Introduction

Since the adoption of glyphosate-resistant (GR) crops and subsequent overuse of glyphosate, herbicide-resistant Palmer amaranth has become common throughout the southeastern cotton-growing region (Sosnoskie et al. Reference Sosnoskie, Kichler, Wallace and Culpepper2011; Wise et al. Reference Wise, Grey, Prostko, Vencill and Webster2009). Because of its multiple resistance to glyphosate and acetolactate synthase (ALS) inhibitors, no effective topical option is available for growers to control GR and ALS inhibitor–resistant Palmer amaranth in glyphosate-based cotton cropping systems (Culpepper et al. Reference Culpepper, York, MacRae and Kichler2008; Sosnoskie et al. Reference Sosnoskie, Kichler, Wallace and Culpepper2011). Although glufosinate can control herbicide-resistant Palmer amaranth, crop cultivars have to be glufosinate-resistant and treatment must be applied early on small Palmer amaranth seedlings less than 12 cm tall (Culpepper Reference Culpepper2009; Marshall Reference Marshall2009). Therefore, it is recommended that cotton growers use residual herbicides with different mechanisms of action to improve Palmer amaranth control and to minimize development of resistance to additional herbicides. These residual herbicides are the key to current weed control programs for cotton in the US Southeast.

Previous research has confirmed that fomesafen effectively controls GR and ALS inhibitor–resistant Palmer amaranth in cotton (Culpepper Reference Culpepper2009; Bond et al. Reference Bond, Oliver and Stephenson2006; Gardner et al. Reference Gardner, York, Jordan and Monks2006; Troxler et al. Reference Troxler, Askew, Wilcut, Smith and Paulsgrove2002). Fomesafen is a diphenylether herbicide that inhibits protoporphyrinogen oxidase. Fomesafen registration in cotton allows PRE surface application to medium- or fine-textured soils at 280 ai ha−1 up to 21 d before planting, and PRE application to coarse-textured soils at 280 to 420 g ai ha−1 (Anonymous 2017a). Fomesafen applied PRE controls annual broadleaf weeds including pigweed species (Amaranthus spp.), morningglory species (Ipomoea spp.), jimsonweed (Datura stramonium L.), wild mustard (Sinapis arvensis L. ssp. arvensis), black nightshade (Solanum nigrum L.), and ragweed species (Ambrosia spp.) (Senseman Reference Senseman2007). Treatments containing fomesafen improved early-season common cocklebur (Xanthium strumarium L.) and Ipomoea spp. control when properly activated by irrigation or precipitation (Stephenson et al. Reference Stephenson, Patterson, Faircloth and Lunsford2004). Fomesafen+pendimethalin (280 and 1,120 g ai ha−1, respectively) applied PRE followed by glufosinate mid-postemergence (POST) provided excellent control (>90%) of Palmer amaranth, common lamb’s quarters (Chenopodium album L.), large crabgrass [Digitaria sanguinalis (L.) Scop.], and goosegrass [Eleusine indica (L.) Gaertn.) (Everman et al. Reference Everman, Clewis, York and Wilcut2009). Fomesafen+fluometuron at 0.42 and 1.68 kg ai ha−1 rates were more effective than either herbicide used alone; fomesafen at 0.42 kg ai ha−1 tank-mixed with MSMA at 2.24 kg ai ha−1 applied POST and directed to cotton, effectively controlled yellow nutsedge (Cyperus esculentus L.), morningglory species, and pigweed species (Lunsford et al. Reference Lunsford, Harrison and Smith1998). Other research indicated that average control of Palmer amaranth by fomesafen at 280 and 426 g ai ha−1 was 94%, and yellow nutsedge control ranged from 68% to 77% and 90% to 98%, respectively, at two South Carolina locations, but fomesafen did not control purple nutsedge (Cyperus rotundus L.) and sicklepod [Senna obtusifolia (L.) H.S. Irwin & Barneby] (Murdock and Keeton Reference Murdock and Keeton1998). Its effectiveness on a wide range of weeds has brought fomesafen into wide used by US cotton growers. USDA-NASS (2016) estimated that fomesafen was one of the top five herbicides applied to cotton across all the US cotton-producing states, with 16% of the total planted acres treated with this herbicide in 2015.

