The origins of the Gruppo Caproni, or Caproni Group, date back to 1910, when Gianni Caproni started manufacturing his first aircraft in the Vizzola plant, in the moorland of Malpensa in northern Italy. World War I proved immensely beneficial for the Group, which provided the state with its famous three-engine bombers. In the interwar period it started incorporating Italy's major engineering/aircraft companies, including Isotta Fraschini, Reggiane, CEMSA, and CAB. Caproni soon became one of Italy's main aircraft producers, as a result of Ministry of War orders and the state's financial backing. Without this active assistance, before and after World War I, Caproni's ambitious plans would never have materialized. Based on Italian and foreign archival sources, this study aims to address a few research questions.

First of all, this public/private cooperation represented a long-term feature of Italy's central role as an “entrepreneurial state,” and the aeronautical sector was no exception. Increasing public financial support allowed Caproni to develop into a huge, vertically integrated group, and when its rising level of indebtedness started to concern government authorities, Mussolini appointed General Augusto Graziani as external supervisor to the Caproni Group in 1938. It was an interesting choice, since the general's letters expressed enthusiastic support for the company's production goals and noticeably underplayed its financial problems. New loans were granted. This special relationship resembled a similar pattern that could be observed in other countries: the state played an essential role in supporting a highly technological infant industry that would have never come of age otherwise.

Second, the defeat of Italy after World War II and the Peace Treaty conditions put a halt on development of the nation's aircraft industry. Italy's aircraft companies were forbidden from accepting new orders and most of them started manufacturing other types of equipment. By the early 1950s the Caproni Group had gone bankrupt along with most aircraft manufacturers. Italy successfully reinserted itself into the international community of nations after the war, but the political and economic costs it incurred included the suspension of aircraft development, the preference for importing allied (American and British) aircraft for civil airlines, and the denial of international assistance. In particular, in the case of Gianni Caproni, his unconditional support of Mussolini also played against his chances of winning the backing of Italy's new democratic government after the war. On the whole, political biases had undoubtedly shrunk the aeronautical industry's feeble chances of recovery.

Last, but not least, in order to keep the sector alive the government nationalized what was left of Italy's aviation firms in the aftermath of the war. Again, this should not be surprising: Italy had the largest public sector (after the USSR) and nationalization was consistent with its industrial history and represented the only way to help this sector survive, establish important records/patents, and sustain its labor force's human capital skills. Today, even after the extensive privatization process of the 1990s, the state has preserved the aeronautical industry's heritage by placing Italy's most important aircraft producers under the direction of its controlled company Leonardo (formerly Finmeccanica).Footnote 1

The Origins of the Caproni Group and World War I

Gianni Caproni was one of the pioneers of Italian aviation, but certainly not the only one. Some of the biggest competitors of the time were Fiat, which began aero engine production in 1907 and built its first airplane in 1914; SIAI (Società Idrovolanti Alta Italia), which was born in 1915 as a seaplane company; Breda, which began aircraft construction in 1917, concentrated production on wartime aircraft, and bought IMAM (Industrie Meccaniche e Aeronautiche Meridionali) in 1936; Macchi, which was founded in 1912 in Varese to build sea and racing planes and then fighters; and Piaggio, which started building Caproni bombers in 1916 but began its own production of biplanes and helicopters after the war.Footnote 2

However, there are a number of reasons that justify the choice of the Caproni Group as a fundamental case study. First, Gianni Caproni was the first Italian businessman to build airplanes when the Italian market was still struggling to cope with the intrusiveness of French providers, which supplied the Italian army until 1912; his first five monoplanes set world records for altitude and speed as early as 1912. Second, Caproni belonged to the handful of Italy's very first aeronautical pioneers but, unlike the others, he had adequate technical preparation and a clear plan on how to build an airplane of his own conception; above all, he was directly familiar with French aviation achievements. With the exception of the planes designed by Caproni, the national industry at the beginning of the war was totally dependent on French models in regard to design.Footnote 3 Third, besides being an engineer, Caproni was also an entrepreneur who expanded his business via vertical integration of the production process, thus giving rise to the leading Italian aircraft group in terms of number of subsidiaries and employees. (According to Francesco Minniti, considering only the labor force employed in the aviation sector in each main industrial group, in 1938 Caproni ranked first with 10,199 workers, followed by SIAI with 5,113, Piaggio with 4,644, and Fiat with 4,420.)Footnote 4 Finally, Caproni was also among the first to open a pilot training center in Italy. The school associated with the factory was situated at the Vizzola Ticino plant and was a key factor in its future development, as will be shown below.Footnote 5

Giovanni Battista Caproni was born in 1886 in Arco, Trentino, which at the time was under Austrian rule. He graduated from the Polytechnic of Munich and then attended an electrical engineering course at the Montefiore Institute in Liège, but, motivated by strong irredentist feelings, he decided to move to Lombardy in 1908. Here he obtained permission from the military authorities to use a flat and easily adaptable area in Malpensa as an airfield and, with his brother, he set up the Società d'Aviazione Fratelli Caproni in 1910.Footnote 6 He built his first biplane (followed by many other aircraft models, patents, and records) and set up one of the first flight schools in Italy, attended by both civil and military pilots.Footnote 7 The presence of numerous soldiers among the pilots in training facilitated contacts between Caproni and the military authorities; these interactions grew into a fruitful relationship when the commander of the Aviators Battalion, Colonel Giulio Douhet, was seconded to Malpensa. Within the framework of a lengthy friendship and productive collaboration, in 1913 Caproni and Douhet conceived a new bomber, equipped with the fuel and bombing capacity required to reach and seriously damage distant objectives.Footnote 8

Production success was matched from the beginning by constant financial problems. In 1913 Caproni was forced to sell his company to the state to avoid bankruptcy, yet retaining his position as designer and director, thanks to a good word from Colonel Giulio Douhet. This was the first active assistance, a bailout indeed, made by the Italian state in support of an aviation company.Footnote 9 In 1915 Gianni Caproni established the SSAI (Società per lo Sviluppo dell'Aviazione in Italia) with headquarters in Milan and rented the same factories and airfield in Vizzola Ticino. The new company grew quickly as a result of generous state orders during World War I (even though many episodes of corruption and overpricing emerged at the end of the conflict).Footnote 10

