1. Introduction

Non-isothermal reactive transport within complicated porous media is widely encountered in energy, environmental science and engineering applications, including natural subsurface smouldering fires (Rein Reference Rein2009; Mokheimer et al. Reference Mokheimer, Hamdy, Abubakar, Shakeel, Habib and Mahmoud2019), smouldering remediation of coal-tar-contaminated soil (Scholes et al. Reference Scholes, Gerhard, Grant, Major, Vidumsky, Switzer and Torero2015), underground coal gasification for coal mining (Bhutto, Bazmi & Zahedi Reference Bhutto, Bazmi and Zahedi2013) and in situ combustion (ISC) for crude oil recovery (Mahinpey, Ambalae & Asghari Reference Mahinpey, Ambalae and Asghari2007). The temperature-dependent chemical reaction rate and transport properties enhance the nonlinear nature of reactive transport. For example, during the ISC process, high-pressure air is injected into the reservoir and reacts with the solid residue formed from thermal/oxidative pyrolysis of the crude oil, referred to as coke, to release combustion heat (Mahinpey et al. Reference Mahinpey, Ambalae and Asghari2007). The combustion front propagates through the reservoir and displaces the heavy oil downstream into the production well and improves oil mobility heating by coke combustion, averaging 773–1173 K (Liang et al. Reference Liang, Guan, Wu, Wang and Huang2013; Mokheimer et al. Reference Mokheimer, Hamdy, Abubakar, Shakeel, Habib and Mahmoud2019). However, unreasonable operating conditions for specified reservoir conditions, including the ignition temperature and air injection rate (Moore et al. Reference Moore, Laureshen, Mehta and Ursenbach1999; Liu et al. Reference Liu, Tang, Zheng and Song2021), may induce combustion instabilities, such as combustion extinction with a low burning temperature, flaming combustion with an extremely high burning temperature and air breakthrough into the production well (Liang et al. Reference Liang, Guan, Jiang, Xi, Wang and Li2012). A deep understanding of the non-isothermal reactive flow at the combustion front is essential to achieve a successful ISC project with sustained combustion front propagation.

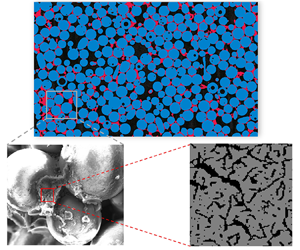

At the combustion front shown in figure 1, coke combustion is coupled with weakly compressible gas flow, species transport, conjugate heat transfer and heterogeneous coke oxidation kinetics in a complex coked porous medium (Xu et al. Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b; Lei, Wang & Luo Reference Lei, Wang and Luo2021). Furthermore, the geometrical structure continually evolves as the coke burns out into gas products, thereby changing the heat and mass transport properties of the channels and their surroundings. The pores in the coked porous medium can be categorized as micrometre-range pores ![]() $({\sim} O(1)\;\mathrm{\mu }\textrm{m)}$ in the rock void space and nanometre-range pores

$({\sim} O(1)\;\mathrm{\mu }\textrm{m)}$ in the rock void space and nanometre-range pores ![]() $({\sim} O(10)\;\textrm{n}\textrm{m)}$ in the coke void space. Commonly, the micrometre-range pores can be resolved by X-ray computed micro-tomography (micro-CT) images (Xu et al. Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a), referred to hereafter as the resolved macropores, while the nanometre-range pores are below the image resolution, referred to hereafter as the unresolved (sub-resolution) nanopores. Nanoscale refined pores introduce different flow regimes and then Knudsen diffusion primarily occurs at the sub-resolution nanopores. The complex nonlinear nature of the multiple physicochemical and thermal processes in multiscale porous media increases the complications compared with isothermal reactive flow problems in stationary porous media. Considerable experimental and numerical studies have been carried out to explore the effect of operating conditions on combustion dynamics (Aleksandrov, Kudryavtsev & Hascakir Reference Aleksandrov, Kudryavtsev and Hascakir2017; Zhu et al. Reference Zhu, Liu, Liu, Wang and Kovscek2019; Yuan et al. Reference Yuan, Sadikov, Varfolomeev, Khaliullin, Pu, Al-Muntaser and Saeed Mehrabi-Kalajahi2020; Liu et al. Reference Liu, Tang, Zheng and Song2021). Among the experimental work, one-dimensional combustion tube experiments were performed to guide the operating conditions at the ISC field project. However, the inconsistent thermal conditions between laboratory investigations and reservoir conditions, such as the high heat capacity of the experimental apparatus designed for elevated temperature and pressure, and the imperfect thermal insulation system designed for adiabatic boundaries, result in conventional combustion tube experiments that cannot operate at low air fluxes to establish stable combustion front propagation (Alamatsaz et al. Reference Alamatsaz, Moore, Mehta and Ursenbach2011). Therefore, the air flux in combustion tube experiments, averaging 30 sm3 (air) (m2 h)−1, is significantly greater than the air flux experienced in the field, where the minimum air flux can be 0.55 sm3 (air) (m2 h)−1 (Moore et al. Reference Moore, Laureshen, Mehta and Ursenbach1999). Regarding unscaled air fluxes, there remains significant concern about whether sustainable combustion can be reproduced in field applications when given the feasible operating parameters from experimental studies. Moreover, high-temperature and high-pressure experiments pose great challenges in revealing the fundamental combustion dynamics regime behind fully coupled thermal and reactive processes (Aleksandrov et al. Reference Aleksandrov, Kudryavtsev and Hascakir2017; Yuan et al. Reference Yuan, Sadikov, Varfolomeev, Khaliullin, Pu, Al-Muntaser and Saeed Mehrabi-Kalajahi2020).

$({\sim} O(10)\;\textrm{n}\textrm{m)}$ in the coke void space. Commonly, the micrometre-range pores can be resolved by X-ray computed micro-tomography (micro-CT) images (Xu et al. Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a), referred to hereafter as the resolved macropores, while the nanometre-range pores are below the image resolution, referred to hereafter as the unresolved (sub-resolution) nanopores. Nanoscale refined pores introduce different flow regimes and then Knudsen diffusion primarily occurs at the sub-resolution nanopores. The complex nonlinear nature of the multiple physicochemical and thermal processes in multiscale porous media increases the complications compared with isothermal reactive flow problems in stationary porous media. Considerable experimental and numerical studies have been carried out to explore the effect of operating conditions on combustion dynamics (Aleksandrov, Kudryavtsev & Hascakir Reference Aleksandrov, Kudryavtsev and Hascakir2017; Zhu et al. Reference Zhu, Liu, Liu, Wang and Kovscek2019; Yuan et al. Reference Yuan, Sadikov, Varfolomeev, Khaliullin, Pu, Al-Muntaser and Saeed Mehrabi-Kalajahi2020; Liu et al. Reference Liu, Tang, Zheng and Song2021). Among the experimental work, one-dimensional combustion tube experiments were performed to guide the operating conditions at the ISC field project. However, the inconsistent thermal conditions between laboratory investigations and reservoir conditions, such as the high heat capacity of the experimental apparatus designed for elevated temperature and pressure, and the imperfect thermal insulation system designed for adiabatic boundaries, result in conventional combustion tube experiments that cannot operate at low air fluxes to establish stable combustion front propagation (Alamatsaz et al. Reference Alamatsaz, Moore, Mehta and Ursenbach2011). Therefore, the air flux in combustion tube experiments, averaging 30 sm3 (air) (m2 h)−1, is significantly greater than the air flux experienced in the field, where the minimum air flux can be 0.55 sm3 (air) (m2 h)−1 (Moore et al. Reference Moore, Laureshen, Mehta and Ursenbach1999). Regarding unscaled air fluxes, there remains significant concern about whether sustainable combustion can be reproduced in field applications when given the feasible operating parameters from experimental studies. Moreover, high-temperature and high-pressure experiments pose great challenges in revealing the fundamental combustion dynamics regime behind fully coupled thermal and reactive processes (Aleksandrov et al. Reference Aleksandrov, Kudryavtsev and Hascakir2017; Yuan et al. Reference Yuan, Sadikov, Varfolomeev, Khaliullin, Pu, Al-Muntaser and Saeed Mehrabi-Kalajahi2020).

Figure 1. General representation of coke combustion in the multiscale porous medium with pore space in different characteristic length: the resolved macropores surrounded by the rock grains and unresolved nanoporous continuum in the coke regions.

Regarding numerical simulations, most existing numerical studies (Cinar, Castanier & Kovscek Reference Cinar, Castanier and Kovscek2011; Nissen et al. Reference Nissen, Zhu, Kovscek, Castanier and Gerritsen2015; Liu et al. Reference Liu, Tang, Zheng and Song2021) employ macroscopic or representative element volume (REV) solutions, which simulate coke combustion in porous media using volume-averaged geometrical properties, transport properties and the coke combustion rate. Without explicit pore-scale details, the REV-based or Darcy-scaled model often filters the flow instability with preferential penetration related to the local geometry (Lei & Luo Reference Lei and Luo2021). Furthermore, the volume-averaged chemical reaction rate is highly nonlinear owing to the effective reaction rate being a complex function of the specific surface area, local advection-diffusion conditions and intrinsic reaction rate determined by the local thermodynamic conditions (Molins Reference Molins2015; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017; Xu et al. Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b; Yang et al. Reference Yang, Dai, Xu, Liu, Zan, Long and Shi2021a). The challenges of REV-scale closure problems remain for obtaining an effective reaction rate (or mass exchange coefficients), effective transport properties and effective geometrical properties (Golfier et al. Reference Golfier, Bazin, Lenormand and Quintard2004). Compared with the chemical rate under isothermal conditions, the intrinsic coke combustion rate is highly sensitive to the local temperature, making upscaling of those effective properties to be more sophisticated. Therefore, the highly nonlinear nature of different coke combustion regimes makes it practically impossible to understand the mechanism based on the REV-based solution.

