Introduction

Many of the concepts and definitions associated with early craft production have been re-examined and refined in recent years (Flad & Hruby Reference Flad and Hruby2008). Crafted objects, for example, are now deemed to hold greater social significance as symbols of identity, legitimising group membership, than for household purposes. Different types of craft specialisation have also been identified, all of which play a role in the creation and maintenance of social networks, wealth and social legitimacy (Costin Reference Costin1991, Reference Costin2008). The link between technological and social complexity has long been identified archaeologically, but the role of craft specialisation in social evolution has been revised and is now considered as catalytic in the social evolutionary process and a major driver of cultural evolution (Dobres Reference Dobres2010: 103).

In South China, the Neolithic Revolution was both social and industrial, characterised by the emergence of (rice) agriculture, village settlements and a sudden acceleration of technological innovations (Chang Reference Chang1986). Neolithic groups occupying settlements surrounding Hangzhou Bay, in modern-day Zhejiang Province, were precocious. Crafts-persons belonging to the Jingtoushan Culture (8300–7800 cal BP)—the earliest Neolithic culture in the Yangzi delta (Table 1), located approximately 15km west of Tianluoshan (7000–5800 cal BP)—produced the earliest lacquered artefacts so far found in China (Zhai et al. Reference Kuanrong2022). The discovery of the earliest wooden boat in East Asia at the site of Kuahuqiao (8000–6000 cal BP) indicates that, by the Early Neolithic, village specialists around Hangzhou Bay were already participating in expanding regional networks (Jiang Reference Leping and Underhill2013). At Xiasun, approximately 12km from Kuahuqiao (Figure 1), the concentration of relatively homogeneous remains of red-slipped and painted pottery led archaeologists to conclude that the site was not a village settlement but a special-purpose pottery-production site (Zhejiang Provincial Institute of Antiquity and Archaeology & Xiaoshan Museum 2004; Jiang Reference Leping and Underhill2013).

Figure 1. Map of sites surrounding Hangzhou Bay (produced by C. Higham using GeoMapApp; www.geomapapp.org).

Table 1. Chronology of lower Yangzi River Valley Neolithic cultures.

In this article, we publish results from the first analysis of a large assemblage of textile-production tools (n = 649), preserved under anaerobic conditions at the waterlogged Middle Neolithic Hemudu Culture site of Tianluoshan. We use Leroi-Gourhan's (Reference Leroi-Gourhan1964) chaîne opératoire approach, whereby technical acts are perceived as metaphors for social acts. This methodology is based on the premise that the actions involved in manufacturing an object may, quite literally, speak louder than words, or than the message conveyed by the final product (Darvill Reference Darvill2009). Developing this approach, Dobres sees technologies as “integrated webs weaving skill, knowledge, dexterity, values, functional needs and goals, attitudes, traditions, power relations, material constraints and end-products together with agency, and the social relations of the technologist” (Dobres Reference Dobres, Dobres and Hoffman1999: 128). By documenting, in detail, the physical sequence of operations employed to produce textiles at Tianluoshan, we expose the underlying human agency and offer new insights into the importance of the textile-production tools recovered from the site.

Tianluoshan

The village site of Tianluoshan (30°01´27″N, 112°22´46″E) is located between two hills in Xiang'ao village, Sanqishi county, Zhejiang Province, approximately 7km north-east of Hemudu (Chekiang Provincial Museum 1978) (Figure 1). Although currently positioned on a slightly raised mound, approximately 1m asl and 22km from the present-day shoreline, the site would have been coastal when occupied c. 7000–5800 cal BP. Extensive excavations (>30 000m2), conducted over five seasons between 2004 and 2009 (Figure 2), identified eight layers divided into Phase I (c. 7000 BP), Phase 2 (c. 7000–6500 BP) and Phase 3 (c. 6000–5800 BP) (Sun et al. Reference Guoping, Huang and Zheng2007).

Figure 2. a) View of Tianluoshan under excavation, showing surviving wooden house posts; b) plan of excavation units (photograph and plan by Gouping Sun).

