Introduction

The significant and unique discovery of a near-complete miliarium in a Roman rural farmstead at Saint-Pathus in the Île-de-France region, some 50km north-east of Paris, offers a rare opportunity to study the water management and technology of a rural site within the late Roman Empire. An archaeological rescue excavation undertaken in 2006 by a team from the French National Institute for Preventive Archaeological Research (Inrap) led to the discovery of a Roman water boiler, made of lead and copper alloy, in an exceptional context inside the small private bath complex of a third–fourth-century AD farmstead (Figure 1).

Figure 1. View of the remains of the Saint-Pathus bath house. The water boiler lies in a pit in the foreground. The hot-air channel is clearly marked by the red colour of the ground. Photograph: G. Bruley-Chabot, Inrap.

Boilers were common enough and, indeed, indispensible pieces of equipment, and yet nearly all have disappeared, being systematically recycled for their valuable metal. The exceptional state of preservation of this water boiler gives us the opportunity to examine in detail the manufacturing techniques used in its production and its decoration, as well as the context of its production and use. The boiler also illustrates the broad distribution of water technology across rural landscapes, as well as the circulation of cultural norms within the middle-ranking elites of northern Gaul. A wider discussion of its social significance and the reasons leading to its survival raises questions concerning the status of the miliarium. Originally an expensive piece of equipment, it finally became an offering and object of symbolic transaction.

The scarcity of boiler finds throughout the Roman Empire

Despite the widespread use of this ordinary piece of equipment in ancient times, only a dozen or so boilers have so far been recovered across the breadth of the Roman Empire. Excavation of a villa at Tourville, near Apt (Vaucluse), led to the discovery of a circular, concave bronze shield, weighing some 50kg and interpreted as the base of a miliarium (Archéologie en Vaucluse 1999). Other important copper alloy fragments were discovered in the bath complex of Longeas (Charente), and in Toulouse in the infilling of a well that was part of a bath complex (Bouet Reference Bouet2003; Loiseau Reference Loiseau2009). A lead tank was also retrieved during the dredging of the River Rhône (Cochet & Hansen Reference Cochet and Hansen1986). Another tank, associated with pipeline parts and sheets, and decorated with two cherubs, was found in 2003 in the ancient town of Ambrussum (Villetelle, Languedoc; Fiches & Rebière Reference Fiches and Rebière2010).

Parts of boiler equipment have usually been found in fragmentary condition and often without context; complete finds are extremely rare. The miliarium found above the furnace of the caldarium at the Villa della Pisanella at Boscoreale (Italy) is a rare complete occurrence (Bouet Reference Bouet2003), and the most similar to our own find. An imposing tank, 1.15m in height and 1.2m in diameter, found in Scheitheim (Switzerland) in the bath complex of Iuliomagus is decorated with a bas-relief of a hunting scene (Bossert Reference Bossert1979). Such cylinder-shaped water boilers also occur among the equipment from Pompeii, Herculaneum and Ostia (Dessales Reference Dessales2004), including one displayed in 1933, still standing in its original location of one of the bath complexes of Pompeii. A picture shows two of these remarkable miliaria superposed one above the other over the praefurnium, complete with pipes and valves (Romana Domus 1933: 103, reproduced here as Figure 2). The dimensions and manufacturing process of these tanks closely resemble those of the boiler from Saint-Pathus, although no stamping or decorations can be observed from the photograph (the current location of these objects is unknown).

Figure 2. Two lead tanks from thermal baths in Pompeii and Herculaneum, photographed in the 1930s (Romana Domus 1933).

Description and method of manufacture of the Saint-Pathus miliarium

The boiler discovered at Saint-Pathus is among the finest and most informative of those still extant. The miliarium takes the form of a cylindrical tank, 1.11m in height and approximately 0.65m in diameter, weighing some 250kg and consisting of two distinctive parts: a cylinder made mainly of lead, and a concave base of copper alloy (Figures 3 & 4). It exhibits a few creases and deformations, which probably occurred during its handling and deposit. The metal is in a fairly good state of overall conservation. The rough exterior texture is probably original, and reflects its casting in a wet sand foundry. The low rate of corrosion indicates a high proportion of lead in the lead-tin alloy.

