Introduction

The English East India Company, which had been importing raw silks from Bengal to London since the end of the seventeenth century,Footnote 1 realized by the mid eighteenth century that it would be necessary to change traditional Bengali reeling technology drastically to increase the sales of its raw silks. The Company thought that it could solve all the problems that Bengali raw silk had met in Europe by both introducing the Piedmontese reeling machine, which allowed the production of raw silk of higher and more standardized quality, and forcing artisans to work in the Company's filatures, which enabled better control of their work.

Thus, when the Company gained political control of the province, the Court of Directors decided to take the radical step of changing Bengali reeling technologies, introducing the most advanced European methods in their newly acquired dominions in the eastern zone of the South Asian subcontinent. In 1769, the Court contacted three managers who were well acquainted with both the Piedmontese reeling machine and the management of the filatures – an Italian, a Frenchman, and an Englishman. The Court also contacted a group of experienced French and Italian reelers, who could teach the new reeling method to native artisans.

The upgrading process desired by the Company met with only partial success, for Bengali raw silk reeled with the new method never reached the highest standards of the Piedmontese raw silks. However, the Company was able to produce huge quantities of low-quality raw silks from the 1770s to the 1830s, while Bengali raw silks improved to the point of competing successfully with raw silks of the same quality, such as those from Calabria and Spain.Footnote 2 Mediterranean producers of lower quality raw silks anxiously watched the British experiment in Bengal, and in the 1780s a wave of panic spread through areas as diverse as Lombardy, the lower Rhone valley, Calabria, and Valencia, when it became clear that improved Bengali raw silks imported by the East India Company were driving equivalent Mediterranean silks out of the London market.Footnote 3 A similar wave of panic unfolded in the late 1820s.

This article investigates the reasons behind this partial success, and the role that the local modes of raw silk production and commercialization played in this process. I show that some of the technical features of the Piedmontese technologies had a crucial impact on peasants specializing in mulberry cultivation and the rearing of silkworms. I also discuss how the Company had to cope with resistance from producers and landlords, and with some structural problems represented by the institutional and social context in which raw silk production took place in rural Bengal in the late eighteenth and early nineteenth centuries. Finally, I show how peasants, rural intermediaries, and landlords were able to profit from the Company's interest in producing raw silk according to European standards, contributing to the partial success of Bengali raw silk on the London market during this period.

Piedmont's technological supremacy

In mid-eighteenth-century Europe, the commercialization of raw silks operated within a long-established, highly competitive, and fast-expanding market, linking scores of specialized production areas spread across the entire Eurasian continent. Competition was very active at all levels of the market. For the leading producing areas, the only way to maintain their market share was constant innovation, not only of techniques but also of labour skills and working organization.Footnote 4

On the European market, the small kingdom of Savoy, in north-east Italy, was acknowledged for the perfection of its silk products. The products of Piedmont, the region of the kingdom where silk production took place, dominated all the European silk-textile centres from the late seventeenth to the early nineteenth century. The kingdom of Savoy had become a model for European silk experts by focusing on two specific phases of the silk-production cycle: silk reeling (winding the cocoons' filaments off to form a silk thread called raw silk) and silk throwing (twisting one or more raw silk threads into a stronger thread to be employed in textile-making).Footnote 5 Contemporaries attributed to Piedmontese technologies a universal capacity to upgrade local production.Footnote 6 In fact, attempts to refine local technologies, similar to those carried out by the East India Company in Bengal, were constantly pursued and transfers of Piedmontese technologies had become a common feature in the late eighteenth century.Footnote 7

It is worth underlining that behind the technological supremacy of the Piedmontese silks lay a complex and specialized socioeconomic local context. It was the final outcome of a long process of economic development, to which many had contributed. Between the 1670s and the 1830s, silk production in Savoy was guided by all the major political and economic interests of the nation. A group of merchants, financiers, and aristocratic landlords, supported by the government, exercised control over all elements of the system, from the production and marketing of cocoons to the production and export of silk threads. In the capital city, major export merchants – whose only interest was in trading thrown silk of the highest quality to be used as warp (organzino) – financed most of the cocoon production, giving advances to the peasantry in the winter season and receiving cocoons at the beginning of the following summer. Any further cocoons required were bought at the end of the harvest season in the main rural markets. The commune (the price that cocoons fetched in all rural markets) equalled what the peasants received as advances in winter for their cocoons. But this was not a market price: rather, it was a price dictated by the merchants, who were able to regulate their purchases of cocoons in the rural markets on the basis of their unique knowledge of the current demand for silk thread in the international markets of Lyon and London. In Piedmont, only the best cocoons went to the filatures, which in turn supplied raw silks to the hydraulic mills. The second-choice cocoons went to smaller rural manufacturers, and some did not even reach the market but were reeled in the peasants' houses. These coarser raw silks were then thrown into weft (trama) in old hand mills and used in local textile industries.

The government had made the use of standardized reeling machines compulsory in 1667, by royal decree. Moreover, the government controlled the quality standard of raw silk production by monitoring the professional level of artisans, through regulations, and by sending government agents on regular visits to filatures and hydraulic mills. Furthermore, in 1722, the king of Savoy prohibited all exports of raw silk from the country, in order to reinforce its monopolistic position. The raw silk export ban was only abolished in 1835, when Piedmont supremacy in silk reeling and throwing was fast disappearing. In Piedmont, everything was done to support the production and export of silk threads of the finest quality.Footnote 8

Technological differences between the Bengali and Piedmontese reeling methods

In contrast to Piedmontese centralized working practices and highly standardized technology, Bengal's technology was very simple and production procedures were not controlled directly by landlords, merchants, or the state. Bengali peasants and artisans used very simple tools to reel cocoons: after having immersed a handful of cocoons in an earthen basin full of hot water, a Bengali reeler would shake them slightly to remove the gummy substance that coated them, take out the ends of the cocoons' filaments, form a thread, stick it to a bamboo reel (nuttah), and start winding off. The thread so reeled was called putney. Although the degree of fineness of raw silk is basically determined by the number of filaments that make up a thread, Bengali reelers did not keep the same number of cocoons in the basin for the entire reeling stage. Thus, it was common to find threads with different degrees of fineness in the same skein of putney. As a result, after the reeling it was necessary to rewind the putney on larger reels and separate them by their different quality.Footnote 9 Not only was re-winding a time-consuming operation, which increased production costs, but Bengali raw silk was also unfit to be worked in Piedmontese hydraulic silk-throwing mills, which had been in operation in England since the 1720s, after the Lombe brothers build the first one in Derby.Footnote 10

