1. Introduction

The impact of liquid droplets on solid and liquid targets has been studied extensively since the seminal work of Worthington (Reference Worthington1876, Reference Worthington1882) and is important to many physical, biological and industrial processes. For instance, the splashing of raindrops on vegetation can eject tiny secondary droplets which may carry seeds, bacteria and pathogenic fungal spores over long distances (Fitt, McCartney & Walklate Reference Fitt, McCartney and Walklate1989; Amador et al. Reference Amador, Yamada, McCurley and Hu2013). Rainfall can damp waves on the ocean surface (Tsimplis & Thorpe Reference Tsimplis and Thorpe1989) and cause soil erosion on agricultural lands (Ellison Reference Ellison1944). Furthermore, drop impact is important in metallurgical spray quenching (Bernardin, Stebbins & Mudawar Reference Bernardin, Stebbins and Mudawar1997), spray painting (Hines Reference Hines1966), pesticide spraying (Alm, Reichard & Hall Reference Alm, Reichard and Hall1987) and chemical dispersant application on oil spills (Fingas Reference Fingas2013).

As reviewed by Rein (Reference Rein1993), droplet impact has been studied in a number of configurations, and the resulting splash behaviour depends greatly on the droplet and target properties. For example, the target may be solid or liquid, which causes large differences in splash behaviour. For liquid targets, the receiving fluid may be the same as or different from the droplet fluid, and, if different, these two fluids may be miscible or immiscible (Lhuissier et al. Reference Lhuissier, Sun, Prosperetti and Lohse2013). The depth of the target liquid also influences the splash behaviour. For example, the underlying boundary of a shallow pool alters the cavity shape and the speed and size of the rebounding jet compared with those occurring in a deep pool (e.g. Hobbs & Osheroff Reference Hobbs and Osheroff1967; Macklin & Hobbs Reference Macklin and Hobbs1969; Macklin & Metaxas Reference Macklin and Metaxas1976; Rein Reference Rein1993). Numerous recent studies have investigated phenomena associated with droplet impact on very thin liquid films over solid boundaries (e.g. Cossali, Coghe & Marengo Reference Cossali, Coghe and Marengo1997; Weiss & Yarin Reference Weiss and Yarin1999; Wang & Chen Reference Wang and Chen2000; Rioboo et al. Reference Rioboo, Bauthier, Conti, Voué and De Coninck2003; Okawa, Shiraishi & Mori Reference Okawa, Shiraishi and Mori2006; Krechetnikov & Homsy Reference Krechetnikov and Homsy2009; Zhang et al. Reference Zhang, Brunet, Eggers and Deegan2010; Thoraval et al. Reference Thoraval, Takehara, Etoh and Thoroddsen2013; Agbaglah & Deegan Reference Agbaglah and Deegan2014; Guildenbecher et al. Reference Guildenbecher, Engvall, Gao, Grasser, Reu and Chen2014; Shetabivash, Ommi & Heidarinejad Reference Shetabivash, Ommi and Heidarinejad2014). However, little is known about splashing phenomena occurring when the droplet falls on a thin layer of liquid floating on a deep pool of a denser fluid. Examples involving immiscible liquid layers include oil slicks created by crude oil spilled or released by natural seeps in oceans (Fingas Reference Fingas2013), oily sheens created when prey fish are consumed by predators (Franklin, Brownrigg & Farish Reference Franklin and Brownrigg1774) and the lipid-rich sea surface microlayer (Hardy Reference Hardy1982). The impact of these oil layers on air–sea interface processes, such as marine aerosol formation (Lewis & Schwartz Reference Lewis and Schwartz2004) and interfacial gas and heat transfer (Csanady Reference Csanady2001), is largely unknown. Crude oil slicks, which range in thickness from less than a micron to several millimetres, are particularly important because of their negative environmental, economic and public health impacts (e.g. see reviews in Teal & Howarth Reference Teal and Howarth1984; Aguilera et al. Reference Aguilera, Méndez, Pásaro and Laffon2010; Fingas Reference Fingas2013). These slicks may cover large areas, up to several thousand square kilometres in the case of the 2010 Deepwater Horizon accident (Grimaldi et al. Reference Grimaldi, Coviello, Lacava, Pergola, Tramutoli, Ji, Liu, MacFayden and Wesiberg2011). This study focuses on thin crude oil slicks on seawater.

Figure 1. The

![]() $\mathit{We}_{d}{-}\mathit{Fr}_{d}$

plane showing classification of miscible droplet impact behaviour into five regimes based on previous studies:

$\mathit{We}_{d}{-}\mathit{Fr}_{d}$

plane showing classification of miscible droplet impact behaviour into five regimes based on previous studies:

![]() $\times$

C&VR, coalescence and vortex ring; ▵ RE, regular entrainment; ○ S&TJ, swell and thin jet; ▫ C&TJ, crown and thick jet; ♢ BC, bubble canopy. Solid black line (raindrop TS), 0.4–5.8 mm raindrops falling at terminal speed (Gunn & Kinzer Reference Gunn and Kinzer1949); solid grey line (drop TS (

$\times$

C&VR, coalescence and vortex ring; ▵ RE, regular entrainment; ○ S&TJ, swell and thin jet; ▫ C&TJ, crown and thick jet; ♢ BC, bubble canopy. Solid black line (raindrop TS), 0.4–5.8 mm raindrops falling at terminal speed (Gunn & Kinzer Reference Gunn and Kinzer1949); solid grey line (drop TS (

![]() $C_{d}=1$

)), constant Fr for drops falling at terminal speed with an assumed drag coefficient

$C_{d}=1$

)), constant Fr for drops falling at terminal speed with an assumed drag coefficient

![]() $C_{d}=1$

; dashed line, onset of the bubble canopy regime at

$C_{d}=1$

; dashed line, onset of the bubble canopy regime at

![]() $\mathit{We}_{d}=2000$

. The

$\mathit{We}_{d}=2000$

. The

![]() $d{-}u$

axes indicate the directions of increasing drop diameter and drop speed respectively. Dotted lines, constant drop diameter of

$d{-}u$

axes indicate the directions of increasing drop diameter and drop speed respectively. Dotted lines, constant drop diameter of

![]() $d=0.5$

and 10 mm; dash-dot lines, constant drop speeds of

$d=0.5$

and 10 mm; dash-dot lines, constant drop speeds of

![]() $u=0.5$

and

$u=0.5$

and

![]() $10~\text{m}~\text{s}^{-1}$

.

$10~\text{m}~\text{s}^{-1}$

.

The introduction of an immiscible crude oil layer on the sea surface alters the processes occurring during droplet (e.g. raindrop or spume droplet) impact, with consequences for marine aerosol creation and oil spill dispersal. These processes are expected to depend on the oil slick thickness, oil properties (viscosity, density, surface tension with air and interfacial tension with seawater) and drop properties (size, speed and surface tension). For high-speed raindrop impact, the resulting splash has the potential to eject secondary droplets of both the thin oil layer and the bulk target fluid into the air as aerosol. While aerosolization of chemicals, phytoplankton and bacteria from the sea surface microlayer is a recognized and important transport process (e.g. Hardy Reference Hardy1982; Blanchard Reference Blanchard1989; Tervahattu et al. Reference Tervahattu, Hartonen, Kerminen, Kupiainen, Aarnio, Koskentalo, Tuck and Vaida2002; Cheng et al. Reference Cheng, Zhou, Irvin, Pierce, Naar, Backer, Fleming, Kirkpatrick and Baden2005; Prather et al. Reference Prather, Bertram, Grassian, Deane, Stokes, DeMott, Aluwihare, Palenik, Azam, Seinfeld, Moffet, Molina, Cappa, Geiger, Roberts, Russell, Ault, Baltrusaitis, Collins, Corrigan, Cuadra-Rodriguez, Ebben, Forestieri, Guasco, Hersey, Kim, Lambert, Modini, Mui, Pedler, Ruppel, Ryder, Schoepp, Sullivan and Zhao2013), aerosolization of polluting hydrocarbons, due to bubble bursting on the ocean surface, has only recently been demonstrated (Ehrenhauser et al. Reference Ehrenhauser, Avij, Shu, Dugas, Woodson, Liyana-Arachchi, Zhang, Hung and Valsaraj2014). Furthermore, droplet impact could entrain the immiscible oil layer into the bulk fluid, thereby contributing to dispersion of the oil slick into the water column (Delvigne & Sweeney Reference Delvigne and Sweeney1988; Thorpe Reference Thorpe1995; Li & Garrett Reference Li and Garrett1998; Li et al. Reference Li, Lee, King, Boufadel and Venosa2008).

