Introduction

Food production and food processing demand large volumes of water but managers and technicians need to address the increasing challenge to access and manage fresh and clean water resources. A more sustainable water use approach is required to tackle the increasing scarcity of water resources in many regions of the world. Moreover, the water problem has also become critical in those countries where rainfall is high (OECD, 2019). Thus, water scarcity and quality have been increasingly recognized as one of the most important environmental threats to humankind (Rockström and Karlberg, Reference Rockström and Karlberg2010; Sivapalan et al., Reference Sivapalan, Konar, Srinivasan, Chhatre, Wutich, Scott and Rodríguez-Iturbe2014; Rockström et al., Reference Rockström, Williams, Daily, Noble, Matthews, Gordon and de Fraiture2017).

Water waste is mainly caused by both inefficient operational and managerial processes. Worldwide, the agricultural sector consumes 29% of the total fresh water (Mekonnen and Hoekstra, Reference Mekonnen and Hoekstra2012; Gerbens-Leenes et al., Reference Gerbens-Leenes, Mekonnen and Hoekstra2013; Bustillo-Lecompte and Mehrvar, Reference Bustillo-Lecompte and Mehrvar2015), with the meat processing industry alone using up to 24% in the food and beverage consumption. Hence, the water footprinting in agricultural food production and processing is considerable.

In the food industry, the bulk of water consumed takes place during operational practices such as washing installations and equipment. In slaughterhouses, most of the consumption is due to strict sanitary requirements which thus increase the intensity of its use (Krieger and Rodriguez, Reference Krieger and Rodriguez2006). In addition, meat processing activities are inherently highly polluting. This is because of the large volumes of blood and other solid and semi-solid materials such as stomach and intestinal content of slaughtered animals. Thus, improper water management within slaughterhouses becomes a general public health problem since should effluents which can contaminate humans and animals are not treated accordingly.

During the Rio Earth Summit in 1992, nation signatories of the Agenda 21 committed to meet economic development in a more sustainable way. The Agenda 21 is a framework proposing a detailed program of actions on measures to protect and renew natural environmental resources, including water (Lee and Lee, Reference Lee and Lee2017). Since then, water scarcity has become critical, and in some food industry cases it has affected a company's economic viability. Thus, tackling some current water use practices is important so that companies start adopting clean production techniques.

Cleaner Production Methods is a concept jointly proposed by the United Nations Industrial Development Organizations and United Nations Environmental Program in preparation for the UN Rio Summit in the 1990s. It aimed at preventing, containing and minimizing the detrimental impact industrial activity could cause on the environment and society. Cleaner Production Methods are an organizational strategy with a methodology that, applied to products, processes and services, is designed to promote business efficiency while reducing its risks to humans, animals and the environment (Eckhard, Reference Eckhard2014). This methodology adopts the continuous application of economic and environmental strategies aimed at the elaboration of preventative measures to minimize waste through the rational use of resources. It also promotes recycling, whenever possible, hence contributing to the reduction of production costs as well as environmental conservation (Rahim and Raman, Reference Rahim and Raman2015; Ozturk et al., Reference Ozturk, Koseoglu, Karaboyaci, Yigit, Yetis and Kitis2016). Cleaner Production Methods applied to the meat industry could largely cut the amount of wastewater produced. Changed in processes such as the handling of animals, slaughter and overall management of the water resource along the production line would help to cut water consumption which would consequently avoid or remedy the detrimental environmental and health impact waste water might have.

New slaughter plants are already using some of these methods, but improvements can still be made regarding the reusing of water. Nonetheless, converting old plants are costly to implement, and not yet widespread in the meat processing industry. However, it is expected that Clean Production Methods will become more of a common practice in the future. In this context, the present study aims to compare and contrast the water consumption for different species such as cattle, swine, poultry, goat, sheep and fish. Shared problems consistent in the different processing lines will be highlighted and recommendations will be made regarding pertinent interventions to improve water management processes.

Materials and methods

The present study was based on a systematic literature review using databases such as Science Direct, Google Scholar and SciELO (Scientific Electronic Library Online). Emphasis was given to identifying publications using search words and terms containing ‘use of water in slaughterhouses’ and ‘cleaner methods production.’ Particularly, the main key-words searched included ‘sustainability,’ ‘slaughterhouse,’ ‘water management,’ ‘cleaner production’ and ‘trends.’ Initially, 67 publications were identified which included books, rulings and articles published in national and international scientific journals of a high impact factor. The publications were selected according to relevance and timeliness. A total of 45% of the articles used had been published in the last 5 yr, and 69% published in the last 10 yr.

