Introduction

The archaeological study of basketry—the weaving of 3D objects, such as containers and mats—is a well-established area of research, undertaken in parallel with, and often informed by, consideration of other perishable types of material culture. In the past, objects made of basketry would have been used in many aspects of everyday life, including for storage, transport and the processing and consumption of goods (Adovasio Reference Adovasio1977; Wendrich Reference Wendrich1990). Yet, archaeologically, the craft of basket weaving is almost invisible, due to the scarcity of direct archaeobotanical evidence (Hurcombe Reference Hurcombe2014). The archaeological record for Late Neolithic to Middle/Late Chalcolithic (c. 5500–3300 BC) south-eastern Europe, for example, has yielded only a single documented example of basketry: the Late Neolithic settlement of Promachon-Topolnitsa, located on the Greek-Bulgarian border, where two basketry objects were preserved (Koukouli-Chrysanthaki et al. Reference Koukouli-Chrysanthaki, Todorova, Stefanovich and Ivanov2007).

This scarce direct evidence for archaeological basketry obscures its general ubiquity in prehistoric society (Hurcombe Reference Hurcombe2014). The uneven representation of plant-based crafts, such as basketry, is due to their particular vulnerability to taphonomic and environmental processes; Hurcombe (Reference Hurcombe2007: 163) captures this inverse relationship thus: “so many materials, so little surviving”. We must therefore turn to indirect evidence to enhance our understanding of plant-based crafts and their perishable products; this is the focus of the present article.

Globally, mat-impressed pottery bases are one of the most frequently encountered types of indirect evidence for prehistoric basketry (Adovasio Reference Adovasio1977). In a regional context, Late Neolithic/Early Chalcolithic mat impressions are relatively abundant in south-eastern Europe, peaking during the Late Neolithic and decreasing significantly during the Chalcolithic (Figure 1). Here, we focus specifically on the mat impressions on Middle/Late Chalcolithic pottery vessels from Provadia-Solnitsata in Bulgaria, which provide the first insights into this technology as part of the Chalcolithic material culture of south-eastern Europe. Our aim is to stimulate discussion of the technology and raw materials used to create the basketry items represented by impressions on vessel bases, as well as the functionality of the pottery as part of the salt-extraction process.

Figure 1. The location of Provadia-Solnitsata, related palynological data (Durankulak Lake; Tonkov et al. Reference Tonkov, Marinova, Filipova-Marinova and Bozilova2014), and Neolithic and Chalcolithic sites with mat-impressed pottery, from north to south: Chelopechene, Kurilo, Kremikovtsi, Slatina, Dolni Lozen, Gorni Bogrov and Jana-Choina (Petkov Reference Petkov1965); Dana Bunar I (Leshtakov et al. Reference Leshtakov2019); Tell Yunatsite (K. Boyadzhiev, pers. comm.); Servia (Mauld & Wardle Reference Mauld, Wardle, Ridely, Wardle and Mould2000); Ryzari (Beloyanni Reference Beloyanni and Sampson2003); Paradimi (Bakalakis & Sakellariou Reference Bakalakis and Sakellariou1981); Kitsos (Lambert Reference Lambert1981); Kolonna (Walter & Felten Reference Walter and Felten1981); Skoteini (Beloyanni Reference Beloyanni and Sampson1993); Franchthi (Jacobsen Reference Jacobsen1973); Alepotrypa (S. Katsarou, pers. comm.); Tigani (Samos; Furness Reference Furness1956); Emporio (Chios; Hood Reference Hood1981); Saliagos (Evans & Renfrew Reference Evans, Renfrew, Evans and Renfrew1968); Kephala (Keos; Smith Reference Smith and Coleman1977); Gyali and Partheni (Leros; Sampson Reference Sampson1988) (map by M. Andonova and R. Natcheva).

At Middle/Late Chalcolithic Provadia-Solnitsata, mat-impressed pottery was used exclusively in the industrial-scale salt-extraction process (Nikolov Reference Nikolov, Nikolov and Bachvarov2012). Its use is specific to that period at the site, attesting an efficient and innovative method of obtaining salt (compared with earlier extraction techniques used at Provadia-Solnitsata; Nikolov Reference Nikolov, Nikolov and Bachvarov2012). This new method involved large pottery vessels with mat-impressed bases. It is this unique combination of basket weaving, potting and salt-extraction technologies that is explored in this article, providing insights into the raw materials chosen for making mats and the pottery production process at Provadia-Solnitsata.