The flow resulting from droplet impact on a deep liquid pool of the same fluid has received considerable attention. For low-viscosity fluids, such as water, we have mapped out previous experimental studies of the splash behaviour in figure 1 as a function of the droplet Weber number (

![]() $\mathit{We}_{d}$

) and Froude number (

$\mathit{We}_{d}$

) and Froude number (

![]() $\mathit{Fr}_{d}$

). Here,

$\mathit{Fr}_{d}$

). Here,

![]() $\mathit{We}_{d}={\it\rho}u^{2}d/{\it\sigma}$

and

$\mathit{We}_{d}={\it\rho}u^{2}d/{\it\sigma}$

and

![]() $\mathit{Fr}_{d}=u^{2}/gd$

,

$\mathit{Fr}_{d}=u^{2}/gd$

,

![]() $u$

is the droplet impact speed,

$u$

is the droplet impact speed,

![]() $d$

is the droplet diameter,

$d$

is the droplet diameter,

![]() ${\it\rho}$

is the fluid density,

${\it\rho}$

is the fluid density,

![]() $g$

is the gravitational acceleration and

$g$

is the gravitational acceleration and

![]() ${\it\sigma}$

is the surface tension of the droplet with air. In cases where only the fall distance

${\it\sigma}$

is the surface tension of the droplet with air. In cases where only the fall distance

![]() $H$

was given, impact speed was calculated from

$H$

was given, impact speed was calculated from

![]() $u=(2gH)^{1/2}$

. The results are classified into five regimes, including (i) droplet coalescence and formation of a subsurface vortex ring (C&VR, Chapman & Critchlow Reference Chapman and Critchlow1967; Esmailizadeh & Mesler Reference Esmailizadeh and Mesler1986; Cai Reference Cai1989; Sigler & Mesler Reference Sigler and Mesler1989; Pumphrey & Elmore Reference Pumphrey and Elmore1990; Rein Reference Rein1996; Elmore, Chahine & Oguz Reference Elmore, Chahine and Oguz2001; Leng Reference Leng2001; Deng, Anilkumar & Wang Reference Deng, Anilkumar and Wang2007; Liow & Cole Reference Liow and Cole2009), (ii) regular entrainment of bubbles (RE, Pumphrey & Elmore Reference Pumphrey and Elmore1990; Rein Reference Rein1996; Morton, Rudman & Leng Reference Morton, Rudman and Leng2000; Elmore et al.

Reference Elmore, Chahine and Oguz2001; Leng Reference Leng2001; Deng et al.

Reference Deng, Anilkumar and Wang2007; Liow & Cole Reference Liow, Cole, Jacobs, McIntyre, Cleary, Buttsworth, Mee, Clements, Morgan and Lemckert2007), (iii) swell and thin jet (S&TJ, Hallet & Christensen Reference Hallet and Christensen1984; Rein Reference Rein1996; Elmore et al.

Reference Elmore, Chahine and Oguz2001; Leng Reference Leng2001; Deng et al.

Reference Deng, Anilkumar and Wang2007), (iv) crown and thick jet (C&TJ, Worthington Reference Worthington1882; Worthington & Cole Reference Worthington and Cole1896; Worthington Reference Worthington1908; Franz Reference Franz1959; van de Sande, Smith & van Oord Reference van de Sande, Smith and van Oord1974; Macklin & Metaxas Reference Macklin and Metaxas1976; Hallet & Christensen Reference Hallet and Christensen1984; Hsiao, Lichter & Quintero Reference Hsiao, Lichter and Quintero1988; Khaleeq-ur-Rahman & Saunders Reference Khaleeq-ur-Rahman and Saunders1988; Cai Reference Cai1989; Pumphrey & Elmore Reference Pumphrey and Elmore1990; Rein Reference Rein1993, Reference Rein1996; Morton et al.

Reference Morton, Rudman and Leng2000; Leng Reference Leng2001; Fedorchenko & Wang Reference Fedorchenko and Wang2004; Tomita, Saito & Ganbara Reference Tomita, Saito and Ganbara2007; Bisighini et al.

Reference Bisighini, Cossali, Tropea and Roisman2010) and (v) bubble canopy (BC, Worthington Reference Worthington1882; Worthington & Cole Reference Worthington and Cole1896; Worthington Reference Worthington1908; Franz Reference Franz1959; Engel Reference Engel1966; van de Sande et al.

Reference van de Sande, Smith and van Oord1974; Hallet & Christensen Reference Hallet and Christensen1984; Snyder Reference Snyder1990; Medwin et al.

Reference Medwin, Nystuen, Jacobus, Ostwald and Snyder1992; Bisighini et al.

Reference Bisighini, Cossali, Tropea and Roisman2010). The jet thickness for splashes with

$u=(2gH)^{1/2}$

. The results are classified into five regimes, including (i) droplet coalescence and formation of a subsurface vortex ring (C&VR, Chapman & Critchlow Reference Chapman and Critchlow1967; Esmailizadeh & Mesler Reference Esmailizadeh and Mesler1986; Cai Reference Cai1989; Sigler & Mesler Reference Sigler and Mesler1989; Pumphrey & Elmore Reference Pumphrey and Elmore1990; Rein Reference Rein1996; Elmore, Chahine & Oguz Reference Elmore, Chahine and Oguz2001; Leng Reference Leng2001; Deng, Anilkumar & Wang Reference Deng, Anilkumar and Wang2007; Liow & Cole Reference Liow and Cole2009), (ii) regular entrainment of bubbles (RE, Pumphrey & Elmore Reference Pumphrey and Elmore1990; Rein Reference Rein1996; Morton, Rudman & Leng Reference Morton, Rudman and Leng2000; Elmore et al.

Reference Elmore, Chahine and Oguz2001; Leng Reference Leng2001; Deng et al.

Reference Deng, Anilkumar and Wang2007; Liow & Cole Reference Liow, Cole, Jacobs, McIntyre, Cleary, Buttsworth, Mee, Clements, Morgan and Lemckert2007), (iii) swell and thin jet (S&TJ, Hallet & Christensen Reference Hallet and Christensen1984; Rein Reference Rein1996; Elmore et al.

Reference Elmore, Chahine and Oguz2001; Leng Reference Leng2001; Deng et al.

Reference Deng, Anilkumar and Wang2007), (iv) crown and thick jet (C&TJ, Worthington Reference Worthington1882; Worthington & Cole Reference Worthington and Cole1896; Worthington Reference Worthington1908; Franz Reference Franz1959; van de Sande, Smith & van Oord Reference van de Sande, Smith and van Oord1974; Macklin & Metaxas Reference Macklin and Metaxas1976; Hallet & Christensen Reference Hallet and Christensen1984; Hsiao, Lichter & Quintero Reference Hsiao, Lichter and Quintero1988; Khaleeq-ur-Rahman & Saunders Reference Khaleeq-ur-Rahman and Saunders1988; Cai Reference Cai1989; Pumphrey & Elmore Reference Pumphrey and Elmore1990; Rein Reference Rein1993, Reference Rein1996; Morton et al.

Reference Morton, Rudman and Leng2000; Leng Reference Leng2001; Fedorchenko & Wang Reference Fedorchenko and Wang2004; Tomita, Saito & Ganbara Reference Tomita, Saito and Ganbara2007; Bisighini et al.

Reference Bisighini, Cossali, Tropea and Roisman2010) and (v) bubble canopy (BC, Worthington Reference Worthington1882; Worthington & Cole Reference Worthington and Cole1896; Worthington Reference Worthington1908; Franz Reference Franz1959; Engel Reference Engel1966; van de Sande et al.

Reference van de Sande, Smith and van Oord1974; Hallet & Christensen Reference Hallet and Christensen1984; Snyder Reference Snyder1990; Medwin et al.

Reference Medwin, Nystuen, Jacobus, Ostwald and Snyder1992; Bisighini et al.

Reference Bisighini, Cossali, Tropea and Roisman2010). The jet thickness for splashes with

![]() $\mathit{We}_{d}<100$

is not well defined. The figure also contains axes pointing in directions of increasing droplet speed and diameter, along with characteristic bounding dimensions. Figure 1 shows that, as droplet size and speed increase with increasing

$\mathit{We}_{d}<100$

is not well defined. The figure also contains axes pointing in directions of increasing droplet speed and diameter, along with characteristic bounding dimensions. Figure 1 shows that, as droplet size and speed increase with increasing

![]() $\mathit{Fr}_{d}$

and

$\mathit{Fr}_{d}$

and

![]() $\mathit{We}_{d}$

, the resulting flow transitions across a number of regimes. For the C&VR domain, slowly falling droplets with negligible momentum coalesce with the bulk fluid. The high surface tension contributes to generation of a downward moving vortex ring as the droplet penetrates (Chapman & Critchlow Reference Chapman and Critchlow1967; Cai Reference Cai1989; Leng Reference Leng2001). With increasing

$\mathit{We}_{d}$

, the resulting flow transitions across a number of regimes. For the C&VR domain, slowly falling droplets with negligible momentum coalesce with the bulk fluid. The high surface tension contributes to generation of a downward moving vortex ring as the droplet penetrates (Chapman & Critchlow Reference Chapman and Critchlow1967; Cai Reference Cai1989; Leng Reference Leng2001). With increasing

![]() $\mathit{Fr}_{d}$

and

$\mathit{Fr}_{d}$

and

![]() $\mathit{We}_{d}$

into the S&TJ regime, impact involves formation of a cavity in the receiving fluid and an outward moving surface wave swell (or rim), which is sometimes followed by a rebound of the cavity to form a high-speed upward jet that breaks into small droplets (Rein Reference Rein1996). The RE domain is a subrange of the S&TJ regime. Here, a capillary wave moving down the crater surface meets to pinch off an air bubble in a reproducible fashion, and this regime is consequently known as regular entrainment (Oguz & Propseretti Reference Oguz and Propseretti1990; Pumphrey & Elmore Reference Pumphrey and Elmore1990). As the impact becomes more energetic, in the C&TJ regime, the cavity grows deeper and the wave swell develops a crown rim from which small jets or ligaments shed secondary splash droplets. Moreover, a thick jet forms from the rebound of the cavity (Rein Reference Rein1996; Leng Reference Leng2001). Even prior to crown formation and associated aerosols, the initial droplet impact generates a cloud of small droplets. Processes involved with the initial impact, and formation and breakup of the ejecta sheet have been investigated both numerically and experimentally (Thoroddsen Reference Thoroddsen2002; Deegan, Brunet & Eggers Reference Deegan, Brunet and Eggers2008; Thoroddsen et al.

