1. Introduction

An important class of fragmentation processes forming spray in nature, industry and health is unsteady with droplets shed continuously and with properties varying over time (Yarin Reference Yarin2006; Traverso et al. Reference Traverso, Laken, Lu, Maa, Langer and Bourouiba2013; Bourouiba, Dehandschoewercker & Bush Reference Bourouiba, Dehandschoewercker and Bush2014; Gilet & Bourouiba Reference Gilet and Bourouiba2014,Reference Gilet and Bourouiba2015; Josserand & Thoroddsen Reference Josserand and Thoroddsen2016; Lejeune, Gilet & Bourouiba Reference Lejeune, Gilet and Bourouiba2018; Wang & Bourouiba Reference Wang and Bourouiba2018; Bourouiba Reference Bourouiba2020). The entire sheet-mediated fragmentation of such unsteady systems can be summarized into four steps: (i) a fluid bulk (jet or drop) transforms into a sheet expanding and then retracting with time-varying deceleration; (ii) destabilization of the rim bounding the sheet with formation of corrugation on it; (iii) corrugation to ligament transition; (iv) droplet shedding from the ligament, one droplet at a time, via end-pinching (Wang & Bourouiba Reference Wang and Bourouiba2018) (figure 1).

Figure 1. (![]() $a$) Schematic diagram of canonical unsteady fragmentation upon drop impact on a surface of comparable size,

$a$) Schematic diagram of canonical unsteady fragmentation upon drop impact on a surface of comparable size, ![]() $d_r$, to that of the impacting drop,

$d_r$, to that of the impacting drop, ![]() $d_0$. (

$d_0$. (![]() $b$) Unsteady fluid fragmentation is described in four steps: (i) sheet evolution; (ii) rim destabilization; (iii) corrugation to ligament transition; (iv) ligament end-pinching and droplet ejection. Key physical quantities for each step of the fragmentation are listed on the right and labelled in the diagram.

$b$) Unsteady fluid fragmentation is described in four steps: (i) sheet evolution; (ii) rim destabilization; (iii) corrugation to ligament transition; (iv) ligament end-pinching and droplet ejection. Key physical quantities for each step of the fragmentation are listed on the right and labelled in the diagram.

In this study, we elucidate the fundamental mechanisms of selection of corrugations that eventually grow into ligaments to shed droplets via end-pinching, one drop at a time. The link between the unsteady sheet evolution and the rim destabilization was established in Wang et al. (Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c) and Wang & Bourouiba (Reference Wang and Bourouiba2020a,Reference Wang and Bourouibab), while the link between the ligaments and secondary droplets was elucidated in Wang & Bourouiba (Reference Wang and Bourouiba2018). Despite recent advances, fundamental questions remain open:

(i) What governs the transition from a corrugation to a ligament? In particular, why do some corrugations on an unsteady rim grow to shed a drop, while others do not?

(ii) Once a corrugation grows, what sets its growth rate? In particular, can linear instability analysis rationalize its growth?

(iii) What determines the population average size and number of ligaments on the unsteady rim at a given time?

(iv) Why does a ligament continuously shed secondary droplets via end-pinching, instead of growing into a long liquid jet?

(v) What sets the time-varying shedding of secondary droplets from the ligaments?

Addressing these questions is critical to gain insight into the spray formed. To do so, we focus on a canonical unsteady sheet fragmentation system upon drop impact on a surface of diameter ![]() $d_r$, of comparable size to that of the impacting drop,

$d_r$, of comparable size to that of the impacting drop, ![]() $d_0$, forming a two-dimensional (2-D) axisymmetric horizontal sheet (figure 1). We start by reviewing the existing theoretical framework of unsteady sheet fragmentation (§ 2), then introduce the precise measurements pertaining to ligament dynamics obtained with our especially developed set of algorithms (§ 3).

$d_0$, forming a two-dimensional (2-D) axisymmetric horizontal sheet (figure 1). We start by reviewing the existing theoretical framework of unsteady sheet fragmentation (§ 2), then introduce the precise measurements pertaining to ligament dynamics obtained with our especially developed set of algorithms (§ 3).

2. Background to unsteady sheet fragmentation

2.1. Sheet evolution

Unsteady sheet dynamics in the air upon drop impact on a small surface of comparable size to that of the drop was studied in prior works (Rozhkov, Prunet-Foch & Vignes-Adler Reference Rozhkov, Prunet-Foch and Vignes-Adler2002; Villermaux & Bossa Reference Villermaux and Bossa2011; Vernay, Ramos & Ligoure Reference Vernay, Ramos and Ligoure2015; Wang & Bourouiba Reference Wang and Bourouiba2018). Here, we chose the characteristic length scale as impacting drop diameter, ![]() $d_0$, and the characteristic time scale as the capillary time,

$d_0$, and the characteristic time scale as the capillary time, ![]() $\tau _{cap} = \sqrt {\rho \varOmega _0/{\rm \pi} \sigma }$, where

$\tau _{cap} = \sqrt {\rho \varOmega _0/{\rm \pi} \sigma }$, where ![]() $\rho$ and

$\rho$ and ![]() $\sigma$ are the fluid density and surface tension, respectively, and

$\sigma$ are the fluid density and surface tension, respectively, and ![]() $\varOmega _0$ is the impacting drop volume. Thus, the non-dimensional variables are

$\varOmega _0$ is the impacting drop volume. Thus, the non-dimensional variables are

where, ![]() $r$ is the radial position in the sheet,

$r$ is the radial position in the sheet, ![]() $t$ is time,

$t$ is time, ![]() $u$ is the sheet radial velocity and

$u$ is the sheet radial velocity and ![]() $h$ is the sheet thickness (figure 1). Wang & Bourouiba (Reference Wang and Bourouiba2017) proposed and validated the spatio-temporal thickness

$h$ is the sheet thickness (figure 1). Wang & Bourouiba (Reference Wang and Bourouiba2017) proposed and validated the spatio-temporal thickness ![]() $h(r,t)$ and velocity

$h(r,t)$ and velocity ![]() $u(r,t)$ profiles of the thin 2-D sheet, which in non-dimensional form, reads

$u(r,t)$ profiles of the thin 2-D sheet, which in non-dimensional form, reads

where ![]() $a_1$,

$a_1$, ![]() $a_2$ and

$a_2$ and ![]() $a_3$ are constant coefficients derived and validated in Wang & Bourouiba (Reference Wang and Bourouiba2017).

$a_3$ are constant coefficients derived and validated in Wang & Bourouiba (Reference Wang and Bourouiba2017). ![]() $We = \rho u_0^2d_0/\sigma$ is the impact Weber number, where

$We = \rho u_0^2d_0/\sigma$ is the impact Weber number, where ![]() $u_0$ is the impacting drop velocity.

$u_0$ is the impacting drop velocity.

Wang & Bourouiba (Reference Wang and Bourouiba2018) showed that the droplets are continuously shed from the thin sheet with most being ejected prior to maximum radial expansion. Wang & Bourouiba (Reference Wang and Bourouiba2020b) showed that the sheet dynamics incorporating unsteadiness and continuous droplet shedding is governed by a non-Galilean Taylor–Culick's law, which, in non-dimensional form, reads

where ![]() $H(R_s,T)$ is the sheet thickness at the rim given by (2.2a,b) and

$H(R_s,T)$ is the sheet thickness at the rim given by (2.2a,b) and ![]() $R_s = r_s/d_0$ is the sheet radius. Wang & Bourouiba (Reference Wang and Bourouiba2020b) also derived and validated the approximate analytic solution

$R_s = r_s/d_0$ is the sheet radius. Wang & Bourouiba (Reference Wang and Bourouiba2020b) also derived and validated the approximate analytic solution

\begin{equation} \left. \begin{aligned} & \frac{R_s(T)}{\sqrt{We}} =Y(T)= 0.15(T-T_m)^3-0.4(T-T_m)^2 + \mathcal{R}_m,\\ & \text{with} \ T_m = 0.43 \quad \text{and} \quad \mathcal{R}_m = R_m/\sqrt{We} = 0.12, \end{aligned} \right\} \end{equation}

\begin{equation} \left. \begin{aligned} & \frac{R_s(T)}{\sqrt{We}} =Y(T)= 0.15(T-T_m)^3-0.4(T-T_m)^2 + \mathcal{R}_m,\\ & \text{with} \ T_m = 0.43 \quad \text{and} \quad \mathcal{R}_m = R_m/\sqrt{We} = 0.12, \end{aligned} \right\} \end{equation}

where ![]() $R_m$ is the maximum radius of the sheet in the air and

$R_m$ is the maximum radius of the sheet in the air and ![]() $T_m$ is the time when this maximum radius is reached.

$T_m$ is the time when this maximum radius is reached.

