1. Introduction

Granular segregation has been widely studied due to its importance in many areas ranging from geophysics to industrial processes (Ottino & Lueptow Reference Ottino and Lueptow2008; Gray & Kokelaar Reference Gray and Kokelaar2010; Gray & Ancey Reference Gray and Ancey2011; Gray Reference Gray2018; Umbanhowar, Lueptow & Ottino Reference Umbanhowar, Lueptow and Ottino2019). Among the particle properties that drive segregation, size and density are usually the dominant factors (Savage & Lun Reference Savage and Lun1988; Khakhar, McCarthy & Ottino Reference Khakhar, McCarthy and Ottino1997). In dense granular flows of size-disperse particles having the same density (S-systems), large particles tend to rise as small particles fall through voids, a segregation mechanism known as percolation (Williams Reference Williams1968; Drahun & Bridgwater Reference Drahun and Bridgwater1983; Savage & Lun Reference Savage and Lun1988; Ottino & Khakhar Reference Ottino and Khakhar2000). For density-disperse mixtures of equal diameter particles (D-systems), segregation is driven by a buoyant force mechanism in which heavy particles sink and light particles rise (Ristow Reference Ristow1994; Khakhar et al. Reference Khakhar, McCarthy and Ottino1997; Khakhar, McCarthy & Ottino Reference Khakhar, McCarthy and Ottino1999; Pereira et al. Reference Pereira, Sinnott, Cleary, Liffman, Metcalfe and Šutalo2011). Various continuum models have been proposed for segregation in S- or D-system (Gray Reference Gray2018; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019), but few studies focus on bidisperse mixtures where the constituent species vary in both size and density (i.e. SD-systems) with the notable exceptions of papers by Jenkins & Yoon (Reference Jenkins and Yoon2002), Marks, Rognon & Einav (Reference Marks, Rognon and Einav2012), Tunuguntla, Bokhove & Thornton (Reference Tunuguntla, Bokhove and Thornton2014) and Gray & Ancey (Reference Gray and Ancey2015). Though size and density differences can reinforce each other, e.g. in mixtures of large light (LL) particles and small heavy (SH) particles, a greater challenge is to predict segregation when the two segregation mechanisms oppose each other, e.g. in mixtures of large heavy (LH) particles and small light (SL) particles. The goal here is to model particle segregation in a two-species mixture of particles differing simultaneously in both particle size and density.

Previous studies used experiments and particle-based simulations to determine the crossover condition between percolation and buoyancy for SD-systems. For vibrated granular materials (the Brazil nut problem), segregation occurs as a consequence of periodic dilation and compaction of the particle bed. The tendency of particles to sink or rise in vibrated systems can be characterized by the ratios of large to small particle diameter, ![]() $R_d=d_l/d_s$, and density,

$R_d=d_l/d_s$, and density, ![]() $R_\rho =\rho _l/\rho _s$ (Hong, Quinn & Luding Reference Hong, Quinn and Luding2001; Jenkins & Yoon Reference Jenkins and Yoon2002; Breu et al. Reference Breu, Ensner, Kruelle and Rehberg2003; Ciamarra et al. Reference Ciamarra, De Vizia, Fierro, Tarzia, Coniglio and Nicodemi2006). These studies show that percolation dominates (i.e. large particles rise) for

$R_\rho =\rho _l/\rho _s$ (Hong, Quinn & Luding Reference Hong, Quinn and Luding2001; Jenkins & Yoon Reference Jenkins and Yoon2002; Breu et al. Reference Breu, Ensner, Kruelle and Rehberg2003; Ciamarra et al. Reference Ciamarra, De Vizia, Fierro, Tarzia, Coniglio and Nicodemi2006). These studies show that percolation dominates (i.e. large particles rise) for ![]() $R_d>R_\rho$. On the other hand, in flowing granular systems segregation is related to the local shear and resulting dilation in the relatively thin gravitationally driven flowing layers that are ubiquitous in industrial settings such as heaps (Fan et al. Reference Fan, Jacob, Freireich and Lueptow2017), chutes (Savage & Lun Reference Savage and Lun1988; Pouliquen Reference Pouliquen1999) and tumblers (Hill et al. Reference Hill, Khakhar, Gilchrist, McCarthy and Ottino1999; Liu, Yang & Yu Reference Liu, Yang and Yu2013), as well as in geophysical flows such as landslides (Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012). For example, free surface flow experiments with an equal-volume mixture of large steel and small glass particles (

$R_d>R_\rho$. On the other hand, in flowing granular systems segregation is related to the local shear and resulting dilation in the relatively thin gravitationally driven flowing layers that are ubiquitous in industrial settings such as heaps (Fan et al. Reference Fan, Jacob, Freireich and Lueptow2017), chutes (Savage & Lun Reference Savage and Lun1988; Pouliquen Reference Pouliquen1999) and tumblers (Hill et al. Reference Hill, Khakhar, Gilchrist, McCarthy and Ottino1999; Liu, Yang & Yu Reference Liu, Yang and Yu2013), as well as in geophysical flows such as landslides (Johnson et al. Reference Johnson, Kokelaar, Iverson, Logan, LaHusen and Gray2012). For example, free surface flow experiments with an equal-volume mixture of large steel and small glass particles (![]() $R_\rho =3$) in a rotating tumbler show that segregation diminishes for

$R_\rho =3$) in a rotating tumbler show that segregation diminishes for ![]() $R_d>2$ (Jain, Ottino & Lueptow Reference Jain, Ottino and Lueptow2005a,Reference Jain, Ottino and Lueptowb). In addition, several studies employ continuum mixture theory (Atkin & Craine Reference Atkin and Craine1976) to quantitively model SD-segregation. For example, by assuming a species-specific stress proportional to the mean diameter ratio of the species to the bulk, the momentum balance equation indicates that large particles should rise for

$R_d>2$ (Jain, Ottino & Lueptow Reference Jain, Ottino and Lueptow2005a,Reference Jain, Ottino and Lueptowb). In addition, several studies employ continuum mixture theory (Atkin & Craine Reference Atkin and Craine1976) to quantitively model SD-segregation. For example, by assuming a species-specific stress proportional to the mean diameter ratio of the species to the bulk, the momentum balance equation indicates that large particles should rise for ![]() $R_d>R_\rho$ (Marks et al. Reference Marks, Rognon and Einav2012). However, discrete element method (DEM) simulations of equal-volume mixtures flowing down a chute indicate that the species-specific stress is proportional to the mean volume ratio of the species to the bulk, rather than the diameter ratio, leading to the result that large particles should rise for

$R_d>R_\rho$ (Marks et al. Reference Marks, Rognon and Einav2012). However, discrete element method (DEM) simulations of equal-volume mixtures flowing down a chute indicate that the species-specific stress is proportional to the mean volume ratio of the species to the bulk, rather than the diameter ratio, leading to the result that large particles should rise for ![]() $R_d^3>R_\rho$ (Tunuguntla et al. Reference Tunuguntla, Bokhove and Thornton2014). In addition to size and density ratios, the crossover condition for when buoyancy or percolation dominates in rotating tumbler experiments also depends on particle species concentration (Alonso, Satoh & Miyanami Reference Alonso, Satoh and Miyanami1991) such that LH particles sink at low concentrations but float at high concentrations. The observed concentration dependent segregation direction is not predicted in the approaches by Marks et al. (Reference Marks, Rognon and Einav2012) or Tunuguntla et al. (Reference Tunuguntla, Bokhove and Thornton2014), but has been explained in context of the mixture theory by assuming the species-specific stress is a quadratic function of mixture concentration (Gray & Ancey Reference Gray and Ancey2015).

$R_d^3>R_\rho$ (Tunuguntla et al. Reference Tunuguntla, Bokhove and Thornton2014). In addition to size and density ratios, the crossover condition for when buoyancy or percolation dominates in rotating tumbler experiments also depends on particle species concentration (Alonso, Satoh & Miyanami Reference Alonso, Satoh and Miyanami1991) such that LH particles sink at low concentrations but float at high concentrations. The observed concentration dependent segregation direction is not predicted in the approaches by Marks et al. (Reference Marks, Rognon and Einav2012) or Tunuguntla et al. (Reference Tunuguntla, Bokhove and Thornton2014), but has been explained in context of the mixture theory by assuming the species-specific stress is a quadratic function of mixture concentration (Gray & Ancey Reference Gray and Ancey2015).