Reference Thoroddsen, Thoraval, Takehara and Etoh2011; Zhang et al.

Reference Zhang, Toole, Fezzaa and Deegan2011; Thoraval et al.

Reference Thoraval, Takehara, Etoh, Popinet, Ray, Josserand and Thoroddsen2012; Agbaglah & Deegan Reference Agbaglah and Deegan2014; Agbaglah et al.

Reference Agbaglah, Thoraval, Thoroddsen, Zhang, Fezzaa and Deegan2015).

$\mathit{We}_{d}$

into the S&TJ regime, impact involves formation of a cavity in the receiving fluid and an outward moving surface wave swell (or rim), which is sometimes followed by a rebound of the cavity to form a high-speed upward jet that breaks into small droplets (Rein Reference Rein1996). The RE domain is a subrange of the S&TJ regime. Here, a capillary wave moving down the crater surface meets to pinch off an air bubble in a reproducible fashion, and this regime is consequently known as regular entrainment (Oguz & Propseretti Reference Oguz and Propseretti1990; Pumphrey & Elmore Reference Pumphrey and Elmore1990). As the impact becomes more energetic, in the C&TJ regime, the cavity grows deeper and the wave swell develops a crown rim from which small jets or ligaments shed secondary splash droplets. Moreover, a thick jet forms from the rebound of the cavity (Rein Reference Rein1996; Leng Reference Leng2001). Even prior to crown formation and associated aerosols, the initial droplet impact generates a cloud of small droplets. Processes involved with the initial impact, and formation and breakup of the ejecta sheet have been investigated both numerically and experimentally (Thoroddsen Reference Thoroddsen2002; Deegan, Brunet & Eggers Reference Deegan, Brunet and Eggers2008; Thoroddsen et al.

Reference Thoroddsen, Thoraval, Takehara and Etoh2011; Zhang et al.

Reference Zhang, Toole, Fezzaa and Deegan2011; Thoraval et al.

Reference Thoraval, Takehara, Etoh, Popinet, Ray, Josserand and Thoroddsen2012; Agbaglah & Deegan Reference Agbaglah and Deegan2014; Agbaglah et al.

Reference Agbaglah, Thoraval, Thoroddsen, Zhang, Fezzaa and Deegan2015).

The most energetic bubble canopy (BC) regime is particularly relevant to the present study. High-speed impacts are characterized by the creation of a large crater and the vertical ejection of a thin cylindrical film from the edge of this cavity (Worthington Reference Worthington1882; Engel Reference Engel1966). Droplets are shed upwards from the thickened upper rim of this film (the crown), as this rim moves radially outward, upward and subsequently radially inward, until it closes violently. This process creates a bubble canopy and sends jets of water upwards and downwards from the canopy apex. The downward jet may impinge on the bottom cavity surface and entrain air bubbles into the bulk fluid or may join with the rebounding crater to form a toroidal bubble floating on the surface (Franz Reference Franz1959; Engel Reference Engel1966; Hallet & Christensen Reference Hallet and Christensen1984; Bisighini et al.

Reference Bisighini, Cossali, Tropea and Roisman2010). The data compilation in figure 1 suggests that the complex processes associated with high-energy (BC) impacts occur for

![]() $\mathit{We}_{d}>2000$

. These processes have received much less attention than those corresponding to lower energy, presumably due to the extremely short time scales involved. Briefly, the growth and collapse of the crater was studied experimentally and modelled by Engel (Reference Engel1966, Reference Engel1967), van de Sande et al. (Reference van de Sande, Smith and van Oord1974) and Bisighini et al. (Reference Bisighini, Cossali, Tropea and Roisman2010). Others mention high-energy impacts in passing (Hallet & Christensen Reference Hallet and Christensen1984) or focus on other aspects, such as sound radiation (Franz Reference Franz1959; Snyder Reference Snyder1990) or coronal discharge (Khaleeq-ur-Rahman & Saunders Reference Khaleeq-ur-Rahman and Saunders1988). Raindrops greater than 2.56 mm in diameter falling on a water surface at terminal speed will fall in the BC regime. The

$\mathit{We}_{d}>2000$

. These processes have received much less attention than those corresponding to lower energy, presumably due to the extremely short time scales involved. Briefly, the growth and collapse of the crater was studied experimentally and modelled by Engel (Reference Engel1966, Reference Engel1967), van de Sande et al. (Reference van de Sande, Smith and van Oord1974) and Bisighini et al. (Reference Bisighini, Cossali, Tropea and Roisman2010). Others mention high-energy impacts in passing (Hallet & Christensen Reference Hallet and Christensen1984) or focus on other aspects, such as sound radiation (Franz Reference Franz1959; Snyder Reference Snyder1990) or coronal discharge (Khaleeq-ur-Rahman & Saunders Reference Khaleeq-ur-Rahman and Saunders1988). Raindrops greater than 2.56 mm in diameter falling on a water surface at terminal speed will fall in the BC regime. The

![]() $\mathit{We}_{d}$

and

$\mathit{We}_{d}$

and

![]() $\mathit{Fr}_{d}$

numbers for raindrops at terminal speed (Gunn & Kinzer Reference Gunn and Kinzer1949) also are shown in figure 1. Using an assumed drag coefficient of 1, which is only relevant for high Reynolds numbers, and equalizing the weight with the drag force would result in

$\mathit{Fr}_{d}$

numbers for raindrops at terminal speed (Gunn & Kinzer Reference Gunn and Kinzer1949) also are shown in figure 1. Using an assumed drag coefficient of 1, which is only relevant for high Reynolds numbers, and equalizing the weight with the drag force would result in

![]() $\mathit{Fr}=1100$

, consistent with the measured values. As is evident, very few studies have extended into the terminal speed regime.

$\mathit{Fr}=1100$

, consistent with the measured values. As is evident, very few studies have extended into the terminal speed regime.

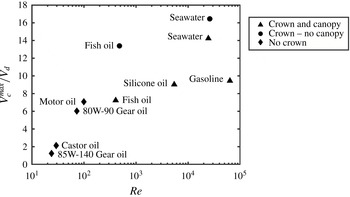

The droplets used in the current study mimic large raindrops falling near terminal velocity on thin layers of crude oil on the ocean surface. The purpose of this study is to determine the effects of varying the oil layer thickness and properties on splash processes, with particular regard to those influencing the aerosolization of droplets. Thus, the effects of oil viscosity, surface tension and interfacial tension are examined, as well the effects of droplet size and impact speed. A non-dimensional scaling is developed to account for these parameters. The effects of premixing the oil with chemical dispersants, which substantially reduce the oil–water interfacial tension, are also investigated. These dispersants are commonly sprayed onto or injected into the oil spill in order to accelerate its breakup to microdroplets and subsequent dispersion in the water column (Li et al. Reference Li, Lee, King, Boufadel and Venosa2008; Fingas Reference Fingas2013). The experiments involve applications of high-speed imaging and holography. We show that the oil layer thickness, surface tension and viscosity have substantial impact on the splash structure and droplet statistics. Careful examination of images elucidates the mechanisms involved and the reasons for variations with the layer thickness and oil properties.

2. Methods

The crude oil used during the present experiments is a Louisiana light sweet crude oil with chemical and physical properties similar to those of the crude oil released during the Deepwater Horizon accident. A variety of commercially available fluids not miscible with water, including gasoline, silicone oil, fish (cod liver) oil, castor oil, motor oil and two gear oils, are also used. The dispersant is Corexit 9500A (Nalco) and in experiments examining the effect of decreased interfacial tension it is mixed with the crude oil at a dispersant to oil volumetric ratio (DOR) of 1:25. To mimic rainfall in the ocean, the droplets consist of filtered tap water, and the bulk fluid is artificial seawater (Instant Ocean) with a salinity of 33 ppt. The measured densities, viscosities, interfacial tensions and surface tensions of the fluids involved in this study are given in table 1. Details concerning fluid provenance and measurement of fluid properties are given in appendix A.

Table 1. The measured physical properties of artificial seawater, different oil types and crude oil–dispersant mixture at a dispersant to oil ratio (DOR) of 1:25.

Figure 2. (a) Set-up for high-speed visualization experiments. (b) A sample image showing the fields of view of holographic observations relative to the splash crown and liquid surface (

![]() $t=3~\text{ms}$

after impact;

$t=3~\text{ms}$

after impact;

![]() $h=400~{\rm\mu}\text{m}$

). The upper field of view (black outline) is used for measuring droplet statistics while the lower field of view (white outline) is used for examination of droplet generation mechanisms at early time points. The scale bar is 4 mm. (c) Top view of the holographic set-up.

$h=400~{\rm\mu}\text{m}$

). The upper field of view (black outline) is used for measuring droplet statistics while the lower field of view (white outline) is used for examination of droplet generation mechanisms at early time points. The scale bar is 4 mm. (c) Top view of the holographic set-up.