Figure 3. Illustration of the water boiler, showing the frontal, side and bottom views and the cross-sections of the bottom. Illustration: P. Raymond, Inrap.

Figure 4. Front view of the water tank, showing the bas-relief decoration on the upper part. Illustration: L. Petit, Inrap.

The cylinder is made of two lead sheets, each made by open wet sand casting, a common manufacturing technique throughout Roman times, using an open, temporary casting floor (Cochet Reference Cochet2000). The sheets were curved then assembled with a clamp. They were placed (without overlapping) then welded together, with a flattened lead weld bead, set outside the ferrule. Initially, each of the lead sheets measured 1.2m in height, 0.9m in width and 55–77mm in thickness before being folded. The weld beads were shaped into strips 12mm thick and 38–46mm wide. The base of the boiler is a circular, concave bronze (copper alloy) cap measuring 0.65m in diameter and 3mm in thickness, probably made by a casting technique. Series of concentric circles on the bronze cap may represent grinding marks made with an abrasive material, such as pumice stone. The edges of the lead cylinder are folded back onto the bronze base. They were soldered together with an inner weld bead that can be seen through a tear at the bottom of the lead cylinder. A tough lead ring—a sort of crown or pedestal, 76–86mm in width—was then welded onto the bottom of the boiler, reinforcing the whole structure and providing the final sealing. This outer ring was probably made froman independent, separately cast piece before being soldered. The red colouration of the alloy here indicates a lower lead content than for the ferrule. The lead cylinder and pedestal were roughly welded to each other, as indicated by different metal inputs around the base. The supporting bars of the oven on which the boiler rested left parallel marks on the lead ring, indicating a distance of about 300mm between the two bars. Two apertures were made on the upper part of the tank, on each side of the lead bead, up to 115mm in diameter. Although somewhat distorted and crushed, they appear to have served as the water inlet and outflow holes. No perforations were found on the bottom of the tank, and no valves, pipes or lid were recovered during the excavations at Saint-Pathus. Similarly, almost no other lead objects or even waste products were found on the site, and there was no evidence of any recycling activities around the boiler. The tank has been estimated to have held some 350 litres. The largest examples at Pompeii and Herculaneum held between 200 and 450 litres (Dessales Reference Dessales2004; Fiches & Rebière Reference Fiches and Rebière2010).

Water management and functioning of the boiler

No water channels, indicating either supply or evacuation of the boiler, have been found around the bath house. We may therefore assume that these operations were carried out using buckets. Indeed, a well was located about 25m away from the building. The provision of wood and water for the bath house could have been effected by a very small number of individuals, even a single person. An intermediary cold water tank might have been set in the praefurnium (furnace) area, in anticipation of the water needs.

The method of circulation of water between different tanks and from the miliarium to the labrum (large basin) is difficult to ascertain, given the absence of any pipes or valves at the site. Our assumptions in this regard are based on comparisons with other examples (listed above) and on descriptions of such systems by ancient authors such as Vitruvius (Vitruvius V, 10.1; see Yegül Reference Yegül1995, Reference Yegül2010); Faventinus, an author of the third century AD, drawing directly upon Vitruvius; and Palladius, in the fifth century AD, drawing on Faventinus (Plommer Reference Plommer1973; Yegül 2010).

The tank from Saint-Pathus presents two inlet and outflow holes placed at the top. As no holes were present in the base, we must exclude the possibility of a lower drain equipped with a pipe and a valve, which would go through the praefurnium wall to the labrum. The imprints of the metal bars on the bottom of the tank clearly suggest that this copper component, more resistant to high temperatures than lead, was directly exposed to the heat of the furnace on which it rested. Once covered by a simple lid, another tank could well have rested upon it. The hypothesis of an internal pipe fitting, coiled unattached within the tank itself, cannot at present be substantiated. Hot water could have reached the upper parts of the filled tank through thermal exchange, as it neared boiling point. We have yet to understand which parts of the heating and water supply equipment are missing (Manderscheid Reference Manderscheid and Wikander2000).

