1. Introduction

Soap bubbles made of thin surfactant-laden films have been not only the object of children's play, but also the subject of scientific research since the time of Leonardo da Vinci (Maxwell Reference Maxwell1878; Burkhardt Reference Burkhardt2021). As presently known, soap films – a constituting element of soap bubbles and foams – represent complex phenomena with sophisticated physics governing their existence and dynamics. After Robert Hooke in 1672 brought to the attention of the Royal Society the optical phenomena they exhibit (Birch Reference Birch1757), soap films stimulated the development of the theories of optics (Newton Reference Newton1704), capillarity (Plateau Reference Plateau1873) including thin-film drainage (Gibbs 1928, Reference Gibbs1931), and minimal surfaces (Plateau Reference Plateau1873; Douglas Reference Douglas1931; Courant & Robbins Reference Courant and Robbins1941; Almgren & Taylor Reference Almgren and Taylor1976). At the same time, soap films served as a tool for detecting the magnetism of gases (Faraday Reference Faraday1851), as an analogue computer for solving boundary-value problems (Prandtl Reference Prandtl1903; Johnston Reference Johnston1935), and in elucidating a number of problems in surface and colloid chemistry (Mysels Reference Mysels1964), such as phase transitions in monolayers and film elasticity. Owing to a high degree of two-dimensionality, soap or other freely suspended thin liquid films have also been used for studying hydrodynamics and turbulence (Couder, Chomaz & Rabaud Reference Couder, Chomaz and Rabaud1989; Gharib & Derango Reference Gharib and Derango1989) in two dimensions as well as shock wave (SW) dynamics (Wen, Chang-Jian & Chuang Reference Wen, Chang-Jian and Chuang2003), since certain features of the soap film flow do resemble those anticipated for a true planar flow. The never-ending interest in thought-provoking soap film phenomena is not only reflected in comprehensive review articles (Mysels, Shinoda & Frankel Reference Mysels, Shinoda and Frankel1959; Rusanov & Krotov Reference Rusanov and Krotov1979), but also culminated in popularizing books (Boys Reference Boys1890; Isenberg Reference Isenberg1992).

In the context of prehistory to the present study, it should be mentioned that McEntee & Mysels (Reference McEntee and Mysels1969), who studied bursting soap films using high-speed flash photography, revealed the presence of a precursor SW preceding the expanding hole in a punctured film. The disturbed region of shrinking film material in between the SW and the hole is usually referred to as the ‘aureole’, which was shown (Frankel & Mysels Reference Frankel and Mysels1969) to be related to large variations in surface tension as the film retracts and thickens. These important observations overturned some misconceptions regarding the bursting process in earlier theoretical and experimental works (Dupré Reference Dupré1867; Plateau Reference Plateau1873), which assumed that a rolled-up rim collects all of the disappearing film, leaving the rest of the film undisturbed (Taylor Reference Taylor1959b). In the present study, we report new phenomena associated with the aureole and offer theoretical insights into the underlying mechanisms.

The paper is organized as follows. In § 2 we discuss the experimental platform and the preparation of the soap solutions. Experimental observations of folds on soap films and detailed measurements of the kinematic conditions under which the phenomena occur are reported in § 3.1. The discussion of possible underlying mechanisms in § 3.2 accompanied by extra experiments testing the effect of the soap film frame geometry leads to a paradox, which is resolved theoretically in § 4 by modelling the soap film dynamics and analysing the corresponding governing equations. Further discussion of the underlying mechanisms in § 5 reveals that the appearance of folds can be interpreted under the umbrella of catastrophe theory.

2. Experimental apparatus and procedure

The main components of the experimental set-up shown schematically in figure 1 include the wire frame, its withdrawal mechanism for creating the soap film (not shown), film thickness measurement system, film release electrical circuit by Joule heating (Mayer & Krechetnikov Reference Mayer and Krechetnikov2017) and high-speed visualization.

Figure 1. The experimental apparatus. Once a capacitor (C) is charged with a high-voltage power supply (HV), a low-voltage power supply (V) sends a 5 V trigger signal to a pulse/delay generator (BNC), which, after a precisely predefined delay, sends a triggering signal to the high-speed camera and thyristor (SCR). Then, the high-speed camera starts recording and the thyristor releases the energy stored in the capacitor to the wire frame and the soap film retracts due to instant boiling on the wire. Before the soap film retraction stage, the thickness of the soap film is measured using a spectrometer consisting of light source, emitter lens and collector.

To achieve a wide range of dynamic viscosities ![]() $\mu =1.16 - 2.13\ \textrm {mPa}\ \textrm {s}$, surface tensions

$\mu =1.16 - 2.13\ \textrm {mPa}\ \textrm {s}$, surface tensions ![]() $\sigma =35 - 47.6\ \textrm {mN}\ \textrm {m}^{-1}$ and film thicknesses

$\sigma =35 - 47.6\ \textrm {mN}\ \textrm {m}^{-1}$ and film thicknesses ![]() $h_{\infty }=4.6 - 19.3\ {\mathrm {\mu }}\mathrm {m}$, we prepared soap solutions using ultrapure water (Millipore Direct-Q 3UV-R) with various concentrations of glycerol (

$h_{\infty }=4.6 - 19.3\ {\mathrm {\mu }}\mathrm {m}$, we prepared soap solutions using ultrapure water (Millipore Direct-Q 3UV-R) with various concentrations of glycerol (![]() $C_g = 5 - 25\,{\%}\, \mathrm {wt}$) and an anionic surfactant, sodium dodecyl sulphate (SDS;

$C_g = 5 - 25\,{\%}\, \mathrm {wt}$) and an anionic surfactant, sodium dodecyl sulphate (SDS; ![]() $C=0.5 - 1.25$ of the critical micelle concentration, CMC) with purity

$C=0.5 - 1.25$ of the critical micelle concentration, CMC) with purity ![]() $\geq 99.5\,{\%}$ (Sigma-Aldrich 75746) as well as five different wire frame withdrawal velocities

$\geq 99.5\,{\%}$ (Sigma-Aldrich 75746) as well as five different wire frame withdrawal velocities ![]() $V$ in the range

$V$ in the range ![]() $5 - 16.1\ \mathrm {mm}\ \mathrm {s}^{-1}$. SDS was chosen for several reasons, one being that it is well characterized and has been used in a number of fluid interface studies (Mysels & Cox Reference Mysels and Cox1962; Lyklema, Scholten & Mysels Reference Lyklema, Scholten and Mysels1965; McEntee & Mysels Reference McEntee and Mysels1969; Evers, Shulepov & Frens Reference Evers, Shulepov and Frens1996; Huibers & Shah Reference Huibers and Shah1997; Berg, Adelizzi & Troian Reference Berg, Adelizzi and Troian2005). While the primary use of glycerol is to stabilize the soap film (Mayer & Krechetnikov Reference Mayer and Krechetnikov2017) and control its thickness, the addition of glycerol may also lead to extraneous ramifications, such as affecting the characteristic time

$5 - 16.1\ \mathrm {mm}\ \mathrm {s}^{-1}$. SDS was chosen for several reasons, one being that it is well characterized and has been used in a number of fluid interface studies (Mysels & Cox Reference Mysels and Cox1962; Lyklema, Scholten & Mysels Reference Lyklema, Scholten and Mysels1965; McEntee & Mysels Reference McEntee and Mysels1969; Evers, Shulepov & Frens Reference Evers, Shulepov and Frens1996; Huibers & Shah Reference Huibers and Shah1997; Berg, Adelizzi & Troian Reference Berg, Adelizzi and Troian2005). While the primary use of glycerol is to stabilize the soap film (Mayer & Krechetnikov Reference Mayer and Krechetnikov2017) and control its thickness, the addition of glycerol may also lead to extraneous ramifications, such as affecting the characteristic time ![]() $\tau$ of settling the edge retraction velocity

$\tau$ of settling the edge retraction velocity ![]() $U_{{TC}}$ (Savva & Bush Reference Savva and Bush2009) and the kinetics of SDS (Khan et al. Reference Khan, Seddon, Law, Brooks, Robles, Cabral and Ces2019). With regard to the former effect, for the glycerol concentrations used in our experiments, the associated Ohnesorge numbers are low,

$U_{{TC}}$ (Savva & Bush Reference Savva and Bush2009) and the kinetics of SDS (Khan et al. Reference Khan, Seddon, Law, Brooks, Robles, Cabral and Ces2019). With regard to the former effect, for the glycerol concentrations used in our experiments, the associated Ohnesorge numbers are low, ![]() $Oh = \mu /\sqrt {2 h_{\infty } \rho \sigma } < 0.1$, with

$Oh = \mu /\sqrt {2 h_{\infty } \rho \sigma } < 0.1$, with ![]() $\rho$ being the density of the liquid, so the time scale

$\rho$ being the density of the liquid, so the time scale ![]() $\tau$ is dictated by the inviscid dynamics,

$\tau$ is dictated by the inviscid dynamics, ![]() $\tau _{{inv}} = \sqrt {\rho h_{\infty }^{3}/\sigma } = O(10)\ \mathrm {\mu }\mathrm {s}$, since the viscous time scale is much shorter,

$\tau _{{inv}} = \sqrt {\rho h_{\infty }^{3}/\sigma } = O(10)\ \mathrm {\mu }\mathrm {s}$, since the viscous time scale is much shorter, ![]() $\tau _{{visc}} = \mu h_{\infty } /2 \sigma = O(0.1)\ \mathrm {\mu }\mathrm {s}$. As for the latter effect, the CMC of SDS increases with addition of glycerol, though this change is insignificant for the concentrations used in our experiments: CMC changes in the range 8.05–8.20 for

$\tau _{{visc}} = \mu h_{\infty } /2 \sigma = O(0.1)\ \mathrm {\mu }\mathrm {s}$. As for the latter effect, the CMC of SDS increases with addition of glycerol, though this change is insignificant for the concentrations used in our experiments: CMC changes in the range 8.05–8.20 for ![]() $C_{g}=0-20\,\%$ (cf. Carnero Ruiz, Diaz-Lopez & Aguiar Reference Carnero Ruiz, Diaz-Lopez and Aguiar2008), though alternative measurements by Khan et al. (Reference Khan, Seddon, Law, Brooks, Robles, Cabral and Ces2019) suggest that the CMC decreases with glycerol added up to

$C_{g}=0-20\,\%$ (cf. Carnero Ruiz, Diaz-Lopez & Aguiar Reference Carnero Ruiz, Diaz-Lopez and Aguiar2008), though alternative measurements by Khan et al. (Reference Khan, Seddon, Law, Brooks, Robles, Cabral and Ces2019) suggest that the CMC decreases with glycerol added up to ![]() $C_{g} = 20\,\%$. The change of CMC in turn affects the adsorption isotherm; cf. figure 2(a) in Fernandez, Krechetnikov & Homsy (Reference Fernandez, Krechetnikov and Homsy2005) or figure 5 in Tajima, Muramatsu & Sasaki (Reference Tajima, Muramatsu and Sasaki1970).

