1. Introduction

In various industrial processes such as manufacturing and aviation, it is inevitable that small, hot particles are produced. Such hot particles are also known as mechanical sparks since they usually glow because of the exceedingly high temperature (Hawksworth et al. Reference Hawksworth, Rogers, Proust, Beyer and Schenk2005; Beyer & Markus Reference Beyer and Markus2012). The nature of the high temperature makes the mechanical spark an efficient ignition source. When a mechanical spark enters a flammable environment, the possibility of unwanted explosion due to ignition on the particle surface is substantially promoted (Eckhoff & Thomassen Reference Eckhoff and Thomassen1994; Hawksworth et al. Reference Hawksworth, Rogers, Proust, Beyer and Schenk2005; Proust et al. Reference Proust, Hawksworth, Rogers, Beyer and Lakic2007). Such accidental ignition and explosion can lead to tremendous damage and hazards. Besides, hot particle induced ignition is one of the important pathways to wildland and urban spot fires (Wang et al. Reference Wang, Huang, Chen and Liu2016; Urban Reference Urban2017; Urban et al. Reference Urban, Zak, Song and Fernandez-Pello2017). Therefore, an in-depth understanding of the underlying physics behind hot particle induced ignition is of crucial importance for industrial and fire safety.

The ignition of a combustible mixture by a mechanical spark takes place close to the hot surface (Law Reference Law2010). Such an ignition process is essentially inhomogeneous since there is large temperature gradient around the hot particle. Stamatov, King & Zhang (Reference Stamatov, King and Zhang2005) conducted experiments on the ignition of quiescent CH4/air mixtures caused by a laser-heated particle. They showed that the ignition delay time depends on the equivalence ratio and has a minimum value for a stoichiometric mixture. Beyer & Markus (Reference Beyer and Markus2012) investigated the ignition capability of inert particles in a static explosive mixture. Their experiments and simulations showed that reducing the particle size promotes the critical ignition temperature. Roth et al. (Reference Roth, Sharma, Haeber, Schiessl, Bockhorn and Maas2014) considered the thermal ignition of a quiescent H2/air mixture by a small hot particle whose diameter was in the range from 0.3 to 0.8 mm. Their experiments showed that the critical ignition temperature strongly depends on the material of the hot particle. However, such a phenomenon can hardly be reproduced in numerical simulation. It was hypothesized that the surface reaction, i.e. quenching and catalysis, might contribute to the large difference in the critical ignition temperatures corresponding to different materials. Roth, Häber & Bockhorn (Reference Roth, Häber and Bockhorn2017) examined the ignition process of different fuel/air mixtures by a silicon nitride particle. They found that the critical ignition temperature varies widely among different fuels and increases consistently as the equivalence ratio approaches the ignition limit. Wang & Chen (Reference Wang and Chen2020) conducted transient one-dimensional simulations on the ignition of CH4/air and H2/air mixtures by an inert hot particle, and found that the ignition delay time strongly depends on the particle size. Besides, Wang et al. (Reference Wang, Zhang, Zirwes, Zhang, Bockhorn and Chen2021) found that the low-temperature chemistry plays an important role in hot particle induced ignition.

In general, the creation of mechanical sparks by means of mechanical action at the solid surface is associated with a non-vanishing momentum of the hot particle. Therefore, in most situations, the hot particle moves relative to the explosive mixture, leading to convective heat transfer around the particle surface in addition to pure heat conduction under quiescent conditions. Coronel et al. (Reference Coronel2016, Reference Coronel, Melguizo-Gavilanes, Mével and Shepherd2018) used a novel experimental set-up in observing the ignition of n-hexane/air mixture by a moving hot particle. Implementing a shear interferometer, they visualized the ignition kernel formation and the subsequent flame propagation. Melguizo-Gavilanes et al. (Reference Melguizo-Gavilanes, Nové-Josserand, Coronel, Mével and Shepherd2016, Reference Melguizo-Gavilanes, Coronel, Mével and Shepherd2017a,Reference Melguizo-Gavilanes, Mével, Coronel and Shepherdb) conducted a series of two-dimensional simulations on ignition induced by a hot particle falling into a combustible mixture. They observed that the boundary layer development and flow separation have crucial impacts on the ignition process, which is consistent with the experimental results of Mével et al. (Reference Mével, Niedzielska, Melguizo-Gavilanes, Coronel and Shepherd2016, Reference Mével, Melguizo-Gavilanes, Boeck and Shepherd2019). Usually, ignition occurs between the front stagnation point and the location of flow separation, and the ignition position moves downstream as the particle temperature decreases. In particular, ignition first takes place adjacent to the separation point when the particle temperature is close to the threshold value. Zirwes et al. (Reference Zirwes, Zhang, Häber and Bockhorn2019) revisited the ignition of a combustible mixture by a moving hot particle based on both two-dimensional (2-D) and 3-D simulations. An in-depth understanding was obtained concerning the dependence of the critical ignition temperature on the relative velocity, ranging from creeping flow to flow with unsteady vortex shedding. They showed that a 2-D simulation assuming axisymmetric flow agrees well with a 3-D simulation in predicting the critical ignition temperature for relatively small velocities. However, the deviation becomes noticeable at higher flow velocities due to the 3-D unsteady vortices appearing behind the hot particle.

Ignition of a combustible mixture by a hot particle can be considered as the particular situation of ignition by a hot surface (Law Reference Law2010). Concerning thermal ignition of methane/air mixtures by a hot surface, Laurendeau (Reference Laurendeau1982) developed a simple scaling correlation among particle temperature, size, pressure and flow velocity, using van't Hoff's ignition criterion. However, the temperature inhomogeneity was not fully considered in his work. The temperature inhomogeneity is represented by its gradient adjacent to the particle surface, whose magnitude is dominated by the local curvature. Law (Reference Law1978a,Reference Lawb, Reference Law1979) conducted a large activation energy asymptotic analysis for hot particle induced ignition in a quiescent reactive mixture and obtained the ignition criterion in terms of a reduced Damköhler number, which interpreted the thermal energy balance between heat release from chemical reaction and heat loss due to conduction in steady state. Su & Sirignano (Reference Su and Sirignano1981) revisited the same problem and in their asymptotic analysis, the second-order correction terms were retained for both temperature and mass fraction of the reactive species. Compared with a transient calculation (Su, Homan & Sirignano Reference Su, Homan and Sirignano1979), the second-order solution provided an improved ignition criterion. Based on the consideration that the ignition process was minimally affected by the geometry of the body, Law (Reference Law1979) analysed the transient ignition of a combustible exposed to hot isothermal bodies. The flow field adjacent to the surface was shown to be diffusive–reactive in nature and satisfied local similarity, which enables the derivation of an explicit expression for the ignition delay time, denoted by ![]() ${\tau _{ig}}$. However, at moderate to large Reynolds numbers, the flow separates at the rear hemisphere of the particle, and moreover the flow field before separation does not satisfy self-similarity. Consequently, the explicit analytical description of the velocity profile becomes unavailable (Johnson & Patel Reference Johnson and Patel1999; Schlichting & Gersten Reference Schlichting and Gersten2016). This imposes further difficulty in analytically solving temperature inhomogeneity at the particle surface due to convection (Riley Reference Riley1986; Paterson & Hayhurst Reference Paterson and Hayhurst2000).

${\tau _{ig}}$. However, at moderate to large Reynolds numbers, the flow separates at the rear hemisphere of the particle, and moreover the flow field before separation does not satisfy self-similarity. Consequently, the explicit analytical description of the velocity profile becomes unavailable (Johnson & Patel Reference Johnson and Patel1999; Schlichting & Gersten Reference Schlichting and Gersten2016). This imposes further difficulty in analytically solving temperature inhomogeneity at the particle surface due to convection (Riley Reference Riley1986; Paterson & Hayhurst Reference Paterson and Hayhurst2000).

Ignition is essentially a transient process involving multiple time scales. Ignition is characterized by the appearance of sustained combustion, where the rate of heat release due to chemical reaction is balanced by the rate of heat loss. For ignition by a hot particle with constant temperature in a quiescent mixture, the heat loss can be solely attributed to the temperature inhomogeneity at the particle surface. The critical ignition condition defines the largest rate of heat loss that can support combustion in the limit situation of steady state, i.e. ![]() ${\tau _{ig}} \to \infty $, and accordingly, the critical ignition temperature can be derived.

${\tau _{ig}} \to \infty $, and accordingly, the critical ignition temperature can be derived.

The relative motion between the hot particle and the combustible mixture introduces additional transient effects during the ignition process. On the one hand, the enhanced heat transfer resulting from both conduction and convection on the particle surface may shorten the cooling time (denoted by ![]() ${\tau _{pc}}$) of the hot particle (Leal Reference Leal2007). On the other hand, ignition takes place at some distance from the hot surface, implying that the fluid parcel where ignition first occurs has a finite residence time (denoted by

${\tau _{pc}}$) of the hot particle (Leal Reference Leal2007). On the other hand, ignition takes place at some distance from the hot surface, implying that the fluid parcel where ignition first occurs has a finite residence time (denoted by ![]() ${\tau _{res}}$) adjacent to the hot particle (Melguizo-Gavilanes et al. Reference Melguizo-Gavilanes, Nové-Josserand, Coronel, Mével and Shepherd2016, Reference Melguizo-Gavilanes, Coronel, Mével and Shepherd2017a; Mével et al. Reference Mével, Niedzielska, Melguizo-Gavilanes, Coronel and Shepherd2016). The time scales

${\tau _{res}}$) adjacent to the hot particle (Melguizo-Gavilanes et al. Reference Melguizo-Gavilanes, Nové-Josserand, Coronel, Mével and Shepherd2016, Reference Melguizo-Gavilanes, Coronel, Mével and Shepherd2017a; Mével et al. Reference Mével, Niedzielska, Melguizo-Gavilanes, Coronel and Shepherd2016). The time scales ![]() ${\tau _{pc}}$ and

${\tau _{pc}}$ and ![]() ${\tau _{res}}$ introduce transient effects to the ignition process. Under such situations, the critical ignition condition is revised to the equality of the ignition delay time and the characteristic time of the corresponding unsteady process, e.g.

