1. Introduction

Nanofluidic transport involves the flow of liquids and flow-driven transport of ions, solutes, bioanalytes and other species in nanochannels and nanopores (Eijkel & Van Den Berg Reference Eijkel and Van Den Berg2005; Sparreboom et al. Reference Sparreboom, van den Berg and Eijkel2009; Das et al. Reference Das, Dubsky, van den Berg and Eijkel2012; Ziemys et al. Reference Ziemys, Kojic, Milosevic and Ferrari2012; Koltonow & Huang Reference Koltonow and Huang2016; Gao et al. Reference Gao, Feng, Guo and Jiang2017; Zhu et al. Reference Zhu, Wang, Tian and Jiang2019). Such transport has received immense attention over the past few decades motivated by its applications in fabricating sensors that require very little sample volumes (Venkatesan & Bashir Reference Venkatesan and Bashir2011; Miles et al. Reference Miles, Ivanov, Wilson, Doan, Japrung and Edel2013), devices capable of ionic gating (Liu et al. Reference Liu, Zhang, Li, Heng, Wang, Tian and Jiang2015; Fang et al. Reference Fang, Zhang, Yang, Wang, Tian, Zhang and Jiang2016), and platforms capable of a variety of biomedical applications (Hood et al. Reference Hood, Hood, Ferrari and Grattoni2017; Weerakoon-Ratnayake et al. Reference Weerakoon-Ratnayake, O'Neil, Uba and Soper2017), water filtration and desalination (Chen et al. Reference Chen2017; Anand et al. Reference Anand, Unnikrishnan, Mao, Lin and Huang2018), oil recovery (Zhang et al. Reference Zhang, Jia, Li and Liu2019), etc. The significantly large interfacial effects in such nanofluidic systems have enabled the utilization of novel and unconventional flow-driving mechanisms such as electro-osmotic (EOS) transport (Eijkel & Van Den Berg Reference Eijkel and Van Den Berg2005). The EOS flows are characterized by the water transport caused by the imposed axial electric-field-driven transport of the net charge imbalance of the electric double layer (EDL) created at the charged walls of the nanochannel. Such EOS transport in nanochannels can also be ‘induced’ by other mechanisms that trigger a migration of the charge imbalance of the EDL. Some of these mechanisms are the presence of an applied axial pressure gradient (this leads to the generation of a streaming electric field and a velocity field that is a combination of this pressure-driven flow field and an induced EOS flow field) (Chakraborty & Das Reference Chakraborty and Das2008; Das & Chakraborty Reference Das and Chakraborty2009, Reference Das and Chakraborty2010), an applied axial concentration gradient of solutes and/or ions (leading to a diffusio-osmotic (DOS) transport) (Qian, Das & Luo Reference Qian, Das and Luo2007; Jing & Das Reference Jing and Das2018), and an applied axial temperature gradient (leading to a thermo-osmotic (TOS) transport) (Dietzel & Hardt Reference Dietzel and Hardt2016, Reference Dietzel and Hardt2017).

The present paper probes the TOS transport in a nanochannel grafted with charged polyelectrolyte (PE) brushes in the presence of an imposed axial temperature gradient (![]() $\textrm {d}T/{\textrm {d} x}$). The presence of such a gradient along a charged nanochannel induces a pressure gradient and an electric field. The formation of an EDL at the nanochannel walls leads to the development of an osmotic pressure that depends on temperature (

$\textrm {d}T/{\textrm {d} x}$). The presence of such a gradient along a charged nanochannel induces a pressure gradient and an electric field. The formation of an EDL at the nanochannel walls leads to the development of an osmotic pressure that depends on temperature (![]() $T$), the number density of ions (

$T$), the number density of ions (![]() $n_\infty$) and the EDL electrostatic potential (

$n_\infty$) and the EDL electrostatic potential (![]() $\psi$). Therefore, the imposed axial gradient in temperature triggers a gradient in the (osmotic) pressure which is dictated by gradients in

$\psi$). Therefore, the imposed axial gradient in temperature triggers a gradient in the (osmotic) pressure which is dictated by gradients in ![]() $T, n_\infty$ and

$T, n_\infty$ and ![]() $\psi$. The induced electric field, on the other hand, is contributed by all the factors that induce a differential migration of the cations and anions. There are three factors that contribute to this electric field: the conduction component, the thermal component and the osmotic component. The conduction component is dictated by the temperature gradient induced concentration gradient: this is an effect that is well-known as the Soret effect and it also depends on the ionic imbalance within the nanochannel EDL. The thermal component, on the other hand, is associated with the different thermophoretic mobilities of the ions. Finally, the osmotic component is associated with the flow-driven downstream advection of the charge imbalance present within the EDL. The TOS transport, therefore, is completely defined through the quantification of the induced electric field and the net flow field. This TOS fluid flow results from the flow associated with the induced pressure gradient (we can either call it a thermochemiosmotic flow, or split it further into a chemiosmotic (COS) flow and a thermal flow) and the flow associated with the induced electric field (i.e. the induced EOS flow). Over the past several years, such TOS transport in nanofluidic systems has been extensively studied (Dietzel & Hardt Reference Dietzel and Hardt2016, Reference Dietzel and Hardt2017) and has been identified to be useful in applications ranging from generating electricity in nanocellulose channels using waste heat (Li et al. Reference Li2019), energy conversion and storage (Chen et al. Reference Chen, Yao, Yan, Liu, Yang and Su2019), enhanced nanofluidic transport in presence of functionalization with PE brushes (Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a), etc. For the past decade and a half, functionalizing nanochannels with PE brushes has been employed for applications such as analyte and biomolecule sensing (Ali et al. Reference Ali, Tahir, Siwy, Neumann, Tremel and Ensinger2011), fabrication of ionic nanofluidic diodes and current rectifiers (Ali et al. Reference Ali, Ramirez, Mafe, Neumann and Ensinger2009, Reference Ali, Nasir, Ramirez, Cervera, Mafe and Ensinger2013; Yameen et al. Reference Yameen, Ali, Neumann, Ensinger, Knoll and Azzaroni2009, Reference Yameen, Ali, Neumann, Ensinger, Knoll and Azzaroni2010; Lin et al. Reference Lin, Lin, Hsu and Tseng2016), etc. Most of these applications rely on the strong environmental stimuli responsiveness of the PE brushes, which in turn significantly affects the ionic transport in such brush-functionalized nanochannels. The fluid flow is often significantly retarded in such brush-functionalized nanochannels stemming from the large drag forces exerted on the flow by the brushes (Chen & Das Reference Chen and Das2015a). Such reduced fluid flows are considered as a critical advantage of such brush-functionalized nanochannel systems: weak flow strength ensures that the differences in the ionic migration of the different ions, which is the key to several of the above applications, does not get masked by the background advective transport that acts equally on all the different types of ions. Very recently, in a series of papers (Chen & Das Reference Chen and Das2017Reference Chen and DasReference Zhulina, Pryamitsyn and Borisov; Chen, Sachar & Das Reference Chen, Sachar and Das2018; Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a,Reference Maheedhara, Sachar, Jing and Dasb; Sachar, Sivasankar & Das Reference Sachar, Sivasankar and Das2019a; Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb), however, we have established that such brush-induced weakening of flow strength in PE-brush-grafted nanochannels might not always be true. We showed that for certain cases where nanochannels are grafted with end-charged PE brushes (Chen & Das Reference Chen and Das2017; Chen et al. Reference Chen, Sachar and Das2018; Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a,Reference Maheedhara, Sachar, Jing and Dasb), some particular combination of grafting density, brush properties and salt concentration will lead to significantly enhanced nanofluidic EOS or induced EOS transport. We argued that such enhancement stemmed from the localization of the EDL charge density (and hence the EOS body force) away from the nanochannel wall (or the location of the maximum drag force). We have further established such localization of EOS-body-force-induced enhanced EOS or induced EOS transport in nanochannels grafted with backbone-charged PE brushes (Sachar et al. Reference Sachar, Sivasankar and Das2019a; Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb). Another possible factor, which was not identified in these papers and might have led to such an enhancement in the EOS or induced EOS transport in nanochannels grafted with end-charged or backbone-charged PE brushes (i.e. the setting that shifted the EDL charge density away from the nanochannel wall), was the possible molecular slip experienced by the liquid along the brush surface. We also compared the results between the cases of EOS and diffusio-osmotic transport in nanochannels grafted with end-charged and backbone-charged brushes. Our comparison revealed that the flow was more augmented for the case of nanochannels grafted with backbone-charged brushes stemming from a more appropriate prediction of the brush-induced drag force on the flow for such cases (Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb). Following this approach, we also compared the findings from this present study to that of diffusio-osmotic transport (Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a) in nanochannels grafted with backbone-charged PE brushes (see appendix A). In this study, we explore the influence of the TOS effects, triggered by the application of an axial temperature gradient, in significantly enhancing the liquid transport in nanochannels grafted with backbone-charged, pH-responsive PE brushes. The PE brushes are modelled using our recently developed augmented strong stretching theory (SST) model (Sachar et al. Reference Sachar, Sivasankar and Das2019a, Reference Sachar, Sivasankar, Etha, Chen and Das2020; Sachar, Sivasankar & Das Reference Sachar, Sivasankar and Das2019b). Our model, by accounting for the excluded volume interactions between PE brush segments and a more expanded form of the mass action law, modified the existing SST model that has been well-known for capturing the thermodynamics, electrostatics and configurations of the strongly stretched PE brushes (Lyatskaya et al. Reference Lyatskaya, Leermakers, Fleer, Zhulina and Birshtein1995; Zhulina & Borisov Reference Zhulina and Borisov1997; Zhulina, Klein Wolterink & Borisov Reference Zhulina, Klein Wolterink and Borisov2000; Lebedeva, Zhulina & Borisov Reference Lebedeva, Zhulina and Borisov2017). We first quantify the thermo-osmotically induced electric field and point out the individual contributions of conduction, thermal and osmotic components. Each of these components has contributions from the salt ions as well as the

