1. Introduction

dilatation/contraction is an intrinsic property of granular materials when subjected to shear deformation and an important determinant of the behaviour of granular flows (Reynolds Reference Reynolds1885; Wood Reference Wood1990; Houssais & Jerolmack Reference Houssais and Jerolmack2017). dilatation/contraction strongly affects the onset of avalanches (Gravish & Goldman Reference Gravish and Goldman2014), the initiation of submarine landslides (Rondon, Pouliquen & Aussillous Reference Rondon, Pouliquen and Aussillous2011) and the liquefaction in debris flows (Kaitna, Dietrich & Hsu Reference Kaitna, Dietrich and Hsu2014). In submerged granular media, dilatation/contraction would induce a corresponding decrease/increase in the interstitial fluid pressure and relative motion between the pore fluid and grains, which has a feedback on the granular skeleton and hence on the behaviour of granular flows (Meruane, Tamburrino & Roche Reference Meruane, Tamburrino and Roche2010; Bouchut et al. Reference Bouchut, Fernández-Nieto, Mangeney and Narbona-Reina2016).

It is crucial to account for dilatancy effects in numerical models for granular flows (Bouchut et al. Reference Bouchut, Fernández-Nieto, Mangeney and Narbona-Reina2016). Although the dilatation/contraction of granular materials has attracted intense interest in the past decades (Wood Reference Wood1990; Pailha, Nicolas & Pouliquen Reference Pailha, Nicolas and Pouliquen2008; Dsouza & Nott Reference Dsouza and Nott2020), a quantitative description of the underlying dynamics and a generally accepted theoretical formulation of the dilatancy effects are still unavailable. Specifically, in continuum models for granular flows, most of the existing formulations of dilatation/contraction are empirical (Pailha & Pouliquen Reference Pailha and Pouliquen2009; Iverson & George Reference Iverson and George2014; Delannay et al. Reference Delannay, Valance, Mangeney, Roche and Richard2017). For example, based on the critical state theory for quasi-static dry granular media in simple shear tests, Pailha & Pouliquen (Reference Pailha and Pouliquen2009) attributed the change in the volume of granular flows only to the quasi-static shear dilatation/contraction, and formulated it as the product of shear rate and the tangent of dilatation angle in the continuity equation of granular flows. However, in the continuum theory, the volumetric change of granular flows is equal to the divergence of flow velocity and is a combined result of various forces and processes such as advection, inter-grain collision and quasi-static dilatation/contraction. The critical state theory of soil mechanics empirically accounts for only the part of the volumetric change in granular flows that arises from the quasi-static dilatation/contraction. Therefore, it is incomprehensive to attribute the total volumetric change of granular flows only to the quasi-static dilatation/contraction and formulate it in the continuity equation based on the critical state theory, as done by Pailha & Pouliquen (Reference Pailha and Pouliquen2009). Similarly, the incomprehensiveness also exists in the formulation of Iverson & George (Reference Iverson and George2014), even though they added one more contribution of the effective inter-grain contact normal stress to the volumetric change. Unlike the above models that involve the dilatation/contraction in the continuity equation, Guo et al. (Reference Guo, Peng, Wu and Wang2016) and Baumgarten & Kamrin (Reference Baumgarten and Kamrin2019) considered the dilatancy effects in the momentum equation by integrating them into the plastic constitutive laws of granular materials. This type of models is consistent with the continuum theory and relates the dilatation/contraction directly to inter-grain stresses.

Understanding the dynamics of dilatation/contraction, i.e. what leads to this resultant behaviour of granular materials, helps to develop a theoretical formulation of the dilatancy effects. The widely-used critical state theory proposed by Roux and Radjai (Reference Roux and Radjai1998) for quasi-static granular materials is an efficient empirical relation for the behaviour but cannot explain the reasons. For quasi-static granular media, Guo et al. (Reference Guo, Peng, Wu and Wang2016) and Baumgarten & Kamrin (Reference Baumgarten and Kamrin2019) assumed that the dilatation/contraction arose from the variation of inter-grain plastic stresses and formulated it by introducing a plastic shear deformation related to dilatancy in the constitutive laws of granular materials. On the other hand, for rapid granular flows, the inter-grain collision force is taken to be the reason of dilatancy for which the kinetic theory (Jenkins & Savage Reference Jenkins and Savage1983; Gonzalez-Ondina, Fraccarollo & Liu Reference Gonzalez-Ondina, Fraccarollo and Liu2018) and rheological laws (Jop, Forterre & Pouliquen Reference Jop, Forterre and Pouliquen2006) have been developed. However, these shear-rate-dependent theories for rapid flows cannot account for the contraction of granular materials and neither can they describe the dilatation of quasi-static granular assemblies in which grains move rather slowly. A combination of the proposed dynamics for quasi-static granular media and rapid particulate flows may be applied to granular materials moving at a wide range of shear rates.

In this paper, a theoretical description of dilatation/contraction is presented for continuum modelling of granular flows based on the spatially-filtered and Favre-averaged continuity and momentum equations. It is proposed that the dilatation/contraction effects in sheared granular flows consist of a frictional portion, which results from the rearrangement of enduring-contact force chains among the particles, and a collisional portion, which arises from an inter-grain collision force. These portions are respectively accounted for by the frictional and the collisional solid pressure in the continuum model. A new formulation of the frictional solid pressure, which considers the rearrangement of contact force chains under shear deformation, is proposed while the collisional solid pressure is estimated by well-established rheological laws. The proposed formulation is analytically validated both in describing the shear-weakening behaviour of dry granular samples in a torsional shear rheometer and in predicting the incipient failure of dry and immersed granular slopes. The frictional and the collisional dilatation/contraction effects are integrated into the two-fluid smoothed particle hydrodynamics (SPH) model for granular flows developed by Shi et al. (Reference Shi, Si, Dong and Yu2019). The model is then used to further verify the proposed theoretical formulation of dilatation/contraction by simulating submerged granular column collapse, a benchmark in which the dilatation/contraction plays a critical role from the initiation of the collapse to the final deposition. The dramatic influences of initial packing fraction on the collapsing column profile and the evolution of interstitial fluid pressure arising from dilatation/contraction of granular materials are all well reproduced.

The rest of the paper is structured as follows. A continuum description of the granular flows is briefly given in § 2. The proposed formulation of dilatation/contraction is introduced in § 3. Analytical validations are presented in § 4 and numerical verifications in simulations of underwater granular column collapse are conducted in § 5. Finally, conclusions are given in § 6.

2. A continuum description of granular flows

The spatially filtered and Favre-averaged continuity and momentum equations in Shi et al. (Reference Shi, Si, Dong and Yu2019) are adopted here for a continuum description of granular flows. They are

in which the subscript s represents the solid phase and f indicates the interstitial fluid in granular media; t is the time; ![]() ${\phi _s}$ is the solid volume fraction;

${\phi _s}$ is the solid volume fraction; ![]() ${\rho _s}$ is the particle material density;

${\rho _s}$ is the particle material density; ![]() ${\boldsymbol{u}_s}$ is the velocity;

${\boldsymbol{u}_s}$ is the velocity; ![]() ${\boldsymbol{\sigma }_s}$ is the inter-grain stress tensor of the solid phase excluding the pressurization of the grains owing to the interstitial fluid pressure;

${\boldsymbol{\sigma }_s}$ is the inter-grain stress tensor of the solid phase excluding the pressurization of the grains owing to the interstitial fluid pressure; ![]() $\boldsymbol{g}$ is gravitational acceleration;

$\boldsymbol{g}$ is gravitational acceleration; ![]() $\boldsymbol{\sigma }_s^t$ is a stress tensor of the solid phase arising from interstitial fluid turbulence;

$\boldsymbol{\sigma }_s^t$ is a stress tensor of the solid phase arising from interstitial fluid turbulence; ![]() ${p_f}$ is the interstitial fluid pressure; and

${p_f}$ is the interstitial fluid pressure; and ![]() $\boldsymbol{F}$ denotes the inter-phase forces other than the buoyancy. Here

$\boldsymbol{F}$ denotes the inter-phase forces other than the buoyancy. Here ![]() $\boldsymbol{F}$ generally consists of the drag force, lift force and virtual-mass force but can be simplified as the drag force when the dense granular flows are studied in which the drag force is predominant (Baumgarten & Kamrin Reference Baumgarten and Kamrin2019). In subaerial granular media, the solid stress

$\boldsymbol{F}$ generally consists of the drag force, lift force and virtual-mass force but can be simplified as the drag force when the dense granular flows are studied in which the drag force is predominant (Baumgarten & Kamrin Reference Baumgarten and Kamrin2019). In subaerial granular media, the solid stress ![]() $\boldsymbol{\sigma }_s^t$, the interstitial air pressure

$\boldsymbol{\sigma }_s^t$, the interstitial air pressure ![]() ${p_f}$ and the drag force

${p_f}$ and the drag force ![]() $\boldsymbol{F}$ by air on the particles are neglected. In immersed granular materials,

$\boldsymbol{F}$ by air on the particles are neglected. In immersed granular materials, ![]() ${p_f}$ is resolved,

${p_f}$ is resolved, ![]() $\boldsymbol{\sigma }_s^t$ is determined by introducing a turbulence model and

$\boldsymbol{\sigma }_s^t$ is determined by introducing a turbulence model and ![]() $\boldsymbol{F}$ is estimated by the formula proposed by Gidaspow (Reference Gidaspow1994), as shown in § 5.1.

$\boldsymbol{F}$ is estimated by the formula proposed by Gidaspow (Reference Gidaspow1994), as shown in § 5.1.

Here ![]() ${\boldsymbol{\sigma }_s}$ consists of stresses resulting from inter-grain collisions and enduring contacts. It is expressed as

${\boldsymbol{\sigma }_s}$ consists of stresses resulting from inter-grain collisions and enduring contacts. It is expressed as

where

![]() $\boldsymbol{I}$ is the identity matrix; and

$\boldsymbol{I}$ is the identity matrix; and ![]() ${\nu _s}$ and

${\nu _s}$ and ![]() ${p_s}$ are respectively the solid viscosity and pressure arising from inter-grain collisions and enduring contacts.

