Introduction

Urbanization is of marked concern in the modern era, and it is expected to increase by 83% from 2018 to 2030 (Antrop, Reference Antrop2004; Jiang and O'Neill, Reference Jiang and O'Neill2017). The rapidly increasing population and economy have forced the world toward more urbanization, rashly reducing permeable and agricultural land on Earth (Barthel et al., Reference Barthel, Isendahl, Vis, Drescher, Evans and van Timmeren2019). Planting more vegetation could offset this phenomenon by improving the environment and aiding food security without using any external energy (Santamouris et al., Reference Santamouris, Pavlou, Doukas, Mihalakakou, Synnefa, Hatzibiros and Patargias2007). For any typical house with 3–4 proximal trees, it is estimated that shading could reduce the cooling load of the building by 17–57% (Akbari, Reference Akbari1997). If the roof of any uninsulated building is covered by plants, the heating load is reduced by up to 5% in winter, and the cooling load is reduced by up to 33% in summer (Santamouris et al., Reference Santamouris, Pavlou, Doukas, Mihalakakou, Synnefa, Hatzibiros and Patargias2007). Green roofs reduce the heat island effect of a city area by providing more permeable surfaces with significant water evaporation. Green roofs contribute to stormwater control and pre-filtration, with acoustic, aesthetic and psychological benefits to the community (van der Meulen, Reference van der Meulen2019; Williams et al., Reference Williams, Lee, Sargent, Johnson, Rayner, Farrell, Miller and Williams2019).

Green roof design and construction guidelines were released by the American Society for Testing and Materials (ASTM) in 2005 and 2006 (ASTM, 2017). Its German counterpart, the Forschungsgesellschaft landschaftsentwicklung landschaftsbau, released updated guidelines in 2008, and the US Environmental Protection Agency (EPA) followed by realizing separate guidance documents for each green roof component (EPA, 2016). In their present state, regular green roof (RGR) systems are less attractive to consumers because of the high cost, unclear cost–benefit analyses, heavy mass and large amounts of polymer use that indirectly affect the environment by releasing high amount of CO2 in its whole life cycle (Hashemi et al., Reference Hashemi, Mahmud and Ashraf2015; Shafique et al., Reference Shafique, Kim and Rafiq2018; Mahdiyar et al., Reference Mahdiyar, Mohandes, Durdyev, Tabatabaee and Ismail2020). To advance design and functionality, most current green roof research has focused intensively on single-layer design, surmounting challenges with some weather conditions, specific crops, new material inclusion or hybridizing with other systems such as solar panels (Shafique et al., Reference Shafique, Kim and Rafiq2018). Hydroponic green roof (HGR) design has become popular because of its special vegetation characteristics and reduced polymer use, with the same hydrological and environmental benefits (Tanaka et al., Reference Tanaka, Kawashima, Hama and Nakamura2017). However, replacing the growing substrates after every growing cycle, special setup requirements, and complex irrigation slow down its adoption to the users. If HGR technology is able to meet these challenges, it could prove to be a superior technology and be more attractive with the development of a new, reusable and durable growing substrate that can produce similar biomass, in addition to providing energy-saving social and environmental benefits (Williams et al., Reference Williams, Lee, Sargent, Johnson, Rayner, Farrell, Miller and Williams2019; Andrenko et al., Reference Andrenko, Montague, McKenney and Plowman2020; Tala et al., Reference Tala, Al-Ajlouni, Ayad, Othman and Hilaire2020).

This review critically investigates the structural components, benefits and limitations of current RGR and HGR systems. Knowledge gaps in research are identified. Lastly, we present the prospect and potential of porous concrete (PC) as a green roof material with hydrological and plant-growing properties, while clarifying the feasibility of PC as a growing substrate for incorporation into HGR technology.

RGR structure and components

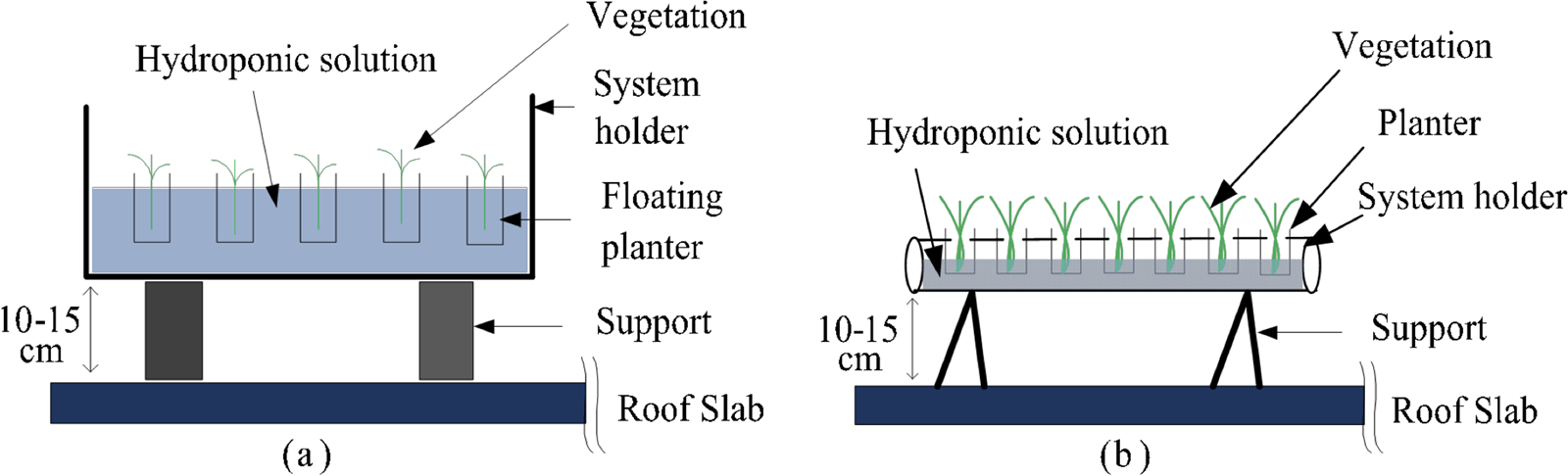

RGR systems comprise several layers: a vegetation layer with plants and water-retaining growing medium (Beck et al., Reference Beck, Johnson and Spolek2011), a filter layer, a drainage layer and a root barrier (roof membrane) that is waterproof (Fig. 1) (She and Pang, Reference She and Pang2010). RGR systems may be further categorized into extensive (simple construction/maintenance, low cost, with or without integrated irrigation systems) and intensive green roofs (complex construction/maintenance, high cost, integrated system with separate drainage) (Table 1).

Fig. 1. Different layers of typical green roof (Hashemi et al., Reference Hashemi, Mahmud and Ashraf2015).

