1. Introduction

A foam, made of inviscid gas and Newtonian liquid, has an effective viscosity that may reach a thousand times the viscosity of the foaming solution (Princen & Kiss Reference Princen and Kiss1989; Prud'homme & Khan Reference Prud'homme and Khan1996; Marze, Langevin & Saint-Jalmes Reference Marze, Langevin and Saint-Jalmes2008; Krishan et al. Reference Krishan, Helal, Höhler and Cohen-Addad2010). Liquid phase confinement is classically assumed to be the origin of this spectacular viscosity enhancement, with a local shear rate scaling as the imposed one multiplied by the confinement factor ![]() $d/h$, with

$d/h$, with ![]() $d$ the bubble size and

$d$ the bubble size and ![]() $h$ the film thickness. However, how and where the imposed stress is transmitted to the liquid phase remain open questions. In the absence of any solid part in the foam structure, the degrees of freedom of the liquid phase are numerous, and an imposed external deformation can lead to many different local deformations and flows, which have been listed in the seminal work of Buzza, Lu & Cates (Reference Buzza, Lu and Cates1995).

$h$ the film thickness. However, how and where the imposed stress is transmitted to the liquid phase remain open questions. In the absence of any solid part in the foam structure, the degrees of freedom of the liquid phase are numerous, and an imposed external deformation can lead to many different local deformations and flows, which have been listed in the seminal work of Buzza, Lu & Cates (Reference Buzza, Lu and Cates1995).

The problem has been addressed experimentally both at the bubble scale and at the foam sample scale. In the first approach, an assembly of few millimetric films are deformed, either due to the structure relaxations after a triggered exchange of neighbouring bubbles (T1 event) (Durand & Stone Reference Durand and Stone2006; Biance, Cohen-Addad & Höhler Reference Biance, Cohen-Addad and Höhler2009; Petit et al. Reference Petit, Seiwert, Cantat and Biance2015), or due to the controlled motion of the supporting frame (Besson & Debrégeas Reference Besson and Debrégeas2007; Costa et al. Reference Costa, Cohen-Addad, Salonen and Höhler2013a; Seiwert et al. Reference Seiwert, Monloubou, Dollet and Cantat2013; Bussonnière et al. Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020). In most of these studies, the local film tensions are deduced from the film structure geometry, and/or the local film thicknesses measured using absorption or interferometry. The observations are rationalized with models involving film extensions and compressions of the bulk phase of the films (Kraynik & Hansen Reference Kraynik and Hansen1986; Khan & Armstrong Reference Khan and Armstrong1987; Schwartz & Princen Reference Schwartz and Princen1987; Reinelt & Kraynik Reference Reinelt and Kraynik1989), or a viscoelastic response of the surfactant monolayer, and a relaxation of the interface area variations by the surfactant monolayer transfer from the compressed films to the stretched ones (Durand & Stone Reference Durand and Stone2006; Besson & Debrégeas Reference Besson and Debrégeas2007; Grassia, Embley & Oguey Reference Grassia, Embley and Oguey2012; Satomi, Grassia & Oguey Reference Satomi, Grassia and Oguey2013). The viscous dissipation induced by a different velocity on each side of a film is not considered. In contrast, at the sample scale, with typical bubble sizes of the order of 100 ![]() $\mathrm {\mu }$m, the rheometric measurements are usually modelled using the assumption of bubbles sliding on top of each other and thus shearing the liquid film that separates them, without any interface extension (Denkov et al. Reference Denkov, Tcholakova, Golemanov, Ananthapadmanabhan and Lips2008). Depending on the physico-chemistry, different scaling laws are experimentally observed, which are difficult to interpret in terms of one model or the other (Denkov et al. Reference Denkov, Subramanian, Gurovich and Lips2005, Reference Denkov, Tcholakova, Golemanov, Ananthapadmanabhan and Lips2008; Krishan et al. Reference Krishan, Helal, Höhler and Cohen-Addad2010; Costa, Höhler & Cohen-Addad Reference Costa, Höhler and Cohen-Addad2013b).

$\mathrm {\mu }$m, the rheometric measurements are usually modelled using the assumption of bubbles sliding on top of each other and thus shearing the liquid film that separates them, without any interface extension (Denkov et al. Reference Denkov, Tcholakova, Golemanov, Ananthapadmanabhan and Lips2008). Depending on the physico-chemistry, different scaling laws are experimentally observed, which are difficult to interpret in terms of one model or the other (Denkov et al. Reference Denkov, Subramanian, Gurovich and Lips2005, Reference Denkov, Tcholakova, Golemanov, Ananthapadmanabhan and Lips2008; Krishan et al. Reference Krishan, Helal, Höhler and Cohen-Addad2010; Costa, Höhler & Cohen-Addad Reference Costa, Höhler and Cohen-Addad2013b).

There is thus a clear need for a full characterization of the flows induced in the foam films by an imposed deformation, with a synchronized measure of both the kinematic quantities (local interface extension and extension rate, interface transfer velocity) and of the local tension in the films, in order to discriminate between both approaches, involving either film shearing or film extension. This is an unavoidable milestone to fully elucidate the local origin of foam viscosity.

To this end, we built a dedicated set-up that allows us to impose controlled deformations to a five-film assembly. In a previous paper, we measured the transfer velocity from one film to its neighbour due to this deformation, as well as other kinematic quantities (Bussonnière et al. Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020). The aim here is to relate these kinematic quantities to the film tensions, in order to build a constitutive law for each part of the foam structure and, eventually, to build the resulting constitutive law for the foam sample.

The main results of this paper are the following: (i) the films are shown to be governed by a perfectly reversible elastic law, with no influence of the shear or extensional interface viscosities. This proves that the viscoelastic response of the interface is not, as often assumed, the origin of the foam dissipation; (ii) we measure the relationship between the interface transfer velocity, from one film to its neighbour, and the tension difference between these films. We evidence a generic geometrical frustration at the meniscus: as it prevents the free transfer of the interface, this frustration is the origin of the largest part of the dissipation; (iii) we predict that this dominant dissipation is localized in a small part of the films that is close to the meniscus and that is sheared. In this domain, a well-controlled scale separation is used to simplify the hydrodynamics and transport equations, which become easily numerically solvable. One important prediction of our model is the scaling law for the length ![]() $\ell$ of this sheared part of the film, as a function of the physico-chemical properties of the foaming solution. This length increases when the surfactant solubility decreases and is typically of the order of 100

$\ell$ of this sheared part of the film, as a function of the physico-chemical properties of the foaming solution. This length increases when the surfactant solubility decreases and is typically of the order of 100 ![]() $\mathrm {\mu }$m. Importantly, it defines a boundary between the foams having bubbles smaller than

$\mathrm {\mu }$m. Importantly, it defines a boundary between the foams having bubbles smaller than ![]() $\ell$, in which the whole film should be sheared, and the foams having bubbles larger than

$\ell$, in which the whole film should be sheared, and the foams having bubbles larger than ![]() $\ell$, in which the main film deformation should be an extension/compression. This reconciles the various classes of model, based either on extension or on shear, found in the literature.

$\ell$, in which the main film deformation should be an extension/compression. This reconciles the various classes of model, based either on extension or on shear, found in the literature.

On these bases, we built a model of foam viscosity for the large bubble regime and/or high surfactant solubility, e.g. for a bubble radius larger than ![]() $\ell$. It reproduces the variations of the foam loss modulus as the square root of the frequency, and as the inverse of the bubble size, which are observed for a large class of foams (Krishan et al. Reference Krishan, Helal, Höhler and Cohen-Addad2010; Costa et al. Reference Costa, Höhler and Cohen-Addad2013b), and predicts the prefactor as a function of well-defined measurable, physico-chemical properties.

$\ell$. It reproduces the variations of the foam loss modulus as the square root of the frequency, and as the inverse of the bubble size, which are observed for a large class of foams (Krishan et al. Reference Krishan, Helal, Höhler and Cohen-Addad2010; Costa et al. Reference Costa, Höhler and Cohen-Addad2013b), and predicts the prefactor as a function of well-defined measurable, physico-chemical properties.

The paper is organized as follows. We first introduce the dedicated experimental set-up in § 2 and then describe the measurement of the relevant kinematic quantities in § 3. In § 4, we describe the technique used to measure the evolution of the tension of the five different films. In §§ 5 and 6 we build the constitutive relationships of the thin film and of the meniscus, respectively. In § 7, we unravel and model the dominant dissipation mechanism associated with the film/meniscus exchange and compare our model to the experiments in § 8. Finally in § 9 we discuss the relevance of our findings in a foam context and in § 10 we offer conclusions.

2. Experimental set-up and foaming solution

The same experimental set-up has been used previously in Bussonnière et al. (Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020), and the measure of the kinematic properties of the film (velocity, extension) has already been presented in this former article for a restricted range of the control parameters. We recall here the main features and describe the physico-chemical properties of the solution.

