Introduction

Iron was an important commodity in the success of the Khmer Empire, which, from the ninth to fifteenth centuries AD, ruled vast parts of Mainland Southeast Asia from its capital of Angkor in northern Cambodia (Hendrickson et al. Reference Hendrickson, Leroy, Hua, Phon and Voeun2017). As with many pre-modern states, such as ancient Rome, Imperial China and across pre-colonial Africa, the Khmer employed this versatile metal for a variety of purposes, including weapons to extend their territories and as tools for rice-farming and other daily activities, and to assist in the construction of monumental projects, such as Angkor Wat and Bayon. Beyond the discovery of iron artefacts and depictions of tools and weapons in temple bas reliefs, determining how iron helped shape the growth of Angkor—or any complex society—requires the holistic investigation of technologies, the scale and organisation of production and the communities involved in the production processes (see Costin Reference Costin, Feinman and Price2001).

Research in and knowledge of historic-period (fifth- to fifteenth centuries AD) iron production in Mainland Southeast Asia has undergone a major transformation over the past decade. Although this versatile metal has been used locally since the fifth century BC, the evidence for primary production and producers during the rise and expansion of state polities is surprisingly limited to a few isolated and often poorly dated sites in north-east Thailand (Nitta Reference Nitta, Soejono and Welch1997; Venunan Reference Venunan2016) and more recent discoveries in Myanmar (Hudson Reference Hudson2006), the Bujang Valley, Malaysia (Mokhtar et al. Reference Mokhtar, Saidin and Abdullah2011), and the upland Saphim site in Laos (Pryce et al. Reference Pryce, Chiemsisouraj, Zeitoun and Forestier2011). The regional exception is the extensive record of iron smelting documented in Cambodia (Living Angkor Road Project 2008; Thuy Reference Thuy2014), particularly around Phnom Dek—the ‘Iron Mountain’—located 135km east of Angkor. This large source of high-grade (75–85 per cent) magnetite/haematite ore sits at the centre of a vast eighth- to twentieth-century AD industrial landscape featuring hundreds of slag concentrations (Hendrickson et al. Reference Hendrickson, Leroy, Hua, Phon and Voeun2017).

Landscape and archaeometallurgical studies indicate that iron was an important resource in the expansion of Angkor's urban complex and imperialism during the peak of the Khmer Empire between the eleventh and thirteenth centuries (Hendrickson & Evans Reference Hendrickson and Evans2015; Leroy et al. Reference Leroy, Hendrickson, Bauvais, Blanchet, Disser, Vega and Delqué-Kolic2017). Absent, however, are the finer-grained details concerning how iron was manufactured and the lifeways of the Angkorian smelting communities. The ‘Industries of Angkor Project’ (INDAP) and ‘Iron and Angkor Project’ (RANGKOR) excavations at Tonle Bak, located to the south of Phnom Dek, provide the first insights into the formation of smelting sites, the presence of a long-term community of producers and associated ritual practices. This excavation campaign reveals direct economic interconnection with Greater Angkor and new clues about the identity of Angkorian ironworkers. It also highlights the growing diversity in smelting technologies employed by historic-period iron producers in Mainland Southeast Asia.

Finding smelting communities

Documenting evidence for smelting communities is one of the most challenging aspects of studying iron production in the archaeological record in general. Ethnographic and historical accounts provide dichotomous views of the spatial relationship between production and habitation. In some cases, a physical separation of smelting and living areas reflects taboos, secrecy and male-dominated practice (Barndon Reference Barndon and Schmidt1996; Schmidt Reference Schmidt1997: 58–71; Blakely Reference Blakely2006), while others show spatial integration, the presence of different craft producers (e.g. metallurgists, potters) working and living together and the inclusion of the wider community in some or all parts of the smelting process (Leuva Reference Leuva1963: 151; Sterner & David Reference Sterner and David1991; Narmo Reference Narmo and Nørbach2003). Further variations in community organisation can result from differences in the scale of production required to meet village- vs state-level demands. Examples of the latter manifest as direct control of iron production inside the capital of imperialist states, as at Vijayanagara in India and Meroë in Sudan (Sinopoli Reference Sinopoli2003: 192–203; Haaland Reference Haaland2014: 658–60; also see recent discussion in Carey et al. Reference Carey, Stremke and Humphris2019), or by positioning state outposts at major ore and fuel sources, as in Roman Britain (Cleere & Crossley Reference Cleere and Crossley1985). These different spatial scenarios are also influenced by whether the iron was produced by state agents or by a secondary group of specialist ironworkers (de Barros Reference de Barros and Vogel2000: 186–98). Without historical records, identifying the ethnicity or group-affiliation of these craftspeople is difficult (Emberling Reference Emberling1997; Costin Reference Costin1998; Mattingly Reference Mattingly2011). An initial step towards addressing this problem is to locate archaeological evidence of occupation and to evaluate it in relation to patterns of spatial organisation, technology and metallurgical analysis.

