1. Introduction

Bedload transport, the coarser sediment load transported by the water flow in close contact with the mobile river bed, is a major process that shapes the Earth's surface with consequences for public safety, water resources, territorial development and fluvial ecology. In mountain streams with steep slopes, large quantities of a wide range of grain sizes are transported, leading to grain size sorting, more generally named size segregation. Size segregation remains a poorly understood phenomenon (Gray Reference Gray2018) impairing our ability to model the interplay between sediment transport rates and channel morphological evolution such as armouring (Bathurst Reference Bathurst2007), bedload sheets (Venditti et al. Reference Venditti, Dietrich, Nelson, Wydzga, Fadde and Sklar2010; Bacchi et al. Reference Bacchi, Recking, Eckert, Frey, Piton and Naaim2014), patching (Nelson, Dietrich & Venditti Reference Nelson, Dietrich and Venditti2010) or downstream fining (Paola et al. Reference Paola, Parker, Seal, Sinha, Southard and Wilcock1992). The physics of granular media has been advocated to address segregation at the granular scale and understand geomorphological evolution (Frey & Church Reference Frey and Church2009, Reference Frey and Church2011). Size segregation largely originates from local interparticle interactions but has huge consequences for the particle size repartition both in the downward and streamwise directions over a much larger scale, potentially affecting sediment mobility and the entire channel geomorphological equilibrium (Gilbert & Murphy Reference Gilbert and Murphy1914; Ferguson et al. Reference Ferguson, Church, Rennie and Venditti2015; Dudill, Frey & Church Reference Dudill, Frey and Church2017; Dudill et al. Reference Dudill, Lafaye de Micheaux, Frey and Church2018, Reference Dudill, Venditti, Church and Frey2020). While investigating segregation at the granular scale (usually with discrete methods) is invaluable (Hill & Tan Reference Hill and Tan2014; Ferdowsi et al. Reference Ferdowsi, Ortiz, Houssais and Jerolmack2017; Chassagne et al. Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b), it is also necessary to consider continuum modelling to improve our theoretical understanding and to provide predictions at larger scales. The focus of this paper is therefore to bridge the gap between the granular-scale processes and continuum modelling, by determining closures based on local granular mechanisms.

This contribution focuses on vertical size segregation processes due to kinetic sieving and associated squeeze expulsion (Savage & Lun Reference Savage and Lun1988; Gray Reference Gray2018). The moving particles act as a random fluctuating sieve, in which small particles are more likely to percolate under the action of gravity than larger particles. This downward movement is balanced by an upward squeeze expulsion which equally applies on small and large particles, resulting in a net downward motion of the small particles. The combination of both processes is called gravity-driven segregation (Gray Reference Gray2018) and is the dominant mechanism in bedload transport. Beyond the few studies made on size segregation in bedload transport (Hergault et al. Reference Hergault, Frey, Métivier, Barat, Ducottet, Böhm and Ancey2010; Ferdowsi et al. Reference Ferdowsi, Ortiz, Houssais and Jerolmack2017; Lafaye de Micheaux, Ducottet & Frey Reference Lafaye de Micheaux, Ducottet and Frey2018; Frey et al. Reference Frey, Lafaye de Micheaux, Bel, Maurin, Rorsman, Martin and Ducottet2020; Chassagne et al. Reference Chassagne, Frey, Maurin and Chauchat2020a,Reference Chassagne, Maurin, Chauchat, Gray and Freyb), these processes have been studied experimentally and numerically in many granular flows such as dry granular avalanches (Savage & Lun Reference Savage and Lun1988; Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Wiederseiner et al. Reference Wiederseiner, Andreini, Epely-Chauvin, Moser, Monnereau, Gray and Ancey2011; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018; Thornton, Gray & Hogg Reference Thornton, Gray and Hogg2006; Guillard, Forterre & Pouliquen Reference Guillard, Forterre and Pouliquen2016), shear cells (Golick & Daniels Reference Golick and Daniels2009; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015) or annular rotating drums (Thomas Reference Thomas2000).

While particularly complex segregation phenomena were observed (Thomas Reference Thomas2000), size segregation has been found to be mainly related to the forcing, the size ratio and the fine particle volume fraction. Savage & Lun (Reference Savage and Lun1988) predicted from dimensional analysis that the shear rate ![]() $\dot {\gamma }^p$ should be the controlling parameter for size segregation. Indeed, when a granular medium is sheared, a layer of particles moves relatively faster than the one beneath, allowing particles to find gaps in which to fall by gravity. This theory agrees with experimental bi-disperse flow down inclined planes (Savage & Lun Reference Savage and Lun1988). In more recent works, Golick & Daniels (Reference Golick and Daniels2009) with shear cell experiments, and Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018) with shear cell discrete element model (DEM) simulations, evidenced the effect of granular pressure, observing less efficient segregation when increasing the pressure. Gray (Reference Gray2018) suggested that size segregation depends on the inertial number, classically used to describe granular rheology (GDR MiDi 2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005),

$\dot {\gamma }^p$ should be the controlling parameter for size segregation. Indeed, when a granular medium is sheared, a layer of particles moves relatively faster than the one beneath, allowing particles to find gaps in which to fall by gravity. This theory agrees with experimental bi-disperse flow down inclined planes (Savage & Lun Reference Savage and Lun1988). In more recent works, Golick & Daniels (Reference Golick and Daniels2009) with shear cell experiments, and Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018) with shear cell discrete element model (DEM) simulations, evidenced the effect of granular pressure, observing less efficient segregation when increasing the pressure. Gray (Reference Gray2018) suggested that size segregation depends on the inertial number, classically used to describe granular rheology (GDR MiDi 2004; da Cruz et al. Reference da Cruz, Emam, Prochnow, Roux and Chevoir2005),

where ![]() $d_l$ is the large particle diameter,

$d_l$ is the large particle diameter, ![]() $\dot {\gamma }^p$ is the granular shear rate,

$\dot {\gamma }^p$ is the granular shear rate, ![]() $p^p$ is the granular pressure and

$p^p$ is the granular pressure and ![]() $\rho ^p$ is the particle density. DEM simulations of dry granular flows (Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2018) and turbulent bedload transport (Chassagne et al. Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) have shown that the segregation velocity indeed scales with the inertial number to a power

$\rho ^p$ is the particle density. DEM simulations of dry granular flows (Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2018) and turbulent bedload transport (Chassagne et al. Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) have shown that the segregation velocity indeed scales with the inertial number to a power ![]() $0.845\pm 0.05$ from quasi-static to dense granular flow regimes.

$0.845\pm 0.05$ from quasi-static to dense granular flow regimes.

Not surprisingly, a number of studies have also found that the segregation depends on the particle size ratio in the kinetic sieving regime. As kinetic sieving is related to the gaps created by shearing, it appears logical that it should be related to the size ratio. However, while Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) have found that segregation increases monotonically with the size ratio in quasi-static regimes (![]() $I<10^{-3}\text {--}10^{-2}$) for size ratio up to 3, Golick & Daniels (Reference Golick and Daniels2009), Guillard et al. (Reference Guillard, Forterre and Pouliquen2016) and Jing et al. (Reference Jing, Ottino, Lueptow and Umbanhowar2020) found that it experiences a maximum efficiency for a size ratio of two,

$I<10^{-3}\text {--}10^{-2}$) for size ratio up to 3, Golick & Daniels (Reference Golick and Daniels2009), Guillard et al. (Reference Guillard, Forterre and Pouliquen2016) and Jing et al. (Reference Jing, Ottino, Lueptow and Umbanhowar2020) found that it experiences a maximum efficiency for a size ratio of two, ![]() $r=2$, for more dynamic granular regimes (

$r=2$, for more dynamic granular regimes (![]() $10^{-3} < I < 1$). Yet, there is still no satisfying theory that explains this difference.

$10^{-3} < I < 1$). Yet, there is still no satisfying theory that explains this difference.

Similarly to the hindrance function for the fluid drag force on a particle, size segregation has also been observed to depend on the concentration of fine particles. Indeed, studies indicate that the efficiency of the segregation process is linked to concentration in small (or large) particles in the granular sample (Fan et al. Reference Fan, Schlick, Umbanhowar, Ottino and Lueptow2014a; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Jones et al. Reference Jones, Isner, Xiao, Ottino, Umbanhowar and Lueptow2018).