${\tau _{res}}$ introduce transient effects to the ignition process. Under such situations, the critical ignition condition is revised to the equality of the ignition delay time and the characteristic time of the corresponding unsteady process, e.g. ![]() ${\tau _{ig}} = {\tau _{pc}}$ or

${\tau _{ig}} = {\tau _{pc}}$ or ![]() ${\tau _{ig}} = {\tau _{res}}$. In comparison with steady state situations, we hypothesize that the finiteness of

${\tau _{ig}} = {\tau _{res}}$. In comparison with steady state situations, we hypothesize that the finiteness of ![]() ${\tau _{pc}}$ and

${\tau _{pc}}$ and ![]() ${\tau _{res}}$ may increase the critical ignition temperature. Coronel (Reference Coronel2016) proposed a simplified ignition model in which the relevant time scales were discussed in the scaling sense. However, quantitative comparison among these time scales was not conducted.

${\tau _{res}}$ may increase the critical ignition temperature. Coronel (Reference Coronel2016) proposed a simplified ignition model in which the relevant time scales were discussed in the scaling sense. However, quantitative comparison among these time scales was not conducted.

Based on the above-mentioned considerations, this work aims to develop a theoretical model for the ignition of a combustible mixture by a hot spherical particle. The present model can quantitatively interpret the role of temperature inhomogeneity and various transient effects on ignition behaviour and provide the dependence of the critical ignition temperature on relevant parameters in explicit form, which is so far not in place. The remaining parts of this paper proceed as follows. In § 2, Semenov's transient ignition criterion is revised by introducing a hypothetical volumetric heat loss to account for the temperature inhomogeneity, and accordingly, the ignition delay time can be evaluated analytically. In § 3, an in-depth discussion is presented on the effect of temperature inhomogeneity, resulting from both conductive and convective heat transfer, on the hot particle induced ignition process. An explicit formula for the critical ignition temperature, interpreting its dependence upon various affecting parameters, is derived. In § 4, the transient effect due to particle cooling is discussed. The particle cooling time is determined by solving the thermal energy equation of the solid particle and is compared with the ![]() ${\tau _{ig}}$ obtained in § 2. In § 5, the transient effect due to the motion of the ignition fluid parcel is taken into account, and its contribution to the change of critical ignition temperature is assessed. The general conclusions are given in § 6.

${\tau _{ig}}$ obtained in § 2. In § 5, the transient effect due to the motion of the ignition fluid parcel is taken into account, and its contribution to the change of critical ignition temperature is assessed. The general conclusions are given in § 6.

2. The inhomogeneous ignition criterion

Discharging a hot particle into a combustible mixture can lead to ignition. According to thermal ignition theory, ignition is most likely to take place first on the particle surface, where the temperature is highest. In addition to thermal runaway, ignition is also controlled by complicated chemical reaction pathways. The active radicals, e.g. H and OH, can be destroyed due to collision with the particle surface (Glassman, Yetter & Glumac Reference Glassman, Yetter and Glumac2014). Therefore, the fluid parcel, where ignition occurs first, should be slightly elevated from the solid surface such that its temperature is almost identical to that of the particle and meanwhile the accumulation of radicals exceeds termination. This fact was found in previous simulations by Melguizo-Gavilanes et al. (Reference Melguizo-Gavilanes, Mével, Coronel and Shepherd2017b).

The hot particle continuously transfers thermal energy into the relatively cool ambient gas, leading to large temperature gradient in the vicinity of the particle surface. Pertaining to such inhomogeneous ignition process, Law (Reference Law1978a) analysed the hot particle induced ignition in the absence of relative motion between the particle and the environmental gas, and the temperature of the particle was assumed constant. The diffusive–reactive nature of the ignition process was analysed via large activation energy asymptotics. Adopting a simplified one-order Arrhenius-type model, the chemical reaction rate is

where B represents the reaction frequency factor, ![]() ${T_a}$ the activation temperature,

${T_a}$ the activation temperature, ![]() ${T_s}$ the particle temperature and

${T_s}$ the particle temperature and ![]() ${c_{F0}}$ the fuel concentration in the mixture. The balance of heat release from chemical reaction and the heat loss due to temperature inhomogeneity gives the critical ignition condition, which is indicated by the following reduced Damköhler number (Law Reference Law2010)

${c_{F0}}$ the fuel concentration in the mixture. The balance of heat release from chemical reaction and the heat loss due to temperature inhomogeneity gives the critical ignition condition, which is indicated by the following reduced Damköhler number (Law Reference Law2010)

where ![]() ${\lambda _g}$,

${\lambda _g}$, ![]() ${\rho _g}$ and

${\rho _g}$ and ![]() ${c_{pg}}$ are respectively the thermal conductivity, density and the heat capacity of the combustible gaseous mixture,

${c_{pg}}$ are respectively the thermal conductivity, density and the heat capacity of the combustible gaseous mixture, ![]() ${R_0}$ is the radius of the spherical particle,

${R_0}$ is the radius of the spherical particle, ![]() ${T_{ad}}$ is the adiabatic flame temperature,

${T_{ad}}$ is the adiabatic flame temperature, ![]() ${T_\infty }$ is the temperature of combustible mixture and

${T_\infty }$ is the temperature of combustible mixture and ![]() $\theta = (T - {T_\infty })/({T_s} - {T_\infty })$ is the normalized temperature. The normalized radial coordinate is defined by

$\theta = (T - {T_\infty })/({T_s} - {T_\infty })$ is the normalized temperature. The normalized radial coordinate is defined by ![]() $\tilde{r} = r/{R_0}$. The term

$\tilde{r} = r/{R_0}$. The term ![]() ${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}$ denotes the non-dimensional temperature gradient on the particle surface, and it depends on the geometry of the particle. For a spherical particle in a quiescent frozen mixture, we have

${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}$ denotes the non-dimensional temperature gradient on the particle surface, and it depends on the geometry of the particle. For a spherical particle in a quiescent frozen mixture, we have ![]() ${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}} ={-} 1$, which will be shown in § 3.1.

${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}} ={-} 1$, which will be shown in § 3.1.

The modified Damköhler number, given by (2.2), is a general formula that interprets the ignition of a quiescent combustible mixture close to the hot surface of a spherical particle of constant and uniform temperature. To derive (2.2) from first principles, the non-dimensional temperature is defined as ![]() $\tilde{T} = {c_p}T/{q_c}$, where

$\tilde{T} = {c_p}T/{q_c}$, where ![]() ${q_c}$ is the heat release from a unit mass of reactant mixture. According to the energy conservation law and the definition of the adiabatic flame temperature

${q_c}$ is the heat release from a unit mass of reactant mixture. According to the energy conservation law and the definition of the adiabatic flame temperature ![]() ${T_{ad}}$, we have

${T_{ad}}$, we have ![]() ${c_p}({T_{ad}} - {T_\infty }) = {q_c}$, which is substituted into the non-dimensional temperature and results in the appearance of

${c_p}({T_{ad}} - {T_\infty }) = {q_c}$, which is substituted into the non-dimensional temperature and results in the appearance of ![]() ${T_{ad}}$ in the modified Damköhler number.

${T_{ad}}$ in the modified Damköhler number.

The condition of ![]() ${\varDelta _I} = 1$ gives the critical ignition temperature of the particle,

${\varDelta _I} = 1$ gives the critical ignition temperature of the particle, ![]() ${T_{cr}}$, below which ignition fails since the heat generation from chemical reaction cannot compete with the heat loss to the ambient gas.

${T_{cr}}$, below which ignition fails since the heat generation from chemical reaction cannot compete with the heat loss to the ambient gas.

Fixing the frame of reference at the centre of the spherical particle, the relative motion between particle and combustible mixture can be equivalently regarded as the uniform flow of the environmental gas. Such relative motion between the combustible mixture and the hot particle modifies the ignition behaviour in three aspects. First, the convection accelerates heat transfer from the hot particle to the surrounding mixture and thus intensifies the temperature inhomogeneity at the particle surface. Second, the enhanced heat transfer facilitates the cooling of the hot particle, which leads to a decrease of the particle temperature. Last but not least, the fluid parcel where ignition occurs has finite residence time close to the hot particle, after which the fluid parcel cools down as it moves downstream. The steady state ignition criterion (Law Reference Law1978a,Reference Lawb, Reference Law2010) considers rigorously the non-homogeneous temperature profile in a quiescent environment and can predict the ignitability of the reactant gas subject to a hot particle with constant temperature. However, it meets exceeding difficulty in describing the temperature inhomogeneity caused by convective heat transfer because the velocity profiles adjacent to the particle surface may not be obtained in a mathematically explicit form. Consequently, the energy equation for the combustible mixture cannot be converted into the conventional conductive–reactive type, and the derivation route leading to (2.2) becomes inaccessible. Besides, the steady ignition theory is unable to evaluate the ignition delay time. To account for the unsteady effect, an additional term involving temporal evolution of the temperature should be included in the energy equation, which escalates the mathematical complexity in obtaining an analytical solution.

