1. Introduction

The dynamics of thin fluid films flowing down a cylindrical fibre plays a significant role in a variety of engineering applications, including mass and heat exchangers for thermal desalination, and water vapour and ![]() $\textrm {CO}_{2}$ capture (Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019; Zeng, Sadeghpour & Ju Reference Zeng, Sadeghpour and Ju2019). These films exhibit complex interfacial flow dynamics. Three distinct flow regimes have been observed in previous experiments by Kliakhandler, Davis & Bankoff (Reference Kliakhandler, Davis and Bankoff2001):

$\textrm {CO}_{2}$ capture (Sadeghpour et al. Reference Sadeghpour, Zeng, Ji, Dehdari Ebrahimi, Bertozzi and Ju2019; Zeng, Sadeghpour & Ju Reference Zeng, Sadeghpour and Ju2019). These films exhibit complex interfacial flow dynamics. Three distinct flow regimes have been observed in previous experiments by Kliakhandler, Davis & Bankoff (Reference Kliakhandler, Davis and Bankoff2001): ![]() $(a)$ a convective regime where irregular wave patterns frequently lead to droplet collisions;

$(a)$ a convective regime where irregular wave patterns frequently lead to droplet collisions; ![]() $(b)$ a Rayleigh–Plateau regime where stable travelling beads move at a constant speed; and

$(b)$ a Rayleigh–Plateau regime where stable travelling beads move at a constant speed; and ![]() $(c)$ an isolated droplet regime where widely spaced travelling beads coexist with secondary small-amplitude wave patterns. These dynamic regimes have been extensively studied both experimentally and theoretically (Quéré Reference Quéré1999; Ruyer-Quil et al. Reference Ruyer-Quil, Trevelyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2009; Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2011; Ruyer-Quil & Kalliadasis Reference Ruyer-Quil and Kalliadasis2012) as a function of the flow rate and fibre radius for different fluids.

$(c)$ an isolated droplet regime where widely spaced travelling beads coexist with secondary small-amplitude wave patterns. These dynamic regimes have been extensively studied both experimentally and theoretically (Quéré Reference Quéré1999; Ruyer-Quil et al. Reference Ruyer-Quil, Trevelyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2009; Kalliadasis et al. Reference Kalliadasis, Ruyer-Quil, Scheid and Velarde2011; Ruyer-Quil & Kalliadasis Reference Ruyer-Quil and Kalliadasis2012) as a function of the flow rate and fibre radius for different fluids.

Classical lubrication theory is widely applied to study the dynamics of films flowing down vertical fibres at small flow rates. Under the assumption that the film thickness is much smaller than the fibre radius, weakly nonlinear thin-film equations are investigated in the work of Frenkel (Reference Frenkel1992), Kalliadasis & Chang (Reference Kalliadasis and Chang1994) and Chang & Demekhin (Reference Chang and Demekhin1999). These evolution equations capture both the stabilizing and destabilizing roles of the surface tension that originate from the axial and azimuthal curvatures of the interface, respectively (Craster & Matar Reference Craster and Matar2009). A fully nonlinear curvature term was incorporated in Kliakhandler et al. (Reference Kliakhandler, Davis and Bankoff2001) to alleviate limitations of the small-interface-slope assumption of the lubrication theory. Using a low-Bond-number, surface-tension-dominated theory, Craster & Matar (Reference Craster and Matar2006) propose an asymptotic model that captures the flow regimes ![]() $(a)$ and

$(a)$ and ![]() $(c)$.

$(c)$.

Recently, Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019) investigated a full lubrication model that includes slip boundary conditions, nonlinear curvature terms and a film stabilization term. The last term brings to focus the presence of a stable liquid layer that plays an important role in the dynamics. Compared with models from previous studies, the combination of these physical effects better characterizes the observed propagation speed, the stability of travelling droplets and their transition to the isolated droplet regime. For moderate-flow-rate cases, Trifonov (Reference Trifonov1992) proposed a system of coupled evolution equations for the film thickness and the flow rate. This model incorporates inertial effects based on the integral boundary layer (IBL) equations for the dynamics of a falling film on inclined planes (Shkadov Reference Shkadov1967). The weighted residual integral boundary layer (WRIBL) models developed by Ruyer-Quil et al. (Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008), Duprat, Ruyer-Quil & Giorgiutti-Dauphiné (Reference Duprat, Ruyer-Quil and Giorgiutti-Dauphiné2009) and Ruyer-Quil & Kalliadasis (Reference Ruyer-Quil and Kalliadasis2012) further extended the IBL models by including the effects of the streamwise viscous diffusion.

These previous studies, however, primarily address the dynamics of downstream flows far away from the inlets. A recent experimental study by Sadeghpour, Zeng & Ju (Reference Sadeghpour, Zeng and Ju2017) revealed that the geometry of the inlet nozzle also has a strong influence on the downstream dynamics. Specifically, distinct regimes of interfacial patterns are observed by simply varying the diameter of the nozzle while keeping other parameters fixed. These results motivate us to further investigate the existing models to better understand the relevant influential physics both near the nozzle and further downstream. An improved understanding of the flow regimes will provide insights for a variety of engineering applications. In this study, we build on previous studies of IBL equations and the film stabilization mechanism, while accounting for inertial effects, gravity modulation and surface tension. We compare a new model to experiments with varying nozzle geometry.

The paper is organized as follows. In § 2 we lay out the experimental set-up. In § 3 a system of coupled evolution equations for the film thickness and the flow rate are formulated. Then § 4.1 presents the stability analysis of the model and discusses the film stabilization term. Numerical results for the model and their comparison to experimental observations are presented in §§ 4.2 and 4.3, followed by concluding remarks in § 5.