Size segregation can be analysed from a particle-scale mechanistic point of view, or a continuum one. On the one hand, considering a large particle in a bath of small particles, size segregation can be seen as a force destabilising the large particle and leading to a migration with respect to the small particles. A number of authors have adopted this approach and have shown that a particle experiences different kind of forces linked to size segregation (Ding, Gravish & Goldman Reference Ding, Gravish and Goldman2011; Tripathi & Khakhar Reference Tripathi and Khakhar2013; Guillard et al. Reference Guillard, Forterre and Pouliquen2016; Staron Reference Staron2018; van der Vaart et al. Reference van der Vaart, van Schrojenstein Lantman, Weinhart, Luding, Ancey and Thornton2018). The forces can be decomposed into a component that drives the segregation and a resulting resisting component linked to the relative motion of the large particle with respect to the small. These two different forces have been isolated by Guillard et al. (Reference Guillard, Forterre and Pouliquen2016) and Tripathi & Khakhar (Reference Tripathi and Khakhar2013). To assess the segregation forces due to the particle size differences, Guillard et al. (Reference Guillard, Forterre and Pouliquen2016) performed two-dimensional (2-D) DEM simulations of a large disk placed in a bed of small disks in the simple shear flow configuration. Maintaining the large disk at a given position with a virtual spring, they were able to assess the vertical segregation force applied by the small particles to the large one, ![]() $f_{seg}$, without generating a resisting force due to the particle motion. Guillard et al. (Reference Guillard, Forterre and Pouliquen2016) found that the vertical segregation force has two contributions: one proportional to the pressure gradient

$f_{seg}$, without generating a resisting force due to the particle motion. Guillard et al. (Reference Guillard, Forterre and Pouliquen2016) found that the vertical segregation force has two contributions: one proportional to the pressure gradient ![]() $\partial p^p / \partial z$ arising from the enduring contact between particles; the other proportional to the granular shear stress gradient

$\partial p^p / \partial z$ arising from the enduring contact between particles; the other proportional to the granular shear stress gradient ![]() $\partial {|\tau ^p|}/\partial {z}$

$\partial {|\tau ^p|}/\partial {z}$

where ![]() $V_l = {\rm \pi}d_l^{3}/6$ is the volume of the intruder and

$V_l = {\rm \pi}d_l^{3}/6$ is the volume of the intruder and ![]() $\mathcal {F}$ and

$\mathcal {F}$ and ![]() $\mathcal {G}$ are empirical functions depending on the friction coefficient

$\mathcal {G}$ are empirical functions depending on the friction coefficient ![]() $\mu = |\tau ^p|/p^p$ and on the size ratio

$\mu = |\tau ^p|/p^p$ and on the size ratio ![]() $r = d_l/d_s$ between the intruder and the surrounding small particles. Guillard et al. (Reference Guillard, Forterre and Pouliquen2016) studied the dependency on both parameters but only provided a dependency with

$r = d_l/d_s$ between the intruder and the surrounding small particles. Guillard et al. (Reference Guillard, Forterre and Pouliquen2016) studied the dependency on both parameters but only provided a dependency with ![]() $\mu$ as

$\mu$ as

where ![]() $\mu _c$ is the critical friction coefficient defining the threshold of movement. It appears that the segregation force proposed in (1.2) accounts for a granular buoyancy force that counter-balances the weight of the particle and a granular lift force arising from multiple inter-particle contact interactions with the intruder (Guillard, Forterre & Pouliquen Reference Guillard, Forterre and Pouliquen2014). Hence the dependencies (1.3a,b) result from the measurements of both these forces.

$\mu _c$ is the critical friction coefficient defining the threshold of movement. It appears that the segregation force proposed in (1.2) accounts for a granular buoyancy force that counter-balances the weight of the particle and a granular lift force arising from multiple inter-particle contact interactions with the intruder (Guillard, Forterre & Pouliquen Reference Guillard, Forterre and Pouliquen2014). Hence the dependencies (1.3a,b) result from the measurements of both these forces.

Tripathi & Khakhar (Reference Tripathi and Khakhar2013) performed 3-D DEM simulations of a settling heavy sphere in a bed of lighter spheres, during a steady dry granular flow on an inclined plan. This density segregation set-up generates a relative motion between the heavy sphere and the lighter ones, without generating segregation forces due to size ratio. By analogy with classical hydrodynamics, light particles playing the role of an ambient fluid, the authors showed that the interaction force could be modelled with a Stokesian form of a solid drag force

where ![]() $v$ is the settling velocity of the heavier particle,

$v$ is the settling velocity of the heavier particle, ![]() $c(\varPhi )$ is a drag coefficient depending on the local solid volume fraction

$c(\varPhi )$ is a drag coefficient depending on the local solid volume fraction ![]() $\varPhi$ and

$\varPhi$ and ![]() $\eta ^p = |\tau ^p|/|\dot {\gamma }^p|$ is the viscosity of the granular medium considered as a non-Newtonian fluid. Tripathi & Khakhar (Reference Tripathi and Khakhar2013) suggested that

$\eta ^p = |\tau ^p|/|\dot {\gamma }^p|$ is the viscosity of the granular medium considered as a non-Newtonian fluid. Tripathi & Khakhar (Reference Tripathi and Khakhar2013) suggested that ![]() $c(\varPhi )$ depends on the local volume fraction

$c(\varPhi )$ depends on the local volume fraction ![]() $\varPhi$ but still remains of the same order as the value observed for a Stokes law in Newtonian fluids, i.e.

$\varPhi$ but still remains of the same order as the value observed for a Stokes law in Newtonian fluids, i.e. ![]() $c=3$. These two forces allow one to understand particle migration locally, and to relate the segregation behaviour of particles to the local characteristics of the granular flow.

$c=3$. These two forces allow one to understand particle migration locally, and to relate the segregation behaviour of particles to the local characteristics of the granular flow.

By contrast, addressing the effect of size segregation processes at the large scale requires a different approach that disregards the particles. Such an approach has been extensively developed in the last few years focusing on a description of segregation as an advection–diffusion model for the percolation of small particles (Dolgunin, Kudy & Ukolov Reference Dolgunin, Kudy and Ukolov1998; Gray & Chugunov Reference Gray and Chugunov2006; Thornton et al. Reference Thornton, Gray and Hogg2006; Hill & Tan Reference Hill and Tan2014; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Ferdowsi et al. Reference Ferdowsi, Ortiz, Houssais and Jerolmack2017; Gray Reference Gray2018; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019; Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019; Umbanhowar, Lueptow & Ottino Reference Umbanhowar, Lueptow and Ottino2019)

where ![]() $t$ denotes for time,

$t$ denotes for time, ![]() $z$ the vertical axis,

$z$ the vertical axis, ![]() $\phi ^s$ and

$\phi ^s$ and ![]() $\phi ^l$ are the small and large particle concentrations and sum to unity (with

$\phi ^l$ are the small and large particle concentrations and sum to unity (with ![]() $\phi ^s+\phi ^l = 1$),

$\phi ^s+\phi ^l = 1$), ![]() $w_s$ is the advection velocity of segregation and

$w_s$ is the advection velocity of segregation and ![]() $D$ is the diffusion coefficient. This equation is characterised by the segregation flux

$D$ is the diffusion coefficient. This equation is characterised by the segregation flux ![]() $\phi ^s w^s$, and the advective velocity

$\phi ^s w^s$, and the advective velocity ![]() $w^s$, which encompass the physical dependencies of the size segregation discussed previously. The advective velocity should therefore have a dependence on the local concentration, which is classically taken as proportional to the large particle concentration,

$w^s$, which encompass the physical dependencies of the size segregation discussed previously. The advective velocity should therefore have a dependence on the local concentration, which is classically taken as proportional to the large particle concentration, ![]() $w_s=\phi ^l S_r$ (Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Gray & Thornton Reference Gray and Thornton2005). Here,

$w_s=\phi ^l S_r$ (Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Gray & Thornton Reference Gray and Thornton2005). Here, ![]() $S_r$ is the advection coefficient of small particles into large particles. The latter has usually been taken as an empirical constant for a given application, or determined from a semi-empirical analysis. Based on a dimensional analysis and DEM simulations, Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) showed that it should depend on both the inertial number and the size ratio. The diffusion coefficient

$S_r$ is the advection coefficient of small particles into large particles. The latter has usually been taken as an empirical constant for a given application, or determined from a semi-empirical analysis. Based on a dimensional analysis and DEM simulations, Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) showed that it should depend on both the inertial number and the size ratio. The diffusion coefficient ![]() $D$ models the diffusive remixing of small particles into large particles. The diffusion coefficient has also received attention in the literature (Bridgwater, Foo & Stephens Reference Bridgwater, Foo and Stephens1985; Fan et al. Reference Fan, Umbanhowar, Ottino and Lueptow2015; Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019). It has been suggested that it should depend on the volume fraction (Cai et al. Reference Cai, Xiao, Zheng and Zhao2019) and on the inertial number (Chassagne et al. Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b).

$D$ models the diffusive remixing of small particles into large particles. The diffusion coefficient has also received attention in the literature (Bridgwater, Foo & Stephens Reference Bridgwater, Foo and Stephens1985; Fan et al. Reference Fan, Umbanhowar, Ottino and Lueptow2015; Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019). It has been suggested that it should depend on the volume fraction (Cai et al. Reference Cai, Xiao, Zheng and Zhao2019) and on the inertial number (Chassagne et al. Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b).