2.2. Rim destabilization and fluid volume shed

The critical first link between the sheet evolution and the ligaments that shed secondary droplets via end-pinching is the rim destabilization into corrugations. Due to mathematical complexity, traditional theoretical studies of rim destabilization conducted linear instability analysis, examining whether the Rayleigh–Plateau instability (Rayleigh Reference Rayleigh1878; Deegan, Brunet & Eggers Reference Deegan, Brunet and Eggers2008; Roisman Reference Roisman2010; Zhang et al. Reference Zhang, Brunet, Eggers and Deegan2010; Agbaglah, Josserand & Zaleski Reference Agbaglah, Josserand and Zaleski2013; Agbaglah & Deegan Reference Agbaglah and Deegan2014) or the Rayleigh–Taylor instability (Taylor Reference Taylor1950; Villermaux & Bossa Reference Villermaux and Bossa2011; Peters, Meer & Gordillo Reference Peters, van der Meer and Gordillo2013) dominates the rim destabilization. Recent studies via numerical simulation (Roisman Reference Roisman2010; Agbaglah et al. Reference Agbaglah, Josserand and Zaleski2013) showed that the nonlinearity plays a key role in the rim destabilization. To elucidate and quantify the linear and nonlinear effects at first order, we (Wang & Bourouiba Reference Wang and Bourouiba2018) showed that the rim initially destabilizes into small corrugations due to the interplay of a coupled instability where both acceleration and interfacial constraints on the rim play key roles. However, when the corrugations grow to a certain size, nonlinear effects dominate, associated with an instantaneous self-adjustment of the rim thickness, ![]() $b$, for it to remain equal to the local capillary length,

$b$, for it to remain equal to the local capillary length, ![]() $\ell _c$, defined based on the instantaneous rim deceleration,

$\ell _c$, defined based on the instantaneous rim deceleration, ![]() $\ddot {r_s}$, by

$\ddot {r_s}$, by ![]() $\ell _c = \sqrt {\sigma /(\rho (-\ddot {r_s}))}$, where

$\ell _c = \sqrt {\sigma /(\rho (-\ddot {r_s}))}$, where ![]() $\rho$ and

$\rho$ and ![]() $\sigma$ are the density and surface tension of the fluid, respectively. Namely, the rim thickness is selected to maintain a local and instantaneous Bond number

$\sigma$ are the density and surface tension of the fluid, respectively. Namely, the rim thickness is selected to maintain a local and instantaneous Bond number ![]() $Bo = \rho b^2 (-\ddot {r_s})/\sigma = 1$. Such a

$Bo = \rho b^2 (-\ddot {r_s})/\sigma = 1$. Such a ![]() $Bo = 1$ constraint on the rim thickness is robust and independent of the impact Weber number. Using the

$Bo = 1$ constraint on the rim thickness is robust and independent of the impact Weber number. Using the ![]() $Bo = 1$ criterion, Wang & Bourouiba (Reference Wang and Bourouiba2020a) showed and validated that the rim thickness

$Bo = 1$ criterion, Wang & Bourouiba (Reference Wang and Bourouiba2020a) showed and validated that the rim thickness ![]() $b$ scales as

$b$ scales as ![]() $We^{-1/4}$ with the approximate analytic expression, in non-dimensional form,

$We^{-1/4}$ with the approximate analytic expression, in non-dimensional form,

Note that the coefficients of (2.5) are theoretically derived, not fitted. The universal ![]() $Bo = 1$ criterion governing the rim links the unsteady non-Galilean sheet evolution (2.3) with the fluid shedding in the form of ligaments and droplets. Wang & Bourouiba (Reference Wang and Bourouiba2020a,Reference Wang and Bourouibab) showed and validated that the volume shed from the rim per unit of time, and radian,

$Bo = 1$ criterion governing the rim links the unsteady non-Galilean sheet evolution (2.3) with the fluid shedding in the form of ligaments and droplets. Wang & Bourouiba (Reference Wang and Bourouiba2020a,Reference Wang and Bourouibab) showed and validated that the volume shed from the rim per unit of time, and radian, ![]() $q_{out}$, is determined by the mass balance between the fluid entering the rim per unit of time, and radian,

$q_{out}$, is determined by the mass balance between the fluid entering the rim per unit of time, and radian, ![]() $q_{in}$, and continuous self-adjustment of the rim thickness to balance inertial and capillary forces via the unsteady local

$q_{in}$, and continuous self-adjustment of the rim thickness to balance inertial and capillary forces via the unsteady local ![]() $Bo = 1$ criterion (Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c), such that

$Bo = 1$ criterion (Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c), such that

\begin{equation} \left. \begin{aligned} q_{out}(t) & = q_{in}(t) - \frac{d}{dt}\left(\frac{\rm \pi}{4}b^2 r_s \right) \quad \text{with}\\ q_{in}(t) & = \rho h(r_s,t)[u(r_s,t)-\dot{r_s}]r_s(t) \quad \text{and} \quad b = \frac{\sigma}{\rho(-\ddot{r_s})}, \end{aligned} \right\} \end{equation}

\begin{equation} \left. \begin{aligned} q_{out}(t) & = q_{in}(t) - \frac{d}{dt}\left(\frac{\rm \pi}{4}b^2 r_s \right) \quad \text{with}\\ q_{in}(t) & = \rho h(r_s,t)[u(r_s,t)-\dot{r_s}]r_s(t) \quad \text{and} \quad b = \frac{\sigma}{\rho(-\ddot{r_s})}, \end{aligned} \right\} \end{equation}

where ![]() $r_s(t)$ is given by (2.4), and

$r_s(t)$ is given by (2.4), and ![]() $h(r_s,t)$ and

$h(r_s,t)$ and ![]() $u(r_s,t)$ are the sheet thickness and velocity profiles evaluated at the rim, i.e. at

$u(r_s,t)$ are the sheet thickness and velocity profiles evaluated at the rim, i.e. at ![]() $r = r_s$ (Wang & Bourouiba Reference Wang and Bourouiba2020b). It was shown (Wang & Bourouiba Reference Wang and Bourouiba2020a) that

$r = r_s$ (Wang & Bourouiba Reference Wang and Bourouiba2020b). It was shown (Wang & Bourouiba Reference Wang and Bourouiba2020a) that ![]() $q_{out}$ is in fact independent of

$q_{out}$ is in fact independent of ![]() $We$ over the capillary time scale

$We$ over the capillary time scale ![]() $\tau _{cap}$, with the approximate analytic expression, in non-dimensional form,

$\tau _{cap}$, with the approximate analytic expression, in non-dimensional form,

Note here too that the coefficients were theoretically derived, not fitted. We show later (§ 6) that such volume shed by the rim per unit of time, ![]() $q_{out}$, is in fact the key determinant in the selection of corrugations that can eventually grow into ligaments and shed droplets.

$q_{out}$, is in fact the key determinant in the selection of corrugations that can eventually grow into ligaments and shed droplets.

2.3. Droplet ejection

Riboux & Gordillo (Reference Riboux and Gordillo2014) stated that both the size and speed of the droplets shed from expanding sheets are equivalent to the size and speed of the expanding rim, respectively. Wang et al. (Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c) showed that the properties of secondary droplets are, in fact, governed by the end-pinching of ligaments, shedding one drop at a time, with population average diameter and speed set by the ligaments, rather than the rim. Two universal relations between the ligaments and droplets were established (Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c). First, the ratio of the diameter, ![]() $d$, of each secondary droplet with the width of its ligament of origin,

$d$, of each secondary droplet with the width of its ligament of origin, ![]() $w$, is

$w$, is ![]() $d/w \approx 1.5$, which remains constant throughout the sheet fragmentation, and is independent of

$d/w \approx 1.5$, which remains constant throughout the sheet fragmentation, and is independent of ![]() $We$. Second, the ejection speed of each secondary droplet,

$We$. Second, the ejection speed of each secondary droplet, ![]() $u_d$, is equal to the tip speed of its ligament of origin,

$u_d$, is equal to the tip speed of its ligament of origin, ![]() $u_{\ell }$, one necking time,

$u_{\ell }$, one necking time, ![]() $t_{neck}$, prior to end-pinching, namely

$t_{neck}$, prior to end-pinching, namely

2.4. Inviscid regime

Here, we note that the unsteady sheet fragmentation theory including that of the dynamics of the sheet (§ 2.1) (Wang & Bourouiba Reference Wang and Bourouiba2020b), the rim (§ 2.2) (Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c) and the ligaments (this paper), is developed for the inviscid regime governed by the balance between fluid inertia and surface tension. Wang et al. (Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c) showed that when the Reynolds number of the rim ![]() $Re_b = v_b b/\nu < 6\sqrt {2}$, viscous effects mitigate rim destabilization, as well as ligament growth and breakup. Here,

$Re_b = v_b b/\nu < 6\sqrt {2}$, viscous effects mitigate rim destabilization, as well as ligament growth and breakup. Here, ![]() $b$ is the rim thickness,

$b$ is the rim thickness, ![]() $\nu$ is the fluid kinematic viscosity and

$\nu$ is the fluid kinematic viscosity and ![]() $v_b = \sqrt {\sigma /\rho b}$ is the characteristic speed of corrugation growth. For

$v_b = \sqrt {\sigma /\rho b}$ is the characteristic speed of corrugation growth. For ![]() $Re_b = v_b b/\nu < 6\sqrt {2}$, the

$Re_b = v_b b/\nu < 6\sqrt {2}$, the ![]() $Bo = 1$ criterion of the rim no longer holds. Thus, the boundary conditions at the rim that determine the ligament dynamics, such as the total volume rate shed by the rim

$Bo = 1$ criterion of the rim no longer holds. Thus, the boundary conditions at the rim that determine the ligament dynamics, such as the total volume rate shed by the rim ![]() $q_{out}$, would differ from (2.7). An extension of the theory combining inertia, viscosity and surface tension beyond what is discussed in this paper, would be required in this regime for capturing and predicting the ligament evolution.

$q_{out}$, would differ from (2.7). An extension of the theory combining inertia, viscosity and surface tension beyond what is discussed in this paper, would be required in this regime for capturing and predicting the ligament evolution.