A major concern from cotton growers regarding fomesafen is potential seedling injury, especially when applied PRE to cool, moist soil (Kichler and Culpepper, Reference Kichler and Culpepper2012). Murdock and Keeton (Reference Murdock and Keeton1998) reported cotton injury was generally greater when fomesafen was applied PRE than PPI; average injury was 5%, 9%, 14%, and 23% when fomesafen was applied PRE at 280, 426, 560, and 840 g ai ha−1, respectively. When applied PPI, average injury was 1%, 4%, 5%, and 15% for those respective rates. Schrage et al. (Reference Schrage, Norsworthy, Smith, Johnson, Bagavathiannan and Riar2012) concluded that low-vigor cotton seed incurred 20% greater fomesafen injury than high-vigor cotton seed, and deep planting at 2.5 cm caused 15% more injury than planting at 0.6 cm when fomesafen was applied PRE at 1×and 2×rates. Similar to fomesafen, other protoporphyrinogen oxidase inhibitors have been reported to cause various levels of injury on cotton and soybean (Glycine max L.).

Researchers noted that significant cotton injury occurred when flumioxazin at 70 g ai ha−1 was applied at planting, but injury was no greater than 12% and cotton yield was not affected (Askew et al. Reference Askew, Wilcut and Cranmer2002). Other researchers reported that flumioxazin severely injured cotton when heavy rainfall splashed treated soil onto leaves of 15-cm-tall cotton (Wilcut et al. Reference Wilcut, Askew, Price, Scott and Cranmer2000). Therefore, flumioxazin application should be restricted to cotton bark, and a misapplication over the top or to small cotton seedlings with green stems could cause serious injury (Wilcut et al. Reference Wilcut, Askew, Price, Scott and Cranmer2000; Cranmer et al. Reference Cranmer, Altom, Braun and Pawlak2000). In soybean, 15 varieties exhibited different levels of tolerance to flumioxazin and sulfentrazone. Injury from sulfentrazone was 10% greater than flumioxazin over three rates evaluated, and sulfentrazone at 224 g ai ha−1 reduced plant height 23% to 53% and caused 18% to 38% visual injury in the greenhouse (Taylor-Lovell et al. Reference Taylor-Lovell, Wax and Nelson2001).

Fluridone inhibits phytoene desaturase in sensitive plants and has been widely used as an aquatic herbicide since the 1970s (Bartels and Watson Reference Bartels and Watson1978; Kowalczyk-Schroder and Sandmann Reference Kowalczyk-Schroder and Sandmann1992). Fluridone can be applied over the water surface or as a layered treatment to the bottom of a water body to provide control of many submersed and emerged aquatic plants (McCowen et al. Reference McCowen, Young, West, Parka and Arnold1979). In recent years, fluridone has been evaluated as a potential PRE option in cotton to prevent the development of weed resistance as a new mechanism of action to cotton. Previous research confirmed that fluridone provided good to excellent control of Palmer amaranth and annual grasses comparable to fomesafen, diuron, and acetochlor (Braswell et al. Reference Braswell, Cahoon, York, Jordan and Seagroves2016). In other research, fluridone controlled Palmer amaranth and pitted morningglory (Ipomoea lacunosa L.) when applied PRE to cotton. However, neither fluometuron nor fluridone provided season-long weed control, and multiple POST treatments were still needed (Hill et al. Reference Hill, Norsworthy, Barber and Gbur2017). Combinations of fluridone+fomesafen, fluridone+fluometuron, or fluridone alone are labeled as Brake F16, Brake FX, and Brake herbicide, respectively, and recently received Section 3 registration for use on cotton (Anonymous 2017b, 2017c, 2017d). However, the injury potential of these two combinations in southeastern US cotton production has not been widely evaluated.

Fomesafen use in cotton production areas has dramatically increased since 2007. Total usage of fomesafen in all cotton-producing states increased by 6.48-fold from 2007 to 2015 (USDA-NASS, 2017). Total usage in Georgia was 18,573 kg on 66,636 ha in 2007 and increased to 85,164 kg on 304,330 ha in 2015. Alabama and Georgia saw 336,705 ha of cotton treated with fomesafen in 2015, which accounted for approximately 58% of the total cotton acreage (USDA-NASS, 2017). However, there is limited information regarding potential injury and yield impact on cotton when fomesafen is used alone or tank-mixed with other herbicides across various soil types and environmental conditions in Alabama and Georgia. The objective of this research was to evaluate cotton growth and yield response to fomesafen-based treatments and fluridone premixes when applied PRE in greenhouse and in field.