2. Experiments

Figure 1 shows a schematic of the experimental set-up, designed to investigate the effects of the inlet nozzle on the flow properties and flow pattern. The experimental set-up includes: (1) a syringe pump to control the volume flow rate of the working liquid, (2) a converter to connect the syringe pump outlet to the nozzle, (3) a stainless-steel nozzle with various diameters (![]() $\text {OD} = 0.84$,

$\text {OD} = 0.84$, ![]() $1.06$,

$1.06$, ![]() $1.27$,

$1.27$, ![]() $1.56$,

$1.56$, ![]() $1.86$ or

$1.86$ or ![]() $2.41$ mm), (4) a transparent tube to protect the flow from noise and air disturbances, (5) a high-speed camera, set to

$2.41$ mm), (4) a transparent tube to protect the flow from noise and air disturbances, (5) a high-speed camera, set to ![]() $1000$ frames per second, mounted on an adjustable stage, (6) a weight connected to the end of the polymer fibre to keep it straight and vertical during the experiment, (7) a weight scale, (8) a liquid container and (9) a data acquisition (DAQ) system to receive/record the information from the camera and the weight scale.

$1000$ frames per second, mounted on an adjustable stage, (6) a weight connected to the end of the polymer fibre to keep it straight and vertical during the experiment, (7) a weight scale, (8) a liquid container and (9) a data acquisition (DAQ) system to receive/record the information from the camera and the weight scale.

Figure 1. Schematic of the experimental set-up with changeable nozzle to study the effect of nozzle diameter (OD) on the fluid dynamics of the flow.

Polymeric fibres with diameters of ![]() ${D}_s=0.2$,

${D}_s=0.2$, ![]() $0.29$ and

$0.29$ and ![]() $0.43$ mm are coated with a liquid mass flow rate in the range of

$0.43$ mm are coated with a liquid mass flow rate in the range of ![]() ${Q}_m=0.02\ \textrm {g}\,\textrm {s}^{-1}$ to

${Q}_m=0.02\ \textrm {g}\,\textrm {s}^{-1}$ to ![]() $0.08\ \textrm {g}\,\textrm {s}^{-1}$. The wetting liquid is Rhodorsil silicone oil v50, with the following physical properties: density

$0.08\ \textrm {g}\,\textrm {s}^{-1}$. The wetting liquid is Rhodorsil silicone oil v50, with the following physical properties: density ![]() $\rho =963\ \textrm {kg}\,\textrm {m}^{-3}$, kinematic viscosity

$\rho =963\ \textrm {kg}\,\textrm {m}^{-3}$, kinematic viscosity ![]() $\nu = 50 \ \text {mm}^{2}\,\textrm {s}^{-1}$ and surface tension

$\nu = 50 \ \text {mm}^{2}\,\textrm {s}^{-1}$ and surface tension ![]() $\sigma = 20.8\ \textrm {mN}\,\textrm {m}^{-1}$ (all at

$\sigma = 20.8\ \textrm {mN}\,\textrm {m}^{-1}$ (all at ![]() $20\,^{\circ }\textrm {C}$). A summary of the experimental conditions is presented in table 1.

$20\,^{\circ }\textrm {C}$). A summary of the experimental conditions is presented in table 1.

Table 1. Experimental cases of varying nozzle diameter and mass flow rate.

3. Model formulation

We build on the first-order WRIBL model (Ruyer-Quil et al. Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008; Duprat et al. Reference Duprat, Ruyer-Quil and Giorgiutti-Dauphiné2009). We consider the flow of a two-dimensional axisymmetric Newtonian fluid coating a vertical cylinder of radius ![]() $R^*$. The kinematic viscosity

$R^*$. The kinematic viscosity ![]() $\nu$, the density

$\nu$, the density ![]() $\rho$ and the surface tension

$\rho$ and the surface tension ![]() $\sigma$ of the liquid are assumed to be constant. Near the nozzle, the fluid coats the fibre with a nearly uniform film that defines the characteristic radial length scale

$\sigma$ of the liquid are assumed to be constant. Near the nozzle, the fluid coats the fibre with a nearly uniform film that defines the characteristic radial length scale ![]() $\mathcal {H}$. The length of this near-nozzle region, from the inlet to the location of the onset of droplet formation, is referred to as the healing length (

$\mathcal {H}$. The length of this near-nozzle region, from the inlet to the location of the onset of droplet formation, is referred to as the healing length (![]() $\varDelta$ in figure 1) (Sadeghpour et al. Reference Sadeghpour, Zeng and Ju2017). Given the dimensional volumetric mass flow rate

$\varDelta$ in figure 1) (Sadeghpour et al. Reference Sadeghpour, Zeng and Ju2017). Given the dimensional volumetric mass flow rate ![]() ${Q}_m$ and fibre radius

${Q}_m$ and fibre radius ![]() $R^*$, we define the volumetric flow rate per circumference unit,

$R^*$, we define the volumetric flow rate per circumference unit, ![]() $q_0^* = {Q}_m/(2{\rm \pi} \rho R^*)$. By balancing the viscosity and gravitational acceleration, the axial velocity

$q_0^* = {Q}_m/(2{\rm \pi} \rho R^*)$. By balancing the viscosity and gravitational acceleration, the axial velocity ![]() $u_0^*$ of a uniform flow, without interfacial variance in the streamwise direction, is given by the Nusselt solution

$u_0^*$ of a uniform flow, without interfacial variance in the streamwise direction, is given by the Nusselt solution

One then obtains the characteristic axial length scale ![]() $\mathcal {H}$ by solving the equation

$\mathcal {H}$ by solving the equation

where ![]() $\phi (X) = (3/(16X^3))[(1+X)^4(4\log (1+X)-3)+4(1+X)^2-1]$.