From the perspective of a Lagrangian description of the flow, we may trace the history of the ignition fluid parcel (abbreviated as IFP hereinafter) which ignites first. Since the size of the IFP can be arbitrarily small, we may assume that it has uniform temperature. In addition, appropriate heat loss must be associated with the IFP to account for the inhomogeneity of the temperature profile close to the particle surface. Therefore, we may equivalently regard ignition as a local, non-adiabatic thermal explosion within the IFP. It is recognized that the consumption of reactant species appears to be negligible prior to ignition (Law Reference Law1978a, Reference Law2010). Consequently, the ignition process is solely characterized by the following energy equation for the IFP:

where ![]() ${T_I}$ represents the temperature of the IFP,

${T_I}$ represents the temperature of the IFP, ![]() ${c_v}$ the heat capacity at constant volume,

${c_v}$ the heat capacity at constant volume, ![]() ${q_c}$ the heat release per unit mass of the reactant and h the effective volumetric heat loss coefficient to be determined. Conventionally, the non-dimensional temperature is defined by

${q_c}$ the heat release per unit mass of the reactant and h the effective volumetric heat loss coefficient to be determined. Conventionally, the non-dimensional temperature is defined by

where ![]() ${c_{vg}}$ is the heat capacity at constant volume and

${c_{vg}}$ is the heat capacity at constant volume and ![]() ${q_c}$ the heat release per unit mass of reactant. According to energy conservation, we may correlate

${q_c}$ the heat release per unit mass of reactant. According to energy conservation, we may correlate ![]() ${q_c}$ with

${q_c}$ with ![]() ${T_{ad}}$ via

${T_{ad}}$ via ![]() ${q_c}{c_{F0}} = {\rho _g}{c_{vg}}({T_{ad}} - {T_\infty })$, and consequently, we may alternatively write

${q_c}{c_{F0}} = {\rho _g}{c_{vg}}({T_{ad}} - {T_\infty })$, and consequently, we may alternatively write ![]() $\tilde{T} = T/({T_{ad}} - {T_\infty })$. The characteristic time for chemical reaction can be defined in terms of the non-dimensional temperature of the particle,

$\tilde{T} = T/({T_{ad}} - {T_\infty })$. The characteristic time for chemical reaction can be defined in terms of the non-dimensional temperature of the particle,

The heat loss coefficient h can also be written in non-dimensional form,

\begin{equation}\tilde{h} = \frac{{h{\tau _{ch}}}}{{{\rho _g}{c_{vg}}}} = \frac{{h\tilde{T}_s^2\ {\rm exp} ({{\tilde{T}}_a}/{{\tilde{T}}_s})}}{{{\rho _g}{c_{vg}}{{\tilde{T}}_a}B}}.\end{equation}

\begin{equation}\tilde{h} = \frac{{h{\tau _{ch}}}}{{{\rho _g}{c_{vg}}}} = \frac{{h\tilde{T}_s^2\ {\rm exp} ({{\tilde{T}}_a}/{{\tilde{T}}_s})}}{{{\rho _g}{c_{vg}}{{\tilde{T}}_a}B}}.\end{equation} In terms of ![]() $\tilde{T}$ and

$\tilde{T}$ and ![]() $\tilde{h}$, we can write (2.3) in dimensionless form

$\tilde{h}$, we can write (2.3) in dimensionless form

Since the IFP is close to the particle surface, we have ![]() ${T_I} \approx {T_s}$. Assuming that

${T_I} \approx {T_s}$. Assuming that ![]() ${\tilde{T}_a} \gg {\tilde{T}_I}$, we can write an asymptotic series for the latter, i.e.

${\tilde{T}_a} \gg {\tilde{T}_I}$, we can write an asymptotic series for the latter, i.e.

where ![]() $\epsilon = \tilde{T}_s^2/{\tilde{T}_a} \ll 1$ is a small parameter, and

$\epsilon = \tilde{T}_s^2/{\tilde{T}_a} \ll 1$ is a small parameter, and ![]() $\chi $ is the first-order perturbation to the non-dimensional temperature of the IFP. Substituting (2.8) into (2.7) and collecting terms of like powers of

$\chi $ is the first-order perturbation to the non-dimensional temperature of the IFP. Substituting (2.8) into (2.7) and collecting terms of like powers of ![]() $\epsilon $, we obtain:

$\epsilon $, we obtain:

The leading-order equation for ![]() ${\tilde{T}_s}$

${\tilde{T}_s}$

The first-order equation for ![]() $\chi $

$\chi $

The leading-order (2.9) demonstrates that the temperature of the IFP continues to decay due to volumetric heat loss characterized by ![]() $\tilde{h}$. However, the magnitude of the first-order correction to the temperature

$\tilde{h}$. However, the magnitude of the first-order correction to the temperature ![]() $\chi $, according to (2.10), is also affected by heat release from chemical reaction. For a sufficiently large heat loss coefficient

$\chi $, according to (2.10), is also affected by heat release from chemical reaction. For a sufficiently large heat loss coefficient ![]() $\tilde{h}$, (2.10) suggests that

$\tilde{h}$, (2.10) suggests that ![]() $\chi $ approaches a finite value in the limit of

$\chi $ approaches a finite value in the limit of ![]() $\tilde{t} \to \infty $. In association with the decay of

$\tilde{t} \to \infty $. In association with the decay of ![]() ${\tilde{T}_s}$ according to (2.9), ignition is prohibited. To achieve successful ignition, the heat loss rate must be bounded from above, which is characterized by the explosive increase of

${\tilde{T}_s}$ according to (2.9), ignition is prohibited. To achieve successful ignition, the heat loss rate must be bounded from above, which is characterized by the explosive increase of ![]() $\chi $ in the course of time (Law Reference Law2010). The condition that ensures successful ignition can be determined according to the Semenov ignition criterion as

$\chi $ in the course of time (Law Reference Law2010). The condition that ensures successful ignition can be determined according to the Semenov ignition criterion as

The equality, ![]() $\tilde{h} = e$, holds for the critical ignition condition, which should be equivalent to

$\tilde{h} = e$, holds for the critical ignition condition, which should be equivalent to ![]() ${\varDelta _I} = 1$ derived by rigorously considering temperature inhomogeneity in the steady state theory. The critical ignition condition defines the reference state, at which the ignition could occur after a sufficiently long time, or the heat release by chemical reaction is balanced by heat transfer to the surroundings during the whole ignition process. Physical plausibility suggests that the heat loss effect could be varied independently from the chemical reaction rate. We solve for the reaction frequency factor B from the condition

${\varDelta _I} = 1$ derived by rigorously considering temperature inhomogeneity in the steady state theory. The critical ignition condition defines the reference state, at which the ignition could occur after a sufficiently long time, or the heat release by chemical reaction is balanced by heat transfer to the surroundings during the whole ignition process. Physical plausibility suggests that the heat loss effect could be varied independently from the chemical reaction rate. We solve for the reaction frequency factor B from the condition ![]() ${\varDelta _I} = 1$ in terms of

${\varDelta _I} = 1$ in terms of ![]() ${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}$ using (2.2) and substitute the results into the equivalent ignition condition

${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}$ using (2.2) and substitute the results into the equivalent ignition condition ![]() $\tilde{h} = e$, in which

$\tilde{h} = e$, in which ![]() $\tilde{h}$ is given by (2.6). Consequently we can obtain

$\tilde{h}$ is given by (2.6). Consequently we can obtain

\begin{equation}h = \frac{{e{\lambda _g}T_a^2{{(1 - {T_\infty }/{T_s})}^2}}}{{2\gamma R_0^2T_s^2}}\left( {\frac{{\textrm{d}\theta }}{{\textrm{d}\tilde{r}}}} \right)_{\tilde{r} = 1}^2,\end{equation}

\begin{equation}h = \frac{{e{\lambda _g}T_a^2{{(1 - {T_\infty }/{T_s})}^2}}}{{2\gamma R_0^2T_s^2}}\left( {\frac{{\textrm{d}\theta }}{{\textrm{d}\tilde{r}}}} \right)_{\tilde{r} = 1}^2,\end{equation}

where ![]() $\gamma = {c_{pg}}/{c_{vg}}$ is the heat capacity ratio. With knowledge of h given by (2.12), the non-dimensional effective heat loss coefficient can be determined according to (2.6) as

$\gamma = {c_{pg}}/{c_{vg}}$ is the heat capacity ratio. With knowledge of h given by (2.12), the non-dimensional effective heat loss coefficient can be determined according to (2.6) as

\begin{equation}\tilde{h}({T_s}) = \frac{{{\alpha _g}{T_a}{{(1 - {T_\infty }/{T_s})}^2}\ {\rm exp} ({T_a}/{T_s} + 1)}}{{2BR_0^2({T_{ad}} - {T_\infty })}}\left( {\frac{{\textrm{d}\theta }}{{\textrm{d}\tilde{r}}}} \right)_{\tilde{r} = 1}^2,\end{equation}

\begin{equation}\tilde{h}({T_s}) = \frac{{{\alpha _g}{T_a}{{(1 - {T_\infty }/{T_s})}^2}\ {\rm exp} ({T_a}/{T_s} + 1)}}{{2BR_0^2({T_{ad}} - {T_\infty })}}\left( {\frac{{\textrm{d}\theta }}{{\textrm{d}\tilde{r}}}} \right)_{\tilde{r} = 1}^2,\end{equation}

where ![]() ${\alpha _g} = {\lambda _g}/{\rho _g}{c_{pg}}$ is the thermal diffusivity of the combustible mixture. Equation (2.13) indicates that the effective heat loss coefficient is inversely proportional to the surface area of the particle, i.e.

