1 Introduction

Turbulent mixing of scalar quantities is of great importance for a wide range of engineering and environmental applications. Key processes in these applications depend on turbulence to mix scalar quantities rapidly. In some applications a single scalar mixes with a background flow (binary mixing) whereas in many others the mixing process is inherently multiscalar. While binary mixing has been studied extensively (e.g. Warhaft Reference Warhaft2000), multiscalar mixing has received much less attention. In the present study, we investigate several important aspects of three-scalar mixing.

The simplest multiscalar mixing process involves three scalars, which nevertheless possesses the essential characteristics of multiscalar mixing. In three-scalar mixing, the initial scalar configuration plays a key role in determining the mixing process. Different configurations will result in qualitatively different scalar fields and statistics. Previous studies have investigated mixing of two scalars introduced into a background scalar (air) (Sirivat & Warhaft Reference Sirivat and Warhaft1982; Warhaft Reference Warhaft1984; Tong & Warhaft Reference Tong and Warhaft1995) and that of three scalars arranged symmetrically (Juneja & Pope Reference Juneja and Pope1996). In a non-premixed reactive flow, however, the mixing configuration is different. For a simple reaction of two reactants forming a product, the product can directly mix with either reactant, but the reactants cannot mix with each other without mixing with the product. Therefore, the mixing process has qualitative differences from those in the previous studies.

In a reactive flow, mixing and reaction interact with each other, making understanding of mixing more challenging. Therefore, when studying mixing it is desirable to isolate it from the reaction, i.e. to study a mixing process that has similar important characteristics to that in a reactive flow, but without the influence of reaction. To better understand multiscalar mixing in turbulent non-premixed reactive flows, Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011) studied three-scalar mixing in a coaxial jet emanating into co-flow air. In this flow the centre jet scalar (

![]() $\unicode[STIX]{x1D719}_{1}$

) and the co-flow air (

$\unicode[STIX]{x1D719}_{1}$

) and the co-flow air (

![]() $\unicode[STIX]{x1D719}_{3}$

) at the jet exit plane are separated by the annulus scalar (

$\unicode[STIX]{x1D719}_{3}$

) at the jet exit plane are separated by the annulus scalar (

![]() $\unicode[STIX]{x1D719}_{2}$

). Thus the initial mixing is between

$\unicode[STIX]{x1D719}_{2}$

). Thus the initial mixing is between

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

and between

$\unicode[STIX]{x1D719}_{2}$

and between

![]() $\unicode[STIX]{x1D719}_{2}$

and

$\unicode[STIX]{x1D719}_{2}$

and

![]() $\unicode[STIX]{x1D719}_{3}$

, but not between

$\unicode[STIX]{x1D719}_{3}$

, but not between

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{3}$

. Subsequent mixing between

$\unicode[STIX]{x1D719}_{3}$

. Subsequent mixing between

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{3}$

must involve

$\unicode[STIX]{x1D719}_{3}$

must involve

![]() $\unicode[STIX]{x1D719}_{2}$

. Therefore, this three-scalar mixing problem possesses the mixing configuration of a non-premixed reactive flow, thereby making it a suitable model problem for understanding mixing in turbulent non-premixed reactive flows. Thus investigations of the three-scalar mixing process and its dependencies on the key parameters will advance the understanding of the mixing process in non-premixed flows.

$\unicode[STIX]{x1D719}_{2}$

. Therefore, this three-scalar mixing problem possesses the mixing configuration of a non-premixed reactive flow, thereby making it a suitable model problem for understanding mixing in turbulent non-premixed reactive flows. Thus investigations of the three-scalar mixing process and its dependencies on the key parameters will advance the understanding of the mixing process in non-premixed flows.

We note that although in a reactive flow the product has a reaction source, making the flow physics more complex than non-reactive flows, the interaction between mixing and reaction is realized through the scalar fields. In a non-premixed reactive flow, once the product is generated, the three-scalar mixing configuration is established, which is the same as that in the coaxial jet.

Three-scalar mixing in a coaxial jet also has relevance to understanding mixing in the near field of piloted flames, such as the Sandia flames (Barlow & Frank Reference Barlow and Frank1998) and the Sidney piloted premixed jet flames (Dunn, Masri & Bilger Reference Dunn, Masri and Bilger2007). In such flames, the main jet and the co-flow are separated by the pilot, resulting in a three-stream mixing problem. While such a mixing process may be more complex since the reactions generate additional scalars, it is multiscalar, and the scalar configuration will play an important role.

Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011) analysed in detail the mixing process in the near field of the flow. In addition to the scalar means, the root-mean-square (r.m.s.) fluctuations, the correlation coefficient, the segregation parameter, the mean scalar dissipation and the mean cross-dissipation, they also investigated the scalar joint probability density function (JPDF) and the mixing terms in the JPDF transport equation. These include the conditional diffusion, conditional dissipation and conditional cross-dissipation, which are important for probability density function (PDF) methods for modelling reactive flows. The results show that the diffusion velocity streamlines in the scalar space representing the conditional diffusion (the effects of molecular diffusion) generally converge quickly to a manifold, along which they continue at a lower rate. This mixing path presents a challenge for mixing models that use only scalar-space variables.

The three-scalar mixing in the coaxial jet has been simulated with the hybrid large-eddy simulation (LES)/filtered mass density function approach by Shetty, Chandy & Frankel (Reference Shetty, Chandy and Frankel2010). While the mean profiles were in good agreement with the experimental data, they failed to capture some key features of the r.m.s. profiles such as the two off-centreline peaks of the

![]() $\unicode[STIX]{x1D719}_{2}$

r.m.s. profile. Rowinski & Pope (Reference Rowinski and Pope2013) used both PDF and LES–PDF to simulate this three-scalar mixing problem. While the basic statistics such as mean and r.m.s. show excellent agreement with the measurements, different mixing models show their limitations in capturing some of the key features such as the bimodal JPDF and the diffusion manifold.

$\unicode[STIX]{x1D719}_{2}$

r.m.s. profile. Rowinski & Pope (Reference Rowinski and Pope2013) used both PDF and LES–PDF to simulate this three-scalar mixing problem. While the basic statistics such as mean and r.m.s. show excellent agreement with the measurements, different mixing models show their limitations in capturing some of the key features such as the bimodal JPDF and the diffusion manifold.

While Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011) revealed important characteristics of the three-scalar mixing process, the velocity ratio between the annular flow and the centre jet was fixed (close to unity). So was the geometry of the coaxial jet. The velocity ratio determines the relative magnitudes of the velocity differences (shear strength) between the centre jet and the annular flow and between the annular flow and the co-flow, and therefore is an important parameter governing the mixing process. Its influence on the mixing process can also help understand the effects of the stoichiometric mixture fraction on the mixing process in turbulent non-premixed reactive flows. Since

![]() $\unicode[STIX]{x1D719}_{2}$

is analogous to a reaction product, which generally has the maximum mass fraction near the stoichiometric mixture fraction, varying the velocity ratio is, as far as mixing is concerned, analogous to shifting the location of the product (the stoichiometric mixture fraction) relative to the velocity profile (shear layer). In the present study we will investigate the effects of the velocity ratio on the three-scalar mixing process.

$\unicode[STIX]{x1D719}_{2}$

is analogous to a reaction product, which generally has the maximum mass fraction near the stoichiometric mixture fraction, varying the velocity ratio is, as far as mixing is concerned, analogous to shifting the location of the product (the stoichiometric mixture fraction) relative to the velocity profile (shear layer). In the present study we will investigate the effects of the velocity ratio on the three-scalar mixing process.

The ratio between the annulus width and the centre jet diameter also has important effects on the mixing process. The velocity and scalar length scales depend on the sizes of the centre jet and the width of the annulus. Due to the similar role in mixing played by

![]() $\unicode[STIX]{x1D719}_{2}$

to that by a reaction product, the width of the

$\unicode[STIX]{x1D719}_{2}$

to that by a reaction product, the width of the

![]() $\unicode[STIX]{x1D719}_{2}$

layer in the three-scalar mixing is analogous to the reaction zone width in a non-premixed reactive flow. Varying the width of the annulus (degree of separation between

$\unicode[STIX]{x1D719}_{2}$

layer in the three-scalar mixing is analogous to the reaction zone width in a non-premixed reactive flow. Varying the width of the annulus (degree of separation between

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{3}$

) will alter the shape of of the JPDF near the peak

$\unicode[STIX]{x1D719}_{3}$

) will alter the shape of of the JPDF near the peak

![]() $\unicode[STIX]{x1D719}_{2}$

region in the scalar space. Investigating the effects of the length scale ratio, therefore, is also important for understanding the influence of the reaction zone width on the multiscalar mixing process in flames.

