1. INTRODUCTION

Computer-aided design (CAD) is ubiquitous in both engineering education (Ye et al., Reference Ye, Peng, Chen and Cai2004) and industrial application (Field, Reference Field2003; Robertson et al., Reference Robertson, Walther and Radcliffe2007). Newly graduating engineers are increasingly competent in using CAD tools throughout the entire product development process. Further, as solid modeling programs become more efficient and more intuitive to use, they have begun to replace the traditional notepad at the conceptual design phase. Modeling is now used to create and display intended functions, to create varying designs from shared components or features, and to evaluate potential solutions. The effect of this rapid shift in the process of engineering design is of interest from both an educational and an industry perspective.

For the purpose of this paper, CAD tools include solid modeling tools, engineering analysis and simulation tools, manufacturing tools, and other computational support tools. Many developers of CAD systems claim that their product supports product development design engineersFootnote 1 (Ullman, Reference Ullman2001). However, little research exists addressing the impact that CAD implementation is having on design quality and creativity (Lawson, Reference Lawson2001; Robertson et al., Reference Robertson, Walther and Radcliffe2007; Robertson & Radcliffe, Reference Robertson and Radcliffe2009). There is however, research that asserts that CAD tools also have the potential to negatively impact the design process (Robertson et al., Reference Robertson, Walther and Radcliffe2007):

• Circumscribed thinking: occurs when the design tool limits the designer through interfering with the designers intent

• Premature fixation: the designer becomes resistant to change as the model takes on a high level of complexity or detail

• Bounded ideation: overuse of CAD tools decrease the designers motivation and creative abilities

1.1. Advancement of CAD in industry and education

The majority of today's highly experienced engineers were educated prior to the widespread availability of advanced CAD programs and solid modeling packages. This led to designers completing the conceptual and embodiment design phase through sketching and performing manual calculations. If a CAD tool was used, it was most likely in the detailed design phase where the design was documented for production and manufacturing concerns. CAD systems have since advanced from two-dimensional (2-D) or three-dimensional (3-D) graphic representation tools to include modules that encompass the larger design process from analysis to manufacture (Rosario & Mulet, Reference Rosario and Mulet2006).

This case study focuses on the use of CAD tools by novice engineers defined as having less than 5 years of industry experience (Ahmed, Reference Ahmed1999). This paper examines the effect that CAD tools have throughout the design process and how the impact of CAD ultimately affects the final design.

1.2. Differences identified between hand sketching and CAD representation

A common criticism of CAD is that it causes the designer to focus on details instead of the underlying principles (Utterback, Reference Utterback2006). It is written that “sketching by hand allows a designer to capture an idea quickly; it concentrates on the essentials rather than on bells and whistles” (Utterback, Reference Utterback2006). This can be supported by examining the information required by a CAD system to generate an object representation with respect to the amount of information required to sketch the concept. Further, based on the representation classification discussed in (Summers & Shah, Reference Summers and Shah2004), Table 1 represents the classification of sketch. The bold text shows the categories for sketch. Sketches have a user-defined flexibility with infinite size of the class. In addition, sketches have no local structure and there are no restriction rules on their global structure. Sketches are self-validating. The expression of the sketches includes mostly pictorial and textual representation. For the research, sketch refers to a hand drawn representation of a concept or idea. Further, instances of sketches discussed in this paper are mainly paper-pencil based. No instances of use of digital media such as stylus tablet for drawing sketches were found in this research.

Table 1. Representation classification for sketches

Note: Adapted from Summers and Shah (Reference Summers and Shah2004).

Sketches are developed mainly for communication and their clarity varies based on the sketcher. The object sketched may not signify the same form or function to every observer. In contrast, a solid model or drafted object is by nature a more exact representation, and thus its true form is less subjective to a group of observers. Table 2 illustrates the representation classification for CAD with bold text showing the categories for CAD.

Table 2. Representation classification for computer-aided design

Note: Adapted from Summers and Shah (Reference Summers and Shah2004).

As illustrated in Table 2, CAD has a predefined flexibility with a finite size of the vocabulary. The local structure is hierarchic and attributed with rules for all possible combinations for global structure. The expression for CAD models is mostly numerical and iconic and they are created with a purpose of communication, synthesis, and analysis with a high abstraction level.

Due to these conflicting arguments, it is difficult to make a definitive statement of the value of hand sketching versus computer-generated representations throughout all design phases. The advantages and disadvantages of each method vary as the designer progresses through the design process.

A case study is conducted to observe a group of senior level mechanical engineering students and explore their use of sketching versus CAD as the students completed a semester long industry sponsored design project. The case study presented in the paper aims at understanding the selection and implementation of various CAD tools in the design process by novice engineers. Referring back to a model of the design process (Pahl & Beitz, Reference Pahl and Beitz1995) and relating it to this case study (Section 2), it is seen that the use of CAD in the planning and clarification of the task step was inefficient (Section 3.1). The time spent modeling the original design exceeded the knowledge gained. This was especially apparent when compared to the knowledge that could have been gained through an abstract sketch (Section 3.2).

CAD representations are exact, yet it is the inexactness of the sketch that can induce creativity (Utterback, Reference Utterback2006). Once the proposed solution was modeled in the sixth week of the design project changes were not made until the physical prototype was created (Section 3.3). That 6 weeks went by without any design change suggests that the group was fixated on the solution that they had modeled. The high level of detail in the model provided unsupported confidence that the solution is optimal. That is, until the model was mentally reexamined when the physical prototype fabrication and assembly began (Section 3.4).