The Saint-Pathus miliarium was kept in a small bath house, access to which was probably limited to those few persons who used the baths and who serviced them. The boiler supplies hot water through a cauldron or labrum, rather than through a pool. The furnace heated the boiler as well as the hypocaust through a simple stove-boiler combination, as seen for the unit found in the Villa Rustica at Boscoreale (Yegül Reference Yegül1995). A single wall probably separated the furnace from the caldarium.

The bas-relief Okeanos mask

One of the two plates from which the tank is made shows a striking bas-relief decoration, placed on the upper part of the sheet (Figure 5). The frieze, measuring 0.51m high × 0.87m long, consists of two horizontal panels, structured with ‘sticks’ and ‘cross-bars’ defining triangular and lozenge shapes, many of which contain imprints of a medallion. Sticks and cross-bars are typical decoration found on other Roman lead objects, such as sarcophagi, boxes or funerary urns (Cochet Reference Cochet2000; Dubuis Reference Dubuis2013; Duvauchelle & Monteix Reference Duvauchelle and Monteix2013).

Figure 5. Latex moulding of the bas-relief decoration (P. Raymond, Inrap).

The panels contain 19 medallion imprints, spread irregularly across the composition. Given that the sticks and cross-bars are also arranged unevenly, it does not seem that the decoration was made following a rigorous plan or even a preparatory sketch. The rough composition and the irregularity of the arrangement indicate a lack of care: this is reinforced by the disparities displayed by the medallion imprints, which are probably due to the uneven stamping of the model-plate, in terms of its depth and positioning, in the wet casting sand. This bas-relief decoration was made in the course of casting the cylinder sheets. The mould was probably a wooden frame filled with wet sand into which the decorative features and the medallion were repeatedly pressed. The medallion, sculpted on a wooden or metallic model-plate, was stamped onto the surface of the wet sand, leaving an imprint that was then filled with the molten metal as casting proceeded. The overlapping of the sticks and cross-bars indicates that they were stamped first, before the medallions.

The medallion itself consists of a masculine mask: a stylised, bearded, moustachioed, high-cheekboned, wrathful face (Figures 6 & 7). The mask represents a mythological being who we propose to identify as Okeanos. Personifying water, he derives from Greek theogonies and was related by extension to the seas, rivers and other streams, and is most often pictured as a dishevelled head, wearing a thick beard and a profuse moustache whose curls of hair each represent a river (Kerenyi Reference Kerenyi1974). The head has spines of crustacean legs and crab claws. On the Saint-Pathus miliarium, Okeanos is rendered with beard, moustache and scrolls of hair while two crab claws are stylised on the forehead, and two other crustacean legs seem to fall down from the top of the head. The identification of Okeanos on an object with aquatic connotations confirms the widespread circulation and recognition of such decorative themes throughout the Romanised world (Beard et al. Reference Beard, North and Price1998). Most are found in mosaics originating from the Mediterranean region, such as two examples from the second century AD, now in the Tunisian museum of Sousse (Foucher Reference Foucher1961). A few have also been discovered in Roman Gaul, such as the mosaic found near Lyon, at Saint-Romain-en-Gal, dating to the end of the second century AD (Cochet & Hansen Reference Cochet and Hansen1986), or the sculpted sandstone capital in the sanctuary of Jublains (near Mayenne) (Naveau Reference Naveau and Naveau1997).

Figure 6. View of one of the medallions of Okeanos. Illustration: S. Hurard, Inrap.

Figure 7. Examples of the best-preserved medallions and restitution of a complete one. Illustration: P. Raymond, Inrap.