$\phi (X) = (3/(16X^3))[(1+X)^4(4\log (1+X)-3)+4(1+X)^2-1]$.

The following scales are introduced for the model. The length scale in the streamwise direction ![]() $x$ is

$x$ is ![]() $\mathcal {L} = \mathcal {H}/\kappa$, where the scale ratio

$\mathcal {L} = \mathcal {H}/\kappa$, where the scale ratio ![]() $\kappa = (\rho g \mathcal {H}^2/\sigma )^{1/3}$ is set by the balance between the surface tension and the gravity. The characteristic streamwise velocity is

$\kappa = (\rho g \mathcal {H}^2/\sigma )^{1/3}$ is set by the balance between the surface tension and the gravity. The characteristic streamwise velocity is ![]() $\mathcal {U}=(g\mathcal {H}^2\phi (\alpha ))/{\nu }$, where

$\mathcal {U}=(g\mathcal {H}^2\phi (\alpha ))/{\nu }$, where ![]() $\alpha = \mathcal {H}/R^*$ represents the ratio of the characteristic film thickness and the fibre radius. The time scale is

$\alpha = \mathcal {H}/R^*$ represents the ratio of the characteristic film thickness and the fibre radius. The time scale is ![]() $\mathcal {T} = \mathcal {L} /\mathcal {U}$ and the Reynolds number is

$\mathcal {T} = \mathcal {L} /\mathcal {U}$ and the Reynolds number is ![]() $Re = {q_0^*}/\nu$.

$Re = {q_0^*}/\nu$.

Using these scalings, we follow the analysis of Ruyer-Quil et al. (Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008) and derive a coupled system of two evolution equations for the dimensionless film thickness ![]() $h$ and flow rate

$h$ and flow rate ![]() $q$. Here the dimensionless flow rate

$q$. Here the dimensionless flow rate ![]() $q$ is defined by

$q$ is defined by ![]() $q = R^{-1}\textstyle {\int _{R}^{R+h} u y \,\textrm {d}y}$, where

$q = R^{-1}\textstyle {\int _{R}^{R+h} u y \,\textrm {d}y}$, where ![]() $R$ and

$R$ and ![]() $u$ are dimensionless fibre radius and radial velocity. By projecting the velocity field on a set of test functions and applying a weighted residual procedure under the lubrication assumption, we obtain a mass conservation equation for

$u$ are dimensionless fibre radius and radial velocity. By projecting the velocity field on a set of test functions and applying a weighted residual procedure under the lubrication assumption, we obtain a mass conservation equation for ![]() $h$ in terms of

$h$ in terms of ![]() $q$,

$q$,

and an averaged axial momentum equation,

\begin{align} \delta \frac{\partial q}{\partial t} &= \delta\left[- F(\alpha h)\frac{q}{h}\frac{\partial q}{\partial x} + G(\alpha h)\frac{q^2}{h^2}\frac{\partial h}{\partial x}\right]\nonumber\\ &\quad + \frac{I(\alpha h)}{\phi(\alpha)}\left[-\frac{3\phi(\alpha)}{\phi(\alpha h)}\frac{q}{h^2}+ h\left\{1-\frac{\partial}{\partial x}\left[ \mathcal{Z}(h) - \frac{\partial^2 h}{\partial x^2}\right]\right\}\right]. \end{align}

\begin{align} \delta \frac{\partial q}{\partial t} &= \delta\left[- F(\alpha h)\frac{q}{h}\frac{\partial q}{\partial x} + G(\alpha h)\frac{q^2}{h^2}\frac{\partial h}{\partial x}\right]\nonumber\\ &\quad + \frac{I(\alpha h)}{\phi(\alpha)}\left[-\frac{3\phi(\alpha)}{\phi(\alpha h)}\frac{q}{h^2}+ h\left\{1-\frac{\partial}{\partial x}\left[ \mathcal{Z}(h) - \frac{\partial^2 h}{\partial x^2}\right]\right\}\right]. \end{align}

Here ![]() $\delta = 3\kappa Re$ is a reduced Reynolds number, and the coefficients

$\delta = 3\kappa Re$ is a reduced Reynolds number, and the coefficients ![]() $F$,

$F$, ![]() $G$ and

$G$ and ![]() $I$ are functions of the aspect ratio

$I$ are functions of the aspect ratio ![]() $\alpha$ and

$\alpha$ and ![]() $h$ defined as follows:

$h$ defined as follows:

with

\begin{align} G_a(X) &= 9b ( 4\ln( b) ( -220{b}^{8}+456{b}^{6 }-303{b}^{4}+6\ln( b) ( 61{b}^{6}-69{b}^{4 }\nonumber\\ &\quad +4\ln( b)( 4\ln( b ) {b}^{4}-12 {b}^{4}+7{b}^{2}+2) {b}^{2}+9{b}^{2}+9) {b}^{2}+58{b}^{2}+9) {b}^{2}\nonumber\\ &\quad + ( {b}^{2}-1) ^{2}( 153{b}^{6}-145{b}^{4}+53{b}^{2}-1)), \quad \mbox{where}\ b = 1+X, \end{align}

\begin{align} G_a(X) &= 9b ( 4\ln( b) ( -220{b}^{8}+456{b}^{6 }-303{b}^{4}+6\ln( b) ( 61{b}^{6}-69{b}^{4 }\nonumber\\ &\quad +4\ln( b)( 4\ln( b ) {b}^{4}-12 {b}^{4}+7{b}^{2}+2) {b}^{2}+9{b}^{2}+9) {b}^{2}+58{b}^{2}+9) {b}^{2}\nonumber\\ &\quad + ( {b}^{2}-1) ^{2}( 153{b}^{6}-145{b}^{4}+53{b}^{2}-1)), \quad \mbox{where}\ b = 1+X, \end{align} \begin{align} F_a(X) &= -301b^8 + 622b^6-441b^4+4\log(b)\{197b^6-234b^4+6\log(b)\nonumber\\ &\quad \times[16\log(b)b^4 - 36b^4+22b^2+3]b^2+78b^2+4\}b^2+130b^2-10 \end{align}

\begin{align} F_a(X) &= -301b^8 + 622b^6-441b^4+4\log(b)\{197b^6-234b^4+6\log(b)\nonumber\\ &\quad \times[16\log(b)b^4 - 36b^4+22b^2+3]b^2+78b^2+4\}b^2+130b^2-10 \end{align}and