Segregation experiments demonstrate the subtle interactions between particle size and density, and DEM simulations reproduce these results for laboratory-scale geometries (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2013, Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Combarros et al. Reference Combarros, Feise, Zetzener and Kwade2014; Garcia et al. Reference Garcia, Feise, Strege and Kwade2016; Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016). However, a first-principles-based predictive theory for combined size and density segregation is lacking. Efforts have been made to extend continuum mixture theory (Atkin & Craine Reference Atkin and Craine1976) beyond segregation in S- and D-systems (Bridgwater, Foo & Stephens Reference Bridgwater, Foo and Stephens1985; Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Gray & Thornton Reference Gray and Thornton2005; Fan & Hill Reference Fan and Hill2011) to model segregation in SD-systems (Marks et al. Reference Marks, Rognon and Einav2012; Tunuguntla et al. Reference Tunuguntla, Bokhove and Thornton2014; Gray & Ancey Reference Gray and Ancey2015). The fundamental mechanisms on which these models are formulated (i.e. partial stresses, interspecies drag) are not fully understood, and studies show that some assumptions in the theory do not match results obtained from DEM simulations (Weinhart, Luding & Thornton Reference Weinhart, Luding and Thornton2013; Tunuguntla, Weinhart & Thornton Reference Tunuguntla, Weinhart and Thornton2017; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020). A more fundamental approach is based on interparticle interactions (i.e. kinetic theory of granular flows) (Arnarson & Jenkins Reference Arnarson and Jenkins2004; Larcher & Jenkins Reference Larcher and Jenkins2013, Reference Larcher and Jenkins2015). However, this approach is limited to mixtures that differ little in particle size or mass and it tends to underestimate the segregation rate (Larcher & Jenkins Reference Larcher and Jenkins2015).

As an alternative, we consider a transport equation approach combined with a mixture-specific segregation velocity model that has previously been used to predict either size or density segregation alone (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016). This approach has been successfully applied to various flow geometries as well as multidisperse and polydisperse particle distributions (Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019), but has not yet been applied to SD-systems where the particles species differ in both size and density. In this model, the local segregation velocity of species ![]() $i$ normal to the free surface is defined as

$i$ normal to the free surface is defined as ![]() $w_{seg,i}=w_i-w$, where

$w_{seg,i}=w_i-w$, where ![]() $w$ is the bulk surface-normal velocity,

$w$ is the bulk surface-normal velocity, ![]() $w_i$ is surface-normal velocity of species

$w_i$ is surface-normal velocity of species ![]() $i$ and concentration-gradient-driven effects are ignored. For bidisperse mixtures of non-cohesive millimetre-sized particles varying in a single property (either size or density), previous studies (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015a; Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016) show that

$i$ and concentration-gradient-driven effects are ignored. For bidisperse mixtures of non-cohesive millimetre-sized particles varying in a single property (either size or density), previous studies (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015a; Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016) show that ![]() $w_{seg,i}$ (previously referred as

$w_{seg,i}$ (previously referred as ![]() $w_{p,i}$ where the

$w_{p,i}$ where the ![]() $p$ subscript is a remnant of the initial application to the percolation velocity in size-disperse systems) can be modelled with reasonable fidelity using

$p$ subscript is a remnant of the initial application to the percolation velocity in size-disperse systems) can be modelled with reasonable fidelity using

where ![]() $d_s$ is the small particle diameter (

$d_s$ is the small particle diameter (![]() $d_s=d_l$ for D-systems),

$d_s=d_l$ for D-systems), ![]() $\dot \gamma$ is the local shear rate,

$\dot \gamma$ is the local shear rate, ![]() $1-c_i$ is the local concentration of the other species comprising the mixture, and the segregation coefficient,

$1-c_i$ is the local concentration of the other species comprising the mixture, and the segregation coefficient, ![]() $A$, is a function of particle size or density ratio for the two species. Equation (1.1) provides an accurate description of the segregation velocity in most situations, but can fall short under certain conditions. First, recent studies indicate that segregation flux,

$A$, is a function of particle size or density ratio for the two species. Equation (1.1) provides an accurate description of the segregation velocity in most situations, but can fall short under certain conditions. First, recent studies indicate that segregation flux, ![]() $\varPhi _{seg,i}=w_{seg,i}c_i$, has an underlying asymmetry (van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018) that depends on local particle concentration (i.e. small (or heavy) particles among mostly large (or light) particles segregate faster than the other way around), whereas (1.1) predicts a segregation flux dependence on concentration that is symmetric with respect to

$\varPhi _{seg,i}=w_{seg,i}c_i$, has an underlying asymmetry (van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018) that depends on local particle concentration (i.e. small (or heavy) particles among mostly large (or light) particles segregate faster than the other way around), whereas (1.1) predicts a segregation flux dependence on concentration that is symmetric with respect to ![]() $c_i=0.5$. Second, (1.1) does not consider size and density ratios simultaneously. That is,

$c_i=0.5$. Second, (1.1) does not consider size and density ratios simultaneously. That is, ![]() $A$ has been expressed as a function of either the size ratio alone (Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015a) (or volume ratio for non-spherical particles Jones et al. (Reference Jones, Ottino, Umbanhowar and Lueptow2020)) in S-systems or the density ratio alone (Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016) in D-systems, but not both. As granular materials of practical interest can vary in both size and density, a more general segregation velocity model is needed.

$A$ has been expressed as a function of either the size ratio alone (Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015a) (or volume ratio for non-spherical particles Jones et al. (Reference Jones, Ottino, Umbanhowar and Lueptow2020)) in S-systems or the density ratio alone (Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016) in D-systems, but not both. As granular materials of practical interest can vary in both size and density, a more general segregation velocity model is needed.

To address the observed asymmetry of the segregation velocity at equal concentrations for size segregation in chute flows, Gajjar & Gray (Reference Gajjar and Gray2014) proposed a flux model equivalent to a two-parameter quadratic form for the segregation velocity,

where ![]() $A_\kappa$ is a magnitude coefficient and

$A_\kappa$ is a magnitude coefficient and ![]() $\kappa$ is an asymmetry coefficient. Jones et al. (Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018) showed that this model characterizes both size- and density-bidisperse mixtures over a wide range of size or density ratios, and expressed (1.2) in a form consistent with the linear segregation velocity model of (1.1) as

$\kappa$ is an asymmetry coefficient. Jones et al. (Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018) showed that this model characterizes both size- and density-bidisperse mixtures over a wide range of size or density ratios, and expressed (1.2) in a form consistent with the linear segregation velocity model of (1.1) as

where ![]() $A_i$ and

$A_i$ and ![]() $B_i$ can be determined from bidisperse heap flow simulations for a wide range of size or density ratios. Comparison of (1.1) and (1.3) is enlightening. Both forms depend on the product of the small particle diameter, the local shear rate and the concentration of the other species, i.e.

$B_i$ can be determined from bidisperse heap flow simulations for a wide range of size or density ratios. Comparison of (1.1) and (1.3) is enlightening. Both forms depend on the product of the small particle diameter, the local shear rate and the concentration of the other species, i.e. ![]() $d_s\dot \gamma (1-c_i)$. Furthermore, the quadratic model has a two-parameter, concentration dependent term

$d_s\dot \gamma (1-c_i)$. Furthermore, the quadratic model has a two-parameter, concentration dependent term ![]() $A_{i}+B_{i}(1-c_i)$ instead of the concentration independent coefficient

$A_{i}+B_{i}(1-c_i)$ instead of the concentration independent coefficient ![]() $A$ in the linear model.

$A$ in the linear model.

In order to model combined size and density segregation, it is necessary to find an expression for the segregation velocity in a bidisperse mixture of particles accounting for both particle size and density. To do this, we perform DEM simulations of particle mixtures having a wide range of particle properties, varying in both size and density, in the canonical free surface flow of a quasi-two-dimensional (quasi-2-D) bounded heap flow. The advantage of this flow geometry is that it is simple to implement, is steady in a frame of reference rising with the heap surface, and generates a wide range of segregation velocities, shear rates and concentrations in a single simulation. Because of our previous success with (1.3), we focus on this model for the combined size and density segregation, knowing that this equation accurately reflects the segregation velocity in the limits of pure size-driven or pure density-driven segregation over a range of concentrations.

Discrete element method simulation of quasi-2-D single-sided bounded heap flow for size and density bidisperse mixtures is described in § 2. Based on simulation results, a segregation velocity model analogous to (1.3) is extended to SD-systems in § 3. Using this model, it is possible to predict the combination of size ratio, density ratio and concentration that minimizes segregation, an important result in practical engineering systems to assure that particle mixtures remain mixed. In § 4, the continuum advection–diffusion–segregation transport equation is solved using the combined size and density segregation model to demonstrate that the model predictions match the simulation results for a range of feed rates, feed concentrations and heap geometries. Conclusions are given in § 5.

