1 Introduction

Suspensions of deformable particles are of great interest in engineering and the applied sciences. Prominent examples of these fluid systems include gels, drilling fluids and lubricants, as well as blood, milk and various other synthetic and naturally existing solutions. The evolution of their microstructure under large deformations gives rise to complex rheological behaviours whose understanding is crucial not only for engineering fluids with desired rheological properties, but also for providing guidelines for the design of industrial pumps, filling stations and novel medical treatments. To this end, effective or homogenized constitutive models that account for the relevant microstructural features, and their evolution, can be a viable alternative to expensive full-scale computational fluid dynamics simulations.

To provide some context, it should be noted that there has been a huge amount of work on the rheology of dispersions of rigid particles. Fortunately, there are excellent reviews, including those of Morris (Reference Morris2009) and Maxey (Reference Maxey2017), so that a detailed review of the literature is not necessary here. However, it is important to point out that the nonlinear viscoelastic rheology of these systems is a consequence of the complex competition between hydrodynamics and Brownian and other interparticle forces, as measured by the Péclet number and other parameters, such as the thermodynamic radius. Because the particles – usually assumed to be spherical – cannot change shape, these interactions affect the evolution of the two-point (and higher) statistics, which can be used, in turn, to rationalize and predict the nonlinear rheological effects (Morris Reference Morris2009). More recently, the effects of the Péclet number, thermodynamic radius and strain amplitude have been considered for rigid particle suspensions subjected to large amplitude oscillatory shear (LAOS) (see, for example, Lin et al. Reference Lin, Goyal, Cheng, Zia, Escobedo and Cohen2013; Swan, Furst & Wagner Reference Swan, Furst and Wagner2014). It should also be noted that there has been quite a bit of activity in recent years on the rheology of suspensions of capsules and vesicles, largely based on numerical simulations due to the complexity of the problem, and on experimental observations motivated by biomedical applications (see, for example, Barthés-Biesel Reference Barthés-Biesel2016). While there are similarities between the response of suspensions of capsules and vesicles and suspensions of soft particles with uniform properties, the focus of this work will be on the latter – with an emphasis on analytical approaches.

Research on the macroscopic behaviour of dispersions of deformable particles dates back to Fröhlich & Sack (Reference Fröhlich and Sack1946), who studied the rheology of suspensions of elastic spheres subjected to extensional flows in the context of infinitesimal strains. They found that, under applied axisymmetric stress, the effective constitutive equations reduce to a small-strain three-parameter Oldroyd model for the magnitude of the applied stress and the strain rate. Cerf (Reference Cerf1952) investigated the dynamic properties of dilute polymeric suspensions under small amplitude oscillatory simple shear conditions, by modelling molecular chains as viscoelastic spheres suspended in a Newtonian solvent, and found good overall agreement with experimental results for polystyrene solutions. Roscoe (Reference Roscoe1967) considered the steady-state behaviour of dilute suspensions of viscoelastic spheres within the context of finite strains and showed that, under certain loading conditions, initially spherical particles may deform into general ellipsoids with a fixed orientation in the shear plane, leading to macroscopically anisotropic behaviour for the steady-state viscosity and non-vanishing normal stress differences. By assuming small particle deformations, Goddard & Miller (Reference Goddard and Miller1967) developed nonlinear effective constitutive equations that describe the time-dependent behaviour of dilute suspensions of viscoelastic particles under general loading and initial conditions. To be able to account for finite particle volume fractions, Pal (Reference Pal2003) used the results derived by Goddard & Miller (Reference Goddard and Miller1967) to propose a differential effective medium approximation for the effective viscosity of non-dilute suspensions of elastic particles under small strains.

Making use of an arbitrary Lagrangian Eulerian (ALE) finite element method (FEM) to track the particle–solvent interface, Gao & Hu (Reference Gao and Hu2009) investigated the dynamics of two-dimensional neo-Hookean particles in shear flows and found that initially circular particles deform into general ellipses with fixed orientation, undergoing a tank-treading motion in the steady state. Other numerical methods for modelling fluid–structure interaction in the context of deformable particles include full Eulerian finite-difference schemes, such as the one described by Sugiyama et al. (Reference Sugiyama, Ii, Takeuchi, Takagi and Matsumoto2011), or the lattice Boltzmann method employed by Wu & Aidun (Reference Wu and Aidun2010). On the experimental side, Desse et al. (Reference Desse, Fraiseau, Mitchell and Budtova2010) investigated the steady-state shapes of individual starch granules suspended in water under shear flows and found that the particle shape becomes ellipsoidal at small or moderate stresses, but the granules eventually burst and eject their content at higher stresses.

More recently, analytical homogenization methods have been employed to estimate the time-dependent macroscopic response of non-dilute suspensions of deformable particles. Building on the work of Gao, Hu & Ponte Castañeda (Reference Gao, Hu and Ponte Castañeda2011, Reference Gao, Hu and Ponte Castañeda2013) for dilute suspensions of neo-Hookean particles, Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015) presented a finite-strain nonlinear viscoelastic model for the effective time-dependent behaviour of non-dilute suspensions of Kelvin–Voigt particles in a Newtonian matrix under general loading conditions. The model is based on a variational estimate of the Hashin–Shtrikman–Willis type (Ponte Castañeda & Willis Reference Ponte Castañeda and Willis1995) for an instantaneous effective (pseudo-dissipation) potential at the current values of suitably defined microstructural variables, in combination with evolution equations for these microstructural variables (Kailasam, Ponte Castañeda & Willis Reference Kailasam, Ponte Castañeda and Willis1997; Kailasam & Ponte Castañeda Reference Kailasam and Ponte Castañeda1998), as well as for the average elastic stresses in the particles. For the special case of purely viscous particles, it agrees with the results presented by Wetzel & Tucker (Reference Wetzel and Tucker2001) for dilute suspensions of viscous droplets, as well as with the results of Kailasam & Ponte Castañeda (Reference Kailasam and Ponte Castañeda1998) for non-dilute particle volume fractions.

In their work, Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015) found that suspensions of deformable particles exhibit shear thickening for extensional flows, while they exhibit shear thinning for shear flows. Furthermore, they found that suspensions of particles with finite extensibility always reach a steady state in extensional flows, in contrast to suspensions of neo-Hookean particles in extensional flows for which steady-state solutions only exist below a critical particle volume fraction and a critical strain rate. Villone et al. (Reference Villone, Greco, Hulsen and Maffettone2014a,Reference Villone, Hulsen, Anderson and Maffettoneb) (see also Villone & Maffettone (Reference Villone and Maffettone2019)) used an ALE FEM method to investigate the deformation and transverse migration of initially spherical neo-Hookean particles, suspended (and confined) in Newtonian and viscoelastic fluids under shear – and, in particular, confirmed some of the findings of Gao et al. (Reference Gao, Hu and Ponte Castañeda2011) for dilute concentrations of initially spherical neo-Hookean particles. Finally, Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2016) made use of the variational linear comparison homogenization method of Ponte Castañeda (Reference Ponte Castañeda1991) to develop a constitutive model for dispersions of viscoelastic particles in yield stress fluids of the Herschel–Bulkley type.

While most of the above-referenced work was concerned with uniform strain-rate loading conditions leading to a steady state, the present work will focus on oscillatory loading conditions. More specifically, the interest is on LAOS (see, for example, Dealy & Wissbrun Reference Dealy and Wissbrun1990; Hyun et al. Reference Hyun, Wilhelm, Klein, Cho, Nam, Ahn, Lee, Ewoldt and McKinley2011), which provides a method to characterize the progressive transition from linear to nonlinear viscoelastic constitutive behaviour as the strain amplitude is increased for a given frequency – and can be displayed in a Pipkin diagram (Pipkin Reference Pipkin1972). In the context of investigations on the rheological properties of a variety of polymer solutions, such as xantham gum, aiming to establish a connection between the microstructure and the qualitative behaviour of the storage and loss moduli at the transition into the large amplitude regime, Hyun et al. (Reference Hyun, Kim, Ahn and Lee2002) define four archetypes of LAOS behaviour: (I) strain thinning; (II) strain hardening; (III) weak strain overshoot; and (IV) strong strain overshoot. In particular, Hyun et al. (Reference Hyun, Kim, Ahn and Lee2002) argue that type I fluids form entangled polymer networks, which, under shear loadings, disentangle at sufficiently large shear rates and tend to align themselves in the direction of flow, thus reducing drag and leading to an overall reduction in viscosity. This shear-thinning behaviour was also reported by Ewoldt et al. (Reference Ewoldt, Winter, Maxey and McKinley2010) for both xantham gum solutions and drilling fluids. Furthermore, under LAOS the viscous projections of the Lissajous–Bowditch curves presented by Ewoldt et al. (Reference Ewoldt, Winter, Maxey and McKinley2010) for xantham gum solutions reveal the formation of so-called secondary loops, or self-intersections in the stress–strain-rate projection of the Lissajous–Bowditch curves. More recently, Lin et al. (Reference Lin, Goyal, Cheng, Zia, Escobedo and Cohen2013) and Swan et al. (Reference Swan, Furst and Wagner2014) have carried out experimental and theoretical LAOS investigations for colloidal dispersions, the latter also incorporating analyses of normal stress differences. In addition, Rogers (Reference Rogers2017) developed model-independent viscoelastic functions for understanding responses to transient nonlinear rheological tests, and applied them to various models and material responses under LAOS conditions.