1.3. Process of creating solid models

Although creating solid models may seem daunting and complex to an outsider or an inexperienced user, recent programs have made solid model creation more intuitive. There are three modeling approaches in which a solid model can be created (Zeid, Reference Zeid2005). A designer does not select an approach in designing; instead, the model most likely will contain a combination of the approaches: primitive uses “union, subtraction, and intersection” (Zeid, Reference Zeid2005) to create shapes; features combines steps of the primitive approach with user friendly commands like “create hole”; sketching allows sketched 2-D shapes to be extruded, revolved, or swept to create 3-D models.

It is possible to create complex shapes in solid modeling packages using advanced functions (Mortenson, Reference Mortenson1997); however a novice user will most likely not be introduced to such functions. Also, since initial geometry must be defined in order to generate complex features, the incentive, especially in the conceptual design phase is to avoid these functions altogether and construct using simple, symmetric shapes. The team members who were the predominant CAD users stated the following when asked whether they felt that CAD tools expanded or limited their creativity:

“CAD can force your design to be more practical, which can limit creativity.” (member 2)

“It can be limiting if the part is very complicated and you don't know how to model it.” (member 3)

Understanding the method of how CAD programs work enables reviewing a design and questioning whether the computer aided the designer or whether it influences the designer to create an object using specific geometry.

2. CASE STUDY

The case study method of design research was used with the overall goal of understanding the role of CAD tools in engineering design. A single design project addressed by a team of four mechanical engineering senior design students was studied. Since sample logic is not enforced by case study as a research method, generalization can be drawn from a single case if well selected (Teegavarapu & Summers, Reference Teegavarapu and Summers2008). In order to triangulate the data, interviews were also conducted.

2.1. Case study objectives

Case studies are conducted in engineering design research to observe and gain insight into the design process that cannot necessarily be measured in a traditional manner (Eisenhardt, Reference Eisenhardt1989; Baird, Reference Baird2000; Ball, Reference Ball2000; Green, Reference Green2002; Summers & Shah, Reference Summers and Shah2004; Demian, Reference Demian2006; Ahmed, Reference Ahmed2007; Breslin, Reference Breslin2008; Teegavarapu et al., Reference Teegavarapu, Summers and Mocko2008; Teegavarapu & Summers, Reference Teegavarapu and Summers2008; Joshi & Summers, Reference Joshi and Summers2010; Summers & Joshi, Reference Summers and Joshi2010). Although the use of case studies is not always well perceived, it provides an opportunity to study an event the way it actually occurs (Yin, Reference Yin2006). As the person conducting the research does not have full control of the events as they occur, the research should be used to gain insight about the event being studied, and use that information to conduct more formal research from which conclusions can be drawn. In this research, the case study serves as a means to explore the use of sketches and CAD within the design process. The specific results will be used to identify trends and draw conclusions relating to this specific case study, and provide direction for future research.

The overall goal of this case study is to understand how novice engineers use sketching and select and implement the various CAD tools in the design process. Further, the case study aims at understanding the gains in terms of design efficiency and effectiveness from use of sketch versus use of CAD tools. To that end, the study of sketches and CAD tools used by the senior design students, throughout the design process is conducted. An overview of what was gained from the participant and the observer's perspective will be included. The time to complete each representation was tracked through self-reported biweekly time sheets. The efficiency of a representation method was found by comparing the knowledge gained to the time that it took to generate the representation. The effectiveness was determined by examining how the representation benefited the objective of creating a design that met the customer requirements. Conclusions are drawn regarding the impact that CAD tools had on process and product performance overall and within each design phase. Before exploring the case study and the results of case study, the followings sections will describe the senior design class at Clemson University: mechanical engineering 402 (ME-402).

2.2. Description of ME-402 at Clemson

ME-402 is a senior design class taught in the mechanical engineering department at Clemson University (Maier et al., Reference Maier, Troy, Johnston, Bobba and Summers2010; Summers & Joshi, Reference Summers and Joshi2010; Teegavarapu et al., n.d.). This is a three credit class spanned over a period of one 17-week semester. The faculty coordinator for the class solicits design projects that are sponsored by industries or other departments at Clemson University. The student teams are formed according to responses to a preference sheet that each student submits at the beginning of the semester. Each project has up to four teams, consisting of three to five students. The students are required to take a one semester course on the use of CAD as part of the curriculum.

As a part of the design project, the students are required to formally define the design problem, elicit requirements, generate, and evaluate alternative design concepts. These activities are typically done in the first half of the semester. Based on their evaluations, the team selects a solution that is then pursued as a final solution. The students work on embodying and detailing the final solution in the second half of the semester.

Each project is assigned an advisory committee that consists of faculty members and sometimes retirees from industry and trained graduate design students. The students are required to have weekly design reviews with their advisory committee and to provide formal design reviews to the industry sponsors twice or thrice in the semester. During these weekly design reviews, the advisory committee provides critical feedback to the students. The typical deliverable for the project includes a midterm and final presentation and report and a physical prototype.

A graduate design coach is assigned to an individual team. Each design coach has taken graduate level class in design research methods (Powers & Summers, Reference Powers and Summers2009; Joshi & Summers, Reference Joshi and Summers2010; Morkos & Summers, Reference Morkos and Summers2010). The design coach does the coaching as a part of the class deliverable. It may be noted that the design coach does not directly participate in the design project but intervenes only when required, for instance during team malfunction or to procure necessary resources. Further, it may be noted that the case study presented in this paper was conducted as a deliverable for the design coaching class.