Benchmarks

At slaughter, despite some processes and stages being similar, there are specific ones applied to particular animal species. Therefore, the literature indicated that the water footprinting and costings would vary when comparing the yields of an identical amount of meat, as shown in Table 1. Despite such a difference each animal case must be treated separately to enable to control different variables. Each slaughterhouse should set up guidelines and benchmark references for the purpose of monitoring and comparison to improve their water use efficiency. Kupusovic et al. (Reference Kupusovic, Midzic, Silajdzic and Bjelavac2007) proposed a methodology that helped in the evaluation and implementation of the practices and activities in slaughterhouses as part of cleaner production practices aiming to reduce water consumption in these establishments. In their study, during the first 3 months of introducing the methodology, 32% water saving was achieved compared to the previous month analyzed proving that benchmarks can be reached by setting goals.

Table 1. Benchmarks per animals and countries.

In doing so, slaughterhouses should have a Good Managerial Practices Plan in place recommending a profile of water use for each animal species and stage of meat processing. Therefore, once the plan was in place, daily monitoring checks would serve to enable corrective actions to reduce water consumption so that the goals set ate gradually reached.

A review of the current literature has highlighted some benchmarks figures for water consumption (Table 1). Water management guidelines vary both within and amongst countries, nevertheless, they serve as targets for the implementation and monitoring of the likely reduction in water use and wastewater.

As indicated in Table 1, the figures from Denmark refer to water consumption using three different models: traditional, better and best technology (UNEP, 2000). Water consumption ranged from 5000 to 1500 L per animal and 1000 L per animal, respectively. These results were compatible with different Cleaner Production Methods whose characteristics were typical of a highly efficient system which used the best technology process available. That was followed by a moderate Cleaner Production Method, typical of an intermediate technology used, and finally a low one notably absent of Cleaner Production practice (UNEP, 2000).

Ferraciolli et al. (Reference Ferraciolli, R, Luiz and Naval2017) proposed that in fish processing, the problems were similar to those in cattle regarding the excessive consumption of water and consequent generation of effluent containing concentrated organic loads. During fish processing, despite the amount of waste being lower than in other species, the environmental impact cause by water consumption and release of residues were considerable (Ferraciollis et al., Reference Ferraciolli, R, Luiz and Naval2017). Depending on the method used, water costs per slaughtered animal would vary amongst the establishments, as well as between countries (Table 1). This discrepancy in cost also gives an indication of the different slaughter techniques used thence the different levels of consumption and waste of water produced.

Generally, the use of water in a slaughterhouse constitutes a complex system where a comparative analysis of different establishments is difficult. This is because each slaughterhouse depending on the location, livestock type processed and specific local conditions as well as legislation has adopted different production methods. Yet, a schematic picture of a slaughtering process follows closely the flow as depicted in Figure 1. Thus, the methods highlighted in this article could be applied to any establishment in any country with a few adjustments. Figure 1, below, attempts to represent the key stages regarding the slaughter practices and respective water consumption from the unloading of animals at reception until packing.

Fig. 1. Simplified steps of a slaughter flowchart.

Transportation, reception and unloading

Prior to leaving the farms, the practice establishes that livestock are restricted to having access to feed to start reducing the solid contents of the stomachs thereby aiding with the cleaning of the intestines and reducing the need water (Kupusovic et al., Reference Kupusovic, Midzic, Silajdzic and Bjelavac2007). With an empty stomach, the risk of breakage during the process is also reduced, preventing fecal contamination of the carcass and consequent condemnation of the contaminated part. After unloading, cattle and pigs in general should rest having plenty access to water to restore the energy spent during transportation as well as for thermal regulation. When handling pigs, providing the animals with adequate protection from the sun and ample ventilation can aid in the reduction of water consumption by the animals. Moreover, the automatic dispensing of water drinking troughs is preferable to reduce waste (Krieger and Rodriguez, Reference Krieger and Rodriguez2006). Since the only water used will be that consumed by the animals. Water waste is hence avoided and drinking water contamination would be minimal. However, in tropical countries, at the reception pens water sprinkles and ample ventilation are commonly employed to regulate temperature and humidity of cattle and pigs. After unloading, both the pens and the trucks should be cleaned by a dry clean method prior to washing them with water (UNEP, 2000; Krieger and Rodriguez, Reference Krieger and Rodriguez2006). The dry cleaning technique consists of the removal of large dirt quantity by squeegees or shovels as well as other physical methods prior to using water hoses. Such a water saving method could reduce from 20 to 30% the use of water in the case of beef cattle and pigs. The angle of the floor of the reception pens being up to 60° would help with the rinsing practices with cold water first. Skilled labor force is needed to also carry out regular monitoring of the spray nozzles and the working of pressure reducers and shut off valves to reduce water consumption. Therefore, the reception pens should bear the water use and water saving in their design layout and construction, not to mention materials and type of flooring to facilitate as much as dry removal as possible (UNEP, 2000).

