette flow of fluids that are both shear-thinning and viscoelastic. Specifically, it remains unclear how the flow states change as ![]() $Re$ is increased for shear-thinning, viscoelastic fluids, what rheological factors control these transitions, how vortex drift and sudden changes in the wavelength are affected by the fluid rheology and how repeatable and deterministic these processes are. In order to address these questions, we present flow visualisation measurements of Taylor–Couette flow for a series of solutions of xanthan gum in a glycerol–water solvent, spanning the inelastic (

$Re$ is increased for shear-thinning, viscoelastic fluids, what rheological factors control these transitions, how vortex drift and sudden changes in the wavelength are affected by the fluid rheology and how repeatable and deterministic these processes are. In order to address these questions, we present flow visualisation measurements of Taylor–Couette flow for a series of solutions of xanthan gum in a glycerol–water solvent, spanning the inelastic (![]() $De \ll 1$), weakly viscoelastic (

$De \ll 1$), weakly viscoelastic (![]() $De/Re \ll 1$) and viscoelastic (

$De/Re \ll 1$) and viscoelastic (![]() $De/Re > 0.1$) regimes. The remainder of the paper is structured as follows; details of our experimental system and the rheological characterisation of the polymer solutions are presented in § 2; the results are discussed in § 3, with specific emphasis on the wavy instability, the splitting and merger of vortices, and the axial drift; additional data is presented in § 4 to confirm that the novel phenomena observed are independent of the acceleration rate of the cylinder; and finally some concluding remarks are made in § 5.

$De/Re > 0.1$) regimes. The remainder of the paper is structured as follows; details of our experimental system and the rheological characterisation of the polymer solutions are presented in § 2; the results are discussed in § 3, with specific emphasis on the wavy instability, the splitting and merger of vortices, and the axial drift; additional data is presented in § 4 to confirm that the novel phenomena observed are independent of the acceleration rate of the cylinder; and finally some concluding remarks are made in § 5.

2. Experimental details

The experiments were performed in a specially designed Taylor–Couette flow cell, which was comprised of a thin acrylic pipe as the outer cylinder, mounted vertically between two acrylic plates, and a nylon inner cylinder, which was spray-painted black to reduce reflections. The inner and outer radii of the flow cell were 21.66 mm and 27.92 mm, respectively, and it had an axial length of ![]() $L = 155\ \textrm {mm}$, yielding a radius ratio of

$L = 155\ \textrm {mm}$, yielding a radius ratio of ![]() $\eta = 0.77$ and an aspect ratio of

$\eta = 0.77$ and an aspect ratio of ![]() $\varGamma = 21.56$. The top acrylic plate was sealed to ensure that a no-slip condition existed at both the top and bottom of the flow cell, i.e. there was no free surface.

$\varGamma = 21.56$. The top acrylic plate was sealed to ensure that a no-slip condition existed at both the top and bottom of the flow cell, i.e. there was no free surface.

The flow cell was surrounded by a rectangular chamber in which water was recirculated via a temperature bath to ensure that the temperature remained constant at ![]() $20\,^{\circ }\textrm {C}$ throughout experiments. The temperature within the flow cell was measured immediately before and after each experiment, and it was found to vary by less than

$20\,^{\circ }\textrm {C}$ throughout experiments. The temperature within the flow cell was measured immediately before and after each experiment, and it was found to vary by less than ![]() $0.2\,^{\circ }\textrm {C}$, with a variation of less than

$0.2\,^{\circ }\textrm {C}$, with a variation of less than ![]() $0.1\,^{\circ }\textrm {C}$ (i.e. the resolution of the temperature sensor) for the vast majority of cases.

$0.1\,^{\circ }\textrm {C}$ (i.e. the resolution of the temperature sensor) for the vast majority of cases.

The inner cylinder was connected to the drive shaft of a stepper motor (Smart Drive Ltd.), the rotation of which was monitored using an optical encoder with a resolution of 2000 pulses per revolution, such that the cylinder speed could be controlled to a high degree of precision.

Experiments were performed using a mixture of three parts deionised water and one part glycerol, with various quantities of xanthan gum (Sigma Aldrich) ranging from 0 to 2000 ppm, as listed in table 1. Gel permeation chromatography was used to characterise the xanthan molecules, which were found to have a mean molecular weight of ![]() $M_w = 1.76 \times 10^6\ \textrm {g} \ \textrm {mol}^{-1}$ and a polydispersity of 1.1. A rotary mixer (Silverson) was used to ensure that the polymer was uniformly dispersed throughout the fluid. The shear rheology of each fluid was measured three times using a rotational rheometer (ARES, TA Instruments) and a cup and bob geometry. The flow curves for each fluid are presented in figure 1. The shear rheology could be well described using the Carreau model,

$M_w = 1.76 \times 10^6\ \textrm {g} \ \textrm {mol}^{-1}$ and a polydispersity of 1.1. A rotary mixer (Silverson) was used to ensure that the polymer was uniformly dispersed throughout the fluid. The shear rheology of each fluid was measured three times using a rotational rheometer (ARES, TA Instruments) and a cup and bob geometry. The flow curves for each fluid are presented in figure 1. The shear rheology could be well described using the Carreau model,

where ![]() $\mu _{\infty }$ and

$\mu _{\infty }$ and ![]() $\mu _0$ are the viscosity values at infinite and zero shear, respectively,

$\mu _0$ are the viscosity values at infinite and zero shear, respectively, ![]() $\lambda _c$ is the characteristic time scale and

$\lambda _c$ is the characteristic time scale and ![]() $n$ is the flow index. The estimated Carreau parameters for each fluid are listed in table 1.

$n$ is the flow index. The estimated Carreau parameters for each fluid are listed in table 1.

Table 1. Rheological properties of each of the solutions of xanthan gum in glycerol–water studied. The mean effective flow index, ![]() $\overline {n_e}$, is obtained by averaging the value of

$\overline {n_e}$, is obtained by averaging the value of ![]() $n_e$ (2.3) found over the range

$n_e$ (2.3) found over the range ![]() $Re = 50\text {--}1000$. The suspension regime is characterised based on the trends in

$Re = 50\text {--}1000$. The suspension regime is characterised based on the trends in ![]() $\mu _0$,

$\mu _0$, ![]() $\lambda _c$ and

$\lambda _c$ and ![]() $\lambda _r$, as shown in figure 3.

$\lambda _r$, as shown in figure 3.

Figure 1. Variation in the measured viscosity with strain rate for each of the eight fluids examined, with varying concentrations of xanthan gum. The lines represent the best fit to the Carreau model, with the various Carreau parameters listed in table 1. Data points where the measured stress was less than 0.02 Pa were neglected.

