Introduction

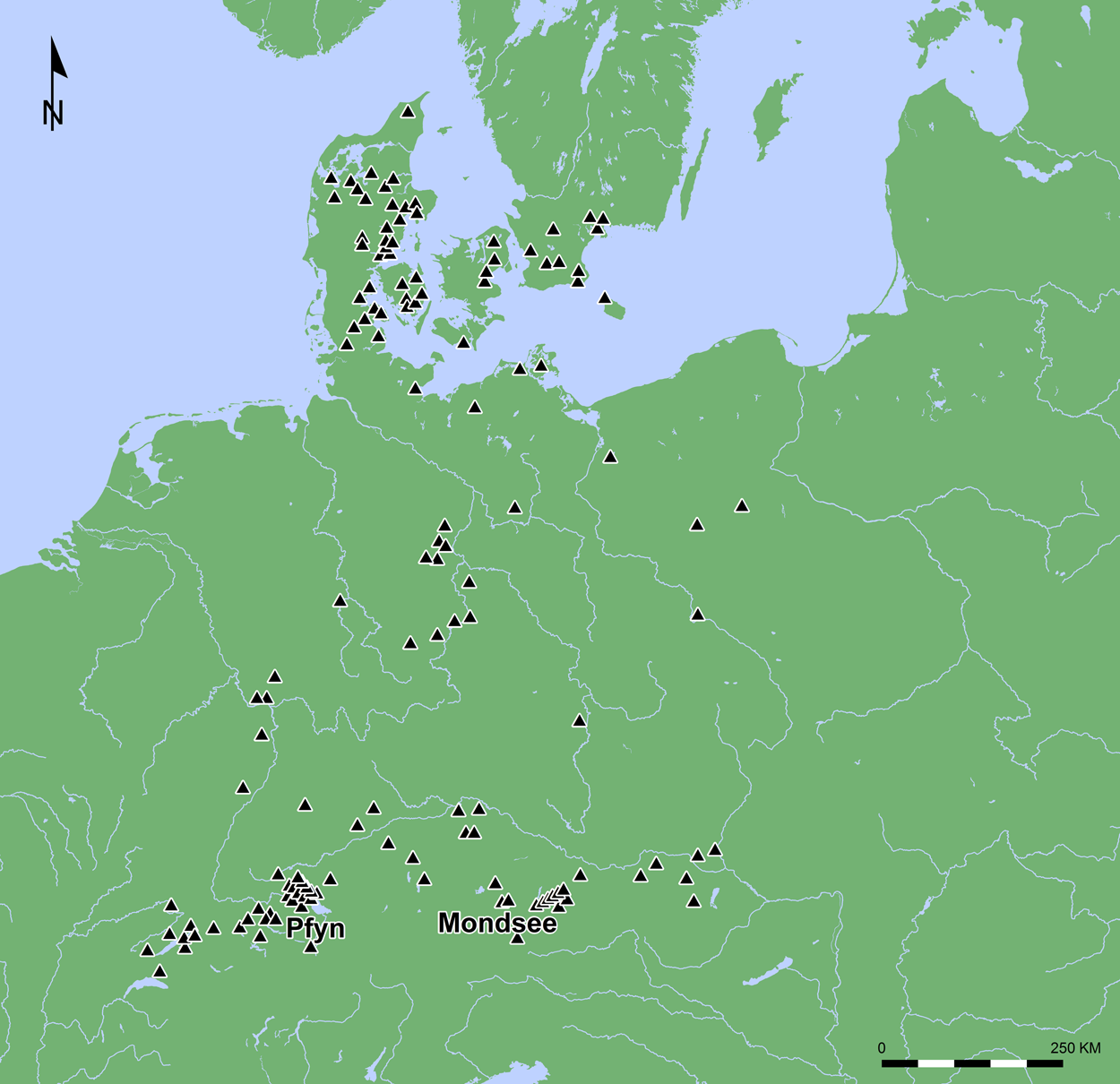

Neolithic Denmark is exceptionally rich in copper artefacts from during the Early Neolithic period of the Funnel Beaker culture, dating to 4000–3300 bc (Klassen, Reference Klassen2000: fig. 111; Sørensen, Reference Sørensen2014: 159; Price & Gebauer, Reference Price, Gebauer, Hansen and Müller2017) (Figure 1). Copper artefacts were brought to southern Scandinavia in such large quantities that, in terms of weight, the quantity of metal found here far exceeds the amount found in the Alpine region and the areas between Scandinavia and the Alps (Klassen, Reference Klassen2000: 273, 2014a: 228). However, no evidence has been found so far that metallurgy was mastered and practised in southern Scandinavia before the Bronze Age. Actual smelting sites are missing, and neither slag nor technical ceramics such as furnaces, crucibles, or tuyères have been found (Vandkilde, Reference Vandkilde1996: 262; Sørensen, Reference Sørensen2014: 175). Nevertheless, the possibility of local metalworking has been discussed for decades (Glob, Reference Glob1952: 38; Midgley, Reference Midgley1992: 298; Klassen, Reference Klassen2000: 225; Melheim, Reference Melheim2015: 139). The discovery of some crudely-made copper flat axes, perhaps locally made in southern Scandinavia, suggest that pyrotechnical knowledge may have followed the copper metal in long-distance movement to northern Europe along the river systems (Klassen, Reference Klassen., Andersen and Nielsen2010: 40; Roberts & Frieman, Reference Roberts, Frieman, Fowler, Harding and Hofmann2015: 717). Furthermore, studies by Klassen show that many copper objects, especially the flat axes, were re-melted and cast into new shapes with the aim of creating larger and heavier axes, more impressive than the original imports (Klassen, Reference Klassen., Andersen and Nielsen2010: 39). The average weight of copper flat axes in the northern Funnel Beaker culture is 381 g (range 100-1200 g), while the average weight of two groups of flat axes from the Alpine area are 222 g (range 50-650 g) and 151 g (range 50-250 g) respectively (Klassen, Reference Klassen2000: 227, fig. 105). Along with the demand for copper adornments and expressions of identity, the potential of re-melting, re-casting, and re-modelling the metal objects may also have played an important role in the development of early metallurgy in southern Scandinavia.

Figure 1. Distribution of artefacts made with Mondsee copper in central and northern Europe.

The discovery of a crucible and a possible tuyère in a secure context dating to the Early Neolithic Funnel Beaker culture (3800–3300 bc) beneath a long barrow dating to 3300–3100 bc at Lønt in Haderslev in southern Jutland is the first evidence that melting of copper actually took place in the northern group of the Funnel Beaker culture. The two pieces of technical ceramics predate the previously known evidence for early Scandinavian metallurgy by more than 1500 years (Jensen, Reference Jensen2002: 117).