Figure 2(a) is a schematic of the experimental set-up for the high-speed visualizations. The droplet size and speed and oil layer composition and thickness are varied in three experimental series, detailed in table 2. In the first series (crude oil only), the droplet size and impact speed are kept constant while the oil layer thickness is varied. The interfacial tension is also varied by the addition of dispersant. In the second series, the oil layer composition and thickness are varied. In the third series, the oil layer composition and thickness and droplet speed are varied. In all cases, filtered tap water ‘raindrops’ are produced by a computer-controlled syringe pump (NE-500, New Era Pump Systems Inc.) connected via flexible tubing to a stainless steel blunt-tip dispensing needle, which is mounted at heights of up to 401.3 cm above the tank base to achieve various raindrop impact speeds. The acrylic tank has interior dimensions of

![]() $15.2\times 15.2\times 15.2~\text{cm}^{3}$

and is filled with artificial seawater to a depth of 8 cm. For the visualizations, the tank is backlit by a 500 W halogen bulb and the light is diffused by translucent bond paper. Images are recorded by a high-speed camera (pco.dimax) equipped with a 200 mm (Nikon Micro Nikkor) lens. For series one visualizations, the CMOS sensor resolution is

$15.2\times 15.2\times 15.2~\text{cm}^{3}$

and is filled with artificial seawater to a depth of 8 cm. For the visualizations, the tank is backlit by a 500 W halogen bulb and the light is diffused by translucent bond paper. Images are recorded by a high-speed camera (pco.dimax) equipped with a 200 mm (Nikon Micro Nikkor) lens. For series one visualizations, the CMOS sensor resolution is

![]() $2016~\text{pixel}\times 2016~\text{pixel}$

, the field of view is

$2016~\text{pixel}\times 2016~\text{pixel}$

, the field of view is

![]() $5.7~\text{cm}\times 5.7~\text{cm}$

, the acquisition rate is 1000 Hz and the exposure time is

$5.7~\text{cm}\times 5.7~\text{cm}$

, the acquisition rate is 1000 Hz and the exposure time is

![]() $100~{\rm\mu}\text{s}$

. The spatial resolution is

$100~{\rm\mu}\text{s}$

. The spatial resolution is

![]() $28.8~{\rm\mu}\text{m}~\text{pixel}^{-1}$

above the water surface and

$28.8~{\rm\mu}\text{m}~\text{pixel}^{-1}$

above the water surface and

![]() $28.2~{\rm\mu}\text{m}~\text{pixel}^{-1}$

below the surface. For visualizations with other oils (series two and three), the sensor size is decreased to

$28.2~{\rm\mu}\text{m}~\text{pixel}^{-1}$

below the surface. For visualizations with other oils (series two and three), the sensor size is decreased to

![]() $1824\times 1888$

and the acquisition rate is increased to 1500 Hz, with an exposure time of

$1824\times 1888$

and the acquisition rate is increased to 1500 Hz, with an exposure time of

![]() $300~{\rm\mu}\text{s}$

. During experiments, droplets are steadily produced at a rate of 0.5 Hz to achieve reproducibility. An absorbent paper placed above the tank serves as a ‘shutter’, allowing only a single droplet through to impact the oil slick when it is momentarily removed. The droplet horizontal diameter

$300~{\rm\mu}\text{s}$

. During experiments, droplets are steadily produced at a rate of 0.5 Hz to achieve reproducibility. An absorbent paper placed above the tank serves as a ‘shutter’, allowing only a single droplet through to impact the oil slick when it is momentarily removed. The droplet horizontal diameter

![]() $d_{h}$

and vertical diameter

$d_{h}$

and vertical diameter

![]() $d_{v}$

are measured, and, based on the calculated volume, an average diameter

$d_{v}$

are measured, and, based on the calculated volume, an average diameter

![]() $d$

is defined. The droplet impact speed

$d$

is defined. The droplet impact speed

![]() $u$

is measured from droplet positions in the last two frames before impact. Tools available in the ImageJ software (Schneider, Rasband & Eliceiri Reference Schneider, Rasband and Eliceiri2012) are used for these measurements. A comparison with data available in Gunn & Kinzer (Reference Gunn and Kinzer1949) for the average diameter

$u$

is measured from droplet positions in the last two frames before impact. Tools available in the ImageJ software (Schneider, Rasband & Eliceiri Reference Schneider, Rasband and Eliceiri2012) are used for these measurements. A comparison with data available in Gunn & Kinzer (Reference Gunn and Kinzer1949) for the average diameter

![]() $d$

for the droplets in series one experiments indicates that the impact speed is approximately 81 % of the terminal velocity of the droplet.

$d$

for the droplets in series one experiments indicates that the impact speed is approximately 81 % of the terminal velocity of the droplet.

Table 2. The parameters of the three experimental series showing fluid layer composition, layer thickness

![]() $h$

, nominal layer thickness for series one, mean droplet width

$h$

, nominal layer thickness for series one, mean droplet width

![]() $d_{h}$

and height

$d_{h}$

and height

![]() $d_{v}$

and mean droplet speed

$d_{v}$

and mean droplet speed

![]() $u$

.

$u$

.

The oil layers are created by gently dripping a known volume of the immiscible fluid from a syringe several millimetres above the surface of the artificial seawater. The oil is manually distributed across the surface in an effort to create a layer of uniform thickness

![]() $h$

. A separate top-view image of the layer is recorded immediately before each experiment in order to measure its area using ImageJ. The thickness of each particular layer is determined from this area and the known oil volume. Experiments are conducted for the oil layer thicknesses listed in table 2. The experiments in series one are repeated multiple times to gain statistics on crown and cavity kinematics while those in series two and three are conducted once or twice for classification of splash phenomena for scaling purposes. Details on oil layer production and dimensions are found in appendix B.

$h$

. A separate top-view image of the layer is recorded immediately before each experiment in order to measure its area using ImageJ. The thickness of each particular layer is determined from this area and the known oil volume. Experiments are conducted for the oil layer thicknesses listed in table 2. The experiments in series one are repeated multiple times to gain statistics on crown and cavity kinematics while those in series two and three are conducted once or twice for classification of splash phenomena for scaling purposes. Details on oil layer production and dimensions are found in appendix B.

Using the optical set-up illustrated in figure 2(c), digital inline holography (e.g. Malkiel et al.

Reference Malkiel, Sheng, Katz and Strickler2003; Sheng, Malkiel & Katz Reference Sheng, Malkiel and Katz2006; Katz & Sheng Reference Katz and Sheng2010) is implemented for the same conditions as series one experiments (with crude oil) to observe how the crown formation process and airborne droplet size distributions are affected by the oil layer thickness and application of chemical dispersants. Accordingly, as indicated in figure 2(b), the sample volume encompasses part of the splash crown. The bottom of the

![]() $8.9~\text{mm}\times 10~\text{mm}$

(width

$8.9~\text{mm}\times 10~\text{mm}$

(width

![]() $\times$

height) field of view is located 13 mm above the water surface, and the resolution,

$\times$

height) field of view is located 13 mm above the water surface, and the resolution,

![]() $6.22~{\rm\mu}\text{m}~\text{pixel}^{-1}$

, is higher than that of the high-speed visualizations. Since the rate of crown growth varies with oil layer thickness, as shown later, the frame selected for comparative analysis of size distributions is the first one recorded after the first upward moving airborne droplet exits the top of the field of view. Most of the droplet size distributions correspond to conditions occurring 3–4 ms after impact. These holograms are acquired at 2000 Hz with a sensor size of

$6.22~{\rm\mu}\text{m}~\text{pixel}^{-1}$

, is higher than that of the high-speed visualizations. Since the rate of crown growth varies with oil layer thickness, as shown later, the frame selected for comparative analysis of size distributions is the first one recorded after the first upward moving airborne droplet exits the top of the field of view. Most of the droplet size distributions correspond to conditions occurring 3–4 ms after impact. These holograms are acquired at 2000 Hz with a sensor size of

![]() $1440~\text{pixel}\times 1612~\text{pixel}$

. In addition, we also record high-speed holograms focusing on the droplet impact/contact area in order to characterize the initial ejecta. These holograms are recorded at multiple frame rates and resolutions. Holograms taken at 3000 Hz with a reduced sensor area of

$1440~\text{pixel}\times 1612~\text{pixel}$

. In addition, we also record high-speed holograms focusing on the droplet impact/contact area in order to characterize the initial ejecta. These holograms are recorded at multiple frame rates and resolutions. Holograms taken at 3000 Hz with a reduced sensor area of

![]() $960~\text{pixel}\times 1572~\text{pixel}$

, field of view of

$960~\text{pixel}\times 1572~\text{pixel}$

, field of view of

![]() $5.95~\text{mm}\times 9.75~\text{mm}$

and resolution of

$5.95~\text{mm}\times 9.75~\text{mm}$

and resolution of

![]() $6.22~{\rm\mu}\text{m}~\text{pixel}^{-1}$

allowed size measurement of fine ejected droplets. Holograms taken at 20 300 Hz with a reduced sensor area of

$6.22~{\rm\mu}\text{m}~\text{pixel}^{-1}$

allowed size measurement of fine ejected droplets. Holograms taken at 20 300 Hz with a reduced sensor area of

![]() $384~\text{pixel}\times 392~\text{pixel}$

, field of view of

$384~\text{pixel}\times 392~\text{pixel}$

, field of view of

![]() $8.3~\text{mm}\times 8.4~\text{mm}$

and resolution of

$8.3~\text{mm}\times 8.4~\text{mm}$

and resolution of

![]() $21.5~{\rm\mu}\text{m}~\text{pixel}^{-1}$

allowed time-resolved characterization of prompt splash processes. Holographic measurements are conducted for the following conditions: a control case without oil (

$21.5~{\rm\mu}\text{m}~\text{pixel}^{-1}$

allowed time-resolved characterization of prompt splash processes. Holographic measurements are conducted for the following conditions: a control case without oil (

![]() $n=25$

), oil layers of

$n=25$

), oil layers of

![]() $h=30~{\rm\mu}\text{m}~(n=14)$

and

$h=30~{\rm\mu}\text{m}~(n=14)$

and

![]() $400~{\rm\mu}\text{m}~(n=13)$

, and an oil and dispersant mixture with DOR of 1:25 and

$400~{\rm\mu}\text{m}~(n=13)$

, and an oil and dispersant mixture with DOR of 1:25 and

![]() $h=500~{\rm\mu}\text{m}~(n=12)$

. Here,

$h=500~{\rm\mu}\text{m}~(n=12)$

. Here,

![]() $n$

is the number of replicated experiments, selected to have a minimum of at least 1000 droplets for the statistical analysis. Droplet diameter distributions are normalized to account for the masked fluid ligament areas and the number of measurements to obtain the average size distributions per realization. Details of hologram acquisition and reconstruction are found in appendix C.