2. Simulation

We numerically simulate combined size and density segregation of bidisperse mixtures in a single-sided quasi-2-D bounded heap where particles flow in a thin surface layer down a slope much like the flow that occurs when filling a silo. An advantage of heap flows over other flow configurations (e.g. plane shear flows and chute flows) is that the local shear rate and the particle species concentration vary throughout the length and depth of a steady flowing layer but remain constant at a particular location in the flow (when analysed from a reference frame that rises with the heap surface), such that time-averaged segregation data for a wide range of flow conditions can be obtained from just one simulation. Segregation model parameters obtained from the steady single-sided quasi-2-D bounded heap geometry are universal in that they can be applied to unsteady flows and other flow geometries (Schlick et al. Reference Schlick, Fan, Umbanhowar, Ottino and Lueptow2015b; Deng et al. Reference Deng, Umbanhowar, Ottino and Lueptow2019; Xiao et al. Reference Xiao, Fan, Jacob, Umbanhowar, Kodam, Koch and Lueptow2019; Deng et al. Reference Deng, Fan, Theuerkauf, Jacob, Umbanhowar and Lueptow2020; Isner et al. Reference Isner, Umbanhowar, Ottino and Lueptow2020a). In this study, we conduct more than 350 simulations with different combinations of particle size and density ratios in developing the SD-disperse segregation model.

Our in-house DEM code (Isner et al. Reference Isner, Umbanhowar, Ottino and Lueptow2020a,Reference Isner, Umbanhowar, Ottino and Lueptowb) runs on CUDA-enabled GPUs and has been previously validated by heap flow experiments with millimetre-sized particles (Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016; Isner et al. Reference Isner, Umbanhowar, Ottino and Lueptow2020b). The bounded heap example shown in figure 1 is confined by two parallel plates in the spanwise (normal to the ![]() $xz$-plane) direction with a gap thickness of

$xz$-plane) direction with a gap thickness of ![]() $T=15$ mm. The heap width between the bounding endwalls is

$T=15$ mm. The heap width between the bounding endwalls is ![]() $W=0.5$ m. To reduce the number of simulated particles and save computation time, the bottom wall is inclined at an angle

$W=0.5$ m. To reduce the number of simulated particles and save computation time, the bottom wall is inclined at an angle ![]() $\beta =28^\circ$, roughly matching the dynamic repose angle

$\beta =28^\circ$, roughly matching the dynamic repose angle ![]() $\alpha$ in steady state. To create a rough bottom boundary, particles that contact the bottom wall are immobilized. After the particle bed exceeds 10–15 particle diameters in depth, the velocity and concentration profiles in the flowing layer become steady, indicating that effects of the bottom boundary can be neglected.

$\alpha$ in steady state. To create a rough bottom boundary, particles that contact the bottom wall are immobilized. After the particle bed exceeds 10–15 particle diameters in depth, the velocity and concentration profiles in the flowing layer become steady, indicating that effects of the bottom boundary can be neglected.

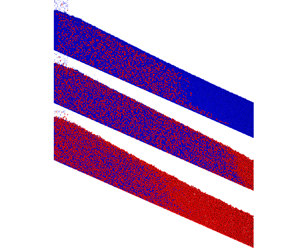

Figure 1. Quasi-2-D bounded heap simulation set-up and segregation example. For these conditions, large heavy particles (red, ![]() $d_l=3$ mm,

$d_l=3$ mm, ![]() $\rho _l=4$ g cm

$\rho _l=4$ g cm![]() $^{-3}$) sink while small, light particles (blue,

$^{-3}$) sink while small, light particles (blue, ![]() $d_s=1.5$ mm,

$d_s=1.5$ mm, ![]() $\rho _s=1$ g cm

$\rho _s=1$ g cm![]() $^{-3}$) rise. Segregation occurs in the flowing layer, which is outlined schematically by the white rectangle (the thickness is exaggerated by a factor of approximately two to make it more visible). Here,

$^{-3}$) rise. Segregation occurs in the flowing layer, which is outlined schematically by the white rectangle (the thickness is exaggerated by a factor of approximately two to make it more visible). Here, ![]() $R_d=2$,

$R_d=2$, ![]() $R_\rho =4$,

$R_\rho =4$, ![]() $W_f=3.3$ cm,

$W_f=3.3$ cm, ![]() $W=50$ cm,

$W=50$ cm, ![]() $L=52$ cm,

$L=52$ cm, ![]() $q=20$ cm

$q=20$ cm![]() $^2$ s

$^2$ s![]() $^{-1}$,

$^{-1}$, ![]() $\delta =1.5$ cm and large particle feed concentration

$\delta =1.5$ cm and large particle feed concentration ![]() $\hat c_l=0.2$.

$\hat c_l=0.2$.

For all simulations, particle–particle and particle–wall contacts use a friction coefficient of ![]() $\mu =0.4$, a binary collision time of

$\mu =0.4$, a binary collision time of ![]() $t_c=0.5$ ms and a restitution coefficient of

$t_c=0.5$ ms and a restitution coefficient of ![]() $e=0.2$. Here we choose

$e=0.2$. Here we choose ![]() $e=0.2$ to minimize particle bouncing in the DEM simulations, a factor that is not considered in the later analysis. Previous results indicate that the flow kinematics and the particle segregation for free surface flows such as those considered here are largely independent of

$e=0.2$ to minimize particle bouncing in the DEM simulations, a factor that is not considered in the later analysis. Previous results indicate that the flow kinematics and the particle segregation for free surface flows such as those considered here are largely independent of ![]() $e$ (Silbert et al. Reference Silbert, Ertaş, Grest, Halsey, Levine and Plimpton2001; Jing, Kwok & Leung Reference Jing, Kwok and Leung2017; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020; Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2020). To fully resolve particle collisions, the DEM simulation time step is

$e$ (Silbert et al. Reference Silbert, Ertaş, Grest, Halsey, Levine and Plimpton2001; Jing, Kwok & Leung Reference Jing, Kwok and Leung2017; Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020; Jing et al. Reference Jing, Ottino, Lueptow and Umbanhowar2020). To fully resolve particle collisions, the DEM simulation time step is ![]() $t_c/50$ (Silbert et al. Reference Silbert, Ertaş, Grest, Halsey, Levine and Plimpton2001; Duan & Feng Reference Duan and Feng2017, Reference Duan and Feng2019). The particle contact model (Cundall & Strack Reference Cundall and Strack1979; Shäfer, Dippel & Wolf Reference Shäfer, Dippel and Wolf1996; Weinhart et al. Reference Weinhart2020) is detailed in the supplementary material are available at https://doi.org/10.1017/jfm.2021.342.

$t_c/50$ (Silbert et al. Reference Silbert, Ertaş, Grest, Halsey, Levine and Plimpton2001; Duan & Feng Reference Duan and Feng2017, Reference Duan and Feng2019). The particle contact model (Cundall & Strack Reference Cundall and Strack1979; Shäfer, Dippel & Wolf Reference Shäfer, Dippel and Wolf1996; Weinhart et al. Reference Weinhart2020) is detailed in the supplementary material are available at https://doi.org/10.1017/jfm.2021.342.

Flow conditions and particle properties differentiated by subscript ![]() $i$ (

$i$ (![]() $i=l$ for large particles and

$i=l$ for large particles and ![]() $i=s$ for small particles regardless of their densities) are listed in table 1. For a given species, the particle diameter

$i=s$ for small particles regardless of their densities) are listed in table 1. For a given species, the particle diameter ![]() $d_i$ is uniformly distributed with a variance of

$d_i$ is uniformly distributed with a variance of ![]() $\pm 0.1d_i$ to reduce ordering, except where noted. A well-mixed bidisperse stream of particles with a feed concentration of large particles,

$\pm 0.1d_i$ to reduce ordering, except where noted. A well-mixed bidisperse stream of particles with a feed concentration of large particles, ![]() $\hat c_l$, (and corresponding small particle feed concentration

$\hat c_l$, (and corresponding small particle feed concentration ![]() $\hat c_s=1-\hat c_l$) is continuously fed into the system from a relatively low height of 4 cm above the rising free surface to reduce bouncing in a

$\hat c_s=1-\hat c_l$) is continuously fed into the system from a relatively low height of 4 cm above the rising free surface to reduce bouncing in a ![]() $3.3$ cm (11

$3.3$ cm (11![]() $d_l$) long feed zone (

$d_l$) long feed zone (![]() $W_f$). Based on volume conservation, the free surface rises at a vertical rise velocity of

$W_f$). Based on volume conservation, the free surface rises at a vertical rise velocity of ![]() $v_r=Q/WT$, where

$v_r=Q/WT$, where ![]() $Q$ is the volumetric feed rate. The flowing layer length is

$Q$ is the volumetric feed rate. The flowing layer length is ![]() $L=W/\cos (\alpha )$, and an effective 2-D feed rate is defined as

$L=W/\cos (\alpha )$, and an effective 2-D feed rate is defined as ![]() $q=Q/T$.

$q=Q/T$.

Table 1. Simulation parameters.