Particularly in fish processing, Araújo (Reference Araújo2017) measured the use of water in different fish processing industries. It is also possible to significantly reduce the demand for water by changing the layout and minimizing consumption. Frequent checks and monitoring of leaks, the use of high-pressure jet, low water wash systems, flow regulators and automatic activation of taps are examples of water minimizing in fish processing. In one tilapia processing plant, water consumption fell by almost half using these methods. In the tanks where the fish is held for depuration, a stage prior to processing to eliminate odors or unpleasant tastes in the fish, it was possible to reduce the use of fresh water by a large percentage (16%). The daily water consumption of the fish industry studied dropped from 457 to 386 m3 after the implementation of physical changes and it could reach 235 m3 if other suggested water-savings recommendations were employed. There were about 15.5% savings at the implementation of interventions and 48.6% cost reduction when adopting the other recommendations. However, the overall reduction could still be significant by at least achieving a 10% lower water use rate. However, these results serve only as a guide since they could not be replicated by other fish processing plants companies.

Stunning, slaughter and bleeding

The Waste and Resource Action Programme (WRAP), an organization from United Kingdom, recommend that after stunning, cattle and pigs progress to a bleeding stage staying a minimum of 7 min similarly to what is generally recommended in conventional systems. The longer the bleeding time, the more it allows for an effective bleeding process, thus maximizing the proportion of blood collected. Since blood is a single largest contributor to environmental pollution in meat processing, the WRAP suggested to collect as much blood as possible for reuse or disposal to reduce the loading on the effluent treatment system (WRAP, 2013). The existence of a two-way blood drain system consisting of two drain outlets, one connected to the blood drum and the other to a septic tank would be an improvement in reducing water waste at this stage. The system works by allowing one outlet to be open whilst the other is closed. After slaughter is completed and all the blood is swept into the collection drum, then the outlet connected to the septic tank would collect all the wastewater used for cleaning (Kupusovic et al., 2005). Hence, such a practice would significantly contribute to the reduction of the pollution load in the effluent water and would enable an efficient separating of blood from wastewater. The blood which is collected is destined to the production of blood flour for the purpose of use in animal feed and/or black pudding.

In fish processing, during the stages of desensitization with ice, bleeding, washing, desquamation and the cut of the head it is also possible to save water by substituting the continuous flow of water for a batch system. The use of pressure nozzles in fish processing and cleaning (Araújo, Reference Araújo2017) allows for water savings which together with the reduction of both the number and size of spray nozzles could save up to 75% of the water volume used (Valta et al., Reference Valta, Moustakas, Sotiropoulos, Malamis and Haralambous2016), emphasizing that each industrial establishment should be treated separately.

Scalding

Particularly in the slaughtering of pigs, scalding involves the use of constant flow of heated water during which the carcass is immersed. In that stage, tank refill/top up should be controlled by a simple ball valve or other level sensing device to avoid wastage from overflow and consequently loss of waster by spillage. To reduce water consumption for cleaning the tank, the tank bottom should have a steep gradient towards the drainage outlets. This would facilitate the easier removal of solids from the tank (Environment Agency, 2009a; Pacheco and Yamanaka, Reference Pacheco and Yamanaka2006).

Scalding by immersion is a water-hungry process which is considered obsolete despite still being in use in many countries. The alternative use of hot water spray, steam and condensation considerably requires less water, therefore being more efficient. Moreover, automatically operated scalding chambers aid in the dehairing of pigs too (UNEP, 2000; WRAP, 2013), whose use should become a trend for new slaughterers to follow these methods.

