1 Introduction

The encapsulation of liquid droplets by an elastic membrane is an effective means of isolating active substances such as aromas, flavours, drugs or even DNA in gene therapy, so that they can be released in a controlled manner through the membrane (Rabanel et al. Reference Rabanel, Banquy, Zouaoui, Mokhtar and Hildgen2009; Barthès-Biesel Reference Barthès-Biesel2016). Applications encompass food, cleaning, cosmetic and pharmaceutical products (Cole, Cad & Benameur Reference Cole, Cad and Benameur2008). For example, targeted drug delivery relies on the release of a capsule’s content at a specific destination, requiring capsules suspended in liquid to travel through complex, branched vessel geometries (Abkarian et al. Reference Abkarian, Faivre, Horton, Smistrup, Best-Popescu and Stone2008). Biological cells are examples of naturally occurring capsules. Haemodynamics in the capillary network (Popel & Johnson Reference Popel and Johnson2005; Balogh & Bagchi Reference Balogh and Bagchi2018) and porous media such as the placenta (Jensen & Chernyavsky Reference Jensen and Chernyavsky2019) involve the transport and deformation of discrete red blood cells, with diagnostic and treatment of micro-circulation conditions relying on advances in the understanding of the resulting rheology. There is also considerable diagnostic potential in isolating circulating cancer cells, which are typically of similar size but more deformable than healthy white blood cells (Geislinger & Franke Reference Geislinger and Franke2013; Lim & Hoon Reference Lim and Hoon2014), or malaria-infected red blood cells, which stiffen by a factor of five due to the parasite that enters them (Bow et al. Reference Bow, Pivkin, Diez-Silva, Goldfless, Dao, Niles, Suresh and Han2011). The transport of a capsule through a vessel bifurcation is a fundamental feature of all these applications. In this type of geometry, the extensional nature of the flow promotes large deformations of the capsule (De Loubens et al. Reference De Loubens, Deschamps, Boedec and Leonetti2015), thus offering prospects for quantifying capsule deformability. Moreover, fluid–structure interaction influences capsule trajectories in the vessel bifurcation so that these complex geometries may be exploited to separate capsules according to their stiffness.

The flow-based transport of capsules in confined geometries has been extensively characterised in straight channels and capillaries both experimentally and numerically (e.g. Pozrikidis Reference Pozrikidis2005; Kuriakose & Dimitrakopoulos Reference Kuriakose and Dimitrakopoulos2013; Barthès-Biesel Reference Barthès-Biesel2016). Most studies have focused on the limit of negligible inertia where capsule deformation results from the balance between viscous shear forces and elastic restoring forces, quantified by the capillary number ![]() $Ca$. In confined channels, spherical capsules elongate along the direction of flow for high values of

$Ca$. In confined channels, spherical capsules elongate along the direction of flow for high values of ![]() $Ca$ and their rear buckles inwards to form a characteristic parachute shape (Risso, Collé-Paillot & Zagzoule Reference Risso, Collé-Paillot and Zagzoule2006; Hu, Salsac & Barthès-Biesel Reference Hu, Salsac and Barthès-Biesel2012). Ellipsoidal capsules may exhibit motions such as tank treading (Walter, Salsac & Barthès-Biesel Reference Walter, Salsac and Barthès-Biesel2011; De Loubens et al. Reference De Loubens, Deschamps, Edwards-Levy and Leonetti2016). If a deformable particle is set into motion from an off-centred position in the channel, it will tend to migrate towards the centre of the channel cross-section because of the interplay between particle deformation and the shear profile (Villone & Maffettone Reference Villone and Maffettone2019). A wall-lift force can be generated due to an upstream–downstream flow asymmetry resulting from the wall-induced deformation of the particle, but migration also arises in unbounded Poiseuille flow as demonstrated for capsules by Doddi & Bagchi (Reference Doddi and Bagchi2008) and for vesicles (droplets encapsulated by an inextensible lipid bilayer membrane) by Coupier et al. (Reference Coupier, Kaoui, Podgorski and Misbah2008) and Kaoui et al. (Reference Kaoui, Ristow, Cantat, Misbah and Zimmermann2008). Flow in straight tubes or square channels is routinely employed to determine the shear modulus of thin-walled capsules through comparison of their deformation with numerical models (Lefebvre et al. Reference Lefebvre, Leclerc, Barthès-Biesel, Walter and Edwards-Lévy2008; Chu et al. Reference Chu, Salsac, Leclerc, Barthès-Biesel, Huynh, Denoeux, Tran, Le and Pham2013; Hu et al. Reference Hu, Sévénié, Salsac, Leclerc and Barthès-Biesel2013). Extensional flows that feature a stagnation point have also been used to measure the constitutive behaviour of capsules by trapping and deforming them in device geometries such as four-roll-mills, cross-junctions and T-junctions (Lee et al. Reference Lee, Dylla-Spears, Teclemariam and Muller2007; De Loubens et al. Reference De Loubens, Deschamps, Georgelin, Charrier, Edwards-Lévy and Leonetti2014).

$Ca$ and their rear buckles inwards to form a characteristic parachute shape (Risso, Collé-Paillot & Zagzoule Reference Risso, Collé-Paillot and Zagzoule2006; Hu, Salsac & Barthès-Biesel Reference Hu, Salsac and Barthès-Biesel2012). Ellipsoidal capsules may exhibit motions such as tank treading (Walter, Salsac & Barthès-Biesel Reference Walter, Salsac and Barthès-Biesel2011; De Loubens et al. Reference De Loubens, Deschamps, Edwards-Levy and Leonetti2016). If a deformable particle is set into motion from an off-centred position in the channel, it will tend to migrate towards the centre of the channel cross-section because of the interplay between particle deformation and the shear profile (Villone & Maffettone Reference Villone and Maffettone2019). A wall-lift force can be generated due to an upstream–downstream flow asymmetry resulting from the wall-induced deformation of the particle, but migration also arises in unbounded Poiseuille flow as demonstrated for capsules by Doddi & Bagchi (Reference Doddi and Bagchi2008) and for vesicles (droplets encapsulated by an inextensible lipid bilayer membrane) by Coupier et al. (Reference Coupier, Kaoui, Podgorski and Misbah2008) and Kaoui et al. (Reference Kaoui, Ristow, Cantat, Misbah and Zimmermann2008). Flow in straight tubes or square channels is routinely employed to determine the shear modulus of thin-walled capsules through comparison of their deformation with numerical models (Lefebvre et al. Reference Lefebvre, Leclerc, Barthès-Biesel, Walter and Edwards-Lévy2008; Chu et al. Reference Chu, Salsac, Leclerc, Barthès-Biesel, Huynh, Denoeux, Tran, Le and Pham2013; Hu et al. Reference Hu, Sévénié, Salsac, Leclerc and Barthès-Biesel2013). Extensional flows that feature a stagnation point have also been used to measure the constitutive behaviour of capsules by trapping and deforming them in device geometries such as four-roll-mills, cross-junctions and T-junctions (Lee et al. Reference Lee, Dylla-Spears, Teclemariam and Muller2007; De Loubens et al. Reference De Loubens, Deschamps, Georgelin, Charrier, Edwards-Lévy and Leonetti2014).

A recent surge in computational effort has focused on characterising the flow of capsules through these more complex geometries, mostly three-dimensional. The capsule is typically modelled as a liquid droplet enclosed by a thin, hyperelastic membrane. Zhu & Brandt (Reference Zhu and Brandt2015) considered the flow past a right-angled corner, while Koolivand & Dimitrakopoulos (Reference Koolivand and Dimitrakopoulos2017) examined the deformation of a capsule trapped at the stagnation point of a T-junction, with both geometries offering new measurement methods of the elastic properties of the membrane based on large deformations of the capsule. Following the two-dimensional numerical model of Woolfenden & Blyth (Reference Woolfenden and Blyth2011), the motion of capsules through branched tubes has recently been addressed in three dimensions by Wang et al. (Reference Wang, Sui, Salsac, Barthès-Biesel and Wang2016, Reference Wang, Sui, Salsac, Barthès-Biesel and Wang2018), who focused on the path selection of the capsule in the presence of inertia with a view to designing an enrichment device. A similar geometry has also been considered by Villone et al. (Reference Villone, Trofa, Hulsen and Maffetone2017) to design a deformability-based sorting device using numerical modelling. Although experiments have been conducted on blood flow in branched capillaries, e.g. see Popel & Johnson (Reference Popel and Johnson2005) and Pries, Secomb & Gaehtgens (Reference Pries, Secomb and Gaehtgens1996), there is a distinct lack of controlled single-capsule experiments due to the challenge of reliably manufacturing objects of controlled shape, with elastic properties which can be characterised independently of the flow experiment.