$n$

is the number of replicated experiments, selected to have a minimum of at least 1000 droplets for the statistical analysis. Droplet diameter distributions are normalized to account for the masked fluid ligament areas and the number of measurements to obtain the average size distributions per realization. Details of hologram acquisition and reconstruction are found in appendix C.

Figure 3. Sample images from a time series showing the impact of a freshwater drop (

![]() $d=4.1~\text{mm}$

;

$d=4.1~\text{mm}$

;

![]() $u=7.2~\text{m}~\text{s}^{-1}$

;

$u=7.2~\text{m}~\text{s}^{-1}$

;

![]() $\mathit{Fr}_{d}=1288$

;

$\mathit{Fr}_{d}=1288$

;

![]() $\mathit{We}_{d}=2964$

) on artificial seawater without an oil layer (control case): (a)

$\mathit{We}_{d}=2964$

) on artificial seawater without an oil layer (control case): (a)

![]() $-2$

ms, (b) 1 ms, (c) 3 ms, (d) 8 ms, (e) 17 ms, (f) 31 ms, (g) 43 ms, (h) 85 ms, (i) 118 ms, (j) 420 ms, (k) 765 ms, (l) 785 ms, inset to (l) 775 ms. Inset to (k): production of film drops from ligaments on the receding bubble cap rim. The arrows in the inset to (l) show fine droplets produced from the impact of the rim onto the surface. White asterisks indicate examples of tracked crown rim positions.

$-2$

ms, (b) 1 ms, (c) 3 ms, (d) 8 ms, (e) 17 ms, (f) 31 ms, (g) 43 ms, (h) 85 ms, (i) 118 ms, (j) 420 ms, (k) 765 ms, (l) 785 ms, inset to (l) 775 ms. Inset to (k): production of film drops from ligaments on the receding bubble cap rim. The arrows in the inset to (l) show fine droplets produced from the impact of the rim onto the surface. White asterisks indicate examples of tracked crown rim positions.

In subsequent sections, splash phenomena resulting from droplet impact on immiscible layers of varying thicknesses are classified and illustrated using visualizations of droplet impact on crude oil layers. A control case without oil is presented first as a baseline, and the effect of dispersant is described last. Splash phenomena from a variety of oils are classified to include the effects of layer thickness and fluid properties, and a dimensionless scaling is presented. For thick layers for which the underlying water plays no role in the splash, the effects of fluid layer viscosity and surface tension on splash phenomena such as canopy closure are investigated. These findings consequently shed light on quantitative measurements of cavity and canopy kinematics for the crude oil layers. In the last section, the early stage of splash behaviour, airborne droplet size and droplet spatial distributions investigated by holography are presented and linked to droplet production processes within the first millisecond of the splash. Finally, implications for both non-oily and oily marine aerosol production resulting from raindrop impact are discussed.

3. Phenomenological observations and scaling trends

3.1. Control case

Figure 3 shows a series of characteristic images of the control case, i.e. the impact of a 4.1 mm drop at a velocity of

![]() $7.2~\text{m}~\text{s}^{-1}$

(

$7.2~\text{m}~\text{s}^{-1}$

(

![]() $\mathit{Fr}_{d}=1288$

;

$\mathit{Fr}_{d}=1288$

;

![]() $\mathit{We}_{d}=2964$

) on artificial seawater without an oil slick. The time point of impact is defined as

$\mathit{We}_{d}=2964$

) on artificial seawater without an oil slick. The time point of impact is defined as

![]() $t=0$

. The horizontal black line in the middle of each image is the water meniscus at the tank wall. Within 1 ms after impact (figure 3), a flat-bottomed disk-shaped cavity forms within the receiving fluid, and expands into a hemispherical shape. As noted by Engel (Reference Engel1966), the raindrop fluid is distributed along the bottom of this cavity and is stretched into a thin layer as the cavity grows. In addition to an initial spray of fine droplets (discussed in detail later), a layer of fluid is ejected upwards and outwards from the bulk and forms a thin-walled crown. This crown is surmounted by a thickened rim due to the effect of surface tension (Worthington & Cole Reference Worthington and Cole1896). Liquid ligaments emanate from fairly regularly spaced vertical extensions in the rim and eject droplets outwards and upwards. In Worthington & Cole (Reference Worthington and Cole1896) and Engel (Reference Engel1966) it is surmised that a very thin layer of the drop fluid is also distributed along the interior surface of the crown. The orientation of the ligaments transitions from almost horizontal to a steep angle in the first several milliseconds. Accordingly, the direction of droplet motion originating from these ligaments sweeps from outwards to upwards over the first 10 ms after impact. Thickening of the rim and its ligaments over this time period also results in an increase of the size of newly produced droplets. By 3 ms, while continuing to grow vertically, the radially outward progress of the upper rim of the sheet ceases, and it begins to move radially inwards under the influence of surface tension. At the same time, as the bulk fluid surface is forced outward by the widening and deepening cavity, more fluid travels up the widening and thickening sheet (Engel Reference Engel1966; Bisighini et al.

Reference Bisighini, Cossali, Tropea and Roisman2010).

$t=0$

. The horizontal black line in the middle of each image is the water meniscus at the tank wall. Within 1 ms after impact (figure 3), a flat-bottomed disk-shaped cavity forms within the receiving fluid, and expands into a hemispherical shape. As noted by Engel (Reference Engel1966), the raindrop fluid is distributed along the bottom of this cavity and is stretched into a thin layer as the cavity grows. In addition to an initial spray of fine droplets (discussed in detail later), a layer of fluid is ejected upwards and outwards from the bulk and forms a thin-walled crown. This crown is surmounted by a thickened rim due to the effect of surface tension (Worthington & Cole Reference Worthington and Cole1896). Liquid ligaments emanate from fairly regularly spaced vertical extensions in the rim and eject droplets outwards and upwards. In Worthington & Cole (Reference Worthington and Cole1896) and Engel (Reference Engel1966) it is surmised that a very thin layer of the drop fluid is also distributed along the interior surface of the crown. The orientation of the ligaments transitions from almost horizontal to a steep angle in the first several milliseconds. Accordingly, the direction of droplet motion originating from these ligaments sweeps from outwards to upwards over the first 10 ms after impact. Thickening of the rim and its ligaments over this time period also results in an increase of the size of newly produced droplets. By 3 ms, while continuing to grow vertically, the radially outward progress of the upper rim of the sheet ceases, and it begins to move radially inwards under the influence of surface tension. At the same time, as the bulk fluid surface is forced outward by the widening and deepening cavity, more fluid travels up the widening and thickening sheet (Engel Reference Engel1966; Bisighini et al.

Reference Bisighini, Cossali, Tropea and Roisman2010).

Table 3. Characteristics of canopy bubble formation and rupture. Here,

![]() $n$

represents the number of replicates and NA indicates a case where measurement was not available.

$n$

represents the number of replicates and NA indicates a case where measurement was not available.

By approximately 20 ms after impact (a sample at 17 ms is shown in figure 3), growth of the cavity depth stops, but it continues to expand radially. The upper rim of the sheet, bearing several residual ligaments, closes, creating a bubble canopy surmounted by a column of fluid. This closure produces a downward liquid jet evident at 31 ms, which pierces through the bottom of the cavity at 43 ms. Air entrained by this jet generates a few bubbles, seen at 85 ms, which remain under the cavity. Rebound of the cavity produces a broad upwards jet, evident at 85 ms, which merges with the previously generated central column of fluid, converting the bubble into a toroid. The column of fluid on top of the bubble canopy then flows down over this bubble exterior. Subsequently, the inner column thickens and coalesces with one of the bubble walls, creating a horseshoe-shaped bubble at 118 ms, which transforms into the hemispherical bubble seen at 420 ms. On average, this bubble eventually pops at 633 ms after impact (765 ms for the case in figure 3), and the hole in the film cap rapidly expands, with fluid collecting in the retracting rim (table 3). The rim becomes unstable and forms regularly spaced ligaments which shed airborne droplets (inset to figure 3 k). These ‘film drops’ are a well-studied source of marine aerosol (Resch, Darrozes & Afeti Reference Resch, Darrozes and Afeti1986; Blanchard Reference Blanchard1989; Afeti & Resch Reference Afeti and Resch1990; Resch & Afeti Reference Resch and Afeti1991; Lhuissier & Villermaux Reference Lhuissier and Villermaux2012). Table 3 shows that 35 film drops form on average for the control case; this number compares well with previous measurements of film drop production for similarly sized bubbles (Resch & Afeti Reference Resch and Afeti1991). Retraction of the bubble wall and the impact of these droplets also cause ejection of fine droplets into the air (marked by black arrows in the inset to figure 3 l, at 775 ms) and entrainment of air bubbles into the water at 785 ms. Before concluding, it should be noted that in a minority of cases (16 %), the crown fails to close into a bubble (table 3). Instead, the crown collapses and merges with the fluid jet rebounding from the crater. The stochastic nature of successful bubble canopy formation is also noted in Worthington (Reference Worthington1882).