Salt extraction at Provadia-Solnitsata

Provadia-Solnitsata is a Late Neolithic and Middle/Late Chalcolithic tell and salt-production complex located in north-eastern Bulgaria (Figure 1). The site also features an extensive settlement, a ‘pit sanctuary’ (consisting of numerous pits dug for ritual purposes; Nikolov Reference Nikolov2011) and two cemeteries (Nikolov Reference Nikolov, Mărgărit and Boroneant2017a, Reference Nikolov and Nikolov2017b). Settlement began here in the early Late Neolithic I (c. 5500 BC), while salt production as a major industrial activity dates to the Late Neolithic II (c. 5200–4900 BC), continuing into the Middle/Late Chalcolithic (c. 4700–4350 BC). There is no evidence for salt working during the Early Chalcolithic (c. 4900–4700 BC). Salt production at Provadia-Solnitsata is considered a key factor in the development of the complex, which exploited the natural rock-salt deposits and brine springs in the nearby Mirovo area.

The process of extracting salt at Provadia-Solnitsata uses one of the most widely documented prehistoric methods, in which ceramic vessels filled with brine were heated over a fire (open or within a kiln) in order to evaporate the water, producing dry, hardened salt ‘cakes’ (Weller Reference Weller, Nikolov and Bachvarov2012; Harding Reference Harding2013; Tencariu et al. Reference Tencariu, Alexianu, Corigă and Vasilache2015). This type of pottery can be categorised as a ‘single-use’ ware because the vessels must be broken to extract the salt cake. This explains the high fragmentation of the vessels recovered.