William Aldersley, the chief of the Kasimbazar factory, who had assisted the European experts in their first experiments with the new technology in 1769, was quite explicit on its advantages. He argued that, while putney had to undergo the operation of re-winding into different qualities, ‘the filature's silk becomes merchantable at once and may be reeled to any fineness … at one operation from the pods’.Footnote 11

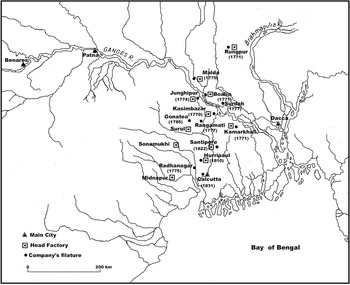

The new reeling method implied, however, a complete revolution of the labour conditions of both reelers and peasants. In fact, Piedmontese reeling technology was very demanding with regard to standardizing procedures. First, two artisans with two different and complementary functions had to work the reeling machine: the reeler, who sat behind the basin, and the turner, who had to turn the reel and stop the operation whenever a break in the thread occurred. The reeler had to put an exact number of cocoons in the basin, a responsibility that determined the degree of fineness. Further, he had to work two threads at the same time, each formed by two separate cocoon assemblies made by the same number of cocoons, and had to make them cross each other, so as to squeeze water from the threads, remove impurities, and render them rounder.Footnote 12 Using Bengali technology, threads were usually formed with filaments coming from ten or more cocoons, whereas using the Piedmontese reeling machine this number could be lowered, thus producing a much thinner and more delicate thread. On the one hand, as one of the European experts of the East India Company argued, the Piedmontese method could give good results only if the work was organized under the same roof in the filature, so that the reelers and the turners could be continuously supervised. On the other hand, the Piedmontese reeling machine could have a high productivity only by working good cocoons of uniform quality. ‘Bad cocoons’, with overly thin filaments, did not resist the tension of the crossing and broke more often than the ‘good’ ones. Too many interruptions slowed down the reeling operations, decreased the quality of the final product, and increased production costs (Fig. 1).Footnote 13

Figure 1. Location of the East India Company’s filatures in Bengal (1770–1833); the year of erection is given in brackets.

Late eighteenth-century and early nineteenth-century Bengal

To interpret the East India Company's partial success in upgrading Bengali raw silk, we first need to place its plans within the general context of late eighteenth-century Bengali economy and society, and recent scholarship has radically revised our thinking about the history of early modern and modern India. In particular, scholars have now refuted a rather ‘Orientalist’ characterization of the late eighteenth and early nineteenth centuries as an age of protracted economic decline and political disruption, setting the stage for the glorious and dynamic British Raj of the mid nineteenth century. Regarding the Company's impact upon the regional economies of the Indian subcontinent, they have demonstrated many instances in which it simply played the role of catalysing specific long-term, pre-existing historical processes. Chris Bayly has argued that all northern and eastern economies of the Indian subcontinent had been growing during the transition from the Mughals to the Company regime, with many regional societies profiting from the Company's rise to power.Footnote 14 It has also been noted how relevant sectors of the Indian economy developed independently of the Company's influence. Rajat Datta, criticizing the pessimistic portrait of a Bengali rural world completely monopolized by the East India Company's colonial state, shows how a large sector of the regional agrarian economy (notably rice production for the internal integrated market of the province) not only thrived but also took advantage of the Company's policies in the late eighteenth and early nineteenth centuries.Footnote 15

From a wider standpoint, some have recently argued that any attempt by the Company to control the interregional trade of India was doomed to failure, for the subcontinent was still integrated into a global economy whose dynamics were located largely in the societies of the Indian Ocean, Central Asia, and the Middle East. Arguing against the assumption that, as a consequence of taking over political control of many Indian territories, the East India Company was successful in redirecting most of the Indian trade to Europe along the Cape route in this period, Scott Levi has noted that the commercial relationship between central Asia and India collapsed only in the late nineteenth century, ‘under the pressure of the British and Russian colonial powers.’Footnote 16 Jos Gommans has showed that, notwithstanding the growth of the political and economic power of the East India Company, the trading patterns between India and its neighbours did not change dramatically between 1770 and 1850.Footnote 17 It is within this general context, in which the Bengal economy still largely depended on pre-existing processes and interacted with a Company's state largely unable to control them, that we have to place the results of the Company's plans to upgrade Bengali silk production.

From coercion to inducement: the East India Company and the mulberry cultivators

The East India Company's weakness, and the relative independence of the Bengali economy, were reflected in the efforts to improve the quality of Bengali raw silk. The overall late eighteenth-century demographic conditions of eastern India were defined by a relative scarcity of labour in relation to the land available. Moreover, the sericulture areas of Bengal were particularly depopulated because they were still slowly recovering from the disruptions and depopulations caused by the Maratha raids of the 1740s and early 1750s, and the effects of the 1769–70 famine.Footnote 18 Thus, in the 1770s, the first problem that the Company had to face was the repopulation of the silk-production areas. Some of the Company's servants (officials) thought that it would be possible to exercise direct control over the peasants and that the government could move peasants to the depopulated areas and force them to cultivate mulberry trees and pay taxes in cocoons.Footnote 19 Others supported the radical idea of asking for land from the local landlords in the neighbourhood of the factories, moving the peasants there, and coercing them into mulberry cultivation and rearing silkworms under the direct supervision of the commercial residents.Footnote 20