${\alpha _g} = {\lambda _g}/{\rho _g}{c_{pg}}$ is the thermal diffusivity of the combustible mixture. Equation (2.13) indicates that the effective heat loss coefficient is inversely proportional to the surface area of the particle, i.e. ![]() $\tilde{h} \sim 1/R_0^2$. This means that ignition becomes more difficult for smaller particles, which is consistent with previous experimental and numerical results. In addition, (2.13) demonstrates that the effective heat loss coefficient varies with the square of the normalized temperature gradient on the particle surface, which substantially increases in the presence of convective heat transfer. Therefore, the relative motion between the hot particle and the combustible mixture may greatly affect the ignition behaviour.

$\tilde{h} \sim 1/R_0^2$. This means that ignition becomes more difficult for smaller particles, which is consistent with previous experimental and numerical results. In addition, (2.13) demonstrates that the effective heat loss coefficient varies with the square of the normalized temperature gradient on the particle surface, which substantially increases in the presence of convective heat transfer. Therefore, the relative motion between the hot particle and the combustible mixture may greatly affect the ignition behaviour.

Taking the derivative of ![]() $\tilde{h}$ with respect to

$\tilde{h}$ with respect to ![]() ${T_s}$, one obtains

${T_s}$, one obtains

\begin{equation}\frac{{\textrm{d}\tilde{h}}}{{\textrm{d}{T_s}}} ={-} \frac{{{\alpha _g}}}{{2BR_0^2}}\left( {1 - \frac{{{T_\infty }}}{{{T_s}}}} \right)\left[ {1 - \frac{{{T_\infty }}}{{{T_s}}}\left( {1 + 2\frac{{{T_s}}}{{{T_a}}}} \right)} \right]\frac{{T_a^2{e^{{T_a}/{T_s} + 1}}}}{{T_s^2({T_{ad}} - {T_\infty })}}\left( {\frac{{\textrm{d}\theta }}{{\textrm{d}\tilde{r}}}} \right)_{\tilde{r} = 1}^2\; .\end{equation}

\begin{equation}\frac{{\textrm{d}\tilde{h}}}{{\textrm{d}{T_s}}} ={-} \frac{{{\alpha _g}}}{{2BR_0^2}}\left( {1 - \frac{{{T_\infty }}}{{{T_s}}}} \right)\left[ {1 - \frac{{{T_\infty }}}{{{T_s}}}\left( {1 + 2\frac{{{T_s}}}{{{T_a}}}} \right)} \right]\frac{{T_a^2{e^{{T_a}/{T_s} + 1}}}}{{T_s^2({T_{ad}} - {T_\infty })}}\left( {\frac{{\textrm{d}\theta }}{{\textrm{d}\tilde{r}}}} \right)_{\tilde{r} = 1}^2\; .\end{equation} The conditions ![]() ${T_s} \gg {T_\infty }$ and

${T_s} \gg {T_\infty }$ and ![]() ${T_s}/{T_a} \ll 1$ suggest that

${T_s}/{T_a} \ll 1$ suggest that ![]() $\textrm{d}\tilde{h}/\textrm{d}{T_s} < 0$. Therefore, as the particle temperature falls, the heat loss coefficient becomes larger and thereby heat loss is more pronounced.

$\textrm{d}\tilde{h}/\textrm{d}{T_s} < 0$. Therefore, as the particle temperature falls, the heat loss coefficient becomes larger and thereby heat loss is more pronounced.

The critical ignition temperature, denoted by ![]() ${T_{ig,cr}}$, can be determined by setting

${T_{ig,cr}}$, can be determined by setting ![]() ${T_s} = {T_{ig,cr}}$ in (2.13) and using the ignition condition of

${T_s} = {T_{ig,cr}}$ in (2.13) and using the ignition condition of ![]() $\tilde{h} = e$. After rearrangement, we have the following expression the for the critical ignition temperature:

$\tilde{h} = e$. After rearrangement, we have the following expression the for the critical ignition temperature:

When the particle temperature is greater than the critical ignition temperature, i.e. ![]() ${T_s} > {T_{ig,cr}}$, the ignition delay time can be evaluated by integrating equation (2.10)

${T_s} > {T_{ig,cr}}$, the ignition delay time can be evaluated by integrating equation (2.10)

In particular, (2.13) indicates that ![]() $\tilde{h}$ vanishes for

$\tilde{h}$ vanishes for ![]() ${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}} = 0$, i.e. the particle temperature is equal to that in the ambient. In such circumstances, the integral in (2.16) is equal to unity, indicating that

${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}} = 0$, i.e. the particle temperature is equal to that in the ambient. In such circumstances, the integral in (2.16) is equal to unity, indicating that ![]() ${\tau _{ig}} = {\tau _{ch}}$, i.e. ignition occurs under adiabatic conditions. For finite temperature difference, the magnitude of

${\tau _{ig}} = {\tau _{ch}}$, i.e. ignition occurs under adiabatic conditions. For finite temperature difference, the magnitude of ![]() ${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}$ describes the temperature inhomogeneity. For a spherical particle in a quiescent mixture, the heat transfer is only through thermal conduction and we have

${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}$ describes the temperature inhomogeneity. For a spherical particle in a quiescent mixture, the heat transfer is only through thermal conduction and we have ![]() ${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}} ={-} 1$, which will be shown in § 3.1. When there is relative motion between the particle and the environment, the heat transfer consists of convection and conduction and we have

${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}} ={-} 1$, which will be shown in § 3.1. When there is relative motion between the particle and the environment, the heat transfer consists of convection and conduction and we have ![]() $|{(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}|> 1$, which will be discussed in §§ 3.2–3.4.

$|{(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}|> 1$, which will be discussed in §§ 3.2–3.4.

3. The effect of temperature inhomogeneity on ignition by a hot particle

According to (2.13), the temperature gradient on the particle surface, ![]() ${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}$, needs to be obtained so that the effective volumetric heat loss coefficient

${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}$, needs to be obtained so that the effective volumetric heat loss coefficient ![]() $\tilde{h}$ can be evaluated, and subsequently the critical ignition temperature can be determined via (2.15). We consider a hot particle placed in a combustible mixture with different flow velocities, including the quiescent situation, creeping flow and flow with separation. For each flow condition, solving the thermal energy equation for the gas mixture yields the temperature distributions, by means of which the temperature gradient on the particle surface

$\tilde{h}$ can be evaluated, and subsequently the critical ignition temperature can be determined via (2.15). We consider a hot particle placed in a combustible mixture with different flow velocities, including the quiescent situation, creeping flow and flow with separation. For each flow condition, solving the thermal energy equation for the gas mixture yields the temperature distributions, by means of which the temperature gradient on the particle surface ![]() ${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}$ can be evaluated. Adopting two assumptions, that the particle temperature remains constant during the ignition process and that the IFP is anchored at the particle surface, the ignition criterion of the combustible mixture by the hot particle can be described by the critical ignition condition in steady state theory, i.e.

${(\textrm{d}\theta /\textrm{d}\tilde{r})_{\tilde{r} = 1}}$ can be evaluated. Adopting two assumptions, that the particle temperature remains constant during the ignition process and that the IFP is anchored at the particle surface, the ignition criterion of the combustible mixture by the hot particle can be described by the critical ignition condition in steady state theory, i.e. ![]() $\tilde{h} = e$, which gives the correlation between the critical ignition temperature and various parameters that affect it, e.g. the radius of the particle, the temperature inhomogeneity and the transport properties of the combustible mixture. The fall of the particle temperature and the motion of the IFP lead to transient effects in the ignition process, and their impacts will be discussed in §§ 4 and 5, respectively.

$\tilde{h} = e$, which gives the correlation between the critical ignition temperature and various parameters that affect it, e.g. the radius of the particle, the temperature inhomogeneity and the transport properties of the combustible mixture. The fall of the particle temperature and the motion of the IFP lead to transient effects in the ignition process, and their impacts will be discussed in §§ 4 and 5, respectively.

3.1. Quiescent combustible mixture

First, we consider the hot particle placed in a quiescent combustible mixture so that the heat transfer at the surface is pure conduction. So far, we have assumed that the particle temperature is constant during the ignition process. The solution of the thermal equation for a solid particle presented in § 4 will confirm that the effect of particle cooling is negligible before ignition occurs. For a particle with a constant temperature, we can employ the quasi-steady state assumption to deal with heat transfer at the particle surface. The energy equation for the gas mixture can be written in the form (Leal Reference Leal2007)

where ![]() $\tilde{\nabla } = {R_0}\boldsymbol{\nabla }$ is the non-dimensional gradient operator. The solution of (3.1) satisfying the boundary conditions of

$\tilde{\nabla } = {R_0}\boldsymbol{\nabla }$ is the non-dimensional gradient operator. The solution of (3.1) satisfying the boundary conditions of ![]() $\theta = 1$ at

$\theta = 1$ at ![]() $\tilde{r} = 1$ and

$\tilde{r} = 1$ and ![]() $\theta = 0$ as

$\theta = 0$ as ![]() $r \to \infty $ is

$r \to \infty $ is

Accordingly, the non-dimensional temperature gradient on the particle surface is

3.2. Creeping flow without separation for  ${Re}$

${Re}$  $\ll 1$

$\ll 1$

In the presence of relative motion between the particle and the ambient gas, convection contributes to additional heat transfer, and the energy equation should be revised to

where the non-dimensional velocity ![]() $\tilde{\boldsymbol{u}}$ is normalized by the uniform flow velocity,

$\tilde{\boldsymbol{u}}$ is normalized by the uniform flow velocity, ![]() ${U_\infty }$, of the ambient gas, i.e.