2.3. Design problem

The design problem at hand consisted of analyzing and redesigning the nose gear assembly for a light weight unmanned aircraft. The overall design project had following major objectives and deliverables:

1. analyze the existing nose gear design

2. provide a solution that will eliminate the reoccurring failure of the nose gear during landing

3. prototype and test the proposed solution

4. document the proposed solution

2.4. Case study activities

In order to understand the role and impact of CAD tools in engineering design, the design project was broken down into design stages following a systematic design process model (Pahl & Beitz, Reference Pahl and Beitz1995). Essentially, the following stages in the design process were considered for this study: (1) plan and clarify the task, (2) conceptual design, (3) embodiment design, and (4) detail design. The CAD data generated in each stage was thoroughly studied to address the case study objectives.

It may be noted that to explore new ideas, the sponsor did not share the solid models of the current design with the students. However, the photographs, screen shots, material specifications, and partially dimensioned prints describing the current design that the team may use to extrapolate details of the current system were shared by the sponsor.

The team members had access to university provided solid modeling, finite element analysis (FEA) and computer-aided manufacturing (CAM) software.Footnote 2 All team members have been introduced to CAD software through an undergraduate level introduction to solids modeling course. Two of the team members have had previous project experience that required them to use solid modeling in industry. All of the team members were in their final undergraduate mechanical engineering semester and they have all had at least one term of intern or coop experience in industry. The team members had not received any formal training in sketching within their undergraduate curriculum.

3. THE DESIGN PROCESS AND THE ROLE OF CAD TOOLS

As mentioned earlier, the goal of this case study is to understand the role of CAD tools in the design process. In order to accomplish the goal, the activities of the design team were followed as they proceeded to address the design problem at hand. A systematic design process model proposed by Pahl and Beitz (Pahl & Beitz, Reference Pahl and Beitz1995) is used to organize and group the accomplishments of the design team in a logical sequence. However, it may be noted that the model was not intentionally followed by the design team throughout the project.

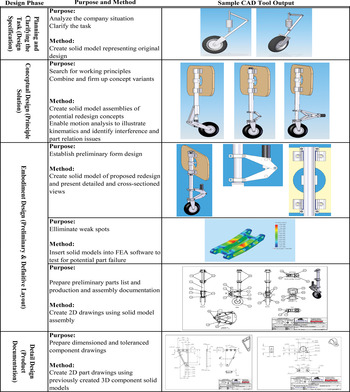

Figure 1 illustrates the type of CAD outputs that were generated at different stages in the design process.

Fig. 1. Phase model of the design process adapted from Pahl and Beitz (Reference Pahl and Beitz1995). [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

3.1. Planning and clarifying the task

Planning and clarifying the task is the first stage in the design process where the team aims to understand the problem at hand. For the project under study, in addition to entailing as much information as possible from the company sponsoring the design project, the team also analyzed the current product in the market. The information gathered was then organized logically.

This was the first time that the design team used CAD to create a solid model of the original design that they were tasked to analyze and improve upon. Figure 2 and Figure 3 respectively illustrate the photograph of the original design and the solid model created by the team.

Fig. 2. Photograph of original design. [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

Fig. 3. Solid model of original design. [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

Creating the simplified model of the original design as shown in Figure 3 was beneficial because it forced the team to identify the basic geometry and pivot points. This, however, was not the purpose of creating the CAD representation. This was evident because when asked the reason for using CAD instead of hand sketching, the responses of the team members were the following:

“CAD looked better in the presentation.”

“Give a better visualization to the advisors.”

“Easier interpretation, visually appealing.”

The team member who created the solid model stated that they gained no knowledge from the process. Only one out of four team members reported of gaining knowledge in terms of being able to identify the “basic placement of joints” and the “basic geometry.” Further, since the exact geometry and material properties of the original design were not made available to the team members at this stage, they could not generate a more exact representation of the original design to calculate mass properties and to perform FEA. Apart from being presented to the advisory committee, the team did not reference or reuse the solid model at any other stage in the design process.

If the team had created an abstract sketch instead of a solid model, they might have been able to represent critical information more effectively and efficiently. In abstraction, the inessential attributes are left out, and the essential attributes are accentuated (Lawson, Reference Lawson2002). To illustrate the type of sketch the teams could have created, the author created a sketch representative as shown in Figure 4.

Fig. 4. Abstract sketch of the original design.

The sketch was completed in a short time. Unlike the solid model illustrated in Figure 3, the sketch created by the author is not able to revolve or augment in any way, does not have scale, and does not appear to be nearly as exact. However, it conveys more information on the essential elements of the original design. For instance, the pivot points and shock elements are clearly shown. These elements may not be clear to an outside observer when viewing the solid model representation as in Figure 3. Key kinematical elements such as motion and wheel rotation are also included in the sketch.

This case represents a single instance of the use of CAD tools in the planning and task clarification phase. Although the sketch may not fulfill various requirements such as use in formal presentation or give better visualization, it represents a more efficient method of identifying key features of the original design in a short period of time compared to various CAD tools. However, had the solid model been an accurate representation of the original design, it could have been used in further analysis, and referenced to create variant designs. Therefore, a broad statement that solid modeling at this stage is not efficient cannot be made for all cases, but the value of an abstract sketch should not be discounted. Table 3 summarizes the purpose and impact of CAD in planning and clarifying the task stage of design process.

Table 3. Summary of purpose and impact of computer-aided design in planning and clarification of task

In summary, the model shown in Figure 3 contains less useful information and took significantly more resources to complete than the abstract sketch shown in Figure 4. In addition, it is important to note that the only reason that group members listed for using CAD at this stage was related to the presentation quality, and not for internal design purposes.

3.2. Conceptual design

The conceptual design stage includes identifying function structures and working principles in order to generate potential design concepts (Pahl & Beitz, Reference Pahl and Beitz1995). These concepts are then evaluated against the objectives set in the planning and clarifying the task stage. After studying the use of CAD in the planning and clarifying the task stage, the next step was to study the use of CAD in conceptual design stage.