$C_{g} = 20\,\%$. The change of CMC in turn affects the adsorption isotherm; cf. figure 2(a) in Fernandez, Krechetnikov & Homsy (Reference Fernandez, Krechetnikov and Homsy2005) or figure 5 in Tajima, Muramatsu & Sasaki (Reference Tajima, Muramatsu and Sasaki1970).

The soap film is formed on a continuous conducting wire (NiC 60, Pelican Wire Co.) with well-characterized properties (Incropera & DeWitt Reference Incropera and DeWitt2002), which is strung around four aluminium posts (DU-BRO brand E/Z connectors) forming the frame capable of adjusting different aspect ratios of a rectangular geometry ![]() $l_1 \times l_2$, though in most of the reported experiments a square frame was employed with side

$l_1 \times l_2$, though in most of the reported experiments a square frame was employed with side ![]() $l = 50\ \mathrm {mm}$. The wire ends are held in place using a clamp manually adjusted to have the wire frame aptly tensioned. Two different configurations of the wire mounted at the corners are used to study the effect of sharp (A) and round (B) corners on the outcome of the soap film patterns. The soap film withdrawal mechanism was contrived and built with the help of two precision stepper motor assemblies (linear Velmex BiSlide and rotary Velmex B5990TS), which are controlled and programmed by Velmex COSMOS software, in order to perform two major tasks: (i) to raise and lower the bath with a soap film solution while keeping the frame stationary (tantamount to dipping the frame assembly in a bath with soap solution and withdrawing it at a known predefined speed); and (ii) to rotate the fresh soap film formed on the wire frame to a horizontal position. The horizontal orientation of the soap film was preferred to minimize gradual thinning due to gravity, which was already known and described by Newton (Reference Newton1704).

$l = 50\ \mathrm {mm}$. The wire ends are held in place using a clamp manually adjusted to have the wire frame aptly tensioned. Two different configurations of the wire mounted at the corners are used to study the effect of sharp (A) and round (B) corners on the outcome of the soap film patterns. The soap film withdrawal mechanism was contrived and built with the help of two precision stepper motor assemblies (linear Velmex BiSlide and rotary Velmex B5990TS), which are controlled and programmed by Velmex COSMOS software, in order to perform two major tasks: (i) to raise and lower the bath with a soap film solution while keeping the frame stationary (tantamount to dipping the frame assembly in a bath with soap solution and withdrawing it at a known predefined speed); and (ii) to rotate the fresh soap film formed on the wire frame to a horizontal position. The horizontal orientation of the soap film was preferred to minimize gradual thinning due to gravity, which was already known and described by Newton (Reference Newton1704).

Once the soap film is positioned horizontally, after ![]() ${\sim }1\ \mathrm {s}$ two steps take place in parallel (the delay is to let the soap film stabilize in the horizontal orientation and relax possible motions in the film caused during the rotation step). First, the soap film is released by impulsive Joule heating of the frame wire (Mayer & Krechetnikov Reference Mayer and Krechetnikov2017). The energy required for the impulsive heating is stored in a capacitor (C) and delivered to the wire through a thyristor (SCR) in a single high-voltage 2.4 kV electrical pulse. A schematic diagram of the electrical circuit used in the experimental set-up is shown in figure 1. The conducting soap film frame forms two parallel resistors of total resistance

${\sim }1\ \mathrm {s}$ two steps take place in parallel (the delay is to let the soap film stabilize in the horizontal orientation and relax possible motions in the film caused during the rotation step). First, the soap film is released by impulsive Joule heating of the frame wire (Mayer & Krechetnikov Reference Mayer and Krechetnikov2017). The energy required for the impulsive heating is stored in a capacitor (C) and delivered to the wire through a thyristor (SCR) in a single high-voltage 2.4 kV electrical pulse. A schematic diagram of the electrical circuit used in the experimental set-up is shown in figure 1. The conducting soap film frame forms two parallel resistors of total resistance ![]() $1.2\times 10^{-6}\ \Omega \ \mathrm {m}$. Two high-voltage capacitors (Condenser Products MQP105-5MN, 1 mF, 5 kV), which are connected in series to form C, are charged with a high-voltage power supply (HV; Matsusada, EQ-30P1-LG) to the desired value

$1.2\times 10^{-6}\ \Omega \ \mathrm {m}$. Two high-voltage capacitors (Condenser Products MQP105-5MN, 1 mF, 5 kV), which are connected in series to form C, are charged with a high-voltage power supply (HV; Matsusada, EQ-30P1-LG) to the desired value ![]() $\varphi =2.4\ \mathrm {kV}$. Upon charging, a low-voltage power supply (V; Instek GPD-3303S) sends a 5 V electrical signal to a pulse/delay generator (BNC; Berkeley Nucleonics Corp., Model 575). Second, after some delay precisely set by the BNC, a 5 V trigger pulse is sent to the high-speed camera (Vision Research, Phantom V5.2) and the thyristor SCR (Astrol Electronics AG, AC-10140-001). The camera starts recording upon receiving the trigger pulse and the thyristor closes the circuit, thus delivering the energy stored in the capacitor C to the wire frame. For visualization with high-speed photography, a back-lighting technique has been used: after the light emitted from the light source (a light-emitting diode (LED) lamp, LEDTronics PAR 38-12x2W-XPW-001S) passes through the optical diffuser plate and the soap film area of interest, it is reflected by the mirror positioned at

$\varphi =2.4\ \mathrm {kV}$. Upon charging, a low-voltage power supply (V; Instek GPD-3303S) sends a 5 V electrical signal to a pulse/delay generator (BNC; Berkeley Nucleonics Corp., Model 575). Second, after some delay precisely set by the BNC, a 5 V trigger pulse is sent to the high-speed camera (Vision Research, Phantom V5.2) and the thyristor SCR (Astrol Electronics AG, AC-10140-001). The camera starts recording upon receiving the trigger pulse and the thyristor closes the circuit, thus delivering the energy stored in the capacitor C to the wire frame. For visualization with high-speed photography, a back-lighting technique has been used: after the light emitted from the light source (a light-emitting diode (LED) lamp, LEDTronics PAR 38-12x2W-XPW-001S) passes through the optical diffuser plate and the soap film area of interest, it is reflected by the mirror positioned at ![]() $45^{\circ }$ into the high-speed camera. Since the time of the soap film retraction is

$45^{\circ }$ into the high-speed camera. Since the time of the soap film retraction is ![]() ${<}10\ \mathrm {ms}$, it was recorded at different frame rates (3000–5000 f.p.s.), exposure times (

${<}10\ \mathrm {ms}$, it was recorded at different frame rates (3000–5000 f.p.s.), exposure times (![]() ${\sim }30 - 100\ \mathrm {\mu }\mathrm {s}$) and resolutions by the high-speed camera with 35 mm and 55 mm Nikkor lens. For the particle image velocimetry (PIV) experiments, a dual-pulse Nd:YAG laser (Evergreen 200 mJ) served as a light source along with a 20X Arcturus

${\sim }30 - 100\ \mathrm {\mu }\mathrm {s}$) and resolutions by the high-speed camera with 35 mm and 55 mm Nikkor lens. For the particle image velocimetry (PIV) experiments, a dual-pulse Nd:YAG laser (Evergreen 200 mJ) served as a light source along with a 20X Arcturus![]() $^{TM}$ HeNe beam expander.

$^{TM}$ HeNe beam expander.

For evaluation of the steady retraction speed ![]() $U_{{TC}}=\sqrt {2\sigma /{\rho }{h_{\infty }}}$ of a soap film (Culick Reference Culick1960; Taylor Reference Taylor1959a), one needs to know its thickness

$U_{{TC}}=\sqrt {2\sigma /{\rho }{h_{\infty }}}$ of a soap film (Culick Reference Culick1960; Taylor Reference Taylor1959a), one needs to know its thickness ![]() $h_{\infty }$. However, despite being previously tested over a wide range of bulk and surface viscosities (Mysels & Cox Reference Mysels and Cox1962), Frankel's law (Mysels et al. Reference Mysels, Shinoda and Frankel1959), i.e.

$h_{\infty }$. However, despite being previously tested over a wide range of bulk and surface viscosities (Mysels & Cox Reference Mysels and Cox1962), Frankel's law (Mysels et al. Reference Mysels, Shinoda and Frankel1959), i.e. ![]() $h_{\infty }=1.88 \sqrt {\sigma /\rho g} (\mu V /\sigma )^{2/3}$ for the thickness of a uniform film created in gravitational field

$h_{\infty }=1.88 \sqrt {\sigma /\rho g} (\mu V /\sigma )^{2/3}$ for the thickness of a uniform film created in gravitational field ![]() $g$ by vertical withdrawal of a wire frame with velocity

$g$ by vertical withdrawal of a wire frame with velocity ![]() $V$ from a bath with surfactant solution having bulk viscosity

$V$ from a bath with surfactant solution having bulk viscosity ![]() $\mu$ and surface tension

$\mu$ and surface tension ![]() $\sigma$, demonstrates significant deviations. The deviations can be caused by drainage when the soap frame is in a vertical position in the stage of withdrawal or when the surfactant film is not expected (Adelizzi & Troian Reference Adelizzi and Troian2004) to be inextensible (though flexible) at

$\sigma$, demonstrates significant deviations. The deviations can be caused by drainage when the soap frame is in a vertical position in the stage of withdrawal or when the surfactant film is not expected (Adelizzi & Troian Reference Adelizzi and Troian2004) to be inextensible (though flexible) at ![]() $Ca \equiv \mu V /\sigma \gtrsim 10^{-3}$, thus violating the central assumption in the Frankel's law derivation.

