1. Introduction

In high-Reynolds-number turbulent boundary layers (TBLs), the requirement for hydrodynamic smoothness becomes unrealistically stringent due to the surface imperfections. It is thus reasonable to expect that the TBLs evolve on a hydrodynamically rough surface as the boundary layer thickness decreases with increasing Reynolds number (![]() $Re$) and may reach the transitionally or fully rough regime. This raises an interesting question regarding the control of TBLs. Indeed, how a control strategy developed for a smooth wall TBL performs when the surface over which the TBL becomes hydrodynamically rough, or can a control strategy for smooth wall TBL be effective for fully rough wall TBLs? Further, since a fully rough wall can become

$Re$) and may reach the transitionally or fully rough regime. This raises an interesting question regarding the control of TBLs. Indeed, how a control strategy developed for a smooth wall TBL performs when the surface over which the TBL becomes hydrodynamically rough, or can a control strategy for smooth wall TBL be effective for fully rough wall TBLs? Further, since a fully rough wall can become ![]() $Re$-independent (Djenidi, Talluru & Antonia Reference Djenidi, Talluru and Antonia2018), is the control of fully rough wall TBL

$Re$-independent (Djenidi, Talluru & Antonia Reference Djenidi, Talluru and Antonia2018), is the control of fully rough wall TBL ![]() $Re$-independent? Therefore, subjecting a rough wall TBL to perturbations similar to those used to investigate the dynamic response of a smooth wall TBL is not only an academic research problem but is of great importance in many engineering applications when the aim of the flow control is to achieve particular outcomes (e.g. drag reduction, lift control and noise attenuation). It is accordingly of quite significant interest to enhance our understanding of the dynamic response of a rough wall TBL to various perturbations with increasing Re. To date, wall suction and injection approaches have had some success in controlling of smooth wall TBLs, particularly at low and moderate Re (see Gad-el Hak & Blackwelder Reference Gad-el Hak and Blackwelder1989; Myose & Blackwelder Reference Myose and Blackwelder1995; Jacobson & Reynolds Reference Jacobson and Reynolds1998; Park & Choi Reference Park and Choi1999; Rathnasingham & Breuer Reference Rathnasingham and Breuer2003; Lockerby, Carpenter & Davies Reference Lockerby, Carpenter and Davies2005; Rebbeck & Choi Reference Rebbeck and Choi2006; Segawa et al. Reference Segawa, Mizunuma, Murakami, Li and Yoshida2007; Kametani et al. Reference Kametani, Fukagata, Örlü and Schlatter2015; Bobke, Örlü & Schlatter Reference Bobke, Örlü and Schlatter2016; Qiao, Zhou & Wu Reference Qiao, Zhou and Wu2017). Antonia et al. (Reference Antonia, Fulachier, Krishnamoorthy, Benabid and Anselmet1988) quantified the influence of wall suction, applied through a porous wall strip, on a low Reynolds number smooth wall TBL. It was found that suction could weaken the bursting process of the near-wall low-speed streaks, resulting in the reduction of turbulence energy and Reynolds stress. Antonia, Zhu & Sokolov (Reference Antonia, Zhu and Sokolov1995) showed that the total skin friction of a smooth wall TBL under localised wall suction via a porous strip decreases linearly with increasing suction rate. A following study (Oyewola, Djenidi & Antonia Reference Oyewola, Djenidi and Antonia2003) indicated that the dynamical behaviour of smooth wall TBL subjected to similar localised wall suction is Re-dependent. The study further demonstrated that

$Re$-independent? Therefore, subjecting a rough wall TBL to perturbations similar to those used to investigate the dynamic response of a smooth wall TBL is not only an academic research problem but is of great importance in many engineering applications when the aim of the flow control is to achieve particular outcomes (e.g. drag reduction, lift control and noise attenuation). It is accordingly of quite significant interest to enhance our understanding of the dynamic response of a rough wall TBL to various perturbations with increasing Re. To date, wall suction and injection approaches have had some success in controlling of smooth wall TBLs, particularly at low and moderate Re (see Gad-el Hak & Blackwelder Reference Gad-el Hak and Blackwelder1989; Myose & Blackwelder Reference Myose and Blackwelder1995; Jacobson & Reynolds Reference Jacobson and Reynolds1998; Park & Choi Reference Park and Choi1999; Rathnasingham & Breuer Reference Rathnasingham and Breuer2003; Lockerby, Carpenter & Davies Reference Lockerby, Carpenter and Davies2005; Rebbeck & Choi Reference Rebbeck and Choi2006; Segawa et al. Reference Segawa, Mizunuma, Murakami, Li and Yoshida2007; Kametani et al. Reference Kametani, Fukagata, Örlü and Schlatter2015; Bobke, Örlü & Schlatter Reference Bobke, Örlü and Schlatter2016; Qiao, Zhou & Wu Reference Qiao, Zhou and Wu2017). Antonia et al. (Reference Antonia, Fulachier, Krishnamoorthy, Benabid and Anselmet1988) quantified the influence of wall suction, applied through a porous wall strip, on a low Reynolds number smooth wall TBL. It was found that suction could weaken the bursting process of the near-wall low-speed streaks, resulting in the reduction of turbulence energy and Reynolds stress. Antonia, Zhu & Sokolov (Reference Antonia, Zhu and Sokolov1995) showed that the total skin friction of a smooth wall TBL under localised wall suction via a porous strip decreases linearly with increasing suction rate. A following study (Oyewola, Djenidi & Antonia Reference Oyewola, Djenidi and Antonia2003) indicated that the dynamical behaviour of smooth wall TBL subjected to similar localised wall suction is Re-dependent. The study further demonstrated that ![]() $Re$ modulates the magnitude and wavelength of the response of the TBL without changing the actual mechanism of pseudo-relaminarisation due to suction. It was also shown that with increasing Re, the departure of the mean velocity profiles from the corresponding undisturbed ones is less pronounced, reflecting a reduced pseudo-relaminarisation. Unfortunately, these results were obtained in smooth wall TBL where the momentum thickness-based Reynolds number (

$Re$ modulates the magnitude and wavelength of the response of the TBL without changing the actual mechanism of pseudo-relaminarisation due to suction. It was also shown that with increasing Re, the departure of the mean velocity profiles from the corresponding undisturbed ones is less pronounced, reflecting a reduced pseudo-relaminarisation. Unfortunately, these results were obtained in smooth wall TBL where the momentum thickness-based Reynolds number (![]() $Re_\theta$) was less than 2000. Relaminarisation is also observed in the study conducted by Khapko et al. (Reference Khapko, Schlatter, Duguet and Henningson2016), who investigated the effects of asymptotic suction on smooth TBL at low

$Re_\theta$) was less than 2000. Relaminarisation is also observed in the study conducted by Khapko et al. (Reference Khapko, Schlatter, Duguet and Henningson2016), who investigated the effects of asymptotic suction on smooth TBL at low ![]() $Re$ (

$Re$ (![]() $<$350). It was found that suction can remove the outer-region large eddy structures leading to development of laminar spots within the TBL which grow with the downstream distance. For a moderate

$<$350). It was found that suction can remove the outer-region large eddy structures leading to development of laminar spots within the TBL which grow with the downstream distance. For a moderate ![]() $Re_\theta$ (

$Re_\theta$ (![]() ${\approx }4000$), Yoshioka & Alfredsson (Reference Yoshioka and Alfredsson2006) subjected a smooth wall TBL to a uniform wall suction with a suction velocity of approximately 0.3 % of free stream velocity and observed that the turbulence production within the logarithmic region is decreased by up to 30 %. Manipulation high-Re wall-bounded turbulent flow using wall-normal jet has also been investigated by Marusic, Talluru & Hutchins (Reference Marusic, Talluru and Hutchins2014) who observed that the streamwise oriented jet can modify the large-scale structures when it actuates on the entire length of large-scale events. It was recognised that the maximum reduction in turbulence intensity occurs when the strength of the jet is correctly scaled to the strength of the detected large-scale events. When investigating the response of the outer-region of a high-Re TBL to external large-scale perturbations, Abbassi et al. (Reference Abbassi, Baars, Hutchins and Marusic2017) showed that a large amount of the wall-normal jet-flow velocity (up to 64 % of free stream) should be synchronised with the high-speed events in order to obtain wall-shear stress reduction.

${\approx }4000$), Yoshioka & Alfredsson (Reference Yoshioka and Alfredsson2006) subjected a smooth wall TBL to a uniform wall suction with a suction velocity of approximately 0.3 % of free stream velocity and observed that the turbulence production within the logarithmic region is decreased by up to 30 %. Manipulation high-Re wall-bounded turbulent flow using wall-normal jet has also been investigated by Marusic, Talluru & Hutchins (Reference Marusic, Talluru and Hutchins2014) who observed that the streamwise oriented jet can modify the large-scale structures when it actuates on the entire length of large-scale events. It was recognised that the maximum reduction in turbulence intensity occurs when the strength of the jet is correctly scaled to the strength of the detected large-scale events. When investigating the response of the outer-region of a high-Re TBL to external large-scale perturbations, Abbassi et al. (Reference Abbassi, Baars, Hutchins and Marusic2017) showed that a large amount of the wall-normal jet-flow velocity (up to 64 % of free stream) should be synchronised with the high-speed events in order to obtain wall-shear stress reduction.