In this paper, we focus on millimetric ovalbumin-alginate capsules and soft beads, and we explore their dynamics as they travel down a channel that splits into two identical daughter channels at a T-junction. We used millimetric capsules in order to achieve a high level of control over their geometry and that of the flow channels, as well as to enable the measurement of the elastic properties of the capsules independently of the flow experiment. As the capsules are neutrally buoyant we expect their dynamics to be representative of capsules and cells on the microscale. We find that for our capsules (which have wall thicknesses up to 26 % of the radius and variable pre-inflation), the stiffness is best quantified by the force required to deform the capsule e.g. by compressing it between parallel plates to 50 % of its initial diameter (Carin et al. Reference Carin, Barthès-Biesel, Edwards-Lévy, Postel and Andrei2003; Risso & Carin Reference Risso and Carin2004; Rachik et al. Reference Rachik, Barthès-Biesel, Carin and Edwards-Lévy2006). We show that the capsule dynamics in the flow depends solely on a capillary number based on this force, which captures the nonlinear elastic properties of the encapsulating membrane. We do not attempt to trap capsules at the stagnation point of the T-junction, and focus instead on their transport through the device. We find that their maximum extension in the T-junction offers a simple and sensitive measure of their relative stiffness. The T-junction is advantageous over straight conduits in that the presence of an extensional flow results in larger deformations of the capsules. In contrast to static compression or trapping in a four-mill device, a T-junction does not require careful time-consuming micro-manipulation so that multiple capsules can be characterised in rapid succession.

Techniques for the flow-based separation of cells and capsules according to stiffness are currently emerging, and are often based on methods employed for the size-based separation of rigid, spherical particles which have been extensively characterised (Sajeesh & Sen Reference Sajeesh and Sen2014). Amongst these, passive methods rely primarily on the device geometry and the hydrodynamic interactions between particles and the device, and include deterministic lateral displacement devices (DLD) consisting of arrays of pillars (Huang et al. Reference Huang, Cox, Austin and Sturm2004; Long et al. Reference Long, Heller, Beech, Linke, Bruus and Tegenfeldt2008), pinched flow fractionation (PFF) where a particle-laden flow is ‘pinched’ against a rigid boundary by a jet orthogonal to the main stream (Yamada, Nakashima & Seki Reference Yamada, Nakashima and Seki2004; Cupelli et al. Reference Cupelli, Borchardt, Steiner, Paust, Zengerle and Santer2013) and inertial separation techniques (Di Carlo Reference Di Carlo2009). Inertial separation techniques have also been applied to deformable particles (e.g. Hur et al. Reference Hur, Henderson-MacLennan, McCabec and Di Carlo2011), albeit with lower efficiency. In the limit of low inertia, Kabacaoǧlu & Biros (Reference Kabacaoǧlu and Biros2019) recently demonstrated separation according to stiffness of fixed-size vesicles in a DLD device with a two-dimensional numerical model. Zhu et al. (Reference Zhu, Rorai, Mitra and Brand2014) used three-dimensional boundary integral simulations to show distinct paths taken by capsules of different elasticity when circumventing a single pillar. Their results have been confirmed and extended by recent experimental studies (Häner Reference Häner2017; Vesperini et al. Reference Vesperini, Chaput, Munier, Maire, Edwards-Lévy, Salsac and Le Goff2017). To our knowledge, sorting according to stiffness in branched geometries is limited to the numerical studies by Wang et al. (Reference Wang, Sui, Salsac, Barthès-Biesel and Wang2016, Reference Wang, Sui, Salsac, Barthès-Biesel and Wang2018) and Villone et al. (Reference Villone, Trofa, Hulsen and Maffetone2017) cited above. In the current paper, we explore the sorting capabilities of the T-junction for capsules of fixed size. We find that at the same driving flow rate, capsules of different stiffness follow distinct paths out of the T-junction and that the position from which the capsule is entrained into the daughter channel depends solely on ![]() $Ca$. By adding a diffuser that enhances initial capsule separation, we demonstrate that a T-junction can be used to sort capsules according to stiffness. In contrast, we find that a PFF device fails to separate fixed-size capsules according to their stiffness.

$Ca$. By adding a diffuser that enhances initial capsule separation, we demonstrate that a T-junction can be used to sort capsules according to stiffness. In contrast, we find that a PFF device fails to separate fixed-size capsules according to their stiffness.

The paper is structured as follows. The manufacture of capsules, their characterisation and the flow devices are presented in § 2. In § 3, we characterise the transport of capsules through the T-junction as they travel from the parent channel into one of the two daughter channels. In § 4, we build on the findings in § 3 to design a T-junction sorting device to separate capsules according to their stiffness. Conclusions are given in § 5.

2 Experimental methods

2.1 Ovalbumin-alginate capsules

2.1.1 Manufacture

The capsules consisted of a liquid core encapsulated in a cross-linked ovalbumin-alginate membrane. They were manufactured using the method introduced by Lévy & Edwards-Lévy (Reference Lévy and Edwards-Lévy1996) (see the Appendix for details). In short, a solution in water of sodium-alginate, propylene glycol alginate (PGA) and ovalbumin was prepared, which was then added dropwise to a solution of calcium chloride in order to gel the drops into spherical beads. The beads were immersed in an alkaline solution (NaOH) to catalyse a transacylation reaction on the surface of the beads between the ester groups of the PGA and the unionised amino groups of the ovalbumin. This resulted in the creation of amide bonds and the formation of a semi-permeable cross-linked membrane encapsulating the beads of diameter ![]() $D_{bead}$. Following neutralisation of the alkaline solution, the gel core of the beads was dissolved by immersing them in a sodium citrate solution. The newly manufactured capsules were stored in a saline solution (11 g l-1 NaCl) and reached equilibrium after approximately 24 h. During this period, water permeated through their membrane, resulting in the inflation of the capsules to a size larger than the initial bead radius by up to 30 %, depending on membrane elasticity and initial size, implying the presence of a significant pre-stress in the capsule membrane. Solid beads were made in a similar manner to capsules, except that their core was not liquefied by exposure to sodium citrate.

$D_{bead}$. Following neutralisation of the alkaline solution, the gel core of the beads was dissolved by immersing them in a sodium citrate solution. The newly manufactured capsules were stored in a saline solution (11 g l-1 NaCl) and reached equilibrium after approximately 24 h. During this period, water permeated through their membrane, resulting in the inflation of the capsules to a size larger than the initial bead radius by up to 30 %, depending on membrane elasticity and initial size, implying the presence of a significant pre-stress in the capsule membrane. Solid beads were made in a similar manner to capsules, except that their core was not liquefied by exposure to sodium citrate.

Following the production of a batch of capsules, the capsules were first sorted by visual inspection and those without defects were coloured with a 10 g l-1 Rhodamine B solution (⩾95 %, Sigma-Aldrich). Compression tests (see § 2.1.2) before and after capsule dyeing showed that the dyeing had no measurable effect on capsule deformability. The capsule diameter ![]() $D$ and thus its inflation

$D$ and thus its inflation ![]() $D/D_{bead}$ and its sphericity (ratio of the minimum to maximum diameter

$D/D_{bead}$ and its sphericity (ratio of the minimum to maximum diameter ![]() $D_{min}/D_{max}$) were measured from top- and side-view images. The measurements of membrane thickness

$D_{min}/D_{max}$) were measured from top- and side-view images. The measurements of membrane thickness ![]() $h$ were performed using side-view images of the capsule (see figure 1a) prior to the experiments; these were found to match measurements conducted on images of frozen capsules cut in half. Capsules with the desired size and sphericity (>90 %) were selected for compression tests followed by flow experiments. The geometric properties of the capsules used in the present study are listed in table 1.

$h$ were performed using side-view images of the capsule (see figure 1a) prior to the experiments; these were found to match measurements conducted on images of frozen capsules cut in half. Capsules with the desired size and sphericity (>90 %) were selected for compression tests followed by flow experiments. The geometric properties of the capsules used in the present study are listed in table 1.

Figure 1. (a–d) Typical side-view images of a capsule immersed in a saline solution at four stages during the compression testing. (a) Before compression. (b) During compression. (c) Compression to 20 % of the capsule’s initial height. (d) One second after the top plate has been returned to its initial position (see a). Note that the capsule has regained its undeformed shape with a height of 99 % of its initial value. (e) An example of force versus compression data for capsule P4. The resistance to compression measured in the saline solution in the absence of a capsule (blue symbols) was subtracted from the force measurements in the presence of the capsule (red symbols) to yield the constitutive curve (orange symbols). The data shown are the average of three experiments. The inset shows a close up of the force versus compression in the vicinity of the first contact with the compression plate. The point of contact is determined from images of the compression. The value of compression corresponding to 50 % of the initial capsule diameter is indicated with a vertical dash-dotted line.

Table 1. Properties of the capsules and solid beads used in the experiments. The capsule diameter ![]() $D$, sphericity

$D$, sphericity ![]() $D_{min}/D_{max}$, membrane thickness

$D_{min}/D_{max}$, membrane thickness ![]() $h$ and inflation

$h$ and inflation ![]() $D/D_{bead}$, where

$D/D_{bead}$, where ![]() $D_{bead}$ is the diameter of the solid bead prior to liquefaction of its core, were measured from top and side-view images of the capsules. Capsules were compressed between parallel plates and the force required to compress them to 50 % of their initial height (

$D_{bead}$ is the diameter of the solid bead prior to liquefaction of its core, were measured from top and side-view images of the capsules. Capsules were compressed between parallel plates and the force required to compress them to 50 % of their initial height (![]() $F_{50\,\%}$) was measured.

$F_{50\,\%}$) was measured.