The site is part of a cluster of Middle Neolithic village settlements assigned to the Hemudu Culture that were based on economies in transition from foraging to the domestication of rice (Oryza sativa japonica) and water chestnuts (Eleocharis dulcis) (Sun et al. Reference Guoping, Huang and Zheng2007; Sun Reference Guoping and Underhill2013; Fuller et al. Reference Fuller, Harvey and Qin2015; Guo et al. Reference Guo2017). From a technological perspective, the site is significant for the discovery of more than 649 textile-production tools that, along with finds from the earlier Kuahuqiao site (Zhejiang Provincial Institute of Antiquity and Archaeology & Xiaoshan Museum 2004; Jiang Reference Leping and Underhill2013), include the earliest loom components found in Asia to date, appearing more than two millennia before similar objects from Nahal Mishmar, Israel (see below). Waterlogging of the site's archaeological deposits has also provided optimum conditions for the preservation of wooden pile dwellings, fences, a bridge, parts of boats, and oars. Geochemical provenancing demonstrates that one third of the lithic raw materials from Tianluoshan were sourced more than 50km from the site, indicating an extensive maritime network around Hangzhou Bay and beyond (Jiao et al. Reference Tianlong2011).

The majority (66 per cent) of all excavated artefacts were textile-production tools, appearing initially in the lowest occupation layers and continuing, albeit in fewer numbers, until the site was abandoned. Table 2 summarises artefact types, quantities and chronological distribution. Although textile fragments were not found at the site, the sheer number of tools confirms the economic significance of textile production during the site's occupation, while the wide range of tool types highlights the technological knowledge and skill of the Neolithic occupants who made and used them. Product specialisation can be characterised by the differential distribution of artefacts within designated work areas. Textile-production tools were concentrated in half of the excavated units located in the designated work area near the remains of a longhouse (Figure 2c), which is estimated to have housed as many as 100 individuals.

Table 2. Chronological distribution of fibre artefacts and textile tools.

The chaîne opératoire

In essence, craft production concerns people and their technical choices. The following reconstruction of the organisation of production uses the chaîne opératoire approach to not only document and explain the function of the various textile tools recovered at Tianluoshan, but also look beyond technical analysis to explore the rationale for the economic emphasis on textile production.

Fibre processing

The first stage in craft production is the procurement of raw materials. Although the wetlands around Hangzhou Bay host an abundance of fibre-producing species (Table 3), no direct evidence for the cultivation or tending of plants for fibre production was found at Tianluoshan. Fibre processing, therefore, is the first stage in the chaîne opératoire that can be observed at the site. Bundles of cut, soaked and dried reed fibres (30mm in width) were recovered from fishbone pit DK3HI. These were loosely twisted (or plied) in one direction to form cordage—possibly, given the context, for fishing nets or lines. Cordage made from Abutilon avicennae (Chinese jute) was identified at Hemudu (Chekiang Provincial Museum 1978). At Tianluoshan, a bone hoe from Layer 8 of excavation unit T302 in the craftworking area was hafted with thick, loosely twisted reed cordage (Figure 3), while nine broken hoe pieces were distributed in the rice paddies (special-purpose refuse areas) surrounding the village.

Figure 3. Examples of fibre-based artefacts at Tianluoshan: a) hoe hafted with twisted cordage from T224; b) matting from T204 (scale = 20mm); c–d) close-ups of structural composition of mat; e) sample dated between 6775 and 6645 cal BP (scale = 5mm); f–g) condition of extant remains on exposure; h–i) diagrams showing how the patterns would have been created (figure by J. Cameron).

Table 3. Principal fibre-producing plants and filaments in the lower Yangzi Valley.

Pieces of remarkably well-preserved matting were recovered from Phase 1 and 2 layers. Three large pieces (Figure 3) were amongst 27 fragments distributed across contiguous units T204, T104 and T203 at the edge of the designated work area (for their material and structural compositions, see Table 4). The sample from T204, AMS dated to 6775–6645 cal BC, derives from the site's earliest period of occupation (Figure 3c). Phytolith analysis (Zhang et al. Reference Jianping2016) reveals that it was made from Phragmites australis (Cav.), a reed of brackish wetlands. The fragment's yellowish colour could be the result of chemo-luminescence, a chemical reaction that occurs when buried fragments are exposed to oxygen and sunlight.

Table 4. Material and structural composition of Tianluoshan matting.