Recently, pore-scale modelling of reactive flow has attracted growing interest to provide deeper insight into the physics of reactive flow in complicated porous media (Rein Reference Rein2009; Qiu et al. Reference Qiu, Dennison, Knehr, Kumbur and Sun2012; Pereira Nunes, Blunt & Bijeljic Reference Pereira Nunes, Blunt and Bijeljic2016; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017, Reference Soulaine, Roman, Kovscek and Tchelepi2018; Soulaine, Creux & Tchelepi Reference Soulaine, Creux and Tchelepi2019; Maggiolo et al. Reference Maggiolo, Picano, Zanini, Carmignato, Guarnieri, Sasic and Ström2020), particularly with the accelerating development of imaging techniques (Bultreys, De Boever & Cnudde Reference Bultreys, De Boever and Cnudde2016) and well-established image processing techniques. Regarding the pore-scale modelling of the combustion front during ISC processes, several attempts have been conducted over the past five years. Xu et al. (Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a) reconstructed micro-CT images of coked packed beds with 500 nm pixel resolution and found that the basic coke deposition pattern was pore filling in narrow pore throats. Based on three-dimensional (3-D) digital rock, single-phase flow and mass diffusion processes were simulated to quantify the effect of coke deposition on the permeability and mass diffusivity, respectively (Xu et al. Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a). However, few studies that are directly based on micro-CT images have been developed to model coke combustion in realistic coked porous structures. Regarding the coke combustion simulation, Xu et al. (Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b) was one of the first to develop a single-relaxation-time (SRT) lattice Boltzmann (LB) model to simulate coke combustion in an ideal and small computational domain meshed in 100 × 480 cells. Lei et al. (Reference Lei, Wang and Luo2021) developed a multiple-relaxation-time (MRT)-LB model instead of the SRT-LB model to improve the numerical accuracy and stabilities. They also included the equation of state for an ideal gas to diminish the constant density assumption that accounts for the thermal expansion effect on coke combustion. These studies (Xu et al. Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b; Lei et al. Reference Lei, Wang and Luo2021) extended our knowledge of coke combustion dynamics and influencing factors during ISC processes, although some limitations in the numerical model still exist. First, the one-way coupling between the coke combustion reaction and the weakly compressible gas flow was made without considering the effect of the dramatic gas production on mass transfer. Second, the energy conversion law broke down when using the volume of pixel (VOP) method (Kang, Lichtner & Zhang Reference Kang, Lichtner and Zhang2006) to handle the temporal evolution of the coke phase in a binary manner for the non-isothermal reactive flow. Third, the computation domain remained restricted to the ideal porous medium consisting of staggered or random arrangements of circle-like grains with all coke deposited on the grain surface (Xu et al. Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b; Lei & Luo Reference Lei and Luo2021). However, the effect of realistic coke deposition on coke combustion was not explored, including the pore-filling deposition pattern and the multiscale nature. Fourth, coke naturally deposits in pore throats and blocks most of the connectable pathways (Xu et al. Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a). However, the previous LB model for idealized porous structures typically considered coke to be an impermeable obstacle regardless of the gas flow through the coke nanopores (Xu et al. Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b; Lei & Luo Reference Lei and Luo2021), which led to the simulation of coke combustion through a multiscale coked porous medium to be difficult or even impossible to perform. Fifth, only the coke combustion reaction that occurred on the external sharp reactive interface between the coke and fluid grid cell was considered without accounting for the internal sub-resolution nanopores (Bhatia & Perlmutter Reference Bhatia and Perlmutter1980) and the Knudsen diffusion through the coke nanopores (Fong, Jorgensen & Singer Reference Fong, Jorgensen and Singer2018). This may introduce inhibited reactivity, leading to varied combustion regimes. Considering the imaging resolution and unacceptable computation cost, direct ‘pore’-scale modelling of the coke combustion dynamics for the multiscale pores is practically impossible. Therefore, multiscale pore-scale modelling of the coupled thermal and reactive flow still must be developed to improve mass and energy conservation during the evolution of the pore-filling coke structure with combustion.

An elegant idea to model multiscale phenomena is hybrid modelling (Neale & Nader Reference Neale and Nader1974; Golfier et al. Reference Golfier, Zarcone, Bazin, Lenormand, Lasseux and Quintard2002, Reference Golfier, Bazin, Lenormand and Quintard2004; Luo et al. Reference Luo, Quintard, Debenest and Laouafa2012, Reference Luo, Laouafa, Guo and Quintard2014, Reference Luo, Laouafa, Debenest and Quintard2015), which describes the fluid dynamics in the larger channel using the Navier–Stokes equation while modelling the flow through the surrounding porous medium by the Darcy law. This idea dates back to the work of Brinkmann (Reference Brinkman1949b), who proposed the Darcy–Brinkmann–Stokes (DBS) equation with the combination of the Brinkmann term and the Darcy law for the flow in a high-porosity porous medium. The DBS equation was also validated for both flows in the larger channels and the matrix (Neale & Nader Reference Neale and Nader1974; Whitaker Reference Whitaker1986). Golfier et al. (Reference Golfier, Zarcone, Bazin, Lenormand, Lasseux and Quintard2002) employed the DBS equation to simulate heterogeneous mineral dissolution in both the fluid and porous regions with a local non-equilibrium dissociation condition. Unlike these Darcy-scale simulations (Golfier et al. Reference Golfier, Zarcone, Bazin, Lenormand, Lasseux and Quintard2002, Reference Golfier, Bazin, Lenormand and Quintard2004) Soulaine et al. (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017) employed pore-scale models based on the DBS approach, which introduced bounding values of the local porosity ![]() ${\varepsilon _f} = 1$ and

${\varepsilon _f} = 1$ and ![]() ${\varepsilon _f} = 0 \equiv 0.01$ to represent the resolved macropores and the impermeable rocks in images and intermediate

${\varepsilon _f} = 0 \equiv 0.01$ to represent the resolved macropores and the impermeable rocks in images and intermediate ![]() $0 < {\varepsilon _f} < 1$ to represent the unresolved pores. Such hybrid modelling of the fluid flow with a single DBS equation was regarded as the micro-continuum DBS approach (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017). Their studies (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017) showed that the pore-scale micro-continuum framework can efficiently bridge the gap between modelling of the resolved and unresolved pores in the images. For the image-based single-phase fluid flow simulation, the pore-scale micro-continuum model can be used to solve for the standard Navier–Stokes flow in the resolved macropore channels, degenerate to Darcy laws in the unresolved nanopore regions, reproduce the non-slip velocity condition at the macropore-rock interface by penalization, and ensure continuity of the stress and velocity in the entire computational domain (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016). With the appealing micro-continuum framework, mineral dissolution and wormholes were simulated by Soulaine et al. (Reference Soulaine, Roman, Kovscek and Tchelepi2017) in micromodel pore networks to observe five different dissolution regimes. Scheibe et al. (Reference Scheibe, Perkins, Richmond, McKinley, Romero-Gomez, Oostrom, Wietsma, Serkowski and Zachara2015) applied the DBS equation to simulate the flow and transport in 3-D micro-CT images with unresolved pores for better agreement with the experimental results. Recently, the micro-continuum framework was further extended to model multiphase flow in a multiscale porous medium (Carrillo, Bourg & Soulaine Reference Carrillo, Bourg and Soulaine2020). Soulaine et al. investigated pore-scale multiphase reactive transport in mineral dissolution with CO2 production (Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2018) and shale formation (Soulaine et al. Reference Soulaine, Creux and Tchelepi2019) for deeper insight into the mechanisms behind such multiscale transport phenomena. To date, these multiscale pore-scale modelling efforts on reactive flow have focused on isothermal processes in the presence of sharp reactive interfaces. To the best of our knowledge, few studies have been devoted to the more nonlinear dynamics of non-isothermal reactive flow accompanied by rich reactive nanopore surfaces within the sub-resolution matrix and their structural evolution with chemical reactions, such as coke combustion during ISC processes.

$0 < {\varepsilon _f} < 1$ to represent the unresolved pores. Such hybrid modelling of the fluid flow with a single DBS equation was regarded as the micro-continuum DBS approach (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017). Their studies (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017) showed that the pore-scale micro-continuum framework can efficiently bridge the gap between modelling of the resolved and unresolved pores in the images. For the image-based single-phase fluid flow simulation, the pore-scale micro-continuum model can be used to solve for the standard Navier–Stokes flow in the resolved macropore channels, degenerate to Darcy laws in the unresolved nanopore regions, reproduce the non-slip velocity condition at the macropore-rock interface by penalization, and ensure continuity of the stress and velocity in the entire computational domain (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016). With the appealing micro-continuum framework, mineral dissolution and wormholes were simulated by Soulaine et al. (Reference Soulaine, Roman, Kovscek and Tchelepi2017) in micromodel pore networks to observe five different dissolution regimes. Scheibe et al. (Reference Scheibe, Perkins, Richmond, McKinley, Romero-Gomez, Oostrom, Wietsma, Serkowski and Zachara2015) applied the DBS equation to simulate the flow and transport in 3-D micro-CT images with unresolved pores for better agreement with the experimental results. Recently, the micro-continuum framework was further extended to model multiphase flow in a multiscale porous medium (Carrillo, Bourg & Soulaine Reference Carrillo, Bourg and Soulaine2020). Soulaine et al. investigated pore-scale multiphase reactive transport in mineral dissolution with CO2 production (Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2018) and shale formation (Soulaine et al. Reference Soulaine, Creux and Tchelepi2019) for deeper insight into the mechanisms behind such multiscale transport phenomena. To date, these multiscale pore-scale modelling efforts on reactive flow have focused on isothermal processes in the presence of sharp reactive interfaces. To the best of our knowledge, few studies have been devoted to the more nonlinear dynamics of non-isothermal reactive flow accompanied by rich reactive nanopore surfaces within the sub-resolution matrix and their structural evolution with chemical reactions, such as coke combustion during ISC processes.