In a reference frame rising with the flowing layer, the origin of the coordinate system is located on the free surface at the front wall at the downstream (right) edge of the vertical feed region with ![]() $x$,

$x$, ![]() $y$ and

$y$ and ![]() $z$ oriented in the streamwise, spanwise and normal directions, respectively. To characterize the flow, the velocity field,

$z$ oriented in the streamwise, spanwise and normal directions, respectively. To characterize the flow, the velocity field, ![]() $\pmb u=u \hat x +v \hat y +w \hat z$ (noting that no subscript is used for variables representing the mixture) and species concentration,

$\pmb u=u \hat x +v \hat y +w \hat z$ (noting that no subscript is used for variables representing the mixture) and species concentration, ![]() $c_i$, are calculated from spatial and temporal averages of simulation data in the flowing layer. To compute the spatial average, we use a volume-weighted binning method (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2013) with right cuboid bins oriented with two faces parallel to the free surface, two faces perpendicular to the free surface and two faces parallel to the sidewalls. Each bin has a streamwise length of

$c_i$, are calculated from spatial and temporal averages of simulation data in the flowing layer. To compute the spatial average, we use a volume-weighted binning method (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2013) with right cuboid bins oriented with two faces parallel to the free surface, two faces perpendicular to the free surface and two faces parallel to the sidewalls. Each bin has a streamwise length of ![]() $1$ cm (3.33

$1$ cm (3.33![]() $d_l$) and a height (normal to the free surface) of

$d_l$) and a height (normal to the free surface) of ![]() $1$ mm (0.33

$1$ mm (0.33![]() $d_l$). Since particles can overlap multiple bins, the partial volumes of particles are applied to the appropriate bin for averaging purposes. As such, the species concentration is defined as

$d_l$). Since particles can overlap multiple bins, the partial volumes of particles are applied to the appropriate bin for averaging purposes. As such, the species concentration is defined as

\begin{equation} c_i=\frac{\displaystyle\sum _{k\in i}^{N_i} V_{k} }{\displaystyle\sum _{k=1}^{N} V_k },\end{equation}

\begin{equation} c_i=\frac{\displaystyle\sum _{k\in i}^{N_i} V_{k} }{\displaystyle\sum _{k=1}^{N} V_k },\end{equation}

where ![]() $N_i$ and

$N_i$ and ![]() $N$ are the number of particles of species

$N$ are the number of particles of species ![]() $i$ and the total number of particles in the bin, respectively and

$i$ and the total number of particles in the bin, respectively and ![]() $V_{k}$ is the volume of particle

$V_{k}$ is the volume of particle ![]() $k$ in the bin. The mean velocity of species

$k$ in the bin. The mean velocity of species ![]() $i$ is calculated as the sum of volume-weighted velocities,

$i$ is calculated as the sum of volume-weighted velocities,

\begin{equation} \pmb u_{i}=\frac{\displaystyle\sum_{k\in i}^{N_i} \pmb u_{k} V_{k} }{\displaystyle\sum_{k\in i}^{N_i} V_k},\end{equation}

\begin{equation} \pmb u_{i}=\frac{\displaystyle\sum_{k\in i}^{N_i} \pmb u_{k} V_{k} }{\displaystyle\sum_{k\in i}^{N_i} V_k},\end{equation}

where ![]() $\pmb u_{k}$ is the vector velocity of particle

$\pmb u_{k}$ is the vector velocity of particle ![]() $k$. The bulk flow velocity,

$k$. The bulk flow velocity, ![]() $\pmb u$, is determined as

$\pmb u$, is determined as ![]() $\pmb u=\sum \pmb u_ic_i$. To perform the temporal average, the concentration and velocity values of each bin are averaged over 5 s at intervals of

$\pmb u=\sum \pmb u_ic_i$. To perform the temporal average, the concentration and velocity values of each bin are averaged over 5 s at intervals of ![]() $0.01$ s after flow reaches steady state. Note that an alternative expression for the bulk velocity,

$0.01$ s after flow reaches steady state. Note that an alternative expression for the bulk velocity, ![]() $\pmb u=\sum \pmb u_i \rho _i c_i/\sum \rho _i c_i$, can be calculated based on the sum of mass-weighted velocities instead of volume-weighted velocities in (2.2). In previous research utilizing the framework of mixture theory (Gray & Ancey Reference Gray and Ancey2015), the segregation velocity was derived from mass and momentum conservation, which requires an evolving bulk density along with mass-weighted mean velocities for density disperse mixtures. Here we assume that volume is approximately conserved, which is equivalent to assuming a nearly constant volume fraction. This allows us to use

$\pmb u=\sum \pmb u_i \rho _i c_i/\sum \rho _i c_i$, can be calculated based on the sum of mass-weighted velocities instead of volume-weighted velocities in (2.2). In previous research utilizing the framework of mixture theory (Gray & Ancey Reference Gray and Ancey2015), the segregation velocity was derived from mass and momentum conservation, which requires an evolving bulk density along with mass-weighted mean velocities for density disperse mixtures. Here we assume that volume is approximately conserved, which is equivalent to assuming a nearly constant volume fraction. This allows us to use ![]() $\pmb u=\sum \pmb u_i c_i$ instead of mass-weighted velocities. And because heap flow kinematics are nearly independent of particle size and density and species concentration as shown in § 4, it is possible to use a volume-based transport equation to model the segregation.

$\pmb u=\sum \pmb u_i c_i$ instead of mass-weighted velocities. And because heap flow kinematics are nearly independent of particle size and density and species concentration as shown in § 4, it is possible to use a volume-based transport equation to model the segregation.

In quasi-2-D bounded heap flow, segregation mainly occurs in the ![]() $z$-direction (normal to the free surface), as noted in previous studies (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Schlick et al. Reference Schlick, Fan, Umbanhowar, Ottino and Lueptow2015b; Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016; Deng et al. Reference Deng, Umbanhowar, Ottino and Lueptow2018). Furthermore, an advection–diffusion transport equation has been successfully used to model the segregation (Bridgwater et al. Reference Bridgwater, Foo and Stephens1985; Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Gray Reference Gray2018; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019). Within this continuum framework, the concentration of species

$z$-direction (normal to the free surface), as noted in previous studies (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Schlick et al. Reference Schlick, Fan, Umbanhowar, Ottino and Lueptow2015b; Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016; Deng et al. Reference Deng, Umbanhowar, Ottino and Lueptow2018). Furthermore, an advection–diffusion transport equation has been successfully used to model the segregation (Bridgwater et al. Reference Bridgwater, Foo and Stephens1985; Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Gray Reference Gray2018; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019). Within this continuum framework, the concentration of species ![]() $i$ can be expressed as

$i$ can be expressed as

Here, the local collisional diffusion coefficient ![]() $D$ is a scalar, although in general it is a tensor. This approximation is accurate for flows with a single dominant shear direction (Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019). Here,

$D$ is a scalar, although in general it is a tensor. This approximation is accurate for flows with a single dominant shear direction (Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019). Here, ![]() $\pmb u^*_i$ represents the diffusionless mean velocity of species

$\pmb u^*_i$ represents the diffusionless mean velocity of species ![]() $i$, which differs from the overall mean velocity,

$i$, which differs from the overall mean velocity, ![]() $\pmb u_i$, determined from simulation according to (2.2). Since there is no net motion of species in the spanwise (

$\pmb u_i$, determined from simulation according to (2.2). Since there is no net motion of species in the spanwise (![]() $y$) direction (i.e. zero spanwise velocity

$y$) direction (i.e. zero spanwise velocity ![]() $v_i=0$), the other velocity components of species

$v_i=0$), the other velocity components of species ![]() $i$ are written most generally as

$i$ are written most generally as ![]() $u^*_i= u + u_{seg,i}$ and

$u^*_i= u + u_{seg,i}$ and ![]() $w^*_i=w+w_{seg,i}$, where

$w^*_i=w+w_{seg,i}$, where ![]() $u_{seg,i}$ and

$u_{seg,i}$ and ![]() $w_{seg,i}$ are the components of the gravity-driven segregation velocity of species

$w_{seg,i}$ are the components of the gravity-driven segregation velocity of species ![]() $i$ relative to the mean flow velocity. However, for the quasi-2-D bounded heap and most other free surface flows,

$i$ relative to the mean flow velocity. However, for the quasi-2-D bounded heap and most other free surface flows, ![]() $u_{seg,i} \ll u$ so that

$u_{seg,i} \ll u$ so that ![]() $u^*_i$ can be accurately approximated by

$u^*_i$ can be accurately approximated by ![]() $u$ (Deng et al. Reference Deng, Umbanhowar, Ottino and Lueptow2018). With these assumptions, (2.3) can be written as