$\psi$. The induced electric field, on the other hand, is contributed by all the factors that induce a differential migration of the cations and anions. There are three factors that contribute to this electric field: the conduction component, the thermal component and the osmotic component. The conduction component is dictated by the temperature gradient induced concentration gradient: this is an effect that is well-known as the Soret effect and it also depends on the ionic imbalance within the nanochannel EDL. The thermal component, on the other hand, is associated with the different thermophoretic mobilities of the ions. Finally, the osmotic component is associated with the flow-driven downstream advection of the charge imbalance present within the EDL. The TOS transport, therefore, is completely defined through the quantification of the induced electric field and the net flow field. This TOS fluid flow results from the flow associated with the induced pressure gradient (we can either call it a thermochemiosmotic flow, or split it further into a chemiosmotic (COS) flow and a thermal flow) and the flow associated with the induced electric field (i.e. the induced EOS flow). Over the past several years, such TOS transport in nanofluidic systems has been extensively studied (Dietzel & Hardt Reference Dietzel and Hardt2016, Reference Dietzel and Hardt2017) and has been identified to be useful in applications ranging from generating electricity in nanocellulose channels using waste heat (Li et al. Reference Li2019), energy conversion and storage (Chen et al. Reference Chen, Yao, Yan, Liu, Yang and Su2019), enhanced nanofluidic transport in presence of functionalization with PE brushes (Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a), etc. For the past decade and a half, functionalizing nanochannels with PE brushes has been employed for applications such as analyte and biomolecule sensing (Ali et al. Reference Ali, Tahir, Siwy, Neumann, Tremel and Ensinger2011), fabrication of ionic nanofluidic diodes and current rectifiers (Ali et al. Reference Ali, Ramirez, Mafe, Neumann and Ensinger2009, Reference Ali, Nasir, Ramirez, Cervera, Mafe and Ensinger2013; Yameen et al. Reference Yameen, Ali, Neumann, Ensinger, Knoll and Azzaroni2009, Reference Yameen, Ali, Neumann, Ensinger, Knoll and Azzaroni2010; Lin et al. Reference Lin, Lin, Hsu and Tseng2016), etc. Most of these applications rely on the strong environmental stimuli responsiveness of the PE brushes, which in turn significantly affects the ionic transport in such brush-functionalized nanochannels. The fluid flow is often significantly retarded in such brush-functionalized nanochannels stemming from the large drag forces exerted on the flow by the brushes (Chen & Das Reference Chen and Das2015a). Such reduced fluid flows are considered as a critical advantage of such brush-functionalized nanochannel systems: weak flow strength ensures that the differences in the ionic migration of the different ions, which is the key to several of the above applications, does not get masked by the background advective transport that acts equally on all the different types of ions. Very recently, in a series of papers (Chen & Das Reference Chen and Das2017Reference Chen and DasReference Zhulina, Pryamitsyn and Borisov; Chen, Sachar & Das Reference Chen, Sachar and Das2018; Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a,Reference Maheedhara, Sachar, Jing and Dasb; Sachar, Sivasankar & Das Reference Sachar, Sivasankar and Das2019a; Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb), however, we have established that such brush-induced weakening of flow strength in PE-brush-grafted nanochannels might not always be true. We showed that for certain cases where nanochannels are grafted with end-charged PE brushes (Chen & Das Reference Chen and Das2017; Chen et al. Reference Chen, Sachar and Das2018; Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a,Reference Maheedhara, Sachar, Jing and Dasb), some particular combination of grafting density, brush properties and salt concentration will lead to significantly enhanced nanofluidic EOS or induced EOS transport. We argued that such enhancement stemmed from the localization of the EDL charge density (and hence the EOS body force) away from the nanochannel wall (or the location of the maximum drag force). We have further established such localization of EOS-body-force-induced enhanced EOS or induced EOS transport in nanochannels grafted with backbone-charged PE brushes (Sachar et al. Reference Sachar, Sivasankar and Das2019a; Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb). Another possible factor, which was not identified in these papers and might have led to such an enhancement in the EOS or induced EOS transport in nanochannels grafted with end-charged or backbone-charged PE brushes (i.e. the setting that shifted the EDL charge density away from the nanochannel wall), was the possible molecular slip experienced by the liquid along the brush surface. We also compared the results between the cases of EOS and diffusio-osmotic transport in nanochannels grafted with end-charged and backbone-charged brushes. Our comparison revealed that the flow was more augmented for the case of nanochannels grafted with backbone-charged brushes stemming from a more appropriate prediction of the brush-induced drag force on the flow for such cases (Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb). Following this approach, we also compared the findings from this present study to that of diffusio-osmotic transport (Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a) in nanochannels grafted with backbone-charged PE brushes (see appendix A). In this study, we explore the influence of the TOS effects, triggered by the application of an axial temperature gradient, in significantly enhancing the liquid transport in nanochannels grafted with backbone-charged, pH-responsive PE brushes. The PE brushes are modelled using our recently developed augmented strong stretching theory (SST) model (Sachar et al. Reference Sachar, Sivasankar and Das2019a, Reference Sachar, Sivasankar, Etha, Chen and Das2020; Sachar, Sivasankar & Das Reference Sachar, Sivasankar and Das2019b). Our model, by accounting for the excluded volume interactions between PE brush segments and a more expanded form of the mass action law, modified the existing SST model that has been well-known for capturing the thermodynamics, electrostatics and configurations of the strongly stretched PE brushes (Lyatskaya et al. Reference Lyatskaya, Leermakers, Fleer, Zhulina and Birshtein1995; Zhulina & Borisov Reference Zhulina and Borisov1997; Zhulina, Klein Wolterink & Borisov Reference Zhulina, Klein Wolterink and Borisov2000; Lebedeva, Zhulina & Borisov Reference Lebedeva, Zhulina and Borisov2017). We first quantify the thermo-osmotically induced electric field and point out the individual contributions of conduction, thermal and osmotic components. Each of these components has contributions from the salt ions as well as the ![]() $\textrm {H}^+$ and