Materials and Methods

Greenhouse Cotton Response

Cotton response to fomesafen was evaluated in the University of Georgia greenhouse in Athens, GA, from February to May 2012. The experiment was a complete randomized design with five replications, repeated twice. Plants were grown with a 30/20 C temperature setting and 16-h photoperiod. Cotton cultivar ‘FM1845LLB2’ (Fibermax®, Bayer Cropscience, Research Triangle Park, NC) was planted 1 cm deep in containers (25 cm deep, 6.5 cm diameter) filled with either Cecil sandy loam from Clarke County, Greenville sandy clay loam from Sumter County, or Tifton loamy sand from Tift County (Table 1). Fomesafen (Reflex®, 239 g ai L−1, Syngenta Crop Protection, LLC, Greensboro, NC) was applied at 0, 70, 140, 280, 560, 1,120, and 2,240 g ai ha−1 using XR 9003VK (Teejet®, Spraying Systems Co., Wheaton, IL) flat-fan nozzles calibrated to deliver 183 L ha−1 at 187 kPa. Herbicide treatments were applied in a spray chamber immediately after planting, and containers were irrigated with 1.5 cm water following the application. After emergence, cotton was irrigated as needed and fertilized biweekly with Miracle Gro® (The Scotts Company, LLC, Marysville, OH). Seedling heights were evaluated up to 1 mo after treatment, then aboveground biomass was harvested for dry weights.

Table 1 Locations, planting and harvesting dates, and soil information of field trials conducted in 2013 and 2016Footnote a

a Soil information was provided by University of Georgia Soil Testing Laboratory (Athens, GA) and Auburn University Soil Testing Laboratory (Auburn, AL).

b Abbreviation: OM, organic matter.

c Pulaski treatments were applied May 17.

d Fine, kaolinitic, thermic Typic Kanhapludults.

e Fine, kaolinitic, thermic Rhodic Kandiudults.

f Fine-loamy, kaolinitic, thermic Plinthic Kandiudults.

g Fine-loamy over sandy or sandy-skeletal, siliceous, semiactive, thermic Typic Hapludults.

h Fine-loamy, kaolinitic, thermic Rhodic Kandiudults.

Field Cotton Tolerance to Herbicide Treatments

Field trials were conducted at three locations in GA during 2013 and three locations in AL and GA during 2016 (Table 1). Soil texture, planting, and harvesting dates are listed in Table 1. Experiments were conducted in a randomized complete block design with four replications except for Tift County (31.509232 N, 83.637003 W), which had three replications. Plots were 7.6 m long, except for Clarke County (33.726926 N, 83.300925 W), where plots were 6 m long, and Sumter County (32.046476 N, 84.366817 W), where plots were 10 m. Cotton was planted in 0.97-m wide rows in Baldwin (30.545106 N, 87.876818 W) and Pulaski (32.256735 N, 83.391549 W) counties, whereas the remaining locations were planted in 0.9-m wide rows. Clarke and Pulaski counties had two-row plots, whereas the remaining locations had four-row plots. Cotton cultivar ‘DP1137B2RF’ (Deltapine®, Monsanto Co., St. Louis, MO) was planted at all locations during 2013. During 2016, cotton cultivars ‘FM 1739 GLT’ (Fibermax®, Bayer Cropscience, Research Triangle Park, NC), ‘PHY499WRF’ (PhytoGen Cottonseed®, Dow AgroSciences, Indianapolis, IN), and ‘DP1555 B2RF’ (Deltapine®, Monsanto Co., St. Louis, MO) were planted at Pulaski, Macon (32.492970 N, 85.891841 W), and Baldwin counties, respectively.