2.1. Mechanical device

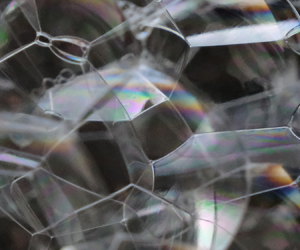

The film assembly is made of five foam films held by two metallic X-shaped pieces, as shown in figure 1. The central horizontal film has a width ![]() $d_c=6$ mm and a length

$d_c=6$ mm and a length ![]() $W=41.5$ mm. The length has been chosen such that

$W=41.5$ mm. The length has been chosen such that ![]() $W\gg d_c$, so the middle part of the central film is not influenced by the boundary effects on the solid frame. The short edges of the central film form menisci with the metallic frames (the supported menisci) while its long edges are menisci connected to the four peripheral films at an angle of 120

$W\gg d_c$, so the middle part of the central film is not influenced by the boundary effects on the solid frame. The short edges of the central film form menisci with the metallic frames (the supported menisci) while its long edges are menisci connected to the four peripheral films at an angle of 120![]() $^{\circ }$ (the free menisci). The external edges of the peripheral films are connected to metallic pieces of length

$^{\circ }$ (the free menisci). The external edges of the peripheral films are connected to metallic pieces of length ![]() $W$ (black pieces in figure 1) which can translate along the lateral arms of the X-shape pieces. The mobile edge positions are controlled by four linear piezo motors (PI U-521.23). This geometry ensures that each film remains flat and stays in the same plane whatever the position of the motor, if the films are at mechanical equilibrium. Unless otherwise specified, an invariance in the

$W$ (black pieces in figure 1) which can translate along the lateral arms of the X-shape pieces. The mobile edge positions are controlled by four linear piezo motors (PI U-521.23). This geometry ensures that each film remains flat and stays in the same plane whatever the position of the motor, if the films are at mechanical equilibrium. Unless otherwise specified, an invariance in the ![]() $y$ direction will be assumed for all quantities. They are expressed as a function of the curvilinear abscissa

$y$ direction will be assumed for all quantities. They are expressed as a function of the curvilinear abscissa ![]() $s$, defined for each film as the position along a line in the

$s$, defined for each film as the position along a line in the ![]() $(x,z)$ plane.

$(x,z)$ plane.

Figure 1. Schematic of the experimental set-up showing the mechanical device controlling film deformation and the different optical devices used to monitor the film motion.

As in Bussonnière et al. (Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020), the deformation studied consists of a compression of the left peripheral films from an initial length ![]() $d^{-}(0)=d_m+{\rm \Delta} d/2$ to

$d^{-}(0)=d_m+{\rm \Delta} d/2$ to ![]() $d^{-}=d_m-{\rm \Delta} d/2$ and a simultaneous symmetric extension of the right films from

$d^{-}=d_m-{\rm \Delta} d/2$ and a simultaneous symmetric extension of the right films from ![]() $d^{+}(0)=d_m-{\rm \Delta} d/2$ to

$d^{+}(0)=d_m-{\rm \Delta} d/2$ to ![]() $d^{+}=d_m+{\rm \Delta} d/2$ at a constant velocity

$d^{+}=d_m+{\rm \Delta} d/2$ at a constant velocity ![]() $V$. In this study, we explore the influence of the motor velocity

$V$. In this study, we explore the influence of the motor velocity ![]() $V$, of the deformation amplitude

$V$, of the deformation amplitude ![]() ${\rm \Delta} d$ and of the mean position

${\rm \Delta} d$ and of the mean position ![]() $d_m$.

$d_m$.

2.2. Optical device

Three cameras are used to monitor the dynamics induced by the film deformations, as shown in figure 1. The meniscus camera records the size and vertical position of one free meniscus. It is magnified with a telecentric lens (Edmund Optics SilverTL × 4) and illuminated with a collimated white LED. The free menisci position in the ![]() $(x,y)$ plane and the gross thickness variations of the central film are recorded with the fluorescence camera located on the top of the set-up. The fluorescein added in the foaming solution is excited with a 488 nm laser (Oxxius LBX 200 mW) and its emission is filtered using a band-pass filter. Finally, more precise thickness profiles

$(x,y)$ plane and the gross thickness variations of the central film are recorded with the fluorescence camera located on the top of the set-up. The fluorescein added in the foaming solution is excited with a 488 nm laser (Oxxius LBX 200 mW) and its emission is filtered using a band-pass filter. Finally, more precise thickness profiles ![]() $h$ are monitored along the line

$h$ are monitored along the line ![]() ${\mathcal {L}}_c$ in the central film or

${\mathcal {L}}_c$ in the central film or ![]() ${\mathcal {L}}_p$ in a peripheral film with a hyperspectral camera (Resonon Pika L). This camera, described in Bussonnière et al. (Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020), measures the interfered spectrum intensity

${\mathcal {L}}_p$ in a peripheral film with a hyperspectral camera (Resonon Pika L). This camera, described in Bussonnière et al. (Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020), measures the interfered spectrum intensity ![]() $I(\lambda )$ of the light emitted by a halogen lamp and reflected by the thin film. The thickness is extracted using the relation (Born & Wolf Reference Born and Wolf1999)

$I(\lambda )$ of the light emitted by a halogen lamp and reflected by the thin film. The thickness is extracted using the relation (Born & Wolf Reference Born and Wolf1999)

\begin{equation} I(\lambda) \propto 1 - \cos\left(\frac{4{\rm \pi} h n}{\lambda} \left(1-\frac{\sin^{2}{\theta}}{n^{2}}\right)^{1/2}\right), \end{equation}

\begin{equation} I(\lambda) \propto 1 - \cos\left(\frac{4{\rm \pi} h n}{\lambda} \left(1-\frac{\sin^{2}{\theta}}{n^{2}}\right)^{1/2}\right), \end{equation}

where ![]() $n=1.33$ is the film refractive index,

$n=1.33$ is the film refractive index, ![]() $\lambda$ the wavelength and

$\lambda$ the wavelength and ![]() $\theta$ the light incident angle. In our set-up,

$\theta$ the light incident angle. In our set-up, ![]() $\theta$ is

$\theta$ is ![]() $45^{\circ }$ for the central camera position and

$45^{\circ }$ for the central camera position and ![]() $58.5^{\circ }$ for the peripheral one.

$58.5^{\circ }$ for the peripheral one.

2.3. Physico-chemical properties of the foaming solution

The foaming solution is a mixture of sodium dodecyl sulphate and dodecanol, that we chose to optimize the film rheological response. Some glycerol is added to improve the film stability and fluorescein is used to visualize the thickness patterns. To prepare the solution, the sodium dodecyl sulphate (SDS) (![]() $c_{{{SDS}}} =5.6$ g l

$c_{{{SDS}}} =5.6$ g l![]() $^{-1}$), the dodecanol (DOH) (

$^{-1}$), the dodecanol (DOH) (![]() $c_{{{DOH}}} =0.05$ g l

$c_{{{DOH}}} =0.05$ g l![]() $^{-1}$) and the fluorescein (

$^{-1}$) and the fluorescein (![]() $c_{{fluo}}=0.8$ g l

$c_{{fluo}}=0.8$ g l![]() $^{-1}$) are dissolved in a solution of distilled water–glycerol (15 % by volume). The equilibrium surface tension was measured at

$^{-1}$) are dissolved in a solution of distilled water–glycerol (15 % by volume). The equilibrium surface tension was measured at ![]() $\gamma _{0}= 33\pm 1$ mN m

$\gamma _{0}= 33\pm 1$ mN m![]() $^{-1}$ using the pendant drop method and the viscosity is

$^{-1}$ using the pendant drop method and the viscosity is ![]() $\eta = 1.5$ mPa s. Four needles located on the top mobile edges of the peripheral films can be used to supply solution to the film assembly during the entire experiment. Two sets of experiments have been performed, one where the foaming solution is injected at a rate of 0.2 ml min

$\eta = 1.5$ mPa s. Four needles located on the top mobile edges of the peripheral films can be used to supply solution to the film assembly during the entire experiment. Two sets of experiments have been performed, one where the foaming solution is injected at a rate of 0.2 ml min![]() $^{-1}$ (0.05 ml min

$^{-1}$ (0.05 ml min![]() $^{-1}$ per needle) and one without injection.

$^{-1}$ per needle) and one without injection.

Such a mixture has been extensively studied for its relevance in foam science and is thus well documented (see the review by Lu, Thomas & Penfold Reference Lu, Thomas and Penfold2000). However, its physico-chemical properties remain difficult to model due to the strong interactions between the anionic surfactant and the non-ionic alcohol, which can lead to the formation of a complex (Lu et al. Reference Lu, Purcell, Lee, Simister, Thomas, Rennie and Penfold1995; Nguyen & Nguyen Reference Nguyen and Nguyen2019; Vollhardt & Emrich Reference Vollhardt and Emrich2000; Kralchevsky et al. Reference Kralchevsky, Danov, Kolev, Broze and Mehreteab2003). Moreover, above the critical micelle concentration (![]() $\hbox{CMC}=2.33$ g l

$\hbox{CMC}=2.33$ g l![]() $^{-1}$ for pure SDS), DOH molecules can be solubilized in SDS micelles. These interactions lead to co-adsorption processes and mixed diffusion (Fang & Joos Reference Fang and Joos1992). As the chemistry has not been varied in this study, the potentially complex equation of state of the interface, adsorption and transport laws, taking into account the different species, cannot be addressed by our experimental results. We thus choose to keep our thermodynamic model of interface as simple as possible by linearizing the different laws.