$u$ (Deng et al. Reference Deng, Umbanhowar, Ottino and Lueptow2018). With these assumptions, (2.3) can be written as

or, rearranging, as

\begin{equation} \frac{\partial c_i}{\partial t} + \frac{\partial{u c_i}}{\partial x}+\frac{\partial \left[wc_i+w_{seg,i}c_i-D\dfrac{\partial c_i}{\partial z} \right]}{\partial z}=\frac{\partial}{\partial x} \left( D\frac{\partial c_i}{\partial x} \right). \end{equation}

\begin{equation} \frac{\partial c_i}{\partial t} + \frac{\partial{u c_i}}{\partial x}+\frac{\partial \left[wc_i+w_{seg,i}c_i-D\dfrac{\partial c_i}{\partial z} \right]}{\partial z}=\frac{\partial}{\partial x} \left( D\frac{\partial c_i}{\partial x} \right). \end{equation}

When the normal component of flux for species ![]() $i$ is measured from DEM simulation, it is the entire quantity within the brackets of (2.5) that is measured. In other words, the measured normal flux

$i$ is measured from DEM simulation, it is the entire quantity within the brackets of (2.5) that is measured. In other words, the measured normal flux ![]() $\varPhi _{i}=w_{i}c_i$ is driven by three distinct mechanisms: advection (

$\varPhi _{i}=w_{i}c_i$ is driven by three distinct mechanisms: advection (![]() $\varPhi _{adv,i}=wc_i$), segregation (

$\varPhi _{adv,i}=wc_i$), segregation (![]() $\varPhi _{seg,i}=w_{seg,i}c_i$) and diffusion (

$\varPhi _{seg,i}=w_{seg,i}c_i$) and diffusion (![]() $\varPhi _{D,i}=-D\partial c_i/\partial z$), and can be written as

$\varPhi _{D,i}=-D\partial c_i/\partial z$), and can be written as

Previous studies indicate that ![]() $\varPhi _{D,i}$ is typically small compared with the segregation flux,

$\varPhi _{D,i}$ is typically small compared with the segregation flux, ![]() $\varPhi _{seg,i}$ (i.e.

$\varPhi _{seg,i}$ (i.e. ![]() $\varPhi _{D,i}<0.1\varPhi _{seg,i}$) for size (or density) only segregation (Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018). As such, the segregation velocity is expressed simply as

$\varPhi _{D,i}<0.1\varPhi _{seg,i}$) for size (or density) only segregation (Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018). As such, the segregation velocity is expressed simply as ![]() $w_{seg,i}\approx w_{i}-w$ (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015a; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018). However, for the combined size and density segregation considered here, the opposing effects of size and density differences can result in very weak segregation. As a result, the concurrent concentration gradient driven diffusion flux,

$w_{seg,i}\approx w_{i}-w$ (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015a; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018). However, for the combined size and density segregation considered here, the opposing effects of size and density differences can result in very weak segregation. As a result, the concurrent concentration gradient driven diffusion flux, ![]() $\varPhi _{D,i}$, can be similar in magnitude to the segregation flux,

$\varPhi _{D,i}$, can be similar in magnitude to the segregation flux, ![]() $\varPhi _{seg,i}$. Thus, it is necessary to include all three terms when calculating the segregation velocity. Using (2.1) and (2.2),

$\varPhi _{seg,i}$. Thus, it is necessary to include all three terms when calculating the segregation velocity. Using (2.1) and (2.2), ![]() $w_i$,

$w_i$, ![]() $w$ and

$w$ and ![]() $c_i$ can be readily calculated from simulations, so the segregation velocity can be determined as

$c_i$ can be readily calculated from simulations, so the segregation velocity can be determined as

Like all the other variables on the right-hand side of (2.7), the diffusion coefficient ![]() $D$ is determined directly from simulation as the mean-square displacement (

$D$ is determined directly from simulation as the mean-square displacement (![]() $MSD$) in the normal direction of every particle in a bin over a period

$MSD$) in the normal direction of every particle in a bin over a period ![]() ${\rm \Delta} t$ (Utter & Behringer Reference Utter and Behringer2004; Wandersman, Dijksman & Van Hecke Reference Wandersman, Dijksman and Van Hecke2012; Fan et al. Reference Fan, Umbanhowar, Ottino and Lueptow2015),

${\rm \Delta} t$ (Utter & Behringer Reference Utter and Behringer2004; Wandersman, Dijksman & Van Hecke Reference Wandersman, Dijksman and Van Hecke2012; Fan et al. Reference Fan, Umbanhowar, Ottino and Lueptow2015),

\begin{equation} MSD_z({\rm \Delta} t)=\frac{1}{N}\sum_{k=1}^{N}[z_k(t+{\rm \Delta} t)-z_k(t)-L({\rm \Delta} t)]^2. \end{equation}

\begin{equation} MSD_z({\rm \Delta} t)=\frac{1}{N}\sum_{k=1}^{N}[z_k(t+{\rm \Delta} t)-z_k(t)-L({\rm \Delta} t)]^2. \end{equation}

Here, ![]() $z_k(t+{\rm \Delta} t)-z_k(t)$ is the displacement of particle

$z_k(t+{\rm \Delta} t)-z_k(t)$ is the displacement of particle ![]() $k$ in the bin in a time interval

$k$ in the bin in a time interval ![]() ${\rm \Delta} t$, and

${\rm \Delta} t$, and ![]() $L({\rm \Delta} t)$ is the mean cumulative displacement of particles in the bin due to the bulk flow in the

$L({\rm \Delta} t)$ is the mean cumulative displacement of particles in the bin due to the bulk flow in the ![]() $z$-direction. The

$z$-direction. The ![]() $MSD_z$ values of each bin for

$MSD_z$ values of each bin for ![]() ${\rm \Delta} t$ are averaged over 200 distinct times

${\rm \Delta} t$ are averaged over 200 distinct times ![]() $t$ at intervals of 0.25 s, consistent with the 5 s sampling window for calculating the concentration and velocity fields. Similar to previous results (Fan et al. Reference Fan, Umbanhowar, Ottino and Lueptow2015),

$t$ at intervals of 0.25 s, consistent with the 5 s sampling window for calculating the concentration and velocity fields. Similar to previous results (Fan et al. Reference Fan, Umbanhowar, Ottino and Lueptow2015), ![]() $MSD_z$ data are linear in

$MSD_z$ data are linear in ![]() ${\rm \Delta} t$ for

${\rm \Delta} t$ for ![]() $0.05\ \text {s}<{\rm \Delta} t<0.3$ s, indicating diffusive behaviour. The diffusion coefficient

$0.05\ \text {s}<{\rm \Delta} t<0.3$ s, indicating diffusive behaviour. The diffusion coefficient ![]() $D$ is then estimated as one half the slope of a linear fit of

$D$ is then estimated as one half the slope of a linear fit of ![]() $MSD_z$ versus

$MSD_z$ versus ![]() ${\rm \Delta} t$ (Utter & Behringer Reference Utter and Behringer2004; Fan et al. Reference Fan, Umbanhowar, Ottino and Lueptow2015). Further details are provided in the supplementary material.

${\rm \Delta} t$ (Utter & Behringer Reference Utter and Behringer2004; Fan et al. Reference Fan, Umbanhowar, Ottino and Lueptow2015). Further details are provided in the supplementary material.

3. Segregation velocity

To illustrate the interplay between size and density, consider a bidisperse mixture of particles with ![]() $R_d=2$ and

$R_d=2$ and ![]() $R_\rho =4$. Since in this case the large particles are also heavier particles, size and density segregation oppose one another. It is also a case in which the rising and sinking behaviour of each species has been shown to depend on the relative concentration of the two species based on experiments in a rotating tumbler (Alonso et al. Reference Alonso, Satoh and Miyanami1991). In their experiments, LH particles segregate to the core of the tumbler bed at low global (mixture) concentrations and segregate to the periphery of the bed at high concentrations.

$R_\rho =4$. Since in this case the large particles are also heavier particles, size and density segregation oppose one another. It is also a case in which the rising and sinking behaviour of each species has been shown to depend on the relative concentration of the two species based on experiments in a rotating tumbler (Alonso et al. Reference Alonso, Satoh and Miyanami1991). In their experiments, LH particles segregate to the core of the tumbler bed at low global (mixture) concentrations and segregate to the periphery of the bed at high concentrations.

