1. Introduction

The impingement of a liquid droplet on another liquid has been studied extensively (Pumphrey & Elmore Reference Pumphrey and Elmore1990; Wang & Chen Reference Wang and Chen2000; Cossali et al. Reference Cossali, Marengo, Coghe and Zhdanov2004; Bisighini et al. Reference Bisighini, Cossali, Tropea and Roisman2010; Castillo-Orozco et al. Reference Castillo-Orozco, Davanlou, Choudhury and Kumar2015; Che & Matar Reference Che and Matar2018; Shaikh et al. Reference Shaikh, Toyofuku, Hoang and Marston2018). When a droplet impinges on a deep pool of the same liquid, e.g. a water droplet on a water bath (Engel Reference Engel1965), a crater and a crown-like structure are created in the target liquid. When a liquid droplet falls onto a solid surface, no crater can be created, and only a crown-like structure is formed (Che & Matar Reference Che and Matar2018; Shaikh et al. Reference Shaikh, Toyofuku, Hoang and Marston2018). In addition, various systems with differing miscibilities between the droplet and the target liquid have been investigated, such as water droplet–water pool and oil droplet–water pool systems (Jain et al. Reference Jain, Jalaal, Lohse and Van der Meer2019) and a water droplet–oil pool (Fujimatsu et al. Reference Fujimatsu, Fujita, Hirota and Okada2003; Xu, Wang & Lu Reference Xu, Wang and Lu2017). A more complex situation arises when a droplet impinges on a two-layer liquid. For example, Murphy et al. (Reference Murphy, Li, d'Albignac, Morra and Katz2015) studied a water drop impacting on oil-covered seawater and observed that the oil layer ruptures on impact. Another study (Wang et al. Reference Wang, Ji, Lin, Wei and Zou2019) found that such an impact produces oil–water emulsions.

In this study, we focused on the impingement of an oil droplet on a two-layered liquid: an oil layer on a deep pool of water. Such a configuration is important when considering the emulsification of oil following a spill in fresh water or seawater. To treat such spills, dispersant-containing droplets are typically released from a low-flying aircraft onto the oil layer on the water's surface (Lessard & DeMarco Reference Lessard and DeMarco2000; Fingas Reference Fingas2012). When a droplet impinges on a deep pool of liquid, the depth of the crater ![]() $d$ is proportional to the fourth root of the Froude number

$d$ is proportional to the fourth root of the Froude number ![]() $Fr\equiv U^2/gD$, where

$Fr\equiv U^2/gD$, where ![]() $U$ is the impact velocity,

$U$ is the impact velocity, ![]() $g$ is the acceleration due to gravity and

$g$ is the acceleration due to gravity and ![]() $D$ is the droplet diameter (Pumphrey & Elmore Reference Pumphrey and Elmore1990; Leng Reference Leng2001; Fedorchenko & Wang Reference Fedorchenko and Wang2004; Ray, Biswas & Sharma Reference Ray, Biswas and Sharma2015). However, such a scaling relation is not necessarily valid when an oil layer exists on top of the water.

$D$ is the droplet diameter (Pumphrey & Elmore Reference Pumphrey and Elmore1990; Leng Reference Leng2001; Fedorchenko & Wang Reference Fedorchenko and Wang2004; Ray, Biswas & Sharma Reference Ray, Biswas and Sharma2015). However, such a scaling relation is not necessarily valid when an oil layer exists on top of the water.

To define the scaling relationship in the presence of an oil layer, we constructed a typical experimental set-up for studying the impingement of a droplet on a liquid bath. We carefully deposited a layer of hexadecane on water, and a hexadecane droplet was then allowed to fall on the layer. We varied the diameter and impact velocity of the droplet and the thickness of the oil layer. We measured the depth of the crater as a function of ![]() $Fr$ and the dimensionless thickness of the oil layer. As the crater closes, a Worthington jet (Worthington Reference Worthington1908) is ejected, and the height of this jet

$Fr$ and the dimensionless thickness of the oil layer. As the crater closes, a Worthington jet (Worthington Reference Worthington1908) is ejected, and the height of this jet ![]() $\ell$ was also monitored.

$\ell$ was also monitored.

We found that the scaling relation between the depth of the crater and ![]() $Fr$ depended on the thickness of the oil layer. When the oil layer was thick, the measurements followed the classical model (Pumphrey & Elmore Reference Pumphrey and Elmore1990), that is

$Fr$ depended on the thickness of the oil layer. When the oil layer was thick, the measurements followed the classical model (Pumphrey & Elmore Reference Pumphrey and Elmore1990), that is

Therefore, we can interpret that, when the layer is sufficiently thick, it can be approximately considered as demonstrating an infinite thickness.

However, when the oil layer was thin, our measurements deviated from the classical model. This is because the ‘second’ (oil–water) interface will play a role in such a situation. For quantitative characterization, we established a dual-interface model. Our model was based on the work of Engel (Reference Engel1965), but it was modified to take into account the presence of the second interface between the oil layer and the underlying water in addition to the first one between the air and the oil layer. When a droplet impinges on the target liquid and creates a crater, the gravitational potential energy of the fluid displaced by the impact depends on the density of the fluid. Therefore, it is correctly estimated only when both the oil and the water are considered. The model allows us to calculate the change in the surface energy due to the deformation of the second interface. The combination of these two effects yielded the correct scaling relationship for our measurements.

Using the dual-interface model, we can estimate the height of the jet and the vertical position at which the pinch-off of a child droplet will occur. First, we define an effective surface tension ![]() $\sigma _e$ and an effective Weber number

$\sigma _e$ and an effective Weber number ![]() $We_e$ such that

$We_e$ such that ![]() $We_e=\rho _{o} U^2 D/\sigma _e$, where

$We_e=\rho _{o} U^2 D/\sigma _e$, where ![]() $\rho _o$ is the density of the oil. The height of the jet increases with

$\rho _o$ is the density of the oil. The height of the jet increases with ![]() $We_e$ or, equivalently, the oil layer thickness. The pinch-off position is determined by the ejection speed of the jet, which is correlated with the jet height (Ghabache, Séon & Antkowiak Reference Ghabache, Séon and Antkowiak2014; Kim, Kim & Jung Reference Kim, Kim and Jung2018). The dual-interface model therefore allows us to classify the pinch-off modes.

$We_e$ or, equivalently, the oil layer thickness. The pinch-off position is determined by the ejection speed of the jet, which is correlated with the jet height (Ghabache, Séon & Antkowiak Reference Ghabache, Séon and Antkowiak2014; Kim, Kim & Jung Reference Kim, Kim and Jung2018). The dual-interface model therefore allows us to classify the pinch-off modes.

The following sections describe our experimental set-up and conditions (§ 2), the overview of the sequential images showing the impact process (§ 3), the details of craters (§ 3.1), a dual-interface model to explain our results (§ 3.2) and the details of jets (§ 3.3). Finally, we summarize and conclude the whole results (§ 4).