However, in pre-colonial Bengal, the use of force to move peasants to particular places would have been considered by the rulers as an extrema ratio, a last resort, to be adopted only in the face of explicit and evident peasant rebellions. This was especially true in times of emergency, as was the case after scarcities, famines, or depopulation brought about by war.Footnote 21 The East India Company inherited this prudent approach, and the repopulation of the sericulture areas was encouraged by prudent policies of protection and inducement, such as low rents and cash advances (taqavi), adopted by the government. In fact, at the end of a long debate, which involved both the Commercial and the Revenue Departments, it was decided to set all possible drastic solutions aside, and to listen to the cautious suggestion of the Naib Dewan, Muhammad Reza Khan, who argued that any kind of coercive measure would only result in the peasants' flight from the fields. Reza Khan concluded his remarks by suggesting that ‘the cultivators of the mulberry plants and breeders of the silk worms should be only encouraged and protected so that knowing their own interest and [the] welfare [of the Company] to consist in this branch they would apply themselves with the greatest industry towards its increase and become plentiful and cheap’.Footnote 22

In the regulations framed by the Company in 1772, it was explicitly affirmed that force would never be exercised to coerce the growers to cultivate mulberry trees and sell the cocoons to the factories' agents. In contrast with the habit of assessing lands cultivated with commercial crops at higher rents than rice land, the government would give particularly favourable rent rates to those who decided to enter the sericulture sector.Footnote 23 In 1789, in a similar situation of declining mulberry cultivation and depopulation, the Company once again needed to convince the peasants of other districts to move to the sericulture areas or to induce those already settled there to return to sericulture, and it proposed the same regulations as in 1772. Most of the residents and collectors, who were asked to report on the sericulture conditions in their districts in 1789, were convinced that, in 1780, mulberry cultivation had reached its maximum possible extension, thanks to the implementation of the 1772 regulations. Moreover, aware that sericulture was a costly activity for peasants, requiring appropriate initial capital and the use of all the labour force of their households, they argued that the government had to adopt not only low rents but also taqavi. Footnote 24 Only through the Company's protection could the peasants be induced to cultivate mulberry trees and rear silkworms.

East India Company attempts to control the Indian merchants' trade

Regarding the possibility of controlling the internal and external trade carried on by local and foreign merchants, the East India Company's policies confirmed the prudent and cautious approaches adopted in dealing with the cultivators of the silk districts. Although, in the 1750s and 1760s, the Company's servants were attracted by intrusive methods, such as evictions of local traders and exporting merchants' agents from the sericulture areas, from the 1770s they developed more cautious and prudent strategies.

In fact, the Company's servants had learned by experience the adverse effects of any attempt to stop Bengal's trade with other Asian regions. In the 1750s and 1760s, officials were able to control the trade in cotton textiles, raw silk, and silk textiles by dealing with peasants through their agents (gomastahs) instead of rural intermediaries, and by checking the internal circulation of goods in the production areas. A graphic description of how this system worked was given by Thomas Pattle, the Commercial Resident at Boalia in 1772. Boalia was a manufacturing centre (aurung) on the left bank of the Ganges river, close to Kasimbazar. Placed at the centre of the zamindari (feudal estate) of Lushkerpur, it produced large quantities of raw silk for the Kasimbazar market over the first half of the eighteenth century.Footnote 25 In the 1750s and 1760s, Pattle argued, the Company's commercial residents had introduced regulations that gave to their gomasthas the authority of imposing written agreements (machulkas) on the mulberry cultivators and silk reelers. In these documents, it was specified that they ‘should be obliged to make the Company's assortment of putney’. Further, the faculty to levy fines and penalties on their agents was given to the commercial residents. This made gomasthas ‘vigilant and attentive to the regulation whilst a notorious and flagrant infringement of it on the part of the chassars [mulberry cultivators] and the cattanies [silk reelers] never escaped punishment’. Regulations were issued that prohibited Asian and private European merchants buying raw silk and silk textiles of the same quality as the Company's assortment. At the same time, the servants imposed a tight control over the internal trade in raw silk and silk textiles, and ‘no silk was permitted to cross the river without obtaining a pass from the factory, which was only given after an inspection of the silk’. By this coercive monopoly, ‘the Residents … got all the fine silk into their own hands and were enabled to fix their own price on it’.Footnote 26

The abandonment of the traditional system of procurement of goods through local merchant intermediaries, and the extensive free hand that the servants had given to their gomastahs, caused disruption in the production of raw silk, silk textiles, and cotton textiles, and the flight of the majority of the Asian merchants from the province.Footnote 27 Desperate, because of the loss of revenue and the scarcity of silver in circulation within the province (the two most relevant macroeconomic consequences of this monopolistic effort), the Company's servants had to re-establish the old system of giving cash advances to peasants by means of rural intermediaries. With this came the need to leave the peasants free to accept or reject their offers, and to trade with Asian merchants if they wished to do so.Footnote 28 This policy informed those servants who subsequently dealt with the problem of Indian merchants trading in Bengali raw silk and silk piece goods.Footnote 29 Moreover, the merchants became aware of the limits that the Company faced in controlling the trade routes. When the servants tried to impose a much tighter control in the 1780s and 1790s, the merchants could threaten to divert their trade in different directions, knowing that the Company would lose significant revenue.Footnote 30 Thus, Indian merchants, partly protected by the Company's rule, continued to trade with peasants in Bengali raw silk and to compete with the Company's intermediaries from the 1770s to the 1830s.

