1. Introduction

Liquid film flow down an inclined or vertical solid surface is of great importance for its many engineering applications as well as its intrinsic scientific interest. There is a considerable body of literature devoted to this topic which has been described in books (Chang & Demekhin Reference Chang and Demekhin2002; Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2012) and in many review articles (see, e.g. Chang Reference Chang1994; Oron, Davis & Bankoff Reference Oron, Davis and Bankoff1997; Weinstein & Ruschak Reference Weinstein and Ruschak2004; Craster & Matar Reference Craster and Matar2009; Bandi et al. Reference Bandi, Modigell, Gross, Reusken, Zhang, Heng, Marquardt and Mhamdi2018). It has long been known that the film surface ceases to remain plane as soon as the Reynolds number exceeds a critical value, which is a decreasing function of the inclination angle and vanishes for a vertical surface. As a result of this instability, the film surface develops a complex wave structure the description and understanding of which has proven a formidable challenge for theory as well as computation. At the same time, it is this very wave structure that makes the film scientifically interesting and endows it with a much greater ability to transfer mass and heat compared to a flat film.

There appear to be two main factors for the enhancement of transport processes in laminar wavy films, both of which depend on the characteristic structure of the free surface, with large ‘roll waves,’ accompanied by a train of much smaller capillary waves on a relatively thin film. The first mechanism is associated with the large waves, and particularly with the fact that, when the Reynolds number exceeds a few tens, in their rest frame the liquid develops a recirculating region. The second mechanism concerns the thin film separating the large waves and the small capillary waves on its surface.

Theory and computation have been important tools used to evaluate the relative importance of the large waves versus the film and accompanying capillary waves. The literature offers different opinions as to which of the two factors is the dominant cause of the increased transfer. Dukler was an early proponent of the dominant role of large waves (Dukler Reference Dukler1977; Wasden & Dukler Reference Wasden and Dukler1990) and his point of view has been supported by several subsequent researchers (see, e.g. Yoshimura, Nosoko & Nagata Reference Yoshimura, Nosoko and Nagata1996; Bontozoglou Reference Bontozoglou1998; Roberts & Chang Reference Roberts and Chang2000; Miyara et al. Reference Miyara, Yamamoto, Iemura and Shimada2003; Islam, Miyara & Setoguchi Reference Islam, Miyara and Setoguchi2009). In this view, the recirculation facilitates the exchange of heat and mass with the gas or vapour on the other side of the free surface by bringing fresh liquid near the film surface.

Other authors have instead focused on the effect of the thin film separating the large waves. Jayanti & Hewitt (Reference Jayanti and Hewitt1997) argue that ‘the overall heat transfer coefficient is determined mainly by conduction through the film, rather than by the recirculation, if any, under the waves,’ adding that the main role of the large waves is to collect much of the liquid thus thinning the film separating them, an idea also espoused by Miyara (Reference Miyara1999) and Serifi, Malamataris & Bontozoglou (Reference Serifi, Malamataris and Bontozoglou2004). Morioka & Kiyota (Reference Morioka and Kiyota1991) find that ‘The local absorption mass flux shows a maximum or minimum at the position where the film thickness is minimum or maximum, respectively.’ A similar statement can be found in Bo et al. (Reference Bo, Ma, Chen and Lan2011), according to which ‘The maximum value of local heat flux is located at the first capillary wave trough, while the minimum in local heat flux lies slightly ahead of the film thickness maximum … The region of capillary waves shows a significant amount of absorption enhancement.’ In fact, work can be found in the literature directed at finding ways to disrupt the large waves thereby increasing the transfer (see, e.g. Valluri et al. Reference Valluri, Matar, Hewitt and Mendes2005; Trifonov Reference Trifonov2011; Dietze Reference Dietze2019).

There are two main reasons for such a controversy to persist. In the first place, as explained below in § 2, in the laminar two-dimensional regime the film flow depends on three dimensionless parameters, to which the Prandtl or Schmidt numbers must be added to account for transport phenomena. As noted by several authors (see, e.g. Yoshimura et al. Reference Yoshimura, Nosoko and Nagata1996; Sisoev, Matar & Lawrence Reference Sisoev, Matar and Lawrence2005; Rastaturin, Demekhin & Kalaidin Reference Rastaturin, Demekhin and Kalaidin2006), these independent parameters have a strong effect on the transfer rates which cannot simply be attributed to either the large waves or the capillary waves. Secondly, as already noted in the literature (see, e.g. Islam et al. Reference Islam, Miyara and Setoguchi2009) and as will be shown below, the transfer process evolves continuously with distance as the film flows, with certain processes dominant near the inlet and others further downstream. Thus, biased conclusions may be drawn unless the computational domain is sufficiently long.

Several papers report measurements of the local instantaneous heat transfer coefficient and Nusselt number for a falling film flow (see, e.g. Al-Sibai, Leefken & Renz Reference Al-Sibai, Leefken and Renz2002; Markides, Mathie & Charogiannis Reference Markides, Mathie and Charogiannis2016; Charogiannis & Markides Reference Charogiannis and Markides2019). Although techniques for similar investigations of mass transfer have been developed (see, e.g. Ruettinger et al. Reference Ruettinger, Spille, Hoffmann and Schlueter2018), they have not been used for the flows of present concern. Adaptation of the information acquired for heat transfer to mass transfer is not straightforward due to the large difference of typical Prandtl versus Schmidt numbers, the temperature dependence of physical properties, including surface tension and the attendant Marangoni flows, the difference in boundary conditions at the solid surface and, last but not least, phase change and latent heat effects. Furthermore, what has been measured is a heat transfer coefficient based on the rate of the heat flux imposed at the solid boundary and the surface-to-wall temperature difference which, particularly for Prandtl numbers as large as typical Schmidt numbers, can be quite different from the local heat flux at the interface. The majority of the data in the most recent paper (Charogiannis & Markides Reference Charogiannis and Markides2019) refers to situations in which the maximum liquid velocity is smaller than the wave velocity so that recirculation, if at all present, is minimal. The authors observed an increased heat transfer coefficient with respect to steady-film flows although, as they state, ‘the observed heat transfer enhancement does not rely on flow recirculation.’ These results point to a strong effect of the entire flow on the transfer process, which may not be simply reduced to the recirculation/no-recirculation question. The results for the largest Prandtl number investigated, ![]() $Pr = 77$, show that, at low

$Pr = 77$, show that, at low ![]() $Re$, there is a direct conduction effect inversely proportional to the film thickness, which decreases as the

$Re$, there is a direct conduction effect inversely proportional to the film thickness, which decreases as the ![]() $Re$ increases and, with it, the film thickness. This direct effect may be expected to be reduced by the order-of-magnitude increase of the Schmidt number for the mass transfer of present concern with respect to the Prandtl number for their heat transfer problem. However, the indirect convective effect of the flow field will operate in a similar way for the mass transfer problem.

$Re$ increases and, with it, the film thickness. This direct effect may be expected to be reduced by the order-of-magnitude increase of the Schmidt number for the mass transfer of present concern with respect to the Prandtl number for their heat transfer problem. However, the indirect convective effect of the flow field will operate in a similar way for the mass transfer problem.

Taking advantage of the large difference between the scale of variation of the flow structures in the streamwise versus the wall-normal directions, several reduced-order models have been introduced (see, e.g. Chang & Demekhin Reference Chang and Demekhin2002; Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2012). While much has been learned from them, as far as the fluid mechanic aspects of the problem are concerned (Ruyer-Quil & Manneville Reference Ruyer-Quil and Manneville2000; Chakraborty et al. Reference Chakraborty, Nguyen, Ruyer-Quil and Bontozoglou2014), the use of equations integrated over the film thickness limits their usefulness for mass or heat transfer problems. Some authors (see, e.g. Sisoev et al. Reference Sisoev, Matar and Lawrence2005; Rastaturin et al. Reference Rastaturin, Demekhin and Kalaidin2006; Bandi et al. Reference Bandi, Modigell, Gross, Reusken, Zhang, Heng, Marquardt and Mhamdi2018) combined the film thickness predicted by such models with a parabolic velocity profile to tackle the diffusion problem. While the actual velocity distribution can be approximately parabolic if the local flow rate is used, an uncertainty remains as to the overall correctness of the approach. These shortcomings point to the need for direct numerical simulations, in spite of several difficulties that must be overcome. In the first place, the streamwise length of the computational domain necessary for the development of the flow field is many hundreds or thousands of times the film thickness. An even longer distance is necessary to gain a full understanding of the evolving physics of the transport problem given the large value of the Schmidt number in most cases of interest. This feature, together with the small scale of the capillary waves and the thinness of the diffusion boundary layer, requires the use of fine grids and a commensurately large computational effort. This difficulty is compounded by the presence of a free surface not necessarily aligned with the computational grid and itself unknown.