In this paper we investigate the oscillatory simple shear rheology of non-dilute suspensions of deformable particles in a Newtonian matrix fluid using the homogenization model proposed by Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015). In the next section we recall the constitutive equations, together with the evolution laws that describe the time-dependent deformation of the microstructure. In § 3 we consider the specialization of the constitutive equations for simple shear loading conditions. We begin by considering small amplitude oscillatory shear (SAOS) and provide the corresponding small-strain linearized equations for the suspensions of viscoelastic spheres. Making use of the homogenization model, we develop expressions for the storage and loss moduli,  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$, as functions of the excitation frequency, the particle volume fraction and the mechanical properties of the constituents. Next we transition into the LAOS regime and present the characteristic stress waveforms, as well as the elastic and viscous projections of the Lissajous–Bowditch curves in the time-periodic steady state for the shear stress and normal stress differences in Pipkin space. In the LAOS regime the model predicts a number of nonlinear features that are frequently observed in the rheology of complex fluids, including a variety of distorted stress waveforms leading to complex intracycle behaviour, as well as secondary loops in the viscous and elastic projections of the Lissajous–Bowditch curves for the shear stress and normal stress differences (Hyun et al. Reference Hyun, Kim, Ahn and Lee2002; Ewoldt & McKinley Reference Ewoldt and McKinley2010; Lin et al. Reference Lin, Goyal, Cheng, Zia, Escobedo and Cohen2013; Swan et al. Reference Swan, Furst and Wagner2014). We relate the various nonlinear features to the evolution of the microstructural variables, specifically, the evolution of the aspect ratios and spatial orientation of the particles. Finally, in § 5, we draw some conclusions from our investigations.

$G^{\prime \prime }$, as functions of the excitation frequency, the particle volume fraction and the mechanical properties of the constituents. Next we transition into the LAOS regime and present the characteristic stress waveforms, as well as the elastic and viscous projections of the Lissajous–Bowditch curves in the time-periodic steady state for the shear stress and normal stress differences in Pipkin space. In the LAOS regime the model predicts a number of nonlinear features that are frequently observed in the rheology of complex fluids, including a variety of distorted stress waveforms leading to complex intracycle behaviour, as well as secondary loops in the viscous and elastic projections of the Lissajous–Bowditch curves for the shear stress and normal stress differences (Hyun et al. Reference Hyun, Kim, Ahn and Lee2002; Ewoldt & McKinley Reference Ewoldt and McKinley2010; Lin et al. Reference Lin, Goyal, Cheng, Zia, Escobedo and Cohen2013; Swan et al. Reference Swan, Furst and Wagner2014). We relate the various nonlinear features to the evolution of the microstructural variables, specifically, the evolution of the aspect ratios and spatial orientation of the particles. Finally, in § 5, we draw some conclusions from our investigations.

2 Effective constitutive equations for non-dilute viscoelastic particle suspensions

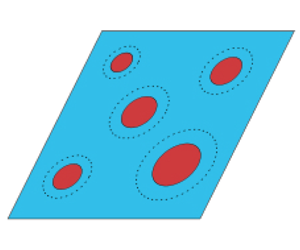

Figure 1. Representative volume element (RVE) of the microstructure. Subjected to a macroscopic velocity gradient  $\bar{\boldsymbol{L}}$, the microstructure will begin to evolve through a sequence of configurations from its initial state (a) at time

$\bar{\boldsymbol{L}}$, the microstructure will begin to evolve through a sequence of configurations from its initial state (a) at time  $t=0$ into its deformed configuration (b) at

$t=0$ into its deformed configuration (b) at  $t=t_{0}$. We consider solid Kelvin–Voigt (KV) particles (red ellipses) suspended in a Newtonian matrix fluid (blue). On average, the particles deform into general ellipsoids, whose shape and orientation with respect to the laboratory axes

$t=t_{0}$. We consider solid Kelvin–Voigt (KV) particles (red ellipses) suspended in a Newtonian matrix fluid (blue). On average, the particles deform into general ellipsoids, whose shape and orientation with respect to the laboratory axes  $\{\boldsymbol{E}_{k}\}_{k=1}^{3}$ are characterized by the ratios of their semi-axes

$\{\boldsymbol{E}_{k}\}_{k=1}^{3}$ are characterized by the ratios of their semi-axes  $w_{1}=z_{2}/z_{1}$,

$w_{1}=z_{2}/z_{1}$,  $w_{2}=z_{3}/z_{1}$ and the orthonormal triad

$w_{2}=z_{3}/z_{1}$ and the orthonormal triad  $\{\boldsymbol{n}_{k}\}_{k=1}^{3}$ (all of which evolve with the deformation), as shown in (c). The larger dotted ellipses surrounding the particles illustrate the ellipsoidal symmetry of the two-point probability function of the particle distribution.

$\{\boldsymbol{n}_{k}\}_{k=1}^{3}$ (all of which evolve with the deformation), as shown in (c). The larger dotted ellipses surrounding the particles illustrate the ellipsoidal symmetry of the two-point probability function of the particle distribution.

In this work we make use of the constitutive model of Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015) for dispersions of neutrally buoyant deformable particles suspended in a Newtonian matrix fluid under Stokes flow conditions ( $\mathit{Re}\ll 1$). The model will be used here to investigate the oscillatory shear rheology of non-dilute suspensions of initially spherical viscoelastic particles. The suspending fluid has viscosity

$\mathit{Re}\ll 1$). The model will be used here to investigate the oscillatory shear rheology of non-dilute suspensions of initially spherical viscoelastic particles. The suspending fluid has viscosity  $\unicode[STIX]{x1D702}^{(1)}$, while the particles are assumed to have Kelvin–Voigt (KV) constitutive behaviour with linear viscosity given by

$\unicode[STIX]{x1D702}^{(1)}$, while the particles are assumed to have Kelvin–Voigt (KV) constitutive behaviour with linear viscosity given by  $\unicode[STIX]{x1D702}^{(2)}$ and nonlinear elastic response described by the Gent (Reference Gent1996) model, which, in turn, is characterized by the ground-state shear modulus

$\unicode[STIX]{x1D702}^{(2)}$ and nonlinear elastic response described by the Gent (Reference Gent1996) model, which, in turn, is characterized by the ground-state shear modulus  $\unicode[STIX]{x1D707}$ and strain-locking parameter

$\unicode[STIX]{x1D707}$ and strain-locking parameter  $J_{m}$, as described in more detail further below. The particles are randomly distributed in volume fraction

$J_{m}$, as described in more detail further below. The particles are randomly distributed in volume fraction  $c$, as illustrated in figures 1(a) and 1(b) depicting respectively ‘snapshots’ of a representative volume element (RVE) of the suspension at the initial time and at a later time. As shown in figure 1(a), the particles are initially spherical in their unstressed state. We note that more general initial shapes could be considered for the particles; however, in this work the focus shall be on suspensions of initially spherical viscoelastic particles. Upon loading, the particles deform and the microstructure evolves through a time-dependent sequence of configurations in which the particles become aligned ellipsoids of identical (on average) evolving shape and orientation, as depicted in figure 1(b). The larger dotted ellipses around the particles illustrate the ellipsoidal symmetry of their two-point probability functions (Ponte Castañeda & Willis Reference Ponte Castañeda and Willis1995), which, for simplicity, are assumed here to have the same ‘shape’ and ‘orientation’ as the particles. Thus, we identify as microstructural variables the particle aspect ratios

$c$, as illustrated in figures 1(a) and 1(b) depicting respectively ‘snapshots’ of a representative volume element (RVE) of the suspension at the initial time and at a later time. As shown in figure 1(a), the particles are initially spherical in their unstressed state. We note that more general initial shapes could be considered for the particles; however, in this work the focus shall be on suspensions of initially spherical viscoelastic particles. Upon loading, the particles deform and the microstructure evolves through a time-dependent sequence of configurations in which the particles become aligned ellipsoids of identical (on average) evolving shape and orientation, as depicted in figure 1(b). The larger dotted ellipses around the particles illustrate the ellipsoidal symmetry of their two-point probability functions (Ponte Castañeda & Willis Reference Ponte Castañeda and Willis1995), which, for simplicity, are assumed here to have the same ‘shape’ and ‘orientation’ as the particles. Thus, we identify as microstructural variables the particle aspect ratios

$$\begin{eqnarray}w_{1}=z_{2}/z_{1},\quad w_{2}=z_{3}/z_{1},\end{eqnarray}$$

$$\begin{eqnarray}w_{1}=z_{2}/z_{1},\quad w_{2}=z_{3}/z_{1},\end{eqnarray}$$ along with the orthonormal triad  $\{\boldsymbol{n}_{k}\}_{k=1}^{3}$ characterizing the orientation of the semi-axes of the particles with respect to the laboratory reference frame

$\{\boldsymbol{n}_{k}\}_{k=1}^{3}$ characterizing the orientation of the semi-axes of the particles with respect to the laboratory reference frame  $\{\boldsymbol{E}_{k}\}_{k=1}^{3}$, as depicted in figure 1(c). In the above equations,

$\{\boldsymbol{E}_{k}\}_{k=1}^{3}$, as depicted in figure 1(c). In the above equations,  $z_{1}$,

$z_{1}$,  $z_{2}$ and

$z_{2}$ and  $z_{3}$ quantify the lengths of the semi-axes of the ellipsoidal particles.

$z_{3}$ quantify the lengths of the semi-axes of the ellipsoidal particles.

Before providing the detailed equations describing the homogenization model of Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015) for the above-described suspensions, it is useful to recall that the model provides a generalization for non-dilute concentrations of viscoelastic particles of the results of Gao et al. (Reference Gao, Hu and Ponte Castañeda2011) for dilute suspensions of elastic particles. As such, the model is exact for dilute particle concentrations, but should still provide reasonably accurate estimates for low-to-moderate particle volume fractions. As discussed in the introduction and in more detail in the above-mentioned references, this is a consequence of the use of a generalization of the Hashin–Shtrikman variational estimates of Ponte Castañeda & Willis (Reference Ponte Castañeda and Willis1995) for elastic composites consisting of random distributions of aligned particles of ellipsoidal shape with ellipsoidal distribution for the particle centres, together with the reinterpretation of Kailasam & Ponte Castañeda (Reference Kailasam and Ponte Castañeda1998) for linearly viscous composites with evolving microstructure. The model is not meant to be used for large volume fractions of mono-disperse particles, because it cannot accurately capture strong interactions of particles in close vicinity. However, as will be seen below, even for dilute suspensions, changes in the shape and orientation of the particles affect the instantaneous macroscopic viscosity and normal stress differences to the same order as the particle volume fraction – and, as a consequence, large volume fractions are not required to generate strongly nonlinear rheological effects.