The present study extends the pore-scale micro-continuum model to non-isothermal reactive flow through a multiscale porous medium in the presence of unresolved reactive nanopores. The single-phase model was introduced to account for the coke combustion between the solid fuel and the high-pressurized gaseous air, because the mobilizing oil, liquid water and light hydrocarbon gas have been vaporized/transported downstream of the combustion zone. Particular attention is given to sub-grid models for reactive transport that occur in the sub-resolution nanopores of the segmented coke phase, including Knudsen diffusion and the reactive surface area. The present study revisits the previous coke combustion problem (Xu et al. Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b) to demonstrate the improvements of the developed micro-continuum model, such as improved energy conservation during geometrical evolution. Furthermore, image-based coke combustion is simulated to investigate the effect of the multiscale porous medium on coke combustion and highlight the significance of sub-grid reactive transfer. The effects of ignition temperature and air flux are investigated to explore the five combustion dynamics regimes for the homogeneous base porous medium with different combustion characteristics in terms of combustion temperature and combustion front morphological pattern. Additionally, the study provides insights into the different combustion regimes that emerge in typical experimental and field operations, as well as risk control for sustainable combustion.

This paper is organized as follows. In § 2, a computational domain based on micro-CT images, governing equations for the coupled non-isothermal reactive flow and sub-grid reactive transfer models are introduced. In § 3, the numerical algorithm developed to solve the nonlinear problem with the open-source simulation platform OpenFOAM is described with more details in Appendix A. The validation and improvement analyses are given with some details in Appendix B and the supplementary material. The grid convergence test is shown in Appendix C. In § 4, the combustion regimes with different combustion characteristics and the effects of air flux and ignition temperature are analysed. We close with a summary and conclusion.

2. Mathematical and physical models

2.1. Pore-scale domain with realistic coke deposition pattern

Coke combustion was investigated in a two-dimensional (2-D) pore-scale computational domain constructed from micro-tomographic images by micro-CT (nanoVoxel-3000) for the coked porous media. The micro-CT system built digital images of 1700 × 1700 × 2100 voxels with a voxel resolution of 500 nm. A 2-D slice consisting of 1200 × 2000 voxels (dimensions 0.6 × 1 mm2) or 2.4 million grid cells, shown in figure 2(a), was cropped from the reconstructed data and imported into the ilastik toolkit (Berg et al. Reference Berg2019) for image segmentation by machine learning algorithms. The image segmentation workflow began from label assignments of the coke, rock and pore pixels through human annotations drawn on the raw greyscale image. Random forest classifiers were trained to learn the labelled features and empower the prediction capacity to partition the image into the coke, rock and pore phases. The labelling–training–prediction workflow was looped in an interactive mode to correct the classification flaw until the desired segmentation was achieved, as illustrated in figure 2(b). After segmentation, the volume fraction of the pore pixels was 23.8 %, while the coke volume fraction was 8.19 %. For the present coke combustion simulation, two additional open flow buffer regions 20 pixels wide were added before and after the entrance of the coked porous medium so that the fully developed boundary condition could be enforced at the inlet and outlet boundaries of the computational domain.

Figure 2. (a) Two-dimensional raw image slice scanned by micro-CT showing rock grains (lightest grey), coke (grey) and pore (darkest grey) and (b) segmented image slice for computational domain with coloured phase of interest for rock grains (blue), coke (red) and pore (black).

As observed in figure 2(b), the base matrix was packed with an idealized sphere-like glass bead pack, regarded as the sandstone proxy. Coke tended to deposit inside the pore throat, which agrees with previous observations from scanning electron microscopy (Xu et al. Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a). The coke deposition pattern blocked all of the connectable pore network if the coke was considered an impermeable obstacle. This implied that the previous numerical method (Xu et al. Reference Xu, Long, Jiang, Ma, Zan, Ma and Shi2018a), which neglected the effect of the sub-resolution continuum on the fluid flow, is not suitable for modelling the reactive flow in such a realistic coked porous medium. Additionally, the non-uniform spatial distribution of the coke deposition resulted in coke accumulations that were rich in some local regions but poor in other regions, increasing the heterogeneity of the coked porous medium. The naturally heterogeneous coke deposition in pore throats showed a significant difference compared with the previous idealized structures (Xu et al. Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b; Lei et al. Reference Lei, Wang and Luo2021), which were composed of staggered or random arrangements of circle-like grains with all coke deposited on the grain surface.

2.2. Governing equation and assumptions

The micro-CT system with micrometre-scale resolution and millimetre-scale field of view cannot resolve the pore structure in coke regions because the characteristic length scales of the coke nanopores and the rock macropores differ by orders of magnitudes. In addition, the direct pore-scale simulation for all the scales is unacceptable owing to the enormous computational cost for billion-cell representations despite the 2-D simulation problems. Therefore, the multiscale modelling framework (i.e. the micro-continuum approach for pore-scale simulation) was introduced to establish the governing equations for the multiscale coke combustion dynamics. With the micro-continuum approach, structured Cartesian-type grid cells directly correspond to the voxel elements of the segmented image in figure 2(b) without requiring a complex mesh technique. The volume fraction of void space in each grid cell, ![]() ${\varepsilon _f}$, referred to as the local porosity, was imposed to represent the complex multiscale pore structure and filter the explicit structural information below the micro-CT resolution limit. In the current filtering strategy, the pore regions labelled in the segmented image were denoted by

${\varepsilon _f}$, referred to as the local porosity, was imposed to represent the complex multiscale pore structure and filter the explicit structural information below the micro-CT resolution limit. In the current filtering strategy, the pore regions labelled in the segmented image were denoted by ![]() ${\varepsilon _f} = 1$ to represent the clear fluid zone, while the rock regions were denoted by

${\varepsilon _f} = 1$ to represent the clear fluid zone, while the rock regions were denoted by ![]() ${\varepsilon _f} = 0$ to represent impermeable solid zones without small pore space. For the coke regions, an intermediate value of

${\varepsilon _f} = 0$ to represent impermeable solid zones without small pore space. For the coke regions, an intermediate value of ![]() $0 < {\varepsilon _f} < 1$ can be given to symbolize the sub-resolution porous medium with an aggregate of nanopores and coke solids, as shown in figure 1. The intermediate value is equal to the intrinsic coke porosity, which depends on coke formation conditions, such as crude oil properties and pyrolysis temperature. In the present study, the sub-resolution coke porosity was specified as 0.7 to account for the gas transport and chemical reactions in such porous coke structures. The grid cells were assumed to not contain both the rock and the coke; therefore, the volume fraction of the rock phase,

$0 < {\varepsilon _f} < 1$ can be given to symbolize the sub-resolution porous medium with an aggregate of nanopores and coke solids, as shown in figure 1. The intermediate value is equal to the intrinsic coke porosity, which depends on coke formation conditions, such as crude oil properties and pyrolysis temperature. In the present study, the sub-resolution coke porosity was specified as 0.7 to account for the gas transport and chemical reactions in such porous coke structures. The grid cells were assumed to not contain both the rock and the coke; therefore, the volume fraction of the rock phase, ![]() ${\varepsilon _{rock}}$, or the volume fraction of the coke phase,

${\varepsilon _{rock}}$, or the volume fraction of the coke phase, ![]() ${\varepsilon _{coke}}$, can be derived according to the known values of

${\varepsilon _{coke}}$, can be derived according to the known values of ![]() ${\varepsilon _f}$ and the constraint relation as

${\varepsilon _f}$ and the constraint relation as

In the micro-continuum approach, partial differential equations (PDEs) are averaged over control volumes, corresponding to the grid cells, to govern the conservation law of energy, mass and species concentrations, which are modelled with averaged field variables. According to the volume averaging theory, these PDEs hold for all computational cells regardless of their contents. Before deriving the governing equations, the following assumptions were made to simplify the modelling of the complex hybrid-scale physics:

(1) the non-slip boundary condition is held at the impermeable rock interface owing to the approximated Knudsen number of 2.28 × 10−3 in the resolved macropores surrounded by the rock grains;

(2) the heat capacities of the gas and solid components are constant and only depend on the initial temperature and pressure (Lei et al. Reference Lei, Wang and Luo2021);

(3) the densities of the solid components are constant;

(4) the gas is an ideal gas with the equation of state as (2.2)

(2.2) \begin{equation}{\rho _f} = {\bar{p}_f}/R\bar{T},\end{equation}

\begin{equation}{\rho _f} = {\bar{p}_f}/R\bar{T},\end{equation}

where ![]() ${\bar{p}_f}$ is the intrinsically phase averaged pressure,

${\bar{p}_f}$ is the intrinsically phase averaged pressure, ![]() ${\bar{p}_f} = (1/{V_f})\int_{{V_f}} {{p_f}} \,\textrm{d}V$;

${\bar{p}_f} = (1/{V_f})\int_{{V_f}} {{p_f}} \,\textrm{d}V$;

(5) the radiative heat transfer is not considered;

(6) the thermal equilibrium condition is valid within each coke cell at 500 nm resolution when the burning temperature is less than 1200 K, which maintains