The Early Neolithic Context of the Crucible

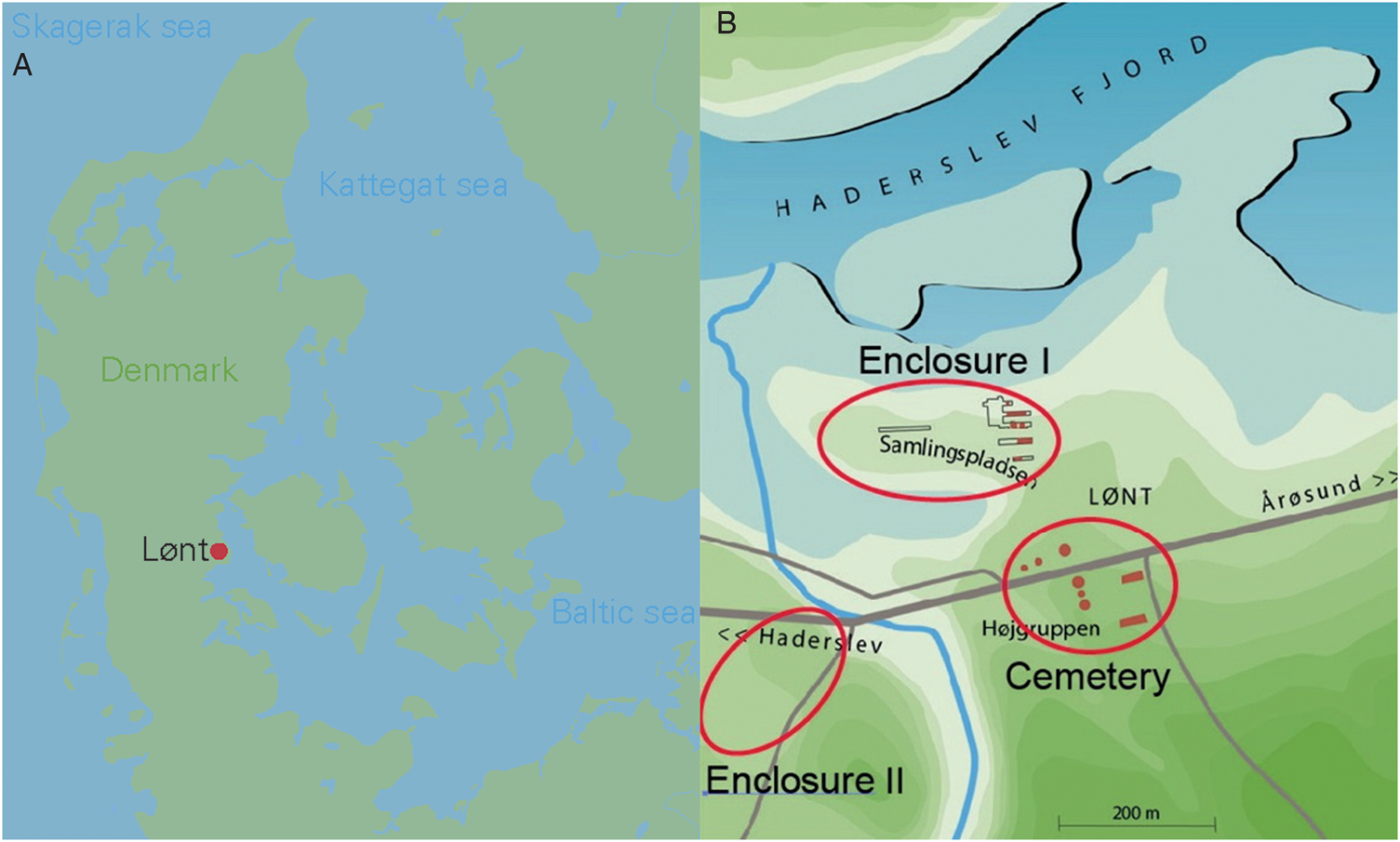

The crucible and possible tuyère were found in a research excavation for the National Museum at Lønt in 1987 by Erik Jørgensen, but only recognized and interpreted as objects related to metallurgy by the current authors in relation to a new study of the material in 2012. Since 1987, the artefacts have been stored at the National Museum. Lønt is the site of a megalithic cemetery with eleven tombs and two causewayed enclosures located on the southern shore of Haderslev Fjord in south-eastern Jutland in Denmark (Jørgensen, Reference Jørgensen1983a & Reference Jørgensenb, Reference Jørgensen1988a & Reference Jørgensenb; Gebauer, Reference Gebauer, Scarre and Laporte2016) (Figure 2). The Starup Langelandsvej enclosure is one of the oldest in the northern Funnel Beaker group with pooled average of 14C dates at 3693–3526 cal bc (2σ) (Pedersen, Reference Pedersen2008; Pedersen & Witte, Reference Pedersen, Witte, Karup, Madsen and Rønne2012; Klassen, Reference Klassen2014a: 202; Sørensen, Reference Sørensen2014: 224).

Figure 2. A. The location of Lønt in Denmark; B. Map of the Lønt area. The crucible was found beneath the southern long mound. The megalithic cemetery is located 250 m south and 600 m east of the two enclosures (after Gebauer, Reference Gebauer, Scarre and Laporte2016, fig. 13.2).