According to the model of Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015), the macroscopic Cauchy stress tensor is given by

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D748}}=-\bar{p}\unicode[STIX]{x1D644}+\bar{\unicode[STIX]{x1D749}}, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D748}}=-\bar{p}\unicode[STIX]{x1D644}+\bar{\unicode[STIX]{x1D749}}, & & \displaystyle\end{eqnarray}$$ where the arbitrary pressure  $\bar{p}$ is the Lagrange multiplier associated with the incompressibility constraint

$\bar{p}$ is the Lagrange multiplier associated with the incompressibility constraint  $\text{tr}\,\bar{\unicode[STIX]{x1D63F}}=0$, and the extra-stress tensor is given by

$\text{tr}\,\bar{\unicode[STIX]{x1D63F}}=0$, and the extra-stress tensor is given by

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D749}}=(1-c)\bar{\unicode[STIX]{x1D749}}^{(1)}+c\bar{\unicode[STIX]{x1D749}}^{(2)}=(1-c)\bar{\unicode[STIX]{x1D749}}^{(1)}+c(\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}+\bar{\unicode[STIX]{x1D749}}_{v}^{(2)}), & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D749}}=(1-c)\bar{\unicode[STIX]{x1D749}}^{(1)}+c\bar{\unicode[STIX]{x1D749}}^{(2)}=(1-c)\bar{\unicode[STIX]{x1D749}}^{(1)}+c(\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}+\bar{\unicode[STIX]{x1D749}}_{v}^{(2)}), & & \displaystyle\end{eqnarray}$$ in terms of the average viscous stresses in the Newtonian matrix and the particle phase,  $\bar{\unicode[STIX]{x1D749}}^{(1)}$ and

$\bar{\unicode[STIX]{x1D749}}^{(1)}$ and  $\bar{\unicode[STIX]{x1D749}}_{v}^{(2)}$, as well as the average elastic stress in the particle phase

$\bar{\unicode[STIX]{x1D749}}_{v}^{(2)}$, as well as the average elastic stress in the particle phase  $\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}$. Making use of the constitutive equation for the viscous stress in the particle, this can be rewritten in the form

$\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}$. Making use of the constitutive equation for the viscous stress in the particle, this can be rewritten in the form

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D749}}=2\unicode[STIX]{x1D702}^{(1)}\bar{\unicode[STIX]{x1D63F}}+2c(\unicode[STIX]{x1D702}^{(1)}-\unicode[STIX]{x1D702}^{(2)})\bar{\unicode[STIX]{x1D63F}}^{(2)}+c\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D749}}=2\unicode[STIX]{x1D702}^{(1)}\bar{\unicode[STIX]{x1D63F}}+2c(\unicode[STIX]{x1D702}^{(1)}-\unicode[STIX]{x1D702}^{(2)})\bar{\unicode[STIX]{x1D63F}}^{(2)}+c\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}, & & \displaystyle\end{eqnarray}$$ where it is noted that  $\bar{\unicode[STIX]{x1D749}}$ need not be deviatoric in general. The effective rate-of-strain tensor will be denoted by

$\bar{\unicode[STIX]{x1D749}}$ need not be deviatoric in general. The effective rate-of-strain tensor will be denoted by  $\bar{\unicode[STIX]{x1D63F}}$ and is the symmetric part of the macroscopic velocity gradient

$\bar{\unicode[STIX]{x1D63F}}$ and is the symmetric part of the macroscopic velocity gradient  $\bar{\boldsymbol{L}}$. In the above equation,

$\bar{\boldsymbol{L}}$. In the above equation,  $\bar{\unicode[STIX]{x1D63F}}^{(2)}$ is the average strain-rate tensor in the particle phase given by

$\bar{\unicode[STIX]{x1D63F}}^{(2)}$ is the average strain-rate tensor in the particle phase given by

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D63F}}^{(2)}=\{\mathbb{I}-2(1-c)(\unicode[STIX]{x1D702}^{(1)}-\unicode[STIX]{x1D702}^{(2)})\mathbb{P}\}^{-1}\{\bar{\unicode[STIX]{x1D63F}}-(1-c)\mathbb{P}\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}\}, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D63F}}^{(2)}=\{\mathbb{I}-2(1-c)(\unicode[STIX]{x1D702}^{(1)}-\unicode[STIX]{x1D702}^{(2)})\mathbb{P}\}^{-1}\{\bar{\unicode[STIX]{x1D63F}}-(1-c)\mathbb{P}\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}\}, & & \displaystyle\end{eqnarray}$$ where  $\mathbb{I}$ is the fourth-order identity tensor with minor and major symmetry. The tensor

$\mathbb{I}$ is the fourth-order identity tensor with minor and major symmetry. The tensor  $\mathbb{P}$ is a fourth-order microstructural tensor that depends on the particle aspect ratios,

$\mathbb{P}$ is a fourth-order microstructural tensor that depends on the particle aspect ratios,  $w_{1}$ and

$w_{1}$ and  $w_{2}$. Expressions for the Cartesian coordinates of

$w_{2}$. Expressions for the Cartesian coordinates of  $\mathbb{P}$ for ellipsoidal particles in a Newtonian host fluid are given in appendix A.

$\mathbb{P}$ for ellipsoidal particles in a Newtonian host fluid are given in appendix A.

As already mentioned, the elastic response of the KV particles is described by the Gent model, which provides a relation between the extra stress in the particles and the deformation gradient and depends on two material parameters: the ground-state shear modulus  $\unicode[STIX]{x1D707}$ and the strain-locking parameter

$\unicode[STIX]{x1D707}$ and the strain-locking parameter  $J_{m}$. The Gent model provides a generalization of the classical neo-Hookean (NH) finite-strain model, where

$J_{m}$. The Gent model provides a generalization of the classical neo-Hookean (NH) finite-strain model, where  $J_{m}$ is used to describe the strong stiffening of elastomers as the macromolecular chains become elongated with the deformation. The limit as

$J_{m}$ is used to describe the strong stiffening of elastomers as the macromolecular chains become elongated with the deformation. The limit as  $J_{m}\rightarrow \infty$ corresponds to neo-Hookean behaviour, which does not exhibit strain locking at any finite strain. As discussed in some detail in § 2.1 of Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015), the Gent model leads to the following evolution equation for the extra elastic stress in the particles:

$J_{m}\rightarrow \infty$ corresponds to neo-Hookean behaviour, which does not exhibit strain locking at any finite strain. As discussed in some detail in § 2.1 of Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015), the Gent model leads to the following evolution equation for the extra elastic stress in the particles:

$$\begin{eqnarray}\displaystyle \stackrel{\!\!\!\!\!\!\triangledown }{\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}}=2\unicode[STIX]{x1D707}\bar{\unicode[STIX]{x1D63F}}^{(2)}+\frac{2}{\unicode[STIX]{x1D707}J_{m}}\text{tr}[\bar{\unicode[STIX]{x1D63F}}^{(2)}(\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}+\unicode[STIX]{x1D707}\unicode[STIX]{x1D644})](\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}+\unicode[STIX]{x1D707}\unicode[STIX]{x1D644}). & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \stackrel{\!\!\!\!\!\!\triangledown }{\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}}=2\unicode[STIX]{x1D707}\bar{\unicode[STIX]{x1D63F}}^{(2)}+\frac{2}{\unicode[STIX]{x1D707}J_{m}}\text{tr}[\bar{\unicode[STIX]{x1D63F}}^{(2)}(\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}+\unicode[STIX]{x1D707}\unicode[STIX]{x1D644})](\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}+\unicode[STIX]{x1D707}\unicode[STIX]{x1D644}). & & \displaystyle\end{eqnarray}$$ Here  $\stackrel{\!\!\!\!\!\!\triangledown }{\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}}$ is the upper-convected time derivative of the average extra elastic stress over the particles. In the limit

$\stackrel{\!\!\!\!\!\!\triangledown }{\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}}$ is the upper-convected time derivative of the average extra elastic stress over the particles. In the limit  $J_{m}\rightarrow \infty$, (2.6) reduces to the known rate form of the neo-Hookean model (Joseph Reference Joseph1990).

$J_{m}\rightarrow \infty$, (2.6) reduces to the known rate form of the neo-Hookean model (Joseph Reference Joseph1990).

Evolution of microstructure. The evolution of the aspect ratios characterizing the average shape of the particles is given by

$$\begin{eqnarray}\displaystyle & \displaystyle \frac{\text{d}w_{1}}{\text{d}t}=w_{1}(\boldsymbol{n}_{2}\boldsymbol{\cdot }\bar{\unicode[STIX]{x1D63F}}^{(2)}\boldsymbol{n}_{2}-\boldsymbol{n}_{1}\boldsymbol{\cdot }\bar{\unicode[STIX]{x1D63F}}^{(2)}\boldsymbol{n}_{1}), & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle \frac{\text{d}w_{1}}{\text{d}t}=w_{1}(\boldsymbol{n}_{2}\boldsymbol{\cdot }\bar{\unicode[STIX]{x1D63F}}^{(2)}\boldsymbol{n}_{2}-\boldsymbol{n}_{1}\boldsymbol{\cdot }\bar{\unicode[STIX]{x1D63F}}^{(2)}\boldsymbol{n}_{1}), & \displaystyle\end{eqnarray}$$ $$\begin{eqnarray}\displaystyle & \displaystyle \frac{\text{d}w_{2}}{\text{d}t}=w_{2}(\boldsymbol{n}_{3}\boldsymbol{\cdot }\bar{\unicode[STIX]{x1D63F}}^{(2)}\boldsymbol{n}_{3}-\boldsymbol{n}_{1}\boldsymbol{\cdot }\bar{\unicode[STIX]{x1D63F}}^{(2)}\boldsymbol{n}_{1}), & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & \displaystyle \frac{\text{d}w_{2}}{\text{d}t}=w_{2}(\boldsymbol{n}_{3}\boldsymbol{\cdot }\bar{\unicode[STIX]{x1D63F}}^{(2)}\boldsymbol{n}_{3}-\boldsymbol{n}_{1}\boldsymbol{\cdot }\bar{\unicode[STIX]{x1D63F}}^{(2)}\boldsymbol{n}_{1}), & \displaystyle\end{eqnarray}$$ where  $\bar{\unicode[STIX]{x1D63F}}^{(2)}$ is the average strain-rate tensor in the particle phase given in (2.5). The orthonormal vectors