Despite the large body of work on the control of turbulent wall shear flows using wall suction garnered over the years, only a handful of studies considered the combination of wall blowing or wall suction and roughness (Healzer, Moffat & Kays Reference Healzer, Moffat and Kays1974; Schetz & Nerney Reference Schetz and Nerney1977; Çuhadaroğlu, Akansu & Turhal Reference Çuhadaroğlu, Akansu and Turhal2007; Miller, Martin & Bailey Reference Miller, Martin and Bailey2014; Djenidi, Kamruzzaman & Dostal Reference Djenidi, Kamruzzaman and Dostal2019a). Miller et al. (Reference Miller, Martin and Bailey2014) examined the scaling effects of combined roughness and blowing in a turbulent channel flow. The roughness consisted of a mesh-like surface with approximately sinusoidal roughness. The surface had microcracked pores distributed uniformly over the surface that allowed mass injection through it. The authors found that the effects of roughness on the mean velocity were confined to the near-wall region, and the addition of blowing was found to be analogous to an increase in roughness effects. Further, they observed that, conversely to a smooth wall configuration, blowing increases rather than decreases the skin friction. They also observed a lack of scaling, which they associated with the blowing rate-dependent suppression of the outer-scaled large-scale motion. They also showed that the effect of blowing on the Reynolds shear stress is greatest in the near-wall region with little influence on the outer part of the boundary layer. Of particular interest, the authors indicated that, in contrast to smooth wall TBL, blowing led to an increase in the skin friction. Lately, Djenidi et al. (Reference Djenidi, Kamruzzaman and Dostal2019a) carried out an experimental study of a rough wall TBL subjected to localised wall suction. They found that conversely to the smooth wall case, pseudo-relaminarisation did not occur. It was argued that the inward deflection of the high-speed flow leads to strong shear layers over the surface, leading to an increase in the turbulence intensities in the vicinity of the roughness elements. The difference in the behaviour between smooth wall TBLs and rough wall TBLs subjected to wall suction stems from this fact that the dynamical behaviour of the latter TBL in the near-wall region is different from that in the former layer. In particular, the viscosity-dominated region is strongly weakened, if not entirely removed, in a rough wall TBL. There is, in fact, strong experimental evidence (Djenidi et al. Reference Djenidi, Talluru and Antonia2018) that a fully rough wall TBLs becomes ![]() $Re$-independent, even at moderate Reynolds numbers. It in this context that it appears to be of interest to investigate whether the response of a rough wall TBL to wall suction can also become

$Re$-independent, even at moderate Reynolds numbers. It in this context that it appears to be of interest to investigate whether the response of a rough wall TBL to wall suction can also become ![]() $Re$-independent. This is not possible for a smooth wall TBL. This investigation was undertaken in the present study. The study should not only provide new insights into the physics of the dynamical response of rough wall turbulent flows to perturbations over a wide range of Re, but also allows us to develop effective TBL control strategies in both nature and engineering applications.

$Re$-independent. This is not possible for a smooth wall TBL. This investigation was undertaken in the present study. The study should not only provide new insights into the physics of the dynamical response of rough wall turbulent flows to perturbations over a wide range of Re, but also allows us to develop effective TBL control strategies in both nature and engineering applications.

The paper is organised as follows. In § 2, we briefly describe the experimental set-up and methodology. Results are presented in § 3 and the conclusion is reported in § 4.

2. Experimental procedure

The experiments are performed in an open-return blower type wind tunnel. Since the details of the facility are available in Djenidi et al. (Reference Djenidi, Kamruzzaman and Dostal2019a), we only present the salient features of the test section. The test section is 4 m long, with a 0.825 m wide and 0.16 m high cross-section. The tunnel has an adjustable roof which consists of two rectangular panels each of dimensions 2 m long and 0.9 m wide to allow the control of the streamwise pressure gradient. The pressure gradient is maintained at zero while the free stream velocity is changed from 5 to ![]() $35\ \textrm {m}\,\textrm {s}^{-1}$. The free stream turbulence level,

$35\ \textrm {m}\,\textrm {s}^{-1}$. The free stream turbulence level,![]() $\sqrt {\overline {u^2}}/U_1$, is nominally 0.5 % (at the test section located nominally 1.3 m from the inlet of the working section) for the range of free stream velocity used, where

$\sqrt {\overline {u^2}}/U_1$, is nominally 0.5 % (at the test section located nominally 1.3 m from the inlet of the working section) for the range of free stream velocity used, where ![]() $\overline {u^2}$ is the velocity variance and

$\overline {u^2}$ is the velocity variance and ![]() $U_1$ is the free stream velocity. The turbulence is tripped at the entrance to the working section by a 100 mm strip of coarse grade P40 sandpaper spanning the width of the test section. Immediately downstream of the sandpaper, the boundary layer develops over a rough surface which consists of a series of cylindrical rods mounted over the entire length of the tunnel floor and spanning the entire width of the test section. The rods have a nominal diameter

$U_1$ is the free stream velocity. The turbulence is tripped at the entrance to the working section by a 100 mm strip of coarse grade P40 sandpaper spanning the width of the test section. Immediately downstream of the sandpaper, the boundary layer develops over a rough surface which consists of a series of cylindrical rods mounted over the entire length of the tunnel floor and spanning the entire width of the test section. The rods have a nominal diameter ![]() $k =1.6\ \textrm {mm}$ and the distance between two consecutive rods is equal to

$k =1.6\ \textrm {mm}$ and the distance between two consecutive rods is equal to ![]() $15k$.

$15k$.

Wall suction is applied locally through a porous strip of streamwise length ![]() $b = 35\ \textrm {mm}$, spanning the full width of the test section. The strip, a sintered bronze with pore sizes in the range of

$b = 35\ \textrm {mm}$, spanning the full width of the test section. The strip, a sintered bronze with pore sizes in the range of ![]() $40\text {--}80\ \mathrm {\mu }\textrm {m}$ and mounted flush with the tunnel flow between two rods, is located 1.2 m downstream from the entrance of the working section. Two uniform suction velocities,

$40\text {--}80\ \mathrm {\mu }\textrm {m}$ and mounted flush with the tunnel flow between two rods, is located 1.2 m downstream from the entrance of the working section. Two uniform suction velocities, ![]() $U_s = 1.45$ and

$U_s = 1.45$ and ![]() $3.5\ \textrm {m}\,\textrm {s}^{-1}$, have been considered for the experiment. The measurements are taken at the midpoint of two consecutive roughness elements at 1.3 m from the test section inlet (between the second and third rods downstream of the porous strip) and different

$3.5\ \textrm {m}\,\textrm {s}^{-1}$, have been considered for the experiment. The measurements are taken at the midpoint of two consecutive roughness elements at 1.3 m from the test section inlet (between the second and third rods downstream of the porous strip) and different ![]() $U_1$ are used. Table 1 summarises the boundary layer characteristics for all values of

$U_1$ are used. Table 1 summarises the boundary layer characteristics for all values of ![]() $U_1$ (

$U_1$ (![]() $\delta$,

$\delta$, ![]() $\delta ^*$ and

$\delta ^*$ and ![]() $\theta$ are the boundary layer, displacement and momentum thicknesses, respectively). The notation is as follows: the streamwise and wall-normal directions are represented by

$\theta$ are the boundary layer, displacement and momentum thicknesses, respectively). The notation is as follows: the streamwise and wall-normal directions are represented by ![]() $x$ and

$x$ and ![]() $y$, respectively, in the Cartesian system; the instantaneous and local mean streamwise velocity, are denoted by

$y$, respectively, in the Cartesian system; the instantaneous and local mean streamwise velocity, are denoted by ![]() $u$ and

$u$ and ![]() $U$, respectively; the superscript ‘+’ indicates the scaling by inner length

$U$, respectively; the superscript ‘+’ indicates the scaling by inner length ![]() $(\nu /U_\tau )$ and friction velocity

$(\nu /U_\tau )$ and friction velocity ![]() $(U_\tau )$, where

$(U_\tau )$, where ![]() $\nu$ is kinematic viscosity. Further notation will be presented in the relevant sections.

$\nu$ is kinematic viscosity. Further notation will be presented in the relevant sections.

Table 1. Flow parameters for all test cases. Measurements are made at mid-distance between the second and third rods downstream of the porous strip.