Phnom Dek and Tonle Bak

The industrial landscape surrounding Phnom Dek (Figure 1) comprises 21 metallurgy sites scattered over an area of 400km2 (Pryce et al. Reference Pryce, Hendrickson, Phon, Sovichetra, Charlton, Leroy, Dillmann and Hua2014; Hendrickson et al. Reference Hendrickson, Leroy, Hua, Phon and Voeun2017). Each site contains up to 50 individual mounds or slag concentrations, evidenced by the presence of slag and technical ceramics (e.g. tuyères, or air-delivery pipes, and furnace-wall fragments). Surface surveys and preliminary excavations of these sites have revealed important temporal variations in mound morphology, size, slag type and technical ceramics, but little evidence of occupation in the form of domestic pottery or temples and infrastructure associated with the Angkorian period. To date, the lone exception is the site of Tonle Bak, located 2km to the south of Phnom Dek.

Figure 1. Location of Tonle Bak and Phnom Dek metallurgical landscape (dotted area) and study area in regional context (inset) (map generated by M. Hendrickson; topography layer courtesy of the Japan International Cooperation Agency).

Tonle Bak (Figure 2) is a typical iron-production site, comprising multiple slag concentrations ranging from scatters of metallurgical debris a few metres across to large mounds up to 4.5m high and 40m in diameter. Excavations conducted by the ‘Iron Kuay Project’ at mound 1 (STB-01), which is located to the north of the main cluster of mounds (Figure 2), revealed iron production dating from the ninth to eleventh centuries, but no distinct furnace structures (Pryce et al. Reference Pryce, Hendrickson, Phon, Sovichetra, Charlton, Leroy, Dillmann and Hua2014). Radiocarbon dating of charcoal recovered from slag cakes from the main cluster identified smelting activities dating to the eleventh- to thirteenth-century peak of the Khmer Empire, concentrating particularly during the territorial expansions of Jayavarman VII (AD 1191–1219) (Hendrickson et al. Reference Hendrickson, Leroy, Hua, Phon and Voeun2017). While other sites in the Phnom Dek landscape present similar scales of production and chronological range, Tonle Bak has two features that warrant further investigation. First is a 265m-long rectilinear reservoir (Figure 2). Such features are characteristic of Angkorian religious and settlement sites, but are rarely encountered around Phnom Dek. The name Tonle Bak, or ‘broken reservoir’, derives from the fact that the low earthen walls no longer hold water in the dry season. Second, recent agricultural activities between mounds 5 and 7 revealed a dense scatter of Angkorian stoneware and earthenware ceramics.

Figure 2. Plan of Tonle Bak showing locations of slag concentrations, ceramic scatter and reservoirs (map generated by M. Hendrickson).

The combination of typical Angkorian infrastructural remains and material culture suggests that Tonle Bak supported a semi-permanent community that was possibly part of the imperial politico-economic system. A critical question is whether the settlement and metallurgical activities were contemporaneous, or represent different phases of use. INDAP's 2017 field season excavated seven trenches at Tonle Bak (Figure 3), with two primary goals:

1) To evaluate local smelting practices by documenting the metallurgical structure and history of a large slag concentration.

2) To determine the nature and spatio-temporal relationship between the metallurgy activities and Angkorian infrastructure and settlement.

Figure 3. Location of trenches and furnaces at Tonle Bak; red features indicate the location of furnaces on mound 2 (map generated by M. Hendrickson).