In order to characterise the viscoelastic properties of each fluid, the storage and loss moduli (![]() $G'$ and

$G'$ and ![]() $G''$, respectively) were measured using oscillatory shear tests, with a peak strain of 5 %, which prior tests indicated was well within the linear viscoelastic regime. Figure 2 summarises the variations in the storage and loss moduli with oscillation frequency for each polymer suspension. Elasticity can be said to dominate the rheology when the storage modulus exceeds the loss modulus, i.e. when

$G''$, respectively) were measured using oscillatory shear tests, with a peak strain of 5 %, which prior tests indicated was well within the linear viscoelastic regime. Figure 2 summarises the variations in the storage and loss moduli with oscillation frequency for each polymer suspension. Elasticity can be said to dominate the rheology when the storage modulus exceeds the loss modulus, i.e. when ![]() $G' \geq G''$. The oscillation frequency at which this crossover occurs,

$G' \geq G''$. The oscillation frequency at which this crossover occurs, ![]() $\omega _r$, can be used to define the relaxation time of the fluid,

$\omega _r$, can be used to define the relaxation time of the fluid, ![]() $\lambda _r = 2 {\rm \pi}/ \omega _r$. These values are found using figure 2 and are listed in table 1. For dilute concentrations,

$\lambda _r = 2 {\rm \pi}/ \omega _r$. These values are found using figure 2 and are listed in table 1. For dilute concentrations, ![]() $c < 100\ \textrm {ppm}$,

$c < 100\ \textrm {ppm}$, ![]() $G'$ does not exceed

$G'$ does not exceed ![]() $G''$ over the range of oscillation frequencies accessible in the rheometer (up to

$G''$ over the range of oscillation frequencies accessible in the rheometer (up to ![]() $100\ \textrm {rad} \ \textrm {s}^{-1}$), which implies a relaxation time of

$100\ \textrm {rad} \ \textrm {s}^{-1}$), which implies a relaxation time of ![]() $\lambda _r \ll 0.063\ \textrm {s}$.

$\lambda _r \ll 0.063\ \textrm {s}$.

Figure 2. Variation in the storage (![]() $G'$) and loss (

$G'$) and loss (![]() $G''$) moduli with oscillations frequency for each of the eight polymer solutions. The open symbols denote the loss moduli, and the closed symbols denote the storage moduli. The relaxation time is defined based on the oscillation frequency at which the magnitude of the

$G''$) moduli with oscillations frequency for each of the eight polymer solutions. The open symbols denote the loss moduli, and the closed symbols denote the storage moduli. The relaxation time is defined based on the oscillation frequency at which the magnitude of the ![]() $G'$ exceeds that of

$G'$ exceeds that of ![]() $G''$, which only occurs for

$G''$, which only occurs for ![]() $c \geq 100\ \textrm {ppm}$, (c,d). The tests were performed using a maximum applied strain of 5 %.

$c \geq 100\ \textrm {ppm}$, (c,d). The tests were performed using a maximum applied strain of 5 %.

Polymer suspensions can be broadly divided into three regimes based on concentration: dilute suspensions, in which individual polymers do not interact; semi-dilute suspensions, in which polymer molecules have limited interactions with each other; and concentrated suspensions, in which the polymers form a network. Wyatt & Liberatore (Reference Wyatt and Liberatore2009) studied the rheology of suspensions of xanthan gum in pure water, and found that the zero shear viscosity increased in a power law fashion with concentration, with a greater slope in the concentrated regime and a kink (a sudden increase followed by a slight plateau) at the boundary between the dilute and semi-dilute regimes. Similarly, they found the relaxation time increased in a power law fashion with ![]() $c$ in the dilute and concentrated regimes (with the sharpest growth in the concentrated regime), and remained roughly constant in the semi-dilute regime (with a slight decrease at the onset of the semi-dilute regime).

$c$ in the dilute and concentrated regimes (with the sharpest growth in the concentrated regime), and remained roughly constant in the semi-dilute regime (with a slight decrease at the onset of the semi-dilute regime).

As the solvent has a significant effect on the rheology of polymer suspensions, the boundaries between the regimes in our case will not be the same as those identified by Wyatt & Liberatore (Reference Wyatt and Liberatore2009). However, figure 3 indicates that our suspensions of xanthan in glycerol–water mixtures exhibit very similar behaviour; the zero shear viscosity increases with polymer concentration, has a kink at relatively low concentration (![]() $c \approx 100\ \textrm {ppm}$) and increases very sharply at high values (

$c \approx 100\ \textrm {ppm}$) and increases very sharply at high values (![]() $c \gtrsim 500\ \textrm {ppm}$). Likewise, both the relaxation time and the Carreau time scale remain roughly constant in the region

$c \gtrsim 500\ \textrm {ppm}$). Likewise, both the relaxation time and the Carreau time scale remain roughly constant in the region ![]() $c \approx 100\text {--}500\ \textrm {ppm}$, before increasing sharply for

$c \approx 100\text {--}500\ \textrm {ppm}$, before increasing sharply for ![]() $c \gtrsim 500\ \textrm {ppm}$. Based on these trends, it is possible to classify the polymer suspensions studied here into different regimes: solutions with

$c \gtrsim 500\ \textrm {ppm}$. Based on these trends, it is possible to classify the polymer suspensions studied here into different regimes: solutions with ![]() $c < 100\ \textrm {ppm}$ are dilute (

$c < 100\ \textrm {ppm}$ are dilute (![]() $\mu _0$ and

$\mu _0$ and ![]() $\lambda _c$ increase with

$\lambda _c$ increase with ![]() $c$); solutions in the range

$c$); solutions in the range ![]() $100\ \mathrm {ppm} \leq c < 1000\ \textrm {ppm}$ are semi-dilute (

$100\ \mathrm {ppm} \leq c < 1000\ \textrm {ppm}$ are semi-dilute (![]() $\lambda _c$ and

$\lambda _c$ and ![]() $\lambda _r$ are independent of

$\lambda _r$ are independent of ![]() $c$ and there is a slight kink in the

$c$ and there is a slight kink in the ![]() $\mu _0$ curve at the onset of the regime); and denser suspensions with

$\mu _0$ curve at the onset of the regime); and denser suspensions with ![]() $c \geq 1000\ \textrm {ppm}$ are in the concentrated regime (

$c \geq 1000\ \textrm {ppm}$ are in the concentrated regime (![]() $\lambda _c$,

$\lambda _c$, ![]() $\lambda _r$ and

$\lambda _r$ and ![]() $\mu _0$ all increase sharply with

$\mu _0$ all increase sharply with ![]() $c$).

$c$).

Figure 3. Variation in the zero shear viscosity ![]() $(a)$ and the relaxation and Carreau time scales

$(a)$ and the relaxation and Carreau time scales ![]() $(b)$ as a function of polymer concentration. The dashed grey lines indicate the approximate boundaries between the dilute (D), semi-dilute (SD) and concentrated (C) regimes, based on qualitative comparison with the rheological measurements of Wyatt & Liberatore (Reference Wyatt and Liberatore2009) for xanthan gum in pure water.

$(b)$ as a function of polymer concentration. The dashed grey lines indicate the approximate boundaries between the dilute (D), semi-dilute (SD) and concentrated (C) regimes, based on qualitative comparison with the rheological measurements of Wyatt & Liberatore (Reference Wyatt and Liberatore2009) for xanthan gum in pure water.