$\unicode[STIX]{x1D719}_{2}$

region in the scalar space. Investigating the effects of the length scale ratio, therefore, is also important for understanding the influence of the reaction zone width on the multiscalar mixing process in flames.

In the present study we investigate experimentally the effects of the velocity ratio (mean shear) and the length scale ratio between the annular flow and the centre jet on the three-scalar mixing process. The objectives are to investigate the physics of three-scalar mixing, and to provide scalar statistics representing the mixing process for model comparison. The dependence of the important scalar statistics characterizing mixing on these ratios will be analysed. These include the mean, the r.m.s. fluctuations, the correlation coefficient, the segregation parameters, the scalar JPDF and the mixing terms in the JPDF transport equation. Scalar mixing is often analysed in physical space, e.g. using the scalar moment equations. However, it is also important to understand the mixing process in scalar space because molecular mixing, which is essential for scalar evolution, is local in both physical and scalar spaces. The scalar JPDF equation can facilitate investigation of the mixing process in both spaces to gain a deeper understanding of the mixing process.

The transport equation for the scalar JPDF,

![]() $f$

, can be derived using the method given by Pope (Reference Pope1985)

$f$

, can be derived using the method given by Pope (Reference Pope1985)

$$\begin{eqnarray}\displaystyle & & \displaystyle \frac{\unicode[STIX]{x2202}f}{\unicode[STIX]{x2202}t}+\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}x_{i}}[f(U_{i}+\langle u_{i}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle )]=-\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{1}}[f\langle D_{1}\unicode[STIX]{x1D6FB}^{2}\unicode[STIX]{x1D719}_{1}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ]-\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{2}}[f\langle D_{2}\unicode[STIX]{x1D6FB}^{2}\unicode[STIX]{x1D719}_{2}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ]\nonumber\\ \displaystyle & & \displaystyle \quad =-\frac{\unicode[STIX]{x2202}^{2}}{\unicode[STIX]{x2202}x_{i}\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{1}}\left[\left\langle \left.D_{1}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{1}}{\unicode[STIX]{x2202}x_{i}}\right|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\right\rangle f\right]-\frac{\unicode[STIX]{x2202}^{2}}{\unicode[STIX]{x2202}x_{i}\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{2}}\left[\left\langle \left.D_{2}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{2}}{\unicode[STIX]{x2202}x_{i}}\right|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\right\rangle f\right]\nonumber\\ \displaystyle & & \displaystyle \qquad -\,\frac{1}{2}\frac{\unicode[STIX]{x2202}^{2}}{\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{1}^{2}}[f\langle \unicode[STIX]{x1D712}_{1}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ]-\frac{1}{2}\frac{\unicode[STIX]{x2202}^{2}}{\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{2}^{2}}[f\langle \unicode[STIX]{x1D712}_{2}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ]-\frac{\unicode[STIX]{x2202}^{2}}{\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{1}\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{2}}[f\langle \unicode[STIX]{x1D712}_{12}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ],\end{eqnarray}$$

$$\begin{eqnarray}\displaystyle & & \displaystyle \frac{\unicode[STIX]{x2202}f}{\unicode[STIX]{x2202}t}+\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}x_{i}}[f(U_{i}+\langle u_{i}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle )]=-\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{1}}[f\langle D_{1}\unicode[STIX]{x1D6FB}^{2}\unicode[STIX]{x1D719}_{1}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ]-\frac{\unicode[STIX]{x2202}}{\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{2}}[f\langle D_{2}\unicode[STIX]{x1D6FB}^{2}\unicode[STIX]{x1D719}_{2}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ]\nonumber\\ \displaystyle & & \displaystyle \quad =-\frac{\unicode[STIX]{x2202}^{2}}{\unicode[STIX]{x2202}x_{i}\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{1}}\left[\left\langle \left.D_{1}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{1}}{\unicode[STIX]{x2202}x_{i}}\right|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\right\rangle f\right]-\frac{\unicode[STIX]{x2202}^{2}}{\unicode[STIX]{x2202}x_{i}\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{2}}\left[\left\langle \left.D_{2}\frac{\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{2}}{\unicode[STIX]{x2202}x_{i}}\right|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\right\rangle f\right]\nonumber\\ \displaystyle & & \displaystyle \qquad -\,\frac{1}{2}\frac{\unicode[STIX]{x2202}^{2}}{\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{1}^{2}}[f\langle \unicode[STIX]{x1D712}_{1}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ]-\frac{1}{2}\frac{\unicode[STIX]{x2202}^{2}}{\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{2}^{2}}[f\langle \unicode[STIX]{x1D712}_{2}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ]-\frac{\unicode[STIX]{x2202}^{2}}{\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{1}\unicode[STIX]{x2202}\hat{\unicode[STIX]{x1D719}}_{2}}[f\langle \unicode[STIX]{x1D712}_{12}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ],\end{eqnarray}$$

where

![]() $U_{i}$

,

$U_{i}$

,

![]() $u_{i}$

are the mean and fluctuating velocities respectively. The diffusion coefficients for

$u_{i}$

are the mean and fluctuating velocities respectively. The diffusion coefficients for

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

,

$\unicode[STIX]{x1D719}_{2}$

,

![]() $D_{1}$

and

$D_{1}$

and

![]() $D_{2}$

, have values of

$D_{2}$

, have values of

![]() $0.1039~\text{cm}^{2}~\text{s}^{-1}$

and

$0.1039~\text{cm}^{2}~\text{s}^{-1}$

and

![]() $0.1469~\text{cm}^{2}~\text{s}^{-1}$

, respectively (Reid, Prausnitz & Poling Reference Reid, Prausnitz and Poling1989). The left-hand side of the equation is the time rate of change of the JPDF and the transport of the JPDF in physical space by the mean velocity and the conditional mean of the fluctuating velocity. The right-hand side gives two forms of the mixing terms. The first involves the conditional scalar diffusion,

$0.1469~\text{cm}^{2}~\text{s}^{-1}$

, respectively (Reid, Prausnitz & Poling Reference Reid, Prausnitz and Poling1989). The left-hand side of the equation is the time rate of change of the JPDF and the transport of the JPDF in physical space by the mean velocity and the conditional mean of the fluctuating velocity. The right-hand side gives two forms of the mixing terms. The first involves the conditional scalar diffusion,

![]() $\langle D_{\unicode[STIX]{x1D6FC}}\unicode[STIX]{x1D6FB}^{2}\unicode[STIX]{x1D719}_{\unicode[STIX]{x1D6FC}}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle$

, whereas the second involves the conditional scalar dissipation,

$\langle D_{\unicode[STIX]{x1D6FC}}\unicode[STIX]{x1D6FB}^{2}\unicode[STIX]{x1D719}_{\unicode[STIX]{x1D6FC}}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle$

, whereas the second involves the conditional scalar dissipation,

![]() $\langle \unicode[STIX]{x1D712}_{\unicode[STIX]{x1D6FC}}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle =\langle 2D_{\unicode[STIX]{x1D6FC}}(\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{\unicode[STIX]{x1D6FC}}/\unicode[STIX]{x2202}x_{i})(\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{\unicode[STIX]{x1D6FC}}/\unicode[STIX]{x2202}x_{i})|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ,\unicode[STIX]{x1D6FC}=1,2$

, and the conditional scalar cross-dissipation,

$\langle \unicode[STIX]{x1D712}_{\unicode[STIX]{x1D6FC}}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle =\langle 2D_{\unicode[STIX]{x1D6FC}}(\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{\unicode[STIX]{x1D6FC}}/\unicode[STIX]{x2202}x_{i})(\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{\unicode[STIX]{x1D6FC}}/\unicode[STIX]{x2202}x_{i})|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle ,\unicode[STIX]{x1D6FC}=1,2$

, and the conditional scalar cross-dissipation,

![]() $\langle \unicode[STIX]{x1D712}_{12}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle =\langle (D_{1}+D_{2})(\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{1}/\unicode[STIX]{x2202}x_{i})(\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{2}/\unicode[STIX]{x2202}x_{i})|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle$

, respectively, where the angle brackets denote an ensemble average. For convenience we omit the sample space variable,

$\langle \unicode[STIX]{x1D712}_{12}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle =\langle (D_{1}+D_{2})(\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{1}/\unicode[STIX]{x2202}x_{i})(\unicode[STIX]{x2202}\unicode[STIX]{x1D719}_{2}/\unicode[STIX]{x2202}x_{i})|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle$

, respectively, where the angle brackets denote an ensemble average. For convenience we omit the sample space variable,

![]() $\hat{\unicode[STIX]{x1D719}}$

, hereafter. The terms with mixed physical–scalar-space derivatives represent mixed transport by conditional molecular fluxes. In the absence of differential diffusion (

$\hat{\unicode[STIX]{x1D719}}$

, hereafter. The terms with mixed physical–scalar-space derivatives represent mixed transport by conditional molecular fluxes. In the absence of differential diffusion (

![]() $D_{1}=D_{2}$

), they reduce to molecular diffusion of the JPDF,

$D_{1}=D_{2}$

), they reduce to molecular diffusion of the JPDF,

![]() $D_{1}(\unicode[STIX]{x2202}^{2}f/\unicode[STIX]{x2202}x_{i}\unicode[STIX]{x2202}x_{i})$

.