(2.3) \begin{equation}\varUpsilon = \frac{{\left|{\frac{{\dot{r}{h_r}}}{{\rho {c_p}}}} \right|}}{{\left|{\alpha \frac{{{\partial^2}T}}{{\partial {x^2}}}} \right|}} = O\left( {\frac{{\dot{r}{h_r}{L^2}}}{{\rho {c_p}\alpha T}}} \right) \ll 1,\end{equation}

\begin{equation}\varUpsilon = \frac{{\left|{\frac{{\dot{r}{h_r}}}{{\rho {c_p}}}} \right|}}{{\left|{\alpha \frac{{{\partial^2}T}}{{\partial {x^2}}}} \right|}} = O\left( {\frac{{\dot{r}{h_r}{L^2}}}{{\rho {c_p}\alpha T}}} \right) \ll 1,\end{equation}

where ![]() $\varUpsilon$ is the ratio of the reaction term and the thermal conductive term in the energy equation, hr is the coke combustion heat,

$\varUpsilon$ is the ratio of the reaction term and the thermal conductive term in the energy equation, hr is the coke combustion heat, ![]() $\dot{r}$ is the coke combustion rate, and L is the cell size, 500 nm;

$\dot{r}$ is the coke combustion rate, and L is the cell size, 500 nm;

(7) the coke combustion is modelled as (2.4), which indicates that the coke reacts with the oxygen in the injected hot air to produce CO2. The reaction rate is estimated according to a first-order Arrhenius equation as (2.5)

(2.4) \begin{gather}\textrm{C} + {\textrm{O}_\textrm{2}} \to \textrm{C}{\textrm{O}_\textrm{2}} + {h_r},\end{gather}(2.5)

\begin{gather}\textrm{C} + {\textrm{O}_\textrm{2}} \to \textrm{C}{\textrm{O}_\textrm{2}} + {h_r},\end{gather}(2.5) \begin{gather}\dot{r} = {a_v}Aexp \left( { - \frac{E}{{R\bar{T}}}} \right)\frac{{{\rho _f}{{\bar{\omega }}_{f\textrm{,}{\textrm{O}_\textrm{2}}}}}}{{{M_{{\textrm{O}_\textrm{2}}}}}},\end{gather}

\begin{gather}\dot{r} = {a_v}Aexp \left( { - \frac{E}{{R\bar{T}}}} \right)\frac{{{\rho _f}{{\bar{\omega }}_{f\textrm{,}{\textrm{O}_\textrm{2}}}}}}{{{M_{{\textrm{O}_\textrm{2}}}}}},\end{gather}

where ![]() ${a_v}$ is the reactive surface area per control volume, which is only non-zero at the grid cells containing the coke. The detailed sub-grid model of the reactive surface area will be discussed in § 2.3. In the coke combustion kinetics formulation, A and E are the pre-exponential factor and activation energy, respectively, while R is the ideal gas constant,

${a_v}$ is the reactive surface area per control volume, which is only non-zero at the grid cells containing the coke. The detailed sub-grid model of the reactive surface area will be discussed in § 2.3. In the coke combustion kinetics formulation, A and E are the pre-exponential factor and activation energy, respectively, while R is the ideal gas constant, ![]() ${\rho _f}$ is the gas density, and

${\rho _f}$ is the gas density, and ![]() ${M_{{\textrm{O}_\textrm{2}}}}$ is the molecular weight of the oxygen. To match the following volume averaging governing equations,

${M_{{\textrm{O}_\textrm{2}}}}$ is the molecular weight of the oxygen. To match the following volume averaging governing equations, ![]() $\bar{T}$ represents the temperature averaged over the control volume,

$\bar{T}$ represents the temperature averaged over the control volume, ![]() $\bar{T} = (1/V)\int_V T \,\textrm{d}V$, and

$\bar{T} = (1/V)\int_V T \,\textrm{d}V$, and ![]() ${\bar{\omega }_{f\textrm{,}{\textrm{O}_\textrm{2}}}}$ is the O2 mass fraction intrinsically averaged over the gas phase,

${\bar{\omega }_{f\textrm{,}{\textrm{O}_\textrm{2}}}}$ is the O2 mass fraction intrinsically averaged over the gas phase, ![]() ${\bar{\omega }_{f\textrm{,}{\textrm{O}_\textrm{2}}}} = (1/{V_f})\int_{{V_f}} {{\omega _{f\textrm{,}{\textrm{O}_\textrm{2}}}}} \,\textrm{d}V$. In this simulation, the coke combustion kinetics of A, E and hr are set as

${\bar{\omega }_{f\textrm{,}{\textrm{O}_\textrm{2}}}} = (1/{V_f})\int_{{V_f}} {{\omega _{f\textrm{,}{\textrm{O}_\textrm{2}}}}} \,\textrm{d}V$. In this simulation, the coke combustion kinetics of A, E and hr are set as ![]() $9.717 \times {10^6}\;\textrm{m}\;{\textrm{s}^{ - 1}}$, 131.09 kJ mol−1 and 388.5 kJ mol−1, respectively (Ren, Freitag & Mahinpey Reference Ren, Freitag and Mahinpey2007), which are the same values as in previous studies (Xu et al. Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b; Lei et al. Reference Lei, Wang and Luo2021) for better comparisons of different numerical models.

$9.717 \times {10^6}\;\textrm{m}\;{\textrm{s}^{ - 1}}$, 131.09 kJ mol−1 and 388.5 kJ mol−1, respectively (Ren, Freitag & Mahinpey Reference Ren, Freitag and Mahinpey2007), which are the same values as in previous studies (Xu et al. Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b; Lei et al. Reference Lei, Wang and Luo2021) for better comparisons of different numerical models.

According to the above analysis and assumptions, a set of the volume averaging governing equations for multiscale coke combustion are shown in (2.6)–(2.10), which are valid throughout the domain regardless of the content of the grid cell:

\begin{gather}\dfrac{{\partial

{\varepsilon _s}{\rho _s}{h_s}}}{{\partial t}} +

\dfrac{{\partial {\varepsilon _f}{\rho _f}{h_f}}}{{\partial

t}} + \boldsymbol{\nabla }\boldsymbol{\cdot }({\rho

_f}\bar{\boldsymbol{U}}{h_f}) + \dfrac{{\partial {\rho

_f}K}}{{\partial t}} + \boldsymbol{\nabla

}\boldsymbol{\cdot }({\rho

_f}\bar{\boldsymbol{U}}K)\nonumber\\

\qquad=

\dfrac{{\partial {{\bar{p}}_f}}}{{\partial t}} +

\boldsymbol{\nabla }\boldsymbol{\cdot }({\lambda

_{eff}}\boldsymbol{\nabla }T) + {\rho

_f}\bar{\boldsymbol{U}}\boldsymbol{\cdot }\boldsymbol{g} +

{{\dot{q}}_r}.\end{gather}

\begin{gather}\dfrac{{\partial

{\varepsilon _s}{\rho _s}{h_s}}}{{\partial t}} +

\dfrac{{\partial {\varepsilon _f}{\rho _f}{h_f}}}{{\partial

t}} + \boldsymbol{\nabla }\boldsymbol{\cdot }({\rho

_f}\bar{\boldsymbol{U}}{h_f}) + \dfrac{{\partial {\rho

_f}K}}{{\partial t}} + \boldsymbol{\nabla

}\boldsymbol{\cdot }({\rho

_f}\bar{\boldsymbol{U}}K)\nonumber\\

\qquad=

\dfrac{{\partial {{\bar{p}}_f}}}{{\partial t}} +

\boldsymbol{\nabla }\boldsymbol{\cdot }({\lambda

_{eff}}\boldsymbol{\nabla }T) + {\rho

_f}\bar{\boldsymbol{U}}\boldsymbol{\cdot }\boldsymbol{g} +

{{\dot{q}}_r}.\end{gather}

The momentum conservation equation, known as the DBS equation (Brinkman Reference Brinkman1949a), is expressed in (2.6), where ![]() $\bar{\boldsymbol{U}}$ is the superficial velocity, namely, the Darcy velocity, t is the time, g is the gravitational acceleration and

$\bar{\boldsymbol{U}}$ is the superficial velocity, namely, the Darcy velocity, t is the time, g is the gravitational acceleration and ![]() ${\mu _f}$ is the gas viscosity. The k −1 in the last term of the (2.6) is the reciprocal of the absolute permeability, which varies with the local porosity via the commonly used Kozeny–Carman equation:

${\mu _f}$ is the gas viscosity. The k −1 in the last term of the (2.6) is the reciprocal of the absolute permeability, which varies with the local porosity via the commonly used Kozeny–Carman equation:

\begin{equation}{k^{ - 1}} = k_0^{ - 1}\frac{{{{(1 - {\varepsilon _f})}^2}}}{{\varepsilon _f^3}}.\end{equation}

\begin{equation}{k^{ - 1}} = k_0^{ - 1}\frac{{{{(1 - {\varepsilon _f})}^2}}}{{\varepsilon _f^3}}.\end{equation} According to the Kozeny–Carman relation, the porous resistance term, ![]() ${\mu _f}{k^{ - 1}}\bar{\boldsymbol{U}}$, vanishes in the resolved macropore region (

${\mu _f}{k^{ - 1}}\bar{\boldsymbol{U}}$, vanishes in the resolved macropore region (![]() ${\varepsilon _f} = 1,\;{k^{ - 1}} = 0\;{\textrm{m}^{ - \textrm{2}}}$) so that the DBS equation degenerates to the standard Navier–Stokes equation to model the weakly compressible gas flow in the pore space. In the rock regions, a very small decimal number

${\varepsilon _f} = 1,\;{k^{ - 1}} = 0\;{\textrm{m}^{ - \textrm{2}}}$) so that the DBS equation degenerates to the standard Navier–Stokes equation to model the weakly compressible gas flow in the pore space. In the rock regions, a very small decimal number ![]() ${\varepsilon _f} = 0.01$ was used to replace

${\varepsilon _f} = 0.01$ was used to replace ![]() ${\varepsilon _f} = 0$ to escape floating-point exceptions, leading to the permeability k of