Treatments in Table 2 were applied immediately following planting (except for Pulaski County), using a CO2-pressurized backpack sprayer with four or six Teejet nozzle boom (XR11003VK flat-fan nozzles in 2013 and TT11025 wide-angle flat nozzles in 2016) (Teejet®, Spraying Systems Co., Wheaton, IL) calibrated to deliver 187 L ha−1. Treated plots were irrigated immediately after herbicide application to ensure soil activation and as needed during the growing season. Total rainfall and irrigation during the season amounted to 84.5 cm in Clarke, 67.5 cm in Sumter, 94.5 cm in Tift, 69 cm in Baldwin, and 63 cm in Macon County. The Pulaski County trial received 32 cm of rain and supplemental irrigation as needed. All treatments including the nontreated check (NTC) were maintained weed-free throughout the growing season with glyphosate or glufosinate and hand-weeding as needed. A 1-m cotton stand from two center rows was counted at 35 to 42 d after treatment (DAT), and cotton height was recorded four times from 29 to 71 DAT at all locations for the 2013 data collection. In 2016, cotton stand was counted using two 1-m stands from two center rows, and cotton heights were recorded for 10 randomly selected plants from two center rows at 18 to 26 DAT and 45 to 57 DAT. Additionally, an injury rating was conducted on the two center rows of cotton 18 to 23 DAT in 2016. Stand count, height measurements, and cotton seed-lint yield were obtained at each location from the two center rows and averaged for statistical analysis.

Table 2 Herbicide treatments and products evaluated.

a 240 g ai L−1, Syngenta Crop Protection, Greensboro, NC 27419.

b 455 g ai L−1, BASF Corp., Research Triangle Park, NC 27709.

c 359 g ai L−1, Monsanto Co., St. Louis, MO 63167.

d 479 g ai L−1, MANA, Raleigh, NC 27609.

e 143+180 g ai L−1, SePro Corp., Carmel, IN 46032.

f 72+359 g ai L−1, SePro Corporation, Carmel, IN 46032.

Statistical Analysis

All greenhouse and field data were converted to a percentage of the NTC prior to statistical analysis. Data were processed with PROC GLIMMIX procedure in SAS® 9.3 and SAS® 9.4 (SAS Institute Inc., Cary, NC). All means were separated with Fisher’s protected LSD (P=0.05) to reveal statistical differences. Herbicide treatment was considered a main effect, and block was treated as a random effect. If treatment-by-location interaction was significant at (P≤0.05), results were separated and analyzed by location and presented by each location. If treatment-by-location interaction was not significant, location was used as a random effect. Because more treatments were added to the 2016 study, data were analyzed and presented by years. To describe greenhouse data, nonlinear regression was performed by Sigmaplot® 12 software (Systat Software, Inc., San Jose, CA) using a two-parameter exponential decay function:

where the responsive variable is greenhouse cotton seedling height and dry weight, b0 is the initial value of the responsive variable when herbicide rate x is zero, b1 is the decline rate of the responsive variable (slope), and x is the herbicide rate. Parameter estimates are prescribed in Tables 3 and 4, and parameter b1 was compared between treatments with LSD.

Table 3 Parameter estimates of greenhouse cotton height as affected by fomesafen rates.Footnote a

a

Two-parameter exponential decay model

![]() $f\left( x \right)\,{\equals}\,b_{0} e^{{{\minus}b1(x)}} $

was used for regression. SEM=standard error of the mean; b0 is the initial value of the responsive variable when herbicide rate x is zero; b1 is the decline rate of the responsive variable (slope), and x is the herbicide rate.

$f\left( x \right)\,{\equals}\,b_{0} e^{{{\minus}b1(x)}} $

was used for regression. SEM=standard error of the mean; b0 is the initial value of the responsive variable when herbicide rate x is zero; b1 is the decline rate of the responsive variable (slope), and x is the herbicide rate.

b Means followed by the same letter were not significant at the 0.05 level using LSD separation.

c GR50 is the herbicide rate causing 50% of height reduction. In this study, 50% or greater height reduction was not observed in Greenville sandy clay loam and Tifton loamy sand at any rates evaluated.

Table 4 Parameter estimates of greenhouse cotton dry weight as affected by fomesafen rates.Footnote a

a

Two-parameter exponential decay model

![]() $f\left( x \right)\, {\equals}\, b_{0} e^{{{\minus}b1(x)}} $

was used for regression. SEM=standard error of the mean; b0 is the initial value of the responsive variable when herbicide rate x is zero; b1 is the decline rate of the responsive variable (slope), and x is the herbicide rate.