${p_s}$ are respectively the solid viscosity and pressure arising from inter-grain collisions and enduring contacts.

A frictional constitutive law that is widely used in granular flows and intense sediment transport (Maurin, Chauchat & Frey Reference Maurin, Chauchat and Frey2016; Heyman et al. Reference Heyman, Delannay, Tabuteau and Valance2017) is adopted to determine the viscosity ![]() ${\nu _s}$ of the granular materials. Here

${\nu _s}$ of the granular materials. Here ![]() ${\nu _s}$ is related to the inter-grain pressure

${\nu _s}$ is related to the inter-grain pressure ![]() ${p_s}$ as

${p_s}$ as

where ![]() $\mu $ is the friction coefficient and is estimated by the rheological law in § 3.3; and the second invariant

$\mu $ is the friction coefficient and is estimated by the rheological law in § 3.3; and the second invariant ![]() $||{{\boldsymbol{S}_s}} ||= \sqrt {{\boldsymbol{S}_s}:{\boldsymbol{S}_s}/2} $. The inter-grain solid pressure

$||{{\boldsymbol{S}_s}} ||= \sqrt {{\boldsymbol{S}_s}:{\boldsymbol{S}_s}/2} $. The inter-grain solid pressure ![]() ${p_s}$ consists of two components (Johnson & Jackson Reference Johnson and Jackson1987):

${p_s}$ consists of two components (Johnson & Jackson Reference Johnson and Jackson1987):

where ![]() $p_s^e$ is caused by enduring contacts among the granular particles and

$p_s^e$ is caused by enduring contacts among the granular particles and ![]() $p_s^c$ arsies from the collisions between the grains. The frictional component

$p_s^c$ arsies from the collisions between the grains. The frictional component ![]() $p_s^e$ accounts for the solid-like behaviour of dense, gently flowing granular materials (Johnson, Nott & Jackson Reference Johnson, Nott and Jackson1990). It generally increases with the volume fraction of the granular assembly

$p_s^e$ accounts for the solid-like behaviour of dense, gently flowing granular materials (Johnson, Nott & Jackson Reference Johnson, Nott and Jackson1990). It generally increases with the volume fraction of the granular assembly ![]() ${\phi _s}$ and vanishes when

${\phi _s}$ and vanishes when ![]() ${\phi _s}$ is below the random loosely packed fraction

${\phi _s}$ is below the random loosely packed fraction ![]() ${\phi _ \ast }$. In almost all of the existing formulae for

${\phi _ \ast }$. In almost all of the existing formulae for ![]() $p_s^e$, the pressure only varies with

$p_s^e$, the pressure only varies with ![]() ${\phi _s}$ and is independent of shear rate (van Wachem et al. Reference van Wachem, Schouten, van den Bleek, Krishna and Sinclair2001). A new formulation of

${\phi _s}$ and is independent of shear rate (van Wachem et al. Reference van Wachem, Schouten, van den Bleek, Krishna and Sinclair2001). A new formulation of ![]() $p_s^e$, which takes the dilatation/contraction effects and the influence of shear rate into account, is proposed in § 3.2. The shear-rate-dependent collisional component

$p_s^e$, which takes the dilatation/contraction effects and the influence of shear rate into account, is proposed in § 3.2. The shear-rate-dependent collisional component ![]() $p_s^c$ is a dominant contribution to

$p_s^c$ is a dominant contribution to ![]() ${p_s}$ in rapid granular flows and is responsible for the increase in the volume of rapidly flowing granular materials (Forterre & Pouliquen Reference Forterre and Pouliquen2008). The formulation of

${p_s}$ in rapid granular flows and is responsible for the increase in the volume of rapidly flowing granular materials (Forterre & Pouliquen Reference Forterre and Pouliquen2008). The formulation of ![]() $p_s^c$ will be detailed in § 3.3.

$p_s^c$ will be detailed in § 3.3.

3. Shear dilatation/contraction

3.1. A new dilatation/contraction framework

To describe the dilatation/contraction process of both quasi-static and rapid flowing granular materials, a new dilatation/contraction framework is proposed. It suggests that the dilatancy effects in sheared granular flows consist of a frictional portion, which results from the rearrangement of enduring-contact force chains among the particles, and a collisional portion, which arises from inter-grain collisions. These portions correspond to the two components of solid pressure. The collisional dilatancy effect has been well studied (Forterre & Pouliquen Reference Forterre and Pouliquen2008), while a formulation of the frictional dilatation/contraction remains unavailable and is the focus of this paper.

Figure 1 presents a schematic representation of the frictional dilatation/contraction. It is postulated that the frictional dilatation and contraction of granular materials arise respectively from the sharp increase and decrease of the frictional solid pressure ![]() $p_s^e$ as a result of the rearrangement of contact force chains among the particles. As shown in figure 1(a), when the initially densely packed granular medium is sheared to a strain of

$p_s^e$ as a result of the rearrangement of contact force chains among the particles. As shown in figure 1(a), when the initially densely packed granular medium is sheared to a strain of ![]() $\gamma $, there is an intensification of the microscopic contact force chains leading to an increase in the macroscopic solid pressure

$\gamma $, there is an intensification of the microscopic contact force chains leading to an increase in the macroscopic solid pressure ![]() $p_s^e$. The increased inter-grain pressure pushes the particles up, which leads to an expansion of the granular medium and an increase in the porosity. In immersed granular media, the enlargement of the void volume between grains results in a decrease of the pore pressure. Conversely, in figure 1(b), the contact force chains in the loosely packed granular assembly break down, which results in the decrease of frictional solid pressure, contraction of the particle assembly and a decrease in the porosity. In immersed granular media, the shrinkage of the inter-grain void volume leads to an increase in the pore pressure. A formulation of the changes in

$p_s^e$. The increased inter-grain pressure pushes the particles up, which leads to an expansion of the granular medium and an increase in the porosity. In immersed granular media, the enlargement of the void volume between grains results in a decrease of the pore pressure. Conversely, in figure 1(b), the contact force chains in the loosely packed granular assembly break down, which results in the decrease of frictional solid pressure, contraction of the particle assembly and a decrease in the porosity. In immersed granular media, the shrinkage of the inter-grain void volume leads to an increase in the pore pressure. A formulation of the changes in ![]() $p_s^e$ arising from the rearrangement of contact force chains is proposed in § 3.2.

$p_s^e$ arising from the rearrangement of contact force chains is proposed in § 3.2.

Figure 1. Schematic illustrations of the frictional (a) dilatation and (b) contraction. The red solid lines linking the grains roughly represent the enduring-contact force chains among granular particles, and the red upward arrows below the symbol ![]() $p_s^e$ represent the macroscopic frictional solid pressure. The thickness of the red lines roughly indicates the magnitude of contact forces and the length of the red arrows denotes that of

$p_s^e$ represent the macroscopic frictional solid pressure. The thickness of the red lines roughly indicates the magnitude of contact forces and the length of the red arrows denotes that of ![]() $p_s^e$.

$p_s^e$.

3.2. Frictional dilatation/contraction

To quantify the frictional dilatation/contraction effect in granular flows, here, a formulation of the changes in ![]() $p_s^e$ arising from the rearrangement of contact force chains is proposed. We consider a granular assembly with a packing fraction of

$p_s^e$ arising from the rearrangement of contact force chains is proposed. We consider a granular assembly with a packing fraction of ![]() ${\phi _s}$ sheared at a finite rate. According to the introduced framework in figure 1, the change in the packing fraction arising from frictional dilatation/contraction against an increment of shear strain

${\phi _s}$ sheared at a finite rate. According to the introduced framework in figure 1, the change in the packing fraction arising from frictional dilatation/contraction against an increment of shear strain ![]() $\partial \gamma $ results from the variation of

$\partial \gamma $ results from the variation of ![]() $p_s^e$, expressed as

$p_s^e$, expressed as

The negative sign in (3.1) indicates that an increase or decrease of ![]() $p_s^e$ respectively leads to a decrease or increase in

$p_s^e$ respectively leads to a decrease or increase in ![]() ${\phi _s}$, as illustrated in figure 1. A similar expression was adopted by Lu, Brodsky & Kavehpour (Reference Lu, Brodsky and Kavehpour2007) to describe the shear-weakening behaviour of granular materials. Through multiplying (3.1) by

${\phi _s}$, as illustrated in figure 1. A similar expression was adopted by Lu, Brodsky & Kavehpour (Reference Lu, Brodsky and Kavehpour2007) to describe the shear-weakening behaviour of granular materials. Through multiplying (3.1) by ![]() $- |{\partial p_s^e/\partial {\phi_s}} |$, the changes in

$- |{\partial p_s^e/\partial {\phi_s}} |$, the changes in ![]() $p_s^e$, when

$p_s^e$, when ![]() $p_s^e \gt 0$ and

$p_s^e \gt 0$ and ![]() ${\phi _s} \gt 0$, can be estimated by

${\phi _s} \gt 0$, can be estimated by

As in Rowe (Reference Rowe1962), a dilatancy angle ![]() $\psi $ is defined as:

$\psi $ is defined as:

where V is the volume of the granular assembly and ![]() $\partial V$ is the volumetric change arising from frictional dilatation/contraction. Equation (3.3) implies that the mass of the granular assembly remains constant during frictional dilatation/contraction. By defining

$\partial V$ is the volumetric change arising from frictional dilatation/contraction. Equation (3.3) implies that the mass of the granular assembly remains constant during frictional dilatation/contraction. By defining ![]() $\Re \equiv |{({\phi_s}/p_s^e)\partial p_s^e/\partial {\phi_s}} |$ and combining (3.2) and (3.3), we have

$\Re \equiv |{({\phi_s}/p_s^e)\partial p_s^e/\partial {\phi_s}} |$ and combining (3.2) and (3.3), we have