3.2. The effect of oil layer thickness

Figure 4 shows the following three regimes of splash behaviour for crude oil layers of increasing thickness: immediate rupture and single crown, delayed rupture and double crown, and non-rupture and single crown. These three regimes will be illustrated with visualizations of droplet impact onto crude oil layers.

Figure 4. Conceptual schematic of the cavity and splash crown behaviour for oil layers of various thicknesses at approximately 1–3 ms after drop impact. Dark grey areas, seawater; black lines, oil; light grey areas/lines, raindrop fluid. (a) The oil layer ruptures immediately on impact; a single crown is formed. (b) The oil layer remains initially stretched over the cavity but then undergoes delayed rupture; a double crown is formed. (c) The oil layer does not rupture; a single crown composed of the layer fluid forms.

Immediate rupture and single crown. The first regime (figure 4

a) occurs when the oil layer ruptures immediately upon impact (e.g. within the first millisecond). Rupture of the layer, illustrated in a series of images in figure 5(a–c) for

![]() $h=100~{\rm\mu}\text{m}$

, causes the oil to retract into thin threads and droplets and allows the freshwater raindrop to mingle with the surrounding seawater. Figure 5(d–i) shows the rupture of crude oil layers of

$h=100~{\rm\mu}\text{m}$

, causes the oil to retract into thin threads and droplets and allows the freshwater raindrop to mingle with the surrounding seawater. Figure 5(d–i) shows the rupture of crude oil layers of

![]() $h=10$

, 30 and

$h=10$

, 30 and

![]() $100~{\rm\mu}\text{m}$

at two time points, with the presence of the layer becoming clearer with increasing thickness. For

$100~{\rm\mu}\text{m}$

at two time points, with the presence of the layer becoming clearer with increasing thickness. For

![]() $h=30~{\rm\mu}\text{m}$

, after 1 ms, several threads of oil emanate from the central portion of a rapidly retracting veil of oil. By 8 ms, most of the oil is concentrated within a string, which splits into droplets, presumably via a capillary instability. This pattern is reminiscent of the ‘bubble chandeliers’ found by Thoroddsen et al. (Reference Thoroddsen, Thoraval, Takehara and Etoh2012) and Tran et al. (Reference Tran, de Maleprade, Sun and Lohse2013), where a thin layer of air is entrained during a low-We impact of a droplet on a water pool. They report that multiple ruptures occur simultaneously in an azimuthal ring due to stretching of the air layer, which creates air strings that extend from a thicker film at the base. In a similar manner, although at a higher We, the present crude oil layer is stretched and broken by the rapidly growing cavity. This pattern disappears for thicker layers, such as for

$h=30~{\rm\mu}\text{m}$

, after 1 ms, several threads of oil emanate from the central portion of a rapidly retracting veil of oil. By 8 ms, most of the oil is concentrated within a string, which splits into droplets, presumably via a capillary instability. This pattern is reminiscent of the ‘bubble chandeliers’ found by Thoroddsen et al. (Reference Thoroddsen, Thoraval, Takehara and Etoh2012) and Tran et al. (Reference Tran, de Maleprade, Sun and Lohse2013), where a thin layer of air is entrained during a low-We impact of a droplet on a water pool. They report that multiple ruptures occur simultaneously in an azimuthal ring due to stretching of the air layer, which creates air strings that extend from a thicker film at the base. In a similar manner, although at a higher We, the present crude oil layer is stretched and broken by the rapidly growing cavity. This pattern disappears for thicker layers, such as for

![]() $h=100~{\rm\mu}\text{m}$

, where the oil film ruptures on one side and retracts to the other, e.g. from right to left in the sample presented in figure 5(h,i), leaving oil droplets behind. After 8 ms, in all three cases, the oil is already collected into several droplets below the air cavity.

$h=100~{\rm\mu}\text{m}$

, where the oil film ruptures on one side and retracts to the other, e.g. from right to left in the sample presented in figure 5(h,i), leaving oil droplets behind. After 8 ms, in all three cases, the oil is already collected into several droplets below the air cavity.

Shifting to the crown, figure 5(a–c) shows that the oil layer also induces changes to the dynamics of the surface-tension-dominated sheet ejected from the cavity. The darker canopy film (compared with the control case) in (b) is a result of the changing composition of the ejected sheet. As illustrated in figure 4(a), the outside of this sheet is coated with a thin layer of oil drawn up from the surrounding oil film. However, since the oil layer is ruptured, the interior of the crown contains water originating from both the raindrop and the bulk fluid. In addition, the canopy in (b) is closed while that of the control case is still open (quantification follows). The higher inward rim speed with the oily canopy surface causes shorter closure times. After crown closure, the extent of the upward liquid jets above the canopy and the depth of the entrained column of air under the cavity increase with oil layer thickness, as is evident from the images of the

![]() $100~{\rm\mu}\text{m}$

layers in (c). In the

$100~{\rm\mu}\text{m}$

layers in (c). In the

![]() $100~{\rm\mu}\text{m}$

case, the entrained air is already partially broken into bubbles. The faster downward jet entrains a greater volume of air into the bulk fluid and forces the oil droplets under the air cavity to a larger depth. As will be shown later, the earlier closure of the crown for the

$100~{\rm\mu}\text{m}$

case, the entrained air is already partially broken into bubbles. The faster downward jet entrains a greater volume of air into the bulk fluid and forces the oil droplets under the air cavity to a larger depth. As will be shown later, the earlier closure of the crown for the

![]() $100~{\rm\mu}\text{m}$

oil layers also results in a smaller cavity and bubble canopy above the surface.

$100~{\rm\mu}\text{m}$

oil layers also results in a smaller cavity and bubble canopy above the surface.

Figure 5. (a–c) Sample images showing the impact of the water droplet (same as in figure 3) on an oil layer of thickness

![]() $h=100~{\rm\mu}\text{m}$

. The insets (all at the same magnification) show magnified sections of the images. The white inset scale bar at 1 ms in (a) is 2 mm: (a) 1 ms, (b) 8 ms and (c) 43 ms. (d–i) Magnified images showing the oil layer rupture and breakup for oil layer thicknesses of (d,e)

$h=100~{\rm\mu}\text{m}$

. The insets (all at the same magnification) show magnified sections of the images. The white inset scale bar at 1 ms in (a) is 2 mm: (a) 1 ms, (b) 8 ms and (c) 43 ms. (d–i) Magnified images showing the oil layer rupture and breakup for oil layer thicknesses of (d,e)

![]() $h=10~{\rm\mu}\text{m}$

, (f,g)

$h=10~{\rm\mu}\text{m}$

, (f,g)

![]() $h=30~{\rm\mu}\text{m}$

and (h,i)

$h=30~{\rm\mu}\text{m}$

and (h,i)

![]() $h=100~{\rm\mu}\text{m}$

. Here,

$h=100~{\rm\mu}\text{m}$

. Here,

![]() $a$

is the air cavity,

$a$

is the air cavity,

![]() $r$

is the raindrop fluid layer and

$r$

is the raindrop fluid layer and

![]() $s$

is the seawater. The arrows show the retracting oil film at 1 ms (d,f,h) and the collected oil droplets at 8 ms (e,g,i).

$s$

is the seawater. The arrows show the retracting oil film at 1 ms (d,f,h) and the collected oil droplets at 8 ms (e,g,i).

Figure 6. (a–h) Sample images showing the impact of the water droplet (same as in figure 3) on an oil layer thickness of

![]() $h=200~{\rm\mu}\text{m}$

: (a) 1 ms, (b) 2 ms, (c) 4 ms, (d) 8 ms, (e) 19 ms, (f) 85 ms, (g) 380 ms, (h) 395 ms. The scale bars in the insets are 2 mm for that time point. The white arrows in (b–d) show the edge of the receding raindrop fluid. The white asterisks indicate examples of tracked lower crown rim positions. Magnified views showing the impact of the water droplet on an oil layer thickness of

$h=200~{\rm\mu}\text{m}$

: (a) 1 ms, (b) 2 ms, (c) 4 ms, (d) 8 ms, (e) 19 ms, (f) 85 ms, (g) 380 ms, (h) 395 ms. The scale bars in the insets are 2 mm for that time point. The white arrows in (b–d) show the edge of the receding raindrop fluid. The white asterisks indicate examples of tracked lower crown rim positions. Magnified views showing the impact of the water droplet on an oil layer thickness of

![]() $h=200~{\rm\mu}\text{m}$

at (i) 1 ms, (j) 2 ms, (k) 15 ms and (l) 19 ms. Here,

$h=200~{\rm\mu}\text{m}$

at (i) 1 ms, (j) 2 ms, (k) 15 ms and (l) 19 ms. Here,

![]() $a$

is the air cavity,

$a$

is the air cavity,

![]() $r$

is the raindrop fluid layer and

$r$

is the raindrop fluid layer and

![]() $s$

is the seawater. The white arrows show the edge of the retracting raindrop fluid, the black arrows show the intact oil sheet in (i) and (j) and oil droplets in (k) and (l), and the dashed black arrows show the annular rim separating the upper and lower crowns in (i) and (k).

$s$

is the seawater. The white arrows show the edge of the retracting raindrop fluid, the black arrows show the intact oil sheet in (i) and (j) and oil droplets in (k) and (l), and the dashed black arrows show the annular rim separating the upper and lower crowns in (i) and (k).