$\textrm {H}^+$ and ![]() $\textrm {OH}^-$ ions (please see the online supplementary materials available at https://doi.org/10.1017/jfm.2021.281). Subsequently, we study the overall TOS liquid transport, characterized by the TOS flow velocity. To better understand the variation of the TOS velocity, we study the individual contributions of the COS component, thermal component and the EOS component. We observe that the thermal and the COS components are invariably in the same direction and the net direction of the flow is eventually dictated by the relative strength (with respect to the other components) and direction of the induced EOS transport (or the induced TOS electric field). We compare both the electric field and the velocity field results with those of the brushless nanochannels having the same overall charge density as the brush-grafted nanochannels. We clearly find that the overall TOS velocity is significantly enhanced for the case of the brush-grafted nanochannels. A key factor responsible for causing the enhancement in the TOS liquid transport in the brush-grafted nanochannels in comparison with that in brush-free nanochannels is the localization of the EDL (and hence the EOS body force) away from the nanochannel walls. Even in our previous papers, probing the EOS flow (Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020b) or diffusio-osmotic flow (one kind of induced EOS flow) (Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a), we have identified and attributed such a flow enhancement in brush-grafted nanochannels (in comparison with the brush-free nanochannels with identical charge density) to this localization of the EDL (and hence the EOS body force) away from the nanochannel wall. To reiterate, we are comparing here two cases: a brush-free nanochannel and a brush-grafted nanochannel. The basis of comparison is that the charges on the walls of the brush-free nanochannel are considered to be distributed on the brushes (grafted on a charge-free wall) in brush-grafted nanochannels. Therefore, the presence of the brushes shifts the centre of the charges (and hence the EDL induced by these charges and the consequent EOS body force) away from the nanochannel wall. One can easily show that for a flow in a nanochannel driven by an external force, the net flow rate increases with an increase in the distance (from the nanochannel wall) at which this external force is localized and this increase becomes maximum if this force is localized at the nanochannel centre. The presence of the brushes causes this localization and hence aids flow enhancement. However, the same very presence of the brushes subjects the flow to an additional drag force. Therefore, the brushes trigger two competing mechanisms (in the context of the electrokinetic fluid flow): localization of the EOS body force that enhances the flow and the presence of the additional brush-induced drag that reduces the flow. For certain parameter combinations, the effect of the localization of the EOS body force overwhelms the effect of the brush-induced drag, thereby enhancing the net flow rate. This is the central idea of this paper. It is also very pertinent to point out here that a large number of studies from other research groups have probed such electrokinetic transport in nanochannels/nanopores grafted with PE brushes (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng, Ai & Qian Reference Zeng, Ai and Qian2014; Zeng et al. Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi, Azari & Hardt Reference Sadeghi, Azari and Hardt2019; Khatibi, Ashrafizadeh & Sadeghi Reference Khatibi, Ashrafizadeh and Sadeghi2020; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Silkina, Bag & Vinogradova Reference Silkina, Bag and Vinogradova2020; Talebi, Ashrafizadeh & Sadeghi Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021). They use exactly the same form of equation (see the 1st equation of (2.17) later) as ours. This equation is a ‘Brinkman’-like equation and is also sometimes denoted as the Stokes–Brinkman equation (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Sadeghi Reference Sadeghi2018). It provides a gross representation of the contribution of the brushes by considering the PE brush layer to be represented as a porous medium. It considers that the brushes do two things: (1) they trigger a particular EDL distribution and hence a particular distribution of the EOS body force (and other possible forces related to the EDL) and (2) they impart an additional gross drag force (with drag coefficient varying quadratically with the monomer distribution) on the fluid flow. In this context, the natural question arises that why these other papers (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi et al. Reference Sadeghi, Azari and Hardt2019, Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Khatibi et al. Reference Khatibi, Ashrafizadeh and Sadeghi2020; Silkina et al. Reference Silkina, Bag and Vinogradova2020; Talebi et al. Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021) did not witness such an increase in the electrokinetic transport in brush-grafted nanochannels as compared with that in brush-free nanochannels. First and foremost, none of these papers even attempted to compare the flow field in a brush-grafted nanochannel with that in a brush-free nanochannel under the condition where the net charge on the wall (for the case of brush-free nanochannel) is distributed on the brushes (for the case of brush-grafted nanochannel). This is exactly what has been done in our present paper as well as our previous papers. Without such a comparison, it is not possible to decipher if the results of these papers (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi et al. Reference Sadeghi, Azari and Hardt2019; Khatibi et al. Reference Khatibi, Ashrafizadeh and Sadeghi2020; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Silkina et al. Reference Silkina, Bag and Vinogradova2020; Talebi et al. Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021) would have shown (for some parameter combination) a flow field that is enhanced in brush-grafted nanochannels, as compared with that in brush-free nanochannels. The second issue is the overprediction of the drag force in these papers (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi et al. Reference Sadeghi, Azari and Hardt2019; Khatibi et al. Reference Khatibi, Ashrafizadeh and Sadeghi2020; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Silkina et al. Reference Silkina, Bag and Vinogradova2020; Talebi et al. Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021). The drag coefficient dictating the drag force is the gross representative contribution of the presence of the brushes. It is considered to vary quadratically with the monomer distribution. The existing papers (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi et al. Reference Sadeghi, Azari and Hardt2019; Khatibi et al. Reference Khatibi, Ashrafizadeh and Sadeghi2020; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Silkina et al. Reference Silkina, Bag and Vinogradova2020; Talebi et al. Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021) did not explicitly model the brushes and simply considered a uniform monomer distribution. Therefore, the drag coefficient has a constant value along the entire height of the grafted brushes. This led to an overprediction of the drag force since the velocity away from the wall was larger and hence a larger drag coefficient at such locations implied a larger drag force exerted on the fluid flow by the PE brushes. On the other hand, in our models (the present paper and Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb), we have considered a much more accurate description of the PE brushes by employing the augmented SST to describe the brushes. In our model, the monomer distribution is significantly higher at locations near the grafting site (i.e. the nanochannel wall). As a result, the drag coefficient is much larger at near-wall locations. This ensures that the contribution of the drag force will be significantly lower since the drag force is calculated by multiplying the drag coefficient with the local velocity and this velocity is smaller at near-wall locations. It might be possible that this overprediction of the drag force in the studies by the other groups (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi et al. Reference Sadeghi, Azari and Hardt2019; Khatibi et al. Reference Khatibi, Ashrafizadeh and Sadeghi2020; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Silkina et al. Reference Silkina, Bag and Vinogradova2020; Talebi et al. Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021) might have made them miss this enhancement in the electrokinetic transport in brush-grafted nanochannels and that is why they do not provide any explicit comparison between the flow field in a brush-grafted nanochannel with that in a brush-free nanochannel under the condition where the net charge on the wall (for the case of brush-free nanochannel) is distributed on the brushes (for the case of brush-grafted nanochannel). There is another critical issue that has been overlooked by all of these above-mentioned papers, including our own papers. This issue is the presence of possible molecular slip that the fluid flow experiences along the PE brushes. The presence of this slip will imply that the brushes are not strictly behaving as rigid solid cylinders, which in turn, coupled with the localization of the EDL body force away from the nanochannel wall, is responsible for the flow enhancement that we observe (both in this paper as well as all our previous papers (Chen & Das Reference Chen and Das2017; Chen et al. Reference Chen, Sachar and Das2018; Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a,Reference Maheedhara, Sachar, Jing and Dasb; Sachar et al. Reference Sachar, Sivasankar and Das2019a; Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb)). How can one justify the presence of such intermolecular slip along the brushes? The brush molecules are 1–2 nm thick, soft and flexible polymer molecules, and there has been no definite study that has predicted such a slip along the brush surface. A thorough understanding of this possible slip behaviour at the brush–liquid interface will require a molecular scale simulation of the behaviour of water at the polymer brush interface. While there have been a few studies probing the liquid transport in brush-grafted nanochannels using molecular scale (or molecular dynamics or MD) simulations (Cao & You Reference Cao and You2016; Cao, Tian & You Reference Cao, Tian and You2018; Cao Reference Cao2019), to the best of our knowledge these studies have not elucidated what happens to the flows at the brush–liquid interface (along the height of the polymer brushes). However, these studies (see Cao & You Reference Cao and You2016; Cao et al. Reference Cao, Tian and You2018; Cao Reference Cao2019) do point to the presence of a finite liquid velocity inside the brush layer. This, in a way, supports the idea of a possible absence of a no-slip condition along the surface of the brushes. Also, there are several studies probing the interaction of a DNA molecule in a background fluid flow: these studies point out that there might be a slip condition on the DNA surface (Galla et al. Reference Galla, Meyer, Spiering, Sischka, Mayer, Hall, Reimann and Anselmetti2014; Hirano et al. Reference Hirano, Iwaki, Ishido, Yoshikawa, Naruse and Yoshikawa2018). The DNA is a charged polymer (or a PE) molecule and along that argument it is not too unreasonable an assumption that there will be a finite slip along the surface of the PE brushes. In our previous work (Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a), we have analysed the TOS transport in a nanochannel grafted with end-charged PE brushes. This study (Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a) also showed enhanced transport, as the localization of the EOS body force is equally prevalent for the case with end-charged brushes. However, this study (Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a) reported a less realistic flow field stemming from the fact that the brushes were modelled using the simplistic Alexander–de Gennes model (De Gennes Reference De Gennes1976b; Alexander Reference Alexander1977), which in turn meant that the brushes had a uniform density distribution along their height leading to an over prediction of the brush-induced drag force (Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb). On the other hand, this current paper that describes the brushes using an augmented SST considers a much more realistic monomer density distribution (having a much larger density at near-wall locations) and hence provides a more accurate description of the brush-induced drag force. Overall, therefore, this paper presents a much more realistic theoretical design that enables a massive enhancement in liquid transport in PE-brush-grafted nanofluidic channels by the facile route of the application of an axial temperature gradient triggering large TOS effects. It is important to point out that, to the best of our knowledge, there are no experimental studies on the TOS transport in PE-brush-grafted nanochannels. It is also important to note that the closed-form solutions exist neither for the pH-responsive brush electrostatics (where the brush physics are appropriately modelled) nor for the TOS transport (or any form of induced electrokinetic transport) in nanochannels grafted with such pH-responsive PE brushes.