Note that (3.4) is applicable for any time instant. As the rearrangement of contact force chains takes place at the particle scale, the corresponding changes in the pressure occur in a very short duration of ![]() $O({d_s}/\sqrt {p_s^e/{\rho _s}} )$ (see Forterre & Pouliquen Reference Forterre and Pouliquen2008, where

$O({d_s}/\sqrt {p_s^e/{\rho _s}} )$ (see Forterre & Pouliquen Reference Forterre and Pouliquen2008, where ![]() ${d_s}$ is the particle diameter), during which there is an exceedingly small shear strain increment of

${d_s}$ is the particle diameter), during which there is an exceedingly small shear strain increment of ![]() ${\gamma _ \ast }$ in the granular assembly. In this strain change, we replace the

${\gamma _ \ast }$ in the granular assembly. In this strain change, we replace the ![]() $p_s^e$ in the definition of

$p_s^e$ in the definition of ![]() $\Re $ by

$\Re $ by ![]() $p_{s0}^e$ as a first approximation and obtain

$p_{s0}^e$ as a first approximation and obtain

in which ![]() $p_{s0}^e$ is the frictional solid pressure excluding the frictional dilatation/contraction effect and is a function of

$p_{s0}^e$ is the frictional solid pressure excluding the frictional dilatation/contraction effect and is a function of ![]() ${\phi _s}$. Hence, both

${\phi _s}$. Hence, both ![]() $\Re $ and

$\Re $ and ![]() $\textrm{tan}\,\psi $ are macroscopic properties of the granular assembly varying with the volume fraction

$\textrm{tan}\,\psi $ are macroscopic properties of the granular assembly varying with the volume fraction ![]() ${\phi _s}$ on a timescale of

${\phi _s}$ on a timescale of ![]() $O(1/2||{{\boldsymbol{S}_s}} ||)$. In granular media, whose behaviour is dominated by inter-grain frictional contacts, the ratio of the timescale for the microscopic contact-force chain rearrangement to that for changes in macroscopic properties, i.e.

$O(1/2||{{\boldsymbol{S}_s}} ||)$. In granular media, whose behaviour is dominated by inter-grain frictional contacts, the ratio of the timescale for the microscopic contact-force chain rearrangement to that for changes in macroscopic properties, i.e. ![]() $O(2{d_s}||{{\boldsymbol{S}_s}} ||/\sqrt {p_s^e/{\rho _s}} )$, has a value of

$O(2{d_s}||{{\boldsymbol{S}_s}} ||/\sqrt {p_s^e/{\rho _s}} )$, has a value of ![]() $O({10^{ - 6}}) \sim O({10^{ - 1}})$ (Lu et al. Reference Lu, Brodsky and Kavehpour2007; Chialvo, Sun & Sundaresan Reference Chialvo, Sun and Sundaresan2012). Therefore, it is reasonable to regard the microscopic rearrangement of contact-force chains and adjustment of the solid pressure as a transient process in a continuum description of granular flows and, during this period, the macroscopic properties of the granular assembly

$O({10^{ - 6}}) \sim O({10^{ - 1}})$ (Lu et al. Reference Lu, Brodsky and Kavehpour2007; Chialvo, Sun & Sundaresan Reference Chialvo, Sun and Sundaresan2012). Therefore, it is reasonable to regard the microscopic rearrangement of contact-force chains and adjustment of the solid pressure as a transient process in a continuum description of granular flows and, during this period, the macroscopic properties of the granular assembly ![]() $\Re $ and

$\Re $ and ![]() $\textrm{tan}\,\psi $ stay unchanged. We can then rearrange (3.4) to

$\textrm{tan}\,\psi $ stay unchanged. We can then rearrange (3.4) to ![]() $\partial p_s^e/p_s^e = (\Re \,\textrm{tan}\,\psi )\partial \gamma$ and integrate it over

$\partial p_s^e/p_s^e = (\Re \,\textrm{tan}\,\psi )\partial \gamma$ and integrate it over ![]() $[0,{\gamma _ \ast }]$, which gives

$[0,{\gamma _ \ast }]$, which gives

In general, the frictional solid pressure excluding the dilatation/contraction effect ![]() $p_{s0}^e$ is a function of the solid volume fraction and can be computed using a few existing formulae (Johnson & Jackson Reference Johnson and Jackson1987; van Wachem et al. Reference van Wachem, Schouten, van den Bleek, Krishna and Sinclair2001; Hsu, Jenkins & Liu Reference Hsu, Jenkins and Liu2004). Without loss of generality,

$p_{s0}^e$ is a function of the solid volume fraction and can be computed using a few existing formulae (Johnson & Jackson Reference Johnson and Jackson1987; van Wachem et al. Reference van Wachem, Schouten, van den Bleek, Krishna and Sinclair2001; Hsu, Jenkins & Liu Reference Hsu, Jenkins and Liu2004). Without loss of generality, ![]() $p_{s0}^e$ can be determined by

$p_{s0}^e$ can be determined by

\begin{equation}p_{s0}^e = \left\{ {\begin{array}{@{}ll} {G{{({\phi_s} - {\phi_ \ast })}^\chi }}&{{\phi_s} \gt {\phi_ \ast }}\\ 0&{{\phi_s} \le {\phi_ \ast }} \end{array}} \right.,\end{equation}

\begin{equation}p_{s0}^e = \left\{ {\begin{array}{@{}ll} {G{{({\phi_s} - {\phi_ \ast })}^\chi }}&{{\phi_s} \gt {\phi_ \ast }}\\ 0&{{\phi_s} \le {\phi_ \ast }} \end{array}} \right.,\end{equation}

where ![]() ${\phi _ \ast }$ is the random loosely packed volume fraction; G is a compressibility coefficient of the grains, which is related to the Young's modulus and the Poisson's ratio of the solid material; and

${\phi _ \ast }$ is the random loosely packed volume fraction; G is a compressibility coefficient of the grains, which is related to the Young's modulus and the Poisson's ratio of the solid material; and ![]() $\chi $ is a parameter to characterize the arrangement of contact force chains, which generally varies from 1.50 to 5.50 (Hsu et al. Reference Hsu, Jenkins and Liu2004; Lee & Huang Reference Lee and Huang2018). Rewriting (3.6) in terms of the packing fraction

$\chi $ is a parameter to characterize the arrangement of contact force chains, which generally varies from 1.50 to 5.50 (Hsu et al. Reference Hsu, Jenkins and Liu2004; Lee & Huang Reference Lee and Huang2018). Rewriting (3.6) in terms of the packing fraction ![]() $0 \lt {\phi _s} - {\phi _ \ast } \lt 1$ as

$0 \lt {\phi _s} - {\phi _ \ast } \lt 1$ as

and combining (3.7) and (3.8), we obtain

for ![]() ${\phi _s} \gt {\phi _ \ast }$. Equation (3.9) indicates that the change of

${\phi _s} \gt {\phi _ \ast }$. Equation (3.9) indicates that the change of ![]() $p_s^e$ results from the adjustment of the parameter

$p_s^e$ results from the adjustment of the parameter ![]() $\chi $ for the arrangement of contact force chains, consistent with the proposed framework in figure 1.

$\chi $ for the arrangement of contact force chains, consistent with the proposed framework in figure 1.

By applying (3.7) to obtain ![]() $\partial p_{s0}^e/\partial {\phi _s}$ and

$\partial p_{s0}^e/\partial {\phi _s}$ and ![]() $p_{s0}^e$ in (3.5) for the case of

$p_{s0}^e$ in (3.5) for the case of ![]() ${\phi _s} \gt {\phi _ \ast }$, we have

${\phi _s} \gt {\phi _ \ast }$, we have

With regards to the dilatancy angle, the critical state theory in Roux & Radjai (Reference Roux and Radjai1998) is employed, i.e.

in which K is a material parameter of granular assembly varying in the range of 1.0–25.0 and can be determined through simple shear tests (Pailha & Pouliquen Reference Pailha and Pouliquen2009; Bonnet, Richard & Philippe Reference Bonnet, Richard and Philippe2010; Gravish & Goldman Reference Gravish and Goldman2014); and ![]() ${\phi _c}$ is the critical volume fraction of dilatancy, at which there is no frictional dilatation/contraction effect. Here

${\phi _c}$ is the critical volume fraction of dilatancy, at which there is no frictional dilatation/contraction effect. Here ![]() ${\phi _c}$ may vary with the imposed force and the shear rate (Bouchut et al. Reference Bouchut, Fernández-Nieto, Mangeney and Narbona-Reina2016) and, in this paper, is related to the flow dimensionless number

${\phi _c}$ may vary with the imposed force and the shear rate (Bouchut et al. Reference Bouchut, Fernández-Nieto, Mangeney and Narbona-Reina2016) and, in this paper, is related to the flow dimensionless number ![]() ${I_m}$ following Iverson & George (Reference Iverson and George2014), written as

${I_m}$ following Iverson & George (Reference Iverson and George2014), written as

where the dimensionless number ![]() ${I_m}$ is a combination of the inertia number and the viscous number of granular flows, defined by (3.18); and

${I_m}$ is a combination of the inertia number and the viscous number of granular flows, defined by (3.18); and ![]() ${\phi _{c0}}$ is the critical volume fraction of dilatancy for static granular materials when

${\phi _{c0}}$ is the critical volume fraction of dilatancy for static granular materials when ![]() ${I_m} = 0$.

${I_m} = 0$.