2.1.2 Capsule characterisation

The constitutive relation that governs capsule deformation was measured by compression testing between parallel plates for each capsule in table 1. Measurements were performed at most three days before conducting the flow experiments since the age of the capsule influences its mechanical properties significantly (Häner Reference Häner2017). An Instron 3345 Single Column Testing System (5 N load cell, accuracy ±0.5 mN) was used to measure the force exerted by a top plate lowered quasi-statically to compress a capsule placed on an anvil within a saline bath. Figure 1(a–d) shows images taken during a typical compression experiment. Initially, the capsule is undeformed (a). The top compression plate is lowered, increasingly compressing the capsule (b,c) and then retracted (d). For the capsules used in the experiments, the maximum compression was 50 % of its initial height but in the example shown in figure 1(c), the capsule is compressed by 80 %. Figure 1(d) shows that the capsule has returned to 99 % of its undeformed height following the return of the top plate to its initial position in (a), and thus demonstrates that these capsules can undergo large deformations elastically. The darker regions in the lower part of the capsule in figure 2(a–d) correspond to core-constituent leftovers. We did not detect any systematic effect of the inhomogeneity of the liquefied core on the dynamics and deformation of the capsules in flow, but suspect that it contributes to the small variations between successive experiments captured in the vertical error bars.

Figure 2. (a) Schematic side-view diagram of the experimental set-up; (b) T-junction flow device; (c) T-junction sorting device. In both devices, the depth of the channels is 3.98 mm.

Figure 1(e) shows an example of force versus compression data recorded for capsule P4 (orange symbols). The top plate was lowered at a rate of 0.01 mm s-1 so that the compression test took approximately 5 min. This rate was sufficiently slow for the deformation to be quasi-static while fast enough to avoid osmotic changes. Doubling and halving the compression rate did not affect the measurement, confirming the rate independence of the process. The first point of contact between capsule and top plate was determined with a precision of ±0.01 mm by interpolating between side-view images taken every 2 s. The resistance to compression measured in the saline solution in the absence of a capsule was subtracted from the force measurements to yield the constitutive curves (force versus upper plate displacement) of the capsules.

Systematic studies of the effect of the concentration of NaOH are described by Häner (Reference Häner2017) and Edwards-Lévy & Lévy (Reference Edwards-Lévy and Lévy1999), which indicate that pre-inflation decreases monotonically with increasing concentration while membrane thickness increases. For example, the larger membrane thickness of capsule TJ2 compared with TJ1 and TJ3 stems from a larger concentration of NaOH used in its manufacture. Although our manufactured capsules showed clear trends, we found that the fabrication process led to significant variability in the properties of the capsules within a single batch so that a few of our capsules bucked these trends. However, the manufacture-induced variability in capsule properties did not affect our flow experiments because we characterised each capsule with compression testing performed before studying their flow behaviour.

The large deformations routinely observed when capsules were propagated in a flow meant that a nonlinear constitutive law was necessary to characterise their deformation. In addition, the capsules feature not only differences in the elastic modulus of the encapsulating membrane, but also in pre-inflation and in the thickness of this membrane (with values up to 26 % of the capsule radius, so that a membrane model is not appropriate). The effects on capsule stiffness of wall thickness and pre-inflation are not captured by the surface shear modulus of the capsule membrane. This is why we chose the force required to deform a capsule to 50 % of its original diameter, ![]() $F_{50\,\%}$, as a direct experimental measurement of the capsule’s resistance to deformation (see table 1). This value of compression is indicated in figure 1(e) with a vertical dash-dotted line.

$F_{50\,\%}$, as a direct experimental measurement of the capsule’s resistance to deformation (see table 1). This value of compression is indicated in figure 1(e) with a vertical dash-dotted line.

2.2 Flow experiments

2.2.1 Experimental set-up

The experimental set-up used for the flow experiments is shown in figure 2(a). It consists of a flow channel levelled horizontally to within 0. 5° and back lit with a custom-made LED light box. Capsule propagation was recorded in top-view at frame rates between 1 and 250 frames per second, using a monochrome CMOS camera (PCO, 1200hs) and a 50 mm micro-lens (Nikon) mounted vertically above the experiment. The capsules were propagated in degassed silicone oil (polydimethylsiloxane, Dow Corning, 5000 cS) of viscosity ![]() $\unicode[STIX]{x1D707}=5.23\pm 0.04~\text{kg}~\text{m}^{-1}$

$\unicode[STIX]{x1D707}=5.23\pm 0.04~\text{kg}~\text{m}^{-1}$![]() $\text{s}^{-1}$ and density

$\text{s}^{-1}$ and density ![]() $\unicode[STIX]{x1D70C}=970\pm 10~\text{kg}~\text{m}^{-3}$ measured at the laboratory temperature of

$\unicode[STIX]{x1D70C}=970\pm 10~\text{kg}~\text{m}^{-3}$ measured at the laboratory temperature of ![]() $21^{\circ }\pm 0.5\,^{\circ }\text{C}$. The capsules were approximately neutrally buoyant, with a downward vertical drift velocity of less than 0.2 mm min-1 when freely suspended in a beaker of silicone oil. A constant flow rate was imposed by injecting silicone oil into the inlet of the flow device using a syringe pump (KDS410, KD Scientific) fitted with a 50 ml stainless steel syringe (WZ-74044-36, Cole-Parmer). A second syringe pump (KDS210a, KD scientific) with two 20 ml syringes (gastight series, Hamilton) was used in the sorting experiments where two fluid inlets were required. In all the flow experiments, the Reynolds number was

$21^{\circ }\pm 0.5\,^{\circ }\text{C}$. The capsules were approximately neutrally buoyant, with a downward vertical drift velocity of less than 0.2 mm min-1 when freely suspended in a beaker of silicone oil. A constant flow rate was imposed by injecting silicone oil into the inlet of the flow device using a syringe pump (KDS410, KD Scientific) fitted with a 50 ml stainless steel syringe (WZ-74044-36, Cole-Parmer). A second syringe pump (KDS210a, KD scientific) with two 20 ml syringes (gastight series, Hamilton) was used in the sorting experiments where two fluid inlets were required. In all the flow experiments, the Reynolds number was ![]() $Re=\unicode[STIX]{x1D70C}QW/(\unicode[STIX]{x1D707}A)<9\times 10^{-2}$, where

$Re=\unicode[STIX]{x1D70C}QW/(\unicode[STIX]{x1D707}A)<9\times 10^{-2}$, where ![]() $W$ is the width and

$W$ is the width and ![]() $A$ the cross-section of the main channel. The propagation of capsules in flow was characterised by an elastic capillary number measuring the ratio of viscous to elastic forces and defined as

$A$ the cross-section of the main channel. The propagation of capsules in flow was characterised by an elastic capillary number measuring the ratio of viscous to elastic forces and defined as

The main source of error on the capillary number is the ±0.5 mN uncertainty on the value on ![]() $F_{50\,\%}$.

$F_{50\,\%}$.

The flow channels (figure 2b,c) were machined out of cast acrylic sheets (Perspex, Gilbert Curry Industrial Plastics Co Ltd.), using a CNC milling machine. Each device consisted of two facing plates screwed together. Each plate was milled flat to within 25 μm prior to the milling of the channels. The top plate featured fluid inlets and reservoirs while the millimetric channels were milled into the bottom plate.

The T-junction flow device (figure 2b) consisted of a main channel bifurcating into two ‘daughter’ channels of equal cross-section and length, oriented at 90° to the main channel. The main channel leading to the T-junction had cross-sectional dimensions of ![]() $A=\text{width}\times \text{depth}=(7.81\times 3.98)\pm 0.02~\text{mm}^{2}$ and the cross-sectional dimensions of the daughter channels were

$A=\text{width}\times \text{depth}=(7.81\times 3.98)\pm 0.02~\text{mm}^{2}$ and the cross-sectional dimensions of the daughter channels were ![]() $A=(3.8\times 3.98)\pm 0.02~\text{mm}^{2}$. A local constriction of the main channel to 4 mm near the inlet enabled the centring of the capsule.

$A=(3.8\times 3.98)\pm 0.02~\text{mm}^{2}$. A local constriction of the main channel to 4 mm near the inlet enabled the centring of the capsule.

The T-junction sorting device (figure 2c) consisted of a main channel that branched into two daughter channels oriented at 90° with respect to the main channel. The main channel and the left daughter channel both had the same cross-sectional dimensions of ![]() $A=\text{width}\times \text{depth}=(3.8\times 3.98)\pm 0.02~\text{mm}^{2}$, whereas the right daughter channel had a 1 mm long section of cross-section of

$A=\text{width}\times \text{depth}=(3.8\times 3.98)\pm 0.02~\text{mm}^{2}$, whereas the right daughter channel had a 1 mm long section of cross-section of ![]() $A=(3.8\times 3.98)\pm 0.02~\text{mm}^{2}$ followed by a 70 mm long section of cross-section

$A=(3.8\times 3.98)\pm 0.02~\text{mm}^{2}$ followed by a 70 mm long section of cross-section ![]() $A=(39.8\times 3.98)\pm 0.02~\text{mm}^{2}$, which we refer to as the diffuser. We note that the width of the main channel was approximately equal to the diameter of the capsule and thus, a centring mechanism was not needed in this device.

$A=(39.8\times 3.98)\pm 0.02~\text{mm}^{2}$, which we refer to as the diffuser. We note that the width of the main channel was approximately equal to the diameter of the capsule and thus, a centring mechanism was not needed in this device.