All things considered, at that time nothing like a Caproni existed anywhere in the world. The aircraft used in bombing operations were mostly single-engine aircraft with a short range and a cargo capacity of about a hundred kilograms, including fuel and bombs.Footnote 11 The Caproni aircraft proved to be practically flawless, easy to fly, extremely reliable, and safe; in the words of Caproni himself, “The three-engine type allows you to continue flying even if an engine [out of three] breaks down.”Footnote 12 The Ca. 32 was the first production version of the Caproni to enter service with the Italian Army Air Force, in August 1915, and the core of Italy's strategic bomber force. It was an excellent plane to handle, with greater range than most aircraft of that time.Footnote 13

The potential and capabilities of the Ca. 32 were enhanced throughout the conflict because of the introduction of improved versions of both the biplane (the model Ca. 33 in 1917 and Ca. 44 in 1918) and the huge triplane Ca. 40 for night bombing (and its updated versions Ca. 41 and 42), which Caproni considered the right design for winning the war.Footnote 14

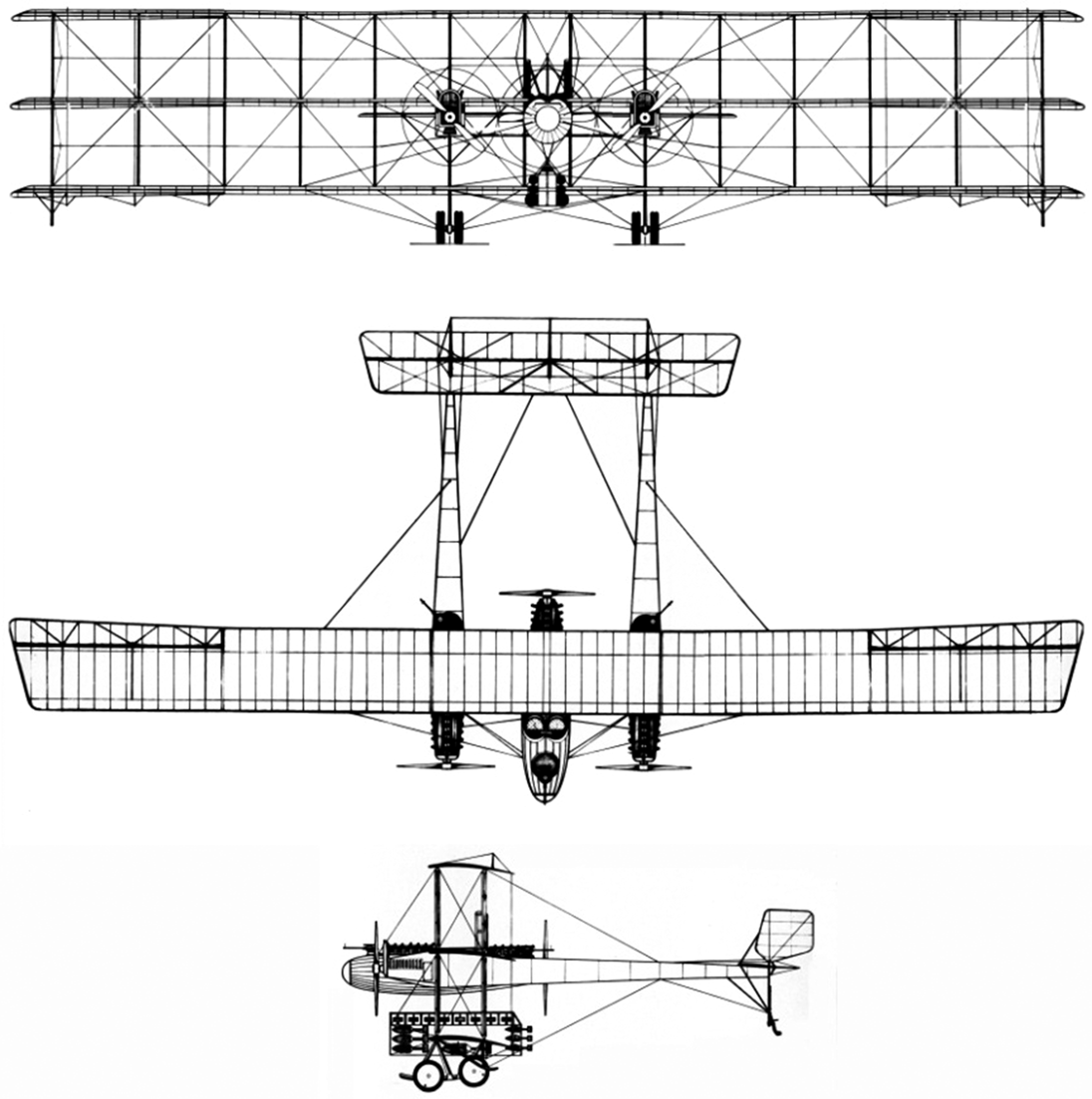

The three-engine night bomber, forerunner of the strategic bombers of World War II, was not built for daylight raids. It was too slow and flew too low, but it had great bomb-carrying capacity. The Ca. 42 (see Figure 1) carried the bombs within a profiled gondola applied at the center of the lower wing. The largest night bomber used in the Great War, it was delivered in twenty-three units usually painted black, with an offensive load of one thousand kilograms or thirty bombs.Footnote 15

Figure 1. The Caproni bomber Ca. 42. (Source: Paolo Miana, I bombardieri Caproni nella Grande Guerra – Senza Cozzar Dirocco (Varese, 2007), 17.)

The report of the first American military mission—the Bolling Mission—to Italy in April 1917 underlined how “Italy was the only allied country which had a functioning long-range bombing program, having already, by the middle of 1917, managed raids with as many as 250 Caproni bombers.”Footnote 16 After the United States entered the war, a number of American pilots, under command of Major Fiorello La Guardia, were trained in Italy and attached to Italian bombardment squadrons.Footnote 17 From June 1918 until the armistice, these U.S. pilots took part in some sixty-five missions with their Italian allies.Footnote 18 In his interesting research work, Paolo Miana underlines the long-lasting impression made by Caproni's bombers and especially of night bombers on American military leaders (Major Edward Gorrell and Colonel William Mitchell).Footnote 19 They were profoundly influenced by Caproni's ideas on the use of aviation and the determinant role of night bombers: “If night bombing is to be conducted on a sufficiently great scale and kept up continuously for a sufficient time, there seems good reason to believe that it might determinate the final outcome of military operations.”Footnote 20