Table 1. Comparison of RGR and HGR systems

RGR benefits

RGR can provide environmental, social and economic benefits to urban dense areas: air quality improvement, stormwater control, heat island reduction [direct radiation absorption and evapotranspiration by plants (Sailor et al., Reference Sailor, Hutchinson and Bokovoy2008)], heating and cooling load reduction, in addition to aesthetic and acoustic improvements (Hilten, Reference Hilten2005; Berardi et al., Reference Berardi, GhaffarianHoseini and GhaffarianHoseini2014; Chow and Bakar, Reference Chow and Bakar2017; van der Meulen, Reference van der Meulen2019). Cooling and heating load savings for a two-story building with a green roof comprising 40% plant coverage are estimated at approximately 6–49% for the whole building, and 12–87% for the top floor (Santamouris et al., Reference Santamouris, Pavlou, Doukas, Mihalakakou, Synnefa, Hatzibiros and Patargias2007). The temperature balancing effect of a green roof for a small building is more apparent than that of a multi-storied building (DeNardo et al., Reference DeNardo, Jarrett, Manbeck, Beattie and Berghage2005; Yao et al., Reference Yao, Chini and Zeng2020).

When retrofitting with a green roof, the building is provided with additional heat storage by adding to the roof mass, allowing for additional direct solar radiation absorption by plants and by providing a reduced cooling load due to water evapotranspiration (Ascione et al., Reference Ascione, Bianco, de'Rossi, Turni and Vanoli2013). Temperature and humidity reducing effects by green roofs in a high temperature and humidity climate have been reported (Pandey et al., Reference Pandey, Hindoliya and Mod2013). For relatively colder cities like Toronto, Canada, and New York, USA, approximately 50% of roof cover with green plants can instantly reduce the area temperature by 0.8–1°C (Rosenzweig et al., Reference Rosenzweig, Solecki and Slosberg2006; MacIvor et al., Reference MacIvor, Margolis, Perotto and Drake2016). During snowfall in Michigan, USA, for example, the roof substrate is approximately 10°C warmer than ambient temperature with herbaceous plants; with sedum plants, however, roof temperature is similar to ambient air (Eksi et al., Reference Eksi, Rowe, Wichman and Andresen2017). In another study of 325 m2 retrofitted extensive green roof in Michigan, USA, it was found that green roof can reduce around 13% of heat flux in winter and 167% in summer compared to traditional gravel roof (Getter et al., Reference Getter, Rowe, Andresen and Wichman2011). Deeper snow layer in green roof reduces the heat flux fluctuation from and to the buildings. The winter thermal benefit of green roof depends on plant type, roof construction and outdoor weather condition of the building (Lundholm et al., Reference Lundholm, Weddle and MacIvor2014).

Green roofs contribute to stormwater runoff control by delaying water runoff, mitigating the large hydraulic pressure into the sewerage system and reducing the risk of flooding (DeNardo et al., Reference DeNardo, Jarrett, Manbeck, Beattie and Berghage2005; Teemusk and Mander, Reference Teemusk and Mander2007; Wolf and Lundholm, Reference Wolf and Lundholm2008; Bianchini and Hewage, Reference Bianchini and Hewage2012). Green roofs can contribute to sustainable drainage system development by exposing large permeable areas in the city (Stovin, Reference Stovin2010). Unfortunately, regular roof material comprising reinforced cement concrete adds chemical runoff and suspended material to rainwater, both of which are problematic for water reservoir ecosystems (Berndtsson, Reference Berndtsson2010; Van Mechelen et al., Reference Van Mechelen, Dutoit and Hermy2015; Shafique et al., Reference Shafique, Kim and Rafiq2018). The fertilized soil/growing substrate of a green roof can release 0.7–2.0 mg l−1 phosphorus, 3–11.4 mg l−1 sulfate and 15.6–31.3 mg l−1 chemical oxygen demand (COD) (Bliss et al., Reference Bliss, Neufeld and Ries2009). In contrast, green roofs have an extensive heavy metal removal capacity; on average, they can remove 97% Cu, 99% Pb, 92% Cd and 96% Zn (Moran et al., Reference Moran, Hunt and Jennings2003; Hashemi et al., Reference Hashemi, Mahmud and Ashraf2015; Shafique et al., Reference Shafique, Kim and Rafiq2018).

RGR challenges

Green roof technology is one partial solution for controlling pollution, climate change and food production, yet the establishment of this technology has been met with several challenges: space and sunlight unavailability in the city, high mass on the roof structure, high cost of green roof manufacturing and research knowledge gaps spanning life-cycle assessment and environmental impact, maintenance and irrigation system requirements (Shafique et al., Reference Shafique, Kim and Rafiq2018; Tang et al., Reference Tang, Mohseni and Wang2018; Susca, Reference Susca2019). Retrofitting a roof with plants is difficult with sunlight in urban centers. Since plants require at least 3 h of sunlight, shadowing by other buildings in an urban center such as Hong Kong is of major concern (Wong and Lau, Reference Wong and Lau2013). Life-cycle analyses of green roofs and their environmental impact are equally problematic. Polymers (polyethylene and polypropylene) used in green roofs produce large amounts of NO2, SO2, O3 and PM10 during manufacturing (Table 2) (Yang et al., Reference Yang, Yu and Gong2008; Bianchini and Hewage, Reference Bianchini and Hewage2012). When examining extensive and intensive green roof manufacturing in Chicago, USA, the polymer requirement for extensive green roof is approximately 4.6 ton ha−1 of low-density polyethylene and approximately 237.5 ton ha−1 of polypropylene, whereas for intensive green roof, the low-density polyethylene requirement is approximately 4.6 ton ha−1 area of roof and the polypropylene requirement is approximately 522.5 ton ha−1 area of the green roof (Yang et al., Reference Yang, Yu and Gong2008; Bianchini and Hewage, Reference Bianchini and Hewage2012). For an extensive RGR system, low-density polythene normally serves as the root barrier layer, where only 1.5–2% polymer by total mass is needed. For an intensive RGR system, the root barrier layer uses a lower proportion of low-density polythene (0.5–1% total polymer), whereas the drainage (72.1% total polymer) and water retention (27.03% total polymer used) layers incorporate higher proportions of polypropylene (Yang et al., Reference Yang, Yu and Gong2008; Bianchini and Hewage, Reference Bianchini and Hewage2012). Extensive use of polymers makes the RGR system questionable when trying to minimize adverse environmental impact.

Table 2. Comparison of particles released to air per 1 kg polymer produced for green roof construction (Yang et al., Reference Yang, Yu and Gong2008; Bianchini and Hewage, Reference Bianchini and Hewage2012)

Challenges are further impacted by roof type, local weather, material availability and labor costs (Yao et al., Reference Yao, Chini and Zeng2020). For example, irrigation is problematic for intensive type roofing systems in cold weather, as increased energy consumption is required to melt ice and surface frost (Teemusk and Mander, Reference Teemusk and Mander2007; Berndtsson, Reference Berndtsson2010). White roof pricing, from $45 to $65 m−2, is dependent upon the materials and green roofs cost $20–25 more for each square meter of roof construction (Yao et al., Reference Yao, Chini and Zeng2020). Most green roof studies (66%) are performed in Europe and the USA, which delays the dissemination of technology in the Arabic and Asian regions where it would be more cost-beneficial because of their warm/tropical climate (Blank et al., Reference Blank, Vasl, Levy, Grant, Kadas, Dafni and Blaustein2013). One 50-year cost–benefit analysis revealed that for a 4400 m2 green roof in Florida, USA, initial costs were $103,320 more than that of a typical white roof. Acoustic and air purification, and overall environmental benefits cannot often be quantified, rendering cost–benefit analyses difficult (Yao et al., Reference Yao, Chini and Zeng2020).