Delayed rupture and double crown. In the second regime, illustrated in figure 4(b), the floating oil layer no longer ruptures within the first millisecond of droplet impact. Instead, the oil layer becomes thinner but remains intact as the cavity grows. Accordingly, a continuous oil layer should presumably extend from the bottom of the cavity to the top of the crown, and to the undisturbed surrounding surface. This intact oil layer, shown in figure 6(a–c,i,j) for impact on a layer of

![]() $h=200~{\rm\mu}\text{m}$

, prevents the raindrop from mixing with the bulk fluid as would occur in the previously described immediate rupture cases. Instead, a thin layer of raindrop fluid travels up the crown wall and subsequently retracts down the wall, at speeds of up to

$h=200~{\rm\mu}\text{m}$

, prevents the raindrop from mixing with the bulk fluid as would occur in the previously described immediate rupture cases. Instead, a thin layer of raindrop fluid travels up the crown wall and subsequently retracts down the wall, at speeds of up to

![]() $0.8~\text{m}~\text{s}^{-1}$

, to the cavity bottom. Retraction of the drop fluid into the cavity bottom is also reported by Fujimatsu et al. (Reference Fujimatsu, Fujita, Hirota and Okada2003) and by Lhuissier et al. (Reference Lhuissier, Sun, Prosperetti and Lohse2013) for water drops impacting silicone oil at lower We than that studied here that do not involve a crown. By this time (

$0.8~\text{m}~\text{s}^{-1}$

, to the cavity bottom. Retraction of the drop fluid into the cavity bottom is also reported by Fujimatsu et al. (Reference Fujimatsu, Fujita, Hirota and Okada2003) and by Lhuissier et al. (Reference Lhuissier, Sun, Prosperetti and Lohse2013) for water drops impacting silicone oil at lower We than that studied here that do not involve a crown. By this time (

![]() ${\sim}8~\text{ms}$

), due to the cavity growth, the oil layer lining its walls has been stretched to a thickness of approximately

${\sim}8~\text{ms}$

), due to the cavity growth, the oil layer lining its walls has been stretched to a thickness of approximately

![]() $4~{\rm\mu}\text{m}$

, estimated by assuming that the circular area underlying the droplet is stretched into a hemisphere. Passage of the retracting raindrop fluid over the thinned oil layer appears to cause its breakup into fine threads and droplets and allows the raindrop fluid to mix with the seawater, as the sample images in figure 6(d,e,k,l) demonstrate. For a thicker layer of

$4~{\rm\mu}\text{m}$

, estimated by assuming that the circular area underlying the droplet is stretched into a hemisphere. Passage of the retracting raindrop fluid over the thinned oil layer appears to cause its breakup into fine threads and droplets and allows the raindrop fluid to mix with the seawater, as the sample images in figure 6(d,e,k,l) demonstrate. For a thicker layer of

![]() $h=400~{\rm\mu}\text{m}$

, as shown in figure 7, passage of the retracting raindrop does not always rupture the layer. Instead, once the retracting droplet reaches the bottom of the cavity, it generates miniature upward and downward liquid jets. The downward jet may puncture the oil layer or may protrude through the oil layer and become encapsulated as a ‘vesicle’, a parcel of water coated with a light-coloured thin film of oil which may remain intact for at least several seconds (shown bursting in figure 7

j–m). Formation of similar structures is observed by Wacheul et al. (Reference Wacheul, Le Bars, Monteux and Aurnou2014) for liquid gallium falling through glycerine solutions.

$h=400~{\rm\mu}\text{m}$

, as shown in figure 7, passage of the retracting raindrop does not always rupture the layer. Instead, once the retracting droplet reaches the bottom of the cavity, it generates miniature upward and downward liquid jets. The downward jet may puncture the oil layer or may protrude through the oil layer and become encapsulated as a ‘vesicle’, a parcel of water coated with a light-coloured thin film of oil which may remain intact for at least several seconds (shown bursting in figure 7

j–m). Formation of similar structures is observed by Wacheul et al. (Reference Wacheul, Le Bars, Monteux and Aurnou2014) for liquid gallium falling through glycerine solutions.

Figure 7. (a–h) Sample images showing the impact of a freshwater drop (same as in figure 3) on crude oil layer with thickness

![]() $h=400~{\rm\mu}\text{m}$

: (a) 2 ms, (b) 5 ms, (c) 8 ms, (d) 31 ms, (e) 52 ms, (f) 118 ms, (g) 219 ms, (h) 255 ms. The inset to (b) shows a magnified section. The scale bar in the inset is 2 mm. The white arrows show the edge of the retracting raindrop fluid, the black arrows show the vesicle, the dashed black arrows show the annular rim between the upper and lower crowns and the white asterisks indicate examples of lower crown rim positions. (i) Magnified view of double-crown formation at 2 ms. The dashed black arrows show the annular rim between the upper and lower crowns. (j–l) Sample images showing an oil vesicle rising to the surface and rupturing. The view is partially obscured by the oil layer at the tank wall: (j) 656 ms, (k) 761 ms, (l) 767 ms, (m) 773 ms.

$h=400~{\rm\mu}\text{m}$

: (a) 2 ms, (b) 5 ms, (c) 8 ms, (d) 31 ms, (e) 52 ms, (f) 118 ms, (g) 219 ms, (h) 255 ms. The inset to (b) shows a magnified section. The scale bar in the inset is 2 mm. The white arrows show the edge of the retracting raindrop fluid, the black arrows show the vesicle, the dashed black arrows show the annular rim between the upper and lower crowns and the white asterisks indicate examples of lower crown rim positions. (i) Magnified view of double-crown formation at 2 ms. The dashed black arrows show the annular rim between the upper and lower crowns. (j–l) Sample images showing an oil vesicle rising to the surface and rupturing. The view is partially obscured by the oil layer at the tank wall: (j) 656 ms, (k) 761 ms, (l) 767 ms, (m) 773 ms.

Delayed rupture of the oil layer also affects the composition and behaviour of the crown. The floating oil layer is propelled upwards first and thus forms the upper part of a double crown. As the cavity grows, it also then propels the underlying seawater. Accordingly, the lower crown contains seawater, coated with oil, as illustrated in figure 4(b), and its thickened rim represents the upper extent of the seawater. For the

![]() $h=200~{\rm\mu}\text{m}$

oil layer, the film of the upper crown, which is composed of oil, collapses by 2 ms, leaving behind a skeleton of fragmenting ligaments protruding from the rim of the lower crown (figure 6

j). In comparison to the

$h=200~{\rm\mu}\text{m}$

oil layer, the film of the upper crown, which is composed of oil, collapses by 2 ms, leaving behind a skeleton of fragmenting ligaments protruding from the rim of the lower crown (figure 6

j). In comparison to the

![]() $200~{\rm\mu}\text{m}$

oil layer, raindrop impact on the

$200~{\rm\mu}\text{m}$

oil layer, raindrop impact on the

![]() $h=400~{\rm\mu}\text{m}$

oil layer produces a taller and more robust upper crown. For example, by comparing figures 6 and 7, the upper crown still exists at 5 ms for

$h=400~{\rm\mu}\text{m}$

oil layer produces a taller and more robust upper crown. For example, by comparing figures 6 and 7, the upper crown still exists at 5 ms for

![]() $h=400~{\rm\mu}\text{m}$

, while it has already disappeared at 2 ms for

$h=400~{\rm\mu}\text{m}$

, while it has already disappeared at 2 ms for

![]() $h=200~{\rm\mu}\text{m}$

. The upper crown for

$h=200~{\rm\mu}\text{m}$

. The upper crown for

![]() $h=400~{\rm\mu}\text{m}$

also appears to be thicker, presumably since a greater oil volume is propelled upward. As the upper crown film collapses into ligaments by 8 ms, it also contracts inward, presumably under the effect of surface tension. Subsequently, the remaining ligaments stretch upward, while continuing their radially inward motion, and eventually, by 10–20 ms, break into droplets.

$h=400~{\rm\mu}\text{m}$

also appears to be thicker, presumably since a greater oil volume is propelled upward. As the upper crown film collapses into ligaments by 8 ms, it also contracts inward, presumably under the effect of surface tension. Subsequently, the remaining ligaments stretch upward, while continuing their radially inward motion, and eventually, by 10–20 ms, break into droplets.

Figure 8. Sample parts of a time series showing the impact of a freshwater drop (same as in figure 3) on a crude oil layer above artificial seawater with thickness of

![]() $h=2300~{\rm\mu}\text{m}$

: (a) 2 ms, (b) 8 ms, (c) 23 ms, (d) 113 ms. The white arrow shows the edge of the retracting raindrop fluid.

$h=2300~{\rm\mu}\text{m}$

: (a) 2 ms, (b) 8 ms, (c) 23 ms, (d) 113 ms. The white arrow shows the edge of the retracting raindrop fluid.