The surface tension plays both a stabilizing and a destabilizing role in the dynamics of flows down vertical fibres. This is characterized by the interaction between an azimuthal curvature term in ![]() $\mathcal {Z}(h)$ and the streamwise curvature terms

$\mathcal {Z}(h)$ and the streamwise curvature terms ![]() $h_{xx}$ in (3.3b). Following the approach in Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019), we also introduce a film stabilization term

$h_{xx}$ in (3.3b). Following the approach in Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019), we also introduce a film stabilization term ![]() $\varPi (h)$. As a result, the functional

$\varPi (h)$. As a result, the functional ![]() $\mathcal {Z}$ in (3.3b) consists of a destabilizing azimuthal curvature term

$\mathcal {Z}$ in (3.3b) consists of a destabilizing azimuthal curvature term ![]() $\beta /(\alpha (1+\alpha h))$ and a film stabilization term

$\beta /(\alpha (1+\alpha h))$ and a film stabilization term ![]() $\varPi (h)$,

$\varPi (h)$,

where the scaling parameter ![]() $\beta = \alpha ^2/\kappa ^2$, and

$\beta = \alpha ^2/\kappa ^2$, and ![]() $A>0$ is a stabilization parameter. The last term of (3.9a,b) takes the functional form of the long-range disjoining pressure of the well-known van der Waals model for wetting liquids. In lubrication theory,

$A>0$ is a stabilization parameter. The last term of (3.9a,b) takes the functional form of the long-range disjoining pressure of the well-known van der Waals model for wetting liquids. In lubrication theory, ![]() $A$ typically refers to a Hamaker constant that characterizes microscopic quantities (de Gennes Reference de Gennes1985; Reisfeld & Bankoff Reference Reisfeld and Bankoff1992). Here we choose the value of

$A$ typically refers to a Hamaker constant that characterizes microscopic quantities (de Gennes Reference de Gennes1985; Reisfeld & Bankoff Reference Reisfeld and Bankoff1992). Here we choose the value of ![]() $A$ based on a coating thickness

$A$ based on a coating thickness ![]() $\epsilon _p$ below which a thin uniform fluid layer on the fibre is stable (see § 4.1).

$\epsilon _p$ below which a thin uniform fluid layer on the fibre is stable (see § 4.1).

The coupled system (3.3) accounts for the surface tension, gravity, azimuthal instabilities and moderate inertial effects. For ![]() $A = 0$, this model is consistent with the first-order WRIBL studied in Ruyer-Quil et al. (Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008) and Duprat et al. (Reference Duprat, Ruyer-Quil and Giorgiutti-Dauphiné2009) except that their model includes a fully nonlinear azimuthal curvature term

$A = 0$, this model is consistent with the first-order WRIBL studied in Ruyer-Quil et al. (Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008) and Duprat et al. (Reference Duprat, Ruyer-Quil and Giorgiutti-Dauphiné2009) except that their model includes a fully nonlinear azimuthal curvature term ![]() $\mathcal {Z} = \mathcal {Z}_{FCM}$,

$\mathcal {Z} = \mathcal {Z}_{FCM}$,

where the FCM subscript stands for fully nonlinear curvature model. In the low-Reynolds-number limit ![]() $\delta \to 0$, (3.3b) gives an expression for

$\delta \to 0$, (3.3b) gives an expression for ![]() $q$ in terms of

$q$ in terms of ![]() $h$. Substituting this expression into (3.3a) leads to a single lubrication equation for

$h$. Substituting this expression into (3.3a) leads to a single lubrication equation for ![]() $h$, which is equivalent to the model (3.11) studied in Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019) and Craster & Matar (Reference Craster and Matar2006),

$h$, which is equivalent to the model (3.11) studied in Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019) and Craster & Matar (Reference Craster and Matar2006),

where ![]() $\mathcal {M}(h) = h^3\phi (\alpha h)/[3\phi (\alpha )]$ is the mobility function. The form of

$\mathcal {M}(h) = h^3\phi (\alpha h)/[3\phi (\alpha )]$ is the mobility function. The form of ![]() $\mathcal {M}(h)$ has also been generalized to include Navier slip boundary conditions in Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019).

$\mathcal {M}(h)$ has also been generalized to include Navier slip boundary conditions in Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019).

4. Results

4.1. Stability analysis and film stabilization mechanism

Next we examine the linear stability of the model (3.3) and derive the stabilization parameter ![]() $A$ in (3.9a,b). We perturb a uniform layer

$A$ in (3.9a,b). We perturb a uniform layer ![]() $h \equiv \bar {h}$ and its corresponding flux

$h \equiv \bar {h}$ and its corresponding flux ![]() $q \equiv \bar {q}$,

$q \equiv \bar {q}$,

Substituting the expansion (4.1) into (3.3b) leads to the ![]() $O(1)$ equation,

$O(1)$ equation, ![]() $\bar {q} = {[\bar {h}^3\phi (\alpha \bar {h})]}/{[3\phi (\alpha )]}$. After obtaining a single equation for

$\bar {q} = {[\bar {h}^3\phi (\alpha \bar {h})]}/{[3\phi (\alpha )]}$. After obtaining a single equation for ![]() $H$ by eliminating