3. Experimental approach

3.1. Experimental conditions

For each experiment, an impacting drop of diameter, ![]() $d_0$, is released by a needle from different heights to set different impacting speeds,

$d_0$, is released by a needle from different heights to set different impacting speeds, ![]() $u_0$. Two high speed cameras are used to record the experiments from side and top views. The diameter and impacting speed of the drop are directly measured from the side view. The frame rate of the top-view and side-view cameras are 20 000 and 8000 frames per second (f.p.s.), respectively. The pixel resolution of videos recorded from top and side views are

$u_0$. Two high speed cameras are used to record the experiments from side and top views. The diameter and impacting speed of the drop are directly measured from the side view. The frame rate of the top-view and side-view cameras are 20 000 and 8000 frames per second (f.p.s.), respectively. The pixel resolution of videos recorded from top and side views are ![]() ${\simeq} 50\ \mathrm {\mu }\textrm {m}\,\textrm {pixel}^{-1}$ and

${\simeq} 50\ \mathrm {\mu }\textrm {m}\,\textrm {pixel}^{-1}$ and ![]() ${\simeq } 30\ \mathrm {\mu }\textrm {m}\,\textrm {pixel}^{-1}$, respectively. Drops are made of de-ionized water and Nigrosine dye of concentration of

${\simeq } 30\ \mathrm {\mu }\textrm {m}\,\textrm {pixel}^{-1}$, respectively. Drops are made of de-ionized water and Nigrosine dye of concentration of ![]() $1.2\ \textrm {g}\,\textrm {l}^{-1}$, with density

$1.2\ \textrm {g}\,\textrm {l}^{-1}$, with density ![]() $\rho = 1.0 \times 10^3\ \textrm {kg}\,\textrm {m}^{-3}$, surface tension

$\rho = 1.0 \times 10^3\ \textrm {kg}\,\textrm {m}^{-3}$, surface tension ![]() $\sigma = 72 \times 10^{-3}\ \textrm {N}\,\textrm {m}^{-1}$ and kinematic viscosity

$\sigma = 72 \times 10^{-3}\ \textrm {N}\,\textrm {m}^{-1}$ and kinematic viscosity ![]() $\nu = 1.0 \times 10^{-6}\ \textrm {m}^2\,\textrm {s}^{-1}$. The surface of the rod is made of stainless steel with contact angle range between

$\nu = 1.0 \times 10^{-6}\ \textrm {m}^2\,\textrm {s}^{-1}$. The surface of the rod is made of stainless steel with contact angle range between ![]() $52^{\circ}\text{ and } 81^{\circ}$ (McMaster 304 Stainless steel with 000-Grit sand-paper polishing). The diameter of the rod is selected to ensure a rod-to-drop size ratio,

$52^{\circ}\text{ and } 81^{\circ}$ (McMaster 304 Stainless steel with 000-Grit sand-paper polishing). The diameter of the rod is selected to ensure a rod-to-drop size ratio, ![]() $1.4<\eta = d_r/d_0<1.9$, within the range ensuring a horizontal sheet and negligible effect of surface stresses (Wang & Bourouiba Reference Wang and Bourouiba2017). To confirm the robustness of experimental results, as well as to obtain standard deviations, 28 videos are taken for each group of centred impact experiment. Two dimensionless groups relevant to our impact conditions are the Weber number,

$1.4<\eta = d_r/d_0<1.9$, within the range ensuring a horizontal sheet and negligible effect of surface stresses (Wang & Bourouiba Reference Wang and Bourouiba2017). To confirm the robustness of experimental results, as well as to obtain standard deviations, 28 videos are taken for each group of centred impact experiment. Two dimensionless groups relevant to our impact conditions are the Weber number, ![]() $We=\rho u_0^2d_0/\sigma$, and the Reynolds number

$We=\rho u_0^2d_0/\sigma$, and the Reynolds number ![]() $Re = u_0d_0/\nu$, respectively. Detailed experimental conditions are summarized in table 1.

$Re = u_0d_0/\nu$, respectively. Detailed experimental conditions are summarized in table 1.

Table 1. Summary of the experimental conditions used for water drop impacts on a rod, including the impact drop diameter, ![]() $d_0$, impacting speed,

$d_0$, impacting speed, ![]() $u_0$, and associated

$u_0$, and associated ![]() $We = \rho u_0^2 d_0/\sigma$ and

$We = \rho u_0^2 d_0/\sigma$ and ![]() $Re= u_0d_0/\nu$, where

$Re= u_0d_0/\nu$, where ![]() $\rho = 1.0\times 10^3\ \textrm {kg}\,\textrm {m}^{-3}$,

$\rho = 1.0\times 10^3\ \textrm {kg}\,\textrm {m}^{-3}$, ![]() $\nu = 1.0\times 10^{-6}\ \textrm {m}^{2}\,\textrm {s}^{-1}$ and

$\nu = 1.0\times 10^{-6}\ \textrm {m}^{2}\,\textrm {s}^{-1}$ and ![]() $\sigma = 72\ \textrm {mN}\,\textrm {m}^{-1}$, are the density, kinematic viscosity, and surface tension of the water drop, respectively.

$\sigma = 72\ \textrm {mN}\,\textrm {m}^{-1}$, are the density, kinematic viscosity, and surface tension of the water drop, respectively. ![]() $N_{exp}$ is the number of experiments carried out for each group.

$N_{exp}$ is the number of experiments carried out for each group. ![]() $d_r$ is the diameter of the impact rod.

$d_r$ is the diameter of the impact rod. ![]() $\eta$ is the ratio of the diameter of the surface,

$\eta$ is the ratio of the diameter of the surface, ![]() $d_r$, with that of the impact drop,

$d_r$, with that of the impact drop, ![]() $d_0$.

$d_0$.

3.2. Advanced image processing algorithms

Due to the rich complexity of the corrugation and ligament dynamics (figure 1), we used especially developed advanced image processing (AIP) algorithms (Wang & Bourouiba Reference Wang and Bourouiba2020b) to measure a range of key quantities. The work flow and validation of our AIP algorithms start with a first step of detection of the inner and outer contours of the rim–ligament system (figure 2![]() $a$). The second step is the separation of the ligaments from the rim based on local morphological analysis (figure 2

$a$). The second step is the separation of the ligaments from the rim based on local morphological analysis (figure 2![]() $b$). With the accurate rim–ligament separation, the AIP algorithms can capture the global (population) information of ligaments along the rim directly and automatically, including their number and population average size evolution over time. Finally, each ligament on the rim is tracked over time, linking its size and position at different times throughout the entire sheet evolution (figure 2

$b$). With the accurate rim–ligament separation, the AIP algorithms can capture the global (population) information of ligaments along the rim directly and automatically, including their number and population average size evolution over time. Finally, each ligament on the rim is tracked over time, linking its size and position at different times throughout the entire sheet evolution (figure 2![]() $c$). The detailed measurements of key ligament dynamics quantities are described in subsequent sections.

$c$). The detailed measurements of key ligament dynamics quantities are described in subsequent sections.

Figure 2. Key steps of our AIP algorithms: (![]() $a$) detection of inner and outer contours of the rim–ligament system; (

$a$) detection of inner and outer contours of the rim–ligament system; (![]() $b$) morphological analysis of the rim–ligament system and the separation of the ligaments from the rim. The inset illustrates the high accuracy of the automatic separation between the rim and the ligaments conducted; (

$b$) morphological analysis of the rim–ligament system and the separation of the ligaments from the rim. The inset illustrates the high accuracy of the automatic separation between the rim and the ligaments conducted; (![]() $c$) the ligament-tracking algorithm links the ligaments detected at different frames to form their trajectories.

$c$) the ligament-tracking algorithm links the ligaments detected at different frames to form their trajectories.

4. Corrugations versus ligaments

To quantify the dynamics of ligaments on the rim, we first need to define precisely what a ligament actually is, and how it differs from a corrugation. We define a ligament as a growing protrusion on the rim that increases in volume over time. Only those elongated ligaments, rather than the short-bulged corrugations of fixed volume, eventually shed drops (figure 3![]() $b$). Thus, the temporal evolution of the properties of the secondary droplets, including their size, speed and number shed per unit of time depends on the properties of ligaments at that time, rather than that of the corrugations. By observation, we can clearly see that each ligament grows from an initial corrugation on the rim, while not all the corrugations on the rim can evolve into ligaments. The ligaments are a subset of the corrugations and a mechanism selects for the corrugations to eventually grow to become ligaments. We first review the mechanism underlying the growth of initial corrugations.

$b$). Thus, the temporal evolution of the properties of the secondary droplets, including their size, speed and number shed per unit of time depends on the properties of ligaments at that time, rather than that of the corrugations. By observation, we can clearly see that each ligament grows from an initial corrugation on the rim, while not all the corrugations on the rim can evolve into ligaments. The ligaments are a subset of the corrugations and a mechanism selects for the corrugations to eventually grow to become ligaments. We first review the mechanism underlying the growth of initial corrugations.

Figure 3. Illustration of the algorithms detecting the local protrusions and corrugations on the rim. (![]() $a$) Inner and outer contours are detected. The local distance between two contours is calculated from the difference in radial positions of the inner and outer contours. The circle dots correspond to the local maxima of distances detected. (

$a$) Inner and outer contours are detected. The local distance between two contours is calculated from the difference in radial positions of the inner and outer contours. The circle dots correspond to the local maxima of distances detected. (![]() $b$) The detected local maxima capture the local protrusions on the rim.

$b$) The detected local maxima capture the local protrusions on the rim.