Evisceration

At this stage, livestock such as cattle, pig, sheep and goat should have the gastrointestinal tract as empty as possible to reduce water consumption (Krieger and Rodriguez, Reference Krieger and Rodriguez2006; WRAP, 2013). Emptying the stomachs and intestines until they are dry before washing them with water would reduce the demand for water (Souza et al., Reference Souza, Paradela and Pizarro2013). Kupusovic et al. (2005) recommend to always carry out dry cleaning before using water in washing. In the processing line of smaller animals, the use of an open or closed conveyor belt system aids in the removal of materials which do not require the use of water.

During the evisceration phase, for washing and sterilization of the evisceration tray, water flow should be constant even when the production process is interrupted. Thus, a water waste control system could be set up, as proposed by Pacheco and Yamanaka (Reference Pacheco and Yamanaka2006), so that the water supply in the evisceration tray is stopped when the production process is interrupted.

Particularly in fish processing, during the filleting process, Valta et al. (Reference Valta, Moustakas, Sotiropoulos, Malamis and Haralambous2016) indicated a reduction of 60 to 75% in water consumption when unnecessary nozzles were moved. Thus, water was only applied where required. Furthermore, replacing existing nozzles with those pulsating ones as well as those with lower water consumption has also proven to be efficient.

Regarding solid materials resulting during meat processing, the UNEP (2000) suggested to collect the solids for use as by-products such as flour for animal feed, rather than washing them down the drain. As for that drains, those should be fit with nets and/or traps to prevent solid materials from entering the effluent system.

Recycling and reusing

The practice of partial or total water recycling and reusing can be applied to any food production process. Yet, the technical conditions regarding the need for water treatment and the quality of recycled water must be evaluated to meet the requirements according to each slaughterhouse. For example, the water used at cleaner areas such as the deboning room, could be reused to clean initial stages of meat processing such as washing the reception pens (Bixio and Wintgens, Reference Bixio and Wintgens2006) and other dirtier areas. Yet, the need to minimize health and environmental risks associated with the reuse of water and effluents have led to a number of countries to develop guidelines and regulations for the safe use of treated effluents. The World Health Organization guidelines apply Hazard Analysis and Critical Points (HACCP) and a risk-management framework in the management of water reuse (WHO, 2006). The ‘Guidelines for the safe use of wastewater, excreta and greywater’ goes in tandem with policy and regulatory aspects to the management of wastewater in agriculture, aquaculture and sewage treatment in industry plants. In the USA, the Environmental Protection Agency has published guidelines for the development of reuse programs based on the experiences of several the USA states (USEPA, 2004). The same has occurred in Australia through the application of the Australian guidelines for water recycling (Hamilton et al., Reference Hamilton, Boland, Stevens, Kelly, Radcliffe, Ziehrl and Paulin2005; Thompson, Reference Thompson2005). In the European Union, several member states and autonomous regions have come up with their own legislative frameworks, regulations and guidelines for water-reuse (Bixio and Wintgens, Reference Bixio and Wintgens2006; Alcalde-Sanz and Gawlik, Reference Alcalde-Sanz and Gawlik2014). In this way, international guidelines should be urgently applied by meat-producing and exporting countries to encourage the industries to adopt total or partial recycling and reusing of water. Tax incentives could be made for establishments which use cleaner production methods, such as exemption or reduction of taxes on products, for example, for the export market, the purchase of equipment and machinery as well as labor and environmental taxes. These, coupled with energy savings through wastewater treatment, environmental preservation, improved corporate institutional image and added value to the product, would be ways to convince companies to migrate to this management system.

It is important to note that in slaughterhouses usually the procedure of water use provides that the return of water to water bodies present an oxygen biochemical demand lower than at the point collected initially, before the use. It must also comply with environmental regulations (Oliveira and Bellaver, Reference Oliveira and Bellaver2009). About 80 to 95% of the water consumed in slaughterhouses end up as effluent containing high levels of organic matter due to the presence of manure, fats and blood (UNEP, 2000). In poultry, the washing of installations and equipment also involves high water consumption for the purpose of general cleaning and the washing of carcasses, thus accounting for more than 80% of the water effluent volume generated (UK, 2000).