$H$ by eliminating ![]() $Q$ using the

$Q$ using the ![]() $O(1)$ equation, we apply the Fourier mode decomposition

$O(1)$ equation, we apply the Fourier mode decomposition ![]() $H = H_1\exp (\textrm {i} k x + \varLambda t)$, where

$H = H_1\exp (\textrm {i} k x + \varLambda t)$, where ![]() $k$ is the wavenumber and

$k$ is the wavenumber and ![]() $\varLambda$ is the growth rate of the perturbation. This yields the dispersion relation

$\varLambda$ is the growth rate of the perturbation. This yields the dispersion relation

\begin{align} \varLambda & = -\frac{3I(\alpha\bar{h})}{2\delta\bar{h}^2\phi(\alpha\bar{h})} + \frac{1}{2\delta}\sqrt{\frac{9I^2(\alpha\bar{h})}{\bar{h}^4\phi^2(\alpha\bar{h})} - \frac{4\delta}{1+\alpha\bar{h}}\left[-k^2\mathcal{S}(\bar{h},\bar{q})+\frac{I(\alpha \bar{h})\bar{h}}{\phi(\alpha)}k^4\right]},\nonumber\\ & \quad \mbox{where} \quad \mathcal{S}(\bar{h},\bar{q}) = \delta G(\alpha \bar{h})\frac{\bar{q}^2}{\bar{h}^2}+\frac{I(\alpha \bar{h}) \bar{h}}{\phi(\alpha)}\left(\frac{\beta}{(1+\alpha \bar{h})^2}-\frac{3A}{\bar{h}^4}\right). \end{align}

\begin{align} \varLambda & = -\frac{3I(\alpha\bar{h})}{2\delta\bar{h}^2\phi(\alpha\bar{h})} + \frac{1}{2\delta}\sqrt{\frac{9I^2(\alpha\bar{h})}{\bar{h}^4\phi^2(\alpha\bar{h})} - \frac{4\delta}{1+\alpha\bar{h}}\left[-k^2\mathcal{S}(\bar{h},\bar{q})+\frac{I(\alpha \bar{h})\bar{h}}{\phi(\alpha)}k^4\right]},\nonumber\\ & \quad \mbox{where} \quad \mathcal{S}(\bar{h},\bar{q}) = \delta G(\alpha \bar{h})\frac{\bar{q}^2}{\bar{h}^2}+\frac{I(\alpha \bar{h}) \bar{h}}{\phi(\alpha)}\left(\frac{\beta}{(1+\alpha \bar{h})^2}-\frac{3A}{\bar{h}^4}\right). \end{align}

For the case ![]() $\mathcal {S} > 0$, we have

$\mathcal {S} > 0$, we have ![]() $\varLambda > 0$ for

$\varLambda > 0$ for ![]() $0 < k < k_c $, where the critical wavenumber

$0 < k < k_c $, where the critical wavenumber ![]() $k_c = \sqrt {\mathcal {S}(\bar {h},\bar {q})\phi (\alpha )/[I(\alpha \bar {h})\bar {h}]}$. For the case

$k_c = \sqrt {\mathcal {S}(\bar {h},\bar {q})\phi (\alpha )/[I(\alpha \bar {h})\bar {h}]}$. For the case ![]() $\mathcal {S} < 0$, we have

$\mathcal {S} < 0$, we have ![]() $\varLambda < 0$ for any

$\varLambda < 0$ for any ![]() $k > 0$. We follow the approach in Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019) and select the stabilization parameter

$k > 0$. We follow the approach in Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019) and select the stabilization parameter ![]() $A$ based on the dimensional thickness

$A$ based on the dimensional thickness ![]() $\epsilon _p = \mathcal {H}h_c$ of a stable undisturbed layer obtained from experimental observations, where

$\epsilon _p = \mathcal {H}h_c$ of a stable undisturbed layer obtained from experimental observations, where ![]() $h_c$ is the dimensionless stable coating film thickness. By setting

$h_c$ is the dimensionless stable coating film thickness. By setting ![]() $\mathcal {S}(h_c) = 0$ and using the

$\mathcal {S}(h_c) = 0$ and using the ![]() $O(1)$ equation, we derive a formula for a critical

$O(1)$ equation, we derive a formula for a critical ![]() $A_c$:

$A_c$:

This form ensures that, for ![]() $A=A_c$, any thin flat film of thickness less than the threshold value

$A=A_c$, any thin flat film of thickness less than the threshold value ![]() $h_c$ is linearly stable, that is,

$h_c$ is linearly stable, that is, ![]() $\varLambda <0$, for all wavenumbers

$\varLambda <0$, for all wavenumbers ![]() $k > 0$. Compared with the film stabilization model introduced in Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019) (equivalent to the case

$k > 0$. Compared with the film stabilization model introduced in Ji et al. (Reference Ji, Falcon, Sadeghpour, Zeng, Ju and Bertozzi2019) (equivalent to the case ![]() $\delta = 0$), the formula (4.3) for

$\delta = 0$), the formula (4.3) for ![]() $A_c$ includes a higher-order term in

$A_c$ includes a higher-order term in ![]() $h_c$.

$h_c$.