$f\left( x \right)\, {\equals}\, b_{0} e^{{{\minus}b1(x)}} $

was used for regression. SEM=standard error of the mean; b0 is the initial value of the responsive variable when herbicide rate x is zero; b1 is the decline rate of the responsive variable (slope), and x is the herbicide rate.

b Means followed by the same letter were not significant at the 0.05 level using LSD separation.

c GR50 is the herbicide rate causing 50% of dry weight reduction. In this study, 50% or greater height reduction was not observed in Greenville sandy clay loam and Tifton loamy sand at any rates evaluated.

Results and Discussion

Greenhouse Cotton Response

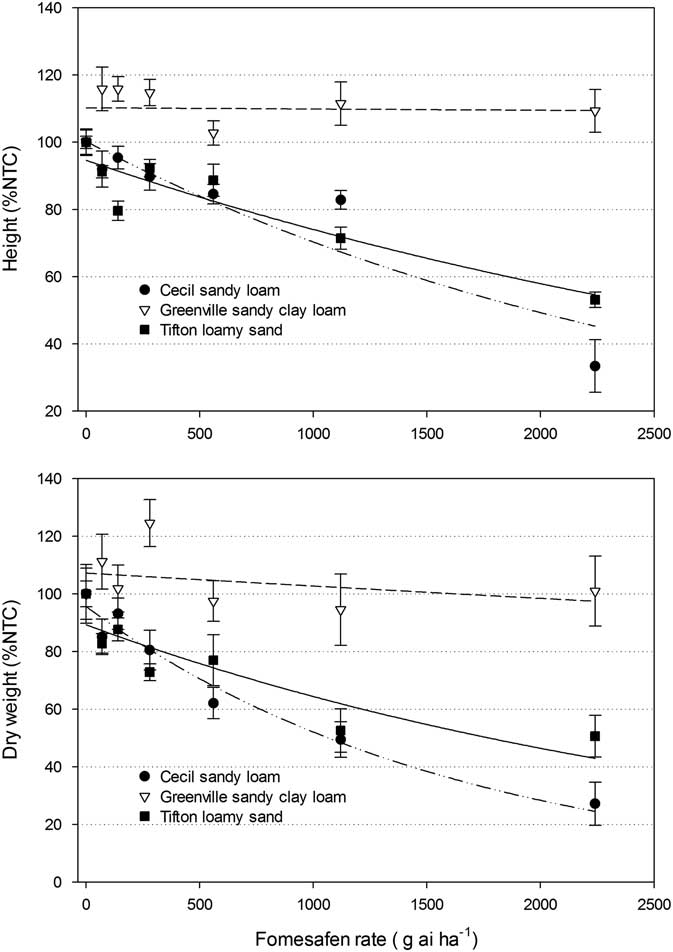

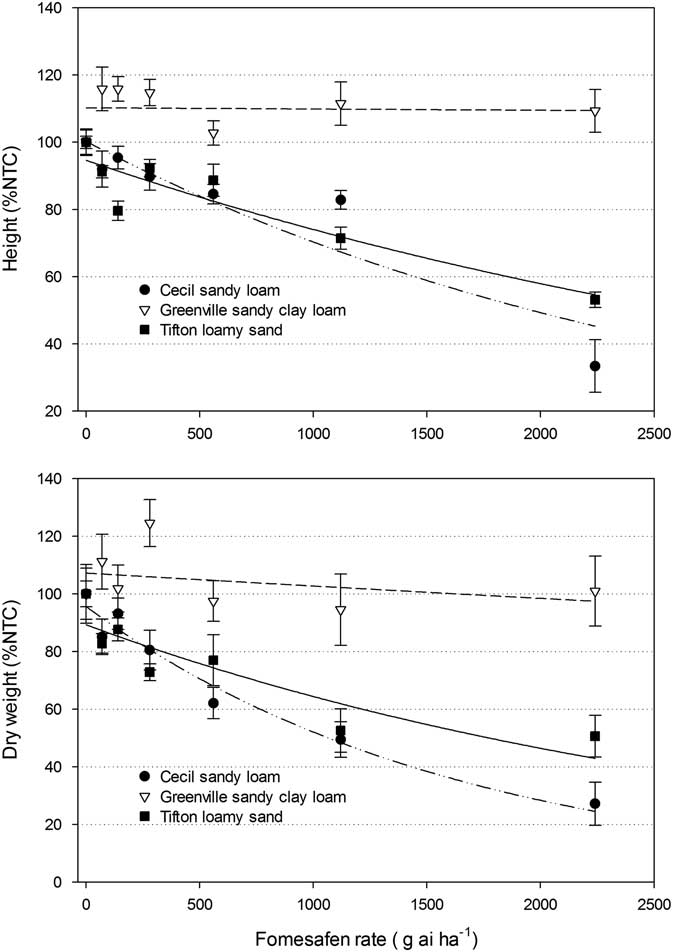

Cotton response to fomesafen varied significantly among the three soil types (Figure 1). Fomesafen reduced cotton height and dry weight in Cecil sandy loam and Tifton loamy sand, but not in Greenville sandy clay loam. Slope (b1 parameter) of nonlinear regression revealed that the height of cotton seedlings in Cecil sandy loam was most responsive to fomesafen, followed by Tifton loamy sand and Greenville sandy clay loam (Table 3). Similar to height, cotton seedling dry weight showed greatest response to fomesafen in Cecil sandy loam, followed by Tifton loamy sand and was not affected by fomesafen in Greenville sandy clay loam (Table 4). The GR50 values in Cecil sandy loam were 1,733 and 1,155 g ai ha−1, respectively, for cotton height and dry weight but could not be calculated with the rates examined in Greenville sandy clay loam and Tifton loamy sand. Cotton seedlings exhibited up to 70% and 59% visual injury at 2 and 4 wk after treatment, respectively, in Cecil sandy loam and Tifton loamy sand, and no significant injury was observed in Greenville sandy clay loam at any rate (data not shown). High OM content and clay fraction in Greenville sandy clay loam may have reduced fomesafen injury on cotton by decreasing the amount of fomesafen available in soil solution for absorption. Similarly, Baumann et al. (Reference Baumann, Keeling, Morgan and Smith1998) reported