$^{-1}$ for pure SDS), DOH molecules can be solubilized in SDS micelles. These interactions lead to co-adsorption processes and mixed diffusion (Fang & Joos Reference Fang and Joos1992). As the chemistry has not been varied in this study, the potentially complex equation of state of the interface, adsorption and transport laws, taking into account the different species, cannot be addressed by our experimental results. We thus choose to keep our thermodynamic model of interface as simple as possible by linearizing the different laws.

Surface tension of pure SDS remains almost constant above the critical micelle concentration (Elworthy & Mysels Reference Elworthy and Mysels1966). The significant variations observed in our experiments are therefore assumed to be associated with the DOH only. At thermodynamic equilibrium, the surface tension ![]() $\gamma _{th}$ is related to the DOH surface excess

$\gamma _{th}$ is related to the DOH surface excess ![]() $\varGamma$ by

$\varGamma$ by

with ![]() $\gamma _0$ the surface tension of the foaming solution,

$\gamma _0$ the surface tension of the foaming solution, ![]() $\varGamma _0$ the corresponding surface excess and

$\varGamma _0$ the corresponding surface excess and ![]() $E=-({\partial \gamma _{th}}/{\partial \varGamma })|_{\varGamma _0}\varGamma _0$ the so called Gibbs–Marangoni elasticity. This elasticity can be estimated using the Langmuir model of DOH/micellar SDS solution proposed in Fang & Joos (Reference Fang and Joos1992) which leads to

$E=-({\partial \gamma _{th}}/{\partial \varGamma })|_{\varGamma _0}\varGamma _0$ the so called Gibbs–Marangoni elasticity. This elasticity can be estimated using the Langmuir model of DOH/micellar SDS solution proposed in Fang & Joos (Reference Fang and Joos1992) which leads to ![]() $E\approx 10$ mN m

$E\approx 10$ mN m![]() $^{-1}$ (see Appendix A).

$^{-1}$ (see Appendix A).

The adsorption of DOH at the interface is characterized by

where ![]() $c$ is the local dodecanol bulk concentration,

$c$ is the local dodecanol bulk concentration, ![]() $c_0$ the initial concentration and

$c_0$ the initial concentration and ![]() $h_{\varGamma }=({\partial \varGamma }/{\partial c})|_{c_0}$, hereafter called the reservoir length. Based on Fang & Joos (Reference Fang and Joos1992), we estimated

$h_{\varGamma }=({\partial \varGamma }/{\partial c})|_{c_0}$, hereafter called the reservoir length. Based on Fang & Joos (Reference Fang and Joos1992), we estimated ![]() $h_\varGamma \approx 5.4\ \mathrm {\mu }$m (see Appendix A). For processes faster than the micellization (Patist, Axelberd & Shah Reference Patist, Axelberd and Shah1998), we need to consider instead the equilibrium between the surface excess and the concentration

$h_\varGamma \approx 5.4\ \mathrm {\mu }$m (see Appendix A). For processes faster than the micellization (Patist, Axelberd & Shah Reference Patist, Axelberd and Shah1998), we need to consider instead the equilibrium between the surface excess and the concentration ![]() $c^{m}$ of DOH in its monomer form, involving the parameter

$c^{m}$ of DOH in its monomer form, involving the parameter ![]() $h^{m}_\varGamma =({\partial \varGamma }/{\partial c^{m}})|_{c^{m}_0}\approx 370\ \mathrm {\mu }$m (see Appendix A).

$h^{m}_\varGamma =({\partial \varGamma }/{\partial c^{m}})|_{c^{m}_0}\approx 370\ \mathrm {\mu }$m (see Appendix A).

The disjoining pressure as a function of the film thickness is also an important physico-chemical property of the system. However, it is negligible in our study as the films are always larger than 100 nm.

Finally, on each interface, we define ![]() $\gamma (s)$ as the full interfacial stress which includes the surface tension

$\gamma (s)$ as the full interfacial stress which includes the surface tension ![]() $\gamma _{th}(\varGamma )$ as well as the potential contributions associated with the surface extensional and shear interfacial viscosities, respectively

$\gamma _{th}(\varGamma )$ as well as the potential contributions associated with the surface extensional and shear interfacial viscosities, respectively ![]() $\eta _s$ and

$\eta _s$ and ![]() $\kappa _s$. Note that the interfacial stress is thus a priori of tensorial nature, and

$\kappa _s$. Note that the interfacial stress is thus a priori of tensorial nature, and ![]() $\gamma (s)$ represents its projection in the direction orthogonal to the direction of invariance

$\gamma (s)$ represents its projection in the direction orthogonal to the direction of invariance ![]() $y$. For the thin films, we also define the film tension

$y$. For the thin films, we also define the film tension ![]() $\sigma$ that takes into account the contribution of both interfaces and of the film bulk (see § 4.2).

$\sigma$ that takes into account the contribution of both interfaces and of the film bulk (see § 4.2).

2.4. Control parameters and experimental protocol

In this study we explored the influence of the deformation parameters on the film assembly dynamic by performing around 480 experiments.

A first experimental campaign was performed with the fluorescence camera used at a frame rate of 130 f.p.s., for ![]() ${\rm \Delta} d$ varying between 2 and 12 mm,

${\rm \Delta} d$ varying between 2 and 12 mm, ![]() $V$ between 1 and 100 mm s

$V$ between 1 and 100 mm s![]() $^{-1}$ and

$^{-1}$ and ![]() $d_m$ between 7 and 17 mm. Each set of parameters has been repeated at least 3 times with and without solution injection representing a total of 186 experiments. For some parameter values, the measurements have been refined in a second campaign, by increasing the frame rate to 300 f.p.s., increasing the number of experiments and/or using the spectral camera in the peripheral position, instead of the central position only.

$d_m$ between 7 and 17 mm. Each set of parameters has been repeated at least 3 times with and without solution injection representing a total of 186 experiments. For some parameter values, the measurements have been refined in a second campaign, by increasing the frame rate to 300 f.p.s., increasing the number of experiments and/or using the spectral camera in the peripheral position, instead of the central position only.

The experimental protocol is as follows: a bucket full of foaming solution is placed on a motorized translation stage below the set-up. We first move the bucket up until the deformable frame is entirely immersed, then we move it down to produce the five films. This process leads to reproducible out of equilibrium films, rapidly draining under gravity. We let them evolve during 15 s before deforming the frame. The frame deformation is synchronized with the different cameras which record the film assembly dynamics during 30 s for the first campaign and 10 s for the second. Note that after the initial 15 s delay, the films are still out of equilibrium, but evolve on a time scale larger than the duration of the investigated deformation and relaxation. Moreover central (respectively peripheral) film remains thicker than 400 nm (respectively 1.5 ![]() $\mathrm {\mu }$m) during the entire experiment so the disjoining pressure is negligible in this study.

$\mathrm {\mu }$m) during the entire experiment so the disjoining pressure is negligible in this study.

3. Determination of the kinematic quantities

As shown in our previous study (Bussonnière et al. Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020) and summarized in figure 2, the typical dynamics is composed of an extension of the peripheral films on the stretched side, and a compression of the peripheral films on the pushed side, at the first instants (figure 2b). The imposed deformation then relaxes through interface transfers between adjacent films (figure 2c). A visible signature of this transfer is the appearance of thick films, extracted from the menisci, in the central and stretched films.

Figure 2. (a–c) Schematic of the typical dynamics of the foam assembly. The coloured dots represent elementary material systems at the interface which are followed along their trajectories, thus illustrating film compression/extension as well as interface transfers from one film to the other. Films thicknesses evolve because of the compression/extension and because of the extraction of thick film from the menisci, associated with the interface transfers. (d,e) Zoom on a film element of volume ![]() ${\rm d} \varOmega$ before and during the deformation. (f) Zoom on a meniscus showing the interface transfer dynamics, at velocity

${\rm d} \varOmega$ before and during the deformation. (f) Zoom on a meniscus showing the interface transfer dynamics, at velocity ![]() $U$.

$U$.

3.1. Definition of the kinematic quantities

The extension of the films and the transfer velocity at the menisci are the two relevant kinematic quantities of the problem and they will be related to the film tensions through constitutive relationships in §§ 5 and 6. To properly define and measure the extensions and the transfer velocities we first clarify here different assumptions.