$Ca \equiv \mu V /\sigma \gtrsim 10^{-3}$, thus violating the central assumption in the Frankel's law derivation.

The range of the capillary numbers ![]() $Ca$ in our experiments is

$Ca$ in our experiments is ![]() $O(10^{-4} - 10^{-3})$. Therefore, an independent film thickness measurement was performed for all test conditions, in particular in order to evaluate theoretically the terminal velocity of the soap film retraction and various wave propagation velocities for comparison with the corresponding experimental values. Measurements of the soap film thickness were performed with the help of a collimated broadband light source (Dolan Jenner MI-150) as a light emitter, and a collimating lens/fibre optic cable (Thorlabs M25L02) as a collector of the light transmitted through the soap film, which in turn sends an optical signal to an ultraviolet–visible (UV-VIS) spectrometer (Ocean Optics USB4000-UV-VIS). A detailed explanation of the soap film thickness measurement can be found in Mayer & Krechetnikov (Reference Mayer and Krechetnikov2017). For each test condition, the measurement was repeated three times and the average value reported, with the maximum deviation being

$O(10^{-4} - 10^{-3})$. Therefore, an independent film thickness measurement was performed for all test conditions, in particular in order to evaluate theoretically the terminal velocity of the soap film retraction and various wave propagation velocities for comparison with the corresponding experimental values. Measurements of the soap film thickness were performed with the help of a collimated broadband light source (Dolan Jenner MI-150) as a light emitter, and a collimating lens/fibre optic cable (Thorlabs M25L02) as a collector of the light transmitted through the soap film, which in turn sends an optical signal to an ultraviolet–visible (UV-VIS) spectrometer (Ocean Optics USB4000-UV-VIS). A detailed explanation of the soap film thickness measurement can be found in Mayer & Krechetnikov (Reference Mayer and Krechetnikov2017). For each test condition, the measurement was repeated three times and the average value reported, with the maximum deviation being ![]() ${\sim }1\ {\mathrm {\mu }}\mathrm {m}$ in all cases.

${\sim }1\ {\mathrm {\mu }}\mathrm {m}$ in all cases.

3. Experiments

3.1. Observations

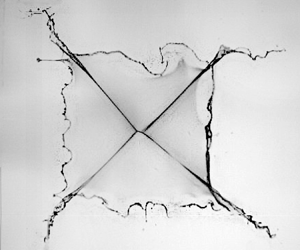

In the course of repeating our earlier experiments to free up soap films from a rectangular wire frame (Mayer & Krechetnikov Reference Mayer and Krechetnikov2010a,Reference Mayer and Krechetnikovb, Reference Mayer and Krechetnikov2017), we encountered the phenomena shown in figure 2, where two outcome patterns can be distinguished: (a) fold and (b) no-fold. While the fold may appear as a standing SW, it proves to be not so. In the fold pattern, SW-like lines along the soap film diagonal are formed shortly (![]() ${\sim }1\ \mathrm {ms}$) after the soap film is released from the wire frame. The folds propagate along the diagonal until they merge at the centre of the film (cf. figure 2a). In the no-fold pattern, the soap film simply retracts with the microdroplets dispatched from the soap film boundaries. Notably, the soap film retracts faster in the case of the no-fold pattern, which is especially evident at

${\sim }1\ \mathrm {ms}$) after the soap film is released from the wire frame. The folds propagate along the diagonal until they merge at the centre of the film (cf. figure 2a). In the no-fold pattern, the soap film simply retracts with the microdroplets dispatched from the soap film boundaries. Notably, the soap film retracts faster in the case of the no-fold pattern, which is especially evident at ![]() $6460\ {\mathrm {\mu }}s$ by juxtaposing surface area of the soap films – the distinction being due to different values of soap film thickness.

$6460\ {\mathrm {\mu }}s$ by juxtaposing surface area of the soap films – the distinction being due to different values of soap film thickness.

Figure 2. Fold (a) versus no-fold (b) patterns. (a) Time sequence of the soap film retraction with developing folds along the diagonal of the soap film surface. Soap film solution properties: ![]() $0.5\ \mathrm {CMC}$ of

$0.5\ \mathrm {CMC}$ of ![]() $\mathrm {SDS}$,

$\mathrm {SDS}$, ![]() $20\,{\%}\,\mathrm {wt}$ glycerol; soap film thickness and withdrawal velocity are

$20\,{\%}\,\mathrm {wt}$ glycerol; soap film thickness and withdrawal velocity are ![]() $16.9\ {\mathrm {\mu }}\mathrm {m}$ and

$16.9\ {\mathrm {\mu }}\mathrm {m}$ and ![]() $12.4\ \mathrm {mm}\ \mathrm {s}^{-1}$, respectively. (b) Time sequence of the soap film retraction without folds. Soap film solution properties:

$12.4\ \mathrm {mm}\ \mathrm {s}^{-1}$, respectively. (b) Time sequence of the soap film retraction without folds. Soap film solution properties: ![]() $1.25\ \mathrm {CMC}$ of

$1.25\ \mathrm {CMC}$ of ![]() $\mathrm {SDS}$,

$\mathrm {SDS}$, ![]() $20\,{\%}\, \mathrm {wt}$ glycerol; soap film thickness and withdrawal velocity are

$20\,{\%}\, \mathrm {wt}$ glycerol; soap film thickness and withdrawal velocity are ![]() $8.5\ {\mathrm {\mu }}\mathrm {m}$ and

$8.5\ {\mathrm {\mu }}\mathrm {m}$ and ![]() $12.4\ \mathrm {mm}\ \mathrm {s}^{-1}$, respectively. The physical image size in both sets of panels is

$12.4\ \mathrm {mm}\ \mathrm {s}^{-1}$, respectively. The physical image size in both sets of panels is ![]() $50\ \mathrm {mm} \times 50\ \mathrm {mm}$.

$50\ \mathrm {mm} \times 50\ \mathrm {mm}$.

It is known that the dynamics of the collapsing soap film is dictated by the soap solution properties (viscosity, surface tension, etc.) and the film thickness (Mysels et al. Reference Mysels, Shinoda and Frankel1959; Couder et al. Reference Couder, Chomaz and Rabaud1989; Brenner & Gueyffier Reference Brenner and Gueyffier1999; Savva & Bush Reference Savva and Bush2009). Therefore, a number of experiments were carried out to understand the transition between the fold and no-fold regimes depending upon the values of these parameters in a wide range, though limited by the soap film lifetime necessary to conduct the experiments. For that, the soap solution properties and withdrawal speed were varied as described in § 2. The corresponding maps of the transition in terms of glycerol concentration ![]() $C_{g}$ with respect to the soap film thickness

$C_{g}$ with respect to the soap film thickness ![]() $h_{\infty }$ are shown in figure 3. The variation in the soap film thickness along the horizontal axis is due to the change in the bath lowering speed. As evident from this figure by increasing SDS concentration the thickness of the soap film decreases, and the resultant pattern transitions from a fold to a no-fold.

$h_{\infty }$ are shown in figure 3. The variation in the soap film thickness along the horizontal axis is due to the change in the bath lowering speed. As evident from this figure by increasing SDS concentration the thickness of the soap film decreases, and the resultant pattern transitions from a fold to a no-fold.

Figure 3. Maps of fold (![]() $\times$) and no-fold (

$\times$) and no-fold (![]() $\square$) patterns with respect to the soap film thickness for five different concentrations of glycerol,

$\square$) patterns with respect to the soap film thickness for five different concentrations of glycerol, ![]() $C_g = 5,\ 10,\ 15,\ 20,\ 25\,\%\, wt$ and four concentrations of surfactant: (a) 0.5, (b) 0.75, (c) 1 and (d) 1.25 CMC.

$C_g = 5,\ 10,\ 15,\ 20,\ 25\,\%\, wt$ and four concentrations of surfactant: (a) 0.5, (b) 0.75, (c) 1 and (d) 1.25 CMC.

To properly understand the physics underlying the fold to no-fold transition, the data in figure 3 are replotted in figure 4 in the key velocity coordinates. This figure demonstrates the relation between theoretically estimated one-dimensional wave propagation speed ![]() $c_{0} = \sqrt {2 E / \rho h_{\infty }}$, arising due to film Marangoni elasticity (Couder et al. Reference Couder, Chomaz and Rabaud1989), and one-dimensional soap film retraction speed

$c_{0} = \sqrt {2 E / \rho h_{\infty }}$, arising due to film Marangoni elasticity (Couder et al. Reference Couder, Chomaz and Rabaud1989), and one-dimensional soap film retraction speed ![]() $U_{{TC}} = \sqrt {2 \sigma / \rho h_{\infty }}$, calculated based on experimental values of the soap film surface tension

$U_{{TC}} = \sqrt {2 \sigma / \rho h_{\infty }}$, calculated based on experimental values of the soap film surface tension ![]() $\sigma$, thickness

$\sigma$, thickness ![]() $h_{\infty }$ and elasticity

$h_{\infty }$ and elasticity ![]() $E=-2\,\mathrm {d}\sigma /\mathrm {d}\ln \varGamma$, where

$E=-2\,\mathrm {d}\sigma /\mathrm {d}\ln \varGamma$, where ![]() $\varGamma$ is surfactant surface concentration. Data for surface tension

$\varGamma$ is surfactant surface concentration. Data for surface tension ![]() $\sigma (\varGamma )$ were extracted from the study of Tajima et al. (Reference Tajima, Muramatsu and Sasaki1970). The use of the formula for elasticity in the Marangoni regime, i.e. when the interface shrinkage only increases the surface surfactant concentration

$\sigma (\varGamma )$ were extracted from the study of Tajima et al. (Reference Tajima, Muramatsu and Sasaki1970). The use of the formula for elasticity in the Marangoni regime, i.e. when the interface shrinkage only increases the surface surfactant concentration ![]() $\varGamma$ without affecting the bulk concentration, is justified by the fact that the characteristic time of the interface shrinkage

$\varGamma$ without affecting the bulk concentration, is justified by the fact that the characteristic time of the interface shrinkage ![]() $t_{{exp}} = l/U_{{TC}} = O(10^{-2}) \ \mathrm {s}$ is much shorter than the characteristic times of desorption