Figure 2 shows the analogous situation in DEM simulations of the same bidisperse particle mixture in bounded heap flow. Varying the feed concentration of large particles ![]() $\hat c_l$ significantly alters the composition of the mixture deposited on the heap just as it does for the rotating tumbler experiments. Specifically, LH particles deposit in the upstream portion of the heap for low feed concentrations (analogous to segregating to the core of the tumbler) and deposit in the downstream portion of the heap at high feed concentrations (analogous to segregating to the tumbler periphery). As is shown below in more detail, this reversal in behaviour occurs because the local segregation flux of the two species depends on their local concentrations. This dependence of the segregation flux on concentration is different from that in either S- or D-systems. In S-systems, the greatest segregation flux occurs for large particle concentrations of approximately 0.6 for this diameter ratio (

$\hat c_l$ significantly alters the composition of the mixture deposited on the heap just as it does for the rotating tumbler experiments. Specifically, LH particles deposit in the upstream portion of the heap for low feed concentrations (analogous to segregating to the core of the tumbler) and deposit in the downstream portion of the heap at high feed concentrations (analogous to segregating to the tumbler periphery). As is shown below in more detail, this reversal in behaviour occurs because the local segregation flux of the two species depends on their local concentrations. This dependence of the segregation flux on concentration is different from that in either S- or D-systems. In S-systems, the greatest segregation flux occurs for large particle concentrations of approximately 0.6 for this diameter ratio (![]() $R_d=2$). Likewise, for D-systems, the greatest segregation flux occurs for heavy particle concentrations of approximately 0.4 for this density ratio (

$R_d=2$). Likewise, for D-systems, the greatest segregation flux occurs for heavy particle concentrations of approximately 0.4 for this density ratio (![]() $R_\rho =4$) (Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018). For the cases shown in figure 2 the direction of the segregation flux depends on concentration. The LH particles segregate downward at low concentrations and segregate upward at high concentrations. Hence, in figure 2(a) the low concentration LH particles segregate downward and deposit along with fewer SL particles on the upstream portion of heap until LH particles are depleted, leaving only SL particles. In figure 2(c), the high concentration LH particles segregate upward so that the SL particles deposit along with fewer LH particles on the upstream portion of the heap until the SL particles are depleted. Figure 2(b) shows an intermediate case where percolation is only slightly stronger than buoyancy.

$R_\rho =4$) (Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018). For the cases shown in figure 2 the direction of the segregation flux depends on concentration. The LH particles segregate downward at low concentrations and segregate upward at high concentrations. Hence, in figure 2(a) the low concentration LH particles segregate downward and deposit along with fewer SL particles on the upstream portion of heap until LH particles are depleted, leaving only SL particles. In figure 2(c), the high concentration LH particles segregate upward so that the SL particles deposit along with fewer LH particles on the upstream portion of the heap until the SL particles are depleted. Figure 2(b) shows an intermediate case where percolation is only slightly stronger than buoyancy.

Figure 2. Heap flow segregation for large particle feed concentration ![]() $\hat c_l$ of (a) 0.2, (b) 0.5 and (c) 0.8. Large heavy particles (red,

$\hat c_l$ of (a) 0.2, (b) 0.5 and (c) 0.8. Large heavy particles (red, ![]() $d_l=3$ mm,

$d_l=3$ mm, ![]() $\rho _l=4$ g cm

$\rho _l=4$ g cm![]() $^{-3}$) sink while small light particles (blue,

$^{-3}$) sink while small light particles (blue, ![]() $d_s=1.5$ mm,

$d_s=1.5$ mm, ![]() $\rho _s=1$ g cm

$\rho _s=1$ g cm![]() $^{-3}$) rise for

$^{-3}$) rise for ![]() $\hat c_l=$0.2, as buoyancy overcomes percolation. In contrast, for

$\hat c_l=$0.2, as buoyancy overcomes percolation. In contrast, for ![]() $\hat c_l=$0.5 and 0.8 segregation reverses as percolation dominates over buoyancy. Here,

$\hat c_l=$0.5 and 0.8 segregation reverses as percolation dominates over buoyancy. Here, ![]() $R_d=2$,

$R_d=2$, ![]() $R_\rho =4$,

$R_\rho =4$, ![]() $W=50$ cm,

$W=50$ cm, ![]() $q=20$ cm

$q=20$ cm![]() $^2$ s

$^2$ s![]() $^{-1}$.

$^{-1}$.

To quantify the segregation for the cases shown in figure 2, it is necessary to use (2.7) to find the segregation velocity, which requires knowledge of ![]() $c_i$,

$c_i$, ![]() $w_i$,

$w_i$, ![]() $w$ and

$w$ and ![]() $D$ found as functions of position using (2.1), (2.2) and (2.8). Segregation occurs in the surface layer having length

$D$ found as functions of position using (2.1), (2.2) and (2.8). Segregation occurs in the surface layer having length ![]() $L=W/\cos (\alpha )$ and local thickness

$L=W/\cos (\alpha )$ and local thickness ![]() $\delta (x)$, which is defined here as the depth at which the streamwise velocity is 1/10th its surface value, i.e.

$\delta (x)$, which is defined here as the depth at which the streamwise velocity is 1/10th its surface value, i.e. ![]() $u(x,-\delta )=0.1u(x,0)$. The location of the flow surface at each streamwise position is estimated based on a cutoff value of solids fraction

$u(x,-\delta )=0.1u(x,0)$. The location of the flow surface at each streamwise position is estimated based on a cutoff value of solids fraction ![]() $\phi _c=0.35$ (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2013) to exclude bouncing particles near the free surface.

$\phi _c=0.35$ (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2013) to exclude bouncing particles near the free surface.

The streamwise velocity, surface-normal velocity, species-specific velocity relative to the bulk, large particle concentration and collisional diffusion coefficient, which are needed to calculate and model the segregation, are shown in figure 3. The rectangular region above the white line corresponds to the flowing layer shown schematically in figure 1. Figure 3(a) shows the local streamwise velocity, which is greatest at the surface and decreases moving downstream and deeper in the flow. The local flowing layer depth, ![]() $\delta (x)$, shown by the dashed curve, remains almost constant for most of the length of flowing layer, except near the downstream bounding endwall where it decreases slightly. Although a varying flowing layer thickness can be implemented in the continuum segregation model (Isner et al. Reference Isner, Umbanhowar, Ottino and Lueptow2020a), a constant flowing layer depth

$\delta (x)$, shown by the dashed curve, remains almost constant for most of the length of flowing layer, except near the downstream bounding endwall where it decreases slightly. Although a varying flowing layer thickness can be implemented in the continuum segregation model (Isner et al. Reference Isner, Umbanhowar, Ottino and Lueptow2020a), a constant flowing layer depth ![]() $\delta =\langle \delta (x)\rangle$ is assumed later in this paper, as the spatial average is easier to implement and provides sufficient accuracy to successfully apply the theory for the quasi-2-D heap flows considered here (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016). Figure 3(b) shows that the normal velocity at the bottom of the flowing layer in the rising reference frame is opposite and approximately equal to the rise velocity of the surface of the heap,

$\delta =\langle \delta (x)\rangle$ is assumed later in this paper, as the spatial average is easier to implement and provides sufficient accuracy to successfully apply the theory for the quasi-2-D heap flows considered here (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014; Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016). Figure 3(b) shows that the normal velocity at the bottom of the flowing layer in the rising reference frame is opposite and approximately equal to the rise velocity of the surface of the heap, ![]() $v_r\cos (\alpha )=0.35$ cm s

$v_r\cos (\alpha )=0.35$ cm s![]() $^{-1}$, except for the upstream portion near the feed zone, where the kinematics are affected by falling particles from the vertical feed. Figure 3(c) shows that large particles rise to the surface as their normal relative velocity is positive over most of the flowing layer. The normal relative velocity of the large particles is zero for the downstream portion of the flowing layer corresponding to the region devoid of small particles and hence no relative velocity between the large particles and the bulk flow. On the other hand, the relative velocity is negative for small particles shown in figure 3(d) except very near the downstream endwall where no small particles are present. In other words, in the limit of

$^{-1}$, except for the upstream portion near the feed zone, where the kinematics are affected by falling particles from the vertical feed. Figure 3(c) shows that large particles rise to the surface as their normal relative velocity is positive over most of the flowing layer. The normal relative velocity of the large particles is zero for the downstream portion of the flowing layer corresponding to the region devoid of small particles and hence no relative velocity between the large particles and the bulk flow. On the other hand, the relative velocity is negative for small particles shown in figure 3(d) except very near the downstream endwall where no small particles are present. In other words, in the limit of ![]() $c_i=0$, the definition of segregation velocity loses its physical meaning. To account for this deficiency in the mathematical description, only data for

$c_i=0$, the definition of segregation velocity loses its physical meaning. To account for this deficiency in the mathematical description, only data for ![]() $0.01< c_i<0.99$ are considered in the later analysis. The concentration of large particles, shown in figure 3(e), is close to 1 at the surface of the flowing layer and downstream where the entire flowing layer thickness is made up of large particles. As shown in figure 3(f), the diffusion coefficient is largest near the surface in the upstream portion of the flowing layer and decreases moving downstream and deeper into the flowing layer.

$0.01< c_i<0.99$ are considered in the later analysis. The concentration of large particles, shown in figure 3(e), is close to 1 at the surface of the flowing layer and downstream where the entire flowing layer thickness is made up of large particles. As shown in figure 3(f), the diffusion coefficient is largest near the surface in the upstream portion of the flowing layer and decreases moving downstream and deeper into the flowing layer.