In the films, the relative velocity of the bulk phase with respect to the interfaces is a Poiseuille flow governed by the gravity forces and by the Laplace pressure gradients. As quantitatively discussed in § 6.2, these relative velocities are negligible far enough from the menisci, and the velocity can be assumed to be constant across the film (figure 2f). In the central part of each film, we can therefore define a film element ![]() ${\mathcal {S}}$ as an elementary material system of volume

${\mathcal {S}}$ as an elementary material system of volume ![]() $\textrm {d}\varOmega = h \, {\textrm {d}}S = h \,{\textrm {d} y} \, {\textrm {d}}s$ (see figure 2d,e) spanning the film from one interface to the other. It is a closed system which can be followed along its trajectory and which is entirely determined by the shape and position of its interface. The invariance in the

$\textrm {d}\varOmega = h \, {\textrm {d}}S = h \,{\textrm {d} y} \, {\textrm {d}}s$ (see figure 2d,e) spanning the film from one interface to the other. It is a closed system which can be followed along its trajectory and which is entirely determined by the shape and position of its interface. The invariance in the ![]() $y$ direction imposes that

$y$ direction imposes that ![]() ${\textrm {d} y}$ is constant. However, stretching or compression modifies

${\textrm {d} y}$ is constant. However, stretching or compression modifies ![]() ${\textrm {d}}s$. In such a film element, the film extension, or equivalently the interface extension, can be defined as

${\textrm {d}}s$. In such a film element, the film extension, or equivalently the interface extension, can be defined as

with ![]() $h_0$ and

$h_0$ and ![]() $ds_0$ the initial characteristic of the film element, before deformation. The second equality is deduced from the volume conservation of the system, which imposes

$ds_0$ the initial characteristic of the film element, before deformation. The second equality is deduced from the volume conservation of the system, which imposes ![]() $h(t) \, {\textrm {d}}s(t)\, \textrm {d} y = h_0 \, {\textrm {d}}s_0 \,\textrm {d} y$. With this definition

$h(t) \, {\textrm {d}}s(t)\, \textrm {d} y = h_0 \, {\textrm {d}}s_0 \,\textrm {d} y$. With this definition ![]() $\varepsilon > 0$ for an extension and

$\varepsilon > 0$ for an extension and ![]() $\varepsilon < 0$ for a compression.

$\varepsilon < 0$ for a compression.

The transfer velocity is a dynamical property associated with each free meniscus. In Bussonnière et al. (Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020) we experimentally checked that, for the imposed deformation, when some film is extracted from one side of a free meniscus, a similar amount of film is absorbed on the other side, at the same rate, as schematized in figure 2(f). The surfactant monolayer slides on the meniscus interface, from one film to its neighbour, with negligible deformation. This allows us to define the transfer velocity ![]() $U$ as, indifferently, the velocity of the film entering the meniscus at one side, the velocity of the film extracted on the other side or the velocity of the surfactant monolayer at the meniscus interface connecting both films. Experimentally,

$U$ as, indifferently, the velocity of the film entering the meniscus at one side, the velocity of the film extracted on the other side or the velocity of the surfactant monolayer at the meniscus interface connecting both films. Experimentally, ![]() $U$ is measured in the central film. The model of § 7 goes beyond this first-order description and provides a prediction for the interface velocity difference between both sides of the free menisci, thus refining this first definition of the transfer velocity.

$U$ is measured in the central film. The model of § 7 goes beyond this first-order description and provides a prediction for the interface velocity difference between both sides of the free menisci, thus refining this first definition of the transfer velocity.

3.2. Measure of the transfer velocity

An image of the central film is shown in figure 3(a). In this film, the relaxation of the peripheral film deformation by interface transfer results in an extraction of a new film from the free meniscus on the compressed side (see figure 3a) and in a film entry in the free meniscus on the stretched side. The film extraction is governed by Frankel's theory (Mysels, Shinoda & Frankel Reference Mysels, Shinoda and Frankel1959; Bussonnière et al. Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020) and the new film, called hereafter Frankel's film, is thicker than the remaining part of the film, which is the film initially present (denoted the initial film hereafter). Frankel's film therefore appears bright on the fluorescence camera, with a very well defined boundary at a distance ![]() $L^{Fr}(t)$ from the pushed meniscus. The extraction begins as soon as the motors start and accelerates until the motors stop. The velocity is maximum at this time (figure 3b) and then the extraction slows down over a characteristic time scale of 1 s.

$L^{Fr}(t)$ from the pushed meniscus. The extraction begins as soon as the motors start and accelerates until the motors stop. The velocity is maximum at this time (figure 3b) and then the extraction slows down over a characteristic time scale of 1 s.

Figure 3. (a) Image of the fluorescence camera (top view) after the deformation showing the Frankel film extraction. This Frankel film is invariant in the ![]() $y$ direction and the black parts on both sides are due to the fact that the illuminated domain size is smaller than

$y$ direction and the black parts on both sides are due to the fact that the illuminated domain size is smaller than ![]() $W$. (b) Typical Frankel film length

$W$. (b) Typical Frankel film length ![]() $L^{Fr}$ (blue) and velocity

$L^{Fr}$ (blue) and velocity ![]() $U= {\textrm {d}}L^{Fr}/ {\textrm {d}}t$ (black) evolution with time for

$U= {\textrm {d}}L^{Fr}/ {\textrm {d}}t$ (black) evolution with time for ![]() ${\rm \Delta} d=10$ mm,

${\rm \Delta} d=10$ mm, ![]() $V=50$ mm s

$V=50$ mm s![]() $^{-1}$ and

$^{-1}$ and ![]() $d_m=12$ mm. Yellow shaded area indicates when the motors move.

$d_m=12$ mm. Yellow shaded area indicates when the motors move.

This motion occurs without compression or extension of the central film, which simply translates in the ![]() $x$ direction (Bussonnière et al. Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020). The central film dynamics is thus fully resolved by tracking the position

$x$ direction (Bussonnière et al. Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020). The central film dynamics is thus fully resolved by tracking the position ![]() $L^{Fr}(t)$ of Frankel's film boundary, with respect to the pushed meniscus position. For experiments recorded at a high frame rate (300 f.p.s.), the central film velocity is computed by smoothing the time derivative of

$L^{Fr}(t)$ of Frankel's film boundary, with respect to the pushed meniscus position. For experiments recorded at a high frame rate (300 f.p.s.), the central film velocity is computed by smoothing the time derivative of ![]() $L^{Fr}$. For longer experiments with slower frame rate (130 f.p.s.), this velocity is extracted by first fitting the evolution of

$L^{Fr}$. For longer experiments with slower frame rate (130 f.p.s.), this velocity is extracted by first fitting the evolution of ![]() $L^{Fr}$ with a fourth-order polynomial during motor motion and a logarithm function after the motor stops. This uniform central film velocity is our experimental definition of the transfer velocity

$L^{Fr}$ with a fourth-order polynomial during motor motion and a logarithm function after the motor stops. This uniform central film velocity is our experimental definition of the transfer velocity ![]() $U$, which happens to be identical at both free menisci, for the deformation we impose.

$U$, which happens to be identical at both free menisci, for the deformation we impose.

3.3. Measure of the film extension

The fact that the films may be absorbed by or extracted from the menisci implies that each individual film cannot be considered as a closed material system. Consequently, the distance ![]() $d$ between the menisci on both sides of a film does not provide a measure of its extension

$d$ between the menisci on both sides of a film does not provide a measure of its extension ![]() $\varepsilon$.

$\varepsilon$.

A first method to determine ![]() $\varepsilon$ is based on thickness measurements. A film thickness profile in the stretched film, measured with the spectral camera, is shown in figure 4(a). After deformation we can see a thin part, corresponding to the initial film, in contact with a thicker part, corresponding to a newly extracted Frankel film, with a sharp transition between both. As shown in Bussonnière et al. (Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020), a Frankel film is extracted both at the free meniscus (at the origin position in figure 4a) and at the supported meniscus, on the bottom right moving edge. However, gravity imposes a stratification of the non-horizontal films, and both Frankel films merge at the film bottom (Shabalina et al. Reference Shabalina, Bérut, Cavelier, Saint-Jalmes and Cantat2019), thus explaining the film profile. The key point here is that the initial film is a well-identified material system, which does not leave or enter the film during the experiment, and which is well separated from the Frankel film by a measurable boundary.

$\varepsilon$ is based on thickness measurements. A film thickness profile in the stretched film, measured with the spectral camera, is shown in figure 4(a). After deformation we can see a thin part, corresponding to the initial film, in contact with a thicker part, corresponding to a newly extracted Frankel film, with a sharp transition between both. As shown in Bussonnière et al. (Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020), a Frankel film is extracted both at the free meniscus (at the origin position in figure 4a) and at the supported meniscus, on the bottom right moving edge. However, gravity imposes a stratification of the non-horizontal films, and both Frankel films merge at the film bottom (Shabalina et al. Reference Shabalina, Bérut, Cavelier, Saint-Jalmes and Cantat2019), thus explaining the film profile. The key point here is that the initial film is a well-identified material system, which does not leave or enter the film during the experiment, and which is well separated from the Frankel film by a measurable boundary.

Figure 4. (a) Thickness profiles of the stretched bottom film at the initial time (black) and after the deformation (blue), as measured with the spectral camera between the right free meniscus (at the origin position) and the meniscus on the bottom right moving edge. The shaded areas correspond to the initial volume of the film (per unit length). (b) Extension as a function of time. Blue: film extension based on the thickness (see (3.2)); red: approximated film extension obtained from the transfer length ![]() $L^{Fr}$ (see (3.3)); black: geometrical extension imposed by the motor positions. Averages (solid line) and standard deviations (shaded area) are calculated over 5 experiments for the thickness definition and 50 for the transfer length definition. The control parameters are

$L^{Fr}$ (see (3.3)); black: geometrical extension imposed by the motor positions. Averages (solid line) and standard deviations (shaded area) are calculated over 5 experiments for the thickness definition and 50 for the transfer length definition. The control parameters are ![]() ${\rm \Delta} d=10$ mm,

${\rm \Delta} d=10$ mm, ![]() $V=50$ mm s

$V=50$ mm s![]() $^{-1}$ and

$^{-1}$ and ![]() $d_m=12$ mm. The dashed line delimits the validity range of the extension based on the transfer length.