${U_\infty }$, of the ambient gas, i.e. ![]() $\tilde{\boldsymbol{u}} = \boldsymbol{u}/{U_\infty }$. The Péclet number is defined as

$\tilde{\boldsymbol{u}} = \boldsymbol{u}/{U_\infty }$. The Péclet number is defined as ![]() $Pe = {U_\infty }{R_0}/{\alpha _g}$. The Péclet number can equivalently be written as the product of the Reynolds number,

$Pe = {U_\infty }{R_0}/{\alpha _g}$. The Péclet number can equivalently be written as the product of the Reynolds number, ![]() $Re = {U_\infty }{R_0}/{\nu _g}$, and the Prandtl number,

$Re = {U_\infty }{R_0}/{\nu _g}$, and the Prandtl number, ![]() $Pr = {\nu _g}/{\alpha _g}$, where

$Pr = {\nu _g}/{\alpha _g}$, where ![]() ${\nu _g}$ is the kinematic viscosity of the ambient gas. The Prandtl number depends only on the fluid properties and is around unity for most gases under atmospheric pressure at room temperature. Consequently, the Péclet number and the Reynolds number are of the same order, i.e.

${\nu _g}$ is the kinematic viscosity of the ambient gas. The Prandtl number depends only on the fluid properties and is around unity for most gases under atmospheric pressure at room temperature. Consequently, the Péclet number and the Reynolds number are of the same order, i.e. ![]() $Pe \sim Re$.

$Pe \sim Re$.

The flow field is affected by changing the Reynolds number. For creeping flow with ![]() $Re \ll 1$, i.e. the flow velocity distribution can be described by the Stokes solution (Landau & Lifshitz Reference Landau and Lifshitz1987)

$Re \ll 1$, i.e. the flow velocity distribution can be described by the Stokes solution (Landau & Lifshitz Reference Landau and Lifshitz1987)

where ![]() $\phi $ represents the polar angle and its origin

$\phi $ represents the polar angle and its origin ![]() $(\phi = 0)$ is selected at the front stagnation point of the sphere, and thereby

$(\phi = 0)$ is selected at the front stagnation point of the sphere, and thereby ![]() $\phi = {\rm \pi} $ corresponds to the rear stagnation point.

$\phi = {\rm \pi} $ corresponds to the rear stagnation point.

For ![]() $Re \ll 1$ and

$Re \ll 1$ and ![]() $Pe \sim Re$, the temperature distribution can be expanded in asymptotic series in terms of

$Pe \sim Re$, the temperature distribution can be expanded in asymptotic series in terms of ![]() $Pe$. However, separate solutions must be sought respectively in the inner region for

$Pe$. However, separate solutions must be sought respectively in the inner region for ![]() $1 \le \tilde{r} \le O(P{e^{ - 1}})$, where the heat conduction term is much larger than the convection term, and in the outer region for

$1 \le \tilde{r} \le O(P{e^{ - 1}})$, where the heat conduction term is much larger than the convection term, and in the outer region for ![]() $O(P{e^{ - 1}}) < \tilde{r} < \infty $, where the convection term is of equal importance to the conduction term. The detailed derivation of the asymptotic solution of the temperature distribution can be found in Leal (Reference Leal2007), and here we only briefly present key processes.

$O(P{e^{ - 1}}) < \tilde{r} < \infty $, where the convection term is of equal importance to the conduction term. The detailed derivation of the asymptotic solution of the temperature distribution can be found in Leal (Reference Leal2007), and here we only briefly present key processes.

In the inner region, the proper length scale is ![]() ${R_0}$, and the asymptotic series for

${R_0}$, and the asymptotic series for ![]() $\theta $ in terms of

$\theta $ in terms of ![]() $Pe$ is

$Pe$ is

Substituting equation (3.6) into (3.4) and collecting terms of like powers of ![]() $Pe$, one obtains the leading-order solution

$Pe$, one obtains the leading-order solution ![]() ${\theta _{in, 0}} = 1/\tilde{r}$, and the first-order correction

${\theta _{in, 0}} = 1/\tilde{r}$, and the first-order correction ![]() ${\theta _{in, 1}}$ which satisfies the following equation

${\theta _{in, 1}}$ which satisfies the following equation

The solution of (3.7) subject to the boundary condition of ![]() ${\theta _{in,1}} = 0$ at

${\theta _{in,1}} = 0$ at ![]() $\tilde{r} = 1$ can be written as

$\tilde{r} = 1$ can be written as

\begin{equation}{\theta _{in, 1}} = \mathop \sum \limits_{n = 0}^\infty {A_n}[{\tilde{r}^n} - {\tilde{r}^{ - (n + 1)}}]{P_n}( - \eta ) + \left( {\frac{1}{2} - \frac{3}{{4\tilde{r}}} + \frac{3}{{8{{\tilde{r}}^2}}} - \frac{1}{{8{{\tilde{r}}^3}}}} \right){P_1}( - \eta ),\end{equation}

\begin{equation}{\theta _{in, 1}} = \mathop \sum \limits_{n = 0}^\infty {A_n}[{\tilde{r}^n} - {\tilde{r}^{ - (n + 1)}}]{P_n}( - \eta ) + \left( {\frac{1}{2} - \frac{3}{{4\tilde{r}}} + \frac{3}{{8{{\tilde{r}}^2}}} - \frac{1}{{8{{\tilde{r}}^3}}}} \right){P_1}( - \eta ),\end{equation}

where ![]() ${P_n}$ represents the Legendre polynomial of order n, and

${P_n}$ represents the Legendre polynomial of order n, and ![]() $\eta = \cos \phi $. The integration constants

$\eta = \cos \phi $. The integration constants ![]() ${A_n}$ should be determined through matching with the asymptotic solution in the outer region. The fact that

${A_n}$ should be determined through matching with the asymptotic solution in the outer region. The fact that ![]() ${P_1}( - \eta )/2$ does not vanish as

${P_1}( - \eta )/2$ does not vanish as ![]() $\tilde{r} \to \infty $ suggests that

$\tilde{r} \to \infty $ suggests that ![]() ${\theta _{in,1}}$ does not satisfy the boundary condition at infinity. Therefore, the solution in the outer region needs to be obtained.

${\theta _{in,1}}$ does not satisfy the boundary condition at infinity. Therefore, the solution in the outer region needs to be obtained.

In the outer region, the length scale should be redefined because the temperature distribution appears to be less sensitive to the particle radius at remote distance. A suitable rescaling is ![]() $\xi = \tilde{r}Pe$, in terms of which, the leading order of the normalized temperature in the outer region,

$\xi = \tilde{r}Pe$, in terms of which, the leading order of the normalized temperature in the outer region, ![]() ${\theta _{out}}$, satisfies

${\theta _{out}}$, satisfies

The right-hand side of the above equation represents the modification of the temperature distribution in the outer region by uniform flow of ambient gas. The solution of (3.9) subject to the boundary condition of ![]() ${\theta _{out}} \to 0$ as

${\theta _{out}} \to 0$ as ![]() $\xi \to \infty $ is

$\xi \to \infty $ is

\begin{equation}{\theta _{out}} = \sqrt {\frac{{\rm \pi} }{\chi }} {e^{ - \chi \eta /2}}\mathop \sum \limits_{k = 0}^\infty {B_k}{K_{k + 1/2}}\left( {\frac{\chi }{2}} \right){P_k}( - \eta ),\end{equation}

\begin{equation}{\theta _{out}} = \sqrt {\frac{{\rm \pi} }{\chi }} {e^{ - \chi \eta /2}}\mathop \sum \limits_{k = 0}^\infty {B_k}{K_{k + 1/2}}\left( {\frac{\chi }{2}} \right){P_k}( - \eta ),\end{equation}

where the coefficients ![]() ${B_k}$ must be determined by matching with the inner solution

${B_k}$ must be determined by matching with the inner solution ![]() ${\theta _{in}}$. The functions

${\theta _{in}}$. The functions ![]() ${K_{k + 1/2}}$ represent the modified Bessel functions of order

${K_{k + 1/2}}$ represent the modified Bessel functions of order ![]() $k + 1/2$. The matching of

$k + 1/2$. The matching of ![]() ${\theta _{in}}$ and

${\theta _{in}}$ and ![]() ${\theta _{out}}$ is conducted in an overlap region in which,

${\theta _{out}}$ is conducted in an overlap region in which, ![]() $\tilde{r}$ and

$\tilde{r}$ and ![]() $\xi $ could be interchangeably selected as the characteristic length scale. From the matching we have

$\xi $ could be interchangeably selected as the characteristic length scale. From the matching we have

Substituting equations (3.11) and (3.12) into (3.8) and (3.10) respectively, the inner and outer solutions for the normalized temperature are fully determined. The composite solution valid in the whole domain can be constituted by summarizing ![]() ${\theta _{in}}$ and

${\theta _{in}}$ and ![]() ${\theta _{out}}$ and subtracting their common part in the overlapping region, and it is

${\theta _{out}}$ and subtracting their common part in the overlapping region, and it is

In contrast to ![]() ${\theta _{in}}$, the composite solution of

${\theta _{in}}$, the composite solution of ![]() $\theta $ given by (3.13) satisfies the boundary condition

$\theta $ given by (3.13) satisfies the boundary condition ![]() $\theta \to 0$ as

$\theta \to 0$ as ![]() $\tilde{r} \to \infty $ at finite

$\tilde{r} \to \infty $ at finite ![]() $Pe$. Subsequently, the negative of the temperature gradient on the particle surface can be obtained as

$Pe$. Subsequently, the negative of the temperature gradient on the particle surface can be obtained as

The heat transfer rate changes with polar angle, represented by ![]() $\eta = \cos \phi $. It takes the largest and smallest values at the front

$\eta = \cos \phi $. It takes the largest and smallest values at the front ![]() $(\eta = 1)$ and rear

$(\eta = 1)$ and rear ![]() $(\eta ={-} 1)$ stagnation points, respectively, i.e.

$(\eta ={-} 1)$ stagnation points, respectively, i.e.