Developing a three-phase continuum mixture theory to model a bi-disperse combination of large and small particles with an interstitial passive fluid, Thornton et al. (Reference Thornton, Gray and Hogg2006) and Gray & Chugunov (Reference Gray and Chugunov2006) were able to analytically derive the advection–diffusion model (1.5). This derivation represented an important step in the understanding of the physical processes at work in size segregation since the advection and diffusion coefficients of the advection–diffusion equation were linked to the particle-scale interactions. In particular, the derivation is based on the assumption that the size segregation directly takes its origin in the heterogeneous distribution of the granular pressure between small and large particles. However, the form of the interaction forces between large and small particles have been postulated without support from independent physical evidence.

This literature review evidences the absence of a direct link between the continuum modelling of grain-size segregation and the local segregation forces experienced by a grain. In this context, the aim of the present paper is to bridge the gap between the granular-scale approach and the continuum modelling. Based on the particle-scale forces proposed by Guillard et al. (Reference Guillard, Forterre and Pouliquen2016) and Tripathi & Khakhar (Reference Tripathi and Khakhar2013), a volume-averaging approach (Jackson Reference Jackson1997, Reference Jackson2000) is adopted here to derive a multi-phase continuum model from granular-scale forces. In addition to the novelty of the developed approach, the derivation proposed by Thornton et al. (Reference Thornton, Gray and Hogg2006) is used to express the advection–diffusion equation from the new multi-phase flow model, providing improved formulations of the advection and diffusion coefficients that contain the particle-scale granular dependencies. In order to test the proposed models, the bi-disperse turbulent bedload transport configurations investigated in Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) are used for comparison. The DEM simulations performed by the authors give a good reference in which granular-scale processes are explicitly resolved. In addition, it is then possible to focus on size segregation by providing an input for the granular viscosity ![]() $\eta ^p = |\tau ^p|/|\dot {\gamma }^p|$ and the friction coefficient

$\eta ^p = |\tau ^p|/|\dot {\gamma }^p|$ and the friction coefficient ![]() $\mu = |\tau ^p| / p^p$, avoiding the use of rheology laws. As the study of Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) focused on the quasi-static part of the bed in turbulent bedload transport, the comparison will be mainly performed in this regime. Since the fluid turbulence can be neglected in this regime (Maurin, Chauchat & Frey Reference Maurin, Chauchat and Frey2016), it will not be taken into account in the derivation of the equations.

$\mu = |\tau ^p| / p^p$, avoiding the use of rheology laws. As the study of Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) focused on the quasi-static part of the bed in turbulent bedload transport, the comparison will be mainly performed in this regime. Since the fluid turbulence can be neglected in this regime (Maurin, Chauchat & Frey Reference Maurin, Chauchat and Frey2016), it will not be taken into account in the derivation of the equations.

The paper is organised as follows: first, the forces acting at the granular scale for a single large intruder in an immersed sheared granular flow are discussed. Then, in § 3, the multi-phase flow model is derived by volume averaging and the associated advection–diffusion equation is derived in § 4. Finally, both models are compared to the DEM simulations (§ 5) and ways to improve the closures are discussed in § 6, including the influence of the size ratio.

2. A large intruder in a bath of small particles

As a first step, the force balance applied on a single large grain in an immersed granular medium made of smaller particles is presented. This Lagrangian equation of motion for the large intruder is then made dimensionless using classical scalings for granular flows, with the large particle diameter as the length scale. An order of magnitude analysis makes it possible to determine the most important forces for bedload transport application.

2.1. Force balance on the large intruder

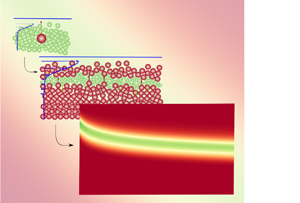

The configuration is sketched in figure 1. The large particle is of diameter ![]() $d_l$, volume

$d_l$, volume ![]() $V_l$ and density

$V_l$ and density ![]() $\rho ^p$ in a bed of height

$\rho ^p$ in a bed of height ![]() $h$ made of small particles. Below this layer the grains are in the quasi-static regime. Applying Newton's second law, the vertical Lagrangian equation of the intruder can be expressed as

$h$ made of small particles. Below this layer the grains are in the quasi-static regime. Applying Newton's second law, the vertical Lagrangian equation of the intruder can be expressed as

In (2.1), the large intruder is submitted to six forces (see figure 1): its weight ![]() $P = - \rho ^p V_l g \cos \theta$, the fluid buoyancy force

$P = - \rho ^p V_l g \cos \theta$, the fluid buoyancy force ![]() $\varPi _f = -\rho ^f V_l g \cos \theta$, the granular buoyancy

$\varPi _f = -\rho ^f V_l g \cos \theta$, the granular buoyancy ![]() $\varPi_p$ due to the reaction of the small particles, the drag force exerted by the fluid

$\varPi_p$ due to the reaction of the small particles, the drag force exerted by the fluid ![]() $f_d^f$, the drag force exerted by the small particles

$f_d^f$, the drag force exerted by the small particles ![]() $f_d^p$ and the lift force

$f_d^p$ and the lift force ![]() $f_l$ responsible for the ascent of the large intruder (Guillard et al. Reference Guillard, Forterre and Pouliquen2014, Reference Guillard, Forterre and Pouliquen2016). In the present configuration, the slope angle is low (

$f_l$ responsible for the ascent of the large intruder (Guillard et al. Reference Guillard, Forterre and Pouliquen2014, Reference Guillard, Forterre and Pouliquen2016). In the present configuration, the slope angle is low (![]() $\tan \theta = 0.1$) and the streamwise gravity component is negligible, making the contribution of the shear stress gradient to the granular buoyancy and lift forces negligible (see (1.2) from Guillard et al. Reference Guillard, Forterre and Pouliquen2016). Thus, the pressure gradient contribution of (1.2) is dominant and the granular buoyancy force is defined as

$\tan \theta = 0.1$) and the streamwise gravity component is negligible, making the contribution of the shear stress gradient to the granular buoyancy and lift forces negligible (see (1.2) from Guillard et al. Reference Guillard, Forterre and Pouliquen2016). Thus, the pressure gradient contribution of (1.2) is dominant and the granular buoyancy force is defined as

where ![]() $p^s$ is the overburden pressure of the surrounding small particles. The lift force is

$p^s$ is the overburden pressure of the surrounding small particles. The lift force is

where ![]() $\mathcal {F}_{l}(\mu ) = (1-\exp ({-70(\mu -\mu _c)}))$ will be called the empirical segregation function and is proposed based on the empirical function

$\mathcal {F}_{l}(\mu ) = (1-\exp ({-70(\mu -\mu _c)}))$ will be called the empirical segregation function and is proposed based on the empirical function ![]() $\mathcal {F}(\mu )$ (see (1.3a,b)) in order to only account for the lift force part of (1.2) (see Appendix A).

$\mathcal {F}(\mu )$ (see (1.3a,b)) in order to only account for the lift force part of (1.2) (see Appendix A).

Figure 1. Vertical component of the forces acting on a large intruder; ![]() $\boldsymbol {\varPi }_{\boldsymbol {f}}$ (blue solid line) is the buoyancy due to the fluid,

$\boldsymbol {\varPi }_{\boldsymbol {f}}$ (blue solid line) is the buoyancy due to the fluid, ![]() $\boldsymbol {\varPi }_{\boldsymbol {p}}$ (——, black solid line) is the granular buoyancy and

$\boldsymbol {\varPi }_{\boldsymbol {p}}$ (——, black solid line) is the granular buoyancy and ![]() $\boldsymbol {f}_{\boldsymbol {l}}$ (——, red solid line) is the lift force identified by Guillard et al. (Reference Guillard, Forterre and Pouliquen2014, Reference Guillard, Forterre and Pouliquen2016). The particle is also submitted to the drag forces

$\boldsymbol {f}_{\boldsymbol {l}}$ (——, red solid line) is the lift force identified by Guillard et al. (Reference Guillard, Forterre and Pouliquen2014, Reference Guillard, Forterre and Pouliquen2016). The particle is also submitted to the drag forces ![]() $\boldsymbol {f}^{\boldsymbol {p}}_{\boldsymbol {d}}$ (——, light green solid line) and

$\boldsymbol {f}^{\boldsymbol {p}}_{\boldsymbol {d}}$ (——, light green solid line) and ![]() $\boldsymbol {f}^{\boldsymbol {f}}_{\boldsymbol {d}}$ (blue solid line), respectively due to the interaction with small particles (Tripathi & Khakhar Reference Tripathi and Khakhar2013) and the fluid.

$\boldsymbol {f}^{\boldsymbol {f}}_{\boldsymbol {d}}$ (blue solid line), respectively due to the interaction with small particles (Tripathi & Khakhar Reference Tripathi and Khakhar2013) and the fluid.

While segregating at a velocity ![]() $w^l$, the large particle is submitted to a fluid drag force. Because the particulate Reynolds number based on the vertical velocity

$w^l$, the large particle is submitted to a fluid drag force. Because the particulate Reynolds number based on the vertical velocity ![]() $Re_p = d_l \rho ^f w^l/ \eta ^f$ is very small in the bed, fluid inertial effects are negligible at the particle length scale and the vertical fluid drag force

$Re_p = d_l \rho ^f w^l/ \eta ^f$ is very small in the bed, fluid inertial effects are negligible at the particle length scale and the vertical fluid drag force ![]() $f^{d}_f$ may be approximated by the Stokes law (Stokes Reference Stokes1851)

$f^{d}_f$ may be approximated by the Stokes law (Stokes Reference Stokes1851)

where ![]() $\eta ^f$ is the fluid dynamic viscosity and

$\eta ^f$ is the fluid dynamic viscosity and ![]() $w^f$ is the vertical velocity of the fluid.