Expansion of the Group in the Interwar Years and the Role of the State

The state's assumption of responsibility for the running of Italy's shaky business has long been a feature of the country's economic history. According to Vera Zamagni, the repeated intervention of the Italian state to rescue its unsteady firms and banks demonstrates not only “the existence of a structural weakness of Italy's economic system” but also the presence of a non-lethargic state as to its intervention in economic affairs. When the 1929 crisis hit Italy's banking system, Alberto Beneduce (grand commis of the state, a central figure within the financial world) set up IRI (Istituto per la Ricostruzione Industriale) and took over the shareholdings of the three largest mixed banks, whose chain-like structure meant that IRI became the major shareholder in companies, representing 42 percent of all joint-stock company capital.Footnote 21 The entrepreneurial state was born as a result of a financial rescue operation but also, according to Franco Amatori and Pier Angelo Toninelli, “to remedy structural deficiencies such as capital scarcity, lack of infrastructure and feeble entrepreneurial spirit.”Footnote 22 This inherent interventionist feature, as we have seen, led the Italian state to buy the Società d'Aviazione Fratelli Caproni and to help the new company, SSAI, from the very beginning through military orders.

The aeronautical industry fits into the larger narrative of public-private partnerships in Europe because it survived thanks to state orders in all European countries at the time. As a matter of fact, military demand governed aircraft production in most countries at the time. The growing importance and costs of innovation in early aircraft and aircraft-engine manufacture were not offset by commercial possibilities in private markets, yet the innovations were of prime significance for the nation's defense and prestige.Footnote 23 Armed forces, in Italy as well as abroad, represented the only existing source of demand, and military aircraft were the only production stereotype to which the aviation industry could refer.Footnote 24 The British government kept most of the country's sixteen aircraft firms alive through small military contracts, providing the British Royal Air Force (RAF) with forty-four different types of aircraft and thirty-five different types of engines by 1931.Footnote 25 Military orders were thus responsible for maintaining Britain's aircraft industry at a reasonable size, while France ended up nationalizing its aircraft industry in 1936.Footnote 26 In Germany, by 1936 the aerial warfare branch of the Wehrmacht, the Luftwaffe, was formally instituted, Hermann Göring became Air Minister, and civil aviation virtually disappeared into the Luftwaffe. The aircraft industry expanded physically, and owing to the state method of awarding contracts and subsidies it abided by the desires of the Luftwaffe, thus building German military air power.Footnote 27 Financing of the American aircraft industry was also governed by military demand. In the 1930s three-fourths of its output in terms of dollar value consisted of military aircraft for the U.S. government.Footnote 28 And a public firm, the Naval Aircraft Factory, was set up and continued to operate in the interwar years in an uneasy partnership with private enterprise to meet the navy's aviation procurement demands.Footnote 29 Thus, a common feature of many industrialized countries at the time was the “omnipresent nature of the government as customer, paymaster and regulator” in the aircraft sector.Footnote 30

After a few difficult postwar years, when Caproni temporarily converted to railway wagons repair works and the construction of furniture, aircraft production resumed with the advent of Fascism and especially from 1923, when Mussolini set up the Air Force Commissariat and the Regia Aeronautica to emphasize its new strategic, economic, and military importance.Footnote 31 As an IMI (Istituto Mobiliare Italiano; a public bank) inspector later testified, “The resumption of aviation construction coincided with the noteworthy expansion of demand coming from the Regia Aeronautica after 1925. Caproni had no viable interest in civil aviation, whereas its military version attracted remarkable Italian and foreign interest. The first significant orders came from Latin America, Belgium and Hungary.”Footnote 32 Between 1934 and 1937, Caproni airplanes were exported to China (L. 3.6 million), Austria (L. 1.9 million), Hungary (L. 5.9 million), Columbia, Sweden, Peru, Chile, Paraguay, Brazil, and Greece.Footnote 33 Also, at the end of the 1920s Caproni signed a joint venture with Curtiss Aeroplane Company (one the most important U.S. aircraft companies) for the building of large commercial aircraft, but unfortunately the 1929 Wall Street crash brought this agreement to an end.Footnote 34

Nonetheless, it was above all the resumption of military activities in Tripolitania that provided the impetus for production of military aircraft. For the conquest of Africa Orientale Italiana (Italian East Africa), Caproni designed and built the Ca. 133 bomber, which performed very well with regard to the altitude of the African fields and brought bombs, troops, and food—even live animals—to the Italian army.Footnote 35

In 1925 Caproni changed the name of SSAI to Aeroplani Caproni and began to plan the expansion of his company and the creation of a group capable of being totally self-sufficient in the production and export of planes and their spare parts. The expansion and development plan began in 1929, when the Caproni Bulgara was set up (at Kuzanlăk) and acquisitions began: Marini Carraro engines in 1929; the Isotta Fraschini Automobile Factory, an Italian luxury car manufacturer, in 1930; and the CAB (“Costruzioni aeronautiche bergamasche,” which was changed to “Caproni aeronautica bergamasca”) in 1931. From the newly created state holding company IRI (1933) Caproni bought two metallurgical-engineering enterprises: the Officine Meccaniche Reggiane in 1935 and CEMSA (Caproni elettromeccanica Saronno) in 1936. These new assets, along with further acquisitions (some apparently remote to the core business, which increasingly extended also to the chemical and mining sectors) and the creation of new firms made the Group self-reliant as far as production was concerned and large enough to defend its market share by the end of the 1930s. Caproni, at Mussolini's request, also set up Aeronautica Predappio, based in a small village in the hills of Forlì where Il Duce was born.Footnote 36