$t_{{exp}} = l/U_{{TC}} = O(10^{-2}) \ \mathrm {s}$ is much shorter than the characteristic times of desorption ![]() $t_{d} = k_{d}^{-1} \sim 0.2 \ \mathrm {s}$ and adsorption

$t_{d} = k_{d}^{-1} \sim 0.2 \ \mathrm {s}$ and adsorption ![]() $t_{a} = \varGamma / (k_{a} C) \sim 0.2 \ \mathrm {s}$. The values of the adsorption

$t_{a} = \varGamma / (k_{a} C) \sim 0.2 \ \mathrm {s}$. The values of the adsorption ![]() $k_{a} = 0.64 \times 10^{-5}\ \textrm {m}\ \textrm {s}^{-1}$ and desorption

$k_{a} = 0.64 \times 10^{-5}\ \textrm {m}\ \textrm {s}^{-1}$ and desorption ![]() $k_{d} = 5.87\ \mathrm {s}^{-1}$ coefficients are calculated via fitting (Fernandez et al. Reference Fernandez, Krechetnikov and Homsy2005) the Langmuir–Hinshelwood equation,

$k_{d} = 5.87\ \mathrm {s}^{-1}$ coefficients are calculated via fitting (Fernandez et al. Reference Fernandez, Krechetnikov and Homsy2005) the Langmuir–Hinshelwood equation, ![]() $\mathrm {d}\varGamma / \mathrm {d} t = k_{a} C (1 - \theta ) - k_{d} \varGamma$, with

$\mathrm {d}\varGamma / \mathrm {d} t = k_{a} C (1 - \theta ) - k_{d} \varGamma$, with ![]() $\theta =\varGamma /\varGamma _{m}$ being the fractional coverage and

$\theta =\varGamma /\varGamma _{m}$ being the fractional coverage and ![]() $\varGamma _{m} = 10^{-5}\ \mathrm {mol}\ \mathrm {m}^{-2}$, to the experimental data (Chang & Franses Reference Chang and Franses1992). When the surfactant concentration increases (thus lowering the surface tension) or glycerol concentration decreases (and thus the viscosity as well), the thickness of the soap film decreases and

$\varGamma _{m} = 10^{-5}\ \mathrm {mol}\ \mathrm {m}^{-2}$, to the experimental data (Chang & Franses Reference Chang and Franses1992). When the surfactant concentration increases (thus lowering the surface tension) or glycerol concentration decreases (and thus the viscosity as well), the thickness of the soap film decreases and ![]() $U_{{TC}}$ approaches

$U_{{TC}}$ approaches ![]() $c_{0}$, with the resultant pattern transitioning from fold to no-fold. The solid line in figure 4 corresponding to

$c_{0}$, with the resultant pattern transitioning from fold to no-fold. The solid line in figure 4 corresponding to ![]() $c_{0}=U_{{TC}}$ convincingly marks this transition.

$c_{0}=U_{{TC}}$ convincingly marks this transition.

Figure 4. Key velocities: theoretically evaluated soap film retraction velocity ![]() $U_{{TC}}$ versus elastic wave propagation velocity

$U_{{TC}}$ versus elastic wave propagation velocity ![]() $c_{0}$. The solid line corresponds to

$c_{0}$. The solid line corresponds to ![]() $c_{0}=U_{{TC}}$.

$c_{0}=U_{{TC}}$.

In support of the conclusions drawn from the map in figure 4 – namely, that folds are observed only for ![]() $c_{0} > U_{{TC}}$ – two sets of direct measurements of the soap film retraction

$c_{0} > U_{{TC}}$ – two sets of direct measurements of the soap film retraction ![]() $U_{{TC}}$ and SW propagation

$U_{{TC}}$ and SW propagation ![]() $c_{0}$ speeds were carried out: (i) when the concentration of SDS was fixed at

$c_{0}$ speeds were carried out: (i) when the concentration of SDS was fixed at ![]() $0.5\ \mathrm {CMC}$ with the concentration of glycerol varied between 5 and 25 % wt in figure 5(a); and (ii) when the concentration of glycerol was set at

$0.5\ \mathrm {CMC}$ with the concentration of glycerol varied between 5 and 25 % wt in figure 5(a); and (ii) when the concentration of glycerol was set at ![]() $20\,{\%}\,\mathrm {wt}$ with the SDS concentration changed in the range 0.5–1.25 CMC in figure 5(b). In both cases, five withdrawal velocities were implemented in the course of the experiments. In figures 5(a) and 5(b) the measured

$20\,{\%}\,\mathrm {wt}$ with the SDS concentration changed in the range 0.5–1.25 CMC in figure 5(b). In both cases, five withdrawal velocities were implemented in the course of the experiments. In figures 5(a) and 5(b) the measured ![]() $U_{{TC}}$ and

$U_{{TC}}$ and ![]() $c_{0}$ are shown with white and black symbols, respectively, confirming that the fold regime corresponds to the condition

$c_{0}$ are shown with white and black symbols, respectively, confirming that the fold regime corresponds to the condition ![]() $c_{0} > U_{{TC}}$. The theoretical estimates of the retraction terminal velocity

$c_{0} > U_{{TC}}$. The theoretical estimates of the retraction terminal velocity ![]() $U_{{TC}}$ are represented with grey symbols.

$U_{{TC}}$ are represented with grey symbols.

Figure 5. Key measured velocities for the case of fold formation. Panels (a) and (b) demonstrate ![]() $c_0$ and

$c_0$ and ![]() $U_{{TC}}$ for different soap films. (a) The wave propagation

$U_{{TC}}$ for different soap films. (a) The wave propagation ![]() $c_{0}$ and soap film retraction

$c_{0}$ and soap film retraction ![]() $U_{{TC}}$ velocities for different soap films prepared at

$U_{{TC}}$ velocities for different soap films prepared at ![]() $0.5\ \mathrm {CMC}$ of SDS and five concentrations of glycerol (

$0.5\ \mathrm {CMC}$ of SDS and five concentrations of glycerol (![]() $5$,

$5$, ![]() $10$,

$10$, ![]() $15$,

$15$, ![]() $20$ and

$20$ and ![]() $25\,{\%}\,\mathrm {wt}$): for each of them, five different withdrawal velocities were applied, which resulted in

$25\,{\%}\,\mathrm {wt}$): for each of them, five different withdrawal velocities were applied, which resulted in ![]() $25$ soap film thicknesses. To guide the eye, we added the solid curve

$25$ soap film thicknesses. To guide the eye, we added the solid curve ![]() $c_0 = \sqrt {2E/{\rho }h_{\infty }}$ fitted to

$c_0 = \sqrt {2E/{\rho }h_{\infty }}$ fitted to ![]() $5$,

$5$, ![]() $10$,

$10$, ![]() $15$ and

$15$ and ![]() $20\,{\%}\,\mathrm {wt}$ glycerol data points, yielding

$20\,{\%}\,\mathrm {wt}$ glycerol data points, yielding ![]() $E = 0.182\ \mathrm {N}\ \mathrm {m}^{-1}$ and the dashed curve fitted to

$E = 0.182\ \mathrm {N}\ \mathrm {m}^{-1}$ and the dashed curve fitted to ![]() $25\,{\%}\,\mathrm {wt}$ glycerol data points, producing

$25\,{\%}\,\mathrm {wt}$ glycerol data points, producing ![]() $E = 0.121\ \mathrm {N}\ \mathrm {m}^{-1}$. The white and black symbols represent the measured wave propagation and the soap film retraction velocities, respectively. The grey symbols correspond to the theoretically evaluated

$E = 0.121\ \mathrm {N}\ \mathrm {m}^{-1}$. The white and black symbols represent the measured wave propagation and the soap film retraction velocities, respectively. The grey symbols correspond to the theoretically evaluated ![]() $U_{{TC}}$. (b) The wave propagation and soap film retraction velocities for different soap films with glycerol concentration fixed at

$U_{{TC}}$. (b) The wave propagation and soap film retraction velocities for different soap films with glycerol concentration fixed at ![]() $20\,{\%}\,\mathrm {wt}$. Surfactant concentration is changed in this set of experiments from

$20\,{\%}\,\mathrm {wt}$. Surfactant concentration is changed in this set of experiments from ![]() $0.5$ to

$0.5$ to ![]() $1.25\ \mathrm {CMC}$. The solid line is a fitted curve

$1.25\ \mathrm {CMC}$. The solid line is a fitted curve ![]() $c_{0}$ to

$c_{0}$ to ![]() $0.5$ and

$0.5$ and ![]() $0.625\ \mathrm {CMC}$ data points, yielding

$0.625\ \mathrm {CMC}$ data points, yielding ![]() $E = 0.186\ \mathrm {N}\ \mathrm {m}^{-1}$; and the dashed line is a fitted curve to

$E = 0.186\ \mathrm {N}\ \mathrm {m}^{-1}$; and the dashed line is a fitted curve to ![]() $0.75$,

$0.75$, ![]() $0.875$ and

$0.875$ and ![]() $1\ \mathrm {CMC}$ velocity data points, yielding

$1\ \mathrm {CMC}$ velocity data points, yielding ![]() $E = 0.082\ \mathrm {N}\ \mathrm {m}^{-1}$. At

$E = 0.082\ \mathrm {N}\ \mathrm {m}^{-1}$. At ![]() $1.25\ \mathrm {CMC}$ the fold pattern was not observed, and hence data for

$1.25\ \mathrm {CMC}$ the fold pattern was not observed, and hence data for ![]() $c_{0}$ for this concentration cannot be shown in panel (b).

$c_{0}$ for this concentration cannot be shown in panel (b).