${\varepsilon _f} = 0$ to escape floating-point exceptions, leading to the permeability k of ![]() $1.02 \times {10^{ - 3}}\;\textrm{mD}$ with the specified parameter

$1.02 \times {10^{ - 3}}\;\textrm{mD}$ with the specified parameter ![]() ${k_0}$ of 10−12 in the Kozeny–Carman relation. The rock permeability of

${k_0}$ of 10−12 in the Kozeny–Carman relation. The rock permeability of ![]() $1.02 \times {10^{ - 3}}\;\textrm{mD}$ is consistent with the properties of the impermeable rock in the literature (Lis-Śledziona Reference Lis-Śledziona2019), which reported the lowest permeability of 10−3 mD in their interpreted wells. More sensitivity analysis of

$1.02 \times {10^{ - 3}}\;\textrm{mD}$ is consistent with the properties of the impermeable rock in the literature (Lis-Śledziona Reference Lis-Śledziona2019), which reported the lowest permeability of 10−3 mD in their interpreted wells. More sensitivity analysis of ![]() ${\varepsilon _f}$ on the coke combustion dynamics and the numerical stability can be found in the supplementary material. The velocity in the rock zones reduces to almost zero so that the DBS equation can recover both the impermeable properties of the internal rock regions and the non-slip boundary conditions at the fluid–rock interface (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016). For the porous coke regions, the DBS equation is reduced towards the Darcy law because the porous resistance term gradually becomes dominant over the dissipative viscous term with

${\varepsilon _f}$ on the coke combustion dynamics and the numerical stability can be found in the supplementary material. The velocity in the rock zones reduces to almost zero so that the DBS equation can recover both the impermeable properties of the internal rock regions and the non-slip boundary conditions at the fluid–rock interface (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016). For the porous coke regions, the DBS equation is reduced towards the Darcy law because the porous resistance term gradually becomes dominant over the dissipative viscous term with ![]() $0 < {\varepsilon _f} < 1$ (Tam Reference Tam1969; Soulaine & Tchelepi Reference Soulaine and Tchelepi2016). When the coke is about to burn out, only a few fragments remain in the sub-resolution continuum, which leads to a porosity of approximately one. Under such conditions, the investigation (Lévy Reference Lévy1983; Auriault Reference Auriault2008) showed that the flow law obeys the Darcy–Brinkmann law with an approximation of

$0 < {\varepsilon _f} < 1$ (Tam Reference Tam1969; Soulaine & Tchelepi Reference Soulaine and Tchelepi2016). When the coke is about to burn out, only a few fragments remain in the sub-resolution continuum, which leads to a porosity of approximately one. Under such conditions, the investigation (Lévy Reference Lévy1983; Auriault Reference Auriault2008) showed that the flow law obeys the Darcy–Brinkmann law with an approximation of ![]() $O(\varepsilon )$. We also recognized that the Kozeny–Carman equation might not be the best choice to relate the permeability and the porosity for coke nanoporous structures. With respect to the problem under consideration, however, the gas transport by Knudsen diffusion was more significant than that by viscous flow, which was located in the transition regime with a Knudsen number of

$O(\varepsilon )$. We also recognized that the Kozeny–Carman equation might not be the best choice to relate the permeability and the porosity for coke nanoporous structures. With respect to the problem under consideration, however, the gas transport by Knudsen diffusion was more significant than that by viscous flow, which was located in the transition regime with a Knudsen number of ![]() $O(1)$. Therefore, the Kozeny–Carman equation was employed to assign an intrinsic permeability of

$O(1)$. Therefore, the Kozeny–Carman equation was employed to assign an intrinsic permeability of ![]() $O(1)\sim O(10)\;\textrm{mD}$ to the coke regions for weak convective fluxes. Therefore, the DBS equation allows for the Darcy/Darcy–Brinkmann and Navier–Stokes flow to be simulated in the present multiscale coked porous medium (Brinkman Reference Brinkman1949b; Neale & Nader Reference Neale and Nader1974; Whitaker Reference Whitaker1986; Golfier et al. Reference Golfier, Zarcone, Bazin, Lenormand, Lasseux and Quintard2002, Reference Golfier, Bazin, Lenormand and Quintard2004; Rein Reference Rein2009; Luo et al. Reference Luo, Quintard, Debenest and Laouafa2012, Reference Luo, Laouafa, Guo and Quintard2014, Reference Luo, Laouafa, Debenest and Quintard2015; Scheibe et al. Reference Scheibe, Perkins, Richmond, McKinley, Romero-Gomez, Oostrom, Wietsma, Serkowski and Zachara2015; Soulaine & Tchelepi Reference Soulaine and Tchelepi2016).

$O(1)\sim O(10)\;\textrm{mD}$ to the coke regions for weak convective fluxes. Therefore, the DBS equation allows for the Darcy/Darcy–Brinkmann and Navier–Stokes flow to be simulated in the present multiscale coked porous medium (Brinkman Reference Brinkman1949b; Neale & Nader Reference Neale and Nader1974; Whitaker Reference Whitaker1986; Golfier et al. Reference Golfier, Zarcone, Bazin, Lenormand, Lasseux and Quintard2002, Reference Golfier, Bazin, Lenormand and Quintard2004; Rein Reference Rein2009; Luo et al. Reference Luo, Quintard, Debenest and Laouafa2012, Reference Luo, Laouafa, Guo and Quintard2014, Reference Luo, Laouafa, Debenest and Quintard2015; Scheibe et al. Reference Scheibe, Perkins, Richmond, McKinley, Romero-Gomez, Oostrom, Wietsma, Serkowski and Zachara2015; Soulaine & Tchelepi Reference Soulaine and Tchelepi2016).

The mass conversion equations for the gas and coke phases are written as (2.7) and (2.8), respectively, where ![]() ${\rho _{coke}}$ is the coke density and

${\rho _{coke}}$ is the coke density and ![]() ${\dot{m}_{coke}}$ is the coke burning rate, computed by

${\dot{m}_{coke}}$ is the coke burning rate, computed by ![]() ${\dot{m}_{coke}} ={-} {M_{coke}}\dot{r}$. Here,

${\dot{m}_{coke}} ={-} {M_{coke}}\dot{r}$. Here, ![]() ${\dot{m}_{coke}}$ is a negative value because the solid coke gradually burns with O2 to release CO2 into the gas phase as the volume fraction of the coke

${\dot{m}_{coke}}$ is a negative value because the solid coke gradually burns with O2 to release CO2 into the gas phase as the volume fraction of the coke ![]() ${\varepsilon _{coke}}$ decreases. Therefore, the coke morphology continually evolves with coke combustion, while the mass of the gas phase progressively increases.

${\varepsilon _{coke}}$ decreases. Therefore, the coke morphology continually evolves with coke combustion, while the mass of the gas phase progressively increases.

The evolution of the species mass fraction, including O2 and CO2, is described by the volume averaging convection–diffusion equation in (2.9) with some additional insignificant terms being discarded (Golfier et al. Reference Golfier, Zarcone, Bazin, Lenormand, Lasseux and Quintard2002), where ![]() ${\bar{\omega }_{f,i}}$ is the mass fraction of species components in gas and

${\bar{\omega }_{f,i}}$ is the mass fraction of species components in gas and ![]() ${\hat{D}_{i,eff}}$ is the effective diffusivity of species i. Here,

${\hat{D}_{i,eff}}$ is the effective diffusivity of species i. Here, ![]() ${\hat{D}_{i,eff}}$ is given by

${\hat{D}_{i,eff}}$ is given by

\begin{equation}{\hat{D}_{i,eff}} =

\left\{ {\begin{array}{*{20}{@{\quad}l}}

{{{\hat{D}}_{i,b}},}&{\textrm{in}\;\textrm{the}\;\textrm{resolved}\;\textrm{macropore}\;\textrm{regions}}\\

{\dfrac{{{\varepsilon_f}}}{\tau } \times \dfrac{1}{{\left(

{\dfrac{1}{{{{\hat{D}}_{i,b}}}} +

\dfrac{1}{{{{\hat{D}}_{i,Knud}}}}} \right)}}\textrm{,

}}&{\textrm{in}\;\textrm{the}\;\textrm{unresolved}\;\textrm{nanopore}\;\textrm{regions}}

\end{array}} \right.\end{equation}

\begin{equation}{\hat{D}_{i,eff}} =

\left\{ {\begin{array}{*{20}{@{\quad}l}}

{{{\hat{D}}_{i,b}},}&{\textrm{in}\;\textrm{the}\;\textrm{resolved}\;\textrm{macropore}\;\textrm{regions}}\\

{\dfrac{{{\varepsilon_f}}}{\tau } \times \dfrac{1}{{\left(

{\dfrac{1}{{{{\hat{D}}_{i,b}}}} +

\dfrac{1}{{{{\hat{D}}_{i,Knud}}}}} \right)}}\textrm{,

}}&{\textrm{in}\;\textrm{the}\;\textrm{unresolved}\;\textrm{nanopore}\;\textrm{regions}}

\end{array}} \right.\end{equation}

where ![]() ${\hat{D}_{i,b}}$ is the effective diffusion coefficient for component i of the mixture in the resolved macropore regions,

${\hat{D}_{i,b}}$ is the effective diffusion coefficient for component i of the mixture in the resolved macropore regions, ![]() ${\hat{D}_{i,Knud}}$ is the Knudsen diffusion coefficient and

${\hat{D}_{i,Knud}}$ is the Knudsen diffusion coefficient and ![]() $\tau$ is the tortuosity of the coke nanoporous structure, taken as 1 owing to the cylindrical pores in coke. The effective diffusion coefficient