4.2. Near-nozzle flow dynamics

We perform numerical investigations to examine the spatio-temporal dynamics of the flow near the inlet and further downstream by solving the coupled system (3.3) for ![]() $0 \le x \le L$. To model the influence of nozzle geometry on the full dynamics, we impose Dirichlet boundary conditions on both the film thickness

$0 \le x \le L$. To model the influence of nozzle geometry on the full dynamics, we impose Dirichlet boundary conditions on both the film thickness ![]() $h$ and the flux

$h$ and the flux ![]() $q$ at

$q$ at ![]() $x = 0$:

$x = 0$: ![]() $h(0, t) = h_{\text {IN}}$ and

$h(0, t) = h_{\text {IN}}$ and ![]() $q(0, t) = {1}/{3}$, where the dimensionless inlet film thickness

$q(0, t) = {1}/{3}$, where the dimensionless inlet film thickness ![]() $h_{\text {IN}} = (\textstyle {\frac {1}{2}}\text {OD}-R^*)/\mathcal {H}$ and

$h_{\text {IN}} = (\textstyle {\frac {1}{2}}\text {OD}-R^*)/\mathcal {H}$ and ![]() $\text {OD}$ represents the dimensional outer nozzle diameter. We select

$\text {OD}$ represents the dimensional outer nozzle diameter. We select ![]() $\text {OD}$ as the nozzle geometric parameter since the liquid wets the nozzle in experiments. Following Ruyer-Quil et al. (Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008), we impose soft boundary conditions at the outlet

$\text {OD}$ as the nozzle geometric parameter since the liquid wets the nozzle in experiments. Following Ruyer-Quil et al. (Reference Ruyer-Quil, Treveleyan, Giorgiutti-Dauphiné, Duprat and Kalliadasis2008), we impose soft boundary conditions at the outlet ![]() $x = L$ by replacing the averaged momentum balance equation (3.3b) with a linear hyperbolic equation

$x = L$ by replacing the averaged momentum balance equation (3.3b) with a linear hyperbolic equation ![]() $q_t + v_f q_x = 0$ at the last two grid points near the outlet, using

$q_t + v_f q_x = 0$ at the last two grid points near the outlet, using ![]() $v_f = 1$ in all simulations. The initial conditions are a piecewise linear profile for the film thickness

$v_f = 1$ in all simulations. The initial conditions are a piecewise linear profile for the film thickness ![]() $h$ and a constant for the flux

$h$ and a constant for the flux ![]() $q$:

$q$:

\begin{equation} q(x, 0) \equiv \frac{1}{3},\quad h(x, 0) = \begin{cases} 1, & x > x_L,\\ h_{\text{IN}}+(1-h_{\text{IN}})x/x_L, & 0\le x \le x_L, \end{cases} \end{equation}

\begin{equation} q(x, 0) \equiv \frac{1}{3},\quad h(x, 0) = \begin{cases} 1, & x > x_L,\\ h_{\text{IN}}+(1-h_{\text{IN}})x/x_L, & 0\le x \le x_L, \end{cases} \end{equation}

where ![]() $x_L = 10$ is used for all simulations.

$x_L = 10$ is used for all simulations.

Centred finite differences in a Keller box scheme are used for numerically solving the model (3.3), where the coupled fourth-order partial differential equation system is decomposed into a system of first-order differential equations:

\begin{equation} \left.\begin{array}{c@{}} k = h_x,\quad p = \mathcal{Z}(h)-k_x, \quad \left(h+\dfrac{\alpha}{2}{h^2}\right)_t + q_x = 0,\\ \delta q_t = \delta\left(- F(\alpha h)\dfrac{q}{h}q_x + G(\alpha h) \dfrac{q^2}{h^2}k\right)+\dfrac{I(\alpha h)}{\phi(\alpha)}\left[-\dfrac{3\phi (\alpha)}{\phi(\alpha h)}\dfrac{q}{h^2}+ h(1- p_x)\right]. \end{array}\right\} \end{equation}

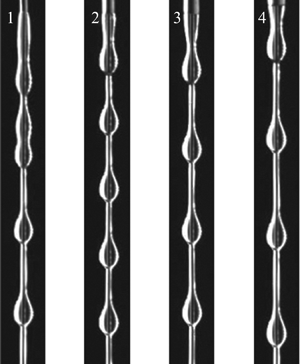

\begin{equation} \left.\begin{array}{c@{}} k = h_x,\quad p = \mathcal{Z}(h)-k_x, \quad \left(h+\dfrac{\alpha}{2}{h^2}\right)_t + q_x = 0,\\ \delta q_t = \delta\left(- F(\alpha h)\dfrac{q}{h}q_x + G(\alpha h) \dfrac{q^2}{h^2}k\right)+\dfrac{I(\alpha h)}{\phi(\alpha)}\left[-\dfrac{3\phi (\alpha)}{\phi(\alpha h)}\dfrac{q}{h^2}+ h(1- p_x)\right]. \end{array}\right\} \end{equation} In figure 2, we show transient numerical results of model (3.3) for the four different nozzle diameters used in our experiments. A fixed flow rate ![]() ${Q}_m=0.04\ \textrm {g}\,\textrm {s}^{-1}$ and a fixed fibre diameter

${Q}_m=0.04\ \textrm {g}\,\textrm {s}^{-1}$ and a fixed fibre diameter ![]() ${D}_s=0.29$ mm are used. The experimental results in figure 2(a) indicate that, as the nozzle diameter increases from

${D}_s=0.29$ mm are used. The experimental results in figure 2(a) indicate that, as the nozzle diameter increases from ![]() $0.84$ mm to

$0.84$ mm to ![]() $1.27$ mm, the droplet dynamics undergoes a transition from the convective instability regime to the Rayleigh–Plateau regime. Moreover, within the Raleigh–Plateau regime, the larger nozzle diameter leads to larger spacing between the moving droplets. This regime transition is captured in the numerical simulation (see figure 2b) where the inter-bead spacing agrees well with experimental observations.

$1.27$ mm, the droplet dynamics undergoes a transition from the convective instability regime to the Rayleigh–Plateau regime. Moreover, within the Raleigh–Plateau regime, the larger nozzle diameter leads to larger spacing between the moving droplets. This regime transition is captured in the numerical simulation (see figure 2b) where the inter-bead spacing agrees well with experimental observations.