$d_m=12$ mm. The dashed line delimits the validity range of the extension based on the transfer length.

To follow this material system, we proceed as follows: the volume ![]() $V_0$ (per unit length in the

$V_0$ (per unit length in the ![]() $y$ direction) of the initial film is calculated by integrating the thickness profile at

$y$ direction) of the initial film is calculated by integrating the thickness profile at ![]() $t=0$ over the total length

$t=0$ over the total length ![]() $d^{+}(0)={\rm \Delta} s_0$ of the film. During the dynamics, its length

$d^{+}(0)={\rm \Delta} s_0$ of the film. During the dynamics, its length ![]() ${\rm \Delta} s(t)$ is deduced from the volume conservation: the thickness profile is integrated from the free meniscus at

${\rm \Delta} s(t)$ is deduced from the volume conservation: the thickness profile is integrated from the free meniscus at ![]() $s=0$ to the position

$s=0$ to the position ![]() ${\rm \Delta} s(t)$ at which the integral equals

${\rm \Delta} s(t)$ at which the integral equals ![]() $V_0$. Note that, consistently,

$V_0$. Note that, consistently, ![]() ${\rm \Delta} s(t)$ coincides with the position of the thickness transition, which is, however, known with a smaller precision.

${\rm \Delta} s(t)$ coincides with the position of the thickness transition, which is, however, known with a smaller precision.

As discussed in § 5.1, the extension is uniform in the film, thus allowing us to integrate (3.1) over the whole initial film to obtain

which is plotted in figure 4(b) as a function of time.

On the compressed side, the initial film is absorbed by the meniscus and the previous method unfortunately fails. Moreover, marginal regeneration plumes form at the bottom meniscus, move upward and merge with the film, draining the compressed film much faster than the other ones and making the extension measure based on (3.1) impossible. In that case, the actual size of the monolayer initially covering the film is estimated as ![]() $d^{-}(t) + L^{Fr}_1(t) + L^{Fr}_2(t)$, with

$d^{-}(t) + L^{Fr}_1(t) + L^{Fr}_2(t)$, with ![]() $d^{-}(t)$ the imposed film length at time

$d^{-}(t)$ the imposed film length at time ![]() $t$ and

$t$ and ![]() $L^{Fr}_1$ and

$L^{Fr}_1$ and ![]() $L^{Fr}_2$ the monolayer areas (per unit length in the

$L^{Fr}_2$ the monolayer areas (per unit length in the ![]() $y$ direction) that have been lost by the compressed film respectively at the free meniscus and at the supported meniscus. As previously discussed, it is shown in Bussonnière et al. (Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020) that

$y$ direction) that have been lost by the compressed film respectively at the free meniscus and at the supported meniscus. As previously discussed, it is shown in Bussonnière et al. (Reference Bussonnière, Shabalina, Ah-Thon, Le Fur and Cantat2020) that ![]() $L^{Fr}_1 \sim L^{Fr}(t)$; at short times, we also observed that

$L^{Fr}_1 \sim L^{Fr}(t)$; at short times, we also observed that ![]() $L^{Fr}_2 \sim L^{Fr}(t)$. The same assumptions can be made for the stretched film to take into account the gain of area on both film sides. The extension can finally be estimated by, using the appropriate sign for each case,

$L^{Fr}_2 \sim L^{Fr}(t)$. The same assumptions can be made for the stretched film to take into account the gain of area on both film sides. The extension can finally be estimated by, using the appropriate sign for each case,

The values of ![]() $\varepsilon$ in the stretched films, obtained using both definitions ((3.2) and (3.3)), are plotted in figure 4(b) for one series. As expected an excellent agreement is obtained at short times, but the two curves become different at longer times. Based on this comparison, we define a cutoff length

$\varepsilon$ in the stretched films, obtained using both definitions ((3.2) and (3.3)), are plotted in figure 4(b) for one series. As expected an excellent agreement is obtained at short times, but the two curves become different at longer times. Based on this comparison, we define a cutoff length ![]() $L_c= 0.1 (d_m+{\rm \Delta} d/2)$, represented by the dashed line in figure 4(b): for

$L_c= 0.1 (d_m+{\rm \Delta} d/2)$, represented by the dashed line in figure 4(b): for ![]() $L^{Fr}(t) < L_c$, the extension can be calculated using (3.3). Then

$L^{Fr}(t) < L_c$, the extension can be calculated using (3.3). Then ![]() $L^{Fr}_1$ and

$L^{Fr}_1$ and ![]() $L^{Fr}_2$ begin to significantly differ from

$L^{Fr}_2$ begin to significantly differ from ![]() $L^{Fr}$ and (3.3) becomes invalid.

$L^{Fr}$ and (3.3) becomes invalid.

In the following, the extension is computed for one parameter set using (3.2), in the stretched film and for the whole time range. For the other cases, extension and compression are computed with (3.3), at short times only, for ![]() $L^{Fr}(t) < 0.1(d_m+{\rm \Delta} d/2)$. As this measure is much faster, it allows us to scan a large set of deformation parameters.

$L^{Fr}(t) < 0.1(d_m+{\rm \Delta} d/2)$. As this measure is much faster, it allows us to scan a large set of deformation parameters.

4. Determination of the film tensions

The set-up is designed so that, as long as the film structure is at equilibrium, the two free menisci stay at a constant position whatever the motor position. A meniscus motion is therefore the signature of some dynamical forces (Besson & Debrégeas Reference Besson and Debrégeas2007). We demonstrate in this section that the dominant forces are the tension differences between the films, which can therefore be modelled by a minimal surface of vanishing mean curvature during the dynamics. The position and shape of the free menisci, that we have extracted over time, can thus be used to measure the film tensions.

4.1. Meniscus motion

During the dynamics, both free menisci delimiting the central film move in the ![]() $(x,y)$ plane toward the stretched side. As shown in figure 5, the meniscus ends slide on the solid frame and the whole meniscus curves in the direction of motion. The displacement

$(x,y)$ plane toward the stretched side. As shown in figure 5, the meniscus ends slide on the solid frame and the whole meniscus curves in the direction of motion. The displacement ![]() $\delta ^{\pm }(y)$ of each free meniscus (the symbols

$\delta ^{\pm }(y)$ of each free meniscus (the symbols ![]() $-$ and

$-$ and ![]() $+$ refer to the compressed and stretched sides, respectively) can be fitted at each time by a second-order polynomial, from which we deduce the sliding motion (the constant term

$+$ refer to the compressed and stretched sides, respectively) can be fitted at each time by a second-order polynomial, from which we deduce the sliding motion (the constant term ![]() $\delta _1^{\pm }$) and the meniscus curvature (from the quadratic term

$\delta _1^{\pm }$) and the meniscus curvature (from the quadratic term ![]() $\delta _2^{\pm }(y)$)

$\delta _2^{\pm }(y)$)

In this expression ![]() $y=0$ is chosen in the middle of the film. The motion in the

$y=0$ is chosen in the middle of the film. The motion in the ![]() $z$ direction is measured with the meniscus camera (see figure 1) and is negligible.

$z$ direction is measured with the meniscus camera (see figure 1) and is negligible.

Figure 5. (a) Fluorescence image of the central film at the initial state showing the position of the free menisci (yellow dashed line). (b) Fluorescence image at the end of the motor motion. New positions of the menisci are highlighted by dashed blue lines.

4.2. Estimation of the tangential forces and film tension definition

To estimate the value of the external forces acting on the films, we use the following orders of magnitude, corresponding to our observations: the film in-plane velocity scales as the transfer velocity ![]() $U \sim 10^{-2}$ m s

$U \sim 10^{-2}$ m s![]() $^{-1}$, the film normal velocity scales as the meniscus velocity

$^{-1}$, the film normal velocity scales as the meniscus velocity ![]() $U_m\sim 10^{-3}$ m s

$U_m\sim 10^{-3}$ m s![]() $^{-1}$, the film extension is up to

$^{-1}$, the film extension is up to ![]() $|\varepsilon | \sim 1$ and the fastest deformation time scale is

$|\varepsilon | \sim 1$ and the fastest deformation time scale is ![]() $T \sim 10^{-1}$ s, corresponding to an extension rate

$T \sim 10^{-1}$ s, corresponding to an extension rate ![]() $\dot {\varepsilon } \sim 10$ s

$\dot {\varepsilon } \sim 10$ s![]() $^{-1}$. Finally, we anticipate that the film tension differences between the different films

$^{-1}$. Finally, we anticipate that the film tension differences between the different films ![]() ${\rm \Delta} \sigma$, that is deduced from the meniscus shape in § 4.5, are of the order of

${\rm \Delta} \sigma$, that is deduced from the meniscus shape in § 4.5, are of the order of ![]() $10^{-3}$ N m

$10^{-3}$ N m![]() $^{-1}$.

$^{-1}$.