The shear strain ![]() ${\gamma _ \ast }$ increases with the temporal duration of the microscopic rearrangement of inter-grain contact force chains, the scale of which is

${\gamma _ \ast }$ increases with the temporal duration of the microscopic rearrangement of inter-grain contact force chains, the scale of which is ![]() ${d_s}/\sqrt {p_{s0}^e/{\rho _s}} $ (for simplification, here we use

${d_s}/\sqrt {p_{s0}^e/{\rho _s}} $ (for simplification, here we use ![]() $p_{s0}^e$ rather than

$p_{s0}^e$ rather than ![]() $p_s^e$), and with the rate of the macroscopic mean deformation of the granular assembly,

$p_s^e$), and with the rate of the macroscopic mean deformation of the granular assembly, ![]() $2||{{\boldsymbol{S}_s}} ||$. A non-dimensional shear rate

$2||{{\boldsymbol{S}_s}} ||$. A non-dimensional shear rate ![]() ${I_d}$ can thus be defined as

${I_d}$ can thus be defined as

and ![]() ${\gamma _ \ast }$ increases with

${\gamma _ \ast }$ increases with ![]() ${I_d}$. It is noted that

${I_d}$. It is noted that ![]() ${I_d}$ is used to quantify the shear strain of granular media in the process of frictional dilatation/contraction and is different from the inertia number

${I_d}$ is used to quantify the shear strain of granular media in the process of frictional dilatation/contraction and is different from the inertia number ![]() ${I_i} \equiv 2{d_s}||{{\boldsymbol{S}_s}} ||/\sqrt {{p_s}/{\rho _s}}$. A preliminary analysis on the magnitude of

${I_i} \equiv 2{d_s}||{{\boldsymbol{S}_s}} ||/\sqrt {{p_s}/{\rho _s}}$. A preliminary analysis on the magnitude of ![]() ${\gamma _ \ast }$ in appendix A suggests that

${\gamma _ \ast }$ in appendix A suggests that ![]() ${\gamma _ \ast }$ has a small order of

${\gamma _ \ast }$ has a small order of ![]() $O({10^{ - 2}})$–

$O({10^{ - 2}})$–![]() $O({10^{ - 1}})$ and

$O({10^{ - 1}})$ and

where ![]() ${c_1}$ and

${c_1}$ and ![]() ${c_2}$ are coefficients. The analysis gives

${c_2}$ are coefficients. The analysis gives ![]() ${c_1} = 0\sim O(10)$ and

${c_1} = 0\sim O(10)$ and ![]() ${c_2} = 0\sim 1$.

${c_2} = 0\sim 1$.

Combining (3.6), (3.10) and (3.11), we have the frictional solid pressure including the frictional dilatation/contraction effect expressed as

In (3.15), the frictional solid pressure is related to the shear strain ![]() ${\gamma _ \ast }$. Further, combining (3.15) and (3.14), we can relate the frictional solid pressure to the shear rate of granular flows as

${\gamma _ \ast }$. Further, combining (3.15) and (3.14), we can relate the frictional solid pressure to the shear rate of granular flows as

Equation (3.16) is valid when ![]() ${\phi _s} \gt {\phi _ \ast }$ and

${\phi _s} \gt {\phi _ \ast }$ and ![]() $p_s^e = p_{s0}^e = 0$ when

$p_s^e = p_{s0}^e = 0$ when ![]() ${\phi _s} \le {\phi _ \ast }$.

${\phi _s} \le {\phi _ \ast }$.

3.3. Collisional dilatancy

The rheological law proposed in Trulsson, Andreotti & Claudin (Reference Trulsson, Andreotti and Claudin2012) was adopted for the collisional dilatancy effect. The shear-rate-dependent collisional solid pressure ![]() $p_s^c$ is determined by

$p_s^c$ is determined by

in which ![]() ${\phi _0}$ is the jamming volume fraction, the maximum packing fraction of sheared granular materials in a steady state;

${\phi _0}$ is the jamming volume fraction, the maximum packing fraction of sheared granular materials in a steady state; ![]() ${\rho _f}$ is the density of interstitial fluid and

${\rho _f}$ is the density of interstitial fluid and ![]() ${\nu _f}$ is its kinematic viscosity;

${\nu _f}$ is its kinematic viscosity; ![]() ${d_s}$ is the diameter of granular particles; and

${d_s}$ is the diameter of granular particles; and ![]() ${c_3}$ and

${c_3}$ and ![]() ${c_4}$ are coefficients. In general,

${c_4}$ are coefficients. In general, ![]() ${c_3} = 0.75\sim 3.00$ and

${c_3} = 0.75\sim 3.00$ and ![]() ${c_4} = 0\sim 1.00$ (Chauchat Reference Chauchat2018; Lee & Huang Reference Lee and Huang2018). The effect of interstitial fluid viscosity is included in (3.17) but can be neglected when considering subaerial granular flows.

${c_4} = 0\sim 1.00$ (Chauchat Reference Chauchat2018; Lee & Huang Reference Lee and Huang2018). The effect of interstitial fluid viscosity is included in (3.17) but can be neglected when considering subaerial granular flows.

The rheological law relates the friction coefficient ![]() $\mu $ in (2.5) to a dimensionless number

$\mu $ in (2.5) to a dimensionless number ![]() ${I_m}$ of granular flows, which is a combination of the inertia number

${I_m}$ of granular flows, which is a combination of the inertia number ![]() ${I_i}$ and the viscous number

${I_i}$ and the viscous number ![]() ${I_\nu } \equiv 2||{{\boldsymbol{S}_s}} ||{\rho _f}{\nu _f}/{p_s}$. It is defined as

${I_\nu } \equiv 2||{{\boldsymbol{S}_s}} ||{\rho _f}{\nu _f}/{p_s}$. It is defined as

in which ![]() ${c_4}$ is the same coefficient as that in (3.17). A small value of

${c_4}$ is the same coefficient as that in (3.17). A small value of ![]() ${I_m}$ indicates that the granular flow moves at a low speed and is in the quasi-static regime, while a large value of

${I_m}$ indicates that the granular flow moves at a low speed and is in the quasi-static regime, while a large value of ![]() ${I_m}$ corresponds to a rapid granular flow in the inertia regime (Forterre & Pouliquen Reference Forterre and Pouliquen2008). According to Trulsson et al. (Reference Trulsson, Andreotti and Claudin2012), the friction coefficient depends on

${I_m}$ corresponds to a rapid granular flow in the inertia regime (Forterre & Pouliquen Reference Forterre and Pouliquen2008). According to Trulsson et al. (Reference Trulsson, Andreotti and Claudin2012), the friction coefficient depends on ![]() ${I_m}$ as

${I_m}$ as

where ![]() ${\mu _1} = \textrm{tan}\,\varphi $ is the friction coefficient when

${\mu _1} = \textrm{tan}\,\varphi $ is the friction coefficient when ![]() ${I_m} = 0$ and the granular assembly is static;

${I_m} = 0$ and the granular assembly is static; ![]() $\varphi $ is the internal friction angle of the grains;

$\varphi $ is the internal friction angle of the grains; ![]() ${\mu _2} = \textrm{tan}\,\varphi \sim 1.0$ is the friction coefficient when

${\mu _2} = \textrm{tan}\,\varphi \sim 1.0$ is the friction coefficient when ![]() ${I_m}$ is infinite and the granular assembly flows fairly rapidly; and

${I_m}$ is infinite and the granular assembly flows fairly rapidly; and ![]() ${I_0}$ is a model parameter and is set to be a value close to the characteristic

${I_0}$ is a model parameter and is set to be a value close to the characteristic ![]() ${I_m}$ of the flow (Boyer, Guazzelli & Pouliquen Reference Boyer, Guazzelli and Pouliquen2011).

${I_m}$ of the flow (Boyer, Guazzelli & Pouliquen Reference Boyer, Guazzelli and Pouliquen2011).

4. Analytical verifications of the dilatation/contraction formulation

4.1. Shear-weakening behaviour of granular samples

The experimental data of sheared granular samples within a torsional shear cell in Lu et al. (Reference Lu, Brodsky and Kavehpour2007) were used to verify the proposed theoretical formulation of dilatation/contraction. In the experiment, a granular sample composed of sifted beach sand, which had a mean diameter of ![]() ${d_s} = 438\;\mathrm{\mu m}$, a density of

${d_s} = 438\;\mathrm{\mu m}$, a density of ![]() ${\rho _s} = 2.65\textrm{ g c}{\textrm{m}^{\textrm{ - 3}}}$ and an internal frictional angle of

${\rho _s} = 2.65\textrm{ g c}{\textrm{m}^{\textrm{ - 3}}}$ and an internal frictional angle of ![]() $\varphi = 37.5^\circ $, was sheared in a top-rotating torsional shear rheometer. The rheometer was a highly sensitive feedback-controlled instrument with the normal force, top-plate height and angular velocity monitored simultaneously, which hence can directly provide the values of inter-grain pressure, packing fraction and shear rate in the granular sample for the validation of the theory. The granular sample was initially loaded up to a height of 6 mm with a packing fraction of

$\varphi = 37.5^\circ $, was sheared in a top-rotating torsional shear rheometer. The rheometer was a highly sensitive feedback-controlled instrument with the normal force, top-plate height and angular velocity monitored simultaneously, which hence can directly provide the values of inter-grain pressure, packing fraction and shear rate in the granular sample for the validation of the theory. The granular sample was initially loaded up to a height of 6 mm with a packing fraction of ![]() ${\phi _s} = 0.61$ when static. It was then sheared by rotating the top plate at a finite angular velocity with the column height staying fixed and the volume fraction of the medium remaining constant. The normal stress on the top plate was recorded. The shear angular velocity

${\phi _s} = 0.61$ when static. It was then sheared by rotating the top plate at a finite angular velocity with the column height staying fixed and the volume fraction of the medium remaining constant. The normal stress on the top plate was recorded. The shear angular velocity ![]() $\omega $ varied from 0.001 to 100 rad s−1 in different experimental cases and the shear rate of the granular sample was correspondingly between 0.001 and 2800 s−1. The results showed that the normal stress on the top plate varied little when the angular shearing velocity

$\omega $ varied from 0.001 to 100 rad s−1 in different experimental cases and the shear rate of the granular sample was correspondingly between 0.001 and 2800 s−1. The results showed that the normal stress on the top plate varied little when the angular shearing velocity ![]() $\omega $ was lower than 0.01 rad s−1 but became negatively correlated with

$\omega $ was lower than 0.01 rad s−1 but became negatively correlated with ![]() $\omega $ when

$\omega $ when ![]() $\omega $ was increased up to 25 rad s−1. This observation demonstrated a shear-weakening rheology with a dip of the normal stress. As

$\omega $ was increased up to 25 rad s−1. This observation demonstrated a shear-weakening rheology with a dip of the normal stress. As ![]() $\omega $ increased further, the normal stress increased almost quadratically with the shear rate when the grains were in the inertia regime.