fomesafen applied at 560 and 840 g ai ha−1 resulted in up to 47% cotton injury in Amarillo sandy clay loam when applied PPI and PRE, but they did not injure cotton in Houston black clay. Li et al. (2014) reported that fomesafen’s Fredundlich soil sorption coefficient (K f ) to Greenville sandy clay loam was 7.76 and K f for Tifton loamy sand was only 1.7. The 4.6-fold difference in K f may explain why cotton responded to increasing rates of fomesafen better in Tifton sandy loam as shown in Figure 1. These results suggested that soil texture could be a critical factor determining fomesafen injury to cotton.

Figure 1 Height and dry weight responses of greenhouse cotton seedlings to various rates of fomesafen applied PRE in three soil types. NTC, nontreated check.

Field Cotton Tolerance to Fomesafen

In the 2013 study, cotton stand was evaluated between 35 and 42 DAT at each location (Table 5). In general, no effect of fomesafen on cotton stand was observed with any treatment except for the highest rate (2,240 g ai ha−1), which reduced stand 24%, 39%, and 52% in Clarke, Sumter, and Tift counties, respectively, as compared to the NTC. Cotton height (Table 6) was recorded four times between 29 to 71 DAT in all three locations and combined for data analysis, as data collection timing failed to be significant at P≤ 0.05. Overall, fomesafen did not adversely impact cotton height in Clarke County, but the highest rate reduced cotton height in Sumter County by 24%. Cotton was more responsive to fomesafen rates at Tift County than other locations: the highest rate and 1,120 g ai ha−1 reduced height by 41% and 27%, respectively, relative to the NTC. Although high rates of fomesafen may reduce cotton height and stand, cotton yield was not affected by fomesafen at any location (data not shown). The only noticeable difference was that the highest rate of fomesafen caused a 29% yield reduction in Tift County as compared to NTC. These results suggested a good overall cotton tolerance to fomesafen, but cotton could respond to high rates of fomesafen in soils with high sand fraction and low OM content.