4.1. Corrugations and rim destabilization

As discussed in § 2, initial corrugations are formed by rim destabilization, the onset of which is governed by a coupled Rayleigh–Plateau (RP) and Rayleigh–Taylor (RT) instability. When the corrugations grow to a certain size, nonlinear effects dominate, associated with a self-adjustment of the rim thickness to maintain a local and instantaneous Bond number ![]() $Bo = 1$ (§ 2.2). However, during the entire sheet fragmentation, new corrugations continuously form on the rim. Even though the rim is governed by the

$Bo = 1$ (§ 2.2). However, during the entire sheet fragmentation, new corrugations continuously form on the rim. Even though the rim is governed by the ![]() $Bo = 1$ criterion, a nonlinear dynamics, the formation of new corrugations on the rim at each time is well captured by a coupled Rayleigh–Plateau and Rayleigh–Taylor instability, the dispersion relation of which, for

$Bo = 1$ criterion, a nonlinear dynamics, the formation of new corrugations on the rim at each time is well captured by a coupled Rayleigh–Plateau and Rayleigh–Taylor instability, the dispersion relation of which, for ![]() $Bo = 1$, approaches that of the Rayleigh–Plateau instability. This is consistent with the results in the literature (Deegan et al. Reference Deegan, Brunet and Eggers2008; Roisman Reference Roisman2010; Zhang et al. Reference Zhang, Brunet, Eggers and Deegan2010; Agbaglah et al. Reference Agbaglah, Josserand and Zaleski2013).

$Bo = 1$, approaches that of the Rayleigh–Plateau instability. This is consistent with the results in the literature (Deegan et al. Reference Deegan, Brunet and Eggers2008; Roisman Reference Roisman2010; Zhang et al. Reference Zhang, Brunet, Eggers and Deegan2010; Agbaglah et al. Reference Agbaglah, Josserand and Zaleski2013).

Prior studies reported factors that can influence the dispersion relation of the instability of the rim, including the attachment of the expanding sheet to the rim (Roisman et al. Reference Roisman, Gambaryan-Roisman, Kyriopoulos, Stephan and Tropea2007; Agbaglah et al. Reference Agbaglah, Josserand and Zaleski2013), and the rim thickening during the sheet evolution (Zhang et al. Reference Zhang, Brunet, Eggers and Deegan2010). Here, the rim thickness is measured by contour detection (figure 3![]() $b$). The sheet thickness

$b$). The sheet thickness ![]() $h(r,t)$ is measured using light absorption, with the intensity response of Nigrosine-dyed liquid to the liquid thickness quantified (Wang & Bourouiba Reference Wang and Bourouiba2017) and shown to follow Beer–Lambert's law of absorption

$h(r,t)$ is measured using light absorption, with the intensity response of Nigrosine-dyed liquid to the liquid thickness quantified (Wang & Bourouiba Reference Wang and Bourouiba2017) and shown to follow Beer–Lambert's law of absorption ![]() $h = \epsilon \log (I_0/I)$, where

$h = \epsilon \log (I_0/I)$, where ![]() $I_0$ is the background light intensity,

$I_0$ is the background light intensity, ![]() $I$ is the intensity of light after passing through the dyed liquid film,

$I$ is the intensity of light after passing through the dyed liquid film, ![]() $\epsilon$ is the fluid absorptivity based on dye property and concentration, which we calibrated.

$\epsilon$ is the fluid absorptivity based on dye property and concentration, which we calibrated.

Figure 4(![]() $a$) shows that the ratio of the sheet thickness at the rim,

$a$) shows that the ratio of the sheet thickness at the rim, ![]() $h(r_s,t)$, with the rim thickness,

$h(r_s,t)$, with the rim thickness, ![]() $b(t)$, remains much smaller than 1 during the entire sheet evolution. In this regime, prior numerical work (Agbaglah et al. Reference Agbaglah, Josserand and Zaleski2013) showed that the sheet attachment to the rim has a negligible effect on destabilization. Namely, the rim can be considered as a standalone cylindrical liquid column. Figure 4(

$b(t)$, remains much smaller than 1 during the entire sheet evolution. In this regime, prior numerical work (Agbaglah et al. Reference Agbaglah, Josserand and Zaleski2013) showed that the sheet attachment to the rim has a negligible effect on destabilization. Namely, the rim can be considered as a standalone cylindrical liquid column. Figure 4(![]() $b$) shows the time evolution of the measured rim thickening time scale

$b$) shows the time evolution of the measured rim thickening time scale ![]() $\tau _h = b/\dot {b}$, the ratio of the rim thickness over its rate of change, compared with the time scale of the fastest-growing mode of the Rayleigh–Plateau instability,

$\tau _h = b/\dot {b}$, the ratio of the rim thickness over its rate of change, compared with the time scale of the fastest-growing mode of the Rayleigh–Plateau instability, ![]() $\tau _{is} = 0.343\sqrt {\rho b^3/(8\sigma )}$ based on the instantaneous measured rim thickness. Figure 4(

$\tau _{is} = 0.343\sqrt {\rho b^3/(8\sigma )}$ based on the instantaneous measured rim thickness. Figure 4(![]() $b$) shows that, during the entire sheet evolution,

$b$) shows that, during the entire sheet evolution, ![]() $\tau _{h} \gg \tau _{is}$. Even at early time, the rim thickening time scale is still twice as large as the instability time scale. Thus, the rim can be considered as quasi-static for the purpose of analysing the local dynamics of onset of rim instability over a given time snapshot.

$\tau _{h} \gg \tau _{is}$. Even at early time, the rim thickening time scale is still twice as large as the instability time scale. Thus, the rim can be considered as quasi-static for the purpose of analysing the local dynamics of onset of rim instability over a given time snapshot.

Figure 4. (![]() $a$) Time evolution of the ratio,

$a$) Time evolution of the ratio, ![]() $\kappa (t)$, of the sheet thickness at the rim,

$\kappa (t)$, of the sheet thickness at the rim, ![]() $h(r_s,t)$, with the rim thickness

$h(r_s,t)$, with the rim thickness ![]() $b(t)$ for impact

$b(t)$ for impact ![]() $We = 679$ and rod-to-drop size ratio

$We = 679$ and rod-to-drop size ratio ![]() $\eta = 1.45$, showing that

$\eta = 1.45$, showing that ![]() $\kappa (t) \ll 1$ during the entire sheet evolution. (

$\kappa (t) \ll 1$ during the entire sheet evolution. (![]() $b$) Time evolution of the instability time scale,

$b$) Time evolution of the instability time scale, ![]() $\tau _{is}$, of the fastest-growing mode of the coupled RP–RT instability of the rim, compared with the rim thickening time scale,

$\tau _{is}$, of the fastest-growing mode of the coupled RP–RT instability of the rim, compared with the rim thickening time scale, ![]() $\tau _h$, based on both the volume influx entering the rim and the stretching of the rim length (sheet perimeter) for the same experimental condition as (

$\tau _h$, based on both the volume influx entering the rim and the stretching of the rim length (sheet perimeter) for the same experimental condition as (![]() $a$). It shows that the instability time scale is much slower than the actual thickening.

$a$). It shows that the instability time scale is much slower than the actual thickening.

Based on figure 4, the average distance between the corrugations on the rim should be equal to the wavelength of the fastest-growing mode of the coupled RP–RT instability, which for ![]() $Bo = 1$, is close to that of the Rayleigh–Plateau instability (Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c):

$Bo = 1$, is close to that of the Rayleigh–Plateau instability (Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c): ![]() $\lambda _{RP} = 9(b/2) = 4.5b$ (Rayleigh Reference Rayleigh1878). Thus, the total number of corrugations on the rim would be

$\lambda _{RP} = 9(b/2) = 4.5b$ (Rayleigh Reference Rayleigh1878). Thus, the total number of corrugations on the rim would be

where ![]() $R_s = r_s/d_0$ and

$R_s = r_s/d_0$ and ![]() $B = b/d_0$ are the dimensionless sheet radius and rim thickness, respectively, non-dimensionalized by the impacting drop diameter

$B = b/d_0$ are the dimensionless sheet radius and rim thickness, respectively, non-dimensionalized by the impacting drop diameter ![]() $d_0$. The evolution of

$d_0$. The evolution of ![]() $R_s(T)$ and

$R_s(T)$ and ![]() $B(T)$ were derived in Wang & Bourouiba (Reference Wang and Bourouiba2020a,Reference Wang and Bourouibab) and recalled in § 2.1.

$B(T)$ were derived in Wang & Bourouiba (Reference Wang and Bourouiba2020a,Reference Wang and Bourouibab) and recalled in § 2.1.

The experimental measurement of the number of corrugations was conducted by detecting and enumerating the number of protrusions, namely, the local maxima of distance between inner and outer contours (figure 3![]() $a$) obtained for each azimuthal angle,

$a$) obtained for each azimuthal angle, ![]() $\theta$, along the contour, from

$\theta$, along the contour, from ![]() $-{\rm \pi}$ to

$-{\rm \pi}$ to ![]() ${\rm \pi}$. However, we note that the pixelization of the image, as well as errors in local contour detection can generate artificial local maxima. To guarantee accurate detection of local maxima free of spurious measurements, we consider a local maximum to be a true protrusion if the local rim thickness of the local maximum is larger than the averaged rim thickness along the entire rim plus the standard deviation of the rim thickness. In addition, we also track each local maximum and capture its evolution over time at a frame rate (20 000 f.p.s.) that is larger than the corrugation growth or decay rate. Thus, if the trajectory of a local maximum only persists for one frame, such a maximum is also discarded from the corrugation count, as it is considered spurious.