In an effort to tackle the first difficulty, several researchers have tried to reduce the development length of the wavy structure by using a time-dependent oscillatory condition at the inflow boundary (see, e.g. Miyara Reference Miyara1999; Islam et al. Reference Islam, Miyara and Setoguchi2009; Albert, Marschall & Bothe Reference Albert, Marschall and Bothe2014; Dietze Reference Dietze2016), a feature that has also been used in experiments (see, e.g. Yoshimura et al. Reference Yoshimura, Nosoko and Nagata1996; Park et al. Reference Park, Nosoko, Gima and Ro2004; Dietze, Al-Sibai & Kneer Reference Dietze, Al-Sibai and Kneer2009; Charogiannis et al. Reference Charogiannis, Denner, van Wachem, Kalliadasis and Markides2017). Others, starting with Salamon, Armstrong & Brown (Reference Salamon, Armstrong and Brown1994), have imposed a spatial periodicity condition, suggested by several experimental observations starting with the original work of the Kapitzas and supported by many subsequent studies(see, e.g. Nosoko et al. Reference Nosoko, Yoshimura, Nagata and Oyakawa1996; Yoshimura et al. Reference Yoshimura, Nosoko and Nagata1996; Park et al. Reference Park, Nosoko, Gima and Ro2004). Several methods have been used to deal with the free surface: MAC (see, e.g. Islam et al. Reference Islam, Miyara and Setoguchi2009), volume of fluid (see, e.g. Doro & Aidun Reference Doro and Aidun2013; Albert et al. Reference Albert, Marschall and Bothe2014; Dietze Reference Dietze2016), finite elements (see, e.g. Salamon et al. Reference Salamon, Armstrong and Brown1994; Ramaswamy, Chippada & Joo Reference Ramaswamy, Chippada and Joo1996; Malamataris, Vlachogiannis & Bontozoglou Reference Malamataris, Vlachogiannis and Bontozoglou2002), together with several ad hoc methods (see, e.g. Wasden & Dukler Reference Wasden and Dukler1990; Jayanti & Hewitt Reference Jayanti and Hewitt1997; Kunugi & Kino Reference Kunugi and Kino2005).

In this paper we study the diffusion of a solute out of a falling liquid film. We take advantage of the spatial periodicity of the wave structure to separate the fluid mechanic aspects of the flow from the transfer aspects. We solve the Navier–Stokes equations numerically in time in the laboratory frame over a periodic domain of specified length until a steady regime is reached. We then use up to a hundred repetitions of this flow structure, consisting of a large hump, or crest, and a thin film with superimposed capillary waves, to effectively mimic a falling film of arbitrary length. In a second step, we solve the diffusion problem as an initial-value problem until steady conditions, periodic in time, are reached accounting for the variation of the concentration along this periodic film.

The picture that emerges is complex. Mass transfer from waves small enough not to exhibit recirculation reaches a steady state before the liquid has lost much solute. Waves with recirculation do not have such a steady regime or, at any rate, it does not set in before most of the solute has left the liquid. Furthermore, the combination of recirculation and waves of an appropriate length is found to enhance transfer, but recirculation in very large waves can also be detrimental if the substrate becomes excessively thin.

Formally, the process of mass diffusion is analogous to that for heat. However, the order-of-magnitude difference between the pertinent diffusivities, as well as the other factors mentioned before, turn quantitative differences into qualitative ones. In particular, the relative balance of convection and diffusion is strongly affected, with the former playing a much bigger role for mass than for heat transfer. As a consequence, the delicate balance among the various physical effects that we discuss for mass transfer would be different in the case of heat transfer. For example, the interplay of wave amplitude and length would be altered and the trapping of mass by recirculating large waves would be less of a concern in the case of heat. These differences prevent drawing from the results of the present work firm conclusions applicable to the analogous heat transfer process, which requires a dedicated study. The point is illustrated in figure 12 of Miyara (Reference Miyara1999) which, while limited to Prandtl numbers only up to 100, gives a clear sense of the major impact of this parameter on the transfer process.

The main results are described in § 7 for large waves and in § 8 for small waves. The preceding sections describe the mathematical model (§ 2), some theoretical considerations (§ 3), a brief summary of flat-film results (§ 4), the numerical method (§ 5) and its validation (§ 6).

2. Mathematical model

The mathematical model for the liquid flow is standard and consists of the condition of incompressibility

with ![]() ${\boldsymbol {u}}$ the liquid velocity field, and of the Navier–Stokes momentum equation

${\boldsymbol {u}}$ the liquid velocity field, and of the Navier–Stokes momentum equation

with ![]() $p$ the pressure relative to the gas pressure,

$p$ the pressure relative to the gas pressure, ![]() $\rho$ and

$\rho$ and ![]() $\nu$ the (constant) density and kinematic viscosity of the liquid and

$\nu$ the (constant) density and kinematic viscosity of the liquid and ![]() ${\boldsymbol {g}}$ the acceleration of gravity. Following a common approach in the literature, we limit ourselves to two space dimensions,

${\boldsymbol {g}}$ the acceleration of gravity. Following a common approach in the literature, we limit ourselves to two space dimensions, ![]() $x$ along the flow direction and

$x$ along the flow direction and ![]() $z$ normal to the plate. Even though three-dimensional waves are known to eventually develop in nominally two-dimensional settings, much of the theoretical knowledge available today is the result of studies based on the two-dimensional approximation (see, e.g. Chang & Demekhin Reference Chang and Demekhin2002; Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2012). This approach has led to the understanding of several basic features of the phenomenon in a simpler setting and, furthermore, its results are applicable also when three-dimensional structures develop, provided they have a slow lateral variation. The development length for three-dimensional features depends not only on parameters such as the Reynolds number, the plate inclination and the type and level of inlet disturbances, but also on the experimental set-up, e.g. films falling inside a tube (see, e.g. Park et al. Reference Park, Nosoko, Gima and Ro2004) or on a smooth or rough flat plate with lateral boundaries (see, e.g. Leontidis et al. Reference Leontidis, Vatteville, Vlachogiannis, Andritsos and Bontozoglou2010). For this reason, it is difficult to find unequivocal information in the literature where three-dimensional development lengths as short as 0.15–0.2 m (Park & Nosoko Reference Park and Nosoko2003) or as long as 1 m (Roberts & Chang Reference Roberts and Chang2000) can be found. Although most of the important conclusions of the present paper are obtained focusing on film lengths which, when converted to dimensional form with the physical properties of water, extend for 0.1 to 0.2 m, in order to provide a more complete picture, in some cases we extend the simulations over longer distances.

$z$ normal to the plate. Even though three-dimensional waves are known to eventually develop in nominally two-dimensional settings, much of the theoretical knowledge available today is the result of studies based on the two-dimensional approximation (see, e.g. Chang & Demekhin Reference Chang and Demekhin2002; Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2012). This approach has led to the understanding of several basic features of the phenomenon in a simpler setting and, furthermore, its results are applicable also when three-dimensional structures develop, provided they have a slow lateral variation. The development length for three-dimensional features depends not only on parameters such as the Reynolds number, the plate inclination and the type and level of inlet disturbances, but also on the experimental set-up, e.g. films falling inside a tube (see, e.g. Park et al. Reference Park, Nosoko, Gima and Ro2004) or on a smooth or rough flat plate with lateral boundaries (see, e.g. Leontidis et al. Reference Leontidis, Vatteville, Vlachogiannis, Andritsos and Bontozoglou2010). For this reason, it is difficult to find unequivocal information in the literature where three-dimensional development lengths as short as 0.15–0.2 m (Park & Nosoko Reference Park and Nosoko2003) or as long as 1 m (Roberts & Chang Reference Roberts and Chang2000) can be found. Although most of the important conclusions of the present paper are obtained focusing on film lengths which, when converted to dimensional form with the physical properties of water, extend for 0.1 to 0.2 m, in order to provide a more complete picture, in some cases we extend the simulations over longer distances.

We assume a negligible gas flow on the free surface of the liquid film. Thus, on the basis of the orders-of-magnitude difference between the dynamic viscosity of gases and liquids, we take the tangential stress on the liquid side of the film to vanish while the normal stress balances the effect of surface tension:

Here ![]() $\boldsymbol {n}$ is the unit normal out of the liquid domain,

$\boldsymbol {n}$ is the unit normal out of the liquid domain, ![]() $\sigma$ is the surface tension coefficient and

$\sigma$ is the surface tension coefficient and ![]() ${\boldsymbol {\tau }} = \rho \nu ({\boldsymbol {\nabla }\boldsymbol {u}} + {\boldsymbol {\nabla }\boldsymbol {u}}^{T} )$ is the viscous stress tensor. The free surface is located at

${\boldsymbol {\tau }} = \rho \nu ({\boldsymbol {\nabla }\boldsymbol {u}} + {\boldsymbol {\nabla }\boldsymbol {u}}^{T} )$ is the viscous stress tensor. The free surface is located at ![]() $z=h(x,t)$ and is governed by the kinematic boundary condition

$z=h(x,t)$ and is governed by the kinematic boundary condition

where ![]() $(u,w) \equiv \boldsymbol {u}$ are the two components of the liquid velocity. We impose the no-slip conditions on the solid surface and, on the remaining surfaces of the computational domain, we impose periodicity boundary conditions.