Another challenge in developing RGR systems is finding an optimal plant-growing substrate for green roof installations that demonstrates high stability, availability, low-cost, ability to retain organic content, high water retention capacity, adequate permeability and porosity, high filtration and sorption capacity and light in mass. Typical plant growth substrates that are commercially available do not meet all structural and hydrological requirements, proving an insurmountable barrier to green roof construction to date (Vijayaraghavan, Reference Vijayaraghavan2016; Shafique et al., Reference Shafique, Kim and Rafiq2018).

HGR systems

HGR structure and components

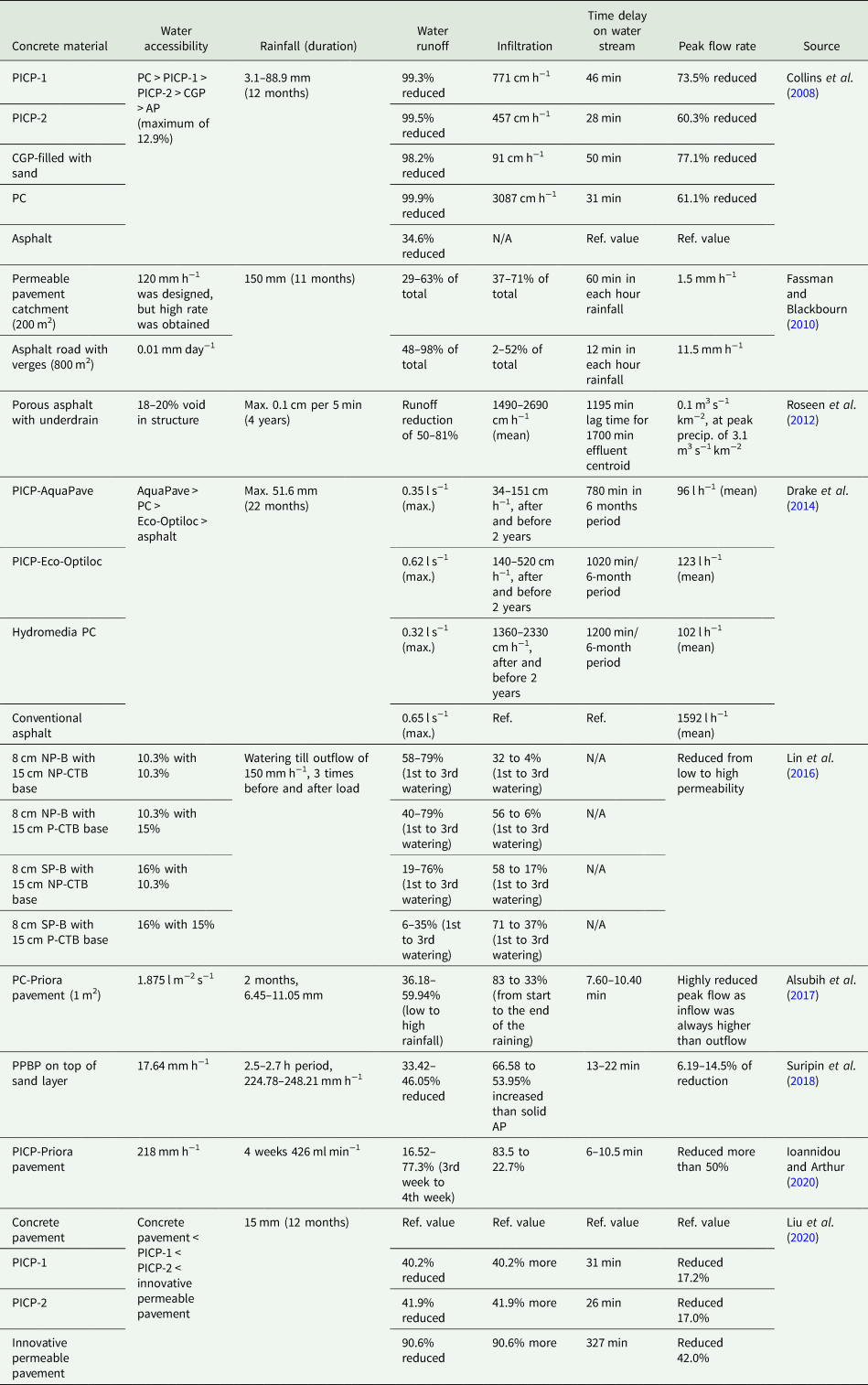

HGR is comparable to RGR for ecological and environmental benefits. HGR is a relatively new technology, with system components and HGR construction that are quite different from those of RGR systems (Fig. 2).

Fig. 2. HGR system components (modified from Tanaka et al., Reference Tanaka, Kawashima, Hama and Nakamura2017).

Roof slab-attached (or with limited gap) HGR systems comprise sealing and holding materials that are similar to RGR systems, with the exception of growing medium. The main problem with floating planters is that the substrate requires changing, and sometimes, planters need replacing after each germination cycle. One of the hardest challenges is identifying a substrate that can be used directly, instead of floating planters, because most current hydroponic growing substrates are not reusable, requiring additional support to keep them stable and water accessible (Hitti, Reference Hitti2018).

HGR benefits

HGR systems with floating planters can reduce a rooftop's temperature by 5°C and heat amplitude by 55% even without vegetation (Huang et al., Reference Huang, Chen and Tsai2016). Temperature was reduced with plants by another 3–5°C, and heat amplitude was reduced by an additional 16% under Taiwanese weather conditions (Huang et al., Reference Huang, Chen and Tsai2016; Tanaka et al., Reference Tanaka, Kawashima, Hama and Nakamura2017). Cooling load savings without plants is due to extra styrofoam, a cement board, and ceramic tile layer directly on top of the roof slab. Apart from annual energy savings, an HGR can reduce fluctuations in roof temperature, and is similar to RGR because of the evaporative cooling effect and heat-storing capacity of the roof materials (Song et al., Reference Song, Kim, Bang, Son, Waldman and Lee2013). HGR is effective at controlling urban water runoff, and at treating and reusing gray water and rainwater. One HGR system showed significant efficiency in removing anionic surfactants, and reduced turbidity by 88 and 75%, respectively, and COD was reduced by 81% when 8 days retention time was used to hold the gray water in the HGR system (Xu et al., Reference Xu, Yang, Zhang, Jin, Huang, Bei, Zhao, Kong and Zheng2020a).