$w^f$ is the vertical velocity of the fluid.

During its segregation motion, the intruder is also submitted to frictional forces from the surrounding small particles. This results in a particle drag force ![]() $f^p_{d}$ modelled as proposed by Tripathi & Khakhar (Reference Tripathi and Khakhar2013) (see (1.4)) as

$f^p_{d}$ modelled as proposed by Tripathi & Khakhar (Reference Tripathi and Khakhar2013) (see (1.4)) as

where ![]() $w^s$ is the vertical velocity of small particles and the drag coefficient

$w^s$ is the vertical velocity of small particles and the drag coefficient ![]() $c$ is first approximated as a constant equal to 3 (Tripathi & Khakhar Reference Tripathi and Khakhar2013).

$c$ is first approximated as a constant equal to 3 (Tripathi & Khakhar Reference Tripathi and Khakhar2013).

2.2. Dimensionless equation for the large intruder

In order to identify the dominant terms in (2.1), it is made dimensionless using classical scalings for granular flows

where ![]() $k=s$,

$k=s$, ![]() $l$ or

$l$ or ![]() $f$ respectively for the surrounding small particles, the large intruder and the fluid. Introducing these variables and (2.3) in (2.1) and taking into account that

$f$ respectively for the surrounding small particles, the large intruder and the fluid. Introducing these variables and (2.3) in (2.1) and taking into account that ![]() $\cos \theta \sim 1$, the dimensionless form of the large intruder Lagrangian equation of motion can be written as

$\cos \theta \sim 1$, the dimensionless form of the large intruder Lagrangian equation of motion can be written as

Equation (2.7) contains two dimensionless numbers. The first one is the fluid Stokes number

in which ![]() $W=\sqrt {d_l g}$ is the characteristic velocity of the large particle. This Stokes number compares the inertia of the large intruder with the viscous friction exerted by the fluid. Similarly, the granular Stokes number

$W=\sqrt {d_l g}$ is the characteristic velocity of the large particle. This Stokes number compares the inertia of the large intruder with the viscous friction exerted by the fluid. Similarly, the granular Stokes number

compares the inertia of the large intruder with the contact friction exerted by the small particles in the vicinity of the intruder.

Assuming a classical bedload configuration, the fluid flows inside the porous matrix of the granular bed. Only the first layer of particles at the top is in a dense flow regime. Below this layer, ![]() $\mu <\mu _c$, meaning that the grains are in the quasi-static regime. Typical values of the granular viscosity for dense granular flows are very high compared with the water viscosity (typical ranges span from

$\mu <\mu _c$, meaning that the grains are in the quasi-static regime. Typical values of the granular viscosity for dense granular flows are very high compared with the water viscosity (typical ranges span from ![]() $10^3\ \textrm {Pa}\ \textrm {s}$ at the bed surface to

$10^3\ \textrm {Pa}\ \textrm {s}$ at the bed surface to ![]() $10^6\ \textrm {Pa}\ \textrm {s}$ at the bed bottom). This results in a fluid Stokes number

$10^6\ \textrm {Pa}\ \textrm {s}$ at the bed bottom). This results in a fluid Stokes number ![]() $St^f$ much larger than the granular Stokes number

$St^f$ much larger than the granular Stokes number ![]() $St^p$ whatever the height into the bed. Therefore, the first term on the right-hand side of (2.7), representing the fluid drag force, can be neglected. In addition, while the large intruder is rising, it only modifies the small particle bed structure locally. Therefore, it is assumed that the vertical velocity of the intruder does not disturb the vertical bulk velocity, implying that

$St^p$ whatever the height into the bed. Therefore, the first term on the right-hand side of (2.7), representing the fluid drag force, can be neglected. In addition, while the large intruder is rising, it only modifies the small particle bed structure locally. Therefore, it is assumed that the vertical velocity of the intruder does not disturb the vertical bulk velocity, implying that ![]() $w^s \sim 0$ (Tripathi & Khakhar (Reference Tripathi and Khakhar2011) showed that the bulk flow around the intruder was disturbed until a distance of 1 diameter of the large intruder for higher shear stress). Focusing on the position of the intruder in the quasi-static part of the bed, it can be deduced from (2.7) that the total solid volume fraction is constant,

$w^s \sim 0$ (Tripathi & Khakhar (Reference Tripathi and Khakhar2011) showed that the bulk flow around the intruder was disturbed until a distance of 1 diameter of the large intruder for higher shear stress). Focusing on the position of the intruder in the quasi-static part of the bed, it can be deduced from (2.7) that the total solid volume fraction is constant, ![]() $\varPhi = cste$. Therefore, for this configuration, a simple equation for the vertical velocity of the large intruder can be written as

$\varPhi = cste$. Therefore, for this configuration, a simple equation for the vertical velocity of the large intruder can be written as

\begin{equation} \dfrac{\textrm{d} \widetilde{w^l}}{\textrm{d}\tilde{t}} + \dfrac{1}{St^p} \widetilde{w^l} = \dfrac{\rho^p - \rho^f}{\rho^p} \varPhi \mathcal{F}_{l}(\mu). \end{equation}

\begin{equation} \dfrac{\textrm{d} \widetilde{w^l}}{\textrm{d}\tilde{t}} + \dfrac{1}{St^p} \widetilde{w^l} = \dfrac{\rho^p - \rho^f}{\rho^p} \varPhi \mathcal{F}_{l}(\mu). \end{equation}In this dimensionless equation the fluid only acts through the fluid density coming from the granular pressure gradient. Therefore, the fluid can be considered as inert and (2.10) should be valid to model the vertical velocity of an intruder segregating in a dry granular flow (in this case the granular pressure gradient does not include the fluid density).

Equation (2.10) allows one to identify the main size segregation mechanisms and shows that the segregation of a large intruder can be seen as a simple relaxation process with characteristic time ![]() $St^p$.

$St^p$.

3. Volume-averaged multi-phase flow model

As discussed in the previous section, the dynamics of a large intruder in an immersed granular flow made of small particles can be described using interparticle forces published in the literature. In this section, the goal is to upscale this result by volume averaging the segregation forces over a collection of large particles in order to make the link between this discrete picture and continuum models for size segregation. This is done in the framework of the volume-averaged equations from Jackson (Reference Jackson1997, Reference Jackson2000) which provides continuum equations for the three phases: large particles, small particles and the interstitial fluid.

3.1. Three-dimensional general governing equations

Following Jackson (Reference Jackson1997, Reference Jackson2000), the mass and momentum balance equations for each class are given by

where ![]() $f$ is the fluid and indices

$f$ is the fluid and indices ![]() $i=l,s$ denote the large particle phase and the small particle phase, respectively (

$i=l,s$ denote the large particle phase and the small particle phase, respectively (![]() $\delta = l$ if

$\delta = l$ if ![]() $i = s$ and

$i = s$ and ![]() $\delta = s$ if

$\delta = s$ if ![]() $i = l$). Here,

$i = l$). Here, ![]() $\varPhi ^l$ and

$\varPhi ^l$ and ![]() $\varPhi ^s$ are the volume fractions for the large and small grains and verify

$\varPhi ^s$ are the volume fractions for the large and small grains and verify ![]() $\varPhi ^s + \varPhi ^l = \varPhi$ where

$\varPhi ^s + \varPhi ^l = \varPhi$ where ![]() $\varPhi$ is the volume fraction of the mixture, i.e. the total solid volume fraction. Consequently, the fluid volume fraction is

$\varPhi$ is the volume fraction of the mixture, i.e. the total solid volume fraction. Consequently, the fluid volume fraction is ![]() $\epsilon = 1- \varPhi ^l - \varPhi ^s$ and

$\epsilon = 1- \varPhi ^l - \varPhi ^s$ and ![]() $\boldsymbol {S}^k$ is the stress tensor associated with phase

$\boldsymbol {S}^k$ is the stress tensor associated with phase ![]() $k$ with

$k$ with ![]() $k = l, s \text { or } f$. They can be separated into pressure and shear stress contribution

$k = l, s \text { or } f$. They can be separated into pressure and shear stress contribution

where ![]() $\boldsymbol {\tau }^k$ is the shear stress tensor and

$\boldsymbol {\tau }^k$ is the shear stress tensor and ![]() $p^k$ is the pressure of phase

$p^k$ is the pressure of phase ![]() $k$. It should be noted that, for a solid phase, the static pressure arises from the enduring contacts between the particles. Thanks to the mixture model approaches (Morland Reference Morland1992), it can be assumed that each particle phase carries the total overburden pressure

$k$. It should be noted that, for a solid phase, the static pressure arises from the enduring contacts between the particles. Thanks to the mixture model approaches (Morland Reference Morland1992), it can be assumed that each particle phase carries the total overburden pressure ![]() $p^m$ according to their local volume fraction as

$p^m$ according to their local volume fraction as

where ![]() $m$ denotes the mixture made of small and large particles. The total overburden pressure

$m$ denotes the mixture made of small and large particles. The total overburden pressure ![]() $p^m$ is computed using the formulation proposed by Johnson & Jackson (Reference Johnson and Jackson1987). For further information, the reader is referred to Chauchat et al. (Reference Chauchat, Cheng, Nagel, Bonamy and Hsu2017) and Chauchat (Reference Chauchat2018).