$\bar{\unicode[STIX]{x1D63F}}^{(2)}$ is the average strain-rate tensor in the particle phase given in (2.5). The orthonormal vectors  $\{\boldsymbol{n}_{k}\}$ characterize the average orientation of the particle semi-axes. Their evolution is governed by

$\{\boldsymbol{n}_{k}\}$ characterize the average orientation of the particle semi-axes. Their evolution is governed by

$$\begin{eqnarray}\displaystyle \dot{\boldsymbol{n}}_{k}=\unicode[STIX]{x1D734}\boldsymbol{n}_{k}, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \dot{\boldsymbol{n}}_{k}=\unicode[STIX]{x1D734}\boldsymbol{n}_{k}, & & \displaystyle\end{eqnarray}$$ where the particle or microstructural spin tensor has Cartesian components with respect to the triad  $\{\boldsymbol{n}_{k}\}$ given by

$\{\boldsymbol{n}_{k}\}$ given by

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D6FA}_{ij}=\bar{W}_{ij}^{(2)}-\frac{(w_{i-1})^{2}+(w_{j-1})^{2}}{(w_{i-1})^{2}-(w_{j-1})^{2}}\bar{D}_{ij}^{(2)}\quad \forall i\neq j, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D6FA}_{ij}=\bar{W}_{ij}^{(2)}-\frac{(w_{i-1})^{2}+(w_{j-1})^{2}}{(w_{i-1})^{2}-(w_{j-1})^{2}}\bar{D}_{ij}^{(2)}\quad \forall i\neq j, & & \displaystyle\end{eqnarray}$$ with  $w_{1-1}=w_{0}=1$. In addition,

$w_{1-1}=w_{0}=1$. In addition,  $\bar{W}_{ij}^{(2)}$ are the Cartesian components of the average vorticity tensor in the particle phase given by

$\bar{W}_{ij}^{(2)}$ are the Cartesian components of the average vorticity tensor in the particle phase given by

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D652}}^{(2)}=\bar{\unicode[STIX]{x1D652}}+(1-c)\mathbb{R}[2(\unicode[STIX]{x1D702}^{(1)}-\unicode[STIX]{x1D702}^{(2)})\bar{\unicode[STIX]{x1D63F}}^{(2)}-\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}], & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D652}}^{(2)}=\bar{\unicode[STIX]{x1D652}}+(1-c)\mathbb{R}[2(\unicode[STIX]{x1D702}^{(1)}-\unicode[STIX]{x1D702}^{(2)})\bar{\unicode[STIX]{x1D63F}}^{(2)}-\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}], & & \displaystyle\end{eqnarray}$$ where  $\bar{\unicode[STIX]{x1D652}}$ is the macroscopic vorticity tensor and the Cartesian components of the microstructural tensor

$\bar{\unicode[STIX]{x1D652}}$ is the macroscopic vorticity tensor and the Cartesian components of the microstructural tensor  $\mathbb{R}$ are given in appendix A as functions of the particle aspect ratios

$\mathbb{R}$ are given in appendix A as functions of the particle aspect ratios  $w_{1}$ and

$w_{1}$ and  $w_{2}$. It should be noted that these evolution laws generalize corresponding expressions (e.g. Goddard & Miller Reference Goddard and Miller1967; Wetzel & Tucker Reference Wetzel and Tucker2001) for dilute suspensions. Due to the hypotheses implicit in its derivation via variational estimates of the Hashin–Shtrikman–Willis type, the above constitutive model is expected to be most appropriate for polydisperse systems, although it should also hold for monodisperse systems up to moderate particle concentrations (Ponte Castañeda & Willis Reference Ponte Castañeda and Willis1995).

$w_{2}$. It should be noted that these evolution laws generalize corresponding expressions (e.g. Goddard & Miller Reference Goddard and Miller1967; Wetzel & Tucker Reference Wetzel and Tucker2001) for dilute suspensions. Due to the hypotheses implicit in its derivation via variational estimates of the Hashin–Shtrikman–Willis type, the above constitutive model is expected to be most appropriate for polydisperse systems, although it should also hold for monodisperse systems up to moderate particle concentrations (Ponte Castañeda & Willis Reference Ponte Castañeda and Willis1995).

Simple shear. Subsequently, we subject suspensions of initially spherical viscoelastic particles  $(w_{1}|_{t=0}=w_{2}|_{t=0}=1)$ to simple shear excitations. Then, prescribing a strain-rate excitation

$(w_{1}|_{t=0}=w_{2}|_{t=0}=1)$ to simple shear excitations. Then, prescribing a strain-rate excitation  $\dot{\unicode[STIX]{x1D6FE}}(t)$, the macroscopic velocity gradient in simple shear can be written as

$\dot{\unicode[STIX]{x1D6FE}}(t)$, the macroscopic velocity gradient in simple shear can be written as

$$\begin{eqnarray}\displaystyle \bar{\boldsymbol{L}}=\dot{\unicode[STIX]{x1D6FE}}(t)\boldsymbol{E}_{1}\boldsymbol{E}_{2}. & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \bar{\boldsymbol{L}}=\dot{\unicode[STIX]{x1D6FE}}(t)\boldsymbol{E}_{1}\boldsymbol{E}_{2}. & & \displaystyle\end{eqnarray}$$ The particles will deform and assume the shape of general ellipsoids characterized – on average – by the aspect ratios  $w_{1}$ and

$w_{1}$ and  $w_{2}$. In simple shear, the particles rotate only in the

$w_{2}$. In simple shear, the particles rotate only in the  $\boldsymbol{E}_{1}$–

$\boldsymbol{E}_{1}$– $\boldsymbol{E}_{2}$ plane of shearing, such that their orientation may be described in terms of a single angle

$\boldsymbol{E}_{2}$ plane of shearing, such that their orientation may be described in terms of a single angle  $\unicode[STIX]{x1D703}$ and (2.9) reduces to

$\unicode[STIX]{x1D703}$ and (2.9) reduces to

$$\begin{eqnarray}\displaystyle \dot{\unicode[STIX]{x1D703}}=\boldsymbol{n}_{\mathbf{2}}\boldsymbol{\cdot }\unicode[STIX]{x1D734}\boldsymbol{n}_{\mathbf{1}}=-\bar{W}_{12}^{(2)}+\frac{1+w_{1}^{2}}{1-w_{1}^{2}}\bar{D}_{12}^{(2)}. & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \dot{\unicode[STIX]{x1D703}}=\boldsymbol{n}_{\mathbf{2}}\boldsymbol{\cdot }\unicode[STIX]{x1D734}\boldsymbol{n}_{\mathbf{1}}=-\bar{W}_{12}^{(2)}+\frac{1+w_{1}^{2}}{1-w_{1}^{2}}\bar{D}_{12}^{(2)}. & & \displaystyle\end{eqnarray}$$We wish to study the behaviour of the suspensions of viscoelastic particles under harmonic strain excitations of the form

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D6FE}(t)=\unicode[STIX]{x1D6FE}_{0}\sin (\unicode[STIX]{x1D714}t), & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D6FE}(t)=\unicode[STIX]{x1D6FE}_{0}\sin (\unicode[STIX]{x1D714}t), & & \displaystyle\end{eqnarray}$$ where  $\unicode[STIX]{x1D6FE}_{0}$ is the amplitude of the strains and

$\unicode[STIX]{x1D6FE}_{0}$ is the amplitude of the strains and  $\unicode[STIX]{x1D714}$ is the angular excitation frequency. Consequently, the strain rate is given by

$\unicode[STIX]{x1D714}$ is the angular excitation frequency. Consequently, the strain rate is given by

$$\begin{eqnarray}\dot{\unicode[STIX]{x1D6FE}}(t)=\dot{\unicode[STIX]{x1D6FE}}_{0}\cos (\unicode[STIX]{x1D714}t),\quad \dot{\unicode[STIX]{x1D6FE}}_{0}=\unicode[STIX]{x1D6FE}_{0}\unicode[STIX]{x1D714}.\end{eqnarray}$$

$$\begin{eqnarray}\dot{\unicode[STIX]{x1D6FE}}(t)=\dot{\unicode[STIX]{x1D6FE}}_{0}\cos (\unicode[STIX]{x1D714}t),\quad \dot{\unicode[STIX]{x1D6FE}}_{0}=\unicode[STIX]{x1D6FE}_{0}\unicode[STIX]{x1D714}.\end{eqnarray}$$In order to conveniently discuss the results, we introduce the dimensionless parameters

$$\begin{eqnarray}K=\frac{\unicode[STIX]{x1D702}^{(2)}}{\unicode[STIX]{x1D702}^{(1)}},\quad G=\frac{\unicode[STIX]{x1D702}^{(1)}\dot{\unicode[STIX]{x1D6FE}}_{0}}{\unicode[STIX]{x1D707}},\end{eqnarray}$$

$$\begin{eqnarray}K=\frac{\unicode[STIX]{x1D702}^{(2)}}{\unicode[STIX]{x1D702}^{(1)}},\quad G=\frac{\unicode[STIX]{x1D702}^{(1)}\dot{\unicode[STIX]{x1D6FE}}_{0}}{\unicode[STIX]{x1D707}},\end{eqnarray}$$as proposed by Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015). Additionally, we define the dimensionless excitation frequency

$$\begin{eqnarray}\displaystyle F=\frac{\unicode[STIX]{x1D702}^{(1)}\unicode[STIX]{x1D714}}{\unicode[STIX]{x1D707}}, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle F=\frac{\unicode[STIX]{x1D702}^{(1)}\unicode[STIX]{x1D714}}{\unicode[STIX]{x1D707}}, & & \displaystyle\end{eqnarray}$$ which is a ratio between the intrinsic time scale  $\unicode[STIX]{x1D702}^{(1)}/\unicode[STIX]{x1D707}$ and the process time scale

$\unicode[STIX]{x1D702}^{(1)}/\unicode[STIX]{x1D707}$ and the process time scale  $\unicode[STIX]{x1D714}^{-1}$.

$\unicode[STIX]{x1D714}^{-1}$.