$\omega $ increased further, the normal stress increased almost quadratically with the shear rate when the grains were in the inertia regime.

At the steady state when the sample is sheared at a rate of ![]() $\dot{\gamma }$, the normal stress on the top plate

$\dot{\gamma }$, the normal stress on the top plate ![]() $\sigma $ is balanced by the inter-grain pressure

$\sigma $ is balanced by the inter-grain pressure ![]() ${p_s}$ as

${p_s}$ as

Excluding the effect of interstitial fluid viscosity in (3.17) for subaerial granular samples and combining (3.12), (3.16), (3.17) and (4.1), the normal stress varies with the shear rate ![]() $\dot{\gamma } = 2||{{\boldsymbol{S}_s}} ||$ as

$\dot{\gamma } = 2||{{\boldsymbol{S}_s}} ||$ as

The frictional solid pressure without the dilatation/contraction effect ![]() $p_{s0}^e$, determined by (3.7), balances the initially imposed normal stress

$p_{s0}^e$, determined by (3.7), balances the initially imposed normal stress ![]() ${\sigma _0}$ to the static granular sample at the start of each experimental case, i.e.

${\sigma _0}$ to the static granular sample at the start of each experimental case, i.e.

Dividing both sides of (4.2) by ![]() ${\sigma _0}$, we have the dimensionless normal stress varying with shear rate as

${\sigma _0}$, we have the dimensionless normal stress varying with shear rate as

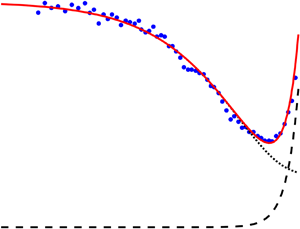

in which the non-dimensional shear rate ![]() ${I_d} = {d_s}\dot{\gamma }/\sqrt {{\sigma _0}/{\rho _s}} $. Figure 2 shows the comparisons between the results of (4.4) and the measured data. In the experiment,

${I_d} = {d_s}\dot{\gamma }/\sqrt {{\sigma _0}/{\rho _s}} $. Figure 2 shows the comparisons between the results of (4.4) and the measured data. In the experiment, ![]() ${\sigma _0} = 1.25 \times {10^4}\;\textrm{Pa}$,

${\sigma _0} = 1.25 \times {10^4}\;\textrm{Pa}$, ![]() ${\phi _ \ast } = 0.590$ and a random close-packing fraction

${\phi _ \ast } = 0.590$ and a random close-packing fraction ![]() ${\phi ^ \ast } = 0.640$. A jamming volume fraction

${\phi ^ \ast } = 0.640$. A jamming volume fraction ![]() ${\phi _0} = 0.630$ is set which is in a reasonable range of

${\phi _0} = 0.630$ is set which is in a reasonable range of ![]() ${\phi _s}\sim {\phi ^ \ast }$. The compressibility coefficient of the natural sand G is

${\phi _s}\sim {\phi ^ \ast }$. The compressibility coefficient of the natural sand G is ![]() ${10^9}\;\textrm{Pa}$ and, according to (4.3), the coefficient

${10^9}\;\textrm{Pa}$ and, according to (4.3), the coefficient ![]() $\chi = \textrm{ln}({\sigma _0}/G)/\textrm{ln}({\phi _s} - {\phi _ \ast })$ is 2.89. A critical volume fraction of dilatancy

$\chi = \textrm{ln}({\sigma _0}/G)/\textrm{ln}({\phi _s} - {\phi _ \ast })$ is 2.89. A critical volume fraction of dilatancy ![]() ${\phi _{{c_0}}} = 0.630$ is estimated in the experiment. The parameter K was not measured and we take

${\phi _{{c_0}}} = 0.630$ is estimated in the experiment. The parameter K was not measured and we take ![]() ${c_1}K$ as a single coefficient. Here,

${c_1}K$ as a single coefficient. Here, ![]() ${c_1}K = 1.50$ and

${c_1}K = 1.50$ and ![]() ${c_2} = 0.42$ are set by fitting the computed results with the data in both quasi-static and transitional regimes, while

${c_2} = 0.42$ are set by fitting the computed results with the data in both quasi-static and transitional regimes, while ![]() ${c_3} = 1.80$ and

${c_3} = 1.80$ and ![]() ${c_4} = 0.0005$ are determined according to the fitness in the inertia regime. The values of the parameters are summarized in table 1.

${c_4} = 0.0005$ are determined according to the fitness in the inertia regime. The values of the parameters are summarized in table 1.

Figure 2. Variation of normal stress on the rheometer top-plate with non-dimensional shear rate in the volume-constant experiments of Lu et al. (Reference Lu, Brodsky and Kavehpour2007). The non-dimensional frictional solid pressure ![]() $p_s^e/{\sigma _0}$ and collisional pressure

$p_s^e/{\sigma _0}$ and collisional pressure ![]() $p_s^c/{\sigma _0}$ are computed by the first and the second terms on the right-hand side of (4.4), respectively.

$p_s^c/{\sigma _0}$ are computed by the first and the second terms on the right-hand side of (4.4), respectively.

Table 1. Parameters in the model. The third column shows whether a parameter is a material parameter, whose value is determined depending on the physical properties of solid grains and according to related experimental observations. In §§ 4.1 and 5, the material parameter K was not measured and we take ![]() ${c_1}K$ as a single adjustable parameter. In § 4.2, when concerning the critical incipient state of granular slopes, the frictional solid pressure is related to the shear strain

${c_1}K$ as a single adjustable parameter. In § 4.2, when concerning the critical incipient state of granular slopes, the frictional solid pressure is related to the shear strain ![]() ${\gamma _ \ast }$ and

${\gamma _ \ast }$ and ![]() ${\gamma _ \ast } = {c_1}I_d^{{c_2}}$ is taken as an adjustable parameter. In specific analytical cases, if its value is not set, the parameter is not involved in the solutions.

${\gamma _ \ast } = {c_1}I_d^{{c_2}}$ is taken as an adjustable parameter. In specific analytical cases, if its value is not set, the parameter is not involved in the solutions.

As shown in figure 2, the predicted variation of the normal stress against shear rate agrees well with the measured data, which demonstrates that the proposed formulation of frictional solid pressure is capable of describing the shear-weakening behaviour of the granular sample. When the sample is in the quasi-static and the transitional regimes, the frictional solid pressure ![]() $p_s^e$ predominates and the decrease in

$p_s^e$ predominates and the decrease in ![]() $p_s^e$, owing to the frictional contraction, is the reason for the dip in the normal stress. When the sample is in the inertia regime, the collisional inter-grain pressure

$p_s^e$, owing to the frictional contraction, is the reason for the dip in the normal stress. When the sample is in the inertia regime, the collisional inter-grain pressure ![]() $p_s^c$ increases quadratically with the shear rate and becomes dominant in the balance with the normal stress on the top-plate. Equation (4.4), which is a direct result of the proposed dilatation/contraction theory, can map the variation of the normal stress imposed to the sheared sample smoothly between the quasi-static and the inertia regimes.

$p_s^c$ increases quadratically with the shear rate and becomes dominant in the balance with the normal stress on the top-plate. Equation (4.4), which is a direct result of the proposed dilatation/contraction theory, can map the variation of the normal stress imposed to the sheared sample smoothly between the quasi-static and the inertia regimes.

4.2. Incipient failure of granular slopes

In this section, the proposed theoretical formulation is assessed through predicting the incipient failure of dry and immersed granular slopes.

Gravish & Goldman (Reference Gravish and Goldman2014) experimentally studied the effects of initial packing fraction on the failure of dry granular slopes. An initially horizontal layer of grains with ![]() ${d_s} = 256\;\mathrm{\mu m}$,

${d_s} = 256\;\mathrm{\mu m}$, ![]() ${\rho _s} = 2.5\,\textrm{g}\;\textrm{c}{\textrm{m}^{ - 3}}$ and volume fraction

${\rho _s} = 2.5\,\textrm{g}\;\textrm{c}{\textrm{m}^{ - 3}}$ and volume fraction ![]() ${\phi _s}$ ranging between 0.58 and 0.63 was prepared on a fluidized bed. The bed was then rotated to a 45° angle at a constant rate. The granular motion in the bed was recorded by cameras and the instant when incipient motion of grains on the surface occurred was detected. The angle of the slope at the instant

${\phi _s}$ ranging between 0.58 and 0.63 was prepared on a fluidized bed. The bed was then rotated to a 45° angle at a constant rate. The granular motion in the bed was recorded by cameras and the instant when incipient motion of grains on the surface occurred was detected. The angle of the slope at the instant ![]() ${\theta _0}$, referred to as the incipient angle, was then obtained according to the rotation rate of the bed. In different experimental cases, the initial packing fraction was varied and different failure behaviours of the granular slopes were observed. It was found that the bed with a packing fraction smaller than the critical value

${\theta _0}$, referred to as the incipient angle, was then obtained according to the rotation rate of the bed. In different experimental cases, the initial packing fraction was varied and different failure behaviours of the granular slopes were observed. It was found that the bed with a packing fraction smaller than the critical value ![]() ${\phi _{{c_0}}} = 0.595 \pm 0.003$ experienced a rapid failure and a compaction, while the bed with a fraction larger than the critical value underwent a slow failure and a dilatation. Specifically, the bed with initial

${\phi _{{c_0}}} = 0.595 \pm 0.003$ experienced a rapid failure and a compaction, while the bed with a fraction larger than the critical value underwent a slow failure and a dilatation. Specifically, the bed with initial ![]() ${\phi _s} = 0.58$ had an incipient angle of

${\phi _s} = 0.58$ had an incipient angle of ![]() ${\theta _0} = 7.7 \pm {1.4^ \circ }$, whereas the

${\theta _0} = 7.7 \pm {1.4^ \circ }$, whereas the ![]() ${\theta _0}$ of the bed with

${\theta _0}$ of the bed with ![]() ${\phi _s} = 0.63$ was

${\phi _s} = 0.63$ was ![]() $32.1 \pm 1.5^\circ $. Overall, the incipient angle of the slopes increased significantly with the initial packing fraction.