$p^m$ is computed using the formulation proposed by Johnson & Jackson (Reference Johnson and Jackson1987). For further information, the reader is referred to Chauchat et al. (Reference Chauchat, Cheng, Nagel, Bonamy and Hsu2017) and Chauchat (Reference Chauchat2018).

The momentum equations (3.3) and (3.4) contain two terms coming from the momentum exchange between the different phases: ![]() $n_i \boldsymbol {f}_{f\rightarrow i}$ and

$n_i \boldsymbol {f}_{f\rightarrow i}$ and ![]() $n_i \boldsymbol {f}_{\delta \rightarrow i}$. The term

$n_i \boldsymbol {f}_{\delta \rightarrow i}$. The term ![]() $n_i \boldsymbol {f}_{f\rightarrow i}$ is the averaged value of the resultant forces exerted by the fluid on the particles of phase

$n_i \boldsymbol {f}_{f\rightarrow i}$ is the averaged value of the resultant forces exerted by the fluid on the particles of phase ![]() $i$. Jackson (Reference Jackson2000) showed that, for a collection of immersed particles, this interaction force can be written as

$i$. Jackson (Reference Jackson2000) showed that, for a collection of immersed particles, this interaction force can be written as

where ![]() $\varPhi ^i \boldsymbol {\nabla } p^f$ is the buoyancy force exerted by the fluid phase on the particles and

$\varPhi ^i \boldsymbol {\nabla } p^f$ is the buoyancy force exerted by the fluid phase on the particles and ![]() $n_i \boldsymbol {f}^{f\rightarrow i}_{d}$ is the particle-averaged viscous drag force between the particles and the fluid phase. The term

$n_i \boldsymbol {f}^{f\rightarrow i}_{d}$ is the particle-averaged viscous drag force between the particles and the fluid phase. The term ![]() $n_i \boldsymbol {f}_{\delta \rightarrow i}$ is the averaged value of all interacting forces between large and small particle phases. It can be directly expressed in three dimensions from the local segregation force of Tripathi & Khakhar (Reference Tripathi and Khakhar2013) and Guillard et al. (Reference Guillard, Forterre and Pouliquen2016).

$n_i \boldsymbol {f}_{\delta \rightarrow i}$ is the averaged value of all interacting forces between large and small particle phases. It can be directly expressed in three dimensions from the local segregation force of Tripathi & Khakhar (Reference Tripathi and Khakhar2013) and Guillard et al. (Reference Guillard, Forterre and Pouliquen2016).

Therefore, the developed model is general and can be applied to 3-D configurations. For simplicity and for the purposes of the present study, the model will be only developed for a 1-D uniform flow.

3.2. Simplified 1-D vertical multi-phase flow model

The multi-phase flow model (3.1) to (3.4) is simplified by considering a uniform flow in the streamwise direction. From now, all the variables only depend on the vertical position ![]() $z$. Therefore, the spatially averaged velocity of the phase

$z$. Therefore, the spatially averaged velocity of the phase ![]() $k$ can be written as

$k$ can be written as ![]() $\boldsymbol {u}^k = u^k(z) \boldsymbol {e}_x + w^k(z) \boldsymbol {e}_z$. The mass conservation equations simplify to

$\boldsymbol {u}^k = u^k(z) \boldsymbol {e}_x + w^k(z) \boldsymbol {e}_z$. The mass conservation equations simplify to

and the momentum balance equations in the vertical direction are

In the two last equations, the solid pressures ![]() $p^l$ and

$p^l$ and ![]() $p^s$ are given by (3.6). To solve these equations, it is necessary to prescribe closures for the spatially averaged fluid/grain interaction and grain–grain interactions, and for the granular and fluid pressures.

$p^s$ are given by (3.6). To solve these equations, it is necessary to prescribe closures for the spatially averaged fluid/grain interaction and grain–grain interactions, and for the granular and fluid pressures.

Considering the fluid–grain interaction, both small and large granular phases interact with the fluid phase through ![]() $\varPhi ^i \partial p^f/ \partial z$ and the drag force

$\varPhi ^i \partial p^f/ \partial z$ and the drag force ![]() $n_i\langle f^{f\rightarrow i}_{d}\rangle$. For an assembly of particles, the spatial averaging of the vertical total drag force applied by the fluid gives

$n_i\langle f^{f\rightarrow i}_{d}\rangle$. For an assembly of particles, the spatial averaging of the vertical total drag force applied by the fluid gives

where ![]() $t_i = \rho ^p d_i^2 (1-\varPhi )^{3} / 18 \eta ^f$ is the particle response time and

$t_i = \rho ^p d_i^2 (1-\varPhi )^{3} / 18 \eta ^f$ is the particle response time and ![]() $d_i$ is the particle diameter of phase

$d_i$ is the particle diameter of phase ![]() $i$. The factor

$i$. The factor ![]() $(1-\varPhi )^{3}$ is a correction proposed by Richardson & Zaki (Reference Richardson and Zaki1954) to take into account hindrance effects. Since the drag is linear, the spatial averaging is simply the drag force applied on one particle (given in (2.4)) multiplied by the number of particles per unit volume

$(1-\varPhi )^{3}$ is a correction proposed by Richardson & Zaki (Reference Richardson and Zaki1954) to take into account hindrance effects. Since the drag is linear, the spatial averaging is simply the drag force applied on one particle (given in (2.4)) multiplied by the number of particles per unit volume ![]() $n_i = \varPhi ^i/ V^i$ (Jackson Reference Jackson2000), where

$n_i = \varPhi ^i/ V^i$ (Jackson Reference Jackson2000), where ![]() $V^i$ is the volume of a single particle of phase

$V^i$ is the volume of a single particle of phase ![]() $i$.

$i$.

The granular phases also interact with each other and the grain–grain interaction closure should be prescribed in the model. For a single large grain in a bath of small particles, it has been shown in § 2 that small particles exert three forces on a large intruder,

In the case of spatially averaged equations, the force balancing the weight ![]() $\varPi _p$ already appears in the term

$\varPi _p$ already appears in the term ![]() $-{\partial p^l}/{\partial z}$. Hence, the granular interaction forces of (3.13) reduce to the granular drag and the granular lift force.

$-{\partial p^l}/{\partial z}$. Hence, the granular interaction forces of (3.13) reduce to the granular drag and the granular lift force.

To extend these forces to a collection of large particles, the interaction force ![]() $f_{s\rightarrow l}$ is spatially averaged. Since this force is linear, it amounts to multiplying

$f_{s\rightarrow l}$ is spatially averaged. Since this force is linear, it amounts to multiplying ![]() $f_{s\rightarrow l}$ by the number of large particles per unit volume

$f_{s\rightarrow l}$ by the number of large particles per unit volume ![]() $n_l = 6 \varPhi ^l / {\rm \pi}d_l^3$. Therefore, the total solid interaction force exerted by the small particles on the large ones is given by

$n_l = 6 \varPhi ^l / {\rm \pi}d_l^3$. Therefore, the total solid interaction force exerted by the small particles on the large ones is given by

where ![]() $t_{ls} = \rho ^p d_l^2 / 6 c \eta ^p$ is the particle response time for the drag force between small and large particles. According to Newton's third law, the force exerted by the large particles on the small ones (3.11) is

$t_{ls} = \rho ^p d_l^2 / 6 c \eta ^p$ is the particle response time for the drag force between small and large particles. According to Newton's third law, the force exerted by the large particles on the small ones (3.11) is

The solid mixture phase is made of both particle phases and is noted with ![]() $i=m$. Its momentum balance is obtained by summing (3.10) and (3.11). Since the mixture phase does not distinguish between small and large particles, the solid interaction forces should not appear in this equation. Equation (3.15) ensures that these forces vanish when developing the mixture momentum equation.

$i=m$. Its momentum balance is obtained by summing (3.10) and (3.11). Since the mixture phase does not distinguish between small and large particles, the solid interaction forces should not appear in this equation. Equation (3.15) ensures that these forces vanish when developing the mixture momentum equation.

The proposed volume-averaged multi-phase flow model describes size segregation of a bi-disperse mixture immersed in a fluid. This represents an improvement upon the model of Thornton et al. (Reference Thornton, Gray and Hogg2006), which was based on semi-empirical parametrisation of the interparticle forces between small and large particles. The present model provides closures based on forces applied on a single particle, and bridges the gap between granular-scale processes and continuum modelling in size segregation. This important result will be used in the following to derive an advection–diffusion model for size segregation.