The CODEX established that in the food industries, regarding the reuse of treated effluents from the production process, it should be adequate to the proposed objective and take into account the likely potential control of pathogenic microorganisms (CODEX, 2001; Levine and Asano, Reference Levine, Asano, Lens, Hulshoff Pol, Wilderer and Asano2002). In dirty areas such as pens, scalding and evisceration, the reusing of water could happen from those areas considered cleaner to those less clean ones. Moreover, the UNEP (2000) recommended, if possible, the partial reuse of water, such as the use of relatively clean wastewaters from cooling systems and vacuum pumps for washing livestock. In pig and cattle processing, the reusing of final rinse waters from the washing of paunches and casings in other non-critical cleaning stages could take place such as: the washing of the slaughter floor and carcass washing; water collected from evisceration tables and hand-wash basins for the purpose of washing of inedible products when possible; reusing cooling water from the singeing process for other application for example in the pig dehairing area; reusing the final rinse from cleaning operations for the initial rinse on the following day; using high pressure rather than high volume for cleaning surfaces; using automatic control systems to operate the flow of water in hand-wash stations and knife sterilizers.

Martins et al. (Reference Martins, Astorga and Silveira2006) investigated water conservation in the processing of sheep and goat and the extent reusing water discarded by the flake-decanter present in the water treatment plant could be used to clean pens. Water quality of the effluent was compatible with the requirements for cleaning the pens, thus reducing the water consumption by 8% at that stage.

Forlani et al. (Reference Forlani, Medeiros and Léo2004) particularly considered the possibility of reuse of bovine effluent from a treatment system by the means of coagulation, flocculation, sedimentation and filtration. They verified that 27% of the total water consumption could be reduced because the recycled water could be reused in many areas. The recycled water had a quality level compatible with the requirements for use at the initial stages such as reception and waiting pens. This is a great benefit since at early stages the water demand is the greatest. Fronza (Reference Fronza2004) carried out a similar research but tested effluents generated during carcass washing. The water quality was also deemed to be good due to its lower concentration of organic matter and the absence of animal feces. In that case, the only treatments needed were filtration and chlorination of the recycled water, making it suitable for use in the bathing of animals, the washing of the pen floors and transportation trucks. Furthermore, Fronza (Reference Fronza2004) proposed the filtration of coarse effluents separated the solids from the liquid and the solids could be used as fertilizers or in ferti-irrigation. As a result, Fronza (Reference Fronza2004) concluded that the total water consumption could be reduced by 28.6%. In pig processing, water used for sterilizing and cleaning butchering knives as well as other cleaning equipment could be recycled and used in the scalding or even the reception and waiting pens (UNEP, 2000; WRAP, 2013; Pacheco and Yamanaka, Reference Pacheco and Yamanaka2006). Thus, following the Cleaner Production Methods strategy each establishment should set its own objectives and account for the reduction in water consumption at different processing stages.

When evaluating the potential effluent reuse in fish processing industries, Ferraciolli et al. (Reference Ferraciolli, R, Luiz and Naval2017) showed that the effluents with lower organic loads, such as those of the sanitary barrier, could be submitted to treatments that prioritized the removal of nutrients and solids for later recycling. As for the effluents collected during the stage of evisceration and the washing of cylinders, it was previously recommended to remove coarse solid waste, so that the treated effluent could reach industrial reuse quality. Yet, it is also worth mentioning these effluents could be treated in a way that drinking water quality characteristics were met. Hence, there is the possibility of reuse recycled water in the processing of the fish itself without infringing the food quality standards. Control measures should be in place to prevent microbiological cross-contamination to the end-product as well as avoiding posing risks to staff and the final consumer.

Furthermore, Barrera et al. (Reference Barrera, Gilbride, Mccarthy, Laursen, Bostan and Pushchak2012) studied the reduction and degradation of total organic carbon and bacteria from a secondary effluent of slaughterhouse wastewater using vacuum-ultraviolet and ultraviolet-C processes and their combination. Further studies have been conducted with the purpose of giving the most appropriate destination to the effluents (WRAP, 2013; Bustillo-Lecompte et al., Reference Bustillo-Lecompte, Mehrvar and Quiñones-Bolaños2014; Bustillo-Lecompte and Mehrvar, Reference Bustillo-Lecompte and Mehrvar2015; Coskun et al., Reference Coskun, Debik, Kabuk, Manav Demir, Basturk, Yildirim and Kucuk2016).