Angkorian iron production: furnace structure, ritual and formation

Previous knowledge of Angkorian smelting practices was based on the morphology of large slag concentrations, the use of medium-gauge tuyères and the presence of large ‘cascade’ tap slag cakes created when waste material is removed from inside the furnace during its operation (Hendrickson et al. Reference Hendrickson, Leroy, Hua, Phon and Voeun2017). Insights into the structural forms of Cambodian furnaces relied solely on nineteenth- and twentieth-century ethnographic analogies of minority Kuay ironworkers (Duffosé Reference Duffosé1934).

Excavation on the top of mound 2 (STB-02) revealed the first in situ evidence of Angkor-period furnaces (Figures 4a–c & 5). Each of the three furnaces are rectilinear in shape, approximately 2m long and 1m wide, with a slag pit placed to the west. While considerable quantities of broken tuyères were discovered, the lack of in situ examples prevents estimation of the number of air-delivery pipes and, more importantly, the location and style of the bellows.

Figure 4. Rectilinear furnaces with slag pits from mound 2 (STB-02): a) furnace 1 in trench 2; b) furnace 2 in trench 6; c) furnace 3 in trench 7 (all images by M. Hendrickson).

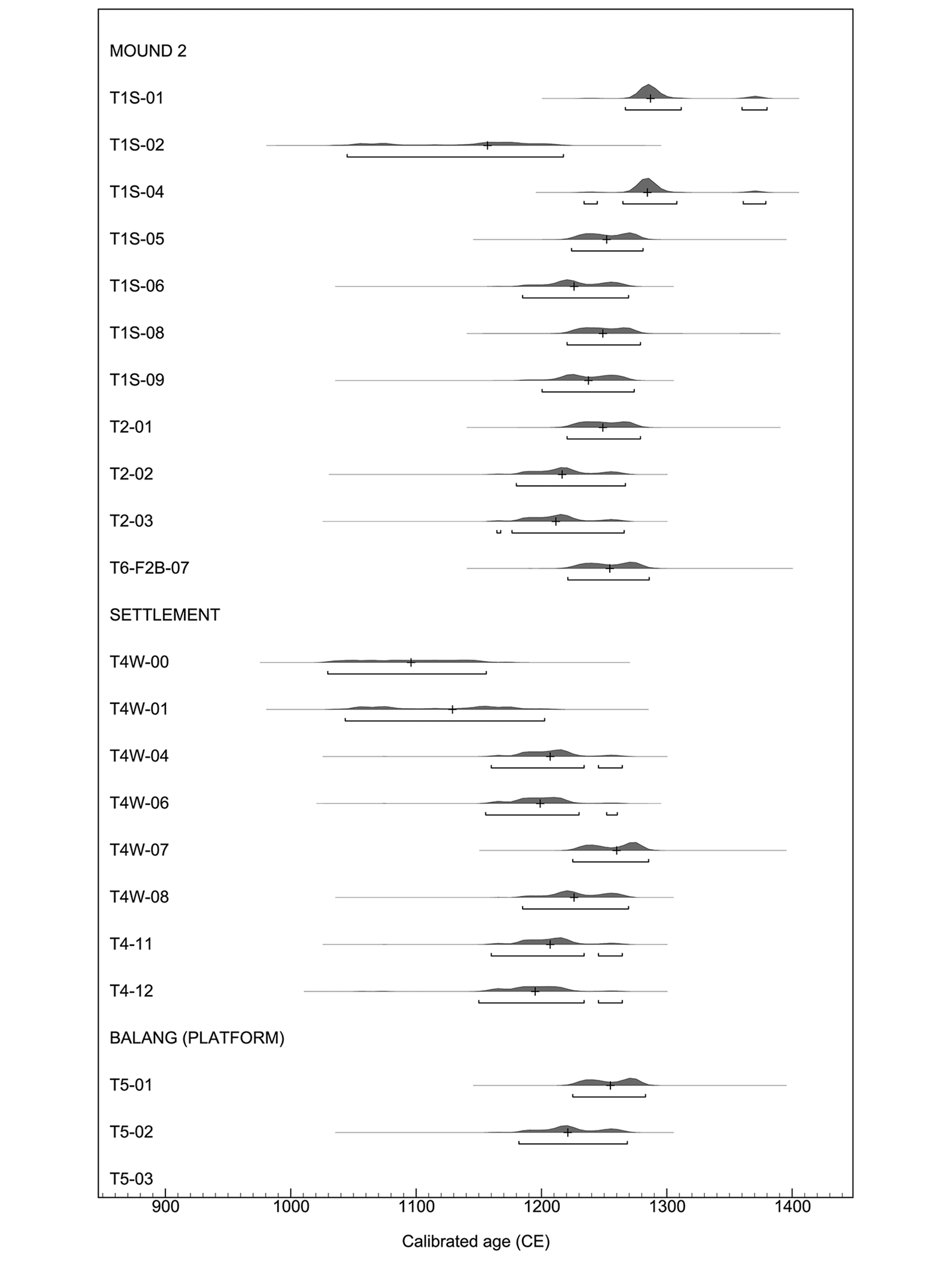

Figure 5. Radiocarbon results from trench excavations at Tonle Bak (see online supplementary material (OSM) for calibration protocol). Sample T5-03 is modern and was not included in the graphic.

All of the furnaces showed evidence of being remodelled or reused. Furnace 1, for example, had three different ash ‘tongues’ extending into the slag pit, while furnace 2 had two distinct bases separated by 0.12m of sediment. Fragments of broken tuyères with prills and hammerscale found to the north of furnace 1 also indicate initial processing of the bloom once extracted from the furnace. Radiocarbon dates on charred wood fragments indicate that furnaces 1 and 2 were generally active at the same time, and combined with their shared stratigraphic positioning and orientation, give the impression that multiple smelting operations were conducted to maximise the production efforts of the work teams.