4. Derivation of the advection–diffusion model

A classical continuum approach to model size segregation is the advection–diffusion model (Dolgunin & Ukolov Reference Dolgunin and Ukolov1995; Gray & Thornton Reference Gray and Thornton2005; Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019; Umbanhowar et al. Reference Umbanhowar, Lueptow and Ottino2019). These models can be derived from the multicomponent mixture theory (Thornton et al. Reference Thornton, Gray and Hogg2006; Gray & Ancey Reference Gray and Ancey2011) by substituting the percolation velocity of one particle size into the mass conservation equation. The advection and diffusion coefficients can be modelled using experimental and theoretical closures (Dolgunin et al. Reference Dolgunin, Kudy and Ukolov1998; van der Vaart et al. Reference van der Vaart, Gajjar, Epely-Chauvin, Andreini, Gray and Ancey2015; Ferdowsi et al. Reference Ferdowsi, Ortiz, Houssais and Jerolmack2017; Cai et al. Reference Cai, Xiao, Zheng and Zhao2019) or can be derived as a simplification from the continuum model of Thornton et al. (Reference Thornton, Gray and Hogg2006) and Gray & Chugunov (Reference Gray and Chugunov2006). In the present section, the multi-phase model developed in the previous section (3.9) to (3.11) makes it possible to derive an advection–diffusion model similar to Thornton et al. (Reference Thornton, Gray and Hogg2006) and Gray & Chugunov (Reference Gray and Chugunov2006), with advection and diffusion coefficients depending on the segregation and the drag forces (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Guillard et al. Reference Guillard, Forterre and Pouliquen2016) determined in independent idealised configurations.

Combining (3.11), (3.12), (3.14) and (3.15), the momentum balance of small particles can be written as

\begin{align} \rho^p \left[\displaystyle\frac{\partial\varPhi^s w^s}{\partial t} + \displaystyle\frac{\partial\varPhi^s w^s w^s}{\partial z}\right] &={-}\displaystyle\frac{\partial p^s}{\partial z} - \varPhi^s \displaystyle\frac{\partial p^f}{\partial z} - \varPhi^s \rho^p g \cos \theta + \dfrac{\rho^p \varPhi^s}{t_s}\left(w^f-w^s\right) \nonumber\\ &\quad - \dfrac{\rho^p \varPhi}{t_{ls}} \left(w^s-w^m\right) + \varPhi^l \mathcal{F}_{l}(\mu) \displaystyle\frac{\partial p^m}{\partial z}. \end{align}

\begin{align} \rho^p \left[\displaystyle\frac{\partial\varPhi^s w^s}{\partial t} + \displaystyle\frac{\partial\varPhi^s w^s w^s}{\partial z}\right] &={-}\displaystyle\frac{\partial p^s}{\partial z} - \varPhi^s \displaystyle\frac{\partial p^f}{\partial z} - \varPhi^s \rho^p g \cos \theta + \dfrac{\rho^p \varPhi^s}{t_s}\left(w^f-w^s\right) \nonumber\\ &\quad - \dfrac{\rho^p \varPhi}{t_{ls}} \left(w^s-w^m\right) + \varPhi^l \mathcal{F}_{l}(\mu) \displaystyle\frac{\partial p^m}{\partial z}. \end{align}

The total volume fraction ![]() $\varPhi = \varPhi ^s + \varPhi ^l$ is assumed to be constant and equal to

$\varPhi = \varPhi ^s + \varPhi ^l$ is assumed to be constant and equal to ![]() $\varPhi _{max} = 0.61$ since particle velocity fluctuations are small. For a deposited bed, the particle momentum balance in the wall-normal direction reduces to a hydrostatic pressure distribution for both the fluid and the particle phases (Chauchat Reference Chauchat2018)

$\varPhi _{max} = 0.61$ since particle velocity fluctuations are small. For a deposited bed, the particle momentum balance in the wall-normal direction reduces to a hydrostatic pressure distribution for both the fluid and the particle phases (Chauchat Reference Chauchat2018)

Assuming a constant mixture solid phase volume fraction, the pressure gradient can be integrated to give the pressure distributions

Following Thornton et al. (Reference Thornton, Gray and Hogg2006), the volume fraction per unit granular volume is introduced as ![]() $\phi ^i = \varPhi ^i/\varPhi$. This notation is more convenient since it ensures

$\phi ^i = \varPhi ^i/\varPhi$. This notation is more convenient since it ensures ![]() $\phi ^s + \phi ^l = 1$. Using (3.6), the momentum equation (4.1) for small particles is rewritten as follows:

$\phi ^s + \phi ^l = 1$. Using (3.6), the momentum equation (4.1) for small particles is rewritten as follows:

\begin{align} \varPhi \rho^p \left[\displaystyle\frac{\partial\phi^s w^s}{\partial t} + \displaystyle\frac{\partial\phi^s w^s w^s}{\partial z}\right]&={-}p^m \displaystyle\frac{\partial\phi^s}{\partial z} + \dfrac{\rho^p \phi^s \varPhi }{t_s}\left(w^f-w^s\right)\nonumber\\ &\quad - \dfrac{\rho^p \varPhi}{t_{ls}} \left(w^s-w^m\right) + \phi^l \varPhi \mathcal{F}_{l}(\mu) \displaystyle\frac{\partial p^m}{\partial z}. \end{align}

\begin{align} \varPhi \rho^p \left[\displaystyle\frac{\partial\phi^s w^s}{\partial t} + \displaystyle\frac{\partial\phi^s w^s w^s}{\partial z}\right]&={-}p^m \displaystyle\frac{\partial\phi^s}{\partial z} + \dfrac{\rho^p \phi^s \varPhi }{t_s}\left(w^f-w^s\right)\nonumber\\ &\quad - \dfrac{\rho^p \varPhi}{t_{ls}} \left(w^s-w^m\right) + \phi^l \varPhi \mathcal{F}_{l}(\mu) \displaystyle\frac{\partial p^m}{\partial z}. \end{align}Using the same scalings as in the Lagrangian equation (2.7) for a single intruder, the equation (4.4) is made dimensionless as follows:

As shown in § 2, ![]() $St^f\gg St^p$ in the bed and the fluid drag force can be neglected. Furthermore, assuming a quasi-steady state and neglecting inertial terms, (4.5) can be rewritten as

$St^f\gg St^p$ in the bed and the fluid drag force can be neglected. Furthermore, assuming a quasi-steady state and neglecting inertial terms, (4.5) can be rewritten as

Assuming a constant depth flow, ![]() $\tilde {w}^m =0$ and the flux of small particles becomes

$\tilde {w}^m =0$ and the flux of small particles becomes

Equation (4.7) is then substituted in the mass conservation equation (3.8a,b) to obtain the following advection–diffusion equation for the percolation of small particles:

with

Since the pressure gradient is negative, ![]() $S_r$ is negative which ensures a downward flux for the small particle phase.

$S_r$ is negative which ensures a downward flux for the small particle phase.

In (4.8), ![]() $S_r$ is the segregation number or advection coefficient of small particles into large particles and

$S_r$ is the segregation number or advection coefficient of small particles into large particles and ![]() $D$ is the diffusion coefficient. Here, (4.9a,b) provides physical closures, which are directly obtained from volume averaging of the particle-scale segregation forces. The advection coefficient

$D$ is the diffusion coefficient. Here, (4.9a,b) provides physical closures, which are directly obtained from volume averaging of the particle-scale segregation forces. The advection coefficient ![]() $S_r$ is therefore expressed as a product between the segregation term

$S_r$ is therefore expressed as a product between the segregation term ![]() $\mathcal {F}_l(\mu ) \partial \tilde {p}^m / \partial \tilde {z}$, which quantifies the ability for the small particles to fall downward, and the solid Stokes number, which quantifies the drag force exerted by the other grains counteracting this downward movement. It is interesting to note that the granular Stokes number is present in both coefficients, which indicates that it is a key parameter for the advection and the diffusive remixing.

$\mathcal {F}_l(\mu ) \partial \tilde {p}^m / \partial \tilde {z}$, which quantifies the ability for the small particles to fall downward, and the solid Stokes number, which quantifies the drag force exerted by the other grains counteracting this downward movement. It is interesting to note that the granular Stokes number is present in both coefficients, which indicates that it is a key parameter for the advection and the diffusive remixing.

These results improve upon the original model from Thornton et al. (Reference Thornton, Gray and Hogg2006) and Gray & Chugunov (Reference Gray and Chugunov2006) since the experimentally based closures (Tripathi & Khakhar Reference Tripathi and Khakhar2013; Guillard et al. Reference Guillard, Forterre and Pouliquen2016) make it possible to link both the advection and the diffusion coefficients to the local physical parameters of the granular flow. This result not only provides closures for the advection–diffusion model based on local granular forces but also highlights the key local physical mechanisms controlling segregation and diffusion. Since the fluid is shown to be inert, this equation is also valid for dry granular flows.