Table 5 Stand count as affected by herbicide treatments 18 to 57 d after treatment (DAT)Footnote a

a Means followed by the same letter in the same column do not differ significantly based on a mixed-model analysis of variance (P=0.05). Data are expressed as percentage of nontreated check.

b Data collected: 35 DAT at Clarke County. 43 DAT Sumter County. 42 DAT at Tift County.

c Data collected: 18 DAT and 45 DAT at Pulaski County, 23 DAT and 57 DAT at Baldwin County, 26 DAT and 56 DAT at Macon County.

d Data was pooled over three locations, as location–herbicide treatment interaction failed to be significant at P=0.05 level.

Table 6 Plant height as affected by herbicide treatments 18 to 57 DAT.Footnote a

a Means followed by the same letter in the same column do not differ significantly based on a mixed-model analysis of variance (P=0.05). Data are expressed as percentage of nontreated check.

b Height data were taken four times from 29 to 71 DAT at all three locations and combined for analysis.

c Data collected: 18 DAT and 45 DAT at Pulaski County, 23 DAT and 57 DAT at Baldwin County, 26 DAT and 56 DAT at Macon County.

In the 2016 study, similar results were observed. The two highest rates of fomesafen (1,120 and 2,240 g ai ha−1) reduced cotton stand at Pulaski County 52% and 83%, respectively, at 18 DAT (Table 5). The highest rate of fomesafen reduced cotton stand by 43% averaged over all locations evaluated at 45 to 57 DAT. Seedling heights were significantly affected by treatments (Table 6). In Pulaski County, fomesafen at 1,120 and 2,240 g ai ha−1 and fomesafen+acetochlor reduced seedling height 55%, 74%, and 35%, respectively, as compared to NTC at 18 DAT. These three treatments also reduced seedling height 55%, 85%, and 42%, respectively, at 45 DAT, whereas fomesafen at 560 g ai ha−1 and fomesafen+diuron reduced seedling height 23% and 39%, respectively, in this county. The highest rate of fomesafen reduced seedling height 23% and 46% at 26 and 56 DAT, respectively, at Macon County (Table 6). Cotton stand and seedling height were not affected by any treatment at Baldwin County, as shown in Tables 5 and 6, and were similar to results observed at Sumter County during 2013. This may be explained by the higher clay content in these two soils. Cotton growth was more responsive to fomesafen and other soil herbicides at Pulaski and Tift counties, and this finding was further confirmed as seedlings in Pulaski County were injured up to 96% by the highest rate of fomesafen, followed by Macon County (71%) and Baldwin County (31%) (Table 7). Cotton seedlings were injured greater than 30% visual injury by six treatments at Pulaski County, three treatments at Macon County, and only one treatment at Baldwin County. Visual injury increased as fomesafen rates increased, but this correlation was more pronounced in Pulaski County than the other two locations, which may be caused by high sand fraction and low clay content in that soil (Table 7). Cotton yield was not affected by any herbicide treatment at Macon and Baldwin counties during 2016, although the highest rate of fomesafen produced numerically less yield but was not statistically different from the NTC in Macon County (Table 8). Pulaski County was the only location with significantly lower yields than NTC: fomesafen at 1,120 and 2,240 g ai ha−1 reduced yield 49% and 72%, respectively. Fomesafen+diuron showed a tendency for yield loss as compared to NTC, but this difference was insufficient to be statistically different. Yield data corresponded well with stand count, height, and visual injury assessment, as cotton seedlings at Pulaski County exhibited higher sensitivity to herbicide treatments evaluated in the 2016 study.

Table 7 Seedling injury as affected by herbicide treatments 18 to 26 DATFootnote a

a Means followed by the same letter in the same column do not differ significantly based on a mixed-model analysis of variance (P=0.05).

b Data collected: 18 DAT at Pulaski County, 23 DAT at Baldwin County, 26 DAT at Macon County.

Table 8 Cotton yield as affected by herbicide treatments in 2016 studyFootnote a

a Means followed by the same letter in the same column do not differ significantly based on a mixed-model analysis of variance (P=0.05). Data are expressed as percentage of nontreated check. Herbicide treatments failed to affect 2015 yield data at P=0.05 level.

b Yields harvested: 171 d after planting (DAP) in Pulaski County, 168 DAP in Baldwin County, and 186 DAP in Macon County. Two center rows were harvested for yield data.