Matting is classified as a sub-class of basketry, distinguished by the manipulation of a single active set of elements (Adovasio Reference Adovasio2010). The Tianluoshan matting from T204 was produced by plaiting using the simplest interlinking process, which would have required more than one person to lay out pre-cut strips of flattened reeds parallel on the ground and hold them in place for interlacing at 90°. The twill plaiting from T203 and T206 was achieved using a stepped system of shifts, whereby the single element was passed over and under three to five other lengths at staggered intervals. The food-storage pits were lined with twill fragments, although matting probably also functioned as flooring, defining spaces and providing comfort.

In the northern Judean Desert, comparable examples of twill plaiting have been preserved in the dry conditions inside the 6000-year-old Cave of the Warrior (Schick et al. Reference Schick1998), while in Russia, carbonised sedge matting fragments, dated to c. 9400–8400 cal BP, were found within Chertovy Vorota Cave, approximately 30km from the East Asian coastline (Kuzmin Reference Kuzmin2012).

At Tianluoshan, fibre preparation is attested by 228 perforated discs, interpreted as spindle whorls. These first appear in the earliest layers, gradually increasing in number during Phase 2 before rapidly declining in Phase 3 (Figure 4a). Whorls are an essential component of hand spindles—simple devices comprising a weight (whorl) and shaft (spindle). They are designed to twist fibres mechanically and simultaneously draw them out to extend their length and tensile strength, thus creating strong, continuous threads for loom weaving.

Figure 4. Graphs concerning spindle whorls from the Tianluoshan site showing: a) distribution; b) material composition; c) location and numbers; d) numbers by diameter and (e) by weight; f) diameters by weight; g) percentage of types; h) chronological distribution of different whorl types (i) (figure by J. Cameron).

The Tianluoshan whorls are predominantly ceramic (tempered with sand, rice chaff and soil); they were hand-built and well-fired, using the same clay used in large, locally produced vessels, confirming they were made at or near the site. Some were roughly formed but most were smoothed, and two were produced by re-working potsherds. A grey fabric was the most common, although buff and black were also represented (Figure 4b).

Hard, polished stone discs of slate, chalcedony, wonderstone and jade, weighing 20–30g (Figure 4b), were also recovered at Tianluoshan, and stone-working tools found in association confirm that they were worked in situ. We interpreted these stone discs as spindle whorls on the basis of ethnographic parallels in British Columbia, where the Salish use stone whorls of the same size and weight to spin nettle (Urtica diocia), a species that originated in China (Loughran-Delahunt Reference Loughran-Delahunt1996). The linear regression in Figure 4f shows whorl diameters increasing with weight.

The size of a whorl's central perforation is diagnostic—by necessity, they must be large enough to fit a spindle—a crucial measurement for differentiating discs that might otherwise be identified as beads. Perforation sizes are standardised across all whorl sizes (5–15mm); the smallest is wide enough for a thin bamboo (?) spindle to be inserted. Off-centred whorls seem counter-intuitive, but experimentation demonstrates that asymmetrical whorls can be functional (Andersson Reference Andersson2003). Use-wear on the Tianluoshan whorls is common. Figure 4c provides the distribution and numbers of whorls across the site, while Figure 4h shows their typological distribution. Seventy-two per cent are discoid (Type I), a shape commonly found elsewhere at early textile sites.

Based on ethnographic, botanical, historical and archaeological evidence, we suggest that several fibre-producing plants and filaments were spun and woven at Tianluoshan (Table 2). Pueraria montana var. lobata (Willd.), the wild progenitor of the domesticated bean-creeper (P. thunbergiania), still grows in streams around Hemudu (B. Cameron, pers. comm.); the species is indigenous to south-east China, where it is known as ko, or kudzu in Japan (Higashimura Reference Higashimura2011). Fibre preparation for bean creeper is very labour intensive—the 1.3–1.8m-long fibrous runners have to be cut, peeled, rinsed in running water, beaten, then dried in the open air (exposure turning the fine strands white (Kuhn Reference Kuhn1988). The Shih Ching (Book of Odes) says that the plants grew along riverbanks where yellow birds settled, and strands of the creeper were made into shoes. A roll of fabric called ‘girl cloth’—woven by unmarried females—took a year to weave (Karlgren Reference Karlgren1950). Ko fibres were also used for embroidery and for lengths consisting of ko warps and silk wefts (Kuhn Reference Kuhn1988). Ko textiles pre-date hemp textiles in the archaeological record, as attested at the Majiabang site of Caoxieshan (Figure 1).