As shown in figure 6, we use on each thin film the normal and tangential unit vectors ![]() ${\hat {\boldsymbol {n}}}$ and

${\hat {\boldsymbol {n}}}$ and ![]() ${\hat {\boldsymbol {t}}}$, along the thin film profile (in the

${\hat {\boldsymbol {t}}}$, along the thin film profile (in the ![]() $(x,z)$ plane), associated with the spatial variables

$(x,z)$ plane), associated with the spatial variables ![]() $\zeta$ and

$\zeta$ and ![]() $s$, respectively. We define the film tension

$s$, respectively. We define the film tension ![]() $\sigma (s) {\hat {\boldsymbol {t}}}$ as the force exerted by the film at an abscissa larger than

$\sigma (s) {\hat {\boldsymbol {t}}}$ as the force exerted by the film at an abscissa larger than ![]() $s$ on the film at an abscissa smaller than

$s$ on the film at an abscissa smaller than ![]() $s$. This quantity takes into account the interfacial stress

$s$. This quantity takes into account the interfacial stress ![]() $\gamma$ on both interfaces, and the contribution of the pressure in the liquid bulk, governed by the Laplace pressure (the latter term being negligible in the central part of each film). The tangential force balance on the piece of film located between

$\gamma$ on both interfaces, and the contribution of the pressure in the liquid bulk, governed by the Laplace pressure (the latter term being negligible in the central part of each film). The tangential force balance on the piece of film located between ![]() $s$ and

$s$ and ![]() $s+ {\textrm {d}}s$ is

$s+ {\textrm {d}}s$ is

with ![]() $\rho$ the solution density,

$\rho$ the solution density, ![]() $g_s$ the gravity component along

$g_s$ the gravity component along ![]() ${\hat {\boldsymbol {t}}}$,

${\hat {\boldsymbol {t}}}$, ![]() $\langle u \rangle$ the tangential velocity averaged in the normal direction, scaling as

$\langle u \rangle$ the tangential velocity averaged in the normal direction, scaling as ![]() $U$, and

$U$, and ![]() $F_t^{g}$ the tangential stress due to the gas phase at both interfaces.

$F_t^{g}$ the tangential stress due to the gas phase at both interfaces.

Figure 6. Schematic of a thin film with the tangential forces. The variable ![]() $s$ in used along the direction

$s$ in used along the direction ![]() $\hat {t}$ and the variable

$\hat {t}$ and the variable ![]() $\zeta$ along

$\zeta$ along ![]() $\hat {n}$.

$\hat {n}$.

The first inertial term scales as ![]() $\rho h U/T \sim 10^{-4}$ Pa, the weight as

$\rho h U/T \sim 10^{-4}$ Pa, the weight as ![]() $\rho g_s h \sim 10^{-2}$ Pa (for the peripheral films) and the airborne stress as

$\rho g_s h \sim 10^{-2}$ Pa (for the peripheral films) and the airborne stress as ![]() $F_t^{g} \sim \eta _g U/\delta _{bl}$, with

$F_t^{g} \sim \eta _g U/\delta _{bl}$, with ![]() $\delta _{bl}$ the thickness of the Blasius visco-inertial boundary layer,

$\delta _{bl}$ the thickness of the Blasius visco-inertial boundary layer, ![]() $\eta _g \sim 10^{-5}$ Pa s the gas shear viscosity and

$\eta _g \sim 10^{-5}$ Pa s the gas shear viscosity and ![]() $\rho _g \sim 1$ kg m

$\rho _g \sim 1$ kg m![]() $^{-3}$ the gas density (Rutgers et al. Reference Rutgers, Wu, Bhagavatula, Petersen and Goldburg1996). The value of

$^{-3}$ the gas density (Rutgers et al. Reference Rutgers, Wu, Bhagavatula, Petersen and Goldburg1996). The value of ![]() $\delta _{bl}$ is of the order of

$\delta _{bl}$ is of the order of ![]() $\sqrt {\eta _g T/\rho _g} \sim 10^{-3}$ m (or

$\sqrt {\eta _g T/\rho _g} \sim 10^{-3}$ m (or ![]() $\sqrt {\eta _g d/(U \rho _g)}$ of similar order) and thus

$\sqrt {\eta _g d/(U \rho _g)}$ of similar order) and thus ![]() $F_t^{g} \sim 10^{-4}$ Pa. The convection term arises from the fact that we considered an open system and scales as

$F_t^{g} \sim 10^{-4}$ Pa. The convection term arises from the fact that we considered an open system and scales as ![]() $\rho h U^{2} /d \sim 10^{-5}$ Pa.

$\rho h U^{2} /d \sim 10^{-5}$ Pa.

In the horizontal film, it results from these orders of magnitude that the Marangoni term ![]() $\partial \sigma /\partial s$, also appearing in (4.2), cannot be larger than

$\partial \sigma /\partial s$, also appearing in (4.2), cannot be larger than ![]() $10^{-4}$ Pa. Its variation between both ends of the film is thus below

$10^{-4}$ Pa. Its variation between both ends of the film is thus below ![]() $10^{-6}$ N m

$10^{-6}$ N m![]() $^{-1}$, which is much smaller than

$^{-1}$, which is much smaller than ![]() ${\rm \Delta} \sigma$. The surface tension variation induced by the gravity in each peripheral film simply balances its weight and is easily determined as

${\rm \Delta} \sigma$. The surface tension variation induced by the gravity in each peripheral film simply balances its weight and is easily determined as ![]() ${\rm \Delta} \sigma ^{grav} \sim \rho g_s h d \sim 10^{-4}$ N m

${\rm \Delta} \sigma ^{grav} \sim \rho g_s h d \sim 10^{-4}$ N m![]() $^{-1}$, which is negligible too (and could be easily taken into account if needed).

$^{-1}$, which is negligible too (and could be easily taken into account if needed).

One important consequence is that, in the parameter range we explored, the film tension is necessarily uniform on each thin film, whatever its physico-chemical properties (Durand & Stone Reference Durand and Stone2006). We thus define the film tension ![]() $\sigma ^{-}$ in the two compressed peripheral films (top and bottom films are identical by symmetry, as gravity is negligible),

$\sigma ^{-}$ in the two compressed peripheral films (top and bottom films are identical by symmetry, as gravity is negligible), ![]() $\sigma ^{+}$ in the two stretched peripheral films, and

$\sigma ^{+}$ in the two stretched peripheral films, and ![]() $\sigma ^{c}$ in the central film.

$\sigma ^{c}$ in the central film.

The contribution of both interfaces and of the film bulk to this film tension will be discussed in § 7. Note that, as tensions and extensions are related to each other, the tension uniformity validates the assumption of uniform extension in each given film made in § 3.3.

4.3. Estimation of the normal forces

We now consider the normal motion of the peripheral films in order to show that they keep a negligible mean curvature during the deformation. Disregarding gravity effects (as discussed in § 4.2), the ![]() $(x,y)$ plane is a symmetry plane, so the central film remains flat and stay in the

$(x,y)$ plane is a symmetry plane, so the central film remains flat and stay in the ![]() $(x,y)$ plane. As shown in figure 7, the normal velocity of a piece of peripheral film is of the order of the meniscus velocity

$(x,y)$ plane. As shown in figure 7, the normal velocity of a piece of peripheral film is of the order of the meniscus velocity ![]() $U_m$. The Newton law in the normal direction applied to this system involves thus an inertial term (per unit film area) scaling as

$U_m$. The Newton law in the normal direction applied to this system involves thus an inertial term (per unit film area) scaling as ![]() $I_f= h \rho U_m/T \sim 10^{-5}$ Pa. The normal forces are the gas pressures on both sides and the Laplace pressure, i.e. the normal component of the film tension contribution (Salkin et al. Reference Salkin, Schmit, Panizza and Courbin2016). The convection term is, as for the tangential projection, negligible.

$I_f= h \rho U_m/T \sim 10^{-5}$ Pa. The normal forces are the gas pressures on both sides and the Laplace pressure, i.e. the normal component of the film tension contribution (Salkin et al. Reference Salkin, Schmit, Panizza and Courbin2016). The convection term is, as for the tangential projection, negligible.

Figure 7. Schematic of the pushed film with the normal forces applied.

In our set-up, the gas constitutes a continuous phase and the pressure variations are thus of dynamical origin only. The inertial gas pressure scales as ![]() $P^{{g}}= \rho _g U_m^{2} \sim 10^{-6}\ \textrm {Pa} \ll I_f$. The gas phase can thus be assumed to be at rest. In the following, the atmospheric pressure is chosen as pressure reference and all the pressures defined in the liquid phase are the actual pressure minus this uniform atmospheric pressure.

$P^{{g}}= \rho _g U_m^{2} \sim 10^{-6}\ \textrm {Pa} \ll I_f$. The gas phase can thus be assumed to be at rest. In the following, the atmospheric pressure is chosen as pressure reference and all the pressures defined in the liquid phase are the actual pressure minus this uniform atmospheric pressure.

The force balance thus only involves the film inertia ![]() $I_f$ and the Laplace pressure

$I_f$ and the Laplace pressure ![]() $\sigma {\mathcal {C}}$. This provides a scaling law for the film mean curvature

$\sigma {\mathcal {C}}$. This provides a scaling law for the film mean curvature ![]() ${\mathcal {C}}$

${\mathcal {C}}$

This mean curvature is much smaller than the observed curvature in the ![]() $(x,y)$ plane, of the order of 20 m

$(x,y)$ plane, of the order of 20 m![]() $^{-1}$ (see figure 5) and is therefore negligible. The peripheral films remain thus minimal surfaces of vanishing mean curvature, even during the motor motion, and their entire shape can be deduced from the position of their boundaries, i.e. from the position and shape of the free menisci.