Different types of internal and tap slag were identified based on how they formed during the smelt. Internal slags are those that solidified within the furnace and show wall lining adhering to the side of the slag. The most numerous type are tap slags that flowed out of the furnace while in use. On the majority of these tap slags, it is possible to identify the impression of the slag pit into which they have been tapped, and the shape of the tapping channel through which they flowed. These characteristics allow us to differentiate the tap slags into two main categories: shallow layers and deep layers of flow slags. This latter category, referred to here as ‘cascade slags’, shows the shape of a deep slag pit and represents the accumulation of multiple tapping events, perhaps from a single smelt, and can weigh up to 80kg (Figure 6a).

Figure 6. Metallurgy-related artefacts recovered from mound 2: a) cross-section of ‘cascade’ tap slag showing multiple flows; b) iron tongs; c–d) slagged crystals from furnaces 2 and 3 (all images by M. Hendrickson).

Further details of specific smelting practices were recovered from the slag pits themselves. The pits from furnaces 1 and 2 contained multiple, large tap slags from previous smelting episodes to frame the hole. Furnace 3 lacked the cascade slags, but had several shallow layers of flow slags. Excavation of the pit in furnace 2 yielded a pair of unbroken iron tongs (Figure 6b)—the first tool found in direct association with an iron-production or -smelting site in Cambodia. More significant was the discovery of individual slagged quartz crystals from the pits in furnaces 2 and 3 (Figure 6c–d). Such crystals are an important part of ritual consecrations of Angkorian temples and have also been found in ritual deposits near the Royal Palace in Angkor Thom (Pottier Reference Pottier1997; Polkinghorne et al. Reference Polkinghorne, Vincent, Thomas and Bourgarit2014: 333). The Tonle Bak crystals may therefore represent an extension of this sacred practice within a craft production context, and the presence of slag on the exterior surfaces of the crystals indicates that they were placed into the pit before the smelt. The inclusion of such objects within furnace construction is a common metallurgical practice, the best known being the numerous African ethnographic examples, in which ‘medicines’ are placed beneath furnaces to ensure successful transformation of ore into metal (Chirikure Reference Chirikure2015: 87–88).