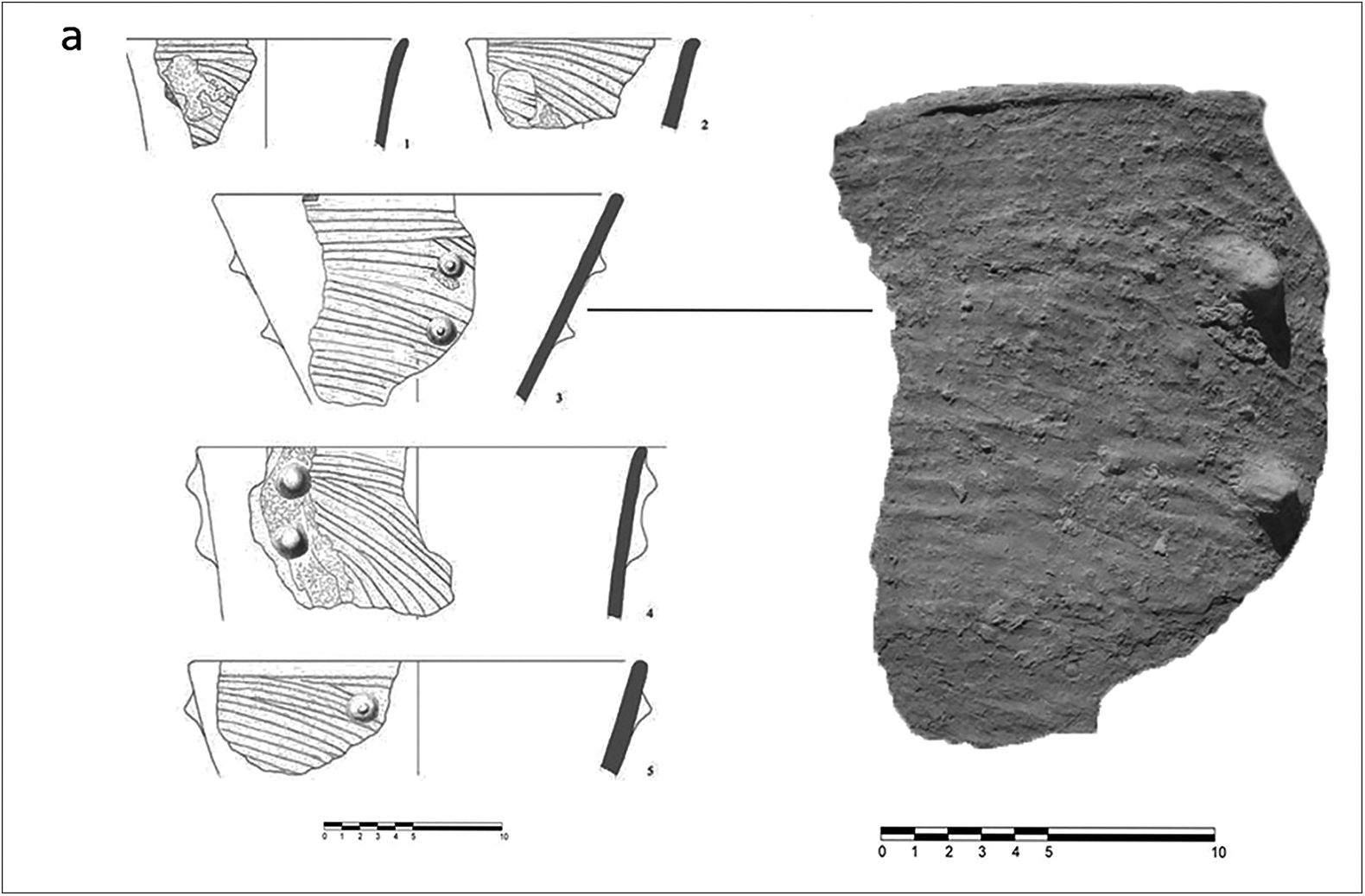

Ceramics for use in salt making were in active circulation at Provadia-Solnitsata during the Late Neolithic I and the Middle/Late Chalcolithic. The earlier Late Neolithic vessels consisted of mould-cast, thin-walled bowls used in dome kilns (Nikolov Reference Nikolov, Nikolov and Bachvarov2012). These biconical bowls could hold between six and 36 litres of brine. It has been estimated that the total brine capacity of each firing of one of the dome kilns was 90 litres (Nikolov Reference Nikolov, Nikolov and Bachvarov2012). The Middle/Late Chalcolithic revival of salt production at Provadia-Solnitsata featured several changes in the organisation of production, including the introduction of significantly larger pottery vessels in the form of deep, thick-walled tubs (Figure 2a–b).

Figure 2. a) Single- (a1–2) and double-lugged (a3–5) Middle/Late Chalcolithic salt-making tubs (scales in cm; illustration by M. Lyuncheva, after Nikolov Reference Nikolov, Nikolov and Bachvarov2012: 26).

The Middle/Late Chalcolithic process still followed the brine-evaporation method practised in the Late Neolithic I, albeit with improved firing techniques that made it possible to use ceramic vessels with a higher capacity. The diameters of the tub rims range between 0.6 and 0.7m, the bases between 0.3 and 0.35m, and the heights between 0.7 and 0.8m; the average volume of each vessel is estimated to be approximately 60–80l of brine, the equivalent of 114kg of hardened salt (Weller Reference Weller, Nikolov and Bachvarov2012). Often, these vessels had double pairs of vertical conical lugs, intended, given their significant weight, to facilitate handling and transport. The exterior surfaces of the vessels were intentionally rusticated, while the interiors were smoothed and often covered with a kaolin film—perhaps intended to aid impermeability and to prevent breakage during heating to evaporate the brine. The heating process took place in pits, with the vessels placed with their rims in contact with each other and the gaps between the vessels probably filled with firewood (Nikolov Reference Nikolov, Nikolov and Bachvarov2012; Figure 3). The lateral heating facilitated evaporation, aiding the salt-crystallisation process. These vessels also had an additional novel feature: mat-impressed bases—a characteristic almost entirely confined at this site to salt-making vessels. These mat impressions are an intriguing feature, since they are absent from other pottery categories at Provadia-Solnitsata and have so far not been found at other Neolithic or Chalcolithic sites in south-eastern Europe (although they have been recorded at Early Bronze Age sites in the Carpathian zone; Carvruk & Harding Reference Carvruk, Harding, Nikolov and Bachvarov2012).

Figure 3. Pit filled with salt-evaporation pottery (illustration by J. Hristov, after Nikolov Reference Nikolov, Nikolov and Bachvarov2012: 27).