2.2.2 Experimental procedure

Before inserting a capsule into the liquid-filled flow channel, any water on its outer surface was removed with a paper towel. The difference between the refractive indices of water and silicone oil makes water easily identifiable in the experimental images. If a water film initially coated the capsule, it could be isolated and removed from the experiment by pushing the capsule through the flow channel at a high flow rate. At the start of each experiment, a capsule was positioned at the inlet of the device. A constant flow was then imposed which propagated the capsules through the T-junction device. Up to 90 consecutive experiments were performed with each capsule, including multiple experiments at the same flow rate. Thus, unless otherwise specified, the measurements shown in § 3 are average values with error bars determined from the unbiased standard deviation of the dataset.

In the sorting device, the distance of the centroid of the particles from the centreline of the main channel was less than 1.6 % of the channel width because of the strong confinement of capsules in the channels leading to the T-junction. In contrast, in the flow device, capsules were aligned along the centreline of the main channel using a short stepwise constriction of the channel to a width of 4 mm near the inlet (see figure 2b). This resulted in a deviation of the centroid of the particles from the centreline of the channel of less than 3.8 %, with a mean of the deviation of all particles of 0.6 %. The symmetry of the flow device was estimated with a sample of 356 experiments: 53 % of capsules turned into the right daughter channel. Using the estimator of true probability ![]() $EP$, a standard deviation corresponds to

$EP$, a standard deviation corresponds to ![]() $EP=(2\sqrt{n})^{-1}=3\,\%$. Therefore, the junction is within a standard deviation of being symmetric. We note that the stiffer solid beads (TJ4) exhibited greater variability in centring compared with the softer capsules. This is because the enhanced deformation of softer particles is associated with larger non-inertial lift forces that displace them faster away from boundaries, and thus promote more effective centring within the channel (Doddi & Bagchi Reference Doddi and Bagchi2008). The flow in the T-junction device exhibits a stagnation point, so that a perfectly centred and spherical capsule under ideal flow conditions could get trapped at this stagnation point. However, in the experiments, all capsules propagated in finite time because the small imperfections in the imposed flow, device and capsule break the symmetry of the flow about the centreline of the main channel.

$EP=(2\sqrt{n})^{-1}=3\,\%$. Therefore, the junction is within a standard deviation of being symmetric. We note that the stiffer solid beads (TJ4) exhibited greater variability in centring compared with the softer capsules. This is because the enhanced deformation of softer particles is associated with larger non-inertial lift forces that displace them faster away from boundaries, and thus promote more effective centring within the channel (Doddi & Bagchi Reference Doddi and Bagchi2008). The flow in the T-junction device exhibits a stagnation point, so that a perfectly centred and spherical capsule under ideal flow conditions could get trapped at this stagnation point. However, in the experiments, all capsules propagated in finite time because the small imperfections in the imposed flow, device and capsule break the symmetry of the flow about the centreline of the main channel.

2.2.3 Data analysis

For each experimental run, between 200 and 1000 images were recorded with a resolution of ![]() $800\times 500$ pixels. We used Python 2.7 and OpenCV (https://opencv.org/), a cross-platform, open-source computer vision library, for the image analysis. We applied background subtraction with either an adaptive threshold or a simple uniform threshold determined via the Otsu method (Otsu Reference Otsu1979). In the resulting black and white image, all contours were identified with a Canny filter (Canny Reference Canny1986).

$800\times 500$ pixels. We used Python 2.7 and OpenCV (https://opencv.org/), a cross-platform, open-source computer vision library, for the image analysis. We applied background subtraction with either an adaptive threshold or a simple uniform threshold determined via the Otsu method (Otsu Reference Otsu1979). In the resulting black and white image, all contours were identified with a Canny filter (Canny Reference Canny1986).

The visualisation in top view yields images of the capsules in an ![]() $x$–

$x$–![]() $y$ plane of view averaged over the depth of field (see figure 2b for coordinate system). Perimeter, area and centroid of the projected area of the capsules were determined from the contours extracted from these images. In the experiments reported here, the perimeter usually consists of 400 pixels and the centroid accuracy is better than 0.1 pixels. The accuracy was determined by creating test images of a perfect sphere with a given resolution and analysing the resulting images. The linear dimensions of the capsules along the

$y$ plane of view averaged over the depth of field (see figure 2b for coordinate system). Perimeter, area and centroid of the projected area of the capsules were determined from the contours extracted from these images. In the experiments reported here, the perimeter usually consists of 400 pixels and the centroid accuracy is better than 0.1 pixels. The accuracy was determined by creating test images of a perfect sphere with a given resolution and analysing the resulting images. The linear dimensions of the capsules along the ![]() $x$ and

$x$ and ![]() $y$ directions were measured by fitting an enclosing box to the outline.

$y$ directions were measured by fitting an enclosing box to the outline.

3 Capsule motion and deformation through the T-junction flow device

3.1 Capsule motion through the T-junction

A typical example of the motion of a capsule (TJ1) through the T-junction is shown in figure 3 in terms of its position (a) and speed (b) for ![]() $Ca=0.17\pm 0.04$. The trajectory of the capsule centroid is shown in the inset of figure 3(a) as a dotted blue line with every tenth measurement point marked by a blue square. The centroid position upon exit of the centring device (at the upstream end of the main channel) is shifted by less than 0.02 mm (0.5 % of the channel half-width) from the centreline of the channel (dashed green line) and thus the capsule follows a straight path through the main channel into the junction. The speed of the capsule in figure 3(b) was determined by finite differencing its centroid position with respect to time and was smoothed with a weighted moving-average filter. The speed in the main channel,

$Ca=0.17\pm 0.04$. The trajectory of the capsule centroid is shown in the inset of figure 3(a) as a dotted blue line with every tenth measurement point marked by a blue square. The centroid position upon exit of the centring device (at the upstream end of the main channel) is shifted by less than 0.02 mm (0.5 % of the channel half-width) from the centreline of the channel (dashed green line) and thus the capsule follows a straight path through the main channel into the junction. The speed of the capsule in figure 3(b) was determined by finite differencing its centroid position with respect to time and was smoothed with a weighted moving-average filter. The speed in the main channel, ![]() $v_{m}$, is approximately constant but in the T-junction the capsule decelerates while it travels along the

$v_{m}$, is approximately constant but in the T-junction the capsule decelerates while it travels along the ![]() $y$-axis to reach a minimum speed,

$y$-axis to reach a minimum speed, ![]() $v_{min}$, close to the bottom wall of the junction. In 15 % of the experiments, the capsules got trapped at the stagnation point in the T-junction for prolonged periods during which

$v_{min}$, close to the bottom wall of the junction. In 15 % of the experiments, the capsules got trapped at the stagnation point in the T-junction for prolonged periods during which ![]() $v_{min}\simeq 0~\text{mm}~\text{s}^{-1}$. As the capsule approaches the bottom wall, it extends in the

$v_{min}\simeq 0~\text{mm}~\text{s}^{-1}$. As the capsule approaches the bottom wall, it extends in the ![]() $x$ direction to reach a maximum length

$x$ direction to reach a maximum length ![]() $L_{max}$ (indicated with a red line segment in the figure) and compresses in the

$L_{max}$ (indicated with a red line segment in the figure) and compresses in the ![]() $y$-direction. Soft capsules extend considerably for sufficiently large flow rate (figure 3a) and develop a dumbbell shape reminiscent of the early extension of bubbles prior to break-up (Fu et al. Reference Fu, Ma, Funfschilling and Li2011; Dawson, Häner & Juel Reference Dawson, Häner and Juel2015). The deformation of the capsule means that its centroid can approach the bottom wall of the junction more closely than the centroid of a rigid particle which retains its spherical shape.

$y$-direction. Soft capsules extend considerably for sufficiently large flow rate (figure 3a) and develop a dumbbell shape reminiscent of the early extension of bubbles prior to break-up (Fu et al. Reference Fu, Ma, Funfschilling and Li2011; Dawson, Häner & Juel Reference Dawson, Häner and Juel2015). The deformation of the capsule means that its centroid can approach the bottom wall of the junction more closely than the centroid of a rigid particle which retains its spherical shape.

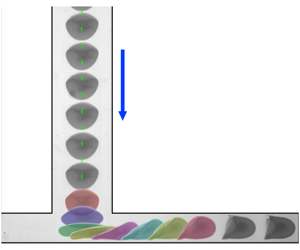

Figure 3. (a) Capsule TJ1 travelling through the T-junction at ![]() $Ca=(1.7\pm 0.4)\times 10^{-1}$ (

$Ca=(1.7\pm 0.4)\times 10^{-1}$ (![]() $Q=40~\text{ml}~\text{min}^{-1}$). Subsequent images have been overlaid to illustrate the dynamics; selected frames were coloured to enhance visibility. The centreline, about which the set-up is symmetric, is shown with a green dashed line. The inset shows the trajectory of the centroid of the projected area of the capsule in the

$Q=40~\text{ml}~\text{min}^{-1}$). Subsequent images have been overlaid to illustrate the dynamics; selected frames were coloured to enhance visibility. The centreline, about which the set-up is symmetric, is shown with a green dashed line. The inset shows the trajectory of the centroid of the projected area of the capsule in the ![]() $x{-}y$ plane as a blue dotted line with every 10th point shown as a blue square. (b) Smoothed speed of capsule TJ1 from the experiment shown in (a).