2. Experimental set-up

Our experiments were carried out using the apparatus shown in figure 1. The set-up is similar to those used in other experimental studies (Castillo-Orozco et al. Reference Castillo-Orozco, Davanlou, Choudhury and Kumar2015; Che & Matar Reference Che and Matar2018; Jain et al. Reference Jain, Jalaal, Lohse and Van der Meer2019). The equipment comprises two parts: a droplet dispenser and an acrylic bath. An oil droplet prepared by the dispenser falls onto the target liquid in the acrylic bath (Smolka & McLaughlin Reference Smolka and McLaughlin2019). The impact between the droplet and the target liquid produces a splash, which is recorded by high-speed video imaging. For the oil component, we used hexadecane, which exhibits the following properties: density ![]() $\rho _{o}=770\ \textrm {kg}\ \textrm {m}^{-3}$, interfacial tension with air

$\rho _{o}=770\ \textrm {kg}\ \textrm {m}^{-3}$, interfacial tension with air ![]() $\sigma _{oa}= 27.2\ \textrm {mN}\ \textrm {m}^{-1}$, interfacial tension with water

$\sigma _{oa}= 27.2\ \textrm {mN}\ \textrm {m}^{-1}$, interfacial tension with water ![]() $\sigma _{ow}=55.2\ \textrm {mN}\ \textrm {m}^{-1}$ and kinematic viscosity

$\sigma _{ow}=55.2\ \textrm {mN}\ \textrm {m}^{-1}$ and kinematic viscosity ![]() $\nu _{o}=3.95\times 10^{-6}\ \textrm {m}^2\ \textrm {s}^{-1}$ at room temperature (Goebel & Lunkenheimer Reference Goebel and Lunkenheimer1999).

$\nu _{o}=3.95\times 10^{-6}\ \textrm {m}^2\ \textrm {s}^{-1}$ at room temperature (Goebel & Lunkenheimer Reference Goebel and Lunkenheimer1999).

Figure 1. A schematic diagram of the experimental set-up. Oil droplets are prepared by pushing oil through a needle using the syringe pump. Each droplet falls onto an oil layer on water, and the event is recorded by a high-speed camera. The impact velocity is varied by changing the height of the needle using a translational stage.

An oil droplet is produced by pushing the oil through a needle using a syringe pump. The syringe pump is connected to the needle and pushes oil at ![]() $1.67\ \mathrm {\mu }\textrm {l}\ \textrm {s}^{-1}$. At the tip of the needle, a pendent droplet grows in time and is released when the gravitational force becomes greater than the surface tension force, i.e.

$1.67\ \mathrm {\mu }\textrm {l}\ \textrm {s}^{-1}$. At the tip of the needle, a pendent droplet grows in time and is released when the gravitational force becomes greater than the surface tension force, i.e. ![]() $\rho _{o}Vg={\rm \pi} \sigma _{oa}D_n$, where

$\rho _{o}Vg={\rm \pi} \sigma _{oa}D_n$, where ![]() $V$ is the volume of the droplet and

$V$ is the volume of the droplet and ![]() $D_n$ is the diameter of the needle. Therefore, the diameter of the falling droplet

$D_n$ is the diameter of the needle. Therefore, the diameter of the falling droplet ![]() $D$ is obtained using

$D$ is obtained using

\begin{equation} D=\left(\frac{6\sigma_{oa}D_n}{\rho_{o}g}\right)^{{1}/{3}}. \end{equation}

\begin{equation} D=\left(\frac{6\sigma_{oa}D_n}{\rho_{o}g}\right)^{{1}/{3}}. \end{equation}

In this study, we used three different needles with ![]() $D_n=0.380$,

$D_n=0.380$, ![]() $0.750$ and

$0.750$ and ![]() $1.60\ \textrm {mm}$ to produce droplets of

$1.60\ \textrm {mm}$ to produce droplets of ![]() $D=2.02$,

$D=2.02$, ![]() $2.53$ and

$2.53$ and ![]() $3.26\ \textrm {mm}$, respectively.

$3.26\ \textrm {mm}$, respectively.

The impact velocity was varied by changing the height of the needle ![]() $z_0$. For

$z_0$. For ![]() $z_0=50$,

$z_0=50$, ![]() $250$,

$250$, ![]() $450$ and

$450$ and ![]() $750\ \text {mm}$, we established velocities of

$750\ \text {mm}$, we established velocities of ![]() $U \simeq 1.0$,

$U \simeq 1.0$, ![]() $2.2$,

$2.2$, ![]() $2.8$ and

$2.8$ and ![]() $3.5\ \textrm {m}\ \textrm {s}^{-1}$, respectively. The calculation of

$3.5\ \textrm {m}\ \textrm {s}^{-1}$, respectively. The calculation of ![]() $U$ was based on a mathematical model in which only the gravitational force and the form drag are considered (Pumphrey & Elmore Reference Pumphrey and Elmore1990), that is,

$U$ was based on a mathematical model in which only the gravitational force and the form drag are considered (Pumphrey & Elmore Reference Pumphrey and Elmore1990), that is,

\begin{equation} U=U_t\left[1-\exp\left(-\frac{2g}{U_t^2}z_0\right)\right]^{{1}/{2}}, \end{equation}

\begin{equation} U=U_t\left[1-\exp\left(-\frac{2g}{U_t^2}z_0\right)\right]^{{1}/{2}}, \end{equation}

where the terminal velocity ![]() $U_t=(4\rho _{o}Dg/3\rho _{a}C_d)^{1/2}$, in which

$U_t=(4\rho _{o}Dg/3\rho _{a}C_d)^{1/2}$, in which ![]() $\rho _a$ is the density of air and

$\rho _a$ is the density of air and ![]() $C_d$ is the drag coefficient of a sphere. We also made the measurement of

$C_d$ is the drag coefficient of a sphere. We also made the measurement of ![]() $U$ by analysing video frames recorded by a high-speed camera, whose set-up is discussed later. The measurement matched the calculation using (2.2) within 4 %, and this agreement also confirms that the estimation of

$U$ by analysing video frames recorded by a high-speed camera, whose set-up is discussed later. The measurement matched the calculation using (2.2) within 4 %, and this agreement also confirms that the estimation of ![]() $D$ using (2.1) is correct.

$D$ using (2.1) is correct.

The tank was filled with water, and hexadecane was gently deposited on the surface using a syringe. We note that the tank was thoroughly cleaned before each run to ensure that all surfaces are free of contamination. As the oil is deposited, it spreads to form a thin layer of thickness ![]() $H$. We used four different thicknesses of oil layer: (i) no oil layer (

$H$. We used four different thicknesses of oil layer: (i) no oil layer (![]() ${\bar {H}}=0$), (ii) a thinner oil layer (

${\bar {H}}=0$), (ii) a thinner oil layer (![]() $\bar {H}=0.98\ \textrm {mm}$), (iii) a thin oil layer (

$\bar {H}=0.98\ \textrm {mm}$), (iii) a thin oil layer (![]() $\bar {H}=2.16\ \textrm {mm}$) and (iv) a thick oil layer (

$\bar {H}=2.16\ \textrm {mm}$) and (iv) a thick oil layer (![]() $\bar {H}=5.51\ \textrm {mm}$), where the bar on

$\bar {H}=5.51\ \textrm {mm}$), where the bar on ![]() $H$ indicates that averages of various runs were taken. However, we defined and used the non-dimensional thickness of the oil layer

$H$ indicates that averages of various runs were taken. However, we defined and used the non-dimensional thickness of the oil layer ![]() $H'=H/D$, and

$H'=H/D$, and ![]() $\overline {H'}$ as the average of

$\overline {H'}$ as the average of ![]() $H'$ for all tested cases, because this is more relevant for physical description and analysis. The parameter

$H'$ for all tested cases, because this is more relevant for physical description and analysis. The parameter ![]() $\overline {H'}$ is used to describe and compare the impingement results depending on the thickness of the oil layer in §§ 3.1–3.3. For thinner oil layers

$\overline {H'}$ is used to describe and compare the impingement results depending on the thickness of the oil layer in §§ 3.1–3.3. For thinner oil layers ![]() $\overline {H'}=0.38$, for thin oil layers

$\overline {H'}=0.38$, for thin oil layers ![]() $\overline {H'}=0.81$, and for thick oil layers

$\overline {H'}=0.81$, and for thick oil layers ![]() $\overline {H'}=2.21$. A full list of the experimental conditions is summarized in table 1. We also note that the size of the tank is large enough (

$\overline {H'}=2.21$. A full list of the experimental conditions is summarized in table 1. We also note that the size of the tank is large enough (![]() $150\ \textrm {mm}\times 150\ \textrm {mm}\times 150\ \textrm {mm}$) that the reflection of capillary waves by the walls of the tank is negligible (Yilmaz & Nelson Reference Yilmaz and Nelson2014).

$150\ \textrm {mm}\times 150\ \textrm {mm}\times 150\ \textrm {mm}$) that the reflection of capillary waves by the walls of the tank is negligible (Yilmaz & Nelson Reference Yilmaz and Nelson2014).

Table 1. Experimental conditions. We tested 12 cases, composed of three different values of ![]() $D$ and four different values of

$D$ and four different values of ![]() $U$. In each case, the droplet impacted four different thicknesses of oil layer. The thicknesses of the oil layers are shown. We categorized the thickness of oil layers by taking an average of all cases such that

$U$. In each case, the droplet impacted four different thicknesses of oil layer. The thicknesses of the oil layers are shown. We categorized the thickness of oil layers by taking an average of all cases such that ![]() $\overline {H'}=0$ (no oil layers), 0.38 (thinner oil layers), 0.81 (thin oil layers) and 2.21 (thick oil layers).

$\overline {H'}=0$ (no oil layers), 0.38 (thinner oil layers), 0.81 (thin oil layers) and 2.21 (thick oil layers).

We recorded shadowgraphic images using a high-speed camera (FASTCAM Mini UX100, Photron) with a zoom lens (MLH-10X, Computar). The droplet was illuminated by a light-emitting diode lamp (E4-1.2BF, Alpha Lite Co. Ltd) installed on the opposite side of the tank to the camera. The images were captured at 10 000 frames per second. The video frames were then processed by using software written in-house using MATLAB (MathWorks), from which we directly measured the length scales relevant to the droplet impact, such as the depth of the crater and the height of the Worthington jet.

Henceforth, we will use the primed variables to denote non-dimensional quantities, i.e. ![]() $H'=H/D$,

$H'=H/D$, ![]() $d'=d/D$ and

$d'=d/D$ and ![]() $\ell '=\ell /D$.

$\ell '=\ell /D$.

3. Results and discussion

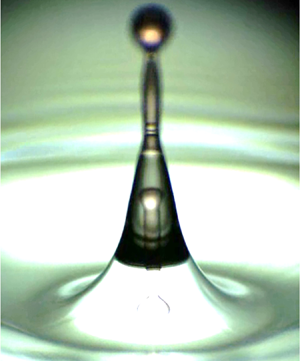

In figure 2, we present four sets of sequential images showing the impact process. Specifically, these sets show the impingement of an oil droplet of ![]() $D=3.26\ \textrm {mm}$ on the underlying oil layers at an impact velocity

$D=3.26\ \textrm {mm}$ on the underlying oil layers at an impact velocity ![]() $U=2.17\ \textrm {m}\ \textrm {s}^{-1}$ (case C2 in table 1). The non-dimensional thicknesses of the oil layer

$U=2.17\ \textrm {m}\ \textrm {s}^{-1}$ (case C2 in table 1). The non-dimensional thicknesses of the oil layer ![]() $H'$ were 0, 0.33, 0.77 and 1.60.

$H'$ were 0, 0.33, 0.77 and 1.60.

Figure 2. The impact process of the case C2 (![]() $D=3.26\ \textrm {mm}$ and

$D=3.26\ \textrm {mm}$ and ![]() $U=2.17\ \textrm {m}\ \textrm {s}^{-1}$). The non-dimensional thicknesses

$U=2.17\ \textrm {m}\ \textrm {s}^{-1}$). The non-dimensional thicknesses ![]() $H'\equiv H/D$ were: (a)

$H'\equiv H/D$ were: (a) ![]() $H'= 0$, no oil layer; (b)

$H'= 0$, no oil layer; (b) ![]() $H'= 0.33$, thinner oil layer; (c)

$H'= 0.33$, thinner oil layer; (c) ![]() $H'= 0.77$, thin oil layer; and (d)

$H'= 0.77$, thin oil layer; and (d) ![]() $H'= 1.60$, thick oil layer. The coloured boxes indicate the crater (red), crown-like structure (blue) and Worthington jet (magenta), and the arrows indicate the oil layer (cyan) and child droplets (magenta).

$H'= 1.60$, thick oil layer. The coloured boxes indicate the crater (red), crown-like structure (blue) and Worthington jet (magenta), and the arrows indicate the oil layer (cyan) and child droplets (magenta).

The impact process presented in figure 2 is, in general, similar to the classical impingement between a water droplet and a water bath (Prosperetti & Oguz Reference Prosperetti and Oguz1993; Leng Reference Leng2001; Manzello & Yang Reference Manzello and Yang2002; Michon, Josserand & Séon Reference Michon, Josserand and Séon2017). As the droplet pushes the target liquid, a crater is formed below the original level of the target liquid, and a crown-like structure rises above the rim of the crater (Macklin & Metaxas Reference Macklin and Metaxas1976). Shortly after the impact, the crater closes, and a Worthington jet is ejected from the point of impact. These features, both the formation of the crater and the ejection of the Worthington jet, are very typical (Ghabache et al. Reference Ghabache, Séon and Antkowiak2014; Michon et al. Reference Michon, Josserand and Séon2017) for the impact of a drop of liquid with the surface of another liquid.

Despite overall similarities, we found that the physical process of the impact was affected by the thickness of the oil layer in a non-monotonic manner. For example, both the depth of the crater ![]() $d$ and the height of the jet

$d$ and the height of the jet ![]() $\ell$ are greater when

$\ell$ are greater when ![]() $H'=0$ and

$H'=0$ and ![]() $H'=1.60$ (figure 2a,d) than when

$H'=1.60$ (figure 2a,d) than when ![]() $H'=0.33$ or

$H'=0.33$ or ![]() $H'=0.77$ (figure 2b,c). This is intriguing, because we speculate that the oil layer acts to attenuate the kinetic energy of the impact, and a thicker oil layer produces a shallower crater. However, this expectation is not borne out by observations. Another example is the pinch-off time of child droplets, which is significantly delayed when the thickness of the oil layer is neither small nor large. In figure 2, it can be seen that the pinch-off occurs at 80 ms when

$H'=0.77$ (figure 2b,c). This is intriguing, because we speculate that the oil layer acts to attenuate the kinetic energy of the impact, and a thicker oil layer produces a shallower crater. However, this expectation is not borne out by observations. Another example is the pinch-off time of child droplets, which is significantly delayed when the thickness of the oil layer is neither small nor large. In figure 2, it can be seen that the pinch-off occurs at 80 ms when ![]() $H'=0.77$ but at 50 ms when

$H'=0.77$ but at 50 ms when ![]() $H'=0$ or

$H'=0$ or ![]() $H'=1.60$. These non-monotonic dependences are also observed in other cases, for example case C4 in table 1 (see figure 3). These observations indicate that the oil layer cannot be approximated as a simple attenuator of the kinetic energy of an impinging droplet. As noted, we developed a dual-interface model, where the finite thickness of the oil layer is considered. This model was compared with the quantitative measurements from experiments.

$H'=1.60$. These non-monotonic dependences are also observed in other cases, for example case C4 in table 1 (see figure 3). These observations indicate that the oil layer cannot be approximated as a simple attenuator of the kinetic energy of an impinging droplet. As noted, we developed a dual-interface model, where the finite thickness of the oil layer is considered. This model was compared with the quantitative measurements from experiments.

Figure 3. The impact process of the case C4 (![]() $D=3.26\ \textrm {mm}$ and

$D=3.26\ \textrm {mm}$ and ![]() $U=3.59\ \textrm {m}\ \textrm {s}^{-1}$). The non-dimensional thicknesses

$U=3.59\ \textrm {m}\ \textrm {s}^{-1}$). The non-dimensional thicknesses ![]() $H'\equiv H/D$ were: (a)

$H'\equiv H/D$ were: (a) ![]() $H'= 0$, no oil layer; (b)

$H'= 0$, no oil layer; (b) ![]() $H'= 0.31$, thinner oil layer; (c)

$H'= 0.31$, thinner oil layer; (c) ![]() $H'= 0.58$, thin oil layer; and (d)

$H'= 0.58$, thin oil layer; and (d) ![]() $H'= 1.64$, thick oil layer. The coloured boxes indicate the crater (red), crown-like structure (blue) and Worthington jet (magenta), and the arrows indicate the oil layer (cyan) and child droplets (magenta).

$H'= 1.64$, thick oil layer. The coloured boxes indicate the crater (red), crown-like structure (blue) and Worthington jet (magenta), and the arrows indicate the oil layer (cyan) and child droplets (magenta).

3.1. The depth of the crater

In figure 4(a), we present the maximum depth of the crater ![]() $d'=d/D$ as a function of the Froude number

$d'=d/D$ as a function of the Froude number ![]() $Fr= U^2/gD$ for four different thicknesses of oil layer. Each data point in the figure represents the average of three repeated measurements, and the error bars show the spreads of the measurements. It is noticeable in figure 4(a) that the relationship between

$Fr= U^2/gD$ for four different thicknesses of oil layer. Each data point in the figure represents the average of three repeated measurements, and the error bars show the spreads of the measurements. It is noticeable in figure 4(a) that the relationship between ![]() $d'$ and

$d'$ and ![]() $Fr$ depends on the thickness of the oil layer. For a thick oil layer, the measurement shows that

$Fr$ depends on the thickness of the oil layer. For a thick oil layer, the measurement shows that ![]() $d'$ follows the scaling relation in (1.1),

$d'$ follows the scaling relation in (1.1), ![]() $d'\sim Fr^{1/4}$, which is observed for the impingement of a liquid droplet onto the same liquid of large depth (Pumphrey & Elmore Reference Pumphrey and Elmore1990). Physically, (1.1) is justified by the energetic analysis where the kinetic energy of the incoming droplet is transferred only to gravitational potential energy. Our data indicate that, when the oil layer is thick enough, it can be effectively approximated as a deep pool. In this condition, the underlying water bath does not influence the impact process, and we assume that

$d'\sim Fr^{1/4}$, which is observed for the impingement of a liquid droplet onto the same liquid of large depth (Pumphrey & Elmore Reference Pumphrey and Elmore1990). Physically, (1.1) is justified by the energetic analysis where the kinetic energy of the incoming droplet is transferred only to gravitational potential energy. Our data indicate that, when the oil layer is thick enough, it can be effectively approximated as a deep pool. In this condition, the underlying water bath does not influence the impact process, and we assume that ![]() $H'>1.60$ is not distinguishable from the case where

$H'>1.60$ is not distinguishable from the case where ![]() $H'\rightarrow \infty$, considering that

$H'\rightarrow \infty$, considering that ![]() $H'=1.60$ for case C2.

$H'=1.60$ for case C2.

Figure 4. The dimensionless maximum depth of the crater, ![]() $d'$, with respect to the Froude number

$d'$, with respect to the Froude number ![]() $Fr \equiv U^2/gD$.

$Fr \equiv U^2/gD$. ![]() $(a)$ The measurement of

$(a)$ The measurement of ![]() $d'$ for

$d'$ for ![]() $\overline {H'}=0$,

$\overline {H'}=0$, ![]() $0.38$,

$0.38$, ![]() $0.81$ and

$0.81$ and ![]() $2.21$.

$2.21$. ![]() $(b)$ The calculated roots of (3.7), where

$(b)$ The calculated roots of (3.7), where ![]() $d'_{e},$ is the dimensionless maximum depth of the crater considering the extra surface energy of the second interface. The dashed lines were drawn to clarify the slope of 1/4.

$d'_{e},$ is the dimensionless maximum depth of the crater considering the extra surface energy of the second interface. The dashed lines were drawn to clarify the slope of 1/4.

However, for the thin or thinner oil layers, the scaling relation in (1.1) is no longer valid. Instead, ![]() $d'$ is much shallower than in the case of the thick oil layer, as shown in figure 4(a). In these cases, a simple energy balance between the kinetic energy of the droplet and the gravitational potential energy of the crater is not valid. Instead, the kinetic energy of the incoming droplet is effectively reduced by the presence of the oil layer, and this effective reduction is more (less) substantial at larger (smaller) scales. This observation indicates that the surface energy from the deformation of the interface is not the sole source of the attenuation, and the gravitational potential energy of the two fluids must be considered individually.

$d'$ is much shallower than in the case of the thick oil layer, as shown in figure 4(a). In these cases, a simple energy balance between the kinetic energy of the droplet and the gravitational potential energy of the crater is not valid. Instead, the kinetic energy of the incoming droplet is effectively reduced by the presence of the oil layer, and this effective reduction is more (less) substantial at larger (smaller) scales. This observation indicates that the surface energy from the deformation of the interface is not the sole source of the attenuation, and the gravitational potential energy of the two fluids must be considered individually.

The scaling relation also fails when there is no oil layer. In this case, considering the miscibility between the impinging droplet and the target liquid is necessary, and a spreading coefficient ![]() $S=\sigma _{ta}-\sigma _{td}-\sigma _{da}$, where the subscripts

$S=\sigma _{ta}-\sigma _{td}-\sigma _{da}$, where the subscripts ![]() $d$,

$d$, ![]() $a$ and

$a$ and ![]() $t$ represent the droplet, air and target liquid, respectively. In detail, when no oil layer (

$t$ represent the droplet, air and target liquid, respectively. In detail, when no oil layer (![]() $H'=0$) exists, the impinging droplet and the target liquid are immiscible, unlike in a classical miscible drop impact. Jain et al. (Reference Jain, Jalaal, Lohse and Van der Meer2019) shows that the scaling relation in (1.1) is also valid when a silicone oil droplet impinges onto water, even though the impinging droplet and the target liquid are immiscible. However, we used hexadecane oil as the impinging droplet, which exhibits a negative spreading coefficient on water (

$H'=0$) exists, the impinging droplet and the target liquid are immiscible, unlike in a classical miscible drop impact. Jain et al. (Reference Jain, Jalaal, Lohse and Van der Meer2019) shows that the scaling relation in (1.1) is also valid when a silicone oil droplet impinges onto water, even though the impinging droplet and the target liquid are immiscible. However, we used hexadecane oil as the impinging droplet, which exhibits a negative spreading coefficient on water (![]() $S=\sigma _{wa}-\sigma _{wo}-\sigma _{oa}\simeq -10\ \textrm {mN}\ \textrm {m}^{-1}<0$, where

$S=\sigma _{wa}-\sigma _{wo}-\sigma _{oa}\simeq -10\ \textrm {mN}\ \textrm {m}^{-1}<0$, where ![]() $\sigma _{wa}=72\ \textrm {mN}\ \textrm {m}^{-1}$). This is in contrast to silicone oil, which exhibits a positive spreading coefficient on water (

$\sigma _{wa}=72\ \textrm {mN}\ \textrm {m}^{-1}$). This is in contrast to silicone oil, which exhibits a positive spreading coefficient on water (![]() $S\simeq 15\ \textrm {mN}\ \textrm {m}^{-1}>0$) (Goebel & Lunkenheimer Reference Goebel and Lunkenheimer1999; Boreyko et al. Reference Boreyko, Polizos, Datskos, Sarles and Collier2014).

$S\simeq 15\ \textrm {mN}\ \textrm {m}^{-1}>0$) (Goebel & Lunkenheimer Reference Goebel and Lunkenheimer1999; Boreyko et al. Reference Boreyko, Polizos, Datskos, Sarles and Collier2014).

3.2. The dual-interface model

To quantitatively account for the presence of the oil layer, we present a simple geometric model, as shown in figure 5, where the target liquid consists of two immiscible fluids. We assume that, as an oil droplet of size ![]() $D$ impinges on the target liquid, a hemispherical crater of radius

$D$ impinges on the target liquid, a hemispherical crater of radius ![]() $d$ is formed. Before the collision, the kinetic energy of the incoming droplet is

$d$ is formed. Before the collision, the kinetic energy of the incoming droplet is

After the collision, the gravitational potential energy of the displaced fluid is expressed as

where ![]() $\rho _t$ is the density of the target liquid,

$\rho _t$ is the density of the target liquid, ![]() $V_c$ is the volume of the crater and

$V_c$ is the volume of the crater and ![]() $d_c$ is the centroid of the crater. The minus sign indicates that the displacement of the target liquid subtracts

$d_c$ is the centroid of the crater. The minus sign indicates that the displacement of the target liquid subtracts ![]() $E_p$ from the system. We then use

$E_p$ from the system. We then use ![]() $V_c=\int _{z_1}^{z_2} {\rm \pi}(d^2-z^2)\ \textrm {d}z$ and

$V_c=\int _{z_1}^{z_2} {\rm \pi}(d^2-z^2)\ \textrm {d}z$ and ![]() $d_c=({1}/{V_c})\int _{z_1}^{z_2} {\rm \pi}(d^2-z^2) z\ \textrm {d}z$, where

$d_c=({1}/{V_c})\int _{z_1}^{z_2} {\rm \pi}(d^2-z^2) z\ \textrm {d}z$, where ![]() $z_1$ and

$z_1$ and ![]() $z_2$ denote the vertical range of the integral. When no oil layer (

$z_2$ denote the vertical range of the integral. When no oil layer (![]() $H=0$) or a thick oil layer (

$H=0$) or a thick oil layer (![]() $H>d$) exists, the range of the integral is simply

$H>d$) exists, the range of the integral is simply ![]() $[-d,0]$ to cover the whole of the hemispherical crater, and we obtain

$[-d,0]$ to cover the whole of the hemispherical crater, and we obtain ![]() $V_c=(2/3){\rm \pi} d^3$ and

$V_c=(2/3){\rm \pi} d^3$ and ![]() $d_c=-(3/8)d$. Therefore,

$d_c=-(3/8)d$. Therefore,

\begin{equation} E_p= \begin{cases} \dfrac{\rm \pi}{4}\rho_wg d^4 & \text{for}\ H=0, \\ \dfrac{\rm \pi}{4}\rho_og d^4 & \text{for}\ H>d, \end{cases} \end{equation}

\begin{equation} E_p= \begin{cases} \dfrac{\rm \pi}{4}\rho_wg d^4 & \text{for}\ H=0, \\ \dfrac{\rm \pi}{4}\rho_og d^4 & \text{for}\ H>d, \end{cases} \end{equation}

where ![]() $\rho _w$ is the density of water. When the thickness of the oil layer is neither zero nor thick enough, i.e.

$\rho _w$ is the density of water. When the thickness of the oil layer is neither zero nor thick enough, i.e. ![]() $0<H<d$, the integral is divided into two ranges to cover the oil part and the water part. Therefore,

$0<H<d$, the integral is divided into two ranges to cover the oil part and the water part. Therefore,

\begin{align} E_p&=-\rho_o g \int_{-H}^0 {\rm \pi}(d^2-z^2)z\ \textrm{d}z -\rho_w g \int_{-d}^{-H} {\rm \pi}(d^2-z^2)z\ \textrm{d}z\nonumber\\ &=\frac{\rm \pi}{4}\rho_o g d^4 + \frac{\rm \pi}{4}(\rho_w-\rho_o)g(d^2-H^2)^2. \end{align}

\begin{align} E_p&=-\rho_o g \int_{-H}^0 {\rm \pi}(d^2-z^2)z\ \textrm{d}z -\rho_w g \int_{-d}^{-H} {\rm \pi}(d^2-z^2)z\ \textrm{d}z\nonumber\\ &=\frac{\rm \pi}{4}\rho_o g d^4 + \frac{\rm \pi}{4}(\rho_w-\rho_o)g(d^2-H^2)^2. \end{align}

We note that (3.4) converges to (3.3) as ![]() $H\rightarrow 0$ or

$H\rightarrow 0$ or ![]() $H\rightarrow d$.

$H\rightarrow d$.

Figure 5. A dual-interface model, showing oil–air interface (red) and oil–water interface (blue). ![]() $(a)$ When no oil layer exists, the surface area to be considered is the sum of the area of the crater. The surface area of the deformed impinging droplet is neglected.

$(a)$ When no oil layer exists, the surface area to be considered is the sum of the area of the crater. The surface area of the deformed impinging droplet is neglected. ![]() $(b)$ When the thickness of the oil layer is comparable to the size of the crater, the deformation of the second interface between the oil and the water needs to be considered.

$(b)$ When the thickness of the oil layer is comparable to the size of the crater, the deformation of the second interface between the oil and the water needs to be considered. ![]() $(c)$ When the oil layer is thick enough, the second interface does not contribute to the energetic analysis.

$(c)$ When the oil layer is thick enough, the second interface does not contribute to the energetic analysis. ![]() $(d)$ The calculation of (3.5) using

$(d)$ The calculation of (3.5) using ![]() $\sigma _{wa}=72\ \textrm {mN}\ \textrm {m}^{-1}$,

$\sigma _{wa}=72\ \textrm {mN}\ \textrm {m}^{-1}$, ![]() $\sigma _{ow}=55.2\ \textrm {mN}\ \textrm {m}^{-1}$ and

$\sigma _{ow}=55.2\ \textrm {mN}\ \textrm {m}^{-1}$ and ![]() $\sigma _{oa}=27.2\ \textrm {mN}\ \textrm {m}^{-1}$. The solid line is (3.5). We note that the model is continuous except at

$\sigma _{oa}=27.2\ \textrm {mN}\ \textrm {m}^{-1}$. The solid line is (3.5). We note that the model is continuous except at ![]() $H/d=0$.

$H/d=0$.

Next, we consider the change in the surface energy before and after the impingement. As shown in figure 5, the target liquid exhibits two interfaces when ![]() $H\neq 0$, the first interface being that between the air and the oil, and the second interface being that between the oil layer and the water. When

$H\neq 0$, the first interface being that between the air and the oil, and the second interface being that between the oil layer and the water. When ![]() $H=0$, the target liquid exhibits only the first interface between air and water. We neglect the deformation of the impinging droplet when there is no oil layer, since the surface area of the deformed droplet is much smaller than the surface area of the crater. When

$H=0$, the target liquid exhibits only the first interface between air and water. We neglect the deformation of the impinging droplet when there is no oil layer, since the surface area of the deformed droplet is much smaller than the surface area of the crater. When ![]() $H=0$ or

$H=0$ or ![]() $H>d$, only the first interface is deformed. In this case, the change in the surface energy is obtained by subtracting the original surface area before the impact,

$H>d$, only the first interface is deformed. In this case, the change in the surface energy is obtained by subtracting the original surface area before the impact, ![]() ${\rm \pi} d^2$, from the area of the hemispherical crater,

${\rm \pi} d^2$, from the area of the hemispherical crater, ![]() $2{\rm \pi} d^2$. Therefore, the change in the surface energy is simply

$2{\rm \pi} d^2$. Therefore, the change in the surface energy is simply ![]() $\Delta E_s=\sigma {\rm \pi}d^2$, where

$\Delta E_s=\sigma {\rm \pi}d^2$, where ![]() $\sigma$ is the surface tension of the first interface: either the surface tension between water and air

$\sigma$ is the surface tension of the first interface: either the surface tension between water and air ![]() $\sigma _{wa}$ or that between oil and air

$\sigma _{wa}$ or that between oil and air ![]() $\sigma _{oa}$. Second, when

$\sigma _{oa}$. Second, when ![]() $0<H<d$, both the first and the second interfaces are deformed. In this model, we assume that the first interface is deformed to become hemispherical and that the second interface is deformed to follow the first interface where

$0<H<d$, both the first and the second interfaces are deformed. In this model, we assume that the first interface is deformed to become hemispherical and that the second interface is deformed to follow the first interface where ![]() $-d<z<-H$. The extra surface area of the second interface is obtained by subtracting the smaller plane circle,

$-d<z<-H$. The extra surface area of the second interface is obtained by subtracting the smaller plane circle, ![]() ${\rm \pi} (d^2-H^2)$, from the area of the hemispherical cap,

${\rm \pi} (d^2-H^2)$, from the area of the hemispherical cap, ![]() $\int _0^{2{\rm \pi} }\ \textrm {d}\phi \int _0^{\theta '} d^2\sin \theta \ \textrm {d}\theta = 2{\rm \pi} (d^2-dH)$, where

$\int _0^{2{\rm \pi} }\ \textrm {d}\phi \int _0^{\theta '} d^2\sin \theta \ \textrm {d}\theta = 2{\rm \pi} (d^2-dH)$, where ![]() $\theta '=\cos ^{-1}(H/d)$.

$\theta '=\cos ^{-1}(H/d)$.

Summing up, the change in the surface energy is expressed using an effective surface tension ![]() $\sigma _{e}$ such that

$\sigma _{e}$ such that ![]() $\Delta E_s = \sigma _{e} {\rm \pi}d^2$, where

$\Delta E_s = \sigma _{e} {\rm \pi}d^2$, where

\begin{equation} \sigma_e=\begin{cases} \sigma_{wa} & \text{for}\ H=0,\\ \sigma_{oa}+\sigma_{ow}(1-H/d)^2 & \text{for}\ 0 < H < d,\\ \sigma_{oa} & \text{for}\ H > d. \end{cases} \end{equation}

\begin{equation} \sigma_e=\begin{cases} \sigma_{wa} & \text{for}\ H=0,\\ \sigma_{oa}+\sigma_{ow}(1-H/d)^2 & \text{for}\ 0 < H < d,\\ \sigma_{oa} & \text{for}\ H > d. \end{cases} \end{equation}

Using the surface tension values ![]() $\sigma _{wa}=72\ \textrm {mN}\ \textrm {m}^{-1}$,

$\sigma _{wa}=72\ \textrm {mN}\ \textrm {m}^{-1}$, ![]() $\sigma _{ow}=55.2\ \textrm {mN}\ \textrm {m}^{-1}$ and

$\sigma _{ow}=55.2\ \textrm {mN}\ \textrm {m}^{-1}$ and ![]() $\sigma _{oa}=27.2\ \textrm {mN}\ \textrm {m}^{-1}$ (Goebel & Lunkenheimer Reference Goebel and Lunkenheimer1999), we present the calculation of (3.5) in figure 5(d). This shows that

$\sigma _{oa}=27.2\ \textrm {mN}\ \textrm {m}^{-1}$ (Goebel & Lunkenheimer Reference Goebel and Lunkenheimer1999), we present the calculation of (3.5) in figure 5(d). This shows that ![]() $\sigma _e$ is smallest when

$\sigma _e$ is smallest when ![]() $H$ is relatively large and that it is greatest (

$H$ is relatively large and that it is greatest (![]() $\sigma _e\simeq \sigma _{oa}+\sigma _{ow}>\sigma _{wa}$) when

$\sigma _e\simeq \sigma _{oa}+\sigma _{ow}>\sigma _{wa}$) when ![]() $H$ is small but non-zero.

$H$ is small but non-zero.

Finally, we postulate that all the kinetic energy of the impinging droplet is transferred to gravitational potential energy and additional surface energy, that is,

Using (3.1), (3.4) and (3.5), equation (3.6) becomes a quartic equation of ![]() $d'$ in terms of

$d'$ in terms of ![]() $Fr$,

$Fr$,

\begin{equation} \left. \begin{array}{ll@{}} (1+\rho')d^{\prime\,4} + 4\sigma'_{wa}d^{\prime\,2} - Fr/3 = 0 & \text{for}\ H'=0, \\ (1+\rho')d^{\prime\,4} + (4\sigma'_{oa}+4\sigma'_{ow}-2\rho'H^{\prime\,2})d^{\prime\,2} & \\ \quad -\,8\sigma'_{ow}H'd'+ (4\sigma'_{ow}H^{\prime\,2} - Fr/3 + \rho' H^{\prime\,4}) = 0 & \text{for}\ 0 < H'< d', \\ d^{\prime\,4} + 4\sigma'_{oa}d^{\prime\,2} - Fr/3 = 0 & \text{for}\ H'> d', \end{array} \right\} \end{equation}

\begin{equation} \left. \begin{array}{ll@{}} (1+\rho')d^{\prime\,4} + 4\sigma'_{wa}d^{\prime\,2} - Fr/3 = 0 & \text{for}\ H'=0, \\ (1+\rho')d^{\prime\,4} + (4\sigma'_{oa}+4\sigma'_{ow}-2\rho'H^{\prime\,2})d^{\prime\,2} & \\ \quad -\,8\sigma'_{ow}H'd'+ (4\sigma'_{ow}H^{\prime\,2} - Fr/3 + \rho' H^{\prime\,4}) = 0 & \text{for}\ 0 < H'< d', \\ d^{\prime\,4} + 4\sigma'_{oa}d^{\prime\,2} - Fr/3 = 0 & \text{for}\ H'> d', \end{array} \right\} \end{equation}

where ![]() $\sigma '=\sigma /(\rho _o g D^2)$ and

$\sigma '=\sigma /(\rho _o g D^2)$ and ![]() $\rho '=\rho _w/\rho _o-1$.

$\rho '=\rho _w/\rho _o-1$.

We solve for the roots of the quartic equation in (3.7), and each root is shown in figure 4(b). For each run of the experiment, we calculated the positive root ![]() $d'_e$ of (3.7) using the inputs

$d'_e$ of (3.7) using the inputs ![]() $U$,

$U$, ![]() $D$ and

$D$ and ![]() $H$ from experiments. Physically,

$H$ from experiments. Physically, ![]() $d'_e$ is the maximum depth of the cavity, as expected when the deformation of the second interface is considered. When

$d'_e$ is the maximum depth of the cavity, as expected when the deformation of the second interface is considered. When ![]() $Fr>100$, it can be seen that

$Fr>100$, it can be seen that ![]() $d'_e$ follows the classical scaling relation in (1.1). Otherwise,

$d'_e$ follows the classical scaling relation in (1.1). Otherwise, ![]() $d'_e$ deviates significantly from the one-fourth power law. For example, when

$d'_e$ deviates significantly from the one-fourth power law. For example, when ![]() $Fr$ is relatively small,

$Fr$ is relatively small, ![]() $d'_e$ in fact decreases as

$d'_e$ in fact decreases as ![]() $Fr$ increases. In this regime, the surface deformation takes a relatively larger portion of the energy than the gravitational potential energy, namely

$Fr$ increases. In this regime, the surface deformation takes a relatively larger portion of the energy than the gravitational potential energy, namely ![]() $\Delta E_s>E_p$, and the one-fourth power law, which was derived using

$\Delta E_s>E_p$, and the one-fourth power law, which was derived using ![]() $E_k=E_p$, does not apply. In the limit of

$E_k=E_p$, does not apply. In the limit of ![]() $\Delta E_s\gg E_p$, the energy balance between

$\Delta E_s\gg E_p$, the energy balance between ![]() $E_k$ and

$E_k$ and ![]() $\Delta E_s$ is simply written as

$\Delta E_s$ is simply written as ![]() $D^3 U^2\sim \sigma d^2$, from which a different scaling relation

$D^3 U^2\sim \sigma d^2$, from which a different scaling relation ![]() $d'\sim {We}^{1/2}$ is inferred. For a fixed

$d'\sim {We}^{1/2}$ is inferred. For a fixed ![]() $U$, the increase of

$U$, the increase of ![]() $D$ increases

$D$ increases ![]() $We$ but decreases

$We$ but decreases ![]() $Fr$, so we observe the inverse scaling between

$Fr$, so we observe the inverse scaling between ![]() $d'$ and

$d'$ and ![]() $Fr$ in figure 4(b). This feature is also observed in experiments, as shown in figure 4(a). The agreement between the simple model and the data suggests that the model accounts correctly for the underlying physics.

$Fr$ in figure 4(b). This feature is also observed in experiments, as shown in figure 4(a). The agreement between the simple model and the data suggests that the model accounts correctly for the underlying physics.

3.3. The height of the jet and the pinch-off modes

In figure 6(a), we present measurements of the maximum height of the Worthington jet ![]() $\ell '=\ell /D$ with respect to the effective Weber number, which we define as

$\ell '=\ell /D$ with respect to the effective Weber number, which we define as ![]() $We_e=\rho _{o} U^2 D/\sigma _e$ using the effective surface tension

$We_e=\rho _{o} U^2 D/\sigma _e$ using the effective surface tension ![]() $\sigma _e$ in (3.5). We note that the error bars are large for the case of

$\sigma _e$ in (3.5). We note that the error bars are large for the case of ![]() $H'=0$, because premature pinch-off of child droplets causes uncertainty in the estimation of

$H'=0$, because premature pinch-off of child droplets causes uncertainty in the estimation of ![]() $\ell$.

$\ell$.

Figure 6. Jet height and the pinch-off of child droplets. ![]() $(a)$ The dimensionless maximum height of the jet,

$(a)$ The dimensionless maximum height of the jet, ![]() $\ell '$, with respect to the effective Weber number

$\ell '$, with respect to the effective Weber number ![]() $We_e\equiv \rho U^2 D/\sigma _e$ for

$We_e\equiv \rho U^2 D/\sigma _e$ for ![]() $\overline {H'}=0$,

$\overline {H'}=0$, ![]() $0.38$,

$0.38$, ![]() $0.81$ and

$0.81$ and ![]() $2.21$. The dashed line is drawn to clarify the slope of 1.

$2.21$. The dashed line is drawn to clarify the slope of 1. ![]() $(b)$ The individual observations of the pinch-off position: no child droplet (

$(b)$ The individual observations of the pinch-off position: no child droplet (![]() $\triangleleft$), upper pinch-off (

$\triangleleft$), upper pinch-off (![]() $\triangledown$) and lower pinch-off (

$\triangledown$) and lower pinch-off (![]() $\triangleright$).

$\triangleright$). ![]() $(c,d)$ Example images of pinch-off modes for case C2:

$(c,d)$ Example images of pinch-off modes for case C2: ![]() $(c)$

$(c)$ ![]() ${H'}=1.60$ (upper pinch-off) and

${H'}=1.60$ (upper pinch-off) and ![]() $(d)$

$(d)$ ![]() ${H'}=0.33$ (lower pinch-off). The arrows indicate the position of the pinch-off.

${H'}=0.33$ (lower pinch-off). The arrows indicate the position of the pinch-off.

We find that ![]() $\ell '$ increases with

$\ell '$ increases with ![]() $We_{e}$, following the power law

$We_{e}$, following the power law ![]() $\ell '\sim We_{e}^{\alpha }$, where

$\ell '\sim We_{e}^{\alpha }$, where ![]() $\alpha =1.0\pm 0.2$ is calculated from linear fitting after transforming

$\alpha =1.0\pm 0.2$ is calculated from linear fitting after transforming ![]() $\ell '$ and

$\ell '$ and ![]() $We_e$ into a logarithmic scale. It is generally reported that

$We_e$ into a logarithmic scale. It is generally reported that ![]() $\ell '\sim We$ in the literature (Ray, Biswas & Sharma Reference Ray, Biswas and Sharma2012; Ray et al. Reference Ray, Biswas and Sharma2015; Che & Matar Reference Che and Matar2018), but the scaling relation does not apply to our case because the conventional definition of the Weber number is independent of

$\ell '\sim We$ in the literature (Ray, Biswas & Sharma Reference Ray, Biswas and Sharma2012; Ray et al. Reference Ray, Biswas and Sharma2015; Che & Matar Reference Che and Matar2018), but the scaling relation does not apply to our case because the conventional definition of the Weber number is independent of ![]() $H'$. To address this problem, we use the effective Weber number from

$H'$. To address this problem, we use the effective Weber number from ![]() $\sigma _e$, and thus

$\sigma _e$, and thus ![]() $We_e$ also depends on

$We_e$ also depends on ![]() $H'$. Our measurement of

$H'$. Our measurement of ![]() $\ell '$ then collapses into a similar scaling relation

$\ell '$ then collapses into a similar scaling relation ![]() $\ell '\sim We_e$, as shown in figure 6(a). This result suggests that the model in (3.5) correctly estimates the surface energy with the presence of the oil layer and that the overall dynamical features of the impingement are well captured by the dual-interface model presented in figure 5.

$\ell '\sim We_e$, as shown in figure 6(a). This result suggests that the model in (3.5) correctly estimates the surface energy with the presence of the oil layer and that the overall dynamical features of the impingement are well captured by the dual-interface model presented in figure 5.

Figure 6(b) shows a map of the pinch-off modes using individual measurements of ![]() $\ell '$, since the average value

$\ell '$, since the average value ![]() $\ell '$ of the repeated measurements includes the different pinch-off modes when a large deviation occurs. We identify two pinch-off modes depending on the location of the detachment of child droplets. When a child droplet is detached in the upper part of the jet, the mode is termed ‘upper pinch-off’. In the opposite case, the mode is termed ‘lower pinch-off’ (Kim et al. Reference Kim, Kim and Jung2018). The sequential images show examples of the pinch-off modes during impingement (figure 6c,d). As a general trend, upper pinch-off modes are observed when the effective Weber number is relatively large or the oil layer is thicker. Lower pinch-off modes are observed when the oil layer is thinner or absent. Both modes are observed only when the jet reaches above a critical height, namely

$\ell '$ of the repeated measurements includes the different pinch-off modes when a large deviation occurs. We identify two pinch-off modes depending on the location of the detachment of child droplets. When a child droplet is detached in the upper part of the jet, the mode is termed ‘upper pinch-off’. In the opposite case, the mode is termed ‘lower pinch-off’ (Kim et al. Reference Kim, Kim and Jung2018). The sequential images show examples of the pinch-off modes during impingement (figure 6c,d). As a general trend, upper pinch-off modes are observed when the effective Weber number is relatively large or the oil layer is thicker. Lower pinch-off modes are observed when the oil layer is thinner or absent. Both modes are observed only when the jet reaches above a critical height, namely ![]() $\ell '>2$. We speculate that the existence of the critical height can be explained by the Plateau–Rayleigh instability. Empirically, the diameter

$\ell '>2$. We speculate that the existence of the critical height can be explained by the Plateau–Rayleigh instability. Empirically, the diameter ![]() $2R_0$ of the jet approximately equals the droplet diameter, namely

$2R_0$ of the jet approximately equals the droplet diameter, namely ![]() $2R_0\simeq D$. This renders the fastest-growing wavelength of the Plateau–Rayleigh instability to be

$2R_0\simeq D$. This renders the fastest-growing wavelength of the Plateau–Rayleigh instability to be ![]() $\lambda _{m}=9R_0$, and

$\lambda _{m}=9R_0$, and ![]() $\ell >\lambda _{m}/2$ is required to have a local minimum of the undulation (Rayleigh Reference Rayleigh1878). This simple theoretical consideration yields

$\ell >\lambda _{m}/2$ is required to have a local minimum of the undulation (Rayleigh Reference Rayleigh1878). This simple theoretical consideration yields ![]() $\ell '>2.25$ as the criterion for pinch-off. The location of the pinch-off is then determined by the inertia of the jet and the surface tension: the upper pinch-off tends to occur at higher Weber number, where the inertial force wins over the surface tension. This picture of the pinch-off is consistent with the work by Kim et al. (Reference Kim, Kim and Jung2018).

$\ell '>2.25$ as the criterion for pinch-off. The location of the pinch-off is then determined by the inertia of the jet and the surface tension: the upper pinch-off tends to occur at higher Weber number, where the inertial force wins over the surface tension. This picture of the pinch-off is consistent with the work by Kim et al. (Reference Kim, Kim and Jung2018).

4. Conclusion

In conclusion, we investigated the phenomena occurring when an oil droplet impinges onto an oil-layered water bath. In the experiment, we varied the diameter and impact velocity of the droplet and the thickness of the oil layer to characterize the impingement dynamics for a two-layer liquid. As with similar studies using a single-layer liquid, a crater is formed at the point of impact, and the ejection of a Worthington jet follows. By using high-speed video imaging, we measured the depth of the crater ![]() $d'$ and the height of the jet

$d'$ and the height of the jet ![]() $\ell '$, normalized by the droplet diameter

$\ell '$, normalized by the droplet diameter ![]() $D$. Our measurements suggest that, even though the overall dynamics of the impingement are similar to the single-layer case, the detailed measurements vary with the thickness of the oil layer

$D$. Our measurements suggest that, even though the overall dynamics of the impingement are similar to the single-layer case, the detailed measurements vary with the thickness of the oil layer ![]() $H'\equiv H/D$. Both

$H'\equiv H/D$. Both ![]() $d'$ and

$d'$ and ![]() $\ell '$ are smaller when a thin oil layer (

$\ell '$ are smaller when a thin oil layer (![]() $0<H'<\,{\sim}\,1.60$) is present than when no oil layer is present. Interestingly, when the thickness of the oil layer further increases (

$0<H'<\,{\sim}\,1.60$) is present than when no oil layer is present. Interestingly, when the thickness of the oil layer further increases (![]() $H'>\,{\sim}\,1.60$), both quantities also increase. This observation indicates that the qualitative features of a thick oil layer are similar those of an oil layer of zero thickness.

$H'>\,{\sim}\,1.60$), both quantities also increase. This observation indicates that the qualitative features of a thick oil layer are similar those of an oil layer of zero thickness.

To rationalize our observation, we established a mathematical model that added a second interface to the classical model for droplet impingement. In the model, we balance the kinetic energy of the impinging droplet with the gravitational potential energy of the displaced liquid and the excess surface energy of the crater. The crater is assumed to be hemispherical, and the gravitational potential energy and the surface energy are integrated using the density and the interfacial tension of each layer. The value of ![]() $d'$ can then be estimated using the model with experimental parameters as inputs, and a rough agreement with the classical scaling relation with the Froude number was observed. Furthermore, based on the model, we also defined an effective surface tension

$d'$ can then be estimated using the model with experimental parameters as inputs, and a rough agreement with the classical scaling relation with the Froude number was observed. Furthermore, based on the model, we also defined an effective surface tension ![]() $\sigma _e$ and a corresponding effective Weber number

$\sigma _e$ and a corresponding effective Weber number ![]() $We_e$ because the conventional Weber number is unable to represent the impingement results with respect to

$We_e$ because the conventional Weber number is unable to represent the impingement results with respect to ![]() $H'$. We found that our measurement of

$H'$. We found that our measurement of ![]() $\ell '$ collapsed into a single scaling relation only when

$\ell '$ collapsed into a single scaling relation only when ![]() $We_e$ was used. These observations suggest that our model captures the dynamics well. This work could be applied to fundamental and industrial problems involving droplets impinging onto a two-layer liquid, such as the spraying of oil dispersants.

$We_e$ was used. These observations suggest that our model captures the dynamics well. This work could be applied to fundamental and industrial problems involving droplets impinging onto a two-layer liquid, such as the spraying of oil dispersants.

Acknowledgements

This study was supported by the National Research Foundation of Korea (NRF) grant funded by the Korean government (MSIT) (No. 2020R1A2C3010568) and the New and Renewable Energy Core Technology Program of the Korea Institute of Energy Technology Evaluation and Planning (KETEP) with a grant of financial resources from the Ministry of Trade, Industry and Energy, Republic of Korea (No. 20193010014740).

Declaration of interests

The authors report no conflict of interest.