Materials and methods

This article presents the analysis of 100 mat-impressed tub bases (50 bases and 50 bases with adjoining walls) selected from the Middle/Late Chalcolithic salt-production pits at Provadia-Solnitsata. These represent approximately three per cent of the total quantity of mat-impressed bases from the site (Nikolov Reference Nikolov and Nikolov2017b). Here, the phrase ‘mat impressions’ is used to describe 2D imprints left by objects woven from vegetable fibres. The mat impressions have been studied using a two-step approach, comprising stereomicroscopic examination and the production of wax casts. Because the transfer of the ceramic samples to a laboratory for high-powered microscopy and microremains analysis (prior to wax casting) was not permitted, it was necessary to base the analysis on the study of the wax casts, which provide a proxy for understanding the woven objects themselves (Wendrich Reference Wendrich1991: 19). The identification of general leaf anatomy follows the Anatomy of the monocotyledons (Metcalfe Reference Metcalfe1960, Reference Metcalfe1971; Cutler Reference Cutler1969).

Vessel shape, size and features

The mat-impressed vessels from Provadia-Solnitsata are classified as mass-produced, medium- to large-sized, conical or oval brine evaporation vessels with two handles (Weller Reference Weller, Nikolov and Bachvarov2012; Nikolov Reference Nikolov, Nikolov and Bachvarov2012, Reference Nikolov, Mărgărit and Boroneant2017a). The analysed bases with adjoining walls show similar ranges of base thickness (mean = 14.98mm; standard deviation (hereafter SD) = 7.93; range = 9–33mm) and wall thickness (mean = 14.82mm; SD = 3.99; range = 9–32mm; Figure 4; see the online supplementary material (OSM)). These values support the hypothesis that the containers had a standardised shape and size, and specific features (i.e. mat impressions)—all indicative of mass-production.

Figure 4. Base/wall thicknesses of 50 fragments from Provadia-Solnitsata, where both bases and walls were present (graph by M. Andonova).

The high concentration of fragmented pottery vessels associated with brine evaporation is a key characteristic of salt-production sites (Weller Reference Weller, Nikolov and Bachvarov2012). At Provadia-Solnitsata, these single-use vessels are of a plain, undecorated form and produced from local clays. They contain a high concentration of organic/inorganic inclusions in the temper, a roughened exterior and a smoothed interior, suggesting an intentionally rapid production process involving the assembly of separate base and wall components. A coiling technique was probably used to produce the vessel bases, with clay coils flattened on a mat to form a disc (Weller Reference Weller, Nikolov and Bachvarov2012). This coiling technique may have served to increase the impermeability of the bases. Many of the ceramic tubs at Provadia-Solnitsata also had a clay (kaolin) coating on their interior surfaces. Weller (Reference Weller, Nikolov and Bachvarov2012) offers two hypotheses concerning this coating: either it was added at the end of the salt-crystallisation process, when plastering the internal surface could have caused a thermal shock that facilitated the separation of the salt cake from its container, or the clay was applied before heating in order to thermo-regulate the vessel's surface and prevent thermal shock during the crystallisation process.

Weaving techniques

Most of the ceramic fragments from Provadia-Solnitsata bear the impressions of woven mats that are either diagonally twilled (64 per cent) or, more rarely (12 per cent), made by simple plaiting (Adovasio Reference Adovasio1977; Wendrich Reference Wendrich1990; Figure 5; see also the OSM). For unequivocal identification of either technique, however, the presence of a mat-edge (selvedge) is required, but no such evidence was identified among the 100 mat-impressed sherds analysed.

Figure 5. Weaving techniques at Provadia-Solnitsata (graph by M. Andonova).

Diagonal twilling consists of multiple strands plaited into separate plaits, or one large plait with numerous strands (Figure 6a–b). Simple plaiting also contains multiple strands, usually forming one plait (Figure 6c–d). Twilling elements are always an odd number, while simple plaiting could comprise an even number of strands. In both techniques, a large surface (fabric) could be created by continuous plating with multiple strands, or by stitching together several plaits (Figure 7). A compact weave could be achieved by the application of force by the weaver (e.g. pulling with fingers or sitting on top of the mat), or by a loom-like device fitted with weights (Adovasio Reference Adovasio1977; Wendrich Reference Wendrich1990).

Figure 6. Diagonal twill in (a) 1:1:1 and (b) 2:2:2 ratios; simple plaiting in (c) 1:1 and (d) 2:2 ratios (illustration by V. Galabova).