$32.1 \pm 1.5^\circ $. Overall, the incipient angle of the slopes increased significantly with the initial packing fraction.

For comparison, the classical saw model of dilatancy (Rowe Reference Rowe1962; Pailha & Pouliquen Reference Pailha and Pouliquen2009) was applied to estimate the incipient angle of granular slopes. In the theory, forces are in equilibrium both along and normal to the slope and the dilatation/contraction affects the slope failure by leading to a change in the angle of shearing. At the critical incipient state, the grains on the bed surface are controlled by

and

where ![]() $\delta $ is the angle of shearing;

$\delta $ is the angle of shearing; ![]() $\varphi $ is the internal friction angle of the grains and

$\varphi $ is the internal friction angle of the grains and ![]() $\textrm{tan}\,\varphi $ is the friction coefficient when there is no dilatancy effect; and h is a characteristic depth of the grains to move. Recall that

$\textrm{tan}\,\varphi $ is the friction coefficient when there is no dilatancy effect; and h is a characteristic depth of the grains to move. Recall that ![]() $\psi $ is the dilatancy angle. Equations (4.5) and (4.6) are respectively for the balance of forces in the directions along and normal to the slope. Combining (4.5)–(4.7) as well as (3.11), we have

$\psi $ is the dilatancy angle. Equations (4.5) and (4.6) are respectively for the balance of forces in the directions along and normal to the slope. Combining (4.5)–(4.7) as well as (3.11), we have

Here, ![]() ${\phi _c} = {\phi _{{c_0}}}$ holds during the incipient failure of the slopes.

${\phi _c} = {\phi _{{c_0}}}$ holds during the incipient failure of the slopes.

We then applied the proposed formulation to predict the incipient angle of granular slopes. It should be noted that the collisional solid pressure ![]() $p_s^c$ vanishes at the incipient failure stage and thus

$p_s^c$ vanishes at the incipient failure stage and thus ![]() ${p_s} = p_s^e$. When the granular bed is static, in the direction normal to the slope, the inter-particle pressure without the frictional dilatation/contraction effect

${p_s} = p_s^e$. When the granular bed is static, in the direction normal to the slope, the inter-particle pressure without the frictional dilatation/contraction effect ![]() $p_{s0}^e$ balances the gravity as

$p_{s0}^e$ balances the gravity as

where

Hence, ![]() $p_{s0}^e = G{({\phi _s} - {\phi _ \ast })^\chi } = {\rho _s}gh\,\textrm{cos}\,{\theta _0}$. As the granular slope approaches to the critical incipient state, before the incipient motion is detected, the grains on the slope surface undergo a small shear strain

$p_{s0}^e = G{({\phi _s} - {\phi _ \ast })^\chi } = {\rho _s}gh\,\textrm{cos}\,{\theta _0}$. As the granular slope approaches to the critical incipient state, before the incipient motion is detected, the grains on the slope surface undergo a small shear strain ![]() ${\gamma _ \ast }$ during the failure. Owing to the rearrangement of contact force chains along with the strain, the solid pressure changes from

${\gamma _ \ast }$ during the failure. Owing to the rearrangement of contact force chains along with the strain, the solid pressure changes from ![]() ${p_s} = p_{s0}^e$ to

${p_s} = p_{s0}^e$ to ![]() ${p_s} = p_{s0}^e\,{\textrm{e}^{\Re {\gamma _ \ast }\,\textrm{tan}\,\psi }}$ in the frictional dilatation/contraction and the forces in the direction normal to the slope cease to be in equilibrium. In the densely packed granular slope, the solid pressure increases and the resultant force in the normal direction becomes upward, which leads to a dilatation of the assembly. Conversely, in the loosely packed granular bed, the solid pressure decreases and the resultant force directs downward, which induces a contraction in the bed. In the direction along the slope, the equilibrium condition is still valid. Hence,

${p_s} = p_{s0}^e\,{\textrm{e}^{\Re {\gamma _ \ast }\,\textrm{tan}\,\psi }}$ in the frictional dilatation/contraction and the forces in the direction normal to the slope cease to be in equilibrium. In the densely packed granular slope, the solid pressure increases and the resultant force in the normal direction becomes upward, which leads to a dilatation of the assembly. Conversely, in the loosely packed granular bed, the solid pressure decreases and the resultant force directs downward, which induces a contraction in the bed. In the direction along the slope, the equilibrium condition is still valid. Hence,

where

The effect of the dilatation/contraction on the friction coefficient during the incipient period is neglected. Combining (4.11) and (4.12) gives

which can be written explicitly as

Substituting ![]() $\chi {\phi _s}/({\phi _s} - {\phi _ \ast })$ for

$\chi {\phi _s}/({\phi _s} - {\phi _ \ast })$ for ![]() $\Re $ and

$\Re $ and ![]() $K({\phi _s} - {\phi _c})$ for

$K({\phi _s} - {\phi _c})$ for ![]() $\textrm{tan}\,\psi $ as in § 3, we finally obtain

$\textrm{tan}\,\psi $ as in § 3, we finally obtain

where ![]() $c = \chi {\gamma _ \ast }K$. It is noted that in this case we do not apply (3.14) to replace

$c = \chi {\gamma _ \ast }K$. It is noted that in this case we do not apply (3.14) to replace ![]() ${\gamma _ \ast }$ with

${\gamma _ \ast }$ with ![]() ${c_1}I_d^{{c_2}}$ but keep

${c_1}I_d^{{c_2}}$ but keep ![]() ${\gamma _ \ast }$ in the equation as a parameter because the shear rate of the slope during the incipient motion is not measurable. Moreover, it is more reasonable to relate the incipient dynamics of granular slopes at the critical state to the shear strain than to the shear rate. In Gravish & Goldman (Reference Gravish and Goldman2014), the measured critical volume fraction of dilatancy

${\gamma _ \ast }$ in the equation as a parameter because the shear rate of the slope during the incipient motion is not measurable. Moreover, it is more reasonable to relate the incipient dynamics of granular slopes at the critical state to the shear strain than to the shear rate. In Gravish & Goldman (Reference Gravish and Goldman2014), the measured critical volume fraction of dilatancy ![]() ${\phi _c}$ was 0.595, the material parameter for dilatancy K was 22.4 and the internal friction angle of grains in the air

${\phi _c}$ was 0.595, the material parameter for dilatancy K was 22.4 and the internal friction angle of grains in the air ![]() $\varphi $ was

$\varphi $ was ![]() $17.0^\circ $. A random loosely packed volume fraction of

$17.0^\circ $. A random loosely packed volume fraction of ![]() ${\phi _ \ast } = 0.570$ was determined according to the experimental setup. Here

${\phi _ \ast } = 0.570$ was determined according to the experimental setup. Here ![]() $\chi \textrm{ = 3}\textrm{.50}$ was set, which was the median value of its range (see § 3.2 and table 1). A shear strain of

$\chi \textrm{ = 3}\textrm{.50}$ was set, which was the median value of its range (see § 3.2 and table 1). A shear strain of ![]() ${\gamma _ \ast } = 0.026$, consistent with the analysis in appendix A, was obtained by fitting the results to the experimental data.

${\gamma _ \ast } = 0.026$, consistent with the analysis in appendix A, was obtained by fitting the results to the experimental data.

Figure 3 compares the computed incipient angles of the granular slope using (4.8) and (4.15) with the measured data. The results given by the present formulation agreed with the data much better than those by the classical saw model, especially when the initial packing fraction of the granular slope was larger than the critical value of dilatancy and the bed dilates.

Figure 3. Variation of the incipient angle of dry granular slope with the initial packing fraction in the experiment of Gravish & Goldman (Reference Gravish and Goldman2014). The measured critical volume fraction ![]() ${\phi _c} = 0.595$ with the grey bar indicating the measurement uncertainty.

${\phi _c} = 0.595$ with the grey bar indicating the measurement uncertainty.

Bonnet et al. (Reference Bonnet, Richard and Philippe2010) conducted a similar experiment to study the failure of immersed granular slopes in static water ![]() $({\rho _f} = 1.0\;\textrm{g}\;\textrm{c}{\textrm{m}^{ - 3}})$. The grains had a diameter of

$({\rho _f} = 1.0\;\textrm{g}\;\textrm{c}{\textrm{m}^{ - 3}})$. The grains had a diameter of ![]() ${d_s} = 600\;\mathrm{\mu m}$ and a density of

${d_s} = 600\;\mathrm{\mu m}$ and a density of ![]() ${\rho _s} = 2.65\;\textrm{g}\;\textrm{c}{\textrm{m}^{ - 3}}$. The initial packing fraction of the granular particles in the bed

${\rho _s} = 2.65\;\textrm{g}\;\textrm{c}{\textrm{m}^{ - 3}}$. The initial packing fraction of the granular particles in the bed ![]() ${\phi _s}$ varied from 0.52 to 0.59 and the corresponding measured incipient angle of the slopes varied significantly with a notably high ratio of 2.5 between the maximal and the minimal values. It should be noted that the shear strain and the deformation of the free granular slope during the incipient stage are expected to be exceedingly small and, accordingly, the variation of pore pressure is not appreciable and neglected here. Therefore, the buoyancy of the grains was accounted for by substituting

${\phi _s}$ varied from 0.52 to 0.59 and the corresponding measured incipient angle of the slopes varied significantly with a notably high ratio of 2.5 between the maximal and the minimal values. It should be noted that the shear strain and the deformation of the free granular slope during the incipient stage are expected to be exceedingly small and, accordingly, the variation of pore pressure is not appreciable and neglected here. Therefore, the buoyancy of the grains was accounted for by substituting ![]() ${\rho _s} - {\rho _f}$ for

${\rho _s} - {\rho _f}$ for ![]() ${\rho _s}$ in (4.5)–(4.6) and (4.9)–(4.12). Consequently, both (4.8) of the saw model and (4.15) of the present frictional dilatation/contraction theory can also be applied to determine the incipient angle of immersed granular slopes.