${\rm \pi}$. However, we note that the pixelization of the image, as well as errors in local contour detection can generate artificial local maxima. To guarantee accurate detection of local maxima free of spurious measurements, we consider a local maximum to be a true protrusion if the local rim thickness of the local maximum is larger than the averaged rim thickness along the entire rim plus the standard deviation of the rim thickness. In addition, we also track each local maximum and capture its evolution over time at a frame rate (20 000 f.p.s.) that is larger than the corrugation growth or decay rate. Thus, if the trajectory of a local maximum only persists for one frame, such a maximum is also discarded from the corrugation count, as it is considered spurious.

A precise measurement for the number of ligaments on the rim is also required. A manifest feature of a ligament distinct from a corrugation is that it eventually sheds droplets. However, this cannot be used as a criterion to count the number of ligaments. Indeed, the shedding of a droplet from a ligament occurs only in one instant, without information about its history and persistence prior and post shedding. Instead what clearly distinguishes a ligament from a corrugation is that a ligament is a growing protrusion with increasing volume over time. Note that with a volume increase, given the fictitious inertial force, ligaments are also characterized by an increasing length (between droplet shedding events). A corrugation can also be measured to occasionally deform and increase in length, but not increase in volume. We can summarize the fate of corrugations in three scenarios:

(i) A corrugation can transition immediately into a ligament upon formation, by increasing in volume.

(ii) A corrugation can maintain a constant volume, remaining a corrugation throughout its lifetime, before either disappearing, or being absorbed by neighbouring drifting ligaments.

(iii) A corrugation can remain a corrugation of constant volume for an extended period of time, and then suddenly transition into a ligament, i.e. increase in volume.

Given the above definitions, a precise measurement of the number of ligaments over time consists in measuring the number of protrusions on the rim that are increasing in volume at that time. Our AIP algorithms track all protrusions on the rim and examine the time evolution of their volume and length. At each time, based on the tracking results, a protrusion with increasing volume is classified as a ligament at that time. Those without change in volume are classified as non-growing, i.e. corrugations.

Figure 5(![]() $a$) shows the time evolution of the measured number of corrugations (including ligaments), compared to the prediction (4.1), which captures the data very well. However, as discussed earlier, not all corrugations can evolve into ligaments (figure 5

$a$) shows the time evolution of the measured number of corrugations (including ligaments), compared to the prediction (4.1), which captures the data very well. However, as discussed earlier, not all corrugations can evolve into ligaments (figure 5![]() $b$). By observation, the physical picture that emerges is that the number and size of ligaments on the rim are constrained by the available fluid volume shed by the rim per unit of time. Indeed, figure 5(

$b$). By observation, the physical picture that emerges is that the number and size of ligaments on the rim are constrained by the available fluid volume shed by the rim per unit of time. Indeed, figure 5(![]() $b$) shows the measured time evolution of the number of ligaments,

$b$) shows the measured time evolution of the number of ligaments, ![]() $N_{\ell }$, growing on the rim, compared with the measured number of corrugations,

$N_{\ell }$, growing on the rim, compared with the measured number of corrugations, ![]() $N_c$, for

$N_c$, for ![]() $We = 679$. The number of ligaments is systematically smaller than the number of corrugations, consistent with a restriction on corrugation growth into ligament. Thus, the number of ligament, as well as other properties of ligaments, cannot be captured by linear stability analysis as we discuss next.

$We = 679$. The number of ligaments is systematically smaller than the number of corrugations, consistent with a restriction on corrugation growth into ligament. Thus, the number of ligament, as well as other properties of ligaments, cannot be captured by linear stability analysis as we discuss next.

Figure 5. (![]() $a$) Time evolution of the number of corrugations, including ligaments, on the rim, compared with the prediction (4.1) from the wavelength of the fastest-growing mode of the Rayleigh–Plateau instability for different Weber numbers. (

$a$) Time evolution of the number of corrugations, including ligaments, on the rim, compared with the prediction (4.1) from the wavelength of the fastest-growing mode of the Rayleigh–Plateau instability for different Weber numbers. (![]() $b$) Time evolution of the measured number of ligaments, compared with the measured number of corrugations as shown in (

$b$) Time evolution of the measured number of ligaments, compared with the measured number of corrugations as shown in (![]() $a$) for

$a$) for ![]() $We = 679$. The number of ligament is systematically smaller than that of the corrugation, indicating, at each time, that not all corrugations can grow into ligaments. Error bars indicate the standard deviation from 28 experiments for each condition (table 1).

$We = 679$. The number of ligament is systematically smaller than that of the corrugation, indicating, at each time, that not all corrugations can grow into ligaments. Error bars indicate the standard deviation from 28 experiments for each condition (table 1).

4.2. Linear stability analysis does not govern ligament growth

Figure 6(![]() $a$) shows a schematic diagram of the growth of a perturbation on the rim based on linear stability analysis. The evolution of the perturbation could be governed by the fastest-growing mode growth rate of the instability. As discussed in § 2.2, when the rim thickness is governed by the

$a$) shows a schematic diagram of the growth of a perturbation on the rim based on linear stability analysis. The evolution of the perturbation could be governed by the fastest-growing mode growth rate of the instability. As discussed in § 2.2, when the rim thickness is governed by the ![]() $Bo = 1$ criterion, the initial growth of a corrugation is governed by

$Bo = 1$ criterion, the initial growth of a corrugation is governed by

where ![]() $b$ is the rim thickness, in which case, the width of the corrugation is

$b$ is the rim thickness, in which case, the width of the corrugation is ![]() $\lambda _{RP}/2$ and its length (figure 6) reads as

$\lambda _{RP}/2$ and its length (figure 6) reads as

where ![]() $\ell _0$ is the initial perturbation amplitude (figure 6

$\ell _0$ is the initial perturbation amplitude (figure 6![]() $a$). Figures 6(

$a$). Figures 6(![]() $b$) and 6(

$b$) and 6(![]() $c$) show that the predictions from linear instability theory (4.3a,b) systematically overestimate the ligament width and length. Such disagreements between predictions and experiments confirm the invalidity of linear stability analysis for the prediction of the ligament growth, the result of a nonlinear process. Indeed, when a corrugation grows into a finite size, detailed analysis of the forces acting on the ligament attached to the rim becomes required.

$c$) show that the predictions from linear instability theory (4.3a,b) systematically overestimate the ligament width and length. Such disagreements between predictions and experiments confirm the invalidity of linear stability analysis for the prediction of the ligament growth, the result of a nonlinear process. Indeed, when a corrugation grows into a finite size, detailed analysis of the forces acting on the ligament attached to the rim becomes required.

Figure 6. (![]() $a$) Schematic diagram of corrugation growth based on linear stability analysis. The corrugation width is half of the wavelength of the fastest-growing mode of the linear instability, and the length is the amplitude of the perturbation, following an exponential growth. (

$a$) Schematic diagram of corrugation growth based on linear stability analysis. The corrugation width is half of the wavelength of the fastest-growing mode of the linear instability, and the length is the amplitude of the perturbation, following an exponential growth. (![]() $b$) Time evolution of the measured population mean width of a single ligament for impact

$b$) Time evolution of the measured population mean width of a single ligament for impact ![]() $We = 693$, compared with the prediction (4.3a,b). (

$We = 693$, compared with the prediction (4.3a,b). (![]() $c$) Time evolution of the measured population average length of ligaments for

$c$) Time evolution of the measured population average length of ligaments for ![]() $We = 693$, compared with prediction (4.3a,b). The ligament length is normalized by the initial measured length of the ligament

$We = 693$, compared with prediction (4.3a,b). The ligament length is normalized by the initial measured length of the ligament ![]() $\ell _0$, which can be considered as the initial amplitude of the rim's perturbation. Time is non-dimensionalized by the local capillary time,

$\ell _0$, which can be considered as the initial amplitude of the rim's perturbation. Time is non-dimensionalized by the local capillary time, ![]() $\tau _b = \sqrt {\rho b^3/8\sigma }$, based on the local rim thickness around the ligament.

$\tau _b = \sqrt {\rho b^3/8\sigma }$, based on the local rim thickness around the ligament.

5. Local dynamics of the growth of a single ligament

5.1. Literature review of single jet dynamics

Prior jet studies focused on jets emitted from a solid orifice or nozzle with fixed flow rate. Figure 7(![]() $a$) shows a schematic diagram of a jet emanating from a fixed orifice of inner diameter,

$a$) shows a schematic diagram of a jet emanating from a fixed orifice of inner diameter, ![]() $w$, with flow rate,

$w$, with flow rate, ![]() $q_{\ell }$. Due to its cylindrical shape, the ligament would be subject to the Rayleigh–Plateau instability. Taking an initial perturbation of amplitude

$q_{\ell }$. Due to its cylindrical shape, the ligament would be subject to the Rayleigh–Plateau instability. Taking an initial perturbation of amplitude ![]() $\delta _0$ and the fastest-growing mode of the Rayleigh–Plateau instability

$\delta _0$ and the fastest-growing mode of the Rayleigh–Plateau instability ![]() $\omega _{RP} = 0.343\sqrt {8\sigma /(\rho w^3)}$, the time evolution of the perturbation amplitude would read

$\omega _{RP} = 0.343\sqrt {8\sigma /(\rho w^3)}$, the time evolution of the perturbation amplitude would read

Assuming the ligament breaks up at the time when the perturbation amplitude reaches the radius of the ligament, the time of instability growth is

Assuming that the fluid entering the jet has a constant speed, ![]() $v_{\ell }$, the breakup length of the ligament is

$v_{\ell }$, the breakup length of the ligament is

However, the above derivation neglects the retraction of the tip of the ligament due to surface tension and the body forces exerted on the ligament, such as gravity or a fictitious force when the ligament is in a non-Galilean frame of reference.