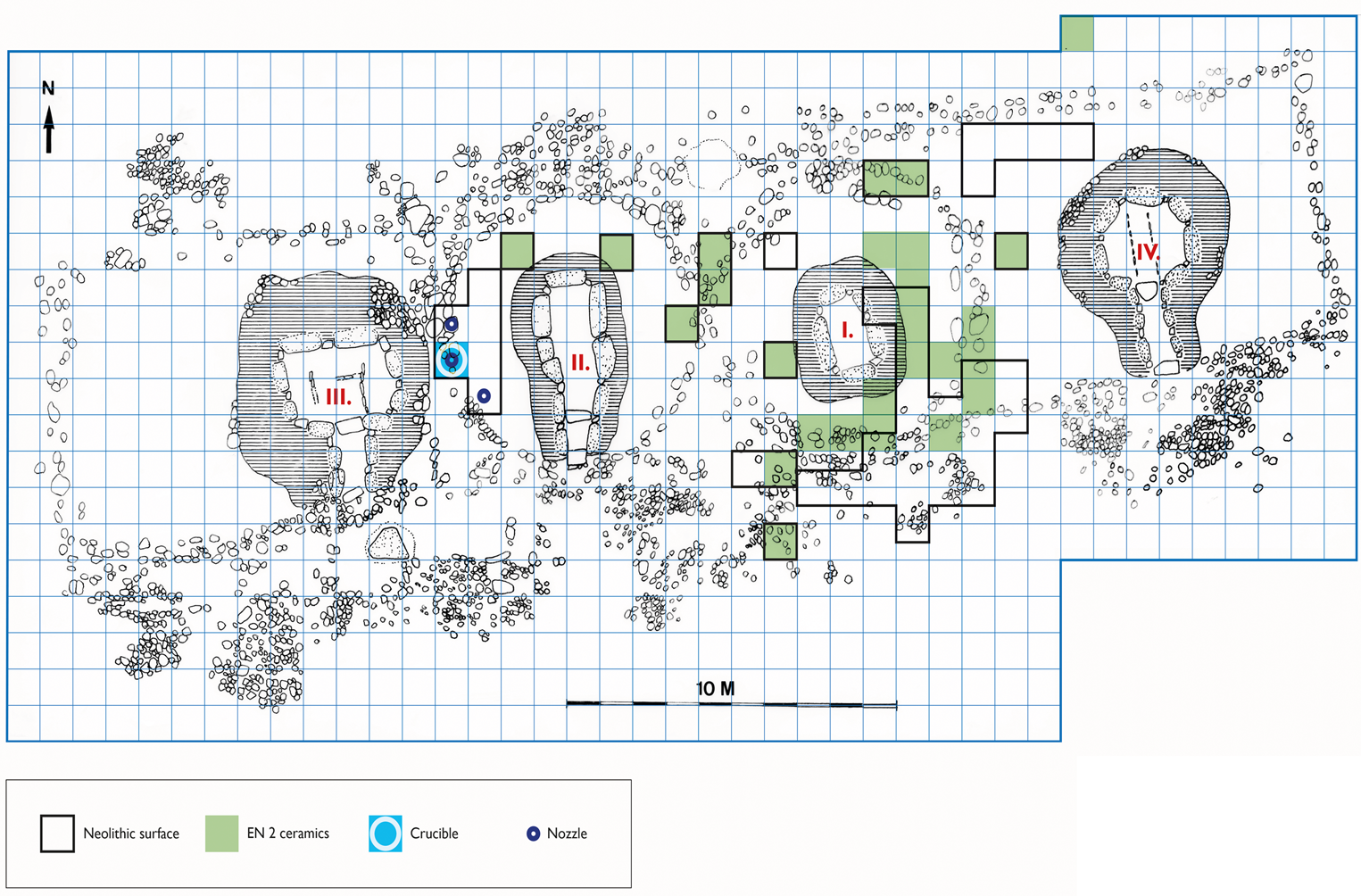

The fragments of the crucible and possible tuyère were found on the original Neolithic surface buried beneath the mound of the second dolmen in a long barrow that included four megalithic tombs (Jørgensen, Reference Jørgensen1988a: 204–07 a & b, Reference Jørgensen1988b, Reference Jørgensen, Ethelberg, Jørgensen, Meyer and Robinson2000: 95; Gebauer, Reference Gebauer, Furholt, Hinz, Mischka, Nobel and Olausson2014, Reference Gebauer, Scarre and Laporte2016) (Figure 3). The Neolithic surface was primarily preserved beneath the two round dolmens in the middle of the long barrow. The first tomb, a closed dolmen chamber, is dated to an early part of period MN I by nine vessels placed in a circle around the circular mound. The construction of all four tombs dates from period MN I of the Danish Funnel Beaker period, around 3300–3100 bc (Dehn & Hansen, Reference Dehn and Hansen2006: 22 fig. 9; Eriksen et al., Reference Eriksen, Andersen and Scarre2014: 52; Hansen, Reference Hansen2016: 14). Based on the stratigraphic evidence, the tombs provide a terminus ante quem for the crucible and possible tuyère of the Early Neolithic Funnel Beaker period, i.e. a period dated to 4000-3300 bc.

Figure 3. The long mound with four megalithic chambers at Lønt. The cultural layer was mainly below the two round dolmens in the middle, chambers I and II. The crucible and the putative tuyère were found beneath the mound covering chamber II (blue square). Only pottery dating from EN I was found in the immediate area around the crucible and possible tuyère. Pottery dating from EN II was distributed further east (green squares). Illustration by Frank Ruszkay.

An Early Neolithic date is supported by the domestic pottery found together with the technical ceramics. A total of 889 sherds were found in the sealed Neolithic surface, including 146 decorated and 746 undecorated sherds. Due to fragmentation, only the shapes of five funnel neck beakers, four clay discs, a lug possibly from a lugged jar, and five flat bases were identified. Crusts of food were observed on five fragments. Only the ceramics were analysed; a small amount of flint debris was not available for this analysis (Jørgensen, Reference Jørgensen1988a: 204).

The dates and distribution of the domestic pottery indicate that two periods of activity are represented. The pottery found west of chamber II together with the crucible and possible tuyère is dated to EN Ib (3800–3650 bc) on the basis of funnel neck beakers of type III (Nielsen, Reference Nielsen and Schülke2009: 15), a Volling-style beaker (Klassen, Reference Klassen2004: 246; Ravn, Reference Ravn, Hartz, Lüth and Terberger2011), and decorated rim sherds associated with the Siggeneben Süd-Stengade II group (Madsen, Reference Madsen and Hoika1994; Klassen, Reference Klassen2004: 241; Müller, Reference Müller2011: fig. 4; Andersen, Reference Andersen, Brink, Hydén, Jennbert, Larsson and Olausson2015: 120), alongside a number of undecorated body sherds (Figure 3, white squares).

The later pottery, dating to EN II (3500–3300 bc), was primarily found in the eastern part of the cultural layer around chamber I (Figure 3, green squares). This material included sherds of two vessels decorated in Fuchberg style, two clay discs, and thirty-six sherds with vertical belly striations (Andersen & Madsen, Reference Andersen and Madsen1978; Jørgensen, Reference Jørgensen1988a: 204 fig. 14; Schirren, Reference Schirren1997: 178; Andersen, Reference Andersen1998: 145, 162). Two undecorated clay discs and the undecorated body sherds can only be dated to the Early Neolithic.

The crucible and the possible tuyère are dated to 3800–3500 bc based on their association with pottery dating from late EN I and the absence of pottery from EN II in the area west of chamber II. The older part of the cultural layer represents the first activities at the Lønt cemetery and is coeval with the neighbouring Starup Langelandsvej enclosure.