$\textrm {OH}^-$ ions (please see the online supplementary materials available at https://doi.org/10.1017/jfm.2021.281). Subsequently, we study the overall TOS liquid transport, characterized by the TOS flow velocity. To better understand the variation of the TOS velocity, we study the individual contributions of the COS component, thermal component and the EOS component. We observe that the thermal and the COS components are invariably in the same direction and the net direction of the flow is eventually dictated by the relative strength (with respect to the other components) and direction of the induced EOS transport (or the induced TOS electric field). We compare both the electric field and the velocity field results with those of the brushless nanochannels having the same overall charge density as the brush-grafted nanochannels. We clearly find that the overall TOS velocity is significantly enhanced for the case of the brush-grafted nanochannels. A key factor responsible for causing the enhancement in the TOS liquid transport in the brush-grafted nanochannels in comparison with that in brush-free nanochannels is the localization of the EDL (and hence the EOS body force) away from the nanochannel walls. Even in our previous papers, probing the EOS flow (Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020b) or diffusio-osmotic flow (one kind of induced EOS flow) (Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a), we have identified and attributed such a flow enhancement in brush-grafted nanochannels (in comparison with the brush-free nanochannels with identical charge density) to this localization of the EDL (and hence the EOS body force) away from the nanochannel wall. To reiterate, we are comparing here two cases: a brush-free nanochannel and a brush-grafted nanochannel. The basis of comparison is that the charges on the walls of the brush-free nanochannel are considered to be distributed on the brushes (grafted on a charge-free wall) in brush-grafted nanochannels. Therefore, the presence of the brushes shifts the centre of the charges (and hence the EDL induced by these charges and the consequent EOS body force) away from the nanochannel wall. One can easily show that for a flow in a nanochannel driven by an external force, the net flow rate increases with an increase in the distance (from the nanochannel wall) at which this external force is localized and this increase becomes maximum if this force is localized at the nanochannel centre. The presence of the brushes causes this localization and hence aids flow enhancement. However, the same very presence of the brushes subjects the flow to an additional drag force. Therefore, the brushes trigger two competing mechanisms (in the context of the electrokinetic fluid flow): localization of the EOS body force that enhances the flow and the presence of the additional brush-induced drag that reduces the flow. For certain parameter combinations, the effect of the localization of the EOS body force overwhelms the effect of the brush-induced drag, thereby enhancing the net flow rate. This is the central idea of this paper. It is also very pertinent to point out here that a large number of studies from other research groups have probed such electrokinetic transport in nanochannels/nanopores grafted with PE brushes (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng, Ai & Qian Reference Zeng, Ai and Qian2014; Zeng et al. Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi, Azari & Hardt Reference Sadeghi, Azari and Hardt2019; Khatibi, Ashrafizadeh & Sadeghi Reference Khatibi, Ashrafizadeh and Sadeghi2020; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Silkina, Bag & Vinogradova Reference Silkina, Bag and Vinogradova2020; Talebi, Ashrafizadeh & Sadeghi Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021). They use exactly the same form of equation (see the 1st equation of (2.17) later) as ours. This equation is a ‘Brinkman’-like equation and is also sometimes denoted as the Stokes–Brinkman equation (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Sadeghi Reference Sadeghi2018). It provides a gross representation of the contribution of the brushes by considering the PE brush layer to be represented as a porous medium. It considers that the brushes do two things: (1) they trigger a particular EDL distribution and hence a particular distribution of the EOS body force (and other possible forces related to the EDL) and (2) they impart an additional gross drag force (with drag coefficient varying quadratically with the monomer distribution) on the fluid flow. In this context, the natural question arises that why these other papers (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi et al. Reference Sadeghi, Azari and Hardt2019, Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Khatibi et al. Reference Khatibi, Ashrafizadeh and Sadeghi2020; Silkina et al. Reference Silkina, Bag and Vinogradova2020; Talebi et al. Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021) did not witness such an increase in the electrokinetic transport in brush-grafted nanochannels as compared with that in brush-free nanochannels. First and foremost, none of these papers even attempted to compare the flow field in a brush-grafted nanochannel with that in a brush-free nanochannel under the condition where the net charge on the wall (for the case of brush-free nanochannel) is distributed on the brushes (for the case of brush-grafted nanochannel). This is exactly what has been done in our present paper as well as our previous papers. Without such a comparison, it is not possible to decipher if the results of these papers (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi et al. Reference Sadeghi, Azari and Hardt2019; Khatibi et al. Reference Khatibi, Ashrafizadeh and Sadeghi2020; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Silkina et al. Reference Silkina, Bag and Vinogradova2020; Talebi et al. Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021) would have shown (for some parameter combination) a flow field that is enhanced in brush-grafted nanochannels, as compared with that in brush-free nanochannels. The second issue is the overprediction of the drag force in these papers (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi et al. Reference Sadeghi, Azari and Hardt2019; Khatibi et al. Reference Khatibi, Ashrafizadeh and Sadeghi2020; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Silkina et al. Reference Silkina, Bag and Vinogradova2020; Talebi et al. Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021). The drag coefficient dictating the drag force is the gross representative contribution of the presence of the brushes. It is considered to vary quadratically with the monomer distribution. The existing papers (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi et al. Reference Sadeghi, Azari and Hardt2019; Khatibi et al. Reference Khatibi, Ashrafizadeh and Sadeghi2020; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Silkina et al. Reference Silkina, Bag and Vinogradova2020; Talebi et al. Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021) did not explicitly model the brushes and simply considered a uniform monomer distribution. Therefore, the drag coefficient has a constant value along the entire height of the grafted brushes. This led to an overprediction of the drag force since the velocity away from the wall was larger and hence a larger drag coefficient at such locations implied a larger drag force exerted on the fluid flow by the PE brushes. On the other hand, in our models (the present paper and Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb), we have considered a much more accurate description of the PE brushes by employing the augmented SST to describe the brushes. In our model, the monomer distribution is significantly higher at locations near the grafting site (i.e. the nanochannel wall). As a result, the drag coefficient is much larger at near-wall locations. This ensures that the contribution of the drag force will be significantly lower since the drag force is calculated by multiplying the drag coefficient with the local velocity and this velocity is smaller at near-wall locations. It might be possible that this overprediction of the drag force in the studies by the other groups (Yeh et al. Reference Yeh, Zhang, Hu, Joo, Qian and Hsu2012a,Reference Yeh, Zhang, Joo, Qian and Hsub,Reference Yeh, Zhang, Qian, Hsu and Tsengc; Benson et al. Reference Benson, Yeh, Chou and Qian2013; Milne et al. Reference Milne, Yeh, Chou and Qian2014; Zeng et al. Reference Zeng, Ai and Qian2014, Reference Zeng, Yeh, Zhang and Qian2015; Poddar et al. Reference Poddar, Maity, Bandopadhyay and Chakraborty2016; Zhou et al. Reference Zhou, Mei, Su, Yeh, Zhang and Qian2016; Zimmermann et al. Reference Zimmermann, Gunkel-Grabole, Bünsow, Werner, Huck and Duval2017; Sadeghi Reference Sadeghi2018; Sin & Kim Reference Sin and Kim2018; Hsu et al. Reference Hsu, Yang, Lin and Tseng2019; Huang & Hsu Reference Huang and Hsu2019; Lin et al. Reference Lin, Hsu, Lin and Tseng2019; Reshadi & Saidi Reference Reshadi and Saidi2019; Sadeghi et al. Reference Sadeghi, Azari and Hardt2019; Khatibi et al. Reference Khatibi, Ashrafizadeh and Sadeghi2020; Sadeghi et al. Reference Sadeghi, Saidi, Moosavi and Kroger2020a,Reference Sadeghi, Saidi, Moosavi and Sadeghib; Silkina et al. Reference Silkina, Bag and Vinogradova2020; Talebi et al. Reference Talebi, Ashrafizadeh and Sadeghi2021; Wu & Hsu Reference Wu and Hsu2021) might have made them miss this enhancement in the electrokinetic transport in brush-grafted nanochannels and that is why they do not provide any explicit comparison between the flow field in a brush-grafted nanochannel with that in a brush-free nanochannel under the condition where the net charge on the wall (for the case of brush-free nanochannel) is distributed on the brushes (for the case of brush-grafted nanochannel). There is another critical issue that has been overlooked by all of these above-mentioned papers, including our own papers. This issue is the presence of possible molecular slip that the fluid flow experiences along the PE brushes. The presence of this slip will imply that the brushes are not strictly behaving as rigid solid cylinders, which in turn, coupled with the localization of the EDL body force away from the nanochannel wall, is responsible for the flow enhancement that we observe (both in this paper as well as all our previous papers (Chen & Das Reference Chen and Das2017; Chen et al. Reference Chen, Sachar and Das2018; Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a,Reference Maheedhara, Sachar, Jing and Dasb; Sachar et al. Reference Sachar, Sivasankar and Das2019a; Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb)). How can one justify the presence of such intermolecular slip along the brushes? The brush molecules are 1–2 nm thick, soft and flexible polymer molecules, and there has been no definite study that has predicted such a slip along the brush surface. A thorough understanding of this possible slip behaviour at the brush–liquid interface will require a molecular scale simulation of the behaviour of water at the polymer brush interface. While there have been a few studies probing the liquid transport in brush-grafted nanochannels using molecular scale (or molecular dynamics or MD) simulations (Cao & You Reference Cao and You2016; Cao, Tian & You Reference Cao, Tian and You2018; Cao Reference Cao2019), to the best of our knowledge these studies have not elucidated what happens to the flows at the brush–liquid interface (along the height of the polymer brushes). However, these studies (see Cao & You Reference Cao and You2016; Cao et al. Reference Cao, Tian and You2018; Cao Reference Cao2019) do point to the presence of a finite liquid velocity inside the brush layer. This, in a way, supports the idea of a possible absence of a no-slip condition along the surface of the brushes. Also, there are several studies probing the interaction of a DNA molecule in a background fluid flow: these studies point out that there might be a slip condition on the DNA surface (Galla et al. Reference Galla, Meyer, Spiering, Sischka, Mayer, Hall, Reimann and Anselmetti2014; Hirano et al. Reference Hirano, Iwaki, Ishido, Yoshikawa, Naruse and Yoshikawa2018). The DNA is a charged polymer (or a PE) molecule and along that argument it is not too unreasonable an assumption that there will be a finite slip along the surface of the PE brushes. In our previous work (Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a), we have analysed the TOS transport in a nanochannel grafted with end-charged PE brushes. This study (Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a) also showed enhanced transport, as the localization of the EOS body force is equally prevalent for the case with end-charged brushes. However, this study (Maheedhara et al. Reference Maheedhara, Jing, Sachar and Das2018a) reported a less realistic flow field stemming from the fact that the brushes were modelled using the simplistic Alexander–de Gennes model (De Gennes Reference De Gennes1976b; Alexander Reference Alexander1977), which in turn meant that the brushes had a uniform density distribution along their height leading to an over prediction of the brush-induced drag force (Sivasankar et al. Reference Sivasankar, Etha, Sachar and Das2020a,Reference Sivasankar, Etha, Sachar and Dasb). On the other hand, this current paper that describes the brushes using an augmented SST considers a much more realistic monomer density distribution (having a much larger density at near-wall locations) and hence provides a more accurate description of the brush-induced drag force. Overall, therefore, this paper presents a much more realistic theoretical design that enables a massive enhancement in liquid transport in PE-brush-grafted nanofluidic channels by the facile route of the application of an axial temperature gradient triggering large TOS effects. It is important to point out that, to the best of our knowledge, there are no experimental studies on the TOS transport in PE-brush-grafted nanochannels. It is also important to note that the closed-form solutions exist neither for the pH-responsive brush electrostatics (where the brush physics are appropriately modelled) nor for the TOS transport (or any form of induced electrokinetic transport) in nanochannels grafted with such pH-responsive PE brushes.