Overall, extensive RGR provides more energy-savings than HGR systems because extensive RGR growing media have more thermal insulating capacity than hydroponic solutions used in HGR systems (Huang et al., Reference Huang, Chen and Tsai2016). HGR provides some advantages over RGR, as water or hydroponic solutions are usually 1.5–2.5 times lighter than traditional RGR growing media (soil or other). If a lightweight and reusable growing substrate could be found, HGR systems would be more attractive than RGR in all measures.

HGR challenges

The main challenge in developing new HGR systems is finding a reusable substrate that can provide long-term benefits. This is exemplified by a Singapore hospital HGR system that produced 190 kg cherry tomatoes annually, but the growing substrate (rockwool) was costly, not easily disposable, and had to be replaced after every growing cycle. As this HGR system is not directly attached to the roof (10–12 cm gap), it does not provide energy-savings equivalent to those of intensive or extensive RGR (Greenroofs, 2020). Research is lacking in HGR systems; this is likely why fruit/vegetable production life cycle and cost–benefit analyses have not provided any clarity, which is another potential barrier in establishing HGR technology (Xu et al., Reference Xu, Yang, Zhang, Jin, Huang, Bei, Zhao, Kong and Zheng2020a).

Feasibility of PC as an HGR component

PC's stormwater control, water purification and plant-growing capacity are outlined below to demonstrate the feasibility of this material as a novel hydroponic growing substrate that could be incorporated into green roof design and mitigate challenges presented by an RGR system, all while providing from the benefits of an HGR system (Park and Tia, Reference Park and Tia2004; Koupai et al., Reference Koupai, Nejad, Mostafazadeh-Fard and Behfarnia2016). Hydrological properties of PC are presented.

Stormwater control ability

PC permeability offers plants' root systems easy access to water and nutrients inside the matrix, rendering it feasible for sustainable hydroponics and in urban agriculture (Hitti, Reference Hitti2018). Since the overall hydrological properties of PC depend mainly on permeability, and permeability highly depends on grain size, other physical properties such as mechanical strength, and thermal capacity, and vegetative properties depend on permeability and grain size. When determining PC's stormwater control ability, these properties, in addition to climatic conditions should be considered.

Permeability

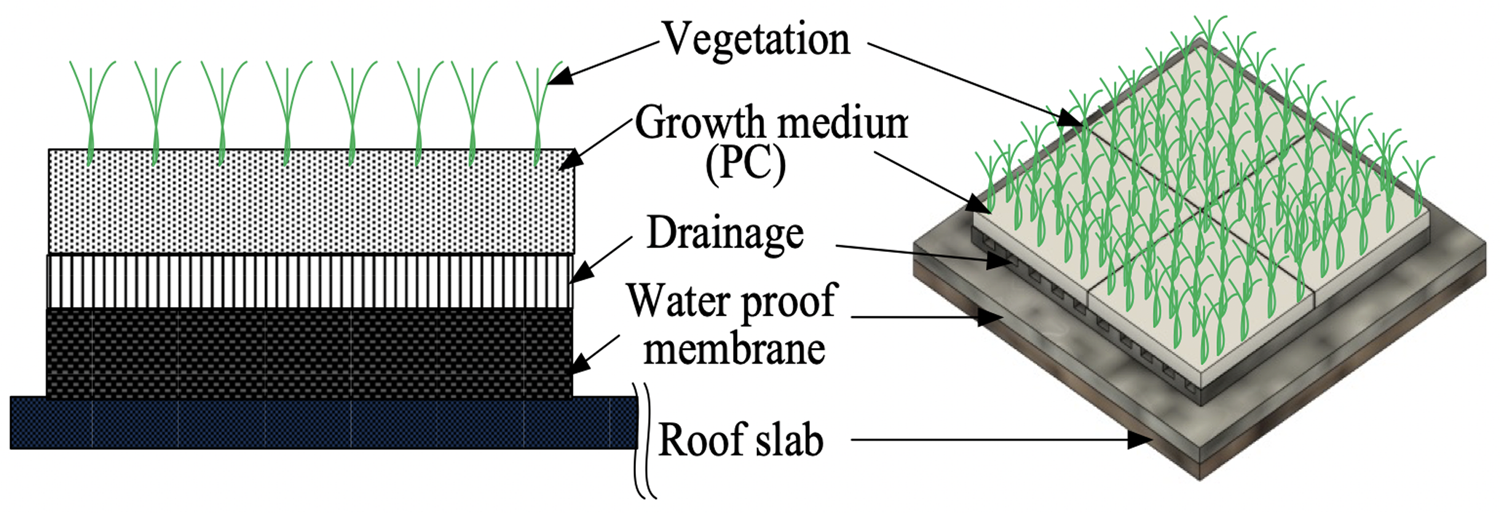

Highly permeable PC provides high infiltration capacity, a longer delay time and reduced peak flow rate for stormwater. With a longer delay time, PC provides more evaporation, resulting in a lower heat island effect (Ahammed, Reference Ahammed2017). PC pavement has proved highly cost-effective as an infiltration system with high runoff control up to 100 mm h−1 of rainfall rate. These properties may be used to explore the applications of PC as a roadway, pedestrian pavement, an artificial riverbank, parking lot or other locations where water cycle control within an urban area is essential (Lin et al., Reference Lin, Ryu and Cho2016). Runoff of two permeable interlocking concrete pavements (PICP-1 and PICP-2), concrete grid pavers (CGPs) and PC with conventional asphalt pavement was compared to determine the hydrologic benefits of concrete permeability. After 1 year, it was determined that high concrete permeability processes the lowest peak flow and a large delay time in stormwater runoff. The water retention and controlling capacity sequence obtained was PC > PICP-1 > PICP-2 > CGPs, in comparison with regular asphalt pavement, demonstrating that all permeable concrete offered substantially better stormwater controlling capacity than conventional asphalt (Collins et al., Reference Collins, Hunt and Hathaway2008). A 2-year runoff comparison of inclined permeable pavement (200 m2) and conventional asphalt road (850 m2) showed that permeable pavement had exceptional runoff control with a reduced peak flow rate when compared to conventional road structures in Auckland, New Zealand; daily, 2-year, 5-year and 10-year storm flows demonstrated a flow rate variation for asphalt pavement that ranged from 0 to 48.6 mm h−1, with a sharp peak following the fluctuation of rainfall. PC showed a more level runoff flow profile, with less variation (0–14.9 mm h−1) regardless of the rainfall depth and fluctuation (Fassman and Blackbourn, Reference Fassman and Blackbourn2010). A summary of comparative PC and asphalt studies for runoff, infiltration and stormwater delay time is provided in Table 3.

Table 3. Comparison of PC and conventional asphalt pavement surface runoff, time delay and water retention studies

CGP, concrete grid pavers; CTB, cement-treated base; ESAL, equivalent single axle load; GB, granular base; GPB, granular porous base; GSB, granular subbase; NPTB, non-porous cement-treated base; PC, porous concrete; PCTB, porous cement-treated base; PICP, permeable interlocking concrete pavement; PPBP, permeable paving block pavement; SP-B, porous herringbone shaped block.