Figure 7. Stitching of two plaits with rear (‘hidden’) stitch (illustration by M. Andonova, after Wendrich Reference Wendrich1990: 61).

The number of strands impressed on the bases from Provadia-Solnitsata was limited by the size of the ceramic surfaces that survived and especially by the state of preservation. Nevertheless, the number of recorded strands averages 14 (mean = 14.2; SD = 6.91; range = 2–39mm; see Table S1 in the OSM). Amongst both the fragments exhibiting twilling and plaiting, the mean angle between the strands is approximately 90° (mean = 90.27°; SD = 0.87; range = 88–92°; Table S1). Hence, application of medium force while weaving should be assumed, as the angle would otherwise be acute. The generally right-angled strands also suggest a somewhat flexible mat.

The dominant weaving pattern of the diagonal twill has a 1:1 ratio (1 strand under, 1 over, 1 shift; 58 per cent; Table S1), with a few examples of a 2:2 ratio (2 strands under, 2 over, 1 shift; 7 per cent). The examples of simple plaiting also show two ratio variations: 1:1 (8 per cent; Figures 7c & 8) and 2:2 with doubled strands (5 per cent; Figure 6d). In some cases, the patterns display ‘errors’ or ‘misses’, such as the doubling of strands in a diagonally twilled weave by passing twice under or over the same element (Figure 9f), along with irregularities due to stitching to create a larger fabric (Figures 8 & 9f).

Figure 8. Mat impressions from Provadia-Solnitsata: a–d) diagonal twilling; e–h) simple plaiting (figure by M. Andonova).

Figure 9. Types of leaf/stem venation recorded at Provadia-Solnitsata: a & d) keel absent; (b & e) keel present; (c & f) presence of conspicuous lateral veins (figure by M. Andonova).

The mat-weaving raw material

The clearest imprints on the Provadia-Solnitsata mat-impressed bases provide information on the types of plants selected for weaving. Stereoscopic analysis excludes the presence of dicotyledonous plant parts, such as wood splints, bark, bast or branches as possible materials for mat weaving because of the presence of prominent parallel venation of their strands and the type of weaving techniques, which require long and flexible wefts. Instead, the stereoscopic analysis shows flat-leaf lamina/stem fragments with parallel venation and pronounced main and secondary veins, which were attributed to monocotyledonous species (Metcalfe Reference Metcalfe1960: xvii). We assume that there are no circular or triangular cross-sections in the analysed material, given that no evidence for folding or compressing of the impressed plant parts was identified. The determination of a cross-section of a monocotyledonous leaf lamina through its tangential plane should be made with caution. Longitudinally, three types of leaf laminae/stem fragments are visible in the mat impressions, according to their venation: 1) with no conspicuous main vein (also called the midrib or keel (Figure 9a & d)); 2) with a clear main vein (keel) (Figure 9b & e); and 3) with two conspicuous lateral veins (Figure 9c & f). The average lowest strand width is 5mm (mean = 5.14mm; SD=1.8; range = 3–14mm), while the highest is 7mm (mean = 7.55mm; SD = 2.36; range = 4–16mm; Table S1).

These descriptions could apply to several monocotyledonous species recorded ethnobotanically as plants used in basketry and weaving in the Balkans (Bichard Reference Bichard2008; Nedelcheva et al. Reference Nedelcheva, Dogan, Obratov-Petkovic and Padure2011; Table 1). Those considered native to Bulgaria (Euro+Med 2006–2011) and present in the study area today (Jordanov et al. Reference Jordanov, Kitanov and Valev1964; Stoyanov et al. Reference Stoyanov, Stefanov and Kitanov1966) include sedges (Cyperaceae), rushes (Juncaceae), grasses (Poaceae) and cattails (Typhaceae). Based on leaf-blade width and venation features, some species can be excluded from the Provadia-Solnitsata sample, as their specific features are unrecorded in the analysed impressions. These include wide-leaf species, such as cattails, species with cylindrical stems and/or leaves, such as rushes, and species with a triangular leaf cross-section, such as sedges. Hence, flat-leaved grasses, including reeds and wild and cultivated grasses (Metcalfe Reference Metcalfe1960, Reference Metcalfe1971; Cutler Reference Cutler1969) are more likely to have been used. To reduce the range of possible choice of species, a brief overview of the palynological and archaeobotanical data related to Provadia-Solnitsata is necessary.