The lower crown for the

![]() $h=400~{\rm\mu}\text{m}$

layer appears slightly later than that for the

$h=400~{\rm\mu}\text{m}$

layer appears slightly later than that for the

![]() $h=200~{\rm\mu}\text{m}$

layer, presumably since entrainment of the seawater begins later. With increased oil layer thickness, the lower crown is also less likely to close into a bubble canopy, with only 13 % of replicates successfully forming a bubble (table 3). While slow bubble canopy closure occurs for

$h=200~{\rm\mu}\text{m}$

layer, presumably since entrainment of the seawater begins later. With increased oil layer thickness, the lower crown is also less likely to close into a bubble canopy, with only 13 % of replicates successfully forming a bubble (table 3). While slow bubble canopy closure occurs for

![]() $h=200~{\rm\mu}\text{m}$

(slower than that of the control case or rupturing layers), it rarely occurs for

$h=200~{\rm\mu}\text{m}$

(slower than that of the control case or rupturing layers), it rarely occurs for

![]() $h=400~{\rm\mu}\text{m}$

, as the image in figure 7(e) shows. Instead, the crown falls on the periphery as the rebounding cavity forms a thick central jet evident at 118 ms. The collapse of this thick jet subsequently creates a high-speed jet (255 ms) with droplet ejection speeds of up to

$h=400~{\rm\mu}\text{m}$

, as the image in figure 7(e) shows. Instead, the crown falls on the periphery as the rebounding cavity forms a thick central jet evident at 118 ms. The collapse of this thick jet subsequently creates a high-speed jet (255 ms) with droplet ejection speeds of up to

![]() $9.9~\text{m}~\text{s}^{-1}$

. When oily canopy bubbles do form, they have shorter lifetimes, presumably due to lower surface tension, with a mean time from impact to bubble bursting of 215 ms for

$9.9~\text{m}~\text{s}^{-1}$

. When oily canopy bubbles do form, they have shorter lifetimes, presumably due to lower surface tension, with a mean time from impact to bubble bursting of 215 ms for

![]() $h=200~{\rm\mu}\text{m}$

(table 3). Kientzler et al. (Reference Kientzler, Arons, Blanchard and Woodcock1954) also found shortened bubble lifetime with the addition of a surface-tension-lowering agent. In contrast to the control case, bursting of this large bubble does not produce ligaments and produces very few film drops (395 ms). Table 3 shows that no more than two film drops are produced on average for any of the cases with oil. The onset of the instability, which would corrugate the receding rim and produce ligaments and droplets, is probably delayed by the higher viscosity of the oil (Lhuissier & Villermaux Reference Lhuissier and Villermaux2012), which, based on colour, covers the entire canopy. Table 3 also shows that the receding rim for the oil layer cases moves more slowly than that of the control case. The rim for the control case travels at a mean speed of

$h=200~{\rm\mu}\text{m}$

(table 3). Kientzler et al. (Reference Kientzler, Arons, Blanchard and Woodcock1954) also found shortened bubble lifetime with the addition of a surface-tension-lowering agent. In contrast to the control case, bursting of this large bubble does not produce ligaments and produces very few film drops (395 ms). Table 3 shows that no more than two film drops are produced on average for any of the cases with oil. The onset of the instability, which would corrugate the receding rim and produce ligaments and droplets, is probably delayed by the higher viscosity of the oil (Lhuissier & Villermaux Reference Lhuissier and Villermaux2012), which, based on colour, covers the entire canopy. Table 3 also shows that the receding rim for the oil layer cases moves more slowly than that of the control case. The rim for the control case travels at a mean speed of

![]() $1.8~\text{m}~\text{s}^{-1}$

while the oily rims travel at mean speeds of

$1.8~\text{m}~\text{s}^{-1}$

while the oily rims travel at mean speeds of

![]() $0.9{-}1.2~\text{m}~\text{s}^{-1}$

due to the decreased surface tension of the oil.

$0.9{-}1.2~\text{m}~\text{s}^{-1}$

due to the decreased surface tension of the oil.

Non-rupture and single crown. In the third regime, illustrated in figure 4(c), the floating oil layer is thick enough so that the influence of the underlying water on splash phenomena is greatly diminished. The oil layer thins as the cavity grows but is thick enough to remain intact as the raindrop retracts to the cavity bottom. As seen in figure 8 for an oil layer of

![]() $h=2300~{\rm\mu}\text{m}$

, because of the increased oil layer thickness, only oil is entrained into the crown, thus producing a single crown similar to the control or rupturing layer cases. Similarly to the rupturing cases, the crown closes more rapidly than the control (at 11 ms – not shown). The resulting oil-comprised bubble is small compared with those previously considered. The rapid closure also creates a jet of oil that moves downward through the splash cavity wall, as seen at 113 ms, and subsequently separates into several large oil droplets (2–6 mm in diameter) which float to the surface and rejoin the oil layer.

$h=2300~{\rm\mu}\text{m}$

, because of the increased oil layer thickness, only oil is entrained into the crown, thus producing a single crown similar to the control or rupturing layer cases. Similarly to the rupturing cases, the crown closes more rapidly than the control (at 11 ms – not shown). The resulting oil-comprised bubble is small compared with those previously considered. The rapid closure also creates a jet of oil that moves downward through the splash cavity wall, as seen at 113 ms, and subsequently separates into several large oil droplets (2–6 mm in diameter) which float to the surface and rejoin the oil layer.

Figure 9. Sample parts of a time series showing the impact of a freshwater drop (same as in figure 3) on artificial seawater with an

![]() $h=500~{\rm\mu}\text{m}$

thick layer of premixed 1:25 DOR oil–dispersant mixture: (a)

$h=500~{\rm\mu}\text{m}$

thick layer of premixed 1:25 DOR oil–dispersant mixture: (a)

![]() $-2$

ms, (b) 1 ms, (c) 3 ms, (d) 18 ms, (e) 28 ms, (f) 43 ms, (g) 75 ms, (h) 111 ms, (i) 168 ms, (j) 241 ms, (k) 721 ms, (l) 2538 ms, inset to (j) 274 ms, inset to (k) 977 ms. The white scale bars in the insets are 2 mm. The dashed black arrows show the upper rim of the lower crown and the white arrow shows the hole in the oil–dispersant layer.

$-2$

ms, (b) 1 ms, (c) 3 ms, (d) 18 ms, (e) 28 ms, (f) 43 ms, (g) 75 ms, (h) 111 ms, (i) 168 ms, (j) 241 ms, (k) 721 ms, (l) 2538 ms, inset to (j) 274 ms, inset to (k) 977 ms. The white scale bars in the insets are 2 mm. The dashed black arrows show the upper rim of the lower crown and the white arrow shows the hole in the oil–dispersant layer.

3.3. Oil premixed with dispersant

Figure 9 shows droplet impact on an

![]() $h=500~{\rm\mu}\text{m}$

layer of oil premixed with dispersant at a DOR of 1:25. As the subsurface cavity expands, the oil–dispersant layer becomes thinner and subsequently ruptures in multiple locations 2–4 ms after impact (inset to (c)). The ruptured oil–dispersant layer contracts into thin strands (e), allowing the freshwater to join with the bulk seawater. Both upper and lower crowns are evident early in the splash (inset to (b)), but, due to low interfacial tension (table 1), the boundary between these layers is not as distinct as those of the cases without dispersant. In contrast to oil layers of similar thicknesses, the front of the retracting raindrop fluid down the interior surface of the crown into the cavity is not as clear, also presumably due to the negligible interfacial tension. The space above the crown at 3–8 ms appears to contain many long ligaments, which stretch upwards as far as 1.5 cm above the crown rim. Their number and elevation are larger than those occurring without dispersant, presumably due to the lower capillary instability of the oil–dispersant mixture. When these ligaments eventually break up due to capillary instability, copious fine droplets appear. Also in contrast to the cases without dispersant, after the upper crown disintegrates, the lower crown collapses inward to form a canopy bubble in all of the replicates (table 3), followed by formation of an upward jet (18 ms) and a downward jet evident at 28 ms. This downward jet plunges through the bottom of the cavity at

$h=500~{\rm\mu}\text{m}$

layer of oil premixed with dispersant at a DOR of 1:25. As the subsurface cavity expands, the oil–dispersant layer becomes thinner and subsequently ruptures in multiple locations 2–4 ms after impact (inset to (c)). The ruptured oil–dispersant layer contracts into thin strands (e), allowing the freshwater to join with the bulk seawater. Both upper and lower crowns are evident early in the splash (inset to (b)), but, due to low interfacial tension (table 1), the boundary between these layers is not as distinct as those of the cases without dispersant. In contrast to oil layers of similar thicknesses, the front of the retracting raindrop fluid down the interior surface of the crown into the cavity is not as clear, also presumably due to the negligible interfacial tension. The space above the crown at 3–8 ms appears to contain many long ligaments, which stretch upwards as far as 1.5 cm above the crown rim. Their number and elevation are larger than those occurring without dispersant, presumably due to the lower capillary instability of the oil–dispersant mixture. When these ligaments eventually break up due to capillary instability, copious fine droplets appear. Also in contrast to the cases without dispersant, after the upper crown disintegrates, the lower crown collapses inward to form a canopy bubble in all of the replicates (table 3), followed by formation of an upward jet (18 ms) and a downward jet evident at 28 ms. This downward jet plunges through the bottom of the cavity at

![]() ${\sim}43~\text{ms}$

and, due to the reduced interfacial tension with the seawater, breaks up into a plume of fine oil droplets and threads as well as entrained air bubbles (43 ms and onward).

${\sim}43~\text{ms}$

and, due to the reduced interfacial tension with the seawater, breaks up into a plume of fine oil droplets and threads as well as entrained air bubbles (43 ms and onward).

When the bubble canopy bursts (111 ms) at about the same time as the corresponding non-dispersant case (see the data in table 3), the receding rim travels slowly due to the low surface tension, and produces very few airborne film drops. However, the canopy collapse also causes entrainment of oil near the surface, starting from 168 ms. Many of the oil droplets entrained by both processes are smaller than the camera resolution (

![]() $28.2~{\rm\mu}\text{m}~\text{pixel}^{-1}$