Alternatively, all the effluents could be collected and set to a biodigester for the purpose of generating energy. In addition, all blood collected could also be used in the production of biogas (Wang et al., Reference Wang, Hawkins, Kiepper and Das2018; Langone et al., Reference Langone, Ferrentino, Freddi and Andreottola2019) to generate energy that could be re-directed to the slaughterhouse itself for use in lighting and the heating–cooling systems (Marcos et al., Reference Marcos, Al-Kassir, Cuadros and Yusaf2017; Granada et al., Reference Granada, Hasan, Marder, Konrad, Vargas, Passaglia and Sperotto2018; Hernández et al., Reference Hernández, Jiménez and García2018; Martí-Herrero et al., Reference Martí-Herrero, Alvarez and Flores2018; Dababat and Shaheen, Reference Dababat and Shaheen2019; Yazdani et al., Reference Yazdani, Ebrahimi-Nik, Heidari and Abbaspour-Fard2019) or sold to the grid.

The term membrane bioreactor (MBR) defines a combination of biological processes and membrane separation. It combines a conventional activated sludge treatment (biological) with a physical solid–liquid separation membrane process (Urase, Reference Urase2016). This kind of treatment can be very useful in effluents from abattoirs with high biochemical oxygen demand (Garg and Chaudhry, Reference Garg and Chaudhry2017). A few animal slaughtering and meat processing manufacturers have adopted MBR technology. However, when employed, these technologies have offered an opportunity for food production facilities to achieve near net zero waste discharge (Theobald, Reference Theobald2017). MBR technology is a modern wastewater treatment technology having several benefits over conventional activated sludge processes (Judd, Reference Judd2010). It has also proven to be efficient for the treatment of many industrial wastewaters in recent years when treatment efficiency was an important consideration.

With the advancement of new technologies, different options for reuse and wastewater treatment have already been available in the market, being a trend for new food processing establishments, however, simple and less expensive methods still in use can also be adapted. Rainwater harvesting, an old but efficient method, is also a way to mitigate water consumption in cattle, pig, sheep and goat slaughterhouses. The recycling and reusing of rain water have the same application in washing the reception and waiting pens which do not require strict water quality standards. Napoli (Reference Napoli2015) showed that the use of rainwater harvesting systems also contributed to reducing the unnecessary consumption of potable water, reducing treatment costs (Goedert, Reference Goedert2012).

The special case of poultry wastewater

The amount of water used per bird varies between different processors and it also would depend on the size of the bird, method of stunning, slaughter, the degree of automation, operational control, amongst others parameters.

Poultry slaughterhouse wastewater is a class of wastewater which is heavily polluted with organic matter including proteins, blood residues, fats and feathers. In a poultry abattoir, the water consumption can be excessive. Matsumura and Mierzwa (Reference Matsumura and Mierzwa2008) evaluated a poultry slaughtering process with rational use and water reuse programs against cleaner production measures. It resulted in reducing the total water consumption by 14.9%. The savings generated allowed for gains in efficiency from 16.9 to 11.25 L per head. However, that result was only achieved when each step of the process was evaluated separately, hence, reinforcing the need to quantitatively ascertain all the stages of processing in question. Kist et al. (Reference Kist, Moutaqi and Machado2009) also evaluated the water consumption in a poultry slaughterhouse. They obtained a reduction of 13% of water use due to the implementation of practices of cleaner production.

At the reception of the birds, they should remain in climate-controlled waiting rooms before proceeding to slaughter. To meet the thermal comfort, depending on the weather and the climate of each country, the birds must be protected from wind, rain, sunlight and have adequate ventilation and moisture (Bailone et al., Reference Bailone, Roça, De Aguiar and Harris2016). When the cage's dimensions and density are adequate to allow good circulation of air, and the construction of the shed provides a suitable microclimate, the use of water by sprinklers could be reduced when the weather is hot.

In the stunning stage, some changes in the method of poultry processing could represent great savings in water consumption. For example, when using stunning by electronarcosis by water immersion there is always the need of a tank filled up with water which is changed every shift. During the hanging of be birds by their feet, such a tank allows the bird's head to touch the water which has an electric current. There could be water savings should it be replaced by gas stunning, which is common practice in many countries, such as England and the Netherlands (Bailone et al., Reference Bailone, Roça, De Aguiar and Harris2016). Alternatively, the birds could be subject to a dry electronarcosis as used in pig slaughter which is a technique already in use.