The main challenge in rough TBL studies is associated with an accurate calculation of the friction velocity (![]() $U_\tau =\sqrt {\tau _w/\rho }$, where

$U_\tau =\sqrt {\tau _w/\rho }$, where ![]() $\tau _w$ is the shear stress at the wall and

$\tau _w$ is the shear stress at the wall and ![]() $\rho$ is the air density), as many scaling laws rely on its accurate estimate (Connelly, Schultz & Flack Reference Connelly, Schultz and Flack2006). While a number of indirect and cost-effective techniques such as cluster chart and power-law methods are available to determine

$\rho$ is the air density), as many scaling laws rely on its accurate estimate (Connelly, Schultz & Flack Reference Connelly, Schultz and Flack2006). While a number of indirect and cost-effective techniques such as cluster chart and power-law methods are available to determine ![]() $U_\tau$ over smooth surfaces, none are truly universally accepted for fully rough TBL due to the required additional parameters such as the fictitious origin for the mean velocity profile which varies with the roughness geometry. Here, the authors used the velocity defect chart method for estimating

$U_\tau$ over smooth surfaces, none are truly universally accepted for fully rough TBL due to the required additional parameters such as the fictitious origin for the mean velocity profile which varies with the roughness geometry. Here, the authors used the velocity defect chart method for estimating ![]() $U_\tau$ in zero pressure-gradient (ZPG) TBLs proposed by Djenidi, Talluru & Antonia (Reference Djenidi, Talluru and Antonia2019b). However, the velocity defect chart method cannot in principle be used in a non-ZPG-TBL, such in the present study, at least at the current measurement location when suction is applied. Indeed, the present measurements are carried out near the suction where the flow experiences an inward deflection (Djenidi et al. Reference Djenidi, Kamruzzaman and Dostal2019a), thus incurring a local favourable pressure gradient. For this reason, in the following we use the friction velocity,

$U_\tau$ in zero pressure-gradient (ZPG) TBLs proposed by Djenidi, Talluru & Antonia (Reference Djenidi, Talluru and Antonia2019b). However, the velocity defect chart method cannot in principle be used in a non-ZPG-TBL, such in the present study, at least at the current measurement location when suction is applied. Indeed, the present measurements are carried out near the suction where the flow experiences an inward deflection (Djenidi et al. Reference Djenidi, Kamruzzaman and Dostal2019a), thus incurring a local favourable pressure gradient. For this reason, in the following we use the friction velocity, ![]() $U_{\tau ,p}$, associated with the form drag measured using the pressure tap around one roughness element (full details of this method can be found in Kamruzzaman et al. (Reference Kamruzzaman, Talluru, Djenidi and Antonia2014)). In table 1 we report values of both

$U_{\tau ,p}$, associated with the form drag measured using the pressure tap around one roughness element (full details of this method can be found in Kamruzzaman et al. (Reference Kamruzzaman, Talluru, Djenidi and Antonia2014)). In table 1 we report values of both ![]() $U_{\tau ,t}$ (estimated friction velocity associated with the total drag (form drag plus viscous drag)) and

$U_{\tau ,t}$ (estimated friction velocity associated with the total drag (form drag plus viscous drag)) and ![]() $U_{\tau ,p}$. We observe that the latter is consistently smaller than the former, indicating that the viscous drag contribution to the total drag is negative which is consistent with the DNS results of Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003).

$U_{\tau ,p}$. We observe that the latter is consistently smaller than the former, indicating that the viscous drag contribution to the total drag is negative which is consistent with the DNS results of Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003).

A Dantec 55P15 single hot-wire with platinum Wollaston wire is used to measure the velocity. The wire diameter (d) of ![]() $2.5\ \mathrm {\mu }\textrm {m}$ with an etched length (l) of 0.5 mm is soldered to the prong-tips to achieve an

$2.5\ \mathrm {\mu }\textrm {m}$ with an etched length (l) of 0.5 mm is soldered to the prong-tips to achieve an ![]() $l$/

$l$/![]() $d$ ratio of 200, as recommended by Ligrani & Bradshaw (Reference Ligrani and Bradshaw1987) and Hutchins et al. (Reference Hutchins, Nickels, Marusic and Chong2009). The wire is operated with an in-house constant temperature circuit at an overheat ratio of 1.5 to maintain the probe temperature at approximately

$d$ ratio of 200, as recommended by Ligrani & Bradshaw (Reference Ligrani and Bradshaw1987) and Hutchins et al. (Reference Hutchins, Nickels, Marusic and Chong2009). The wire is operated with an in-house constant temperature circuit at an overheat ratio of 1.5 to maintain the probe temperature at approximately ![]() $200\,^\circ \textrm {C}$ above ambient temperature. The wall-normal distance from the wall is determined using a fixed focal length microscope with a high magnification of 200 (Celestron digital microscope) mounted on a fine threaded traverse system allowing incremental steps of

$200\,^\circ \textrm {C}$ above ambient temperature. The wall-normal distance from the wall is determined using a fixed focal length microscope with a high magnification of 200 (Celestron digital microscope) mounted on a fine threaded traverse system allowing incremental steps of ![]() $1\ \mathrm {\mu }\textrm {m}$. The hot-wire is mounted on a Mitutoyo height gauge, with a resolution of 0.01 m, and the velocity measurements are conducted at 32 logarithmically spaced points from 0.2 mm to 90 mm above the surface. The free stream temperature drift is monitored using a BAT-10 thermocouple, which has an accuracy of

$1\ \mathrm {\mu }\textrm {m}$. The hot-wire is mounted on a Mitutoyo height gauge, with a resolution of 0.01 m, and the velocity measurements are conducted at 32 logarithmically spaced points from 0.2 mm to 90 mm above the surface. The free stream temperature drift is monitored using a BAT-10 thermocouple, which has an accuracy of ![]() ${\pm }0.1\,^\circ \textrm {C}$, allowing the hot-wire data to be compensated accordingly. Before and after each series of measurements of velocity profiles, the hot-wire is calibrated against a stationary Pitot-static tube located in the free stream flow at 17 different flow speeds ranging between 0 and

${\pm }0.1\,^\circ \textrm {C}$, allowing the hot-wire data to be compensated accordingly. Before and after each series of measurements of velocity profiles, the hot-wire is calibrated against a stationary Pitot-static tube located in the free stream flow at 17 different flow speeds ranging between 0 and ![]() $35\ \textrm {m}\,\textrm {s}^{-1}$. A fifth-order polynomial fit to the calibration data is used to convert the hot-wire voltages to velocities and the intermediate single point recalibration technique is used to account for calibration drift during all measurements (Talluru et al. Reference Talluru, Kulandaivelu, Hutchins and Marusic2014). The lowest frequency response of the system to an external square wave is approximately 16 kHz, occurring at zero free stream velocity, and the data are sampled at 30 kHz for 180 s. The bias error associated with the temporal resolution and sampling time is estimated to be

$35\ \textrm {m}\,\textrm {s}^{-1}$. A fifth-order polynomial fit to the calibration data is used to convert the hot-wire voltages to velocities and the intermediate single point recalibration technique is used to account for calibration drift during all measurements (Talluru et al. Reference Talluru, Kulandaivelu, Hutchins and Marusic2014). The lowest frequency response of the system to an external square wave is approximately 16 kHz, occurring at zero free stream velocity, and the data are sampled at 30 kHz for 180 s. The bias error associated with the temporal resolution and sampling time is estimated to be ![]() ${\pm }2\,\%$. We also carried out an analysis of the overall uncertainty associated with the hot-wire measurements. It was found that the estimated uncertainty derived from the experimental apparatus (i.e. data acquisition (known as DAQ) board, pressure transmitter, analogue-to-digital (known as A/D) convertor, constant temperature anemometry (CTA) system, hot-wire probe) was less than 2 %, while the uncertainty of a given measurement position is estimated to be

${\pm }2\,\%$. We also carried out an analysis of the overall uncertainty associated with the hot-wire measurements. It was found that the estimated uncertainty derived from the experimental apparatus (i.e. data acquisition (known as DAQ) board, pressure transmitter, analogue-to-digital (known as A/D) convertor, constant temperature anemometry (CTA) system, hot-wire probe) was less than 2 %, while the uncertainty of a given measurement position is estimated to be ![]() ${\pm }0.05\ \textrm {mm}$ within the measurement region.

${\pm }0.05\ \textrm {mm}$ within the measurement region.

A comment is warranted regarding the spatial resolution. As reported by Hutchins et al. (Reference Hutchins, Nickels, Marusic and Chong2009), this issue is quite pronounced in the near-wall region of the smooth TBL. They show that, when the wall normalised hot-wire length ![]() $l^+ > 40$, increasing the Reynolds number attenuates the near-wall turbulence resulting in the inability to capture correctly the peak in the streamwise velocity variance in the viscous-dominated inner region; this is in agreement with the results of Ligrani & Bradshaw (Reference Ligrani and Bradshaw1987). Interestingly, Ligrani & Bradshaw argue that the reason for the attenuation is because length

$l^+ > 40$, increasing the Reynolds number attenuates the near-wall turbulence resulting in the inability to capture correctly the peak in the streamwise velocity variance in the viscous-dominated inner region; this is in agreement with the results of Ligrani & Bradshaw (Reference Ligrani and Bradshaw1987). Interestingly, Ligrani & Bradshaw argue that the reason for the attenuation is because length ![]() $l^+$ is larger than 20–25 which is larger than spanwise extends of the spanwise streak spacing (or low-speed regions), which is approximately 25. Johansson & Alfredsson (Reference Johansson and Alfredsson1983) also suggested that this attenuation could be attributed to spatial averaging of narrow low-speed regions. These low-speed regions are intimately linked to the mechanism of the turbulent energy at the wall. However, there is no viscous-dominated near-wall region in a fully rough wall TBL and the turbulence energy mechanism is different to that on a smooth wall (there are no low-speed streaks in the present rough wall TBL, and the turbulent energy production is associated with the shedding of vortical structures by the rods). Further, so far there is no existing study in fully rough wall bounded turbulent flows showing or demonstrating the effects of