$(u,w) \equiv \boldsymbol {u}$ are the two components of the liquid velocity. We impose the no-slip conditions on the solid surface and, on the remaining surfaces of the computational domain, we impose periodicity boundary conditions.

To model the scalar transfer process, we solve the convection-diffusion equation

with ![]() $D$ the mass diffusivity and

$D$ the mass diffusivity and ![]() $c$ the mass concentration. We set

$c$ the mass concentration. We set ![]() $c=c_0$ at the inlet of the computational domain, downstream of which the surface concentration of the film is set to

$c=c_0$ at the inlet of the computational domain, downstream of which the surface concentration of the film is set to ![]() $c=c_i$, with

$c=c_i$, with ![]() $c_i$ a constant interfacial value. The associated normal flux vanishes on the solid surface, which is appropriate for a plate impervious to the solute. At the downstream boundary we use a linear extrapolation to two ghost nodes outside the computational domain writing

$c_i$ a constant interfacial value. The associated normal flux vanishes on the solid surface, which is appropriate for a plate impervious to the solute. At the downstream boundary we use a linear extrapolation to two ghost nodes outside the computational domain writing ![]() $c_{N+1}=2c_N-c_{N-1}$ and

$c_{N+1}=2c_N-c_{N-1}$ and ![]() $c_{N+2}=2c_{N+1}-c_N$, in which

$c_{N+2}=2c_{N+1}-c_N$, in which ![]() $c_N$ is the value of the concentration at the last grid node and

$c_N$ is the value of the concentration at the last grid node and ![]() $c_{N+1}$ and

$c_{N+1}$ and ![]() $c_{N+2}$ the extrapolated values. In any event, the treatment of the outlet boundary is not of particular importance, as the liquid flows out of the downstream boundary for most of the time, with back flow only during the very short time periods during which the capillary waves are near the outlet. Therefore, numerical errors introduced by the boundary condition are flushed out of the domain. In consideration of these brief periods of back flow, the sampling points we use for calculation and presentation are far upstream of the outlet to prevent possible contamination from the outlet neighbourhood.

$c_{N+2}$ the extrapolated values. In any event, the treatment of the outlet boundary is not of particular importance, as the liquid flows out of the downstream boundary for most of the time, with back flow only during the very short time periods during which the capillary waves are near the outlet. Therefore, numerical errors introduced by the boundary condition are flushed out of the domain. In consideration of these brief periods of back flow, the sampling points we use for calculation and presentation are far upstream of the outlet to prevent possible contamination from the outlet neighbourhood.

We solve an initial-value problem starting with ![]() $c=c_0$ throughout the computational domain except for the free surface where

$c=c_0$ throughout the computational domain except for the free surface where ![]() $c=c_i$. We monitor the integrals of the mass transfer quantities over successive wave periods until steady spatial distributions are reached. From this point on every quantity attains the same value at the same position once every wave period. All the results reported in this paper are based on the steady state.

$c=c_i$. We monitor the integrals of the mass transfer quantities over successive wave periods until steady spatial distributions are reached. From this point on every quantity attains the same value at the same position once every wave period. All the results reported in this paper are based on the steady state.

Aside from the inclination angle of the plate, which is taken to be ![]() $90^{\circ }$ in this paper, the fluid mechanics of the problem has five control parameters: one is the acceleration of gravity in the direction of the flow

$90^{\circ }$ in this paper, the fluid mechanics of the problem has five control parameters: one is the acceleration of gravity in the direction of the flow ![]() $g$, two refer to the liquid physical properties,

$g$, two refer to the liquid physical properties, ![]() $\nu$ and

$\nu$ and ![]() $\sigma /\rho$, and one is the volume flow rate

$\sigma /\rho$, and one is the volume flow rate ![]() $q$ of the liquid per unit length in the transverse direction. In a laboratory setting in which the film is subject to an inlet disturbance, a situation commonly referred to as an open system, a fifth parameter is the period

$q$ of the liquid per unit length in the transverse direction. In a laboratory setting in which the film is subject to an inlet disturbance, a situation commonly referred to as an open system, a fifth parameter is the period ![]() $T$ of the disturbance. Here we prescribe instead the wavelength

$T$ of the disturbance. Here we prescribe instead the wavelength ![]() $\lambda$ thus placing ourselves in a so-called closed system. The two systems are related by

$\lambda$ thus placing ourselves in a so-called closed system. The two systems are related by ![]() $\lambda = u_w T$, with

$\lambda = u_w T$, with ![]() $u_w$ the velocity of the wave. With these parameters one can form three dimensionless groups, which may be taken to be the Kapitza and Reynolds numbers,

$u_w$ the velocity of the wave. With these parameters one can form three dimensionless groups, which may be taken to be the Kapitza and Reynolds numbers,

and the ratio of the wavelength to the Nusselt film thickness

\begin{equation} \varPi = \frac{\lambda}{h_{Nu}} ,\quad \textrm{with} \ h_{Nu} = \left(\frac{3q\nu}{g}\right)^{1/3} . \end{equation}

\begin{equation} \varPi = \frac{\lambda}{h_{Nu}} ,\quad \textrm{with} \ h_{Nu} = \left(\frac{3q\nu}{g}\right)^{1/3} . \end{equation}The form of these quantities assumes a vertical plate, which is the case to which the present study refers.

Table 1 lists the parameter values for the cases that we have simulated and on which we base our conclusions. The parameter ![]() $\delta$, originally introduced by Shkadov (see, e.g. Chang & Demekhin Reference Chang and Demekhin2002; Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2012; Denner et al. Reference Denner, Charogiannis, Pradas, Markides, van Wachem and Kalliadasis2018), is defined by

$\delta$, originally introduced by Shkadov (see, e.g. Chang & Demekhin Reference Chang and Demekhin2002; Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2012; Denner et al. Reference Denner, Charogiannis, Pradas, Markides, van Wachem and Kalliadasis2018), is defined by

This is an important quantity because, in the limit of the boundary layer approximation, the dependence of the results on ![]() $Re$ and

$Re$ and ![]() $Ka$ collapses into a dependence upon this single parameter. We have found, however, that the performance of the correlations (7.2) and (8.4) developed later in §§ 7 and 8 improves by allowing a separate dependence on

$Ka$ collapses into a dependence upon this single parameter. We have found, however, that the performance of the correlations (7.2) and (8.4) developed later in §§ 7 and 8 improves by allowing a separate dependence on ![]() $Re$ and

$Re$ and ![]() $Ka$, even though the ratio of their exponents is close to that implied by (2.8). The table also shows the equivalent Strouhal number defined by

$Ka$, even though the ratio of their exponents is close to that implied by (2.8). The table also shows the equivalent Strouhal number defined by

Table 1. The table shows the parameter values for the simulations carried out in the course of the present study. The Reynolds ![]() $Re$ and Kapitza

$Re$ and Kapitza ![]() $Ka$ numbers are defined in (2.6a,b), the dimensionless wavelength

$Ka$ numbers are defined in (2.6a,b), the dimensionless wavelength ![]() $\varPi =\lambda /h_{Nu}$ in (2.7), the Shkadov parameter

$\varPi =\lambda /h_{Nu}$ in (2.7), the Shkadov parameter ![]() $\delta$ in (2.8), the Nusselt film thickness in (2.7) and the Strouhal number in (2.9);

$\delta$ in (2.8), the Nusselt film thickness in (2.7) and the Strouhal number in (2.9); ![]() $h_m$,

$h_m$, ![]() $h_{min}$ and

$h_{min}$ and ![]() $h_{eff}$ are the computed mean, minimum and effective film thicknesses (3.4a,b), (8.2) and (9.1),

$h_{eff}$ are the computed mean, minimum and effective film thicknesses (3.4a,b), (8.2) and (9.1), ![]() $u_{max}$ is the computed maximum liquid velocity,

$u_{max}$ is the computed maximum liquid velocity, ![]() $u_w$ is the wave velocity,

$u_w$ is the wave velocity, ![]() $u_m$ is the liquid mean velocity defined in (3.4a,b),

$u_m$ is the liquid mean velocity defined in (3.4a,b), ![]() $u_{Nu}$ is the velocity (4.2) of the Nusselt theory and

$u_{Nu}$ is the velocity (4.2) of the Nusselt theory and ![]() $Sh_\infty$ is the numerically calculated value of the asymptotic Sherwood number. For cases 3, 5 and 12 either no asymptotic state was reached in the computational domain or the asymptotic value was strongly dependent on the Schmidt number.

$Sh_\infty$ is the numerically calculated value of the asymptotic Sherwood number. For cases 3, 5 and 12 either no asymptotic state was reached in the computational domain or the asymptotic value was strongly dependent on the Schmidt number.