Figure 2. (a) Experiments and (b) numerical simulations of (3.3) for nozzle diameters ![]() $\text {OD} = 0.84$, 1.27, 1.56 and 1.86 mm showing the transition from the convective to the Rayleigh–Plateau regime as

$\text {OD} = 0.84$, 1.27, 1.56 and 1.86 mm showing the transition from the convective to the Rayleigh–Plateau regime as ![]() $\text {OD}$ increases from

$\text {OD}$ increases from ![]() $\text {OD}=0.84$ mm to

$\text {OD}=0.84$ mm to ![]() $\text {OD}=1.27$ mm. Other system parameters are

$\text {OD}=1.27$ mm. Other system parameters are ![]() ${D}_s = 0.29$ mm,

${D}_s = 0.29$ mm, ![]() ${Q}_m = 0.04\ \textrm {g}\,\textrm {s}^{-1}$ and

${Q}_m = 0.04\ \textrm {g}\,\textrm {s}^{-1}$ and ![]() $\epsilon _p = 0.15$ mm.

$\epsilon _p = 0.15$ mm.

Next we discuss the influence of nozzle geometry on the flow dynamics within the healing length. Previous studies assumed that the film thickness and velocity profiles in this part of the flow are specified only by the flow rate and fibre radius. However, our study reveals that, for flows in the convective and Rayleigh–Plateau regimes, the healing length decreases as the nozzle diameter increases. Figure 3 presents one such comparison of the near-nozzle film profiles between experiments and simulations for the flow rate ![]() ${Q}_m=0.06\ \textrm {g}\,\textrm {s}^{-1}$ and the fibre diameter

${Q}_m=0.06\ \textrm {g}\,\textrm {s}^{-1}$ and the fibre diameter ![]() ${D}_s=0.43$ mm. This observation is reminiscent of the study by Duprat et al. (Reference Duprat, Ruyer-Quil and Giorgiutti-Dauphiné2009) on the spatial response of the film to inlet forcing, which concluded that the healing length tends to decrease as the forcing amplitude increases.

${D}_s=0.43$ mm. This observation is reminiscent of the study by Duprat et al. (Reference Duprat, Ruyer-Quil and Giorgiutti-Dauphiné2009) on the spatial response of the film to inlet forcing, which concluded that the healing length tends to decrease as the forcing amplitude increases.

Figure 3. (a) Experiments and (b) numerical simulations with the nozzle diameter ranging from ![]() $\text {OD} = 0.84$ to

$\text {OD} = 0.84$ to ![]() $2.41$ mm showing that the healing length (marked by arrows) decreases as the nozzle size increases. Other parameters are

$2.41$ mm showing that the healing length (marked by arrows) decreases as the nozzle size increases. Other parameters are ![]() ${D}_s = 0.43$ mm,

${D}_s = 0.43$ mm, ![]() ${Q}_m = 0.06\ \textrm {g}\,\textrm {s}^{-1}$ and

${Q}_m = 0.06\ \textrm {g}\,\textrm {s}^{-1}$ and ![]() $\epsilon _p = 0.15$ mm.

$\epsilon _p = 0.15$ mm.

4.3. Liquid bead properties

In figure 4, we show plots of the predicted bead velocities ![]() $V_b$ and inter-bead spacing

$V_b$ and inter-bead spacing ![]() $S_b$ for varying nozzle sizes. The rows from top to bottom show results with fibre diameters

$S_b$ for varying nozzle sizes. The rows from top to bottom show results with fibre diameters ![]() ${D}_s=0.43$, 0.29 and 0.20 mm, respectively, with two choices of flow rates

${D}_s=0.43$, 0.29 and 0.20 mm, respectively, with two choices of flow rates ![]() ${Q}_m$ for each fibre diameter. Our model (3.3) agrees well with the experimental observations across all the cases, provided a suitable stable film thickness

${Q}_m$ for each fibre diameter. Our model (3.3) agrees well with the experimental observations across all the cases, provided a suitable stable film thickness ![]() $\epsilon _p$ is applied.

$\epsilon _p$ is applied.

Figure 4. Bead properties (spacing and velocity) for the best ![]() $\epsilon _p$ values. For thin fibres of diameter

$\epsilon _p$ values. For thin fibres of diameter ![]() ${D}_s=0.2$ mm, we choose

${D}_s=0.2$ mm, we choose ![]() $\epsilon _p = 0.2$, 0.3 mm for

$\epsilon _p = 0.2$, 0.3 mm for ![]() ${Q}_m = 0.04$,

${Q}_m = 0.04$, ![]() $0.08\ \textrm {g}\,\textrm {s}^{-1}$, respectively. For the intermediate fibre

$0.08\ \textrm {g}\,\textrm {s}^{-1}$, respectively. For the intermediate fibre ![]() ${D}_s=0.29$ mm cases, we set

${D}_s=0.29$ mm cases, we set ![]() $\epsilon _p = 0.2$,

$\epsilon _p = 0.2$, ![]() $0.255$ mm for

$0.255$ mm for ![]() ${Q}_m = 0.04$,

${Q}_m = 0.04$, ![]() $0.08\,\textrm {g}\,\textrm {s}^{-1}$. For the thick fibre

$0.08\,\textrm {g}\,\textrm {s}^{-1}$. For the thick fibre ![]() ${D}_s=0.43$ mm cases, we set

${D}_s=0.43$ mm cases, we set ![]() $\epsilon _p = 0.15$, 0.215 mm for

$\epsilon _p = 0.15$, 0.215 mm for ![]() ${Q}_m = 0.02$,

${Q}_m = 0.02$, ![]() $0.06\,\textrm {g}\,\textrm {s}^{-1}$, respectively.