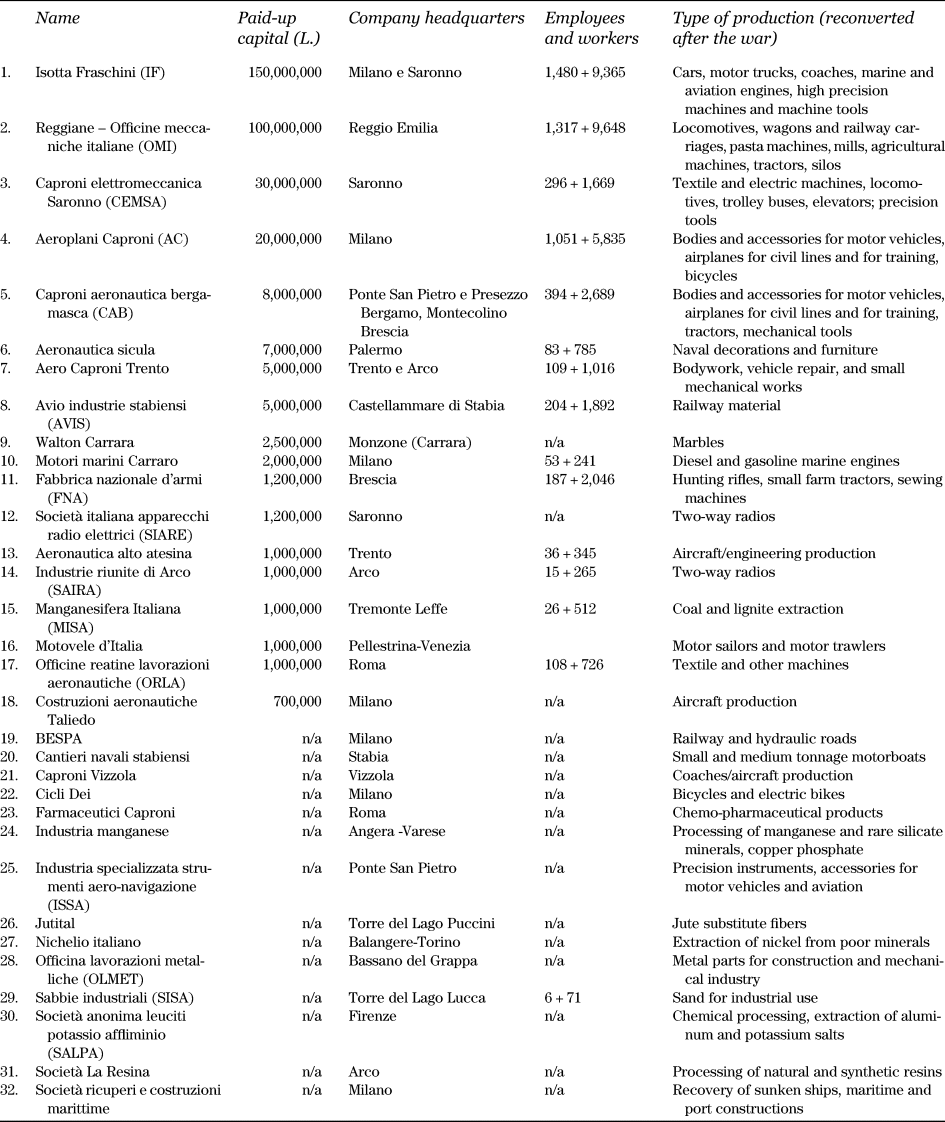

The choice to develop a growing vertically integrated group based on a large number of companies was shaped by several factors, according to Amilcare Mantegazza. First of all, the companies of the Caproni Group complemented one another and operated in a coordinated manner, exchanging materials, intermediate products, finished products, and services. Secondarily, the Royal Air Force Ministry farmed orders out to all the companies involved in the aeronautical cycle; having more companies meant receiving more orders. Third, this intertwining of companies and financial relationships made, and continues to make, the exact perception of the Group's debt exposures more difficult.Footnote 37 At the end of the 1930s the Caproni Group comprised about twenty-six companies. It increased thereafter (see a detailed list in Appendix 1), employing more than thirty thousand people and producing about a quarter of Italy's aircraft and the largest proportion of exports (Fiat, Breda, and IRI were its main competitors).

The Group's construction entailed a sharp increase in its financial exposure. Gianni Caproni increasingly turned to external credit, thus weakening the Group financially. He borrowed money, often asking for advances on state orders, from ordinary banks, from the CSVI (Consorzio sovvenzioni su valori industriali; the Bank of Italy financial credit instrument for industry), and from the IMI.Footnote 38 The Group's financial weakness led to a gradual tightening of credit as its debt exposure became excessive. When in 1936 Isotta Fraschini presented yet another request for funding to the CSVI, the Consorzio referred the request to the Discount Committee in Milan for further checks and appointed Mr. Terenzio Chiesa to investigate the technical and financial situation of the Group's companies. At this stage, the general climate worsened rapidly. The Group's creditor private banks—including Banca Popolare di Novara, Banca Provinciale Depositi e Sconti Milano, Banca Mutua di Lodi, and Banca Nazionale dell'Agricoltura—became much more demanding, and local political authorities received complaints that some of Caproni's firms did not have enough money to pay their workers’ salaries.Footnote 39 Under Mussolini's pressing request, the governor of the Bank of Italy, Vincenzo Azzolini, urged the conclusion of the investigation into the Group; the related report was finally delivered in June 1938.Footnote 40 After a comprehensive analysis of the Group's structure, financial situation, and industrial potential, the report proposed to set up a state technical supervisory committee that could help the company solve its financial problems, put a brake on new investments, and implement a financial consolidation program.Footnote 41

Mussolini appointed General Rodolfo Graziani as head of the newly established Control and Supervisory Committee, which also included Silvio Borri, member of IMI and CSVI, and Mario Solza, representing the Caproni Group “and its 30,000 workers and 3,000 employees.”Footnote 42 At the first meeting, on September 5, 1938, Graziani, who had been given full powers to implement the recovery plan, backed the Caproni Group's new financial requests. Governor Azzolini, in turn, could only give his assent to the new requests for funds authorized by the committee, upon IMI's final approval.Footnote 43 As Table 1 shows, the Caproni Group's financial exposure toward CSVI reached L. 30 million in 1938; in that same year, IMI opened a credit line for L. 75 million, of which the company used L. 42.5 million.

Table 1 The Caproni Group Financial Exposure toward CSVI and IMI, 1938

Source: Consorzio Sovvenzioni sui Valori Industriali (CSVI), Sede Principale, n.76, file 1, Archivio Storico della Banca d'Italia (ASBIT).