Figure 7. (![]() $a$) Schematic diagram of a jet emanating from an orifice. (

$a$) Schematic diagram of a jet emanating from an orifice. (![]() $b$) Schematic diagram for a classic ligament analysis, selecting a control volume at the tip of the ligament (§ 5.1).

$b$) Schematic diagram for a classic ligament analysis, selecting a control volume at the tip of the ligament (§ 5.1).

A more physically sound model for the jet ejection from a solid orifice can be derived by choosing the control volume as the jet's tip on which mass conservation and momentum balance are applied. Remaining in the reference frame of the orifice, and taking the fluid speed, ![]() $v_{\ell }$, entering the jet to be constant and taking a constant average jet width away from the tip, mass conservation at the tip reads

$v_{\ell }$, entering the jet to be constant and taking a constant average jet width away from the tip, mass conservation at the tip reads

where ![]() $A = ({{\rm \pi} }/{4})w^2$ is the jet's cross-sectional area,

$A = ({{\rm \pi} }/{4})w^2$ is the jet's cross-sectional area, ![]() $z$ is the position of the tip and

$z$ is the position of the tip and ![]() $\textrm {d}z/\textrm {d}t$ is the tip velocity. The momentum balance at the tip reads

$\textrm {d}z/\textrm {d}t$ is the tip velocity. The momentum balance at the tip reads

where ![]() $g$ is the body force exerted on the ligament and

$g$ is the body force exerted on the ligament and ![]() $p$ is the curvature pressure in the jet. Assuming a cylindrical shape,

$p$ is the curvature pressure in the jet. Assuming a cylindrical shape, ![]() $p = 2\sigma /w$. By substituting (5.4) into (5.5) and rearranging gives

$p = 2\sigma /w$. By substituting (5.4) into (5.5) and rearranging gives

With the physical restriction of the solid wall, the width of the jet emanating from the orifice is equal to the diameter of the orifice, which is known. Thus, with the initial position and volume of the tip, we can directly derive the evolution of the growth of the jet. However, the base of the ligaments growing on the rim does not have a fixed width. The ligament width remains unknown. Namely, during its deformation, both the length, ![]() $\ell$, and width,

$\ell$, and width, ![]() $w$, change over time. Thus, the prediction of ligament dynamics requires elucidating the local rim–ligament dynamics discussed next.

$w$, change over time. Thus, the prediction of ligament dynamics requires elucidating the local rim–ligament dynamics discussed next.

5.2. Modified theory of ligament growth on a rim

5.2.1. Physical picture

What is the criterion by which an initial perturbation/corrugation can grow into a ligament? Figure 8 shows the typical steps of growth of a corrugation into a ligament. We can see that at first, due to rim destabilization governed by the coupled Rayleigh–Plateau Rayleigh–Taylor instability (§ 4.1), an initial perturbation (figure 8a i) gradually grows thicker to become a corrugation (figure 8a ii) of which the protruded height, ![]() $h_c$, is on the same order of magnitude as that of the rim thickness.

$h_c$, is on the same order of magnitude as that of the rim thickness.

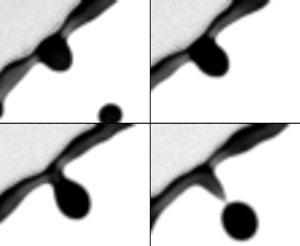

Figure 8. (![]() $a$) Sequence illustrating the growth of a ligament from initial perturbation to a corrugation that is finally pulled away from the rim to form a long ligament in the reference frame of the rim. Time increment between images is 0.5 ms. Scale bar is 0.5 mm. (

$a$) Sequence illustrating the growth of a ligament from initial perturbation to a corrugation that is finally pulled away from the rim to form a long ligament in the reference frame of the rim. Time increment between images is 0.5 ms. Scale bar is 0.5 mm. (![]() $b$) Schematic diagram of the model of ligament growth from corrugation without solid-boundary constraints at its root (§ 5.2.2). (

$b$) Schematic diagram of the model of ligament growth from corrugation without solid-boundary constraints at its root (§ 5.2.2). (![]() $c$) Schematic diagram of the reduced model of ligament dynamics (§ 5.2.3).

$c$) Schematic diagram of the reduced model of ligament dynamics (§ 5.2.3).

We analyse the ligament dynamics in the reference frame of the rim. Recall that, during the entire unsteady sheet fragmentation, the rim is continuously decelerating due to the pull of surface tension acting on the rim at the rim–sheet junction, with the rim acceleration, ![]() $\ddot {r_s}$, following the

$\ddot {r_s}$, following the ![]() $Bo = \rho b^2 (-\ddot {r_s})/\sigma = 1$ criterion (§ 2.2) (Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c). Thus, the reference frame of the rim is a non-Galilean frame, where the rim acceleration,

$Bo = \rho b^2 (-\ddot {r_s})/\sigma = 1$ criterion (§ 2.2) (Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c). Thus, the reference frame of the rim is a non-Galilean frame, where the rim acceleration, ![]() $\ddot {r_s}$, is a fictitious body force,

$\ddot {r_s}$, is a fictitious body force, ![]() $f_c$, acting on the rim in the direction opposite to that of the rim's acceleration. The rim continuously decelerates, with an acceleration vector pointing radially inward toward the centre of the sheet. Thus, the fictitious force points radially outward:

$f_c$, acting on the rim in the direction opposite to that of the rim's acceleration. The rim continuously decelerates, with an acceleration vector pointing radially inward toward the centre of the sheet. Thus, the fictitious force points radially outward: ![]() $f_c = -\ddot {r_s}$, which pushes the fluid outward, away from the rim.

$f_c = -\ddot {r_s}$, which pushes the fluid outward, away from the rim.

When the mass of the corrugation ![]() $m_g$ grows further, such a fictitious outward force,

$m_g$ grows further, such a fictitious outward force, ![]() $m_g f_c = m_g(-\ddot {r_s})$, becomes eventually larger than surface tension, the fluid in the corrugation is pulled away from the rim (figure 8a iv) and becomes an obtuse protrusion. After that, under the effect of both surface tension and the acceleration force, the protrusion deforms further into an elongated ligament (figure 8a v). When the ligament is formed, its tip grows into a bulged shape due to surface tension (figure 8a vi). Finally, after the bulge forms, the neck between the bulged tip and the root of the ligament appears, and exacerbate until the tip breaks away into a secondary droplet.

$m_g f_c = m_g(-\ddot {r_s})$, becomes eventually larger than surface tension, the fluid in the corrugation is pulled away from the rim (figure 8a iv) and becomes an obtuse protrusion. After that, under the effect of both surface tension and the acceleration force, the protrusion deforms further into an elongated ligament (figure 8a v). When the ligament is formed, its tip grows into a bulged shape due to surface tension (figure 8a vi). Finally, after the bulge forms, the neck between the bulged tip and the root of the ligament appears, and exacerbate until the tip breaks away into a secondary droplet.

5.2.2. Full model of ligament growth

The difficulty of the analysis of ligament dynamics lies in the complex deformation of its shape due to capillary forces. Figure 8(![]() $b$) shows a schematic diagram of ligament growth on a rim. For simplicity, we assume that during its growth, the ligament remains axisymmetric and cylindrical. We define

$b$) shows a schematic diagram of ligament growth on a rim. For simplicity, we assume that during its growth, the ligament remains axisymmetric and cylindrical. We define ![]() $r$ as the radial direction along the width of the ligament, and

$r$ as the radial direction along the width of the ligament, and ![]() $z$ as the direction of the ligament length which is perpendicular to the rim. We define

$z$ as the direction of the ligament length which is perpendicular to the rim. We define ![]() $v_{\ell }$ as the speed of fluid emanating from the rim into the ligament during its growth. By choosing a control volume around the entire ligament, mass conservation reads

$v_{\ell }$ as the speed of fluid emanating from the rim into the ligament during its growth. By choosing a control volume around the entire ligament, mass conservation reads

where ![]() $w(z,t)$ and

$w(z,t)$ and ![]() $A(z,t)$ are the local instantaneous width (diameter) and cross-sectional area of the ligament at height

$A(z,t)$ are the local instantaneous width (diameter) and cross-sectional area of the ligament at height ![]() $z$ and time

$z$ and time ![]() $t$, respectively.

$t$, respectively. ![]() $\ell (t)$ is the instantaneous total length of the ligament at time

$\ell (t)$ is the instantaneous total length of the ligament at time ![]() $t$.