For each fluid, a series of measurements were performed in which the cylinder was slowly accelerated from rest at a fixed rate, as listed in table 2. The maximum speed was chosen such that the maximum Reynolds number was above 1000, with ![]() $Re$ defined using the Carreau viscosity (2.1), assuming a nominal strain rate of

$Re$ defined using the Carreau viscosity (2.1), assuming a nominal strain rate of ![]() $\dot {\gamma } = \omega r_i / d$, as has been used in previous studies (Lockett et al. Reference Lockett, Richardson and Worraker1992; Coronado-Matutti et al. Reference Coronado-Matutti, Souza Mendes and Carvalho2004; Bahrani et al. Reference Bahrani, Nouar, Neveu and Becker2015; Sinevic, Kuboi & Nienow Reference Sinevic, Kuboi and Nienow1986). The non-dimensional acceleration rate,

$\dot {\gamma } = \omega r_i / d$, as has been used in previous studies (Lockett et al. Reference Lockett, Richardson and Worraker1992; Coronado-Matutti et al. Reference Coronado-Matutti, Souza Mendes and Carvalho2004; Bahrani et al. Reference Bahrani, Nouar, Neveu and Becker2015; Sinevic, Kuboi & Nienow Reference Sinevic, Kuboi and Nienow1986). The non-dimensional acceleration rate,

(where ![]() $t^* = \mu t / \rho d^2$ is time non-dimensionalised with respect to the viscous time scale) must be kept low to ensure that the flow state is independent of the acceleration rate, i.e. the system can be treated as quasi-static (Dutcher & Muller Reference Dutcher and Muller2009). The mean values of

$t^* = \mu t / \rho d^2$ is time non-dimensionalised with respect to the viscous time scale) must be kept low to ensure that the flow state is independent of the acceleration rate, i.e. the system can be treated as quasi-static (Dutcher & Muller Reference Dutcher and Muller2009). The mean values of ![]() $\mathrm {d}Re/\mathrm {d}t^*$ for each polymer solution are listed in table 2, along with the value at onset of Taylor vortex flow,

$\mathrm {d}Re/\mathrm {d}t^*$ for each polymer solution are listed in table 2, along with the value at onset of Taylor vortex flow, ![]() $( \mathrm {d}Re/\mathrm {d}t^* )_c$.

$( \mathrm {d}Re/\mathrm {d}t^* )_c$.

Table 2. Experimental conditions used in the measurements for each polymer solution. The mean quantity of ![]() $De/Re$ is found by averaging the values in figure 5 over the range

$De/Re$ is found by averaging the values in figure 5 over the range ![]() $Re = 50\text {--}1000$. The number of tests,

$Re = 50\text {--}1000$. The number of tests, ![]() $N_{tests}$, refers to the repeated measurements in which the Reynolds number was slowly increased (i.e. it does not include tests in which the cylinder was decelerated).

$N_{tests}$, refers to the repeated measurements in which the Reynolds number was slowly increased (i.e. it does not include tests in which the cylinder was decelerated).

It should be noted that the non-dimensional acceleration rates listed in table 2 are all above unity, and as such, the experiments are not quasi-static as defined by Dutcher & Muller (Reference Dutcher and Muller2009) and may be influenced by the acceleration rate of the inner cylinder. In many other studies, authors choose to use a high viscosity solvent, which allows for higher acceleration rates and shorter experiments, as well as simplifying the physics by suppressing shear-thinning effects. However, examining the effects of shear-thinning rheology as well as viscoelastic effects is a central aim of this study, thus necessitating a relatively low viscosity. This problem is compounded by other experimental factors which prevent the use of very long experiments, including the desire to continuously monitor the flow throughout each experiment at a sampling rate that is sufficiently high to capture all relevant frequencies, the limited camera memory, the need to avoid any noticeable sedimentation of the flakes used for visualisation at low rotation speeds (i.e. in the CCF regime), particularly at low concentration suspensions. However, for the highest concentration solution, it was possible to perform a very long experiment over the course of several hours in which ![]() $\mathrm {d}Re/\mathrm {d}t^*$ was maintained at a very low magnitude (below 0.05), in order to ensure that the existence of the various phenomena discussed in this paper were not reliant on the choice of acceleration rate. These experiments and results will be discussed in § 4.

$\mathrm {d}Re/\mathrm {d}t^*$ was maintained at a very low magnitude (below 0.05), in order to ensure that the existence of the various phenomena discussed in this paper were not reliant on the choice of acceleration rate. These experiments and results will be discussed in § 4.

The acceleration rate can be expected to affect the results of parameters such as the critical Reynolds number, as will be discussed later, especially in dilute suspensions (![]() $c \leq 50\ \textrm {ppm}$), where

$c \leq 50\ \textrm {ppm}$), where ![]() $(\mathrm {d}Re/\mathrm {d}t^*)_c$ can be large (table 2). However, we note that estimates of

$(\mathrm {d}Re/\mathrm {d}t^*)_c$ can be large (table 2). However, we note that estimates of ![]() $Re_c$ for the Newtonian case (for which

$Re_c$ for the Newtonian case (for which ![]() $(\mathrm {d}Re/\mathrm {d}t^*)_c = 5.94$) were within

$(\mathrm {d}Re/\mathrm {d}t^*)_c = 5.94$) were within ![]() ${\pm }2$ of the theoretical predictions for this radius ratio (Esser & Grossmann Reference Esser and Grossmann1998; Dutcher & Muller Reference Dutcher and Muller2007).

${\pm }2$ of the theoretical predictions for this radius ratio (Esser & Grossmann Reference Esser and Grossmann1998; Dutcher & Muller Reference Dutcher and Muller2007).

For each polymer suspension, after the cylinder rotation speed was gradually increased and the maximum Reynolds number was reached, the cylinder rotation speed was held constant for approximately five minutes to allow the data to be saved from the camera, and the cylinder was then decelerated using the same magnitude of acceleration as in the ramp-up stage, in order to study the effects of hysteresis. Following this, the accelerating stage of the measurements was repeated a number of times (![]() $N_{tests}$ in table 2) under the same conditions to assess the repeatability of the dynamics.

$N_{tests}$ in table 2) under the same conditions to assess the repeatability of the dynamics.

The flow was visualised by adding a small quantity (volume fraction of ![]() ${\approx }10^{-4}$) of reflective flakes of mica and illuminating the flow using a white LED (SugarCUBE, Edmund Optics) as indicated in figure 4. The mica flakes are small and highly anisotropic, such that they align with the flow. As the amount of light scattered by the flakes strongly depends on their orientation, the flakes represent a useful means of visualising the direction of the flow (Dutcher & Muller Reference Dutcher and Muller2009; Abcha et al. Reference Abcha, Latrache, Dumouchel and Mutabazi2008; Martinez-Arias & Peixinho Reference Martínez-Arias and Peixinho2017; Majji, Banerjee & Morris Reference Majji, Banerjee and Morris2018). For such small volume fractions, the flakes had a negligible effect on the fluid viscosity, which was confirmed using rheology measurements.

${\approx }10^{-4}$) of reflective flakes of mica and illuminating the flow using a white LED (SugarCUBE, Edmund Optics) as indicated in figure 4. The mica flakes are small and highly anisotropic, such that they align with the flow. As the amount of light scattered by the flakes strongly depends on their orientation, the flakes represent a useful means of visualising the direction of the flow (Dutcher & Muller Reference Dutcher and Muller2009; Abcha et al. Reference Abcha, Latrache, Dumouchel and Mutabazi2008; Martinez-Arias & Peixinho Reference Martínez-Arias and Peixinho2017; Majji, Banerjee & Morris Reference Majji, Banerjee and Morris2018). For such small volume fractions, the flakes had a negligible effect on the fluid viscosity, which was confirmed using rheology measurements.