$D_{1}(\unicode[STIX]{x2202}^{2}f/\unicode[STIX]{x2202}x_{i}\unicode[STIX]{x2202}x_{i})$

.

While transport by the mean and conditional velocities are essentially the mean-flow advection and the turbulent convection of the JPDF in physical space, respectively, the mixing terms transport the JPDF in scalar space, and represent the effects of molecular mixing on the evolution of the scalar JPDF. The two forms of the mixing terms focus on different aspects of mixing. While the conditional dissipation rates quantifies the intensity of mixing for different compositions (the location in the scalar space), the conditional diffusion represents the velocity (direction and speed) at which mixing transports the JPDF in the scalar space. These terms can help us separate and understand the effects of the mean flow, the large-scale turbulent transport and small-scale mixing on the evolution in the scalar space. Note that transport of the JPDF by the conditional velocity will result in production and turbulent transport of the scalar variances and covariance.

The rest of the paper is organized as follows. Section 2 describes the experimental set-up and the data reduction procedures. The results are shown in § 3, with the conclusions following in § 4. The Appendix provides an estimate of the measurement resolution for the scalar dissipation rates using the Rayleigh scattering and acetone laser-induced fluorescence (LIF) techniques.

2 Experimental set-up and data reduction procedures

The measurements in this study were carried out in the turbulent flame facility at Clemson University. The coaxial jets used are similar to that in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011), which consists of two round tubes of different diameters placed concentrically (figure 1), resulting in a three-stream configuration. The mass fractions of the scalars emanating from the three streams are denoted as

![]() $\unicode[STIX]{x1D719}_{1}$

,

$\unicode[STIX]{x1D719}_{1}$

,

![]() $\unicode[STIX]{x1D719}_{2}$

and

$\unicode[STIX]{x1D719}_{2}$

and

![]() $\unicode[STIX]{x1D719}_{3}$

, which therefore sum to unity. The centre stream,

$\unicode[STIX]{x1D719}_{3}$

, which therefore sum to unity. The centre stream,

![]() $\unicode[STIX]{x1D719}_{1}$

, is unity at the centre jet exit, while the annular stream,

$\unicode[STIX]{x1D719}_{1}$

, is unity at the centre jet exit, while the annular stream,

![]() $\unicode[STIX]{x1D719}_{2}$

, is unity at the annular flow exit. The co-flow air represents the third scalar,

$\unicode[STIX]{x1D719}_{2}$

, is unity at the annular flow exit. The co-flow air represents the third scalar,

![]() $\unicode[STIX]{x1D719}_{3}$

.

$\unicode[STIX]{x1D719}_{3}$

.

Two coaxial jets with the same centre tube but different outer tubes were constructed for this work (the jet dimensions are listed in table 1), with the smaller one having identical dimensions to those used in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). See Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011) for the details of the construction. The centre stream was air seeded with approximately 9 % of acetone by volume, while the annular stream was pure ethylene. The densities of the centre stream and the annular stream were approximately 1.09 and 0.966 times the air density. The density differences are sufficiently small for the scalars to be considered as dynamically passive.

For each coaxial jet, measurements were made for the same centre jet (bulk) velocity with two annular flow (bulk) velocities, resulting in a total of four coaxial jet flows (table 2). The velocity ratio of the annular flow to the centre jet is close to unity for cases I and III while it is approximately 0.5 for cases II and IV. The velocities and Reynolds numbers of the four cases are listed in table 2. Note that case I is identical to the flow studied in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). The Reynolds numbers are calculated as

![]() $Re_{j}=U_{jb}D_{ji}/\unicode[STIX]{x1D708}_{air}$

and

$Re_{j}=U_{jb}D_{ji}/\unicode[STIX]{x1D708}_{air}$

and

![]() $Re_{a}=U_{ab}(D_{ai}-(D_{ji}+2\unicode[STIX]{x1D6FF}_{j}))/\unicode[STIX]{x1D708}_{eth}$

, where

$Re_{a}=U_{ab}(D_{ai}-(D_{ji}+2\unicode[STIX]{x1D6FF}_{j}))/\unicode[STIX]{x1D708}_{eth}$

, where

![]() $\unicode[STIX]{x1D708}_{air}=1.56\times 10^{-5}~\text{m}^{2}~\text{s}^{-1}$

and

$\unicode[STIX]{x1D708}_{air}=1.56\times 10^{-5}~\text{m}^{2}~\text{s}^{-1}$

and

![]() $\unicode[STIX]{x1D708}_{eth}=0.86\times 10^{-5}~\text{m}^{2}~\text{s}^{-1}$

(Prausnitz, Poling & O’Connell Reference Prausnitz, Poling and O’Connell2001) are the kinematic viscosities of air and ethylene respectively;

$\unicode[STIX]{x1D708}_{eth}=0.86\times 10^{-5}~\text{m}^{2}~\text{s}^{-1}$

(Prausnitz, Poling & O’Connell Reference Prausnitz, Poling and O’Connell2001) are the kinematic viscosities of air and ethylene respectively;

![]() $D_{ji}$

,

$D_{ji}$

,

![]() $\unicode[STIX]{x1D6FF}_{j}$

,

$\unicode[STIX]{x1D6FF}_{j}$

,

![]() $D_{ai}$

and

$D_{ai}$

and

![]() $\unicode[STIX]{x1D6FF}_{a}$

are the inner diameter and the wall thickness of the inner tube and the annulus tube, respectively; and

$\unicode[STIX]{x1D6FF}_{a}$

are the inner diameter and the wall thickness of the inner tube and the annulus tube, respectively; and

![]() $U_{jb}$

and

$U_{jb}$

and

![]() $U_{ab}$

are the bulk velocities of the centre stream and the annular stream, respectively. The tube diameter

$U_{ab}$

are the bulk velocities of the centre stream and the annular stream, respectively. The tube diameter

![]() $D_{ji}$

and the hydraulic diameter of the annulus

$D_{ji}$

and the hydraulic diameter of the annulus

![]() $D_{ai}-(D_{ji}+2\unicode[STIX]{x1D6FF}_{j})$

are used in calculating the Reynolds numbers.

$D_{ai}-(D_{ji}+2\unicode[STIX]{x1D6FF}_{j})$

are used in calculating the Reynolds numbers.

Table 1. Dimensions of the coaxial jets. Here

![]() $D_{ji}$

,

$D_{ji}$

,

![]() $\unicode[STIX]{x1D6FF}_{j}$

,

$\unicode[STIX]{x1D6FF}_{j}$

,

![]() $D_{ai}$

and

$D_{ai}$

and

![]() $\unicode[STIX]{x1D6FF}_{a}$

are the inner diameter and the wall thickness of the inner tube and the annulus tube, respectively.

$\unicode[STIX]{x1D6FF}_{a}$

are the inner diameter and the wall thickness of the inner tube and the annulus tube, respectively.

Table 2. Characteristics of the coaxial jets. Here

![]() $U_{jb}$

and

$U_{jb}$

and

![]() $U_{ab}$

are the bulk velocities of the centre stream and the annular stream, respectively. The Reynolds numbers are calculated using the tube diameter

$U_{ab}$

are the bulk velocities of the centre stream and the annular stream, respectively. The Reynolds numbers are calculated using the tube diameter

![]() $D_{ji}$

and the hydraulic diameter of the annulus

$D_{ji}$

and the hydraulic diameter of the annulus

![]() $D_{ai}-(D_{ji}+2\unicode[STIX]{x1D6FF}_{j})$

, respectively.

$D_{ai}-(D_{ji}+2\unicode[STIX]{x1D6FF}_{j})$

, respectively.