Circular/oval whorls (Type VIII) weighing less than 10g are still used to spin broken silk filaments from hatched wild silkworm pupae (Bombyx sinensis) (Kuhn Reference Kuhn1988); the presence of similar whorls at Tianluoshan may therefore suggest the spinning of silk. At Hemudu (Chekiang Provincial Museum 1978), there is indirect evidence of silk production based on two silkworms carved on the outer surface of an ivory basin. At the Liangzhu site of Qianshanyang (Zhou Reference Kuanjming1980) (Figure 1), S- and Z-spun silks with thread counts as high as 72–64 warps/68 wefts were identified in a braided belt, along with a fragment of tabby weave and untwisted filaments reeled from at least 20 cocoons. Fragments of textile woven from ramie (Boehmeria nivea (China Grass))—an indigenous species with high tensile strength and absorbency, suitable for the hot conditions of South China—were also represented at Qianshanyang (Vainker Reference Vainker2004). The processing of this bast fibre is extremely labour intensive: long stems are cut, soaked, scraped to obtain the bast, de-gummed by boiling in water or lime, washed, then spliced and spun. On Hainan Island, cultural continuity is observable in Li minorities who still spin ramie using biconical whorls. Our unpublished experiments reproducing whorl types represented in the Tianluoshan assemblage showed that biconical whorls were easily replicated—the shape forms naturally in the palm of the hand during production. Only 3 per cent of Tianluoshan's whorls are conical (Type III)—a type associated with the spinning of bast fibres.