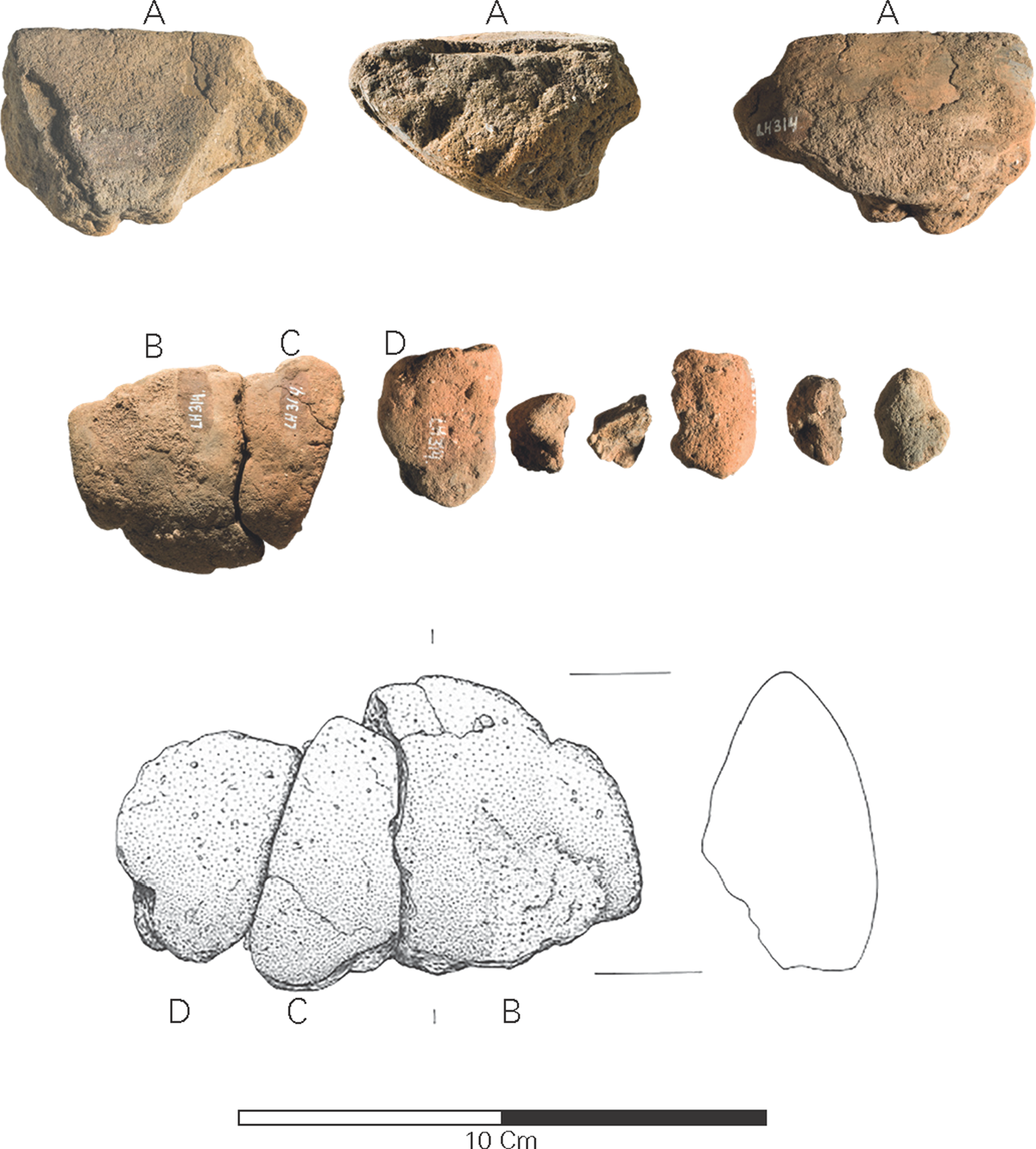

The Crucible

Nine fragments of a crucible were found, three of which conjoin (Figure 4). The vessel is made of lumps of clay pressed together with the fingers, unlike the coil-built domestic Funnel Beaker pottery. Despite its incomplete state, it is clearly a shallow vessel with a wide mouth, a form that allows the greatest area of contact between metal and charcoal. The shape is oblong oval and 10 cm minimum in length (Figure 4, B–D). No spout or handle was preserved. The base of the vessel is thick, measuring 3.6 cm, while the thickness of the vessel wall tapers off to 0.8 cm at the rim. The shape with the heavy base is important for heat retention in crucibles that are heated from above (Martinon-Torres & Rehren, Reference Martinon-Torres, Rehren, Roberts and Thornton2014: 120). The highly porous fabric of more than 75 per cent quartz (sand) tempered with burnt flint ensured the refractoriness of the crucible, i.e. the ability to withstand thermal shock and improved heat retention (Martinon-Torres & Rehren, Reference Martinon-Torres, Rehren, Roberts and Thornton2014: 114; Vernon et al., Reference Vernon, White, Hamilton, White and Hamilton2019: 111).

Figure 4. The nine crucible fragments from Lønt. A. The largest and best-preserved fragment with views of the interior with a whitish burnt area at the bottom, a cross-section, and the exterior showing its coating with a fine-grained slurry. The piece is lightly curved along the outer perimeter (9.1 cm long, 6.4 cm high, 0.7 cm thick at the rim and 3.6 cm thick toward the bottom of the object). B. The second-largest fragment has a stronger curvature (5.7 cm long, 5.7 cm high, 0.8 cm thick at the rim, maximum thickness 3.5 cm). The outer surface is only preserved on fragments A and B. Three matching fragments B, C, and D form a 10-cm-long curved piece (photographs by J. Lee, drawing by F. Oldenburg, illustration by M. L. Bendtsen, National Museum of Denmark).

The vessel is covered by a slurry of fine-grained silt and sand that forms a 0.2 cm thick layer on the surface, especially on the inside (Figure 4, A). This layer enhances the refractory qualities of the crucible, reduces absorption of metal in the vessel wall, and enables reuse if the crucible remains intact (Martinon-Torres & Rehren, Reference Martinon-Torres, Rehren, Roberts and Thornton2014: 124; Vernon et al., Reference Vernon, White, Hamilton, White and Hamilton2019: 113). The crucible is reddish with the lower part of the inside wall coloured white from high thermal impact (Figure 4, A). The centre of the vessel wall is grey. There is no visible vitrification of the surface.

Based on the physical attributes alone—the shape of the vessel, the fabric, the coating with a slurry, as well as the heat impact on part of the interior—the crucible from Lønt was interpreted by Gebauer and Sørensen as a vessel for processing metal. Further verification of this interpretation came from comparison with other European finds and instrumental analyses.

European crucibles

Although the Lønt crucible is incomplete, the shape and measurements are compatible with contemporary crucibles found in continental Europe (Strahm, Reference Strahm1994, Strahm et al., Reference Strahm, Wiermann, Müller-Scheessel and Meller2013) (Figure 5). These crucibles are round or oblong and may have a handle; measurements vary between 13 and 18 cm in length, 8 and 12 cm in width, and about 5 cm in height (Strahm, Reference Strahm, Lichter and Weber2010: 378). A heavy base and porous, quartz-rich fabric is typical. The effect of high heat is visible in the interior of the vessel, with evidence of vitrification at the rim and transition to the handle due to the heat being provided from above (Martinon-Torres & Rehren, Reference Martinon-Torres, Rehren, Roberts and Thornton2014: 113). Some crucibles show less thermal impact and not all crucibles show traces of metal (Strahm, Reference Strahm, Lichter and Weber2010: catalogue no. 320), which perhaps suggests that they were not used (Melheim et al., Reference Melheim, Prescott and Anfinset2016: 55). Most crucibles have been found in the Alpine area, only a few in central Europe, and none north of Harzen, Germany (Schlichterle & Rottländer, Reference Schlichterle and Rottländer1982).

Figure 5. Crucibles of the Pfyn culture from the sites of Zürich-Rentenanstalt, Wetzikon, and Robenhausen (after Strahm, Reference Strahm1994, fig 8). The crucible from Lønt resembles the oval example, whose length is 17 cm. Reproduced by permission of Helvetia Archaeologica.

The crucibles may have been used for smelting ore as well as melting metal for casting (Martinon-Torres & Rehren, Reference Martinon-Torres, Rehren, Roberts and Thornton2014: 111). The size of the crucibles was adequate for melting enough metal to produce common objects (Melheim et al., Reference Melheim, Prescott and Anfinset2016: 62). For example, crucibles from the Pfyn culture hold 125–135 cm3 or the equivalent of 1.1–1.2 kg of copper, if filled to the brim (Schlichterle & Rottländer, Reference Schlichterle and Rottländer1982: 69). However, remnants of slag suggest that these crucibles were only filled halfway, to about 65 cm3 of copper, enough to produce two local copper flat axes weighing 295 g. An average Scandinavian flat axe weighs 381 g, requiring 43 cm3 of copper.

Scientific analyses of the crucible

Several independent analyses demonstrate the presence of traces of copper (Cu) and arsenic (As) on/in the interior surface of the crucible. Copper was mainly detected in the whitish area with the most heat impact on the interior surface, but not in the rim area or on the outside of the object. In 2013, an X-ray fluorescence (XRF) analysis with a hand-held instrument was undertaken by Michelle Taube at the Laboratory for Environmental Archaeology and Material Science at the National Museum of Denmark (case no. 11042003) (Figure 6). In 2014, Arne Jouttijärvi at the Heimdal Archaeometry Laboratory carried out a scanning electron microscopy with energy dispersive analysis (SEM-EDS) on a cross-section of the crucible and an XRF analysis with a stationary instrument (Jouttijärvi, Reference Jouttijärvi2014). The degree of penetration into the ceramic was low with a content of copper at about 0.1 per cent Cu in the thin surface layer, but no copper beyond a depth of 2 mm. Compared with Bronze Age crucibles, the lack of fractures in the grains of sand in the temper suggest a lower heat impact.