Figure 4. Sketch of the test section and flow visualisation system used, showing the flow cell, the axis of rotation of the inner cylinder, the light source and the camera.

Images were acquired using a Phantom Miro 340 camera along the entire span of the flow cell at a fixed frame rate (table 2). The frame rate was at least three times the maximum rotation speed of the cylinder and could resolve all the frequencies present in the flow. Each image had a size of ![]() $2560 \times 16$ pixels (2224 of which spanned the flow cell). All images were averaged to form a single profile along the axial direction of 2224 pixels, and all the profiles acquired as the cylinder accelerated were compiled into a matrix, which we refer to as a ‘flow map’. A similar approach has been used by previous authors in the literature (Coronado-Matutti et al. Reference Coronado-Matutti, Souza Mendes and Carvalho2004; Bahrani et al. Reference Bahrani, Nouar, Neveu and Becker2015; Sinevic et al. Reference Sinevic, Kuboi and Nienow1986; Baumert & Muller Reference Baumert and Muller1997).

$2560 \times 16$ pixels (2224 of which spanned the flow cell). All images were averaged to form a single profile along the axial direction of 2224 pixels, and all the profiles acquired as the cylinder accelerated were compiled into a matrix, which we refer to as a ‘flow map’. A similar approach has been used by previous authors in the literature (Coronado-Matutti et al. Reference Coronado-Matutti, Souza Mendes and Carvalho2004; Bahrani et al. Reference Bahrani, Nouar, Neveu and Becker2015; Sinevic et al. Reference Sinevic, Kuboi and Nienow1986; Baumert & Muller Reference Baumert and Muller1997).

For Carreau fluids, the degree of shear-thinning depends on the strain rate, with the fluid behaving as Newtonian at very low or high strain rates. This means that the degree of shear-thinning will vary throughout an experiment as the Reynolds number increases. Figure 5 shows how the ‘effective’ flow index, which is given by the local slope of the stress-strain curve in log-log space (Coronado-Matutti et al. Reference Coronado-Matutti, Souza Mendes and Carvalho2004),

varies throughout each experiment. As can be seen from table 1, the estimates for ![]() $n$ and

$n$ and ![]() $\lambda _c$ can be somewhat scattered, due to the difficulty in acquiring reliable rheological measurements at low strain rates when the magnitude of stress is low. While the estimates of

$\lambda _c$ can be somewhat scattered, due to the difficulty in acquiring reliable rheological measurements at low strain rates when the magnitude of stress is low. While the estimates of ![]() $n$ vary non-monotonically with polymer concentration, in opposition to the trends seen from the flow curves in figure 1, the effective flow index decreases with

$n$ vary non-monotonically with polymer concentration, in opposition to the trends seen from the flow curves in figure 1, the effective flow index decreases with ![]() $c$ and represents a more useful means of characterising the degree of shear-thinning in each fluid. Table 1 lists the mean effective flow index,

$c$ and represents a more useful means of characterising the degree of shear-thinning in each fluid. Table 1 lists the mean effective flow index, ![]() $\overline {n_e}$, which is found by averaging the values of

$\overline {n_e}$, which is found by averaging the values of ![]() $n_e$ that occur over the range

$n_e$ that occur over the range ![]() $Re = 50\text {--}1000$.

$Re = 50\text {--}1000$.

Figure 5![]() $(b)$ shows the variation in the elasticity as a function of Reynolds number for the cases in which the relaxation time was large enough to be measured. The trends in figure 5

$(b)$ shows the variation in the elasticity as a function of Reynolds number for the cases in which the relaxation time was large enough to be measured. The trends in figure 5![]() $(b)$ show that the change in

$(b)$ show that the change in ![]() $De/Re$ are relatively small over the course of each experiment, but that the importance of the elasticity changes dramatically over the range of

$De/Re$ are relatively small over the course of each experiment, but that the importance of the elasticity changes dramatically over the range of ![]() $c$ examined. Using this data, the measurements can be divided into three regimes; inelastic (

$c$ examined. Using this data, the measurements can be divided into three regimes; inelastic (![]() $c \leq 50\ \textrm {ppm}$,

$c \leq 50\ \textrm {ppm}$, ![]() $De \ll 1$), weakly viscoelastic (

$De \ll 1$), weakly viscoelastic (![]() $c = 100\text {--}500\ \textrm {ppm}$,

$c = 100\text {--}500\ \textrm {ppm}$, ![]() $De/Re \ll 1$) and viscoelastic (

$De/Re \ll 1$) and viscoelastic (![]() $c \geq 1000\ \textrm {ppm}$,

$c \geq 1000\ \textrm {ppm}$, ![]() $De/Re \gtrsim 0.1$), as indicated in table 2.

$De/Re \gtrsim 0.1$), as indicated in table 2.

These regimes are equivalent to dilute, semi-dilute and concentrated regimes, as discussed with respect to the rheology (table 1).

3. Results

3.1. Overview

The critical Reynolds number for the onset of Taylor vortex flow found for each of the experiments is summarised in figure 6. For completeness, ![]() $Re_c$ is presented as a function of the polymer concentration, as well as the effective flow index and elasticity ratio, allowing the effect of both the shear-thinning and viscoelastic rheology to be examined. The observed critical Reynolds numbers for the Newtonian case range between 89.3 and 92.3, which are in good agreement with the analytical predictions of Esser & Grossmann (Reference Esser and Grossmann1998) (

$Re_c$ is presented as a function of the polymer concentration, as well as the effective flow index and elasticity ratio, allowing the effect of both the shear-thinning and viscoelastic rheology to be examined. The observed critical Reynolds numbers for the Newtonian case range between 89.3 and 92.3, which are in good agreement with the analytical predictions of Esser & Grossmann (Reference Esser and Grossmann1998) (![]() $Re_c = 91.2$) and Dutcher & Muller (Reference Dutcher and Muller2007) (

$Re_c = 91.2$) and Dutcher & Muller (Reference Dutcher and Muller2007) (![]() $Re_c = 89.8$) for this radius ratio. There is a general trend of decreasing

$Re_c = 89.8$) for this radius ratio. There is a general trend of decreasing ![]() $Re_c$ with polymer concentration, although the data show more scatter for the xanthan solutions compared to the Newtonian case. Some of the scatter at low concentrations may be a result of the rate of change of

$Re_c$ with polymer concentration, although the data show more scatter for the xanthan solutions compared to the Newtonian case. Some of the scatter at low concentrations may be a result of the rate of change of ![]() $Re$ (table 2), as the experiments are not quasi-static (Dutcher & Muller Reference Dutcher and Muller2009), with non-dimensional acceleration rates ranging from 0.72 to 9.86, depending on the solution.

$Re$ (table 2), as the experiments are not quasi-static (Dutcher & Muller Reference Dutcher and Muller2009), with non-dimensional acceleration rates ranging from 0.72 to 9.86, depending on the solution.