$x{-}y$ plane as a blue dotted line with every 10th point shown as a blue square. (b) Smoothed speed of capsule TJ1 from the experiment shown in (a).

After reaching its minimum speed, the capsule accelerates into the daughter channel to reach a constant speed ![]() $v_{d}$, as shown in figure 3(b). The value of

$v_{d}$, as shown in figure 3(b). The value of ![]() $v_{d}$ is lower than the speed in the main channel,

$v_{d}$ is lower than the speed in the main channel, ![]() $v_{m}$, because of the enhanced confinement in the daughter channel (which has a width of 3.8 mm, similar to the diameter of the capsule and half of the width of the main channel). Once inside the daughter channel, the capsule migrates towards the centreline over distances of several capsule diameters due to viscous shear forces, and regains symmetry about the centreline of the channel towards the end of the visualisation window (figure 3a).

$v_{m}$, because of the enhanced confinement in the daughter channel (which has a width of 3.8 mm, similar to the diameter of the capsule and half of the width of the main channel). Once inside the daughter channel, the capsule migrates towards the centreline over distances of several capsule diameters due to viscous shear forces, and regains symmetry about the centreline of the channel towards the end of the visualisation window (figure 3a).

Figure 3(a) shows that the rear of the capsule adopts a parachute shape in both main and daughter channels, consistent with previous studies (Risso et al. Reference Risso, Collé-Paillot and Zagzoule2006; Lefebvre et al. Reference Lefebvre, Leclerc, Barthès-Biesel, Walter and Edwards-Lévy2008; Hu et al. Reference Hu, Sévénié, Salsac, Leclerc and Barthès-Biesel2013). We find that its rear is deformed into a concave shape for ![]() $Ca\geqslant 0.07\pm 0.02$ in the main channel, while in the daughter channel this occurs for

$Ca\geqslant 0.07\pm 0.02$ in the main channel, while in the daughter channel this occurs for ![]() $Ca\geqslant 0.05\pm 0.02$. The increased viscous drag in the daughter channel translates into the increased deformation (more indented parachute shape) of the re-centred capsule compared to the capsule in the main channel.

$Ca\geqslant 0.05\pm 0.02$. The increased viscous drag in the daughter channel translates into the increased deformation (more indented parachute shape) of the re-centred capsule compared to the capsule in the main channel.

3.2 Capsule speed in the straight sections of channels

The ratio of capsule speed to mean flow velocity (fractional speed) is shown in figure 4 as a function of flow rate and ![]() $Ca$, respectively, for propagation in both main (figure 4a,b) and daughter channels (figure 4c,d). Rigid spheres travel at speeds of one to two times the mean velocity of the fluid, depending on their size (see, e.g., Al Quddus, Moussa & Bhattacharjee (Reference Al Quddus, Moussa and Bhattacharjee2008)). The fractional speed of capsules depends on their deformation, and thus on flow rate, even if their size is fixed. In figure 4(a), the propagation of the solid bead (TJ4) corresponds to that expected for a near-rigid object: it travels at an almost constant fraction of the mean flow velocity over the range of flow rates investigated. In contrast, the fractional capsule speed increases with flow rate towards a single constant value larger than that measured for the solid bead. At low values of the flow rate (e.g.

$Ca$, respectively, for propagation in both main (figure 4a,b) and daughter channels (figure 4c,d). Rigid spheres travel at speeds of one to two times the mean velocity of the fluid, depending on their size (see, e.g., Al Quddus, Moussa & Bhattacharjee (Reference Al Quddus, Moussa and Bhattacharjee2008)). The fractional speed of capsules depends on their deformation, and thus on flow rate, even if their size is fixed. In figure 4(a), the propagation of the solid bead (TJ4) corresponds to that expected for a near-rigid object: it travels at an almost constant fraction of the mean flow velocity over the range of flow rates investigated. In contrast, the fractional capsule speed increases with flow rate towards a single constant value larger than that measured for the solid bead. At low values of the flow rate (e.g. ![]() $Q=5~\text{ml}~\text{min}^{-1}$), the fractional speed increases as the stiffness of the capsule decreases. The plot of the same data against

$Q=5~\text{ml}~\text{min}^{-1}$), the fractional speed increases as the stiffness of the capsule decreases. The plot of the same data against ![]() $Ca$ in figure 4(b) indicates that the data collapse onto a master curve and thus, that the capillary number governs the motion of capsules (of fixed size) in the straight sections of channel. This suggests that the deformation of different capsules at the same capillary number is the same. This is confirmed in figure 5, which shows that the capsules remain approximately spherical at low

$Ca$ in figure 4(b) indicates that the data collapse onto a master curve and thus, that the capillary number governs the motion of capsules (of fixed size) in the straight sections of channel. This suggests that the deformation of different capsules at the same capillary number is the same. This is confirmed in figure 5, which shows that the capsules remain approximately spherical at low ![]() $Ca$ (figure 5a,b), while at higher

$Ca$ (figure 5a,b), while at higher ![]() $Ca$, the capsules exhibit the characteristic parachute shape (figure 5c,d).

$Ca$, the capsules exhibit the characteristic parachute shape (figure 5c,d).

Figure 4. Ratio of capsule speed to average flow velocity as a function of flow rate ![]() $Q$ (a,c); capillary number

$Q$ (a,c); capillary number ![]() $Ca$ (b,d). Results shown in (a,b) are for the main channel, and in (c,d) for the daughter channel. The symbols represent capsules TJ1 (red circles), TJ2 (orange squares), TJ3 (light blue hexagons) and the solid bead TJ4 (blue triangles). All the capsules and the solid bead are of similar size with

$Ca$ (b,d). Results shown in (a,b) are for the main channel, and in (c,d) for the daughter channel. The symbols represent capsules TJ1 (red circles), TJ2 (orange squares), TJ3 (light blue hexagons) and the solid bead TJ4 (blue triangles). All the capsules and the solid bead are of similar size with ![]() $3.77~\text{mm}\leqslant D\leqslant 3.87~\text{mm}$. The data collapse onto a master curve when plotted against

$3.77~\text{mm}\leqslant D\leqslant 3.87~\text{mm}$. The data collapse onto a master curve when plotted against ![]() $Ca$, which confirms that

$Ca$, which confirms that ![]() $Ca$ governs the motion of capsules of fixed size in a straight channel.

$Ca$ governs the motion of capsules of fixed size in a straight channel.

Figure 5. Capsules of different stiffness show similar deformation at the same value of ![]() $Ca$ in the main channel. The arrow indicates the direction of flow. (a) TJ3,

$Ca$ in the main channel. The arrow indicates the direction of flow. (a) TJ3, ![]() $Q=2~\text{ml}~\text{min}^{-1}$,

$Q=2~\text{ml}~\text{min}^{-1}$, ![]() $Ca=(2.2\pm 0.1)\times 10^{-2}$. (b) TJ1,

$Ca=(2.2\pm 0.1)\times 10^{-2}$. (b) TJ1, ![]() $Q=5~\text{ml}~\text{min}^{-1}$,

$Q=5~\text{ml}~\text{min}^{-1}$, ![]() $Ca=(2.1\pm 0.5)\times 10^{-2}$. (c) TJ1,

$Ca=(2.1\pm 0.5)\times 10^{-2}$. (c) TJ1, ![]() $Q=35~\text{ml}~\text{min}^{-1}$,

$Q=35~\text{ml}~\text{min}^{-1}$, ![]() $Ca=(15\pm 3)\times 10^{-2}$. (d) TJ2,

$Ca=(15\pm 3)\times 10^{-2}$. (d) TJ2, ![]() $Q=70~\text{ml}~\text{min}^{-1}$,

$Q=70~\text{ml}~\text{min}^{-1}$, ![]() $Ca=(14\pm 1)\times 10^{-2}$.

$Ca=(14\pm 1)\times 10^{-2}$.

In the daughter channels, the increased confinement is associated with an increased sensitivity to the initial sphericity of the undeformed capsule, which results in larger scatter of the data (figure 4c). Despite this scatter, the fractional capsule speed approximately collapses onto a master curve as a function of ![]() $Ca$ and appears to reach a plateau at higher

$Ca$ and appears to reach a plateau at higher ![]() $Ca$ (figure 4d).

$Ca$ (figure 4d).

We find that at large ![]() $Ca$ the capsules in the main and daughter channels travel at approximately

$Ca$ the capsules in the main and daughter channels travel at approximately ![]() $v_{m}/\bar{v}_{m}=1.5$ and

$v_{m}/\bar{v}_{m}=1.5$ and ![]() $v_{d}/\bar{v}_{d}=1.35$, where

$v_{d}/\bar{v}_{d}=1.35$, where ![]() $\bar{v}_{m}$ and

$\bar{v}_{m}$ and ![]() $\bar{v}_{d}$ denote the mean fluid velocities in the main and daughter channels, respectively. This latter value is consistent with the numerical result of Hu et al. (Reference Hu, Sévénié, Salsac, Leclerc and Barthès-Biesel2013) in a square channel for a capsule with a ratio of diameter to channel width of 0.95 (0.94–0.97 in our experiments; see table 1), and a thin membrane characterised by a Skalak constitutive law, where the fractional speed increased from 1.2 to 1.3 over a representative range of

$\bar{v}_{d}$ denote the mean fluid velocities in the main and daughter channels, respectively. This latter value is consistent with the numerical result of Hu et al. (Reference Hu, Sévénié, Salsac, Leclerc and Barthès-Biesel2013) in a square channel for a capsule with a ratio of diameter to channel width of 0.95 (0.94–0.97 in our experiments; see table 1), and a thin membrane characterised by a Skalak constitutive law, where the fractional speed increased from 1.2 to 1.3 over a representative range of ![]() $Ca$, based on the shear modulus of the capsules. Our experimental results yield a similar range of

$Ca$, based on the shear modulus of the capsules. Our experimental results yield a similar range of ![]() $1.2\leqslant v_{d}/\bar{v}_{d}\leqslant 1.35$. This suggests that capsule propagation in straight sections of tube is not strongly influenced by the exact constitutive behaviour of the capsule.