3. Some theoretical considerations

In view of the liquid incompressibility, the term ![]() $\boldsymbol {u}\boldsymbol {\cdot } \boldsymbol {\nabla }c$ in (2.5) can be written as

$\boldsymbol {u}\boldsymbol {\cdot } \boldsymbol {\nabla }c$ in (2.5) can be written as ![]() $\boldsymbol {\nabla } \boldsymbol {\cdot }(\boldsymbol {u} c)$. With this step, upon integrating the convection-diffusion equation (2.5) over the liquid volume enclosed between two adjacent surfaces perpendicular to the wall, located at

$\boldsymbol {\nabla } \boldsymbol {\cdot }(\boldsymbol {u} c)$. With this step, upon integrating the convection-diffusion equation (2.5) over the liquid volume enclosed between two adjacent surfaces perpendicular to the wall, located at ![]() $x$ and

$x$ and ![]() $x+\textrm {d}x$, and dividing by

$x+\textrm {d}x$, and dividing by ![]() $\textrm {d}x$, we find that

$\textrm {d}x$, we find that

with

In deriving (3.1) we have used the kinematic condition (2.4); ![]() $\textrm {d}s =\sqrt {1+(\partial _xh)^{2}}\,\textrm {d}x$ is the arc length of the interface cut by the two surfaces at

$\textrm {d}s =\sqrt {1+(\partial _xh)^{2}}\,\textrm {d}x$ is the arc length of the interface cut by the two surfaces at ![]() $x$ and

$x$ and ![]() $x+\textrm {d}x$. The characteristic length for the horizontal gradient is at least the wavelength, which is much larger than the film thickness. This circumstance, coupled with the large value of the Schmidt number, justifies the neglect of streamwise diffusion (first term on the right-hand side).

$x+\textrm {d}x$. The characteristic length for the horizontal gradient is at least the wavelength, which is much larger than the film thickness. This circumstance, coupled with the large value of the Schmidt number, justifies the neglect of streamwise diffusion (first term on the right-hand side).

As already noted, we envisage a system of waves with, in the laboratory frame, a temporal period ![]() $T$ at any fixed position

$T$ at any fixed position ![]() $x$, and a corresponding spatial period

$x$, and a corresponding spatial period ![]() $\lambda = u_wT$ in the wave rest frame. The time-average volume flow rate per unit transverse length in the film is given by

$\lambda = u_wT$ in the wave rest frame. The time-average volume flow rate per unit transverse length in the film is given by

In view of the temporal (or spatial) periodicity, ![]() $q$ is independent of time and position along the plate. The average film thickness

$q$ is independent of time and position along the plate. The average film thickness ![]() $h_m$ and velocity

$h_m$ and velocity ![]() $u_m$ are defined by

$u_m$ are defined by

We define a local time-averaged mass flux out of the film per unit plate length by

and a local time- and thickness-averaged solute concentration ![]() $c_m(x)$ in the film by

$c_m(x)$ in the film by

In a sense, this quantity may be considered as analogous to what is usually referred to as ‘mixing-cup concentration’ in steady conditions. In the present time-dependent problem it is not possible to define the precise instantaneous analog of that quantity because the local instantaneous flow rate may vanish. In terms of these quantities, upon averaging (3.1) over time, we find the time-averaged local relation

With the introduction of a time-averaged mass transfer coefficient

(3.7) can be integrated formally to find that

Upon introducing the time-averaged local Sherwood number according to

in which ![]() $h_{Nu}$ is the film thickness of the Nusselt theory given in (2.7), the previous relation may be written in dimensionless form as

$h_{Nu}$ is the film thickness of the Nusselt theory given in (2.7), the previous relation may be written in dimensionless form as

\begin{equation} c_m^{*}(x) = \frac{c_m(x)-c_i}{c_0-c_i}= \exp \left(-\frac{1}{Pe} \int_0^{x^{*}} Sh\,\textrm{d}x^{*} \right) , \end{equation}

\begin{equation} c_m^{*}(x) = \frac{c_m(x)-c_i}{c_0-c_i}= \exp \left(-\frac{1}{Pe} \int_0^{x^{*}} Sh\,\textrm{d}x^{*} \right) , \end{equation}

in which ![]() $x^{*}=x/h_{Nu}$, and the Péclet number is defined by

$x^{*}=x/h_{Nu}$, and the Péclet number is defined by

Equation (3.11) can be rearranged to express the running average of the Sherwood number, ![]() $\langle Sh\rangle$ in terms of

$\langle Sh\rangle$ in terms of ![]() $c_m^{*}$:

$c_m^{*}$:

At this point, (3.11) and (3.13) are purely formal as the Sherwood number, in general, will depend on the Kapitza and Reynolds numbers and ![]() $\varPi$ to account for the effects of the fluid mechanics of the problem on the diffusion process, and on the Schmidt number

$\varPi$ to account for the effects of the fluid mechanics of the problem on the diffusion process, and on the Schmidt number ![]() $Sc=\nu /D$ for the diffusion itself.

$Sc=\nu /D$ for the diffusion itself.

4. Flat film

For future reference it is useful to briefly review some aspects of mass transfer from a flat film. The theory for a film of large thickness is textbook material and can be found, e.g. in Bird, Stewart & Lightfoot (Reference Bird, Stewart and Lightfoot2007). If the free surface of the film is placed at the position ![]() $z=h_{Nu}$, the concentration field may be written as

$z=h_{Nu}$, the concentration field may be written as

\begin{equation} \frac{c-c_i}{c_0-c_i}=\textrm{erf} \left(\frac{h_{Nu}-z}{\sqrt{8Dx/3u_{Nu}}} \right) , \end{equation}

\begin{equation} \frac{c-c_i}{c_0-c_i}=\textrm{erf} \left(\frac{h_{Nu}-z}{\sqrt{8Dx/3u_{Nu}}} \right) , \end{equation}where

is the mean liquid velocity according to Nusselt's theory. For a flat film, ![]() $h_{Nu}$ equals the mean value of the film thickness. The average concentration calculated according to (3.6) is found to be

$h_{Nu}$ equals the mean value of the film thickness. The average concentration calculated according to (3.6) is found to be

with ![]() $\zeta = \sqrt {3 h_{Nu} u_{Nu}/[8D(x/h_{Nu})]} = \sqrt {\frac {3}{8} Pe/(x/h_{Nu})}$. For large

$\zeta = \sqrt {3 h_{Nu} u_{Nu}/[8D(x/h_{Nu})]} = \sqrt {\frac {3}{8} Pe/(x/h_{Nu})}$. For large ![]() $x$ this is

$x$ this is

\begin{equation} \frac{c_m-c_i}{c_0-c_i}\simeq \frac{3}{4\sqrt{\rm \pi}}\zeta= \frac{3}{8}\sqrt{\frac{3h_{Nu}u_{Nu}}{2{\rm \pi} D (x/h_{Nu})}} . \end{equation}

\begin{equation} \frac{c_m-c_i}{c_0-c_i}\simeq \frac{3}{4\sqrt{\rm \pi}}\zeta= \frac{3}{8}\sqrt{\frac{3h_{Nu}u_{Nu}}{2{\rm \pi} D (x/h_{Nu})}} . \end{equation} For a flat film, the instantaneous mass flux (3.2) equals the local, time-averaged mass flux, ![]() $\dot {m}=\dot {M}$, and is given by

$\dot {m}=\dot {M}$, and is given by

The Sherwood number (3.10) becomes

\begin{equation} Sh(x)=\frac{4\zeta^{2}}{2\sqrt{\rm \pi}\zeta \,\textrm{erf}(\zeta) + (1-\textrm{e}^{-\zeta^{2}}) \left(\dfrac{1}{\zeta^{2} }-3\right) - \textrm{e}^{-\zeta^{2}}} , \end{equation}

\begin{equation} Sh(x)=\frac{4\zeta^{2}}{2\sqrt{\rm \pi}\zeta \,\textrm{erf}(\zeta) + (1-\textrm{e}^{-\zeta^{2}}) \left(\dfrac{1}{\zeta^{2} }-3\right) - \textrm{e}^{-\zeta^{2}}} , \end{equation}with the asymptotic limit

For a film with a finite thickness, the asymptotic value of the Sherwood number was calculated by Pigford (see, e.g. van Baten & Krishna Reference van Baten and Krishna2004) who found the value ![]() $Sh_\infty \simeq 3.41$. The transient (4.6) equals this value for

$Sh_\infty \simeq 3.41$. The transient (4.6) equals this value for

which can be taken as an estimate of the transition from developing to fully developed conditions.

In the following we will show the running average of the Sherwood number for the wavy film. For purposes of comparison, the dashed lines in those figures show the same quantity for the flat film with the same flow rate.

5. Numerical method

The numerical method is based on a finite-difference discretization with co-located variables except that, following Yang & Shen (Reference Yang and Shen2011), the ![]() $z$-velocity component is staggered in the direction

$z$-velocity component is staggered in the direction ![]() $z$ normal to the wall. In order to deal with the grid motion due to the time-dependent free-surface profile, in the

$z$ normal to the wall. In order to deal with the grid motion due to the time-dependent free-surface profile, in the ![]() $z$ direction we use a stretched coordinate

$z$ direction we use a stretched coordinate ![]() $Z$ defined by

$Z$ defined by ![]() $Z = z / h(x,t)$, with

$Z = z / h(x,t)$, with ![]() $h(x,t)$ the local instantaneous film thickness;

$h(x,t)$ the local instantaneous film thickness; ![]() $Z = 0$ at the solid wall while

$Z = 0$ at the solid wall while ![]() $Z=1$ at the free surface.