Climate considerations

The stormwater control properties and durability of PC highly depend on climatic conditions. In a cold climate such as northern Canada, the use of PC (as permeable pavement) resulted in a significant reduction of peak stormwater flow. PC showed 91% smaller peak flow than conventional asphalt runoff, and it reduced the outflow volume by 43%. PC had zero runoff during a rainfall of 7 mm or less, and the total captured water was removed by infiltration and evaporation (Drake et al., Reference Drake, Bradford and Van Seters2014). During spring and fall, hydrological testing showed that high concrete permeability reduced the average peak flow rate from 1592 to 102 l h−1, with delay time up to 1200 min during the 6-month experimental period (Drake et al., Reference Drake, Bradford and Van Seters2014). Stormwater control with PC at any location where temperature falls below 0°C for approximately 6 months of the year has been inconsistently reported, with an infiltration rate ranging from 1490 to 2690 cm h−1 (Roseen et al., Reference Roseen, Ballestero, Houle, Briggs and Houle2012). Frost penetration (approximately 75 cm) was observed inside the PC, reducing stormwater management capacity. PC had a higher infiltration rate during the first winter of use, but for the next 3 years, the summer-time infiltration rate was higher than that of winter. The permeable cover reduced the peak flow rate by 90%, i.e., from 5.5 to 0.58 m3 s−1 km−2, when compared to an impervious cover during the 4-year experimental period (Roseen et al., Reference Roseen, Ballestero, Houle, Briggs and Houle2012).

PC blocks are incorporated into roads used for vehicle transport because of their potential in urban water system development (Lin et al., Reference Lin, Ryu and Cho2016). Permeable surfaces within cities are decreasing day by day; for instance, in Seoul, South Korea, impermeable surface increased from 7.8 to 47.8% in the period from 1962 to 2010. This resulted in reduced water infiltration (47 to 21%) and evaporation (47 to 25%) during rainfall, and consequently, raised surface runoff from 11 to 49% of total rainwater. This urban water cycle change can lead to urban flooding, heat islands and water quality deterioration (Lin et al., Reference Lin, Ryu and Cho2016). A pavement testing simulation showed that the hydrological efficiency of permeable blocks depends on base type and load (Lin et al., Reference Lin, Ryu and Cho2016). The load-bearing capacity of PC rises with the base depth of its cage. Porous asphalt with 15.9% porosity had a higher compressive strength and is suitable for use in roads with traffic. The water storage capacity of different concrete structures and storm water delay times are listed in Table 3 with performance variation before and after loaded conditions, with a rainfall rate of 150 mm h−1.

Effect of uses and thickness

Stormwater delay time and peak flow inside PC highly depends on the number of uses, and age of the PC. Used PC has a lower delay time than unused PC, due to its reduced water holding capacity (Alsubih et al., Reference Alsubih, Arthur, Wright and Allen2017). A first use PC samples absorb the highest amount of water with the lowest discharge runoff; this decreased consistently with time. Ultimately, the water holding capacity of PC doesn't depend on rainfall intensity or outdoor weather conditions. However, water retention in the top layer of concrete varied, to a maximum of 0.12 m3 m−3 from one rainfall event to another when outdoor conditions were too dry. After a long application period, PC water holding capacity and permeability reached zero, as no maintenance was carried out (Sañudo-Fontaneda et al., Reference Sañudo-Fontaneda, Andres-Valeri, Costales-Campa, Cabezon-Jimenez and Cadenas-Fernandez2018).

In an experimental life-cycle analysis, 37 different pavement systems were analyzed (9 modified PC, 9 typical asphalt and 17 PICPs with two different designs) in car parking bays over a 10-year period. Modified PC was completely clogged, and operational lifetime ended after 9 years. PICP samples showed the highest resilience to clogging by providing a maximum infiltration rate. Permeability of the modified PC reduced sharply (from 24,480 to 3096 mm h−1) in the first 5 years, leading to <5–10 mm h−1 over the next 5 years. Typical asphalt pavement (AP) systems had a similar profile in permeability decrement. Both PICP systems exhibited reduced permeability changes, yet the thick PC provided higher permeability over time (Sañudo-Fontaneda et al., Reference Sañudo-Fontaneda, Andres-Valeri, Costales-Campa, Cabezon-Jimenez and Cadenas-Fernandez2018).

Data suggest that PC of the same thickness provide the same compression strength and Poison ratio as regular concrete (Ghafoori and Dutta, Reference Ghafoori and Dutta1995). For use as a parking lot or road pavement, the American Association of State Highway and Transport Organization (AASHTO) recommendations are to follow the user-defined road failure concept, where empirical regression equations obtained from road tests were used to design thick pavement. The Portland Cement Association recommends the strict structural failure method (includes crack initiation, propagation and failure) when designing thin PC pavement. Both design methods provide similar results with respect to intermediate loading and pavement thickness (Ghafoori and Dutta, Reference Ghafoori and Dutta1995).

Pollution control by PC depends on the vegetation present, and plants' symbiotic relationships with bacteria and fungi (Ahammed, Reference Ahammed2017). The addition of nanoparticles has been recommended to control the mechanical strength of PC, while maintaining optimal hydrological properties such as stormwater retention, runoff delay and prefiltration (Winston et al., Reference Winston, Arend, Dorsey and Hunt2020).

Pollution control and water purification capacity

Pollution control and stormwater purification are necessary, as the presence of higher nitrogen (N) and phosphorus (P) content causes eutrophication. As effective N and P removal is in high demand, the water purification capacity of PC, determined by different casting parameters [binders, grain size, binder–aggregate (B/A) ratio, etc.] and physical properties (void ratio, porosity, permeability), is promising. If PC is placed anywhere among the water channel such as a pedestrian walkway, riverbanks or anywhere before the final water destination (river or sea), it could reduce total N (T-N), total P (T-P) and total suspended solids (TSSs), as well as other heavy metals in the water as pre-treatment (Jianming et al., Reference Jianming, Xu and Lu2008; Winston et al., Reference Winston, Arend, Dorsey and Hunt2020). Due to the pre-treatment system in the water cycle, the flow path becomes slower than usual, which helps in preventing soil erosion and in reducing the stormwater stress on the surface. PC can reduce to a maximum of 98% of metal from water (Sansalone and Teng, Reference Sansalone and Teng2004). An optimum PC design was recommended, with 10–20 mm grain size and 25% porosity, which could remove 72.5% of T-N, 95% of T-P and 95% of TSSs (Jianming et al., Reference Jianming, Xu and Lu2008). Without any chemical treatment, PICP reportedly reduced T-N by 65%, T-P by 90% and TSSs by 99.5%, just by flowing water through the concrete (Winston et al., Reference Winston, Arend, Dorsey and Hunt2020). The addition of nanoparticles is helpful in water filtration as well (Winston et al., Reference Winston, Arend, Dorsey and Hunt2020). Other PC components, including porosity, grain size, B/A ratio, different binder and reinforcement further affect water purification capacity.