The tendency for shear-thinning to cause a reduction in the critical Reynolds number has been noted in previous studies (Lockett et al. Reference Lockett, Richardson and Worraker1992; Escudier et al. Reference Escudier, Gouldson and Jones1995; Alibenyahia et al. Reference Alibenyahia, Lemaitre, Nouar and Ait-Messaoudene2012; Cagney & Balabani Reference Cagney and Balabani2019b). The elasticity also appears to be associated with a progressive destabilisation of the flow (figure 6c), which is not always the case for Boger fluids (Muller Reference Muller2008), although it is not straightforward to disentangle the effects of shear-thinning and viscoelasticity.

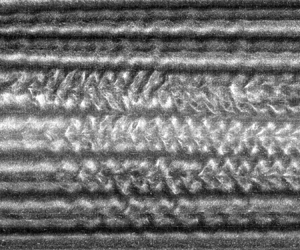

Sample flow maps for each of the solutions are presented in figure 7. The dashed vertical lines denote the boundaries of the different flow regimes, with the left-most line in each case indicating the transition from circular Couette flow to Taylor vortex flow (![]() $Re_c$) and the other line at high Reynolds number indicating the transition to wavy vortex flow (

$Re_c$) and the other line at high Reynolds number indicating the transition to wavy vortex flow (![]() $Re_{c,w}$). These maps reveal spatial variations in the flow, but it is difficult to detect by visual inspection the onset of any unsteadiness or WVF. In order to do this, it is helpful to view the maps alongside their corresponding ‘frequency maps’, which are shown in figure 8. These were compiled by dividing the flow maps into segments of 256 columns (with an overlap of 50 %), and calculating the average fast Fourier transform (FFT) for each row in each segment, before compiling all the averaged spectra to form a stack (in a similar manner to how the instantaneous images were averaged to compile the flow maps).

$Re_{c,w}$). These maps reveal spatial variations in the flow, but it is difficult to detect by visual inspection the onset of any unsteadiness or WVF. In order to do this, it is helpful to view the maps alongside their corresponding ‘frequency maps’, which are shown in figure 8. These were compiled by dividing the flow maps into segments of 256 columns (with an overlap of 50 %), and calculating the average fast Fourier transform (FFT) for each row in each segment, before compiling all the averaged spectra to form a stack (in a similar manner to how the instantaneous images were averaged to compile the flow maps).

Figure 7. Flow maps for solutions of xanthan gum in a glycerol–water solvent for various concentrations. The vertical dashed white lines denote the critical Reynolds numbers for the onset of Taylor vortex flow and the wavy instability, while the large white circles indicate merger of neighbouring vortices. The corresponding frequency maps are shown in figure 8. ![]() $(a)$ 0 ppm.

$(a)$ 0 ppm. ![]() $(b)$ 20 ppm.

$(b)$ 20 ppm. ![]() $(c)$ 50 ppm.

$(c)$ 50 ppm. ![]() $(d)$ 100 ppm.

$(d)$ 100 ppm. ![]() $(e)$ 200 ppm.

$(e)$ 200 ppm. ![]() $(f)$ 500 ppm.

$(f)$ 500 ppm. ![]() $(g)$ 1000 ppm.

$(g)$ 1000 ppm. ![]() $(h)$ 2000 ppm.

$(h)$ 2000 ppm.

Figure 8. Frequency maps for solutions of xanthan gum in a glycerol–water solvent for various concentrations. The dashed line represents the rotation speed of the inner cylinder (which does not vary linearly with Reynolds number for the non-Newtonian cases), while the dark regions indicate frequencies at which significant energy is occurring. The scales are arbitrary. See text for a description of how the frequency maps are calculated. The corresponding flow maps are shown in figure 7. ![]() $(a)$ 0 ppm.

$(a)$ 0 ppm. ![]() $(b)$ 20 ppm.

$(b)$ 20 ppm. ![]() $(c)$ 50 ppm.

$(c)$ 50 ppm. ![]() $(d)$ 100 ppm.

$(d)$ 100 ppm. ![]() $(e)$ 200 ppm.

$(e)$ 200 ppm. ![]() $(f)$ 500 ppm.

$(f)$ 500 ppm. ![]() $(g)$ 1000 ppm.

$(g)$ 1000 ppm. ![]() $(h)$ 2000 ppm.

$(h)$ 2000 ppm.

By firstly examining the Newtonian case in figures 7(a) and 8(a), we can see that for ![]() $Re < Re_c$, circular Couette flow dominates, and all the flakes are aligned with the streamlines, leading to a uniform texture in the flow maps (with slight axial variations due to the positioning of the light source), while the frequency maps indicate that any unsteady energy in the flow is limited to low frequencies. As the rotation speed is increased, Görtler vortices form at either end of the flow cell, before the flow becomes unstable at

$Re < Re_c$, circular Couette flow dominates, and all the flakes are aligned with the streamlines, leading to a uniform texture in the flow maps (with slight axial variations due to the positioning of the light source), while the frequency maps indicate that any unsteady energy in the flow is limited to low frequencies. As the rotation speed is increased, Görtler vortices form at either end of the flow cell, before the flow becomes unstable at ![]() $Re_c$. The formation of the toroidal Taylor vortices leads to the appearance of several light and dark horizontal banks in the flow map. As the Reynolds number is increased up to 1000, the flow map does not indicate any further clear changes, but at

$Re_c$. The formation of the toroidal Taylor vortices leads to the appearance of several light and dark horizontal banks in the flow map. As the Reynolds number is increased up to 1000, the flow map does not indicate any further clear changes, but at ![]() $Re = 428$, a dark band appears at

$Re = 428$, a dark band appears at ![]() $f/N_{max} \approx 0.3$ in the frequency map (where

$f/N_{max} \approx 0.3$ in the frequency map (where ![]() $N_{max} = 2 {\rm \pi}\omega _{max}$, and

$N_{max} = 2 {\rm \pi}\omega _{max}$, and ![]() $N$ is the cylinder rotation speed in Hz), indicating the onset of wavy vortex flow. As the Reynolds number is increased further, the frequency of the wavy instability also increases, appearing to maintain a fixed proportionality to the rotation speed.

$N$ is the cylinder rotation speed in Hz), indicating the onset of wavy vortex flow. As the Reynolds number is increased further, the frequency of the wavy instability also increases, appearing to maintain a fixed proportionality to the rotation speed.