$Z=1$ at the free surface.

The second-order Crank–Nicolson method is used for time discretization. The convection terms in (2.2), however, are updated in time with the second-order Adams–Bashforth scheme, as in Yang & Shen (Reference Yang and Shen2011). For the spatial discretization, the second-order central-difference scheme is used for the equations of liquid flow whereas, for the convection-diffusion equation (2.5), a third-order upwind-biased finite-difference scheme, useful for the suppression of spurious oscillations where the gradient of the concentration is large, is applied in the streamwise direction.

A standard projection method (Kim & Moin Reference Kim and Moin1985; Ferziger & Perić Reference Ferziger and Perić2002) is used to deal with the pressure-velocity coupling in (2.1) and (2.2). The continuity and momentum equations are then solved together with the kinematic condition (2.4) iteratively for convergence of the whole flow system at each time step. We solve the initial-value problem for the fluid prescribing periodicity conditions in the flow direction ![]() $x$ running the code until a steady regime is reached, with a wave of permanent form exiting the computational domain on the downstream (right) side and re-entering it on the upstream side. The code is capable of three-dimensional calculations but, in this work, the initialization is two-dimensional and no spontaneous perturbation in the third dimension develops.

$x$ running the code until a steady regime is reached, with a wave of permanent form exiting the computational domain on the downstream (right) side and re-entering it on the upstream side. The code is capable of three-dimensional calculations but, in this work, the initialization is two-dimensional and no spontaneous perturbation in the third dimension develops.

The wave and flow fields found at steady state are taken as the basis for the mass transfer process. This treatment is justified by the approximation that the solute distribution in the liquid has negligible influence on the flow field, which is a reasonable assumption in many practical situations. In this way, we are able to simulate the flow field for a single spatial period and then ‘glued together’ many copies of it to extend the solution over a sufficiently long downstream distance. This procedure is necessary as, unlike the flow, the mass transfer process is not periodic in space. This procedure saves a considerable amount of computational time compared with solving the flow field and scalar transfer simultaneously.

A straightforward way to implement this idea would be to store all the information contained in a one-wavelength-long domain during one time period, and then duplicate it in both space and time. However, at each time step, this procedure would require a large number of repeated assignments and would therefore not be very efficient. The same result can be obtained in a more efficient way as follows.

We choose an integration time step for the diffusion equation given by ![]() $\delta t = \delta x/u_w$, in which

$\delta t = \delta x/u_w$, in which ![]() $\delta x=\frac {1}{4}{\rm \Delta} x$ equals one fourth of the streamwise spatial step

$\delta x=\frac {1}{4}{\rm \Delta} x$ equals one fourth of the streamwise spatial step ![]() ${\rm \Delta} x$ used in the fluid mechanic calculation and

${\rm \Delta} x$ used in the fluid mechanic calculation and ![]() $u_w$ is the calculated wave speed. The factor of

$u_w$ is the calculated wave speed. The factor of ![]() $\frac {1}{4}$ is introduced to satisfy the Courant–Friedrichs–Lewy condition. Thus, during one

$\frac {1}{4}$ is introduced to satisfy the Courant–Friedrichs–Lewy condition. Thus, during one ![]() $\delta t$, the wave travels a distance equal to one fourth of the flow spatial step. The use of intermediate positions

$\delta t$, the wave travels a distance equal to one fourth of the flow spatial step. The use of intermediate positions ![]() $x_a\equiv x_i$,

$x_a\equiv x_i$, ![]() $x_b=x_i+\delta x$,

$x_b=x_i+\delta x$, ![]() $x_c=x_i+2\delta x$ and

$x_c=x_i+2\delta x$ and ![]() $x_d=x_i+3\delta x$ requires interpolation of the flow fields which is effected with third-order accuracy by following the Lagrangian interpolation procedure which leads to setting

$x_d=x_i+3\delta x$ requires interpolation of the flow fields which is effected with third-order accuracy by following the Lagrangian interpolation procedure which leads to setting

\begin{equation} \left| \begin{matrix} \psi_a \\ \psi_b \\ \psi_c \\ \psi_d \end{matrix} \right| = \frac{1}{128} \left| \begin{matrix} 0 & 128 & 0 & 0\\ -7 & 105 & 35 & -5 \\ -8 & 72 & 72 & -8 \\ -5 & 35 & 105 & -7 \end{matrix} \right| \, \left| \begin{matrix} \psi_{i-1} \\ \psi_i \\ \psi_{i+1} \\ \psi_{i+2} \end{matrix} \right| , \end{equation}

\begin{equation} \left| \begin{matrix} \psi_a \\ \psi_b \\ \psi_c \\ \psi_d \end{matrix} \right| = \frac{1}{128} \left| \begin{matrix} 0 & 128 & 0 & 0\\ -7 & 105 & 35 & -5 \\ -8 & 72 & 72 & -8 \\ -5 & 35 & 105 & -7 \end{matrix} \right| \, \left| \begin{matrix} \psi_{i-1} \\ \psi_i \\ \psi_{i+1} \\ \psi_{i+2} \end{matrix} \right| , \end{equation}

in which ![]() $\psi$ is any generic flow or geometric quantity (velocity component, interface position, Jacobian of the transformation from

$\psi$ is any generic flow or geometric quantity (velocity component, interface position, Jacobian of the transformation from ![]() $z$ to

$z$ to ![]() $Z$).

$Z$).

By the definition of ![]() $\delta t$, we have a discrete time–space mapping:

$\delta t$, we have a discrete time–space mapping:

in which ![]() $i$ and

$i$ and ![]() $m$ are integers. Thus, only one saved snapshot of the flow field at an arbitrarily chosen time

$m$ are integers. Thus, only one saved snapshot of the flow field at an arbitrarily chosen time ![]() $t = t_0$ is needed to reconstruct the history of the flow quantity

$t = t_0$ is needed to reconstruct the history of the flow quantity ![]() $\psi$ in a discrete manner. At each time step we adjust the

$\psi$ in a discrete manner. At each time step we adjust the ![]() $x$-indices of each node of the computational grid used for the diffusion calculation by using periodicity and replacing (5.2) by

$x$-indices of each node of the computational grid used for the diffusion calculation by using periodicity and replacing (5.2) by

with

in which ![]() $N_x$ is the number of nodes in the finer grid, mod is the modulo operation and

$N_x$ is the number of nodes in the finer grid, mod is the modulo operation and ![]() $\ell$ is an integer that renders the quantity in parentheses positive. With this index mapping, information on the flow field at the same relative position of the snapshot is available at the same memory location avoiding repeated assignment operations and memory use.

$\ell$ is an integer that renders the quantity in parentheses positive. With this index mapping, information on the flow field at the same relative position of the snapshot is available at the same memory location avoiding repeated assignment operations and memory use.

The mesh lengths were kept constant in the ![]() $x$ and

$x$ and ![]() $Z$ directions, with the cell length in the

$Z$ directions, with the cell length in the ![]() $x$ direction typically about 10 times larger than that in the

$x$ direction typically about 10 times larger than that in the ![]() $Z$ direction. We typically used 300 and 35 cells in the streamwise and wall-normal directions, respectively, for the fluid mechanics calculation. The resolution of the thin film regions achieved in this way is superior to that of other studies in which the volume-of-fluid method required a time-independent grid size irrespective of the local film thickness. For the diffusion equation, we carried out grid convergence studies for the various Schmidt numbers. For example, for case 0 and

$Z$ direction. We typically used 300 and 35 cells in the streamwise and wall-normal directions, respectively, for the fluid mechanics calculation. The resolution of the thin film regions achieved in this way is superior to that of other studies in which the volume-of-fluid method required a time-independent grid size irrespective of the local film thickness. For the diffusion equation, we carried out grid convergence studies for the various Schmidt numbers. For example, for case 0 and ![]() $Sc$ 1000, we used 35, 69, 103 and 137 cells observing negligible differences between the two finest grids even for the smallest value of

$Sc$ 1000, we used 35, 69, 103 and 137 cells observing negligible differences between the two finest grids even for the smallest value of ![]() $x/h_{Nu}$ shown in our figures, a region in which the boundary layer is very thin, which amounts to about 10 % of the first wavelength. The results presented below have been obtained with 103 cells. Analogous studies showed that 35, 52 and 69 cells gave an adequate resolution for

$x/h_{Nu}$ shown in our figures, a region in which the boundary layer is very thin, which amounts to about 10 % of the first wavelength. The results presented below have been obtained with 103 cells. Analogous studies showed that 35, 52 and 69 cells gave an adequate resolution for ![]() $Sc = 100$, 200 and 500, respectively. The other cases were treated in a similar way. The velocity and Jacobian fields were quadratically interpolated from the three closest points onto the finer grids used for diffusion. Thus, on the basis of our own experience and of information in the literature (see, e.g. Albert et al. Reference Albert, Marschall and Bothe2014; Denner et al. Reference Denner, Charogiannis, Pradas, Markides, van Wachem and Kalliadasis2018) we are confident to have a good spatial resolution. The time step was conservatively set on the basis of standard stability conditions.