$^{-1}$ (see figure 5) and is therefore negligible. The peripheral films remain thus minimal surfaces of vanishing mean curvature, even during the motor motion, and their entire shape can be deduced from the position of their boundaries, i.e. from the position and shape of the free menisci.

4.4. Determination of the angles between the films

Figure 8 shows the scheme of the pushed film shape ensuring vanishing mean curvature and geometrical constrains (see also Embley & Grassia Reference Embley and Grassia2007). The relevant geometrical quantity is the angle ![]() $2 \theta ^{-}$ (respectively

$2 \theta ^{-}$ (respectively ![]() $2 \theta ^{+}$) between the tangent vectors of the top and bottom pushed (respectively stretched) film, measured at the free meniscus position, in the

$2 \theta ^{+}$) between the tangent vectors of the top and bottom pushed (respectively stretched) film, measured at the free meniscus position, in the ![]() $y=0$ plane (i.e. in the middle of the film). Its expression as a function of the free meniscus shape in the

$y=0$ plane (i.e. in the middle of the film). Its expression as a function of the free meniscus shape in the ![]() $(x,y)$ plane (figure 8) is derived in Appendix B and is given by

$(x,y)$ plane (figure 8) is derived in Appendix B and is given by

\begin{equation} \theta^{{\pm}}=\tan^{{-}1}\left(\frac{d^{{\pm}}\sin\theta_0}{d^{{\pm}}\cos\theta_0+ \delta_1^{{\pm}}}\right)-\frac{\delta_2^{{\pm}}(0)}{w}\frac{{\rm \pi}\sin\theta_0}{\tanh \left(\dfrac{{\rm \pi} d^{{\pm}}}{w} \right)}. \end{equation}

\begin{equation} \theta^{{\pm}}=\tan^{{-}1}\left(\frac{d^{{\pm}}\sin\theta_0}{d^{{\pm}}\cos\theta_0+ \delta_1^{{\pm}}}\right)-\frac{\delta_2^{{\pm}}(0)}{w}\frac{{\rm \pi}\sin\theta_0}{\tanh \left(\dfrac{{\rm \pi} d^{{\pm}}}{w} \right)}. \end{equation}

The first term on the right-hand side is due to the meniscus sliding displacement (![]() $\delta _1$) and the second term is a correction induced by the meniscus curvature (

$\delta _1$) and the second term is a correction induced by the meniscus curvature (![]() $\delta _2$), as defined in (4.1). Note that, free menisci translate (displacement

$\delta _2$), as defined in (4.1). Note that, free menisci translate (displacement ![]() $\delta _1$) due to the finite frame thickness (1 mm) which allows peripheral films to accommodate such deformation. The initial equilibrium angle is

$\delta _1$) due to the finite frame thickness (1 mm) which allows peripheral films to accommodate such deformation. The initial equilibrium angle is ![]() $\theta _0={\rm \pi} /3$.

$\theta _0={\rm \pi} /3$.

Figure 8. (a) Three-dimensional schematic of the pushed film shape ensuring zero mean curvature. (b) Cutting scheme of the pushed film at the middle of the film.

4.5. Determination of the film tensions

The film tensions ![]() $\sigma ^{+}$,

$\sigma ^{+}$, ![]() $\sigma ^{-}$ and

$\sigma ^{-}$ and ![]() $\sigma _c$ in the stretched, compressed and central films can now be obtained from the force balance on the meniscus. As the film tensions are uniform, they can be measured at any arbitrary point: we write the force balance on the elementary piece of free meniscus located around

$\sigma _c$ in the stretched, compressed and central films can now be obtained from the force balance on the meniscus. As the film tensions are uniform, they can be measured at any arbitrary point: we write the force balance on the elementary piece of free meniscus located around ![]() $y=0$ (middle of the film). Importantly, at this point, the plane

$y=0$ (middle of the film). Importantly, at this point, the plane ![]() $y=0$ is normal to the meniscus, so the tension forces acting on the system are in this plane. After a projection in the

$y=0$ is normal to the meniscus, so the tension forces acting on the system are in this plane. After a projection in the ![]() $x$ direction we get

$x$ direction we get

with ![]() $\alpha _{men} r_m^{2}$ the section area of the meniscus. The meniscus inertia scales as

$\alpha _{men} r_m^{2}$ the section area of the meniscus. The meniscus inertia scales as ![]() $\rho r_m^{2} U_m/T \sim 10^{-6}$ N m

$\rho r_m^{2} U_m/T \sim 10^{-6}$ N m![]() $^{-1}$ and is much smaller than

$^{-1}$ and is much smaller than ![]() ${\rm \Delta} \sigma$. We thus obtained the sought relationship

${\rm \Delta} \sigma$. We thus obtained the sought relationship

with ![]() $\theta ^{-}$ and

$\theta ^{-}$ and ![]() $\theta ^{+}$ expressed as a function of the meniscus displacement in (4.4).

$\theta ^{+}$ expressed as a function of the meniscus displacement in (4.4).

We show in the next section that any variation of film tension is associated with a film extension ![]() $\varepsilon$. As the central film is never stretched or compressed, we can assume

$\varepsilon$. As the central film is never stretched or compressed, we can assume ![]() $\sigma _c = \sigma _0 = 2\gamma _0$. The film tension variations in the stretched and compressed peripheral films, with respect to their equilibrium values, are thus given by

$\sigma _c = \sigma _0 = 2\gamma _0$. The film tension variations in the stretched and compressed peripheral films, with respect to their equilibrium values, are thus given by

An example of film tension variation is shown in figure 9 as a function of time. We find, as anticipated, an order of magnitude of a few mN m![]() $^{-1}$ for

$^{-1}$ for ![]() ${\rm \Delta} \sigma$. As soon as the motors start, the film tension begins to deviate from its equilibrium value. It reaches a maximum/minimum when the motors stop and then relaxes.

${\rm \Delta} \sigma$. As soon as the motors start, the film tension begins to deviate from its equilibrium value. It reaches a maximum/minimum when the motors stop and then relaxes.

Figure 9. Typical time evolution of the film tension variation of the stretched (in red) and compressed (in blue) sides for ![]() ${\rm \Delta} d=10$ mm,

${\rm \Delta} d=10$ mm, ![]() $V=50$ mm s

$V=50$ mm s![]() $^{-1}$ and

$^{-1}$ and ![]() $d_m=12$ mm. Solid lines (respectively shaded areas) represents the average (respectively the standard deviation) over 50 experiments. These values are deduced from the meniscus displacement using (4.4) and (4.6).

$d_m=12$ mm. Solid lines (respectively shaded areas) represents the average (respectively the standard deviation) over 50 experiments. These values are deduced from the meniscus displacement using (4.4) and (4.6).

Note that, by symmetry, the final state reached by the system is identical to its initial state. The total amount of dissipated energy ![]() ${\mathcal {D}}$ (per unit length) is therefore the total work provided by the motor to the system

${\mathcal {D}}$ (per unit length) is therefore the total work provided by the motor to the system

with ![]() $V$ the motor velocity and

$V$ the motor velocity and ![]() $[0-t_m]$ the duration of the motor motion. The tension difference between the stretched and compressed films is thus a direct signature of the system dissipation.

$[0-t_m]$ the duration of the motor motion. The tension difference between the stretched and compressed films is thus a direct signature of the system dissipation.

5. Constitutive relation for the film

In the previous sections we determined the tension and the extension of the different films, which now allows us to build the film experimental constitutive relation, i.e. the relationship between the two quantities.

5.1. Experimental results

We first plot, in figure 10, the tension variation in term of the film extension for the experiments where the extension has been deduced from the thickness measurements in stretched films. This allows us to monitor the relationship over the entire experiment, during 10 s. The film is first stretched (blue data) and then relaxes toward its initial length (purple data). The most noticeable result of the paper is that the two parts of the curve are perfectly superimposed, thus proving unambiguously the purely elastic behaviour of the film.

Figure 10. Film tension relative variation as a function of ![]() $\varepsilon$ deduced from the film thickness (using (3.2)) during the motor motion (blue) and after motor stops (purple) for

$\varepsilon$ deduced from the film thickness (using (3.2)) during the motor motion (blue) and after motor stops (purple) for ![]() ${\rm \Delta} d=10$ mm,

${\rm \Delta} d=10$ mm, ![]() $V=50$ mm s

$V=50$ mm s![]() $^{-1}$ and

$^{-1}$ and ![]() $d_m=12$ mm. The solid lines (shaded areas) represent the averages (standard deviations).

$d_m=12$ mm. The solid lines (shaded areas) represent the averages (standard deviations).

To investigate further the role of the extension rate, we varied the motor motion parameters in a large range. The amount of data was too large to use the definition (3.2) of the extension (which requires manual check during the data processing) and we used the definition (3.3) instead, for the stretched and compressed films, at short times (i.e. during motor motion and just after).