$1.2\leqslant v_{d}/\bar{v}_{d}\leqslant 1.35$. This suggests that capsule propagation in straight sections of tube is not strongly influenced by the exact constitutive behaviour of the capsule.

We also analysed the relation between the capsules’ speed and their geometrical confinement, i.e. their maximum width relative to the width of the channel. We found that for capsules propagating along the relatively narrow daughter channels, the behaviour is qualitatively similar to that found in Gubspun et al.’s (Reference Gubspun, de Loubens, Trozzo, Deschamps, Georgelin, Edwards-Levy and Leonetti2017) study of capsules in circular tubes, in the sense that their width decreases with an increase in ![]() $Ca$. The speed of our capsules is generally higher because our rectangular channels offer less resistance to the capsules than the circular tubes used by Gubspun et al. (Reference Gubspun, de Loubens, Trozzo, Deschamps, Georgelin, Edwards-Levy and Leonetti2017); this is consistent with the behaviour found by Ilic et al. (Reference Ilic, Tullock, Phan-Tien and Graham1992) for rigid spheres.

$Ca$. The speed of our capsules is generally higher because our rectangular channels offer less resistance to the capsules than the circular tubes used by Gubspun et al. (Reference Gubspun, de Loubens, Trozzo, Deschamps, Georgelin, Edwards-Levy and Leonetti2017); this is consistent with the behaviour found by Ilic et al. (Reference Ilic, Tullock, Phan-Tien and Graham1992) for rigid spheres.

Conversely, when propagating along the main channel, which is more than twice as wide as the diameter of the undeformed capsules, the capsules were found to widen as ![]() $Ca$ increases. We note that this difference in the behaviour of capsules in narrow and wide channels of rectangular cross-section is consistent with the results of numerical simulations by Kuriakose & Dimitrakopoulos (Reference Kuriakose and Dimitrakopoulos2013) and Kuriakose & Dimitrakopoulos (Reference Kuriakose and Dimitrakopoulos2011).

$Ca$ increases. We note that this difference in the behaviour of capsules in narrow and wide channels of rectangular cross-section is consistent with the results of numerical simulations by Kuriakose & Dimitrakopoulos (Reference Kuriakose and Dimitrakopoulos2013) and Kuriakose & Dimitrakopoulos (Reference Kuriakose and Dimitrakopoulos2011).

3.3 Capsule deformation in the T-junction

3.3.1 Maximum deformation

The deformation of a single capsule (TJ2) as it travels through the junction for three values of the flow rate is shown in figure 6. The overall deformation of the capsule in the T-junction increases with flow rate, leading to considerable shape changes particularly in figure 6(c). Similar deformation patterns were obtained for all the capsules tested. The membrane that encapsulates the liquid core routinely exhibits bending radii of the order of the (undeformed) membrane thickness, between 16 % and 26 % of the capsule radius, without suffering permanent deformation.

Figure 6. Series of snapshots illustrating the travel of capsule TJ2 through a T-junction for three different flow rates. (a) ![]() $Q=5~\text{ml}~\text{min}^{-1}$,

$Q=5~\text{ml}~\text{min}^{-1}$, ![]() $Ca=(1.1\pm 0.1)\times 10^{-2}$. (b)

$Ca=(1.1\pm 0.1)\times 10^{-2}$. (b) ![]() $Q=35~\text{ml}~\text{min}^{-1}$,

$Q=35~\text{ml}~\text{min}^{-1}$, ![]() $Ca=(7.7\pm 0.8)\times 10^{-2}$. (c)

$Ca=(7.7\pm 0.8)\times 10^{-2}$. (c) ![]() $Q=70~\text{ml}~\text{min}^{-1}$,

$Q=70~\text{ml}~\text{min}^{-1}$, ![]() $Ca=(15.4\pm 1.6)\times 10^{-2}$.

$Ca=(15.4\pm 1.6)\times 10^{-2}$.

The maximum length ![]() $L_{max}$ of three capsules and of the solid bead is plotted in figure 7 as a function of

$L_{max}$ of three capsules and of the solid bead is plotted in figure 7 as a function of ![]() $Ca$. The graph indicates that the near-rigid solid bead barely deforms (<3 %) for the range of flow rates investigated. The most deformable capsule (TJ1) reaches the largest values of

$Ca$. The graph indicates that the near-rigid solid bead barely deforms (<3 %) for the range of flow rates investigated. The most deformable capsule (TJ1) reaches the largest values of ![]() $L_{max}$, while the stiffest capsule (TJ3) exhibits the least deformation. Figure 7 indicates that the values of

$L_{max}$, while the stiffest capsule (TJ3) exhibits the least deformation. Figure 7 indicates that the values of ![]() $L_{max}$ collapse onto a master curve to within error bars as a function of

$L_{max}$ collapse onto a master curve to within error bars as a function of ![]() $Ca$. This indicates that

$Ca$. This indicates that ![]() $Ca$ uniquely determines the deformation of these capsules (which are of similar size) and the moderate error bars indicate that the method yields reproducible results.

$Ca$ uniquely determines the deformation of these capsules (which are of similar size) and the moderate error bars indicate that the method yields reproducible results.

Figure 7. Maximum length of the capsules in the T-junction as a function of ![]() $Ca$. The symbols represent capsules TJ1 (red circles), TJ2 (orange squares), TJ3 (light blue hexagons) and the solid bead TJ4 (blue triangles). All the capsules and the solid bead are of similar size with

$Ca$. The symbols represent capsules TJ1 (red circles), TJ2 (orange squares), TJ3 (light blue hexagons) and the solid bead TJ4 (blue triangles). All the capsules and the solid bead are of similar size with ![]() $3.77~\text{mm}\leqslant D\leqslant 3.87~\text{mm}$. The plot indicates that

$3.77~\text{mm}\leqslant D\leqslant 3.87~\text{mm}$. The plot indicates that ![]() $L_{max}$ depends uniquely on

$L_{max}$ depends uniquely on ![]() $Ca$ for fixed particle size to within experimental error.

$Ca$ for fixed particle size to within experimental error.

The significant variation of the maximum length as a function of ![]() $Ca$ makes it a promising metric for quantifying the relative stiffness of capsules in flow. At fixed flow rate, the three capsules (

$Ca$ makes it a promising metric for quantifying the relative stiffness of capsules in flow. At fixed flow rate, the three capsules (![]() $2.4~\text{mN}\leqslant F_{50\,\%}\leqslant 9.2~\text{mN}$; see table 1) exhibit a measurable shift in their values of

$2.4~\text{mN}\leqslant F_{50\,\%}\leqslant 9.2~\text{mN}$; see table 1) exhibit a measurable shift in their values of ![]() $L_{max}$. This indicates that factors of 2 and 4 in the force required to compress the capsule to 50 % of its initial height are easily resolved over the entire range of flow rates investigated. The data in figure 7 also suggest that the deformation of soft capsules is captured most accurately. At

$L_{max}$. This indicates that factors of 2 and 4 in the force required to compress the capsule to 50 % of its initial height are easily resolved over the entire range of flow rates investigated. The data in figure 7 also suggest that the deformation of soft capsules is captured most accurately. At ![]() $Q=50~\text{ml}~\text{min}^{-1}$; the softest capsule (TJ2) has extended by ∼90 %; TJ1 which is stiffer by a factor of two has extended by ∼50 %; whereas TJ3 which is stiffer by a factor of four has extended by more than 40 %. The resolution of this method for highly deformable capsules means that it complements the compression method commonly used to measure the stiffness of millimetric capsules (Carin et al. Reference Carin, Barthès-Biesel, Edwards-Lévy, Postel and Andrei2003; Risso & Carin Reference Risso and Carin2004; Rachik et al. Reference Rachik, Barthès-Biesel, Carin and Edwards-Lévy2006).

$Q=50~\text{ml}~\text{min}^{-1}$; the softest capsule (TJ2) has extended by ∼90 %; TJ1 which is stiffer by a factor of two has extended by ∼50 %; whereas TJ3 which is stiffer by a factor of four has extended by more than 40 %. The resolution of this method for highly deformable capsules means that it complements the compression method commonly used to measure the stiffness of millimetric capsules (Carin et al. Reference Carin, Barthès-Biesel, Edwards-Lévy, Postel and Andrei2003; Risso & Carin Reference Risso and Carin2004; Rachik et al. Reference Rachik, Barthès-Biesel, Carin and Edwards-Lévy2006).