Mound 2 also provided new insights into the processes through which these Angkorian slag concentrations formed. Trench 1 revealed at least five distinct alternating layers of furnace wall and slag (Figure 7). Based on the orientation of the debris and furnace wall ‘crusts’, which demarcate different smelting episodes on the mound, the lower half of the mound was being discarded from furnace(s) located to the south-east, and the upper half came from furnaces to the east. Radiocarbon dates (see Figure 5) through the section indicate that mound 2 began to form sometime in the late twelfth to early thirteenth centuries, and was in operation for at least 20 years—a period corresponding to Angkor's zenith.

Figure 7. South section of trench 1, showing alternating layers of slag and furnace wall in mound 2 (see inset) (image generated by M. Hendrickson).

The smelting community and ritual practice

Trenches 4 and 6 were positioned to evaluate the nature of habitation and its relationship to smelting activities at Tonle Bak (Figure 3). Trench 4 revealed an approximately 1m-deep deposit of cultural material extending 33m from the edge of mound 5 to the centre of the ceramic surface scatter. The north end of the trench, nearest the slag concentration, revealed multiple layers of smelting activity that date between the early twelfth to mid thirteenth centuries AD (see Figure 5). These metallurgical deposits are interspersed with layers of domestic occupation that continue across the trench and ultimately overlie the earliest settlement layers visible at its southern end. This stratigraphic relationship demonstrates that mound 5's iron production post-dates the earliest settlement activity in this part of the site. Although the upper layers of trench 4 have been disturbed by recent agricultural activity, it is possible to identify five distinct habitation layers, three of which extend across the entire trench. The material culture from these layers includes hearth features, faunal and plant remains, multiple types of iron tools, and substantial Angkorian and imported ceramics (Figure 8).

Figure 8. Artefacts recovered from occupation and metallurgical layers in trench 4: a) Khmer earthenwares; b) Khmer stonewares, including brown and green glazed Buriram and Torp Chey and lie du vin types from Choeung Ek; c) Chinese imported wares, including celadon and Qingbai; d–e) iron blades (all images by M. Hendrickson).

Metallurgical analysis of the iron tools is underway to determine whether the objects were produced at the site and to confirm the use of ores from nearby Phnom Dek. The ceramic assemblage includes a range of earthenware forms, brown, green and unglazed stonewares from each of the main production regions across the Khmer territories (e.g. Kulen, Buriram, Torp Chey and Cheung Ek), and Chinese green celadon and white porcelain wares. Given the distance from the capital and function of Tonle Bak, it is unsurprising that the ratio of stoneware and foreign ceramics from Tonle Bak (5–10 per cent) is lower than that recovered from temples such as Ta Prohm (38 per cent) and Angkor Wat (26 per cent) (Carter et al. Reference Carter, Heng, Stark, Chhay and Evans2018) or from occupation mounds at Trapeang Phong (19 per cent) (Pottier et al. Reference Pottier2007: 23–24) in the Greater Angkor region. The diversity and ceramics at Tonle Bak, however, demonstrate that the community was directly integrated with broader Angkorian economic trade networks.

Figure 9. Botanical remains recovered from trench 4: a) rice (Oryza sativa) spikelet; b) domesticated type rice spikelet base; c) left: whole mung bean (Vigna radiata), right: cotyledon showing pumule; d) foxtail millet (Setaria italica) grains with adhering husk; and e) lotus seed (Nelumbo nucifera) (all images from 4004 column 2 by C. Castillo).

Soil samples taken from sections in the walls of trench 4 processed using flotation and wet-sieving show a diverse range of economic crops. Rice (Oryza sativa) comprises approximately 60–70 per cent of the total archaeobotanical sample from trench 4; all of the rice spikelet parts (i.e. caryopses, glumes, spikelet bases and embryos) are present and most of the complete grains have intact husks. This probably implies that the samples derive from a burnt store of rice that had not yet been dehusked and were stored as spikelets. The rest of the assemblage consists of around 2 per cent mung beans (Vigna radiata), 2 per cent foxtail millet (Setaria italica), plus lotus seeds (Nelumbo nucifera), a few sesame seeds (Sesamum indicum), cooked food, nut and fruit fragments, and approximately 10 per cent charred wood fragments. The mung beans and foxtail millet grains are also found predominantly unprocessed, further suggesting the presence of food storage. Mung beans and sesame have previously been identified in Cambodia, but unlike those found in a ritual context in the Terrace of the Leper King (Castillo et al. Reference Castillo, Polkinghorne, Vincent, Tan and Fuller2018), the Tonle Bak examples were probably being stored for a meal. This is the first time lotus seeds have been identified in a Southeast Asian archaeological context. The Tonle Bak lotus remains are smaller than modern reference seeds, which may be due to subsequent domestication processes or the harvesting of immature seeds for consumption—a practice known in various parts of Southeast Asia, including Cambodia (Jacquat & Bertossa Reference Jacquat and Bertossa1990).