2. Theory

In this study, we investigate the TOS flow in a backbone-charged pH-responsive PE-brush-grafted nanochannel whose height is ![]() $2h$ (

$2h$ (![]() $-h\leq y \leq h$) and length

$-h\leq y \leq h$) and length ![]() $L$ (see figure 1). The nanochannel is connected to reservoirs on both sides filled with an electrolyte whose bulk salt concentration and pH are

$L$ (see figure 1). The nanochannel is connected to reservoirs on both sides filled with an electrolyte whose bulk salt concentration and pH are ![]() $n_\infty$ and

$n_\infty$ and ![]() $\textrm {pH}_\infty$, respectively. The equilibrium configuration and electrostatics of the PE brush are modelled using our recently developed augmented SST (Sachar et al. Reference Sachar, Sivasankar and Das2019a,Reference Sachar, Sivasankar and Dasb, Reference Sachar, Sivasankar, Etha, Chen and Das2020). The brush configuration, quantified by brush height

$\textrm {pH}_\infty$, respectively. The equilibrium configuration and electrostatics of the PE brush are modelled using our recently developed augmented SST (Sachar et al. Reference Sachar, Sivasankar and Das2019a,Reference Sachar, Sivasankar and Dasb, Reference Sachar, Sivasankar, Etha, Chen and Das2020). The brush configuration, quantified by brush height ![]() $H$ and the monomer distribution along the brush height

$H$ and the monomer distribution along the brush height ![]() $\phi$ as well as the electrostatic potential

$\phi$ as well as the electrostatic potential ![]() $\psi$ of the brush-induced EDL are obtained in a thermodynamically self-consistent fashion. Here, we consider a TOS flow induced in the nanochannel by an applied axial temperature gradient (

$\psi$ of the brush-induced EDL are obtained in a thermodynamically self-consistent fashion. Here, we consider a TOS flow induced in the nanochannel by an applied axial temperature gradient (![]() $\boldsymbol {\nabla } T = \textrm {d}T/{\textrm {d} x}$) across the length

$\boldsymbol {\nabla } T = \textrm {d}T/{\textrm {d} x}$) across the length ![]() $L$ of the channel. The temperature gradient is such that

$L$ of the channel. The temperature gradient is such that ![]() $L({\boldsymbol {\nabla } T}/{T})\ll 1$. This implies a weak gradient in temperature, which due to Soret effect, will induce a weak gradient in the concentration of bulk ions (

$L({\boldsymbol {\nabla } T}/{T})\ll 1$. This implies a weak gradient in temperature, which due to Soret effect, will induce a weak gradient in the concentration of bulk ions (![]() $\boldsymbol {\nabla } n_{i,\infty } = {\textrm {d}n_{i,\infty }}/{\textrm {d} x}$, where

$\boldsymbol {\nabla } n_{i,\infty } = {\textrm {d}n_{i,\infty }}/{\textrm {d} x}$, where ![]() $i = \pm ,\textrm {H}^+,\textrm {OH}^-$) across the length of the channel. Hence the change in the concentration across the nanochannel length will be negligibly small as compared with the bulk concentration within the reservoirs. Under such circumstances, we can still assume that the concentration within the two reservoirs is nearly similar. This weak gradient in temperature also implies a weak gradient in brush height, EDL potential, monomer distribution and the ion distribution within the EDL. The TOS transport will induce an electric field, which will be described in detail later. In the first section, we shall review the key equations of the augmented SST model for backbone-charged PE brushes followed by the theory for the TOS transport. The detailed procedure for modelling of PE brushes by augmented SST has been provided in our previous studies (Sachar et al. Reference Sachar, Sivasankar and Das2019a,Reference Sachar, Sivasankar and Dasb, Reference Sachar, Sivasankar, Etha, Chen and Das2020) and we provide a summary of the key equations here for the sake of continuity.

$i = \pm ,\textrm {H}^+,\textrm {OH}^-$) across the length of the channel. Hence the change in the concentration across the nanochannel length will be negligibly small as compared with the bulk concentration within the reservoirs. Under such circumstances, we can still assume that the concentration within the two reservoirs is nearly similar. This weak gradient in temperature also implies a weak gradient in brush height, EDL potential, monomer distribution and the ion distribution within the EDL. The TOS transport will induce an electric field, which will be described in detail later. In the first section, we shall review the key equations of the augmented SST model for backbone-charged PE brushes followed by the theory for the TOS transport. The detailed procedure for modelling of PE brushes by augmented SST has been provided in our previous studies (Sachar et al. Reference Sachar, Sivasankar and Das2019a,Reference Sachar, Sivasankar and Dasb, Reference Sachar, Sivasankar, Etha, Chen and Das2020) and we provide a summary of the key equations here for the sake of continuity.

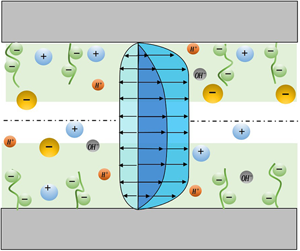

Figure 1. Schematic representing the flow induced by temperature gradient induced in (a) a brush-free nanochannel and (b) a backbone-charged PE-brush-grafted nanochannel. It shows a situation where the EOS component of the flow (![]() $u_{EOS}$) opposes the COS component of the flow (

$u_{EOS}$) opposes the COS component of the flow (![]() $u_{COS}$) and the thermal component of the flow (

$u_{COS}$) and the thermal component of the flow (![]() $u_T$) as the thermo-osmotically induced electric field is negative (i.e. directed from right to left). Of course, it is equally possible that the thermo-osmotically induced electric field is positive (i.e. directed left to right) and the EOS flow aids the COS component and the thermal component. Here

$u_T$) as the thermo-osmotically induced electric field is negative (i.e. directed from right to left). Of course, it is equally possible that the thermo-osmotically induced electric field is positive (i.e. directed left to right) and the EOS flow aids the COS component and the thermal component. Here ![]() $\lambda _{EDL}$ is the EDL thickness.

$\lambda _{EDL}$ is the EDL thickness.

2.1. Modelling of pH-responsive PE brushes using augmented strong stretching theory

The brush configuration and electrostatics are modelled using our recently developed augmented SST which improves the existing SST (Lyatskaya et al. Reference Lyatskaya, Leermakers, Fleer, Zhulina and Birshtein1995; Zhulina & Borisov Reference Zhulina and Borisov1997; Zhulina et al. Reference Zhulina, Klein Wolterink and Borisov2000; Lebedeva et al. Reference Lebedeva, Zhulina and Borisov2017) by taking into account the effects of excluded volume effect and a more generic mass action law. In this model, the total free energy functional (![]() $F$) of the PE brush molecule is minimized to obtain the equilibrium configuration. The total free energy functional of the PE brush molecule is given by

$F$) of the PE brush molecule is minimized to obtain the equilibrium configuration. The total free energy functional of the PE brush molecule is given by

where ![]() $F_{els}$ is the elastic contribution to the free energy,

$F_{els}$ is the elastic contribution to the free energy, ![]() $F_{EV}$ is the energy associated with excluded volume effect,

$F_{EV}$ is the energy associated with excluded volume effect, ![]() $F_{elec}$ is the electrostatic free energy,

$F_{elec}$ is the electrostatic free energy, ![]() $F_{EDL}$ is the free energy associated with electrostatic energy of the brush-induced EDL,

$F_{EDL}$ is the free energy associated with electrostatic energy of the brush-induced EDL, ![]() $F_{ion}$ is ionization free energy and

$F_{ion}$ is ionization free energy and ![]() $k_BT$ is the thermal energy. Kindly refer to our previous work (Sachar et al. Reference Sachar, Sivasankar and Das2019b) for detailed description and the step-by-step minimization procedure.

$k_BT$ is the thermal energy. Kindly refer to our previous work (Sachar et al. Reference Sachar, Sivasankar and Das2019b) for detailed description and the step-by-step minimization procedure.