$Sc = 100$, 200 and 500, respectively. The other cases were treated in a similar way. The velocity and Jacobian fields were quadratically interpolated from the three closest points onto the finer grids used for diffusion. Thus, on the basis of our own experience and of information in the literature (see, e.g. Albert et al. Reference Albert, Marschall and Bothe2014; Denner et al. Reference Denner, Charogiannis, Pradas, Markides, van Wachem and Kalliadasis2018) we are confident to have a good spatial resolution. The time step was conservatively set on the basis of standard stability conditions.

6. Validation

We compare in figure 1 the results of our simulations with those reported by Dietze et al. (Reference Dietze, Al-Sibai and Kneer2009). The pertinent parameter values are given in the first line of table 2; for inclined plates, the proper definition of the Kapitza number is

Figure 1. The open circles show the measured film height (a) and streamwise velocity at a distance of 120 ![]() ${\rm \mu}$m from the wall (b) reported by Dietze et al. (Reference Dietze, Al-Sibai and Kneer2009). The solid lines are the results of the present simulations and the barely distinguishable dotted lines are the numerical results of Dietze (Reference Dietze2016). The pertinent parameter values are shown in the first line of table 2.

${\rm \mu}$m from the wall (b) reported by Dietze et al. (Reference Dietze, Al-Sibai and Kneer2009). The solid lines are the results of the present simulations and the barely distinguishable dotted lines are the numerical results of Dietze (Reference Dietze2016). The pertinent parameter values are shown in the first line of table 2.

Table 2. Parameter values for the waves of figures 1 and 2 used to validate the present simulations. The Reynolds ![]() $Re$ and Kapitza

$Re$ and Kapitza ![]() $Ka$ numbers are defined in (2.6a,b) and (6.1);

$Ka$ numbers are defined in (2.6a,b) and (6.1); ![]() $\lambda$ is the wavelength,

$\lambda$ is the wavelength, ![]() $h_{Nu}$ the Nusselt film thickness (2.7) and

$h_{Nu}$ the Nusselt film thickness (2.7) and ![]() $\theta$ the inclination angle of the plate. The last column gives the figure number in the original reference shown in the next-to-last column.

$\theta$ the inclination angle of the plate. The last column gives the figure number in the original reference shown in the next-to-last column.

The open circles in the figure are the film height (a) and streamwise velocity at a distance of ![]() $120\ \mathrm {{\rm \mu} }\textrm {m}$ from the wall (b) reported in the reference. The solid lines are our simulations and the barely distinguishable dotted lines under it the numerical results of Dietze (Reference Dietze2016). In order to show this comparison we have converted our results from space to time using the computed phase velocity. As can be seen, the two computations are virtually identical and both closely match the data.

$120\ \mathrm {{\rm \mu} }\textrm {m}$ from the wall (b) reported in the reference. The solid lines are our simulations and the barely distinguishable dotted lines under it the numerical results of Dietze (Reference Dietze2016). In order to show this comparison we have converted our results from space to time using the computed phase velocity. As can be seen, the two computations are virtually identical and both closely match the data.

For another comparison we turn to the study by Denner et al. (Reference Denner, Charogiannis, Pradas, Markides, van Wachem and Kalliadasis2018). The black dots in figure 2 show the measured film heights (top row) and free-surface streamwise velocity (bottom row) reported in the reference; our numerical results are shown by the solid lines. The mean film thicknesses ![]() $h_m$ used in our simulations was deduced from the values of

$h_m$ used in our simulations was deduced from the values of ![]() $Re$ and

$Re$ and ![]() $Ka$ given by Denner et al. (Reference Denner, Charogiannis, Pradas, Markides, van Wachem and Kalliadasis2018); the wavelength

$Ka$ given by Denner et al. (Reference Denner, Charogiannis, Pradas, Markides, van Wachem and Kalliadasis2018); the wavelength ![]() $\lambda$ was measured from the graphs in the reference except for the cases which do not include more than one full wave which, therefore, we cannot simulate. Once again, the comparison is very good and shows the reliability of our simulations.

$\lambda$ was measured from the graphs in the reference except for the cases which do not include more than one full wave which, therefore, we cannot simulate. Once again, the comparison is very good and shows the reliability of our simulations.

Figure 2. Comparison of our simulations, shown by the solid lines, with the experimental results of Denner et al. (Reference Denner, Charogiannis, Pradas, Markides, van Wachem and Kalliadasis2018); the pertinent parameter values are given in table 2. The top row is the local film height normalized by the Nusselt value; the bottom row is the surface velocity parallel to the plate normalized by the Nusselt velocity (4.2).

Yet another comparison of our results with relations in the literature is afforded by the correlations of the wave celerity ![]() $u_w$ and peak wave height

$u_w$ and peak wave height ![]() $h_p$ for film flow along a vertical surface presented in Nosoko et al. (Reference Nosoko, Yoshimura, Nagata and Oyakawa1996) which, in our notation, are

$h_p$ for film flow along a vertical surface presented in Nosoko et al. (Reference Nosoko, Yoshimura, Nagata and Oyakawa1996) which, in our notation, are

and

The two plots of figure 3 compare our computational results with these correlations. It is seen that the computed points fall very close to the values predicted by the correlations.

Figure 3. Comparison of the present computational results (open squares) with the correlations (6.2) for the wave celerity ![]() $u_w$ and (6.3) for the peak wave height

$u_w$ and (6.3) for the peak wave height ![]() $h_p$ proposed by Nosoko et al. (Reference Nosoko, Yoshimura, Nagata and Oyakawa1996).

$h_p$ proposed by Nosoko et al. (Reference Nosoko, Yoshimura, Nagata and Oyakawa1996).

Experiments in open systems show that, when the excitation frequency is low, disturbances evolve into multipeaked forms (see, e.g. Alekseenko, Nakoryakov & Pokusaev Reference Alekseenko, Nakoryakov and Pokusaev1985; Liu & Gollub Reference Liu and Gollub1994; Argyriadi, Serifi & Bontozoglou Reference Argyriadi, Serifi and Bontozoglou2004). It is not known what is the analog of this behaviour for closed systems, such as the ones investigated here and, in particular, whether the waveforms that we have studied are physically realizable. To gain some assurance on this aspect, we have carried out simulations in a domain twice as long as the longest one on which we report (case 5, discussed in § 7) and we have found that a second large hump emerges within the periodic domain in this case. We have also carried out a simulation mimicking an open system with the approximate model of Mudunuri & Balakotaiah (Reference Mudunuri and Balakotaiah2006) and the parameters of our case 5 finding a stable waveform and wavelength. Our base case (case 0) is based on the work of Nosoko & Miyara (Reference Nosoko and Miyara2004) and, with the exception of case 5, all other cases have a comparable or smaller wavelength, Reynolds number and Kapitza number. Thus, we are fairly confident that the waves that we study are not an artifact of our computational method but are, in fact, physically realizable.

When it comes to validation of the mass transfer component of the calculation, there is not much suitable information in the literature as the reported results are all affected by the transient nature of the developing flow. Thus, we are forced to limit ourselves to the flat-film case. The analytic solution for a film of infinite depth, given in the previous section, is suitable for comparison in the initial stage of the process, while the asymptotic value of the Sherwood number for a film with a finite thickness is suitable for the final stages of the process. Figure 4(a) shows the computed ![]() $Sh$ versus

$Sh$ versus ![]() $x/(h_{Nu}Pe)$ and compares it with the short-time, infinite-depth case and long-time finite-depth one. The numerical results have been obtained with

$x/(h_{Nu}Pe)$ and compares it with the short-time, infinite-depth case and long-time finite-depth one. The numerical results have been obtained with ![]() $Re = 16.1$,

$Re = 16.1$, ![]() $Sc = 100$ and 1000, and

$Sc = 100$ and 1000, and ![]() $Re = 4.02$ and

$Re = 4.02$ and ![]() $Sc = 1000$. According to the flat-film theory of § 4, the specific values of these quantities should have no effect if

$Sc = 1000$. According to the flat-film theory of § 4, the specific values of these quantities should have no effect if ![]() $Sh$ is plotted as a function of

$Sh$ is plotted as a function of ![]() $x/(h_{Nu}Pe)$. The three results very nearly superpose.

$x/(h_{Nu}Pe)$. The three results very nearly superpose.

Figure 4. ![]() $(a)$ The (barely distinguishable) three lines which asymptote to the horizontal dashed line are the present computational results for the local Sherwood number for flat films with

$(a)$ The (barely distinguishable) three lines which asymptote to the horizontal dashed line are the present computational results for the local Sherwood number for flat films with ![]() $Re = 16.1$,

$Re = 16.1$, ![]() $Sc = 100$ and 1000, and for

$Sc = 100$ and 1000, and for ![]() $Re = 4.02$ and

$Re = 4.02$ and ![]() $Sc = 1000$. The dashed line is the analytic result for a thick film, (4.6); the horizontal dashed line is the asymptotic result for a film with a finite thickness.