Thus, for oscillatory simple shear loading conditions, the constitutive model requires the time integration of (2.7), (2.8) and (2.13) for the particle aspect ratios  $w_{1}$ and

$w_{1}$ and  $w_{2}$ and orientation angle

$w_{2}$ and orientation angle  $\unicode[STIX]{x1D703}$, together with (2.6) for the Cartesian components of particle average elastic stress

$\unicode[STIX]{x1D703}$, together with (2.6) for the Cartesian components of particle average elastic stress  $\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}$. These equations are solved numerically using an explicit fourth-order Runge–Kutta time-integration scheme. The solutions in the time-periodic steady state were obtained by time-walking the system through at least ten loading cycles until the limit orbits were attained. In this connection, it is noted that the limit cycles are fairly insensitive to the initial conditions. The numerical integration for obtaining the components of the microstructural tensor

$\bar{\unicode[STIX]{x1D749}}_{e}^{(2)}$. These equations are solved numerically using an explicit fourth-order Runge–Kutta time-integration scheme. The solutions in the time-periodic steady state were obtained by time-walking the system through at least ten loading cycles until the limit orbits were attained. In this connection, it is noted that the limit cycles are fairly insensitive to the initial conditions. The numerical integration for obtaining the components of the microstructural tensor  $\mathbb{P}$ were carried out using a Gauss–Legendre quadrature.

$\mathbb{P}$ were carried out using a Gauss–Legendre quadrature.

In the context of the above-mentioned equations for simple shear loading conditions, it is also relevant to recall that a linear stability analysis carried out for dilute concentrations of NH elastic particles (of initially spherical shape) showed that the steady-state solution under constant shear rate is stable (Gao, Hu & Ponte Castañeda Reference Gao, Hu and Ponte Castañeda2012). In addition, recent numerical simulations of the time-dependent response of such soft particle systems (Villone & Maffettone Reference Villone and Maffettone2019) have confirmed the analytical solutions (Gao et al. Reference Gao, Hu and Ponte Castañeda2012) and not shown any indication of the possible development of instabilities. This may suggest that the solutions of the above system of equations for simple shear loading under more general oscillatory conditions will also be stable, provided that the particles are initially spherical (and that the suspending fluid is Newtonian). However, this remains to be investigated further. On the other hand, it should be noted that Gao et al. (Reference Gao, Hu and Ponte Castañeda2012) found that, depending on the initial particle shape and dimensionless parameter  $G$, three types of long-time solutions are possible for suspensions of initially non-spherical NH particles subjected to constant shear rate: tank-treading, tumbling and trembling – with an interesting bifurcation phenomenon from the trembling to the tumbling solution.

$G$, three types of long-time solutions are possible for suspensions of initially non-spherical NH particles subjected to constant shear rate: tank-treading, tumbling and trembling – with an interesting bifurcation phenomenon from the trembling to the tumbling solution.

3 Small amplitude oscillatory shear (SAOS)

To put our results for LAOS into context, we begin by exploring the rheological properties of moderately concentrated suspensions of initially spherical viscoelastic particles under small amplitude oscillatory shear (SAOS). For small strains and initially spherical particles in simple shear, the constitutive equations presented in the previous section can be shown to reduce to the Oldroyd equations

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D749}}+\unicode[STIX]{x1D706}_{1}\dot{\bar{\unicode[STIX]{x1D749}}}=2\unicode[STIX]{x1D702}_{0}(\bar{\unicode[STIX]{x1D63F}}+\unicode[STIX]{x1D706}_{2}\dot{\bar{\unicode[STIX]{x1D63F}}}), & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D749}}+\unicode[STIX]{x1D706}_{1}\dot{\bar{\unicode[STIX]{x1D749}}}=2\unicode[STIX]{x1D702}_{0}(\bar{\unicode[STIX]{x1D63F}}+\unicode[STIX]{x1D706}_{2}\dot{\bar{\unicode[STIX]{x1D63F}}}), & & \displaystyle\end{eqnarray}$$with an effective viscosity

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D702}_{0}=\frac{2+3c}{2(1-c)}\unicode[STIX]{x1D702}^{(1)}, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D702}_{0}=\frac{2+3c}{2(1-c)}\unicode[STIX]{x1D702}^{(1)}, & & \displaystyle\end{eqnarray}$$ and where the two macroscopic time scales  $\unicode[STIX]{x1D706}_{1}$ and

$\unicode[STIX]{x1D706}_{1}$ and  $\unicode[STIX]{x1D706}_{2}$ can be identified as

$\unicode[STIX]{x1D706}_{2}$ can be identified as

$$\begin{eqnarray}\unicode[STIX]{x1D706}_{1}=\frac{3+2c}{2(1-c)}\frac{\unicode[STIX]{x1D702}^{(1)}}{\unicode[STIX]{x1D707}}+\frac{\unicode[STIX]{x1D702}^{(2)}}{\unicode[STIX]{x1D707}},\quad \unicode[STIX]{x1D706}_{2}=\frac{3(1-c)}{2+3c}\frac{\unicode[STIX]{x1D702}^{(1)}}{\unicode[STIX]{x1D707}}+\frac{\unicode[STIX]{x1D702}^{(2)}}{\unicode[STIX]{x1D707}}.\end{eqnarray}$$

$$\begin{eqnarray}\unicode[STIX]{x1D706}_{1}=\frac{3+2c}{2(1-c)}\frac{\unicode[STIX]{x1D702}^{(1)}}{\unicode[STIX]{x1D707}}+\frac{\unicode[STIX]{x1D702}^{(2)}}{\unicode[STIX]{x1D707}},\quad \unicode[STIX]{x1D706}_{2}=\frac{3(1-c)}{2+3c}\frac{\unicode[STIX]{x1D702}^{(1)}}{\unicode[STIX]{x1D707}}+\frac{\unicode[STIX]{x1D702}^{(2)}}{\unicode[STIX]{x1D707}}.\end{eqnarray}$$ In obtaining (3.1), use was made of the fact that the constitutive equations for NH solids are the small-strain limit of the Gent model (2.6) for reasonable values of  $J_{m}$. It can be shown (see appendix B) that the above equations reduce to the constitutive equations of the Newtonian solvent phase and to the linear small-strain viscoelasticity model for the KV particle phase, respectively, in the limits

$J_{m}$. It can be shown (see appendix B) that the above equations reduce to the constitutive equations of the Newtonian solvent phase and to the linear small-strain viscoelasticity model for the KV particle phase, respectively, in the limits  $c\rightarrow 0$ and

$c\rightarrow 0$ and  $c\rightarrow 1$. Furthermore, equation (3.2) for

$c\rightarrow 1$. Furthermore, equation (3.2) for  $\unicode[STIX]{x1D702}_{0}$ recovers the well-known Einstein result in the dilute limit.

$\unicode[STIX]{x1D702}_{0}$ recovers the well-known Einstein result in the dilute limit.

Figure 2. Storage and loss moduli normalized by the shear modulus  $\unicode[STIX]{x1D707}$ as functions of the dimensionless frequency

$\unicode[STIX]{x1D707}$ as functions of the dimensionless frequency  $F=\unicode[STIX]{x1D702}^{(1)}\unicode[STIX]{x1D714}/\unicode[STIX]{x1D707}$ in the SAOS regime. (a)

$F=\unicode[STIX]{x1D702}^{(1)}\unicode[STIX]{x1D714}/\unicode[STIX]{x1D707}$ in the SAOS regime. (a)  $G^{\prime }/\unicode[STIX]{x1D707}$ and

$G^{\prime }/\unicode[STIX]{x1D707}$ and  $G^{\prime \prime }/\unicode[STIX]{x1D707}$ for suspensions of NH particles (

$G^{\prime \prime }/\unicode[STIX]{x1D707}$ for suspensions of NH particles ( $K=0.0$) at different particle volume fractions

$K=0.0$) at different particle volume fractions  $c$. (b)

$c$. (b)  $G^{\prime }/\unicode[STIX]{x1D707}$ and

$G^{\prime }/\unicode[STIX]{x1D707}$ and  $G^{\prime \prime }/\unicode[STIX]{x1D707}$ for suspension with 20 vol.% KV particles for different viscosity ratios

$G^{\prime \prime }/\unicode[STIX]{x1D707}$ for suspension with 20 vol.% KV particles for different viscosity ratios  $K$.

$K$.

After an initial transient phase under harmonic loading such as (2.14), the suspension will reach a dynamic steady state in which the shear stress component  $\bar{\unicode[STIX]{x1D70F}}_{12}$ can be written as

$\bar{\unicode[STIX]{x1D70F}}_{12}$ can be written as

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D70F}}_{12}(t)=\unicode[STIX]{x1D6FE}_{0}G^{\prime }\sin (\unicode[STIX]{x1D714}t)+\unicode[STIX]{x1D6FE}_{0}G^{\prime \prime }\cos (\unicode[STIX]{x1D714}t), & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \bar{\unicode[STIX]{x1D70F}}_{12}(t)=\unicode[STIX]{x1D6FE}_{0}G^{\prime }\sin (\unicode[STIX]{x1D714}t)+\unicode[STIX]{x1D6FE}_{0}G^{\prime \prime }\cos (\unicode[STIX]{x1D714}t), & & \displaystyle\end{eqnarray}$$ where  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$ are the storage and loss moduli, respectively. By substituting the above ansatz for

$G^{\prime \prime }$ are the storage and loss moduli, respectively. By substituting the above ansatz for  $\bar{\unicode[STIX]{x1D70F}}_{12}$ into (3.1), we obtain the expressions

$\bar{\unicode[STIX]{x1D70F}}_{12}$ into (3.1), we obtain the expressions

$$\begin{eqnarray}G^{\prime }=\frac{(\unicode[STIX]{x1D706}_{1}-\unicode[STIX]{x1D706}_{2})\unicode[STIX]{x1D702}_{0}\unicode[STIX]{x1D714}^{2}}{1+\unicode[STIX]{x1D706}_{1}^{2}\unicode[STIX]{x1D714}^{2}},\quad G^{\prime \prime }=\frac{(1+\unicode[STIX]{x1D706}_{1}\unicode[STIX]{x1D706}_{2}\unicode[STIX]{x1D714}^{2})\unicode[STIX]{x1D702}_{0}\unicode[STIX]{x1D714}}{1+\unicode[STIX]{x1D706}_{1}^{2}\unicode[STIX]{x1D714}^{2}},\end{eqnarray}$$

$$\begin{eqnarray}G^{\prime }=\frac{(\unicode[STIX]{x1D706}_{1}-\unicode[STIX]{x1D706}_{2})\unicode[STIX]{x1D702}_{0}\unicode[STIX]{x1D714}^{2}}{1+\unicode[STIX]{x1D706}_{1}^{2}\unicode[STIX]{x1D714}^{2}},\quad G^{\prime \prime }=\frac{(1+\unicode[STIX]{x1D706}_{1}\unicode[STIX]{x1D706}_{2}\unicode[STIX]{x1D714}^{2})\unicode[STIX]{x1D702}_{0}\unicode[STIX]{x1D714}}{1+\unicode[STIX]{x1D706}_{1}^{2}\unicode[STIX]{x1D714}^{2}},\end{eqnarray}$$ as functions of the excitation frequency  $\unicode[STIX]{x1D714}$. We recall that in the above equations the two macroscopic time scales