The Company's servants were aware of the activities of the Asian merchants and of the developmental potential of the Indian internal markets that they supplied. For instance, in 1819 the two commissioners of the Board of Trade, Mr Bayley and Mr Rutherford, reported that Indian merchants had carried out an extensive trade between Amritsar, the capital of the Punjab kingdom, and Bengal, at least since the 1780s. The merchants exported raw silks and silk piece goods from Bengal to the Punjab, where they could use the local system of efficient transport infrastructures and market services, and from where they could export to Bengal huge quantities of shawls, the main product of the northern areas.Footnote 31 All this made that trade extremely safe and profitable, and the two commissioners thought that: ‘The raw silk of letters too coarse for the Europe market together with the Chassum [waste silk products] and refuse silk, the produce of the Hon'ble Company's filatures, might perhaps be beneficially appropriated to this channel’.Footnote 32 During the same period, similar favourable opportunities were reported from other regional markets of the Indian sub-continent and Indian Ocean.Footnote 33 However, the Company had little intention of developing these markets, or inducing an internal demand for its raw silk, considering any investment in Indian commodities as merely the simplest way to remit to England the profit it received from collecting the Bengali revenues.Footnote 34

Although the interregional raw silk trade declined under the East India Company Raj,Footnote 35 the Company's inability to establish a complete monopoly had a crucial impact upon its relationship with the peasants and the rural agents of intermediation because the competition of Asian merchants represented an essential advantage for rural producers in their dealings with the Company. Stressing this side of the story, I want also to highlight that the hegemony of the Company in the raw silk trade of late eighteenth- and early nineteenth-century Bengal was due more to its financial capacity, which gave to its servants the possibility of buying up the cocoon harvest by paying higher prices, than to any monopolistic control over production. In other words, forced to follow the interregional and internal markets within the pre-existing conditions in which the silk trade had developed before the mid 1750s, and unable to profit fully from the potentialities of this trade, the Company represented more a catalytic factor than a fully dominant monopolistic power.

The profitability of sericulture from the peasant's point of view

An old proverb, still remembered by the peasants of north-western Bengal, is very explicit on the idea that sericulture could represent a source of prosperity and wealth. The peasants say Jo na korè pute to korè tute (‘What you can't do with a son you can do with mulberry’).Footnote 36 The proverb reveals in a concise way that sericulture is such a source of wealth and prosperity that it can be compared with a put, a son and a future korta, a possible provider of food for the family and the village.Footnote 37 However, the peasants were always reluctant to be completely involved in silk production for the Company, so it is worth asking when and why silk production was profitable for them.

To understand this key point we first have to remember that, within the institutional context of late eighteenth-century Bengal, peasants made their economic choices without interference from superior or external powers, such as the state, local magnates, or merchants. In fact, they were the only economic agents in rural society to have an exact knowledge of the vagaries of seasonal rains and river floods, and of other ecological factors of production, such as the local system of collecting water on the ground and the ratio between low and high lands, which had a crucial bearing on the productivity of cultivation. In other words, they were the only ones who could build economic predictions and production strategies with an updated local knowledge of all the natural factors involved in agrarian production, as is evident from agricultural manuals and collections of old rural sayings.Footnote 38

To explain the reluctance of the peasants, we also have to take into account that any kind of cash-crop production in Bengal was more costly, more labour intensive, and more land intensive than rice cultivation. The land rent for mulberry cultivation was higher than that for rice. Moreover, mulberry fields required several ploughings in a year, had to be protected from floods and wild animals by costly embankments and fences, and needed regular manuring with expensive fertilizers. The plants also required highly fertile lands close to the peasants' settlements and water reservoirs, lands which were apt for alternative profitable crops.Footnote 39 Besides food crops, which were always at the centre of the peasants' economy, other cash crops might represent a valid choice. For instance, mango cultivation, to supply the local industry of dried fruit, was an alternative to mulberry in Maldah, and indigo represented a valid option in Kamarkhali. In general, in all the silk districts, sugar cane could be cultivated on the same kind of land that was used for mulberry trees.Footnote 40 Therefore peasants had to consider carefully all the possible options, and the market demand for other cash crops had a crucial bearing on the final decision to start sericulture. Furthermore, the next stage – cocoon-rearing – was highly labour intensive. Peasants harvested cocoons four or five times a year, and all the women and younger members of the family were involved in rearing silkworms and in transporting leaves from the plantations to the huts, where cocoons were reared. Furthermore, the many cocoon crops forced the peasants into mulberry cultivation on a yearly basis, which meant that both lands and producer teams would be engaged in this activity for long periods. In other words, when Bengali peasants began sericulture, they were well aware that they were going to engage the totality of their familial labour force and the best part of their land for a long period of time.

It is also important to take into account that, with the new and unfamiliar filature system introduced by the Company, peasants were expected to deliver their best cocoons to the Company's filatures, while reeling in Bengal was traditionally under peasant control. Peasants could either have their cocoons reeled within the familial network (by women), or they could have them worked in putney by the cuttani, the reelers who visited the village market (hath) during the harvest season.Footnote 41 This working organization implied that peasants had complete autonomy over the quality that they wanted to achieve. They decided whether to obtain a fast-reeled coarse silk or a finer quality, achieved through slower and more accurate reeling. They could also raise their productivity by ‘artfully concealing curkaw (waste silk products)’, so that the weight of the putney's skein rose.Footnote 42 Then, as Thomas Pattle argued in 1772, behind the peasants' reluctance to sell cocoons lay, in all probability, the fear of losing control of the production process, because ‘whilst the worm remains in the pod … [they] cannot judge with exactness [the] weight or value of the silk, whereas by reeling it in their own houses into putney its produce becomes ascertained with the utmost precision’.Footnote 43

Besides these technological considerations, it was, above all, the knowledge of trends on the raw silk market that could make peasants reluctant to change their cycle of silk production. In the early 1770s, the Company servants were aware that the main economic reason for the peasants' resistance to selling their cocoons to the Company's filatures was simply the fact that, by producing putney and selling it to the agents of Indian and European merchants, they could obtain a higher price. In addition, they internalized the production costs, employing the labour resources of their families more efficiently and controlling the quality and quantity of their production.Footnote 44

The reluctance of the peasants to sell cocoons

As I have argued above, notwithstanding its political and economic powers, the East India Company was unable to control the demand for putney and could not put a stop to its trade. This is crucial for understanding the problem that the Company met in procuring cocoons from the peasants, because the persistence of the interregional raw silk trade made them sensitive to the market and influenced their dealings with the Company.