$Sc = 1000$. The dashed line is the analytic result for a thick film, (4.6); the horizontal dashed line is the asymptotic result for a film with a finite thickness. ![]() $(b)$ Comparison between the correlation (6.4) for the running average of the Sherwood number defined in (3.13) and the present computational results.

$(b)$ Comparison between the correlation (6.4) for the running average of the Sherwood number defined in (3.13) and the present computational results.

As shown in figure 4(b), for the flat film, the numerical results for the running average of the Sherwood number defined in (3.13) are closely approximated by the correlation

\begin{equation} \langle Sh\rangle=\left[3.41^{2.5} +\left(-\frac{\log c_m^{*}}{x/(h_{Nu}Pe)}\right)^{2.5} \right]^{0.4} , \end{equation}

\begin{equation} \langle Sh\rangle=\left[3.41^{2.5} +\left(-\frac{\log c_m^{*}}{x/(h_{Nu}Pe)}\right)^{2.5} \right]^{0.4} , \end{equation}

in which ![]() $c_m^{*}$ is given by (4.3).

$c_m^{*}$ is given by (4.3).

7. Large-wave regime

We begin the discussion of the present results focusing on what may be called the large-wave regime, in which the wave develops a recirculation region in its rest frame. The threshold for this occurrence can be identified with the condition in which the maximum liquid velocity ![]() $u_{max}$ in the absolute frame equals the velocity

$u_{max}$ in the absolute frame equals the velocity ![]() $u_w$ of the wave itself. The empirical correlation

$u_w$ of the wave itself. The empirical correlation

based on our numerical results, provides a reasonable fit to them as can be seen in figure 5(a), which includes all the cases that we have simulated. As figure 5(b) shows, after removing the points with small values of ![]() $u_{max}/u_w$ identified by the (blue) circles in figure 5(a), a better fit is obtained with the slightly modified expression

$u_{max}/u_w$ identified by the (blue) circles in figure 5(a), a better fit is obtained with the slightly modified expression

The three cases removed to generate this correlation also show a poorer fit with the original correlation in the left plot of figure 3. We identify as large waves such that the computed value of ![]() $u_{max}/u_w$ exceeds 1. Cases for which

$u_{max}/u_w$ exceeds 1. Cases for which ![]() $u_{max}/u_w\lesssim 1$ will be considered in the next section. The value

$u_{max}/u_w\lesssim 1$ will be considered in the next section. The value ![]() $u_{max}/u_w = 1$ is introduced mostly for convenience as it is not a hard threshold. Waves for which the ratio falls slightly below or slightly above share features of both small and large waves. (It may be noted that the ratio of the exponents of

$u_{max}/u_w = 1$ is introduced mostly for convenience as it is not a hard threshold. Waves for which the ratio falls slightly below or slightly above share features of both small and large waves. (It may be noted that the ratio of the exponents of ![]() $Re$ to

$Re$ to ![]() $Ka$ in the previous correlations are 3.54 and 4.18, not too different from the ratio

$Ka$ in the previous correlations are 3.54 and 4.18, not too different from the ratio ![]() $11/3\simeq 3.67$ implied by the Shkadov parameter

$11/3\simeq 3.67$ implied by the Shkadov parameter ![]() $\delta$.)

$\delta$.)

Figure 5. Comparison of the computational results with the correlation (7.1), plot (a), and (7.2), plot (b), for the ratio ![]() $u_{max}/u_w$ of the maximum flow velocity in the absolute frame to the wave velocity. Plot (a) includes the results for all the cases of table 1. Plot (b) only includes the cases with

$u_{max}/u_w$ of the maximum flow velocity in the absolute frame to the wave velocity. Plot (a) includes the results for all the cases of table 1. Plot (b) only includes the cases with ![]() $u_{max}/u_w \gtrsim 0.9$; the circles in (a) (blue) identify the points deleted in (b).

$u_{max}/u_w \gtrsim 0.9$; the circles in (a) (blue) identify the points deleted in (b).

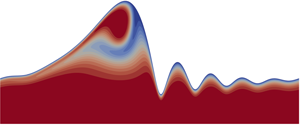

The upper frames in each row of figure 6 show the wave shape for case 0 at successive positions downstream of the inlet with the colour indicating the solute concentration; the first frame also includes the streamlines in the wave rest frame which, due to the steadiness of the flow in this frame, do not change in the course of the propagation. An animation of this sequence is available as supplementary movies at https://doi.org/10.1017/jfm.2020.587. The lower frames in each row are the corresponding normalized mass flux ![]() $\dot {m}^{*}$ defined by

$\dot {m}^{*}$ defined by

at the same instant of time; similar results for the mass transfer rate have been shown by Sisoev et al. (Reference Sisoev, Matar and Lawrence2005) and for the local Sherwood number by Albert et al. (Reference Albert, Marschall and Bothe2014). The horizontal axis is the dimensionless downstream distance ![]() $x/h_{Nu}$. The parameter values for this case are given in the first line of table 1.

$x/h_{Nu}$. The parameter values for this case are given in the first line of table 1.

Figure 6. Successive snapshots of the wave propagating along the plate for the conditions of case 0 of table 1. The colour is the solute concentration for ![]() $Sc =1000$. The graph under each wave shape shows the local instantaneous mass flux

$Sc =1000$. The graph under each wave shape shows the local instantaneous mass flux ![]() $\dot {m}$ at the wave surface normalized according to (7.3). The vertical scale is amplified by a factor of 25 with respect to the horizontal scale; a detail with equal scales in the two directions is shown in figure 7. The two circles are the stagnation points associated to the recirculation.

$\dot {m}$ at the wave surface normalized according to (7.3). The vertical scale is amplified by a factor of 25 with respect to the horizontal scale; a detail with equal scales in the two directions is shown in figure 7. The two circles are the stagnation points associated to the recirculation.

In the wave rest frame, recirculation is the result of the appearance of the two stagnation points marked in figure 6 on the right and left faces of the wave. In the laboratory frame these would be downstream and upstream faces, while they become the upstream and downstream faces, respectively, in the wave rest frame, which is the frame we use in the following discussion. We refer to the streamline joining the stagnation points as the separation streamline.

Figure 7. Snapshots of the region around the ‘whisker’ of solute-rich liquid on the back of the main crest corresponding to the last five frames of figure 6. The solid lines identify the boundary of the region where the solute concentration exceeds 50 % of the initial value. The arrows indicate the downstream end of the solute-rich ‘whisker.’ Here the vertical scale is not magnified but is equal to the horizontal scale.

The liquid in the neighbourhood of the front (right) stagnation point comes from the boundary layer on the surface of the film upstream (to the right) of the large crest and is therefore depleted of solute. Accordingly, as can be seen from the figure, the mass flux in this neighbourhood remains close to zero for all times. As noted, among others, by Yoshimura et al. (Reference Yoshimura, Nosoko and Nagata1996), Rastaturin et al. (Reference Rastaturin, Demekhin and Kalaidin2006) and Dietze (Reference Dietze2019), this liquid from the previous boundary layer is deflected under the separation streamline penetrating the large wave toward its rear face thus acquiring a velocity component normal to the interface. Interestingly, these streamlines do not reach the free surface at the back (to the left) of the wave but are deflected thus leaving a thin ‘whisker’ of relatively solute-rich fluid, particularly evident in frame (c), between themselves and the free surface on which, therefore, a new boundary layer forms; as cited in Yoshimura et al. (Reference Yoshimura, Nosoko and Nagata1996) a similar pattern was also shown in a conference contribution by Nagasaki & Hijikata (1990). Yoshimuraet al. (Reference Yoshimura, Nosoko and Nagata1996) used it to develop a double-boundary-layer model. In this way the concentration field becomes multi-layered, which is responsible for the complex features of the process.

A more detailed view of the development of this multi-layered structure is provided by figure 7, which focuses on this region using equal scales in the horizontal and vertical directions; the five images correspond to the last five frames of figure 6. The dark solid line marks the ![]() $c_m^{*}=0.5$ boundary. As long as this whisker has not been depleted, the largest mass flux occurs from the new boundary layer forming along the back of the main crest. However, it is seen from frame (e) of figure 6 onward that the mass flux from the back of the wave, after the two boundary layers merge, becomes quite comparable to that from the rest of the film except for a very small increase in the region where the recirculation brings fresh solute-reach liquid near the surface. Of course, superimposed on this fairly constant value of the mass flux are maxima and minima in correspondence of the minima and maxima of the film thickness. Indeed, from the local

$c_m^{*}=0.5$ boundary. As long as this whisker has not been depleted, the largest mass flux occurs from the new boundary layer forming along the back of the main crest. However, it is seen from frame (e) of figure 6 onward that the mass flux from the back of the wave, after the two boundary layers merge, becomes quite comparable to that from the rest of the film except for a very small increase in the region where the recirculation brings fresh solute-reach liquid near the surface. Of course, superimposed on this fairly constant value of the mass flux are maxima and minima in correspondence of the minima and maxima of the film thickness. Indeed, from the local ![]() $\dot {m}^{*}$ shown under the wave shapes in figure 6, we observe a good correspondence between mass transfer and wave shapes in the sense that the mass flux is roughly inversely proportional to the local film thickness as remarked by several authors (see, e.g. Morioka & Kiyota Reference Morioka and Kiyota1991; Bo et al. Reference Bo, Ma, Chen and Lan2011). More than because of an inverse proportionality of

$\dot {m}^{*}$ shown under the wave shapes in figure 6, we observe a good correspondence between mass transfer and wave shapes in the sense that the mass flux is roughly inversely proportional to the local film thickness as remarked by several authors (see, e.g. Morioka & Kiyota Reference Morioka and Kiyota1991; Bo et al. Reference Bo, Ma, Chen and Lan2011). More than because of an inverse proportionality of ![]() $\partial c/\partial z$ to the local film thickness (or, possibly, in addition to this factor), the enhanced gradient may be due to the convergence of the streamlines under the wave troughs, clearly visible in the first frame of figure 6, since, in a large-Schmidt-number system, streamlines approximate iso-concentration lines away from the main crest.