In both figures 5(a) and 5(b), there is some deviation between the theoretical and measured ![]() $U_{{TC}}$, which is due to a number of competing factors. First, the film thickens after the SW and hence

$U_{{TC}}$, which is due to a number of competing factors. First, the film thickens after the SW and hence ![]() $U_{{TC}}$ decreases compared to that evaluated at the initial (equilibrium) film thickness

$U_{{TC}}$ decreases compared to that evaluated at the initial (equilibrium) film thickness ![]() $h_{\infty }$ in front of the SW. Second, the surfactant monolayer is compressed between the SW and the retracting edge, thus decreasing the surface tension in this area, compared to the surface tension of the original soap film, and hence

$h_{\infty }$ in front of the SW. Second, the surfactant monolayer is compressed between the SW and the retracting edge, thus decreasing the surface tension in this area, compared to the surface tension of the original soap film, and hence ![]() $U_{{TC}}$. Third, owing to the difference in surface tension before and after the SW, there is a Marangoni force accelerating the soap film edge and thus increasing

$U_{{TC}}$. Third, owing to the difference in surface tension before and after the SW, there is a Marangoni force accelerating the soap film edge and thus increasing ![]() $U_{{TC}}$. Given this understanding, in figure 5(a) we can see that, due to the substantial difference between

$U_{{TC}}$. Given this understanding, in figure 5(a) we can see that, due to the substantial difference between ![]() $U_{{TC}}$ and

$U_{{TC}}$ and ![]() $c_{0}$, the monolayer is not substantially compressed, so that the effect of film thickening after the SW overcomes that of the Marangoni force and hence the theoretical

$c_{0}$, the monolayer is not substantially compressed, so that the effect of film thickening after the SW overcomes that of the Marangoni force and hence the theoretical ![]() $U_{{TC}}$ overpredicts the measured values. This trend can also be partially discerned in figure 5(b) for

$U_{{TC}}$ overpredicts the measured values. This trend can also be partially discerned in figure 5(b) for ![]() $0.5 \ \mathrm {CMC}$ and some of the

$0.5 \ \mathrm {CMC}$ and some of the ![]() $0.625 \ \mathrm {CMC}$ points, but for other SDS concentrations, due to weaker compression of the monolayer (as measured by smaller difference between

$0.625 \ \mathrm {CMC}$ points, but for other SDS concentrations, due to weaker compression of the monolayer (as measured by smaller difference between ![]() $U_{{TC}}$ and

$U_{{TC}}$ and ![]() $c_{0}$), film thickening is overtaken by the initially subdominant Marangoni effect leading to higher measured values of

$c_{0}$), film thickening is overtaken by the initially subdominant Marangoni effect leading to higher measured values of ![]() $U_{{TC}}$.

$U_{{TC}}$.

Lastly, there is also a concomitant inhibiting effect due to friction between air and the retracting part (aureole) of the soap film as happens in all soap film flows (Couder et al. Reference Couder, Chomaz and Rabaud1989). In our case, however, the dissipation due to the presence of the air phase is negligible, which can be seen from the corresponding ratio of damping forces due to the film (bulk ![]() $\mu _{{film}}$ and surface

$\mu _{{film}}$ and surface ![]() $\mu _{{surface}}$) viscosities and the air viscosity

$\mu _{{surface}}$) viscosities and the air viscosity ![]() $\mu _{{air}}$, i.e.

$\mu _{{air}}$, i.e. ![]() $F_{{film}}/F_{{air}} \sim 2 \rho _{{air}} \sqrt {\nu _{{air}} U L^{3}} / (\mu _{{film}} h_{\infty } + 2 \mu _{{surface}}) = O(10)$ (cf. formula (39) in Couder et al. Reference Couder, Chomaz and Rabaud1989), evaluated for typical values in our experiments, namely,

$F_{{film}}/F_{{air}} \sim 2 \rho _{{air}} \sqrt {\nu _{{air}} U L^{3}} / (\mu _{{film}} h_{\infty } + 2 \mu _{{surface}}) = O(10)$ (cf. formula (39) in Couder et al. Reference Couder, Chomaz and Rabaud1989), evaluated for typical values in our experiments, namely, ![]() $L = 5\ \mathrm {cm}$,

$L = 5\ \mathrm {cm}$, ![]() $U = 5\ \mathrm {m\ s^{-1}}$,

$U = 5\ \mathrm {m\ s^{-1}}$, ![]() $\mu _{{film}} = 10^{3}\ \mathrm {Pa}\ \mathrm {s}$ and

$\mu _{{film}} = 10^{3}\ \mathrm {Pa}\ \mathrm {s}$ and ![]() $h_{\infty } = 10^{-5}\ \mathrm {m}$. In this formula we took

$h_{\infty } = 10^{-5}\ \mathrm {m}$. In this formula we took ![]() $\mu _{{surface}}$ to be the dilatational surface viscosity

$\mu _{{surface}}$ to be the dilatational surface viscosity ![]() $\kappa = 10^{-5}\ \mathrm {N}\ \mathrm {s}\ \mathrm {m}^{-1}$ (Wantke, Fruhner & Örtegren Reference Wantke, Fruhner and Örtegren2003), as most of the surface of the collapsing soap film is subject to dilatation only (Edwards, Brenner & Wasan Reference Edwards, Brenner and Wasan1991), rather than shear (which takes place only near the folds). In any case, dilatation viscosity has the dominant effect compared to that due to the shear

$\kappa = 10^{-5}\ \mathrm {N}\ \mathrm {s}\ \mathrm {m}^{-1}$ (Wantke, Fruhner & Örtegren Reference Wantke, Fruhner and Örtegren2003), as most of the surface of the collapsing soap film is subject to dilatation only (Edwards, Brenner & Wasan Reference Edwards, Brenner and Wasan1991), rather than shear (which takes place only near the folds). In any case, dilatation viscosity has the dominant effect compared to that due to the shear ![]() $\mu _{s} \approx 5 \times 10^{-6} \ \mathrm {N}\ \mathrm {s}\ \mathrm {m}^{-1}$ and bulk

$\mu _{s} \approx 5 \times 10^{-6} \ \mathrm {N}\ \mathrm {s}\ \mathrm {m}^{-1}$ and bulk ![]() $\mu _{{film}} h_{\infty } \approx 10^{-8} \ \mathrm {N}\ \mathrm {s}\ \mathrm {m}^{-1}$ viscosities. Therefore, for example, the lower measured values of

$\mu _{{film}} h_{\infty } \approx 10^{-8} \ \mathrm {N}\ \mathrm {s}\ \mathrm {m}^{-1}$ viscosities. Therefore, for example, the lower measured values of ![]() $U_{{TC}}$ compared to the theoretically predicted ones in figure 5(a) are not due to the retarding effect of the air, but primarily are due to the film thickening after the SW compared to the initial (before the soap film release) film thickness.

$U_{{TC}}$ compared to the theoretically predicted ones in figure 5(a) are not due to the retarding effect of the air, but primarily are due to the film thickening after the SW compared to the initial (before the soap film release) film thickness.

3.2. Mechanism

The experiments reported above identify the necessary kinematic conditions for the occurrence of folds, but do not address the crux of the problem – the question of the origin of the dynamic folds. The subsonic nature of the folds, ![]() $U_{{TC}}< c_{0}$, delineates them from SWs in aerodynamics and hence the underlying mechanism must be different. This becomes obvious from yet another discovered key condition for the observed phenomena: the enigmatic effect of the soap film frame corner when experiments were conducted on frames with sharp (figure 6a) and smoothed out (figure 6b) corners under otherwise the same conditions. Evidently, the curvature of the frame corner directly affects the outcome soap film pattern: the fold pattern is observed for the sharp

$U_{{TC}}< c_{0}$, delineates them from SWs in aerodynamics and hence the underlying mechanism must be different. This becomes obvious from yet another discovered key condition for the observed phenomena: the enigmatic effect of the soap film frame corner when experiments were conducted on frames with sharp (figure 6a) and smoothed out (figure 6b) corners under otherwise the same conditions. Evidently, the curvature of the frame corner directly affects the outcome soap film pattern: the fold pattern is observed for the sharp ![]() $90^{\circ }$ corner, while in the case of the smoothed corner no fold pattern is formed in the course of the soap film retraction.

$90^{\circ }$ corner, while in the case of the smoothed corner no fold pattern is formed in the course of the soap film retraction.

Figure 6. Time sequence of the soap film retraction demonstrating the effect of frame corner (a quarter of the soap film area is shown). In the time sequence shown in (a), the corners of the frame are sharp ![]() $90^{\circ }$, while in the set of images shown in (b) the

$90^{\circ }$, while in the set of images shown in (b) the ![]() $90^{\circ }$ frame corners are smoothed out. Soap film solution properties:

$90^{\circ }$ frame corners are smoothed out. Soap film solution properties: ![]() $1\ \mathrm {CMC}$ of

$1\ \mathrm {CMC}$ of ![]() $\mathrm {SDS}$,

$\mathrm {SDS}$, ![]() $20\,{\%}\,\mathrm {wt}$ glycerol; the soap film thickness and withdrawal velocity are

$20\,{\%}\,\mathrm {wt}$ glycerol; the soap film thickness and withdrawal velocity are ![]() $10.5\ {\mathrm {\mu }}\mathrm {m}$ and

$10.5\ {\mathrm {\mu }}\mathrm {m}$ and ![]() $12.4\ \mathrm {mm}\ \mathrm {s}^{-1}$, respectively. The physical image size is

$12.4\ \mathrm {mm}\ \mathrm {s}^{-1}$, respectively. The physical image size is ![]() $22\ \mathrm {mm} \times 19\ \mathrm {mm}$.

$22\ \mathrm {mm} \times 19\ \mathrm {mm}$.

The appearance of folds, at least visually, might be thought of as related to some sort of buckling. The first candidate is the buckling instability of a sheared thin viscous film, cf. Benjamin & Mullin (Reference Benjamin and Mullin1988) and Slim, Teichman & Mahadevan (Reference Slim, Teichman and Mahadevan2012), to name a few. If one considers a fluid element travelling from the soap film edge towards the diagonal (cf. figure 8c), it is clear that it will experience both rotation ![]() $\omega _{z} = ({\partial v}/{\partial x} - {\partial u}/{\partial y})/2$ and shear (strain)

$\omega _{z} = ({\partial v}/{\partial x} - {\partial u}/{\partial y})/2$ and shear (strain) ![]() $\varepsilon _{xz} = ({\partial v}/{\partial x} + {\partial u}/{\partial y})/2$, though the shear is compensated by rotation as

$\varepsilon _{xz} = ({\partial v}/{\partial x} + {\partial u}/{\partial y})/2$, though the shear is compensated by rotation as ![]() ${\partial v}/{\partial x} = 0$ (note that

${\partial v}/{\partial x} = 0$ (note that ![]() ${\partial u}/{\partial y} \neq 0$ because

${\partial u}/{\partial y} \neq 0$ because ![]() $u=0$ before reaching the diagonal and

$u=0$ before reaching the diagonal and ![]() $u=v$ upon reaching it due to symmetry); here

$u=v$ upon reaching it due to symmetry); here ![]() $u$ and

$u$ and ![]() $v$ are the

$v$ are the ![]() $x$ and

$x$ and ![]() $y$ components of the velocity vector. Despite the fact that shear of the base soap film flow is indeed present at the diagonal, it does not propagate into the interior of the soap film, as is seen from figure 8(a,c) and hence no buckling instability is observed. Moreover, as figure 6(b) demonstrates, when the corner is smoothed out, no folds are formed in spite of the fact that shear must still be present along the diagonal. Hence shear-induced buckling cannot be deemed responsible for fold formation.