Porosity

The water purification capacity of PC increases with porosity (or void ratio). A higher void ratio demonstrates a higher ability to remove T-P and T-N due to increased contact surface area inside the PC. In changing porosity from 20 to 30%, the T-P removal capacity of PC changed from 1.1 to 1.3 mg l−1 with 5–10 mm aggregates, and from 0.4 to 1.2 mg l−1 for PC with 10–20 mm aggregates. For T-N removal capacity, the effect of porosity was low, where the eliminated amount increased from 1.0 to 1.5 mg l−1 by changing porosity from 20 to 30% (Park and Tia, Reference Park and Tia2004). Different PC void ratios (37–22%) showed that the T-N abruption rate increased 2 and 7% for every 1% increase in void ratio for Portland cement and calcium sulfoaluminate cement (CASC), respectively. The amount of T-P changed slightly (1–2%) with the same change (1%) in void ratio (Kim et al., Reference Kim, Jang, Khalid and Lee2017). For the same porosity, PC size or the area of exposure affects absorption of dissolved oxygen (DO), T-N, T-P, TSSs and other minerals (Teymouri et al., Reference Teymouri, Mousavi, Karami, Farzin and Kheirabad2020). Reductions in water turbidity are highly dependent on PC porosity because the PC with 0% added fine-grain reduced turbidity from 650 NTU (nephelometric turbidity unit) to 44 NTU, whereas the PC with 20% added fine-grain reduced turbidity till 53 NTU. However, fine-grain addition enhanced the TSS removal capacity of PC regardless of mineral absorbent, and fine grain addition showed better performance in DO removal, especially with zeolite absorbent (Teymouri et al., Reference Teymouri, Mousavi, Karami, Farzin and Kheirabad2020).

Grain size

Two different aggregate grain sizes, 5–10 and 10–20 mm, were tested for water filtration capacity with a 30, 40 and 50% B/A ratio (volumetric) in the total blend. Both grain sizes, with the same specific gravity (2.69) had identical water absorption capacity at 0.66% (Park and Tia, Reference Park and Tia2004). The small grain size concrete had high T-P and T-N removal capacity (Park and Tia, Reference Park and Tia2004). Compressive strength increased from 3 to 6 N mm−2 after varying the B/A ratio from 30 to 50%. The DO, T-N and T-P in the standard sample were 7.90, 2.06 and 0.53 mg l−1, respectively. For 5–10 mm grain size, DO consumption was in the range of 0.38–0.42 mg l−1 depending on the binding agents, T-N elimination was approximately 3.0–3.25 mg l−1, and T-P elimination was approximately 1.18–1.35 mg l−1 (96% of reduction). The PC with 10–20 mm aggregates showed DO consumption in the range of 0.05–0.18 mg l−1, T-N elimination of 1.0–1.5 mg l−1 and T-P elimination of 0.4–1.17 mg l−1. Therefore, the PC comprising 5–10 mm aggregates removed around 1.5–2.8 times more pollutants than the 10–20 mm PC (Park and Tia, Reference Park and Tia2004). Another study compared water purification of two different PCs having 5–10 and 10–15 mm grain sizes, with a varying void ratio of 20–30% (Zhang et al., Reference Zhang, Kanemaru and Nakazawa2015). The concrete behaved similarly with respect to T-N, T-P and DO reduction. However, smaller grain sizes resulted in a higher reduction of carbon. Most importantly, the alkalinity of the PC sample itself did not affect the pH of flowing water (Zhang et al., Reference Zhang, Kanemaru and Nakazawa2015). For the TiO2-soaked recycled aggregates, the nitrous oxide (NO) absorption rate of the PC increased from 71 to 80% due to the change in aggregate size, from 15–20 to 5–10 mm (Xu et al., Reference Xu, Jin, Hu, Li, Chen, Shen, Wu and Fang2020b). Studies investigating the effects of concrete type, grain size and porosity in water purification are listed in Table 4. To summarize, 90–95% of pollution can be removed from water by using PC as regular or reinforcing something on it. In general, fly-ash, CASC and slags have better performance than Portland cement as a binder. The reinforcement, addition of nanoparticles or a photocatalyst also significantly improves the water purification capacity of PC.

Table 4. Comparison of water purification properties for different PC types

CASC, calcium sulfoaluminate cement; COD, chemical oxygen demand; PC, porous concrete; PICP, porous interlocking concrete pavement; T-N, total nitrogen; T-P, total phosphorus; TSS, total suspended solid.

Effect of B/A ratio

Higher B/A ratios reduce the T-N and T-P elimination capacity of water when passing through PC. DO consumption decreases from 0.02 to 0.08 when the B/A ratio was increased from 30 to 50% (Park and Tia, Reference Park and Tia2004). The effect was less pronounced with small grain size; T-N removal capacity decreases from 1.5 to 1.0 mg l−1, and T-P consumption was reduced from 1.17 to 0.4 mg l−1 (Park and Tia, Reference Park and Tia2004). As a higher B/A ratio reduces the void ratio inside the PC, water purification capacity is reduced. Using CASC as a binder, T-N removal capacity was reduced by 8% when the B/A ratio increased from 30 to 40%. This differs from when a Portland cement binder is used, as the cement itself enhances the absorption capacity of the PC (Kim et al., Reference Kim, Jang, Khalid and Lee2017). Notably, B/A ratio does not affect dissolved phosphorus removal (Kim et al., Reference Kim, Jang, Khalid and Lee2017).

Effect of binder and reinforcement

Portland cement, silica fume, fly ash and a water-reducing agent were used as binders and admixtures in PC developed by Park and Tia (Reference Park and Tia2004). Concrete consisting of both fly ash and silica fume showed maximum comprehensive strength. PC containing 20% fly ash exhibited more DO consumption regardless of grain size. For water purification, the CASC binder showed slightly higher T-N (8%) and T-P (2%) removal rates than Portland cement, and CASC is highly recommended for its quick casting and high compressive strength with the same B/A ratio (1.7 MPa higher at 40%) (Kim et al., Reference Kim, Jang, Khalid and Lee2017). Both Portland cement and CASC showed similar turbidity and metal removal (Kim et al., Reference Kim, Jang, Khalid and Lee2017). In general, water purification performance of the PC decreased as the number of use-cycles increased, regardless of void ratio, binder types and B/A ratio. In terms of T-N, T-P and TSS removal, CASC demonstrated a slightly better performance (Table 4).

Demolished concrete from construction was used as a recycled aggregate, resulting in significant NO removal after shocking with TiO2 (Xu et al., Reference Xu, Jin, Hu, Li, Chen, Shen, Wu and Fang2020b). However, the NO removal rate decreased from 61.4 to 42.2% after changing the TiO2 concentration from 0.1 to 0.5%. The removal rate reached a maximum of approximately 71.4% at an optimum TiO2 mixture of 0.3%, with an aggregate size of 15–20 mm and permeability measured at 15.45 mm s−1 (Xu et al., Reference Xu, Jin, Hu, Li, Chen, Shen, Wu and Fang2020b).