$\partial c/\partial z$ to the local film thickness (or, possibly, in addition to this factor), the enhanced gradient may be due to the convergence of the streamlines under the wave troughs, clearly visible in the first frame of figure 6, since, in a large-Schmidt-number system, streamlines approximate iso-concentration lines away from the main crest.

In order to study the connection between film thickness and mass transfer rate, following Charogiannis & Markides (Reference Charogiannis and Markides2019), we show in figure 8 a graph of the dimensionless time-dependent mass transfer rate

versus the local film thickness non-dimensionalized by division by ![]() $h_{Nu}$ for three values of

$h_{Nu}$ for three values of ![]() $x$; time runs counter-clockwise. The dashed line is the flat-film asymptotic value

$x$; time runs counter-clockwise. The dashed line is the flat-film asymptotic value ![]() $Sh_\infty =3.41$ for the corresponding film thickness. The largest loop is for

$Sh_\infty =3.41$ for the corresponding film thickness. The largest loop is for ![]() $x/h_{Nu} = 50$, which is close to half a wavelength from the start of the mass transfer. It shows a very large mass transfer from the freshly exposed top and back of the wave, that becomes smaller and oscillatory in the capillary-wave substrate. The intense mass transfer from the top of the wave is due to the velocity normal to the interface close to the left stagnation point mentioned before. The substrate does not benefit from a similar mechanism and the transfer rate is correspondingly smaller. At

$x/h_{Nu} = 50$, which is close to half a wavelength from the start of the mass transfer. It shows a very large mass transfer from the freshly exposed top and back of the wave, that becomes smaller and oscillatory in the capillary-wave substrate. The intense mass transfer from the top of the wave is due to the velocity normal to the interface close to the left stagnation point mentioned before. The substrate does not benefit from a similar mechanism and the transfer rate is correspondingly smaller. At ![]() $x/h_{Nu} = 500$ (blue line), about five wavelengths downstream of the beginning of the mass transfer, there still is a fairly sustained mass flux from the top and back side of the wave, with a maximum near the left stagnation point due to the recirculating flow. The last line (violet) is for

$x/h_{Nu} = 500$ (blue line), about five wavelengths downstream of the beginning of the mass transfer, there still is a fairly sustained mass flux from the top and back side of the wave, with a maximum near the left stagnation point due to the recirculating flow. The last line (violet) is for ![]() $x/h_{Nu} = 5000$. The effect of recirculation is nearly gone and the general trend is similar to, although mostly above, that of a flat film.

$x/h_{Nu} = 5000$. The effect of recirculation is nearly gone and the general trend is similar to, although mostly above, that of a flat film.

Figure 8. Dimensionless time-dependent mass transfer rate defined in (7.4) versus local film thickness for case 0. The large loop (red) is for ![]() $x/h_{Nu} = 50$, the intermediate one (blue) for

$x/h_{Nu} = 50$, the intermediate one (blue) for ![]() $x/h_{Nu} = 500$ and the smallest one (violet) for

$x/h_{Nu} = 500$ and the smallest one (violet) for ![]() $x/h_{Nu} = 5000$; the dashed line is the flat-film result.

$x/h_{Nu} = 5000$; the dashed line is the flat-film result.

The left plot of figure 9 shows the normalized time-averaged local mass transfer rate ![]() $\dot {M}^{*}$ versus

$\dot {M}^{*}$ versus ![]() $x/h_{Nu}$ for, in ascending order,

$x/h_{Nu}$ for, in ascending order, ![]() $Sc = 100$, 200, 500 and 1000. The main features of these curves are interpreted with the help of the right plot which reproduces the line for

$Sc = 100$, 200, 500 and 1000. The main features of these curves are interpreted with the help of the right plot which reproduces the line for ![]() $Sc = 500$ on a log-log scale. Initially there is a short period of rapid decrease, stage 1, similar to that for a flat film, which lasts less than one wavelength. This is followed by a near-plateau (stage 2), which is fed by the component of the convection velocity normal to the interface on the left side of the large wave. When the solute-poor liquid reaches the back of the wave forming the whisker, the mass transfer declines fairly rapidly as this structure is eroded, stage 3, and, when the whisker has completely disappeared, the decline temporarily decreases, stage 4, and then picks up speed similarly to the flat-film case as the finite thickness of the liquid layer becomes a limiting factor.

$Sc = 500$ on a log-log scale. Initially there is a short period of rapid decrease, stage 1, similar to that for a flat film, which lasts less than one wavelength. This is followed by a near-plateau (stage 2), which is fed by the component of the convection velocity normal to the interface on the left side of the large wave. When the solute-poor liquid reaches the back of the wave forming the whisker, the mass transfer declines fairly rapidly as this structure is eroded, stage 3, and, when the whisker has completely disappeared, the decline temporarily decreases, stage 4, and then picks up speed similarly to the flat-film case as the finite thickness of the liquid layer becomes a limiting factor.

If the same data were plotted as in figure 15 below by showing ![]() $Sh$ defined as in (3.10), the graph would be quite similar, the main difference being a shallow maximum corresponding to the near constant

$Sh$ defined as in (3.10), the graph would be quite similar, the main difference being a shallow maximum corresponding to the near constant ![]() $\dot {M}$ divided by the decreasing

$\dot {M}$ divided by the decreasing ![]() $c_m-c_i$ in stage 2. The combination of the different physics determining these two quantities would cloud the interpretation of the Sherwood number and perhaps also its practical usefulness.

$c_m-c_i$ in stage 2. The combination of the different physics determining these two quantities would cloud the interpretation of the Sherwood number and perhaps also its practical usefulness.

The complexity of the processes just described prevents a simple scaling of the local mass transfer rate or of the local Sherwood number. However, some useful conclusions can be derived for the running average ![]() $\langle Sh\rangle (x)$ of the Sherwood number defined in (3.13), which is presented in three different ways in figure 10. The solid lines in the first plot show

$\langle Sh\rangle (x)$ of the Sherwood number defined in (3.13), which is presented in three different ways in figure 10. The solid lines in the first plot show ![]() $\langle Sh\rangle (x)$ for, in ascending order,

$\langle Sh\rangle (x)$ for, in ascending order, ![]() $Sc = 100$, 200, 500 and 1000. The lines are nearly parallel for some distance demonstrating the influence of convection, which affects all Schmidt numbers equally. The dashed lines are the corresponding results for a flat film with the same flow rate. Initially, the curves closely follow the flat-film results. This feature is particularly clear from the central plot which shows the ratio of the running averages of the Sherwood number of the wavy to the flat film. Here, all the curves start from

$Sc = 100$, 200, 500 and 1000. The lines are nearly parallel for some distance demonstrating the influence of convection, which affects all Schmidt numbers equally. The dashed lines are the corresponding results for a flat film with the same flow rate. Initially, the curves closely follow the flat-film results. This feature is particularly clear from the central plot which shows the ratio of the running averages of the Sherwood number of the wavy to the flat film. Here, all the curves start from ![]() $\langle Sh \rangle /\langle Sh \rangle _\infty = 1$.

$\langle Sh \rangle /\langle Sh \rangle _\infty = 1$.

Figure 10. Three views of the running average ![]() $\langle Sh\rangle (x)$ of the Sherwood number defined in (3.13) for case 0 of table 1. (a) The solid lines show

$\langle Sh\rangle (x)$ of the Sherwood number defined in (3.13) for case 0 of table 1. (a) The solid lines show ![]() $\langle Sh\rangle$ for, in ascending order,

$\langle Sh\rangle$ for, in ascending order, ![]() $Sc = 100$, 200, 500 and 1000, while the dashed lines show the same quantity for a flat film with the same flow rate. (b) Ratio of

$Sc = 100$, 200, 500 and 1000, while the dashed lines show the same quantity for a flat film with the same flow rate. (b) Ratio of ![]() $\langle Sh\rangle (x)$ for the wavy film to the same quantity for the flat film. (c) The Sherwood number for the wavy film normalized by