$l^+$ is larger than 20–25 which is larger than spanwise extends of the spanwise streak spacing (or low-speed regions), which is approximately 25. Johansson & Alfredsson (Reference Johansson and Alfredsson1983) also suggested that this attenuation could be attributed to spatial averaging of narrow low-speed regions. These low-speed regions are intimately linked to the mechanism of the turbulent energy at the wall. However, there is no viscous-dominated near-wall region in a fully rough wall TBL and the turbulence energy mechanism is different to that on a smooth wall (there are no low-speed streaks in the present rough wall TBL, and the turbulent energy production is associated with the shedding of vortical structures by the rods). Further, so far there is no existing study in fully rough wall bounded turbulent flows showing or demonstrating the effects of ![]() $l^+$ on the statistics near the wall. It is thus not trivial to extrapolate the effects of spatial resolution on the statistics in the near-wall region of a smooth wall TBL to rough wall TBL since the dynamics of the flow in that region is entirely different between the two. While Hultmark et al. (Reference Hultmark, Vallikivi, Bailey and Smits2013) commented that correction accounting for spatial filtering in smooth wall TBL has not been validated for measurements in rough wall TBL, they nevertheless used it to estimate where the spatial filtering may become important over their rough wall TBL. They showed that the correction affects only the near-wall region leaving the logarithmic and wake regions practically unaffected. We performed a similar correction (not shown here) and found the effects are localised to the region

$l^+$ on the statistics near the wall. It is thus not trivial to extrapolate the effects of spatial resolution on the statistics in the near-wall region of a smooth wall TBL to rough wall TBL since the dynamics of the flow in that region is entirely different between the two. While Hultmark et al. (Reference Hultmark, Vallikivi, Bailey and Smits2013) commented that correction accounting for spatial filtering in smooth wall TBL has not been validated for measurements in rough wall TBL, they nevertheless used it to estimate where the spatial filtering may become important over their rough wall TBL. They showed that the correction affects only the near-wall region leaving the logarithmic and wake regions practically unaffected. We performed a similar correction (not shown here) and found the effects are localised to the region ![]() $y \leq k$, which suggests that if corrections are required, they will be localised to the very near-wall region of the TBL. This observation seems to be supported by noticing that the near-wall peak in the

$y \leq k$, which suggests that if corrections are required, they will be localised to the very near-wall region of the TBL. This observation seems to be supported by noticing that the near-wall peak in the ![]() $u$ distributions (see the related figure) does not seem to be attenuated as the Reynolds number increases or equivalently as

$u$ distributions (see the related figure) does not seem to be attenuated as the Reynolds number increases or equivalently as ![]() $l^+$ increases (

$l^+$ increases (![]() $l^+$ varies from approximately 12–94), as it would if spatial resolution effects were important. It is thus reasonable to believe that for this rough wall TBL, at least in the region

$l^+$ varies from approximately 12–94), as it would if spatial resolution effects were important. It is thus reasonable to believe that for this rough wall TBL, at least in the region ![]() $y \geq k$ which is the focus of this study, the spatial resolution is good enough and quite reliable for the purpose of the present study.

$y \geq k$ which is the focus of this study, the spatial resolution is good enough and quite reliable for the purpose of the present study.

3. Results

3.1. Mean velocity

The origin ![]() $y = 0$ for the profiles presented here is taken at the virtual origin (

$y = 0$ for the profiles presented here is taken at the virtual origin (![]() $d_0$), estimated based on the average moment per unit plan area acting on the roughness elements (see Jackson (Reference Jackson1981) and Kamruzzaman et al. (Reference Kamruzzaman, Talluru, Djenidi and Antonia2014) for further details on the method). It is found that the value of

$d_0$), estimated based on the average moment per unit plan area acting on the roughness elements (see Jackson (Reference Jackson1981) and Kamruzzaman et al. (Reference Kamruzzaman, Talluru, Djenidi and Antonia2014) for further details on the method). It is found that the value of ![]() $d_0$ remained practically unchanged over the range of free stream and suction velocities used,

$d_0$ remained practically unchanged over the range of free stream and suction velocities used, ![]() $d_0 \approx 0.46k$.

$d_0 \approx 0.46k$.

Figure 1 shows distributions of the inner-normalised mean streamwise velocity, ![]() $U^+$, for the different suction velocities and different

$U^+$, for the different suction velocities and different ![]() $Re_\tau$ (

$Re_\tau$ (![]() $=\delta U_{\tau ,p} /\nu$) ranging from 1079 to 8362. The distributions are plotted as functions of

$=\delta U_{\tau ,p} /\nu$) ranging from 1079 to 8362. The distributions are plotted as functions of ![]() $y^+$ and

$y^+$ and ![]() $y/k$, respectively. When no suction is applied the distributions are in agreement with the results of Djenidi et al. (Reference Djenidi, Kamruzzaman and Dostal2019a). There is a very good collapse of the profiles when they are plotted as function of

$y/k$, respectively. When no suction is applied the distributions are in agreement with the results of Djenidi et al. (Reference Djenidi, Kamruzzaman and Dostal2019a). There is a very good collapse of the profiles when they are plotted as function of ![]() $y/k$. Note that

$y/k$. Note that ![]() $U^+_{max} = U_1/U_{\tau ,p}=[2/C_f]^{1/2}$ remains practically constant as

$U^+_{max} = U_1/U_{\tau ,p}=[2/C_f]^{1/2}$ remains practically constant as ![]() $Re_\tau$ increases showing that

$Re_\tau$ increases showing that ![]() $C_f$ is constant, i.e. the form drag coefficient is

$C_f$ is constant, i.e. the form drag coefficient is ![]() $Re$-independent, at least when

$Re$-independent, at least when ![]() $Re_{\tau } > 2000$. When the profiles are plotted as functions of

$Re_{\tau } > 2000$. When the profiles are plotted as functions of ![]() $y^+$, the profiles simply shift to higher

$y^+$, the profiles simply shift to higher ![]() $y^+$. This continuous shifting, which results from a continuous increase of

$y^+$. This continuous shifting, which results from a continuous increase of ![]() $U_\tau$ with

$U_\tau$ with ![]() $Re_\tau$, indicates that

$Re_\tau$, indicates that ![]() $\nu /U_{\tau ,p}$ may not be an appropriate length scale when assessing the

$\nu /U_{\tau ,p}$ may not be an appropriate length scale when assessing the ![]() $Re$ effect on the velocity field.

$Re$ effect on the velocity field.

Figure 1. Inner-normalised mean streamwise velocity profiles as a function of (a) ![]() $y/k$ and (b)

$y/k$ and (b) ![]() $y^+$, at different

$y^+$, at different ![]() $Re$. See table 1 for symbols.

$Re$. See table 1 for symbols.

When suction is applied for a given ![]() $U_1$, the boundary layer thickness decreases and

$U_1$, the boundary layer thickness decreases and ![]() $U_{\tau ,p}$ increases (see table 1). But as observed in figure 1, suction also alters the shape of the velocity profile as compared with that without suction: the larger the suction velocity, the larger the effect on the velocity profile. The effect of suction on the velocity profiles is qualitatively similar at all Reynolds number. The profile exhibits a downward shift, which reflects an increase of

$U_{\tau ,p}$ increases (see table 1). But as observed in figure 1, suction also alters the shape of the velocity profile as compared with that without suction: the larger the suction velocity, the larger the effect on the velocity profile. The effect of suction on the velocity profiles is qualitatively similar at all Reynolds number. The profile exhibits a downward shift, which reflects an increase of ![]() $U_{\tau ,p}$ and intensifies with increasing

$U_{\tau ,p}$ and intensifies with increasing ![]() $U_s$. However, for a given value of

$U_s$. However, for a given value of ![]() $U_1$, this downward shift reaches a limit. Indeed, for

$U_1$, this downward shift reaches a limit. Indeed, for ![]() $U_s = 1.45$ and

$U_s = 1.45$ and ![]() $3.5\ \textrm {m}\,\textrm {s}^{-1}$ the profiles for

$3.5\ \textrm {m}\,\textrm {s}^{-1}$ the profiles for ![]() $U_1 = 25$ and

$U_1 = 25$ and ![]() $35\ \textrm {m}\,\textrm {s}^{-1}$ remain unchanged – they are practically indiscernible in the figure. This shows that the form drag coefficient recovers its

$35\ \textrm {m}\,\textrm {s}^{-1}$ remain unchanged – they are practically indiscernible in the figure. This shows that the form drag coefficient recovers its ![]() $Re$-independent state.

$Re$-independent state.