In fact, the acumen of the peasants in negotiating the price of their cocoons was soon to be experienced by the Company's servants. In the early 1770s, when the Company was trying for the first time to overcome the reluctance of the peasants to sell their cocoons, the Controlling Committee of Commerce suggested offering them the same price that they would receive if they had sold their production as putney.Footnote 45 But, in a context with so many competitors interested in traditional silks, the decisions of the Committee resulted in the very opposite effect. In fact, the Company had to start negotiating with the peasants at the beginning of the season, giving them advances, in order to be able to buy up the greater part of the harvest before other competitors came in. During the final part of the same harvest season, when more agents of Indian merchants were ready to buy putney and were offering higher prices for it, peasants started asking the Company's agents for a higher price for their cocoons. As Thomas Pattle argued in November 1772, it was sufficient to have someone in the village selling putney instead of cocoons to start the speculative trend.Footnote 46 The advantage that the peasants held in dealing with the Company's agents is evident in the description sketched by the commercial resident of Malda in 1820. According to him, in every village there was a certain proportion of peasants who did not accept advances from the Company's agents because: ‘Whenever there is still at all a demand for silk in the Bazaar, the profits of these people are enormous’.Footnote 47 Besides, when a silkworm rearer was indebted to the Company, he knew that liquidating the debt completely was not profitable. So, when he had any surplus cocoons, he immediately transferred them to the house of one of the men who refused to receive advances, ‘to whom he sells them for ready money’.Footnote 48

Where the demand for traditional silks was high, as for example in the area around Kasimbazar in the early nineteenth century, the resident always had to take the price of putney into consideration in bargaining with peasants over the price of cocoons. In March 1817, the resident of Kasimbazar explained to the Board of Trade that he could not impose his cocoon price because it ‘invariably fluctuates according … to the degree of competition encountered from the contending interests of rival traders’ and, without allowing the factory intermediaries (pykars) to pay a higher price to the peasants, they would not sell their cocoons.Footnote 49 At the same time, his intermediaries, in a petition sent to the resident, underlined the difficulties of working in that area because ‘Cossimbazar is a putney aurung where merchants and weavers equally purchase their thannah [warp] thread. We like others are obliged to consult the market and buy cocoons accordingly’.Footnote 50 In fact, this phenomenon was typical of most of the factories that the Company had in the sericulture areas of western Bengal. In those years, the Gonatea factory was the biggest filature of the Company, and the resident of Sonamukhy, responsible for the Gonatea filature, used to fix the cocoon price in relation to the price that putney fetched in the rural markets of Kasimbazar.Footnote 51

In general, the Company was only able to purchase the majority of cocoons of each harvest by bidding higher than all other competitors. In 1830, Andrew Ramsey, who had spent thirty-four years in Bengal as a Company servant, and had worked as commercial resident of the factory of Junghipur from 1804 to 1818, told the parliamentary commission that was enquiring about the situation of raw silk production in Bengal that its production of cocoons was almost completely bought up by the Company. Ramsey told the Commission that the Company was successful because, given its enormous financial capacity, it was always able to offer the producer a higher price, and no private English merchant could find the production of filature raw silk profitable at such a high cost.Footnote 52 However, the servants could not directly control either the quality or the price of what they bought, and often had the impression that peasants used the best of their cocoons to produce putney.

Wealthy peasants as pykars

Since the times of Hastings and Cornwallis, the East India Company servants had had to rely on a special category of rural intermediaries, the pykars, in carrying out their cocoon purchases.Footnote 53 The servants argued that, because the villages of the mulberry cultivators were dispersed in the countryside and located quite far from the principal factories, they were hardly controllable through direct supervision.Footnote 54 More crucially, as many have remarked, an average Bengali cultivator controlled a very limited number of draught cattle and ploughs, and owned plot of lands of limited extension, so that his overall productive capacity was very low. These general circumstances made him unable to accumulate enough capital to re-invest in extensive commercial enterprises. Consequently, he was always in need of external resources to carry on commercial agriculture.Footnote 55 According to the opinion of the Company's servants, these were also the economic conditions of the majority of the mulberry cultivators in the late eighteenth century.Footnote 56 Therefore, the Company had to finance sericulture by distributing large cash advances among producers who, carrying on a subsistence economy, could not offer any sort of security. Both the risk of wasting capital and of being unable to buy cocoons forced the Company's servants to look for economically trustworthy intermediaries with the power of influencing the decisions of peasants.

In eighteenth-century Bengali silk districts, there were peasants within the village community who possessed these characteristics. They belonged to the local dominant caste or were village partners of the landlords' officials, and the original founders of the villages. They usually owned more land, more rice stocks, and more draught cattle than most of the village's inhabitants, and could help them in times of scarcity. These wealthy peasants often played the role of intermediary between the village and external powers.Footnote 57 One of them was usually the village headman (mandall, paramanick, muqqudam), who dealt with the officials of the zamindars (the local landlords and rent collectors) in the operation of collecting the land rent.Footnote 58

As Gautam Bhadra has shown, the Company selected its pykars from this wealthy section of the peasantry. In fact, they were often the mandal (headmen) of a village. Not only mandal, but also the village moneylenders and moneychangers, who traditionally played the strategic role of transforming the peasants' crops into cash to be paid as tax, were enlisted among the Company's pykars. Some Company pykars also belonged to the local trader community. Finally, pykars could have connections with native clerks of the Company's factories, a further assurance for the servants that they could get back the established amount of cocoons from the peasants.Footnote 59

The importance of the wealthy peasants in helping the East India Company to carry out its plans is also revealed by their role in repopulating the sericulture areas in the 1770s and 1780s. The growing interest of the Company in the silk business offered opportunities for wealthy peasants to invest their resources in mulberry cultivation, following the famines of the 1770s and 1780s. It has been argued that, of the two types of tenancy in Bengal, the khud-kasht (resident cultivator) had greater security of tenure, whereas the pai-kasht (non-resident cultivator) had far less bargaining power and could be evicted at the zamindar's discretion.Footnote 60 However, scholars who have analysed peasant mobility in late eighteenth-century west and north Bengal, suggest that the pai-kashts, who were able to procure land for farming at lower rents, were not simply vagrant peasants. They were supposed to be an influential class of villagers, who possessed capital to clear the jungles or repopulate deserted villages, and who could benefit from the labour mobility of their villages.Footnote 61 The Company's need for rural resources to be employed in cultivating wasteland with mulberry lured this richer class of pai-kasht cultivators into cooperation. In fact, the commercial residents were well aware that the only cultivators who could re-establish the cycle of silk production after a famine were those enterprising peasants who held command over village communities. Speke, the Collector of Raishahi, one of the largest and most productive silk districts, argued explicitly that inducements and protection should be given only ‘to the better and middling class of people, generally described by the appellation of Khosbassee or “residing where they please”, in contradistinction to the mere ryott, who is always on, or near his land, personally attending to it’.Footnote 62