$y$ components of the velocity vector. Despite the fact that shear of the base soap film flow is indeed present at the diagonal, it does not propagate into the interior of the soap film, as is seen from figure 8(a,c) and hence no buckling instability is observed. Moreover, as figure 6(b) demonstrates, when the corner is smoothed out, no folds are formed in spite of the fact that shear must still be present along the diagonal. Hence shear-induced buckling cannot be deemed responsible for fold formation.

Second, the observed wave propagation is closely related to the nature of the surfactant molecules, which have polar and non-polar ends and therefore form a monolayer at the interface between a polar substance such as water and a non-polar one such as air. The surfactant monolayer separates the two substances and reduces surface tension. As happens in our experiments on collapsing soap films, under compression, a surfactant monolayer may experience a mechanical instability, similar to the buckling instability of a beam or a plate, with the wavelength of the surface undulations in the range of ![]() $1 - 10 \ \mathrm {\mu }\mathrm {m}$ and amplitude of a few nanometres (Milner, Joanny & Pincus Reference Milner, Joanny and Pincus1989; Saint-Jalmes & Gallet Reference Saint-Jalmes and Gallet1998), which makes them inadequate to explain the observed folds, as the latter apparently have a much larger amplitude. The velocity of the associated wave propagation in surfactant monolayers is dictated by their compressibility (Griesbauer, Wixforth & Schneider Reference Griesbauer, Wixforth and Schneider2009) and could be of the order of

$1 - 10 \ \mathrm {\mu }\mathrm {m}$ and amplitude of a few nanometres (Milner, Joanny & Pincus Reference Milner, Joanny and Pincus1989; Saint-Jalmes & Gallet Reference Saint-Jalmes and Gallet1998), which makes them inadequate to explain the observed folds, as the latter apparently have a much larger amplitude. The velocity of the associated wave propagation in surfactant monolayers is dictated by their compressibility (Griesbauer, Wixforth & Schneider Reference Griesbauer, Wixforth and Schneider2009) and could be of the order of ![]() $10^{2} \ \mathrm {m}\ \mathrm {s}^{-1}$. While we cannot observe nanometre-amplitude deformations on the soap film surface, the optical properties of the surfactant monolayer change drastically under compression, which may lead to the discernible dark region, i.e. ‘aureole’ (cf. figure 7). Because of the surfactant used in our experiments (SDS), its monolayer compressibility properties (Khattari et al. Reference Khattari, Langer, Aliaskarisohi, Ray and Fischer2011) allow for significantly lower wave propagation speeds

$10^{2} \ \mathrm {m}\ \mathrm {s}^{-1}$. While we cannot observe nanometre-amplitude deformations on the soap film surface, the optical properties of the surfactant monolayer change drastically under compression, which may lead to the discernible dark region, i.e. ‘aureole’ (cf. figure 7). Because of the surfactant used in our experiments (SDS), its monolayer compressibility properties (Khattari et al. Reference Khattari, Langer, Aliaskarisohi, Ray and Fischer2011) allow for significantly lower wave propagation speeds ![]() $c_{0}$, making them comparable to the edge retraction speeds

$c_{0}$, making them comparable to the edge retraction speeds ![]() $U_{{TC}}$, thus enabling the phenomena presented here: transition from no-fold to fold regime. We should also note that for the two concentrations of surfactant (

$U_{{TC}}$, thus enabling the phenomena presented here: transition from no-fold to fold regime. We should also note that for the two concentrations of surfactant (![]() $0.875$ and

$0.875$ and ![]() $1\ \mathrm {CMC}$) an aureole is developed on the soap film surface (figure 7), while for low concentrations (

$1\ \mathrm {CMC}$) an aureole is developed on the soap film surface (figure 7), while for low concentrations (![]() $0.5$ and

$0.5$ and ![]() $0.625\ \mathrm {CMC}$) we have not observed any darkening (figure 2a), though a compressed surfactant monolayer may not always be visible. Yet, the higher SDS concentration

$0.625\ \mathrm {CMC}$) we have not observed any darkening (figure 2a), though a compressed surfactant monolayer may not always be visible. Yet, the higher SDS concentration ![]() $1.25\ \mathrm {CMC}$ implies no SW propagation and hence no aureole (figure 2b), while at low SDS concentrations there are not enough surfactant molecules at the interface to darken the film.

$1.25\ \mathrm {CMC}$ implies no SW propagation and hence no aureole (figure 2b), while at low SDS concentrations there are not enough surfactant molecules at the interface to darken the film.

Figure 7. Time sequence of the soap film retraction to show the appearance of a dark region on its surface with the camera zoomed on a quarter of the film area. The dark region develops as the SW propagates on the soap film surface. Soap film solution properties: ![]() $0.875\ \mathrm {CMC}$ of

$0.875\ \mathrm {CMC}$ of ![]() $\mathrm {SDS}$,

$\mathrm {SDS}$, ![]() $20\,{\%}\,\mathrm {wt}$ glycerol. Withdrawal velocity and film thickness are

$20\,{\%}\,\mathrm {wt}$ glycerol. Withdrawal velocity and film thickness are ![]() $9.1\ \mathrm {mm}\ \mathrm {s}^{-1}$ and

$9.1\ \mathrm {mm}\ \mathrm {s}^{-1}$ and ![]() $11.4\ {\mathrm {\mu }}\mathrm {m}$, respectively. The physical image size is

$11.4\ {\mathrm {\mu }}\mathrm {m}$, respectively. The physical image size is ![]() $22\ \mathrm {mm} \times 19\ \mathrm {mm}$.

$22\ \mathrm {mm} \times 19\ \mathrm {mm}$.

4. Theory

Given the inability of the known phenomena – buckling of sheared thin viscous films and compressed monolayers – to expound the origin of folds, we must turn to the fundamental description of the soap film dynamics in our setting. Since the subsonic soap film dynamics, ![]() $U_{{TC}} < c_{0}$, alone is not sufficient to explain the origin of folds, further insights are needed into the underlying mechanisms, which is done in this section with theoretical tools. First, we identify the soap film dynamical model, the numerical solution of which (§ 4.1) replicates the experimental observations of the velocity field and soap film thickening along the diagonal. With confidence in the model thereby built, we are then able to extract the SW relations (§ 4.2) and the phenomena on the diagonal leading to folds (§ 4.3), also contributed by acoustic effects (§ 4.4).

$U_{{TC}} < c_{0}$, alone is not sufficient to explain the origin of folds, further insights are needed into the underlying mechanisms, which is done in this section with theoretical tools. First, we identify the soap film dynamical model, the numerical solution of which (§ 4.1) replicates the experimental observations of the velocity field and soap film thickening along the diagonal. With confidence in the model thereby built, we are then able to extract the SW relations (§ 4.2) and the phenomena on the diagonal leading to folds (§ 4.3), also contributed by acoustic effects (§ 4.4).

4.1. Soap film dynamics

In the Cartesian ![]() $(x,y)$ coordinates corresponding to the soap film plane, the continuity and momentum conservation equations governing the soap film dynamics (Wen & Lai Reference Wen and Lai2003) with velocity

$(x,y)$ coordinates corresponding to the soap film plane, the continuity and momentum conservation equations governing the soap film dynamics (Wen & Lai Reference Wen and Lai2003) with velocity ![]() $\boldsymbol {v}=(u,v)$ and thickness

$\boldsymbol {v}=(u,v)$ and thickness ![]() $h(t,x,y)$, written here in analogy to Euler's equations of ideal fluid motion (Landau & Lifshitz Reference Landau and Lifshitz1987), are

$h(t,x,y)$, written here in analogy to Euler's equations of ideal fluid motion (Landau & Lifshitz Reference Landau and Lifshitz1987), are

non-dimensionalized according to

where ![]() $\boldsymbol{\mathsf{I}}$ is the unit tensor and

$\boldsymbol{\mathsf{I}}$ is the unit tensor and ![]() $\hat {c} = c_{0}/v_{\infty }$ is the Marangoni elasticity speed scaled with respect to

$\hat {c} = c_{0}/v_{\infty }$ is the Marangoni elasticity speed scaled with respect to ![]() $v_{\infty } = U_{{TC}}(h_{\infty })$. The existence of an elasticity-mediated speed of propagation, similar to that for sound speed, provides the means for generating SWs in soap films. The presence of the blob along the soap film edge is not crucial for our considerations – there are cases in soap film dynamics when a blob is not formed, for example in highly viscous films (Debrégeas, Martin & Brochard-Wyart Reference Debrégeas, Martin and Brochard-Wyart1995), in which an ‘instantaneous’ thickening of the film is observed due to elastic propagation. Thus the initial and boundary conditions at the soap film edge (rim) for (4.1) are posed, respectively, as

$v_{\infty } = U_{{TC}}(h_{\infty })$. The existence of an elasticity-mediated speed of propagation, similar to that for sound speed, provides the means for generating SWs in soap films. The presence of the blob along the soap film edge is not crucial for our considerations – there are cases in soap film dynamics when a blob is not formed, for example in highly viscous films (Debrégeas, Martin & Brochard-Wyart Reference Debrégeas, Martin and Brochard-Wyart1995), in which an ‘instantaneous’ thickening of the film is observed due to elastic propagation. Thus the initial and boundary conditions at the soap film edge (rim) for (4.1) are posed, respectively, as

above we have taken into account that the blob-free soap film rim moves with the speed ![]() $U_{{TC}}(h_{r})$ corresponding to the film thickness

$U_{{TC}}(h_{r})$ corresponding to the film thickness ![]() $h_{r}$ at the rim.

$h_{r}$ at the rim.