It may be noted that the typical CAD process requires that parts be first defined by exact geometry. These parts are then constrained with respect to other components in order to create an assembly (Zeid, Reference Zeid2005). This process is sequentially opposite when compared to the human thought process in which an individual will first examine the intended function, then the assembly, and then individual component geometry.

Because the CAD process operates in contrast to the human idea generation process, it was suggested by the design coach that CAD tools be omitted from the initial idea generation process. Each team member independently created four abstract sketches of different solutions to the design problem. The sixteen sketches generated by the group members were then examined and each group member made comments on the sketches. At the end of this process, the number of potential solutions was narrowed down to four working concepts. These four working concepts are illustrated in Figure 5, Figure 6, Figure 7, and Figure 8. The advantages and the disadvantages of each concept as suggested by the team member upon examination of the sketch are also shown in the figures.

Fig. 5. Leading arm concept. [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

Fig. 6. Rocker arm concept.

Fig. 7. Telescoping concept.

Fig. 8. Beam spring concept.

Figure 5 through Figure 8 supported the members in determining the advantages and disadvantages of the potential solutions quickly. This can be attributed in part to the fact that the abstract nature of the sketches suggested that they do not represent final concepts. The leading arm concept even had an “or” on it to display two different geometries for the shock struts in addition to the use for the theta symbol defining the rake angle. Since the exact value of the angle is not specified at this stage, it suggests that the angle is variable at this point. These symbols and annotations suggest that the idea has not been fully thought out, and that it is being presented as an opportunity to comment on.

The four design concepts shown in Figures 5 to 8 were further evaluated and then narrowed down to two concepts. It took the group 0.5 h to do so. The “rocker arm” and the “telescoping” concepts were selected as potential final solutions. The “leading arm” concept was discarded because of difficulty incorporating a steering mechanism into it, and the “beam spring” idea was eliminated because of the absence of adjustability, and the high perceived risk of mechanical failure. Table 4 summarizes the impact of creating sketches in the second week of the conceptual design stage.

Table 4. Summary of impact of sketching in conceptual design stage week 3

The sketches were further developed, and three design options were modeled as illustrated in Figure 9.

Fig. 9. Lever arm, telescoping and hybrid design options. [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

The team took it upon themselves to create solid models of three potential designs that did provide the team with useful knowledge. For instance, by modeling each component and creating the assemblies, the relative complexity of each design option was made apparent. Modeling also clarified how the motion of the shock caused translation in the wheel. For example, the lever arm operated at a constant ratio of approximately 3 in. of wheel travel per each inch of shock absorption. The lever arm also had a large trail distance measured from the steering column to the wheel axle. It was evident to the group that this would cause a large moment applied to the steering column that could result in failure. The telescoping design operated at a 1:1 ratio of wheel travel to shock travel, resulting in inefficient use of the shock. The hybrid design had a nonlinear relationship of wheel to shock travel that suggested difficulty in shock adjustment.

It can thus be stated that the use of solid modeling did generate knowledge that was unknown at the idea generation and sketching phase. Prior to modeling, team members preferred the hybrid design, but the level of complexity and the nonlinear relationship of shock absorption to wheel motion were not considered. Had the group had more experience designing linkages or completed hand calculations, they may have reached the same conclusion in less time.

The differences in resources used between the sketched concepts and the CAD generated models are significant. The team members worked for a combined 2 h to create 16 abstract sketches, whereas the three detailed CAD models represented 30 h of independent labor. Although it can be presumed that an experienced CAD operator could generate the models in less time, there is a significant difference between the time required to sketch concepts versus the time required to model the concepts. When creating a solid model all component geometry and assembly relations must be defined. This is in contrast to sketches that represent approximate component geometry and part relations.

Another difference noted between sketching and CAD generation is the instance at which relationships are defined. In sketching, the working concept is defined and then components are designed based on calculated values to determine geometry. As opposed to this, in CAD applications, geometry and relations are defined first to express the working concept. The member who did the majority of the CAD work stated that they used CAD for the following reason:

“Relationships (distances) between parts could be measured instead of calculated, dimensional changes were easier to make, fits were easy to determine, and kinematics could be measured instead of calculated.”

Avoiding calculations early on in the design may speed up the overall design process. However, this lack of analytical calculations may cause potential disadvantages by not letting the designer understand why a relation is apparent. If the designer does not define or understand the equations describing the system, it may not be possible to systematically optimize certain geometrical relations. The model thus created may be able to realize the function but it may not necessarily be optimized. Table 5 summarizes the impact of CAD in week 4 of conceptual design phase.

Table 5. Summary of impact of computer-aided design in conceptual phase week 4

3.3. Embodiment design

In the embodiment design stage, the working concepts determined in conceptual design are used to define geometry and material selection. The concepts are evaluated with respect to the objectives, constraints, and criteria and potential problem areas are identified (Pahl & Beitz, Reference Pahl and Beitz1995).

The knowledge gained by modeling the three assemblies in conceptual design stage was used to generate a single design which incorporated the desired linear relationship of wheel to shock travel, a tube-in-tube design for linear travel and a minimized moment applied to the steering column upon impact. The design also features a 1:3 shock travel to wheel travel ratio that enables the use of a smaller shock to attain the desired wheel translation. The recommended solution is illustrated below in Figure 10.

Fig. 10. The recommended solution. [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

Figure 10 presents three views generated from the same model. The leftmost view illustrates the overall assembly. This view shows scale of components, the number of parts that make up the design, and the general complexity.

The center view depicts a detailed view of the shock absorbing mechanism. From this view, the five pivot locations are identified. Clearances and overlap of moving parts can be visualized as the shock absorbs load. For example, it is evident that the lower pin that joins the shock to the lower plate must be located such that it will not interfere with the upper link at the maximum travel.