So far, I have discussed the social and economic conditions of the Company's pykars and wealthy peasants. But what were their methods for imposing their decisions on the rest of the villagers? How could pykars and wealthy peasants control the peasants' cycle of production? Studies of the agrarian economy of late eighteenth-century and nineteenth-century eastern India show how advances in rice or cash were strategically given to rice cultivators in those periods of the year when they had no stocks, or had to pay their taxes to the state. The debt so created was to be repaid later on, at harvest time, when prices in the rural markets were low. These unfavourable terms of exchange created a bond of debt, which forced peasants to produce for the market; not to accumulate profits but only to subsist.Footnote 63

In fact, there is evidence that the Company's pykars also had recourse to the debt bond to force mulberry cultivators and silkworm rearers to sell them cocoons at the lowest price possible.Footnote 64 For instance, in the 1790s, the mulberry cultivators and cocoon rearers of Lushkarpur were accusing the pykars of the factory of Boalia of using any possible means to control them through debt. Many of the Boalia pykars were also village moneylenders and moneychangers, and, under the protection of the factory, they asked for higher interest on the advances on both rice and cocoon harvests. The pykars could also practise a higher discount on the exchange of several kinds of rupees, which the peasants received as advances. Ultimately, the Company's pykars could use physical force and confine the peasants in their homes, if they did not sell them what they had produced.Footnote 65

However, it is worth noting that the cash advances that the pykars gave to the mulberry cultivators were probably a better and less binding option than the rice and cash advances given to rice cultivators. Advances to growers of mulberry trees were evenly distributed over the year, in instalments regulated by the many cocoon crops, and less integrated with the revenue calendar. Moreover, as B. B. Chowdhury has recently noted with regard to indigo cultivators, peasants always cultivated some land with rice and received advances from both indigo planters and rice merchants, in an attempt to improve their economic conditions.Footnote 66 These circumstances were also valid for mulberry cultivators and silkworm rearers.Footnote 67 Finally, in contrast to the rice cultivators, the mulberry cultivators could petition both the revenue collectors and the commercial residents, threatening to move to other districts if they did not have justice, because they were well aware that such an occurrence would cause significant losses to both of the Company's departments.

Landlord resistance

So far we have taken into consideration resistance and adaptation by those sections of rural Bengali society who lived in the villages and who were directly engaged in the production process. But the East India Company also had to face resistance from zamindars and talukdars, the local landed elites and collectors of the revenue, who saw the Company's interest in peasant production as an unbearable intrusion of the state into their relationship with cultivators, consolidated over long periods of time.

In the context of the Company's regulations of the 1770s and 1780s, this resistance is quite understandable. From the zamindars' point of view, the lowering of rents on lands that were traditionally rated by the state higher than lands cultivated with rice and the protection that the state promised to peasants were likely to result in loss of both economic profits and social control of their territory. For instance, the zamindars could not impose any extra taxes on mulberry cultivators and silkworm rearers, as required by the traditional customs of the province. All the social mechanisms on which zamindars had built their control of local production (described by John McLane in his study of the Burdwan zamindari Footnote 68 ) were put into question by the Company's regulations.

This resistance is best exemplified by the zamindars' and talukdars' persistent inclination to raise rents. In 1789, the residents attributed the main reason for the declining state of Bengali mulberry cultivation to ‘the oppressions of zamindars, in taking from year to year an increased rent’.Footnote 69 Furthermore, zamindars could traditionally resort to their private armies to coerce peasants, and this was a strategy that they sometimes adopted to oppose the plans of the Company, whenever these went against their established economic interests.Footnote 70 For instance, in 1771, the Rajshai zamindar seized the lands of all the relatives of the peasants who worked as reelers and winders in the Company's factory of Boalia, allegedly because ‘they were indebted to the Hazanna [the government]’. This practically put a stop to the work of the Boalia factory's silk investment for that year.Footnote 71

Cocoons and raw silk belonging to the Company were exempted from local duties when they travelled through landlords' territories. This represented another loss of profit for the landlords, and a break with their established rights of imposing duties on any goods passing through their territories.Footnote 72 However, taking advantage of their traditional control of rural markets, consolidated by the unintended outcomes of the Company's initiatives regarding the circulation of goods in the province,Footnote 73 local landlords could influence peasants' transactions by partaking in the smuggling trade of Asian merchants and individual European merchants. Although evidence of their direct involvement in the Asian interregional raw silk trade is still scanty, documents from the extensive surveys of rural markets, carried out by the government in the early 1790s, show that putney and other silk materials belonging to private merchants were taxed by the rural landed elites when these goods passed through their markets.Footnote 74 This clearly represented a good reason for the landed elites to favour the trade of Asian and private European merchants, in contrast to trade in products of the Company's filatures.

Two more illustrative instances of zamindars' resistance – one from the early 1780s and the other from the 1820s – give us an idea of how the clash of interests between zamindars and the Company could be so intense as to put a stop to any plan by the latter of spreading sericulture in the countryside. James Frushard was an English silk expert who arrived in Bengal to improve the Company's silk investment in the early 1780s. He was convinced by Governor Hastings of the favourable opportunities to erect a filature in Gonateah, a village in the Beerbhom zamindari.Footnote 75 Under the patronage of Hastings, Frushard approached the Birbhum zamindar, who granted him the status of pai-kasht ryat (non-resident peasant), and gave him the right to occupy 2,500 beghas of land in Gonateah for twelve years.Footnote 76 From the outset, notwithstanding the protection of the government, Frushard had to cope with the zamindar and his officials. First of all, the zamindar was able to impose higher rents on Frushard than the ones paid by the peasants in the neighbourhood of his filature. Moreover, the majority of Frushard's lands were covered by thick jungle and he needed peasants to clear the woods.Footnote 77 The zamindar controlled the labour market within his territories and, when Frushard offered cash inducement to the peasants of the Gonateah neighbourhood to help him in clearing the jungle, the zamindar promptly imposed on the Board of Revenue a change in the contract, which explicitly stated that Frushard ‘shall not entice the neighbouring Khodkasht ryots [resident peasants] to quit their lands’. Footnote 78 As a matter of fact, Frushard was unable to pay the established rents, and was forced to flee and settle temporarily in another district.Footnote 79 At the end of this long controversy, Frushard could only find some cultivators from the Santal tribes of the hilly districts bordering the zamindari, over whom the zamindar exercised no control,Footnote 80 and some highly paid wage cultivators (nijabad).Footnote 81