${\rho _s}$ in (4.5)–(4.6) and (4.9)–(4.12). Consequently, both (4.8) of the saw model and (4.15) of the present frictional dilatation/contraction theory can also be applied to determine the incipient angle of immersed granular slopes.

Figure 4 shows the comparisons between the computed results and the measured data. According to the experimental results of Bonnet et al. (Reference Bonnet, Richard and Philippe2010), the parameter ![]() $K = 20.8$, the critical volume fraction of dilatancy

$K = 20.8$, the critical volume fraction of dilatancy ![]() ${\phi _c} = 0.545$ and the internal friction angle of gains in the water

${\phi _c} = 0.545$ and the internal friction angle of gains in the water ![]() $\varphi = 38.6^\circ $. A random loosely packed volume fraction of

$\varphi = 38.6^\circ $. A random loosely packed volume fraction of ![]() ${\phi _ \ast } = 0.510$ was roughly determined, as the minimal value of the packing fraction prepared in the experiment was between 0.51 and 0.52. Same as that in the dry slope case, a value of

${\phi _ \ast } = 0.510$ was roughly determined, as the minimal value of the packing fraction prepared in the experiment was between 0.51 and 0.52. Same as that in the dry slope case, a value of ![]() $\chi = 3.50$ was also set. According to the verification against the measured data, a shear strain of

$\chi = 3.50$ was also set. According to the verification against the measured data, a shear strain of ![]() ${\gamma _ \ast } = 0.019$ was adopted, which had the same order as that in the dry slope case. Values of the parameters are summarized in table 1. Figure 4 shows that the computed incipient angle by the present formulation agreed generally well with the measured data and the fitness was better than that between the results of the classical saw model and the data. The present formulation performs well in the dilatation situation and only slightly overestimates the incipient angle when the bed experiences a contraction. For the cases of

${\gamma _ \ast } = 0.019$ was adopted, which had the same order as that in the dry slope case. Values of the parameters are summarized in table 1. Figure 4 shows that the computed incipient angle by the present formulation agreed generally well with the measured data and the fitness was better than that between the results of the classical saw model and the data. The present formulation performs well in the dilatation situation and only slightly overestimates the incipient angle when the bed experiences a contraction. For the cases of ![]() ${\phi _s} - {\phi _c} \le - 0.02$, where the incipient angle seems to vary little with the packing fraction, both the present theory and the classical saw model have an underestimation, which may arise from the lack of effect from the fluid viscosity on slope failures. In immersed granular media, solid particles have an additional cohesion owing to the viscosity of interstitial fluid, noted as

${\phi _s} - {\phi _c} \le - 0.02$, where the incipient angle seems to vary little with the packing fraction, both the present theory and the classical saw model have an underestimation, which may arise from the lack of effect from the fluid viscosity on slope failures. In immersed granular media, solid particles have an additional cohesion owing to the viscosity of interstitial fluid, noted as ![]() $c^{\prime}$. At the critical state, there is a balance along the slope among the additional particle cohesion, the inter-particle shear stress and the gravity as

$c^{\prime}$. At the critical state, there is a balance along the slope among the additional particle cohesion, the inter-particle shear stress and the gravity as ![]() ${\phi _s}(c^{\prime} + {p_s}\,\textrm{tan}\,\varphi ) = {\phi _s}({\rho _s} - {\rho _f})gh\,\textrm{sin}\,{\theta _0}$. In the cases of

${\phi _s}(c^{\prime} + {p_s}\,\textrm{tan}\,\varphi ) = {\phi _s}({\rho _s} - {\rho _f})gh\,\textrm{sin}\,{\theta _0}$. In the cases of ![]() ${\phi _s} - {\phi _c} \le - 0.02$, owing to frictional contraction, the inter-particle pressure and shear stress decrease significantly and could have a smaller value than

${\phi _s} - {\phi _c} \le - 0.02$, owing to frictional contraction, the inter-particle pressure and shear stress decrease significantly and could have a smaller value than ![]() $c^{\prime}$. As a result, the additional particle cohesion predominates in resisting the incipient motion of the slope, which yields

$c^{\prime}$. As a result, the additional particle cohesion predominates in resisting the incipient motion of the slope, which yields ![]() ${\theta _0} = \arcsin [c^{\prime}/({\rho _s} - {\rho _f})gh]$. Assuming a same value of

${\theta _0} = \arcsin [c^{\prime}/({\rho _s} - {\rho _f})gh]$. Assuming a same value of ![]() $c^{\prime}$ for the cases with different packing fractions, we can find that the slope incipient angle varies little with the packing fraction. For an accurate quantification of the phenomenon, more measured data are required in further investigations.

$c^{\prime}$ for the cases with different packing fractions, we can find that the slope incipient angle varies little with the packing fraction. For an accurate quantification of the phenomenon, more measured data are required in further investigations.

Figure 4. Variation of the incipient angle of immersed granular slopes in water with the initial packing fraction in the experiment of Bonnet et al. (Reference Bonnet, Richard and Philippe2010). The measured critical volume fraction is ![]() ${\phi _c} = 0.545$ and the grey bar represents the uncertainty in the measurement.

${\phi _c} = 0.545$ and the grey bar represents the uncertainty in the measurement.

5. Numerical validations by simulations of submerged granular column collapse

The proposed dilatation/contraction formulation is integrated into the two-fluid model of Shi et al. (Reference Shi, Si, Dong and Yu2019), which is validated in laminar bed-load transport by Poiseuille flow (see appendix B), and, in this section, is applied to simulate submerged granular column collapse. The submerged granular mass collapse is a benchmark for studying the dilatation/contraction of granular materials, in which the frictional dilatation/contraction plays a critical role in the whole process from the initiation of the crash to the final deposition (Houssais & Jerolmack Reference Houssais and Jerolmack2017; Baumgarten & Kamrin Reference Baumgarten and Kamrin2019). The experiments showed that the initially loosely packed columns exhibited a fast initiation of motion and compacted in the collapse with an increase in the pore fluid pressure, while the densely packed columns collapsed rather slowly and dilated with a decrease in the pore fluid pressure (Rondon et al. Reference Rondon, Pouliquen and Aussillous2011; Wang et al. Reference Wang, Wang, Peng and Meng2017). A two-phase model fully resolving the primary variables of the solid and the liquid phases helps to capture the dynamics in the dilatation/contraction of the saturated granular materials.

5.1. Two-phase continuum model based on the smoothed particle hydrodynamics method

The present dilatation/contraction theory is integrated into the model of Shi et al. (Reference Shi, Si, Dong and Yu2019), which is a two-phase continuum model based on the weakly compressible smoothed particle hydrodynamics (WCSPH) method. The controlling equations, i.e. conservation equations of mass and momentum of the two phases, are obtained by first averaging the physical variables of each phase in a control volume following Drew (Reference Drew1983) for a continuum description of both phases, and then spatially filtering through Favre averaging for the turbulence. The equations are then written into Lagrangian form for numerical implementation using the SPH method. Here, for brevity, we only give a minimum description of the model. Detailed derivation of the equations and numerical implementations of the model can be found in Shi, Yu & Dalrymple (Reference Shi, Yu and Dalrymple2017) and Shi et al. (Reference Shi, Si, Dong and Yu2019).

The governing equations of the solid phase are

\begin{gather}\begin{array}{ccccc} \dfrac{{\textrm{d}{\boldsymbol{u}_s}}}{{\textrm{d}t}} & ={-} [({\boldsymbol{u}_s} - {\boldsymbol{u}_f})\boldsymbol{\cdot }\boldsymbol{\nabla }]{\boldsymbol{u}_s} + \dfrac{1}{{{\phi _s}{\rho _s}}}\boldsymbol{\nabla }\boldsymbol{\cdot }({\phi _s}{\boldsymbol{\sigma }_s}) + \boldsymbol{g} + \dfrac{1}{{{\phi _s}{\rho _s}}}\boldsymbol{\nabla }\boldsymbol{\cdot }({\phi _s}\boldsymbol{\sigma }_s^t)\\ & \quad - \dfrac{1}{{{\rho _s}}}\boldsymbol{\nabla }{p_f} + \dfrac{\boldsymbol{F}}{{{\phi _s}{\rho _s}}}, \end{array}\end{gather}

\begin{gather}\begin{array}{ccccc} \dfrac{{\textrm{d}{\boldsymbol{u}_s}}}{{\textrm{d}t}} & ={-} [({\boldsymbol{u}_s} - {\boldsymbol{u}_f})\boldsymbol{\cdot }\boldsymbol{\nabla }]{\boldsymbol{u}_s} + \dfrac{1}{{{\phi _s}{\rho _s}}}\boldsymbol{\nabla }\boldsymbol{\cdot }({\phi _s}{\boldsymbol{\sigma }_s}) + \boldsymbol{g} + \dfrac{1}{{{\phi _s}{\rho _s}}}\boldsymbol{\nabla }\boldsymbol{\cdot }({\phi _s}\boldsymbol{\sigma }_s^t)\\ & \quad - \dfrac{1}{{{\rho _s}}}\boldsymbol{\nabla }{p_f} + \dfrac{\boldsymbol{F}}{{{\phi _s}{\rho _s}}}, \end{array}\end{gather}and those of the interstitial fluid phase are

In the equations, ![]() ${\rho _f}$,

${\rho _f}$, ![]() ${\boldsymbol{u}_f}$ and

${\boldsymbol{u}_f}$ and ![]() ${\phi _f}$ are respectively the density, velocity and volumetric fraction of the fluid phase; and

${\phi _f}$ are respectively the density, velocity and volumetric fraction of the fluid phase; and ![]() ${\boldsymbol{\tau}_f}$ and

${\boldsymbol{\tau}_f}$ and ![]() $\boldsymbol{\tau }_f^t$ are the kinetic and the turbulent shear stresses of the fluid phase, respectively. The other notations have the same meaning as in § 2. For any physical variable X,

$\boldsymbol{\tau }_f^t$ are the kinetic and the turbulent shear stresses of the fluid phase, respectively. The other notations have the same meaning as in § 2. For any physical variable X, ![]() $\textrm{d}X/\textrm{d}t = \partial X/\partial t + ({\boldsymbol{u}_f}\boldsymbol{\cdot }\boldsymbol{\nabla })X$. This indicates that the velocity of a SPH particle is set to be the same as the fluid velocity it carries. When concerning saturated granular flows, we have

$\textrm{d}X/\textrm{d}t = \partial X/\partial t + ({\boldsymbol{u}_f}\boldsymbol{\cdot }\boldsymbol{\nabla })X$. This indicates that the velocity of a SPH particle is set to be the same as the fluid velocity it carries. When concerning saturated granular flows, we have ![]() ${\phi _s} + {\phi _f} = 1$.