$t$. ![]() $q_{\ell }(t)$ is the instantaneous rate of fluid volume entering the ligament, expressed by the product of the cross-sectional area of the ligament,

$q_{\ell }(t)$ is the instantaneous rate of fluid volume entering the ligament, expressed by the product of the cross-sectional area of the ligament, ![]() $A(0,t)$, and the fluid influx speed,

$A(0,t)$, and the fluid influx speed, ![]() $v_{\ell }(t)$. In addition, momentum balance at the ligament gives

$v_{\ell }(t)$. In addition, momentum balance at the ligament gives

\begin{equation} \underbrace{\frac{\textrm{d}}{\textrm{d}t}\int_0^{\ell(t)} \rho A(z,t)u(z,t)\,\textrm{d}z}_{\text{inertia}} = \underbrace{\rho q_{\ell}v_{\ell}}_{\text{momentum influx}} -\underbrace{{\rm \pi} w(0,t) \sigma + p A(0,t)}_{\text{surface tension}} + \underbrace{m(-\ddot{r_s})}_{\text{fictitious force}}, \end{equation}

\begin{equation} \underbrace{\frac{\textrm{d}}{\textrm{d}t}\int_0^{\ell(t)} \rho A(z,t)u(z,t)\,\textrm{d}z}_{\text{inertia}} = \underbrace{\rho q_{\ell}v_{\ell}}_{\text{momentum influx}} -\underbrace{{\rm \pi} w(0,t) \sigma + p A(0,t)}_{\text{surface tension}} + \underbrace{m(-\ddot{r_s})}_{\text{fictitious force}}, \end{equation}

where ![]() $u(z,t)$ is the fluid velocity profile in the ligament along the

$u(z,t)$ is the fluid velocity profile in the ligament along the ![]() $z$-direction;

$z$-direction; ![]() $\rho q_{\ell } v_{\ell }$ is the momentum influx entering the ligament;

$\rho q_{\ell } v_{\ell }$ is the momentum influx entering the ligament; ![]() ${\rm \pi} w(0,t) \sigma$ is the surface tension force acting on the root of the ligament pulling it toward the rim;

${\rm \pi} w(0,t) \sigma$ is the surface tension force acting on the root of the ligament pulling it toward the rim; ![]() $p A(0,t)$ is the pressure force acting on the root cross-section,

$p A(0,t)$ is the pressure force acting on the root cross-section, ![]() $A(0,t)$, of the ligament, induced by the local curvature there. Such a term was initially neglected by prior studies aiming to predict the retraction speed of ligament tips (Keller Reference Keller1983; Clanet & Lasheras Reference Clanet and Lasheras1999), but was subsequently shown experimentally to be important in the dynamics of a cylindrical liquid column (Hoepffner & Paré Reference Hoepffner and Paré2013). Here,

$A(0,t)$, of the ligament, induced by the local curvature there. Such a term was initially neglected by prior studies aiming to predict the retraction speed of ligament tips (Keller Reference Keller1983; Clanet & Lasheras Reference Clanet and Lasheras1999), but was subsequently shown experimentally to be important in the dynamics of a cylindrical liquid column (Hoepffner & Paré Reference Hoepffner and Paré2013). Here, ![]() $m(-\ddot {r_s})$ is the fictitious body force introduced by the non-Galilean frame of the rim (Wang & Bourouiba Reference Wang and Bourouiba2020b).

$m(-\ddot {r_s})$ is the fictitious body force introduced by the non-Galilean frame of the rim (Wang & Bourouiba Reference Wang and Bourouiba2020b).

The mass and momentum balance equations (5.7) and (5.8) are still not closed. First, the speed ![]() $v_{\ell }$ of fluid entering the ligament remains unknown. Second, with no physical constraint, the width of the ligament,

$v_{\ell }$ of fluid entering the ligament remains unknown. Second, with no physical constraint, the width of the ligament, ![]() $w(z,t)$, on the rim remains unknown. It is non-uniform along the ligament height,

$w(z,t)$, on the rim remains unknown. It is non-uniform along the ligament height, ![]() $z$, and also changes with time

$z$, and also changes with time ![]() $t$. Third, the fluid velocity profile,

$t$. Third, the fluid velocity profile, ![]() $u(z,t)$, in the ligament remains unknown as well.

$u(z,t)$, in the ligament remains unknown as well.

Assuming ![]() $v_{\ell }$ to be known, which we will discuss in § 5.4, the fluid velocity profile

$v_{\ell }$ to be known, which we will discuss in § 5.4, the fluid velocity profile ![]() $u(z,t)$ in the ligament can be determined by continuity

$u(z,t)$ in the ligament can be determined by continuity

The kinematic boundary condition at the free surface of the ligament gives

where ![]() $\textrm {D}/\textrm {D}t$ is the material derivative in cylindrical coordinates. To determine the full geometric evolution of the ligament, the full system (5.7)–(5.10) would have to be solved numerically. However, to gain physical insights and tractable predictions, we next reduce further the model to capture the leading-order geometric evolution of the ligament analytically.

$\textrm {D}/\textrm {D}t$ is the material derivative in cylindrical coordinates. To determine the full geometric evolution of the ligament, the full system (5.7)–(5.10) would have to be solved numerically. However, to gain physical insights and tractable predictions, we next reduce further the model to capture the leading-order geometric evolution of the ligament analytically.

5.2.3. Reduced analytical model of ligament growth

The core insight is that the variation of thickness along the ligament is actually small (figure 8![]() $a$). Here, we thus neglect the variation of the ligament width

$a$). Here, we thus neglect the variation of the ligament width ![]() $w(z,t)$ along its length (figure 8

$w(z,t)$ along its length (figure 8![]() $c$). The ligament, thus, becomes approximately a cylinder of uniform width

$c$). The ligament, thus, becomes approximately a cylinder of uniform width ![]() $\bar {w}$ at each time. Physically, the uniform width can be considered to be the width of the original ligament averaged along its central axis (figure 8

$\bar {w}$ at each time. Physically, the uniform width can be considered to be the width of the original ligament averaged along its central axis (figure 8![]() $c$)

$c$)

where ![]() $\bar {A}(t)$ is the average cross-sectional area of the ligament along its central axis. For reduced cumbersomeness, we drop the symbol ‘

$\bar {A}(t)$ is the average cross-sectional area of the ligament along its central axis. For reduced cumbersomeness, we drop the symbol ‘![]() $\ \bar{}\ $’ from

$\ \bar{}\ $’ from ![]() $\bar {w}$ and

$\bar {w}$ and ![]() $\bar {A}$ hereafter;

$\bar {A}$ hereafter; ![]() $w(t)$ now represents the average width along the ligament, which depends only on time. The mass of the ligament is thus

$w(t)$ now represents the average width along the ligament, which depends only on time. The mass of the ligament is thus

which reduces the mass conservation equation (5.7) to

The continuity equation can then be simplified to

Since both ![]() $\ell$ and

$\ell$ and ![]() $v_{\ell }$ are independent of

$v_{\ell }$ are independent of ![]() $z$, we take the integral over

$z$, we take the integral over ![]() $z$ on both sides of (5.15), which gives

$z$ on both sides of (5.15), which gives

where ![]() $u(0,t)$ is the fluid velocity at the root of the ligament, equal to the speed of fluid entering the ligament, namely,

$u(0,t)$ is the fluid velocity at the root of the ligament, equal to the speed of fluid entering the ligament, namely, ![]() $u(0,t) = v_{\ell }(t)$.

$u(0,t) = v_{\ell }(t)$.

Under the uniform-width approximation we made, the variation of the ligament width along its length is neglected. Thus, the kinematic boundary condition (5.10) that governs the free surface become trivial. Finally, the momentum balance (5.8), based on uniform-width approximation, simplifies to

where the curvature-induced pressure at the root of the ligament is approximately ![]() $p = 2\sigma /w(t)$. Using (5.12), (5.14), and (5.16), the momentum balance can be re-written, after algebraic manipulation, as

$p = 2\sigma /w(t)$. Using (5.12), (5.14), and (5.16), the momentum balance can be re-written, after algebraic manipulation, as

Therefore, using the uniform-width approximation, we arrive at a reduced theoretical model to capture the leading-order evolution of ligament growth on the rim, which, combining mass conservation and momentum balance, reads

\begin{equation} \left. \begin{gathered} \frac{\textrm{d}\ell}{\textrm{d}t} + \frac{2\ell}{w}\frac{\textrm{d}w}{\textrm{d}t} = v_{\ell},\\ \ell\frac{\textrm{d}}{\textrm{d}t}\left(\frac{\textrm{d}\ell}{\textrm{d}t}+v_{\ell} \right) = v_{\ell}\left(v_{\ell}-\frac{\textrm{d}\ell}{\textrm{d}t} \right) -\frac{4\sigma}{\rho w} + 2(-\ddot{r_s})\ell. \end{gathered} \right\} \end{equation}

\begin{equation} \left. \begin{gathered} \frac{\textrm{d}\ell}{\textrm{d}t} + \frac{2\ell}{w}\frac{\textrm{d}w}{\textrm{d}t} = v_{\ell},\\ \ell\frac{\textrm{d}}{\textrm{d}t}\left(\frac{\textrm{d}\ell}{\textrm{d}t}+v_{\ell} \right) = v_{\ell}\left(v_{\ell}-\frac{\textrm{d}\ell}{\textrm{d}t} \right) -\frac{4\sigma}{\rho w} + 2(-\ddot{r_s})\ell. \end{gathered} \right\} \end{equation}Compared to the original full ligament dynamics model (5.7)–(5.10), which involved four partial differential equations, the reduced model (5.19) only involves two coupled ordinary differential equations, which ensures tractability. Before solving (5.19), we first examine its dynamics. In particular, we elucidate under which conditions can a corrugation elongate into a ligament.

