I. INTRODUCTION

The Moche civilization flourished approximately in the period 100–600 AD on the north coast of present-day Peru and produced painted pottery, tissues, and ornaments on gold and silver. The Moche is known as sophisticated metal smiths, both in terms of their technology and in the beauty of their jewels. Their metalworking ability was impressively demonstrated when Walter Alva and coworkers discovered in 1987 the Tumbas Reales de Sipán (Alva and Donnan, Reference Alva and Donnan1993; Alva, Reference Alva2004), and more recently, when Régulo Franco Jordán discovered the tomb of the “Lady of Cao” in 2005 (Jordan, Reference Jordan2009, Reference Jordan2010, Reference Jordan2011). Spectacular gold and silver funerary ornaments were excavated and are now exposed in the Museum Tumbas Reales de Sipán in Lambayeque, close to Chiclayo, and in the site Museum of Cao, about 60 km north to Trujillo. The two tombs are dated around 300–350 AD.

The technology used by the goldsmith of this ancient civilization varies, according to main factors such as metals joining technique and gold–silver alloy composition. Thus, metal artifacts investigative that analyses from the Moche civilization have been carried out in recent years using energy-dispersive X-ray fluorescence (EDXRF), X-ray monoenergetic transmission (XMT), X-ray digital radiography (DR), and X-ray computed microtomography (microCT). Metal objects from the Royal Tombs of Sipán have been analyzed in recent years mainly using EDXRF. The investigation showed that the objects are mainly composed of gold, silver, and copper alloys, gilded copper, and tumbaga, the last being a poor gold alloy enriched at the surface by depletion gilding, i.e., removing copper from the surface (Cesareo et al., Reference Cesareo, Bustamante, Fabian, Calza, Anjos, Lopes, Elera, Shimada, Curay and Rizzuto2010a, Reference Cesareo, Calza, Anjos, Lopes, Bustamante, Fabian, Alva and Chero2010b, Reference Cesareo, Bustamante, Fabian, Calza, Anjos, Lopes, Alva, Chero, Espinoza, Gutierrez, Rodrigues and Seclen2011, Reference Cesareo, Bustamante, Fabian, Alva, Chero, Espinoza, Rodriguez, Seclen, Gutierrez, Bracamonte, Levano, Gonzalez, Rizzutto, Poli, Calza, Dos Anjos, Freitas, Lopes, Elera, Shimada, Curay, Castilho, Gigante, Ingo, Lopes, Holmquist and Diestra2013). Gold and silver funerary ornaments from the Moche tomb Señora de Cao also were analyzed to determine their metallurgic characteristics as, for example, the gold–silver joining process. At least three joining methods were possibly identified such as gluing gold and silver sheets, brazing using a proper solder, and using a mercury amalgam (Cesareo et al., Reference Cesareo, Jordan, Fernandez, Bustamante, Fabian, Zambrano, Azeredo, Lopes, Ingo, Riccucci, Di Carlo and Gigante2016, Reference Cesareo, Bustamante, Azeredo, Lopes, Jordan, Fernandez and Gigante2017, Reference Cesareo, Ridolfi, Brunetti, Lopes and Gigante2018; Azeredo et al., Reference Azeredo, Cesareo, Jordan, Fernandez, Bustamante and Lopes2018a, Reference Azeredo, Cesareo, Jordan, Fernandez, Bustamante and Lopes2018b, Reference Azeredo, Cesareo, Jordan, Fernandez, Gigante, Bustamante and Lopes2019; Gigante et al., Reference Gigante, Cesareo, Bustamante, Jordan, Fernandez, Brunetti, Ridolfi and Lopes2018).

In the present investigation, results are reported on three earrings from the Royal Tombs of Sipán, of which the cylindrical gold supports were studied using computed microtomography. MicroCT is a nondestructive method which importance is growing in the archaeological area for the structural analysis of artifacts (Bozzini et al., Reference Bozzini, Gianoncelli, Mele, Siciliano and Mancini2014; Agostino et al., Reference Agostino, Donato, Caruso, Colavita, Zanini, D'Alessio, Pisarra and Grasso2016; Azeredo et al., Reference Azeredo, Cesareo, Jordan, Fernandez, Gigante, Bustamante and Lopes2019; Machado et al., Reference Machado, Silva, Campos, Gomes, Oliveira and Lopes2019).