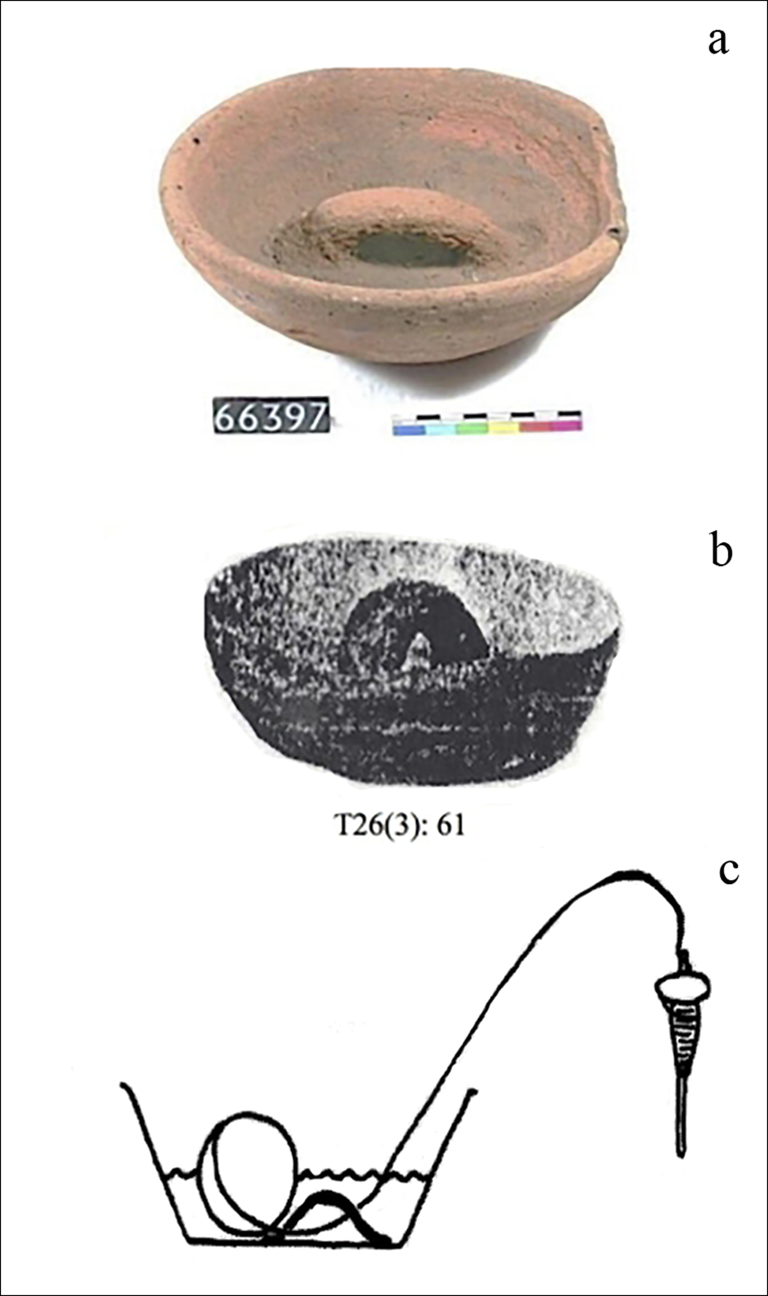

Hemudu excavations also produced a ceramic bowl with a strap on its base that resembles a spinning bowl from the Egyptian pre-dynastic site of El-Badari (Brunton & Caton-Thompson Reference Brunton and Caton-Thompson1928). Figure 5 explains how spliced flax fibres are dampened by running them through water in special-purpose fibre-wetting bowls. These specialised tools were also used to prepare flax from the fifth millennium BC onwards in Egypt and Greece, before later becoming more widely distributed. Although they do not appear to be represented ethnographically in China, in Japan, similar bowls are used to process nettle fibres (Barber Reference Barber1991). Truncated conical whorls with narrow waists (Type XVII) are of functional significance, as they provide space for thread to be wound around the whorl body—a precursor to the modern cotton reel (L. Bo, pers. comm.).

Figure 5. Prehistoric fibre-processing equipment: a) Badarian spinning bowl, Egypt, Middle Kingdom, 1938–1630 BC (photograph courtesy Petrie Museum UC 66397); b) ceramic spinning bowl? Hemudu site (courtesy Hemudu Site Museum); c) schematic diagram showing bast fibres being processed in a fibre-wetting bowl (diagram courtesy E. Barber).

Nine per cent of the whorls displayed smoothed and decorated surfaces created using several techniques. Type I whorls were decorated with cord impressions. A hollow (bamboo?) tube was also used to stamp small, equidistant concentric circles on the upper surface of conical whorls, creating a motif similar to the grain pattern described on jade discs from dynastic sites (Laufer Reference Laufer1912). Some of the parallel and intersecting lines resemble needlework stitches. Two figurative motifs are naturalistic (Figure 6). The motif incised with a sharp instrument on the upper surfaces of jade whorl T003(6):1 resembles fish bones—an interpretation supported by the prevalence of demersal and pelagic species in the diet of Tianluoshan inhabitants. The deeply incised motif on whorl T204(8):36 resembles the yellow-billed grosbeak (Eophona migratoria), a migratory finch that is distinguished by its very thick beak, and which breeds in the temperate forests of Russia and winters around the East China Sea.

Figure 6. Naturalistic incised motifs on whorls T003 and T204 identified by J. Cameron (photograph by Gouping Sun).

Loom weaving

The next stage in the chaîne opératoire is loom weaving. Looms provide a framework for arranging threads in sequence to keep them straight and under tension. Based on depictions of foot-braced backstrap looms in a weaving scene on a Western Han (226 BC–AD 206) bronze drum from Tomb M1 at Shizhaishan, Yunnan (Yunnan Sheng Bowugan Reference Bowugan1959), in which a series of warp threads were stretched between a beam attached to the weaver's waist and held in place by another beam at the feet (Figure 7f), the dominant paradigm has long been that this was the earliest type in China. Wang Chen, the early fourteenth-century AD author of the Nung Shu (cited in Kuhn Reference Kuhn1988), suggested the possibility of an earlier type of loom in China but archaeological evidence for this has so far been lacking.

Figure 7. Archaeological and ethnographic correlates for Tianluoshan looms: a) reconstruction of a ground loom from Nahal Mishmar (drawing by J. Liger, courtesy P. Bar-Adon & Israel Exploration Society); b) painting of a ground loom inside a ceramic bowl, El Badari (courtesy Petrie Museum UC 9547); c) model of a ground loom, Tomb of Daga, Egypt, Middle Kingdom (as reproduced in Broudy Reference Broudy1979: figs 3–4, courtesy Brandeis University Press); d) Japanese backstrap loom (illustration by M. Junichiro, reproduced in Mori Koichi (Reference Mori1979); e) Yunnan backstrap loom with cong-shaped shed, Zha Yu Village, Yunnan (photograph by C. Pillitz, Alamy BRF7KX); f) foot-braced backstrap loom, Hainan (as reproduced in Stübel Reference Stübel1937: fig. 2, courtesy Klinkhardt & Biermann).