Fomesafen+pendimethalin was included in this study as a standard weed control practice in cotton-growing areas, and this treatment did not induce any negative impact on cotton growth and yield at any location. Fomesafen+acetochlor and fomesafen+diuron are two popular PRE–tank mixes among cotton growers in Alabama and Georgia. These treatments caused only lower stand count and seedling height at Pulaski County, and failed to affect cotton growth at the other two locations with no yield impact at all three locations. Main et al. (Reference Main, Faircloth, Steckel, Culpepper and York2012) evaluated cotton tolerance to fomesafen at 0 to 840 g ai ha−1 in five southern states. Fomesafen caused injury early to mid-season in three states, and cotton yield was only reduced in a North Carolina trial by 23% to 25% with 560 and 840 g ai ha−1 rates, respectively. Baumann et al. (Reference Baumann, Keeling, Morgan and Smith1998) reported fomesafen applied PPI at 560 and 840 g ai ha−1 caused 22% and 47% early-season cotton injury, respectively, in an Amarillo sandy clay loam, whereas mid-season injury decreased to 15% and 23% for the respective rates, and no yield reduction was observed for any treatments applied to this soil. These previous findings are in accordance with the results of this study. These results suggested that cotton demonstrated good tolerance to fomesafen and yield was not affected when following label rates (280 to 420 g ai ha−1), but initial injury may be apparent if higher rates than the label rates are applied. Therefore, growers should not be overly concerned with fomesafen injury when following label instructions and rates, but they should be cautious to prevent accidentally applying high rates of fomesafen through miscalculation, spraying error, spray overlap, or incorrect spray settings. Fluridone+fluometuron (Brake FX) at 1×label rate and fluridone+fomesafen (Brake F16) at 1×and 2×rates did not cause any stand, height, or yield reduction, which indicates good cotton tolerance to these two premixes across the locations included in this study. Although this study yielded promising results, more evaluations regarding cotton tolerance to fluridone premixes and fluridone tank mixes as affected by different soil types and environmental conditions are needed, as it is a new herbicide registered in cotton and very limited published data and information are available for cotton growers.

Overall, cotton exhibited acceptable tolerance to fomesafen up to 1,120 g ai ha−1 and fomesafen tank mixes in this study, although lower height, stand reduction, and visual injury can occur in sandy soil. Significant cotton visual injury (up to 96%) was common in early season especially for high-rate treatments (1,120 and 2,240 g ai ha−1), but most of the injured plants gradually recovered during the course of this experiment, resulting in few yield losses relative to NTC. Fomesafen soil adsorption was negatively correlated with soil pH and positively correlated to clay content, whereas desorption was positively correlated to sand fraction and pH, and negatively correlated to OM, silt, and clay content (Li 2014). Therefore, in soils with high sand fraction and low OM, fomesafen may cause crop injury due to greater herbicide presence in soil solution and less adsorption to soil particles and OM surface. This finding may explain why little injury was seen at trials in Sumter and Baldwin counties, where soils contain more clay than the other locations. Although crop injury could be a concern for cotton growers, the benefits fomesafen provides in controlling resistant Palmer amaranth still far exceed the injury potential (Main et al. Reference Main, Faircloth, Steckel, Culpepper and York2012; Kichler et al. Reference Kichler, Culpepper and Chafin2010).

In addition, field trials in this study were planted during first 3 wk of May when soil temperatures were in the optimal range for cotton. Most of the injured cotton seedlings were able to recover and produced yields similar to NTC after a full growing season. However, if cotton is planted early in April and receives excessive rainfall after PRE application of fomesafen tank mixes, the injury potential may be higher because of a combination of low soil temperature, slow growth, oversaturation, and more herbicide presence in the soil moisture, inducing weak stands. These weak stands may be more prone to disease and insect problems, such as fusarium wilt (Fusarium oxysporum) and thrips (Thysanoptera spp.). Furthermore, in a replanting situation where the growing season is already shorter, potential fomesafen injury or stunting may further delay cotton maturity and increase the possibility of yield loss, if the rate applied is too high and applied in combination with other soil herbicides, such as acetochlor or diuron on sandy soils. These situations warrant further investigation to prevent unacceptable cotton seedling injury caused by fomesafen and fomesafen-based tank mixes.

Acknowledgments

The authors would like to thank Alabama Cotton Commission and Georgia Cotton Commission for providing funding support for this project. No conflicts of interest have been declared.