Figure 3. Spatial distributions of various quantities for an example simulation with ![]() $R_d=2$,

$R_d=2$, ![]() $R_\rho =4$,

$R_\rho =4$, ![]() $\hat c_l=0.5$ (i.e. data from figure 2b rotated by repose angle

$\hat c_l=0.5$ (i.e. data from figure 2b rotated by repose angle ![]() $\alpha$). Average fields of (a) streamwise velocity, (b) normal velocity (note that particles deposited on the bed have a velocity of

$\alpha$). Average fields of (a) streamwise velocity, (b) normal velocity (note that particles deposited on the bed have a velocity of ![]() $-v_r\cos {\alpha }=-0.35$ cm s

$-v_r\cos {\alpha }=-0.35$ cm s![]() $^{-1}$ due to the rising reference frame), relative normal velocities of (c) large and (d) small particles, (e) large particle concentration and (f) diffusion coefficient. Dashed curve in panel (a) represents

$^{-1}$ due to the rising reference frame), relative normal velocities of (c) large and (d) small particles, (e) large particle concentration and (f) diffusion coefficient. Dashed curve in panel (a) represents ![]() $\delta (x)$ using the criterion

$\delta (x)$ using the criterion ![]() $u(x,-\delta )=0.1u(x,0)$. Region above solid white line in panels (a–f) corresponds to the constant depth flowing layer defined by the average flowing layer depth

$u(x,-\delta )=0.1u(x,0)$. Region above solid white line in panels (a–f) corresponds to the constant depth flowing layer defined by the average flowing layer depth ![]() $\delta =\langle \delta (x)\rangle$.

$\delta =\langle \delta (x)\rangle$.

The local values of the velocities, concentrations and diffusion coefficients shown in figure 3 are used to determine the local segregation velocity using (2.7) for different values of the feed concentration of large particles, ![]() $\hat c_l$. An example of the resulting dimensionless segregation velocity data scaled by

$\hat c_l$. An example of the resulting dimensionless segregation velocity data scaled by ![]() $d_s$ and shear rate,

$d_s$ and shear rate, ![]() $\dot \gamma$, plotted against the concentration of the other species is shown in figure 4 for

$\dot \gamma$, plotted against the concentration of the other species is shown in figure 4 for ![]() $R_d=2$ and

$R_d=2$ and ![]() $R_\rho =4$. Different colours in figure 4(a) represent simulations with different values for

$R_\rho =4$. Different colours in figure 4(a) represent simulations with different values for ![]() $\hat c_l$, which ensures a full range of local concentrations (

$\hat c_l$, which ensures a full range of local concentrations (![]() $0.01< c_i<0.99$) in the plot. Because the data come from different depths and positions along the flowing layer of the bounded heap, a wide range of shear rates, concentrations and segregation velocities are represented in the figure. Although there is substantial scatter in the data due to the stochastic nature of granular flows, it is clear that there are two distinct curves represented in figure 4(a), an upper one for the LH particles and a lower one for the SL particles. It is also clear that

$0.01< c_i<0.99$) in the plot. Because the data come from different depths and positions along the flowing layer of the bounded heap, a wide range of shear rates, concentrations and segregation velocities are represented in the figure. Although there is substantial scatter in the data due to the stochastic nature of granular flows, it is clear that there are two distinct curves represented in figure 4(a), an upper one for the LH particles and a lower one for the SL particles. It is also clear that ![]() $w_{seg,l}$ (upper set of data) changes from positive (upward segregation) to negative (downward segregation), depending on concentration. For

$w_{seg,l}$ (upper set of data) changes from positive (upward segregation) to negative (downward segregation), depending on concentration. For ![]() $1-c_l<0.6$ (circles at the top left of figure 4a)

$1-c_l<0.6$ (circles at the top left of figure 4a) ![]() $w_{seg,l}$ is positive, indicating that LH particles tend to rise in the flowing layer for small values of

$w_{seg,l}$ is positive, indicating that LH particles tend to rise in the flowing layer for small values of ![]() $1-c_l=c_s$; for

$1-c_l=c_s$; for ![]() $1-c_l>0.6$ (circles at the top right of figure 4a)

$1-c_l>0.6$ (circles at the top right of figure 4a) ![]() $w_{seg,l}$ is negative, indicating that LH particles sink deeper in the flowing layer. Results are analogous for SL particles, i.e. for small values of

$w_{seg,l}$ is negative, indicating that LH particles sink deeper in the flowing layer. Results are analogous for SL particles, i.e. for small values of ![]() $1-c_s=c_l$ (

$1-c_s=c_l$ (![]() $1-c_s<0.4$) SL particles rise, albeit at a smaller segregation velocity than LH particles, while for larger values of

$1-c_s<0.4$) SL particles rise, albeit at a smaller segregation velocity than LH particles, while for larger values of ![]() $1-c_s$, SL particles sink. The overlap between the data shown in figure 4(a) for separate simulations with seven different feed concentrations indicates the robustness of the results.

$1-c_s$, SL particles sink. The overlap between the data shown in figure 4(a) for separate simulations with seven different feed concentrations indicates the robustness of the results.

Figure 4. Segregation velocity dependence of large heavy (![]() $\circ$) and small light (

$\circ$) and small light (![]() $\times$) particles on local concentration of the other species,

$\times$) particles on local concentration of the other species, ![]() $1-c_i$, for

$1-c_i$, for ![]() $R_d=2$ and

$R_d=2$ and ![]() $R_\rho =4$. (a) Local segregation velocity for different feed concentrations

$R_\rho =4$. (a) Local segregation velocity for different feed concentrations ![]() $\hat c_l$ (symbol colours) calculated in each bin throughout the entire flowing layer averaged over 500 frames corresponding to 5 s of simulated time. (b) Data from panel (a) averaged over 0.02 increments of

$\hat c_l$ (symbol colours) calculated in each bin throughout the entire flowing layer averaged over 500 frames corresponding to 5 s of simulated time. (b) Data from panel (a) averaged over 0.02 increments of ![]() $1-c_i$ to reduce scatter and more clearly show the data trend. Error bars represent the standard deviation for each increment of

$1-c_i$ to reduce scatter and more clearly show the data trend. Error bars represent the standard deviation for each increment of ![]() $1-c_i$. Solid curves are fits to (1.3).

$1-c_i$. Solid curves are fits to (1.3).

To more clearly show trends, figure 4(b) averages the data in figure 4(a) over 0.02 increments of ![]() $1-c_i$. Here the small positive segregation velocity for both species at small values of

$1-c_i$. Here the small positive segregation velocity for both species at small values of ![]() $1-c_i$ and the negative segregation velocity for both species at large values of

$1-c_i$ and the negative segregation velocity for both species at large values of ![]() $1-c_i$ is evident. The segregation velocity of both species is zero at

$1-c_i$ is evident. The segregation velocity of both species is zero at ![]() $1-c_i=0$, which corresponds to the limit of no particles of the other species being present (monodisperse flow with no segregation possible). However, the segregation velocity as

$1-c_i=0$, which corresponds to the limit of no particles of the other species being present (monodisperse flow with no segregation possible). However, the segregation velocity as ![]() $1-c_i$ approaches 1 is finite, as would be expected since this corresponds to a very low concentration of species

$1-c_i$ approaches 1 is finite, as would be expected since this corresponds to a very low concentration of species ![]() $i$ amongst many particles of the other species (a single intruder particle in the limit). However, this low concentration leads to large variability in the measurement of

$i$ amongst many particles of the other species (a single intruder particle in the limit). However, this low concentration leads to large variability in the measurement of ![]() $w_{seg,i}$ and correspondingly large error bars.

$w_{seg,i}$ and correspondingly large error bars.

Returning to the expressions for the segregation velocity discussed in § 1, it is clear that the linear relation of (1.1) is inappropriate for the data in figure 4, even though it works well under many other circumstances, particularly for mixtures of particles having similar concentrations (Schlick et al. Reference Schlick, Fan, Isner, Umbanhowar, Ottino and Lueptow2015a; Xiao et al. Reference Xiao, Umbanhowar, Ottino and Lueptow2016). However, since previous studies have shown that the segregation velocity can be more accurately modelled using a quadratic polynomial, (1.3) (Gajjar & Gray Reference Gajjar and Gray2014; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018), particularly for values of ![]() $1-c_i$ near 0 or 1, we consider that form here. Figure 4(b) shows that fits to (1.3) match well with the segregation velocity data. In particular, the fitted curves intersect the dashed horizontal line corresponding to

$1-c_i$ near 0 or 1, we consider that form here. Figure 4(b) shows that fits to (1.3) match well with the segregation velocity data. In particular, the fitted curves intersect the dashed horizontal line corresponding to ![]() $w_{seg,i}=0$ at

$w_{seg,i}=0$ at ![]() $c_l\approx 0.35$ and

$c_l\approx 0.35$ and ![]() $c_s\approx 0.65$. At these concentrations, which sum to 1 as they should, particles no longer segregate, apparently due to the balance between percolation and buoyancy.