The source of the centre jet air was a facility compressor, while ethylene came from a high pressure gas cylinder with chemically pure ethylene. Alicat mass flow controllers were used to control the air and ethylene flow rates. All controllers had been calibrated by the manufacturer. Particles were removed from both streams before the gases enter the flow controllers. Three acetone containers in a series were used for seeding spectroscopic grade acetone into air through bubbling (figure 2). Each acetone container has a volume of 1 litre, and was approximately 70 % full. Most of the acetone seeded came from the first container, which was placed in a hot water bath maintained at approximately

![]() $35\,^{\circ }\text{C}$

. The second and third containers ensured that the acetone vapour pressure reached the saturation level at room temperature. As a result there were no observable variations of the seeding level during the course of the experiment. Approximately 30 % of the centre jet air flow bubbled through the three acetone containers. The acetone-doped air stream mixed with the rest of the air flow before entering the centre tube. A very fine particle filter (

$35\,^{\circ }\text{C}$

. The second and third containers ensured that the acetone vapour pressure reached the saturation level at room temperature. As a result there were no observable variations of the seeding level during the course of the experiment. Approximately 30 % of the centre jet air flow bubbled through the three acetone containers. The acetone-doped air stream mixed with the rest of the air flow before entering the centre tube. A very fine particle filter (

![]() $0.01~\unicode[STIX]{x03BC}\text{m}$

) was placed in the path of the acetone-seeded air flow to remove any acetone mist, which would interfere with Rayleigh scattering imaging. In order to monitor the pulse-to-pulse fluctuations of the laser energy, the laser intensity profile across the image height and the acetone seeding concentration for normalization, a laminar flow reference jet was placed at approximately 0.5 m upstream of the main jet along the laser beam path. Approximately 5 % of the centre jet acetone-doped air was teed off from the main jet to the reference jet. Additional air (also controlled by an Alicat flow controller) was added to the reference jet to increase the velocity to maintain a steady laminar jet flow.

$0.01~\unicode[STIX]{x03BC}\text{m}$

) was placed in the path of the acetone-seeded air flow to remove any acetone mist, which would interfere with Rayleigh scattering imaging. In order to monitor the pulse-to-pulse fluctuations of the laser energy, the laser intensity profile across the image height and the acetone seeding concentration for normalization, a laminar flow reference jet was placed at approximately 0.5 m upstream of the main jet along the laser beam path. Approximately 5 % of the centre jet acetone-doped air was teed off from the main jet to the reference jet. Additional air (also controlled by an Alicat flow controller) was added to the reference jet to increase the velocity to maintain a steady laminar jet flow.

Figure 2. Schematic of the experimental set-up.

Simultaneous planar laser-induced fluorescence (PLIF) and planar laser Rayleigh scattering were employed to measure the mass fractions of the acetone-doped air (

![]() $\unicode[STIX]{x1D719}_{1}$

) and ethylene (

$\unicode[STIX]{x1D719}_{1}$

) and ethylene (

![]() $\unicode[STIX]{x1D719}_{2}$

). The experimental set-up (figure 2) is similar to that in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). The second harmonic (532 nm) of a Q-switched Nd:YAG laser (Quanta-Ray LAB-170 operated at

$\unicode[STIX]{x1D719}_{2}$

). The experimental set-up (figure 2) is similar to that in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). The second harmonic (532 nm) of a Q-switched Nd:YAG laser (Quanta-Ray LAB-170 operated at

![]() $10~\text{pulses}~\text{s}^{-1}$

) having a pulse energy of approximately 325 mJ was used for Rayleigh scattering. The fourth harmonic (266 nm) of another Q-switched Nd:YAG laser (Quanta-Ray PRO-350 also operated at

$10~\text{pulses}~\text{s}^{-1}$

) having a pulse energy of approximately 325 mJ was used for Rayleigh scattering. The fourth harmonic (266 nm) of another Q-switched Nd:YAG laser (Quanta-Ray PRO-350 also operated at

![]() $10~\text{pulses}~\text{s}^{-1}$

) was used for acetone PLIF, with a pulse energy approximately

$10~\text{pulses}~\text{s}^{-1}$

) was used for acetone PLIF, with a pulse energy approximately

![]() $80~\text{mJ}~\text{pulse}^{-1}$

. A telescope consisting of a planar-concave cylindrical lens (

$80~\text{mJ}~\text{pulse}^{-1}$

. A telescope consisting of a planar-concave cylindrical lens (

![]() $-200$

mm focal length) followed by a spherical lens (750 mm focal length) was placed in the beam path of the 532 nm beam to form a collimated laser sheet above the coaxial jets. The telescope in the 266 nm beam path also consisted of a planar-concave cylindrical lens and a spherical lens with focal lengths of

$-200$

mm focal length) followed by a spherical lens (750 mm focal length) was placed in the beam path of the 532 nm beam to form a collimated laser sheet above the coaxial jets. The telescope in the 266 nm beam path also consisted of a planar-concave cylindrical lens and a spherical lens with focal lengths of

![]() $-150$

mm and 1000 mm, respectively. A dichroic mirror reflecting 266 nm wavelength and transmitting 532 nm was employed to combine the two beams into a single one. The focal points of the two spherical lens were located approximately above the jet centreline. The height of the laser sheets were approximately 40 mm and 60 mm, respectively for the 532 nm beam and the 266 nm beam. However, only the centre 12 mm portion having a relative uniform intensity was imaged.

$-150$

mm and 1000 mm, respectively. A dichroic mirror reflecting 266 nm wavelength and transmitting 532 nm was employed to combine the two beams into a single one. The focal points of the two spherical lens were located approximately above the jet centreline. The height of the laser sheets were approximately 40 mm and 60 mm, respectively for the 532 nm beam and the 266 nm beam. However, only the centre 12 mm portion having a relative uniform intensity was imaged.

A Cooke Corp. PCO-1600 interline-transfer charge-coupled device (CCD) camera was used to collect both LIF and Rayleigh signals. The camera is 14-bit with two analogue-to-digital converters (ADCs), with a interframe transfer time of 150 ns. Its quantum efficiency is over 50 % for green light and the readout noise is only 11 e– at 10 MHz readout rate. Each 532 nm pulse for Rayleigh scattering was placed 210 ns before a 266 nm pulse for LIF. With the jet velocity less than

![]() $35~\text{m}~\text{s}^{-1}$

, the time lag between the beams was sufficiently short to be considered as instantaneous. It was however longer than the interframe transfer time of the camera to ensure that the Rayleigh image was transferred before the exposure for the LIF image begins. To operate the camera with frame rate at

$35~\text{m}~\text{s}^{-1}$

, the time lag between the beams was sufficiently short to be considered as instantaneous. It was however longer than the interframe transfer time of the camera to ensure that the Rayleigh image was transferred before the exposure for the LIF image begins. To operate the camera with frame rate at

![]() $20~\text{frames}~\text{s}^{-1}$

with two ADCs, the imaging array of the camera was cropped and the pixels binned

$20~\text{frames}~\text{s}^{-1}$

with two ADCs, the imaging array of the camera was cropped and the pixels binned

![]() $2\times 2$

before readout, resulting in an image of 800 pixels wide by 500 pixels high. The timing of lasers and cameras were controlled by a delay generator (Stanford Research Systems DG535). A custom lens arrangement consisting of a Zeiss 135 mm

$2\times 2$

before readout, resulting in an image of 800 pixels wide by 500 pixels high. The timing of lasers and cameras were controlled by a delay generator (Stanford Research Systems DG535). A custom lens arrangement consisting of a Zeiss 135 mm

![]() $f/2$

Apo lens followed by a Zeiss planar 85 mm

$f/2$

Apo lens followed by a Zeiss planar 85 mm

![]() $f/1.4$

lens was used for the PCO-1600 camera. The lenses, both focused at infinity, were connected face to face with the 85 mm lens mounted on the camera. The pixel size of the camera is

$f/1.4$

lens was used for the PCO-1600 camera. The lenses, both focused at infinity, were connected face to face with the 85 mm lens mounted on the camera. The pixel size of the camera is

![]() $7.4~\unicode[STIX]{x03BC}\text{m}$

(square), corresponding to

$7.4~\unicode[STIX]{x03BC}\text{m}$

(square), corresponding to

![]() $22.9~\unicode[STIX]{x03BC}\text{m}$

in the image plane after binning

$22.9~\unicode[STIX]{x03BC}\text{m}$

in the image plane after binning

![]() $2\times 2$

. The full width at half-maximum (FWHM) of line spread function (LSF) for the lens arrangement in the present study was approximately

$2\times 2$

. The full width at half-maximum (FWHM) of line spread function (LSF) for the lens arrangement in the present study was approximately

![]() $38~\unicode[STIX]{x03BC}\text{m}$

. The increased measurement resolution (camera lenses and pixel size) than that in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011) (38 versus

$38~\unicode[STIX]{x03BC}\text{m}$

. The increased measurement resolution (camera lenses and pixel size) than that in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011) (38 versus

![]() $76~\unicode[STIX]{x03BC}\text{m}$

) resulted in improved measured dissipation rates and cross-dissipation rate, which are approximately twice the previous values (see the Appendix for more details). The smallest scalar dissipation length scale is determined to be approximately

$76~\unicode[STIX]{x03BC}\text{m}$

) resulted in improved measured dissipation rates and cross-dissipation rate, which are approximately twice the previous values (see the Appendix for more details). The smallest scalar dissipation length scale is determined to be approximately

![]() $14~\unicode[STIX]{x03BC}\text{m}$

. The field of view was 11.45 mm (high) by 18.3 mm (wide). The LIF and Rayleigh images of the reference jet were recorded with two Andor intensified CCDs (ICCDs) (both are iStar 334T), placed face to face on either sides of the laser sheet. The images were not intensified. Background light was suppressed using a series of hard blackboards to enclose the wind tunnel, cameras and the reference jet.