We minimize the net free energy (see (2.1)) by using the variational formalism in the presence of the following constraints:

Here, ![]() $N$ is the number of monomers in a PE chain,

$N$ is the number of monomers in a PE chain, ![]() $\bar {U}(y,y^\prime )={\textrm {d} y}/\textrm {d}n$ quantifies the local stretching of the chain at a location

$\bar {U}(y,y^\prime )={\textrm {d} y}/\textrm {d}n$ quantifies the local stretching of the chain at a location ![]() $y$ (the chain is characterized by the fact that its end is located at

$y$ (the chain is characterized by the fact that its end is located at ![]() $y^\prime$), where

$y^\prime$), where ![]() $n$ is the order number of monomer unit. Also,

$n$ is the order number of monomer unit. Also, ![]() $a, H, \phi (y), \sigma \sim {1}/{\ell ^2}$ (

$a, H, \phi (y), \sigma \sim {1}/{\ell ^2}$ (![]() $\ell$ is the separation between the adjacent PE grafting sites) are the Kuhn length, the brush height, dimensionless monomer distribution of the PE brushes, and the grafting density of the PE brushes, respectively. The variational minimization of (2.1) (see (Sachar et al. Reference Sachar, Sivasankar and Das2019b) for step-by-step details) provides the following governing equations describing the equilibrium behaviour of the system (the lower half of the nanochannel):

$\ell$ is the separation between the adjacent PE grafting sites) are the Kuhn length, the brush height, dimensionless monomer distribution of the PE brushes, and the grafting density of the PE brushes, respectively. The variational minimization of (2.1) (see (Sachar et al. Reference Sachar, Sivasankar and Das2019b) for step-by-step details) provides the following governing equations describing the equilibrium behaviour of the system (the lower half of the nanochannel):

\begin{gather} n_{A^-}=\frac{K_a'\gamma}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)},\end{gather}

\begin{gather} n_{A^-}=\frac{K_a'\gamma}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)},\end{gather} \begin{gather} \left. \begin{array}{c@{}} \epsilon_{0}\epsilon_{r}\left(\dfrac{\textrm{d}^2\psi}{{\textrm{d} y}^2}\right)+e(n_+{-}n_-{+}n_{\textrm{H}^+}-n_{\textrm{OH}^-}-n_{A^-}\phi)=0 \quad ({-}h\leq y\leq{-}h+H),\\ \epsilon_{0}\epsilon_{r}\left(\dfrac{\textrm{d}^2\psi}{{\textrm{d} y}^2}\right)+e(n_+{-}n_-{+}n_{\textrm{H}^+}-n_{\textrm{OH}^-})=0 \quad ({-}h+H\leq y\leq 0), \end{array}\right\} \end{gather}

\begin{gather} \left. \begin{array}{c@{}} \epsilon_{0}\epsilon_{r}\left(\dfrac{\textrm{d}^2\psi}{{\textrm{d} y}^2}\right)+e(n_+{-}n_-{+}n_{\textrm{H}^+}-n_{\textrm{OH}^-}-n_{A^-}\phi)=0 \quad ({-}h\leq y\leq{-}h+H),\\ \epsilon_{0}\epsilon_{r}\left(\dfrac{\textrm{d}^2\psi}{{\textrm{d} y}^2}\right)+e(n_+{-}n_-{+}n_{\textrm{H}^+}-n_{\textrm{OH}^-})=0 \quad ({-}h+H\leq y\leq 0), \end{array}\right\} \end{gather} \begin{align} \nonumber\\ \phi (y)& = \frac{\nu}{3\omega}\left[\left\{1+\kappa_B^2\left(\lambda-(y+h)^2 +\beta\frac{K_a'\gamma}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\psi \right.\right.\right.\nonumber\\ & \quad {-\rho\left(1-\frac{K_a'}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\right)\ln\left(1-\frac{K_a'}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\right)}\nonumber\\ &\quad {-\rho\frac{K_a'}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\ln\left(\frac{K_a'}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\right)}\nonumber\\ &\quad \left.\left.{\left.-\rho\frac{K_a'}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\ln\left(\frac{n_{\textrm{H}^+,\infty}}{K_a'}\right) \right)}\right\}^{1/2}-1\right], \end{align}

\begin{align} \nonumber\\ \phi (y)& = \frac{\nu}{3\omega}\left[\left\{1+\kappa_B^2\left(\lambda-(y+h)^2 +\beta\frac{K_a'\gamma}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\psi \right.\right.\right.\nonumber\\ & \quad {-\rho\left(1-\frac{K_a'}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\right)\ln\left(1-\frac{K_a'}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\right)}\nonumber\\ &\quad {-\rho\frac{K_a'}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\ln\left(\frac{K_a'}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\right)}\nonumber\\ &\quad \left.\left.{\left.-\rho\frac{K_a'}{K_a'+n_{\textrm{H}^+,\infty}\exp\left(-\gamma a^3\dfrac{e\psi}{k_BT}\right)}\ln\left(\frac{n_{\textrm{H}^+,\infty}}{K_a'}\right) \right)}\right\}^{1/2}-1\right], \end{align} \begin{gather}g(y)=\frac{(y+h)}{\sigma Na^3}\left[\frac{\phi({-}h+H)}{\sqrt{H^2-(y+h)^2}}- \int_{y}^{H-h}\frac{\textrm{d}\phi(y')}{{\textrm{d} y}'}\frac{{\textrm{d} y}'}{\sqrt{{(y'+h)}^2-(y+h)^2}}\right]. \end{gather}

\begin{gather}g(y)=\frac{(y+h)}{\sigma Na^3}\left[\frac{\phi({-}h+H)}{\sqrt{H^2-(y+h)^2}}- \int_{y}^{H-h}\frac{\textrm{d}\phi(y')}{{\textrm{d} y}'}\frac{{\textrm{d} y}'}{\sqrt{{(y'+h)}^2-(y+h)^2}}\right]. \end{gather}

Equation (2.4) gives the relation for the number density of the ![]() $A^-$ ion (

$A^-$ ion (![]() $n_{A^-}$) produced by acid-like disassociation of HA (here HA represents the acid) on the brush backbone. In (2.4),

$n_{A^-}$) produced by acid-like disassociation of HA (here HA represents the acid) on the brush backbone. In (2.4), ![]() $K_a'=10^3N_{A}K_a$, where

$K_a'=10^3N_{A}K_a$, where ![]() $K_a$ is the ionization constant of the acid-like disassociation of HA,

$K_a$ is the ionization constant of the acid-like disassociation of HA, ![]() $n_{\textrm {H}^+,\infty }=10^3N_{A}c_{\textrm {H}^+,\infty }$ (

$n_{\textrm {H}^+,\infty }=10^3N_{A}c_{\textrm {H}^+,\infty }$ (![]() $c_{\textrm {H}^+,\infty }$ is the bulk concentration of the H

$c_{\textrm {H}^+,\infty }$ is the bulk concentration of the H![]() $^+$ ions in Molars and can be related to

$^+$ ions in Molars and can be related to ![]() $\textrm {pH}_\infty$ as

$\textrm {pH}_\infty$ as ![]() $c_{\textrm {H}^+,\infty }=10^{-\textrm {pH}_\infty }, N_A$ is the Avagdro number),

$c_{\textrm {H}^+,\infty }=10^{-\textrm {pH}_\infty }, N_A$ is the Avagdro number), ![]() $e$ is the elementary charge and

$e$ is the elementary charge and ![]() $\gamma$ is the polyelectrolyte chargeable sites (PCS) density in units of

$\gamma$ is the polyelectrolyte chargeable sites (PCS) density in units of ![]() $1/\textrm {m}^3$. Equation (2.5) provides the distribution of the EDL electrostatic potential

$1/\textrm {m}^3$. Equation (2.5) provides the distribution of the EDL electrostatic potential ![]() $\psi$ for the bottom half of the nanochannel (

$\psi$ for the bottom half of the nanochannel (![]() $-h\le y\le 0$). Equations (2.6)–(2.8) express the ion number densities through the Boltzmann distributions. Here,

$-h\le y\le 0$). Equations (2.6)–(2.8) express the ion number densities through the Boltzmann distributions. Here, ![]() $n_i$ and