Mineral absorbents were integrated into the PC to enhance its water purification capacity (Teymouri et al., Reference Teymouri, Mousavi, Karami, Farzin and Kheirabad2020). Zeolite, perlite, pumice and LECA were tested with different PC porosities and grain proportions, where zeolite showed maximum mineral absorption capacity. Mineral absorber (0.6–1.2 mm) and fine grain (2.36–4.75 mm) were added to the main aggregate (4–9.5 mm). Overall permeability varied by adding 0–20% fine grain to the concrete mix, but it allowed for a water flow rate of 0.5 l min−1.

PC was reinforced with iron slag and sand to compare the water purification capacity of regular PC to reinforced PC. COD and TSS removal efficiency increased, as well as turbidity and metal removal, due to the reinforcement (Koupai et al., Reference Koupai, Nejad, Mostafazadeh-Fard and Behfarnia2016). However, reinforcement reduced the electrical conductivity of the PC from 15.10 to 13.80 dS m−1, and pH values of the regular PC and reinforced PC were constant at approximately 8. The authors concluded that the increment of reported pollution absorption was mainly due to the larger surface exposure as mechanical trapping of iron slag (Koupai et al., Reference Koupai, Nejad, Mostafazadeh-Fard and Behfarnia2016).

The use of a photocatalyst for improving PC water purification capacity has been recently reviewed (Hasan et al., Reference Hasan, Zain, Hamid, Kaish and Nahar2017). If TiO2 can be used in building tiles, PC or other construction materials, the material can be used for water or air filtration. In the presence of light, TiO2 can produce both the electron and positive charge and then free hydroxyl radical, this contributes to the removal of toxic/carbon particles, NOx, SOx and other metallic particles from air and water (Lackhoff et al., Reference Lackhoff, Prieto, Nestle, Dehn and Niessner2003; Chen and Poon, Reference Chen and Poon2009; Hasan et al., Reference Hasan, Zain, Hamid, Kaish and Nahar2017). Nano-metric TiO2 incorporated during PC casting provided the pollution removal rate of approximately 60–90%. However, when the PC was exposed to external conditions, its purification capacity was reduced by an estimated 50% of its indoor pollution removal rate (Liang et al., Reference Liang, Cui, Li, Abdelhady, Wang and Zhou2019).

Plant-growing capacity of PC

Research exploring the plant-growing capacity of PC has expanded. PC-grown vegetation can be limited due to its alkalinity (pH) and sodic characteristics, but this may be partly solved with improvements to PC mixtures and additives (Hitti, Reference Hitti2018). To be considered as a structurally sound and feasible growing substrate in a rooftop hydroponic system, PC should meet other requirements as well. Because all other commercial inorganic rooting substrates, including rockwool, have common issues surrounding disposal after one or two rounds of germination (Inden and Torres, Reference Inden and Torres2001; Jones, Reference Jones2016; Hitti et al., Reference Hitti, Chapelat, Wu and Lefsrud2021), the possibility of long-term use, reuse or multiple growing cycles with PC must be explored. Common growing substrates (rockwool, perlite, carbonized rice hull, cypress bark, coconut coir, etc.) have minimal strength and very short lifetime when exposed to outdoor weather conditions (Bougoul et al., Reference Bougoul, Ruy, De Groot and Boulard2005). The reusability and non-adverse disposal after its lifetime make PC an inevitable growing substrate in the field of hydroponics (Hitti, Reference Hitti2018). To investigate PC's plant-growing potential, different model plants, including grasses (turf grass) plants with hypocotyl extension (radish, Raphanus raphanistrum), and leafy greens (romaine lettuce, Lactuca sativa), leafy greens and fruit (tomato, Solanum lycopersicum) were propagated in PC, serving as a hydroponic substrate (Fig. 3) (Hitti, Reference Hitti2018). When compared to growth in rockwool with the same nutrient solution, germination was comparable. Fresh mass was lower for all plants grown in PC when compared to rockwool, yet dry mass for radishes grown in concrete was 125% more than the rockwool-grown control (Fig. 3) (Hitti, Reference Hitti2018, Hitti et al., Reference Hitti, Chapelat, Wu and Lefsrud2021). This previous work further underlines the importance of permeability, porosity and water retention capacity when improving PC admixtures. In the context of plant growth substrates, healthy plant growth and development, PC runoff should be considered, not only when determining potential harm to urban ecological systems, but also when optimizing nutrient concentrations in hydroponic solutions. They can be easily manipulated for favorable plant growth outcomes in PC, as is commonly done for other hydroponic growth substrates. Nevertheless, plant species screening is required to investigate which plant parameters (stem height and diameter), types (grasses, flowers, short season vegetables, etc.) and root systems (e.g., fibrous, tap roots, adventitious) are conducive to this hydroponic substrate, particularly when challenged with abiotic and biotic stress factors on a roof top setting.

Fig. 3. Potentiality of replacing rockwool with PC as a growing substrate (Hitti, Reference Hitti2018).

Non-cement alkali-activated PC containing 0.2% jute fiber further supports vegetation, despite alkaline (pH 9–10) growing conditions and water purification capacity of vegetated (with grass) PC reduced suspended solids, COD, T-N and T-P by 48.9, 49.1, 81.2 and 43.5%, respectively (Oh et al., Reference Oh, Cha, Park, Lee, Park and Park2014). Mixing of biochar at levels up to 5 kg m−3 enhanced ryegrass germination rate, root height and plant height by 12.0, 21.1 and 22.2%, respectively, after 25 days. However, by increasing biochar content from 5 to 20%, plant-growing ability decreased because of decreasing permeability, porosity and plant compatibility (Zhao et al., Reference Zhao, Jia, Yuan, Qiu and Xie2019); if used as a growing substrate, 24.9% porosity and 15.6 mm s−1 permeability was recommended. To summarize, pH inside the PC must be within a suitable range for plant growth, and the pore matrix must be suitable for plant root growth. PC must have enough strength and porosity to hold the structure together during root expansion.

Other advantages of integrating PC into HGR

Apart from water purification, runoff control and plant-growing ability, PC could provide some additional benefits over other growing substrates, as it offers enough mechanical strength to be a part of the static building structure and offers more thermal resistance when covered with vegetation (Ouldboukhitine et al., Reference Ouldboukhitine, Belarbi and Djedjig2012). PC containing dolomite as an aggregate has a compressive strength of 16 and 19 MPa, and flexural strength of 2.9 and 3 MPa, after 7 and 28 days curing, respectively. This strength can be improved, up to 46.2 MPa, by using a superplasticizer in the concrete paste (Lian and Zhuge, Reference Lian and Zhuge2010). For durability, PC containing 25 and 30% water can tolerate 12 freeze–thaw cycles (Gao et al., Reference Gao, Zhou, Xu, Liu, Shen, Peng and Du2020). Therefore, PC's potential as an outdoor growing substrate is expected for 12 consecutive years, even in cold climates. Use of recycled aggregate when casting new PC may be considered, leading to improved management of waste materials and to reduce carbon footprint of new concrete manufacturing. However, recycled aggregate has a lower mechanical strength than new aggregate. Strength could be improved up to 79% by reinforcing PC with polymer (Bhutta et al., Reference Bhutta, Hasanah, Farhayu, Hussin, bin Md Tahir and Mirza2013). PC allows more conduction and convection heat transfer with higher heat-storing capacity in its body than typical growing substrates (Sun et al., Reference Sun, Gao, Geng, Li, Zhang and Liu2017). Without force convection, the heat transfer rate inside the PC decreases sharply after 50% porosity, at higher porosity the heat transfer is led by convection rather than conduction inside the porous body. The heat transfer rate of PC increases with decreasing porosity of its structure (Bessenouci et al., Reference Bessenouci, Triki, Khelladi, Draoui and Abene2011). Therefore, PC is expected to offer a more stable temperature profile when incorporated into an HRG design, resulting in an extensive hydroponic green roof (EHGR) system with different structural components.