$0.06\,\textrm {g}\,\textrm {s}^{-1}$, respectively.

The presence of the film stabilization term is important for maintaining a stable train of beads flowing down the fibre. Figure 5 shows the relation between the bead characteristics and the nozzle outer diameter ![]() $\text {OD}$ for varying film stabilization thicknesses

$\text {OD}$ for varying film stabilization thicknesses ![]() $\epsilon _p$. Since a larger value of the stabilization parameter

$\epsilon _p$. Since a larger value of the stabilization parameter ![]() $A$ in (3.9a,b) corresponds to stronger stabilization effects in (3.3), increasing

$A$ in (3.9a,b) corresponds to stronger stabilization effects in (3.3), increasing ![]() $\epsilon _p$ is expected to yield more stabilized moving beads. For a fibre diameter

$\epsilon _p$ is expected to yield more stabilized moving beads. For a fibre diameter ![]() ${D}_s=0.43$ mm at a small flow rate

${D}_s=0.43$ mm at a small flow rate ![]() ${Q}_m=0.02\ \textrm {g}\,\textrm {s}^{-1}$, the film stabilization model with

${Q}_m=0.02\ \textrm {g}\,\textrm {s}^{-1}$, the film stabilization model with ![]() $\epsilon _p=0.15$ mm best captures both bead profiles and speeds. Without the film stabilization mechanism (

$\epsilon _p=0.15$ mm best captures both bead profiles and speeds. Without the film stabilization mechanism (![]() $\epsilon _p=0$), the model produces large variations in the downstream bead characteristics, contradicting experimental observations of a stable train of beads.

$\epsilon _p=0$), the model produces large variations in the downstream bead characteristics, contradicting experimental observations of a stable train of beads.

Lastly, we study the influence of inertial effects, nonlinear curvature terms and the film stabilization term on the bead characteristics. Figure 6 shows a comparison of the experimental bead spacing and downstream bead velocity against those obtained from the Craster–Matar (CM) model in (3.11), the full curvature model with ![]() $\mathcal {Z}(h)$ given by (3.10) and

$\mathcal {Z}(h)$ given by (3.10) and ![]() $A = 0$, the linear curvature model with

$A = 0$, the linear curvature model with ![]() $\mathcal {Z}(h)$ in (3.9a,b) and

$\mathcal {Z}(h)$ in (3.9a,b) and ![]() $A = 0$, and the film stabilization model (3.9a,b) with

$A = 0$, and the film stabilization model (3.9a,b) with ![]() $A > 0$. Whereas these models all yield qualitatively reasonable trends as the nozzle size increases, the film stabilization model provides the best quantitative agreement with the experiment. The other models overestimate the bead spacing and velocity. For large nozzles (

$A > 0$. Whereas these models all yield qualitatively reasonable trends as the nozzle size increases, the film stabilization model provides the best quantitative agreement with the experiment. The other models overestimate the bead spacing and velocity. For large nozzles (![]() $\text {OD} \ge 1.27$ mm), the CM model (3.11) with the film stabilization term for

$\text {OD} \ge 1.27$ mm), the CM model (3.11) with the film stabilization term for ![]() $\epsilon _p = 0.15$ mm also predicts bead characteristics that match well with experiments (not shown in the figure). However, without inertial effects, this model fails to predict a steady train of beads for smaller nozzles (

$\epsilon _p = 0.15$ mm also predicts bead characteristics that match well with experiments (not shown in the figure). However, without inertial effects, this model fails to predict a steady train of beads for smaller nozzles (![]() $\text {OD} \le 1.06$ mm).

$\text {OD} \le 1.06$ mm).

Figure 6. Averaged bead spacing and velocity obtained from experiments with ![]() ${D}_s=0.43$ mm and

${D}_s=0.43$ mm and ![]() ${Q}_m = 0.02\ \textrm {g}\,\textrm {s}^{-1}$, compared to the characteristics predicted by the CM model (3.11) (without inertial effects), the full curvature model (3.10) and linear curvature model (3.9a,b) with

${Q}_m = 0.02\ \textrm {g}\,\textrm {s}^{-1}$, compared to the characteristics predicted by the CM model (3.11) (without inertial effects), the full curvature model (3.10) and linear curvature model (3.9a,b) with ![]() $A = 0$ (

$A = 0$ (![]() $\epsilon _p = 0$), and the film stabilization model (3.9a,b) with

$\epsilon _p = 0$), and the film stabilization model (3.9a,b) with ![]() $A > 0$ (

$A > 0$ (![]() $\epsilon _p = 0.15$ mm).

$\epsilon _p = 0.15$ mm).

5. Conclusions

We have performed a detailed study of viscous flows of a thin liquid film down vertical fibres, focusing on the influence of the inlet nozzle diameter on the regime transition and downstream bead dynamics. We propose a boundary layer model that incorporates a film stabilization term to the pressure, and compare the predicted film dynamics to a range of experiments. Numerical simulations show that, in addition to the fibre size and flow rate, the downstream flow regime transitions and bead characteristics are also affected by the nozzle geometry. In the Rayleigh–Plateau regime, our simulation results show good experimental agreement with the observed bead spacing and velocity throughout the fibre and with the film profile within the healing length near the nozzle.

Acknowledgements

This work was supported by the Simons Foundation ![]() $\textrm {Math}{+}\textrm {X}$ investigator award number 510776 and the National Science Foundation under grant CBET-1358034. The first and second authors contributed equally to this paper.

$\textrm {Math}{+}\textrm {X}$ investigator award number 510776 and the National Science Foundation under grant CBET-1358034. The first and second authors contributed equally to this paper.

Declaration of interests

The authors report no conflict of interest.