$\unicode[STIX]{x1D714}$. We recall that in the above equations the two macroscopic time scales  $\unicode[STIX]{x1D706}_{1}$ and

$\unicode[STIX]{x1D706}_{1}$ and  $\unicode[STIX]{x1D706}_{2}$, as well as the effective viscosity

$\unicode[STIX]{x1D706}_{2}$, as well as the effective viscosity  $\unicode[STIX]{x1D702}_{0}$, are functions of the mechanical properties of the constituents and the particle volume fraction. In the dilute limit, a Taylor series expansion of (3.5) about

$\unicode[STIX]{x1D702}_{0}$, are functions of the mechanical properties of the constituents and the particle volume fraction. In the dilute limit, a Taylor series expansion of (3.5) about  $c=0$ recovers the first-order correction terms for the dynamic rigidity and the dynamic viscosity given in equations (69) and (70) in Roscoe (Reference Roscoe1967). In the limit

$c=0$ recovers the first-order correction terms for the dynamic rigidity and the dynamic viscosity given in equations (69) and (70) in Roscoe (Reference Roscoe1967). In the limit  $\unicode[STIX]{x1D714}\rightarrow 0$, the viscous stresses in the solvent phase do not suffice to elastically deform the particles, so that

$\unicode[STIX]{x1D714}\rightarrow 0$, the viscous stresses in the solvent phase do not suffice to elastically deform the particles, so that  $G^{\prime }\rightarrow 0$ as

$G^{\prime }\rightarrow 0$ as  $\unicode[STIX]{x1D714}\rightarrow 0$, while the dynamic state viscosity

$\unicode[STIX]{x1D714}\rightarrow 0$, while the dynamic state viscosity  $G^{\prime \prime }/\unicode[STIX]{x1D714}\rightarrow \unicode[STIX]{x1D702}_{0}$. In the high-frequency limit, the storage modulus plateaus at

$G^{\prime \prime }/\unicode[STIX]{x1D714}\rightarrow \unicode[STIX]{x1D702}_{0}$. In the high-frequency limit, the storage modulus plateaus at

$$\begin{eqnarray}\displaystyle \lim _{\unicode[STIX]{x1D714}\rightarrow \infty }G^{\prime }=(\unicode[STIX]{x1D706}_{1}-\unicode[STIX]{x1D706}_{2})\unicode[STIX]{x1D702}_{0}/\unicode[STIX]{x1D706}_{1}^{2}, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \lim _{\unicode[STIX]{x1D714}\rightarrow \infty }G^{\prime }=(\unicode[STIX]{x1D706}_{1}-\unicode[STIX]{x1D706}_{2})\unicode[STIX]{x1D702}_{0}/\unicode[STIX]{x1D706}_{1}^{2}, & & \displaystyle\end{eqnarray}$$while the dynamic viscosity is given by

$$\begin{eqnarray}\displaystyle \lim _{\unicode[STIX]{x1D714}\rightarrow \infty }G^{\prime \prime }/\unicode[STIX]{x1D714}=\unicode[STIX]{x1D706}_{2}\unicode[STIX]{x1D702}_{0}/\unicode[STIX]{x1D706}_{1}. & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \lim _{\unicode[STIX]{x1D714}\rightarrow \infty }G^{\prime \prime }/\unicode[STIX]{x1D714}=\unicode[STIX]{x1D706}_{2}\unicode[STIX]{x1D702}_{0}/\unicode[STIX]{x1D706}_{1}. & & \displaystyle\end{eqnarray}$$ Figure 2(a) shows two small-strain frequency sweeps of storage and loss moduli for suspensions of purely elastic particles with different particle volume fractions  $c$. We see that as

$c$. We see that as  $c$ increases from 10 vol.% to 30 vol.%, the loss modulus decreases and the storage modulus increases. The suspension becomes less dissipative and the macroscopic response appears more solid-like for larger particle volume fractions. Figure 2(b) shows storage and loss moduli as functions of the excitation frequency for suspensions with 20 vol.% KV particles and different viscosity ratios

$c$ increases from 10 vol.% to 30 vol.%, the loss modulus decreases and the storage modulus increases. The suspension becomes less dissipative and the macroscopic response appears more solid-like for larger particle volume fractions. Figure 2(b) shows storage and loss moduli as functions of the excitation frequency for suspensions with 20 vol.% KV particles and different viscosity ratios  $K$. For higher values of

$K$. For higher values of  $K$, the overall small-strain response of the suspension becomes more dissipative and less elastic, as expected.

$K$, the overall small-strain response of the suspension becomes more dissipative and less elastic, as expected.

Figure 3. Storage and loss moduli as a function of the excitation frequency  $\unicode[STIX]{x1D714}$ for a suspension of purely elastic (

$\unicode[STIX]{x1D714}$ for a suspension of purely elastic ( $K=0.0$) particles at high volume fractions. (a) For

$K=0.0$) particles at high volume fractions. (a) For  $c=c_{cr}\approx 0.41$, the curves for

$c=c_{cr}\approx 0.41$, the curves for  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$ just intersect at one frequency

$G^{\prime \prime }$ just intersect at one frequency  $\unicode[STIX]{x1D714}=\unicode[STIX]{x1D714}_{cr}$. (b) For

$\unicode[STIX]{x1D714}=\unicode[STIX]{x1D714}_{cr}$. (b) For  $c=0.6$,

$c=0.6$,  $G^{\prime }>G^{\prime \prime }$ for a finite range of frequencies

$G^{\prime }>G^{\prime \prime }$ for a finite range of frequencies  $\unicode[STIX]{x1D714}_{1}<\unicode[STIX]{x1D714}<\unicode[STIX]{x1D714}_{2}$.

$\unicode[STIX]{x1D714}_{1}<\unicode[STIX]{x1D714}<\unicode[STIX]{x1D714}_{2}$.

Figure 3 shows the behaviour of  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$ for a suspension of purely elastic particles (

$G^{\prime \prime }$ for a suspension of purely elastic particles ( $K=0.0$) at larger particle concentrations. In particular, figure 3(a) shows that, for sufficiently large concentrations (

$K=0.0$) at larger particle concentrations. In particular, figure 3(a) shows that, for sufficiently large concentrations ( $c=c_{cr}$), the curves for

$c=c_{cr}$), the curves for  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$ just intersect at a critical frequency

$G^{\prime \prime }$ just intersect at a critical frequency  $\unicode[STIX]{x1D714}=\unicode[STIX]{x1D714}_{cr}$, while figure 3(b) shows that, for

$\unicode[STIX]{x1D714}=\unicode[STIX]{x1D714}_{cr}$, while figure 3(b) shows that, for  $c>c_{cr}$, there is a range of frequencies for which

$c>c_{cr}$, there is a range of frequencies for which  $G^{\prime }>G^{\prime \prime }$, indicating a predominantly solid-like behaviour for the suspension. To determine conditions for the existence of intersection points for

$G^{\prime }>G^{\prime \prime }$, indicating a predominantly solid-like behaviour for the suspension. To determine conditions for the existence of intersection points for  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$ more precisely, we use (3.5) and set

$G^{\prime \prime }$ more precisely, we use (3.5) and set  $G^{\prime }|_{\unicode[STIX]{x1D714}=\unicode[STIX]{x1D714}_{1/2}}=G^{\prime \prime }|_{\unicode[STIX]{x1D714}=\unicode[STIX]{x1D714}_{1/2}}$. Solving for

$G^{\prime }|_{\unicode[STIX]{x1D714}=\unicode[STIX]{x1D714}_{1/2}}=G^{\prime \prime }|_{\unicode[STIX]{x1D714}=\unicode[STIX]{x1D714}_{1/2}}$. Solving for  $\unicode[STIX]{x1D714}_{1/2}$, we find two roots

$\unicode[STIX]{x1D714}_{1/2}$, we find two roots

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D714}_{1/2}=\frac{1}{2\unicode[STIX]{x1D706}_{1}\unicode[STIX]{x1D706}_{2}}(\unicode[STIX]{x1D706}_{1}-\unicode[STIX]{x1D706}_{2}\mp \sqrt{(\unicode[STIX]{x1D706}_{1}-\unicode[STIX]{x1D706}_{2})^{2}-4\unicode[STIX]{x1D706}_{1}\unicode[STIX]{x1D706}_{2}}), & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \unicode[STIX]{x1D714}_{1/2}=\frac{1}{2\unicode[STIX]{x1D706}_{1}\unicode[STIX]{x1D706}_{2}}(\unicode[STIX]{x1D706}_{1}-\unicode[STIX]{x1D706}_{2}\mp \sqrt{(\unicode[STIX]{x1D706}_{1}-\unicode[STIX]{x1D706}_{2})^{2}-4\unicode[STIX]{x1D706}_{1}\unicode[STIX]{x1D706}_{2}}), & & \displaystyle\end{eqnarray}$$ suggesting that storage and loss moduli can intersect if the inequality  $(\unicode[STIX]{x1D706}_{1}-\unicode[STIX]{x1D706}_{2})^{2}-4\unicode[STIX]{x1D706}_{1}\unicode[STIX]{x1D706}_{2}\geqslant 0$ is satisfied. Using (3.3), the above inequality may be rewritten as