Figure 6. XRF spectra of the thin crust on the exterior of the crucible (grey line) and the whitish area on the interior (black line). Copper (Cu) and Arsenic (As) was found in the whitish area of the interior where the thermal impact was also most pronounced.

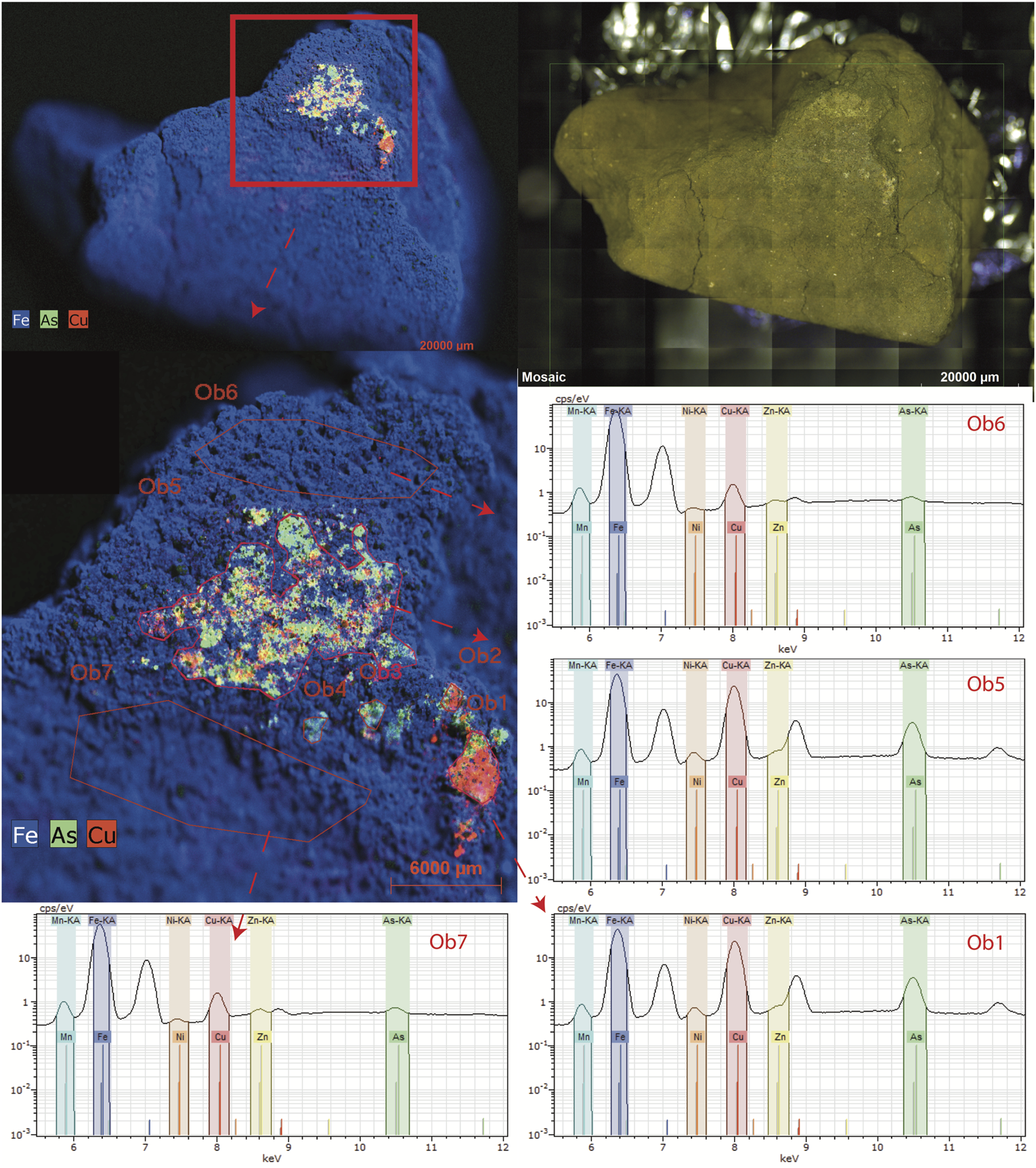

The third analysis, by Daniel Wielandt, involved a Bruker Tornado μ-X-Ray-fluorescence (μ-XRF) scanner, hosted at the Quadlab research group of the Natural History Museum of Denmark, to map the elements present on the entire presumed inner surfaces of three of the fragments. Given the peculiarities of this type of instrument, as compared to, for example, an SEM, which is typically used for microanalytical studies, a description of the operating principles is warranted.

The Tornado provides comparatively rapid and high sensitivity mapping by scanning the sample stage under an intense and focused primary X-ray beam, generated by a rhodium X-ray tube. The primary X-rays are focused by polycapillary optics to an approximately ≈ 25 μm spot at the focal point on the sample, where they generate fluorescent X-rays from a comparable or larger region, providing an upper limit on the achievable resolution that is lower than an SEM. The resulting fluorescent X-rays are detected by a 30 mm2 silicon drift detector energy dispersive spectrometer, which is capable of effectively identifying K-alpha and L-alpha emission from elements of interest for cuprolithic alloys, such as copper, arsenic, tin, antimony, and lead. Of critical importance for studies of rare, fragile, and irreplaceable materials, the sample preparation requirements are significantly relaxed compared to those of traditional electron microscope and microprobe analysis, at least for semi-quantitative mapping applications. The Tornado does not require destructive cutting and/or polishing, and the sample chamber can operate at atmospheric pressure and accommodates comparatively large, uncoated samples.

The mapping revealed enhanced levels of Cu in two of the three measured fragments (fragments A and B), with one fragment in particular showing significant coupled enrichment of Cu and As in a number of hotspots present on the most heat-affected area (fragment A) (Figure 7). Although the heterogeneous nature, high X-ray penetration, and non-ideal geometry of the sample limits the accuracy and application of quantitative analysis, the built-in data reduction software suggests a substantial copper and arsenic component, summarized and illustrated in Table 1 and Figure 7. The Ob1-5 regions mark areas with significant Cu and As, while the Ob6-7 regions probe the composition of comparatively unaffected areas of the surface, reflecting a manner of background determination for the instrument and crucible material. Although Cu and As enrichments are coupled, the As is generally less variable at ≈ 1 per cent in the affected areas as opposed to Cu that varies between 6 per cent and 1 per cent. Elevated levels of nickel (Ni) also occur in the hotspot area with the highest apparent Cu concentration. The optical depth at Cu-Ka X-ray energies is ≈ 50 microns, and the resulting large interaction volume would appear to dilute the elemental abundance; it is therefore possible that the Cu is in fact present as thinner flakes or particles of Cu metal close to the surface. These particles could have been transferred by direct contact. The As could be alloyed into these materials but given its more uniform distribution and the volatility of As, it could also have evaporated and then condensed in a more uniform pattern on the crucible surface during processing of the metal. Since an accurate quantitative measure of the amount of the individual minerals is not provided by the analysis, we cannot define a lower limit where the occurrence of other minerals may be excluded. However, it seems likely that the metal used in the crucible derives from a different type of arsenic copper than the copper used in trinkets and flat axes in southern Scandinavia during the Early Neolithic period. All these artefacts contain an amount of antimony (Sb) and silver (Ag) (Klassen, Reference Klassen2004: 66; Liversage, Reference Liversage1992: 97). An analysis of lead isotopes was not carried out due to difficulties in separating lead from the copper residue and the fabric of the crucible itself.