The rightmost view contains a cross section of the steering shaft, bearing guide, and clamp assembly. This view displays the critical fits between press fit components such as the bearing block to sleeve bearings, and the sliding fit components such as the sleeve bearing to steering shaft.

In this stage, the designer starts increasing the focus toward manufacturability. Creating the solid representation encourages the designer to model and assemble components in a way that resembles the actual manufacturing and assembly process. It is possible to represent components or an assembly in a CAD program that cannot be duplicated in reality; however the process of modeling each component and assembling them properly make manufacturing issues more evident to the designer. Without any dimensions given, it is clear that a press fit is required between the guide blocks and the liners, and that a sliding fit is required between the liners and the steering shaft. This means that there are two hole features of critical diameter, and one component with a critical outside diameter. This is of course possible in manufacturing, but tight tolerances add cost.

It should be noted that solid models and CAD drawings represent the components in their nominal geometry. This provides a false comfort to a novice engineer when viewing an assembly such as the cross-sectional view shown in Figure 10. In this view, the blue bushings secure the rod and are held in place by the bearing blocks. The flanges on the bushings mate against the collars that retain the tube vertically. This design is easily represented, but difficult to machine and assemble. Table 6 illustrates the summary of impact of CAD in the embodiment design stage.

Table 6. Summary of impact of computer-aided design in embodiment design stage

Two other activities that occurred during the embodiment design stage involved the use of CAD. Specifically these activities consisted of conducting a FEA and preliminary documentation. The use of CAD in both these activities is explained in detail in Sections 3.3.1 and 3.3.2.

3.3.1. Implementing FEA

FEA divides a component into smaller elements, and equilibrium equations are computed for each element and assembled to approximate the solution of the system (Zeid, Reference Zeid2005) FEA allows a complex design to be analyzed when an exact solution may not be possible to compute. For the design project under study, FEA was implemented to perform stress analysis on the torque link component. The torque link was more complex than other load bearing elements of constant cross section such as the shafts used for the steering column. Whereas stress could be calculated by hand for the shafting, obtaining accurate results for the torque link shown below in Figure 11 would be very difficult.

Fig. 11. Finite element analysis of third link iteration. [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

Implementing FEA at this stage allowed the team to modify the torque link geometry and obtain rapid results to understand the effect of the change in the geometry on the stress distribution. Since the solid model already existed in the assembly, running FEA did not require the part to be remodeled. Further, the capabilities of FEA software enabled the designer to complete weight reduction measures by performing detailed analysis at a level that would be inconceivable through hand calculations.

FEA provides an output that is an approximate solution according to the environment described by the user. Any errors in assumptions or loading criteria defined by the user will result in incorrect stress values. As the results generated by FEA programs appear to be exact, they are trusted in the same way that a detailed solid model is trusted for being a well-designed component or assembly. The team did not perform any hand calculations to verify that the FEA output fell within an expected range. Like solid modeling, FEA is a powerful tool that provides a high level of detail. Similar to solid modeling, the designer must be aware of the cognitive bias to accept a detailed representation as being superior to abstract representations. Table 7 summarizes the impact of the use of CAD in implementing FEA during the embodiment design phase.

Table 7. Summary of impact of computer-aided design in implementing finite element analysis

3.3.2. Preliminary documentation

The embodiment phase also includes preparing the assembly documentation and a components list (Pahl & Beitz, Reference Pahl and Beitz1995). The assembly documentation completed by the team is shown in Figure 12.

Fig. 12. Assembly drawing. [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

The assembly layout represents the first example of 2-D documentation that the team has created. The drawing is directly associated with the component and assembly solid models. Thus, the documentation procedure occurs quickly in contrast to the drawing being completed by hand. The drawing is an active document that is linked to the solid models so if a component or assembly is modified, the drawing is also automatically revised accordingly. Table 8 summarizes the impact of CAD in the preliminary documentation during embodiment design stage.

Table 8. Summary of impact of computer-aided design in preliminary documentation

3.4. Detail design

In the detail design stage, the design is finalized and fully documented. Component dimensions, tolerances, and surface finishes are defined. Materials are selected, and production methods are determined (Pahl & Beitz, Reference Pahl and Beitz1995). Although solid models are becoming more useful in the manufacturing and production phases, physical drawings are still a required component of a design (Ullman et al., Reference Ullman, Wood and Craig1990). The physical drawing includes the geometric dimensioning and tolerance information that will dictate the method of manufacturing, and in turn influence the final product cost. Figure 13 illustrates 1 of the 11 component drawings that were created by the team.

Fig. 13. Detailed component drawing of the shock trunnion collar. [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

The amount of resources to complete all part drawings by hand would have drained the team of time. The team member that completed the detailed drawings stated that CAD was used to generate the detail drawings for the following reasons: “Easy to read, consistent visual presentation, linked to the models, significantly faster.”

CAD programs will automatically generate part views from the solid model, but they still rely on the user to provide dimensioning and tolerance information. The cost to manufacture increases as tolerances are tightened, but “if the tolerances are too loose” (Zeid, Reference Zeid2005) the components may fail to assemble or function properly.

Almost all of the dimensions expressed on the part prints have an associated ±0.005-in. tolerance. This tolerance is according to standard block tolerances for a three-place decimal dimension. The three-place decimal dimension is the default set by the CAD software. Although the design allows for many of these tolerances to be increased, CAD designers may not spend the additional time required to calculate tolerance stack ups to determine the maximum allowable tolerance of each component. The only tolerances that were not left at the default three-place decimal were the tightened tolerances listed for the reamed holes in which bushings were inserted. No tolerances were expanded beyond ±0.005 in.