In assessing its own work less than one year after its institution, the Control and Supervisory Committee underlined how its authority made it possible to restore confidence in the Group, find new lenders (Istituto S. Paolo di Torino for L. 40 million and the Banco di Roma for L. 30 million), and establish greater understanding between the government and the Group concerning the need for prompter payments.Footnote 44

Caproni's Production Records, the Neutrality Chance, and War Orders

From 1938 to June 1940 (when Italy entered the war) the Caproni Group could in fact count on increasing state and private credits; the banks, reassured by the new supervisory committee, swiftly secured new loans. But the onset of World War II also meant that the Group could count on new orders from the Royal Air Force Ministry and from foreign countries, and even from already belligerent states. In 1939 the company was working on orders worth L. 784 million and was evidently taking advantage of Italy's neutrality.Footnote 45

On September 29, 1939, the French government signed an agreement for the purchase of two hundred airframes from Caproni. According to the contract, “The Società Anonima Aeroplani Caproni will supply the following material: 200 airframes RFB school, reconnaissance and light bomber type for Isotta Fraschini Delta RC 35 I engines. … The price of the present material to be supplied is established in US $10,350,000.”Footnote 46 On January 26, 1940, the British director of aircraft contracts wrote to Caproni: “I'm directed by the Secretary of State for Air to inform you that he undertakes to purchase 300 Caproni CA. 313 type aeroplanes and 100 CA. 311 aeroplanes without armament … to the price of the 400 aeroplanes not exceeding US $26,375,000.”Footnote 47

Gianni Caproni pledged to start production immediately, despite Mussolini's veto. As a matter of fact, in February 1940 Mussolini stated that he refused to consider the sale of war material to the United Kingdom for at least six months. However, “Caproni assured Wing Commander Thornton at Milan on Saturday that he would proceed with the production of our Ca. 311's and Ca. 313's as if nothing had happened. He was confident that matters would eventually be arranged to our satisfaction.” Gianni Caproni even called the British Embassy to say that “he confidently expected by the end of this week to secure the Duce's ratification of the contract for 400 aircraft. He was also hopeful, though less confident, that permission would also be secured for additional aircraft orders.”Footnote 48 Dashing Caproni's hopes, Mussolini did not change his mind on the sale of war material to future enemies and ultimately entered the war on June 10, 1940. At this point, Caproni understood his only chance of increasing production was with the state and concentrated his efforts on obtaining new orders from the Royal Air Force Ministry and on General Graziani's favorable intercession.

In a letter to Azzolini the day after Italy entered World War II, Graziani urged the CSVI to increase credit to the Group against the signing of state contracts. Graziani was acting as a key link between Caproni and Azzolini: “In support of his request, Caproni points out that the orders placed with the Group's various companies reached 1.5 billion lire and almost tripled compared to 1938. Since the economic and industrial situation of the company has actually improved … I submit to you a request from Caproni, which could at least be partially accepted, also bearing in mind the current circumstances.”Footnote 49

The new request for L. 95 million was based on “a significant improvement in the situation and performance of the Group as shown in the Table (2) … while the Group's production has increased by more than L.200 million and orders by more than L.1.4 billion between 1937 and 1940, unsecured debt has decreased [-22.6 mil. lire]. The company's operations have been financed through customer advances [L. 120 million increase], advances on contracts [L. 96 million increase] and the growth in the Group's assets.”Footnote 50

Table 2 Economic Indicators of the Caproni Group

Source: Consorzio Sovvenzioni sui Valori Industriali (CSVI), Sede Principale, n.115 file 5, Archivio Storico della Banca d'Italia (ASBIT).

In the end, the Bank of Italy decided to grant a new loan of L. 88 million and, as emerges in later documents, by 1941 Caproni's credit line had been raised to L. 200 million and its output had soared to twenty planes per month.Footnote 51

As reported by the IMI soon after the end of the conflict, the company reached maximum production efficiency during the war when “Caproni's production was essentially absorbed by the national air force and exports to Germany.”Footnote 52 Indeed, the Luftwaffe purchased significant quantities of Ca. 312s for logistical transport. To be more precise, between 1940 and 1943 the Group as a whole produced 1,897 planes, six submarines, more than three thousand engines, and various types of munitions including bombs and machine guns.Footnote 53

The data in Table 3 comes from the personal papers of Gianni Caproni, housed in the Province of Trento Archives. Its accuracy and reliability might be limited; however, it confirms the rapid increase between 1938 and 1943 in the turnover of the Caproni Group's main companies, which tripled over these years.

Table 3 Turnover of the Caproni Group's Main Producers, 1938–1943 (in L. millions)

Note: Main producers were IF, Reggiane, AC, CAB, CEMSA, Aeronautica Sicula, FNA, Caproni Trento, and ORLA.

Source: Note personali, Archivio Provinciale Trento fondo Gruppo Caproni (APTC).

When the war ended, aircraft production collapsed, mainly because of severe production limitations put on aircraft production by the Peace Treaty. In 1945 the Caproni Group was deeply affected by war damages “aggravated by the paralysis of production, but the Aeroplani Caproni (AC) made a small profit in 1946 of about L.7 million [during the war the AC's profits amounted to 16.358 billion lire].”Footnote 54 At the end of the conflict, despite the prompt state allotments to help redress war damages (law no. 532 of 1945), help from FIM (Fondo Industria Meccanica; a new state body coordinating the first public financing program specifically designed for the engineering industry), and Gianni Caproni's conversion program, the Group was no longer able to make profits.

The Caproni Group in the Aftermath of the War

It is very hard to reconstruct the events and the responsibilities involved in the dismantling and business failure of the Caproni Group. Certainly, the fact that Gianni Caproni was denounced and tried immediately after Italy's liberation in April 1945 for “acting to keep the fascist regime in force and collaboration with the German invader” cut him off from the Group's leadership until the middle of 1946, when he was finally acquitted. There is no doubt from a political point of view that Gianni Caproni's involvement with the Fascist regime worked against him after the war.

On the one hand, Count Caproni(Mussolini awarded him the title in 1940) had gained favor with the regime, thanks to the purchase of companies in crisis and/or located in the South (thus helping implement the Fascist plans for expanding the air force in the Mezzogiorno) and to the setting up of new production companies to comply with Mussolini's requests (for example, Caproni Predappio), among other things. On the other hand, he obtained generous aid, increasing credit, and orders that kept his Group constantly growing. In 1946 the number of controlled subsidiaries had increased to thirty-two (see Appendix 1).