Table 1. Abundance of selected elements in regions of interest, as suggested by the Tornado μ-XRF analysis (see Figure 5 for location of fragments and EDS spectra). Given the heterogenous nature of the sample and software limitations, these data are provided without individual error estimates. We estimate that the relative pure counting statistical error is always better than ≈ 10% 2 sigma.

Figure 7. Optical mosaic image and FeAsCu (blue-green-red) K-alpha XRF maps and spectra generated with the Quadlab Tornado μ-XRF. The red-boxed area in the overview XRF (upper left) is shown in more detail in the middle left. The areas of interest with concentration data (Ob1–Ob7) are shown alongside logarithmic-scale spectra of selected areas. The heights of the multiple thin lines rising from the abscissa denote the approximate relative intensity of the various K-alpha and K-beta emission lines, coloured according to the general spectra scheme. Fe traces the shape of the crucible fragment, and the maps and spectra clearly reveal a number of superimposed Cu(red) and As (blue) hotspots. Background spectra collected in Ob6 and Ob7 show no or minor Cu, As and Ni K-alpha peaks, while Ob5 and Ob1 show significant increases above these levels (D. K. P. Wielandt).

The crucible is interpreted as a vessel for processing metal based on the shape of the vessel, the fabric, the coating with a slurry, as well as the heat impact on the lower part of the interior. The scientific analyses confirm that the vessel has been in contact with molten copper. Substantial amounts of copper were found on fragment A by using an μ-X-Ray-fluorescence scanner. Some copper was also detected on fragment B, while no traces were found on the remaining fragments where the outer surface is eroded. According to Jouttijärvi (Reference Jouttijärvi2014), the thermal impact was relatively modest given the lack of heat fractures and vitrification. The limited impact of heat may be explained by the thermal conductivity of the crucible, the amount of metal, the length of the period of use, as well as control of the melting process. The content of arsenic may somewhat lower the melting point of the copper. Perhaps technological differences, e.g. using bellows rather than blow pipes, mean that heat fractures are more likely to occur in Bronze Age crucibles. Furthermore, parts of a crucible may not be vitrified, and vitrification is not seen in all Neolithic crucibles elsewhere in Europe.

Alternatively, the crucible may have been a ‘holding crucible’ used for excess metal in a casting process or for cooling the metal into an ingot (Vernon et al., Reference Vernon, White, Hamilton, White and Hamilton2019: 110). The first option would be more likely as no evidence of ingots has been found in Scandinavia. The crucible is not considered to be a mould because of the heavy base, where the thickness of the vessel wall of moulds is more even (Winiger, Reference Winiger1971: pl. 79, 24–27). The shape of the rounded, oblong interior of the Lønt crucible is also different from the outline of known copper flat axes or trinkets from southern Scandinavia. One possible exception is the unique copper axe from Bedeager, Bornholm, that imitates a jadeite axe and is thought to be a local product, possibly from Zealand, Denmark (Klassen, Reference Klassen., Andersen and Nielsen2010: fig. 1.40). However, this axe is one of a kind. Thus, the crucible from Lønt is interpreted as a vessel for melting copper or as a ‘holding crucible’ used for excess metal.

The Possible Tuyère

A tuyère is a nozzle or ceramic tip protecting a blowpipe or a bellows of organic material from heat. The end of the tuyère facing the fire has a stricture that allows manipulation of the direction and quantity of the airflow in the crucible (Martinon-Torres & Rehren, Reference Martinon-Torres, Rehren, Roberts and Thornton2014: 110). A socket-like piece with an almost bell-shaped outline is tentatively interpreted as a tuyère for a blow pipe (Jørgensen, Reference Jørgensen1988a: 204, fig. 14h; Roden, Reference Roden1988: 68), although the end with the narrow air channel is missing (Figure 8). The surviving length of the artefact is 5 cm. The vessel wall is quite thick at 1 cm, while the diameter of the rim is 5 cm and 3 cm at the exterior and interior respectively. No indication of exposure to high heat was found, but that is usually not the case (Roden, Reference Roden1988: 72; Bourgarit, Reference Bourgarit2007: 7). The dimensions and funnel-shape of the object indicate that it is not part of other Funnel Beaker objects with a similar restricted diameter and strong curvature, such as collared flasks, clay ladles, biberons, or handles of vessels (Bakker, Reference Bakker1979: 57; Knöll, Reference Knöll1981: 26; Andersen, Reference Andersen2000: 35 fig. 14, 36 fig. 15; Wunderlich, Reference Wunderlich, Hinz and Müller2012).

Figure 8. A and B: The possible tuyère from Lønt. Length and maximum diameter: 5 cm (drawing: F. Oldenburg; photograph: A.B. Gebauer, National Museum of Denmark). C: Examples of complete tuyères: Haid, Austria (C1; length: 4.6 cm); Sendschirli, Turkey (C2; length: 4.2 cm); Sialk, Iran (C3; length: 3.6 cm) Roden Reference Roden1988: fig. 6.5; fig. 7, 1 and 3. Reproduced by permission of Der Anschnitt (illustration by M.L. Bendtsen, National Museum of Denmark).

Almost no finds of tuyères predate the Bronze Age and very little is known about the kind of air supply used in early metallurgy. However, blow pipes are often suggested as the means of delivering air in small-scale crucible production (Roden, Reference Roden1988; Thrane, Reference Thrane2006: 271; Krismer, Reference Krismer, Töchterle, Goldenberg, Tropper and Vavtar2013: 943; Vernon et al., Reference Vernon, White, Hamilton, White and Hamilton2019: 122). In experimental work and Egyptian wall paintings, two to six pipes were used (Roden, Reference Roden1988: fig. 1; Hauptmann, Reference Hauptmann2007: 221; Hamilton, Reference White, Hamilton, White and Hamilton2018: 176). Small bell-shaped tuyères are usually associated with blow pipes. This kind of tuyère dates from the third millennium bc in the eastern Mediterranean and the Levant and the middle of the second millennium in central Europe around the middle Danube (Roden, Reference Roden1988; Thrane, Reference Thrane2006: 271). Small bell-shaped tuyères have not been found previously in Denmark, but a larger type of tuyère with a perpendicular bend was introduced around 1300 bc in the late Bronze Age (Thrane, Reference Thrane2006: 271). Before the Bronze Age, only a few tuyères of unknown shape are associated with the Bell Beaker, Zlota and Funnel Beaker cultures in Poland (Roden, Reference Roden1988: 71; Midgley, Reference Midgley1992: 295). Two other cases of tube-like objects in Funnel Beaker contexts in the north are not considered to be tuyères since the interior diameter is the same along the whole length of the objects without the defining stricture at the end which, if they were nozzles, would face the fire (Andersen, Reference Andersen1999: fig. V.93.5; Hage, Reference Hage, Hinz and Müller2012, 235–39, Reference Hage2016, fig. 132).