Leaving the drawings dimensioned as such may increase the cost to manufacture since parts must now be fully machined, or formed by a high precision process. If the designer was forced to insert each dimension such as is the case for manual drawings, they may give the tolerances associated further thought, and allow for less expensive manufacturing methods. Table 9 summarizes the impact of the use of CAD in the detailed design stage.

Table 9. Summary of the impact of computer-aided design in detailed design stage

4. INTERVIEW PROTOCOL

The case study exposed how prevalent the utilization of CAD has become at the novice engineering level. The results also showed that particular attention should be paid to when and how CAD tools are applied within the design process. The tendency of the group was to head for a computer and begin modeling at the start of the redesign project. Overall gains were realized through the use of CAD tools; however the use of these tools in the initial design phases proved to be detrimental toward efficiency, and offered no gains in design effectiveness.

The case study observations provided motivation to further research the causes and effects of the reduced use of sketching and the increasing use of CAD in engineering design and education. The CAD habits of a group of novice engineers were examined, but was the finding representative of the overall engineering community? In order to expand on the case study findings, interviews were conducted with the following groups to get various perspectives on the role of CAD in engineering design:

1. experienced educators: four Clemson University professors and one lecturer who have 5 to 20 years of experience teaching CAD to college students

2. novice educators: one master's level and one PhD level graduate student who have taught or assisted in teaching a solid modeling course for less than 2 years

3. experienced industry professionals: an engineering director and a senior engineer with a minimum of 18 years of experience. Experienced industry professionals interviewed work in design and manufacturing companies that utilize a variety of solid modeling and CAD applications. They have also spent time with senior level engineering students, as the sponsors of funded senior design projects.

4. novice industry professionals: two mechanical engineers who have less than 5 years industry experience in design and manufacturing companies. Both engineers have postgraduate degrees within mechanical engineering.

The objective of the interviews was to identify beliefs and practices inherent in different groups of engineers. Questions were structured to compile information on each interviewee's CAD experience levels, their opinion on proper CAD usage, and their thoughts on the direction and importance of education relating to sketching and CAD usage. Interview responses were then be compiled so that trends emerge between different engineering groups.

To conduct a structured interview, a set of general interview questions (Table 10) were developed to serve as the backbone of the interview process. If clarification or more detail was required, follow-up questions were as needed.

Table 10. General interview questions (Q1–Q7)

Note: CAD, computer-aided design.

This paper will provide the responses specifically for nonbackground questions Q4, Q5, Q6, and Q7. The questions will relate the use of CAD tools in the design process and their perceived benefits and drawbacks relative to hand sketching.

4.1. Definition of CAD

When asked to define CAD, the respondent's responses varied vastly. Generally novice educators tend to view CAD as a tool that improves a design. For example, for question 4, the graduate instructors responded:

“A tool that finishes the design faster”

“A tool to design in a better way”

“The ability to capture what's in your mind on the screen without losing accuracy and quality”

In contrast, experienced educators listed the technical attributes of CAD with responses such as

“Anytime you use a computer to help you in the design process”

“Tying together optimization and representation”

“Information management”

Industry representative's definition of CAD was mixed:

“Using the power of the computer to assist an engineer in designing things correctly”

“Computer graphics programs that aid in the visual representation of a design idea”

Novice educators place more value into the capabilities of CAD programs to improve design quality, as opposed to experienced educators who view CAD functionality as a tool. This provides initial indication that the opinion of the capabilities of CAD may be bounded by age or generation rather than years of experience with CAD. The responses from industry varied between the interviewees and were a mix of opinions matching both that of novice and experienced educators and did not indicate a correlation between professional experience levels.

4.2. Using CAD for idea generation

Interview question 5 asked whether CAD tools should be used for idea generation, and the responses between novice and experienced test subjects once again did not align. Figure 14 shows the consensus of each group of respondents.

Fig. 14. Should computer-aided design tools be used for idea generation? [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

The general consensus among experienced educators was that CAD should not be used for idea generation. This group suggested that hand sketches are a better representation to use at this stage. In contrast, the majority of graduate student educator's responded that CAD tools should be used for idea generation. The experienced educator and novice educator responses to the interview question are the following:

Experienced educator response: “It's not something I would personally use CAD for. That's what a pencil and paper are for.”

“They shouldn't be because at that point you have committed to a very detailed solution.”

“The amount of time invested in creating a model will typically relate to the amount of effort that you will try and sell and “fix” it.”

Novice educator response:

“Yeah, I think you definitely can simply because the freedom you have on it. The freedom number one, and number two, it doesn't consume time. On a sketch, if we're drawing it by hand I have to either redraw it or do it and erase it. When you have so much freedom to do it with such ease, I believe it almost encourages you.”

Industry professionals were also divided along experience lines. Experienced professionals did not completely agree for or against the use of CAD in the idea generation phase, but instead stated some concerns of using CAD during idea generation. These concerns include the following:

“The initial use of CAD tools should not be so detailed that you don't try other ideas because of the time input required.”

“CAD can be limiting in the idea generation because you may not know how to draw the complex shape required by the idea so you settle for a shape that you can draw.”

Novice professionals agreed that CAD should be used in the idea generation phase. Both of the respondents in this category thought of CAD as a way to visualize concepts and stimulate further thought.

“Sure, not only to visualize concepts, but also to stimulate cognitive solution generation before visualization occurs.”

There is a general consensus between experienced educators and experienced professionals warning against creating detailed models in the idea generation phase. Experienced faculty were generally opposed to the use of CAD during the idea generation phase, but industry sponsors were not opposed to the idea although they voiced concerns of idea fixation.