Concerning the stages of industrial slaughtering itself, half of the total water consumption is used in the scalding and plucking stages (Amorim et al., Reference Amorim, De Nardi and Del Nery2007). Regarding the scalding process, it is recommended a reduction in the size of the scalding tank which should account for the binomial time-temperature. Alternatively, a change in the conventional process from hot water immersion to a drier process, such as scalding by spraying hot water and steam could be considered. In the plucking stage which is considered a very dirty area, the collection of the feathers should be performed preferably by using the dry method, with the use of squeegees.

According to Amorim et al. (Reference Amorim, De Nardi and Del Nery2007), the evisceration stage represents 15% of total consumption of water (Table 2). In relation to evisceration, as well as in the slaughter of other species, it should be ensured that fat, oil and grease do not block the drains (WRAP, 2013), a very common problem when the machinery is not well regulated accounting for the size of the batch of animals. Therefore, trained labor is important to deliver adequate maintenance of equipment.

Table 2. Water consumption in a poultry slaughterhouse (adapted from Amorim et al., Reference Amorim, De Nardi and Del Nery2007).

Another important point, the pre-cooling is a stage in poultry slaughter that aims to reduce the temperature down to 7°C in order to decrease bacterial proliferation. It represents around 14% of total use of water in a poultry abattoir when made by immersion in cold water (Amorim et al., Reference Amorim, De Nardi and Del Nery2007) during which there are two large tanks filled up with cold water and ice being constantly renewed. The birds are immersed for about 30 min to an hour at this stage depending on the processing plant and the speed of slaughter. Using this method, it is recommended a decrease in water renewal flow in the cooling tanks taking into account the binomial time-temperature. Nonetheless, the best water saving alternative which is being used mainly in new establishments, is would be to replace the immersion pre-cooling system by refrigerated air pre-cooling. The air pre-cooling allows for the birds to pass a corridor where air cooling and sometimes air and water spray is also used (Bailone and Roça, Reference Bailone and Roça2017). Water used in scalding and pre-cooling can be reused in most poultry processing plants for flushing water to remove offal and feathers (Valta et al., Reference Valta, Moustakas, Sotiropoulos, Malamis and Haralambous2016).

The food industry faces great challenges in adopting alterative innovative techniques for the generation of industrial cold without the use of water. In air-conditioned chambers which correspond to large areas, for the purpose of cold generation, water-cooled ammonia refrigeration systems are commonly used (Bailone and Roça, Reference Bailone and Roça2017). The generation of cold in acclimatized rooms, such as the deboning room, should remain at a temperature close to 10°C. Yet more studies are needed aimed at alternative methods for the production of industrial cold.

Bailone et al. (Reference Bailone, Roça, De Aguiar and Harris2016) posited that based on a slaughterhouse processing 100,000 poultries daily some 80% water consumed could be saved along the main stages of slaughter only by modifying some key practices along the process. For example, by substituting electronarcosis stunning for controlled atmosphere; by scaling down the scalding tank and/or changing from water to steam scalding; replacing water-immersion pre-cooling for air-cooled pre-cooling, and reducing the water renewal in the cooling tanks. The reduction in these procedures would allow savings from 356,815 to 59,84 m3 day−1 in that case.

For better management of water in poultry slaughterhouses, it is recommended to install taps with automatic timed closing to minimize waste; use hoses for floor washing with pressurized nozzles; avoid the use of large amounts of treated water to remove residues with preferably using mechanical cleaning of solids; reuse of effluents from cleaner stages in areas where potable water quality is not needed. Finally, it is also recommended the reuse of cleaning washing in the prewash of residues that would be sent to produce tallow and flour for animal feed (Amorim et al., Reference Amorim, De Nardi and Del Nery2007; De Aguiar Camargo et al., Reference De Aguiar Camargo, Henkes and De Fátima Rossato2016). As discussed previously, water reuse and effluent reduction techniques can be adapted to the slaughter poultry from others species too.