Local craftsmen and second-rate household item

The discovery of the boiler in a rural settlement of the Late Roman period in northern Gaul puts into perspective the rarity of such items. While it is exceptional to find them in archaeological contexts, this is, emphatically, not because they were rare in ancient times. On the contrary, such water boilers must have been very common all over the Roman Empire, as they were an essential piece of equipment in order to operate a bath in any rural settlement or urban context (Yegül Reference Yegül1995, Reference Yegül2010). The scarcity of contemporary finds is far more likely to be due to the high value of the metal—essentially lead—used in the boilers, and its ready potential for recycling, being particularly easy to meltdown and recast. Indeed, the recycling of such a voluminous and expensive piece of equipment—a recycling that must have been anticipated and carried out on a wide scale throughout the Roman Empire—is a key subject that requires further research, and involves a range of technical, economic and social considerations. Recent studies of the ancient workshops of Pompeii and Herculaneum have already usefully addressed several aspects of this recycling phenomenon, including the careful management of resources and the deployment of skills by master craftsmen (Dubuis Reference Dubuis2013; Duvauchelle & Monteix Reference Duvauchelle and Monteix2013). The manufacturing process of the miliarium, with its estimated weight of over 250kg, implied a skilled labour force and required numerous people for the handling and assembling of the pieces. Such an object was undoubtedly manufactured by lead smiths or metal artisans. To our knowledge, however, no lead workshops have yet been discovered in this part of the Parisian basin. The mediocre quality of the object, exhibited by the rough methods applied to the bas-relief, indicates that it was neither a high-quality, custom-made item nor one imported from a highly regarded distant workshop. A local origin is more probable, and it can be surmised that workshops would have been located in Meaux, the nearest substantial town at that time, about 18km to the south-east. The fairly crude and unassuming decoration on the boiler's surface need not imply that the object itself was a luxury item to be admired as such: even in provincial Gaul, guests would hardly be invited to admire the proud owner's boiler. Rather, the decoration probably played a role in the commercial strategy of an expensive yet essential piece of equipment. It was, above all, the ownership and good working order of the bath house that would have mattered to middle-ranking rural elites such as those from Saint-Pathus.