At each time, for each experiment and each film, we measure the data set (![]() $\varepsilon , \dot {\varepsilon }, \sigma$). All data points are then considered together, whatever the values of the control parameters. They are binned by extension rate

$\varepsilon , \dot {\varepsilon }, \sigma$). All data points are then considered together, whatever the values of the control parameters. They are binned by extension rate ![]() $|\dot {\varepsilon }|$, and averaged. The bins have been chosen to show the whole range of extension rate while keeping a significant number of points in each bin. Most of the points are associated with a small

$|\dot {\varepsilon }|$, and averaged. The bins have been chosen to show the whole range of extension rate while keeping a significant number of points in each bin. Most of the points are associated with a small ![]() $|\dot {\varepsilon }|$, but there are still 8500 data points for the

$|\dot {\varepsilon }|$, but there are still 8500 data points for the ![]() $[5 ; 25]$ s

$[5 ; 25]$ s![]() $^{-1}$ bin.

$^{-1}$ bin.

The obtained results are shown in figure 11. Negative ![]() $\varepsilon$ corresponds to a compression and positive

$\varepsilon$ corresponds to a compression and positive ![]() $\varepsilon$ to an extension. Note that to provide a better readability of the data, we shifted the

$\varepsilon$ to an extension. Note that to provide a better readability of the data, we shifted the ![]() $x$ and

$x$ and ![]() $y$ axis of the two lowest extension rates. The three curves would otherwise be perfectly superimposed, as indicated by the theoretical law (dashed black lines) plotted on each graph, which is each time the same curve. For the investigated parameters, i.e.

$y$ axis of the two lowest extension rates. The three curves would otherwise be perfectly superimposed, as indicated by the theoretical law (dashed black lines) plotted on each graph, which is each time the same curve. For the investigated parameters, i.e. ![]() $|\dot {\varepsilon }|$ in the range

$|\dot {\varepsilon }|$ in the range ![]() $[0 ; 25]$ s

$[0 ; 25]$ s![]() $^{-1}$ and

$^{-1}$ and ![]() $\varepsilon$ in the range

$\varepsilon$ in the range ![]() $[-0.5 ; 2]$, the film tension is thus a function of the extension only. The relationship between both quantities is discussed in the next section, on the basis of the classical models.

$[-0.5 ; 2]$, the film tension is thus a function of the extension only. The relationship between both quantities is discussed in the next section, on the basis of the classical models.

Figure 11. Film tension relative variation as a function of the local film extension ![]() $\varepsilon$. Each colour corresponds to the average over all the data having an extension rate in a given range. The 3 curves are perfectly superimposed and the red and blue curves have been shifted for the sake of visibility: the corresponding axis origins are the cross of the same colour. The error bar (shaded area) is the standard deviation and is less than

$\varepsilon$. Each colour corresponds to the average over all the data having an extension rate in a given range. The 3 curves are perfectly superimposed and the red and blue curves have been shifted for the sake of visibility: the corresponding axis origins are the cross of the same colour. The error bar (shaded area) is the standard deviation and is less than ![]() $10\,\%$ on average. The dashed lines are 3 copies of the same curve: the theoretical prediction of (5.5), with the relative elasticity

$10\,\%$ on average. The dashed lines are 3 copies of the same curve: the theoretical prediction of (5.5), with the relative elasticity ![]() $E/\gamma _0=0.16$. The solid line corresponds to the nonlinear model using Langmuir adsorption of reference (Fang & Joos Reference Fang and Joos1992), derived in Appendix C, with an initial DOH concentration of

$E/\gamma _0=0.16$. The solid line corresponds to the nonlinear model using Langmuir adsorption of reference (Fang & Joos Reference Fang and Joos1992), derived in Appendix C, with an initial DOH concentration of ![]() $0.6 c_0$.

$0.6 c_0$.

5.2. Gibbs–Marangoni elasticity

The full interfacial stress ![]() $\gamma$ of an interface involves the thermodynamic definition of the surface tension

$\gamma$ of an interface involves the thermodynamic definition of the surface tension ![]() $\gamma _{th}$ which depends solely on the local surfactant interfacial excess (

$\gamma _{th}$ which depends solely on the local surfactant interfacial excess (![]() $\varGamma$) and the intrinsic surface extensional and shear viscosities, respectively

$\varGamma$) and the intrinsic surface extensional and shear viscosities, respectively ![]() $\kappa _s$ and

$\kappa _s$ and ![]() $\eta _s$. In our

$\eta _s$. In our ![]() $y$-invariant geometry, similar to a Langmuir trough geometry, this stress is (Edwards, Brenner & Wasan Reference Edwards, Brenner and Wasan1991; Stone Reference Stone2010)

$y$-invariant geometry, similar to a Langmuir trough geometry, this stress is (Edwards, Brenner & Wasan Reference Edwards, Brenner and Wasan1991; Stone Reference Stone2010)

The local surface excess might deviate from its initial equilibrium value and depends on the surfactant transport processes. In the general case, the surfactant advection–diffusion and the exchanges between the bulk and the interface result in an elastic and an apparent viscous behaviour due to, respectively, the in-phase and out-of-phase (delayed) response of the surface excess with the deformation.

Here, the diffusion time scales of the surfactants in the directions parallel or transverse to a thin film scale as ![]() $\tau ^{p} \sim d^{2}/D \sim 10^{6}$ s and

$\tau ^{p} \sim d^{2}/D \sim 10^{6}$ s and ![]() $\tau ^{t} \sim h^{2}/D \sim 10^{-2}$ s, respectively, whereas the experimental time scale is of the order of 1 s. This scale separation allows us to assume that (i) there is no diffusive transport along the film; (ii) at a given location

$\tau ^{t} \sim h^{2}/D \sim 10^{-2}$ s, respectively, whereas the experimental time scale is of the order of 1 s. This scale separation allows us to assume that (i) there is no diffusive transport along the film; (ii) at a given location ![]() $s$ in the film, the equilibrium between the bulk concentration and the interface excess is immediately reached. From these assumptions, and following Prins, Arcuri & Van Den Tempel (Reference Prins, Arcuri and Van Den Tempel1967) and Couder, Chomaz & Rabaud (Reference Couder, Chomaz and Rabaud1989), we can deduce the relation between the surface excess and the film extension.

$s$ in the film, the equilibrium between the bulk concentration and the interface excess is immediately reached. From these assumptions, and following Prins, Arcuri & Van Den Tempel (Reference Prins, Arcuri and Van Den Tempel1967) and Couder, Chomaz & Rabaud (Reference Couder, Chomaz and Rabaud1989), we can deduce the relation between the surface excess and the film extension.

As established in § 4, the film tension ![]() $\sigma$ is homogeneous in each film. However, some important dynamical processes, discussed in § 7, occur close to the meniscus and lead to variations of the interface tension

$\sigma$ is homogeneous in each film. However, some important dynamical processes, discussed in § 7, occur close to the meniscus and lead to variations of the interface tension ![]() $\gamma$ on both film interfaces, while keeping the resulting film tension constant. Here, we focus on the central part of the films, where the bulk pressure is the reference pressure, both interface tensions are identical and the velocity field across the film is homogeneous (see § 6.2 for more details). In this domain we thus simply have

$\gamma$ on both film interfaces, while keeping the resulting film tension constant. Here, we focus on the central part of the films, where the bulk pressure is the reference pressure, both interface tensions are identical and the velocity field across the film is homogeneous (see § 6.2 for more details). In this domain we thus simply have ![]() $\sigma = 2 \gamma$. Moreover, the interface

$\sigma = 2 \gamma$. Moreover, the interface ![]() ${\textrm {d}}S(t)$ of a film element

${\textrm {d}}S(t)$ of a film element ![]() $\mathcal{S}$ of volume

$\mathcal{S}$ of volume ![]() $d\varOmega = h(t) \, {\textrm {d}}S(t)$ is always in contact with the same liquid bulk. At our experimental time scale

$d\varOmega = h(t) \, {\textrm {d}}S(t)$ is always in contact with the same liquid bulk. At our experimental time scale ![]() $\tau ^{t} \ll T \ll \tau ^{p}$, we can thus assume that (i) the film element

$\tau ^{t} \ll T \ll \tau ^{p}$, we can thus assume that (i) the film element ![]() ${\mathcal {S}}$ is a closed system (both for the liquid phase and for the surfactants); (ii) the bulk concentration

${\mathcal {S}}$ is a closed system (both for the liquid phase and for the surfactants); (ii) the bulk concentration ![]() $c$ has a homogeneous value

$c$ has a homogeneous value ![]() $c_0+ {\rm \Delta} c$ in

$c_0+ {\rm \Delta} c$ in ![]() $d\varOmega$ and is at equilibrium with the interface concentration, so that

$d\varOmega$ and is at equilibrium with the interface concentration, so that ![]() $\varGamma =\varGamma _0+h_\varGamma {\rm \Delta} c$ (see (2.3)). The surfactant mass conservation leads to (Prins et al. Reference Prins, Arcuri and Van Den Tempel1967; Couder et al. Reference Couder, Chomaz and Rabaud1989)

$\varGamma =\varGamma _0+h_\varGamma {\rm \Delta} c$ (see (2.3)). The surfactant mass conservation leads to (Prins et al. Reference Prins, Arcuri and Van Den Tempel1967; Couder et al. Reference Couder, Chomaz and Rabaud1989)