Decoration of the nozzle

The lip of the possible tuyère is decorated with fingertip imprints and vertical strokes incised along the edge. The side is covered by curved strokes reminiscent of fingernail impressions but incised with a sharp tool and a few vertical strokes impressed with a short, curved tool with very fine teeth. The overall impression is that of a scaly skin (Figure 8, A and B).

The decoration is atypical of the Funnel Beaker culture, and no parallels have been found. Fingernail impressions were used in a few all-over designs dating from period EN I or early EN II in Denmark and Poland (Skaarup, Reference Skaarup1975: 72–73 fig. 29.8, 80 fig. 36.2, 145 fig. 61.2; Meurers-Balke, Reference Meurers-Balke1983: pl. 22, 3; Pedersen, Reference Pedersen2008: vessel 81; Papiernik, Reference Papiernik2012: 222, 224 pl. II). However, fingernail impressions are commonly used in the Pfyn culture when this culture served as a secondary production centre of metallurgy between 3800 and 3650 bc (Winiger, Reference Winiger1971: pls. 8, 26, 73, 74, 77, 78, 84; Mainberger, Reference Mainberger1998: pls. 2, 13).

Decoration on a tuyère is rare, but a few objects are covered in carpet-like designs (Roden, Reference Roden1988: fig. 5.2, fig. 7.1–2 and fig. 8) (Figure 8, C3). The roughening of the vessel surface with an all-over design may have served practical purposes, providing a more secure grip and a better heat absorption due to the greater surface area of the uneven exterior (Müller, Reference Müller1906: 212; Rice, Reference Rice1987: 232). Additionally, the decoration may have had a symbolic significance, marking the boundary between the craftsman and the powers and dangers of the melting process (Hodder, Reference Hodder1982: 191; Melheim, Reference Melheim2015: 101, Reference Melheim, Prescott and Anfinset2016: 61).

Metallurgy in the Funnel Beaker Culture

Metallurgy was invented in the Near East, with the first copper smelting in Europe documented at Belovode in eastern Serbia in the early fifth millennium (Roberts et al., Reference Roberts, Thornton and Pigott2009: 1014; Radivojevic et al., Reference Radivojevic, Rehren, Pernicka, Slijvar and Brauns2010: 2776). In central Europe, the earliest evidence of copper metallurgy is found at Mariahilfbergl in Brixlegg (Tyrol, Austria) associated with the Münchhöfen culture and dated to the second half of the fifth millennium (Höpner et al., Reference Höppner, Bartelheim, Huijsmans, Krauss, Martinek, Pernicka and Schwap2005). From around 3800 bc, extensive production of copper artefacts took place in the north Alpine region and pyrotechnical knowhow reached western and northern Europe in the fourth and third millennia bc (Dolfini, Reference Dolfini2013; Bartelheim & Pearce, Reference Bartelheim, Pearce, Fowler, Harding and Hofmann2015: 694; Roberts & Frieman, Reference Roberts, Frieman, Fowler, Harding and Hofmann2015). However, evidence of metallurgy in the form of ceramics from technical processes, such as furnaces, crucibles, moulds, and tuyères are not found in the Nordic region before the Bronze Age in the second millennium bc aside from a few finds in the northern Fenno-Scandian area and finds associated with the Rhomp-Pit Ware and Typical Comb Ware in the eastern Baltic area in the first half of the fourth millennium bc (Vandkilde, Reference Vandkilde1996: 262; Nordqvist et al., Reference Nordqvist, Ikäheimo, Herva and Lahelma2011, Reference Nordqvist, Herva, Ikäheimo and Lahelma2012; Hage, Reference Hage, Hinz and Müller2012: 238; Melheim, Reference Melheim2015: 139; O'Brien, Reference O'Brien2015: 155). Thus, the crucible and possible tuyère from Lønt represents the only evidence so far of local metallurgy in the fourth millennium (Figure 9).

Figure 9. Finds of crucibles and other indications of metallurgy in groups belonging to the wider TRB culture as well as contemporary groups in the Alpine forelands. A. Lønt, Denmark (Funnel Beaker): crucible, possible tuyère. B. Grossobringen, Thüringen (Bernburg): crucible. C. Klingenberg bei Heilbronn, Baden-Württemberg (Michelsberg): several crucibles. D. Makotracy, Bohemia (Baalberg): crucible, slag. E. Laskov, Moravia, Czech Republic (Funnel Beaker): crucible, slag. F. Cmielow, southern Poland (Funnel Beaker): crucible, slag. G. Grodek Nadbuzny, southern Poland (Funnel Beaker): crucible, slag. H. Janówek, southern Poland (Funnel Beaker): crucible, nozzle, slag (L. Sørensen based on Klassen Reference Klassen2014a, 231 fig. 135).

Scandinavian copper objects were imported from secondary production centres in the Alpine region related to the Mondsee, Altheim, and Pfyn cultures dating to 3800–3300 bc (Klassen, Reference Klassen2000, Reference Klassen., Andersen and Nielsen2010: 228). The source of the arsenical copper, so-called Mondsee copper, used in most objects found in Scandinavia has yet to be identified, but may be located further east or south-east of Mondsee in the eastern Alpine area (Frank & Pernicka, Reference Frank, Pernicka, Midgley and Sanders2012: 127; Klassen, Reference Klassen2014a: 228). Local Scandinavian sources of copper were probably not exploited at this time. The chemical composition of copper ore from Helgoland is different from the patterns seen in southern Scandinavian copper artefacts including the crucible from Lønt (Klassen, Reference Klassen2000: 211–17, catalogue nos. T1–14). An origin in Sweden is unlikely because of differences in the lead isotopes (Klassen & Stürup, Reference Klassen and Stürup2001). No evidence supports connections between the southern Scandinavian Funnel Beaker culture and the Rhomp-Pit Ware or Comb Ware culture in the northern Fenno-Scandian area (Melheim, Reference Melheim2015: 11). Recent research into the possible sources of southern Scandinavian Neolithic copper points to central Europe as a likely source (Frank & Pernicka, Reference Frank, Pernicka, Midgley and Sanders2012: 131).

Cultural and social norms rather than accessibility appear to regulate the presence of copper items north of central Europe; a regular tapering-off pattern in the distribution is not observed (Bogucki, Reference Bogucki1988: 190). Copper trinkets and axes are known throughout the area of the Funnel Beaker culture, but in limited numbers and with an uneven distribution. Copper ornaments were deposited in megalithic tombs in the Netherlands, north-western and central Germany, and Denmark, while axes are mainly found in Denmark and Poland (Schlicht, Reference Schlicht1973; Midgley, Reference Midgley1992: 294, Reference Midgley2008: 144; Klassen, Reference Klassen2014a: 229 fig. 134). Additionally, a limited number of copper objects, such as needles, awls, spirals, rings, and axes, are found on Polish Funnel Beaker settlements. The Danish and Polish trinkets and most of the axes are made from arsenical copper and seem unrelated to the Polish copper artefacts from late Lengyel (4250–3800 bc) that were cold-hammered and made from non-arsenical copper (Midgley, Reference Midgley1992: 299). Likewise, the copper from the western Funnel Beaker culture comes from a different source of mainly non-arsenical copper and dates from MN I–II (Schlicht, Reference Schlicht and Schirnig1979).