${\phi _s} + {\phi _f} = 1$.

The constitutive law integrating the present dilatation/contraction formulation is used to determine the inter-grain stress of the solid phase as

\begin{align}{\boldsymbol{\sigma }_s} & = 2{\rho _s}{\nu _s}{\boldsymbol{S}_s} - {p_s}\boldsymbol{I} = 2{\rho _s}{\nu _s}{\boldsymbol{S}_s}\nonumber\\ & \quad - \left\{ {p_{s0}^e\,\textrm{exp}\left[ {{c_1}K\dfrac{{\chi {\phi_s}}}{{{\phi_s} - {\phi_ \ast }}}({\phi_s} - {\phi_c})I_d^{{c_2}}} \right] + 2{{\left( {\dfrac{{{c_3}{\phi_s}}}{{{\phi_0} - {\phi_s}}}} \right)}^2}({{\rho_f}{\nu_f} + 2{c_4}{\rho_s}d_s^2||{{\boldsymbol{S}_s}} ||} )||{{\boldsymbol{S}_s}} ||} \right\}\boldsymbol{I}, \end{align}

\begin{align}{\boldsymbol{\sigma }_s} & = 2{\rho _s}{\nu _s}{\boldsymbol{S}_s} - {p_s}\boldsymbol{I} = 2{\rho _s}{\nu _s}{\boldsymbol{S}_s}\nonumber\\ & \quad - \left\{ {p_{s0}^e\,\textrm{exp}\left[ {{c_1}K\dfrac{{\chi {\phi_s}}}{{{\phi_s} - {\phi_ \ast }}}({\phi_s} - {\phi_c})I_d^{{c_2}}} \right] + 2{{\left( {\dfrac{{{c_3}{\phi_s}}}{{{\phi_0} - {\phi_s}}}} \right)}^2}({{\rho_f}{\nu_f} + 2{c_4}{\rho_s}d_s^2||{{\boldsymbol{S}_s}} ||} )||{{\boldsymbol{S}_s}} ||} \right\}\boldsymbol{I}, \end{align}and

The combined dimensionless number for immersed granular flows, ![]() ${I_m}$, is calculated by (3.18), which is recalled here as

${I_m}$, is calculated by (3.18), which is recalled here as

Here ![]() ${\boldsymbol{S}_s}$ is defined as in (2.4) and

${\boldsymbol{S}_s}$ is defined as in (2.4) and ![]() $||{{\boldsymbol{S}_s}} ||= \sqrt {{\boldsymbol{S}_s}:{\boldsymbol{S}_s}/2}$. The notations have the same meaning as in §§ 2 and 3. The frictional solid pressure without the dilatation/contraction effect

$||{{\boldsymbol{S}_s}} ||= \sqrt {{\boldsymbol{S}_s}:{\boldsymbol{S}_s}/2}$. The notations have the same meaning as in §§ 2 and 3. The frictional solid pressure without the dilatation/contraction effect ![]() $p_{s0}^e$ can be determined by (3.7), which is a general form of the existing formulae for

$p_{s0}^e$ can be determined by (3.7), which is a general form of the existing formulae for ![]() $p_{s0}^e$. However, for comparison with the model of Shi et al. (Reference Shi, Si, Dong and Yu2019) excluding the frictional dilatation/contraction effect, the formula of

$p_{s0}^e$. However, for comparison with the model of Shi et al. (Reference Shi, Si, Dong and Yu2019) excluding the frictional dilatation/contraction effect, the formula of ![]() $p_{s0}^e$ adopted in Shi et al. (Reference Shi, Si, Dong and Yu2019) is also used in this section. It is shown as

$p_{s0}^e$ adopted in Shi et al. (Reference Shi, Si, Dong and Yu2019) is also used in this section. It is shown as

\begin{equation}p_{s0}^e = \left\{ {\begin{array}{@{}ll} {G{{({\phi_s} - {\phi_ \ast })}^\chi }\left[ {1 + \sin \left( {\dfrac{{{\phi_s} - {\phi_ \ast }}}{{{\phi^ \ast } - {\phi_ \ast }}}\pi - \dfrac{\pi }{2}} \right)} \right]}&{{\phi_s} \gt {\phi_ \ast }}\\ 0&{{\phi_s} \le {\phi_ \ast }} \end{array}} \right.,\end{equation}

\begin{equation}p_{s0}^e = \left\{ {\begin{array}{@{}ll} {G{{({\phi_s} - {\phi_ \ast })}^\chi }\left[ {1 + \sin \left( {\dfrac{{{\phi_s} - {\phi_ \ast }}}{{{\phi^ \ast } - {\phi_ \ast }}}\pi - \dfrac{\pi }{2}} \right)} \right]}&{{\phi_s} \gt {\phi_ \ast }}\\ 0&{{\phi_s} \le {\phi_ \ast }} \end{array}} \right.,\end{equation}

where ![]() ${\phi ^ \ast }$ is the random close-packing volume fraction of the granular assembly. The difference between (5.9) and (3.7) is simply the inclusion of the volume fraction

${\phi ^ \ast }$ is the random close-packing volume fraction of the granular assembly. The difference between (5.9) and (3.7) is simply the inclusion of the volume fraction ![]() ${\phi _s}$ for the compressibility of grains. This inclusion only leads to a minor difference in the values of

${\phi _s}$ for the compressibility of grains. This inclusion only leads to a minor difference in the values of ![]() $\chi $ and has no notable effect on the results.

$\chi $ and has no notable effect on the results.

The stress of the solid phase induced by interstitial fluid turbulence ![]() $\boldsymbol{\sigma }_s^t$ is usually neglected in subaerial granular flows. In submerged cases, it is expressed as

$\boldsymbol{\sigma }_s^t$ is usually neglected in subaerial granular flows. In submerged cases, it is expressed as

in which ![]() $\nu _s^t$ and

$\nu _s^t$ and ![]() $p_s^t$ are respectively the turbulent viscosity and pressure of the solid phase, which indicate the effects of interstitial fluid turbulence on grains. In dense granular flows,

$p_s^t$ are respectively the turbulent viscosity and pressure of the solid phase, which indicate the effects of interstitial fluid turbulence on grains. In dense granular flows, ![]() $p_s^t$ is generally much smaller than

$p_s^t$ is generally much smaller than ![]() ${p_s}$ and can therefore be neglected (Bouchut et al. Reference Bouchut, Fernández-Nieto, Mangeney and Narbona-Reina2016; Baumgarten & Kamrin Reference Baumgarten and Kamrin2019). The turbulent viscosity

${p_s}$ and can therefore be neglected (Bouchut et al. Reference Bouchut, Fernández-Nieto, Mangeney and Narbona-Reina2016; Baumgarten & Kamrin Reference Baumgarten and Kamrin2019). The turbulent viscosity ![]() $\nu _s^t$ is estimated by the Smagorinsky turbulence model in (5.13).

$\nu _s^t$ is estimated by the Smagorinsky turbulence model in (5.13).

The kinetic and the turbulent shear stresses of the fluid phase are formulated as

and

where ![]() ${\nu _f}$ is the fluid kinematic viscosity and

${\nu _f}$ is the fluid kinematic viscosity and ![]() $\nu _f^t$ is the turbulent viscosity of the fluid phase. Here

$\nu _f^t$ is the turbulent viscosity of the fluid phase. Here ![]() $\nu _f^t$, together with the turbulent solid viscosity

$\nu _f^t$, together with the turbulent solid viscosity ![]() $\nu _s^t$, is estimated by the Smagorinsky model proposed in Dalrymple & Rogers (Reference Dalrymple and Rogers2006) but integrated with a modification for the turbulence damping by solid particles. It is shown as

$\nu _s^t$, is estimated by the Smagorinsky model proposed in Dalrymple & Rogers (Reference Dalrymple and Rogers2006) but integrated with a modification for the turbulence damping by solid particles. It is shown as

in which the subscript ![]() $k = f,\,s$;

$k = f,\,s$; ![]() $\mathrm{\Delta }$ is the size of the SPH particles;

$\mathrm{\Delta }$ is the size of the SPH particles; ![]() ${C_{S,k}}$ is the Smagorinsky coefficient and, in this paper, we set

${C_{S,k}}$ is the Smagorinsky coefficient and, in this paper, we set ![]() ${C_{S,f}} = {C_{S,s}} = 0.1$; and the index n is for the effects of turbulence damping by solid particles and

${C_{S,f}} = {C_{S,s}} = 0.1$; and the index n is for the effects of turbulence damping by solid particles and ![]() $n = 5$ is adopted according to Chen et al. (Reference Chen, Li, Niu, Chen and Yu2011) and Shi et al. (Reference Shi, Si, Dong and Yu2019).

$n = 5$ is adopted according to Chen et al. (Reference Chen, Li, Niu, Chen and Yu2011) and Shi et al. (Reference Shi, Si, Dong and Yu2019).

In submerged dense granular flows, the inter-phase force ![]() $\boldsymbol{F}$ can be simplified to include only the drag force that is predominant. The formula proposed by Gidaspow (Reference Gidaspow1994) is adopted to estimate the drag force as