Future challenges and gaps when considering PC applications

The main challenges for future PC applications are unclear costs and benefits, no optimization between mechanical, thermal and hydrological properties, insufficient application-specific solutions, actual maintenance and property restoration, and less load and speed-bearing capacity with more brittleness (Kuruppu et al., Reference Kuruppu, Rahman and Rahman2019). During the course of this review, additional knowledge gaps were identified in stormwater controlling capacities: (1) analyses of highly porous PC (porosity >20%) as a means of stormwater control have not yet been performed; (2) specific solutions for clogging and PC maintenance have not been considered; (3) stormwater control with vegetated PC has not been examined and (4) PC's infiltration rate, strength and water holding capacity in practical applications when covered by plants have not been determined. An evaluation of PC's stormwater purification capacity has highlighted several additional research gaps. PC used for water purification in previous studies has a low porosity range (10–20%). However, highly porous (>25%) concrete has the potential for water purification if similar compressive strength can be maintained. To our knowledge, no studies published to date have tested the water purification capacity of vegetative PC. Published research uses a grain size higher than 5 mm for bulk water purification and to maintain more strength at low porosity. Because smaller grain size improves the removal of some specific impurities from water, the water purification capacity of PC with smaller grain size (<5 mm) with similar permeability and porosity merits further investigation.

In this work, PC has been considered for stormwater control and water purification when covered with vegetation in a new EHGR system. Since vegetation present on concrete changes its strength, porosity and hydrological properties, the analysis of PC in a similar hydrological application and as a plant-growing substrate should be explored (Tang et al., Reference Tang, Mohseni and Wang2018). For better water filtration, the PC could be cast with a small grain size (2–3.2 mm) but with higher porosity (25–35%) and adequate compressive strength (3–5 MPa).

Prospects of PC as a green roof material

The prospect of combining PC with HGR technology, resulting in a novel EHGR system (Fig. 4), is expected to open up a new and sustainable area of building structure and masonry work. Vegetation on PC may further increase water holding capacity, filtering capacity and delay time significantly when it would be used in the EHGR system (Hitti et al., Reference Hitti, Chapelat, Wu and Lefsrud2021). Therefore, successful PC-integrated EHGR design and implementation could improve water management and reduce the heat island effect. In both the water and temperature management standpoints for urban settings, the PC-integrated EHGR system will be explored as a possible impactful and realistic tool that could replace typical RGR systems. Plant species screening will be required to determine maximum number of growth cycles permitted and as mentioned above, and which vegetation types may be well adapted to rooftop environments and hydroponic growth, with root systems that are favorable for this new application. With this, partial solutions to greening dense urban areas, increasing biological diversity in cities and the possibility of locally produced food crops could be explored.

Fig. 4. Schematic and 3-D view of proposed EHGR system with PC growing medium.

The proposed EHGR system setup would be similar to RGR to extract full heating and cooling load benefits by completely sealing the roof. A PC layer can be placed directly on top of the drainage layer, reducing the use of environmentally harmful polymers by approximately 95 ton m−2 compared to extensive green roofs. The polymer reducing amount may be up to 142.5 tons in building 1 ha of green roof area of an EHGR system compared to intensive green roofs (Yang et al., Reference Yang, Yu and Gong2008; Bianchini and Hewage, Reference Bianchini and Hewage2012). A separate filter is not required for this new EHGR system, yet typical (used in RGR systems) membrane insulation can be installed on top of the roof slab. In the installed EHGR, the growing substrate (PC) will be submerged into hydroponic solution, and the drainage layer will be used in flowing and exchanging solutions from and to the system. If this EHGR system is installed on any roof, that roof will provide all the benefits of a regular extensive green roof in terms of hydrology and energy savings, with even fewer materials and less weight on the roof. In addition, the EHG–PC system provides all the benefits of an HGR in terms of easy vegetation and crop production potential. Therefore, the proposed EHGR systems will be a complete green roof technology that maximizes green roof benefits while using less materials and design complicacy.

Summary and future research directions

Hydrological properties, such as water retention capacity, pollution control and water purification capacity make PC attractive as a reusable hydroponic plant-growing substrate for green roofs. PC strength can be adjusted by varying grain size, binders, porosity and permeability during casting, expanding its applicability as a vegetation-covered structural material rather than adding more load to a building. PC as a plant-growing substrate represents a new direction to explore in green building technology. Primarily, grain size, B/A ratio and casting procedure could be further optimized. Lower pH and lightweight binders and/or aggregate types that convey high compressive strength are under investigation. PC leachate will be analyzed to determine runoff, and nutrient uptake and heavy metal accumulation analyses for PC-grown plants is being prioritized, to expand the list of plants that may be grown in this novel hydroponic substrate. There is room to improve PC durability, as well as easy and affordable PC recycling methods.

Conclusions

Green roofs can positively impact the ecological and environmental conditions of an impermeable urban area, yet design and development to date appear limited. Extensive and intensive RGR provides large heating and cooling load savings but they incorporate large amounts of polymer. HGR systems show potential in higher biomass production and yield, with little heating and cooling energy savings due to necessary design features. RGR/HGR design and sustainable benefits were compared to those offered by PC as an innovative hydroponic growth substrate and green roof structural component. PC has proven stormwater and pollution control, water purification capacity and airflow capability with heating and cooling energy saving potential, with additional advantages including less polymer use, possible integration of recycled materials and plant-growing ability over several growth cycles. Improvements to PC's mechanical and hydrological properties will broaden applications with biological benefits, such as the proposed sustainable and innovative growth substrate as part of the green roof design described. PC permeability, porosity and water retention capacity are critical for plant root systems. Environmental gains provided by the proposed EHGR system that incorporate PCs make this an important prospect worthy of further consideration by structural engineers, green building architects and climate experts alike.

Acknowledgements

The authors acknowledge Natural Sciences and Engineering Research Council (NSERC) (NSERC CRDPJ 520145 - 17), CEMEX Global Research and Development in Brügg, Switzerland and Innovertec Inc., Canada for financial support for this research. The authors are additionally grateful to McGill University's Graduate and Postdoctoral Studies (GPS) for awarding a Schulich Graduate Fellowship, and to Fonds de recherche du Québec- Nature et technology (FRQNT) for awarding Doctoral Research Scholarship (Grant: 306102) to the first author (M. S. R.).

Conflict of interest

The authors have no conflict of interest to declare.