4.3. Free-hand technical drawings in the engineering curriculum

When asked whether free-hand technical drawings should be included in the engineering curriculum, the responses varied widely among respondent groups. Results are displayed in Figure 15.

Fig. 15. Should free-hand technical drawing be included in the curriculum? [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

The significant statistic illustrated by Figure 15 is that the novice educators were unanimously against the incorporation of free-hand technical drawing within the engineering curriculum whereas all novice professionals were of the opposite opinion. From the quotes of novice professionals, it can be deduced that once the recent graduates entered industry they realized the importance of sketching in a way that was not apparent in the educational environment.

Novice professional response:

“It would probably help engineers to communicate their thoughts, which is really half of an engineer's job.”

“A quick sketch on a white board or back of a piece of paper during a meeting or at a coworkers office is the absolutely fastest way to accurately convey an idea. It is also a valuable tool in explaining how something works to a client or supplier.”

On the other side of the spectrum, most novice educators thought that educating engineering students in sketching would be a waste of time. They were of the opinion that there is no need to sketch if CAD is available because it is “easier” and CAD does not require extensive knowledge of sketching.

Novice educator response:

“Even in the initial model, if we have CAD tools it's easier.”

“You don't need much background knowledge in sketching.”

The opinion of experienced professionals and experienced educators were mixed. The majority of experienced educators agreed that sketching skills are important, but they were divided on whether sketching skills warranted class time or whether students can be expected to learn sketching on their own outside of the classroom. Because the group of experienced professionals received training in free-hand technical drawing throughout their education, perhaps they take these skills for granted in comparison to the novice professionals that may have recently been asked to sketch for the first time in design meetings and workplace discussions. This could account for the opinion of the majority of experienced professionals that is not necessary to include free-hand sketching within the engineering curriculum.

4.4. Potential negative effects of CAD usage

Question 7 asks the interviewees whether they agree that circumscribed thinking and premature fixation are present in CAD usage. The definition of each term per Robertson was read to each respondent prior to stating their answer. Figure 16 depicts the interview results.

Fig. 16. Are circumscribed thinking and premature fixation present in computer-aided design usage? [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

All respondents agreed that both effects are present. In addition, respondents agreed that students should be told how to avoid falling into these potential “traps” of CAD usage. One experienced faculty member had the following to say in reference to circumscribed thinking:

“I would definitely see that students would be forced into this circumscribed thinking. We're teaching them the basic mechanical shapes so to speak, so they are limited in how they think, extremely limited.”

A graduate student educator made the statement below, which can serve as a definition for premature fixation:

“Sometimes designers think, it looks really good, I think I'm going to go with it. You still have all this design freedom you can mess with but you decide not to tap into it. So, maybe ambiguity is good in that sense.”

The quote above lends strong support to the use of sketching in conceptual design. The respondent brings up the fact that ambiguity in a design can be positive, which by nature is easier represented in a hand sketch. The strong consensus among respondents offers strong evidence that these effects are real, and that their definitions should be taught to engineering students.

4.5. Summary of interview responses

The responses from the four engineering groups showed clear trends pertaining to hand sketching and CAD tools. Experienced educators viewed CAD tools as a means to support the design process, whereas novice educators view CAD tools as a way of enabling and creating higher quality design quicker. Experienced educators and experienced professionals supported the ideas of the sketching and delaying the use of CAD until after the idea generation stage, whereas both novice engineering groups suggested using CAD immediately in the idea generation phase without creating any hand drawings. The experienced professionals often perceived a benefit from using CAD even in the idea generation phase, but also raised concerns of possible traps that users could fall into when implementing directly into CAD before sketching. The direct shift in opinion pertaining to the inclusion of free-hand sketching instruction in the engineering curriculum between the novice educators and the novice professionals is of interest in determining whether the engineering educational process is misaligned with industry. Last, that all respondents recognized the effects of circumscribed thinking and premature fixation within CAD usage suggests that CAD users need to be made aware of these phenomena.

5. CONCLUDING STATEMENTS

Although the overall effect of CAD tools in this case study was positive, it is not possible to make a general conclusion on whether replacing sketching with CAD tools would positively or negatively affect all examples of product design. Computers clearly perform certain tasks better than humans. These tasks include calculating speed and accuracy, information retrieval, and memory (Lawson, Reference Lawson2002). However, humans are better at interpreting design concepts, recognizing potential issues, and making judgments on conflicting requirements (Lawson, Reference Lawson2002).

When examining the design phase model, it is possible to make a determination on whether CAD tools had a positive or negative impact on the design phase level. For example, conceptual design requires more of the human centered tasks while detail design depends largely on the computer driven tasks. These findings are expected to extend throughout the majority of product design projects outside of this case study.

Figure 17 illustrates the CAD tool output for each phase of the design process. The contributions of the CAD tool toward design efficiency, effectiveness, and creativity are also listed.

Fig. 17. Phase model of the design process listing computer-aided design tool contributions. [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

5.1. CAD efficiency and effectiveness

At each step of the design phase in which CAD tools were used, the output was judged in terms of contribution toward design efficiency and effectiveness. The relative contributions were calculated by comparing the CAD output to the noncomputer aided alternative, be it free-hand sketching, manual calculations, or hand drawn 2-D technical drawings.

The ideal design representation will consume the least amount of resources while conveying the maximum amount of information (Macomber & Yang, Reference Macomber and Yang2011). Hence, the efficiency of a particular representation is formulated by comparing the value of the output with respect to the time that it took to generate the output. If the design team spent several hours creating a solid model that conveys the same knowledge that could be represented by a quick freehand sketch, and the digital output is not reused in later processes, the efficiency contribution is negative. If CAD enabled the group to complete a design step faster through model reuse, provided quick solutions to complex calculations, or automated print creation, the efficiency contribution is positive. If the efficiency is doubled, meaning that the CAD tool enabled the completion of a task in equal to or less than half the time that it would otherwise take, the efficiency contribution was determined to be strongly positive.