5.2.4. Dynamical criterion for elongation of a corrugation

We first examine the case where no fluid enters the root of the corrugation, namely ![]() $v_{\ell } = 0$. In this case, the reduced model can be further simplified to

$v_{\ell } = 0$. In this case, the reduced model can be further simplified to

\begin{equation} \left. \begin{array}{c@{}} \displaystyle \dfrac{\textrm{d}}{\textrm{d}t}(w^2 \ell) = 0, \\ \displaystyle \ell\dfrac{\textrm{d}^2\ell}{\textrm{d}t^2} = -\dfrac{4\sigma}{\rho w} + 2(-\ddot{r_s})\ell, \end{array}\right\} \quad \Longrightarrow \quad \left. \begin{array}{c@{}} \displaystyle w^2 \ell = \varOmega_{\ell}, \\ \displaystyle w\ell[\ddot{\ell} - (-2\ddot{r_s})] = -\dfrac{4\sigma}{\rho}, \end{array} \right\} \end{equation}

\begin{equation} \left. \begin{array}{c@{}} \displaystyle \dfrac{\textrm{d}}{\textrm{d}t}(w^2 \ell) = 0, \\ \displaystyle \ell\dfrac{\textrm{d}^2\ell}{\textrm{d}t^2} = -\dfrac{4\sigma}{\rho w} + 2(-\ddot{r_s})\ell, \end{array}\right\} \quad \Longrightarrow \quad \left. \begin{array}{c@{}} \displaystyle w^2 \ell = \varOmega_{\ell}, \\ \displaystyle w\ell[\ddot{\ell} - (-2\ddot{r_s})] = -\dfrac{4\sigma}{\rho}, \end{array} \right\} \end{equation}

where ![]() $\varOmega _{\ell }$ is the initial volume of the corrugation. Based on mass conservation

$\varOmega _{\ell }$ is the initial volume of the corrugation. Based on mass conservation ![]() $w^2 \ell = \varOmega _{\ell }$, the ligament width can be expressed as

$w^2 \ell = \varOmega _{\ell }$, the ligament width can be expressed as

Substituting into the momentum equation leads to

Such an equation, in fact, has a critical dynamical property. Taking,

and noting that both ![]() $\alpha$ and

$\alpha$ and ![]() $\beta$ are positive, (5.22) becomes

$\beta$ are positive, (5.22) becomes

We first examine the case without the fictitious force associated with the rim deceleration on the corrugation, namely the case ![]() $\alpha = 0$. In this case, (5.24) becomes

$\alpha = 0$. In this case, (5.24) becomes

Since ![]() $\ell$ and

$\ell$ and ![]() $w$ are the length and width of the ligament, respectively, which are positive, the above equation gives

$w$ are the length and width of the ligament, respectively, which are positive, the above equation gives ![]() $\ddot {\ell }< 0$. Since the initial stage of the ligament formation without volume influx should have zero initial growth speed, namely

$\ddot {\ell }< 0$. Since the initial stage of the ligament formation without volume influx should have zero initial growth speed, namely ![]() $\dot {\ell }(0) = 0$, then, the case of no fictitious force with associated

$\dot {\ell }(0) = 0$, then, the case of no fictitious force with associated ![]() $\ddot {\ell } < 0$ implies that the corrugation cannot elongate into a ligament.

$\ddot {\ell } < 0$ implies that the corrugation cannot elongate into a ligament.

However, the interesting dynamics of (5.24) arises when ![]() $\alpha \neq 0$, i.e. the fictitious force acts on the corrugation. In this case, the ligament can grow only if the initial length and width of the corrugation satisfy a certain dynamical criterion. We can rewrite (5.24) as

$\alpha \neq 0$, i.e. the fictitious force acts on the corrugation. In this case, the ligament can grow only if the initial length and width of the corrugation satisfy a certain dynamical criterion. We can rewrite (5.24) as

Recalling the definition of ![]() $\alpha$ and

$\alpha$ and ![]() $\beta$ from (5.23a,b),

$\beta$ from (5.23a,b),

which shows that, for a corrugation of initial growth speed ![]() $\dot {\ell }(0) = 0$, if its initial length

$\dot {\ell }(0) = 0$, if its initial length ![]() $\ell (0) > \beta ^2/\alpha ^2$, then its growth acceleration is positive,

$\ell (0) > \beta ^2/\alpha ^2$, then its growth acceleration is positive, ![]() $\ddot {\ell }>0$, with a length increase rate

$\ddot {\ell }>0$, with a length increase rate ![]() $\dot {\ell } > 0$. Otherwise, if

$\dot {\ell } > 0$. Otherwise, if ![]() $\ell (0) < \beta ^2/\alpha ^2$, then the ligament length further decreases with

$\ell (0) < \beta ^2/\alpha ^2$, then the ligament length further decreases with ![]() $\dot {\ell }<0$. Therefore,

$\dot {\ell }<0$. Therefore, ![]() $\beta ^2/\alpha ^2$ is the critical length that a corrugation has to reach to trigger its transition to an elongated ligament in the absence of fluid feeding the corrugation from the rim. Given that

$\beta ^2/\alpha ^2$ is the critical length that a corrugation has to reach to trigger its transition to an elongated ligament in the absence of fluid feeding the corrugation from the rim. Given that ![]() $\varOmega _{\ell } = w^2 \ell$, we can also re-write the criterion (5.27) as

$\varOmega _{\ell } = w^2 \ell$, we can also re-write the criterion (5.27) as

Based on the local rim criterion of ![]() $Bo = 1$ (Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c) (§ 2.2) with

$Bo = 1$ (Wang et al. Reference Wang, Dandekar, Bustos, Poulain and Bourouiba2018c) (§ 2.2) with

the final expression for the elongation criterion, (5.28), is

In sum, if the initial size of a corrugation satisfies (5.30), even if no fluid feeds it from the rim, the corrugation can deform and elongate, under the fictitious force acting on it in the reference frame of the decelerating rim. Similarly, if the initial size of the corrugation does not satisfy (5.30), the corrugation is pulled back by surface tension force and cannot elongate, remaining a blob of comparable height to that of the rim (figure 1![]() $a$). With this key insight, it is critical to examine now whether corrugations satisfy (5.30).

$a$). With this key insight, it is critical to examine now whether corrugations satisfy (5.30).

5.2.5. Size of initial corrugations for a rim of fixed volume

As described in § 4.1, the initial growth of corrugations on the rim is governed by the interplay of coupled Rayleigh–Plateau and Rayleigh–Taylor instabilities. When the local Bond number of the rim equals 1, the coupled instability wavelength approaches that of the Rayleigh–Plateau instability. Due to such rim destabilization, even without fictitious force acting on corrugations, it remains energy-favourable for the rim to transition into spherical drops of diameters set by the wavelength of the instability's fastest-growing mode

As shown in figure 4(![]() $b$), the rim's thickening time scale,

$b$), the rim's thickening time scale, ![]() $\tau _h$, from injection of fluid from the sheet is much larger than its instability time scale,

$\tau _h$, from injection of fluid from the sheet is much larger than its instability time scale, ![]() $\tau _{is}$. Thus, we take the rim thickness,

$\tau _{is}$. Thus, we take the rim thickness, ![]() $b$, to be quasi-constant for the purpose of the analysis of the corrugation dynamics (Agbaglah et al. Reference Agbaglah, Josserand and Zaleski2013; Li et al. Reference Li, Thoraval, Marston and Thoroddsen2018). Therefore, the maximum size of a corrugation growing on the rim would be of diameter

$b$, to be quasi-constant for the purpose of the analysis of the corrugation dynamics (Agbaglah et al. Reference Agbaglah, Josserand and Zaleski2013; Li et al. Reference Li, Thoraval, Marston and Thoroddsen2018). Therefore, the maximum size of a corrugation growing on the rim would be of diameter ![]() $d_c \approx 1.89b$. Taking an initial corrugation of width,

$d_c \approx 1.89b$. Taking an initial corrugation of width, ![]() $w = d_c= 1.89b$, and length

$w = d_c= 1.89b$, and length ![]() $\ell = d_c-b = 0.89b$, the product of the width and length of the maximum size of the initial corrugation (5.30) gives

$\ell = d_c-b = 0.89b$, the product of the width and length of the maximum size of the initial corrugation (5.30) gives

which does not satisfy the criterion enabling corrugation elongation (5.30). This conclusion shows that without fluid injection from the sheet into the rim and rim shedding, the corrugation due to initial linear rim destabilization alone can only remain a short bulge but cannot elongate into a long slim ligament nor can it grow. This exactly explains why not all corrugations can grow into ligaments: sufficient fluid injection into corrugations, ![]() $v_{\ell } \neq 0$, and the fictitious force, are both necessary.

$v_{\ell } \neq 0$, and the fictitious force, are both necessary.

5.3. Verification of the modified theory of ligament growth: measured  $v_{\ell }$

$v_{\ell }$

Using the uniform-width ligament approximation, a reduced model describing the leading-order ligament dynamics on the rim was developed. In (5.19), the speed ![]() $v_{\ell }$ of fluid entering the ligament remains unknown. We will determine it in § 5.4. Here, we first validate the reduced model (5.19) based on the measured

$v_{\ell }$ of fluid entering the ligament remains unknown. We will determine it in § 5.4. Here, we first validate the reduced model (5.19) based on the measured ![]() $v_{\ell }$.

$v_{\ell }$.

Figure 9(![]() $a$) shows the time evolution of the measured and predicted rim deceleration during the sheet evolution (Wang & Bourouiba Reference Wang and Bourouiba2020b). We first take the measured rim deceleration (

$a$) shows the time evolution of the measured and predicted rim deceleration during the sheet evolution (Wang & Bourouiba Reference Wang and Bourouiba2020b). We first take the measured rim deceleration (![]() $-\ddot {r_s}$). The inset of figure 9(

$-\ddot {r_s}$). The inset of figure 9(![]() $a$) illustrates the experimental measurement of ligament size. Figure 9(

$a$) illustrates the experimental measurement of ligament size. Figure 9(![]() $b$) shows the measured time evolution of the volume,

$b$) shows the measured time evolution of the volume, ![]() $\varOmega _{\ell }$, of a single ligament on the rim, which continuously increases over time. Time

$\varOmega _{\ell }$, of a single ligament on the rim, which continuously increases over time. Time ![]() $t_1$ is the time at which the corrugation is first detected by the algorithm. Time