$14~\unicode[STIX]{x03BC}\text{m}$

. The field of view was 11.45 mm (high) by 18.3 mm (wide). The LIF and Rayleigh images of the reference jet were recorded with two Andor intensified CCDs (ICCDs) (both are iStar 334T), placed face to face on either sides of the laser sheet. The images were not intensified. Background light was suppressed using a series of hard blackboards to enclose the wind tunnel, cameras and the reference jet.

The PLIF signal is linearly proportional to the laser intensity and acetone mole fraction, while the Rayleigh scattering signal is linearly proportional to the laser intensity and the effective Rayleigh cross-section, which is a mole-weighted average of Rayleigh cross-section of the three species in the flow (acetone, ethylene and air). With these relationships and the fact that mass fractions of the three scalars sum to unity, the three mass fractions can be obtained from the PLIF and Rayleigh scattering signals. More details about the data reduction procedures can be found in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). The background signals were subtracted from both the main camera images and the reference jet images. The background images were taken with pure helium emanating from a McKenna burner and lasers operating normally, because helium does not have LIF emission with a 266 nm excitation beam and the Rayleigh cross-section of helium is negligible compared to that of air. The LIF and Rayleigh scattering images of a flat field, i.e. a uniform acetone doped air flow field, were used for calibration of the system response (obtaining the constant of proportionality). Issues in using LIF such as quenching and laser intensity attenuation, which is due to absorption, are accounted for in the data reduction procedures (Cai et al. Reference Cai, Dinger, Li, Carter, Ryan and Tong2011).

Table 3. Noise correction coefficients.

![]() $\langle n_{\unicode[STIX]{x1D719}_{1}}^{2}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle =\unicode[STIX]{x1D6FC}_{0}+\unicode[STIX]{x1D6FC}_{1}\hat{\unicode[STIX]{x1D719}}_{1}$

,

$\langle n_{\unicode[STIX]{x1D719}_{1}}^{2}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle =\unicode[STIX]{x1D6FC}_{0}+\unicode[STIX]{x1D6FC}_{1}\hat{\unicode[STIX]{x1D719}}_{1}$

,

![]() $\langle n_{\unicode[STIX]{x1D719}_{2}}^{2}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle =\unicode[STIX]{x1D6FD}_{0}$

$\langle n_{\unicode[STIX]{x1D719}_{2}}^{2}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle =\unicode[STIX]{x1D6FD}_{0}$

![]() $+\unicode[STIX]{x1D6FD}_{1}\hat{\unicode[STIX]{x1D719}}_{1}+\unicode[STIX]{x1D6FD}_{2}\hat{\unicode[STIX]{x1D719}}_{2}$

and

$+\unicode[STIX]{x1D6FD}_{1}\hat{\unicode[STIX]{x1D719}}_{1}+\unicode[STIX]{x1D6FD}_{2}\hat{\unicode[STIX]{x1D719}}_{2}$

and

![]() $\langle n_{\unicode[STIX]{x1D719}_{1}}n_{\unicode[STIX]{x1D719}_{2}}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle =\unicode[STIX]{x1D6FE}_{0}+\unicode[STIX]{x1D6FE}_{1}\hat{\unicode[STIX]{x1D719}}_{1}$

.

$\langle n_{\unicode[STIX]{x1D719}_{1}}n_{\unicode[STIX]{x1D719}_{2}}|\hat{\unicode[STIX]{x1D719}}_{1},\hat{\unicode[STIX]{x1D719}}_{2}\rangle =\unicode[STIX]{x1D6FE}_{0}+\unicode[STIX]{x1D6FE}_{1}\hat{\unicode[STIX]{x1D719}}_{1}$

.

Typically 7500–7800 images were used to obtain the scalar statistics. Two components of scalar dissipation rates and diffusion were obtained with the scalar derivatives calculated using the tenth-order central difference schemes. Noise correction was performed for the r.m.s., correlation coefficient, segregation parameter, mean and conditional dissipation rates using the same method as in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). The conditional noise variances obtained experimentally are given in table 3. Due to the increased resolution, the variances are approximately twice the values of those obtained in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). The JPDF, conditional diffusion magnitudes and conditional dissipation rates were calculated using kernel density estimation (KDE) (Wand & Jones Reference Wand and Jones1995) in two dimensions with a resolution of 400 by 400 in the scalar sample space with an oversmooth parameter of 1.3. The statistical uncertainties and bias for the JPDF were estimated using the bootstrap method (Hall Reference Hall1990), while the uncertainties for the conditional dissipation rates were estimated using the method given by Ruppert (Reference Ruppert1997). The magnitudes of the statistical uncertainties are similar to those in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011).

3 Results

In this section analyses of the scalar means, r.m.s. fluctuations, fluctuation intensities, correlation coefficient, segregation parameter, JPDF, mean and conditional dissipation rates and conditional scalar diffusion computed from the two-dimensional images are presented. In the present study, the velocity field is not measured. Nevertheless, its qualitative effects can be inferred.

Figure 3. Evolution of the mean scalars on the jet centreline.

3.1 Effects on the evolution on the jet centreline

The scalar mean profiles on the jet centreline are shown in figure 3. For

![]() $x/d<6$

(for convenience we use

$x/d<6$

(for convenience we use

![]() $d$

to denote the inner diameter of the inner tube

$d$

to denote the inner diameter of the inner tube

![]() $D_{ji}$

in table 1), the profiles for both

$D_{ji}$

in table 1), the profiles for both

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

and

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

and

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

overlap for cases I and II and for cases III and IV and the sum of

$\langle \unicode[STIX]{x1D719}_{2}\rangle$

overlap for cases I and II and for cases III and IV and the sum of

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

and

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

and

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

is close to unity. Further downstream,

$\langle \unicode[STIX]{x1D719}_{2}\rangle$

is close to unity. Further downstream,

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

decreases monotonically while

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

decreases monotonically while

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

increases and reach a maximum before decreasing further downstream. Case I (III) has smaller

$\langle \unicode[STIX]{x1D719}_{2}\rangle$

increases and reach a maximum before decreasing further downstream. Case I (III) has smaller

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

values but larger

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

values but larger

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

values than case II (IV). While the cross-stream turbulent scalar fluxes are larger for case I (III) (see the discussions on the JPDF for more details), the different trends for

$\langle \unicode[STIX]{x1D719}_{2}\rangle$

values than case II (IV). While the cross-stream turbulent scalar fluxes are larger for case I (III) (see the discussions on the JPDF for more details), the different trends for

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

and

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

and

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

are because their total streamwise flux across a cross-stream plane is conserved (Tennekes & Lumley Reference Tennekes and Lumley1972). The mean velocity cross-stream profile near the jet exit is wider (inferred from the jet exit conditions) for cases I (III), resulting in a slower decay of the centreline mean velocity. As a result,

$\langle \unicode[STIX]{x1D719}_{2}\rangle$

are because their total streamwise flux across a cross-stream plane is conserved (Tennekes & Lumley Reference Tennekes and Lumley1972). The mean velocity cross-stream profile near the jet exit is wider (inferred from the jet exit conditions) for cases I (III), resulting in a slower decay of the centreline mean velocity. As a result,

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

decreases faster than cases II (IV) in order to maintain a constant total streamwise mean flux. At a more detailed level, the slower decay of the mean velocity results in smaller mean-flow advection and therefore lower

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

decreases faster than cases II (IV) in order to maintain a constant total streamwise mean flux. At a more detailed level, the slower decay of the mean velocity results in smaller mean-flow advection and therefore lower

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

values. The higher

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

values. The higher

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

values for cases I (III) are due to larger mean-flow advection, which results from the faster decay of the mean velocity there. We will discuss this issue further along with the cross-stream profiles.

$\langle \unicode[STIX]{x1D719}_{2}\rangle$

values for cases I (III) are due to larger mean-flow advection, which results from the faster decay of the mean velocity there. We will discuss this issue further along with the cross-stream profiles.