The behaviour of the present rough wall velocity profile when suction is applied is in sharp contrast to the behaviour observed on a smooth wall under similar localised wall suction (Antonia et al. Reference Antonia, Zhu and Sokolov1995; Oyewola et al. Reference Oyewola, Djenidi and Antonia2003). The smooth wall TBL velocity profile is observed to shift upward when suction is applied. Further, the shape of the profile approaches that of a laminar profile when relaminarisation, shown to be controlled by the suction rate and the Reynolds number, is strong. No such relaminarisation is suggested by the present velocity profiles, even at the lowest ![]() $U_1$ and highest

$U_1$ and highest ![]() $U_s$. Djenidi et al. (Reference Djenidi, Kamruzzaman and Dostal2019a) showed that just after the suction strip, the flow is subjected to a relatively strong inward deviation, where high-speed fluid from the outer region of the TBL deflects toward the wall and impacts with the roughness elements ‘feeding’ the process of vortex shedding taking place at the roughness element level, and thus maintaining the production of turbulent energy. Note that, an attempt at reducing

$U_s$. Djenidi et al. (Reference Djenidi, Kamruzzaman and Dostal2019a) showed that just after the suction strip, the flow is subjected to a relatively strong inward deviation, where high-speed fluid from the outer region of the TBL deflects toward the wall and impacts with the roughness elements ‘feeding’ the process of vortex shedding taking place at the roughness element level, and thus maintaining the production of turbulent energy. Note that, an attempt at reducing ![]() $Re_\theta$ to reach the same value (

$Re_\theta$ to reach the same value (![]() ${\approx }1400$) as those used in Antonia et al. (Reference Antonia, Zhu and Sokolov1995) and Oyewola et al. (Reference Oyewola, Djenidi and Antonia2003) and to assess whether relaminarisation in the rough wall TBL can be achieved at low Reynolds numbers was unsuccessful since that required values of

${\approx }1400$) as those used in Antonia et al. (Reference Antonia, Zhu and Sokolov1995) and Oyewola et al. (Reference Oyewola, Djenidi and Antonia2003) and to assess whether relaminarisation in the rough wall TBL can be achieved at low Reynolds numbers was unsuccessful since that required values of ![]() $U_1$ to be less than approximately

$U_1$ to be less than approximately ![]() $3\ \textrm {m}\,\textrm {s}^{-1}$, which is too small for running the wind tunnel steadily. It is interesting to observe that, regardless of the suction velocity, the mean velocity profile exhibits a logarithmic region, although the slope and the extent of the logarithmic region decrease with increasing

$3\ \textrm {m}\,\textrm {s}^{-1}$, which is too small for running the wind tunnel steadily. It is interesting to observe that, regardless of the suction velocity, the mean velocity profile exhibits a logarithmic region, although the slope and the extent of the logarithmic region decrease with increasing ![]() $U_s$ for a given Reynolds number. The persistence of a logarithmic region as

$U_s$ for a given Reynolds number. The persistence of a logarithmic region as ![]() $U_s$ increases supports the idea that relaminarisation cannot be reached on this rough wall.

$U_s$ increases supports the idea that relaminarisation cannot be reached on this rough wall.

Another representation of the mean velocity profile which shows the effect of suction is seen in figure 2 where the velocity data are reported in the form of normalised velocity defect ![]() $(U_1-U)/U_{\tau ,p}$. We also report on the figure a profile (dashed line) where

$(U_1-U)/U_{\tau ,p}$. We also report on the figure a profile (dashed line) where ![]() $U_{\tau ,t}$ is used instead of

$U_{\tau ,t}$ is used instead of ![]() $U_{\tau ,p}$. That profile is representative of the universal profile onto which ZPG smooth wall and rough wall TBLs collapse (Djenidi et al. Reference Djenidi, Talluru and Antonia2019b) and is used only as a reference. Notice this reference profile is shifted upward with respect to the ones when

$U_{\tau ,p}$. That profile is representative of the universal profile onto which ZPG smooth wall and rough wall TBLs collapse (Djenidi et al. Reference Djenidi, Talluru and Antonia2019b) and is used only as a reference. Notice this reference profile is shifted upward with respect to the ones when ![]() $U_{\tau ,p}$ is used since

$U_{\tau ,p}$ is used since ![]() $U_{\tau ,t} < U_{\tau ,p}$. When there is no suction, the profiles shift downward as

$U_{\tau ,t} < U_{\tau ,p}$. When there is no suction, the profiles shift downward as ![]() $Re_\tau$ increases, although the profiles for two largest

$Re_\tau$ increases, although the profiles for two largest ![]() $Re_\tau$ collapse, indicating that the downward shift reaches a limit. When suction is applied, the profiles show a different trend as

$Re_\tau$ collapse, indicating that the downward shift reaches a limit. When suction is applied, the profiles show a different trend as ![]() $Re_\tau$ increases: they shift upward, albeit seemingly approaching a limiting profile situated well below the reference profile; the higher the suction velocity, the larger the gap between this limiting profile and the reference one.

$Re_\tau$ increases: they shift upward, albeit seemingly approaching a limiting profile situated well below the reference profile; the higher the suction velocity, the larger the gap between this limiting profile and the reference one.

Figure 2. The mean velocity defect profiles normalised by friction velocity at different ![]() $Re$: (a)

$Re$: (a) ![]() $U_s = 0$; (b)

$U_s = 0$; (b) ![]() $U_s = 1.45\ \textrm {m}\,\textrm {s}^{-1}$; (c)

$U_s = 1.45\ \textrm {m}\,\textrm {s}^{-1}$; (c) ![]() $U_s = 3.3\ \textrm {m}\,\textrm {s}^{-1}$. See table 1 for symbols.

$U_s = 3.3\ \textrm {m}\,\textrm {s}^{-1}$. See table 1 for symbols.

It should be recalled that the measurements are carried out at a downstream distance close to the suction strip. When suction is applied, the flow experiences an inward deflection where the outer high-speed fluid deviates toward the wall behind the suction strip before it recovers further downstream (Djenidi et al. Reference Djenidi, Kamruzzaman and Dostal2019a). This flow deflection intensifies the shedding of vortical structures from the roughness elements, at least those strongly impacted by the inward high-velocity fluid. Further, the deflection is reflected in the reduced boundary layer thickness (see table 1), while the increase in the shedding intensity is manifested in the increase of ![]() $U_{\tau ,p}$. Notice that for a given

$U_{\tau ,p}$. Notice that for a given ![]() $Re_\tau$,

$Re_\tau$, ![]() $U_{\tau ,p}$ increases when the suction velocity increases lending credence to the idea that the vortex shedding intensifies with increasing suction.

$U_{\tau ,p}$ increases when the suction velocity increases lending credence to the idea that the vortex shedding intensifies with increasing suction.

3.2. Streamwise Reynolds normal stress

In order to better understand the dynamical response of the boundary layer to suction, the variation of the streamwise turbulence intensity across the entire boundary layer has also been investigated. We report in figure 3 the effect of suction on the distribution of ![]() ${\overline {u^{2}}}^+$ for the same cases considered in figure 1; note the upward displacement for better presentation.

${\overline {u^{2}}}^+$ for the same cases considered in figure 1; note the upward displacement for better presentation.

Figure 3. Distributions of the streamwise velocity variance: (a) ![]() $Re$-effect for a given suction velocity, (b)

$Re$-effect for a given suction velocity, (b) ![]() $U_s$-effect for a given

$U_s$-effect for a given ![]() $Re$ (black,

$Re$ (black, ![]() $U_s = 0$; blue,

$U_s = 0$; blue, ![]() $U_s = 1.45 \ \textrm {m}\,\textrm {s}^{-1}$; red,

$U_s = 1.45 \ \textrm {m}\,\textrm {s}^{-1}$; red, ![]() $U_s = 3.3\ \textrm {m}\,\textrm {s}^{-1}$). See table 1 for symbols.

$U_s = 3.3\ \textrm {m}\,\textrm {s}^{-1}$). See table 1 for symbols.

Before, we carry on the analysis, some remarks are warranted regarding the distributions in the near-wall region. One can see in figure 3 that the distributions exhibit a near-wall peak, which is reminiscent of that observed in smooth wall TBL. This is in contrast with the distributions shown in Djenidi et al. (Reference Djenidi, Talluru and Antonia2018) at similar Reynolds numbers and, as here, at mid-distance between two rods. This difference can be explained by the fact that the present spacing between two rods is twice that used in Djenidi et al. (Reference Djenidi, Talluru and Antonia2018) and reflects the difference in the flow dynamics near the wall and between the rods. This was well illustrated by the numerical simulations of Leonardi et al. (Reference Leonardi, Orlandi, Smalley, Djenidi and Antonia2003). These authors show that a recirculation zone extends up to approximately ![]() $4k$ behind the first rod when the rod spacing was equal or larger than

$4k$ behind the first rod when the rod spacing was equal or larger than ![]() $7k$. Thus, while the measurements in Djenidi et al. (Reference Djenidi, Talluru and Antonia2018) were located at practically the reattachment point, the measurements in the present study are beyond this point.

$7k$. Thus, while the measurements in Djenidi et al. (Reference Djenidi, Talluru and Antonia2018) were located at practically the reattachment point, the measurements in the present study are beyond this point.