After September 8, 1943, the companies of the Caproni Group that were not in liberated territory were declared protected industries by the German government and placed under its control. Caproni decided to collaborate with the Germans and undertook the production of various types of military supplies, fearing the requisition of the factories and stocks and the deportation of the workers. He also transferred part of his companies’ plants to the gallery of Torbole, on Lake Garda. After the war, Caproni defended himself by saying that the industrial decentralization in Torbole was coercively imposed by the Germans, that all the works carried out in the gallery were directly ordered by them without the possibility of opposition, and that the decentralization of Caproni to Torbole caused enormous damage to the company.Footnote 55 But the image of the company suffered long-lasting damage, and his collaboration with the Salò Republic was never forgiven. Therefore, it should not be surprising that in 1946, even though Caproni had been acquitted of all charges, the newly established Inter-ministerial Committee for Reconstruction (CIR) decided to reserve future civil aviation orders for Fiat and some smaller companies (Macchi, Piaggio), thus deliberately excluding the Caproni Group.Footnote 56

Despite everything, Gianni Caproni did not give up and instead organized an innovative conversion plan focused on engineering production. In his own words,

After the war, I thought of grouping Isotta Fraschini, Aeroplani Caproni, and CEMSA in order to form an organic unit for automotive and motor manufacturing. I deemed grouping them together necessary because the companies could thus avail themselves of a commercial organization capable of penetrating the Italian and foreign civil markets. Then I was planning on taking over the “Dei” bicycle factory [which he eventually did] for the future production of bicycles and electric/motor bikes. … During the war, we had already prepared prototypes and the necessary equipment for making vehicles: the Isotta Fraschini company had built and tested with good results a 2500 cl. with a rear engine that gave encouraging results [the future Monterosa]. CEMSA had created a 1100 cl. car with front-wheel drive in the immediate postwar period [the future F.11], and had started the mass production of the Garelli engines, looms for the processing of wool, silk and cotton and machine tools. Besides, foreign demand for lorries and coaches (especially from Argentina) was growing and could support production levels.

Surely, events unfolded rapidly after the war, and Gianni Caproni's financial requests and ideas on the relaunching of the company were turned down. “I asked the International Bank for $25 million, but although [Prime Minister] De Gasperi had promised his intervention, my request was rejected. As a consequence, all the work programs with America faded away and thus I appealed to the FIM.” The proposal to merge IF, AC, and CEMSA was indeed presented to the FIM, but the project was rejected because, according to Gianni Caproni, “the managers of the IF were afraid of losing their job and the FIM executive committee feared the possible competition emerging from the creation of an important business coalition with significant technical and production possibilities.” As we shall see, the FIM helped the single firms in the Group, with no farsighted vision of the possibility of closer collaboration among them, thus “condemning the future recovery of the Group” and of Italy's aviation industry. In the words of Caproni, “The aviation industry is indispensable to a country's industrial structure. A country without aviation is a diminished country.”

The Debacle of Italy's Aircraft Production after World War II and the Political Constraints

“Nowadays,” wrote Attilio Jacoboni in the first detailed postwar evaluation study of the engineering industry, “aircraft construction activity can be considered non-existent.”Footnote 57 Many factors worked against the recovery of Italy's aircraft industry; the Armistice (Art. 13) and then Peace Treaty (Art. 64) transitory dispositions, practically forbidding aircraft production, surely worsened the technological and scientific delay that aircraft building was accumulating in those years, when only a few prototypes were constructed. Yet part of the responsibility rested on a controversial political attitude that, in the end, chose not to bet on the future recovery of Italy's aircraft industry and instead turned to the U.S. and British markets for the necessary postwar civil aircraft supplies.

The FIM, the Eximbank loan, and the European Recovery Program (ERP, or Marshall Plan), just to mention the biggest aid programs, almost completely neglected those Italian companies that were building airplanes before and during the war, unless they were going to use the funds to convert to other mechanical productions, as the FIM's aid program toward Caproni had foreseen. The Italian government set up the FIM in 1947 to finance engineering firms needing to invest in reconstruction and modernization, with the aim of increasing exports and employment. The fund was managed by a highly professional technical committee. Still, its results were meager: between 1947 and 1950 the FIM gave loans to thirty-seven companies totaling L. 66 billion, but only L. 23 billion had been repaid by the end of 1950. The FIM technical committee was attacked by the press of the time, and its president soon resigned. Despite the best of intentions, the FIM was difficult to handle. Many firms were already on the verge of collapse when the fund stepped in; others employed an excessive number of workers, which kept worsening their financial position. Defaults mainly concerned two large industrial groups, Breda (railway construction, civil and military aircraft, trucks, motorcycles, industrial, agricultural, and construction machinery) and the Caproni Group, and resulted in closures or nationalization. Breda and Caproni brought FIM to its knees: the two groups were given L. 36.9 billion (more than a half of the FIM's budget) but were not able to return the money.Footnote 58 Therefore, between 1949 and 1951 the FIM acquired more than 90 percent of their share capital and essentially controlled the two companies. As far as Breda is concerned, the FIM appointed a lawyer, Pietro Sette, as extraordinary commissioner, with the task of reorganizing the industrial complex that basically was returned in the hands of the state (and its aeronautical branch, IMAM, was transferred in 1951 to the company Aerfer, which belonged to IRI's subholding Finmeccanica).Footnote 59

In the case of the Caproni Group, the story is a bit more complicated. FIM's loan to the Caproni Group amounted to L. 15.4 billion and the Group's repayments, though feeble, had been higher than Breda's (10 percent versus 0.5 percent). The FIM had technically become the holder of the majority of the Group's shares and decided to close down or nationalize most of its companies’ plants—which had all tried to convert to production of motor vehicles, engines, and spare parts. For example, the Aeroplani Caproni was closed down in 1951, despite having turned to the production of tools for aeronautics, trucks and cars, tractors, pumps, and injectors and, together with the subsidiary Caproni Vizzola, having started negotiations with the Twin Coach Company of Kent, Ohio, regarding the production of duralumin suburban coaches for export to European countries.Footnote 60 It needed money to “complete the conversion of its plants” but both the FIM and the ERP quota loan program denied further assistance.Footnote 61 Caproni Vizzola was able to survive for a longer time and to resume aeronautical production in 1968 with the construction of Calif gliders; however, in 1983 the company was acquired by the state through the Agusta Group. Also, the CAB, having produced more advanced aircraft than any other subsidiary of the Group, continued to produce spare parts and even started designing a small touring plane (T.40) after the war. However, without the essential support of state orders, the Bergamo company was not able to avoid bankruptcy.Footnote 62