Table 1. Monocotyledonous basketry species recorded ethnobotanically (A = Bichard (Reference Bichard2008); B = Nedelcheva et al. (Reference Nedelcheva, Dogan, Obratov-Petkovic and Padure2011)) and archaeobotanically (C = Marinova (Reference Marinova and Nikolov2008); Hristova et al. (Reference Hristova2019)).

Available pollen data from the sites closest to Provadia-Solnitsata—Varna Lake, Lake Durankulak, Shabla Ezerets and Bolata (Marinova & Atanasova Reference Marinova and Atanasova2006; Filipova-Marinova et al. Reference Filipova-Marinova2013; Tonkov et al. Reference Tonkov, Marinova, Filipova-Marinova and Bozilova2014)—suggest that the local palaeo-habitats during the Late Neolithic, Middle Chalcolithic and Early Bronze Age consisted of a relatively open forest-steppe (Figure 1; Table 1). The surrounding forests were dominated by oak (Quercus sp.) and hornbeam (Carpinus sp.), along with abundant light-demanding species, forest understorey and grassland vegetation. The humid zones in close proximity to Provadia-Solnitsata were covered with riparian forests of willow (Salix sp.), alder (Alnus sp.) and European ash (Fraxinus excelsior), along with communities dominated by reeds, cattails, sedges and rushes.

Increased local agricultural activity is documented during the Late Neolithic and Chalcolithic periods, as attested by frequent Hordeum-type pollen, scarce Triticum-type pollen, and a continuous presence of Cerealia-type pollen (Filipova et al. Reference Filipova-Marinova2013). In addition, the dominant cereal crops recorded archaeobotanically at Provadia-Solnitsata (Marinova Reference Marinova and Nikolov2008; Hristova et al. Reference Hristova2019; E. Marinova pers. comm.) are einkorn (Triticum monococcum), emmer (T. dicoccum), cf. new type wheat (cf. T. thimopheevi), free-threshing wheat (T. aestivum/durum) and barley (Hordeum vulgare) (Table 1). Alongside the species recorded in the Late Neolithic layers, wild grass species (needlegrass (Stipa sp.) and Timothy grass (Phleum sp.)) and fragmented reed stems (Phragmites sp.) from Middle Chalcolithic architectural features are also relevant to mat production.

Of the monocotyledonous species potentially used to make mats at Provadia-Solnitsata (Table 1), needlegrass can be excluded, as its narrow leaf-blade width does not match any mat impressions from Provadia-Solnitsata (Stoyanov et al. Reference Stoyanov, Stefanov and Kitanov1966). Hence, amongst the archaeobotanically recorded species, the grain cultivars, wild Timothy grass and reeds remain valid choices. Of the ethnobotanically recorded species, reed canary grass (Phalaris arundinacea) can be excluded, because the length of its leaf blade is too short, reaching a maximum length of 0.35m (Stoyanov et al. Reference Stoyanov, Stefanov and Kitanov1966). Ecologically, the species listed above are found in two habitat types: reeds on marshy lakeshores, and grain cultivars and Timothy grass in open meadows and cultivated fields. Mature Timothy grass has the longest leaf blade (1.2m), while barley reaches 1m, einkorn 0.9m, and emmer 0.8m (Stoyanov et al. Reference Stoyanov, Stefanov and Kitanov1966; Zorovski et al. Reference Zorovski, Popov and Georgieva2018).

The leaf length of a plant is important because the plait must be continuous and homogeneous, and the weaver must be efficient, for example, when making multiple adjustments (e.g. stitching, extending or repairing). Long leaves enable more elaborate weaving, featuring, for example, rear (hidden) stitching and invisible extensions. Nevertheless, the archaeobotanically identified species that would be suitable for mat weaving in Chalcolithic Provadia-Solnitsata all have similar characteristics. Hence, at the current stage of research, the discussion cannot be extended to species level.