A final area of research interest was a low mound positioned along the main axis of the Tonle Bak reservoir. Local villagers indicated that this mound once displayed a stone statue of a deity that was part of a pedestal shrine, or balang, made of perishable materials (Figure 3). Trench 5 was positioned on the western edge of this mound and uncovered substantial quantities of ceramic roof tiles, burnt wood fragments and large iron nails and clamps (Figure 10). These materials were typically used in Angkorian wooden structures, and their presence indicates the burning and collapse of a superstructure that sheltered the sacred statue. Combined, the presence of a shrine and reservoir and the use of quartz ‘deposit’ crystals in the slag pits shows a remarkable affinity with Khmer ritual practices. Furthermore, the scale of iron production and density of material culture related to daily life clearly show that Tonle Bak supported a long-term (and potentially full-time) smelting community that was directly integrated with the economic and religious networks of the Angkorian state.

Figure 10. Architectural remains associated with the balang platform in trench 5: a–b) ceramic roof tiles; c–f) iron nails and clamps (all images by M. Hendrickson).

Who made Angkor's iron?

A key challenge in understanding the role of iron in Angkorian history is to establish who was responsible for producing large quantities of this valuable metal for the state. To address this problem, we must consider evidence derived from historical analogy and technological practices. As there is no historical evidence for primary iron smelting within the Khmer Empire, it is presumed that this task was completed by other groups in their own territories. Both Dupaigne (Reference Dupaigne2016) and Jacques (Jacques & Lafond Reference Jacques and Lafond2004: 259–61) suggest that primary reduction was completed by the Kuay, an ethnic minority who currently live in the Phnom Dek region and who smelted bloomery iron until the 1940s. This hypothesis is based primarily on documentary evidence, including a sixteenth-century account from Cambodian chronicles, nineteenth-century French colonial records and mid twentieth-century ethnographic interviews with Kuay metalworkers (Harmand Reference Harmand1876; Duffosé Reference Duffosé1934; Lévy Reference Lévy1943; Khin Reference Khin1988; Dupaigne Reference Dupaigne2016). These records show that the Kuay were responsible for manufacturing the sacred sword (or preah khan) for Cambodia's kings, paid their taxes in iron and were called on to serve as militia by Khmer elite. Dupaigne's (Reference Dupaigne2016) ethnographic account of the Kuay, collected more than 20 years after the last known smelt in the Phnom Dek region, described furnaces being placed near a water source at a remote location east of a settlement. Men and women from a Kuay village participated in the process of preparing ores, fuels, food and ritual offerings leading up to the smelt. During the smelt, girls and women were only allowed to bring food to the chief smelter (the chhay) and a small group of male assistants (Dupaigne Reference Dupaigne2016: 231–32). Pregnant and menstruating females were banned from participating at any stage of the process, and, once the smelt was started, were not permitted to view the furnace or pass by its opening at any distance for fear of stealing its creative energy (Dupaigne Reference Dupaigne2016: 244–45). While it is impossible to identify such practices at Tonle Bak, the extensive occupation evidence and its close proximity to the smelting spaces suggest a more lenient organisation of ritualised space during the Angkorian period.