As can be expected, and is illustrated in figure 3(a), suction impacts on the distribution of ![]() ${\overline {u^{2}}}^+$. For

${\overline {u^{2}}}^+$. For ![]() $Re_\tau = 1000$, the outer region of the initial distribution undergoes a significant change when suction is applied. However, as

$Re_\tau = 1000$, the outer region of the initial distribution undergoes a significant change when suction is applied. However, as ![]() $Re_\tau$ increases the distribution tends to recover its original shape, although, as seen in figure 3(a), the magnitude of the former remains below the latter, as it should be since suction yields a larger

$Re_\tau$ increases the distribution tends to recover its original shape, although, as seen in figure 3(a), the magnitude of the former remains below the latter, as it should be since suction yields a larger ![]() $U_{\tau ,p}$; the larger the suction velocity the larger

$U_{\tau ,p}$; the larger the suction velocity the larger ![]() $U_{\tau ,p}$, and thus the larger the different between the perturbed and unperturbed distributions for a given Reynolds number. Of interest is the behaviour of the distributions at the lowest

$U_{\tau ,p}$, and thus the larger the different between the perturbed and unperturbed distributions for a given Reynolds number. Of interest is the behaviour of the distributions at the lowest ![]() $Re_\tau$. The

$Re_\tau$. The ![]() ${\overline {u^{2}}}^+$ distributions for

${\overline {u^{2}}}^+$ distributions for ![]() $U_s=1.45$ and

$U_s=1.45$ and ![]() $3.3\ \textrm {m}\,\textrm {s}^{-1}$, respectively, collapse in the outer region (see figure 3b). This is consistent with the following process: a large part of the inner region of the incoming TBL is removed and replaced by a fluid with lower

$3.3\ \textrm {m}\,\textrm {s}^{-1}$, respectively, collapse in the outer region (see figure 3b). This is consistent with the following process: a large part of the inner region of the incoming TBL is removed and replaced by a fluid with lower ![]() ${\overline {u^{2}}}^+$ deflected inward from the outer region. On the other hand, the distributions in the near-wall region deviate from each other. This deviation reduces with increasing

${\overline {u^{2}}}^+$ deflected inward from the outer region. On the other hand, the distributions in the near-wall region deviate from each other. This deviation reduces with increasing ![]() $Re_\tau$ until it vanishes, indicating that the perturbed near-wall region becomes insensible to

$Re_\tau$ until it vanishes, indicating that the perturbed near-wall region becomes insensible to ![]() $Re_\tau$, although the deviation with respect to undisturbed profile still remains.

$Re_\tau$, although the deviation with respect to undisturbed profile still remains.

For the present study, normalising the data by ![]() $U_{\tau ,p}$ and

$U_{\tau ,p}$ and ![]() $\nu /U_{\tau ,p}$ can make the data interpretation somewhat difficult since it is observed that

$\nu /U_{\tau ,p}$ can make the data interpretation somewhat difficult since it is observed that ![]() $U_{\tau ,p}$ is impacted by suction. Therefore, we report the distributions of the ratio

$U_{\tau ,p}$ is impacted by suction. Therefore, we report the distributions of the ratio ![]() $(\sqrt {\overline {u^2}}/U_1)$ as a function of

$(\sqrt {\overline {u^2}}/U_1)$ as a function of ![]() $y/k$ in figure 4(a) for the three suction velocities at different Reynolds numbers. At low Reynolds numbers (

$y/k$ in figure 4(a) for the three suction velocities at different Reynolds numbers. At low Reynolds numbers (![]() $Re_\tau < 1300$), the data show that perturbed distributions collapse well in the region

$Re_\tau < 1300$), the data show that perturbed distributions collapse well in the region ![]() $0 \le y/k \le 10$, while they deviate from the unperturbed one. Also,

$0 \le y/k \le 10$, while they deviate from the unperturbed one. Also, ![]() $(\sqrt {\overline {u^2}}/U_1)$ for the perturbed TBL is larger than that for the unperturbed TBL for

$(\sqrt {\overline {u^2}}/U_1)$ for the perturbed TBL is larger than that for the unperturbed TBL for ![]() $y/k \le 1$. This indicates that the turbulence activity increases in this region when suction is applied. For

$y/k \le 1$. This indicates that the turbulence activity increases in this region when suction is applied. For ![]() $1 \le y/k \le 10$, the perturbed TBL presents a much-reduced turbulence activity than in the unperturbed TBL. The change in the

$1 \le y/k \le 10$, the perturbed TBL presents a much-reduced turbulence activity than in the unperturbed TBL. The change in the ![]() $(\sqrt {\overline {u^2}}/U_1)$ distribution is consistent with the physical mechanism discussed above: suction deviates high-velocity fluid from the outer region towards the wall, causing some structural changes in the flow which results in a strongly altered turbulence energy distribution within the TBL. As

$(\sqrt {\overline {u^2}}/U_1)$ distribution is consistent with the physical mechanism discussed above: suction deviates high-velocity fluid from the outer region towards the wall, causing some structural changes in the flow which results in a strongly altered turbulence energy distribution within the TBL. As ![]() $Re_\tau$ increases, the inward deflection of outer-layer fluid weakens as seen in the recovery of the perturbed distributions toward the unperturbed, although the perturbed distributions still deviate from the unperturbed one at the largest

$Re_\tau$ increases, the inward deflection of outer-layer fluid weakens as seen in the recovery of the perturbed distributions toward the unperturbed, although the perturbed distributions still deviate from the unperturbed one at the largest ![]() $Re_\tau$, illustrating the lingering effect of suction on the TBL. This is consistent with the remark that the perturbed boundary layer does not return to its undisturbed state (Oyewola et al. Reference Oyewola, Djenidi and Antonia2003).

$Re_\tau$, illustrating the lingering effect of suction on the TBL. This is consistent with the remark that the perturbed boundary layer does not return to its undisturbed state (Oyewola et al. Reference Oyewola, Djenidi and Antonia2003).

Figure 4. Effect of suction on the ratio (a) ![]() $\sqrt {\overline {u^2}}/U_1$ and (b)

$\sqrt {\overline {u^2}}/U_1$ and (b) ![]() $\sqrt {\overline {u^2}}/U$ for different Reynolds numbers (see table 1 for symbols).

$\sqrt {\overline {u^2}}/U$ for different Reynolds numbers (see table 1 for symbols).

The results of figure 4(a) clearly illustrate the modulating role of the Reynolds number on the effect of suction. This modulating role is clearly seen in figure 4(b) which shows the ratio ![]() $(\sqrt {\overline {u^2}}/U)$. This ratio measures the importance of the velocity fluctuation

$(\sqrt {\overline {u^2}}/U)$. This ratio measures the importance of the velocity fluctuation ![]() $u$ in relation to the local mean velocity

$u$ in relation to the local mean velocity ![]() $U$,

$U$, ![]() $viz.$ turbulence level. This ratio is reduced across the entire boundary layer thickness when suction is applied at low Reynolds number (

$viz.$ turbulence level. This ratio is reduced across the entire boundary layer thickness when suction is applied at low Reynolds number (![]() $Re_\tau < 1300$), this reduction is up to 27 % near the wall. This is likely to reflect an increase in the local mean velocity, due to an intense downwash of the high-speed fluid, rather than a reduction in

$Re_\tau < 1300$), this reduction is up to 27 % near the wall. This is likely to reflect an increase in the local mean velocity, due to an intense downwash of the high-speed fluid, rather than a reduction in ![]() $u$. Indeed, for the same range of

$u$. Indeed, for the same range of ![]() $Re$, figure 4(a) shows that

$Re$, figure 4(a) shows that ![]() $\sqrt {\overline {u^2}}$ increases in this near-wall region when suction is applied. As the Reynolds number increases, the ratio recovers to that of the undisturbed TBL across the boundary layer thickness. Note that the ratio

$\sqrt {\overline {u^2}}$ increases in this near-wall region when suction is applied. As the Reynolds number increases, the ratio recovers to that of the undisturbed TBL across the boundary layer thickness. Note that the ratio ![]() $(\sqrt {\overline {u^2}}/U)$ reaches a finite non-zero value as

$(\sqrt {\overline {u^2}}/U)$ reaches a finite non-zero value as ![]() $y/k \rightarrow 0$. The non-zero magnitude of the wall-shear stress on a smooth wall varies between 0.35 and 0.43 depending on

$y/k \rightarrow 0$. The non-zero magnitude of the wall-shear stress on a smooth wall varies between 0.35 and 0.43 depending on ![]() $Re$ (

$Re$ (![]() $300 < Re_\theta < 10^4$) (Oyewola et al. Reference Oyewola, Djenidi and Antonia2003; Örlü & Schlatter Reference Örlü and Schlatter2011). This is, however, less than the present value which is approximately 0.5. This shows that the turbulence level is higher in a rough wall TBL than in a smooth TBL and reflects different turbulence production mechanics between the two TBLs.

$300 < Re_\theta < 10^4$) (Oyewola et al. Reference Oyewola, Djenidi and Antonia2003; Örlü & Schlatter Reference Örlü and Schlatter2011). This is, however, less than the present value which is approximately 0.5. This shows that the turbulence level is higher in a rough wall TBL than in a smooth TBL and reflects different turbulence production mechanics between the two TBLs.