For numerical implementation, (4.1) can be rewritten as

where ![]() $G$ and

$G$ and ![]() $H$ are nonlinear functions of

$H$ are nonlinear functions of ![]() $W$:

$W$:

\begin{equation} W = \begin{bmatrix} h\\ hu\\ hv \end{bmatrix},\quad G = \begin{bmatrix} hu\\ hu^2+F\\ huv \end{bmatrix},\quad H = \begin{bmatrix} hv\\ huv\\ hv^2+F \end{bmatrix}. \end{equation}

\begin{equation} W = \begin{bmatrix} h\\ hu\\ hv \end{bmatrix},\quad G = \begin{bmatrix} hu\\ hu^2+F\\ huv \end{bmatrix},\quad H = \begin{bmatrix} hv\\ huv\\ hv^2+F \end{bmatrix}. \end{equation}

In order to numerically integrate this two-dimensional soap film model, it is discretized as appropriate for solving nonlinear systems of hyperbolic conservative equations (Toro Reference Toro1999) using finite differences with a backward scheme. First we integrate (4.4) by sweeping in the ![]() $x$ direction,

$x$ direction,

and then, as is common in splitting schemes (Toro Reference Toro1999), sweeping in the ![]() $y$ direction,

$y$ direction,

here the index ![]() $n$ stands for the time stamp and indices

$n$ stands for the time stamp and indices ![]() $i$ and

$i$ and ![]() $j$ for mesh numbers in the

$j$ for mesh numbers in the ![]() $x$ and

$x$ and ![]() $y$ directions, respectively. For the system of equations (4.4), the Courant condition

$y$ directions, respectively. For the system of equations (4.4), the Courant condition

allows one to choose the time step ![]() $\Delta t$ as well as the spatial steps

$\Delta t$ as well as the spatial steps ![]() $\Delta x$ and

$\Delta x$ and ![]() $\Delta y$ in the

$\Delta y$ in the ![]() $x$ and

$x$ and ![]() $y$ directions, respectively. The results of the numerical simulation after performing

$y$ directions, respectively. The results of the numerical simulation after performing ![]() $80$ time steps are reported in figure 8(c,d).

$80$ time steps are reported in figure 8(c,d).

Figure 8. Experiments versus theory. (a) PIV velocity field acquired ![]() $2.4\ \mathrm {ms}$ after the triggering pulse. The time difference between the two PIV images is

$2.4\ \mathrm {ms}$ after the triggering pulse. The time difference between the two PIV images is ![]() $100\ {\mathrm {\mu }}\mathrm {s}$. The size of the grey area is

$100\ {\mathrm {\mu }}\mathrm {s}$. The size of the grey area is ![]() $19.8\ \mathrm {mm} \times 22\ \mathrm {mm}$. The experimentally measured one-dimensional shock and retraction velocities are

$19.8\ \mathrm {mm} \times 22\ \mathrm {mm}$. The experimentally measured one-dimensional shock and retraction velocities are ![]() $c_0 = 4.02 \ \mathrm {m}\ \mathrm {s}^{-1}$ and

$c_0 = 4.02 \ \mathrm {m}\ \mathrm {s}^{-1}$ and ![]() $U_{{TC}} = 1.86 \ \mathrm {m}\ \mathrm {s}^{-1}$, respectively. (b) Fold formation on the soap film

$U_{{TC}} = 1.86 \ \mathrm {m}\ \mathrm {s}^{-1}$, respectively. (b) Fold formation on the soap film ![]() $2.6\ \mathrm {ms}$ after the triggering pulse. The physical image size is

$2.6\ \mathrm {ms}$ after the triggering pulse. The physical image size is ![]() $22\ \mathrm {mm} \times 22\ \mathrm {mm}$. The soap solution in (a,b) consists of ultrapure water,

$22\ \mathrm {mm} \times 22\ \mathrm {mm}$. The soap solution in (a,b) consists of ultrapure water, ![]() $20\,{\%}\,\mathrm {wt}$ glycerol and

$20\,{\%}\,\mathrm {wt}$ glycerol and ![]() $0.5\ \mathrm {CMC}$ of SDS. The soap film thickness and withdrawal velocity are

$0.5\ \mathrm {CMC}$ of SDS. The soap film thickness and withdrawal velocity are ![]() $16.9\ \mathrm {\mu }\mathrm {m}$ and

$16.9\ \mathrm {\mu }\mathrm {m}$ and ![]() $12.4\ \mathrm {mm}\ \mathrm {s}^{-1}$, respectively. (c) Numerical result for the velocity field distribution on the soap film in the presence of fold. (d) Contour plot of numerically calculated

$12.4\ \mathrm {mm}\ \mathrm {s}^{-1}$, respectively. (c) Numerical result for the velocity field distribution on the soap film in the presence of fold. (d) Contour plot of numerically calculated ![]() $h(t,x,y)$ for the conditions corresponding to those in panel (c).

$h(t,x,y)$ for the conditions corresponding to those in panel (c).

Modelling based on numerical implementation of (4.1) and (4.3) shows that the computed velocity field distribution in figure 8(c) is in good agreement with the experimental PIV measurements in figure 8(a). In figure 8(c), ![]() $\hat {c}=2.3$ was chosen to fit the kinematics in figure 8(a), which is close to the experimental value

$\hat {c}=2.3$ was chosen to fit the kinematics in figure 8(a), which is close to the experimental value ![]() $\hat {c} = 2.16$. A contour plot of the numerical solution of (4.1) and (4.3) for the film thickness

$\hat {c} = 2.16$. A contour plot of the numerical solution of (4.1) and (4.3) for the film thickness ![]() $h(t,x,y)$ demonstrates a fold on the diagonal of the soap film as a result of wave propagation ahead of the retracting edge (cf. figure 8d) in analogy to the experimental observations in figure 8(b).

$h(t,x,y)$ demonstrates a fold on the diagonal of the soap film as a result of wave propagation ahead of the retracting edge (cf. figure 8d) in analogy to the experimental observations in figure 8(b).

4.2. Shock wave speed

For convenience, here we consider the dimensional version of (4.1) with ![]() $c$ being the elastic wave speed. When integrated across the surface of discontinuity, the mass conservation equation (4.1a) yields

$c$ being the elastic wave speed. When integrated across the surface of discontinuity, the mass conservation equation (4.1a) yields ![]() $[h v]_{1}^{2}=0$ for the difference in mass flux on either side of the SW (cf. figure 9a), which in the frame of reference associated with the moving SW (cf. figure 9b) reads (Landau & Lifshitz Reference Landau and Lifshitz1987)

$[h v]_{1}^{2}=0$ for the difference in mass flux on either side of the SW (cf. figure 9a), which in the frame of reference associated with the moving SW (cf. figure 9b) reads (Landau & Lifshitz Reference Landau and Lifshitz1987)

in this formula, on the left-hand side, ![]() $c$ plays the role of the velocity of the soap film of thickness

$c$ plays the role of the velocity of the soap film of thickness ![]() $h_{\infty }$ incoming onto (in front of) the SW, while, on the right-hand side,

$h_{\infty }$ incoming onto (in front of) the SW, while, on the right-hand side, ![]() $c-v_{-}$ is the soap film velocity behind the SW and the corresponding soap film thickness is

$c-v_{-}$ is the soap film velocity behind the SW and the corresponding soap film thickness is ![]() $h_{-}$. Equation (4.9) signifies some important properties: one must have

$h_{-}$. Equation (4.9) signifies some important properties: one must have ![]() $c>v_{-}$ and

$c>v_{-}$ and ![]() $h_{-} \neq h_{\infty }$. To (4.9) we should add a momentum conservation condition following from the conservative form of the differential momentum conservation equation (4.1b), i.e.

$h_{-} \neq h_{\infty }$. To (4.9) we should add a momentum conservation condition following from the conservative form of the differential momentum conservation equation (4.1b), i.e. ![]() $[h (v^{2} + c^{2})]_{1}^{2} = 0$ in the frame of reference moving with the SW, thus producing

$[h (v^{2} + c^{2})]_{1}^{2} = 0$ in the frame of reference moving with the SW, thus producing

where we took into account that in general the SW speed ![]() $c$ is different from the sound speed

$c$ is different from the sound speed ![]() $c_{\infty }$ in front of the SW and from

$c_{\infty }$ in front of the SW and from ![]() $c_{-}$ behind it. By eliminating

$c_{-}$ behind it. By eliminating ![]() $c-v_{-}$ from (4.9) and (4.10), we find the (squared) SW speed

$c-v_{-}$ from (4.9) and (4.10), we find the (squared) SW speed

which tells us that, if the sound speed is calculated as for elastic waves, i.e. ![]() $c_{\infty } = \sqrt {E/\rho h_{\infty }}$ and similarly for

$c_{\infty } = \sqrt {E/\rho h_{\infty }}$ and similarly for ![]() $c_{-}$, then SW cannot form unless the elasticities

$c_{-}$, then SW cannot form unless the elasticities ![]() $E_{\infty }$ in front of and

$E_{\infty }$ in front of and ![]() $E_{-}$ behind the SW are different.

$E_{-}$ behind the SW are different.

Figure 9. SW propagation in the laboratory (a) and moving (b) frames of reference.