Similar trends are observed in the flow and frequency maps for the relatively weak xanthan solutions of ![]() $20\text {--}100\ \textrm {ppm}$ (figures 7b–d and 8b–d). In these cases, non-Newtonian rheology means that the Reynolds number is no longer linearly dependent on the cylinder rotation speed, and, hence, the dashed lines indicating the rotation speed in the frequency maps are no longer linear. The only significant changes relative to the Newtonian case occur at

$20\text {--}100\ \textrm {ppm}$ (figures 7b–d and 8b–d). In these cases, non-Newtonian rheology means that the Reynolds number is no longer linearly dependent on the cylinder rotation speed, and, hence, the dashed lines indicating the rotation speed in the frequency maps are no longer linear. The only significant changes relative to the Newtonian case occur at ![]() $c = 100\ \textrm {ppm}$, where we observe a sudden increase in the critical Reynolds number for the onset of the wavy instability and a reduction in the wavy frequency at which it occurs. At slightly higher concentrations (figure 8e,f), the frequency maps continue to be dominated by single ridges. However, there are some notable differences, with the ridges observed for the 200 ppm and 500 ppm solutions being less clearly defined and appearing to meander slightly without a fixed proportionality with the rotation speed. Other weak ridges can also be seen, indicating a more disorganised and less periodic flow. This increased disorganisation is apparent in the corresponding flow maps in figure 7, particularly at high Reynolds numbers where the spacing of vortices varies gradually with

$c = 100\ \textrm {ppm}$, where we observe a sudden increase in the critical Reynolds number for the onset of the wavy instability and a reduction in the wavy frequency at which it occurs. At slightly higher concentrations (figure 8e,f), the frequency maps continue to be dominated by single ridges. However, there are some notable differences, with the ridges observed for the 200 ppm and 500 ppm solutions being less clearly defined and appearing to meander slightly without a fixed proportionality with the rotation speed. Other weak ridges can also be seen, indicating a more disorganised and less periodic flow. This increased disorganisation is apparent in the corresponding flow maps in figure 7, particularly at high Reynolds numbers where the spacing of vortices varies gradually with ![]() $Re$. There are also two points in each flow map (highlighted by the large white circles), where the number of bands is abruptly reduced, corresponding to the sudden disappearance of a vortex pair, as the vortices merge with their neighbours of opposite sign.

$Re$. There are also two points in each flow map (highlighted by the large white circles), where the number of bands is abruptly reduced, corresponding to the sudden disappearance of a vortex pair, as the vortices merge with their neighbours of opposite sign.

Finally, in the most dense xanthan solutions (figure 7g,h), several merger events occur and much of the flow maps are characterised by gradual fluctuations in the position of vortices. This drift in the size and position of vortices is evident in regions of the maps near merger events, but also appears to occur independently of the vortex merger phenomenon; for example, in the range ![]() $Re = 200\text {--}400$ in both maps, the bands are no longer purely horizontal, indicating the gradual contraction of some vortices and the widening or dilatation of others. The merger and drift processes result in a relatively small number of very wide vortices by

$Re = 200\text {--}400$ in both maps, the bands are no longer purely horizontal, indicating the gradual contraction of some vortices and the widening or dilatation of others. The merger and drift processes result in a relatively small number of very wide vortices by ![]() $Re = 1000$, with the largest vortices being found near the centre of the flow cell, i.e.

$Re = 1000$, with the largest vortices being found near the centre of the flow cell, i.e. ![]() $z/d \approx 11$.

$z/d \approx 11$.

There is also a significant reduction in the critical Reynolds number for the onset of wavy flow, which now occurs relatively soon after the formation of Taylor vortices. The frequency maps (figure 8g,h) show that the nature of the wavy instability has also been significantly altered, with multiple bands present throughout different ranges of ![]() $Re$. The increase in the disorder in the frequency maps and the amount of energy occurring at frequencies other than harmonics of

$Re$. The increase in the disorder in the frequency maps and the amount of energy occurring at frequencies other than harmonics of ![]() $N$ or the primary ridge for

$N$ or the primary ridge for ![]() $c \geq 200\ \textrm {ppm}$ is likely to be associated with the corresponding increase in

$c \geq 200\ \textrm {ppm}$ is likely to be associated with the corresponding increase in ![]() $De/Re$, as the effective flow index does not change significantly (table 1).

$De/Re$, as the effective flow index does not change significantly (table 1).

Perhaps the most significant observation from the flow and frequency maps is not the change in the dynamics as the concentration is increased, but the similarity between the dynamics in all eight fluids. While there are clear changes in the dynamics in each case, the overall pattern of the flow maps remains the same, i.e. a transition from circular Couette flow to Taylor vortex flow to a wavy state. This stands in contrast to several previous studies, which showed that for similar ranges of ![]() $De/Re$ (

$De/Re$ (![]() $\gtrsim 0.01$), the flow was characterised by disordered oscillations (Groisman & Steinberg Reference Groisman and Steinberg1996, Reference Groisman and Steinberg1997), standing waves (Groisman & Steinberg Reference Groisman and Steinberg1996; Baumert & Muller Reference Baumert and Muller1999), diwhirls (Groisman & Steinberg Reference Groisman and Steinberg1997; Kumar & Graham Reference Kumar and Graham2000; Lange & Eckhardt Reference Lange and Eckhardt2001), or ribbons or spirals (Thomas et al. Reference Thomas, Al-Mubaiyadh, Sureshkumar and Khomami2006).

$\gtrsim 0.01$), the flow was characterised by disordered oscillations (Groisman & Steinberg Reference Groisman and Steinberg1996, Reference Groisman and Steinberg1997), standing waves (Groisman & Steinberg Reference Groisman and Steinberg1996; Baumert & Muller Reference Baumert and Muller1999), diwhirls (Groisman & Steinberg Reference Groisman and Steinberg1997; Kumar & Graham Reference Kumar and Graham2000; Lange & Eckhardt Reference Lange and Eckhardt2001), or ribbons or spirals (Thomas et al. Reference Thomas, Al-Mubaiyadh, Sureshkumar and Khomami2006).

To demonstrate the differences between the current results and those of previous studies, figure 9 shows the change in flow regime for the polymer solutions for ![]() $c \geq 100\ \textrm {ppm}$ (i.e. the cases in which the relaxation time could be reliably measured), as a function of

$c \geq 100\ \textrm {ppm}$ (i.e. the cases in which the relaxation time could be reliably measured), as a function of ![]() $De/Re$ and

$De/Re$ and ![]() $Re/Re_{c,0}$ (where

$Re/Re_{c,0}$ (where ![]() $Re_{c,0}$ is the critical Reynolds number in the absence of polymers), along with the regime boundaries reported by Groisman & Steinberg (Reference Groisman and Steinberg1998). The polymer solutions examined by Groisman & Steinberg were very weakly shear-thinning, with a change in viscosity of approximately 10 % over the course of their measurements, which they neglected, treating the solutions as Boger fluids.

$Re_{c,0}$ is the critical Reynolds number in the absence of polymers), along with the regime boundaries reported by Groisman & Steinberg (Reference Groisman and Steinberg1998). The polymer solutions examined by Groisman & Steinberg were very weakly shear-thinning, with a change in viscosity of approximately 10 % over the course of their measurements, which they neglected, treating the solutions as Boger fluids.

Figure 9. Comparison between the flow regimes observed in the current study (as seen in figure 7), and the boundaries identified by Groisman & Steinberg (Reference Groisman and Steinberg1998) for a viscoelastic fluid with negligible shear-thinning. The black lines with circular markers denote the regime boundaries measured by Groisman & Steinberg, and the thick lines are from the current experiments, with line style and colour denoting the different regimes encountered. The nonlinear relationship between viscosity and strain rate means that as ![]() $Re$ is increased, the experiments follow a curved path through the

$Re$ is increased, the experiments follow a curved path through the ![]() $Re_c/Re_{c,0} - De/Re$ plane, starting from the bottom right of the graph.