One possible rudimentary way for assessing the global effect of a control technique on the TBL would be to evaluate the following quantity:

which is simply the integral of the velocity root mean square (r.m.s.) across the boundary layer thickness. Figure 5 reports the ratio ![]() $\tilde {u}_{s}/\tilde {u}_{ws}$, where the subscripts

$\tilde {u}_{s}/\tilde {u}_{ws}$, where the subscripts ![]() $s$ and

$s$ and ![]() $ws$ represent with suction and without suction, respectively. A ratio less than one would indicate a global reduction of the turbulence intensity, which is the case for all conditions. This may not be too surprising since suction removes high turbulence intensity fluid as seen in figure 4(a). Note, as one may have expected, that the behaviour of this ratio is in complete correspondence with the behaviour of distributions in figure 4(a). Indeed, for example, the distributions for

$ws$ represent with suction and without suction, respectively. A ratio less than one would indicate a global reduction of the turbulence intensity, which is the case for all conditions. This may not be too surprising since suction removes high turbulence intensity fluid as seen in figure 4(a). Note, as one may have expected, that the behaviour of this ratio is in complete correspondence with the behaviour of distributions in figure 4(a). Indeed, for example, the distributions for ![]() $Re_\tau$ show that

$Re_\tau$ show that ![]() $\sqrt {\overline {u^2}}/U_1$ for

$\sqrt {\overline {u^2}}/U_1$ for ![]() $U_s = 3.3\ \textrm {m}\,\textrm {s}^{-1}$ is significantly below that for

$U_s = 3.3\ \textrm {m}\,\textrm {s}^{-1}$ is significantly below that for ![]() $U_s = 1.45\ \textrm {m}\,\textrm {s}^{-1}$ across most of the boundary layer thickness and accordingly yields a smaller ratio

$U_s = 1.45\ \textrm {m}\,\textrm {s}^{-1}$ across most of the boundary layer thickness and accordingly yields a smaller ratio ![]() $\tilde {u}_{s}/\tilde {u}_{ws}$. Also, consistent with the results of figure 4(a) is the effect of the Reynolds number on the suction effectiveness in reducing this ratio, which increases with the Reynolds number. Interestingly though, the ratio does not reach unity, which is consistent with the remark that the perturbed TBL does not return to its undisturbed stated. Rather, the TBL recovers an unperturbed state whose initial conditions are at the porous strip and controlled by suction. It is worth noticing that the difference in the ratios between the two suction cases is the largest at

$\tilde {u}_{s}/\tilde {u}_{ws}$. Also, consistent with the results of figure 4(a) is the effect of the Reynolds number on the suction effectiveness in reducing this ratio, which increases with the Reynolds number. Interestingly though, the ratio does not reach unity, which is consistent with the remark that the perturbed TBL does not return to its undisturbed stated. Rather, the TBL recovers an unperturbed state whose initial conditions are at the porous strip and controlled by suction. It is worth noticing that the difference in the ratios between the two suction cases is the largest at ![]() $U_1=10\ \textrm {m}\,\textrm {s}^{-1}$. To determine whether this actually reflects a genuine dynamical response of the TBL to suction we carried out repeatability tests where the velocity measurements were repeated three times and averaged. Accounting for the systematic and measurement errors, we found that the overall uncertainty of the measured mean and r.m.s. velocities was less than

$U_1=10\ \textrm {m}\,\textrm {s}^{-1}$. To determine whether this actually reflects a genuine dynamical response of the TBL to suction we carried out repeatability tests where the velocity measurements were repeated three times and averaged. Accounting for the systematic and measurement errors, we found that the overall uncertainty of the measured mean and r.m.s. velocities was less than ![]() ${\pm }2\,\%$. Therefore, the difference in the ratio between the two suction cases at

${\pm }2\,\%$. Therefore, the difference in the ratio between the two suction cases at ![]() $U_1=10\ \textrm {m}\,\textrm {s}^{-1}$ is genuine as the difference falls outside the experimental uncertainty. Note that the difference in the ratio decreases as

$U_1=10\ \textrm {m}\,\textrm {s}^{-1}$ is genuine as the difference falls outside the experimental uncertainty. Note that the difference in the ratio decreases as ![]() $U_1$ increases and practically vanishes when

$U_1$ increases and practically vanishes when ![]() $U_1=35\ \textrm {m}\,\textrm {s}^{-1}$.

$U_1=35\ \textrm {m}\,\textrm {s}^{-1}$.

Figure 5. Ratio ![]() $\tilde {u}_{s}/\tilde {u}_{ws}$ for the four different values of

$\tilde {u}_{s}/\tilde {u}_{ws}$ for the four different values of ![]() $U_1$ (grey bars,

$U_1$ (grey bars, ![]() $U_s = 1.45\ \textrm {m}\,\textrm {s}^{-1}$; black bars,

$U_s = 1.45\ \textrm {m}\,\textrm {s}^{-1}$; black bars, ![]() $U_s = 3.3\ \textrm {m}\,\textrm {s}^{-1}$).

$U_s = 3.3\ \textrm {m}\,\textrm {s}^{-1}$).

The above analysis was also carried out where the normalised suction rate defined as ![]() $\sigma = (U_s b)/(U_1 \theta )$, introduced by Antonia et al. (Reference Antonia, Zhu and Sokolov1995), was kept constant while changing the Reynolds number. This suction rate, also called severity index, represents the ratio of momentum flux loss due to suction and the momentum flux of the incoming boundary layer. In the present study, to maintain a constant

$\sigma = (U_s b)/(U_1 \theta )$, introduced by Antonia et al. (Reference Antonia, Zhu and Sokolov1995), was kept constant while changing the Reynolds number. This suction rate, also called severity index, represents the ratio of momentum flux loss due to suction and the momentum flux of the incoming boundary layer. In the present study, to maintain a constant ![]() $\sigma$ while the Reynolds number, or equivalently

$\sigma$ while the Reynolds number, or equivalently ![]() $U_1$, varies one must change the suction velocity

$U_1$, varies one must change the suction velocity ![]() $U_s$ accordingly. Unfortunately, it is not possible to carry out a systematic parametric analysis of the influence of

$U_s$ accordingly. Unfortunately, it is not possible to carry out a systematic parametric analysis of the influence of ![]() $Re$ at given

$Re$ at given ![]() $\sigma$ due to the limitation imposed by the wind tunnel set-up and suction system; such study would require varying

$\sigma$ due to the limitation imposed by the wind tunnel set-up and suction system; such study would require varying ![]() $U_s$ from

$U_s$ from ![]() $0.3\ \textrm {m}\,\textrm {s}^{-1}$ to

$0.3\ \textrm {m}\,\textrm {s}^{-1}$ to ![]() $20\ \textrm {m}\,\textrm {s}^{-1}$ for the range of Reynolds number in this work. We nevertheless were able to carry out a set of measurements with

$20\ \textrm {m}\,\textrm {s}^{-1}$ for the range of Reynolds number in this work. We nevertheless were able to carry out a set of measurements with ![]() $\sigma = 0$, 0.5 and 2.5. The results are reported in figure 6. First, we observe that although

$\sigma = 0$, 0.5 and 2.5. The results are reported in figure 6. First, we observe that although ![]() $\sigma$ is not relatively large, the effect of suction is nonetheless important. Second, the figure illustrates well the somewhat expected result that the higher

$\sigma$ is not relatively large, the effect of suction is nonetheless important. Second, the figure illustrates well the somewhat expected result that the higher ![]() $\sigma$ for a given Reynolds number, the larger the suction effect, quantified using (3.1); in other words the effect of suction diminishes as Re increases. Third, the entire distributions are affected in term of magnitude. These results are similar to that observed in figure 3.

$\sigma$ for a given Reynolds number, the larger the suction effect, quantified using (3.1); in other words the effect of suction diminishes as Re increases. Third, the entire distributions are affected in term of magnitude. These results are similar to that observed in figure 3.

Figure 6. Combined effect of Reynolds number and ![]() $\sigma$ on the streamwise velocity variance (black symbols,

$\sigma$ on the streamwise velocity variance (black symbols, ![]() $\sigma =0$; red symbols, (a)

$\sigma =0$; red symbols, (a) ![]() $\sigma =0.5$, (b)

$\sigma =0.5$, (b) ![]() $\sigma =2.5$). See table 1 for symbols.

$\sigma =2.5$). See table 1 for symbols.

3.3. Higher-order moments

To gain further insight into the combined effect of the Reynolds number and suction on the TBL structure we now focus our attention on the third- and fourth-order statistics of the streamwise velocity. Figure 7 shows the distributions of the skewness, ![]() $S_u = \overline {u^{3}}/(\overline {u^{2}})^{3/2}$, and flatness factor,

$S_u = \overline {u^{3}}/(\overline {u^{2}})^{3/2}$, and flatness factor, ![]() $F_u = \overline {u^{4}}/(\overline {u^{2}})^{2}$, for the different suction velocities and Reynolds numbers. The general shape of the distributions is similar to that of a canonical TBL (not shown here) reported in the literature. Considering that we already observed that the effects of suction are stronger at low Reynolds numbers, it is then not surprising to note that these effects on the higher-order moments are stronger at the lowest Reynolds number, while they are more pronounced for the highest velocity suction. Also, these effects are more noticeable on

$F_u = \overline {u^{4}}/(\overline {u^{2}})^{2}$, for the different suction velocities and Reynolds numbers. The general shape of the distributions is similar to that of a canonical TBL (not shown here) reported in the literature. Considering that we already observed that the effects of suction are stronger at low Reynolds numbers, it is then not surprising to note that these effects on the higher-order moments are stronger at the lowest Reynolds number, while they are more pronounced for the highest velocity suction. Also, these effects are more noticeable on ![]() $S_u$ than

$S_u$ than ![]() $F_u$, which indicates that the skewness is more sensitive to the perturbation than the flatness factor.

$F_u$, which indicates that the skewness is more sensitive to the perturbation than the flatness factor.

Figure 7. Distribution of (a) skewness, ![]() $S_u = \overline {u^{3}}/(\overline {u^{2}})^{3/2}$ and (b) flatness,

$S_u = \overline {u^{3}}/(\overline {u^{2}})^{3/2}$ and (b) flatness, ![]() $F_u = \overline {u^{4}}/(\overline {u^{2}})^{2}$ of the streamwise velocity fluctuations over a range of

$F_u = \overline {u^{4}}/(\overline {u^{2}})^{2}$ of the streamwise velocity fluctuations over a range of ![]() $Re_\tau$. See table 1 for symbols.