In West Asia, the ground loom—which was fixed to the ground—is evidenced both archaeologically and ethnographically. In Israel, the earliest loom parts were found wrapped in matting in a remote Chalcolithic cave (c. 4000–3300 BC) above Nahal Mishmar (Bar-Adon Reference Bar-Adon1980). Reconstruction in Figure 7a of the disassembled components shows that it would have been anchored to the ground with four pegs. This type is also depicted on a clay plaque from level 11 at Çatalhöyük (c. 9750 BC) (Mellaart et al. Reference Mellaart, Hirst and Balipu1989) and painted inside a ceramic dish from the Egyptian Predynastic site of El-Badari (c. 4400–3800 BC) (Brunton & Caton-Thompson Reference Brunton and Caton-Thompson1928: xxxviii) (Figure 7b). Clay models (Figure 7c) of looms were also found buried in Middle Kingdom tombs in Egypt (Roth Reference Roth1917). Significantly, 34 pegs were recovered from the earliest phases at Tianluoshan, along with 280 broken beams (breast and end), suggesting the use of ground looms (Figure 8). The backstrap loom evidenced at Tianluoshan, and ethnographically throughout East Asia (Figure 7d), is more transportable than the fixed horizontal or vertical types. The foot-braced loom is clearly a later development.

Figure 8. a–i) Tianluoshan loom components reconstructed; top right) location of equivalent components on a contemporary backstrap loom (as reproduced in Broudy Reference Broudy1979: figs 5–6, courtesy Brandes University Press).

A number of wooden ‘tubes’ (Figures 8b & 9) recovered from layer 7 at Tianluoshan probably functioned as shed rods (n = 76), used on looms to raise alternate threads to create a space (the shed) for wefts to pass through (Figure 7e). Some were lacquered, a time-consuming process mentioned earlier, where glossy mixtures made from the toxic constituents of lacquer trees (Toxicodendron vernincifera) were applied in multiple, thin layers. Black lacquer was produced by adding carbon to sap, while red was produced by adding mercuric sulphide (cinnabar). Lacquered bowls were also represented at Hemudu (Chekiang Provincial Museum 1978), but the Tianluoshan lacquered loom components are unparalleled. Threads called ‘heddles’, which are attached to shed rods to raise alternate threads during interlacing, were not recovered at Tianluoshan, but they may not have used them. In South America, small picks were used for this purpose before the introduction of heddles (Bird Reference Bird, Emery, Fiske and Freshley1979). At Tianluoshan, wooden picks (<100mm in length) were recovered, including an engraved bone example from T305 that resembles a hairpin (Figure 8i).

Figure 9. a) Jade spindle inserted in a jade bi (whorl), Tomb 139, Fuquanshan; b) jade cylindrical and rectangular cong (shed rods), Tomb 139, Fuquanshan; c) jade finials from three looms, Tomb 23, Fuchan, Yuhang, Zhejiang Province (longest component = 45mm) (photographs courtesy Liangzhu Culture Museum).

Sixteen excavation units close to the dwelling(s) also produced wooden and bone beaters (n = 46) of differing shapes (Figure 8d) that would have been used to straighten threads and press them firmly at right angles to warps during weaving. These included large numbers of small, intricately carved and highly polished bone (deer and water buffalo) beaters, many of which were broken. Some 35 spools that would have carried spun threads through warps have also been identified (Figure 8h). Four shuttles find firm parallels at nearby Hemudu.

The most ingenious devices in the Tianluoshan assemblage are warp-spacers (n = 32), identifiable by a series of evenly spaced ‘teeth’ carved along their lengths, which allowed two or more threads to pass evenly through each notch, thus preventing tangles that slow down production (Roth Reference Roth1917) (Figure 8f). Parallels are known from El Badari (Brunton & Caton-Thompson Reference Brunton and Caton-Thompson1928). Considering that efficiency is determined by a combination of technology and organisation of production (Costin Reference Costin1991), the presence of such devices at Tianluoshan suggests that weavers were both skilled and efficient.