$Re_c/Re_{c,0} - De/Re$ plane, starting from the bottom right of the graph.

For the weakly viscoelastic fluids in our experiments, the flow transitions from CCF to TVF at ![]() $Re/Re_{c,0} \approx 0.8$, and the flow does not become unsteady until a much higher

$Re/Re_{c,0} \approx 0.8$, and the flow does not become unsteady until a much higher ![]() $Re$. In contrast, for the Boger fluids examined by Groisman & Steinberg, shortly after entering the TVF regime, the flow transitions to rotating standing waves and finally to disordered oscillations. The difference between our results and those of Groisman & Steinberg are even starker for

$Re$. In contrast, for the Boger fluids examined by Groisman & Steinberg, shortly after entering the TVF regime, the flow transitions to rotating standing waves and finally to disordered oscillations. The difference between our results and those of Groisman & Steinberg are even starker for ![]() $De/Re > 0.1$; while the xanthan gum solutions in our study still follow the path of

$De/Re > 0.1$; while the xanthan gum solutions in our study still follow the path of ![]() $\textrm {CCF} \to \textrm {TVF} \to \textrm {WVF}$, the Boger fluids transition from CCF to a state of either diwhirls or oscillating strips at very low Reynolds numbers before exhibiting disordered oscillations. Based on the data of Groisman & Steinberg (Reference Groisman and Steinberg1998), one would expect disordered oscillations to occur for almost the entirety of the experiments for

$\textrm {CCF} \to \textrm {TVF} \to \textrm {WVF}$, the Boger fluids transition from CCF to a state of either diwhirls or oscillating strips at very low Reynolds numbers before exhibiting disordered oscillations. Based on the data of Groisman & Steinberg (Reference Groisman and Steinberg1998), one would expect disordered oscillations to occur for almost the entirety of the experiments for ![]() $c \geq 1000\ \textrm {ppm}$.

$c \geq 1000\ \textrm {ppm}$.

The differences between our experiments and those of Groisman & Steinberg are unlikely to be attributed to transient effects, because, while the non-dimensional acceleration rates are above unity, they remain relatively small (table 2), especially for high polymer concentrations (this is confirmed in § 4 for the ![]() $c = 2000\ \textrm {ppm}$ case).

$c = 2000\ \textrm {ppm}$ case).

The absence of disordered oscillations, rotating standing waves, oscillatory strips, diwhirls or any other regime associated with Boger fluids, and the clear differences between our results and those of Groisman & Steinberg (Reference Groisman and Steinberg1998) appear to be related to the relatively low solvent viscosity in our study. The low solvent viscosity means that the viscosity component due to the polymers, ![]() $\mu _p$, is more significant, which in turn allows for the significant shear-thinning behaviour, and it is possible that this shear-thinning may act to suppress the elastic and inertio-elastic instabilities that have been extensively described for Boger fluids.

$\mu _p$, is more significant, which in turn allows for the significant shear-thinning behaviour, and it is possible that this shear-thinning may act to suppress the elastic and inertio-elastic instabilities that have been extensively described for Boger fluids.

The low viscosity of the solvent may also affect the stability of the system via the first normal stress difference. Groisman & Steinberg (Reference Groisman and Steinberg1998) argued that ![]() $N_1$ is responsible for inducing elastic instabilities, and predicted (for a Newtonian fluid) that in the Couette regime,

$N_1$ is responsible for inducing elastic instabilities, and predicted (for a Newtonian fluid) that in the Couette regime, ![]() $N_1 = -2 \mu _p \lambda _r \dot {\gamma }^2$. In our case, the low solvent viscosity increases the relative importance of

$N_1 = -2 \mu _p \lambda _r \dot {\gamma }^2$. In our case, the low solvent viscosity increases the relative importance of ![]() $\mu _p$ and, thus, is likely to increase the relative strength of

$\mu _p$ and, thus, is likely to increase the relative strength of ![]() $N_1$ for a given value of

$N_1$ for a given value of ![]() $Re$ and

$Re$ and ![]() $De$ (Zirnsak, Boger & Tirtaatmadja Reference Zirnsak, Boger and Tirtaatmadja1999); therefore, the low solvent viscosity can be expected to promote elastic instabilities relative to Boger fluids, i.e. the opposite trend to that seen in figure 9. It appears to be unlikely that the normal stresses are responsible for the absence of elastic instabilities in the current experiments.

$De$ (Zirnsak, Boger & Tirtaatmadja Reference Zirnsak, Boger and Tirtaatmadja1999); therefore, the low solvent viscosity can be expected to promote elastic instabilities relative to Boger fluids, i.e. the opposite trend to that seen in figure 9. It appears to be unlikely that the normal stresses are responsible for the absence of elastic instabilities in the current experiments.

In any case, the presence of the polymers induces clear changes in the flow which are of interest. The most significant changes can be grouped into three categories: (i) changes in the nature of the wavy instability; (ii) the abrupt changes in the wavelength of the flow which occur via the sudden merger of vortices; and (iii) the slow drift of vortices. These three issues will be explored in turn in the following sections.

3.2. Wavy instabilities

The variation in the measured critical Reynolds number for the onset of wavy flow is shown in figure 10 in terms of the polymer concentration, effective flow index and elasticity. In contrast to the critical Reynolds number for the onset of Taylor vortex flow, the addition of moderate concentrations of xanthan gum lead to an increase in ![]() $Re_{c,w}$. As with the critical Reynolds number for TVF, the experimental results show some scatter, which may be influenced by the magnitude of the rate of change of

$Re_{c,w}$. As with the critical Reynolds number for TVF, the experimental results show some scatter, which may be influenced by the magnitude of the rate of change of ![]() $Re$ (table 2) for the dilute cases.

$Re$ (table 2) for the dilute cases.

Figure 10. Critical Reynolds number for the onset of wavy vortex flow, as a function of polymer concentration ![]() $(a)$, effective flow index

$(a)$, effective flow index ![]() $(b)$ and elasticity

$(b)$ and elasticity ![]() $(c)$. Each data point corresponds to a single test run, as detailed in table 2.

$(c)$. Each data point corresponds to a single test run, as detailed in table 2.

The trend of increasing ![]() $Re_{c,w}$ with concentration ceases as it reaches 1000 ppm, where

$Re_{c,w}$ with concentration ceases as it reaches 1000 ppm, where ![]() $Re_{c,w}$ experiences a dramatic reduction. This effect is unlikely to be explained solely by differences in the rate of change of

$Re_{c,w}$ experiences a dramatic reduction. This effect is unlikely to be explained solely by differences in the rate of change of ![]() $Re$, and appears to be clearly linked to the growing importance of elasticity on the fluid rheology; the change in the effective flow index is relatively small (table 1) for the 1000 ppm and 2000 ppm solutions, but they show a sharp increase in the elastic time scale (figure 5b). This is consistent with the observation of many previous researchers that for viscoelastic fluids, the flow transitions directly from circular Couette flow to an unsteady state (Muller Reference Muller2008; Khayat Reference Khayat1999; Avgousti & Beris Reference Avgousti and Beris1993).