At the end of the conflict the Officine Reggiane obtained financing from IMI for restoration works and resumed making its “traditional products,” such as railway materials, Fiat 666 bus bodies, and various engineering constructions. Despite a growing demand for its traditional products, financial and redundant labor problems—which, according to the IMI inspector, represented the company's biggest burdenFootnote 63—became pressing while the constant “workforce turmoil and unrest precipitated the unsteady business firm into the abyss.”Footnote 64 The FIM calculated that the Reggiane factory had received L. 1.6 billion by October 1948 but it had not solved the problem of its 2,000 excessive workers on a total of 5,800.Footnote 65 In 1950 the ERP stepped in and granted the company a $975,000 loan to buy machinery and plants on the American market.Footnote 66 Yet only seven of the thirty-one machines purchased were collected from the port of Genoa and installed in the factory; in the meantime, the firm had been occupied by its workers, production had stopped, and no solution was found. Occupation led to forced administrative liquidation. The Economic Cooperation Administration (ECA) authorities in Rome started worrying about the loss of ERP money, since the U.S. machines had became superfluous and unusable. Hence, after liquidation, the FIM reopened the firm as a state company in 1952 under the name Nuove Reggiane Officine Meccaniche Italiane. The new company collected the ERP shipment that had been left at customs in Genoa and equipped the new company with modern American machinery.Footnote 67

At the end of the war Isotta Fraschini engaged in the production of a model of automotive superiority: the Tipo 8C Monterosa, a car equipped with modern technical features in terms of engine, power, speed, suspension, and brakes. However, despite the presentation of the model at the 1947 Paris Motor Show, the “Monterosa” represented the swan song of the prestigious Milanese brand and did not reach the production stage. In March 1949 Isotta Fraschini's outstanding debt with the FIM reached L. 6.4 billion and in November the firm faced compulsory winding-up.Footnote 68 In 1955 what was left of the company was merged with the Breda Motori of Milan to create the state-owned F.A. Isotta Fraschini e Motori Breda (based in the old plants in Saronno).Footnote 69

Finally, CEMSA concentrated on the production of engines and cars after the war. Some work orders came from Garelli of Sesto San Giovanni for the construction of the “Mosquito” engine, and from the company Cicli Umberto Dei for the construction of hubs for bicycles. Responsibility for planning and development of the automotive sector was assigned to Antonio Fessia, a mechanical engineer who had left Fiat, where he had designed the Topolino and the 1100; in just eighteen months Fessia had built the CEMSA F.11. The new car had innovative features: front-wheel drive, maximum speed of 125 kilometers per hour, average fuel economy of 10 liters per 100 kilometers, and modern styling. In September 1947 an IMI inspector reported that “the company hopes to build 4,000 cars in 1948 and 8,000 in 1949. This project is extremely optimistic. The car is expected to be sold at L. 1,750,000 per unit—a brilliant but economically impractical program since it would require fixed assets of the order of at least 4–5 billion lire and it is difficult to understand how the company, in its current financial position, can propose such a program.”Footnote 70

The F.11 was also presented at the Paris Motor Show in 1947, where the American Tucker Corporation negotiated a commitment with CEMSA for importing large quantities of the automobile. Unfortunately, Tucker went bankrupt soon after, the economic situation of CEMSA worsened, and automobile production was suspended at the end of 1949. “The economic and financial difficulties of the Caproni Group, cornered by a shortsighted government policy … led to the liquidation of CEMSA. About 1,500 workers and employees of the factory in Saronno were laid off and operations ceased on 30 November 1949.”Footnote 71

The Denial of International Assistance

It was generally hoped that the Marshall Plan could step in and solve Italy's industrial modernization problems. The European Recovery Program Act had in fact been signed on April 3, 1948; between 1948 and 1951 the value of the industrial equipment sent to Italy amounted to L. 171 billion and was distributed among 358 firms.Footnote 72 Big private firms received 70 percent of the loans and seized the opportunity to renew their production apparatus, thanks to U.S. machinery and plants.Footnote 73 The first three beneficiaries—Fiat (cars, engineering production), Edison (electricity), and Acciaierie di Cornigliano (a state-owned steel company)—radically renewed their production apparatus with subsequent documented gains in productivity and reductions in production costs. Big firms, but also small ones (Piaggio and Necchi, for instance), were thus able to get adequate aid, which helped them modernize and increase sales.Footnote 74

However, not all requests coming from Italian companies were finalized by Italian and American authorities. In particular, the aircraft industry was the engineering sector most penalized after World War II, and also as far as Marshall Plan aid was concerned. As we have seen, most of the companies belonging to Caproni had turned to engineering production; however, Aeroplani Caproni (along with a couple of other subsidiary plants) did not give up aircraft production completely and in 1948 asked the ERP authorities for new machinery at a cost of $486,460 for expanding civil aircraft production. The initial response was positive, but on November 26, 1948, the Ministry of Defense in a letter to the Ministry of Industry made things clear: “Despite the fact that a four-engine aircraft (the Breda's BZ 308) has been built and it is suitable for intercontinental flights, we don't think we can expect Caproni to produce the number of aircrafts we need in due time. Therefore this Ministry thinks we should face the current situation through imports of four-engine aircrafts from the USA with ERP loans.”Footnote 75

As a matter of fact, the ECA office in Rome had made clear from the beginning that aircraft factories were classified as “negative priority,” meaning that investment in that direction would represent “an actual waste of resources under present conditions.”Footnote 76 Priority classifications included top, high, intermediate, and negative. In contrast, Italy's main civil aviation corporations, Alitalia and LAI, were considered “high priority” and were generously helped after the war. Both companies obtained Eximbank funds and Marshall Plan aid to restore their aviation fields and put together the necessary fleet.Footnote 77 Despite an initial undertaking on the part of Alitalia to “buy Italian,” all the planes were bought on the American and British markets. Umberto Nobile, a military aircraft engineer elected in the ranks of the Communist Party at the Constituency Assembly, underlined how Italy was “sacrificing its national industry and the human capital built up in the past and damaging our economy by buying abroad what we could manufacture in Italy. … Italy's experience in aircraft construction is 30 years old now, we have exported to America and Great Britain. … It's humiliating for our engineers and expert technicians.”Footnote 78