In the following, the relevance of the obtained advection–diffusion model with respect to the multi-phase flow model will be tested.

5. Comparison with existing discrete numerical simulations

In this section, the multi-phase flow model presented in § 3 and the corresponding advection–diffusion model presented in § 4 are tested against the discrete numerical simulations of Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b). This study focused on the segregation of small particles initially resting on top of large ones. It provides a comprehensive dataset to evaluate local granular parameters such as the volume fraction and the segregation velocities. In addition, since it is not the purpose of this work to develop a granular rheology, the shear stress and shear rate profiles obtained from the DEM will be used as input parameters for the continuum models.

The 3-D DEM configuration and the main results from Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) are first summarised (§ 5.1). Then, in § 5.2, the multi-phase flow model is compared with the DEM results using default parameters (see §§ 3 and 4) for the segregation of the small particles. Finally, in § 5.3, the results predicted by the advection–diffusion model and the multi-phase flow model are compared to determine the validity of the former with respect to the latter.

5.1. DEM investigation of Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b)

In this section, the configuration explored and the main results of Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) are briefly presented. The authors investigated grain-size segregation in turbulent bedload transport using a coupled fluid–DEM originally developed by Maurin et al. (Reference Maurin, Chauchat, Chareyre and Frey2015) and used to study bedload rheology (Maurin et al. Reference Maurin, Chauchat and Frey2016) and the slope influence (Maurin, Chauchat & Frey Reference Maurin, Chauchat and Frey2018). For further details, the interested reader is referred to Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b). The 3-D bi-periodic DEM set-up consisted in depositing a layer of small particles over large ones, and letting the particles be entrained by the fluid flow at a fixed Shields number. The latter is the dimensionless fluid bed shear stress ![]() $Sh = \tau ^f /[(\rho ^p-\rho ^f)g d_l]$ and was taken equal to

$Sh = \tau ^f /[(\rho ^p-\rho ^f)g d_l]$ and was taken equal to ![]() $0.1$. The bed slope was fixed to

$0.1$. The bed slope was fixed to ![]() $10\,\%$, which is representative of mountain streams. The size ratio was taken as

$10\,\%$, which is representative of mountain streams. The size ratio was taken as ![]() $r=1.5$ with small particles of diameter

$r=1.5$ with small particles of diameter ![]() $d_s = 4\ \textrm {mm}$ and large particles of diameter

$d_s = 4\ \textrm {mm}$ and large particles of diameter ![]() $d_l = 6\ \textrm {mm}$. The large and small particles were assimilated to a number of layers,

$d_l = 6\ \textrm {mm}$. The large and small particles were assimilated to a number of layers, ![]() $N_l$ and

$N_l$ and ![]() $N_s$. The number of layers of a given class represents the height, in terms of particle diameter of this class, occupied by particles if the concentration was equal to the random close packing (

$N_s$. The number of layers of a given class represents the height, in terms of particle diameter of this class, occupied by particles if the concentration was equal to the random close packing (![]() $\varPhi _{max} = 0.61$). In this way, the bed height at rest was defined as

$\varPhi _{max} = 0.61$). In this way, the bed height at rest was defined as ![]() $h = N_l d_l + N_s d_s$ and was fixed to

$h = N_l d_l + N_s d_s$ and was fixed to ![]() $h=10 d_l$ with a random close packing volume fraction

$h=10 d_l$ with a random close packing volume fraction ![]() $\varPhi _{max} = 0.61$ (profile in figure 2a). In the study of Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b), different simulations have been performed with

$\varPhi _{max} = 0.61$ (profile in figure 2a). In the study of Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b), different simulations have been performed with ![]() $N_s$ varying from

$N_s$ varying from ![]() $0.01$ (a few isolated particles) to

$0.01$ (a few isolated particles) to ![]() $N_s=2$. In this section it was decided that the comparison would be made with

$N_s=2$. In this section it was decided that the comparison would be made with ![]() $N_s = 1.5$. The bulk response of the granular mixture to this fluid forcing is represented by the dimensionless mixture streamwise velocity profile in figure 2(a). The inset is a semi-log plot of the dimensionless velocity profile and shows that it is exponential. As shown in figure 2(b), the linearity of the curve in the semi-log plot confirms that the shear rate is exponentially decreasing in the quasi-static part of the bed (delimited by the two horizontal black dashed lines). As expected for a uniform flow, the mixture shear stress

$N_s = 1.5$. The bulk response of the granular mixture to this fluid forcing is represented by the dimensionless mixture streamwise velocity profile in figure 2(a). The inset is a semi-log plot of the dimensionless velocity profile and shows that it is exponential. As shown in figure 2(b), the linearity of the curve in the semi-log plot confirms that the shear rate is exponentially decreasing in the quasi-static part of the bed (delimited by the two horizontal black dashed lines). As expected for a uniform flow, the mixture shear stress ![]() $\tilde {\tau }_{xz}^m$ shown in figure 2(c) is linear with depth. For both quantities, the following fits were proposed and plotted as a red dotted line in figure 2:

$\tilde {\tau }_{xz}^m$ shown in figure 2(c) is linear with depth. For both quantities, the following fits were proposed and plotted as a red dotted line in figure 2:

The simulations performed by Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) in this configuration were focused on the downward segregation of small particles. It was observed that the layer of small particles percolates rapidly for ![]() $\tilde {z}> 8.5$ (flowing layer) and then slows down below (this limit is marked in figures 2(b) and 2(c)). Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) showed that the small particles are advected downward like a travelling wave into the bed made of large particle with a layer of constant thickness. As figure 2(e) shows, the small particle concentration has a Gaussian-like shape and remains self-similar in time while segregating. The centre of mass of small particles,

$\tilde {z}> 8.5$ (flowing layer) and then slows down below (this limit is marked in figures 2(b) and 2(c)). Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) showed that the small particles are advected downward like a travelling wave into the bed made of large particle with a layer of constant thickness. As figure 2(e) shows, the small particle concentration has a Gaussian-like shape and remains self-similar in time while segregating. The centre of mass of small particles, ![]() $\tilde {z}_c$, is therefore representative of the dynamics of the entire layer. Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) observed that the small particle layer travels down as a logarithmic function of time

$\tilde {z}_c$, is therefore representative of the dynamics of the entire layer. Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) observed that the small particle layer travels down as a logarithmic function of time

where ![]() $a_1$ is a constant characterising the segregation velocity (

$a_1$ is a constant characterising the segregation velocity (![]() $\textrm {d}\tilde {z}_c(t)/\textrm {d} \tilde {t} = - a_1/\tilde {t}$). The authors demonstrated that this logarithmic descent of small particles is a consequence of the dependency of the segregation velocity on the inertial number as

$\textrm {d}\tilde {z}_c(t)/\textrm {d} \tilde {t} = - a_1/\tilde {t}$). The authors demonstrated that this logarithmic descent of small particles is a consequence of the dependency of the segregation velocity on the inertial number as

Using (5.3) in the framework of the advection–diffusion model of Thornton et al. (Reference Thornton, Gray and Hogg2006) and Gray & Chugunov (Reference Gray and Chugunov2006) (see (1.5)) it was shown that the advection coefficient could be written as

where ![]() $S_{r0} = 0.049$, extending the inertial number dependency found by Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018) to bi-disperse size segregation in the quasi-static regime. Then, with the help of a travelling wave method, they evidenced that the small particles percolate as a layer and with a self-similar concentration profile because the ratio between the advection coefficient and the diffusion coefficient is constant. The Péclet number reads

$S_{r0} = 0.049$, extending the inertial number dependency found by Fry et al. (Reference Fry, Umbanhowar, Ottino and Lueptow2018) to bi-disperse size segregation in the quasi-static regime. Then, with the help of a travelling wave method, they evidenced that the small particles percolate as a layer and with a self-similar concentration profile because the ratio between the advection coefficient and the diffusion coefficient is constant. The Péclet number reads

and is therefore constant with ![]() $\tilde {z}$, so that the diffusion coefficient has to have the same dependency on the inertial number as the segregation coefficient

$\tilde {z}$, so that the diffusion coefficient has to have the same dependency on the inertial number as the segregation coefficient

where ![]() $D_0$ is taken as

$D_0$ is taken as ![]() $D_0 = 0.01$ and should be pressure independent (Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019).

$D_0 = 0.01$ and should be pressure independent (Fry et al. Reference Fry, Umbanhowar, Ottino and Lueptow2019).