3.3.2 Change of direction within the T-junction

The change of direction of the capsule in the T-junction is a key feature of its trajectory. We will show in § 4.1 that it enables the use of the T-junction as a device for sorting capsules according to their stiffness. To characterise the entrainment of the capsule into the daughter channel, we record the distance, ![]() $L_{tp}$, of the capsule centroid from the bottom wall of the T-junction when the velocity vector is angled at 45° to the centreline of both channels (see inset of figure 8). The dependence of

$L_{tp}$, of the capsule centroid from the bottom wall of the T-junction when the velocity vector is angled at 45° to the centreline of both channels (see inset of figure 8). The dependence of ![]() $L_{tp}$ on

$L_{tp}$ on ![]() $Ca$ is shown in figure 8, which indicates a slight decrease of

$Ca$ is shown in figure 8, which indicates a slight decrease of ![]() $L_{tp}$ with increasing

$L_{tp}$ with increasing ![]() $Ca$, with values of approximately 2 mm for the lowest values of

$Ca$, with values of approximately 2 mm for the lowest values of ![]() $Ca$ while for

$Ca$ while for ![]() $Ca=0.2$,

$Ca=0.2$, ![]() $L_{tp}<1.5~\text{mm}$. This means that the more deformed capsules start their propagation into the daughter channel from a position closer to the bottom wall.

$L_{tp}<1.5~\text{mm}$. This means that the more deformed capsules start their propagation into the daughter channel from a position closer to the bottom wall.

Figure 8. Distance from the bottom wall of the T-junction at which the capsules turn into the daughter channel as a function of capillary number ![]() $Ca$. The symbols represent capsules TJ1 (red circles), TJ2 (orange squares), TJ3 (light blue hexagons) and the solid bead TJ4 (blue triangles). All the capsules and the solid bead are of similar size with

$Ca$. The symbols represent capsules TJ1 (red circles), TJ2 (orange squares), TJ3 (light blue hexagons) and the solid bead TJ4 (blue triangles). All the capsules and the solid bead are of similar size with ![]() $3.77~\text{mm}\leqslant D\leqslant 3.87~\text{mm}$.

$3.77~\text{mm}\leqslant D\leqslant 3.87~\text{mm}$.

3.4 Relaxation upon exit from the T-junction

Figure 9(a) illustrates the evolution of capsule TJ1 as it propagates along the daughter channel. When the capsule changes direction within the T-junction, it is highly deformed and its centroid is displaced from the centreline of the daughter channel towards the bottom wall. The elongated capsule (snapshot labelled 1 in figure 9a) is subject to a shear gradient and to wall-lift forces which incline its nose towards the centreline (snapshot 2) and force it to migrate towards the centreline (Coupier et al. Reference Coupier, Kaoui, Podgorski and Misbah2008; Doddi & Bagchi Reference Doddi and Bagchi2008). Once the nose of the particle has reached the centreline (snapshot 3), elastic restoring forces promote relaxation of the capsule towards a symmetric shape (snapshot 4), but this process typically occurs over a distance of several capsule diameters. In contrast, the solid bead exhibits minimal deformation, turns into the daughter channel close to its centreline and reaches a steady mode of propagation after covering less than half the distance required by TJ1 (see figure 9b).

Figure 9. (a) A series of images illustrating the evolution of capsule TJ1 in the daughter channel for ![]() $Q=50~\text{ml}~\text{min}^{-1}$ (

$Q=50~\text{ml}~\text{min}^{-1}$ (![]() $Ca=(21\pm 5)\times 10^{-2}$). (b) Trajectories of the centroids of capsule TJ1 (red circles) and solid bead TJ4 (green squares) as they propagate towards a steady state in the daughter channel.

$Ca=(21\pm 5)\times 10^{-2}$). (b) Trajectories of the centroids of capsule TJ1 (red circles) and solid bead TJ4 (green squares) as they propagate towards a steady state in the daughter channel.

Figure 10. Relaxation distance as a function of (a) flow rate ![]() $Q$ and (b)

$Q$ and (b) ![]() $Ca$. Relaxation time as a function of (c) flow rate

$Ca$. Relaxation time as a function of (c) flow rate ![]() $Q$ and (d)

$Q$ and (d) ![]() $Ca$. (e) Average relaxation speed with the line of best fit shown in blue (the 95 % confidence interval is indicated by a light-blue shaded band around the line of best fit). The symbols represent capsules TJ1 (red circles), TJ2 (orange squares), TJ3 (light blue hexagons) and the solid bead TJ4 (blue triangles). All the capsules and the solid bead are of similar size with

$Ca$. (e) Average relaxation speed with the line of best fit shown in blue (the 95 % confidence interval is indicated by a light-blue shaded band around the line of best fit). The symbols represent capsules TJ1 (red circles), TJ2 (orange squares), TJ3 (light blue hexagons) and the solid bead TJ4 (blue triangles). All the capsules and the solid bead are of similar size with ![]() $3.77~\text{mm}\leqslant D\leqslant 3.87~\text{mm}$.

$3.77~\text{mm}\leqslant D\leqslant 3.87~\text{mm}$.

We define the relaxation distance ![]() $\unicode[STIX]{x1D6FF}_{relax}$, and the associated relaxation time

$\unicode[STIX]{x1D6FF}_{relax}$, and the associated relaxation time ![]() $\unicode[STIX]{x1D70F}_{relax}$, as the distance travelled by the centroid and time elapsed, respectively, from the point of maximum capsule deformation to the position at which the capsule reaches a state in the daughter channel where the transverse velocity of its centroid is 0.25 mm s-1 (the limit of our resolution of the velocity). Results are shown as a function of flow rate in figure 10(a,c) for the three capsules and the solid bead previously shown in figures 4 and 7. The relaxation distance increases with increasing flow rate and the relaxation time scale consistently decreases. Upon reduction of the stiffness, both

$\unicode[STIX]{x1D70F}_{relax}$, as the distance travelled by the centroid and time elapsed, respectively, from the point of maximum capsule deformation to the position at which the capsule reaches a state in the daughter channel where the transverse velocity of its centroid is 0.25 mm s-1 (the limit of our resolution of the velocity). Results are shown as a function of flow rate in figure 10(a,c) for the three capsules and the solid bead previously shown in figures 4 and 7. The relaxation distance increases with increasing flow rate and the relaxation time scale consistently decreases. Upon reduction of the stiffness, both ![]() $\unicode[STIX]{x1D6FF}_{relax}$ and

$\unicode[STIX]{x1D6FF}_{relax}$ and ![]() $\unicode[STIX]{x1D70F}_{relax}$ increase, which confirms that softer capsules travel further and longer before reaching a new steady state. When plotted as a function of

$\unicode[STIX]{x1D70F}_{relax}$ increase, which confirms that softer capsules travel further and longer before reaching a new steady state. When plotted as a function of ![]() $Ca$ in figure 10(b),

$Ca$ in figure 10(b), ![]() $\unicode[STIX]{x1D6FF}_{relax}$ collapses onto a master curve within error bars indicating that it is governed by the fluid–structure interaction in the system like the maximum length and the turning point plotted in figures 7 and 8, respectively. In contrast, figure 10(c,d) shows that

$\unicode[STIX]{x1D6FF}_{relax}$ collapses onto a master curve within error bars indicating that it is governed by the fluid–structure interaction in the system like the maximum length and the turning point plotted in figures 7 and 8, respectively. In contrast, figure 10(c,d) shows that ![]() $\unicode[STIX]{x1D70F}_{relax}$ is not uniquely governed by

$\unicode[STIX]{x1D70F}_{relax}$ is not uniquely governed by ![]() $Ca$. This is because the time scale of capsule propagation is set by the imposed flow rate. In fact, figure 10(e) shows that the average speed of relaxation,

$Ca$. This is because the time scale of capsule propagation is set by the imposed flow rate. In fact, figure 10(e) shows that the average speed of relaxation, ![]() $\bar{v}_{relax}=\unicode[STIX]{x1D6FF}_{relax}/\unicode[STIX]{x1D70F}_{relax}$, is directly proportional to the flow rate. This means that although the shape relaxation of softer particles is initiated from a more deformed state imposed by the flow pressure in the T-junction, they are also positioned closer to the wall of the daughter channel. Hence, the same flow in turn imposes larger wall-lift forces, which return the capsules to the centreline with the same average speed.

$\bar{v}_{relax}=\unicode[STIX]{x1D6FF}_{relax}/\unicode[STIX]{x1D70F}_{relax}$, is directly proportional to the flow rate. This means that although the shape relaxation of softer particles is initiated from a more deformed state imposed by the flow pressure in the T-junction, they are also positioned closer to the wall of the daughter channel. Hence, the same flow in turn imposes larger wall-lift forces, which return the capsules to the centreline with the same average speed.