Another instance of how effective the zamindars' resistance to the Company's plans could be is demonstrated by the vicissitudes of the Kamarkhali factory's agents in 1819–20. Because the raw silk produced in the Kamarkhali factory's filature and in the other Company's filatures in the district of Muhammadshahi had sold very well in the London market in the late 1810s, the Court of Directors had suggested to the Board of Trade that they should augment the productions of that district by erecting new filatures. Therefore, in 1817, the commercial resident had planned to erect a new filature in Chunal, a small zamindari on the left bank of the Ganges river, where the Company already had a cocoon warehouse and where the resident's intermediaries had carried on a profitable cocoon trade in previous years. But, in 1819, the resident complained that his plan to build ‘the projected filature at Chundoobul [Chunal] has not yet commenced upon the inveterate prejudice which appears to prevail in the mind of the zamindar of the place against the formation of such an establishment’.Footnote 82

In fact, behind this alleged prejudice lay strong and effective opposition, organized by Kasubnath Malick, the local zamindar, and his people, against what they considered a fatal menace to their interests in the locality. In August 1819, the pykars of the Kamarkhali factory, Kasubnath argued, ‘assembled a body of men to the number of 100 or 125, and having by force destroyed the paddy that was cultivated on about 15 bigahs of land’ of the Chunal zamindari, they built a house, with the purpose of making bricks to erect the Company's new filature. With this invasion, Kasubnath complained, ‘the men and women of the said village have been deprived of the road by which they went to perform their diurnal ablutions’.Footnote 83 The zamindar feared that because ‘oppressions have been far practised … the tenants of the said village will probably be reduced to the necessity of deserting this place of residence’.Footnote 84 This fight culminated in December 1819 with the destruction of the pykars' brick factory by Kasubnath's people, who ‘came to the working place accompanied by a body of about 400 men, who we [the zamindar and his relatives] had collected together by beating a drum in the village’.Footnote 85 Notwithstanding the great demand on the London market for the raw silks produced by the Kamarkhali factory, the local rural power-brokers were able to stop the ambitious plans of the Company, and the Company was forced to find a different method to increase local production.

The East India Company as a catalyst for local entrepreneurial potentialities

There is also a reverse side of the story to be underlined. By the 1790s, the East India Company's interest in raw silk production was a catalytic factor for the entrepreneurial potentialities of Bengal's agrarian sector. Those wealthy sections of Bengali rural societies who came into contact with the Company's silk factories, such as wealthy peasants and local landlords, discovered new opportunities to employ their capital and resources in the silk business by becoming acquainted with the new features of silk production introduced by the Company.

Regarding the Company's silk intermediaries, not only were the servants unable to get rid of the pykars' intermediation in the procurement of cocoons for the Company's filatures but they also could not stop their direct engagement in the production of filature raw silks. Pykars had shown interest in Piedmontese reeling technologies since the 1770s, when they had started building rudimentary filatures in their villages. The spreading of these ‘native filatures’ was such a rapid process that the commercial residents argued that pykar owners of small filatures had entered into competition with the Company, by selling raw silk to other European companies in the late 1770s.Footnote 86 Within the context of the wars between France and England of the late eighteenth and early nineteenth centuries, the role the pykars played in meeting the rising demand of the English market for Bengali silk was crucial. From the 1790s to the 1810s, the Company did not try to interfere with the pykars' filatures, and stipulated contracts with them for raw silk or rented their filatures. However, in the 1820s, the Company bought those pykars' filatures that were indispensable for its investment, so that they were finally set aside in the latter part of the period. All this notwithstanding, it is worth emphasizing that the role that the pykars played in the spreading of the Piedmontese technologies is noteworthy, and that they showed remarkable entrepreneurial capacities from the 1770s to the 1820s.Footnote 87

The zamindars were also involved in the Company's silk business. Rajat Datta has recently argued against the established view that, in eighteenth-century Bengal, the role of the zamindars and other landed magnates in the countryside lay in politics and in their role as tax collectors, rather than in agricultural production and commerce.Footnote 88 The engagements of the zamindars and talukdars in the Company's silk business may well confirm this overall interpretation.

The first zamindars to be involved in the Company's silk business belonged to that section of the Bengali merchant communities who had become banians (commercial partners) of the top-ranking servants of the Company in the 1770s. Through their intimate connections with the Company, they were the first among the local merchant community to become acquainted with the technological novelties that the Company had imported from Italy. Most of them had acted as contractors of raw silks for the Company in the early period of the Company's rule. Since the late 1780s, they had bought vast zamindari lands and had favoured the development of sericulture on their estates. For instance, Kantu Babu Nandi's career was quite exemplary. He started out as private banian of several top-ranking servants of the Company in the 1750s.Footnote 89 In the early 1770s, his relationship with Warren Hastings introduced him to the experiments that the Italians were carrying out in those years in the Kasimbazar factory, and he provided cocoons for the Kasimbazar filature.Footnote 90 By the late 1780s, he owned several estates and filatures in the neighbourhood of the Kasimbazar factory, in which he had favoured the spreading of sericulture.Footnote 91

Another banian who played a pioneering role in the Company's silk business was Darpa Narayan Tagore. After amassing a fortune as middleman for the French East India Company at Chandernagore, in the mid 1770s he rented the Company filatures in the Kasimbazar and Boalia factories and became a Company silk contractor for Bengali raw silk. In the 1780s, he participated in the dismemberment of the Nattor Raj, a large estate in the Rajshahi district, situated in the middle of one of the most fruitful silk-production areas, and bought several zamindari there.Footnote 92