The penetration of water technology into rural landscapes of Roman Gaul

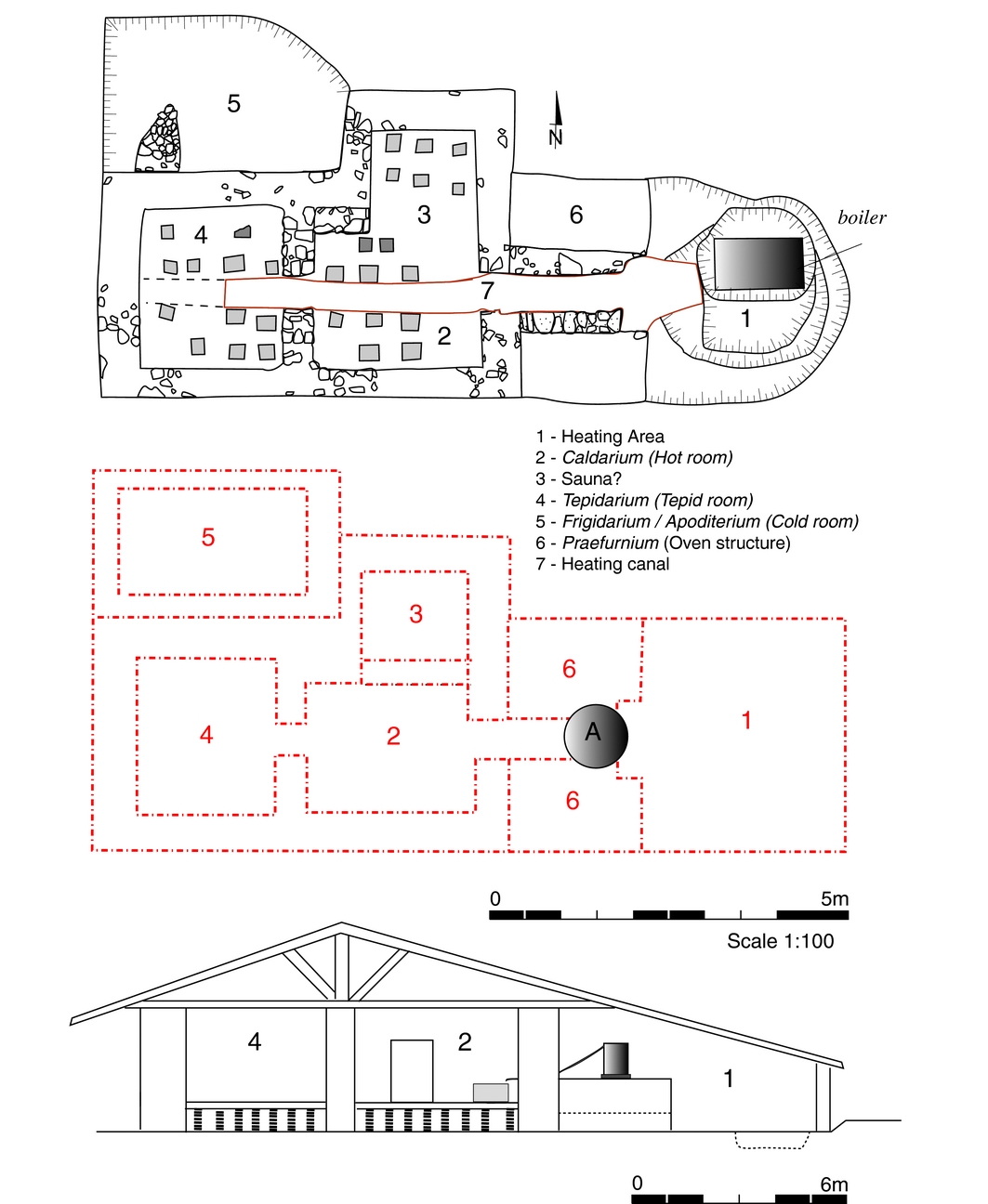

In comparison with the rest of the farmstead, the bath complex of Saint-Pathus stands out as the only building showing the use of stone, tiles and other hard materials. The existence of a private bath house and its equipment would be a sign of wealth and social distinction, and a very strong symbol of Romanitas. Through bathing activity, the inhabitants of the site displayed a degree of sophistication and bodily hygiene that can be seen as signs of assimilation into a cultural model, which in turn served to express social and economic wealth. The plan of the Saint-Pathus bath house, reduced to its essentials, was a building 10.3m long and 4.3m wide (42m²). Small and compact, this building respects the usual norms of the Roman bathing sequence and represents the adaptation of a model, widespread all over the Empire, to local conditions and tight resources (Nielsen Reference Nielsen1993) (Figure 8).

Figure 8. Archaeological plan and hypothetical reconstruction of the bath house. Illustration: P. Raymond, A. Lefeuvre and S. Hurard, Inrap.

Although hundreds of rural settlements dating to the Roman period have been excavated across the Île-de-France region in the last few decades—a result of the development of rescue archaeology—only a few examples of such small bath houses have been found. Such bath houses appear as an exception in rural settlements of the Late Roman period in northern Gaul, and can definitely be read as a marker of social distinction and wealth.

The discovery of the boiler in such a context highlights the penetration of water technology into rural landscapes. Not restricted to the urban high-status houses, it had spread within the middle-ranking rural elites, who were concerned to demonstrate their attachment to, and recognition of, the cultural norms and common codes of representation. It is therefore not only evidence of commercial and economic dynamics on a regional scale, but also of the wider currency of cultural patterns, from both a technological and symbolic point of view, as shown by the choice of decoration.

A valuable stash or a symbolic deposit?