Smelting and melting of copper is associated with the southern Funnel Beaker culture from 3800 bc onwards, coeval with the production centres in the Alpine area (Schlichterle & Rottländer, Reference Schlichterle and Rottländer1982; Midgley, Reference Midgley1992: 296; Klassen, Reference Klassen2000: 283) (Figure 9). Evidence of metalworking in the form of crucibles as well as copper slag has been found at Makotracy in Bohemia, Laskov in Moravia, and Grodek Nabudzny, Janówek, and Cmielow in southern Poland (Klassen, Reference Klassen2000: 284 fig. 125) (Figure 9). At the site of Janówek, fragments of tuyères were found as well as arsenical copper, crucibles, and slag (Wislanski, Reference Wislanski, Hensel and Wislanski1979: 237; Midgley, Reference Midgley1992: 295). Preconditions for local metallurgy in the form of raw materials and knowledge of copper imports was likewise available in central Germany, where production of copper artefacts has been found in a few cases (Klassen, Reference Klassen2000: 285; Müller, Reference Müller2011: 296), although local production, for instance in the Salzmünde group, has been disputed by others (Strahm et al., Reference Strahm, Wiermann, Müller-Scheessel and Meller2013: 72).

Discussion

The adoption of metallurgy by early farmers in southern Scandinavia raises a number of questions about the role of metal and metalworking in society.

The fact that metal objects were re-melted and re-created according to regionally and locally desirable forms suggests that copper objects were perceived in the same way as other exotic and visually distinct objects, such as jadeite axes, amber, and polished stone axes. Metal in itself was not conceptually different from other shiny objects with distinctive colours and limited accessibility. Indeed, the re-creation of copper axes to conform to local fashions in southern Scandinavia only produced larger axes, not axes of superior quality or new types of artefacts (Klassen, Reference Klassen., Andersen and Nielsen2010). The potential of metal for tool production may not have been fully appreciated in the region during the Early Neolithic (Bray, Reference Bray, Allen, Gardiner and Sheridan2012). The question may also be raised whether the axes were initially made for utilitarian purposes, e.g. as weapons or tools, or as a valuable. The axes may have circulated in a rough form as cast until someone decided not to recast them and turned them into a finished axe through forging, hammering, and grinding (Kienlin & Stöllner, Reference Kienlin, Stöllner, Kienlin and Roberts2009). Furthermore, the mastering of pyrotechnology has been associated with the ritual sphere and is thought to have contributed to the prestige and social control by the elite (Kaul, Reference Kaul, Anglert, Artursson and Svanberg2006: 107f; Midgley, Reference Midgley2008: 176; Klassen, Reference Klassen., Andersen and Nielsen2010: 40; Nielsen & Sørensen, Reference Nielsen and Sørensen2018: 23). On the other hand, the role of copper in social differentiation in Neolithic society is debated (Roberts & Frieman, Reference Roberts, Frieman, Fowler, Harding and Hofmann2015: 719; White & Hamilton, Reference White, Hamilton, White and Hamilton2018: 125); the copper objects may have functioned as valuables in reciprocity/gift exchanges in a more group-oriented society. A striking number of copper axes are stray finds; only trinkets were used in graves, perhaps indicating that they played another role in society than as the exclusive property of the elite (Price & Gebauer, Reference Price, Gebauer, Hansen and Müller2017: 148).

According to Klassen (Reference Klassen2014a: 246), the spread of metallurgy north of the Alpine production centres appears to follow in the wake of the tradition of enclosure construction, with both features forming a part of the establishment of fully Neolithic societies in the Funnel Beaker area around 3800–3700 bc (Furholt, Reference Furholt, Furholt, Lüth and Müller2011; Gron & Sørensen, Reference Gron and Sørensen2018: 969). The transmission of metallurgy to southern Scandinavia is coeval with the introduction of long barrows, causewayed enclosures, and two-aisled houses (Sørensen, Reference Sørensen2014: 148, 178; Gron & Sørensen, Reference Gron and Sørensen2018: fig. 7). Such long-distance connections to central Europe and the Alpine area are visible in the distribution pattern of point-butted stone axes with a perforated butt of type Zug that had a limited occurrence in Switzerland and a number of imitations in southern Scandinavia, as well as the presence of some early types of polygonal battle axes in the Michelsberg and Baalberg culture groups, and southern Scandinavia (Klassen, Reference Klassen, Arbogast and Geffier-Richard2014b; Sørensen, Reference Sørensen2014: 148 fig.V.88, 177). Apparently, metallurgy was one of the components of these new networks that transformed Scandinavian society into a fully Neolithic community.

The reasons why the ceramics from technical processes were found in the cultural layer at Lønt remain obscure, but depositions of objects related to metallurgy in the Bronze Age are often assumed to represent special events (Kaul, Reference Kaul1987: 43; Bradley, Reference Bradley2005: 164; Melheim, Reference Melheim2015: 131). The presence of such exotic objects at Lønt is less surprising. Lønt is located in a prosperous and fairly densely populated region, as reflected in the high number of megalithic tombs (Klatt, Reference Klatt and Terberger2009: fig. 12; Ebbesen, Reference Ebbesen2011: maps 1 and 2). The location is optimal in terms of communication and transport by sea and land (Klassen, Reference Klassen2014a: 72 fig. 34, 79 tb. 7). Evidence of long-distance contacts and exchange is provided by the finds of copper flat axes and trinkets in the surrounding area (Madsen, Reference Madsen1978; Vandkilde, Reference Vandkilde1996: 401 no. 22; Klassen, Reference Klassen2000: 81, 115, pl. 12.48, 183–84). Another instance of these contacts might be represented by the unique clavicle-shaped ditches surrounding the Starup Langelandsvej enclosure, which are similar to the ditches found at the Sandomierz enclosure in southern Poland (Klassen, Reference Klassen2014a: 255). The Starup Langelandsvej enclosure and the find of the Lønt crucible are situated only a few hundred metres apart and both phenomena are coeval. We can hypothesize that the introduction of early metallurgy and the tradition of enclosure building were the first steps in creating a ceremonial centre at Lønt.

Conclusion

Traces of arsenical copper in the crucible were confirmed by several independent analyses and indicate that metallurgy was indeed practised during the Early Neolithic in the northern Funnel Beaker culture. In addition, a funnel-shaped socket may have served as a tuyère for a blow pipe. The two objects were found together in a secure context dating to the mid-fourth millennium and sealed beneath a megalithic tomb dated to 3300–3100 bc. This example of metallurgy in the north is coeval with evidence of metallurgy in the southern Funnel Beaker group and the peak of the production centres in the Alpine area. The transmission of metallurgy followed in the wake of the introduction of other phenomena, such as long barrows and causewayed enclosures, that led to the establishment of fully Neolithic societies in the northern Funnel Beaker group between 3800 and 3500 bc. The two pieces of technical ceramics provide evidence of metallurgy in Scandinavian more than 1500 years earlier than previously thought.

Acknowledgements

We wish to thank the reviewers for useful comments, Lene Melheim for generously sharing her knowledge, as well as Niels H. Andersen, Lutz Klassen, Torsten Madsen, Poul Otto Nielsen, and T. Douglas Price for their thoughtful comments on the manuscript. Funding for the analysis of Lønt is provided by The Archaeological Foundation of Queen Margrethe II (grant number 13080-28-2012). The Quadlab research group at the Natural History Museum of Denmark is funded by the Villum Foundation.