The heat transfer on the particle surface plays the role of heat loss during the ignition process. Equations (3.15) and (3.16) indicate that ignition first occurs at the rear stagnation point (i.e. ![]() $\phi = {\rm \pi}$) where the temperature inhomogeneity is the smallest over the particle surface. This is consistent with previous simulation results (Zirwes et al. Reference Zirwes, Zhang, Häber and Bockhorn2019; Wang et al. Reference Wang, Zhang, Zirwes, Zhang, Bockhorn and Chen2021).

$\phi = {\rm \pi}$) where the temperature inhomogeneity is the smallest over the particle surface. This is consistent with previous simulation results (Zirwes et al. Reference Zirwes, Zhang, Häber and Bockhorn2019; Wang et al. Reference Wang, Zhang, Zirwes, Zhang, Bockhorn and Chen2021).

3.3. Boundary layer flow with separation for Re  $\gg 1$

$\gg 1$

At high Reynolds number, i.e. increasing either the particle size or the flow velocity of the ambient gas, flow separation takes place at the rear hemisphere of the spherical particle. The IFP adjacent to the particle surface continues to absorb thermal energy from the front stagnation location to the separation point, beyond which the IFP is taken away from the particle surface by the recirculating flow. The relative motion between the particle and the combustible mixture facilitates the heat transfer on the particle surface due to convection, which thereby increases the critical ignition temperature.

Previous studies (Mével et al. Reference Mével, Niedzielska, Melguizo-Gavilanes, Coronel and Shepherd2016, Reference Mével, Melguizo-Gavilanes, Boeck and Shepherd2019; Melguizo-Gavilanes et al. Reference Melguizo-Gavilanes, Coronel, Mével and Shepherd2017a,Reference Melguizo-Gavilanes, Mével, Coronel and Shepherdb) demonstrated that, at the critical ignition state, i.e. ![]() ${T_s} = {T_{cr}}$, ignition first occurs around the separation point. This can be understood as follows. Flow decelerates on approaching the separation point, suggesting that convective heat transfer becomes less intensive and hence decreases the heat loss for ignition. Near the separation point, the temperature variation becomes gentle and thereby provides favourable conditions for ignition. Accordingly, we define the critical ignition condition based on the assumption that the resulting ignition location coincides with the separation point, where the local temperature gradient has the least magnitude and thus preferentially supports ignition. Moreover, the IFP would be taken away from the hot particle passing over the separation point and therefore lose the capability of ignition. While, as the particle temperature continues to increase, the ignition location moves upstream since an elevation of particle temperature can sustain more severe heat loss during ignition.

${T_s} = {T_{cr}}$, ignition first occurs around the separation point. This can be understood as follows. Flow decelerates on approaching the separation point, suggesting that convective heat transfer becomes less intensive and hence decreases the heat loss for ignition. Near the separation point, the temperature variation becomes gentle and thereby provides favourable conditions for ignition. Accordingly, we define the critical ignition condition based on the assumption that the resulting ignition location coincides with the separation point, where the local temperature gradient has the least magnitude and thus preferentially supports ignition. Moreover, the IFP would be taken away from the hot particle passing over the separation point and therefore lose the capability of ignition. While, as the particle temperature continues to increase, the ignition location moves upstream since an elevation of particle temperature can sustain more severe heat loss during ignition.

For large Reynolds number, i.e. ![]() $Re \gg 1$, the flow field consists of a boundary layer on the particle surface. Across the boundary layer, the flow velocity decelerates to zero on the particle surface. In the outer region above the boundary layer, viscous stress can be neglected. For uniform flow across a spherical particle, the velocity components in the outer region are given by (Leal Reference Leal2007; Schlichting & Gersten Reference Schlichting and Gersten2016)

$Re \gg 1$, the flow field consists of a boundary layer on the particle surface. Across the boundary layer, the flow velocity decelerates to zero on the particle surface. In the outer region above the boundary layer, viscous stress can be neglected. For uniform flow across a spherical particle, the velocity components in the outer region are given by (Leal Reference Leal2007; Schlichting & Gersten Reference Schlichting and Gersten2016)

On the particle surface with ![]() $\tilde{r} = 1$, the radial component becomes zero while the tangential component is

$\tilde{r} = 1$, the radial component becomes zero while the tangential component is ![]() ${\tilde{u}_{\phi ,\tilde{r} = 1}} = (3/2)\sin \phi \ne 0$, which does not satisfy the no-slip condition. This indicates the necessity of solving the velocity distribution in the momentum boundary layer.

${\tilde{u}_{\phi ,\tilde{r} = 1}} = (3/2)\sin \phi \ne 0$, which does not satisfy the no-slip condition. This indicates the necessity of solving the velocity distribution in the momentum boundary layer.

The boundary layer theory suggests rescaling the non-dimensional transverse coordinate and velocity component, defined by

for suitable description of the velocity distribution in the boundary layer. In the limit of ![]() $Re \to \infty $, the governing equations for the momentum boundary layer covering a spherical particle are

$Re \to \infty $, the governing equations for the momentum boundary layer covering a spherical particle are

where we denote the non-dimensional tangential component of the flow velocity in the momentum boundary layer by u. Since the flow outside the momentum boundary layer is almost potential, the pressure gradient can be solved in terms of the ![]() ${\tilde{u}_\phi }$ given by (3.17a,b) based on Bernoulli's equation, which, at the particle surface

${\tilde{u}_\phi }$ given by (3.17a,b) based on Bernoulli's equation, which, at the particle surface ![]() $\tilde{r} = 1$, yields

$\tilde{r} = 1$, yields

where the pressure is non-dimensionalized by ![]() ${\rho _g}U_\infty ^2$.

${\rho _g}U_\infty ^2$.

Equations (3.19) and (3.20) can be solved by means of a Blasius series, i.e. a series of velocity components in terms of ![]() ${\phi ^n}$ with n being integer. The detailed description of the mathematical method can found in Leal (Reference Leal2007) and Schlichting & Gersten (Reference Schlichting and Gersten2016). Here, we only briefly present key steps in our solution.

${\phi ^n}$ with n being integer. The detailed description of the mathematical method can found in Leal (Reference Leal2007) and Schlichting & Gersten (Reference Schlichting and Gersten2016). Here, we only briefly present key steps in our solution.

According to (3.17a,b), the tangential component of the potential flow ![]() ${\tilde{u}_\phi }$ at

${\tilde{u}_\phi }$ at ![]() $\tilde{r} = 1$ can be expanded in a series of

$\tilde{r} = 1$ can be expanded in a series of ![]() $\phi $,

$\phi $,

Correspondingly, the tangential velocity in the momentum boundary layer can also be expanded as a series of ![]() $\phi $ with coefficients being general functions of the rescaled transverse coordinate Y. To obtain a relatively accurate interpretation to the velocity profile in the rear hemisphere, we retain terms of

$\phi $ with coefficients being general functions of the rescaled transverse coordinate Y. To obtain a relatively accurate interpretation to the velocity profile in the rear hemisphere, we retain terms of ![]() ${\phi ^n}$ with

${\phi ^n}$ with ![]() $n \le 7$ in the expansion of u, i.e.

$n \le 7$ in the expansion of u, i.e.

where the prime in coefficient function F refers to derivative with respect to Y. The no-slip boundary condition requires that the coefficient functions F's satisfy

Matching with outer potential flow suggests that

Substituting the series of u given by (3.23) into the continuity equation (3.19), one obtains the series for ![]() $\partial V/\partial Y$. Integrating with respect to Y yields

$\partial V/\partial Y$. Integrating with respect to Y yields

\begin{align}V &={-} 2{F_1} +

({\textstyle{1 \over 3}}{F_1} - 4{F_3}){\phi ^2} +

({\textstyle{1 \over {45}}}{F_1} + {\textstyle{1 \over

3}}{F_3} - 6{F_5}){\phi ^4}\nonumber\\ &\quad + ({\textstyle{2 \over

{945}}}{F_1} + {\textstyle{1 \over {45}}}{F_3} +

{\textstyle{1 \over 3}}{F_5} - 8{F_7}){\phi

^6},\end{align}

\begin{align}V &={-} 2{F_1} +

({\textstyle{1 \over 3}}{F_1} - 4{F_3}){\phi ^2} +

({\textstyle{1 \over {45}}}{F_1} + {\textstyle{1 \over

3}}{F_3} - 6{F_5}){\phi ^4}\nonumber\\ &\quad + ({\textstyle{2 \over

{945}}}{F_1} + {\textstyle{1 \over {45}}}{F_3} +

{\textstyle{1 \over 3}}{F_5} - 8{F_7}){\phi

^6},\end{align}

whose coefficients are functions of Fi values instead of their derivative with respect to Y. The no-penetration boundary condition on the particle surface, i.e. ![]() $V = 0$ at

$V = 0$ at ![]() $Y = 0$, requires that the functions

$Y = 0$, requires that the functions ![]() $F$ satisfy

$F$ satisfy

Substituting the series forms of (3.23) and (3.26) into the momentum equation (3.20) and collecting the powers of ![]() $\phi $, we have

$\phi $, we have

\begin{gather}\begin{array}{ccccc} & {{F^{\prime\prime\prime}_5}} + 2{F_1}{{F^{\prime\prime}_5}} - 6{{F^{\prime}_1}}{{F^{\prime}_5}} - {\textstyle{1 \over {45}}}{{F^{\prime\prime}_1}}({F_1} + 15{F_3} - 270{F_5})\\ & \hspace{-5pc}- F_3^{^{\prime\prime}}({\textstyle{1 \over 3}}{F_1} - 4{F_3}) - 3F^{\prime 2}_3 + {\textstyle{3 \over {10}}} = 0, \end{array}\end{gather}

\begin{gather}\begin{array}{ccccc} & {{F^{\prime\prime\prime}_5}} + 2{F_1}{{F^{\prime\prime}_5}} - 6{{F^{\prime}_1}}{{F^{\prime}_5}} - {\textstyle{1 \over {45}}}{{F^{\prime\prime}_1}}({F_1} + 15{F_3} - 270{F_5})\\ & \hspace{-5pc}- F_3^{^{\prime\prime}}({\textstyle{1 \over 3}}{F_1} - 4{F_3}) - 3F^{\prime 2}_3 + {\textstyle{3 \over {10}}} = 0, \end{array}\end{gather}Which, subject to boundary conditions given by (3.24), (3.25) and (3.27), and can be solved numerically.