4.3. Dynamics on the diagonal

While the numerical solution in § 4.1 replicates the experimental observations, it does not provide deeper insights offered by an analytical study. To that end, using (4.1) we derive the Rankine–Hugoniot conditions analogous to SWs in aerodynamics (Landau & Lifshitz Reference Landau and Lifshitz1987) along the soap film diagonal ![]() $\varGamma$ defined by

$\varGamma$ defined by ![]() $x=y$, where a fold is observed:

$x=y$, where a fold is observed:

with the notation introduced ![]() $1$ is the phase below and

$1$ is the phase below and ![]() $2$ above the diagonal (cf. figure 8c),

$2$ above the diagonal (cf. figure 8c), ![]() $I_{x} = (1,\,0)^\textrm {T}$ and

$I_{x} = (1,\,0)^\textrm {T}$ and ![]() $I_{y} = (0,\,1)^\textrm {T}$. The analysis of (4.12) leads to

$I_{y} = (0,\,1)^\textrm {T}$. The analysis of (4.12) leads to

which are the natural conditions across the diagonal ![]() $\varGamma$ due to the symmetry of the problem with respect to it. Effectively, the diagonal serves as an impermeable wall or, in fact, two impermeable walls in between which (on a set of measure zero) there exists a dynamics mostly independent of the rest of the soap film, because the initial perturbation of large enough amplitude at the corner is confined by the soap film flows on either side, and hence can evolve only along the diagonal without propagating sidewise. On the other hand, any perturbation coming from the edge of the soap film away from the corner decays quickly due to being non-confined. Since the diagonal has its own dynamics, it must be governed by the corresponding equations, which are naturally the same soap film equations (4.1), but collapsed on the diagonal. Since the system (4.1) is in a coordinate-free form, the equations on the diagonal straightforwardly follow from substitution of the gradient

$\varGamma$ due to the symmetry of the problem with respect to it. Effectively, the diagonal serves as an impermeable wall or, in fact, two impermeable walls in between which (on a set of measure zero) there exists a dynamics mostly independent of the rest of the soap film, because the initial perturbation of large enough amplitude at the corner is confined by the soap film flows on either side, and hence can evolve only along the diagonal without propagating sidewise. On the other hand, any perturbation coming from the edge of the soap film away from the corner decays quickly due to being non-confined. Since the diagonal has its own dynamics, it must be governed by the corresponding equations, which are naturally the same soap film equations (4.1), but collapsed on the diagonal. Since the system (4.1) is in a coordinate-free form, the equations on the diagonal straightforwardly follow from substitution of the gradient ![]() $\boldsymbol {\nabla }$ by the directional derivative

$\boldsymbol {\nabla }$ by the directional derivative ![]() $\partial / \partial _{\varGamma }$ along the diagonal

$\partial / \partial _{\varGamma }$ along the diagonal ![]() $\varGamma$, analogous in spirit to Hadamard's method of descent (Hadamard Reference Hadamard1923).

$\varGamma$, analogous in spirit to Hadamard's method of descent (Hadamard Reference Hadamard1923).

Moreover, the diagonal proves to be one of the characteristics. Indeed, the characteristic surface ![]() $\varOmega (t,x,y)$ in the space of independent variables

$\varOmega (t,x,y)$ in the space of independent variables ![]() $(t,x,y)$ is defined in the context of proving the Cauchy–Kovalevskaya theorem: namely, an initial value (Cauchy) problem does not have a unique solution, and thus is ill-posed, if the initial data are given at

$(t,x,y)$ is defined in the context of proving the Cauchy–Kovalevskaya theorem: namely, an initial value (Cauchy) problem does not have a unique solution, and thus is ill-posed, if the initial data are given at ![]() $\varOmega (t,x,y)$. This allows a straightforward determination of the characteristic surface by making a transformation from the original independent variables

$\varOmega (t,x,y)$. This allows a straightforward determination of the characteristic surface by making a transformation from the original independent variables ![]() $(t,x,y)$ to

$(t,x,y)$ to ![]() $\varOmega (t,x,y)$, in which resolution of the governing partial differential equations (4.1) for the highest-order derivatives of the solution becomes impossible (Petrovsky Reference Petrovsky1954):

$\varOmega (t,x,y)$, in which resolution of the governing partial differential equations (4.1) for the highest-order derivatives of the solution becomes impossible (Petrovsky Reference Petrovsky1954):

\begin{equation} \begin{pmatrix} \varDelta & h \varOmega_{x} & h \varOmega_{y}\\ c^{2} \varOmega_{x} & h \varDelta & 0\\ c^{2} \varOmega_{y} & 0 & h \varDelta \end{pmatrix} \begin{pmatrix} h_{\varOmega}\\ u_{\varOmega}\\ v_{\varOmega} \end{pmatrix} = 0, \end{equation}

\begin{equation} \begin{pmatrix} \varDelta & h \varOmega_{x} & h \varOmega_{y}\\ c^{2} \varOmega_{x} & h \varDelta & 0\\ c^{2} \varOmega_{y} & 0 & h \varDelta \end{pmatrix} \begin{pmatrix} h_{\varOmega}\\ u_{\varOmega}\\ v_{\varOmega} \end{pmatrix} = 0, \end{equation}

where ![]() $\varDelta = \varOmega _{t} + u \varOmega _{x} + v \varOmega _{y}$. Hence, the characteristic determinant reads

$\varDelta = \varOmega _{t} + u \varOmega _{x} + v \varOmega _{y}$. Hence, the characteristic determinant reads

implying that the system (4.1) is hyperbolic with one of the characteristics being the instantaneous streamline ![]() $\varOmega _{t} + u \varOmega _{x} + v \varOmega _{y} = 0$ – the diagonal

$\varOmega _{t} + u \varOmega _{x} + v \varOmega _{y} = 0$ – the diagonal ![]() $\varGamma$ is one of them – while the other ones are dictated by the soap film ‘compressibility’ with some correction terms:

$\varGamma$ is one of them – while the other ones are dictated by the soap film ‘compressibility’ with some correction terms:

4.4. Acoustic effects

Further insights into the origin of folds can be gained with the help of geometric acoustics, the basic assumption of which (Landau & Lifshitz Reference Landau and Lifshitz1987) is that locally a sound wave ![]() $\phi (t,\boldsymbol {r}) = A(t,\boldsymbol {r}) \, \textrm {e}^{\mathrm {i} \psi (t,\boldsymbol {r})}$ with the wavevector

$\phi (t,\boldsymbol {r}) = A(t,\boldsymbol {r}) \, \textrm {e}^{\mathrm {i} \psi (t,\boldsymbol {r})}$ with the wavevector ![]() $\boldsymbol {k} = \boldsymbol {\nabla } \psi$ and frequency

$\boldsymbol {k} = \boldsymbol {\nabla } \psi$ and frequency ![]() $\omega = - {\partial \psi / \partial t}$ can be considered plane (cf. figure 11a), provided the amplitude

$\omega = - {\partial \psi / \partial t}$ can be considered plane (cf. figure 11a), provided the amplitude ![]() $A$ and the wave direction

$A$ and the wave direction ![]() $\boldsymbol {k}$ do not change appreciably over the sound wavelength

$\boldsymbol {k}$ do not change appreciably over the sound wavelength ![]() $\lambda = 2{\rm \pi} /|\boldsymbol {k}|$, i.e.

$\lambda = 2{\rm \pi} /|\boldsymbol {k}|$, i.e. ![]() $\lambda /L \ll 1$ relative to the characteristic length scale

$\lambda /L \ll 1$ relative to the characteristic length scale ![]() $L$ of the phenomena at hand (the soap film span). Let us try to understand the fold formation in the soap film dynamics with the help of a single eikonal equation, which relates

$L$ of the phenomena at hand (the soap film span). Let us try to understand the fold formation in the soap film dynamics with the help of a single eikonal equation, which relates ![]() $\omega$ and

$\omega$ and ![]() $\boldsymbol {k}$ and is known to admit multivalued solutions corresponding to caustics. Taking into account the motion of the soap film itself (Kritikos Reference Kritikos1967) with the velocity field

$\boldsymbol {k}$ and is known to admit multivalued solutions corresponding to caustics. Taking into account the motion of the soap film itself (Kritikos Reference Kritikos1967) with the velocity field ![]() $\boldsymbol {v}=(u,v)$ furnishes

$\boldsymbol {v}=(u,v)$ furnishes

which is a modification of the steady-state eikonal equation (Landau & Lifshitz Reference Landau and Lifshitz1987) ![]() $|\boldsymbol {k}|^{2} = \omega ^{2}/c_{0}^{2}$. While the general case

$|\boldsymbol {k}|^{2} = \omega ^{2}/c_{0}^{2}$. While the general case ![]() $|\boldsymbol {v}| \sim c_{0}$ can be formally considered, in order to make the implications of the presence of the soap film flow transparent, let us treat the limit

$|\boldsymbol {v}| \sim c_{0}$ can be formally considered, in order to make the implications of the presence of the soap film flow transparent, let us treat the limit ![]() $|\boldsymbol {v}| \ll c_{0}$. Using the standard characteristic analysis for the first-order nonlinear partial differential equations (Zauderer Reference Zauderer2006), we arrive at the acoustic ray equation:

$|\boldsymbol {v}| \ll c_{0}$. Using the standard characteristic analysis for the first-order nonlinear partial differential equations (Zauderer Reference Zauderer2006), we arrive at the acoustic ray equation:

above the velocity vector is scaled as ![]() $\boldsymbol {v} \rightarrow \boldsymbol {v}/c_{0}$,

$\boldsymbol {v} \rightarrow \boldsymbol {v}/c_{0}$, ![]() $\boldsymbol {t} = \mathrm {d} \boldsymbol {r} / \mathrm {d} s$ is the vector tangent to the ray,

$\boldsymbol {t} = \mathrm {d} \boldsymbol {r} / \mathrm {d} s$ is the vector tangent to the ray, ![]() $s$ the arclength,

$s$ the arclength, ![]() $n=\omega /c_{0}$ the refractive index and

$n=\omega /c_{0}$ the refractive index and ![]() $\boldsymbol {t} \boldsymbol {\cdot } \boldsymbol {\nabla } \boldsymbol {v}$ the usual vector–tensor product:

$\boldsymbol {t} \boldsymbol {\cdot } \boldsymbol {\nabla } \boldsymbol {v}$ the usual vector–tensor product:

The first term on the right-hand side of (4.18) is responsible for the ray bending in the direction of decreasing sound speed ![]() $c_{0}$ or, equivalently, in the direction of increasing refractive index

$c_{0}$ or, equivalently, in the direction of increasing refractive index ![]() $n$. Since

$n$. Since ![]() $|\mathrm {d}^{2} \boldsymbol {r} / \mathrm {d} s^{2}| = \kappa (s)$ is the curvature of the ray, then, in the presence of an inhomogeneous refractive index

$|\mathrm {d}^{2} \boldsymbol {r} / \mathrm {d} s^{2}| = \kappa (s)$ is the curvature of the ray, then, in the presence of an inhomogeneous refractive index ![]() $n=n(x,y)$, the ray bends in the direction of the gradient

$n=n(x,y)$, the ray bends in the direction of the gradient ![]() $\boldsymbol {\nabla } n$ (e.g. for the ray in figure 8(c) the vector

$\boldsymbol {\nabla } n$ (e.g. for the ray in figure 8(c) the vector ![]() $\boldsymbol {\nabla } n$ points towards the diagonal). On the soap film diagonal