The technique of microCT was carried out, in the present case, to obtain 3D images of the internal structure of the cylinders, to investigate if the Moche artisans used any additional structure or material (for example, wood) as support for the thin gold cylinders, to better understand and visualize the joining process, and to evaluate the homogeneity of the gold layer and related thickness.

II. EXPERIMENTAL SET-UP

The microCT system was assembled using a mini X-ray tube with an Au-anode from Amptek (Azeredo et al., Reference Azeredo, Cesareo, Jordan, Fernandez, Gigante, Bustamante and Lopes2019), working at 50 kV and 100 μA maximum voltage and current, with approximately 2 mm focal spot size and output cone angle of 120°, and a CDR flat panel from Schick (Azeredo et al., Reference Azeredo, Cesareo, Jordan, Fernandez, Bustamante and Lopes2018a). The scans were carried out with the X-ray tube operating between 30 and 50 kV and current between 70 and 100 μA, at about one frame per second, and with the source–detector distance of 40 mm. The flat panel is an image receptor with Active Pixel Sensor-CMOS technology. It is capable of producing images with a linear gray scale of 12 bits per pixel, that is, 4096 gray levels, with the pixel size of 40 × 40 μm (Farman and Farman, Reference Farman and Farman2005) and the active area sensor of 43 × 30 mm2 (Azeredo et al., Reference Azeredo, Cesareo, Jordan, Fernandez, Gigante, Bustamante and Lopes2019). Overall, the system is composed of the following subsystems: flat panel detector, X-ray source, electromechanical control (CTRL), acquisition and control software, and reconstruction process (Vilar et al., Reference Vilar, Santos, Machado, Oliveira, Azeredo and Lopes2017; Azeredo et al., Reference Azeredo, Cesareo, Jordan, Fernandez, Gigante, Bustamante and Lopes2019). The rotation table was controlled by a set consisting of an Arduino Uno and the Adafruit motor Shield, based in the L293D device. The sample is attached to the stepper motor and is rotated in steps of 0.9°. For each angle, one digital image was obtained. These images are then used for the image reconstruction process and the production of the 3D image (Azeredo et al., Reference Azeredo, Cesareo, Jordan, Fernandez, Gigante, Bustamante and Lopes2019). The spatial resolution (SR) was measured using a tungsten plate juxtaposed to the sensor and determining the modulation transfer function (MTF). The experiment was implemented according to the standard EN 14784-1. The image of the plate was carried out with the X-ray tube operating at a voltage of 50 kV and the current of 77 μA. The specified value of MTF20% was obtained at 6.25 pl mm−1. Therefore, the SR obtained was 80 μm. The average thickness measurement of the objects was measured using Avizo software, version 9.0.

Following earrings were studied, all from the Museum “Royal Tombs of Sipán, Lambayeque, Peru: S/T1-O:6 (Figure 1), S/T6-O:1A (Figure 2), and S/T6-O:4A (Figure 3). The first one comes from the tomb of the Lord of Sipán, while the other two come from the tomb of the warrior and are dated earlier. All these earrings are composed of a circular main body showing the figure of a deer (O:6), a human figure (O:1A), and the figure of a warrior (O:4A), respectively. They have, at the border, 30 spheres on gold, 24 spheres on gold and turquoises, and 11 foxes, respectively. The main body is soldered with a golden cylinder made with rolled gold alloy sheets.

Figure 1. (a) Main body of earring S/T1-O:6 from the Museum “Royal Tombs of Sipán” and (b) cylinder and related area analyzed by microCT.

Figure 2. (a) Earring S/T6-O:1A from the Museum “Royal Tombs of Sipán” and (b) cylindrical structure and area analyzed by microCT.

Figure 3. (a) Earring S/T6-O:4A from the Museum “Royal Tombs of Sipán” and (b) cylindrical structure and area analyzed by microCT.