$(\unicode[STIX]{x1D706}_{1}-\unicode[STIX]{x1D706}_{2})^{2}-4\unicode[STIX]{x1D706}_{1}\unicode[STIX]{x1D706}_{2}\geqslant 0$ is satisfied. Using (3.3), the above inequality may be rewritten as

$$\begin{eqnarray}\displaystyle \left[\frac{3+2c}{2(1-c)}-\frac{3(1-c)}{2+3c}\right]^{2}-4\left[\frac{3+2c}{2(1-c)}+K\right]\left[\frac{3(1-c)}{2+3c}+K\right]\geqslant 0, & & \displaystyle\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle \left[\frac{3+2c}{2(1-c)}-\frac{3(1-c)}{2+3c}\right]^{2}-4\left[\frac{3+2c}{2(1-c)}+K\right]\left[\frac{3(1-c)}{2+3c}+K\right]\geqslant 0, & & \displaystyle\end{eqnarray}$$ which can be seen to be dependent on the particle volume fraction  $c$ as well as the ratio between particle and solvent viscosity

$c$ as well as the ratio between particle and solvent viscosity  $K$. We conclude that there is a frequency range,

$K$. We conclude that there is a frequency range,  $\unicode[STIX]{x1D714}_{1}\leqslant \unicode[STIX]{x1D714}\leqslant \unicode[STIX]{x1D714}_{2}$, for which

$\unicode[STIX]{x1D714}_{1}\leqslant \unicode[STIX]{x1D714}\leqslant \unicode[STIX]{x1D714}_{2}$, for which  $G^{\prime }\geqslant G^{\prime \prime }$, such that the small-strain response of the suspension is predominantly solid-like. As seen in figure 3 for suspensions of purely elastic particles (

$G^{\prime }\geqslant G^{\prime \prime }$, such that the small-strain response of the suspension is predominantly solid-like. As seen in figure 3 for suspensions of purely elastic particles ( $K=0.0$), the model predicts a solid-like region for particle volume fractions

$K=0.0$), the model predicts a solid-like region for particle volume fractions  $c\geqslant c_{cr}=0.40721$.

$c\geqslant c_{cr}=0.40721$.

Figure 4. Shear stress normalized by shear modulus  $\unicode[STIX]{x1D707}$ for suspensions with 20 vol.% purely elastic particles under SAOS at

$\unicode[STIX]{x1D707}$ for suspensions with 20 vol.% purely elastic particles under SAOS at  $\unicode[STIX]{x1D6FE}_{0}=0.05$ and

$\unicode[STIX]{x1D6FE}_{0}=0.05$ and  $F=1.0$. (a) Normalized shear stress

$F=1.0$. (a) Normalized shear stress  $\bar{\unicode[STIX]{x1D70F}}_{12}/\unicode[STIX]{x1D707}$ as a function of dimensionless time

$\bar{\unicode[STIX]{x1D70F}}_{12}/\unicode[STIX]{x1D707}$ as a function of dimensionless time  $\unicode[STIX]{x1D702}^{(1)}\unicode[STIX]{x1D714}/\unicode[STIX]{x1D707}$. (b) Normalized shear stress

$\unicode[STIX]{x1D702}^{(1)}\unicode[STIX]{x1D714}/\unicode[STIX]{x1D707}$. (b) Normalized shear stress  $\bar{\unicode[STIX]{x1D70F}}_{12}/\unicode[STIX]{x1D707}$ in the stress–strain-rate space at small excitation amplitude

$\bar{\unicode[STIX]{x1D70F}}_{12}/\unicode[STIX]{x1D707}$ in the stress–strain-rate space at small excitation amplitude  $\unicode[STIX]{x1D6FE}_{0}=0.05$.

$\unicode[STIX]{x1D6FE}_{0}=0.05$.

Figure 4(a) shows the stress response as a function of time  $t$ for a suspension with 20 vol.% purely elastic particles in the SAOS regime. The stress waveform is sinusoidal and shifted in phase with respect to the excitation

$t$ for a suspension with 20 vol.% purely elastic particles in the SAOS regime. The stress waveform is sinusoidal and shifted in phase with respect to the excitation  $\unicode[STIX]{x1D6FE}$. In the phase space

$\unicode[STIX]{x1D6FE}$. In the phase space  $\bar{\unicode[STIX]{x1D70F}}_{12}$ versus

$\bar{\unicode[STIX]{x1D70F}}_{12}$ versus  $\dot{\unicode[STIX]{x1D6FE}}$, the sinusoidal stress waveform is an ellipse as can be seen in figure 4(b). The stress waveform and the limit cycle shown in figure 4 are characteristic of linear material responses. Normal stress differences are not observed in the small-strain regime.

$\dot{\unicode[STIX]{x1D6FE}}$, the sinusoidal stress waveform is an ellipse as can be seen in figure 4(b). The stress waveform and the limit cycle shown in figure 4 are characteristic of linear material responses. Normal stress differences are not observed in the small-strain regime.

At this point, it should also be noted that, given a soft particle suspension, experimentally obtained SAOS sweeps could be used to determine some of the model parameters, provided that we can measure accurately at least one of them. As we have seen, the SAOS response, as determined by expressions (3.5) for  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$, is a function of the fluid viscosity, the particle viscosity and elasticity, as well as the particle volume fraction. Therefore, using the asymptotic expressions for

$G^{\prime \prime }$, is a function of the fluid viscosity, the particle viscosity and elasticity, as well as the particle volume fraction. Therefore, using the asymptotic expressions for  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$ as

$G^{\prime \prime }$ as  $\unicode[STIX]{x1D714}$ approaches 0 and

$\unicode[STIX]{x1D714}$ approaches 0 and  $\infty$, three equations could be generated for the four parameters. For example, if the easy-to-measure fluid viscosity is known, the volume fraction, elasticity and viscosity of the particles could be determined.

$\infty$, three equations could be generated for the four parameters. For example, if the easy-to-measure fluid viscosity is known, the volume fraction, elasticity and viscosity of the particles could be determined.

4 Large amplitude oscillatory shear (LAOS)

As we transition into the regime of large-strain amplitudes, the evolution of the microstructure gives rise to a number of nonlinear features as well as anisotropic behaviour. In this section we want to provide a detailed study of the nonlinearities that characterize the macroscopic large-strain behaviour of non-dilute dispersions of highly deformable particles.

Figure 5. Amplitude sweep for storage and loss moduli for suspensions with 20 vol.% purely elastic particles ( $K=0.0$) under oscillatory simple shear at frequency

$K=0.0$) under oscillatory simple shear at frequency  $F=1.0$. (a) Storage modulus

$F=1.0$. (a) Storage modulus  $G^{\prime }$ normalized by

$G^{\prime }$ normalized by  $\unicode[STIX]{x1D707}$ for suspensions of NH and Gent particles. (b) Loss modulus

$\unicode[STIX]{x1D707}$ for suspensions of NH and Gent particles. (b) Loss modulus  $G^{\prime \prime }$ normalized by

$G^{\prime \prime }$ normalized by  $\unicode[STIX]{x1D707}$ for suspensions of NH and Gent particles.

$\unicode[STIX]{x1D707}$ for suspensions of NH and Gent particles.

Figures 5(a) and 5(b) show  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$, respectively, as functions of the strain amplitude for suspensions of purely elastic particles (

$G^{\prime \prime }$, respectively, as functions of the strain amplitude for suspensions of purely elastic particles ( $K=0.0$). Results are given for suspensions of Gent particles with strain-locking behaviour characterized by

$K=0.0$). Results are given for suspensions of Gent particles with strain-locking behaviour characterized by  $J_{m}=10$ and dispersions of NH particles with no strain locking characterized by

$J_{m}=10$ and dispersions of NH particles with no strain locking characterized by  $J_{m}\rightarrow \infty$. For sufficiently large-strain amplitudes

$J_{m}\rightarrow \infty$. For sufficiently large-strain amplitudes  $\unicode[STIX]{x1D6FE}_{0}$, figure 5 reveals that the storage and loss moduli become general functions of the strain amplitude

$\unicode[STIX]{x1D6FE}_{0}$, figure 5 reveals that the storage and loss moduli become general functions of the strain amplitude  $\unicode[STIX]{x1D6FE}_{0}$, in addition to the excitation frequency

$\unicode[STIX]{x1D6FE}_{0}$, in addition to the excitation frequency  $\unicode[STIX]{x1D714}$. Since the small-strain limit of the Gent model (2.6) is identical to the NH model,

$\unicode[STIX]{x1D714}$. Since the small-strain limit of the Gent model (2.6) is identical to the NH model,  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$ are independent of the strain-locking parameter in the small amplitude regime (

$G^{\prime \prime }$ are independent of the strain-locking parameter in the small amplitude regime ( $\unicode[STIX]{x1D6FE}_{0}<0.3$). However, as we move into the large amplitude regime, figure 5 shows that, for suspensions of NH particles (

$\unicode[STIX]{x1D6FE}_{0}<0.3$). However, as we move into the large amplitude regime, figure 5 shows that, for suspensions of NH particles ( $J_{m}\rightarrow \infty$), both storage and loss moduli monotonically decrease. On the other hand, for suspensions of Gent particles (

$J_{m}\rightarrow \infty$), both storage and loss moduli monotonically decrease. On the other hand, for suspensions of Gent particles ( $J_{m}=10.0$), figure 5(b) reveals that

$J_{m}=10.0$), figure 5(b) reveals that  $G^{\prime \prime }$ assumes a local maximum at

$G^{\prime \prime }$ assumes a local maximum at  $\unicode[STIX]{x1D6FE}_{0}\approx 3.0$.

$\unicode[STIX]{x1D6FE}_{0}\approx 3.0$.