With knowledge of Fi values, the profiles of u and V can be determined through (3.23) and (3.26), respectively. According to the boundary layer theory, the separation point is characterized by the relation (Leal Reference Leal2007)

\begin{equation}{\left( {\frac{{\partial u}}{{\partial Y}}} \right)_{Y = 0,\phi = {\phi _{sep}}}} = 0,\end{equation}

\begin{equation}{\left( {\frac{{\partial u}}{{\partial Y}}} \right)_{Y = 0,\phi = {\phi _{sep}}}} = 0,\end{equation}

which, with our numerical results of u and V, gives ![]() ${\phi _{sep}} \approx 108^\circ $ and is consistent with previous studies (Schlichting & Gersten Reference Schlichting and Gersten2016). This separation angle holds for

${\phi _{sep}} \approx 108^\circ $ and is consistent with previous studies (Schlichting & Gersten Reference Schlichting and Gersten2016). This separation angle holds for ![]() $Re \to \infty $ which can be understood as meaning that the boundary layer equations (3.19) and (3.20) in fact give the leading-order solution of the flow field at the limit

$Re \to \infty $ which can be understood as meaning that the boundary layer equations (3.19) and (3.20) in fact give the leading-order solution of the flow field at the limit ![]() $Re \to \infty $. For moderate

$Re \to \infty $. For moderate ![]() $Re$, the polar angle representing the separation point moves downstream on reducing the Reynolds number (Rimon & Cheng Reference Rimon and Cheng1969). To interpret such relation, we have to retain higher-order terms in the boundary layer equations, which results in exceeding difficulty in the mathematics and is thus beyond the scope of the present study.

$Re$, the polar angle representing the separation point moves downstream on reducing the Reynolds number (Rimon & Cheng Reference Rimon and Cheng1969). To interpret such relation, we have to retain higher-order terms in the boundary layer equations, which results in exceeding difficulty in the mathematics and is thus beyond the scope of the present study.

Figure 1 shows that the tangential velocity increases from zero on the particle surface to the potential flow solution in the outer region. According to (3.21), the outer potential flow accelerates from the front stagnation point ![]() $(\phi = 0)$ to the peripheral side of the sphere

$(\phi = 0)$ to the peripheral side of the sphere ![]() $(\phi = {\rm \pi}/2)$, after which the pressure gradient becomes adverse, leading to flow separation around

$(\phi = {\rm \pi}/2)$, after which the pressure gradient becomes adverse, leading to flow separation around ![]() $\phi \approx 0.6{\rm \pi} = 108^\circ $.

$\phi \approx 0.6{\rm \pi} = 108^\circ $.

Figure 1. Change of the tangential velocity u with scaled transverse coordinate Y across the momentum boundary layer for different polar angles of ![]() $\phi = 0.1{\rm \pi} \sim 0.6{\rm \pi} $.

$\phi = 0.1{\rm \pi} \sim 0.6{\rm \pi} $.

The outer edge of the boundary layer is characterized by ![]() $u = 0.99{\tilde{u}_{\phi ,\tilde{r} = 1}}$, and its distance from the particle surface is defined as the thickness of the momentum boundary layer, denoted by

$u = 0.99{\tilde{u}_{\phi ,\tilde{r} = 1}}$, and its distance from the particle surface is defined as the thickness of the momentum boundary layer, denoted by ![]() ${\delta _m}$. Figure 2 shows that

${\delta _m}$. Figure 2 shows that ![]() ${\delta _m}$ increases monotonically with

${\delta _m}$ increases monotonically with ![]() $\phi $, particularly beyond

$\phi $, particularly beyond ![]() $\phi = {\rm \pi}/4$, where the favourable pressure gradient at

$\phi = {\rm \pi}/4$, where the favourable pressure gradient at ![]() $Y = 0$ is of largest magnitude according to (3.21). Besides, the tangential velocity gradient, interpreting the frictional resistance experienced by the particle, achieves the largest value around

$Y = 0$ is of largest magnitude according to (3.21). Besides, the tangential velocity gradient, interpreting the frictional resistance experienced by the particle, achieves the largest value around ![]() $\phi = 1.0$ and vanishes around

$\phi = 1.0$ and vanishes around ![]() ${\phi _{sep}} = 0.6{\rm \pi} \; $. This is consistent with the velocity profiles shown in figure 1.

${\phi _{sep}} = 0.6{\rm \pi} \; $. This is consistent with the velocity profiles shown in figure 1.

Figure 2. Change of the tangential velocity gradient adjacent to the particle surface and the thickness of the momentum boundary layer with polar angle ![]() $\phi $.

$\phi $.

Since ![]() $Pe \sim Re$, large Reynolds number also implies that

$Pe \sim Re$, large Reynolds number also implies that ![]() $Pe \gg 1$. This indicates that the temperature of the gaseous premixture also exhibits a rapid transition from

$Pe \gg 1$. This indicates that the temperature of the gaseous premixture also exhibits a rapid transition from ![]() $\theta = 1$ on the particle surface to

$\theta = 1$ on the particle surface to ![]() $\theta \to 0$ in the ambient, which is known as the thermal boundary layer. Since the Prandtl number of the gaseous premixture is of

$\theta \to 0$ in the ambient, which is known as the thermal boundary layer. Since the Prandtl number of the gaseous premixture is of ![]() $O(1)$, the rescaling relation (3.18a,b) holds in the thermal boundary layer as well. Therefore, neglecting dissipation of kinetic energy to thermal energy, the governing equation for the thermal boundary layer can be written in the following form:

$O(1)$, the rescaling relation (3.18a,b) holds in the thermal boundary layer as well. Therefore, neglecting dissipation of kinetic energy to thermal energy, the governing equation for the thermal boundary layer can be written in the following form:

where the coefficients u and V, given by (3.23) and (3.26), are known functions of ![]() $\phi $ and Y. Equation (3.33) is subject to the following boundary conditions:

$\phi $ and Y. Equation (3.33) is subject to the following boundary conditions:

In analogy to the Blasius series representing the velocity profiles u and V, the normalized temperature in the thermal boundary layer can also be expanded in the series form as

Since the temperature profile is an even function about the axis of symmetry, i.e. ![]() $\theta (\phi ) = \theta ( - \phi )$, only terms of even power in

$\theta (\phi ) = \theta ( - \phi )$, only terms of even power in ![]() $\phi $ appear. To obtain consistent accuracy with the Blasius series of the velocity profiles, we retain four terms up to

$\phi $ appear. To obtain consistent accuracy with the Blasius series of the velocity profiles, we retain four terms up to ![]() ${\phi ^6}$. Substituting the series representations of u, V and

${\phi ^6}$. Substituting the series representations of u, V and ![]() $\theta $, given by (3.23), (3.36) and (3.36), respectively, into (3.33), we obtain

$\theta $, given by (3.23), (3.36) and (3.36), respectively, into (3.33), we obtain

\begin{gather}\begin{array}{ccccc} & \hspace{-1pc}\dfrac{{{{H^{\prime\prime}_6}}}}{{Pr}} = \left( {\dfrac{{2{F_1}}}{{945}} + \dfrac{{{F_3}}}{{45}} + \dfrac{{{F_5}}}{3} - 8{F_7}} \right){{H^{\prime}_0}} + 2{{F^{\prime}_5}}{H_2} + \left( {\dfrac{{{F_1}}}{{45}} + \dfrac{{{F_3}}}{3} - 6{F_5}} \right){{H^{\prime}_2}} + 4{{F^{\prime}_3}}{H_4}\\ & \hspace{-12pc} + \left( {\dfrac{{{F_1}}}{3} - 4{F_3}} \right){{H^{\prime}_4}} + 6{{F^{\prime}_1}}{H_6} - 2{F_1}{{H^{\prime}_6}}. \end{array}\end{gather}

\begin{gather}\begin{array}{ccccc} & \hspace{-1pc}\dfrac{{{{H^{\prime\prime}_6}}}}{{Pr}} = \left( {\dfrac{{2{F_1}}}{{945}} + \dfrac{{{F_3}}}{{45}} + \dfrac{{{F_5}}}{3} - 8{F_7}} \right){{H^{\prime}_0}} + 2{{F^{\prime}_5}}{H_2} + \left( {\dfrac{{{F_1}}}{{45}} + \dfrac{{{F_3}}}{3} - 6{F_5}} \right){{H^{\prime}_2}} + 4{{F^{\prime}_3}}{H_4}\\ & \hspace{-12pc} + \left( {\dfrac{{{F_1}}}{3} - 4{F_3}} \right){{H^{\prime}_4}} + 6{{F^{\prime}_1}}{H_6} - 2{F_1}{{H^{\prime}_6}}. \end{array}\end{gather}The boundary conditions for Hi are given by

The numerical solution to (3.37)–(3.40) subject to boundary conditions (3.41) and (3.42) can be sought following the same procedure as that used to obtain the coefficients Fi for the Blasius series of u and V. The representative parameter of the Prandtl number is selected to be that of air, i.e. ![]() $Pr = 0.71$, in the numerical solution.