4 Sorting capsules according to their stiffness in a T-junction device

4.1 T-junction mode of operation

The ![]() $Ca$-dependent deformation and separation of monodisperse capsules in the T-junction, demonstrated in §§ 3.3 and 3.4, suggests that the T-junction may be exploited to passively sort capsules of fixed size according to their stiffness. For this purpose, the separation of capsules achieved within the T-junction needs to be enhanced in the daughter channels. In the geometry investigated so far, this separation is reduced post-junction by the convergence of the capsules onto the centreline of the daughter channel, which has a smaller cross-section than the main channel. We therefore turn to the investigation of a modified T-junction where one of the daughter channels is substantially enlarged to act as a particle diffuser in order to amplify capsule separation; see the schematic diagram of the T-junction sorting device presented in figure 2(c). Note that the main channel is straight only over the last 4 mm closest to the T-junction in order to reduce the thickness of the wall between the main channel and the diffuser to 1 mm, which is the smallest practically feasible value. Hence, the diffusing daughter channel (right hand-side of the T-junction) widens 1 mm downstream of its intersection with the main channel. Capsules were propagated through the main channel into the T-junction by imposing different values of the flow rate

$Ca$-dependent deformation and separation of monodisperse capsules in the T-junction, demonstrated in §§ 3.3 and 3.4, suggests that the T-junction may be exploited to passively sort capsules of fixed size according to their stiffness. For this purpose, the separation of capsules achieved within the T-junction needs to be enhanced in the daughter channels. In the geometry investigated so far, this separation is reduced post-junction by the convergence of the capsules onto the centreline of the daughter channel, which has a smaller cross-section than the main channel. We therefore turn to the investigation of a modified T-junction where one of the daughter channels is substantially enlarged to act as a particle diffuser in order to amplify capsule separation; see the schematic diagram of the T-junction sorting device presented in figure 2(c). Note that the main channel is straight only over the last 4 mm closest to the T-junction in order to reduce the thickness of the wall between the main channel and the diffuser to 1 mm, which is the smallest practically feasible value. Hence, the diffusing daughter channel (right hand-side of the T-junction) widens 1 mm downstream of its intersection with the main channel. Capsules were propagated through the main channel into the T-junction by imposing different values of the flow rate ![]() $Q$. A flow rate

$Q$. A flow rate ![]() $Q_{d}$ which controlled the withdrawal of fluid from the left daughter channel was imposed with a second syringe pump (see § 2.2). All experiments were performed for

$Q_{d}$ which controlled the withdrawal of fluid from the left daughter channel was imposed with a second syringe pump (see § 2.2). All experiments were performed for ![]() $Q_{d}/Q=1/2$. This is because the two flow rates are independent parameters and the flow in the device requires their ratio to be constant in order to remain similar.

$Q_{d}/Q=1/2$. This is because the two flow rates are independent parameters and the flow in the device requires their ratio to be constant in order to remain similar.

The propagation of capsules through the T-junction sorting device is shown in figure 11, with a sequence of snapshots taken at variable time intervals. The final position of each capsule in the diffuser is quantified by the offset of the capsule centroid from the centreline of the diffuser, ![]() $\unicode[STIX]{x1D706}$. Each value of

$\unicode[STIX]{x1D706}$. Each value of ![]() $\unicode[STIX]{x1D706}$ was obtained by averaging

$\unicode[STIX]{x1D706}$ was obtained by averaging ![]() $y$-positions of the centroid for

$y$-positions of the centroid for ![]() $x=24.5~\text{mm}$, where the origin of the

$x=24.5~\text{mm}$, where the origin of the ![]() $x$ axis is chosen as the left wall of the main channel (see figure 12). Figure 11(a,b) shows a comparison between the trajectories of the same capsule (P4) for two values of the flow rate

$x$ axis is chosen as the left wall of the main channel (see figure 12). Figure 11(a,b) shows a comparison between the trajectories of the same capsule (P4) for two values of the flow rate ![]() $Q$. It indicates a significant reduction of

$Q$. It indicates a significant reduction of ![]() $\unicode[STIX]{x1D706}$ with increasing flow rate, which is associated with enhanced capsule deformation in the T-junction and the turning of the capsule into the diffuser closer to the outlet of the main channel. Figure 11(a,c) shows two different capsules (P4, P1) subject to the same flow rate. The softer capsule (P1) has approximately the same value of

$\unicode[STIX]{x1D706}$ with increasing flow rate, which is associated with enhanced capsule deformation in the T-junction and the turning of the capsule into the diffuser closer to the outlet of the main channel. Figure 11(a,c) shows two different capsules (P4, P1) subject to the same flow rate. The softer capsule (P1) has approximately the same value of ![]() $Ca$ as capsule (P4) in figure 11(b). As a result, it exhibits a deformation and trajectory in the T-junction very similar to that shown in figure 11(b), resulting in a similar reduced value of

$Ca$ as capsule (P4) in figure 11(b). As a result, it exhibits a deformation and trajectory in the T-junction very similar to that shown in figure 11(b), resulting in a similar reduced value of ![]() $\unicode[STIX]{x1D706}$. This suggests that the T-junction sorting device can separate capsules according to stiffness and that the process is primarily governed by

$\unicode[STIX]{x1D706}$. This suggests that the T-junction sorting device can separate capsules according to stiffness and that the process is primarily governed by ![]() $Ca$ for capsules of fixed size.

$Ca$ for capsules of fixed size.

Figure 11. Sequences of images illustrating the propagation of capsules through the sorting device operated in T-junction mode. The red line indicates the centreline of the daughter channels and the green line that of the main channel. ![]() $\unicode[STIX]{x1D706}$ is the offset of the capsule centroid from the centreline of the diffuser. The capillary number

$\unicode[STIX]{x1D706}$ is the offset of the capsule centroid from the centreline of the diffuser. The capillary number ![]() $Ca$ is based on the flow rate

$Ca$ is based on the flow rate ![]() $Q$ and cross-section of the main channel. (a) Capsule P4,

$Q$ and cross-section of the main channel. (a) Capsule P4, ![]() $Q_{d}=2.47~\text{ml}~\text{min}^{-1}$,

$Q_{d}=2.47~\text{ml}~\text{min}^{-1}$, ![]() $Q=5~\text{ml}~\text{min}^{-1}$

$Q=5~\text{ml}~\text{min}^{-1}$ ![]() $Ca=(6.2\pm 0.2)\times 10^{-3}$. (b) Capsule P4,

$Ca=(6.2\pm 0.2)\times 10^{-3}$. (b) Capsule P4, ![]() $Q_{d}=20~\text{ml}~\text{min}^{-1}$,

$Q_{d}=20~\text{ml}~\text{min}^{-1}$, ![]() $Q=40~\text{ml}~\text{min}^{-1}$,

$Q=40~\text{ml}~\text{min}^{-1}$, ![]() $Ca=(5.0\pm 0.2)\times 10^{-2}$. (c) Capsule P1,

$Ca=(5.0\pm 0.2)\times 10^{-2}$. (c) Capsule P1, ![]() $Q_{d}=2.5~\text{ml}~\text{min}^{-1}$,

$Q_{d}=2.5~\text{ml}~\text{min}^{-1}$, ![]() $Q=5~\text{ml}~\text{min}^{-1}$

$Q=5~\text{ml}~\text{min}^{-1}$ ![]() $Ca=(5.6\pm 1.6)\times 10^{-2}$.

$Ca=(5.6\pm 1.6)\times 10^{-2}$.

Figure 12. Capsule trajectories and deformation in the sorting device operated in T-junction mode with a flow rate of ![]() $Q=10~\text{ml}~\text{min}^{-1}$ and

$Q=10~\text{ml}~\text{min}^{-1}$ and ![]() $Q_{d}/Q=1/2$. Red circles: capsule P1; orange squares: P3; light blue hexagons: P4. Average trajectories of the centroids of the capsules. The error bars indicate the standard deviation of multiple experiments. Inset: close-up view of trajectories in the T-junction.

$Q_{d}/Q=1/2$. Red circles: capsule P1; orange squares: P3; light blue hexagons: P4. Average trajectories of the centroids of the capsules. The error bars indicate the standard deviation of multiple experiments. Inset: close-up view of trajectories in the T-junction.

Figure 12 shows the trajectories of the centroids of three capsules (P1, P3, P4) spanning a ninefold variation in stiffness, at a constant value of the flow rate. The data show that the capsule centroids follow distinct paths in the diffuser, resulting in monotonically increasing values of ![]() $\unicode[STIX]{x1D706}$ with increasing stiffness. This separation is initiated inside the T-junction where the distance from the end wall at which the centroids turn into the diffuser decreases monotonically with increasing capsule stiffness (see inset of figure 12). This initial separation is then significantly enhanced as the capsules are entrained into the diffuser where streamlines diverge.

$\unicode[STIX]{x1D706}$ with increasing stiffness. This separation is initiated inside the T-junction where the distance from the end wall at which the centroids turn into the diffuser decreases monotonically with increasing capsule stiffness (see inset of figure 12). This initial separation is then significantly enhanced as the capsules are entrained into the diffuser where streamlines diverge.

In figure 13, we quantify the distance from the end-wall of the T-junction at which the capsules are entrained into the diffuser, ![]() $L_{tp}$ (see figure 8 for definition), as a function of

$L_{tp}$ (see figure 8 for definition), as a function of ![]() $Q$ and

$Q$ and ![]() $Ca$. At constant flow rate,

$Ca$. At constant flow rate, ![]() $L_{tp}$ increases monotonically with stiffness as previously illustrated in figure 12, and collapses approximately onto a monotonically growing master curve as a function of

$L_{tp}$ increases monotonically with stiffness as previously illustrated in figure 12, and collapses approximately onto a monotonically growing master curve as a function of ![]() $Ca$. This behaviour contrasts with the results in the T-junction flow device, where a small reduction in

$Ca$. This behaviour contrasts with the results in the T-junction flow device, where a small reduction in ![]() $L_{tp}$ was observed for increasing