$Re_\tau$. See table 1 for symbols.

When suction is applied, ![]() $S_u$ is mostly affected in the region above the roughness canopy. In this region,

$S_u$ is mostly affected in the region above the roughness canopy. In this region, ![]() $S_u$ decreases with increasing

$S_u$ decreases with increasing ![]() $U_s$. When

$U_s$. When ![]() $U_s = 0$, the values of

$U_s = 0$, the values of ![]() $S_u$ is positive, indicating that events with large negative values of

$S_u$ is positive, indicating that events with large negative values of ![]() $\overline {u^{3}}$ are not as frequent as events with large positive values of

$\overline {u^{3}}$ are not as frequent as events with large positive values of ![]() $\overline {u^{3}}$ (Tennekes et al. Reference Tennekes1972). The situation inverses when suction is applied as indicated by the negative values of

$\overline {u^{3}}$ (Tennekes et al. Reference Tennekes1972). The situation inverses when suction is applied as indicated by the negative values of ![]() $S_u$, particularly for

$S_u$, particularly for ![]() $U_s=3.3\ \textrm {m}\,\textrm {s}^{-1}$. Here, large negative values of

$U_s=3.3\ \textrm {m}\,\textrm {s}^{-1}$. Here, large negative values of ![]() $\overline {u^{3}}$ are more frequent than large positive values. This inversion process is illustrated in figure 8 which shows the probability density function (p.d.f.) of

$\overline {u^{3}}$ are more frequent than large positive values. This inversion process is illustrated in figure 8 which shows the probability density function (p.d.f.) of ![]() $u$ at

$u$ at ![]() $y/\delta = 0.12$; this is clearly visible for the lowest Reynolds number. The undisturbed p.d.f. deviates from a Gaussian distribution with the deviation weakening as the Reynolds number increases. When suction is applied, the p.d.f. is skewed towards the positive side with its tail on the negative side being longer than that on the positive side, which is characteristic of a negative

$y/\delta = 0.12$; this is clearly visible for the lowest Reynolds number. The undisturbed p.d.f. deviates from a Gaussian distribution with the deviation weakening as the Reynolds number increases. When suction is applied, the p.d.f. is skewed towards the positive side with its tail on the negative side being longer than that on the positive side, which is characteristic of a negative ![]() $S_u$. As the Reynolds number increases the perturbed p.d.f. approaches the Gaussian distribution. The behaviour of the p.d.f. when suction is applied is consistent with the description of the response of the TBL: suction deflects the TBL outer region fluid towards the wall which brings high velocity and strongly intermittent flow. This inrush of intermittent flow is also felt in the flatness factor which increases in comparison with the undisturbed case, albeit the increase may appear less pronounced than the decrease observed on

$S_u$. As the Reynolds number increases the perturbed p.d.f. approaches the Gaussian distribution. The behaviour of the p.d.f. when suction is applied is consistent with the description of the response of the TBL: suction deflects the TBL outer region fluid towards the wall which brings high velocity and strongly intermittent flow. This inrush of intermittent flow is also felt in the flatness factor which increases in comparison with the undisturbed case, albeit the increase may appear less pronounced than the decrease observed on ![]() $S_u$. As the Reynolds number increases the inward deflection weakens, thus reducing the intrusion of high-speed and strongly intermittent fluid from the outer region into the inner region, which in turn reduces the intermittency level leading to the recovery of

$S_u$. As the Reynolds number increases the inward deflection weakens, thus reducing the intrusion of high-speed and strongly intermittent fluid from the outer region into the inner region, which in turn reduces the intermittency level leading to the recovery of ![]() $S_u$ and the p.d.f.

$S_u$ and the p.d.f.

Figure 8. Probability density function of ![]() $u$ at

$u$ at ![]() $y/\delta = 0.12$. Dashed line, Gaussian distribution; solid black line,

$y/\delta = 0.12$. Dashed line, Gaussian distribution; solid black line, ![]() $U_s = 0$; blue line,

$U_s = 0$; blue line, ![]() $U_s = 1.45\ \textrm {m}\,\textrm {s}^{-1}$; red line,

$U_s = 1.45\ \textrm {m}\,\textrm {s}^{-1}$; red line, ![]() $U_s = 3.3\ \textrm {m}\,\textrm {s}^{-1}$. The

$U_s = 3.3\ \textrm {m}\,\textrm {s}^{-1}$. The ![]() $Re_\tau$ is the lowest in (a) and highest in (e).

$Re_\tau$ is the lowest in (a) and highest in (e).

3.4. Spectral analysis

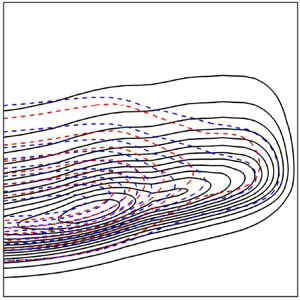

While the above results provide some insight into the response of the TBL to the localised wall suction, they only inform on the global response of the TBL. Ascertaining how the perturbation may impact on the various length scales of the TBL can be achieved in the spectral domain. We report in figure 9 the two-dimensional contour maps of the (streamwise) velocity spectra normalised by ![]() $U_{\tau ,p}$ as a function of

$U_{\tau ,p}$ as a function of ![]() $y/\delta$ and

$y/\delta$ and ![]() $\lambda _x/\delta$;

$\lambda _x/\delta$; ![]() $\lambda _x = U_c/f$ is the streamwise wavelength, which is calculated using Taylor's frozen hypothesis (Taylor Reference Taylor1938) where the local mean velocity

$\lambda _x = U_c/f$ is the streamwise wavelength, which is calculated using Taylor's frozen hypothesis (Taylor Reference Taylor1938) where the local mean velocity ![]() $U$ is taken as the convection velocity,

$U$ is taken as the convection velocity, ![]() $U_c$. This latter is critical in the application of the Taylor hypothesis and has been the subject of many investigations (see for example Squire et al. (Reference Squire, Hutchins, Morrill-Winter, Schultz, Klewicki and Marusic2017) where the reader can find a brief literature review). Interestingly, Squire et al. (Reference Squire, Hutchins, Morrill-Winter, Schultz, Klewicki and Marusic2017) found that, to within experimental uncertainty, the Taylor hypothesis is appropriate for the streamwise velocity component over both smooth and rough walls. However, the level of turbulence intensity measured by the ratio

$U_c$. This latter is critical in the application of the Taylor hypothesis and has been the subject of many investigations (see for example Squire et al. (Reference Squire, Hutchins, Morrill-Winter, Schultz, Klewicki and Marusic2017) where the reader can find a brief literature review). Interestingly, Squire et al. (Reference Squire, Hutchins, Morrill-Winter, Schultz, Klewicki and Marusic2017) found that, to within experimental uncertainty, the Taylor hypothesis is appropriate for the streamwise velocity component over both smooth and rough walls. However, the level of turbulence intensity measured by the ratio ![]() $\sqrt {\overline {u^2}}/U$ across their TBL was less than approximately 0.3, which is approximately the upper limit for the validity of Taylor's frozen hypothesis. In the present work and as can be seen in figure 4(b), the ratio

$\sqrt {\overline {u^2}}/U$ across their TBL was less than approximately 0.3, which is approximately the upper limit for the validity of Taylor's frozen hypothesis. In the present work and as can be seen in figure 4(b), the ratio ![]() $\sqrt {\overline {u^2}}/U$ exceeds 0.45 in the region

$\sqrt {\overline {u^2}}/U$ exceeds 0.45 in the region ![]() $0 \leq y/k \leq 1$, indicating that the Taylor's frozen hypothesis is violated in this region; beyond that region though

$0 \leq y/k \leq 1$, indicating that the Taylor's frozen hypothesis is violated in this region; beyond that region though ![]() $\sqrt {\overline {u^2}}/U$ drops below 0.3. Considering that the Taylor hypothesis is invalid in the region

$\sqrt {\overline {u^2}}/U$ drops below 0.3. Considering that the Taylor hypothesis is invalid in the region ![]() $0 \leq y/k \leq 1$, we did not attempt any near-wall correction (Chung & McKeon Reference Chung and McKeon2010). We simply used the local velocity as the convective velocity to compute the spectra contour maps and shaded the region

$0 \leq y/k \leq 1$, we did not attempt any near-wall correction (Chung & McKeon Reference Chung and McKeon2010). We simply used the local velocity as the convective velocity to compute the spectra contour maps and shaded the region ![]() $0 \leq y/k \leq 1$ on those maps (see figure 9). Thus, as delimited by the vertical dashed line in the figure, the discussion will focus only on the region

$0 \leq y/k \leq 1$ on those maps (see figure 9). Thus, as delimited by the vertical dashed line in the figure, the discussion will focus only on the region ![]() $y/k > 1$.

$y/k > 1$.

Figure 9. Two-dimensional spectrograms of the inner-normalised premultiplied velocity spectra (![]() $k_x\phi _{uu}/{U_{\tau , p}}^2$) with (i)

$k_x\phi _{uu}/{U_{\tau , p}}^2$) with (i) ![]() $U_s = 0$; (ii)

$U_s = 0$; (ii) ![]() $U_s = 1.45\ \textrm {m}\,\textrm {s}^{-1}$; (iii)