Discussion

Pots on mats

It is likely that, during their production, the bases of the vessels used for salt extraction at Provadia-Solnitsata were in contact with woven mats. This probably occurred when the clay was still moist, but already shaped as a base and/or attached to the vessel walls. The complete pots presumably ‘rested’ on the mat surfaces and were not moved or transported until dried, as suggested by the absence of shifting in the impressions, even when ‘repair’ or stitching was recorded. ‘Repair’ within the mat fabric could indicate secondary use or recycling of a woven object. It is also possible that the primary function of the mats was linked to the pottery-making process. The lack of evidence for mat-edge (selvedge) impressions supports the latter hypothesis, as it suggests the use of a rapidly woven mat with no finish, perhaps created to help dry the vessels. Furthermore, the impressions provided a rusticated surface that facilitated the application of a coating to aid the vessels’ impermeability during salt extraction.

Mat-weaving material

If the raw materials detailed above were consistently used in mat-weaving at Provadia-Solnitsata, two aspects can be highlighted. First, the intensive use of cultivated plants for consumption (grains) and as raw material for crafts (i.e. by-products of crop processing, such as the leaves and stems). Second, the choice of specific wild species suitable for basketry suggests a thorough knowledge of the properties of both cultivated and wild plant resources.

Baskets and salt

Basketry potentially played a role in the salt-production process beyond pottery manufacture. The hardened salt cakes, for example, may have been transported within perishable containers, such as woven bags, mats or baskets (Carvruc & Harding Reference Carvruk, Harding, Nikolov and Bachvarov2012; Urem-Kotsou Reference Urem-Kotsou and Molloy2016). This scenario is particularly valid for Chalcolithic Provadia-Solnitsata, as the increased size and weight of the brine-evaporation vessels would make it impractical to transport the salt cakes within the pots. Indeed, it has been hypothesised that the salt cakes were transferred to dedicated, lighter and smaller ceramic cylinders to transport them (Nikolov Reference Nikolov, Nikolov and Bachvarov2012). In either case, the method used to transport the salt is challenging to identify, especially if it involved perishable containers. In this regard, further ethnographic work on the possible salt-roads may provide insights into this aspect of the process.

Disposable pottery?

Further studies may also illuminate the link between the basketry products and the single-use ceramic vessels employed in salt production in Chalcolithic south-eastern Europe. The plain appearance of the brine-evaporation pottery at Provadia-Solnitsata may find an echo in the mat impressions, suggesting the expedient weaving of mats. If the primary use of both the pottery and the mats was to produce salt at Chalcolithic Provadia-Solnitsata, then both may have acted as disposable, single-use materials to be intentionally destroyed and discarded on site.

Why are mat impressions on ceramic salt-production vessels important?

Our case study provides an almost complete sequence of three different prehistoric crafts associated with an essential on-site industry, not only at Provadia-Solnitsata but also across south-eastern Europe. The knowledge of mat making using suitable raw vegetal fibres and weaving techniques supported a dedicated ceramic production process to enable salt extraction. Basketry may also have played a part in the storage, transport and exchange of salt. At a broader level, this link between different crafts may not always be present or obvious in the archaeological record. We hope to have shown that combining multiple strands of indirect evidence for perishable goods, including basketry and salt, can bring to light such ‘invisible’ objects (and perhaps their agents) and emphasise their importance within the wider repertoire of prehistoric material culture.

Conclusions

The mat impressions at Provadia-Solnitsata provide a first glimpse into Chalcolithic basket weaving and related salt production in south-eastern Europe, revealing the relationship between two crafts used to make seemingly ‘invisible’ products. The insights obtained about the choice of raw materials for mat weaving and the role of these mats in the production of ceramic vessels used for salt extraction at Provadia-Solnitsata also have a wider significance. Not only do our results illuminate the industrial process at a particular prehistoric site in Bulgaria, but they also reveal crafts that are often archaeologically ‘invisible’. Our study, combining analyses of the technology and raw materials used, allows the tangible and material evidence to bring us closer to some of the invisible, perishable materials of prehistoric south-eastern Europe. We hope that our study will stimulate archaeologists to uncover evidence of ‘hidden’ crafts in other contexts.

Acknowledgements

We would like to thank M. Lyuncheva and J. Hristov (graphics), R. Natcheva (GIS), V. Galabova (vectors), and S. Price, A. Livarda and E. Marinova-Wolf (revision of the manuscript and comments).

Funding statement

This research was funded by the Vice-Chancellor Scholarship for Research Excellence of the University of Nottingham (RFDX42DB1) and the Bulgarian Ministry of Education and Science (DCM#577/17.08.2018).

Supplementary material

To view supplementary material for this article, please visit https://doi.org/10.15184/aqy.2021.145