Figure 2. Profiles and configuration from the DEM simulations. (a) Streamwise mixture velocity profile in the bed (——, blue solid line) and mixture volume fraction (——, green solid line). The inset is the semi-log plot of the velocity profile. (b) Solid shear rate (——, blue solid line) and the corresponding fit ![]() $\tilde {\dot {\gamma }}^m = \gamma _0 \,\textrm {e}^{\tilde {z}/s_0}$ (- - - -, red dashed line) with

$\tilde {\dot {\gamma }}^m = \gamma _0 \,\textrm {e}^{\tilde {z}/s_0}$ (- - - -, red dashed line) with ![]() $\gamma _0 = 1.64 \times 10^{-7}$ and

$\gamma _0 = 1.64 \times 10^{-7}$ and ![]() $s_0 = 0.74$. (c) Solid shear stress and the corresponding fit

$s_0 = 0.74$. (c) Solid shear stress and the corresponding fit ![]() $\tilde {\tau }_{xz}^m = a_0 \tilde {z} + \tau _0$ (- - - -, red dashed line) with

$\tilde {\tau }_{xz}^m = a_0 \tilde {z} + \tau _0$ (- - - -, red dashed line) with ![]() $a_0=-0.078$ and

$a_0=-0.078$ and ![]() $\tau _0=0.91$. The top and lower boundaries of the quasi-static bed are represented by (- - - -, black dashed lines). (d) Sketch of the numerical experiment with the input profiles for the rheology. (e) Concentration profile of small particles at the initial state for the multi-phase flow model (——, green solid line), the DEM (- - - -, black dashed line) and the mixture concentration profile

$\tau _0=0.91$. The top and lower boundaries of the quasi-static bed are represented by (- - - -, black dashed lines). (d) Sketch of the numerical experiment with the input profiles for the rheology. (e) Concentration profile of small particles at the initial state for the multi-phase flow model (——, green solid line), the DEM (- - - -, black dashed line) and the mixture concentration profile ![]() $\phi$ (——, black solid line).

$\phi$ (——, black solid line).

This work also demonstrated that the dynamics of the fine particle layer is controlled by its bottom position, which acts as a lower bound for the segregation velocity. In this way, the particles in the layer cannot segregate faster.

The numerical resolution of the 1-D multi-phase model a priori requires us to solve the granular rheology in order to estimate the granular viscosity required to evaluate the granular drag force contribution. The goal of the present study is to focus on grain-size segregation modelling. In addition, the results of Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) were obtained in the quasi-static regime, for which there is still no consensus regarding granular rheology. For these reasons, the granular viscosity is directly determined by the DEM results here. This makes it possible to focus on the effect of the segregation model and to put aside potential discrepancies linked to a non-accurate description of the granular rheology. The friction coefficient is therefore computed from the DEM results using the definition

Similarly, the granular viscosity is computed using the definition

As shown by the red dashed lines in figures 2(b) and 2(c), the fits presented in (5.1a,b) match the DEM results in the region ![]() $8.5>\tilde {z}>3$. Thus, using these expressions in (5.8) provides an accurate estimate of the granular viscosity for the particle–particle drag closure. For this reason, the validation of the multi-phase flow model will only be carried out in this part of the bed. Therefore, the initial state consists in placing the small particles in the upper limit of the quasi-static part with the centre of mass

$8.5>\tilde {z}>3$. Thus, using these expressions in (5.8) provides an accurate estimate of the granular viscosity for the particle–particle drag closure. For this reason, the validation of the multi-phase flow model will only be carried out in this part of the bed. Therefore, the initial state consists in placing the small particles in the upper limit of the quasi-static part with the centre of mass ![]() $\tilde {z}^0_c = 8.5$. The sketch of this configuration is shown in figure 2(d). Figure 2(e) shows the small particle concentration profile of this numerical set-up at the initial state. The initial concentration is taken with a Gaussian fit on the DEM initial concentration (figure 2e), and ensures that the mass of particles is the same in the DEM and in the continuum simulations.

$\tilde {z}^0_c = 8.5$. The sketch of this configuration is shown in figure 2(d). Figure 2(e) shows the small particle concentration profile of this numerical set-up at the initial state. The initial concentration is taken with a Gaussian fit on the DEM initial concentration (figure 2e), and ensures that the mass of particles is the same in the DEM and in the continuum simulations.

5.2. Comparison with the multi-phase flow model

The system of partial differential equations (3.8a,b)–(3.11) is solved numerically for the configuration shown in figure 2(d) with the initial concentration profile of figure 2(e). In these equations, the empirical segregation function is ![]() $\mathcal {F}_l(\mu )$ and the drag coefficient

$\mathcal {F}_l(\mu )$ and the drag coefficient ![]() $c$ is equal to 3, as suggested by Tripathi & Khakhar (Reference Tripathi and Khakhar2013). Because the fluid is incompressible, there is no equation of state for the fluid pressure. Nevertheless, remembering that

$c$ is equal to 3, as suggested by Tripathi & Khakhar (Reference Tripathi and Khakhar2013). Because the fluid is incompressible, there is no equation of state for the fluid pressure. Nevertheless, remembering that ![]() $\epsilon +\varPhi =1$ and defining the volume-averaged velocities,

$\epsilon +\varPhi =1$ and defining the volume-averaged velocities, ![]() $w = \epsilon w^f+ \varPhi w^m$, it can be demonstrated that the particle–fluid mixture is incompressible. A PISO (pressure implicit with splitting of operators) algorithm classically developed for thw incompressible Navier–Stokes equations is used to solve the pressure–velocity coupling. As the fluid pressure

$w = \epsilon w^f+ \varPhi w^m$, it can be demonstrated that the particle–fluid mixture is incompressible. A PISO (pressure implicit with splitting of operators) algorithm classically developed for thw incompressible Navier–Stokes equations is used to solve the pressure–velocity coupling. As the fluid pressure ![]() $p^f$ is the sum of the hydrostatic pressure and of the excess pore pressure

$p^f$ is the sum of the hydrostatic pressure and of the excess pore pressure ![]() $p^f = \overline {p^f} + \rho ^f g z$, the PISO algorithm consists in solving the momentum balance equations without

$p^f = \overline {p^f} + \rho ^f g z$, the PISO algorithm consists in solving the momentum balance equations without ![]() $\overline {p^f}$ in a predictor step. Then, using the predicted velocity fields, a Poisson equation is solved to find

$\overline {p^f}$ in a predictor step. Then, using the predicted velocity fields, a Poisson equation is solved to find ![]() $\overline {p^f}$. Once the pressure is found, the velocity fields are corrected. This kind of algorithm has already been used to model sediment transport in Chauchat et al. (Reference Chauchat, Cheng, Nagel, Bonamy and Hsu2017) and Chauchat (Reference Chauchat2018).

$\overline {p^f}$. Once the pressure is found, the velocity fields are corrected. This kind of algorithm has already been used to model sediment transport in Chauchat et al. (Reference Chauchat, Cheng, Nagel, Bonamy and Hsu2017) and Chauchat (Reference Chauchat2018).

Figure 3 shows the results of the spatio-temporal evolution of the small particle concentration for the multi-phase flow model (figure 3a) and for the DEM (figure 3b). First, it can be seen that the dynamics predicted by the multi-phase flow model is similar to the DEM. The position of the bottom of the layer is approximately the same in both cases. More quantitatively, the centre of mass ![]() $\tilde {z}_c$ of the small particle layer as a function of time is compared with the DEM in figure 4(a). After a first transient phase (

$\tilde {z}_c$ of the small particle layer as a function of time is compared with the DEM in figure 4(a). After a first transient phase (![]() $\tilde {t}>1\times 10^3$), the centre of mass position is linear in the semi-log plot, indicating that the logarithmic descent observed in the DEM simulation is well reproduced by the multi-phase flow model. The slope of the curve, representing coefficient

$\tilde {t}>1\times 10^3$), the centre of mass position is linear in the semi-log plot, indicating that the logarithmic descent observed in the DEM simulation is well reproduced by the multi-phase flow model. The slope of the curve, representing coefficient ![]() $a_1$ of (5.2) is

$a_1$ of (5.2) is ![]() $0.68$ in the DEM simulation and

$0.68$ in the DEM simulation and ![]() $0.49$ for the multi-phase flow model, corresponding to an error of

$0.49$ for the multi-phase flow model, corresponding to an error of ![]() $28\,\%$. In addition, figure 4(b) shows that, in both models, the bottom of the layer is positioned at the same depth indicating that the multi-phase model reproduces well the bottom controlled behaviour observed by Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) with DEM simulations. However, the Gaussian-like profile is not reproduced by the multi-phase flow model and a wider profile is obtained. In figure 3(a) the maximum concentration

$28\,\%$. In addition, figure 4(b) shows that, in both models, the bottom of the layer is positioned at the same depth indicating that the multi-phase model reproduces well the bottom controlled behaviour observed by Chassagne et al. (Reference Chassagne, Maurin, Chauchat, Gray and Frey2020b) with DEM simulations. However, the Gaussian-like profile is not reproduced by the multi-phase flow model and a wider profile is obtained. In figure 3(a) the maximum concentration ![]() $\max (\phi ^s)$ (indicated by

$\max (\phi ^s)$ (indicated by ![]() $\blacksquare$ in figure 4b) is almost two times smaller than the one predicted by the DEM simulation, while the extent of the small particle layer is much larger. These results indicate that, with the current parametrisation the multi-phase flow model is relevant to qualitatively predict the segregation dynamics. However, the error on the segregation velocity and the discrepancies on the concentration profile clearly show that the model needs to be improved.