Based on the above observations and in accordance with the terminology of Hyun et al. (Reference Hyun, Kim, Ahn and Lee2002), we can identify the suspensions of NH particles as ‘type I’ (strain thinning) fluids, characterized by monotonically decreasing  $G^{\prime }$ and

$G^{\prime }$ and  $G^{\prime \prime }$ at the transition into the nonlinear regime, while we classify the dispersions of Gent particles as ‘type III’ (weak strain overshoot) fluids, characterized by the local maximum that

$G^{\prime \prime }$ at the transition into the nonlinear regime, while we classify the dispersions of Gent particles as ‘type III’ (weak strain overshoot) fluids, characterized by the local maximum that  $G^{\prime \prime }$ assumes near

$G^{\prime \prime }$ assumes near  $\unicode[STIX]{x1D6FE}_{0}=3.0$. Furthermore, it is useful to recall (Hyun et al. Reference Hyun, Kim, Ahn and Lee2002) that type I fluids typically exhibit shear-thinning behaviour, as a result of the microstructure aligning itself in the direction of flow, which is consistent with the predictions of the model of Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015) for suspensions of NH particles under steady shear and sufficiently large-strain rates

$\unicode[STIX]{x1D6FE}_{0}=3.0$. Furthermore, it is useful to recall (Hyun et al. Reference Hyun, Kim, Ahn and Lee2002) that type I fluids typically exhibit shear-thinning behaviour, as a result of the microstructure aligning itself in the direction of flow, which is consistent with the predictions of the model of Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015) for suspensions of NH particles under steady shear and sufficiently large-strain rates  $\dot{\unicode[STIX]{x1D6FE}}$; in fact, the model predicts that effective steady-state viscosity may even drop below the solvent viscosity

$\dot{\unicode[STIX]{x1D6FE}}$; in fact, the model predicts that effective steady-state viscosity may even drop below the solvent viscosity  $\unicode[STIX]{x1D702}^{(1)}$. On the other hand, the local maximum in

$\unicode[STIX]{x1D702}^{(1)}$. On the other hand, the local maximum in  $G^{\prime \prime }$ appears to coincide with the occurrence of a peak in the distorted stress waveform for suspensions of Gent particles (as will be discussed later), which suggests that the observed type III behaviour is due to the strain locking of the Gent particles at the larger strain amplitudes.

$G^{\prime \prime }$ appears to coincide with the occurrence of a peak in the distorted stress waveform for suspensions of Gent particles (as will be discussed later), which suggests that the observed type III behaviour is due to the strain locking of the Gent particles at the larger strain amplitudes.

For large-strain amplitudes, the storage and loss moduli do not suffice to describe the rheological behaviour of the suspensions of interest here. Higher-order Fourier coefficients must be considered in order to provide a complete picture of the mechanical response. However, instead of discussing the higher-order Fourier coefficients, we proceed to examine the characteristic stress waveforms, as well as the elastic and viscous projections of the so-called Lissajous–Bowditch curve for suspensions of highly deformable particles in the LAOS regime. The various stress waveforms and limit cycles were obtained by numerically evolving the system through at least ten loading cycles in order to erase all memory of the initial conditions. In this context, it should be noted that the limit cycles were found to be insensitive to the initial conditions.

Figure 6. Microstructural evolution for suspensions with 20 vol.% purely elastic particles ( $K=0.0$) in LAOS at

$K=0.0$) in LAOS at  $\unicode[STIX]{x1D6FE}_{0}=5.0$ and

$\unicode[STIX]{x1D6FE}_{0}=5.0$ and  $F=1.0$. In their unstressed state the particles are spheres of radius

$F=1.0$. In their unstressed state the particles are spheres of radius  $a$. (a,b) Evolution of the in-plane and out-of-plane particle aspect ratios for suspensions of NH and Gent particles, as functions of the dimensionless time

$a$. (a,b) Evolution of the in-plane and out-of-plane particle aspect ratios for suspensions of NH and Gent particles, as functions of the dimensionless time  $\unicode[STIX]{x1D707}t/\unicode[STIX]{x1D702}^{(1)}$. (c) Evolution of the average particle orientation angle for suspensions of NH and Gent particles, as a function of the dimensionless time

$\unicode[STIX]{x1D707}t/\unicode[STIX]{x1D702}^{(1)}$. (c) Evolution of the average particle orientation angle for suspensions of NH and Gent particles, as a function of the dimensionless time  $\unicode[STIX]{x1D707}t/\unicode[STIX]{x1D702}^{(1)}$. (d) Snapshot of the microstructure as the strain excitation reaches its maximum

$\unicode[STIX]{x1D707}t/\unicode[STIX]{x1D702}^{(1)}$. (d) Snapshot of the microstructure as the strain excitation reaches its maximum  $\unicode[STIX]{x1D6FE}_{0}$: projection of the average particle shape and orientation onto the plane of shearing. The

$\unicode[STIX]{x1D6FE}_{0}$: projection of the average particle shape and orientation onto the plane of shearing. The  $x$ and

$x$ and  $y$ axes are normalized by the radius

$y$ axes are normalized by the radius  $a$ of the particles in their unstressed state.

$a$ of the particles in their unstressed state.

4.1 Microstructural evolution and stress waveforms for suspensions of elastic particles

Microstructural evolution. Figure 6 shows the microstructural evolution in the dynamic steady state for a suspension with 20 vol.% NH ( $J_{m}\rightarrow \infty$) and Gent (

$J_{m}\rightarrow \infty$) and Gent ( $J_{m}=10.0$) particles at

$J_{m}=10.0$) particles at  $\unicode[STIX]{x1D6FE}_{0}=5.0$ and

$\unicode[STIX]{x1D6FE}_{0}=5.0$ and  $F=1.0$. Figure 6(a,b) shows the evolution of the in-plane and out-of-plane particle aspect ratios,

$F=1.0$. Figure 6(a,b) shows the evolution of the in-plane and out-of-plane particle aspect ratios,  $w_{1}$ and

$w_{1}$ and  $w_{2}$, in the dynamic steady state, as functions of the non-dimensional time

$w_{2}$, in the dynamic steady state, as functions of the non-dimensional time  $\unicode[STIX]{x1D707}t/\unicode[STIX]{x1D702}^{(1)}$ throughout one cycle of loading, for different values of

$\unicode[STIX]{x1D707}t/\unicode[STIX]{x1D702}^{(1)}$ throughout one cycle of loading, for different values of  $J_{m}$. It is observed that

$J_{m}$. It is observed that  $w_{2}$ oscillates about a larger mean value than

$w_{2}$ oscillates about a larger mean value than  $w_{1}$, indicating that the out-of-plane particle stretching is less severe than the in-plane stretching of the particles. Since the aspect ratios are independent of the shearing direction, their frequency is double the excitation frequency. Note that, due to elastic stiffening, the mean particle stretches in suspensions of Gent particles are smaller. Figure 6(c) shows the evolution of the average particle orientation throughout a loading cycle. The evolution of the orientation angle

$w_{1}$, indicating that the out-of-plane particle stretching is less severe than the in-plane stretching of the particles. Since the aspect ratios are independent of the shearing direction, their frequency is double the excitation frequency. Note that, due to elastic stiffening, the mean particle stretches in suspensions of Gent particles are smaller. Figure 6(c) shows the evolution of the average particle orientation throughout a loading cycle. The evolution of the orientation angle  $\unicode[STIX]{x1D703}$ appears to be in-phase with the strain excitation, i.e. upon reversing the strain direction, the particles reorient themselves in the direction of flow. For suspensions of Gent particles,

$\unicode[STIX]{x1D703}$ appears to be in-phase with the strain excitation, i.e. upon reversing the strain direction, the particles reorient themselves in the direction of flow. For suspensions of Gent particles,  $\unicode[STIX]{x1D703}$ reaches slightly higher amplitudes indicating that the alignment of Gent particles in the flow direction is not as complete as for NH particles. Similar observations were reported for the steady-state orientation angle by Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015) for suspensions in steady shear. Upon reversing the direction of shearing, Gent particles reorient their major axis slightly faster than their NH counterparts. Figure 6(d) presents an instantaneous ‘snapshot’ of the microstructure at time

$\unicode[STIX]{x1D703}$ reaches slightly higher amplitudes indicating that the alignment of Gent particles in the flow direction is not as complete as for NH particles. Similar observations were reported for the steady-state orientation angle by Avazmohammadi & Ponte Castañeda (Reference Avazmohammadi and Ponte Castañeda2015) for suspensions in steady shear. Upon reversing the direction of shearing, Gent particles reorient their major axis slightly faster than their NH counterparts. Figure 6(d) presents an instantaneous ‘snapshot’ of the microstructure at time  $t=t_{0}$ when the strain excitation

$t=t_{0}$ when the strain excitation  $\unicode[STIX]{x1D6FE}(t_{0})$ reaches its maximum

$\unicode[STIX]{x1D6FE}(t_{0})$ reaches its maximum  $\unicode[STIX]{x1D6FE}_{0}$. The ‘snapshot’ is a projection of the average particle shape and orientation onto the

$\unicode[STIX]{x1D6FE}_{0}$. The ‘snapshot’ is a projection of the average particle shape and orientation onto the  $\boldsymbol{E}_{1}{-}\boldsymbol{E}_{2}$ plane of shearing. For reference, the light blue dotted line represents the initial shape of the particles in their unstressed state. Due to elastic stiffening, it can be seen that the particles become less stretched and their major axis less aligned in the direction of shearing for finite values of

$\boldsymbol{E}_{1}{-}\boldsymbol{E}_{2}$ plane of shearing. For reference, the light blue dotted line represents the initial shape of the particles in their unstressed state. Due to elastic stiffening, it can be seen that the particles become less stretched and their major axis less aligned in the direction of shearing for finite values of  $J_{m}$ (e.g. 10).

$J_{m}$ (e.g. 10).

Figure 7. Stress waveforms and limit cycles for suspensions with 20 vol.% purely elastic particles ( $K=0.0$) in LAOS at

$K=0.0$) in LAOS at  $\unicode[STIX]{x1D6FE}_{0}=5.0$ and

$\unicode[STIX]{x1D6FE}_{0}=5.0$ and  $F=1.0$. (a) and (b) Evolution of the effective shear stress

$F=1.0$. (a) and (b) Evolution of the effective shear stress  $\bar{\unicode[STIX]{x1D70F}}_{12}$ for suspensions of NH particles and Gent particles, respectively. (c) Stress–strain curves for suspensions of NH particles and Gent particles. (d) Corresponding stress–strain-rate curves for suspensions of NH and Gent particles.

$\bar{\unicode[STIX]{x1D70F}}_{12}$ for suspensions of NH particles and Gent particles, respectively. (c) Stress–strain curves for suspensions of NH particles and Gent particles. (d) Corresponding stress–strain-rate curves for suspensions of NH and Gent particles.