$Pr = 0.71$, in the numerical solution.

Figure 3 indicates that the normalized temperature tends to decrease linearly with Y around the particle surface, whose slope continues to reduce as ![]() $\phi $ increases. At some elevated distance in the transverse direction, the change of

$\phi $ increases. At some elevated distance in the transverse direction, the change of ![]() $\theta $ becomes very slow and exhibits a long tail on relaxing to

$\theta $ becomes very slow and exhibits a long tail on relaxing to ![]() $\theta = 0$. The outer edge of the thermal boundary layer refers to the transverse coordinate where

$\theta = 0$. The outer edge of the thermal boundary layer refers to the transverse coordinate where ![]() $\theta = 0.01$, and its distance from the particle surface is defined as the thickness of the thermal boundary layer, denoted by

$\theta = 0.01$, and its distance from the particle surface is defined as the thickness of the thermal boundary layer, denoted by ![]() ${\delta _T}$.

${\delta _T}$.

Figure 3. Change of the normalized temperature with scaled transverse coordinate across the thermal boundary layer for different polar angles of ![]() $\phi = 0.1{\rm \pi} \sim 0.6{\rm \pi} $.

$\phi = 0.1{\rm \pi} \sim 0.6{\rm \pi} $.

Figure 4 shows the temperature gradient adjacent to the particle surface and the thickness of the thermal boundary layer. Similar to ![]() ${\delta _m}$, the thermal boundary layer grows monotonically with

${\delta _m}$, the thermal boundary layer grows monotonically with ![]() $\phi $. Besides, comparison between figures 2 and 4 indicates that the thermal boundary layer is thicker than the momentum boundary layer. This is because

$\phi $. Besides, comparison between figures 2 and 4 indicates that the thermal boundary layer is thicker than the momentum boundary layer. This is because ![]() $Pr < 1$.

$Pr < 1$.

Figure 4. Change of the temperature gradient adjacent to the particle surface and the thickness of the thermal boundary layer with polar angle ![]() $\phi $.

$\phi $.

The rate of heat transfer on the particle surface can be quantified by the magnitude of the temperature gradient there, which, as seen from figure 4, decreases to almost one third from the front stagnation point to the separation point. According to (2.13), the fall in temperature gradient reduces the heat loss for ignition of the combustible mixture. This is consistent with the experimental observation (Coronel Reference Coronel2016; Coronel et al. Reference Coronel, Melguizo-Gavilanes, Mével and Shepherd2018) that ignition most probably takes place near the separation point, where the temperature gradient calculated from (3.36) is

\begin{equation}{-}{\left( {\frac{{\partial \theta }}{{\partial \tilde{r}}}} \right)_{\tilde{r} = 1,\phi = {\phi _{sep}}}} = \sqrt {Re} [{H^{\prime}_0}(0) + {H^{\prime}_2}(0)\phi _{sep}^2 + {H^{\prime}_4}(0)\phi _{sep}^4 + {H^{\prime}_6}(0)\phi _{sep}^6] = 0.276\sqrt {Re} .\end{equation}

\begin{equation}{-}{\left( {\frac{{\partial \theta }}{{\partial \tilde{r}}}} \right)_{\tilde{r} = 1,\phi = {\phi _{sep}}}} = \sqrt {Re} [{H^{\prime}_0}(0) + {H^{\prime}_2}(0)\phi _{sep}^2 + {H^{\prime}_4}(0)\phi _{sep}^4 + {H^{\prime}_6}(0)\phi _{sep}^6] = 0.276\sqrt {Re} .\end{equation}3.4. The critical ignition temperature

According to (2.13), the non-dimensional heat loss coefficient is proportional to the square of the temperature gradient. Consequently, ignition occurs at the point where the magnitude of the local temperature gradient is the smallest, which is defined as the ignition temperature gradient, denoted by ![]() ${(\textrm{d}\theta /\textrm{d}\tilde{r})_{ig}}$. In a quiescent environment, the temperature gradient is uniform over the particle surface according to (3.3), yielding

${(\textrm{d}\theta /\textrm{d}\tilde{r})_{ig}}$. In a quiescent environment, the temperature gradient is uniform over the particle surface according to (3.3), yielding

For creeping flow over the hot particle, the lowest heat transfer rate occurs at the rear stagnation point, for which the temperature gradient is given by (3.16). Consequently, the ignition temperature gradient for creeping flow is

At large ![]() $Re$, flow separation takes place and the ignition temperature can be evaluated by the boundary layer solution given by (3.43). Therefore, the ignition temperature gradient for large

$Re$, flow separation takes place and the ignition temperature can be evaluated by the boundary layer solution given by (3.43). Therefore, the ignition temperature gradient for large ![]() $Re$ is

$Re$ is

The correlations between the ignition temperature gradients and the Reynolds number for ![]() $Re \ll 1$ and

$Re \ll 1$ and ![]() $Re \to 1$ are respectively presented by (3.45) and (3.46). However, for hot particle induced ignition, the Reynolds number usually varies in the intermediate range from

$Re \to 1$ are respectively presented by (3.45) and (3.46). However, for hot particle induced ignition, the Reynolds number usually varies in the intermediate range from ![]() $O(1)$ to

$O(1)$ to ![]() $O({10^2})$, in which there exists a gap in the ignition temperature gradients predicted by (3.45) and (3.46) because the controlling mechanism of heat transfer alters as

$O({10^2})$, in which there exists a gap in the ignition temperature gradients predicted by (3.45) and (3.46) because the controlling mechanism of heat transfer alters as ![]() $Re$ increases.

$Re$ increases.

Since the Blasius series holds at the limit condition of ![]() $Re \to \infty $, the result given by (3.46) is not qualitatively accurate in the intermediate range of

$Re \to \infty $, the result given by (3.46) is not qualitatively accurate in the intermediate range of ![]() $Re$. It would be convenient to obtain an explicit formula that can predict the ignition temperature gradient in a wide range of Reynolds numbers from

$Re$. It would be convenient to obtain an explicit formula that can predict the ignition temperature gradient in a wide range of Reynolds numbers from ![]() $Re = 0$ (for pure conduction) to

$Re = 0$ (for pure conduction) to ![]() $Re \sim O({10^2})$ (flow separation without unsteady vortex shedding) (Johnson & Patel Reference Johnson and Patel1999; Schlichting & Gersten Reference Schlichting and Gersten2016). Combining the mathematical forms of (3.45) and (3.46), we can specify the dependence of

$Re \sim O({10^2})$ (flow separation without unsteady vortex shedding) (Johnson & Patel Reference Johnson and Patel1999; Schlichting & Gersten Reference Schlichting and Gersten2016). Combining the mathematical forms of (3.45) and (3.46), we can specify the dependence of ![]() ${(\textrm{d}\theta /\textrm{d}\tilde{r})_{ig}}$ on

${(\textrm{d}\theta /\textrm{d}\tilde{r})_{ig}}$ on ![]() $Re$ in the following form:

$Re$ in the following form:

which reduces to pure conduction for ![]() $Re = 0$ and scales with

$Re = 0$ and scales with ![]() $\sqrt {Re} $ for large Reynolds numbers. The parameter

$\sqrt {Re} $ for large Reynolds numbers. The parameter ![]() ${\alpha _T}$ shall be determined with the help of the Frossling formula (Hughmark Reference Hughmark1980; McAllister, Chen & Fernandez-Pello Reference McAllister, Chen and Fernandez-Pello2011). The detailed procedures are presented as follows.

${\alpha _T}$ shall be determined with the help of the Frossling formula (Hughmark Reference Hughmark1980; McAllister, Chen & Fernandez-Pello Reference McAllister, Chen and Fernandez-Pello2011). The detailed procedures are presented as follows.

The Frossling formula (Hughmark Reference Hughmark1980; McAllister et al. Reference McAllister, Chen and Fernandez-Pello2011) interprets the total heat transfer from the particle in terms of the Nusselt number, which can be equivalently correlated to an average temperature gradient, i.e.

In spite of a similar mathematical form, the coefficient ![]() ${\alpha _T}$ in (3.47) differs from that in (3.48). Considering similarity in the boundary layer, we suppose that the proportionality between the temperature gradient at the flow separation point,

${\alpha _T}$ in (3.47) differs from that in (3.48). Considering similarity in the boundary layer, we suppose that the proportionality between the temperature gradient at the flow separation point, ![]() ${(\textrm{d}\theta /\textrm{d}r)_{ig,m}}$ given by (3.47), and its average value over the whole particle surface,

${(\textrm{d}\theta /\textrm{d}r)_{ig,m}}$ given by (3.47), and its average value over the whole particle surface, ![]() ${(\textrm{d}\theta /\textrm{d}r)_{ave}}$ given by (3.48), would be less than unity and tends to vary slowly with

${(\textrm{d}\theta /\textrm{d}r)_{ave}}$ given by (3.48), would be less than unity and tends to vary slowly with ![]() $Re$. Thereby, we can determine the coefficient

$Re$. Thereby, we can determine the coefficient ![]() ${\alpha _T}$ with the help of both the Frossling formula and the Blasius series solution of thermal boundary layer.

${\alpha _T}$ with the help of both the Frossling formula and the Blasius series solution of thermal boundary layer.

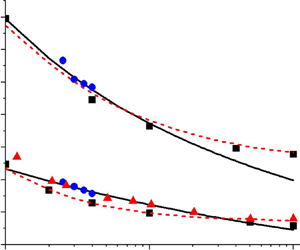

The average temperature gradient in the limit of ![]() $Re \to \infty $ can be calculated via the boundary layer solution, giving

$Re \to \infty $ can be calculated via the boundary layer solution, giving