$c_s\approx 0.65$. At these concentrations, which sum to 1 as they should, particles no longer segregate, apparently due to the balance between percolation and buoyancy.

The measurement uncertainty for the segregation velocity increases with ![]() $1-c_i$ resulting in a mismatch between the data and the curve for large

$1-c_i$ resulting in a mismatch between the data and the curve for large ![]() $1-c_i$ shown in figure 4. To reduce uncertainty, particularly near the single particle intruder limit, the segregation velocity data in figure 4 can be recast as the species segregation flux

$1-c_i$ shown in figure 4. To reduce uncertainty, particularly near the single particle intruder limit, the segregation velocity data in figure 4 can be recast as the species segregation flux ![]() $\varPhi _{seg,i}=w_{seg,i}c_i$. As is evident for both the entire data set in figure 5(a) and the averaged data in figure 5(b), the two measured species segregation fluxes are always equal and opposite at any particular local value of the large particle concentration,

$\varPhi _{seg,i}=w_{seg,i}c_i$. As is evident for both the entire data set in figure 5(a) and the averaged data in figure 5(b), the two measured species segregation fluxes are always equal and opposite at any particular local value of the large particle concentration, ![]() $c_l$, as expected. It is also evident that the segregation flux direction reverses at

$c_l$, as expected. It is also evident that the segregation flux direction reverses at ![]() $c_l=0.35$ where the segregation velocity in figure 4 is zero. The data in figure 5 are well-fitted by the quadratic-in-concentration segregation velocity given in (1.3), which corresponds to a cubic in

$c_l=0.35$ where the segregation velocity in figure 4 is zero. The data in figure 5 are well-fitted by the quadratic-in-concentration segregation velocity given in (1.3), which corresponds to a cubic in ![]() $c_i$ segregation flux,

$c_i$ segregation flux,

where ![]() $A_i$ and

$A_i$ and ![]() $B_i$ are coefficients that we will show depend on both the size and density ratios. Equation (3.1) automatically satisfies the requirement that the flux is 0 at

$B_i$ are coefficients that we will show depend on both the size and density ratios. Equation (3.1) automatically satisfies the requirement that the flux is 0 at ![]() $c_l=0$ and 1.

$c_l=0$ and 1.

Figure 5. Segregation flux dependence of large heavy (![]() $\circ$) and small light (

$\circ$) and small light (![]() $\times$) particles on local concentration of large heavy particles,

$\times$) particles on local concentration of large heavy particles, ![]() $c_l$, for

$c_l$, for ![]() $R_d=2$ and

$R_d=2$ and ![]() $R_\rho =4$. (a) Local segregation flux for different feed concentrations

$R_\rho =4$. (a) Local segregation flux for different feed concentrations ![]() $\hat c_l$ (symbol colours) calculated in each bin throughout the entire flowing layer and averaged over 500 frames corresponding to 5 s of simulation time. (b) Data from panel (a) averaged over 0.02 increments of

$\hat c_l$ (symbol colours) calculated in each bin throughout the entire flowing layer and averaged over 500 frames corresponding to 5 s of simulation time. (b) Data from panel (a) averaged over 0.02 increments of ![]() $c_l$. Error bars represent the standard deviation for each averaging interval of

$c_l$. Error bars represent the standard deviation for each averaging interval of ![]() $c_l$. Red dashed curves are quadratic fits of (3.1) using only the data for large heavy particles (

$c_l$. Red dashed curves are quadratic fits of (3.1) using only the data for large heavy particles (![]() $\circ$) in the plot, while black solid curves (which appear dashed because they are behind the red dashed curves) are fits to the data for small light particles (

$\circ$) in the plot, while black solid curves (which appear dashed because they are behind the red dashed curves) are fits to the data for small light particles (![]() $\times$) in the plot.

$\times$) in the plot.

Although (3.1) can be made to fit the data in figure 5 quite well, it is a phenomenological model that lacks a physical basis. An alternative approach for considering the segregation is to solve the momentum equation supplied with species-specific stresses and an interspecies drag (Gray & Thornton Reference Gray and Thornton2005) such that the reversed segregation flux can be justified from the standpoint of force balance. However, both approaches require empirical fits, either of the coefficients ![]() $A_i$ and

$A_i$ and ![]() $B_i$ in the segregation flux model (3.1) or through the force models related to species-specific stresses (Tunuguntla et al. Reference Tunuguntla, Weinhart and Thornton2017) or drag (Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020) in momentum-based models. In fact, Gray & Ancey (Reference Gray and Ancey2015) assume a simple stress partitioning function and a linear interspecies drag and mathematically prove that the segregation can reverse direction for different values of concentration in SD-systems. This is different from the other momentum-based models (Marks et al. Reference Marks, Rognon and Einav2012; Tunuguntla et al. Reference Tunuguntla, Bokhove and Thornton2014), in which the segregation direction is determined purely by size and density ratios. Hence, neither of these two models account for dependence of the segregation direction on concentration that is inherent in the data in figure 5 and later figures in this paper. An extended discussion of why these models cannot account for concentration dependence is included in Appendix A. On the other hand, though an explicit expression for the segregation flux as a function of size and density ratios is not given, the model of Gray & Ancey (Reference Gray and Ancey2015) utilizes a segregation flux that is quadratic in concentration. Although there is qualitative similarity between the quadratic segregation model in (3.1) and the segregation model by Gray & Ancey (Reference Gray and Ancey2015) in certain parameter regions, their model does not quantitively capture the observed concentration dependent segregation, as described in detail in Appendix A. In addition, their model does not account for the asymmetric concentration dependence of size segregation (Gajjar & Gray Reference Gajjar and Gray2014; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018).

$B_i$ in the segregation flux model (3.1) or through the force models related to species-specific stresses (Tunuguntla et al. Reference Tunuguntla, Weinhart and Thornton2017) or drag (Duan et al. Reference Duan, Umbanhowar, Ottino and Lueptow2020) in momentum-based models. In fact, Gray & Ancey (Reference Gray and Ancey2015) assume a simple stress partitioning function and a linear interspecies drag and mathematically prove that the segregation can reverse direction for different values of concentration in SD-systems. This is different from the other momentum-based models (Marks et al. Reference Marks, Rognon and Einav2012; Tunuguntla et al. Reference Tunuguntla, Bokhove and Thornton2014), in which the segregation direction is determined purely by size and density ratios. Hence, neither of these two models account for dependence of the segregation direction on concentration that is inherent in the data in figure 5 and later figures in this paper. An extended discussion of why these models cannot account for concentration dependence is included in Appendix A. On the other hand, though an explicit expression for the segregation flux as a function of size and density ratios is not given, the model of Gray & Ancey (Reference Gray and Ancey2015) utilizes a segregation flux that is quadratic in concentration. Although there is qualitative similarity between the quadratic segregation model in (3.1) and the segregation model by Gray & Ancey (Reference Gray and Ancey2015) in certain parameter regions, their model does not quantitively capture the observed concentration dependent segregation, as described in detail in Appendix A. In addition, their model does not account for the asymmetric concentration dependence of size segregation (Gajjar & Gray Reference Gajjar and Gray2014; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018).

Of the four empirical coefficients of the model described by (3.1) (equivalently (1.3)), ![]() $A_l$,

$A_l$, ![]() $B_l$ and

$B_l$ and ![]() $A_s$,

$A_s$, ![]() $B_s$ (two for each species), only two are independent due to the constraint of volume conservation at all local concentrations, i.e.

$B_s$ (two for each species), only two are independent due to the constraint of volume conservation at all local concentrations, i.e. ![]() $\varPhi _{seg,l}+\varPhi _{seg,s}=0$. For example, if

$\varPhi _{seg,l}+\varPhi _{seg,s}=0$. For example, if ![]() $A_l$ and

$A_l$ and ![]() $B_l$ are determined for the large species, then the coefficients for the small species are

$B_l$ are determined for the large species, then the coefficients for the small species are ![]() $A_s = -(A_l + B_l)$ and

$A_s = -(A_l + B_l)$ and ![]() $B_s=B_l$. Consequently, although there are two sets of data in figure 5(b), either curve fit can be used to determine the values of

$B_s=B_l$. Consequently, although there are two sets of data in figure 5(b), either curve fit can be used to determine the values of ![]() $A_i$ and

$A_i$ and ![]() $B_i$ for the other curve fit. For example, the segregation flux data for large particles in figure 5(b) (red circles) are used to find

$B_i$ for the other curve fit. For example, the segregation flux data for large particles in figure 5(b) (red circles) are used to find ![]() $A_l$ and

$A_l$ and ![]() $B_l$ first, and then

$B_l$ first, and then ![]() $A_s$ and