To examine the effects of the annulus width (the

![]() $\unicode[STIX]{x1D719}_{2}$

length scale), we compare profiles for cases I and III and for cases II and IV. The

$\unicode[STIX]{x1D719}_{2}$

length scale), we compare profiles for cases I and III and for cases II and IV. The

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

values are larger for case III than for case I (figure 3

a), because the shear layer between the annular flow and the co-flow is farther from the centreline, resulting in smaller cross-stream turbulent convection. In addition, the mean advection is also smaller for case III. The

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

values are larger for case III than for case I (figure 3

a), because the shear layer between the annular flow and the co-flow is farther from the centreline, resulting in smaller cross-stream turbulent convection. In addition, the mean advection is also smaller for case III. The

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

values are essentially the same for cases I and III for

$\langle \unicode[STIX]{x1D719}_{2}\rangle$

values are essentially the same for cases I and III for

![]() $x/d<12$

(figure 3

b), a result of the competition between the opposite effects of the smaller turbulent convection for case III and the wider

$x/d<12$

(figure 3

b), a result of the competition between the opposite effects of the smaller turbulent convection for case III and the wider

![]() $\unicode[STIX]{x1D719}_{2}$

stream, which tends to result in more

$\unicode[STIX]{x1D719}_{2}$

stream, which tends to result in more

![]() $\unicode[STIX]{x1D719}_{2}$

reaching the centreline. Further downstream (

$\unicode[STIX]{x1D719}_{2}$

reaching the centreline. Further downstream (

![]() $x/d=24$

), the

$x/d=24$

), the

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

values are very close for case I and case III, and also for case II and case IV. However, the

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

values are very close for case I and case III, and also for case II and case IV. However, the

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

values for the larger annulus are higher, because the total

$\langle \unicode[STIX]{x1D719}_{2}\rangle$

values for the larger annulus are higher, because the total

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

flux is larger. There is also more

$\langle \unicode[STIX]{x1D719}_{2}\rangle$

flux is larger. There is also more

![]() $\unicode[STIX]{x1D719}_{3}$

(smaller

$\unicode[STIX]{x1D719}_{3}$

(smaller

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle +\langle \unicode[STIX]{x1D719}_{2}\rangle$

) on the centreline for case III than for case IV, which is similar to

$\langle \unicode[STIX]{x1D719}_{1}\rangle +\langle \unicode[STIX]{x1D719}_{2}\rangle$

) on the centreline for case III than for case IV, which is similar to

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

, due to the smaller mean-flow advection.

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

, due to the smaller mean-flow advection.

Figure 4. Evolution of the r.m.s. fluctuations on the jet centreline.

The scalar r.m.s. profiles for both

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

(

$\unicode[STIX]{x1D719}_{2}$

(

![]() $\unicode[STIX]{x1D70E}_{1}$

and

$\unicode[STIX]{x1D70E}_{1}$

and

![]() $\unicode[STIX]{x1D70E}_{2}$

respectively) are shown in figure 4. The maximum values of both

$\unicode[STIX]{x1D70E}_{2}$

respectively) are shown in figure 4. The maximum values of both

![]() $\unicode[STIX]{x1D70E}_{1}$

and

$\unicode[STIX]{x1D70E}_{1}$

and

![]() $\unicode[STIX]{x1D70E}_{2}$

are larger for case I (III) than for case II (IV), a result of the larger production rates for case I (III), in which the cross-stream scalar mean gradients are larger for both scalars (see figure 9 in § 3.2). At

$\unicode[STIX]{x1D70E}_{2}$

are larger for case I (III) than for case II (IV), a result of the larger production rates for case I (III), in which the cross-stream scalar mean gradients are larger for both scalars (see figure 9 in § 3.2). At

![]() $x/d=21$

,

$x/d=21$

,

![]() $\unicode[STIX]{x1D70E}_{1}$

is slightly smaller while

$\unicode[STIX]{x1D70E}_{1}$

is slightly smaller while

![]() $\unicode[STIX]{x1D70E}_{2}$

is slightly larger for case I than case II. This trend is also consistent with the relative magnitudes of the scalar mean profiles (and gradients). At this downstream location

$\unicode[STIX]{x1D70E}_{2}$

is slightly larger for case I than case II. This trend is also consistent with the relative magnitudes of the scalar mean profiles (and gradients). At this downstream location

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

are already very well mixed; therefore, the relative magnitudes of the r.m.s. fluctuations should be consistent with those of the relative values of the mean scalars.

$\unicode[STIX]{x1D719}_{2}$

are already very well mixed; therefore, the relative magnitudes of the r.m.s. fluctuations should be consistent with those of the relative values of the mean scalars.

The

![]() $\unicode[STIX]{x1D70E}_{2}$

profiles appear to have minimum values between

$\unicode[STIX]{x1D70E}_{2}$

profiles appear to have minimum values between

![]() $x/d=15$

and 18, after which the values increase slightly, due to the inward shifting of the two off-centreline peaks of the cross-stream

$x/d=15$

and 18, after which the values increase slightly, due to the inward shifting of the two off-centreline peaks of the cross-stream

![]() $\unicode[STIX]{x1D719}_{2}$

r.m.s. profiles (see figure 10 in § 3.2). We will further discuss these results along with cross-stream r.m.s. profiles.

$\unicode[STIX]{x1D719}_{2}$

r.m.s. profiles (see figure 10 in § 3.2). We will further discuss these results along with cross-stream r.m.s. profiles.

Comparisons between the annuli show that an increased annulus width generally pushes the locations of the peak r.m.s. values further downstream. The maximum values for both

![]() $\unicode[STIX]{x1D70E}_{1}$

and

$\unicode[STIX]{x1D70E}_{1}$

and

![]() $\unicode[STIX]{x1D70E}_{2}$

are generally larger for the larger annulus cases, except that the peak value of

$\unicode[STIX]{x1D70E}_{2}$

are generally larger for the larger annulus cases, except that the peak value of

![]() $\unicode[STIX]{x1D70E}_{1}$

is slightly smaller for case IV compared to case II. Although the larger annulus width delays the growth of the fluctuations, it also allows the large eddies to grow further, generating larger fluctuations. The increased annulus length scale also reduces the decay rate of the scalar fluctuations beyond the peak locations, a trend similar to that of Sirivat & Warhaft (Reference Sirivat and Warhaft1982).

$\unicode[STIX]{x1D70E}_{1}$

is slightly smaller for case IV compared to case II. Although the larger annulus width delays the growth of the fluctuations, it also allows the large eddies to grow further, generating larger fluctuations. The increased annulus length scale also reduces the decay rate of the scalar fluctuations beyond the peak locations, a trend similar to that of Sirivat & Warhaft (Reference Sirivat and Warhaft1982).

Figure 5. Evolution of the scalar fluctuation intensities on the jet centreline.

The

![]() $\unicode[STIX]{x1D719}_{1}$

fluctuation intensity (figure 5),

$\unicode[STIX]{x1D719}_{1}$

fluctuation intensity (figure 5),

![]() $\unicode[STIX]{x1D70E}_{1}/\langle \unicode[STIX]{x1D719}_{1}\rangle$

, reaches a peak before decreasing toward an asymptotic value for cases I and III, whereas it appears to increase monotonically toward the asymptotic value for cases II and IV. The asymptotic values for all cases should be the same. The faster approach to the asymptotic value for cases II and IV suggests faster

$\unicode[STIX]{x1D70E}_{1}/\langle \unicode[STIX]{x1D719}_{1}\rangle$

, reaches a peak before decreasing toward an asymptotic value for cases I and III, whereas it appears to increase monotonically toward the asymptotic value for cases II and IV. The asymptotic values for all cases should be the same. The faster approach to the asymptotic value for cases II and IV suggests faster

![]() $\unicode[STIX]{x1D719}_{1}$

mixing, due to the presence of mean shear between the centre stream and the annular stream. The

$\unicode[STIX]{x1D719}_{1}$

mixing, due to the presence of mean shear between the centre stream and the annular stream. The

![]() $\unicode[STIX]{x1D719}_{2}$

fluctuation intensity,

$\unicode[STIX]{x1D719}_{2}$

fluctuation intensity,

![]() $\unicode[STIX]{x1D70E}_{2}/\langle \unicode[STIX]{x1D719}_{2}\rangle$

, decreases rapidly for

$\unicode[STIX]{x1D70E}_{2}/\langle \unicode[STIX]{x1D719}_{2}\rangle$

, decreases rapidly for

![]() $x/d<14$

, after which it appears to increase slightly, due to the mild increase of

$x/d<14$

, after which it appears to increase slightly, due to the mild increase of

![]() $\unicode[STIX]{x1D70E}_{2}$

on the centreline. Comparisons between profiles of the two annulus widths show that the fluctuation intensities approach the asymptotic values further downstream with increased annulus width. The peak value of the

$\unicode[STIX]{x1D70E}_{2}$

on the centreline. Comparisons between profiles of the two annulus widths show that the fluctuation intensities approach the asymptotic values further downstream with increased annulus width. The peak value of the

![]() $\unicode[STIX]{x1D719}_{1}$

fluctuation intensity for case III is also larger than for case I.