Aeronautical production, according to American officials, was part of that group of industries “that grew to their present position largely as a result of the autarchic efforts of the Fascist regime” and could be dismissed.Footnote 79 Only two small Marshall Plan loans were directed specifically to the construction of aircraft spare parts: the largest one (L. 3.1 billion, of a total of L. 3.7 billion) was allocated to Fiat for the production of jet engines for military planes, and the other to Aerfer, an IRI/Finmeccanica firm in Naples, to produce parts of the fuselage.Footnote 80 The small private producers were left on their own, and most of them failed, like Caproni, or became state-owned or started manufacturing something else. A very interesting survival case is the Agusta Group, which continued to produce small biplanes after the war and specialized in repairing American planes. In 1952, it entered the pioneer sector of helicopter production by signing a licensing agreement with the company Bell and was the first in Europe to build the Bell 47 model. Agusta was later nationalized under EFIM (Ente partecipazioni e finanziamenti industrie manifatturiere) and then Finmeccanica.Footnote 81

In 1949, Italy's admission to the North Atlantic Treaty Organization (NATO) marked a turning point, as it finally meant the end of the Peace Treaty punitive blockade of aircraft construction and the resumption of production. The 1966 Istituto centrale di statistica (Istat) industrial census counted 6,877 employees in the aeronautical industrial sector and twenty manufacturers.Footnote 82 Italy's aeronautical output was developing according to three production lanes: the first related to NATO programs and demand (in 1958 the first Fiat jet aircraft, the G.91 by engineer Gabrielli, was selected as NATO's light fighter); the second concentrated on the construction of training aircraft (which were produced both by Finmeccanica and by Piaggio, the latter however had successfully converted to the construction of the famous Vespa scooter and did not consider aircraft production its core business anymore); and the third invested in the development of an advanced helicopter hub (Agusta).Footnote 83

Last, but not least, it should be underlined that it was the U.S. aviation industry that started to dominate world markets after the end of World War II, projecting and building the absolute majority of the world's military and civil aircraft. By the early 1980s, “U.S. exports of large transports represent[ed] approximately two-thirds of total sales in the rest of the world.” This great market success is explained by “the long record of technological leadership of American manufacturers” and the U.S. political hegemony.Footnote 84

Conclusions

State assumption of responsibility for the running of Italy's unstable businesses extended to aircraft production from its very first steps. The first bailout in favor of Caproni, as we have seen, took place in 1913 when the newborn company avoided failure, resulting from overwhelming financial difficulties, because it was bought by the state. Thereafter, the development and rapid expansion of the Caproni Group was bolstered by generous public orders during and after World War I, with the onset of the colonial conquest of East Africa. Despite the economic troubles that Caproni constantly ran into (owing in part to the very expensive expansion strategy adopted in adjuvant sectors to aeronautics), the state never ceased its active assistance—a historically intrinsic tendency and also one in line with what most states at the time were doing for their fledgling aviation industries.

As said, this public-private cooperation echoes a long-term feature of Italy's special subsidiary/supporting role in relation to its frail entrepreneurs. From 1938, with the setting up of General Graziani's Control and Supervisory Committee, the Caproni Group could count on increasing loans from the state and from private banks. The advent of World War II endowed the Group with new orders from the Royal Air Force Ministry, which allowed the Group to reach remarkable production records.

A few larger lessons can be gleaned about state-sponsored private entities in Europe. First of all, the historical-political framework is important and influenced the whole continent. At the beginning of the twentieth century the state indeed became a Gerschenkronian substitutive factor, which allowed Europe to remain on the world's “playing field” (to use Amatori's term) and, after the 1930s crisis, to survive in a globally devastated market.Footnote 85 The Great Depression accelerated the state's presence in industry, as either sponsor or direct owner of many enterprises, which were thus able to continue operating and retain their labor force.Footnote 86 Therefore, in these years state sponsorship allowed many sectors of the European industrial apparatus, including aircraft construction, to avoid bankruptcy while keeping unemployment at bay and avoiding the heavy toll of the 1929 stock market crash on the U.S. economy. In Italy, as said, the state set up IRI, which was seen as a successful example of competitive public enterprise and was imitated in Spain and the United Kingdom. It seemed a good means to counterbalance the growing power of U.S. multinationals and protect selected industrial sectors from decline.Footnote 87

Italy's defeat in World War II had political consequences that translated into economic costs and industrial downsizing. In general, most of the decline experienced by the aeronautical industry was accounted for by the Armistice's and Peace Treaty's temporary limitations to the manufacturing of new aircraft, the preference for importing Allied aircraft for civil airlines, denial of international assistance, and increasing technological obsolescence. Except for the latter, all of these reasons for failure arose from political choices either to comply with Allied requests or to act in line with the U.S. policy of negative priority given to aircraft factories’ recovery. Political constraints played a fundamental role in the fading out of Italy's aircraft sector. In our specific case, the fall of the huge Caproni organization was also the result of a domestic political stumbling block (which made Caproni expendable) and overly diversified industrial interests (thirty-two affiliate companies). Despite the undisputable successes of the 1930s and solid reconversion attempts to shift to the construction of cars, buses, engines, and engineering products, most of the Caproni Group's companies went bankrupt between 1949 and 1951. The ensuing government's industrial bailout policy took divergent paths. Some of Caproni's controlled firms were closed down; others were nationalized under the FIM. Nationalization, as we have seen, was consistent with Italy's industrial history.

The state's long-term rescue policy extended to the postwar period when, in 1962, all of the FIM's industrial properties were transferred to EFIM, established specifically to manage the Fund's nationalized engineering companies. It, together with IRI and ENI, represented the most important public holding company in Italy's industrial sector for thirty years. EFIM properties, among others, included ex–Caproni Group firms and aeronautical companies that the state decided to nationalize rather than shut down: Industria Aeronautica Meridionale, AVIS, Nuove Reggiane, Isotta Fraschini, and, later on, Caproni Vizzola, as well as, outside the Caproni Group, IMAM (formerly Breda). With few exceptions—notably Fiat and Piaggio—all that was left of Italian aircraft production became state-owned by the end of the 1950s, and between 1973 and 2002 Finmeccanica bought Agusta, Savoia-Marchetti, Macchi,Footnote 88 and CANT (Cantieri Riuniti dell'Adriatico). Not only did nationalization prove a clever entrepreneurial move, but it was also the only way to avoid squandering Italy's technical capabilities and preserve the aeronautical industry's heritage. Even today, after the huge privatization process of the 1990s, the state—through the controlled company Leonardo, formerly Finmeccanica—is the main Italian producer of helicopters (AgustaW) and military aircraft (Airbus).

Appendix 1 The Caproni Group and Its Most Important Subsidiaries in order of Paid-Up Capital, 1946