However, it was after the Permanent Settlement of 1793, when the Company began to appeal directly to zamindars and talukdars for better control over the mulberry cultivators and silkworm rearers, that the landlords of the silk-production areas began specializing in this business. For instance, the zamindar of Surul, Srinibash Sarkar, was an agent of the factory of Soonomukhy in Birbhum district, employed by the commercial resident in 1799 as agent in silk cloth and raw silk investments. His zamindari in Surul would become the main supplier of cocoons for the Gonateah filature by the early nineteenth century.Footnote 93 A further instance is represented by the Kasimbazar factory, which was unable to meet the great demand of the London market for Kasimbazar raw silks without the help of local landlords in the 1820s. In this area, the zamindars specialized in silk production, having lands cultivated with mulberry trees and owning several big filatures. Moreover, they played a crucial role in keeping the price of cocoons as low as possible, by controlling the trade of putney within their territories.Footnote 94

In point of fact, the most impressive instance of the zamindars' involvement in raw silk production is represented by Dwarkanath Tagore, the famous entrepreneur and civic leader of Calcutta in the 1830s and 1840s. Kamarkhali, an important silk-manufacture centre where the Company had had a factory specializing in the production of filature silk since the 1770s, was located in the middle of Berhampore, Dwarkanath's ancestral zamindari.Footnote 95 The Company had six big filatures here in the late 1820sFootnote 96 and the mulberry cultivators and silkworms rearers in the neighbourhood of Kamarkhali were all tenants of Dwarkanath. To understand the importance of the role that he played in the silk production of the Kamarkhali factory, it is worth noting that, when the Company was called upon by the Charter Act of 1833 to give up its commercial operations in India and dispose of its silk factories at auction, Tagore soon entered a bid on the Kamarkhali filatures. Although the Board of Trade set the value of the Kamarkhali filatures at Rs175,000, Tagore offered only Rs60,000, confident of his control of the people settled on the lands encircling the Company's filatures and explicitly warning the Company that he could stop the business of any other person who bought the filatures. Because of the insuperable influence that Dwarkanath had on the Kamarkhali peasantry, other potential buyers declined to bid against him and, after almost two years of haggling, he purchased Kamarkhali's filatures for only Rs84,500.Footnote 97

Conclusions

Despite the many attempts to incorporate some or all of the Piedmontese novelties that European experts brought to several silk-producing areas of the world, only the upgrading of reeling technology had yielded successful quantitative outcomes in Bengal by the mid nineteenth century. Most of the other attempts had not gone beyond an experimental phase.Footnote 98 According to Claudio Zanier, ‘the long Piedmontese supremacy in the field shows, how technical innovations in themselves are no “wizard's wands”’.Footnote 99 These innovations do not have in themselves the capacity to create favourable conditions of development and growth, or to change the pre-existing context of production. Where sericulture operated as part of a long local tradition, the introduction of the Piedmontese reeling technology (which required a host of changes in the silk-production cycle) affected many of the social factors involved in the production process and in the commercialization of the semi-finished products.

A summary review of some of the experimental transfers of Piedmontese technologies into different local contexts in the late eighteenth century can only confirm this general impression. For instance, the failure met by the Amati brothers to introduce and develop Piedmontese sericulture in the English colony of Georgia in North America in the 1750s shows how the absence of a previous tradition of silk production had a crucial effect on the outcomes of such technological transfers. In the countryside surrounding Savannah, where the Amatis settled in the 1750s, lands were very fertile, mulberry could be easily cultivated, and the climate was favourable to silkworm rearing. However, what represented a truly insuperable barrier was the lack of a labour force. There were no settled populations who could begin mulberry cultivation and no local artisans who could learn the new techniques. Experiments with the native population did not give appreciable results and, after the introduction of the slave plantation system in the 1770s, experiments in using slave labour for mulberry cultivation and rearing silkworms led to similar failure.Footnote 100

In contrast to the Amatis' failures in Georgia, in regions where sericulture already had an old tradition, Piedmontese silk-reeling practices came up against local conflicts. For instance, in the region of Trás-os-Montes, in north-eastern Portugal, not only did the local silk industry have a long history, dating back to the fifteenth century, but the rearing of the silkworm was an even older activity, begun in the thirteenth century. A strongly rooted community of artisans and merchants, of Jewish origins, had been settled in the region since the sixteenth century and dominated local silk production up to the eighteenth century. In the 1780s, a remarkable process of technological upgrading took place in the region, with the contributions of local businessmen, magistrates, and politicians. This culminated in a transfer of Piedmontese technologies led by the Arnauds, an important Piedmontese family of raw silk producers and merchants. The Arnauds came to Trás-os-Montes and settled in Chachim, where they built a reeling school, a filature, and a silk-throwing hydraulic mill. But the local reelers, weavers, and merchants, who were tied to their traditional methods of production and marketing, resisted the technological novelties. With the exception of the few cultivators and artisans who worked under the direct supervision of the Arnauds, the new techniques were scarcely adopted in the region.Footnote 101

The Bengali case is somewhat different from these instances of failure and can also be compared with the outcome of introducing European reeling technologies into Meiji Japan in the second half of the nineteenth century. By this time, the model was no longer Piedmontese (for that had already been superseded) but rather the French advanced steam-reeling mill. Steady progress in quality and quantity was obtained in Japan by the engagement of a very large group of raw silk producers, who adopted new techniques or invented new ones inspired by Western models. According to Zanier, this demonstrated the receptivity to novelty by a certain type of society, with an old tradition of silk production, and its diffusion through adaptation.Footnote 102 In contrast to the direct and strong influence of the Meiji state in Japan, the East India Company's structural weakness in controlling the Bengali agrarian economy, with its intrinsically alien nature, favoured and catalysed local entrepreneurial individuals. They began to adopt, imitate, and change the Piedmontese reeling technologies and working practices and actively contributed to the partial success of Bengali raw silk on the London market in the late eighteenth and early nineteenth centuries.