$\unicode[STIX]{x1D719}_{1}$

fluctuation intensity for case III is also larger than for case I.

Figure 6. Evolution of the correlation coefficient and segregation parameter between

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

on the jet centreline.

$\unicode[STIX]{x1D719}_{2}$

on the jet centreline.

Different from the scalar mean and r.m.s., which characterize individual scalar fields, the correlation coefficient between

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

fluctuations,

$\unicode[STIX]{x1D719}_{2}$

fluctuations,

![]() $\unicode[STIX]{x1D70C}=\langle \unicode[STIX]{x1D719}_{1}^{\prime }\unicode[STIX]{x1D719}_{2}^{\prime }\rangle /\unicode[STIX]{x1D70E}_{1}\unicode[STIX]{x1D70E}_{2}$

, is a measure of the extent of (molecular) mixing between the scalars. A positive correlation requires mixing between

$\unicode[STIX]{x1D70C}=\langle \unicode[STIX]{x1D719}_{1}^{\prime }\unicode[STIX]{x1D719}_{2}^{\prime }\rangle /\unicode[STIX]{x1D70E}_{1}\unicode[STIX]{x1D70E}_{2}$

, is a measure of the extent of (molecular) mixing between the scalars. A positive correlation requires mixing between

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

as well as entrainment of the co-flow air. The correlation coefficient (figure 6

a) should equal negative one close to the jet exit since there is no co-flow air there. It begins to increase downstream and reaches the maximum value earlier for case II than case I, indicating that the mean shear between the centre jet and the annular flow enhances mixing. The correlation coefficient for the larger annulus cases (figure 6

a) is still increasing at the furthest downstream measurement location. It appears that it would reach the value of unity earlier for case IV than case III, again indicating faster mixing. The correlation for the small annulus begins to increase and reaches the maximum value earlier than for the larger annulus, because both the entrainment and small-scale mixing are faster with the smaller annulus width (see the results on the evolution of the JPDF evolution for discussions).

$\unicode[STIX]{x1D719}_{2}$

as well as entrainment of the co-flow air. The correlation coefficient (figure 6

a) should equal negative one close to the jet exit since there is no co-flow air there. It begins to increase downstream and reaches the maximum value earlier for case II than case I, indicating that the mean shear between the centre jet and the annular flow enhances mixing. The correlation coefficient for the larger annulus cases (figure 6

a) is still increasing at the furthest downstream measurement location. It appears that it would reach the value of unity earlier for case IV than case III, again indicating faster mixing. The correlation for the small annulus begins to increase and reaches the maximum value earlier than for the larger annulus, because both the entrainment and small-scale mixing are faster with the smaller annulus width (see the results on the evolution of the JPDF evolution for discussions).

The segregation parameter,

![]() $\unicode[STIX]{x1D6FC}=\langle \unicode[STIX]{x1D719}_{1}^{\prime }\unicode[STIX]{x1D719}_{2}^{\prime }\rangle /\langle \unicode[STIX]{x1D719}_{1}\rangle \langle \unicode[STIX]{x1D719}_{2}\rangle$

, is also a measure of the extent of mixing between the scalars. Its evolution on the jet centreline is non-monotonic (figure 6

b). It is (and should be) close to zero near the jet exit (Cai et al.

Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). It then becomes negative before increasing to positive values for the smaller annulus cases. At the farthermost downstream measurement location it appears to be still in the process of approaching an asymptotic value far downstream for all cases. The smaller annulus profiles evolve faster than the larger annulus, and case II evolves faster than for case I. However,

$\unicode[STIX]{x1D6FC}=\langle \unicode[STIX]{x1D719}_{1}^{\prime }\unicode[STIX]{x1D719}_{2}^{\prime }\rangle /\langle \unicode[STIX]{x1D719}_{1}\rangle \langle \unicode[STIX]{x1D719}_{2}\rangle$

, is also a measure of the extent of mixing between the scalars. Its evolution on the jet centreline is non-monotonic (figure 6

b). It is (and should be) close to zero near the jet exit (Cai et al.

Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). It then becomes negative before increasing to positive values for the smaller annulus cases. At the farthermost downstream measurement location it appears to be still in the process of approaching an asymptotic value far downstream for all cases. The smaller annulus profiles evolve faster than the larger annulus, and case II evolves faster than for case I. However,

![]() $\unicode[STIX]{x1D6FC}$

for case III evolves faster than for case IV with two minimum values, indicating that the evolution of case III is different from the other cases.

$\unicode[STIX]{x1D6FC}$

for case III evolves faster than for case IV with two minimum values, indicating that the evolution of case III is different from the other cases.

Figure 7. Evolution of the scalar JPDF on the jet centreline for the smaller annulus. Case I: (a,c,e,g), case II: (b,d,f,h). The downstream locations are listed in the top of each figure. The last three contours correspond to boundaries within which the JPDF integrates to 90 %, 95 % and 99 %, respectively throughout the paper. The rest of the contours scale linearly over the remaining range.

The evolution of the scalar JPDF of

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

on the jet centreline is shown in figures 7 and 8. For scalars with equal diffusivities, the JPDF in the

$\unicode[STIX]{x1D719}_{2}$

on the jet centreline is shown in figures 7 and 8. For scalars with equal diffusivities, the JPDF in the

![]() $\unicode[STIX]{x1D719}_{1}$

–

$\unicode[STIX]{x1D719}_{1}$

–

![]() $\unicode[STIX]{x1D719}_{2}$

space should be confined to a triangle with the vertices at

$\unicode[STIX]{x1D719}_{2}$

space should be confined to a triangle with the vertices at

![]() $(1,0)$

,

$(1,0)$

,

![]() $(0,1)$

and

$(0,1)$

and

![]() $(0,0)$

, which represent the inflow conditions (pure

$(0,0)$

, which represent the inflow conditions (pure

![]() $\unicode[STIX]{x1D719}_{1}$

,

$\unicode[STIX]{x1D719}_{1}$

,

![]() $\unicode[STIX]{x1D719}_{2}$

and

$\unicode[STIX]{x1D719}_{2}$

and

![]() $\unicode[STIX]{x1D719}_{3}$

), respectively. In the present study, acetone in the centre jet has a slightly lower diffusivity; therefore, it may possible for the scalar values to be slightly outside of the triangle. The straight line connecting

$\unicode[STIX]{x1D719}_{3}$

), respectively. In the present study, acetone in the centre jet has a slightly lower diffusivity; therefore, it may possible for the scalar values to be slightly outside of the triangle. The straight line connecting

![]() $(1,0)$

and

$(1,0)$

and

![]() $(0,1)$

represents the

$(0,1)$

represents the

![]() $\unicode[STIX]{x1D719}_{1}$

–

$\unicode[STIX]{x1D719}_{1}$

–

![]() $\unicode[STIX]{x1D719}_{2}$

mixing line. The general evolution for case I has been discussed in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). Here we focus on the differences among the cases.

$\unicode[STIX]{x1D719}_{2}$

mixing line. The general evolution for case I has been discussed in Cai et al. (Reference Cai, Dinger, Li, Carter, Ryan and Tong2011). Here we focus on the differences among the cases.