Conclusions

Water is an essential resource during the production and processing of animal protein. The everyday management practice could be seriously affected by the increasing water scarcity due to the climate change and environmental degradation. The adoption of Cleaner Production Methods is a reality particularly for the animal origin product to improve its sustainability. Yet, its implementation requires governmental support in many meat-producing countries around the world to encourage the recycling and reuse of water as a matter of urgency.

The review of the literature throws light into many practices and identifies suggestions to enable the food industry to use water more sustainably. Consequently, companies are rewarded for implementing cost-effective measures and possible aggregation of value in the final product through becoming more sustainable.

Recommendations

• The company must initially create a team (may belong to the quality control sector);

• Then there should be training and division of tasks specific to each employee;

• A self-control program for the company's water management with clean method production (see BEST PRACTICES) and Action Plan should be prepared by the team to be used in case of deviations in the process;

• This program should contain in detail the company's water layout and processes to ensure efficient water management and be based on scientific technical studies.

• Application of self-control program by staff members through implementation, monitoring, corrective actions and verifications must be done daily;

• Constant meetings with presentation of results, assessment and elaboration of new goals.

Best practices

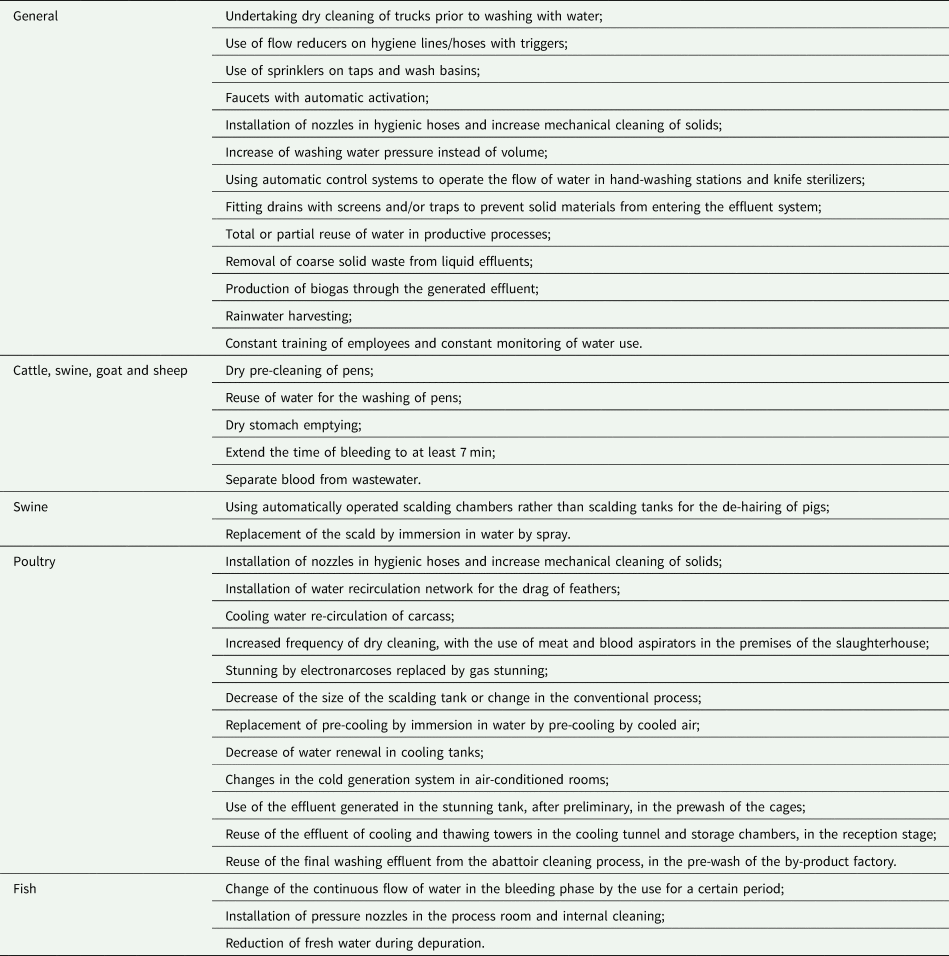

See Table 3.

Table 3. Main recommendations for reducing water consumption and generating effluents through cleaner production methods.

Acknowledgements

We thanks Dr José Antônio Perrella Balestieri, mechanical engineer professor of São Paulo State University, Guaratinguetá for the cooperation. This research did not receive any specific grant from funding agencies in the public, commercial or not-for-profit sectors.