Technologically, the Kuay smelted iron using a direct, or ‘bloomery’, technique in a 2.5m-long rectangular clay furnace pierced by 20–30 thin-gauge clay tuyères (Dupaigne Reference Dupaigne2016: 135–42). The Tonle Bak examples correspond with both the basic shape and structure of these later iron-production sites. Furthermore, preliminary metallurgical comparisons of Angkorian period and Kuay smelting recipes indicate a shared technological heritage (Pryce et al. Reference Pryce, Hendrickson, Phon, Sovichetra, Charlton, Leroy, Dillmann and Hua2014). Direct attribution of Angkorian-era smelting to the Kuay people, however, is complicated by several technological and cultural details from Tonle Bak (Table 1). Kuay slag mounds tend to have a relatively low (1–2m), undulating and irregular profile and ring-shaped plan, littered with long, thin-gauge tuyères (Hendrickson et al. Reference Hendrickson, Leroy, Hua, Phon and Voeun2017). In this configuration, the furnace(s) were probably positioned in the centre and sheltered beneath a wooden structure, as described in early French colonial reports (Moura Reference Moura1883). By contrast, Angkorian slag concentrations form raised or ridged mounds up to 6m in height, with a broad ovate plan and littered with fewer, medium-gauge tuyères. This mound form is the product of ironworkers repeatedly constructing new furnaces on previous deposits of metallurgical waste.

Table 1. Comparison of Angkorian and ethnographic Kuay metallurgical traits.

* Based on radiocarbon dates from Hendrickson et al. (Reference Hendrickson, Hua and Pryce2013, Reference Hendrickson, Leroy, Hua, Phon and Voeun2017) and Pryce et al. (Reference Pryce, Hendrickson, Phon, Sovichetra, Charlton, Leroy, Dillmann and Hua2014), and the research presented here.

In terms of smelting rituals, the Kuay introduced different types of perishable offerings, such as tiger incisors, snake heads and sharp thorns into the furnace, along with the prepared ore (Dupaigne Reference Dupaigne2016: 233). There is, however, no record of their incorporating crystals or other such materials into the fabric of the furnace. Perhaps the most significant discrepancies are the close integration of smelting and living spaces and the associated presence of major hallmarks of Angkorian culture, such as reservoirs and shrines.

These results do not disprove the hypothesis that Kuay smelters manufactured iron for Angkor's elite. Instead, the Tonle Bak site raises cautionary points concerning ethnographic interpretation by evidencing technological and organisational changes within smelting communities during and after the Angkorian period. The differences between these early historic and more recent Kuay smelting systems could represent the introduction of new ideas, rather than new practitioners or adaptations to changing conditions, such as an environmentally driven shift in fuel type, as seen in Tanzania (Schmidt Reference Schmidt1997). Ethnographic studies have shown that the Kuay have a fluid sense of cultural identity and have historically adapted to different socio-political situations (Swift Reference Swift2013). As one of the region's potential smelting communities, the Kuay may have become more integrated with the Angkorian state, which required increasing quantities of iron to support its territorial ambitions. This corresponds with Lowman's (Reference Lowman2011) epigraphic study of Angkorian identity, which, while dominated by the Khmer, was not limited to one group. In times of imperial expansion, specific cultural requirements and social organisations may be put aside, or transformed, to ensure that the volume of material required by the state is met.

The combination of technological, settlement and ritual evidence allows us to propose four different scenarios concerning the identity of the iron smelters at Tonle Bak:

1) Kuay smelters, who were directly involved with Angkorian Khmer lifeways.

2) Khmer smelters, who lived in the region occupied by the Kuay or other groups.

3) A combination of Khmer and Kuay smelters who co-occupied the site.

4) A currently unknown group.

Regardless of who smelted Angkor's iron, however, these results demonstrate the need for more intensive site-based studies of metallurgical practice and settlement history in the Phnom Dek industrial landscape.

Angkorian iron production in regional and global contexts

The Tonle Bak sites offer a further example of the dynamic nature of Cambodia's iron smelting traditions and potential for regional and global comparisons. New information concerning furnace shape and settlement evidence, combined with mound morphology and the types of slag and tuyères present, confirm that ironworkers in the Phnom Dek region employed at least three different smelting systems over the course of 1200 years (see Table 1). Both medium- and broad-gauge tuyère systems were active during the Angkorian period, and the enormous volumes produced at many of the Phnom Dek sites supported the large-scale demand for iron. Further research into the formation processes and metallurgical characteristics of the broad-gauge system is required to assess potential differences in iron-production techniques and outputs, and how this iron was consumed by the Khmer Empire.