The effectiveness of the use of CAD was determined by examining how CAD use benefited the creation of a design that met all desired functions and specifications established by the customer (in this case the project sponsor). If the use of CAD led the team away from this goal, the contribution to effectiveness was negative. If the use of CAD aided in guiding the design team towards satisfying the customer requirements, the contribution was positive. If a CAD tool enabled the design group to perform a beneficial task that would otherwise not be possible to complete the contribution to effectiveness would be rated as strongly positive. This information was compiled, and is presented below in Figure 18.

Fig. 18. Computer-aided design tool efficiency and effectiveness per design phase. [A color version of this figure can be viewed online at http://journals.cambridge.org/aie]

Figure 18 indicates that CAD tools begin to positively contribute to design efficiency and effectiveness in the later stages of the design process. Thus, as the level of abstraction in the design decreases, the efficiency gained by CAD tools increases. There was no phase where a negative influence towards effectiveness was seen.

Literature suggests that sketching may have a nondirect effect role in improving design effectiveness. It has been identified that a designer's spatial ability is improved through sketching (Chester, Reference Chester2007). A designer's ability to successfully generate technical artifacts is positively correlated with their spatial ability (Tseng & Yang, Reference Tseng and Yang2011). These effects of the use of sketching to promote design effectiveness cannot be studied in a short-term case study, but they are factors that deserve consideration.

5.2. Effect of CAD tools on final product

The group of novice engineers realized the following advantages and disadvantages from the use of CAD tools. The advantages are the following:

• A common format was used to judge designs. This prohibited choosing a design based on appearance rather that principle. (Section 3.2)

• Clear models were made that could be understood by a faculty review board. (Section 3.2, 3.3)

• CAM applications allowed complex geometries to be computer numerical control machined. Without access to CAM software, these geometries would not be an option. (Section 3.3)

• Mass properties were automatically calculated. This simplified optimizing the strength to weight ratio of certain members. (Section 3.3.1)

• FEA was used in analyzing the stress distribution of load bearing elements. This analysis would have otherwise been complex. (Section 3.3.1)

• Detailed drawings were generated efficiently by re-using the solid models to automatically illustrate drawing views and dimensions. (Section 3.3.2, 3.4)

The disadvantages are the following:

• The group did not critique designs that were modeled with the same rigor that they did on sketched concepts. This can be attributed to premature fixation. (Section 3.2, 3.3)

• The group spent nonvalue added time creating solid models too early in the design stage. These models were never referenced after being completed, and could have been replaced with sketches. (Section 3.1)

Overall, the advantages that the team realized from CAD tools did outweigh the disadvantages. The team was able to create a full-scale prototype that functioned properly within the given project duration. It is hard to predict what their solution would resemble had they not used CAD tools. It is possible that the level of creativity may have been higher and that the lack of a detailed part representation would have raised the risk of missing a critical interference issue or the failure to identify a difficult to machine part relation.

5.3. Suggestions for approaching CAD

As the level of abstraction decreases throughout the design process, the method of representing the design should become less abstract as well. Novice engineers and educators are inclined to employ the use of CAD tools at the earliest stages of design. This has the potential to cause a loss of design efficiency and effectiveness. It is recommended that the potential pitfalls of CAD usage including circumscribed thinking and premature fixation be ingrained into the mind of all CAD users. All interview respondents recognized these effects as present and it would be beneficial to teach novice engineers how to avoid them.

It is hard to predict the future of CAD tools based on how rapid their integration into industry has been, but it is clear that the prevalence of computerized design tools will continue to increase, particularly among graduating engineers. It is also clear that educational programs must adapt so that engineering students are not only made aware of CAD systems and the principles behind them, but also of their practical limitations.

Dave Veisz is currently employed as the Manager of Industrial and Lean Manufacturing Engineering at The Reliable Automatic Sprinkler Co., Inc., located in Liberty, South Carolina. He has served on various product design teams and has designed mechanical and manufacturing systems, primarily for use within the fire protection industry. Dave earned his MS in mechanical engineering from Clemson University and his BS in industrial and manufacturing engineering from Penn State University.

Essam Z. Namouz received his BS degree (2008) and MS degree (mass and assembly time reduction in vehicles, 2010) in mechanical engineering at Clemson University. Essam has remained at Clemson University and has continued his research toward a PhD. He is currently funded by the General Engineering Department at Clemson University to teach EG208 (Engineering Graphics and Design) to sophomore engineering students. Essam's interests include design for manufacturing and assembly, with a specific interest in assembly time estimation and reduction of assembly time in current manufacturing processes.

Shraddha Joshi completed her MS degree at Clemson University in 2010. She is currently pursuing her PhD with a focus on requirements for driven design. She is funded by the Mechanical Engineering Department at Clemson University and is currently a Teaching Fellow teaching ME-202 Foundations of Mechanical Systems class. Her research interests include requirements driven design with special focus on using requirements in ideation.

Joshua D. Summers is an Associate Professor in mechanical engineering and IDEaS Professor at Clemson University, where he codirects the Clemson Engineering Design Applications and Research Group. Dr. Summers earned his PhD in mechanical engineering from Arizona State University (design automation) and his MS (submarine design) and BS (fluidized bed design) from the University of Missouri. He has worked at the Naval Research Laboratory (VR Lab and NCARAI). Joshua's research has been funded by government, large industry, and small-medium sized enterprises. His areas of interest include collaborative design, knowledge management, and design enabler development with the overall objective of improving design through collaboration and computation.