The reason why a high-value metal object such as this boiler came to survive greed and recycling is no doubt related to the history of the bath complex. The site was occupied from the second part of the third century until the fifth century AD as a classic farmstead. Evidence shows that a short break occurred in the occupation of the site in the second part of the fourth century, coinciding with the destruction of the buildings, including the bath complex. The site was very quickly resettled by the end of the fourth century, respecting the former layout and organisation of the farmstead, except that all the buildings had walls of cob. The abandonment or neglect of the site therefore lasted only for a very short spell, maybe a decade, and during this time the bath house appears to have been dismantled methodically. Part of the floor of the heating area or furnace (praefurnium) was dug up to create a pit equivalent to the dimensions of the miliarium. The boiler was then moved from the furnace, on which it had originally been standing, and buried inside this pit, which was then backfilled with heterogeneous materials to a depth of 1.3m (Figures 1 & 8). Several hypotheses can be proposed to explain this burial. The most evident is an intention to protect this precious mass of metal from unauthorised attempts to melt and reuse it, until it could be collected by its owners. This hypothesis implies that the rightful owners had to abandon the site without being able to take with them all of their belongings, especially the heaviest.

A second hypothesis has recently emerged following re-evaluation of the burial of parts or whole carcasses of non-consumed animals in the north-eastern sector of the site (23 deposits in a dozen locations). Radiocarbon dating of bone samples from four different burials shows that the phenomenon occurred between the end of the third and the mid fourth centuries AD. Deposits were located either around the edges of residential buildings—where mostly cattle are buried—or in the decommissioning of cellars, where mostly juvenile pigs are buried. A few pits contain an accumulation of cattle, horses, cats and even human remains (calvarium and teeth). Almost half of the deposits of cattle and horses were concentrated around the bath complex and buried within 10–30m of the building. A complete cow was deposited in a pit adjacent to the north wall of the building. Just as the boiler was buried in the furnace area of the bath complex, so were a complete juvenile pig and a little owl (Athene noctua) found in the infill of the hot and warm rooms respectively.

The ritual interpretation of those deposits in a private domestic settlement is supported by their repetition, the diversity and the combination of species, the largely complete nature of the carcasses and the juvenile character of the victims, as much as by the choice of species. The recurrence of the phenomenon and the specific location of the burials lead us to hypothesise that they might represent foundation and abandonment rituals, of a kind known for that time period in the Rhine region (Lepetz & Van Andringa Reference Lepetz and Van Andringa2008; Groot Reference Groot and Pluskowski2011). While the origin and nature of these practices cannot be explored in the present article, they offer a very different perspective on the reason why the boiler was buried and preserved. The combination inside the bath complex of domestic and wild species (juvenile pig being often associated with the cult of Tellus and Ceres and the owl with that of Athena) and a high-value water tank decorated with Okeanos masks gives special significance to the decommissioned building and its contents. Integrated into a ritual based on animal sacrifices, the miliarium may then have been offered to the gods, a material sacrifice of an expensive item in a symbolic exchange for protection and prosperity. It can be assumed that the decorative masks of the water divinity would have further increased the significance of the offering.

Conclusion

Preserved from destruction by its deposit in a pit when the bath building was demolished in the mid fourth century, the boiler found at Saint-Pathus is testimony to the spread of technology, culture and symbolic practices in Roman Gaul. This unique discovery of a boiler, an object at once ubiquitous and nearly invisible, is an exception that brings into focus a common piece of equipment of the Roman lifestyle. Thanks to its intentional burial (be it through recycling or some ritual practice), a very rare example of a massive piece of lead hydraulic equipment in a rural, isolated farmstead has been preserved. Its bath house context highlights the water technology that was employed and the scale of metalworking far away from an urban centre. The specific context of deposition, in combination with a repeated practice of animal burial, confers a strong symbolic and religious significance on the item. The object was diverted from its initial function and spared from recycling to be used in a different type of bargain, where its symbolic value was more important than its intrinsic one.

Acknowledgements

We wish to thank our colleagues Thomas Le Paon, for his advice and insights, and Nathan Schlanger, for his support and careful reading.