The evidence from Cambodia provides additional insights into the diversity of smelting systems employed by historic-era iron workers across Mainland Southeast Asia. The sub-circular furnaces at Saphim (Pryce et al. Reference Pryce, Chiemsisouraj, Zeitoun and Forestier2011) contrast with the rectangular-shaped furnaces found at Tonle Bak and Zi-O near Bagan (Hudson Reference Hudson2006). The latter, however, are distinguished by differences in construction (e.g. the presence of a chimney at Zi-O) and the delivery of air into the chamber (e.g. via a single side of tuyères at Zi-O). Further excavation at sites across Southeast Asia is needed to assess how these types of furnace were powered (e.g. natural updraft vs forced air) (see discussion in Juleff Reference Juleff2009). An additional aspect that distinguishes Cambodian technological systems is the repeated construction of furnaces at the same site, which resulted in vast mounds of metallurgical debris particularly during the Angkorian period. Overall, the diversity of furnace construction in Southeast Asia provides yet another example of heterogeneous smelting practices within a region, akin to that seen in Iron Age and Roman Britain, and across sub-Saharan Africa (Paynter Reference Paynter, Niece, Hook and Craddock2007; Chirikure Reference Chirikure2015: 61–98; Iles Reference Iles2018).

Finally, the increased interest in iron production highlights temporal shifts in the organisation of production and clientele within Mainland Southeast Asia. Metal Age production at Ban Kruat in north-east Thailand shows long-term use and multiple independent workshops, whose products met the demands of surrounding agricultural villages (Venunan Reference Venunan2016: 410). Similar situations can be envisaged at the large mounds discovered around Chhep in Cambodia, and also within the Bujang Valley in Malaysia. Historic-era smelting shows two marked patterns of iron production. Clusters of furnaces and small quantities of metallurgical debris at sites such as Saphim in Laos (eighth to ninth centuries AD), Khvao in Cambodia (fourteenth century AD), and Zi-O in Myanmar (sixteenth century AD) indicate short-term production again oriented towards local consumption. In contrast, the large, densely clustered mounds at Tonle Bak and dozens of other sites within the Phnom Dek region support the idea of organised smelting practices designed to meet state-level needs. While future studies will identify evidence of iron metallurgical activities associated with other Southeast Asian states, it is clear that Angkorian iron production was unrivalled between the eleventh and thirteenth centuries.

Conclusions

The results from Tonle Bak provide the first evidence for technological and ritual smelting practices and the intensive and specialised nature of ore procurement and iron production for the Khmer Empire. Trade goods and signs of long-term occupation found at Tonle Bak demonstrate the site's integration within the broader Angkorian economic system. In combination with the presence of typical Khmer infrastructure, such as the reservoir and balang shrine, this site raises questions concerning the identity of the smelting community, and specifically, whether the Kuay ethnic minority were responsible for iron production here. Continued excavation and detailed analyses of the formation, morphology and spatial relationships of slag concentrations around Phnom Dek will provide further important information for discussing the organisation of craft producers and the shifting politico-economic relationships between smelters and patron states. Overall, this article reconfirms the importance of the Phnom Dek metallurgical landscape as one of the richest iron-production zones in Southeast Asia. While the scale of the remains around Phnom Dek does not exceed the vast metallurgical sites associated with Roman Britain or medieval France, it represents another example of how states located and exploited large-scale ore deposits to facilitate their imperial objectives.

Acknowledgements

We thank the Ministry of Culture and Fine Arts of Cambodia, Sylvain Bauvais, Shaun Mackey and the rest of the 2017 INDAP field team. Funding for the INDAP and IRANGKOR projects was provided by the National Science Foundation Senior Research Grant (1550850), the Agence Nationale de la Recherche, and the Australian Government's National Collaborative Research Infrastructure Strategy for the Centre for Accelerator Science at the Australian Nuclear Science and Technology Organisation. Finally, we thank the anonymous reviewers who provided insightful comments to enhance the original manuscript. Any mistakes or omissions are solely our own.

Supplementary material

To view supplementary material for this article, please visit https://doi.org/10.15184/10.15184/aqy.2019.174