$Re$, and appears to be clearly linked to the growing importance of elasticity on the fluid rheology; the change in the effective flow index is relatively small (table 1) for the 1000 ppm and 2000 ppm solutions, but they show a sharp increase in the elastic time scale (figure 5b). This is consistent with the observation of many previous researchers that for viscoelastic fluids, the flow transitions directly from circular Couette flow to an unsteady state (Muller Reference Muller2008; Khayat Reference Khayat1999; Avgousti & Beris Reference Avgousti and Beris1993).

For the Newtonian fluid (0 ppm) and more dilute solutions, the frequency maps in figure 8(a–f) indicated a clear relationship between the dominant frequency of the wavy instability (i.e. the wave speed) and the rotation speed of the inner cylinder. In order to quantify this relationship, segments of the frequency maps covering the Reynolds number range shortly after the onset of wavy flow (![]() $Re_{c,w} \leq Re \leq Re_{c,w}+200$) were examined to identify the non-dimensional frequency,

$Re_{c,w} \leq Re \leq Re_{c,w}+200$) were examined to identify the non-dimensional frequency, ![]() $f /N$, at which most energy was occurring. This equated to the frequency of the wavy instability,

$f /N$, at which most energy was occurring. This equated to the frequency of the wavy instability, ![]() $f_w$, which is plotted in figure 11 for all the measurements as a function of polymer concentration, flow index and elasticity. For the Newtonian mixture and dilute solutions, the wave frequency remains locked at

$f_w$, which is plotted in figure 11 for all the measurements as a function of polymer concentration, flow index and elasticity. For the Newtonian mixture and dilute solutions, the wave frequency remains locked at ![]() $f_w/N \approx 0.76$, before transitioning at 100 ppm to

$f_w/N \approx 0.76$, before transitioning at 100 ppm to ![]() $f_w/N \approx 0.48$. Returning to the frequency map for the slightly more dilute case of 50 ppm (figure 8c), it can be seen that at

$f_w/N \approx 0.48$. Returning to the frequency map for the slightly more dilute case of 50 ppm (figure 8c), it can be seen that at ![]() $Re \approx 900$, the wavy instability undergoes a transition whereby its frequency changes from

$Re \approx 900$, the wavy instability undergoes a transition whereby its frequency changes from ![]() $f_w/N \approx 0.76$, as seen for the Newtonian and dilute fluids, to 0.48, as seen for the more dense cases (i.e. 200 ppm and 500 ppm). This suggests that the presence of the xanthan gum chains encourages the wavy instability to operate at a lower relative frequency, but that this shift is itself Reynolds-number dependent. The fact that the wavy frequency occurs at either

$f_w/N \approx 0.76$, as seen for the Newtonian and dilute fluids, to 0.48, as seen for the more dense cases (i.e. 200 ppm and 500 ppm). This suggests that the presence of the xanthan gum chains encourages the wavy instability to operate at a lower relative frequency, but that this shift is itself Reynolds-number dependent. The fact that the wavy frequency occurs at either ![]() $f_w/N \approx 0.48$ or 0.76 for all six solutions with

$f_w/N \approx 0.48$ or 0.76 for all six solutions with ![]() $c \leq 500\ \textrm {ppm}$, irrespective of any differences in rheology or experimental conditions, such as the rate of change of

$c \leq 500\ \textrm {ppm}$, irrespective of any differences in rheology or experimental conditions, such as the rate of change of ![]() $Re$, indicates the robustness of the relationship between the non-dimensional frequency of the wavy instability and the polymer concentration.

$Re$, indicates the robustness of the relationship between the non-dimensional frequency of the wavy instability and the polymer concentration.

Figure 11. Variation in the dominant frequency of the wavy instability with polymer concentration ![]() $(a)$, effective flow index

$(a)$, effective flow index ![]() $(b)$ and elasticity

$(b)$ and elasticity ![]() $(c)$. The frequency was measured over the range

$(c)$. The frequency was measured over the range ![]() $Re_{c,w} \leq Re \leq Re_{c,w}+200$. Each data point corresponds to a single test run, as detailed in table 2.

$Re_{c,w} \leq Re \leq Re_{c,w}+200$. Each data point corresponds to a single test run, as detailed in table 2.

As the concentration is increased further and the effects of elasticity become dominant and ![]() $Re_{c,w}$ is reduced, the wavy frequency experiences another reduction (although this change was not observed in all test runs). However, the frequency maps for the dense solutions of 1000 ppm and 2000 ppm (figure 8g,h) show that the instability is more complex than in previous cases and characterising the unsteady flow using a single frequency component may represent an over-simplification of the physics. It is clear that the addition of polymers for

$Re_{c,w}$ is reduced, the wavy frequency experiences another reduction (although this change was not observed in all test runs). However, the frequency maps for the dense solutions of 1000 ppm and 2000 ppm (figure 8g,h) show that the instability is more complex than in previous cases and characterising the unsteady flow using a single frequency component may represent an over-simplification of the physics. It is clear that the addition of polymers for ![]() $c \geq 1000\ \textrm {ppm}$ significantly affects not just the critical Reynolds number for the onset of the wavy instability, but also the nature of the instability.

$c \geq 1000\ \textrm {ppm}$ significantly affects not just the critical Reynolds number for the onset of the wavy instability, but also the nature of the instability.

In order to examine the nature of the wavy instability in more detail, the frequency maps can be examined over a relatively short number of cycles, such that the change in the Reynolds number is relatively small. Such ‘snapshots’ of the flow map over 20 cylinder revolutions are shown in figure 12 for four polymer solutions at ![]() $Re = 700$. The changes in

$Re = 700$. The changes in ![]() $Re$ over the course of each snapshot are less than 6.5. The wavy instability can clearly be seen in figure 12(a) (the Newtonian case), with several dark ridges undergoing periodic oscillations. These dark ridges correspond to the inward and outward jets between vortices, where the flat surfaces of the mica flakes are facing perpendicular to the direction of light and the viewing angle of the camera, resulting in a lack of reflected light in the images. The amplitude of the waves tends to be highest near the centre of the flow cell (

$Re$ over the course of each snapshot are less than 6.5. The wavy instability can clearly be seen in figure 12(a) (the Newtonian case), with several dark ridges undergoing periodic oscillations. These dark ridges correspond to the inward and outward jets between vortices, where the flat surfaces of the mica flakes are facing perpendicular to the direction of light and the viewing angle of the camera, resulting in a lack of reflected light in the images. The amplitude of the waves tends to be highest near the centre of the flow cell (![]() $z/d \approx 11$), as was noted by Crawford et al. (Reference Crawford, Park and Donnelly1985) for a large aspect ratio (

$z/d \approx 11$), as was noted by Crawford et al. (Reference Crawford, Park and Donnelly1985) for a large aspect ratio (![]() $\varGamma = 70.4$).

$\varGamma = 70.4$).

Figure 12. Brief ‘snapshots’ of the flow maps at ![]() $Re = 700$ for four suspensions of xanthan gum; 0 ppm

$Re = 700$ for four suspensions of xanthan gum; 0 ppm ![]() $(a)$, 50 ppm

$(a)$, 50 ppm ![]() $(b)$, 100 ppm