$\tau$ is the tortuosity of the coke nanoporous structure, taken as 1 owing to the cylindrical pores in coke. The effective diffusion coefficient ![]() ${\hat{D}_{i,b}}$ can be computed by the Wilke relation (Fairbanks & Wilke Reference Fairbanks and Wilke1950) as (2.13). The average pore radius in the sub-resolution nanopores is of the order of magnitude of 10 nm (Fei et al. Reference Fei, Hu, Xiang, Sun, Fu and Chen2011; Wang et al. Reference Wang, Liu, Li, Yang, Wang and Song2018), which leads to a Knudsen number of

${\hat{D}_{i,b}}$ can be computed by the Wilke relation (Fairbanks & Wilke Reference Fairbanks and Wilke1950) as (2.13). The average pore radius in the sub-resolution nanopores is of the order of magnitude of 10 nm (Fei et al. Reference Fei, Hu, Xiang, Sun, Fu and Chen2011; Wang et al. Reference Wang, Liu, Li, Yang, Wang and Song2018), which leads to a Knudsen number of ![]() $O(1)$ and a transition regime. Therefore, Knudsen diffusion should be considered for the coke regions and can be determined by kinetic theory as (2.14). The well-known Bosanquet relation (Krishna & Wesselingh Reference Krishna and Wesselingh1997), as the second term of (2.12), was introduced to combine the effect of molecular diffusion and Knudsen diffusion, which is consistent with the dusty-gas model with acceptable deviations (Veldsink et al. Reference Veldsink, Van Damme, Versteeg and Van Swaaij1995). The additional factor

$O(1)$ and a transition regime. Therefore, Knudsen diffusion should be considered for the coke regions and can be determined by kinetic theory as (2.14). The well-known Bosanquet relation (Krishna & Wesselingh Reference Krishna and Wesselingh1997), as the second term of (2.12), was introduced to combine the effect of molecular diffusion and Knudsen diffusion, which is consistent with the dusty-gas model with acceptable deviations (Veldsink et al. Reference Veldsink, Van Damme, Versteeg and Van Swaaij1995). The additional factor ![]() ${\varepsilon _f}/\tau$ before the Bosanquet formula accounts for diffusion resistances owing to the porous structures (Wakao & Smith Reference Wakao and Smith1962; Soulaine & Tchelepi Reference Soulaine and Tchelepi2016; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017). The mechanical dispersion in the sub-resolution continuum was not coupled in the diffusion term owing to its insignificance compared with the molecular and Knudsen diffusion under the low Péclet number during coke combustion (Bijeljic & Blunt Reference Bijeljic and Blunt2007),

${\varepsilon _f}/\tau$ before the Bosanquet formula accounts for diffusion resistances owing to the porous structures (Wakao & Smith Reference Wakao and Smith1962; Soulaine & Tchelepi Reference Soulaine and Tchelepi2016; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017). The mechanical dispersion in the sub-resolution continuum was not coupled in the diffusion term owing to its insignificance compared with the molecular and Knudsen diffusion under the low Péclet number during coke combustion (Bijeljic & Blunt Reference Bijeljic and Blunt2007),

\begin{gather}{\hat{D}_{i,b}} = \frac{{1 - {{\bar{\chi }}_{f,i}}}}{{\sum\limits_{j{\ne}i} {({{\bar{\chi }}_{f,j}}/{{\hat{D}}_{ij}})} }},\quad i = {\textrm{O}_\textrm{2}}\textrm{,C}{\textrm{O}_\textrm{2}}\textrm{,}{\textrm{N}_\textrm{2}},\end{gather}

\begin{gather}{\hat{D}_{i,b}} = \frac{{1 - {{\bar{\chi }}_{f,i}}}}{{\sum\limits_{j{\ne}i} {({{\bar{\chi }}_{f,j}}/{{\hat{D}}_{ij}})} }},\quad i = {\textrm{O}_\textrm{2}}\textrm{,C}{\textrm{O}_\textrm{2}}\textrm{,}{\textrm{N}_\textrm{2}},\end{gather}

where ![]() ${\bar{\chi }_{f,i}}$ is the molar fraction of component i,

${\bar{\chi }_{f,i}}$ is the molar fraction of component i, ![]() ${\hat{D}_{ij}}$ is the binary diffusion coefficient of component i in component j (Cussler & Cussler Reference Cussler and Cussler2009) and

${\hat{D}_{ij}}$ is the binary diffusion coefficient of component i in component j (Cussler & Cussler Reference Cussler and Cussler2009) and ![]() ${d_p}$ is the average pore diameter, specified as 20 nm (Fei et al. Reference Fei, Hu, Xiang, Sun, Fu and Chen2011; Wang et al. Reference Wang, Liu, Li, Yang, Wang and Song2018). The source term in (2.9) represents the O2 consumption rate or CO2 production rate owing to coke combustion, which is given by

${d_p}$ is the average pore diameter, specified as 20 nm (Fei et al. Reference Fei, Hu, Xiang, Sun, Fu and Chen2011; Wang et al. Reference Wang, Liu, Li, Yang, Wang and Song2018). The source term in (2.9) represents the O2 consumption rate or CO2 production rate owing to coke combustion, which is given by ![]() ${\dot{m}_{{\textrm{O}_\textrm{2}}}} ={-} {M_{{\textrm{O}_\textrm{2}}}}\dot{r}$ or

${\dot{m}_{{\textrm{O}_\textrm{2}}}} ={-} {M_{{\textrm{O}_\textrm{2}}}}\dot{r}$ or ![]() ${\dot{m}_{\textrm{C}{\textrm{O}_\textrm{2}}}} = {M_{\textrm{C}{\textrm{O}_\textrm{2}}}}\dot{r}$. Similar to the DBS equation, (2.9) tends asymptotically to the ordinary advection–diffusion equation in the resolved macropores but also considers the effect of gas rarefaction in the unresolved nanopores without separate solvers and domains.

${\dot{m}_{\textrm{C}{\textrm{O}_\textrm{2}}}} = {M_{\textrm{C}{\textrm{O}_\textrm{2}}}}\dot{r}$. Similar to the DBS equation, (2.9) tends asymptotically to the ordinary advection–diffusion equation in the resolved macropores but also considers the effect of gas rarefaction in the unresolved nanopores without separate solvers and domains.

The thermal equilibrium condition is assumed to hold within each control volume, which consists of solid coke and its internal micropore voids. This allows the energy conservation equations for the solid and fluid phase to be combined into a single equation, as shown in (2.10), where ![]() ${h_s}$ and

${h_s}$ and ![]() ${h_f}$ are the specific enthalpy for the solid phase and fluid phase, respectively, K is the specific kinetic energy,

${h_f}$ are the specific enthalpy for the solid phase and fluid phase, respectively, K is the specific kinetic energy, ![]() $K = |\bar{\boldsymbol{U}}{|^2}/2$, and

$K = |\bar{\boldsymbol{U}}{|^2}/2$, and ![]() ${\lambda _{eff}}$ is the effective thermal conductivity, given by

${\lambda _{eff}}$ is the effective thermal conductivity, given by ![]() ${\lambda _{eff}} = {\varepsilon _f}{\lambda _f} + {\varepsilon _{coke}}{\lambda _{coke}} + {\varepsilon _{rock}}{\lambda _{rock}}$ (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016). The last term of (2.10),

${\lambda _{eff}} = {\varepsilon _f}{\lambda _f} + {\varepsilon _{coke}}{\lambda _{coke}} + {\varepsilon _{rock}}{\lambda _{rock}}$ (Soulaine & Tchelepi Reference Soulaine and Tchelepi2016). The last term of (2.10), ![]() ${\dot{q}_r}$, corresponds to the heat source term released by exothermic coke combustion, which can be calculated by

${\dot{q}_r}$, corresponds to the heat source term released by exothermic coke combustion, which can be calculated by ![]() ${\dot{q}_r} = {h_r}\dot{r}$. Equation (2.10) cannot be directly solved because it contains two unknown field variables,

${\dot{q}_r} = {h_r}\dot{r}$. Equation (2.10) cannot be directly solved because it contains two unknown field variables, ![]() ${h_s}$ and

${h_s}$ and ![]() ${h_f}$. Along with the constant heat capacity assumption,

${h_f}$. Along with the constant heat capacity assumption, ![]() ${h_s}$ can be obtained by

${h_s}$ can be obtained by ![]() ${h_s} = {C_{p,s}}T = {C_{p,s}}({h_f}/{C_{p,f}})$; therefore, the energy balance equation can be recast into (2.15), which retains

${h_s} = {C_{p,s}}T = {C_{p,s}}({h_f}/{C_{p,f}})$; therefore, the energy balance equation can be recast into (2.15), which retains ![]() ${h_f}$ as the primary variable. In the simulation, the thermophysical properties of the gas species, such as the specific heat capacity, viscosity and Prandtl number, came from REFPROP Version 8.0 (Lemmon, Huber & McLinden Reference Lemmon, Huber and McLinden2002), while the thermophysical properties of the rock phase were the same as in Xu et al. (Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b),