III. RESULTS AND DISCUSSION

The composition of the various parts of the main body and of the cylinder of the three studied earrings, determined using EDXRF, is shown in Table I.

TABLE I. EDXRF analysis of significant areas of earrings S/T1-O:6, S/T6-O:1A, and S/T6-O:4A.

Microtomographic images of the three earrings are shown in Figures 4–6. Figures 4(a), 5(a), and 6(a) show the cross-section of the earrings, while Figures 4(b), 5(b), and 6(b) show a longitudinal section of the cylindrical structure. Additional structures or materials of support inside of the analyzed area of the earrings are not visible. However, it could be supposed that the Moche from Sipán would use a wooden cylinder which was then extracted.

Figure 4. Earring S/T1-O:6 microCT images of the (a) cross-section and (b) longitudinal section.

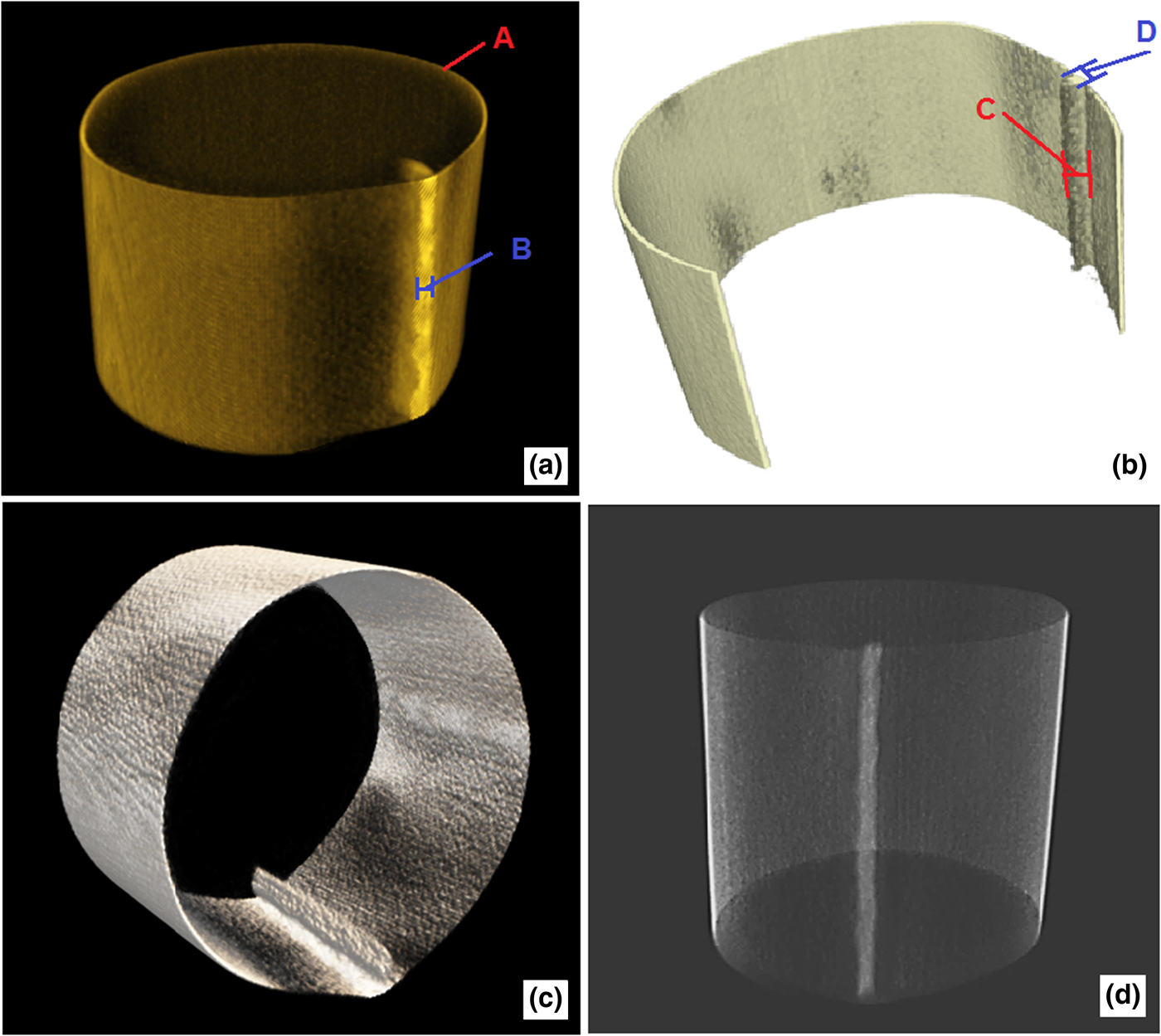

Figure 5. Earring S/T6-O:1A microCT images (a), (b and c) cross-sections, and (d) longitudinal section. A, B, C, and D are the thickness measurement points.

Figure 6. Earring S/T6-O:4A microCT images of the (a) longitudinal section and (b) cross-section. A, B, C, and D are the thickness measurement points.

The average metal sheet thickness in point A, in Figures 4a, 5a, and 6a, was determined by microCT images, and the values are: 390 μm (SD ± 30 μm), 450 μm (SD ± 30 μm) and 395 μm (SD ± 30 μm), respectively, while the average gap thickness in Figure 4(b), point B, was measured to 930 μm (SD ± 80 μm). In the case of earring S/T1-O:6, no welding metals are visible in the junction of the gold alloy sheet [see, for example, Figure 4(b)]; thus, it may be deduced that the junction was produced mechanically (Azeredo et al., Reference Azeredo, Cesareo, Jordan, Fernandez, Bustamante and Lopes2018a, Reference Azeredo, Cesareo, Jordan, Fernandez, Bustamante and Lopes2018b).

Following specific details could be visualized by microCT.

A. Earring S/T1-O:6 (tomb of the Lord of Sipán)

In this case, the slot is quite regular compared with the other two earrings [see Figure 4(b)]. Furthermore, the joining process of the gold sheet is clearly mechanical, obtained by claw fitting (at the base of the structure) made by only modeling the gold sheet.