$n_i$ and ![]() $n_{i,\infty } (=10^3 N_A c_{i,\infty }$, where

$n_{i,\infty } (=10^3 N_A c_{i,\infty }$, where ![]() $c_{i,\infty }$ is the bulk concentration of ion

$c_{i,\infty }$ is the bulk concentration of ion ![]() $i$ in Molars) represent the number density and bulk number density for ion

$i$ in Molars) represent the number density and bulk number density for ion ![]() $i$ [where

$i$ [where ![]() $i=\pm$, H

$i=\pm$, H![]() $^+$, OH

$^+$, OH![]() $^-$],

$^-$], ![]() $\epsilon _0$ is the permittivity of free space and

$\epsilon _0$ is the permittivity of free space and ![]() $\epsilon _r$ is relative permittivity of the electrolyte solution. Equation (2.9) provides the monomer distribution profile and

$\epsilon _r$ is relative permittivity of the electrolyte solution. Equation (2.9) provides the monomer distribution profile and ![]() $\kappa _B^2={9\pi ^2\omega }/{8N^2a^2\nu ^2}, \rho ={8a^2N^2}/{3\pi ^2}, \lambda =-\lambda _1\rho =-\lambda _1({8a^2N^2}/{3\pi ^2}) (\lambda _1$ is the Lagrange multiplier associated with the constraint expressed in (2.3), and

$\kappa _B^2={9\pi ^2\omega }/{8N^2a^2\nu ^2}, \rho ={8a^2N^2}/{3\pi ^2}, \lambda =-\lambda _1\rho =-\lambda _1({8a^2N^2}/{3\pi ^2}) (\lambda _1$ is the Lagrange multiplier associated with the constraint expressed in (2.3), and ![]() $\nu $ and

$\nu $ and ![]() $\omega $ are the virial coefficients associated with excluded volume free energy and

$\omega $ are the virial coefficients associated with excluded volume free energy and ![]() $\beta ={8N^2ea^5}/{3\pi ^2k_BT}$. Equation (2.10) provides the condition of local stretching. Equation (2.11) considers the net unbalanced charge

$\beta ={8N^2ea^5}/{3\pi ^2k_BT}$. Equation (2.10) provides the condition of local stretching. Equation (2.11) considers the net unbalanced charge ![]() $q_{net}$ in the system (see (2.12)) and provides a condition for quantifying the equilibrium brush height

$q_{net}$ in the system (see (2.12)) and provides a condition for quantifying the equilibrium brush height ![]() $H_0$. Finally, (2.13) quantifies the normalized chain end distribution (

$H_0$. Finally, (2.13) quantifies the normalized chain end distribution (![]() $g(y')$) that also satisfies the condition

$g(y')$) that also satisfies the condition ![]() ${\int _{-h}^{H-h}g(y^\prime )\,{\textrm {d} y}^\prime =1}$. The brush configuration and electrostatics (which eventually provide the brush height, monomer distribution and the brush-induced EDL distribution) are finally obtained by solving ((2.4)–(2.13)) in the presence of the following boundary condition for the EDL electrostatics (assuming an uncharged grafting surface):

${\int _{-h}^{H-h}g(y^\prime )\,{\textrm {d} y}^\prime =1}$. The brush configuration and electrostatics (which eventually provide the brush height, monomer distribution and the brush-induced EDL distribution) are finally obtained by solving ((2.4)–(2.13)) in the presence of the following boundary condition for the EDL electrostatics (assuming an uncharged grafting surface):

\begin{align} &(\psi)_{y=({-}h+H)^-}=(\psi)_{y=({-}h+H)^+},\quad \left(\frac{\textrm{d}\psi}{\textrm{d} y}\right)_{y=({-}h+H)^-}=\left(\frac{\textrm{d}\psi}{\textrm{d} y}\right)_{y=({-}h+H)^+},\nonumber\\ &\quad \left(\frac{\textrm{d}\psi}{\textrm{d} y}\right)_{y={-}h}=0,\quad \left(\frac{\textrm{d}\psi}{\textrm{d} y}\right)_{y=0}=0. \end{align}

\begin{align} &(\psi)_{y=({-}h+H)^-}=(\psi)_{y=({-}h+H)^+},\quad \left(\frac{\textrm{d}\psi}{\textrm{d} y}\right)_{y=({-}h+H)^-}=\left(\frac{\textrm{d}\psi}{\textrm{d} y}\right)_{y=({-}h+H)^+},\nonumber\\ &\quad \left(\frac{\textrm{d}\psi}{\textrm{d} y}\right)_{y={-}h}=0,\quad \left(\frac{\textrm{d}\psi}{\textrm{d} y}\right)_{y=0}=0. \end{align}

Here the superscript ‘![]() $+$’ refers to the location of the tip of the brush when approached from the brush-free bulk side and the superscript ‘

$+$’ refers to the location of the tip of the brush when approached from the brush-free bulk side and the superscript ‘![]() $-$’ refers to the location of the tip of the brush when approached from the brush side.

$-$’ refers to the location of the tip of the brush when approached from the brush side.

2.2. TOS transport in brush-grafted nanochannels

Thermo-osmotic flow, induced by a temperature gradient (![]() $\boldsymbol {\nabla } T$) across the nanochannel length (

$\boldsymbol {\nabla } T$) across the nanochannel length (![]() $L$), is considered to be unidirectional, steady and fully developed based on space charge theory (SCT) (Gross & Osterle Reference Gross and Osterle1968; Peters et al. Reference Peters, Van Roij, Bazant and Biesheuvel2016; Ryzhkov et al. Reference Ryzhkov, Lebedev, Solodovnichenko, Shiverskiy and Simunin2017, Reference Ryzhkov, Lebedev, Solodovnichenko, Minakov and Simunin2018). According to SCT, there exists a local equilibrium in the transverse direction at any location along the length of the channel. Here, we can apply the SCT to the ionic number density, the ionic and thermal fluxes, the EDL and the local flow field, as we consider the flow in a long nanochannel, i.e.

$L$), is considered to be unidirectional, steady and fully developed based on space charge theory (SCT) (Gross & Osterle Reference Gross and Osterle1968; Peters et al. Reference Peters, Van Roij, Bazant and Biesheuvel2016; Ryzhkov et al. Reference Ryzhkov, Lebedev, Solodovnichenko, Shiverskiy and Simunin2017, Reference Ryzhkov, Lebedev, Solodovnichenko, Minakov and Simunin2018). According to SCT, there exists a local equilibrium in the transverse direction at any location along the length of the channel. Here, we can apply the SCT to the ionic number density, the ionic and thermal fluxes, the EDL and the local flow field, as we consider the flow in a long nanochannel, i.e. ![]() $L\gg h$. We have also shown in our previous work that when a very small gradient of salt concentration is applied across this long nanochannel, the SCT is applicable (see the supplementary material of Jing & Das Reference Jing and Das2018). Similarly, for a very weak gradient in temperature applied in a long and thin nanochannel, the SCT will be applicable. The fluid transport in the presence of temperature gradient is governed by the Navier–Stokes (NS) equations which are expressed below. The pressure field (

$L\gg h$. We have also shown in our previous work that when a very small gradient of salt concentration is applied across this long nanochannel, the SCT is applicable (see the supplementary material of Jing & Das Reference Jing and Das2018). Similarly, for a very weak gradient in temperature applied in a long and thin nanochannel, the SCT will be applicable. The fluid transport in the presence of temperature gradient is governed by the Navier–Stokes (NS) equations which are expressed below. The pressure field (![]() $p$), obtained from the

$p$), obtained from the ![]() $y$-momentum NS equation using the number density relations provided in (2.6)–(2.8), is as follows:

$y$-momentum NS equation using the number density relations provided in (2.6)–(2.8), is as follows: