1. Introduction

Understanding the dynamic behaviour of granular flows is crucial for dealing with some natural phenomena (Bagnold Reference Bagnold1954; MiDi Reference MiDi2004; Zhang et al. Reference Zhang, Huang, Ge, Man and Huppert2025), such as debris flows, landslides and pyroclastic flows (Bougouin, Lacaze & Bonometti Reference Bougouin, Lacaze and Bonometti2019), and is also important for solving some engineering issues related to civil engineering (Man Reference Man2023; Ge et al. Reference Ge, Man, Huppert, Hill and Galindo-Torres2024), chemical engineering (Ottino & Khakhar Reference Ottino and Khakhar2000; Zhang et al. Reference Zhang, Du, Man, Ge and Huppert2024), waste clearance (Chen et al. Reference Chen, Li, Thiem, Neshamar and Cuthbertson2023), seashore erosion (Böttner et al. Reference Böttner, Stevenson, Englert, Schönke, Pandolpho, Geersen, Feldens and Krastel2024) as well as pharmaceutical engineering (Boonkanokwong, Khinast & Glasser Reference Boonkanokwong, Khinast and Glasser2021). While rheological models based on the inertial number, ![]() $I$, and the viscous number,

$I$, and the viscous number, ![]() $I_v$, successfully describe steady-state behaviours of granular systems (Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006; Pouliquen et al. Reference Pouliquen, Cassar, Jop, Forterre and Nicolas2006; Boyer, Guazzelli & Pouliquen Reference Boyer, Guazzelli and Pouliquen2011; Trulsson, Andreotti & Claudin Reference Trulsson, Andreotti and Claudin2012), most natural and engineering systems are in unsteady state conditions, which may require transient rheological models. The investigation of granular column collapses on either horizontal planes or inclined planes provides us with a simple example of transient granular flows so that both their macroscopic behaviour and local rheological property can be explored accordingly.

$I_v$, successfully describe steady-state behaviours of granular systems (Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006; Pouliquen et al. Reference Pouliquen, Cassar, Jop, Forterre and Nicolas2006; Boyer, Guazzelli & Pouliquen Reference Boyer, Guazzelli and Pouliquen2011; Trulsson, Andreotti & Claudin Reference Trulsson, Andreotti and Claudin2012), most natural and engineering systems are in unsteady state conditions, which may require transient rheological models. The investigation of granular column collapses on either horizontal planes or inclined planes provides us with a simple example of transient granular flows so that both their macroscopic behaviour and local rheological property can be explored accordingly.

Lube et al. (Reference Lube, Huppert, Sparks and Hallworth2004) and Lajeunesse, Monnier & Homsy (Reference Lajeunesse, Monnier and Homsy2005) first investigated the dynamics of granular column collapses in a dry condition and on a horizontal plane, and quantified the run-out behaviour of the relationship between the relative run-out distance, ![]() $\mathcal {R}_{axsym} = (R_{\infty } - R_i)$, and the initial aspect ratio,

$\mathcal {R}_{axsym} = (R_{\infty } - R_i)$, and the initial aspect ratio, ![]() $\alpha _{axsym} = H_i/R_i$, where

$\alpha _{axsym} = H_i/R_i$, where ![]() $R_{\infty }$ is the final deposition radius of the axisymmetric granular column,

$R_{\infty }$ is the final deposition radius of the axisymmetric granular column, ![]() $R_i$ is the initial column radius and

$R_i$ is the initial column radius and ![]() $H_i$ is the initial column height. To show that this is for axisymmetric granular column collapses, we add a subscript of ‘axsym’ to both the relative run-out distance,

$H_i$ is the initial column height. To show that this is for axisymmetric granular column collapses, we add a subscript of ‘axsym’ to both the relative run-out distance, ![]() $\mathcal {R}$, and the initial aspect ratio,

$\mathcal {R}$, and the initial aspect ratio, ![]() $\alpha$. Previous research concluded that

$\alpha$. Previous research concluded that ![]() $\mathcal {R}_{axsym}$ approximately scales with

$\mathcal {R}_{axsym}$ approximately scales with ![]() $\alpha _{axsym}$ when

$\alpha _{axsym}$ when ![]() $\alpha _{axsym}$ is smaller than a threshold

$\alpha _{axsym}$ is smaller than a threshold ![]() $\alpha _c$, and scales with

$\alpha _c$, and scales with ![]() $\alpha _{axsym}^{0.5}$ when

$\alpha _{axsym}^{0.5}$ when ![]() $\alpha _{axsym}>\alpha _c$. Staron & Hinch (Reference Staron and Hinch2005, Reference Staron and Hinch2007) emphasized the influence of particle properties, such as inter-particle frictional coefficients and coefficients of restitution, with numerical investigations, and found that changing particle properties could influence the energy dissipation process, which lead to different final run-out distances and different collapse kinematics, but did not provide quantitative analyses of these influences. Later, more research has been conducted to study the complexity of granular column collapses with different particle size polydispersities (Cabrera & Estrada Reference Cabrera and Estrada2019; Martinez et al. Reference Martinez, Tamburrino, Casis and Ferrer2022), fluid saturation or immersion condition (Rondon, Pouliquen & Aussillous Reference Rondon, Pouliquen and Aussillous2011; Fern & Soga Reference Fern and Soga2017; Bougouin et al. Reference Bougouin, Lacaze and Bonometti2019), different complex particle shapes (Zhang et al. Reference Zhang, Yin, Wu and Jin2018) and erodible boundaries (Vo et al. Reference Vo, Dinh Minh, Nguyen, Nguyen and Bui2024).

$\alpha _{axsym}>\alpha _c$. Staron & Hinch (Reference Staron and Hinch2005, Reference Staron and Hinch2007) emphasized the influence of particle properties, such as inter-particle frictional coefficients and coefficients of restitution, with numerical investigations, and found that changing particle properties could influence the energy dissipation process, which lead to different final run-out distances and different collapse kinematics, but did not provide quantitative analyses of these influences. Later, more research has been conducted to study the complexity of granular column collapses with different particle size polydispersities (Cabrera & Estrada Reference Cabrera and Estrada2019; Martinez et al. Reference Martinez, Tamburrino, Casis and Ferrer2022), fluid saturation or immersion condition (Rondon, Pouliquen & Aussillous Reference Rondon, Pouliquen and Aussillous2011; Fern & Soga Reference Fern and Soga2017; Bougouin et al. Reference Bougouin, Lacaze and Bonometti2019), different complex particle shapes (Zhang et al. Reference Zhang, Yin, Wu and Jin2018) and erodible boundaries (Vo et al. Reference Vo, Dinh Minh, Nguyen, Nguyen and Bui2024).

Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011) first took granular columns onto inclined planes to explore the influence of inclination angles, where they considered five different inclination angles (![]() $\theta =4.2^{\circ }$,

$\theta =4.2^{\circ }$, ![]() $10^{\circ }$,

$10^{\circ }$, ![]() $15^{\circ }$,

$15^{\circ }$, ![]() $20^{\circ }$ and

$20^{\circ }$ and ![]() $25^{\circ }$) and, with dimensional analysis combined with analytical solutions for granular dam-break flows by Mangeney, Heinrich & Roche (Reference Mangeney, Heinrich and Roche2000), analysed run-out behaviours, deposition patterns and the kinematics of granular columns in different conditions (detailed description of this work will be reviewed in § 2 since part of this work is directly based on the work of Lube et al. Reference Lube, Huppert, Sparks and Freundt2011). Due to the inclination, granular column collapses on inclined planes exhibit much more complex characteristics. Therefore, it is convenient to use them as a benchmark for verifying certain rheological models or testing different continuum modelling approaches. Crosta, Imposimato & Roddeman (Reference Crosta, Imposimato and Roddeman2015) investigated granular column collapses on inclined planes with either erodible or unerodible features with a combined Eulerian–Lagrangian method model. Chou, Yang & Hsiau (Reference Chou, Yang and Hsiau2023) also studied the erosion and deposition process of granular collapses on an erodible inclined plane, but focused on experimental investigations. Ionescu et al. (Reference Ionescu, Mangeney, Bouchut and Roche2015) used granular column collapses on both horizontal and inclined planes to verify a viscoplastic pressure-dependent rheological model. Similarly, Ikari & Gotoh (Reference Ikari and Gotoh2016) simulated granular collapses on inclined planes with smooth particle hydrodynamics and the Drucker–Prager yield function, while Salehizadeh & Shafiei (Reference Salehizadeh and Shafiei2019) investigated the behaviour of granular column collapses to test their smooth particle hydrodynamics code incorporated with the

$25^{\circ }$) and, with dimensional analysis combined with analytical solutions for granular dam-break flows by Mangeney, Heinrich & Roche (Reference Mangeney, Heinrich and Roche2000), analysed run-out behaviours, deposition patterns and the kinematics of granular columns in different conditions (detailed description of this work will be reviewed in § 2 since part of this work is directly based on the work of Lube et al. Reference Lube, Huppert, Sparks and Freundt2011). Due to the inclination, granular column collapses on inclined planes exhibit much more complex characteristics. Therefore, it is convenient to use them as a benchmark for verifying certain rheological models or testing different continuum modelling approaches. Crosta, Imposimato & Roddeman (Reference Crosta, Imposimato and Roddeman2015) investigated granular column collapses on inclined planes with either erodible or unerodible features with a combined Eulerian–Lagrangian method model. Chou, Yang & Hsiau (Reference Chou, Yang and Hsiau2023) also studied the erosion and deposition process of granular collapses on an erodible inclined plane, but focused on experimental investigations. Ionescu et al. (Reference Ionescu, Mangeney, Bouchut and Roche2015) used granular column collapses on both horizontal and inclined planes to verify a viscoplastic pressure-dependent rheological model. Similarly, Ikari & Gotoh (Reference Ikari and Gotoh2016) simulated granular collapses on inclined planes with smooth particle hydrodynamics and the Drucker–Prager yield function, while Salehizadeh & Shafiei (Reference Salehizadeh and Shafiei2019) investigated the behaviour of granular column collapses to test their smooth particle hydrodynamics code incorporated with the ![]() $\mu (I)$ rheology. Lee (Reference Lee2019) further considered granular column collapses on inclined planes in a subaqueous environment to study the influence of the Darcy number on the behaviour of underwater granular flows.

$\mu (I)$ rheology. Lee (Reference Lee2019) further considered granular column collapses on inclined planes in a subaqueous environment to study the influence of the Darcy number on the behaviour of underwater granular flows.

However, previous research often lacks physics-based quantitative representation of the influence of frictional properties. Thus, our recent studies introduced an effective initial aspect ratio,

where ![]() $\mu _w$ is the frictional coefficient between particles and the plane,

$\mu _w$ is the frictional coefficient between particles and the plane, ![]() $\mu _p$ is the inter-particle frictional coefficient and

$\mu _p$ is the inter-particle frictional coefficient and ![]() $\beta = 2$ is a constant, and analysed the deposition morphology (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a), finite-size scaling (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021b) as well as the influence of cross-section shapes (Man et al. Reference Man, Huppert, Zhang and Galindo-Torres2022), and also introduced a mixture theory to consider the condition when a granular system consists of particles with different frictional properties (Man et al. Reference Man, Zhang, Huppert and Galindo-Torres2023). In our previous studies (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a, Reference Man, Huppert, Li and Galindo-Torresb), we derived the dimensionless number based on dimensional analysis, which results in a useful aspect ratio that can be seen as the ratio between the inertial effect and the frictional effect, where the frictional effect is calculated as a multiplication of a combined frictional effect and a theoretical normal stress. Based on our analyses, the inertial effect drives the granular system to move forward and frictional influence dissipates the energy, while the inertial effect can be associated with the energy being transformed from potential to kinetic energy.

$\beta = 2$ is a constant, and analysed the deposition morphology (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a), finite-size scaling (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021b) as well as the influence of cross-section shapes (Man et al. Reference Man, Huppert, Zhang and Galindo-Torres2022), and also introduced a mixture theory to consider the condition when a granular system consists of particles with different frictional properties (Man et al. Reference Man, Zhang, Huppert and Galindo-Torres2023). In our previous studies (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a, Reference Man, Huppert, Li and Galindo-Torresb), we derived the dimensionless number based on dimensional analysis, which results in a useful aspect ratio that can be seen as the ratio between the inertial effect and the frictional effect, where the frictional effect is calculated as a multiplication of a combined frictional effect and a theoretical normal stress. Based on our analyses, the inertial effect drives the granular system to move forward and frictional influence dissipates the energy, while the inertial effect can be associated with the energy being transformed from potential to kinetic energy.

In this paper, based on the work of Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011), we aim to use the previously defined ![]() $\alpha _{eff}$ to explore the scaling of granular column collapses on inclined planes with the assistance of the sphero-polyhedral discrete element method. The simulation set-up is similar to that presented by Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011), with slight modification of the boundary conditions, such as using periodic boundaries and the inclined plane considered smooth with constant frictional coefficients. Based on dimensional analysis and simulation results, we are able to relate the relative run-out distance to a scaling solution, and shed light on the prediction of both dynamic behaviours and deposition patterns of granular column collapses on inclined planes. This paper is organized as follows. Section 2 provides readers with a detailed description of the problem faced and presents the dimensional analysis for deriving a new dimensionless number with the incorporation of the inclination angle. In § 3, we describe the simulation set-up and provide the numerical method. We further investigate the influence of inclination angles on flow kinematics and run-out behaviours in § 4 and the residue height in § 5. We will discuss the influence of the initial solid fraction in § 6. Further discussions on the run-out and the collapse duration scaling, and the influence of restitution coefficients are introduced in § 7, before concluding remarks are made in § 8. The main point of this paper is to first derive a physics-based dimensionless parameter to help describe granular column collapses on inclined planes, and then show that, with both the newly derived and previously proposed physics-based dimensionless numbers, we obtain functional relationships for macroscopic variables, such as the run-out distance, the collapse duration and the deposition height, which are of great interest to both geophysicists and geotechnical engineers.

$\alpha _{eff}$ to explore the scaling of granular column collapses on inclined planes with the assistance of the sphero-polyhedral discrete element method. The simulation set-up is similar to that presented by Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011), with slight modification of the boundary conditions, such as using periodic boundaries and the inclined plane considered smooth with constant frictional coefficients. Based on dimensional analysis and simulation results, we are able to relate the relative run-out distance to a scaling solution, and shed light on the prediction of both dynamic behaviours and deposition patterns of granular column collapses on inclined planes. This paper is organized as follows. Section 2 provides readers with a detailed description of the problem faced and presents the dimensional analysis for deriving a new dimensionless number with the incorporation of the inclination angle. In § 3, we describe the simulation set-up and provide the numerical method. We further investigate the influence of inclination angles on flow kinematics and run-out behaviours in § 4 and the residue height in § 5. We will discuss the influence of the initial solid fraction in § 6. Further discussions on the run-out and the collapse duration scaling, and the influence of restitution coefficients are introduced in § 7, before concluding remarks are made in § 8. The main point of this paper is to first derive a physics-based dimensionless parameter to help describe granular column collapses on inclined planes, and then show that, with both the newly derived and previously proposed physics-based dimensionless numbers, we obtain functional relationships for macroscopic variables, such as the run-out distance, the collapse duration and the deposition height, which are of great interest to both geophysicists and geotechnical engineers.

2. Problem statement and dimensional analysis

In this work, we aim to investigate granular column collapses on an inclined plane as shown in figure 1(a), which represents a two-dimensional granular column collapse. The initial granular column with height ![]() $H_i$ and horizontal length

$H_i$ and horizontal length ![]() $L_i$ is placed on a horizontal plane. The width of the system is

$L_i$ is placed on a horizontal plane. The width of the system is ![]() $W_i$. The horizontal plane is connected to an inclined plane with inclination angle

$W_i$. The horizontal plane is connected to an inclined plane with inclination angle ![]() $\theta$, so that the initial granular packing (coloured blue in figure 1a) will collapse onto it once the material is released. After the collapse of the granular column, we can measure the residue deposition height

$\theta$, so that the initial granular packing (coloured blue in figure 1a) will collapse onto it once the material is released. After the collapse of the granular column, we can measure the residue deposition height ![]() $H_\infty$ and the total horizontal deposition length

$H_\infty$ and the total horizontal deposition length ![]() $L_{\infty }$. Then, we can calculate the horizontal run-out distance

$L_{\infty }$. Then, we can calculate the horizontal run-out distance ![]() $\delta L = L_{\infty } - L_i$ and the inclined run-out distance

$\delta L = L_{\infty } - L_i$ and the inclined run-out distance ![]() $\delta L^{\prime } = \delta L/\cos \theta$. We are interested in how changing inclination angles and interparticle contact properties influences the behaviour of (i) relative run-out distances, (ii) deposition heights and (iii) flow kinematics.

$\delta L^{\prime } = \delta L/\cos \theta$. We are interested in how changing inclination angles and interparticle contact properties influences the behaviour of (i) relative run-out distances, (ii) deposition heights and (iii) flow kinematics.

Figure 1. (a) Sketch of the problem set-up, where black lines denote solid boundaries, light blue body represents the initial granular column and the sand-like body is the final deposition. (b,c) Two different types of granular column collapses on inclined planes.

We note that our inclined plane is similar to the experimental set-up of Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011) because this set-up ensures no pre-defined slippery boundary for the column and no free-falling particles exist at the beginning. This set-up is slightly different from the other two options shown in figures 1(b) and 1(c), which were often used in previous research (Crosta et al. Reference Crosta, Imposimato and Roddeman2015; Chou et al. Reference Chou, Yang and Hsiau2023). In figure 1(b), granular materials are placed vertically on the inclined plane as the initial condition, and the inclined plane beneath it can be regarded as a pre-defined slipping boundary and a possible failure surface, which may influence the run-out results and the deposition pattern. Similarly, in figure 1(c), not only is there a pre-defined slipping boundary for the initial granular packing, but a few particles at the upper right corner (around Point ![]() $A$ in figure 1c) are initially in a free-fall regime with almost no supporting particles beneath them, which may also influence the collapse phenomenon.

$A$ in figure 1c) are initially in a free-fall regime with almost no supporting particles beneath them, which may also influence the collapse phenomenon.

We extract results of run-out distances of Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011) and plot them in figure 2(a), which shows that changing inclination angles scatters the run-out results. In figure 2(a), the ![]() $y$-axis,

$y$-axis, ![]() $\mathcal {L}^{\prime }$, is the relative run-out distance along the inclination, and increasing the inclination angle from 4.2

$\mathcal {L}^{\prime }$, is the relative run-out distance along the inclination, and increasing the inclination angle from 4.2![]() $^{\circ }$ to 25

$^{\circ }$ to 25![]() $^{\circ }$ greatly increases the run-out distance. They found that, when

$^{\circ }$ greatly increases the run-out distance. They found that, when ![]() $\theta \leqslant 20^{\circ }$, the run-out distance behaves similar to a system on horizontal planes and the relationship between

$\theta \leqslant 20^{\circ }$, the run-out distance behaves similar to a system on horizontal planes and the relationship between ![]() $\mathcal {L}^{\prime }$ and

$\mathcal {L}^{\prime }$ and ![]() $\alpha$ scales linearly below a threshold of

$\alpha$ scales linearly below a threshold of ![]() $\alpha$ and scales with

$\alpha$ and scales with ![]() $\alpha ^{2/3}$ above that threshold. When the inclination angle is close to the maximum angle of repose of the tested granular material and

$\alpha ^{2/3}$ above that threshold. When the inclination angle is close to the maximum angle of repose of the tested granular material and ![]() $\alpha$ is large enough, the power law will be different. We believe that the increase of the run-out distance is due to two factors: (1) the inclination allows more potential energy to be transformed into kinetic energy, which inevitably increases the run-out distance; and (2) the existence of the inclination angle decreases the pressure subjected to the slope from granular materials, which also decreases the resulting frictional effect. These two factors enable more energy for the system to propagate and, meanwhile, reduce the energy dissipation during the column collapse.

$\alpha$ is large enough, the power law will be different. We believe that the increase of the run-out distance is due to two factors: (1) the inclination allows more potential energy to be transformed into kinetic energy, which inevitably increases the run-out distance; and (2) the existence of the inclination angle decreases the pressure subjected to the slope from granular materials, which also decreases the resulting frictional effect. These two factors enable more energy for the system to propagate and, meanwhile, reduce the energy dissipation during the column collapse.

Figure 2. (a) Experimental results extracted from Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011). The ![]() $y$-axis is the relative run-out distance along the inclination,

$y$-axis is the relative run-out distance along the inclination, ![]() $\mathcal {L}^{\prime } = \delta L^{\prime }/L_i$. (b) Results when we plot the horizontal relative run-out distance,

$\mathcal {L}^{\prime } = \delta L^{\prime }/L_i$. (b) Results when we plot the horizontal relative run-out distance, ![]() $\mathcal {L} = \delta L/L_i$, against the new dimensionless number,

$\mathcal {L} = \delta L/L_i$, against the new dimensionless number, ![]() $\tilde {\alpha }$. The red and blue dashed lines in the inset of panel (b) are to show the slope change from approximately 1.25 to 0.9 as we increase

$\tilde {\alpha }$. The red and blue dashed lines in the inset of panel (b) are to show the slope change from approximately 1.25 to 0.9 as we increase ![]() $\tilde {\alpha }$.

$\tilde {\alpha }$.

In previous works, for granular systems with different frictional properties, we introduced an effective aspect ratio, ![]() $\alpha _{eff}$, as mentioned in § 1, which denotes the ratio of inertial effects and frictional dissipation, and we derived the dimensionless number from the non-dimensionalization of the governing equation of an arbitrary grain within the granular column. In this work, we follow this logic, but have to adjust the additional potential energy, which could enhance the run-out. First, we consider the same governing equation of the dynamics of a single arbitrary particle in a granular system to be

$\alpha _{eff}$, as mentioned in § 1, which denotes the ratio of inertial effects and frictional dissipation, and we derived the dimensionless number from the non-dimensionalization of the governing equation of an arbitrary grain within the granular column. In this work, we follow this logic, but have to adjust the additional potential energy, which could enhance the run-out. First, we consider the same governing equation of the dynamics of a single arbitrary particle in a granular system to be

where ![]() $m_p$ is the particle mass,

$m_p$ is the particle mass, ![]() $F_n$ and

$F_n$ and ![]() $F_t$ are total normal and tangential contact forces subjected to this particle,

$F_t$ are total normal and tangential contact forces subjected to this particle, ![]() $\hat {n}$,

$\hat {n}$, ![]() $\hat {t}$ and

$\hat {t}$ and ![]() $\hat {z}$ are unit vectors in the contact normal, the contact normal tangential and vertical directions, respectively, and

$\hat {z}$ are unit vectors in the contact normal, the contact normal tangential and vertical directions, respectively, and ![]() $g$ represents the acceleration of gravity. We then non-dimensionalize this equation based on following the dimensionless variables:

$g$ represents the acceleration of gravity. We then non-dimensionalize this equation based on following the dimensionless variables:

where ![]() $t^{\ast }$,

$t^{\ast }$, ![]() $\boldsymbol{x}^{\ast }$ and

$\boldsymbol{x}^{\ast }$ and ![]() $m^{\ast }$ are dimensionless time, position vector and mass. Here,

$m^{\ast }$ are dimensionless time, position vector and mass. Here, ![]() $\delta h$ is the height between the run-out front and the original bottom of the granular column, which is given by

$\delta h$ is the height between the run-out front and the original bottom of the granular column, which is given by ![]() $\delta h = \delta L \tan {\theta }$. Additionally,

$\delta h = \delta L \tan {\theta }$. Additionally, ![]() $W_i$ is the width of the system. We note that the way we non-dimensionalize the time is by constructing a characteristic time scale, which is the ratio between a length scale,

$W_i$ is the width of the system. We note that the way we non-dimensionalize the time is by constructing a characteristic time scale, which is the ratio between a length scale, ![]() $H_i+\delta h$, and a characteristic velocity,

$H_i+\delta h$, and a characteristic velocity, ![]() $\sqrt {gH_i}$. Here,

$\sqrt {gH_i}$. Here, ![]() $F_n^{\ast }$ represents the dimensionless normal forces acting on a particle, and the tangential force should be

$F_n^{\ast }$ represents the dimensionless normal forces acting on a particle, and the tangential force should be ![]() $F_n$ times a function of both the inclination angle

$F_n$ times a function of both the inclination angle ![]() $\theta$ and the frictional property

$\theta$ and the frictional property ![]() $\mu$. Our previous work (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a) showed that the normal and tangential forces can be combined into a total force

$\mu$. Our previous work (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a) showed that the normal and tangential forces can be combined into a total force

where ![]() $\mathcal {H}(\theta, \mu )$ represents the influence of

$\mathcal {H}(\theta, \mu )$ represents the influence of ![]() $\theta$ and

$\theta$ and ![]() $\mu$ on the combination of the normal and tangential forces. After the non-dimensionalization, the dimensional factor before

$\mu$ on the combination of the normal and tangential forces. After the non-dimensionalization, the dimensional factor before ![]() $m^{\ast }({\rm d}^2 \boldsymbol{x}^{\ast })/({\rm d}{t^{\ast }}^2)$ becomes

$m^{\ast }({\rm d}^2 \boldsymbol{x}^{\ast })/({\rm d}{t^{\ast }}^2)$ becomes ![]() $\rho _p d_p^3 gH_i L_i/(H_i +\delta h)^2$. Similar to our previous paper (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a), we can obtain a new dimensionless number by dividing the dimensional factor in (2.3) by the dimensional factor before

$\rho _p d_p^3 gH_i L_i/(H_i +\delta h)^2$. Similar to our previous paper (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a), we can obtain a new dimensionless number by dividing the dimensional factor in (2.3) by the dimensional factor before ![]() $m^{\ast }({\rm d}^2 \boldsymbol{x}^{\ast })/({\rm d}{t^{\ast }}^2)$, so that

$m^{\ast }({\rm d}^2 \boldsymbol{x}^{\ast })/({\rm d}{t^{\ast }}^2)$, so that

where ![]() $L_i^2W_i/d_p^3$ represents the size effect of the system, which is a constant and can be neglected in this study. Here,

$L_i^2W_i/d_p^3$ represents the size effect of the system, which is a constant and can be neglected in this study. Here, ![]() $\mathcal {H}(\mu,\theta )$ shows the influence of both the frictional property and the inclination angle. However, we have already included the inclination effect in

$\mathcal {H}(\mu,\theta )$ shows the influence of both the frictional property and the inclination angle. However, we have already included the inclination effect in ![]() $\delta L\tan {\theta }$, and we hypothesize that

$\delta L\tan {\theta }$, and we hypothesize that ![]() $\theta$ plays a minor role in

$\theta$ plays a minor role in ![]() $\mathcal {H}(\mu, \theta )$ so that

$\mathcal {H}(\mu, \theta )$ so that ![]() $\mathcal {H}(\mu, \theta ) = 1/(\mu _w + \beta \mu _p)$, which is the same as what we proposed in our previous study (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a). The square root of

$\mathcal {H}(\mu, \theta ) = 1/(\mu _w + \beta \mu _p)$, which is the same as what we proposed in our previous study (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a). The square root of ![]() $\mathcal {I}$ can be seen as an effective aspect ratio for inclined column collapses,

$\mathcal {I}$ can be seen as an effective aspect ratio for inclined column collapses, ![]() $\tilde {\alpha }_{eff}$, and

$\tilde {\alpha }_{eff}$, and

where ![]() $\delta L$ is the run-out distance in the horizontal direction. Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011) singled out the initial aspect ratio,

$\delta L$ is the run-out distance in the horizontal direction. Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011) singled out the initial aspect ratio, ![]() $\alpha$, and attributed the deviation in

$\alpha$, and attributed the deviation in ![]() $\mathcal {L}^{\prime }\unicode{x2013}\alpha$ relationship of systems with different inclination angles to the influence of inclinations, but we, in this work, mix the two influences together and investigate the system from a viewpoint of an energy balance. Here,

$\mathcal {L}^{\prime }\unicode{x2013}\alpha$ relationship of systems with different inclination angles to the influence of inclinations, but we, in this work, mix the two influences together and investigate the system from a viewpoint of an energy balance. Here, ![]() $\tilde {\alpha }_{eff}$ can be named as an inclined effective ratio. We have to clarify that, in our previous work (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a), we derived the dimensionless number based on dimensional analysis of the forces acting on one arbitrary particle. The resulting dimensionless number can be seen as the ratio between the inertial effect and the frictional effect, where the frictional effect is calculated as a multiplication of a combined frictional effect and a theoretical normal stress. When we put the granular column onto an inclined plane, the inertial effect needs an additional term that takes the materials that flow downward into account. That is why the numerator has an added

$\tilde {\alpha }_{eff}$ can be named as an inclined effective ratio. We have to clarify that, in our previous work (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a), we derived the dimensionless number based on dimensional analysis of the forces acting on one arbitrary particle. The resulting dimensionless number can be seen as the ratio between the inertial effect and the frictional effect, where the frictional effect is calculated as a multiplication of a combined frictional effect and a theoretical normal stress. When we put the granular column onto an inclined plane, the inertial effect needs an additional term that takes the materials that flow downward into account. That is why the numerator has an added ![]() $\delta L\tan \theta$. Also, since the plane is inclined, the friction is reduced by

$\delta L\tan \theta$. Also, since the plane is inclined, the friction is reduced by ![]() $\cos \theta$. This is why the denominator is multiplied by a factor of

$\cos \theta$. This is why the denominator is multiplied by a factor of ![]() $\cos \theta$. We note that Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011) treated the relative run-out distance along the inclination,

$\cos \theta$. We note that Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011) treated the relative run-out distance along the inclination, ![]() $\delta L^{\prime } = \delta L/\cos \theta$, as a key result. However, the horizontal and vertical run-out distances are correlated, and it should be the horizontal run-out distance that measures directly the ability of the granular column to transform stored potential energy to kinetic energy. Thus, in this work, we focus on the horizontal run-out distance,

$\delta L^{\prime } = \delta L/\cos \theta$, as a key result. However, the horizontal and vertical run-out distances are correlated, and it should be the horizontal run-out distance that measures directly the ability of the granular column to transform stored potential energy to kinetic energy. Thus, in this work, we focus on the horizontal run-out distance, ![]() $\delta L$, instead of the inclined run-out distance,

$\delta L$, instead of the inclined run-out distance, ![]() $\delta L^{\prime }$. We also need to clarify that the way we normalize the time in (2.2) is by dividing the time with a time scale,

$\delta L^{\prime }$. We also need to clarify that the way we normalize the time in (2.2) is by dividing the time with a time scale, ![]() $(H_i+\delta h)/\sqrt {gH_i}$, where the numerator is a length scale and the denominator is a characteristic velocity. Since this length scale should be related to the final run-out distance and the additional potential energy being transformed, we add an additional

$(H_i+\delta h)/\sqrt {gH_i}$, where the numerator is a length scale and the denominator is a characteristic velocity. Since this length scale should be related to the final run-out distance and the additional potential energy being transformed, we add an additional ![]() $\delta h$ as explained earlier. For the characteristic velocity, we believe that it should be related to the front velocity, and most of the front velocity is generated during the column failure stage, where its associated length scale is still the initial height

$\delta h$ as explained earlier. For the characteristic velocity, we believe that it should be related to the front velocity, and most of the front velocity is generated during the column failure stage, where its associated length scale is still the initial height ![]() $H_i$ of the system.

$H_i$ of the system.

In figure 2(b) and its inset, we plot the relationship between the relative horizontal run-out distance, ![]() $\mathcal {L} = \delta L/L_i$, and the new dimensionless number,

$\mathcal {L} = \delta L/L_i$, and the new dimensionless number, ![]() $\tilde {\alpha } = (H_i + \delta L\tan \theta )/L_i$. The

$\tilde {\alpha } = (H_i + \delta L\tan \theta )/L_i$. The ![]() $x$-axis is

$x$-axis is ![]() $\tilde {\alpha }$ because the original experiments do not provide the detailed information of particle and boundary frictional coefficients, and we simply neglect the part in

$\tilde {\alpha }$ because the original experiments do not provide the detailed information of particle and boundary frictional coefficients, and we simply neglect the part in ![]() $\tilde {\alpha }_{eff}$ that constituents frictional coefficients. Most results of inclined granular column collapses with different inclination angles collapse nicely once we plot

$\tilde {\alpha }_{eff}$ that constituents frictional coefficients. Most results of inclined granular column collapses with different inclination angles collapse nicely once we plot ![]() $\mathcal {L}$ against

$\mathcal {L}$ against ![]() $\tilde {\alpha }$, but some deviations appear when

$\tilde {\alpha }$, but some deviations appear when ![]() $\theta = 4.2$ and

$\theta = 4.2$ and ![]() $\tilde {\alpha } > 10$. The inset of figure 2(b) plots the

$\tilde {\alpha } > 10$. The inset of figure 2(b) plots the ![]() $\mathcal {L} - \tilde {\alpha }$ relationship in double-logarithmic coordinates, which shows that the

$\mathcal {L} - \tilde {\alpha }$ relationship in double-logarithmic coordinates, which shows that the ![]() $\mathcal {L}\unicode{x2013} \tilde {\alpha }$ relationship transforms from one power-law relation to another, as we increase

$\mathcal {L}\unicode{x2013} \tilde {\alpha }$ relationship transforms from one power-law relation to another, as we increase ![]() $\tilde {\alpha }$. This transformation occurs at

$\tilde {\alpha }$. This transformation occurs at ![]() $\tilde {\alpha }\approx 3.5$, but the slope change in the log–log plot is not so obvious as that in the

$\tilde {\alpha }\approx 3.5$, but the slope change in the log–log plot is not so obvious as that in the ![]() $\mathcal {L}\unicode{x2013}\alpha$ relationship for horizontal granular column collapses.

$\mathcal {L}\unicode{x2013}\alpha$ relationship for horizontal granular column collapses.

Figure 2(b) shows the applicability and advantage of ![]() $\tilde {\alpha }$ and the possibility of using

$\tilde {\alpha }$ and the possibility of using ![]() $\tilde {\alpha }_{eff}$ to quantify granular column collapses on inclined planes with grains of different frictional properties. However, it is difficult to control the particle friction, particle shapes, the boundary friction and the inclination angle in an experiment. Thus, we further investigate this behaviour using numerical methods, so that we can tune both frictional parameters and inclination angles more carefully.

$\tilde {\alpha }_{eff}$ to quantify granular column collapses on inclined planes with grains of different frictional properties. However, it is difficult to control the particle friction, particle shapes, the boundary friction and the inclination angle in an experiment. Thus, we further investigate this behaviour using numerical methods, so that we can tune both frictional parameters and inclination angles more carefully.

3. Discrete element modelling and simulation set-up

3.1. Sphero-polyhedral discrete element method

In this work, we use the discrete element method to reflect particle-scale behaviours of granular flows on an inclined plane. A major advantage of the discrete element method is that the particle motion is calculated explicitly based on particle contact mechanics and Newton's laws. To use this method, we first need to determine particle shapes and the corresponding contact law. Since we are exploring granular column collapse on inclined planes, we expect that a granular avalanche is initiated and, most importantly, can be stopped naturally. Introducing spherical particles in this system requires us to set up a rolling resistance (both choosing a rolling resistance model and its corresponding parameters), which introduces more parameters that need to be calibrated. Therefore, we naturally choose to generate particles based on the Voronoi tessellation.

For a simulation, once we identify the initial material domain, a Voronoi tessellation will be performed so that we can obtain a packing of Voronoi-based polyhedrons with initial solid fraction equal to 1. The inset of figure 3(a) shows a few Voronoi-based polyhedra generated from Voronoi tessellation. Figure 3(a) shows the histogram of volumes of approximately 36 000 particles generated from Voronoi tessellation within a ![]() $3\times 3\times 40\ {\rm cm}^3$ domain. We see that most particle volumes are in the range between

$3\times 3\times 40\ {\rm cm}^3$ domain. We see that most particle volumes are in the range between ![]() $3\ {\rm mm}^3$ and

$3\ {\rm mm}^3$ and ![]() $15\ {\rm mm}^3$ with mean volume of approximately

$15\ {\rm mm}^3$ with mean volume of approximately ![]() $8.28\ {\rm mm}^3$ and median volume of

$8.28\ {\rm mm}^3$ and median volume of ![]() $8.00\ {\rm mm}^3$. The standard deviation of generated particle volumes is

$8.00\ {\rm mm}^3$. The standard deviation of generated particle volumes is ![]() $7.65\ {\rm mm}^3$.

$7.65\ {\rm mm}^3$.

Figure 3. (a) Histogram of particle volumes, ![]() $V_{p}$, generated from Voronoi tessellation. The inset shows typical Voronoi-based particles generated from Voronoi tessellation. (b) Histogram of the effective particle diameter,

$V_{p}$, generated from Voronoi tessellation. The inset shows typical Voronoi-based particles generated from Voronoi tessellation. (b) Histogram of the effective particle diameter, ![]() $d_{ep} = (6V_p/{\rm \pi} )^{1/3}$. The solid curve in this figure represents a Gaussian distribution.

$d_{ep} = (6V_p/{\rm \pi} )^{1/3}$. The solid curve in this figure represents a Gaussian distribution.

It is difficult to conclude a possible size distribution function for particle volumes, but the effective particle diameter, as shown in figure 3(b), clearly follows a normal distribution, as shown by the solid curve in figure 3(b). An effective particle diameter, ![]() $d_{ep}$, is calculated based on regarding each polyhedron as a sphere with the same volume, so that

$d_{ep}$, is calculated based on regarding each polyhedron as a sphere with the same volume, so that ![]() $d_{ep} = (6V_p/{\rm \pi} )^{1/3}$, where

$d_{ep} = (6V_p/{\rm \pi} )^{1/3}$, where ![]() $V_p$ is the particle volume. Most

$V_p$ is the particle volume. Most ![]() $d_{ep}$ values fall between 2 and 3 mm with the mean value equal to 2.475 mm and the standard deviation of approximately 0.225 mm. The randomness of both particle shapes and particle sizes ensures that no granular crystallization will be formed during the granular column collapse.

$d_{ep}$ values fall between 2 and 3 mm with the mean value equal to 2.475 mm and the standard deviation of approximately 0.225 mm. The randomness of both particle shapes and particle sizes ensures that no granular crystallization will be formed during the granular column collapse.

We calculate the contact between Voronoi-based particles based on the sphero-polyhedral method, where each polyhedron is eroded and dilated by a spherical element to obtain a particle with similar shape as the original polyhedron, but with rounded edges and corners, as discussed by Galindo-Torres (Reference Galindo-Torres2013) and Man et al. (Reference Man, Zhang, Huppert and Galindo-Torres2023). The contact between two Voronoi-based particles can then be calculated based on the overlap ![]() $\delta _n$, relative tangential displacement vector

$\delta _n$, relative tangential displacement vector ![]() $\boldsymbol {\varXi }$ and relative normal velocity vector

$\boldsymbol {\varXi }$ and relative normal velocity vector ![]() $\boldsymbol {v}_{\boldsymbol {n}}$ between contacting spherical elements. The normal and tangential forces between two contacting Voronoi-based particles are calculated as

$\boldsymbol {v}_{\boldsymbol {n}}$ between contacting spherical elements. The normal and tangential forces between two contacting Voronoi-based particles are calculated as

where ![]() $K_n$ and

$K_n$ and ![]() $K_t$ are normal and tangential stiffness of particles,

$K_t$ are normal and tangential stiffness of particles, ![]() $m_e = 2(1/m_1 + 1/m_2)^{-1}$ is the reduced mass,

$m_e = 2(1/m_1 + 1/m_2)^{-1}$ is the reduced mass, ![]() $m_1$ and

$m_1$ and ![]() $m_2$ are masses of contacting particles, respectively,

$m_2$ are masses of contacting particles, respectively, ![]() $\mu _p$ is the frictional coefficient of particle interactions, and

$\mu _p$ is the frictional coefficient of particle interactions, and ![]() $\boldsymbol {\hat {n}}$ and

$\boldsymbol {\hat {n}}$ and ![]() $\boldsymbol {\hat {t}}$ are unit vectors of normal and tangential direction. We neglect the tangential dissipation term in (3.1b) because we want to limit the tangential energy dissipation to only frictional effects. However, the normal dissipation term in (3.1a) is kept unchanged, and

$\boldsymbol {\hat {t}}$ are unit vectors of normal and tangential direction. We neglect the tangential dissipation term in (3.1b) because we want to limit the tangential energy dissipation to only frictional effects. However, the normal dissipation term in (3.1a) is kept unchanged, and ![]() $\gamma _n$, being the normal energy dissipation constant, depends on the coefficient of restitution

$\gamma _n$, being the normal energy dissipation constant, depends on the coefficient of restitution ![]() $e$ as defined by Alonso-Marroquín et al. (Reference Alonso-Marroquín, Ramírez-Gómez, González-Montellano, Balaam, Hanaor, Flores-Johnson, Gan, Chen and Shen2013) and Galindo-Torres, Zhang & Krabbenhoft (Reference Galindo-Torres, Zhang and Krabbenhoft2018),

$e$ as defined by Alonso-Marroquín et al. (Reference Alonso-Marroquín, Ramírez-Gómez, González-Montellano, Balaam, Hanaor, Flores-Johnson, Gan, Chen and Shen2013) and Galindo-Torres, Zhang & Krabbenhoft (Reference Galindo-Torres, Zhang and Krabbenhoft2018),

The restitution coefficient and the corresponding energy dissipation coefficient will ensure that, if a particle is colliding with a fixed particle, the outward velocity is the multiplication of the inward velocity and the restitution coefficient, and will not generate cohesive effects for the system. Furthermore, MiDi (Reference MiDi2004) has shown that, for dry granular systems, changing the restitution coefficient does not result in changes in the rheological behaviour (at least when the inertial number is smaller than 0.3). However, for clarification, we conducted multiple simulations with ![]() $e_n$ equal to 0.5 or 0.8 and present the results in § 7. Additionally, the comparisons between Hertz contact and Hookean contact were conducted by Brewster et al. (Reference Brewster, Silbert, Grest and Levine2008), where they showed that, for both contact laws, (1) the dissipative coefficients do not strongly influence the granular rheology and (2) the details of the interaction do not appear to matter, but it is vital to use large stiffness,

$e_n$ equal to 0.5 or 0.8 and present the results in § 7. Additionally, the comparisons between Hertz contact and Hookean contact were conducted by Brewster et al. (Reference Brewster, Silbert, Grest and Levine2008), where they showed that, for both contact laws, (1) the dissipative coefficients do not strongly influence the granular rheology and (2) the details of the interaction do not appear to matter, but it is vital to use large stiffness, ![]() $k_n > 10^6\ {\rm mg}\ {\rm d}^{-1}$, to avoid possible artefacts that may arise from using particles that are too soft. The motion of particles is then calculated by step-wise resolution of Newton's second law with the normal and contact forces using the velocity-Verlet method (Scherer Reference Scherer2017). The discrete element method was incorporated in an open-source computing package, MechSys, developed and maintained by one of the authors of this work (Galindo-Torres Reference Galindo-Torres2013), and was validated by various peer-reviewed articles (Galindo-Torres & Pedroso Reference Galindo-Torres and Pedroso2010; Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a, Reference Man, Huppert, Zhang and Galindo-Torres2022). We refer the readers to Galindo-Torres et al. (Reference Galindo-Torres, Alonso-Marroquín, Wang, Pedroso and Castano2009) and Galindo-Torres & Pedroso (Reference Galindo-Torres and Pedroso2010) for more information about the details of the contact detection of sphero-polyhedral DEM.

$k_n > 10^6\ {\rm mg}\ {\rm d}^{-1}$, to avoid possible artefacts that may arise from using particles that are too soft. The motion of particles is then calculated by step-wise resolution of Newton's second law with the normal and contact forces using the velocity-Verlet method (Scherer Reference Scherer2017). The discrete element method was incorporated in an open-source computing package, MechSys, developed and maintained by one of the authors of this work (Galindo-Torres Reference Galindo-Torres2013), and was validated by various peer-reviewed articles (Galindo-Torres & Pedroso Reference Galindo-Torres and Pedroso2010; Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a, Reference Man, Huppert, Zhang and Galindo-Torres2022). We refer the readers to Galindo-Torres et al. (Reference Galindo-Torres, Alonso-Marroquín, Wang, Pedroso and Castano2009) and Galindo-Torres & Pedroso (Reference Galindo-Torres and Pedroso2010) for more information about the details of the contact detection of sphero-polyhedral DEM.

3.2. Simulation set-up

The simulation set-up is similar to that in the experiment presented by Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011), but we can explicitly control the frictional properties of both boundaries and particles and set up periodic boundary conditions. The periodic boundary condition, which is different from the experimental set-up of Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011), is used to decrease the influence of the lateral boundaries. In our study, our main goal is to explore the collapsing behaviour and deposition morphology of granular column collapses on inclined planes while not introducing more controlling parameters to further increase the complexity of the system. Thus, we chose to use a periodic boundary condition to eliminate the influence of the finite width. We show the simulation set up in figure 4. The ![]() $x$-axis is in the horizontal direction, the

$x$-axis is in the horizontal direction, the ![]() $z$ direction is in the vertical direction and the

$z$ direction is in the vertical direction and the ![]() $y$-axis is pointing into the

$y$-axis is pointing into the ![]() $x\unicode{x2013}z$ plane. The simulation has three boundary plates: (1) a vertical plate with the frictional coefficient of

$x\unicode{x2013}z$ plane. The simulation has three boundary plates: (1) a vertical plate with the frictional coefficient of ![]() $\mu _{bv} = 0$ so that the collapsing granular materials will not face resistance from the vertical wall; (2) a horizontal plane, on which we place the granular packing at the initial state; and (3) an inclined plane, which the granular column will collapse onto once we release particles. The length of the horizontal plate along the

$\mu _{bv} = 0$ so that the collapsing granular materials will not face resistance from the vertical wall; (2) a horizontal plane, on which we place the granular packing at the initial state; and (3) an inclined plane, which the granular column will collapse onto once we release particles. The length of the horizontal plate along the ![]() $x$-axis is the initial horizontal length,

$x$-axis is the initial horizontal length, ![]() $L_i$, of the granular column. The boundaries vertical to the

$L_i$, of the granular column. The boundaries vertical to the ![]() $y$-axis are periodic boundaries. The distance between two periodic boundaries is the width,

$y$-axis are periodic boundaries. The distance between two periodic boundaries is the width, ![]() $W_i$, of the two-dimensional column collapse; and we set

$W_i$, of the two-dimensional column collapse; and we set ![]() $W_i = 3$ cm. We note that, in this study, we set

$W_i = 3$ cm. We note that, in this study, we set ![]() $K_n=4\times 10^6\ {\rm dyne}\ {\rm cm}^{-1}$ and

$K_n=4\times 10^6\ {\rm dyne}\ {\rm cm}^{-1}$ and ![]() $K_t=0.4K_n$. The coefficient of restitution,

$K_t=0.4K_n$. The coefficient of restitution, ![]() $e$, is 0.2 to reflect a rather rough particle surface so that normal collision is easily dissipated. We note that, later in this work, we will also include additional sets of simulations with larger

$e$, is 0.2 to reflect a rather rough particle surface so that normal collision is easily dissipated. We note that, later in this work, we will also include additional sets of simulations with larger ![]() $e$ to see how this factor influences the collapse behaviour. We also set the time step to be 0.75 times the critical time scale of

$e$ to see how this factor influences the collapse behaviour. We also set the time step to be 0.75 times the critical time scale of ![]() $\sqrt {\langle m_p\rangle /K_n}$, where

$\sqrt {\langle m_p\rangle /K_n}$, where ![]() $\langle m_p\rangle$ is the average particle mass, and the time step is approximately

$\langle m_p\rangle$ is the average particle mass, and the time step is approximately ![]() $2.2\times 10^{-6}$ s.

$2.2\times 10^{-6}$ s.

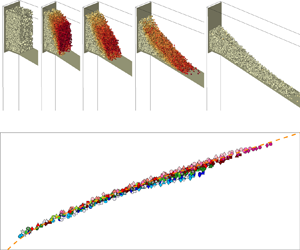

Figure 4. A discrete element simulation of granular column collapses onto an inclined plane of ![]() $\theta = 10^{\circ }$. Snapshots are taken at (a)

$\theta = 10^{\circ }$. Snapshots are taken at (a) ![]() $t = 0$ s, (b)

$t = 0$ s, (b) ![]() $t = 0.08$ s, (c)

$t = 0.08$ s, (c) ![]() $t = 0.12$ s, (d)

$t = 0.12$ s, (d) ![]() $t = 0.2$ s and (e)

$t = 0.2$ s and (e) ![]() $t = 0.5$ s. The

$t = 0.5$ s. The ![]() $x$-axis is towards the horizontal direction, and the

$x$-axis is towards the horizontal direction, and the ![]() $z$-axis is towards the vertical direction. Different colours represent different velocity magnitudes of particles. The colour bar in the figure shows the range of colour that corresponds to the velocity magnitude varying from 0 to its maximum.

$z$-axis is towards the vertical direction. Different colours represent different velocity magnitudes of particles. The colour bar in the figure shows the range of colour that corresponds to the velocity magnitude varying from 0 to its maximum.

At the initial condition shown in figure 4(a), we identify the initial domain of the granular column within ![]() $L_i \times W_i \times H_i$ and perform the Voronoi tessellation to form a Voronoi granular packing with solid fraction 1. To make sure that granular materials are loosely packed at the initial state, we choose to reduce the initial solid fraction to

$L_i \times W_i \times H_i$ and perform the Voronoi tessellation to form a Voronoi granular packing with solid fraction 1. To make sure that granular materials are loosely packed at the initial state, we choose to reduce the initial solid fraction to ![]() $\phi _{init} = 0.6$ by randomly removing 40 % of grains from the Voronoi tessellation. The removal of grains has almost no influence on the mean value and standard deviation of the effective particle diameter of the granular system. Then, we release the packing and let it flow onto the incline plane. We set the boundary frictional coefficients on the horizontal plate and on the incline plane at the same value, which is

$\phi _{init} = 0.6$ by randomly removing 40 % of grains from the Voronoi tessellation. The removal of grains has almost no influence on the mean value and standard deviation of the effective particle diameter of the granular system. Then, we release the packing and let it flow onto the incline plane. We set the boundary frictional coefficients on the horizontal plate and on the incline plane at the same value, which is ![]() $\mu _w = 0.4$. We also found that a novel null friction boundary could be imposed for reducing computational times proposed by Chung, Kuo & Hsiau (Reference Chung, Kuo and Hsiau2022). However, in this work, we choose a more traditional way to impose frictional conditions since it is consistent with our previous studies (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a). We also note that, in the simulation work, the boundary condition of imposing merely frictional coefficients is also different from the experimental study of Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011), where the inclined channel was rough and bumpy. Thus, we do not expect our simulation results to be exactly the same as the experimental work of Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011). Figures 4(b)–4(e) show the initiation, propagation and termination of the collapse of a granular column with

$\mu _w = 0.4$. We also found that a novel null friction boundary could be imposed for reducing computational times proposed by Chung, Kuo & Hsiau (Reference Chung, Kuo and Hsiau2022). However, in this work, we choose a more traditional way to impose frictional conditions since it is consistent with our previous studies (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a). We also note that, in the simulation work, the boundary condition of imposing merely frictional coefficients is also different from the experimental study of Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011), where the inclined channel was rough and bumpy. Thus, we do not expect our simulation results to be exactly the same as the experimental work of Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011). Figures 4(b)–4(e) show the initiation, propagation and termination of the collapse of a granular column with ![]() $H_i = 10$ cm. During the collapse process, we record the translational and angular velocities, positions, translational and rotational kinetic energies and particle interactions of the system. We also measure the front velocity during the collapse and determine the terminal time,

$H_i = 10$ cm. During the collapse process, we record the translational and angular velocities, positions, translational and rotational kinetic energies and particle interactions of the system. We also measure the front velocity during the collapse and determine the terminal time, ![]() $T_f$, based on the magnitude of the front velocity.

$T_f$, based on the magnitude of the front velocity.

After the flow termination, we measure the final horizontal length, ![]() $L_{\infty }$, and the deposition height,

$L_{\infty }$, and the deposition height, ![]() $H_{\infty }$, of the granular pile, to obtain the parameters shown in figure 1(a). In this work, to quantify the propagation capacity of granular column collapses, we focus on the horizontal relative run-out distance,

$H_{\infty }$, of the granular pile, to obtain the parameters shown in figure 1(a). In this work, to quantify the propagation capacity of granular column collapses, we focus on the horizontal relative run-out distance, ![]() $\delta L$, instead of the run-out distance along the inclination,

$\delta L$, instead of the run-out distance along the inclination, ![]() $\delta L^{\prime }$. We note that the way we generate the initial packing leads to a much more stable initial state than loosely packed sand. The initial Voronoi-based packing with a initial solid fraction,

$\delta L^{\prime }$. We note that the way we generate the initial packing leads to a much more stable initial state than loosely packed sand. The initial Voronoi-based packing with a initial solid fraction, ![]() $\phi _{init}$, is similar to a fissured porous rock. The face-to-face interactions naturally dominate inter-particle contacts at the initial state, which results in a more stable status for the granular packing. This indicates that the scaling results of simulated granular column collapses may be different from the experimental results obtained by Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011), but the underlying physics should be similar. In this work, to investigate the scaling of the run-out behaviour and kinematics of granular column collapses on inclined planes, we set up three different inter-particle frictional coefficients, which are 0.2, 0.4 and 0.6, vary the initial height between 1 and 50 cm, so that the initial aspect ratio,

$\phi _{init}$, is similar to a fissured porous rock. The face-to-face interactions naturally dominate inter-particle contacts at the initial state, which results in a more stable status for the granular packing. This indicates that the scaling results of simulated granular column collapses may be different from the experimental results obtained by Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011), but the underlying physics should be similar. In this work, to investigate the scaling of the run-out behaviour and kinematics of granular column collapses on inclined planes, we set up three different inter-particle frictional coefficients, which are 0.2, 0.4 and 0.6, vary the initial height between 1 and 50 cm, so that the initial aspect ratio, ![]() $\alpha = H_i/L_i$, varies from 0.33 to 16.67 and change the inclination angle,

$\alpha = H_i/L_i$, varies from 0.33 to 16.67 and change the inclination angle, ![]() $\theta$, from

$\theta$, from ![]() $2.5^{\circ }$ to

$2.5^{\circ }$ to ![]() $20^{\circ }$.

$20^{\circ }$.

4. Run-out behaviour and flow kinematics

4.1. Horizontal run-out distance

The final run-out distance is a major property for granular column collapses since it exhibits the ability of a granular system to transform potential energy to kinetic energy, and links to propagation capacity and damage level of geophysical flows, such as landslides and pyroclastic flows, in natural systems. Lube et al. (Reference Lube, Huppert, Sparks and Freundt2011) examined the run-out behaviour of granular column collapses on inclined planes and treated the run-out distance on the inclination as a key parameter. However, in this work, we focus on the horizontal run-out behaviour and treat the vertical run-out as a result of both horizontal run-out distance and the inclination angle, and regard the horizontal run-out distance as a direct measurement quantifying the transformation from potential to kinetic energy.

We plot the relative horizontal run-out distance, ![]() $\mathcal {L} = (L_{\infty } - L_i)/L_i = \delta L/L_i$, against the initial aspect ratio,

$\mathcal {L} = (L_{\infty } - L_i)/L_i = \delta L/L_i$, against the initial aspect ratio, ![]() $\alpha = H_i/L_i$, of systems with

$\alpha = H_i/L_i$, of systems with ![]() $\phi _{init} = 0.6$ in figure 5(a). For each set of simulations with the same inclination angle

$\phi _{init} = 0.6$ in figure 5(a). For each set of simulations with the same inclination angle ![]() $\theta$, we have three different inter-particle frictional properties, i.e.

$\theta$, we have three different inter-particle frictional properties, i.e. ![]() $\mu _p = 0.2$, 0.4 and 0.6. We can see from figure 5(a) that increasing the inter-particle frictional coefficient from 0.2 to 0.6 helps decrease the run-out distance, and changing frictional properties scatters corresponding data points. Increasing the inclination angle greatly increases the run-out distance. For instance, for systems with

$\mu _p = 0.2$, 0.4 and 0.6. We can see from figure 5(a) that increasing the inter-particle frictional coefficient from 0.2 to 0.6 helps decrease the run-out distance, and changing frictional properties scatters corresponding data points. Increasing the inclination angle greatly increases the run-out distance. For instance, for systems with ![]() $\alpha \approx 1.0$ and

$\alpha \approx 1.0$ and ![]() $\mu _p = 0.4$,

$\mu _p = 0.4$, ![]() $\mathcal {L}$ is less than 1 when

$\mathcal {L}$ is less than 1 when ![]() $\theta = 2.5^{\circ }$, but

$\theta = 2.5^{\circ }$, but ![]() $\mathcal {L}$ is already larger than 10 when

$\mathcal {L}$ is already larger than 10 when ![]() $\theta = 20^{\circ }$. This indicates that increasing

$\theta = 20^{\circ }$. This indicates that increasing ![]() $\theta$ by only a factor of 8 results in a run-out distance more than 10 times longer, which implies that the relationship between the initial aspect ratio and the relative run-out distance is nonlinear.

$\theta$ by only a factor of 8 results in a run-out distance more than 10 times longer, which implies that the relationship between the initial aspect ratio and the relative run-out distance is nonlinear.

Figure 5. Relative horizontal run-out distance of systems with ![]() $\phi _{init} = 0.6$ plotted against (a) initial aspect ratio,

$\phi _{init} = 0.6$ plotted against (a) initial aspect ratio, ![]() $\alpha$, (b) effective aspect ratio,

$\alpha$, (b) effective aspect ratio, ![]() $\alpha _{eff}$, and (c) inclined effective aspect ratio,

$\alpha _{eff}$, and (c) inclined effective aspect ratio, ![]() $\tilde {\alpha }_{eff}$, for 21 different sets of simulations. The red curve represents the fitting relationship of

$\tilde {\alpha }_{eff}$, for 21 different sets of simulations. The red curve represents the fitting relationship of ![]() $\mathcal {L}\sim \tilde {\alpha }_{eff}^{1.35}$ and the blue curve denotes the fitting of

$\mathcal {L}\sim \tilde {\alpha }_{eff}^{1.35}$ and the blue curve denotes the fitting of ![]() $\mathcal {L}\sim \tilde {\alpha }_{eff}$.

$\mathcal {L}\sim \tilde {\alpha }_{eff}$.

Using the effective aspect ratio ![]() $\alpha _{eff}$ that we proposed previously, we are able to collapse the simulation results of systems with the same

$\alpha _{eff}$ that we proposed previously, we are able to collapse the simulation results of systems with the same ![]() $\theta$ onto one curve as shown in figure 5(b). We reiterate that the derivation of

$\theta$ onto one curve as shown in figure 5(b). We reiterate that the derivation of ![]() $\alpha _{eff}$ is based on the assumption that the granular column collapse is governed by the ratio between the inertial effect and the frictional resistance. The ability of

$\alpha _{eff}$ is based on the assumption that the granular column collapse is governed by the ratio between the inertial effect and the frictional resistance. The ability of ![]() $\alpha _{eff}$ to quantify horizontal granular column collapses has been verified in many previous works (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a, Reference Man, Huppert, Li and Galindo-Torresb, Reference Man, Huppert, Zhang and Galindo-Torres2022, Reference Man, Zhang, Huppert and Galindo-Torres2023), and it still works for a system with an inclined run-out. However,

$\alpha _{eff}$ to quantify horizontal granular column collapses has been verified in many previous works (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a, Reference Man, Huppert, Li and Galindo-Torresb, Reference Man, Huppert, Zhang and Galindo-Torres2022, Reference Man, Zhang, Huppert and Galindo-Torres2023), and it still works for a system with an inclined run-out. However, ![]() $\alpha _{eff}$ fails to combine all the data into a master curve since the influence of

$\alpha _{eff}$ fails to combine all the data into a master curve since the influence of ![]() $\theta$ is missing in the definition of it, but most importantly, changing the

$\theta$ is missing in the definition of it, but most importantly, changing the ![]() $x$-axis from

$x$-axis from ![]() $\alpha$ to

$\alpha$ to ![]() $\alpha _{eff}$ imposes no effect to the nature that larger inclination angles lead to longer run-out distances. Based on the analysis in § 2, we hypothesize that the inclined effective ratio,

$\alpha _{eff}$ imposes no effect to the nature that larger inclination angles lead to longer run-out distances. Based on the analysis in § 2, we hypothesize that the inclined effective ratio, ![]() $\tilde {\alpha }_{eff}$, which includes both frictional properties and the inclination information, where the calculations of both the inertial effect and the frictional resistance already consider the influence of the inclination angle, could help quantify and unify the relationship between run-out distances and initial geometries.

$\tilde {\alpha }_{eff}$, which includes both frictional properties and the inclination information, where the calculations of both the inertial effect and the frictional resistance already consider the influence of the inclination angle, could help quantify and unify the relationship between run-out distances and initial geometries.

Figure 5(c) plots the relationship between ![]() $\mathcal {L}$ and

$\mathcal {L}$ and ![]() $\tilde {\alpha }_{eff}$ in a log–log coordinate system for simulation results obtained from granular column collapses with

$\tilde {\alpha }_{eff}$ in a log–log coordinate system for simulation results obtained from granular column collapses with ![]() $\theta = 2.5^{\circ }\unicode{x2013}20^{\circ }$. As expected, changing the

$\theta = 2.5^{\circ }\unicode{x2013}20^{\circ }$. As expected, changing the ![]() $x$-axis to

$x$-axis to ![]() $\tilde {\alpha }_{eff}$ helps tremendously, in that almost all the data points fall onto a master curve, except for systems with large

$\tilde {\alpha }_{eff}$ helps tremendously, in that almost all the data points fall onto a master curve, except for systems with large ![]() $\tilde {\alpha }_{eff}$ and

$\tilde {\alpha }_{eff}$ and ![]() $\theta \leqslant 5^{\circ }$. The

$\theta \leqslant 5^{\circ }$. The ![]() $\mathcal {L}\text {-- }\tilde {\alpha }_{eff}$ relationship consists of two parts. When

$\mathcal {L}\text {-- }\tilde {\alpha }_{eff}$ relationship consists of two parts. When ![]() $\tilde {\alpha }_{eff} \lessapprox 4$,

$\tilde {\alpha }_{eff} \lessapprox 4$, ![]() $\mathcal {L}$ approximately scales with

$\mathcal {L}$ approximately scales with ![]() $\tilde {\alpha }_{eff}^{1.35}$, as shown by the red line in figure 5(b), but when

$\tilde {\alpha }_{eff}^{1.35}$, as shown by the red line in figure 5(b), but when ![]() $\tilde {\alpha }_{eff} \gtrapprox 4$,

$\tilde {\alpha }_{eff} \gtrapprox 4$, ![]() $\mathcal {L}$ approximately scales proportionally to

$\mathcal {L}$ approximately scales proportionally to ![]() $\tilde {\alpha }_{eff}$, as shown by the blue line in this figure. The parameters of the power-law scaling are different from those in the

$\tilde {\alpha }_{eff}$, as shown by the blue line in this figure. The parameters of the power-law scaling are different from those in the ![]() $\mathcal {L}\unicode{x2013} \alpha _{eff}$ relationship reported by Man et al. (Reference Man, Huppert, Li and Galindo-Torres2021a), since

$\mathcal {L}\unicode{x2013} \alpha _{eff}$ relationship reported by Man et al. (Reference Man, Huppert, Li and Galindo-Torres2021a), since ![]() $\tilde {\alpha }_{eff}$ contains information of the final run-out distance

$\tilde {\alpha }_{eff}$ contains information of the final run-out distance ![]() $L_{\infty }$ inside its definition. When

$L_{\infty }$ inside its definition. When ![]() $\tilde {\alpha }_{eff}\gtrapprox 4$ and

$\tilde {\alpha }_{eff}\gtrapprox 4$ and ![]() $\theta \leqslant 5^{\circ }$, the simulation results slightly deviate from other data points, and the master curve would over-predict the run-out distance. In one of our previous works (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a), we classified granular column collapses into three different regimes: quasi-static, inertial and fluid-like. One key characteristic of a granular collapse within the fluid-like regime is that the inertial effect becomes so large that the memory of the initial packing, i.e. the initial contact structure and the initial geometry, will be lost, which results in the behaviour that particles initially at the bottom of the packing flow to the very front of the final deposition pile. The data deviation of granular columns with

$\theta \leqslant 5^{\circ }$, the simulation results slightly deviate from other data points, and the master curve would over-predict the run-out distance. In one of our previous works (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a), we classified granular column collapses into three different regimes: quasi-static, inertial and fluid-like. One key characteristic of a granular collapse within the fluid-like regime is that the inertial effect becomes so large that the memory of the initial packing, i.e. the initial contact structure and the initial geometry, will be lost, which results in the behaviour that particles initially at the bottom of the packing flow to the very front of the final deposition pile. The data deviation of granular columns with ![]() $\tilde {\alpha }_{eff}$ and

$\tilde {\alpha }_{eff}$ and ![]() $\theta \leqslant 5^{\circ }$ implies that the fluid-like regimes for systems with different inclination angles might be different from each other.

$\theta \leqslant 5^{\circ }$ implies that the fluid-like regimes for systems with different inclination angles might be different from each other.

We choose two cases to investigate and plot the deposition pattern on the ![]() $x\unicode{x2013}z$ plane in figure 6. The red region represent the deposition pattern of a granular column collapse with

$x\unicode{x2013}z$ plane in figure 6. The red region represent the deposition pattern of a granular column collapse with ![]() $\theta = 2.5^{\circ }, \mu _p = 0.4, H_i = 50$ cm,

$\theta = 2.5^{\circ }, \mu _p = 0.4, H_i = 50$ cm, ![]() $\tilde {\alpha }_{eff} = 15.94$, and the blue region shows the pattern of a collapse with

$\tilde {\alpha }_{eff} = 15.94$, and the blue region shows the pattern of a collapse with ![]() $\theta = 15^{\circ }, \mu _p = 0.4, H_i = 25$ cm,

$\theta = 15^{\circ }, \mu _p = 0.4, H_i = 25$ cm, ![]() $\tilde {\alpha }_{eff} = 15.94$. Two systems have similar

$\tilde {\alpha }_{eff} = 15.94$. Two systems have similar ![]() $\tilde {\alpha }_{eff}$ and both reached the fluid-like regime, as we have argued previously (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a), but have different inclination angles. The red region shows that, after the granular column collapse, the granular pile is similar to a horizontal granular column collapse with a triangular-like deposition pattern. However, for a granular column collapse with a larger inclination angle, the deposition structure becomes different. The blue region shows that a large part of the deposition is covered by only one or two layers of particles, which indicates a larger relative run-out distance than systems with

$\tilde {\alpha }_{eff}$ and both reached the fluid-like regime, as we have argued previously (Man et al. Reference Man, Huppert, Li and Galindo-Torres2021a), but have different inclination angles. The red region shows that, after the granular column collapse, the granular pile is similar to a horizontal granular column collapse with a triangular-like deposition pattern. However, for a granular column collapse with a larger inclination angle, the deposition structure becomes different. The blue region shows that a large part of the deposition is covered by only one or two layers of particles, which indicates a larger relative run-out distance than systems with ![]() $\theta = 2.5^{\circ }$ and 5

$\theta = 2.5^{\circ }$ and 5![]() $^{\circ }$. We believe that it is the ability to generate a large area of one-layer particle cover that results in the deviation in the

$^{\circ }$. We believe that it is the ability to generate a large area of one-layer particle cover that results in the deviation in the ![]() $\mathcal {L}\unicode{x2013}\tilde {\alpha }_{eff}$ plot. In the system represented by the red region, the thin-layered region is small compared with the length of the granular pile. We can find one particle that reaches

$\mathcal {L}\unicode{x2013}\tilde {\alpha }_{eff}$ plot. In the system represented by the red region, the thin-layered region is small compared with the length of the granular pile. We can find one particle that reaches ![]() $X = 80$ cm and a few particles present between

$X = 80$ cm and a few particles present between ![]() $X = 60$ cm and

$X = 60$ cm and ![]() $X = 80$ cm, but those particles are all detached from the main pile and cannot be regarded as a thin-layered area.

$X = 80$ cm, but those particles are all detached from the main pile and cannot be regarded as a thin-layered area.

Figure 6. Deposition pattern for granular column collapses with ![]() $\theta = 2.5^{\circ }$,

$\theta = 2.5^{\circ }$, ![]() $H_i = 50$ cm,

$H_i = 50$ cm, ![]() $\tilde {\alpha }_{eff} = 15.94$ (as the red region) and

$\tilde {\alpha }_{eff} = 15.94$ (as the red region) and ![]() $\theta = 15^{\circ }$,

$\theta = 15^{\circ }$, ![]() $H_i = 25$ cm,

$H_i = 25$ cm, ![]() $\tilde {\alpha }_{eff} = 15.88$ (as the light blue region).