${h_f}$ as the primary variable. In the simulation, the thermophysical properties of the gas species, such as the specific heat capacity, viscosity and Prandtl number, came from REFPROP Version 8.0 (Lemmon, Huber & McLinden Reference Lemmon, Huber and McLinden2002), while the thermophysical properties of the rock phase were the same as in Xu et al. (Reference Xu, Long, Jiang, Zan, Huang, Chen and Shi2018b),

\begin{gather}

\dfrac{{\partial {\varepsilon _f}{\rho _f}{h_f}}}{{\partial

t}} + \dfrac{{\partial {\varepsilon _{coke}}({\rho

_{coke}}{C_{p,coke}}/{C_{p,f}}){h_f}}}{{\partial t}} +

\dfrac{{\partial {\varepsilon _{rock}}({\rho

_{rock}}{C_{p,rock}}/{C_{p,f}}){h_f}}}{{\partial t}}\nonumber\\

\quad + \,\boldsymbol{\nabla }\boldsymbol{\cdot }({\rho

_f}\bar{\boldsymbol{U}}{h_f}) + \dfrac{{\partial {\rho

_f}K}}{{\partial t}} + \boldsymbol{\nabla

}\boldsymbol{\cdot }({\rho _f}\bar{\boldsymbol{U}}K)\nonumber\\

\qquad\quad = \dfrac{{\partial {{\bar{p}}_f}}}{{\partial t}} +

\boldsymbol{\nabla }\boldsymbol{\cdot }\left( {\textrm{

}\dfrac{{{\lambda_{eff}}}}{{{C_{p,f}}}}\boldsymbol{\nabla

}{h_f}} \right) + {\rho

_f}\bar{\boldsymbol{U}}\boldsymbol{\cdot }\boldsymbol{g} +

\dot{q}.\end{gather}

\begin{gather}

\dfrac{{\partial {\varepsilon _f}{\rho _f}{h_f}}}{{\partial

t}} + \dfrac{{\partial {\varepsilon _{coke}}({\rho

_{coke}}{C_{p,coke}}/{C_{p,f}}){h_f}}}{{\partial t}} +

\dfrac{{\partial {\varepsilon _{rock}}({\rho

_{rock}}{C_{p,rock}}/{C_{p,f}}){h_f}}}{{\partial t}}\nonumber\\

\quad + \,\boldsymbol{\nabla }\boldsymbol{\cdot }({\rho

_f}\bar{\boldsymbol{U}}{h_f}) + \dfrac{{\partial {\rho

_f}K}}{{\partial t}} + \boldsymbol{\nabla

}\boldsymbol{\cdot }({\rho _f}\bar{\boldsymbol{U}}K)\nonumber\\

\qquad\quad = \dfrac{{\partial {{\bar{p}}_f}}}{{\partial t}} +

\boldsymbol{\nabla }\boldsymbol{\cdot }\left( {\textrm{

}\dfrac{{{\lambda_{eff}}}}{{{C_{p,f}}}}\boldsymbol{\nabla

}{h_f}} \right) + {\rho

_f}\bar{\boldsymbol{U}}\boldsymbol{\cdot }\boldsymbol{g} +

\dot{q}.\end{gather}

For boundary conditions, as illustrated in figure 2(b), the inlet is imposed by the Poiseuille velocity profile and the Dirichlet boundary condition for the temperature and mass fraction of gas species, which contain a mixture of 78 % N2 and 22 % O2. At the outlet of the computational domain, fully developed thermal and reactive flows are enforced. At the top and bottom boundaries, the wall-type boundary is specified with adiabatic conditions.

The developed pore-scale micro-continuum model involves more physics than the previous LB models, including modelling of the sub-resolution reactive transport, two-way coupling between the chemical reaction and fluid flow, improved energy conservation during the structural evolution, and fewer assumptions in the thermal and transport properties. During the structural evolution of the sub-resolution continuum, the effective medium coefficients were also temporally updated, including the permeability, effective diffusivity and effective thermal conductivity. More discussions on these improvements can be found in the supplementary material. The current numerical model enforced the no-slip velocity condition on the interfaces between the resolved macropores and the rock grains for the high-permeability sandstone-like rock under consideration. However, when the numerical model is applied to simulate coke combustion through low-permeability carbonate rock or under low-pressure conditions with increasing Knudsen number, the slip or even transition flow regime should be accounted for in the resolved mesopores and possibly nanopores so that the slip velocity condition can be recovered at the rock walls. The unified pore-scale micro-continuum approach that applies to all flow regimes can be found in these studies (Guo, Ma & Tchelepi Reference Guo, Ma and Tchelepi2018; Soulaine et al. Reference Soulaine, Creux and Tchelepi2019).

2.3. Reactive surface area model

The variables ![]() ${\varepsilon _f}$, k and

${\varepsilon _f}$, k and ![]() ${\hat{D}_{i,eff}}$ in the volume averaging governing models above are used to model the flow and diffusion behaviours within the coke cells with sub-resolution nanopores. The sub-grid models of the permeability k and the diffusion coefficient

${\hat{D}_{i,eff}}$ in the volume averaging governing models above are used to model the flow and diffusion behaviours within the coke cells with sub-resolution nanopores. The sub-grid models of the permeability k and the diffusion coefficient ![]() ${\hat{D}_{i,eff}}$ are introduced in § 2.2 to quantify these transport properties with respect to the local porosity,

${\hat{D}_{i,eff}}$ are introduced in § 2.2 to quantify these transport properties with respect to the local porosity, ![]() ${\varepsilon _f}$. The last component to complete the mathematical models is the sub-grid model of the reactive surface area within the coke. The integration of the reactive surface area model with micro-continuum models can avoid the explicit treatment of the reactive fluid–solid interface with complex interfacial conditions. In the present study, the diffuse interface model (DIM) (Luo et al. Reference Luo, Quintard, Debenest and Laouafa2012) and the random pore model (RPM) (Bhatia & Perlmutter Reference Bhatia and Perlmutter1980) are presented to investigate the effect of the reactive surface area models on the coke combustion dynamics. The diffuse interface model is commonly adopted in the mineral dissolution problem to reproduce a sharp diffuse interface where the dissolution phenomenon occurs (Luo et al. Reference Luo, Quintard, Debenest and Laouafa2012; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017). In this work, the diffuse interface model is expressed as

${\varepsilon _f}$. The last component to complete the mathematical models is the sub-grid model of the reactive surface area within the coke. The integration of the reactive surface area model with micro-continuum models can avoid the explicit treatment of the reactive fluid–solid interface with complex interfacial conditions. In the present study, the diffuse interface model (DIM) (Luo et al. Reference Luo, Quintard, Debenest and Laouafa2012) and the random pore model (RPM) (Bhatia & Perlmutter Reference Bhatia and Perlmutter1980) are presented to investigate the effect of the reactive surface area models on the coke combustion dynamics. The diffuse interface model is commonly adopted in the mineral dissolution problem to reproduce a sharp diffuse interface where the dissolution phenomenon occurs (Luo et al. Reference Luo, Quintard, Debenest and Laouafa2012; Soulaine et al. Reference Soulaine, Roman, Kovscek and Tchelepi2017). In this work, the diffuse interface model is expressed as

where the term ![]() $2||\boldsymbol{\nabla }{\varepsilon _{coke}}||$ is the gradient of the coke volume fraction with a correction factor of 2, which characterizes the average interfacial surface of a control volume based on the volume averaging theorem (Whitaker Reference Whitaker2013). As a result, reactive surface areas are non-zero only at the gas–coke interface. The term

$2||\boldsymbol{\nabla }{\varepsilon _{coke}}||$ is the gradient of the coke volume fraction with a correction factor of 2, which characterizes the average interfacial surface of a control volume based on the volume averaging theorem (Whitaker Reference Whitaker2013). As a result, reactive surface areas are non-zero only at the gas–coke interface. The term ![]() $(1 - \varepsilon _f^2)$ controls the diffuse thickness, which follows the recommended formulation in Luo's work (Luo et al. Reference Luo, Quintard, Debenest and Laouafa2012). Therefore, the diffuse interface model can serve as an immersed boundary condition to recover the reactive flux boundary condition at the edge of the coke regions.

$(1 - \varepsilon _f^2)$ controls the diffuse thickness, which follows the recommended formulation in Luo's work (Luo et al. Reference Luo, Quintard, Debenest and Laouafa2012). Therefore, the diffuse interface model can serve as an immersed boundary condition to recover the reactive flux boundary condition at the edge of the coke regions.

The random pore model is written as (Bhatia & Perlmutter Reference Bhatia and Perlmutter1980)

where x denotes the coke conversion rate, ![]() ${a_v}_0$ is the initial pore surface area of coke and

${a_v}_0$ is the initial pore surface area of coke and ![]() $\psi$ is the called structural parameter, set as 10 in this work. The random pore model assumes that the porous coke structure comprises cylindrical pores with arbitrary pore size distribution and orientations. In contrast to the diffuse interface model, the heterogeneous gas–solid reaction is not limited to the edge of the coke cell but occurs on the internal surfaces of cylindrical nanopores. Therefore, the effective surface areas derived from the random pore model are non-zero within the coke cells. From (2.17), the effective surface area changes as a function of the coke conversion rate, x. The random pore model is formulated to model the initial growth of the reaction surface with increasing conversion as experimentally observed (Bhatia & Perlmutter Reference Bhatia and Perlmutter1980). The maximum reaction surface occurs at a conversion rate of 0.393 (Bhatia & Perlmutter Reference Bhatia and Perlmutter1980), while the enlargement ratio relative to the initial pore surface area can be adjusted by the structural parameter

$\psi$ is the called structural parameter, set as 10 in this work. The random pore model assumes that the porous coke structure comprises cylindrical pores with arbitrary pore size distribution and orientations. In contrast to the diffuse interface model, the heterogeneous gas–solid reaction is not limited to the edge of the coke cell but occurs on the internal surfaces of cylindrical nanopores. Therefore, the effective surface areas derived from the random pore model are non-zero within the coke cells. From (2.17), the effective surface area changes as a function of the coke conversion rate, x. The random pore model is formulated to model the initial growth of the reaction surface with increasing conversion as experimentally observed (Bhatia & Perlmutter Reference Bhatia and Perlmutter1980). The maximum reaction surface occurs at a conversion rate of 0.393 (Bhatia & Perlmutter Reference Bhatia and Perlmutter1980), while the enlargement ratio relative to the initial pore surface area can be adjusted by the structural parameter ![]() $\psi$.

$\psi$.