Near the nozzle exit, cases I and II are very similar. The difference begins to emerge near

![]() $x/d=4$

(not shown). At

$x/d=4$

(not shown). At

![]() $x/d=7.5$

, the JPDF area is significantly larger and extends further away from

$x/d=7.5$

, the JPDF area is significantly larger and extends further away from

![]() $(1,0)$

for case I than for case II, indicating stronger large-scale transport of the JPDF in physical space by the conditional velocity for case I. Note that transport of the JPDF can result in both production and transport of the scalar variances. The movement of the peak of JPDF towards smaller

$(1,0)$

for case I than for case II, indicating stronger large-scale transport of the JPDF in physical space by the conditional velocity for case I. Note that transport of the JPDF can result in both production and transport of the scalar variances. The movement of the peak of JPDF towards smaller

![]() $\unicode[STIX]{x1D719}_{1}$

values is faster for case I, consistent with the evolution of the scalar mean, which is primarily due to the smaller mean-flow advection of the JPDF. At

$\unicode[STIX]{x1D719}_{1}$

values is faster for case I, consistent with the evolution of the scalar mean, which is primarily due to the smaller mean-flow advection of the JPDF. At

![]() $x/d=10.9$

, the ridgeline of the JPDF is almost horizontal for case II, while it still has a negative slope for case I, indicating a negative correlation between

$x/d=10.9$

, the ridgeline of the JPDF is almost horizontal for case II, while it still has a negative slope for case I, indicating a negative correlation between

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

. The shapes of the JPDFs are also quite different for the two cases. There are larger fluctuations of

$\unicode[STIX]{x1D719}_{2}$

. The shapes of the JPDFs are also quite different for the two cases. There are larger fluctuations of

![]() $\unicode[STIX]{x1D719}_{2}$

and

$\unicode[STIX]{x1D719}_{2}$

and

![]() $\unicode[STIX]{x1D719}_{3}$

toward the left end of the JPDF for case I. Here the single but stronger shear layer between the

$\unicode[STIX]{x1D719}_{3}$

toward the left end of the JPDF for case I. Here the single but stronger shear layer between the

![]() $\unicode[STIX]{x1D719}_{2}$

–

$\unicode[STIX]{x1D719}_{2}$

–

![]() $\unicode[STIX]{x1D719}_{3}$

streams generates energy-containing eddies with larger length scales and fluctuations, resulting in stronger large-scale transport. The JPDF for case II is narrower in the

$\unicode[STIX]{x1D719}_{3}$

streams generates energy-containing eddies with larger length scales and fluctuations, resulting in stronger large-scale transport. The JPDF for case II is narrower in the

![]() $\unicode[STIX]{x1D719}_{2}$

direction than for case I, indicating better mixing of

$\unicode[STIX]{x1D719}_{2}$

direction than for case I, indicating better mixing of

![]() $\unicode[STIX]{x1D719}_{2}$

with

$\unicode[STIX]{x1D719}_{2}$

with

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{3}$

, due to the shear layers on both sides of the annular flow generating eddies with smaller length scales. Further downstream, the ridgeline of the JPDF begins to have a positive slope, indicating positive correlation. At

$\unicode[STIX]{x1D719}_{3}$

, due to the shear layers on both sides of the annular flow generating eddies with smaller length scales. Further downstream, the ridgeline of the JPDF begins to have a positive slope, indicating positive correlation. At

![]() $x/d=23.6$

,

$x/d=23.6$

,

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

are well correlated. The JPDF for case II is closer to the eventual near-Gaussian shape; therefore, although the initial evolution of the JPDF for case I is faster, the small-scale mixing is actually slower.

$\unicode[STIX]{x1D719}_{2}$

are well correlated. The JPDF for case II is closer to the eventual near-Gaussian shape; therefore, although the initial evolution of the JPDF for case I is faster, the small-scale mixing is actually slower.

Figure 8. Evolution of the scalar JPDF on the jet centreline for the larger annulus. Case III: (a,c,e,g), case IV: (b,d,f,h).

For the larger annulus the JPDF extends much further along the

![]() $\unicode[STIX]{x1D719}_{1}$

–

$\unicode[STIX]{x1D719}_{1}$

–

![]() $\unicode[STIX]{x1D719}_{2}$

mixing line before bending toward

$\unicode[STIX]{x1D719}_{2}$

mixing line before bending toward

![]() $(0,0)$

(figure 8), because the larger annulus width tends to keep the co-flow air from reaching the centreline. A major difference between cases III and IV is that at

$(0,0)$

(figure 8), because the larger annulus width tends to keep the co-flow air from reaching the centreline. A major difference between cases III and IV is that at

![]() $x/d=14.6$

, near the peak location for

$x/d=14.6$

, near the peak location for

![]() $\unicode[STIX]{x1D70E}_{1}/\langle \unicode[STIX]{x1D719}_{1}\rangle$

, the JPDF for case III is bimodal. The peaks represent a mostly

$\unicode[STIX]{x1D70E}_{1}/\langle \unicode[STIX]{x1D719}_{1}\rangle$

, the JPDF for case III is bimodal. The peaks represent a mostly

![]() $\unicode[STIX]{x1D719}_{1}$

–

$\unicode[STIX]{x1D719}_{1}$

–

![]() $\unicode[STIX]{x1D719}_{2}$

mixture and a mostly

$\unicode[STIX]{x1D719}_{2}$

mixture and a mostly

![]() $\unicode[STIX]{x1D719}_{2}$

–

$\unicode[STIX]{x1D719}_{2}$

–

![]() $\unicode[STIX]{x1D719}_{3}$

mixture respectively. The two mixtures are less mixed compared to case I due to the large annulus width, and are transported by the strong large-scale velocity fluctuations (flapping) generated by the larger mean shear between the

$\unicode[STIX]{x1D719}_{3}$

mixture respectively. The two mixtures are less mixed compared to case I due to the large annulus width, and are transported by the strong large-scale velocity fluctuations (flapping) generated by the larger mean shear between the

![]() $\unicode[STIX]{x1D719}_{2}$

–

$\unicode[STIX]{x1D719}_{2}$

–

![]() $\unicode[STIX]{x1D719}_{3}$

streams, resulting in the bimodal JPDF. Thus, the effects of the velocity ratio of the JPDF is more pronounced for the larger annulus. For case IV at this location, the JPDF is unimodal. Here,

$\unicode[STIX]{x1D719}_{3}$

streams, resulting in the bimodal JPDF. Thus, the effects of the velocity ratio of the JPDF is more pronounced for the larger annulus. For case IV at this location, the JPDF is unimodal. Here,

![]() $\unicode[STIX]{x1D719}_{1}$

is better mixed with

$\unicode[STIX]{x1D719}_{1}$

is better mixed with

![]() $\unicode[STIX]{x1D719}_{2}$

than for case III, similar to the differences between cases II and I. At

$\unicode[STIX]{x1D719}_{2}$

than for case III, similar to the differences between cases II and I. At

![]() $x/d=16.4$

, the JPDF becomes unimodal for case III. Moving further downstream, the JPDF has a positive slope.

$x/d=16.4$

, the JPDF becomes unimodal for case III. Moving further downstream, the JPDF has a positive slope.

We note that while figure 6 shows that the values of the correlation coefficient between

![]() $\unicode[STIX]{x1D719}_{1}$

and

$\unicode[STIX]{x1D719}_{1}$

and

![]() $\unicode[STIX]{x1D719}_{2}$

are nearly equal for cases III and IV at

$\unicode[STIX]{x1D719}_{2}$

are nearly equal for cases III and IV at

![]() $x/d=14.6$

, the JPDF shows that the states of mixing have some qualitative differences for these cases, an indication of the limitation of the correlation coefficient in representing the state of mixing, especially when it is small or negative.

$x/d=14.6$

, the JPDF shows that the states of mixing have some qualitative differences for these cases, an indication of the limitation of the correlation coefficient in representing the state of mixing, especially when it is small or negative.

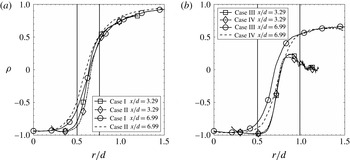

Figure 9. Cross-stream scalar mean profiles. The downstream locations are given in the legend. The locations of the inner walls of the centre jet tube and the annulus tube are each indicated by a vertical line here and hereafter.

Figure 10. Cross-stream scalar r.m.s. profiles. The downstream locations are given in the legend.

3.2 Effects on the cross-stream profiles

The cross-stream scalar mean profiles for the smaller annulus are shown in figure 9(a,b). The

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

profiles are narrower and the

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

profiles are narrower and the

![]() $\langle \unicode[STIX]{x1D719}_{1}\rangle$

values are generally smaller for case I than for case II, again due to the smaller mean-flow advection, as discussed in § 3.1. The maximum slopes of the profiles, however, are larger for case I. The cross-stream

$\langle \unicode[STIX]{x1D719}_{1}\rangle$

values are generally smaller for case I than for case II, again due to the smaller mean-flow advection, as discussed in § 3.1. The maximum slopes of the profiles, however, are larger for case I. The cross-stream

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

profiles have off-centreline peaks, at approximately the same locations for both cases at the upstream location (

$\langle \unicode[STIX]{x1D719}_{2}\rangle$

profiles have off-centreline peaks, at approximately the same locations for both cases at the upstream location (

![]() $x/d=3.29$

). The

$x/d=3.29$

). The

![]() $\langle \unicode[STIX]{x1D719}_{2}\rangle$

values are larger for case I than for case II at all radial locations. These trends are because of the faster decay of the mean velocity of the annulus stream for case I, which leads to larger mean advection, although the turbulent convection is also larger, partially countering the mean advection. Figure 9(b) also shows that the mean gradient of

$\langle \unicode[STIX]{x1D719}_{2}\rangle$