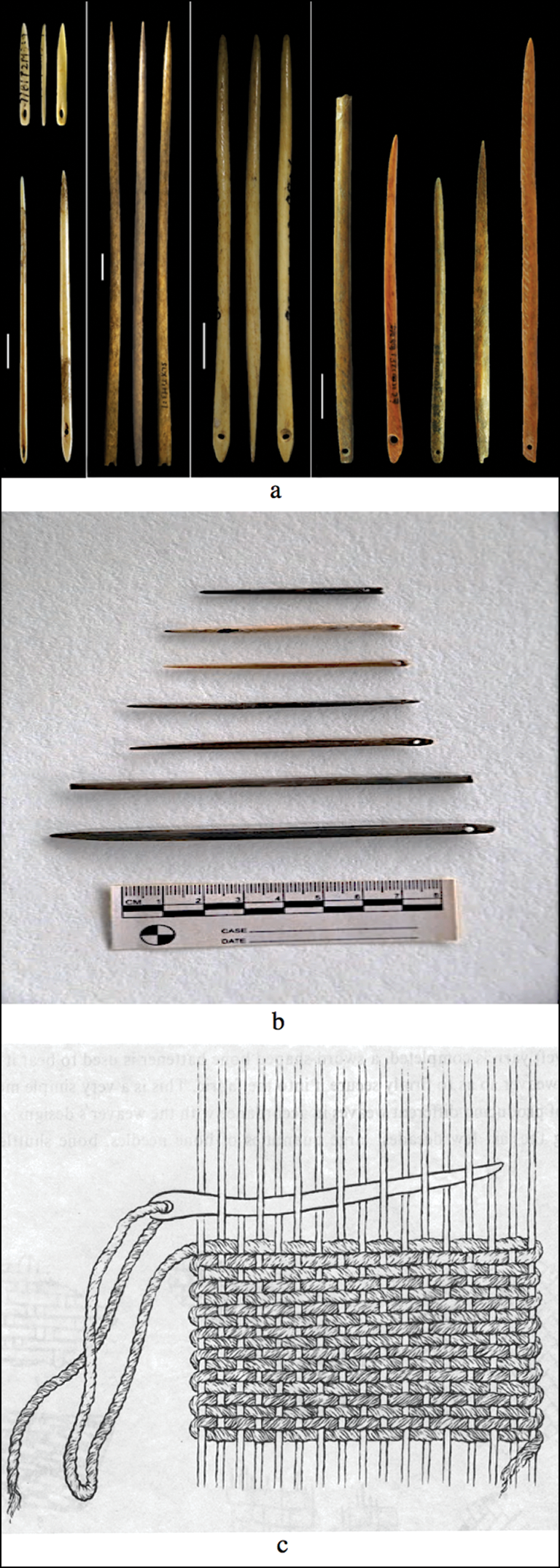

Needles

The final procedure in the chaîne involved the use of needles (Figure 10). A recent synthesis of 1619 needles from 138 Chinese sites (Wang et al. Reference Wei, Bae and Xu2020) demonstrates the simultaneous appearance of bone needles at Palaeolithic sites in Europe and China, with continued use in the Chinese archaeological record, until they are superseded by iron needles in the Han Dynasty (202 BC–AD 220). At Xianrendong, nine bone needles were recovered from Layer 3 (McNeish et al. Reference McNeish2017: fig. 8). In the lower Yangzi Valley, bone needles are found with painted pottery at the Early Neolithic sites of Zenpiyan (n = 10) and Kuahuqiao (n = 13), increasing in number during the Middle Neolithic at Tianluoshan (n = 46) and Hemudu (n = 77), the latter representing 4.7 per cent of all Chinese finds. The Tianluoshan needles measure 39–111mm in length (Figure 10b). The eyes of 15 needles were broken; the remaining unbroken examples were shorter and straighter, with narrower eyes (10–20mm) than their Palaeolithic counterparts.

Figure 10. Comparable bone needles from Middle Neolithic sites: a) Hemudu (photograph courtesy Wei Wang); b) Tianluoshan (photograph by J. Cameron); c) reconstruction using Palaeolithic bone needle from Banpo functioning as a weaving shuttle (illustration courtesy of Cheng Weiji).