B. Earrings S/T6-O:1A and S/T6-O:4A (tomb of the warrior)

In these two cases, corresponding to the tomb of the warrior, the joining process of the gold sheet cylinder was by brazing, joining the gold sheet by heating, and melting a filler that bonds the two pieces of gold and joins them. In Figures 5 and 6, the presence of a filler material is clearly visible. The EDXRF spectrum of area B of Figure 6(a) showed that the filler is an Ag–Cu alloy (with an approximate composition Cu = 60%, Ag = 40%). The low variation in the gray level indicates that the filler should have lower density (Ag–Cu alloy) but greater thickness.

IV. CONCLUSION

Three earrings from the Royal Tombs of Sipán were studied by microCT. The 3D images show no additional structures or materials of support inside of the area analyzed of the earrings (cylindrical region of the earring). The microCT revealed that the artisans produced the gold cylindrical structure by two types of the joining process: by only gold sheet modeling (earring S/T1-O:6), using claw fitting made with the gold sheet itself, or by brazing using a Ag–Cu filler. The joining process with the Ag–Cu alloy was used for the earrings S/T6-O:1A and S/T6-O:4A, evidencing that earring S/T1-O:6 was produced at a later time. The 3D images were proved to be useful in order to enlarge the investigate of manufacturing techniques of gold jewelery specifically from the Royal Tombs of Sipán, providing important information for archaeologists investigating Peruvian cultural heritage. Furthermore, the microCT scanner was specifically designed, assembled, and optimized to visualize thin gold sheets and has the advantage of being portable and sufficiently rapid.

ACKNOWLEDGEMENTS

This work was partially supported by Conselho Nacional de Desenvolvimento Científico e Tecnológico, CNPq, (process no. 159285/2018-6, Brazil) and Fundação de Amparo à Pesquisa do Estado do Rio de Janeiro (FAPERJ). Dr. Walter Alva, discoverer of the Tombs of Sipán and Director of the Museum Royal Tombs of Sipán, was acknowledged for his kind cooperation.