3. Numerical methods and validation

3.1. Equation discretization

The solver was developed based on the open-source CFD software OpenFOAM (Jasak Reference Jasak1996; Weller et al. Reference Weller, Tabor, Jasak and Fureby1998; Jasak, Jemcov & Tukovic Reference Jasak, Jemcov and Tukovic2007) to solve the governing equations and the sub-grid models formed by (2.6)–(2.17) with the finite-volume method (FVM). In the FVM, the governing equations were first discretized by integrating over each control volume at the time step to yield a set of algebraic equations. The first-order Euler time scheme was used to discretize time derivative ![]() $\partial /\partial t$ terms, while the spatial terms were discretized in second-order numerical schemes. The gradient

$\partial /\partial t$ terms, while the spatial terms were discretized in second-order numerical schemes. The gradient ![]() $\boldsymbol{\nabla }$ term was assigned the Gauss linear scheme with a linear scheme implemented for the value interpolation from cell centres to face centres. The Gauss linearUpwind scheme was employed for the divergence

$\boldsymbol{\nabla }$ term was assigned the Gauss linear scheme with a linear scheme implemented for the value interpolation from cell centres to face centres. The Gauss linearUpwind scheme was employed for the divergence ![]() $\boldsymbol{\nabla }\boldsymbol{\cdot }(({\rho _f}/{\varepsilon _f})\boldsymbol{\bar{U}\bar{U}})$ term, while other divergence terms for advection of scalar fields, such as

$\boldsymbol{\nabla }\boldsymbol{\cdot }(({\rho _f}/{\varepsilon _f})\boldsymbol{\bar{U}\bar{U}})$ term, while other divergence terms for advection of scalar fields, such as ![]() $\boldsymbol{\nabla }\boldsymbol{\cdot }({\rho _f}\bar{\boldsymbol{U}}{h_f})$, were discretized with the bounded Gauss limitedLinear scheme to ensure the boundedness. The Laplacian term for thermal diffusion

$\boldsymbol{\nabla }\boldsymbol{\cdot }({\rho _f}\bar{\boldsymbol{U}}{h_f})$, were discretized with the bounded Gauss limitedLinear scheme to ensure the boundedness. The Laplacian term for thermal diffusion ![]() $\boldsymbol{\nabla }\boldsymbol{\cdot }(({\lambda _{eff}}/{C_{p,f}})\boldsymbol{\nabla }{h_f})$ was calculated using the Gauss harmonic orthogonal scheme to guarantee diffusion flux continuity at the fluid–solid interface during conjugate heat transfer, while the Gauss linear orthogonal scheme was used for other Laplacian terms, such as

$\boldsymbol{\nabla }\boldsymbol{\cdot }(({\lambda _{eff}}/{C_{p,f}})\boldsymbol{\nabla }{h_f})$ was calculated using the Gauss harmonic orthogonal scheme to guarantee diffusion flux continuity at the fluid–solid interface during conjugate heat transfer, while the Gauss linear orthogonal scheme was used for other Laplacian terms, such as ![]() $\boldsymbol{\nabla }\boldsymbol{\cdot }({\varepsilon _f}{\rho _f}{\hat{D}_{i,eff}}\boldsymbol{\nabla }{\bar{\omega }_{f,i}})$.

$\boldsymbol{\nabla }\boldsymbol{\cdot }({\varepsilon _f}{\rho _f}{\hat{D}_{i,eff}}\boldsymbol{\nabla }{\bar{\omega }_{f,i}})$.

3.2. Solution algorithms

Sequential coupling strategies were introduced to solve the discretized governing equations for the nonlinear problem, as illustrated in figure 3. In the numerical workflow, the pressure–velocity coupling in the transient non-isothermal reactive flow was handled by the iterative PIMPLE algorithm to improve numerical stabilities, which combined the pressure implicit with splitting of operator (PISO) algorithm (Issa Reference Issa1986) and semi-implicit method for pressure-linked equations (SIMPLE) algorithm (Patankar & Spalding Reference Patankar and Spalding1983). The equation discretization for the PIMPLE algorithm can be found in Appendix A.

Figure 3. Flow chart of the numerical models for the coupled thermal and reactive transport.

The main iterative procedure to advance the time step from n to n + 1 is described as follows:

(1) the coke reaction rate

${\dot{r}^\ast }$ is calculated by (2.5) with the temperature, mass fraction of O2 and specific surface area from the previous iteration step or time step;

${\dot{r}^\ast }$ is calculated by (2.5) with the temperature, mass fraction of O2 and specific surface area from the previous iteration step or time step;(2) the volume fraction of coke,

$\varepsilon _{coke}^\ast $, is explicitly solved by (2.8). The cell porosity

$\varepsilon _{coke}^\ast $, is explicitly solved by (2.8). The cell porosity  $\varepsilon _f^\ast $ is computed according to the constraint (2.1). Based on

$\varepsilon _f^\ast $ is computed according to the constraint (2.1). Based on  $\varepsilon _f^\ast $ and

$\varepsilon _f^\ast $ and  $\varepsilon _{coke}^\ast $, the sub-grid properties are updated, including the permeability

$\varepsilon _{coke}^\ast $, the sub-grid properties are updated, including the permeability  ${k^\ast }$, the diffusion coefficient

${k^\ast }$, the diffusion coefficient  $\hat{D}_{i,eff}^\ast $ and the specific coke surface area

$\hat{D}_{i,eff}^\ast $ and the specific coke surface area  $\alpha _v^\ast $;

$\alpha _v^\ast $;(3) the gas continuity equation is explicitly solved to obtain the new gas density

$\rho _f^\ast $;

$\rho _f^\ast $;(4) solve the discretized momentum equation (2.6) with the preconditioned biconjugate gradient (PBiCGStab) method to predict the velocity

${\bar{\boldsymbol{U}}^\ast }$ and the mass flux

${\bar{\boldsymbol{U}}^\ast }$ and the mass flux  $\textrm{ph}{\textrm{i}^\ast }$. Note that the predicted fields

$\textrm{ph}{\textrm{i}^\ast }$. Note that the predicted fields  ${\bar{\boldsymbol{U}}^\ast }$ and

${\bar{\boldsymbol{U}}^\ast }$ and  $\textrm{ph}{\textrm{i}^\ast }$ do not satisfy the mass conservation after this prediction step;

$\textrm{ph}{\textrm{i}^\ast }$ do not satisfy the mass conservation after this prediction step;(5) the evolution of O2 mass fraction, (2.9), is solved with the implicit source term scheme to update

${\bar{\omega }_{f,{\textrm{O}_\textrm{2}}}}$. With the new

${\bar{\omega }_{f,{\textrm{O}_\textrm{2}}}}$. With the new  $\bar{\omega }_{f,\textrm{C}{\textrm{O}_\textrm{2}}}^\ast $, the coke reaction rate is recalculated for the following CO2 equation to obtain a new

$\bar{\omega }_{f,\textrm{C}{\textrm{O}_\textrm{2}}}^\ast $, the coke reaction rate is recalculated for the following CO2 equation to obtain a new  $\bar{\omega }_{f,\textrm{C}{\textrm{O}_\textrm{2}}}^\ast $. In this step, each discretized equation for the species transfer is solved with the PBiCGStab method;

$\bar{\omega }_{f,\textrm{C}{\textrm{O}_\textrm{2}}}^\ast $. In this step, each discretized equation for the species transfer is solved with the PBiCGStab method;(6) the thermophysical properties are updated based on the new mass fractions of species compositions. The energy equation, (2.15), is implicitly solved with the PBiCGStab method to compute the new temperature

${\bar{T}^\ast }$;

${\bar{T}^\ast }$;(7) update the density

$\rho _f^{{\ast}{\ast} }$ and the compressibility

$\rho _f^{{\ast}{\ast} }$ and the compressibility  ${\beta ^\mathrm{\ast }}$ with the new temperature

${\beta ^\mathrm{\ast }}$ with the new temperature  ${\bar{T}^\ast }$. Then, the pressure equation is implicitly solved with the geometric-algebraic multigrid (GAMG) method to correct the pressure

${\bar{T}^\ast }$. Then, the pressure equation is implicitly solved with the geometric-algebraic multigrid (GAMG) method to correct the pressure  ${\bar{p}^{{\ast}{\ast} }}$ and update the velocity

${\bar{p}^{{\ast}{\ast} }}$ and update the velocity  ${\bar{\boldsymbol{U}}^{{\ast}{\ast} }}$ and mass flux

${\bar{\boldsymbol{U}}^{{\ast}{\ast} }}$ and mass flux  $\textrm{ph}{\textrm{i}^{{\ast}{\ast} }}$. After this inner corrector step, the density

$\textrm{ph}{\textrm{i}^{{\ast}{\ast} }}$. After this inner corrector step, the density  $\rho _f^{{\ast}{\ast} \ast }$ is also recalculated with the new mass flux

$\rho _f^{{\ast}{\ast} \ast }$ is also recalculated with the new mass flux  $\textrm{ph}{\textrm{i}^{{\ast}{\ast} }}$ through the gas continuity equation, (2.7). This inner corrector step can be looped several times to improve the result accuracy. In this work, 1–2 loops are suggested;

$\textrm{ph}{\textrm{i}^{{\ast}{\ast} }}$ through the gas continuity equation, (2.7). This inner corrector step can be looped several times to improve the result accuracy. In this work, 1–2 loops are suggested;(8) check if the PIMPLE algorithm converges at the current time step or reaches the maximum number of outer correctors. The criteria for the time step convergence are defined as absolute tolerances of the energy equation and species equations, all of which should reach 10−6 in this work. The maximum number of outer correctors is set as 15 with regard to the numerical stability. If the time step convergence or maximum outer corrector number reaches the specified conditions, the time moves onto the next step, otherwise it loops over the entire equation system again.