This pattern is mirrored in northern China at the contemporaneous Yangshao site of Banpo (c. 6700–5670 BP), where 281 needles were recovered, some measuring 160mm in length and with eyes less than 2mm wide. As temperatures were 3°C higher than present, it is doubtful that needles were used for sewing animal skins or fur clothing—a behavioural adaptation long associated with Upper Palaeolithic sites. According to Chang (Reference Chang1986), these small-sized eyes could not have been threaded with hide strips, plant roots or stalks, instead indicating the use of hemp, silk and other fibres. Cheng (1992) maintains that large bone needles were multi-functional, used as weaving shuttles (Figure 10c) to sew mats and woven textiles, and to apply embroidery and embellishments.

Discussion

The chaîne opératoire tells us ‘what happened’ during different stages of textile production at Tianluoshan. The strongest evidence for specialisation comes from patterning: the concentration of large numbers and varieties of textile-processing tools in specific areas on the eastern side of the village. Textile production is a transformative process, with each tool deployed, in turn, to manufacture fibre-based products. Spindle whorls are mini flywheels that function exclusively to convert fibres and filaments into continuous threads. Looms, in turn, transform threads into woven fabrics. The construction of such complex prehistoric machines pre-supposes technical knowledge and skills passed down from one generation to another. Weaving a square metre of textile on a backstrap loom has been calculated to take 30–40 hours and 6–8 times as long to spin the thread required (Barber Reference Barber1994: 94). Without extant remains, however, it is impossible to quantify accurately the amount of time invested in production, particularly as most textile work is intermittent and pursued alongside other activities (Costin Reference Costin1991). In the absence of extant textiles from the site, the varied functions of the products of Tianluoshan's looms remain hypothetical; as well as functional uses, such as clothing, textiles are important semiotic systems that articulate socio-cultural relationships, and are objects for exchange.

Conclusions

Tianluoshan exemplifies community specialisation, defined as “households producing for unrestricted regional consumption” (Costin Reference Costin1991: 8), where the economic expenditure on textile production at the site was not determined by material necessity. The inhabitants of Tianluoshan were part-time craft specialists using ‘cutting-edge’ developments in loom technology to increase efficiency and improve the quality of products. Tools such as warp-spacers would have increased production, making it easier to produce surplus textiles for exchange. Sites such as Tianluoshan and Xiasun, located along the shores of an inlet of the East China Sea, were strategically placed to specialise in the production of novel commodities, such as textiles, lacquer and pottery, for exchange within Hangzhou Bay and beyond, with demand increasing with the emergence of stratified societies.

The link between technological and social complexity is well supported by archaeological evidence; the data from Tianluoshan and other Neolithic sites in the lower Yangzi Valley, however, demonstrate advanced levels of technological and social complexity usually only associated with later states. Indeed, it seems far from coincidental that the first regional state emerged in the Yangzi Valley during the Late Neolithic at Liangzhu (c. 5300–4300 BP), characterised by walled structures, large-scale hydraulic works to support rice cultivation, and flood control and canals for transport (Zhejiang Provincial Institute of Antiquity & Archaeology 1988, 1989). There, inhabitants had transitioned from small-scale Neolithic societies to a large, integrated political unit, with social hierarchy, rituals and craft production (Renfrew & Liu Reference Renfrew and Liu2018). The socio-economic significance of textile production at Liangzhu is symbolised by jade models of spindle whorls (Green Reference Green1993) and other previously unidentified textile tools (Figure 9) in high-status burials.

Chinese textile production has always been gendered. Mortuary data and countless historical and ethnographic analogies (Rode Reference Rode, Linduff and Sun2004) attest to the role of women in spinning and weaving—so much so that archaeologists have used the presence of spindle whorls in graves to estimate the sex of buried individuals. The evidence for community specialisation in textile production presented here suggests that female labour not only contributed to but almost certainly underwrote the development of early complex societies in the Yangzi Valley.

Acknowledgements

We thank Feng Zhao, Long Bo, Tracy Martens, Jim Adovasio and Brigitte Borell for assistance, and two anonymous reviewers whose recommendations greatly improved the article. Charles Higham created the map in Figure 1 and improved Figure 10.

Funding statement

Tianluoshan's excavations, led by Guoping Sun, were funded by the Zhejiang Provincial Institute of Cultural Relics & Archaeology, Hangzhou. The analysis of the tools, conducted by Judith Cameron, was funded by an Australian Research Council Future Fellowship (FT120100757).